Page 1

C141-E219-01EN

MAV2073RC

MAV2036RC

HARD DISK DRIVES

PRODUCT/MAINTENANCE MANUAL

Page 2

FOR SAFE OPERATION

Handling of This Manual

This manual contains important information for using this product. Read thoroughly before using the product.

Use this product only after thoroughly reading and understanding especially the section "Important Alert

Items" in this manual. Keep this manual handy, and keep it carefully.

FUJITSU makes every effort to prevent users and bystanders from being injured or from suffering damage to

their property. Use the product according to this manual.

IMPORTANT NOTE TO USERS

READ THE ENTIRE MANUAL CAREFULLY BEFORE USING THIS PRODUCT. INCORRECT

USE OF THE PRODUCT MAY RESULT IN INJURY OR DAMAGE TO US ERS, BYSTANDERS OR

PROPERTY.

While FUJITSU has sought to ensure the accuracy of all information in this manual, FUJITSU assumes no

liability to any party for any damage caused by any error or omission contained in this manual, its updates or

supplements, whether such errors or omissions result from negligence, accident, or any other cause. In

addition, FUJITSU assumes no liability with respect to the application or use of any product or system in

accordance with the descriptions or instructions contained herein; including any liability for incidental or

consequential damages arising therefrom.

FUJITSU DISCLAIMS ALL WARRANTIES REGARDING THE INFORMATION CONTAINED

HEREIN, WHETHER EXPRESSED, IMPLIED, OR STATUTORY.

FUJITSU reserves the right to make changes to any products described herein without further notice and

without obligation.

This product is designed and manufactured for use in standard applications such as office work, personal

devices and household appliances. This product is not intended for special uses (atomic cont rols , aeronaut ic or

space systems, mass transport vehicle operating controls, medical devices for life support, or weapons firing

controls) where particularly hig h reliability requirements exist, where th e p e r tinent levels of safety are not

guaranteed, or where a failure or operational error could threaten a life or cause a physical injury (hereafter

referred to as "mission-critical" use). Customers considering the use of these products for mission-critical

applications must have safety-assurance measures in place beforehand. Moreover, they are requested to

consult our sales representative before embarking on such specialized use.

The contents of this manual may be revised without prior notice.

The contents of this manual shall not be disclosed in any way or reproduced in any media without the express

written permission of Fujitsu Limited.

All Rights Reserved, Copyright FUJITSU LIMITED 2005

C141-E219

Page 3

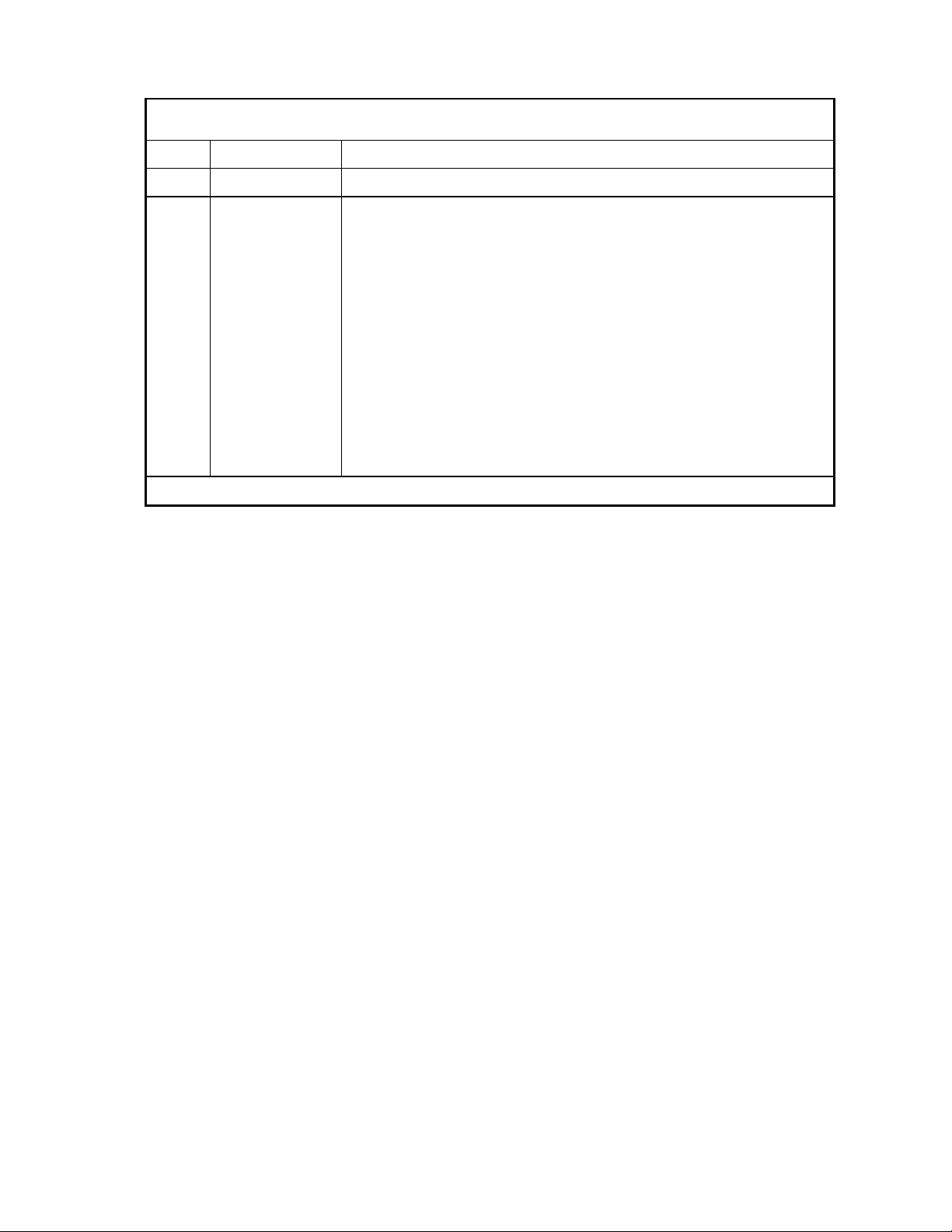

REVISION RECORD

Edition Date published Revised contents

01 January, 2005

Specification No.: C141-E219-**EN

C141-E219

Page 4

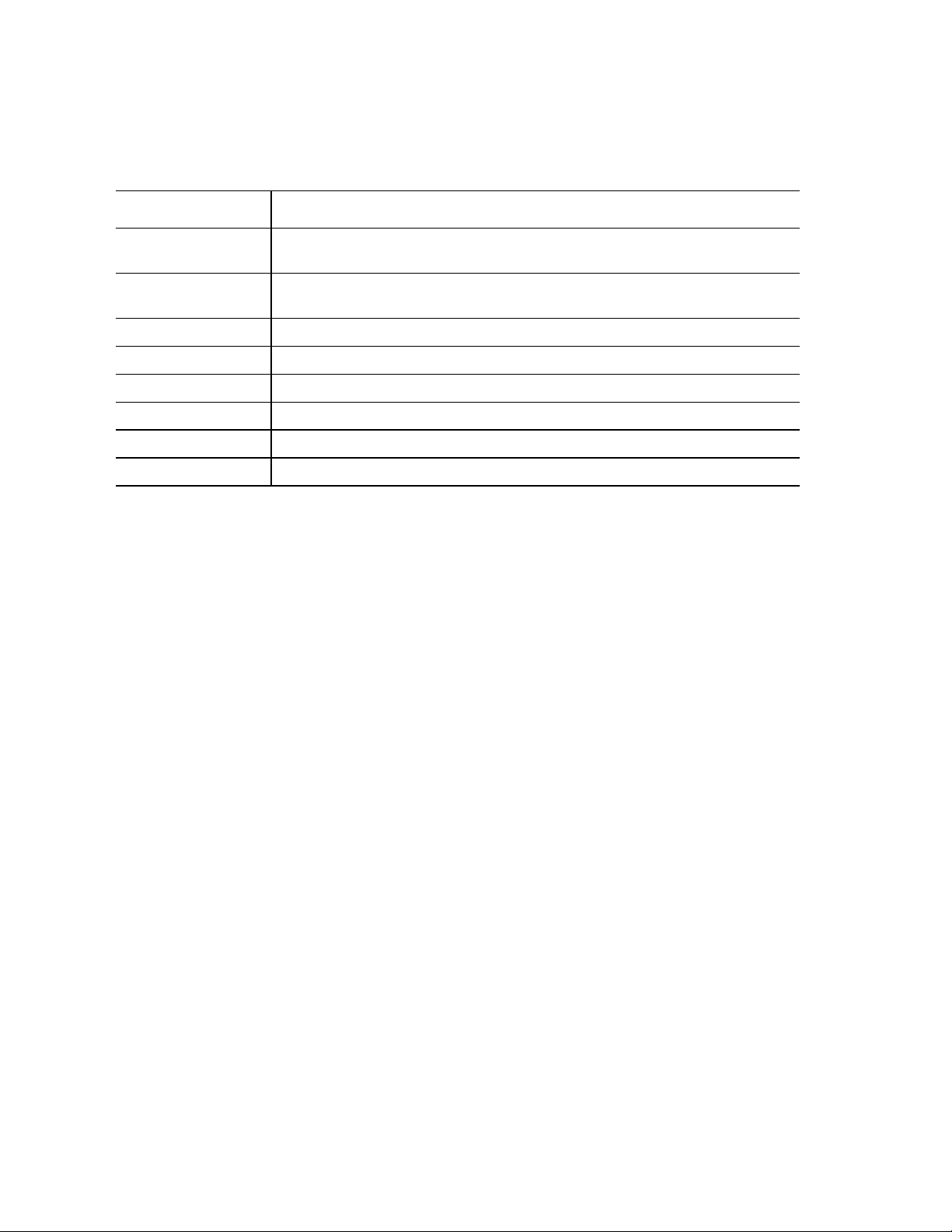

Related Standards

Product specifications and functions described in this manual comply with the following ANSI (*1)

standards and SFF Committee specifications.

Document number Title

T10/1236D Rev.20

[NCITS.351:2001]

T10/996D Rev. 8c

[NCITS.306:1998]

T10/1157D Rev. 24 SCSI Architecture Model-2 (SAM-2)

T10/1561D Rev. 14 SCSI Architecture Model-3 (SAM-3)

T10/1562D Rev. 05 Serial Attached SCSI (SAS)

T10/1601D Rev. 07 Serial Attached SCSI Model-1.1 (SAS 1.1)

SFF-8201 Rev. 2.3 Form Factor of 2.5" Disk Drives

SFF-8223 Rev. 2.4 2.5" Drive Form Factor with Serial Connector

*1 ANSI = American National Standard Institute

In case of conflict between this manual and any referenced document, this manual takes precedence.

SCSI Primary Command s- 2 (SPC-2)

SCSI-3 Block Commands (SBC)

C141-E219

Page 5

Preface

This manual describes MAV2073RC and MAV2036RC, 2.5" type hard disk drives with an

embedded Serial Attached SCSI (SAS).

This manual details the specifications and functions of the above disk drive, and gives the

requirements and procedures for installing it into a host computer system.

This manual is written for users who have a basic understanding of hard disk drives and

their use in computer systems. The MANUAL ORGANIZATION section describes

organization and scope of this manual. The need arises, use the other manuals.

The organization of this manual, related reference manual and conventions for alert

messages follow.

Overview of Manual

This manual consists of the following seven chapters and one appendix:

Chapter 1 General Description

This chapter introduces the disk drives and discusses their standard features, hardware, and

system configuration.

Chapter 2 Specifications

This chapter gives detailed specification s o f the disk drives and their installation

environment.

Chapter 3 Data Format

This chapter describes the data structure of the disk, the address method, and what to do

about media defects.

Chapter 4 Installation Requirements

This chapter describes the basic physical and electrical requirements for installing the disk

drives.

Chapter 5 Installation

This chapter explains how to install the disk drives. It includes the notice and procedures

for setting device number and operation modes, mounting the disk drive, and confirming

drive operation.

Chapter 6 Diagnostics and Maintenance

This chapter describes the automatic diagnosis, and maintenance of the disk drive. This

chapter also describes diagnostic methods for operation check and the basics of

troubleshooting the disk drives.

Chapter 7 Error Analysis

This chapter describes in details how collect the information for error an alysis and how

analyze collected error information.

C141-E219 i

Page 6

Preface

CONVENTIONS USED IN THIS MANUAL

MAV2073RC and MAV2036RC disk drives are described as "the hard disk drives

(HDD)", "the disk drive" or "the device" in this manual.

Decimal number is represented normally.

Hexadecimal number is represented as X'17B9', 17B9h or 17B9H.

Binary number is represented as "010".

Conventions for Alert Messages

This manual uses the following conventions to show the alert messages. An alert message

consists of an alert signal and alert statements. The alert signal consists of an alert symbol

and a signal word or just a signal word.

The following are the alert signals and their meanings:

This indicates a hazardous situation could result in minor

or moderate personal injury if the user does not perform

the procedure correctly. This alert signal also indicates

that damages to the product or other property, may occur if

the user does not perform the product correctly.

Attention

This indicates information that could help the user use the

product more efficiently.

In the text, the alert signal is centered, followed below by the indented message. A wider

line space precedes and follows the alert message to show where the alert message begins

and ends. The following is an example:

(Example)

Damage

Never open the disk enclosure for any reason. Doing so will void any

warranties.

The main alert messages in the text are also listed in the “Important Alert Items.”

Please forward any comments you may have regarding this manual.

To make this manual easier for users to understand, opinions from readers are needed.

Please write your opinions or requests on the Comment at the back of this manual and

forward it to the address described in the sheet.

ii C141-E219

Page 7

Important Alert Items

Important Alert Messages

The important alert messages in this m a nual are as follows:

A hazardous situation could result in minor or moderate personal injury if the

user does not perform the procedure correctly. Also, damage to the product

or other property, may occur if the user does not perform the procedure

correctly.

Task Alert message Page

Installation

Damage

Never remove any labels from the drive or deface them in any way.

High temperature

To prevent injury, never touch the drive while it is hot. The DE and LSI

become hot during operation and remain hot immediately after turning off

the power.

Damage

1. When dismounting the drive which is mounted on the

system while power is supplied to it.

• The spindle motor can be stopped by a START/STOP command. It

takes about 15 seconds for the spindle motor to stop completely.

• Then, dismount the drive using the drive mounting/dismounting

mechanism, etc. of the system. If the drive is dismounted while the

spindle motor is running, special care is required to avoid excessive

vibration or shock to the drive. It is recommended to stop the

operation once the connector breaks off contact and wait until the

spindle motor stops (about 15 seconds) before dismount the drive.

• When storing or transporting the drive, put it in the antistatic bag

(refer to Section 5.1).

4-4

5-1, 5-10

5-10

C141-E219 iii

Page 8

Important Alert Items

Task Alert message Page

Installation

Diagnostics

and

Maintenance

2. When dismounting the drive which is mounted on the

system while power is not supplied to it.

• Do not move the drive until the drive stops completely (about 15

seconds if the spindle motor was stopped by a START/STOP UNIT

command, and about 15 seconds after powering-off when the power

was simply turned off).

• Then, dismount the drive using the drive mounting/dismounting

mechanism, etc. of the system.

• When storing or transporting the drive, put it in the antistatic bag

(refer to Section 5.1).

Data loss

Save data stored on the disk drive to other media before requesting repair.

Fujitsu does not assume responsibility if data is destroyed during servicing

or repair.

Electreical shock

1. To avoid injury, do not touch the PCA.

2. Never use any solvents to clean the disk drive during operation

Damage

1. Always ground yourself with a wrist strap connected to ground before

handling. ESD (Electrostatics Discharge) may cause the damage to the

device.

5-10

6-5

6-5

6-5

2. Never use a conductive cleaner to clean the HDD.

3. Never remove any labels from the drive or deface them in any way.

4. Never remove the PCA.

5. Never open the disk enclosure for any reason.

Damage

1. Never remove any labels from the drive.

2. Never open the disk enclosure for an y reason. Doing so will void any

warranties.

6-13

iv C141-E219

Page 9

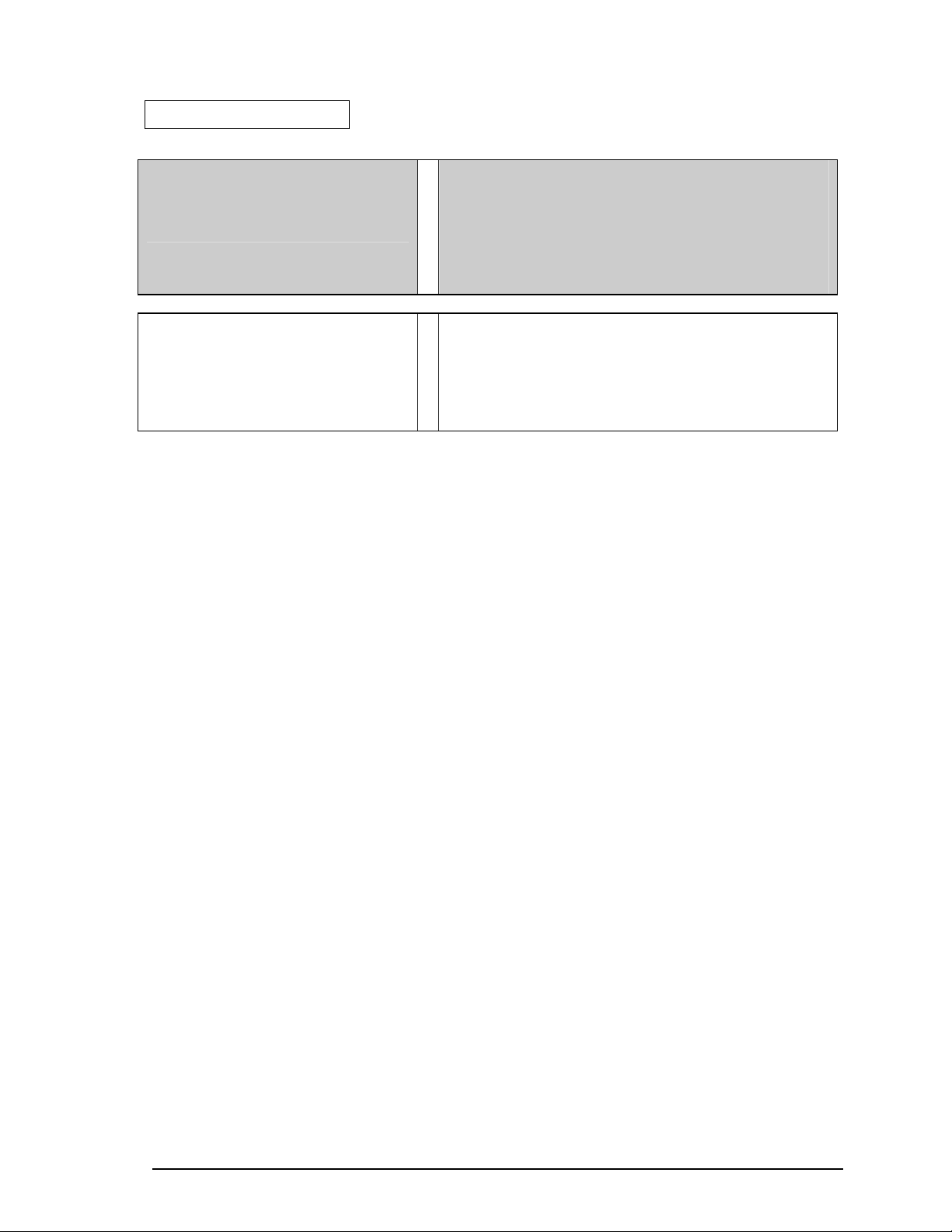

MANUAL ORGANIZATION

PRODUCT/

MAINTENANCE MANUAL

(This manual)

INTERFACE

SPECIFICATIONS

1. General Description

2. Specifications

3. Data Format

4. Installation Requirements

5. Installation

6. Diagnostics and Maintenance

7. Error Analysis

1. Interface

2. Command Processing

3. Data Buffer Management

4. Command Specifications

5. Sense Data and Error Recovery Methods

6. Disk Media Management

C141-E219 v

Page 10

This page is intentionally left blank.

Page 11

CONTENTS

CHAPTER 1 General Description.................................................................. 1-1

1.1 Standard Features................................................................................ 1-2

1.2 Hardware Structure .............................................................................. 1-5

1.3 System Configuration.......................................................................... 1-6

CHAPTER 2 Specifications ........................................................................... 2-1

2.1 Hardware Specifications...................................................................... 2-1

2.1.1 Model name and order number ............................................................ 2-1

2.1.2 Function specifications........................................................................ 2-2

2.1.3 Environmental specifications............................................................... 2-4

2.1.4 Error rate............................................................................................. 2-5

2.1.5 Reliability............................................................................................2-5

CHAPTER 3 Data Format............................................................................... 3-1

3.1 Data Space........................................................................................... 3-1

3.1.1 Cylinder configuration......................................................................... 3-1

3.1.2 Alternate spare area ............................................................................. 3-4

3.1.3 Track format........................................................................................ 3-5

3.1.4 Sector format....................................................................................... 3-6

3.1.5 Format capacity................................................................................... 3-8

3.2 Logical Data Block Addressing ........................................................... 3-8

3.3 Defect Management ........................................................................... 3-10

3.3.1 Defect list.......................................................................................... 3-10

3.3.2 Alternate block allocation.................................................................. 3-10

CHAPTER 4 Installation Requirements........................................................ 4-1

4.1 Mounting Requirements...................................................................... 4-1

C141-E219 vii

Page 12

Contents

4.1.1 Dimensions..........................................................................................4-1

4.1.2 Mounting orientations ..........................................................................4-2

4.1.3 Notes on mounting...............................................................................4-3

4.2 Power Supply Requirements.................................................................4-7

4.3 Connection Requirements.....................................................................4-8

4.3.1 Connector.............................................................................................4-8

4.3.2 Interface connector ...............................................................................4-9

CHAPTER 5 Installation .................................................................................5-1

5.1 Notes on Handling Drives.....................................................................5-1

5.2 Setting..................................................................................................5-3

5.2.1 Port Address.........................................................................................5-3

5.3 Mounting Drives ..................................................................................5-3

5.3.1 Mounting procedures............................................................................5-3

5.4 Checking Operation aft er Inst al l ati on and P repari ng th e HDD

for Use .................................................................................................5-4

5.4.1 Checking initial operation.....................................................................5-4

5.4.2 Formatting............................................................................................5-5

5.4.3 Setting parameters ................................................................................5-7

5.5 Dismounting Drives ...........................................................................5-10

5.6 Spare Disk Drive................................................................................5-10

CHAPTER 6 Diagnostics and Maintenance..................................................6-1

6.1 Diagnostics...........................................................................................6-1

6.1.1 Self-diagnostics....................................................................................6-1

6.1.2 Test programs.......................................................................................6-4

6.2 Maintenance Information......................................................................6-5

6.2.1 Precautions...........................................................................................6-5

6.2.2 Maintenance requirements....................................................................6-6

6.2.3 Maintenance levels...............................................................................6-7

6.2.4 Revision numbers.................................................................................6-7

viii C141-E219

Page 13

Contents

6.2.5 Tools and test equipment..................................................................... 6-8

6.2.6 Tests.................................................................................................... 6-9

6.3 Operation Check................................................................................ 6-10

6.3.1 Initial seek operation check................................................................ 6-10

6.3.2 Operation test.................................................................................... 6-10

6.3.3 Diagnostic test................................................................................... 6-10

6.4 Troubleshooting Procedures............................................................... 6-11

6.4.1 Outline of troubleshooting procedures ............................................... 6-11

6.4.2 Troubleshooting with di s k dri ve repl acem ent i n t he fi el d ................... 6-11

6.4.3 Troubleshooting at the repair site....................................................... 6-13

6.4.4 Troubleshooting with part s repl acem ent i n t he fact ory ....................... 6-14

6.4.5 Finding possibly faulty parts.............................................................. 6-14

CHAPTER 7 Error Analysis........................................................................... 7-1

7.1 Error Analysis Information Collection................................................. 7-1

7.1.1 Sense data............................................................................................ 7-1

7.1.2 Sense key, additional sense code, and additional sense code qualifier... 7-1

7.2 Sense Data Analysis............................................................................ 7-3

7.2.1 Error information indicated with sense data ......................................... 7-3

7.2.2 Sense data (3-0C-03), (4-40-xx), and (4-C4-xx) ................................... 7-4

7.2.3 Sense data (1-1x-xx), (3-1x-xx) and (E-1D-00): Disk read error.......... 7-4

7.2.4 Sense data (4-44-xx), (5-2x-xx), (B-44-xx), (B-47-xx), (B-4B-xx)

and (B-4E-00) : i n t erface error.............................................................. 7-4

Glossary........................................................................................................... GL-1

Abbreviation.................................................................................................... AB-1

Index ..................................................................................................................IN-1

C141-E219 ix

Page 14

Contents

Illustrations

Figures

Figure 1.1 Example of SAS system configuration

(Single port internal cabled environment)..................................1-6

Figure 1.2 Example of SAS system configuration

(Single port internal backplane environment)............................. 1-6

Figure 3.1

Figure 3.2 Spare area in cell ....................................................................... 3-4

Figure 3.3 Alternate cylinder...................................................................... 3-4

Figure 3.4 Track format.............................................................................. 3-5

Figure 3.5 Track skew/head skew............................................................... 3-6

Figure 3.6 Sector format............................................................................. 3-6

Figure 3.7 Alternate block allocation by FORMAT UNIT command ........ 3-11

Figure 3.8 Alternate block allocation by REASSIGN BLOCKS

Figure 4.1

Figure 4.2 HDD orientations ...................................................................... 4-2

Figure 4.3 Mounting frame structure .......................................................... 4-4

Figure 4.4 Breathing hole location.............................................................. 4-4

Figure 4.5 Surface temperatur e m eas u rem en t p o i n t s ................................... 4-5

Figure 4.6 Service clearance area ................................................................ 4-6

Figure 4.7 Current waveform (+12V DC)................................................... 4-7

Figure 4.8 AC noise filter (recommended).................................................. 4-8

Figure 4.9 Connector location.................................................................... 4-8

Figure 4.10 SAS plug connector overview.................................................... 4-9

Figure 6.1

Figure 6.2 Indicating revision numbers ....................................................... 6-8

Figure 6.3 Test flowchart............................................................................6-9

Figure 7.1

Cylinder configuration............................................................... 3-2

command................................................................................. 3-12

Dimensions............................................................................... 4-1

Revision label (example)........................................................... 6-7

Format of extended sense data................................................... 7-2

x C141-E219

Page 15

Contents

Tables

Table 2.1 Model names and order numbers..................................................2-1

Table 2.2 Function specifications.................................................................2-2

Table 2.3 Environmental/Power requirements .............................................2-4

Table 3.1

Table 4.1

Table 4.2 Interface connector (SAS plug) signal allocation:CN1..............4-10

Table 6.1

Table 6.2 System-level field troubleshooting.............................................6-12

Table 6.3 Disk drive troubleshooting..........................................................6-13

Table 7.1

Format capacity.............................................................................3-8

Surface temperature check point and maximum temperature......4-5

Self-diagnostic functions ..............................................................6-1

Definition of sense data ................................................................7-3

C141-E219 xi

Page 16

This page is intentionally left blank.

Page 17

CHAPTER 1 General Description

1.1 Standard Features

1.2 Hardware Structure

1.3 System Configuration

This chapter describes the feature and configuration of the hard disk drives (HDD).

The HDD are high performance large capacity 2.5" fixed disk drives with an embedded Serial Attached SCSI

(SAS) controller.

The interface used to connect the HDD to the host system complies with ANSI T10/1601-D Serial Attached

SCSI-1.1 (SAS-1.1), which covers items ranging from SAS physical layers to SCSI command protocols.

The high-speed data transfer and long-distance transmission capabilities of SAS technology and the powerful

command set the HDD facilitate creation of high-performance and highly reliab le d isk subsystems with large

storage capacities.

C141-E219 1-1

Page 18

General Description

1.1 Standard Features

(1) Compactness

The disk drive is a compact enclosure which complies with the 2.5" disk drive form factor.

(2) SAS Standard

The HDD is equipped with a serial attached SCSI (SAS) as a host interface.

• Transfer rate: 1.5Gbps, 3.0Gbps

• Number of SAS ports: One

• Full-duplex (simultaneous bidirectional data transfer) is supported.

SCSI commands can manipulate data through logical block addressing, regardless of the physical

characteristics of the disk drive. This enables software to accommodate expansion of system

functionality.

(3) Single SAS port support

The HDD has single pair of driver and receiver set (PHY) for the SAS to support single SAS port

connection.

On MAV2073RC and MAV2036RC, Primary Port on SAS plug connector (2 physical links plus

power connections) is used for SAS port connection.

(4) High-speed data transfer

The maximum data-transfer speed on the SAS is 300.0 MB/s. The large-capacity data buffer of the

HDD enables the effective use of such high-speed data transfers available on the SAS connection.

(5) Continuous block proce ssing

The addressing method of data blocks is logical block address. The initiator can access data by

specifying block number in a logically continuous data space without concerning the physical

structure of the track or cylinder boundaries.

The continuous processing up to [64K-1] blocks in a command can be achieved, and th e HDD can perform

continuous read/write operation when processing data blocks on several tracks or cylinder.

(6) Multi-segment data buffer

The data buffe r is 8M bytes. Data is transferred between SAS port and disk med i a through this data

buffer. This feature provides the suitable usage environment for users.

1-2 C141-E219

Page 19

1.1 Standard Features

(7) Cache feature

After executing the READ command, the HDD reads automatically and sto r es (prefetches) the

subsequent data blocks into the data buffer (Read-ahead caching).

The high speed sequential data access can be achieved by tran sferrin g th e data from the data bu ff er w ithou t

reaccessing the disk in cas e the su bsequen t com m and reques ts the pref etched data block s.

The Write Cache feature is supported. When this feature is enabled, the status report is issued

without waiting for completion of write processing to disk media, thereby enabling high speed write

processing.

When Write Cache is enabled, you should ensure that the cached data is

surely flushed to the disk media befo re you turn off the drive's power.

To ensure it, you should issue either the SYNCHRONIZE CACHE

command or the STOP UNIT command with specifying “0” to the

Immediate bit, and then confirm that the command is surely terminated

with the GOOD STATUS.

(8) Command queuing fe ature

The HDD can queue maximum 128 commands, and optimizes the issuing order of queued commands

by the reordering function. This feature realizes the high speed processing.

(9) Reserve and release functions

The HDD can be accessed exclusively in the multi-host or multi-initiator environment by using the

reserve and release functions.

(10) Error recovery

The HDD can try to recover from errors in the disk drive using its powerful retry processing. If a

recoverable data check occurs, error-free data can be transferred to the initiator after being corrected

in the data buffer. The initiator software is released from the complicated error recover processing

by these error recovery functions of the HDD.

(11) Automatic alternate block reassignment

If a defective data block is detected during read or write the HDD can automatically reassign its

alternate data block.

(12) Programmable data block length

Data can be accessed in fixed-block length units. The data block length is programmable, and can be

specified at initializing with a multiple of four within the range of 512 to 528 bytes.

C141-E219 1-3

Page 20

General Description

Error rate increase

1. The drive format at factory shipment is generally 512 bytes.

2. The recoverable Error of the drive might increase when the format would

be modified from 512 bytes to the following values:

516 bytes, 520 bytes, 524 bytes, 528 bytes.

3. The recoverable Error referred here is sense data (1-13-xx).

(13) Defective block slipping

A logical data block can be reallocated in a physical sequence by slipping the defective data block at

formatting. This results in high speed contiguous data block processing without a revolution delay

due to defective data block.

(14) High speed positioning

A rotary voice coil motor achieves fast positioning with high performance access control.

(15) Large capacity

A large capacity can be obtained from the HDD by dividing all cylinders into several partitions and

changing the recording density on each partition (constant density recording). The disk subsystem

with large capacity can be constructed in the good space efficiency.

(16) Start/Stop of spindle motor

Using the SAS primitive or the SCSI command, the host system can start and stop the spindle motor.

(17) Diagnosis

The HDD has a diagnostic capability which checks internal controller functions and drive operations

to facilitate testing and repair.

(18) Low power consumption

By using highly integrated LSI components, the power consumption of the HDD is very low, and this

enables the unit to be used in wide range of environmental conditions.

(19) Low noise and low vibration

The noise level is low; approx. 2.9 Bels at Ready for the drive. This makes it ideal for office use.

1-4 C141-E219

Page 21

1.1 Standard Features

(20) Microcode downloading

The HDD implements the microcode download feature. This feature achieves easy maintainability of

the HDD and function enhancing.

1.2 Hardware Structure

The HDD is composed of the disks, heads, and spindle motor mounted disk enclosure (DE) with

actuator as well as read/write pre-amp with the printed circuit assembly (PCA) of the controller.

(1) Disks

The disks have an outer diameter of 65 mm (2.56 inch).

(2) Heads

The heads have MR (Magnet-Resistive) read element Ramp Load type slider.

(3) Spindle motor

The disks are rotated by a direct-drive hall-less DC motor. The motor speed is controlled by a

feedback circuit using the counter electromotive current to precisely maintain the specified speed.

(4) Actuator

The actuator, which uses a rotary voice coil motor (VCM), consumes little power and generates little

heat. The heads at the end of the actuator arm are controlled and positioned via feedback servo loop.

The heads are positioned on the ramp when the power is off or the spindle motor is stopped.

(5) Read/write circuit

The read/write circuit utilizes a read channel mounted with a head IC that supports high-speed

transmission and an MEEPR4ML (Modified Enhanced Extended Partial Response Class 4 Maximum

Likelihood) modulation/demodulation circuit in order to prevent errors being triggered by external

noise and to improve data reliability.

(6) Controller circuit

The controller circuit uses LSIs to increase the reliability and uses a high speed microprocessing unit

(MPU) to increase the performance of the SAS controller.

C141-E219 1-5

Page 22

General Description

1.3 System Configuration

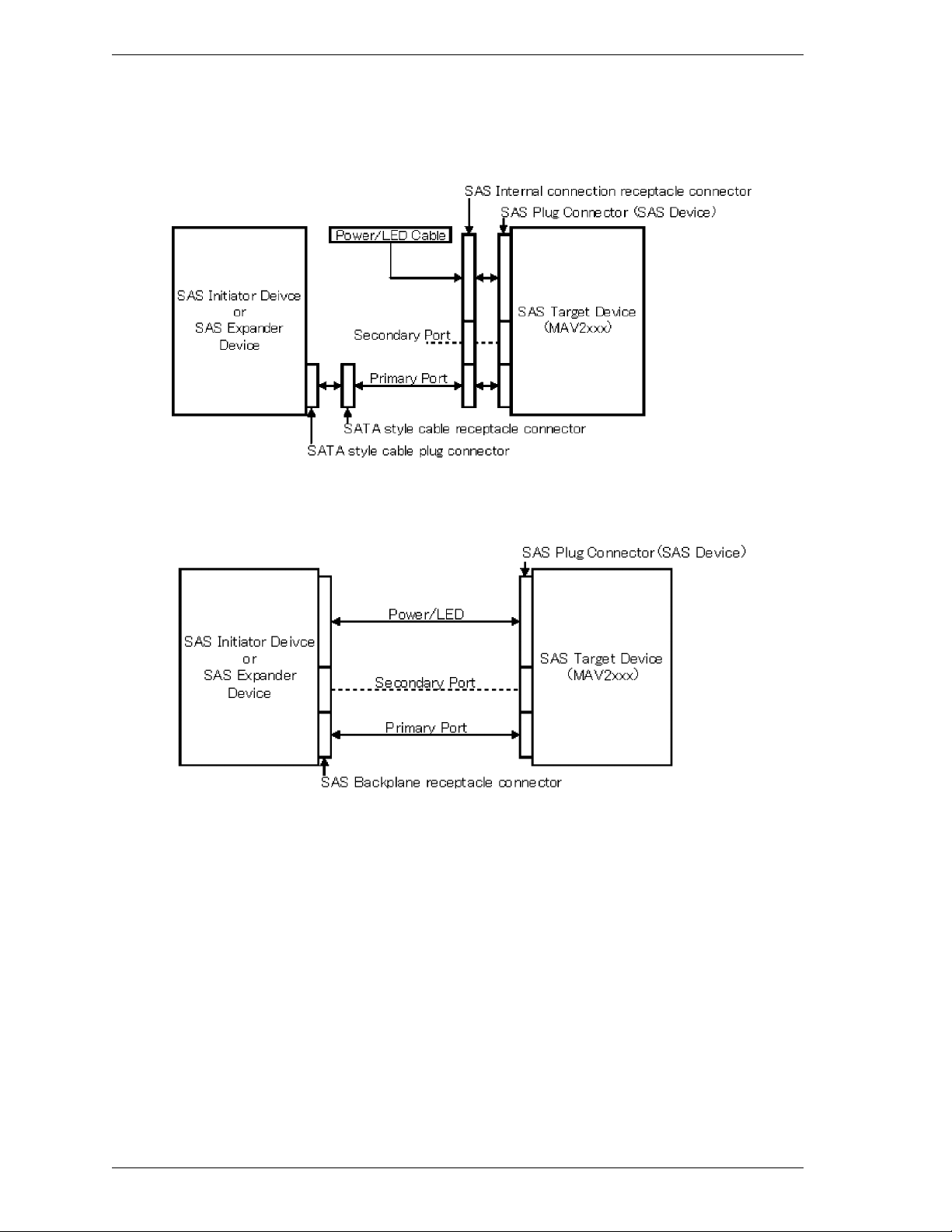

For the Serial Attached SCSI, the ANSI standard defines Point-to-Point technology. Figure 1.1 and

Figure 1.2 give examples of the SAS system configuration.

Figure 1.1 Example of SAS system configuration (Single port internal cabled environment)

Figure 1.2 Example of SAS system configuration (Single port internal backplane environment)

(1) Port addressing

Every device connected with the SAS protocol has a unique address (SAS address). SAS addresses

are in the Name Address Authority (NAA) IEEE Registered format defined by SCSI Primary

Command-3 (SPC-3).

An SAS address consists of 8 bytes as a unique value set for each device.

The initiator can implement an I/O operation on a disk drive by using the corresponding SAS address

stored by the HDD.

1-6 C141-E219

Page 23

CHAPTER 2 Specifications

2.1 Hardware Specifications

This chapter describes specifications of the HDD.

2.1 Hardware Specifications

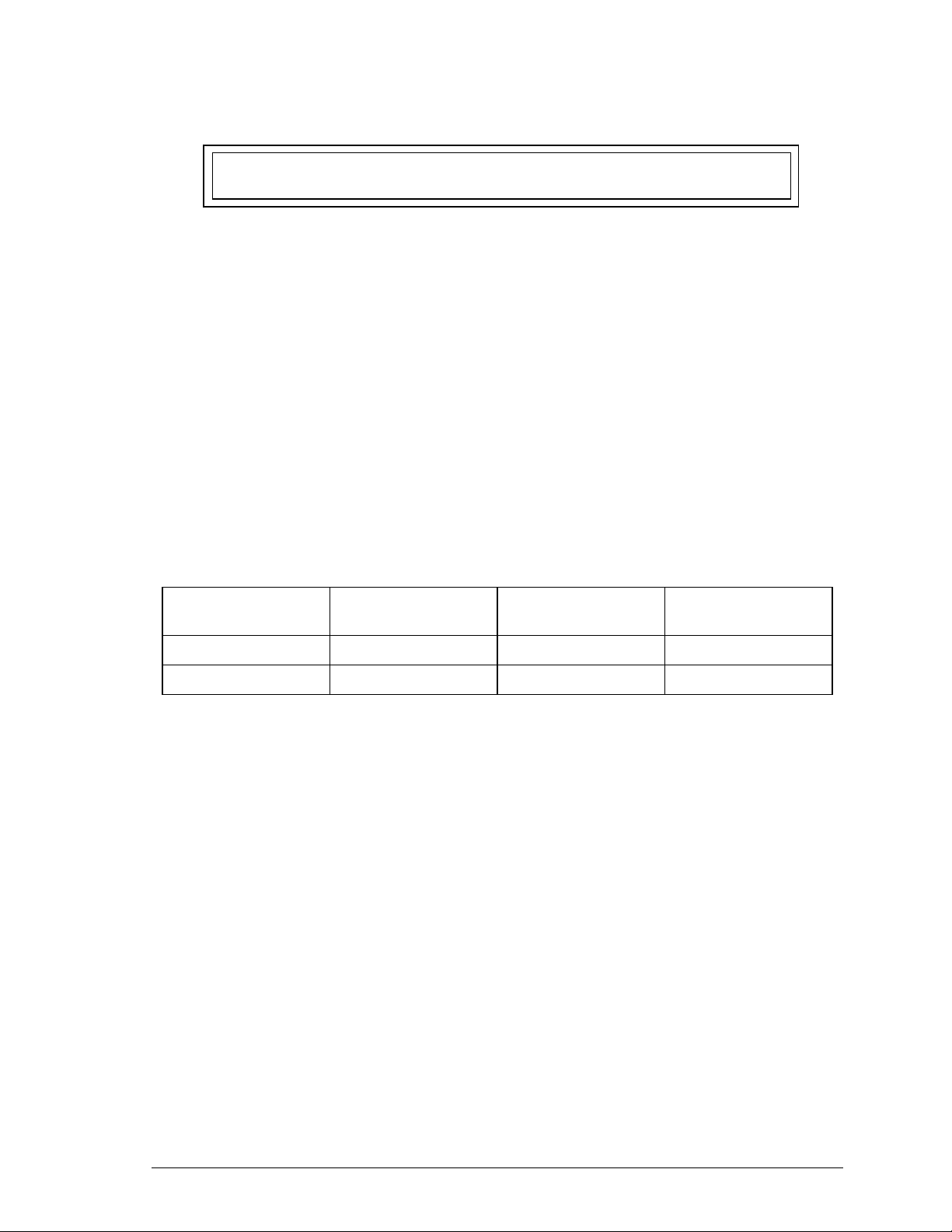

2.1.1 Model name and order number

Each model has different recording capacities when shipped.

Table 2.1 lists the model name and order number.

The data format can be changed by reinitializing with the user's system.

Model name Order number Interface type

MAV2073RC CA06473-B260 SAS 73.5 GB (*)

MAV2036RC CA06473-B160 SAS 36.7 GB (*)

(*) 1GB=1,000,000,000 bytes

Table 2.1 Model names and order numbers

Capacity

(user area)

C141-E219 2-1

Page 24

Specifications

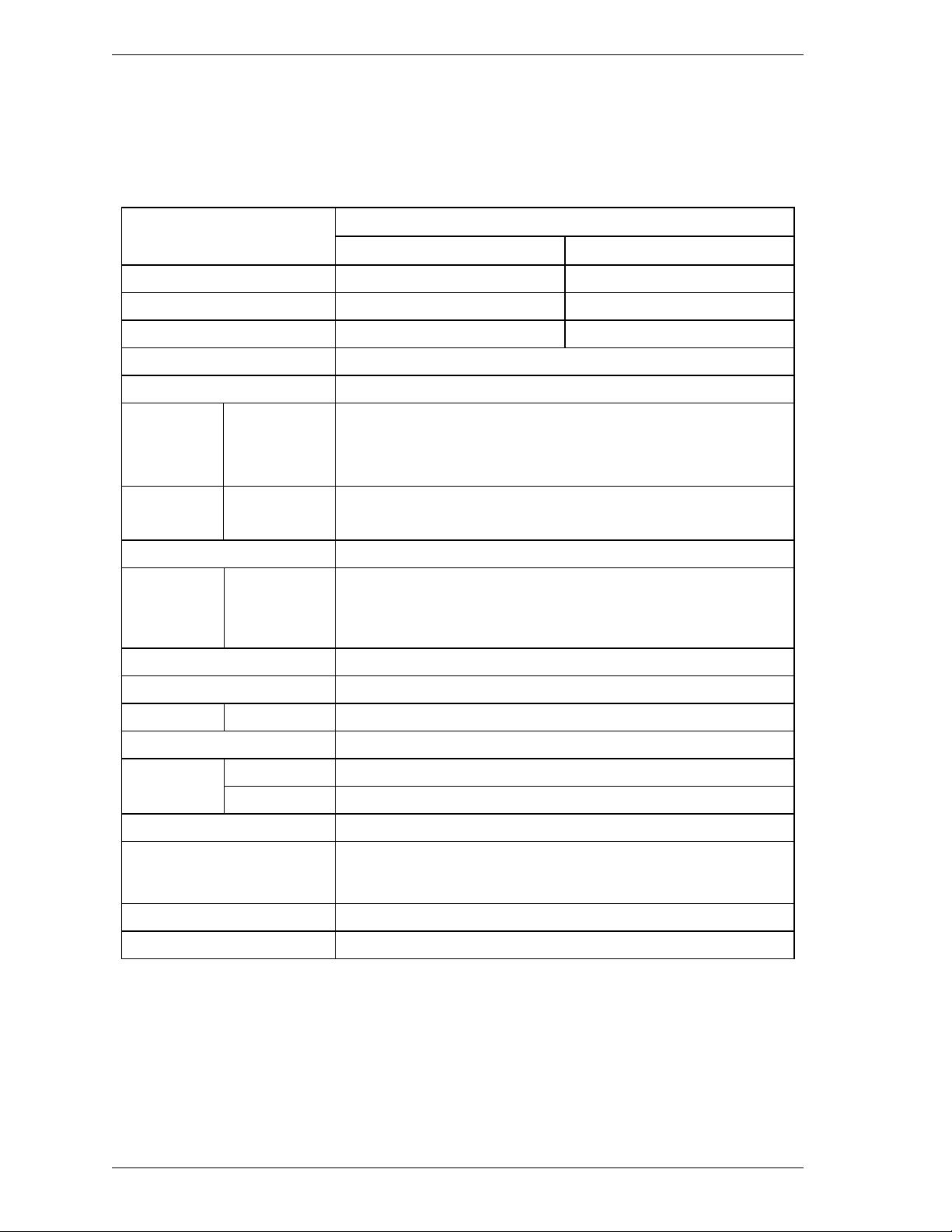

2.1.2 Function specifications

Table 2.2 shows the function specifications of the HDD.

Table 2.2 Function specifications

Item

Formatted capacity/device (*1) 73.5 GB (*2) 36.7 GB (*2)

Number of disks 2 1

Number of heads 4 2

Number of rotations min-1 (rpm) 10,025 ± 0.2%

Average latency time 2.99 msec

Track to Track 0.2 ms/0.4 ms

Seek time (*3)

(Read/Write)

Start/stop time

(*4)

Recording mode 32/34 MEEPRML

External

dimensions

Weight (max) 0.22 kg

Average 4.0 ms/4.5 ms

Full stroke 8.0 ms/9.0 ms

Start time

Stop time

Height:

Width:

Depth:

MAV2073RC MAV2036RC

Specification

15 s typ. (30 s max.)

15 s typ.

15.0 mm max

69.85+/-0.25 mm

100.45 mm max

Power consumption (*5) 4.5 W

Interface SAS Cable length: 8 m max

Areal density 70.2 Gbit/inch2

Data transfer

rate (*6)

Logical data block length 512 to 528 byte (Fixed length) (*7)

Command specification

Data buffer 8 MB FIFO ring buffer (*8)

Acoustic noise (Ready) 2.9 Bels typ.

(*1) T he formatted capacity can be changed by changing the logical block length and using spare sector

space. See Chapter 3 for the further information. The formatted capacity listed in the table is an

estimate for 512 bytes per sector.

(*2) 1GB=1,000,000,000 bytes

Disk drive 56.4 to 94.1 MB/s

SAS 1.5Gbps, 3Gbps

SAS (T10/1562D Rev. 05), SAS1.1 (T10/1601D Rev. 07),

SAM-3 (T10/1561D Rev. 14), SAM-2 (T10/1157D Rev. 24),

SPC-2 (T10/1236D Rev. 20), SBC (T10/996D Rev. 8c)

2-2 C141-E219

Page 25

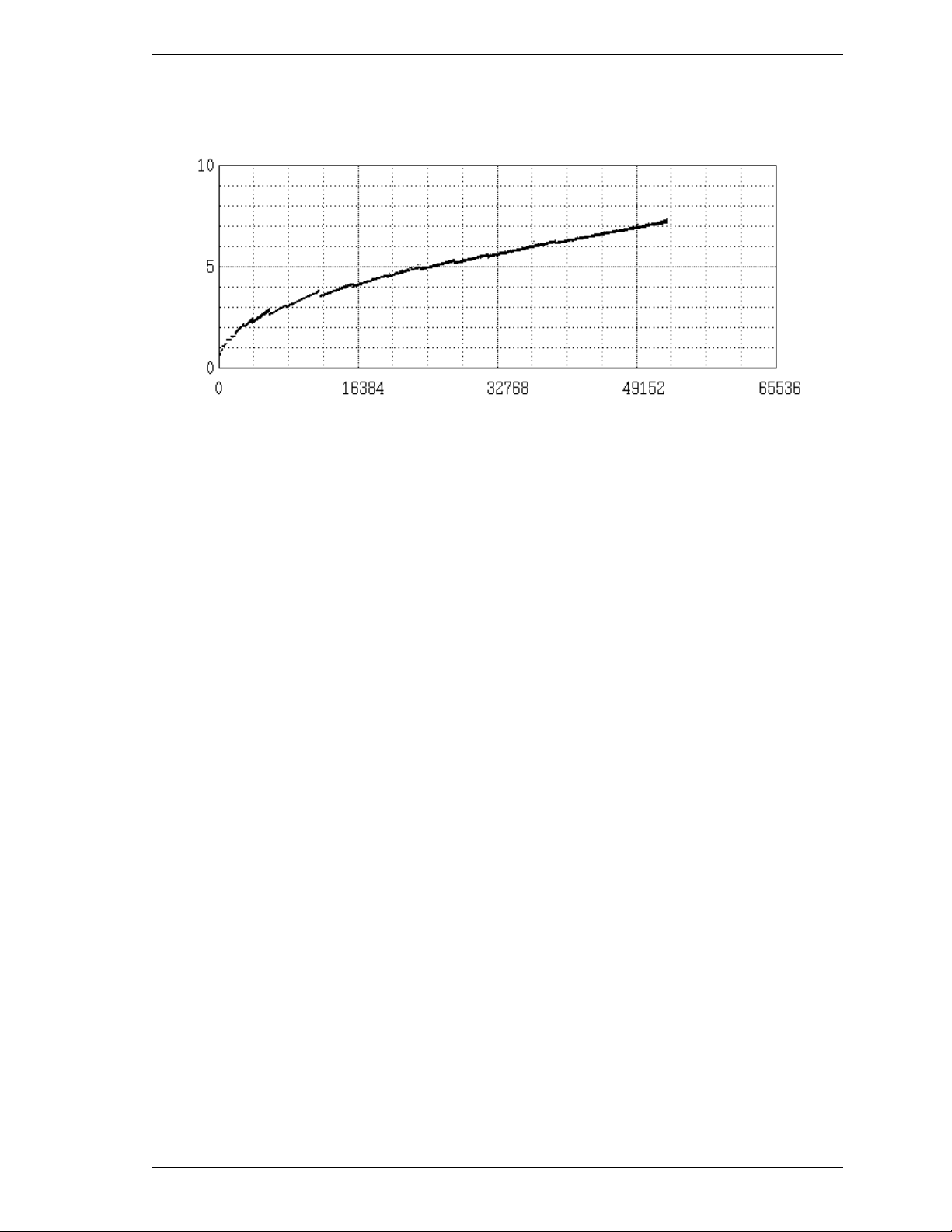

(*3) The seek time is as follows:

Seek time [ms]

2.1 Hardware Specifications

Seek Difference [4096 Cyl/div]

(*4) The start time is the time from power on or start command to when the HDD is ready, and the stop

time is the time for disks to completely stop from power off or stop command.

(*5) This value indicates at ready mode. Power supply at nominal voltage ±1%. 25°C ambient.

(*6) The maximum data transfer rate may be restricted to the response speed of initiator and by

transmission characteristics. 1MB/s=1,000,000 bytes/s.

(*7) Refer to 1.1 (12).

(*8) 1MB=1,048,576 bytes.

C141-E219

2-3

Page 26

Specifications

2.1.3 Environmental specifications

Table 2.3 lists environmental and power requirements.

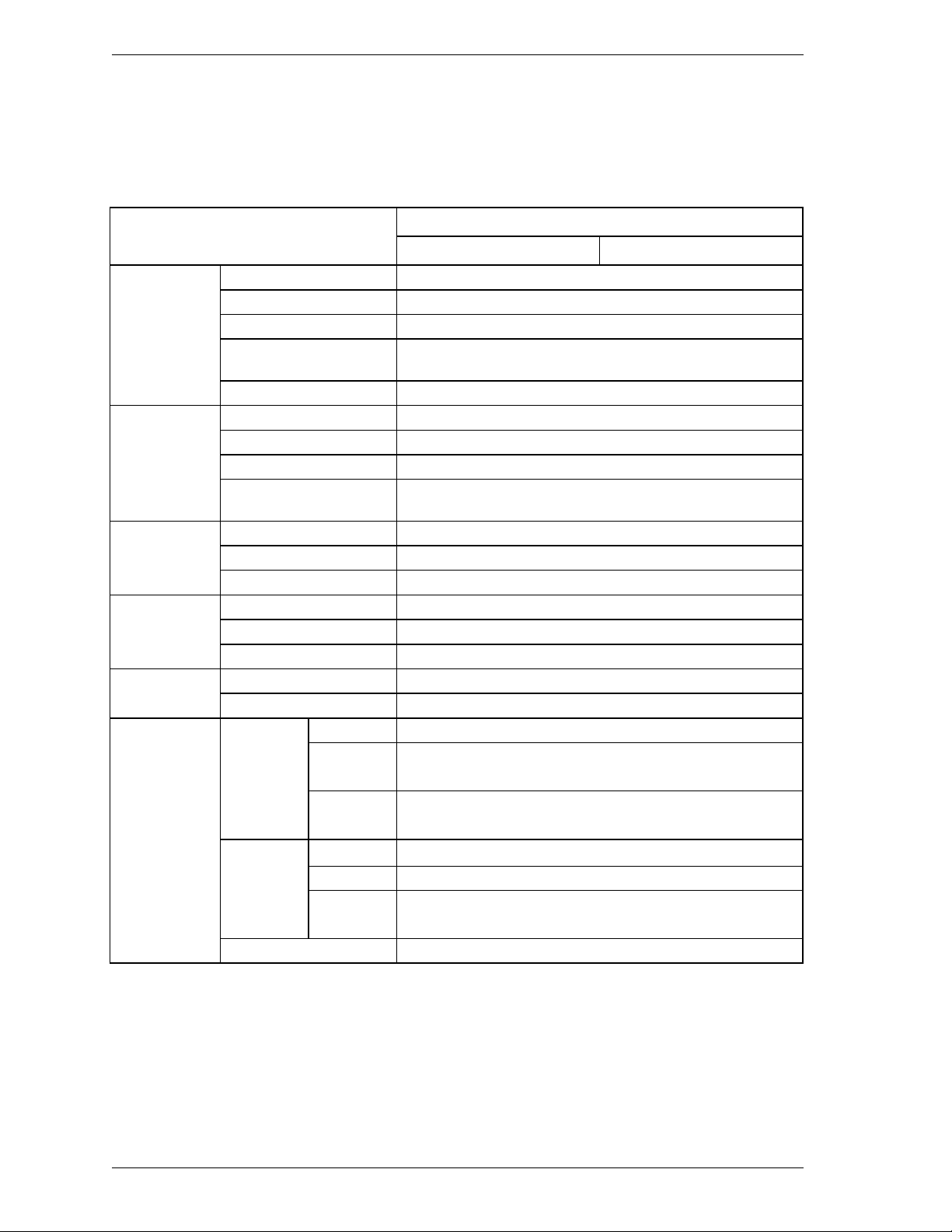

Table 2.3 Environmental/Power requirements

Temperature

(*1)

Relative

humidity

Vibration (*2)

Shock (*2)

Altitude

Power

requirements

(*5)

Item

Specification

MAV2073RC MAV2036RC

Operating 5 to 55°C

Non-operating –40 to 70°C

Transport (within a week) –40 to 70°C

DE surface temperature at

operating

5 to 60°C

Gradient 15°C/h or less

Operating 5 to 95%RH

Non operating 5 to 95%RH

Transport (within a week) 5 to 95%RH

Maximum wet bulb

temperature

29°C (no condensation)

Operating (*3) 0.6 mm (5 to 20Hz)/9.8 m/s2 (1G) (20 to 300 Hz) or less

Non-operating (*4) 3.1 mm (5 to 20Hz)/49m/s2 (5G) (20 to 300Hz) or less

Transport (packaged) 3.1 mm (5 to 20Hz)/49m/s

2

(5G) (20 to 300Hz) or less

Operating 980m/s2 (100G) / 1 ms duration

Non-operating 3,920m/s2 (400G) / 1 ms duration

Transport (packaged) 3,920m/s

2

(400G) / 1 ms duration

Operating –305 to +3.048 m (–1,000 to +10,000 feet)

Non-operating –305 to +12,192 m (–1,000 to +40,000 feet)

Idle 0.18 A (ave.)

+12V DC

±5%

Spin-up

Operating

(reference)

1.20 A (max.)

1.50 A (peak)

0.35 A (about 80 IOPS)

0.40 A (about 200 IOPS)

Idle 0.46 A (ave.)

+5V DC

±5%

Operating 1.20 A (max.)

Operating

(reference)

0.76 A (about 80 IOPS)

0.74 A (about 200 IOPS)

Ripple (*6) +5 V/+12 V less than 250 mVp -p

2-4 C141-E219

Page 27

2.1 Hardware Specifications

(*1) For detail condition, see Section 4.1.

(*2) Vibration applied to the drive is measured at near the mounting screw hole on the frame as much as

possible.

(*3) At random seek write/read and default on retry setting with log sweep vibration.

(*4) At power-off state after installation

Vibration displacement should be less than 2.5 mm.

(*5) Input voltages are specified at the drive connector side, during drive ready state.

(*6) High frequency noise (over 20MHz) is less than 100 mVp-p.

2.1.4 Error rate

Errors detected during initialization and replaced by alternate block assignments are not included in

the error rate. Data blocks to be accessed should be distributed over the disk medium equally.

(1) Unrecoverable error rate

Errors which cannot be recovered within 63 retries and ECC correction should not exceed 10 per

16

bits read.

10

(2) Positioning error rate

8

Positioning errors which can be recovered by one retry should be 10 or less per 10

seeks.

2.1.5 Reliability

(1) Mean Time Between Failures (MTBF)

MTBF of the HDD during its life time is 1,400,000 hours (operating: 24 hours/day, 7 days/week

average DE surface temperature: 50°C or less).

Note:

The MTBF is defined as:

Operating time (hours) at all field sites

MTBF=

The number of equipment failures from all field sites

Failure of the equipment means failure that requires repair, adjustments, or replacement.

Mishandling by the operator, failures due to bad environmental conditions, power trouble, host

system trouble, cable failures, or other failures not caused by the equipment are not considered.

C141-E219 2-5

Page 28

Specifications

(2) Mean Time To Repair (MTTR)

MTTR is the average time taken by a well-trained service mechanic to diagnose and repair a drive

malfunction. The drive is designed for a MTTR of 30 minutes or less.

(3) Service life

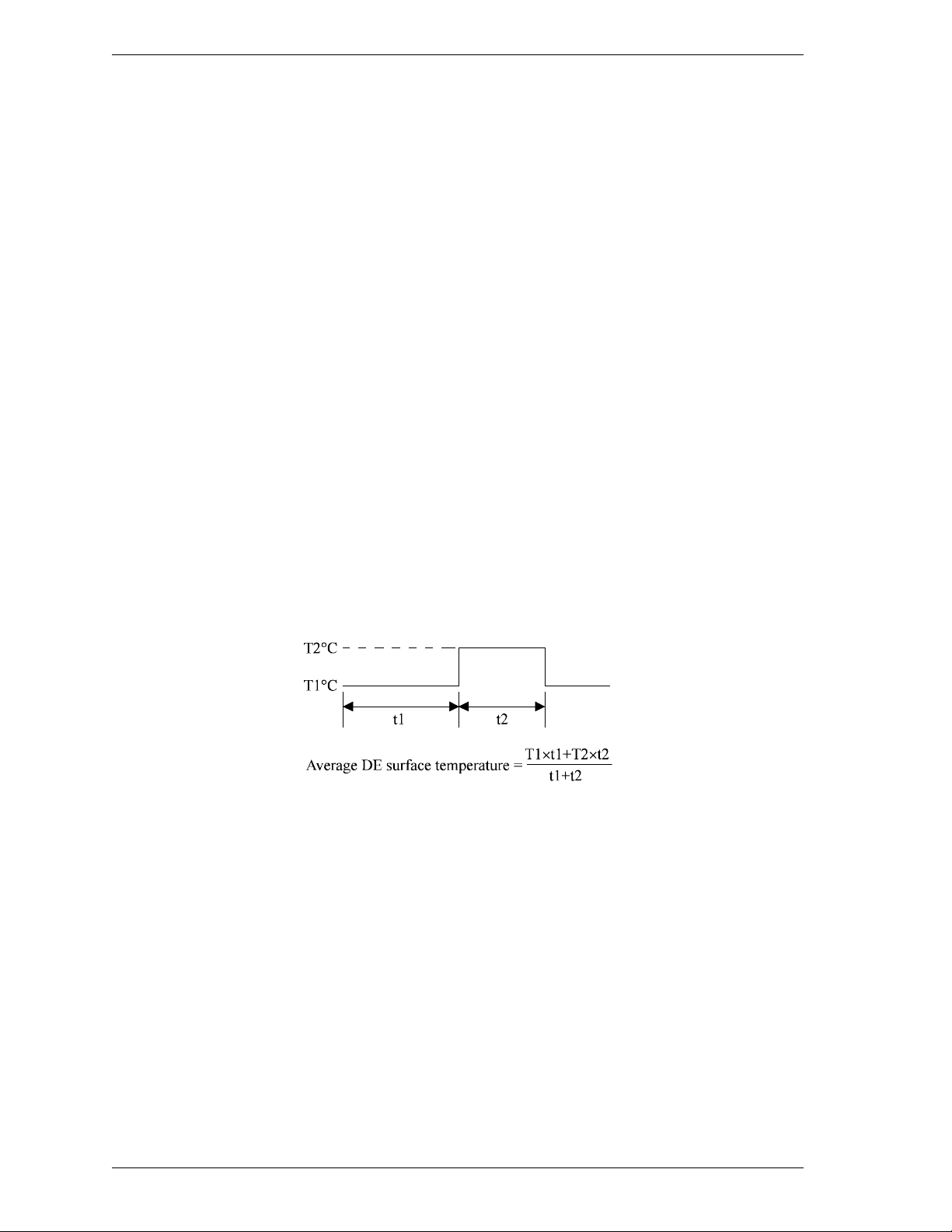

The service life under suitable conditions and treatment is as follows.

The service life is depending on the environment temperature. Therefore, the user must design the

system cabinet so that the average DE surface temperature is as low as possible.

• DE surface temperature: 40°C or less 5 years

• DE surface temperature: 41°C to 45°C 4.5 years

• DE surface temperature: 46°C to 50°C 4 years

• DE surface temperature: 51°C to 55°C 3.5 years

• DE surface temperature: 56°C to 60°C 3 years

• DE surface temperature: 61°C and more Strengthen cooling power so that DE surface

temperature is 60°C or less.

Even if the HDD is used intermittently, the longest service life is 5 years.

Note:

The "average DE surface temperature" means the average temperature at the DE surface

throughout the year when the HDD is operating.

(4) Data security at power failure

Integrity of the data on the disk is guaranteed against all forms of DC power failure except on

blocks where a write operation is being performed. The above does not applied to formatting disks

or assigning alternate blocks.

2-6 C141-E219

Page 29

CHAPTER 3 Data Format

3.1 Data Space

3.2 Logical Data Block Addressing

3.3 Defect Management

This chapter explains data space definition, logical data block addressing, and defect management on the

HDD.

3.1 Data Space

The HDD manages the entire data storage area divided into the following three data spaces.

• User space: Storage area for user data

• Internal test space: Reserved area for diagnostic purposes

• System space: Area for exclusive use of HDD itself

The user space allows a user access by specifying data. These spaces can be accessed with the

logical data block addressing method described in Section 3.2. The internal test space is used by

Read/write test of self-diagnostics test, but user can’t use direct access. The system space is accessed

inside the HDD at power-on or during the execution of a specific command, but the user cannot

directly access the system space.

3.1.1 Cylinder configuration

The HDD allocates cylinders to the user space, Internal test space, and system space. Figure 3.1 is

the cylinder configuration.

Spare areas (alternate areas) for defective sectors are provided in the user space. Several sectors in

the last track of one cell and the last cylinder (alternate cylinders) in one zone are allocated as

alternate areas according to the user's assignment (MODE SELECT command). See Subsection 3.1.2

for details.

C141-E219 3-1

Page 30

Data Format

N

Zone0

Physics Cylinder

Cylinder0

Head0

Head1

Cylinder0

Cylinder0

Head

(a-1)

-Z

m-1

m-1

m-1

Track

m-1

System space

-4

1

1

Spare sectors for each cell

User space

Spare sectors for each cell

Change

for cell

(b-1)

1

Alternate Cell

(b)

m-1

Zone1

Zone

(X-1)

(C)

Last Cylinder

ote: Spare sectors on the last track in each cylinder are not necessarily placed at the end of the track

(b-1)

because of a track skew or a cylinder skew. (Details are explained in Subsection 3.1.3.)

Spare Cylinder

Figure 3.1 Cylinder configuration

Apart from the above logical configuration, the HDD intends to increase the storage capacity by

dividing all cylinders into several zones and changing a recording density of each zone.

3-2 C141-E219

Page 31

3.1 Data Space

(1) User space

The user space is a storage area for user data. The data format on the user space (the length of data

block and the number of data blocks) can be specified with the MODE SELECT or MODE SELECT

EXTENDED command.

The user can also specify the number of logical data blocks to be placed in the user space with the

MODE SELECT or MODE SELECT EXTENDED command. When the number of logical data

blocks is specified, as many cylinders as required to place the specified data blocks are allocated in

the user space.

A number starting with 0 is assigned to each cylinder required in the user space in ascending order.

If the number of cylinders do not reach the maximum, the rest of the cylinders will not be used.

Always one cylinder is located at the end of each zone in the user space as an alternate cylinder.

Alternate cylinders will be used for alternate blocks. See Subsections 3.1.2 and 3.3.2 for details.

(2) Internal test space

The Internal test space is an area for diagnostic purposes only and its data block length is always

512Byte. The Internal test space consists of 8 cylinders and outer-most cylinder is always assigned

(cylinder −147 to −154). The user cannot change the number of cylinders in the Internal test space or

their positions.

(3) System space

The system space is an area for exclusive use of the HDD itself and the following information are

recorded.

• Defect list (P list and G list)

• MODE SELECT parameter (saved value)

• Statistical information (log data)

• Controller control information

The above information is duplicated in several different locations for safety.

Note:

The system space is also called SA space.

C141-E219 3-3

Page 32

Data Format

3.1.2 Alternate spare area

The alternate spare area consists of the last track of each cell in the user space and an alternate

cylinder allocated to the last cylinder of each zone.

The spare area in each cell is placed at the end of the last track as shown in Figure 3.2. These spare

sectors are located in the end of the track logically, not necessarily located at the end physically

because of track skew or cylinder skew. (Details are explained on Subsection 3.1.3.)

Size can be specified by the MODE SELECT command.

The number of spare sectors per cell can be specified from 0 to 200. The default for the spare sectors

number is 200.

Cell

Note: This drive manages alternate spare areas for each cell, which is a set of cylinders. One cell

consists of 27 cylinders.

Figure 3.2 Spare area in cell

An alternate cylinder is used when spare sectors in a cell are used up or 0 is specified as the number

of spare sectors in a cell. 1 cylinder at the end of each zone of the user space is allocated as alternate

cylinders as shown in Figure 3.3.

The user space and the CE space share the alternate cylinders.

Zone

Note: The number of alternate cylinders cannot be changed.

Figure 3.3 Alternate cylinder

3-4 C141-E219

Page 33

3.1 Data Space

3.1.3 Track format

(1) Physical sector allocation

Figure 3.4 shows the allocation of the physical sectors in a track. The length in bytes of each

physical sector and the number of sectors per track vary depending on the logical data block length.

The unused area (G4) exists at the end of the track in formats with most logical data block lengths.

The interval of the sector pulse (length of the physical sector) is decided by multiple of 50MHz free

running frequency. This clock is not equal to the interval of the byte clock for each zone. Therefore,

the physical sector length cannot be described with a byte length.

Servo frame

Figure 3.4 Track format

(2) Track skew and head skew

To avoid waiting for one turn involved in head and cylinder switching, the first logical data block in

each track is shifted by the number of sectors (track skew and head skew) corresponding to the

switching time. Figure 3.5 shows how the data block is allocated in each track.

At the head switching location in a cylinder, the first logical data block in track t + 1 is allocated at

the sector position which locates the track skew behind the sector position of the last logical data

block sector in track t.

At the cylinder switching location, like the head switching location, the first logical data block in a

cylinder is allocated at the sector position which locates the head skew behind the last logical sector

position in the preceding cylinder. The last logical sector in the cylinder is allocated when

formatting, and is an unused spare sector.

C141-E219 3-5

Page 34

Data Format

w

Head

Head

Track skew

Track skew

Figure 3.5 Track skew/head skew

Head ske

Leading logical

sector in head p+1

The number of physical sectors (track skew factor and head skew factor) corresponding to the skew

time varies depending on the logical data block length because the track skew and the head skew are

managed for individual sectors. The IDD automatically determines appropriate values for the track

skew factor and the head skew factor according to the specified logical data block length. The value

can be read out by the MODE SENSE or MODE SENSE EXTENDED command after the track has

been formatted.

3.1.4 Sector format

Each sector on the track consists of an ID field, a data field, and a gap field which separates them.

Figure 3.6 gives sector format examples.

SCT

SCT

G1

PLO

SyncG1

PLO

Sync

SM1

SM1

DATA1

DATA1

SM2 BCRCDATA2 ECC

Servo

SM2 DATA3

PAD

G2

PAD

G2

PLO

SyncG1

SCT

SM1

DATA1 SM2 DATA4

BCRC ECC

PAD

Figure 3.6 Sector format

SCT

G3

3-6 C141-E219

Page 35

3.1 Data Space

Each sector on the track consists of the following fields:

(1) Gaps (G1, G2, G3)

No pattern is written on the gap field.

(2) PLO Sync

In this field, pattern X'00' is written.

(3) Sync Mark (SM1, SM2)

In this field, special pattern is written. This special pattern indicates the beginning of the data field.

(4) Data field (DATA1-DATA4)

User data is stored in the data field of the sector. The length of the data field is equal to that of the

logical data block which is specified with a parameter in the MODE SELECT command. Any

multiple of 4 between 512 and 528 bytes can be specified as the length.

(5) BCRC

It is a 4-byte error detection code. Errors in the ID field. Single burst errors with lengths of up to 32

bits for each logical block can be detected.

(6) ECC

This is the 54-byte code that allows detection and correction of errors in the data field, which is

capable of correcting the single burst error up to 216 bits max. on the fly.

(7) PAD

A specified length of x‘00’ pattern is written in this field. This field includes the variation by rotation

and circuit delay till reading/writing.

C141-E219 3-7

Page 36

Data Format

3.1.5 Format capacity

The size of the usable area for storing user data on the IDD (format capacity) varies according to the

logical data block or the size of the spare sector area. Table 3.1 lists examples of the format capacity

when the typical logical data block length and the default spare area are used. The following is the

general formula to calculate the format capacity.

[Number of sectors of each zone] = [number of sectors per track × number of tracks per cell –

number of alternate spare sectors per cell] × [number of cells in the zone]

[Formatted capacity] = [total of sectors of all zones] ÷ [number of physical sectors in logical block] ×

[logical data block length]

The following formula must be used when the number of logical data blocks are specified with the

parameter in the MODE SELECT or MODE SELECT EXTENDED command.

[Format capacity] = [logical data block length] × [number of logical data blocks]

The logical data block length, the maximum logical block address, and the number of the logical data

blocks can be read out by a READ CAPACITY, MODE SENSE, or MODE SENSE EXTENDED

command after initializing the disk medium.

Table 3.1 Format capacity

Model Data block length User blocks Format capacity (GB)

MAV2073RC 287,277,984 73.5 (*)

MAV2036RC

(*) 1GB=1,000,000,000 bytes

Note:

Total number of spare sectors is calculated by adding the number of spare sectors in each primary

cylinder and the number of sectors in the alternate cylinders.

3.2 Logical Data Block Addressing

Independently of the physical structure of the disk drive, the HDD adopts the logical data block

addressing as a data access method on the disk medium. The HDD relates a logical data block

address to each physical sector at formatting. Data on the disk medium is accessed in logical data

block units. The INIT specifies the data to be accessed using the logical data block address of that

data.

512

143,638,992 36.7 (*)

The logical data block addressing is a function whereby individual data blocks are given addresses of

serial hexadecimal numbers in each drive.

3-8 C141-E219

Page 37

3.2 Logical Data Block Addressing

(1) Block address of user space

The logical data block address number is consecutively assigned to all of the data blocks in the user

space starting with 0 to the first data block.

The HDD treats sector 0, track 0, cylinder 0 as the first logical data block. The data block is

allocated in ascending order of addresses in the following sequence (refer to Figure 3.5):

1) Logical data blocks are assigned in ascending order of sector number in the same track.

2) Subsequent logical data blocks are assigned in ascending order of track number in the same head.

Within the same track, logical data blocks are assigned in the same way as step 1).

3) Subsequent logical data blocks are assigned to sectors in every track except the last track in

ascending order of track number in the same cell. Within the same track, logical data blocks are

assigned in the same way as step 1) and 2).

4) For the last track in the same cell, subsequent logical data blocks are assigned to sectors other

than spare sectors in ascending order of sector number.

5) After blocks have been assigned in the same cell according to steps 1) to 4), subsequent logical

data blocks are assigned in ascending order of cell number in the same way as in steps 1) to 4).

Logical data blocks are assigned starting from track 0 in the next cell until the last cylinder

(immediately preceding the alternate cylinder n-1 shown in Figure 3.1) of the zone except

alternate cylinders in cells in the user space.

When the logical data block is allocated, some sectors (track skew and head skew) shown in Figure

3.5 are provided to avoid waiting for one turn involving head and cylinder switching at the location

where the track or the head is physically switched.

See Subsection 3.3.2 for defective/alternate block treatment and the logical data block allocation

method in case of defective sectors exist on the disk.

(2) Alternate area

Alternate areas in the user space (spare sectors in the cell and alternate cylinders) are not included in

the above logical data block addresses. Access to sectors which are allocated as an alternate block in

the alternate area is made automatically by means of the HDD sector slip treatment or alternate block

treatment (explained in Subsection 3.3.2), so the user does not have to worry about accessing the

alternate area. The user cannot access with specifying the data block on the alternate area explicitly.

C141-E219 3-9

Page 38

Data Format

3.3 Defect Management

3.3.1 Defect list

Information of the defect location on the disk is managed by the defect list. The following are defect

lists which the HDD manages.

• P list (Primary defect list): This list consists of defect location information available at the disk

drive shipment and is recorded in a system space. The defects in this list are permanent, so the

INIT must execute the alternate block allocation using this list when initializing the disk.

• D list (Data defect list): This list consists of defect location information specified in a FORMAT

UNIT command by the INIT at the initialization of the disk. This information is recorded in the

system space of the disk drive as the G list. To execute the alternate block allocation, the

FORMAT UNIT command must be specified.

• G list (Growth defect list): This list consists of defective logical data block location information

specified in a REASSIGN BLOCKS command by the INIT, information on defective logical data

blocks assigned alternate blocks by means of the HDD automatic alternate block allocation,

information specified as the D list, and information generated as the C list. They are recorded in

the system space on the disk drive.

The INIT can read out the contents of the P and G lists by the READ DEFECT DATA command.

3.3.2 Alternate block allocation

The alternate data block is allocated to a defective data block (= sectors) in defective sector units by

means of the defect management method inside the HDD.

The INIT can access all logical data blocks in the user space, as long as there is no error.

Spare sectors to which alternate blocks are allocated can be provided in "alternate cylinders". See

Subsection 3.1.2 for details.

The INIT can specify the size and area for spare sectors by the MODE SELECT command at the

time of the initialization of the disk.

Both of the following are applicable to the alternate block allocation.

• Sector slip treatment: Defective sectors are skipped and the logical data block corresponding to

those sectors is allocated to the next physical sectors. This treatment is made on the same cell as

the defective sector's and is effective until all spare sectors in that cell are used up.

• Alternate sector treatment: The logical data block corresponding to defective sectors is allocated

to unused spare sectors in the alternate cylinder.

The alternate block allocation is executed by the FORMAT UNIT command, the REASSIGN

BLOCKS command, or the automatic alternate block allocation. Refer to Chapter 4 “Command

Specifications” and Subsection 5.3.2 “Auto alternate block allocation processing” of the Fibre

Channel Interface Specifications for details of specifications on these commands. The logical data

block is allocated to the next physically continued sectors after the above sector slip treatment is

made. On the other hand, the logical data block is allocated to spare sectors which are not physically

consecutive to the adjacent logical data blocks. If a command which processes several logical data

blocks is specified, the IDD processes those blocks in ascending order of logical data block.

3-10 C141-E219

Page 39

3.3 Defect Management

(1) Alternate block allocation during FORMAT UNIT command execution

When the FORMAT UNIT command is specified, the allocation of the alternate block to those

defective sectors included in the specified lists (P, G, or D) is continued until all spare sectors in the

same cell are used up. When they are used up, unused spare sectors in the alternate cylinder are

allocated to the subsequent sectors in the cylinder by means of alternate sector treatment. Figure 3.7

is examples of the alternate block allocation during the FORMAT UNIT command execution.

: n represents a logical data block number

: Defective sector

: Unused spare sector

Figure 3.7 Alternate block allocation by FORMAT UNIT command

During FORMAT UNIT command, alternate block allocation is conducted in following cases:

1) Unrecovered write offtrack condition during a media write

2) Uncorrectable Data Error during a media read (certification) *1

C141-E219 3-11

Page 40

Data Format

If above errors are detected during FORMAT UNIT command, the HDD allocates the alternate

block(s) to the defective data blocks. Reassign procedure itself is the same as one in REASSIGN

BLOCKS command.

*1 Certification is permitted when DCRT flag is cleared (DCRT flag=0) in FORMAT UNIT

command.

The HDD checks all initialized logical data blocks by reading them out after the above alternate

block allocation is made to initialize (format) the disk.

(2) Alternate block allocation by REASSIGN BLOCKS command

When the REASSIGN BLOCKS command is specified, the alternate block is allocated to the

defective logical data block specified by the initiator by means of alternate sector treatment. The

alternate block is allocated to unused spare sectors in the alternate cylinder.

Figure 3.8 is examples of the alternate block allocation by the REASSIGN BLOCKS command.

Example Reassign: Block 16

: n represents a logical data block number

: Defective sector

: Unused spare sector

Figure 3.8 Alternate block allocation by REASSIGN BLOCKS command

3-12 C141-E219

Page 41

3.3 Defect Management

(3) Automatic alternate block allocation

• Automatic alternate block allocation at read operation

If the ARRE flag in the MODE SELECT parameter permits the automatic alternate block allocation,

the HDD automatically executes the alternate block allocation and data duplication on the defective

data block detected during the READ or READ EXTENDED command. This allocation method is

the same as with the REASSIGN BLOCKS command (alternate sector treatment).

• Automatic alternate block allocation at write operation

If AWRE flag in the MODE SELECT parameter permits the automatic alternate block allocation, the

HDD executes two kinds of automatic alternate processing during WRITE command processing as

described below:

Type 1 (Reassignment of Uncorrectable Read Error)

1) Commands to be applied

- WRITE

- WRITE EXTEND

- WRITE at executing WRITE AND VERIFY

2) Application requirements

When any of the above commands is issued to LBA registered in the uncorrectable error log of

the READ command (LBA log of uncorrectable error while the READ command is executed),

the AWRE processing is applied.

3) AWRE processing

The following processings are performed when the LBA matches the one in the uncorrectable

error log:

a) Primary media check

- Creates an uncorrectable error pattern (invalid LBA pattern) in the position of the error

LBA, repeats the primary media check up to three times. If the error still occurs after the

check repeated three times, it is judged to be defective. Then, it performs the alternate

processing.

b) Alternate processing

- Alternate media check

Writes the data that causes an unrecoverable error into the alternate block, and performs

the media check.

(If the alternate block is a defective sector, the block is registered to the G list, another

alternate block is allocated.)

c) SA and defect map update processing (on alternate side)

When an error occurs in the alternate processing, this WRITE command terminates with error.

When the alternate processing normally terminates, the WRITE command is executed.

C141-E219 3-13

Page 42

Data Format

Type 2 (Reassignment of write fail sector)

1) Commands to be applied

- WRITE

- WRITE EXTENDED

- FORMAT UNIT

- WRITE at executing WRITE AND VERIFY

2) Application requirements / processing

When WRITE/WRITE EXTENDED command detects any Servo error (e.g. Write offtrack error)

and cannot be recovered within pre-determined retry number (specified in Mode Parameter). For

the sectors around defective Servo, alternate blocks are allocated and the data of this WRITE

commands are re-written.

Sectors to be made AWRE shall be following:

- the sector where the error occurs and the latter sectors and,

- the sectors whose data are logically continual and stored in Cache,

- the sectors which will be processed in this Write command and,

- the sectors which locate between erroneous Servo -1 and +1 (including Split sector)

This function is also applied for the sector that has already been re-assigned.

Remark:

When a write protection is prohibited through the setting terminal, the auto alternate block

allocation processing specification is disabled.

Automatic alternate block allocation is made up to the following

quantities during the execution of one command:

ARRE = Twice

AWRE (Type 1) = Eight times

AWRE (Type 2) = Maximum number which can be processed within

the recovery time limit

If more than the above mentioned defective block is detected, the

alternate block assignment processing for the first defective block is

executed but the alternate block assignment processing for the second

one is not executed and the command being executed terminates.

However, the initiator can recover the twice error by issuing the same

command again.

When an error is detected in a data block in the data area, recovery

data is rewritten and verified in automatic alternate block allocation

during the execution of the READ or READ EXTENDED command.

Alternate block allocation will not be made for the data block if

recovery is successful.

Example: Even if the data error which is recoverable by the WRITE

LONG command is simulated, automatic alternate block

allocation will not be made for the data block.

3-14 C141-E219

Page 43

CHAPTER 4 Installation Requirements

4.1 Mounting Requirements

4.2 Power Supply Requirements

4.3 Connection Requirements

This chapter describes the environmental, mounting, power supply, and connection requirements.

4.1 Mounting Requirements

4.1.1 Dimensions

Figures 4.1 show the dimensions of the HDD and the location of the mounting screw holes.

[Units: mm]

Figure 4.1 Dimensions

C141-E219 4-1

Page 44

Installation Requirements

4.1.2 Mounting orientations

The permissible orientations of the HDD are shown in Figure 4.2, and the tolerance of the angle is

±5° from the horizontal plane.

As show in Figure 4.2, the drive can be installed flat on any of its six sides. Inclination from a

vertical or horizontal plane should not exceed 5°.

(a) Horizontal –1 (b) Horizontal –2

(c) Vertical –1 (d) Vertical –2

(e) Upright mounting –1 (f) Upright mounting –2

Direction of gravity

Figure 4.2 HDD orientations

4-2 C141-E219

Page 45

4.1.3 Notes on mounting

Damage

Never remove any labels from the drive or deface them in any way.

(1) The mounting screws must use M3 × 0.5 metric

(2) Examples of mounting frame structure

Special attention must be given to mount the HDD as follows.

a) As shown in Figure 4.3, use the frame with an embossed structure, or the like. Mount the

HDD with making a gap of 2.5 mm or more between the HDD and the frame of the system.

4.1 Mounting Requirements

b) The inward projection of the screw from the HDD frame wall at the corner must be 2.5 mm

±0.5 mm.

c) Tightening torque of screw must be secured with 0.49N·m (5kgf·cm) ±12%.

d) Impact caused by the electric screwdriver must be within the drive specifications.

e) Must be handled on an anti-static mat.

(3) Limitation of side-mounting

Use all 4 mounting holds on the both sides.

(4) Limitation of bottom-mounting

Use all 4 mounting holds on the bottom face.

C141-E219 4-3

Page 46

Installation Requirements

Figure 4.3 Mounting frame structure

(5) Never cover the vent hole as shown in Figure 4.4.

Vent hole

Figure 4.4 Breathing hole location

Label

4-4 C141-E219

Page 47

4.3 Connection Requirements

(6) Environmental temperature

Temperature condition at installed in a cabinet is indicated with ambient temperature measured

30 mm from the disk drive. At designing the system cabinet, consider following points.

• Make a suitable air flow so that the DE surface temperature never exceed 60°C.

• Cool the PCA side especially with air circulation inside the cabinet. Confirm the cooling effect

by measuring the surface temperature of specific ICs and the DE. These measurement results

must satisfy the temperature condition listed in Table 4.1.

• Keeping the DE surface temperature at 50°C or below at ambient temperature 30°C, which is a

condition for assuring an MTBF of 1,400,000 hours, requires an air flow of 0.5 m/s or more.

Table 4.1 Surface temperature check point and maximum temperature

No. Measurement point Maximum temperature

1 DE Surface 60°C

2 Read channel LSI 80°C

3 VCM/SPM Driver 93°C

4 HDC 92°C

5 MPU 90°C

Figure 4.5 Surface temperature measurement points

C141-E219 4-5

Page 48

Installation Requirements

(7) Service clearance area

The service clearance area, or the sides which must allow access to the HDD for installation or

maintenance, is shown in Figure 4.6.

[Surface X]

•

Holes for mounting screw

[Surface Y]

• Interface connection

(Both Side)

(8) Environmental magnetic field

Do not install the HDD in the vicinity of equipment giving off strong magnetic fields, such as

monitors, televisions, or loudspeakers.

(9) Leakage magnetic flux

Do not mount the HDD near the devices that the leakage magnetic flux influence easily.

[Surface Z]

• Holes for mounting screw

Figure 4.6 Service clearance area

4-6 C141-E219

Page 49

4.2 Power Supply Requirements

4.2 Power Supply Requirements

(1) Allowable input voltage and current

The power supply input voltage measured at the power supply connector pin of the HDD (receiving

end) must satisfy the requirement given in Subsection 2.1.3. (For other requirements, see Items (4)

below.)

(2) Current waveform (reference)

Figure 4.7 shows the waveform of +12V DC.

MAV2073RC

MAV2036RC

Current (500mA/div)

Current (500mA/div)

(3) Power on/off sequence

The order of the power on/off sequence of +5V DC and +12V DC, supplied to the HDD, does not

matter.

(4) Sequential starting of spindle motors

After power is turned on to the HDD, a large amo unt of current flows in the +12V DC line when the

spindle motor rotation starts. Therefore, if more than one HDD is used, the spindle motors should be

started sequentially using one of the following procedures to prevent overload of the power supply

unit.

a) Control the sending of the NOTIFY (ENABLE SPINUP) primitive so that the spindle motors of

individual disk drives are started in intervals of 12 seconds or more.

b) Turn on the +12V DC power in the power supply unit at more than 12-second intervals to start

the spindle motors sequentially.

Time (2 sec/div)

Figure 4.7 Current waveform (+12V DC)

Time (2 sec/div)

C141-E219 4-7

Page 50

Installation Requirements

(5) Noise filter

To eliminate AC line noise, a noise filter should be installed at the AC input terminal on the HDD

power supply unit. The specification of this noise filter is as follows:

• Attenuation: 40 dB or more at 10 MHz

• Circuit construction: T-configuration as shown in Figure 4.8 is recommended.

Figure 4.8 AC noise filter (recommended)

4.3 Connection Requirements

4.3.1 Connector

Figure 4.9 shows the locations of interface connector.

Interface connector (CN1)

(power lines included)

Figure 4.9 Connector location

4-8 C141-E219

Page 51

4.3 Connection Requirements

4.3.2 Interface connector

Figure 4.10 shows the SAS type interface connector (SAS plug) overview.

Table 4.2 lists the signal allocation of the SAS plug on the HDD.

S1

S7

P1

P15

S14

S8

Figure 4.10 SAS plug connector overview

C141-E219 4-9

Page 52

Installation Requirements

Table 4.2 Interface connector (SAS plug) signal allocation:CN1

Pin No. Signal Description

S1 GND GND for SAS Primary Port

S2 RP+ SAS Primary Port Receive(positive) signal

S3 RP- SAS Primary Port Receive(negative) signal

S4 GND GND for SAS Primary Port

S5 TP- SAS Primary Port Transmit(negative) signal

S6 TP+ SAS Primary Port Transmit(positive) signal

S7 GND GND for SAS Primary Port

Note1

S8

GND GND for SAS Secondary Port

Note1

S9

Reserved (not used) Not used

Note1

S10

S11

S12

S13

S14

P1

P2

P3

Note 1) S8 - S14 are SAS Secondary Port signals, and not used on MAV2073RC and MAV2036RC.

Reserved (not used) Not used

Note1

GND GND for SAS Secondary Port

Note1

Reserved (not used) Not used

Note1

Reserved (not used) Not used

Note1

GND GND for SAS Secondary Port

Note2

Reserved (not used) Not used

Note2

Reserved (not used) Not used

Note2

Reserved (not used) Not used

P4 GND GROUND

P5 GND GROUND

P6 GND GROUND

P7 +5V-Charge Pre-charge pin for +5V

P8 +5V +5V power supply input

P9 +5V +5V power supply input

P10 GND GROUND

P11 READY LED READY LED output

P12 GND GROUND

P13 +12V-Charge Pre-charge pin for +12V

P14 +12V +12V power supply input

P15 +12V +12V power supply input

Note 2) P1 to P3 are 3.3V power supply input and pre-charge signals, and not used on MAV2073RC and

MAV2036RC.

4-10 C141-E219

Page 53

CHAPTER 5 Installation

5.1 Notes on Handling Drives

5.2 Setting

5.3 Mounting Drives

5.4 Checking Operation after Installation and Preparing

the HDD for Use

5.5 Dismounting Drives

5.6 Spare Disk Drive

This chapter describes the notes on handling drives, setting, mounting drives, confirming drive operations

after installation and preparation for use, and dismounting drives.

5.1 Notes on Handling Drives

The items listed in the specifications in Table 2.3 must be strictly observed.

(1) General notes

a) Do not give the drive shocks or vibrations exceeding the value defined in the specifications

because it may cause critical damage to the drive. Especially be careful when unpacking.

b) Do not leave the drive in a dirty or contaminated environment.

c) Since static discharge may destroy the CMOS semiconductors in the drive, note the following

after unpacking:

• Use an antistatic mat and body grounding when handling the drive.

• Hold the DE when handling the drive. Do not touch PCAs except for setting.

High temperature

To prevent injury, never touch the drive while it is hot. The DE and

LSI become hot during operation and remain hot immediately after

turning off the power.

C141-E219 5-1

Page 54

Installation

(2) Unpackaging

a) Use a flat work area. Check that the "This Side Up" sign side is up. Handle the package on soft

material such as a rubber mat, not on hard material such as a desk.

b) Be careful not to give excess pressure to the internal unit when removing cushions.

c) Be careful not to give excess pressure to the PCA and interface connector when removing the

drive from the antistatic bag.

d) Do not remove any labels from the drive. Never open the DE for any reason.

(3) Installation/removal/replacement

a) Do not move the drive when power is turned on or until the drive completely stops (for

15 seconds) after power is turned off.

b) Place and keep removed screws and other parts where they will not get lost or damaged.

c) Keep a record of all maintenance work for replacing.

(4) Packaging

a) Store the drive in the antistatic bag.

b) It is recommended to use the same cushions and packages as those at delivery. If those at

delivery cannot be used, use a package with shock absorption so that the drive is free from direct

shocks. In this case, fully protect the PCA and interface connector so that they are not damaged.

(5) Delivery

a) When delivering the drive, provide packaging and do not turn it over.

b) Minimize the delivery distance after unpacking and avoid shocks and vibrations with cushions.

For the carrying direction at delivery, use one of the mount allowable directions in Subsection

4.1.2.

(6) Storage

a) Provide moistureproof packaging for storage.

b) The storage environment must satisfy the requirements specified in Subsection 2.1.3 when the

drive is not operating.

c) To prevent condensation, avoid sudden changes in temperature.

5-2 C141-E219

Page 55

5.2 Setting

5.2 Setting

5.2.1 Port Address

Every device that uses the SAS interface has a unique SAS address, and commands use an SAS