Page 1

C150-E071-01EN

M3093DE/DG Image Scanner

Cleaning and Maintenance

Page 2

Page 3

01

Date publishedEdition

September,1996 First edition

Revised contents

Specification No. C150-E071-01EN

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his

own expense.

This digital apparatus does not exceed the Class A limit for radio noise emissions

from digital apparatus set out in the Radio interference Regulations of the Canadian

Department of Communications.

Le pésent appareil numérique n’ément pas de bruits radioélectriques dépassant les

limites applicables aux appareils numériques de la classe A prescridtes dans le

Réglesment sur le brouillage radioélectrique dicté par le ministere des Communications du Canada.

MaschinenlärmInformationsverordnung 3. GSGV, 18.01.1991:Der arbeisplatzbezogene Schalldruckpegel beträgt 70dB(A)oder weniger gemäß ISO 7779.

The contents of this manual may be revised without prior notice.

All Rights Reserved, Copyright © 1996 FUJITSU LIMITED.

Printed in Japan.

No part of this manual may be reproduced in any form without permission.

Page 4

Please send your comments on this manual or on Fujitsu products

to the following addresses:

FUJITSU COMPUTER PRODUCTS OF

AMERICA,INC.

2904 Orchard Parkway,San Jose.

California 95134-2022,U.S.A.

TEL:1-408-432-6333

FAX:1-408-432-3908

Home page:http://www.fcpa.com/

FUJITSU AUSTRALIA LIMITED

475 Victoria Avenue Chatswood.

N.S.W2067,AUSTRALIA

TEL:61-2-410-4555

FAX:61-2-411-8603

FUJITSU CANADA,INC.

2800 Matheson Blvd.East,Mississauga.

Ontario 4X5,CANADA

TEL:1-905-602-5454

FAX:1-905-602-5457

FUJITSU DEUTSCHLAND GmbH.

Frankfurter Ring 211,

8000 München 40,F.R,GERMANY

TEL:49-89-32378-0

FAX:49-89-32378-100

FUJITSU ESPAÑA,S.A

Edificio torre Europa 5

Paseo de la Castellana 95 Madrid 28046,SPAIN

TEL:34-1-581-8400

FAX:34-1-581-8125

FUJITSU EUROPE LTD.

2,Longwalk Road,Stockey Park,Uxbridge

Middlesex,UB11 1AB,U.K

TEL:44-81-573-4444

FAX:44-81-573-2643

Home page:http://www.fujitsu-europe.com/

a

FUJITSU FRANCE S.A.

Bâtiment Aristote,17 rue Olof palme

94006 Créteil cedex,FRANCE

TEL:33-14-513-1616

FAX:33-14-399-0700

FUJITSU HONG KONG Limited

Room 2521,Sum Hung Kai Centre

30 Harbour Road Wanchal,Hong Kong

TEL:852-827-5780

FAX:852-827-4724

TLX:62667

FUJITSU ITALIA S.p.A.

Via Melchiorre Gioia,No.8-20124

Milano,ITALY

TEL:39-2-6351

FAX:39-2-6572257

FUJITSU NORDIC AB

Kung Hans vag,S-19176

Sollentuna,SWEDEN

TEL:46-8-626-6000

FAX:46-8-626-6711

FUJITSU LIMITED

International Operations

Marunouchi 1-6-1, Chiyoda-ku,Tokyo 100

JAPAN

TEL:(81-3)3216-3211

FAX:(81-3)3213-7174

TLX:J2283

Cable:”FUJITSU LIMITED TOKYO”

Home page:http://www.fujitsu.co.jp/

Page 5

IMPORTANT NOTE TO USERS

READ CAREFULLY ALL OF THIS MANUAL BEFORE USING THIS PRODUCT.

IF NOT USED CORRECTLY, UNEXPECTED DAMAGES MAY BE CAUSED TO

THE USERS OR THE BYSTANDERS.

While all efforts have been made to ensure the accuracy of all information in this

manual, FUJITSU assumes no liability to any party for any damage caused by

errors or omissions or by statements of any kind in this manual, its updates or

supplements, whether such errors are omissions or statements resulting from

negligence, accidents, or any other cause. FUJITSU further assumes no liability

arising from the application or use of any product or system described herein; nor

any liability for incidental or consequential damages arising from the use of this

manual. FUJITSU disclaims all warranties regarding the information contained

herein, whether expressed, implied, or statutory.

FUJITSU reserves the right to make changes to any products herein, to improve

reliability, function, or design, without further notice and without obligation.

i

Page 6

Preface

This manual explains how to clean and maintain the M3093DE/DG image

scanner.

The M3093DE/DG is highly functional image scanner developed for volume

filing, using charge-coupled device (CCD) image sensors. This scanner

features duplex scanning and high quality image, processing with an

automatic document feeder (ADF).

Refer to Operator’s Guide for basic information about the M3093DE/DG.

ii

Page 7

Conventions

Special information, such as warnings, cautions are indicated as follows:

WARNING

WARNING indicates that personal injury may result if you do not follow a

procedure correctly.

CAUTION

CAUTION indicates that damage to the scanner may result if you do not follow a

procedure correctly.

The following symbols are used in this manual.

Used for general WARNING and CAUTION.

Be careful not to pinch your fingers or hands.

iii

Page 8

Page 9

CONTENTS

CHAPTER 1 DESCRIPTION ............................................................................. 1-1

CHAPTER 2 OPERATING INSTRUCTION....................................................... 2-1

CHAPTER 3 CLEANING................................................................................... 3-1

Units ............................................................................................. 1-2

Assemblies ................................................................................... 1-4

Indicators ...................................................................................... 1-5

LED functions ........................................................................ 1-5

Loading Document on the ADF .................................................... 2-2

Loading Document on the Flatbed ............................................... 2-7

Loading Document Larger than the Document Board .................. 2-8

Reading a Page from a Thick Book.............................................. 2-9

Cleaning Supplies and Cleaning Area.......................................... 3-2

Supplies................................................................................. 3-2

Cleaning area ........................................................................ 3-3

Cleaning the ADF ......................................................................... 3-4

Cleaning the Flatbed .................................................................... 3-9

CHAPTER 4 REPLACEMENT OF PARTS ....................................................... 4-1

Pad ASY or Pad ........................................................................... 4-2

Pick Roller .................................................................................... 4-4

CHAPTER 5 TROUBLESHOOTING ................................................................. 5-1

Paper JAM.................................................................................... 5-2

Initial Checks ................................................................................ 5-3

Test Mode for Maintenance........................................................ 5-17

Problem Checklist....................................................................... 5-19

v

Page 10

Page 11

CHAPTER

OPERATING

INSTRUCTION

CLEANING

TROUBLESHOOTING

REPLACEMENT

OF PARTS

1

DESCRIPTION

DESCRIPTION

DESCRIPTION

CHAPTER

CHAPTER

CHAPTER

2

OPERATING INSTRUCTION

CHAPTER

4

REPLACEMENT OF PARTS

5

TROUBLESHOOTING

3

CLEANING

Page 12

Page 13

CHAPTER

1

DESCRIPTION

This chapter describes units, assemblies, indicators and LED

functions.

Units

DESCRIPTION

Assemblies

Indicators

1-1

Page 14

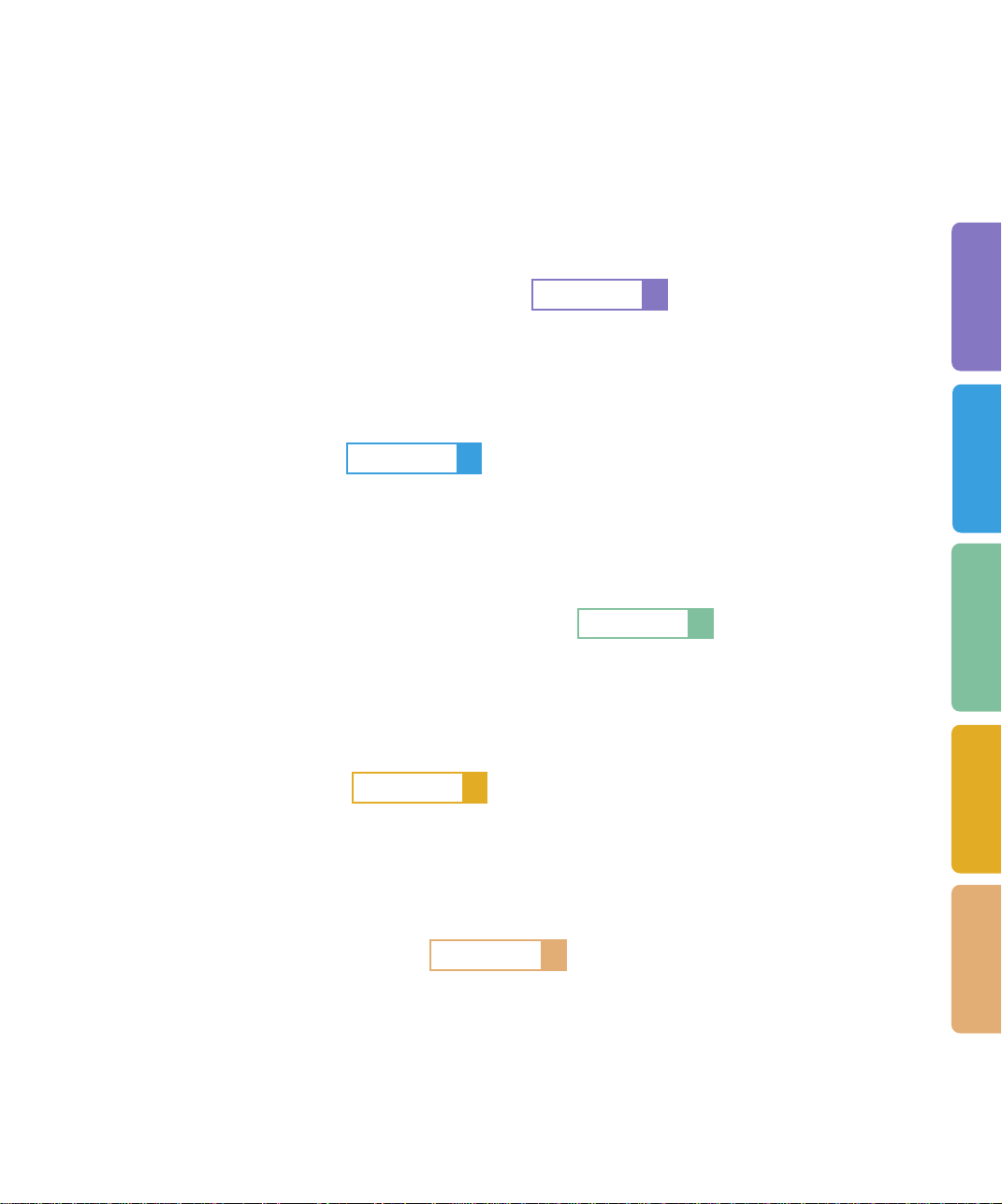

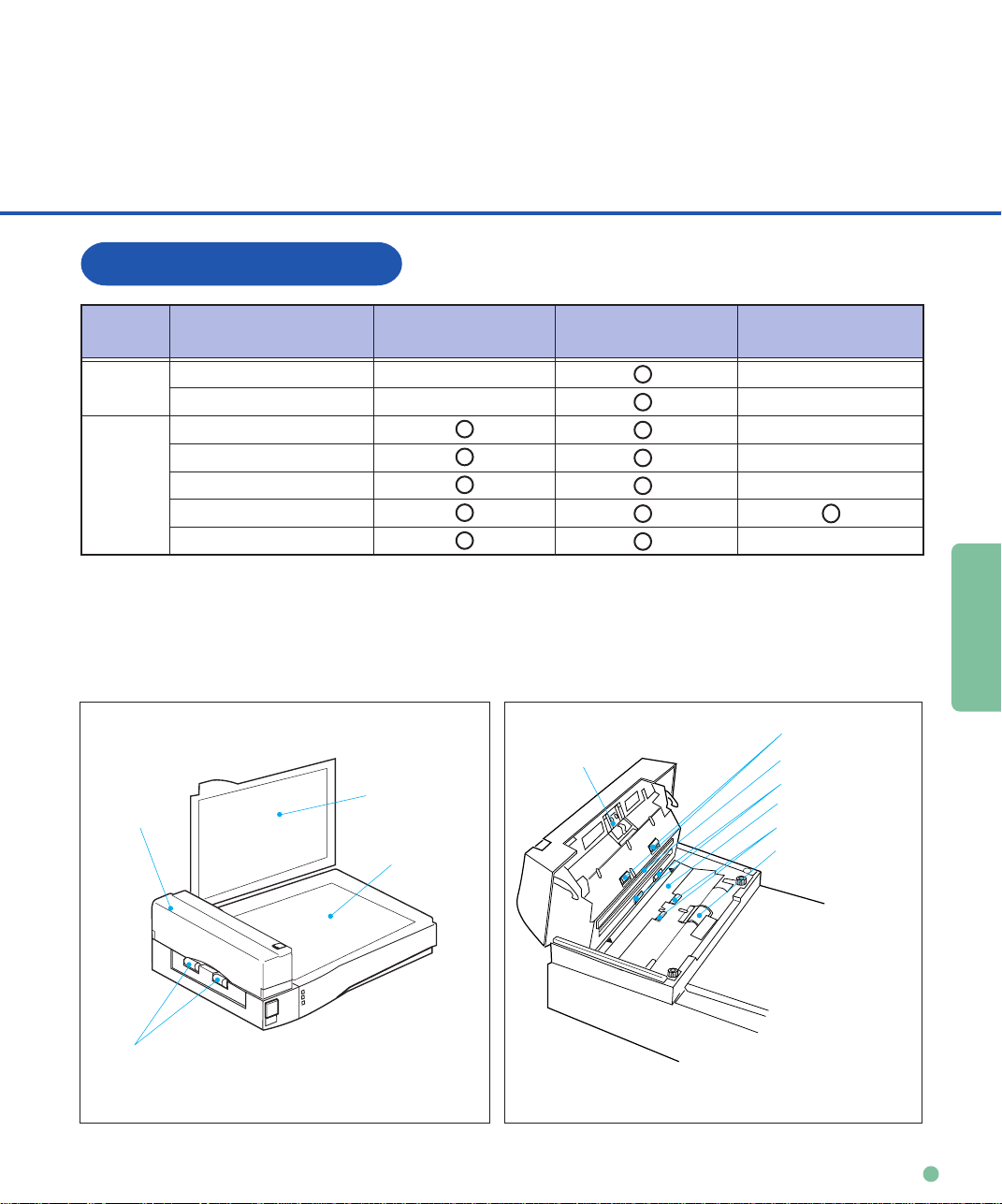

Units

1

ADF

5

Stacker

ADF lever2 ADF paper chute

3

Indicators

4

M3093DE

6

Document holding padDocument cover

7

M3093DG

8

Document bed

1-2

13

Power switch

12

Power inlet

10

11

Memory cover

Interface cable

9

Third party slot

14

Address switch

Page 15

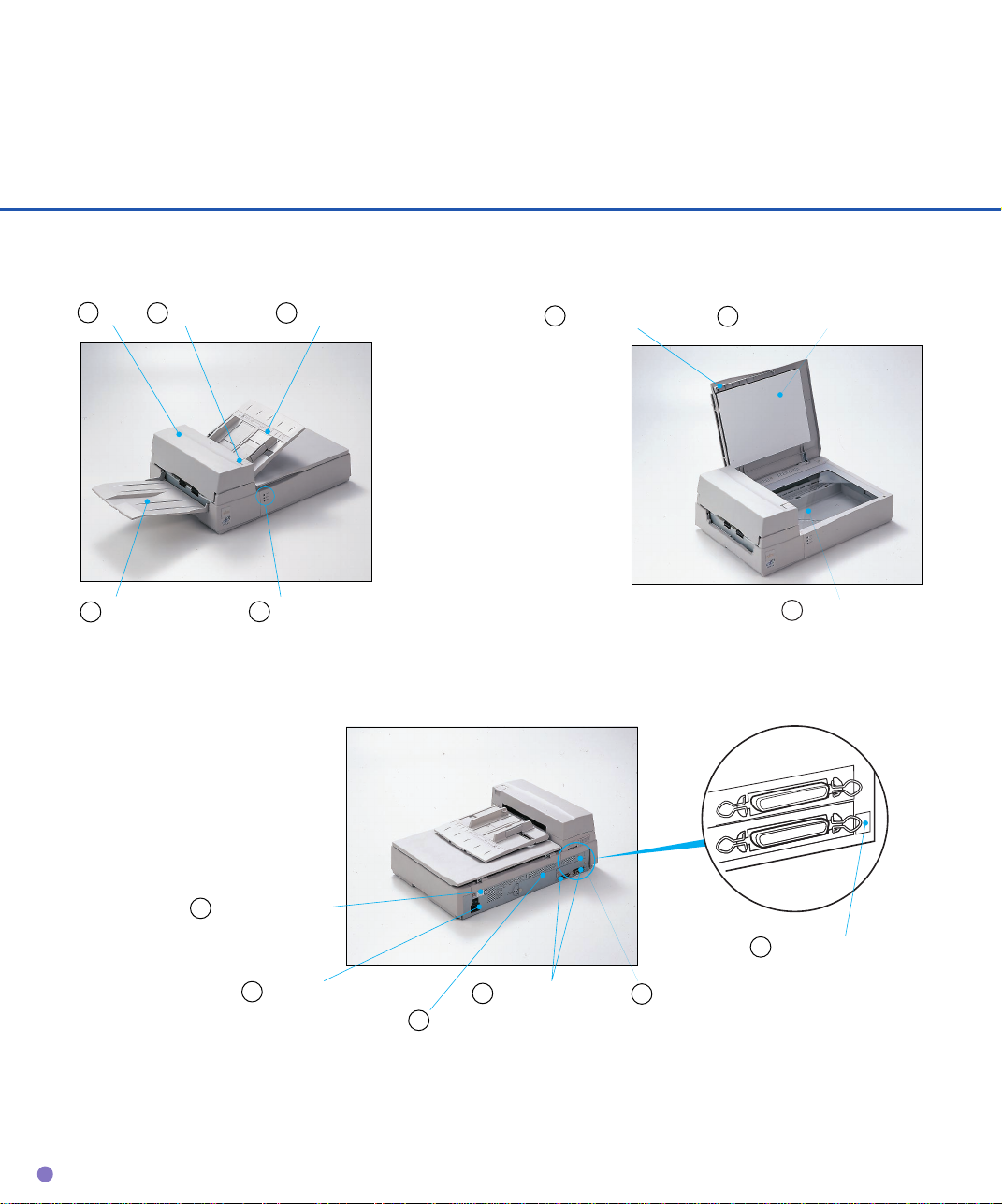

No. Function

1

2

3

4

5

6

7

8

9

Connected to the host system with interface cables.

10

11

Automatically feeds documents to the reading position.

Opens/closes ADF to remove the jammed documents.

Holds the documents to be fed by ADF.

Indicate the status of the scanner.

Stacks the read documents.

Covers a document to be read.

Presses a document to the document bed.

A document to be read is placed. Also called Flatbed. (FB)

Third party slot (M3093DE)

Open here when installing or replacing Memory option.

DESCRIPTION

12

13

14

Connect the power cable from an AC power outlet here.

Power switch.

Used for setting SCSI-ID. (M3093DG)

1-3

Page 16

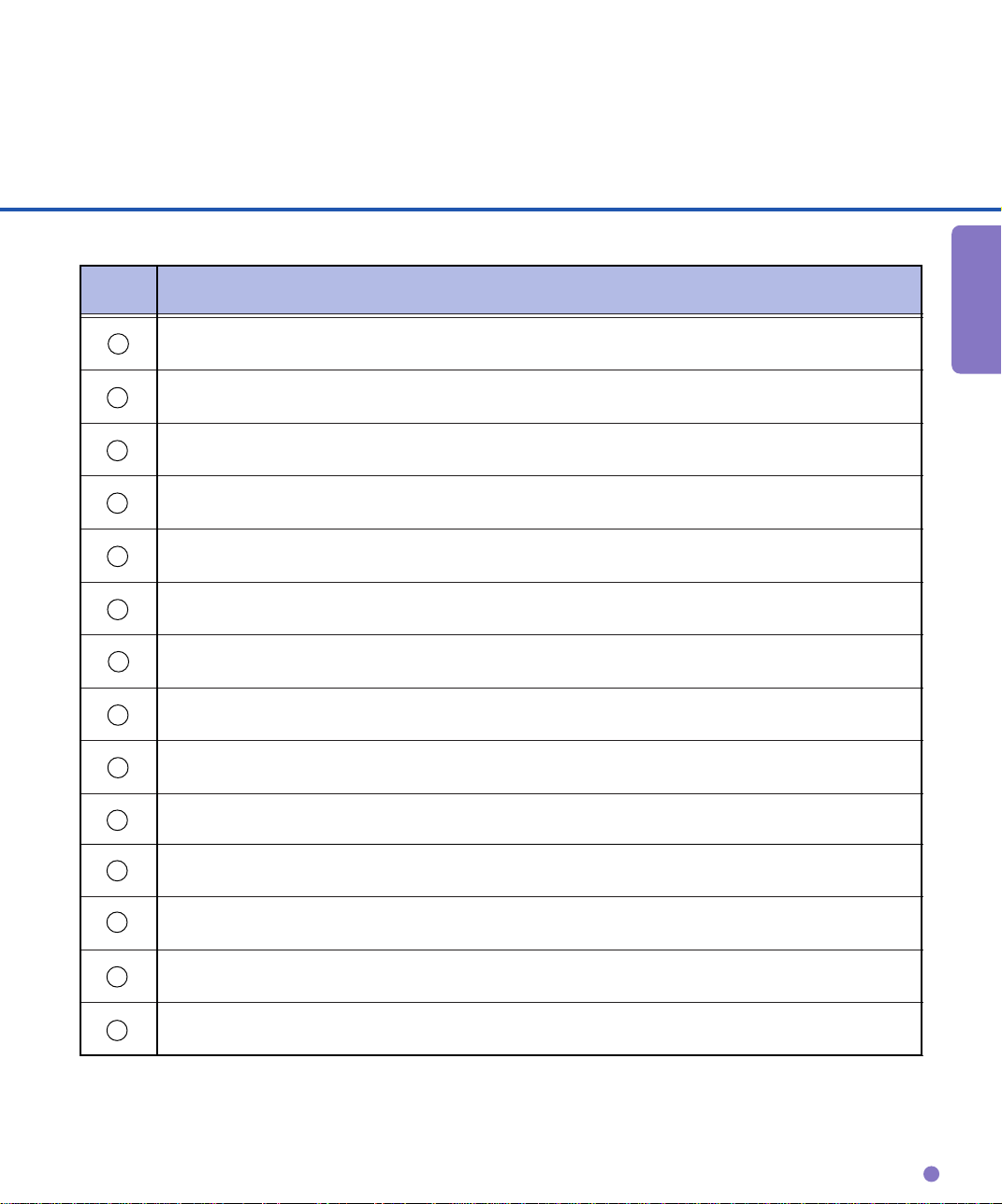

Assemblies

Stacker

*Pad ASY

(PA02201-0020)

Pad

Pad holder

**Pick roller

Pad spring

(PA02212-K001)

Guide A

Retaining

Thumb screw

spring

**:Consumables

Bearing

**:Consumables

These parts may not be provided in some countries because they are not compliant with safety

regulations. Before ordering the pick roller, contact your sales agent or Fujitsu service

representative.

1-4

Page 17

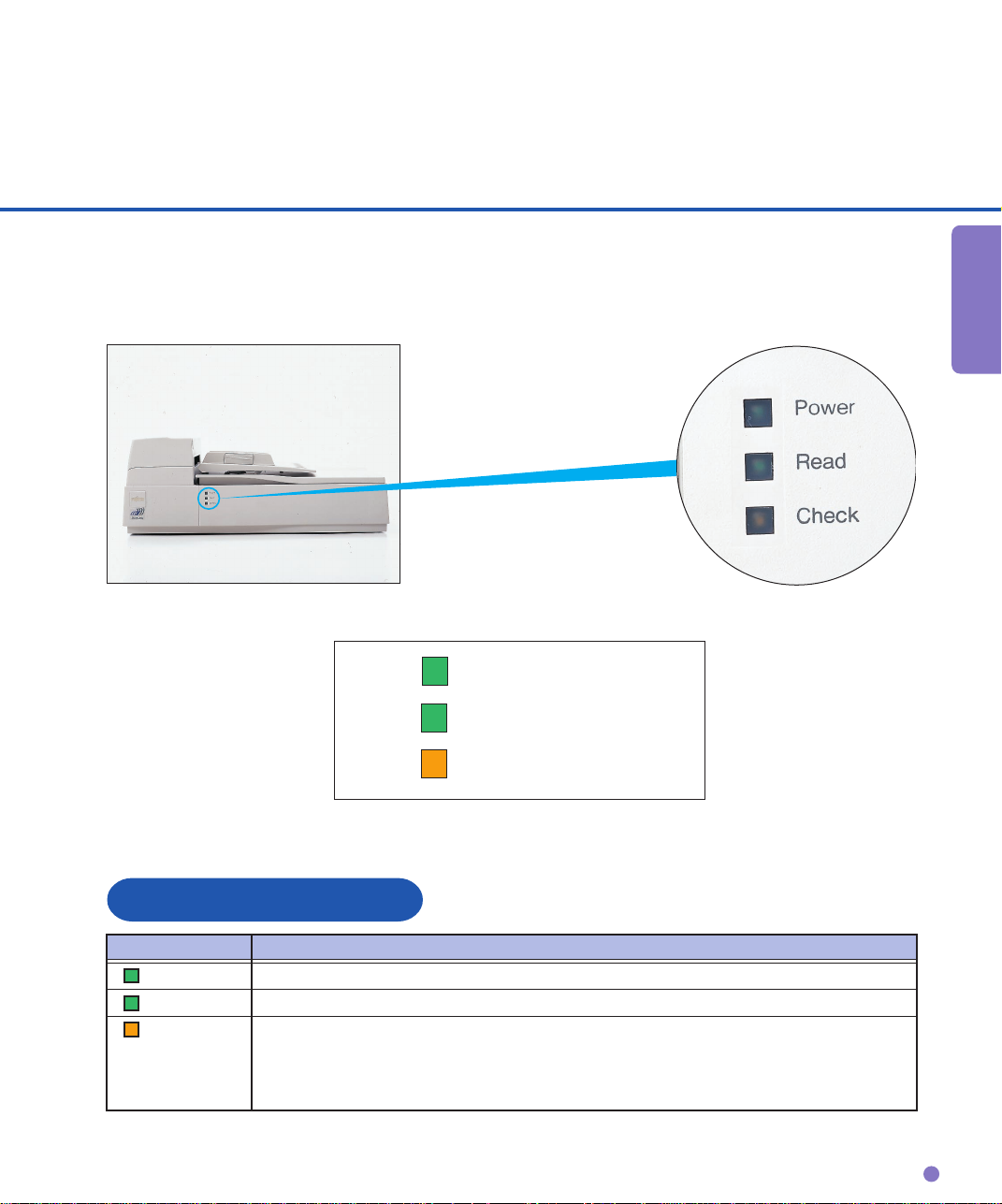

Indicators

DESCRIPTION

Power

Read

Check

LED functions

LED Function

Power Lights to indicate the power is on.

Read Lights to indicate scanning is in progress.

Check Lights if a device error occurs that may result in a service call.

Blinks if a document is jammed in the ADF. Turns off when the jammed

documents are removed from the ADF and ADF is closed. Blinks at four

seconds intervals if the ADF cleaning is necessary.

1-5

Page 18

Page 19

OPERATING

INSTRUCTION

CHAPTER

2

OPERATING INSTRUCTION

This chapter describes how to load document on the ADF and

flatbed, how to load document larger than the document board

and how to read a page from a thick book.

Loading Document on the ADF

Loading Document on the Flatbed

Loading Document Larger than the Document Board

Reading a Page from a Thick Book

2-1

Page 20

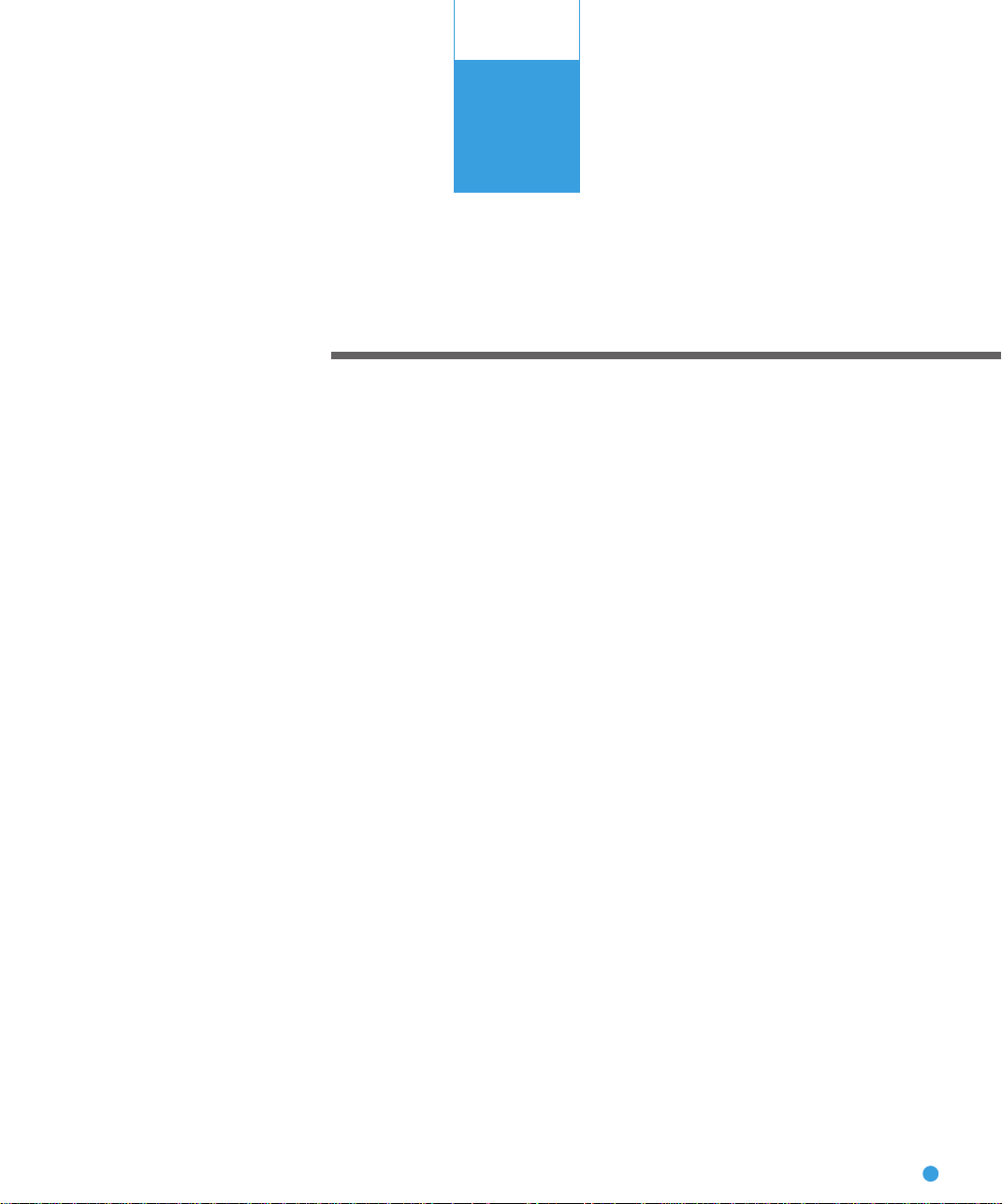

Loading Document on the ADF

1

CAUTION

Be sure to change the position of the carrier fixing bracket according to “INSTALLATION AND CONNECTION” in OPERATOR’S GUIDE before operation. This may prevent the scanner from being damaged.

ADF

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

ADF paper chute

Guide

Guide lever

ADF lever

Stacker

Lift up the ADF lever to open the

ADF.

UP

2-2

Page 21

OPERATING

INSTRUCTION

Select lever

2

Set the paper select lever as

follows.

N

N:NORMAL

T:THICK

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

3

Close the ADF.

T

Paper

Plain paper

Heavy paper

NOTE

Be sure to reset the paper select lever

to “NORMAL” when you load the

paper other

than the heavy paper.

Mode

NORMAL

THICK

ADF paper chute

Pull up the ADF paper chute until

4

it clicks.

2-3

Page 22

Document

5

Fan the sheets before setting

the document on the ADF paper

chute.

NOTE

• Remove paper clips and staples. Flatten the staple

holes .

10mm

• Read the following documents using the flatbed.

- Paper with a clip or staple.

- Paper that has ink which is not dry.

- Paper thickness is not constant, such as an envelope.

- Paper that has large rumples or curl.

- Paper that has folds or tears.

- Tracing paper.

- Coating paper.

- Carbon paper.

- Paper that is smaller than A6 size or larger than A4

width.

- Items other than paper, such as clothes, metal sheet,

or OHP film.

- Photographic paper.

- Paper that has perforations on its side.

- Paper that has a shape other than square.

- Paper that is very thin.

2-4

• Set the paper so that the top of it is curled as shown

below.

More than 30mm

Less than

3mm

Top of the paper Read surface

Feed direction

More than 30mm

Less than

5mm

Top of the paper

• Do not mix different width documents.

Feed direction

Read surface

Page 23

OPERATING

INSTRUCTION

Angle the document edges as follows:

6

• Place the documents face down with the top to the left as shown in A. The long side is the top for

landscape mode and the short side is the top for portrait mode.

• Lift the documents holding the both ends with both hands.

• Hold the documents tightly with your left hand and bend the documents as shown in B.

• Grip tightly with your right hand, loosen the grip of your left hand, and straighten the documents

as shown in C.

• Repeat these operations until the top is angled 20° or less as shown in D.

Top

AB

C

B

A

D

(For portrait mode)

C

222

20 or Less

2-5

Page 24

Set the guides so that there is a

max 4mm

(0.16")

7

little amount of clearance between

the side edges and the guides.

Load the document face down on

the ADF paper chute and adjust

the guides to the document size.

NOTE

• Squeeze the guide lever to free the guides.

• Load documents so that the thickness is less than 4mm.

• Set the guides so that they touch the document sides.

Documents

Guide

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Guide lever

(Both sides)

After the read command is issued

8

from the host system, scanned

documents are stacked in the

stacker for removal.

2-6

Page 25

OPERATING

INSTRUCTION

WARNING

4

Do not look directly at the light source during read operation.

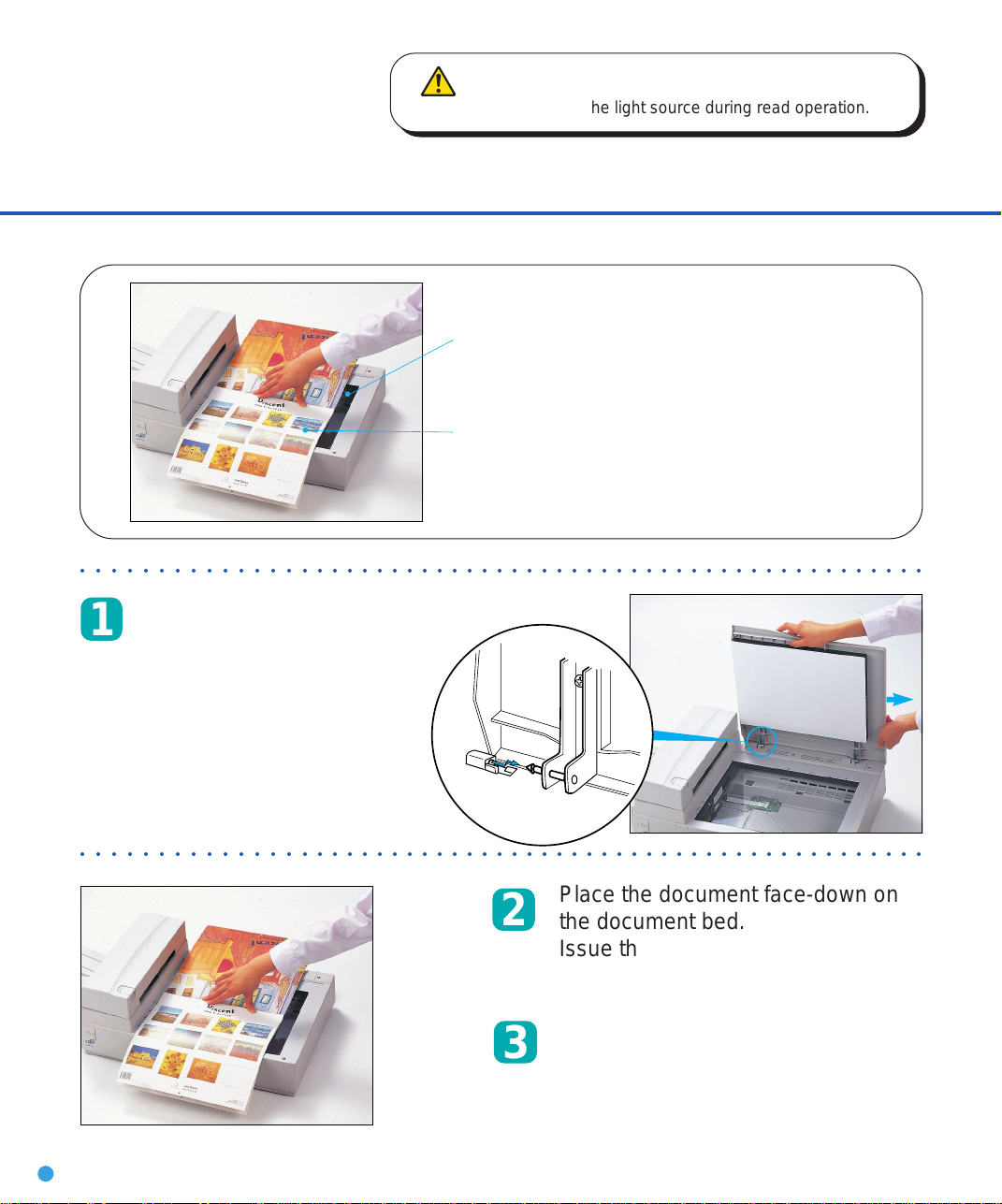

Loading Document on the Flatbed

Document cover

Document holding pad

Document bed

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

1

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Open the document cover.

Reference mark

2

3

Place the document facedown and align the top left of

it with the reference mark.

Close the document cover

slowly.

Issue the read command

from the host system.

2-7

Page 26

WARNING

Do not look directly at the light source during read operation.

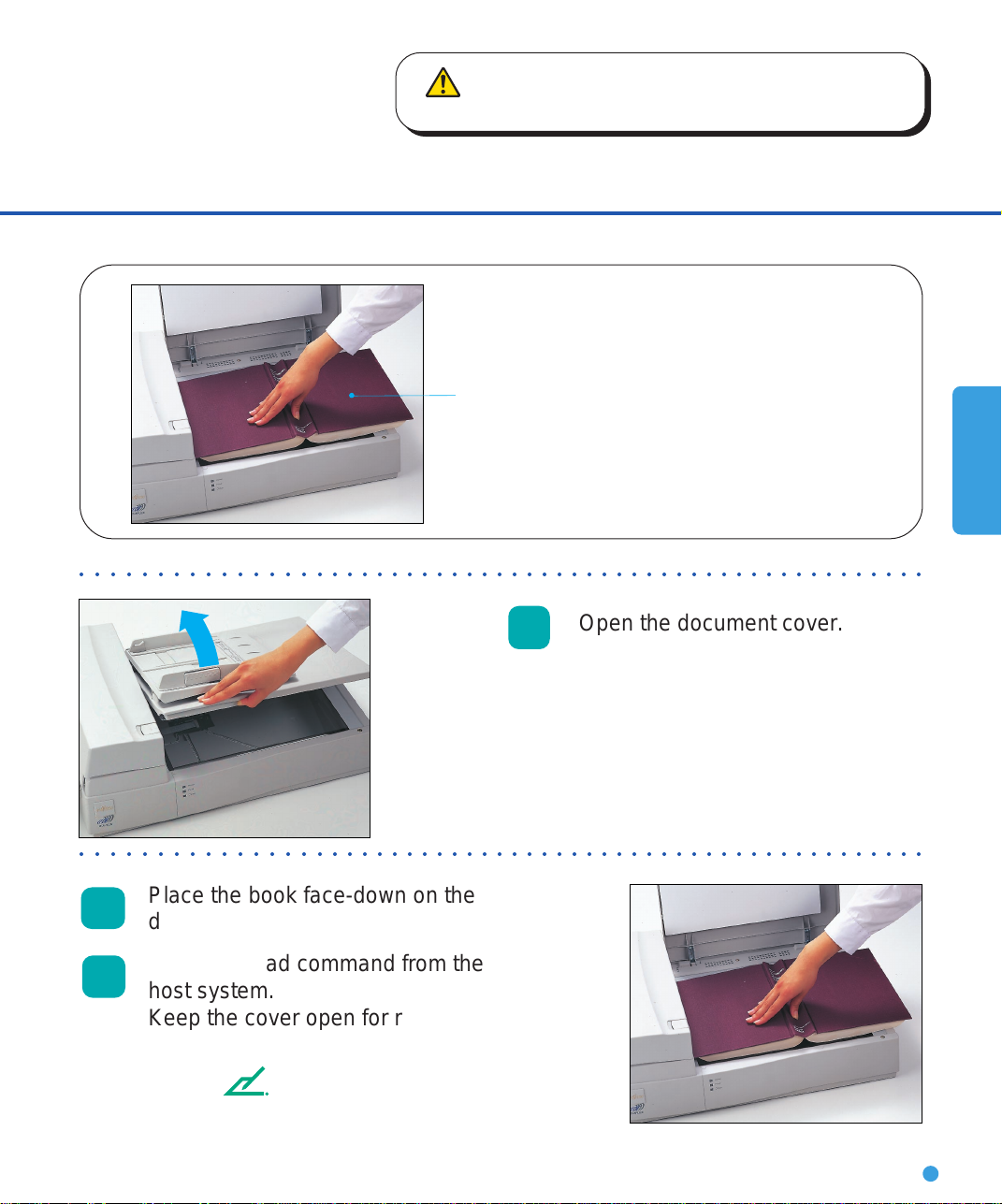

Loading Document Larger than the Document Board

Document bed

Document

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Open the document cover

1

approx. 80 degrees and slide

the cover in the direction of

the arrow to remove it.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Place the document face-down on

2

3

2-8

the document bed.

Issue the read command from the

host system.

After the read operation, remove the

document, re-attach the document

cover and close the document

cover.

Page 27

OPERATING

INSTRUCTION

WARNING

Do not look directly at the light source during read operation.

Reading a Page from a Thick Book

Thick book

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

1

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Open the document cover.

Place the book face-down on the

2

document bed.

Issue the read command from the

3

host system.

Keep the cover open for reading.

NOTE

Do not move the book during read operation.

2-9

Page 28

Page 29

CLEANING

CHAPTER

3

CLEANING

This chapter describes the cleaning supplies and area, and

how to clean the ADF and flatbed.

Cleaning Supplies and Cleaning Area

Cleaning the ADF

Cleaning the Flatbed

3-1

Page 30

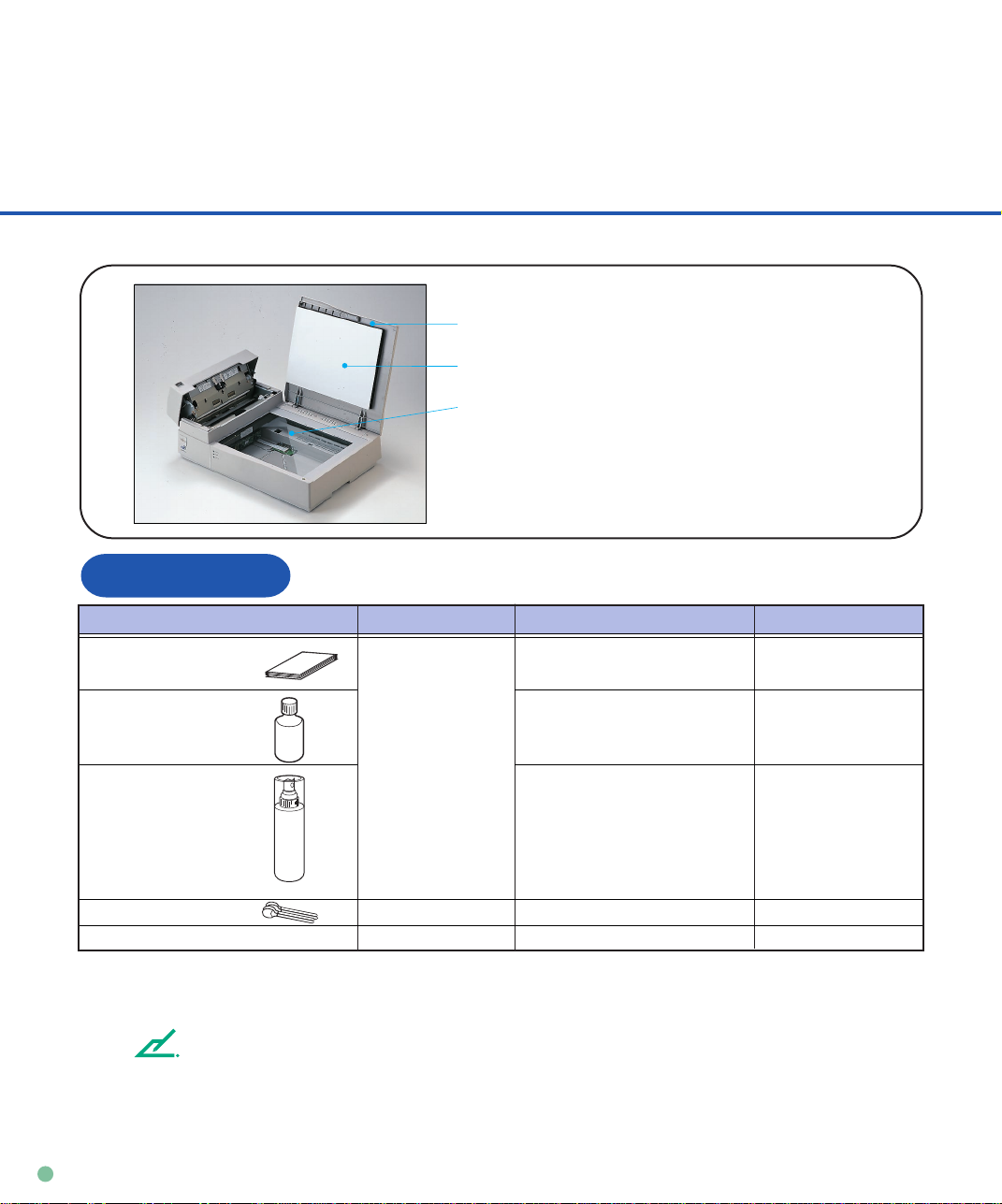

Cleaning Supplies and Cleaning Area

Document cover

Document holding pad

Document bed

Supplies

Type No. RemarksSupplies

Cleaning paper Contact your Every 5,000 sheets

dealer or

Cleaner F2 distributer • Plastic rollers (*2) 1 bottle

Cleaner F1 or • PAD ASY 1 bottle.

Isopropyl alcohol Every 5,000 sheets Apply Cleaner F1

Cotton swab

Dry cloth

*1 When the CHECK indicator starts blinking at 4-second intervals, clean the scanner regardless of the

frequencies.

*2 Clean the plastic rollers when they are soiled with dirt. Do not clean the rubber rollers with cleaner F2.

NOTE

When the following paper is used, it may be necessary to clean more frequently.

• Paper with smooth surface such as coated paper.

• Paper with almost all printed area.

• Paper with special coating such as carbon-less paper.

Frequencies (*1)

Apply Cleaner F2

to cotton swab.

• Pick roller/Feed rollers/ to cloth.

Glass/Sheet guide

Every 5,000 sheets

3-2

Page 31

CLEANING

Cleaning area

Area

Flatbed

ADF

ADF

Name

Document holding pad

Document bed

Pad

Glass/Sheet guide

Pick roller

Plastic rollers

Feed rollers

Cleaning paper

with Cleaner F1

Document

holding pad

Document bed

Dry cloth

with Cleaner F1

Pad

Cotton swab

with Cleaner F1 or F2

Feed rollers

Sheet guide(White part)

Feed rollers

Glass

Plastic rollers

Pick roller

Plastic rollers

3-3

Page 32

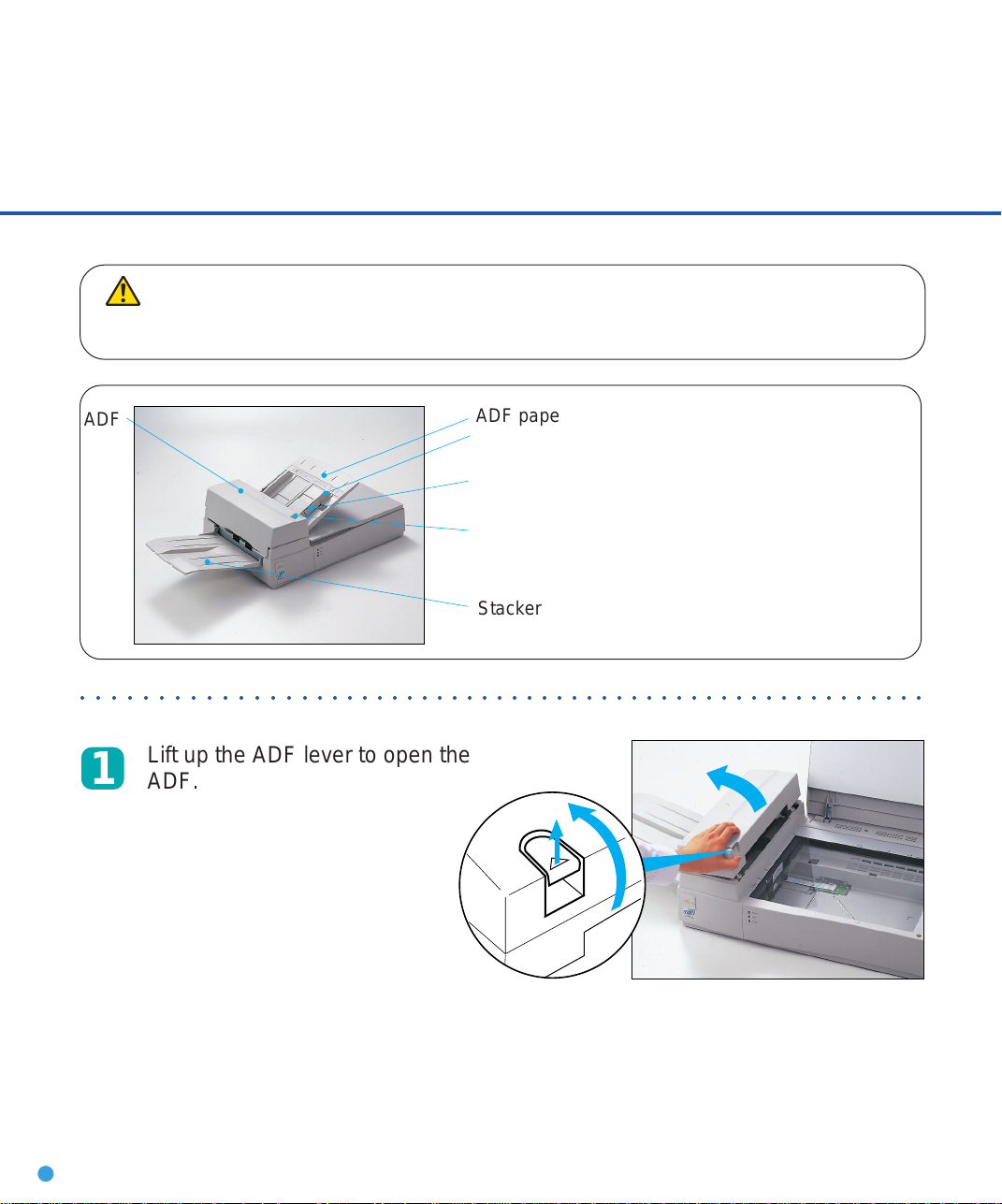

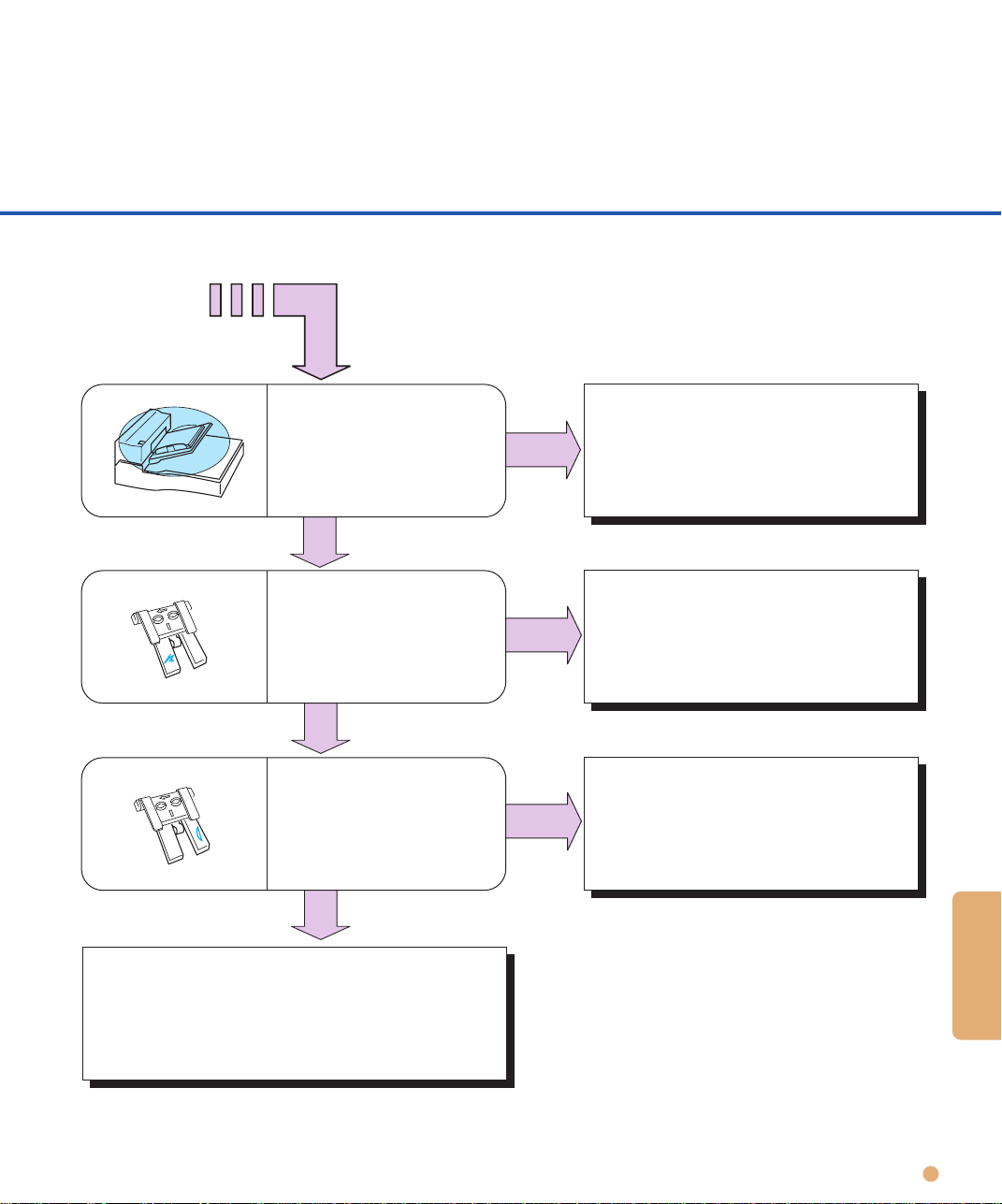

Cleaning the ADF

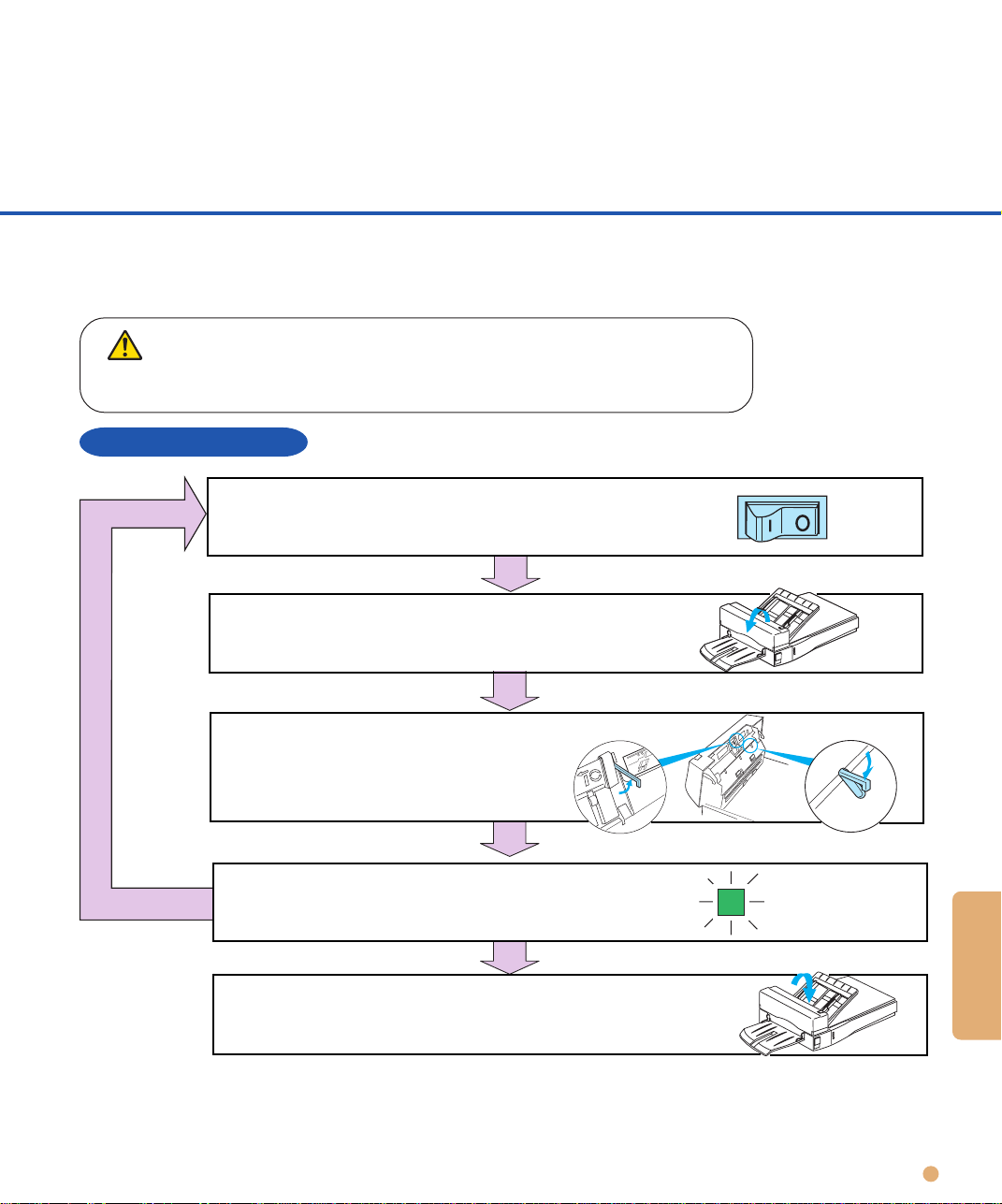

pow-on

Cleaning the ADF with cleaning paper

UP

Lift up the ADF lever to open

1

2

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

the ADF.

Apply cleaner F1 to a new

cleaning paper.

Cleaning

paper

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Close the ADF and turn

4

5

6

the power on to start the

cleaning.

Turn the power off.

Repeat steps 1 through 5.

Cleaning paper

Plastic

rollers

3

Place the cleaning paper on the

ADF so that the short side edge

touches the plastic roller.

3-4

Page 33

CLEANING

Cleaning the ADF with Dry cloth with Cleaner F1

1

Lift up the ADF lever to open the ADF.

Use a dry cloth or a cloth moistened with Cleaner F1 to softly

2

remove dirt and dust as follows.

Pad

Pad

Wipe the pad in the downward

direction (indicated by the arrow).

Be careful not to hook the pick

spring when wiping.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Glass

Wipe the glass lightly.

NOTE

If the glass is dirty, the image may include vertical

stripes.

Glass

3-5

Page 34

Plastic rollers

Pick roller

Wipe the roller.

Be careful not to damage the

surface of the roller and the

mylar strip above the Pick

roller.

Pick roller

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Feed rollers

and Plastic rollers

Wipe the rollers.

Be careful not to

damage the surface of

the rollers.

3-6

Feed rollers Plastic rollers

Page 35

CLEANING

Sheet guide (white part)

Sheet guide (white part)

Wipe the sheet

guide.

NOTE

If the sheet guide is dirty, the front image may include

vertical stripes.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

3

Close the ADF to lock the ADF lever.

3-7

Page 36

Cleaning the Plastic rollers with Cleaner F2

Plastic rollers

Plastic rollers

1

2

3

4

Lift up the ADF lever to open

the ADF.

Moisten a cotton swab with

Cleaner F2.

Wipe the Plastic roller

surfaces.

Wipe the Plastic roller

surface with clean and dry

cloth. Allow to dry.

3-8

Page 37

CLEANING

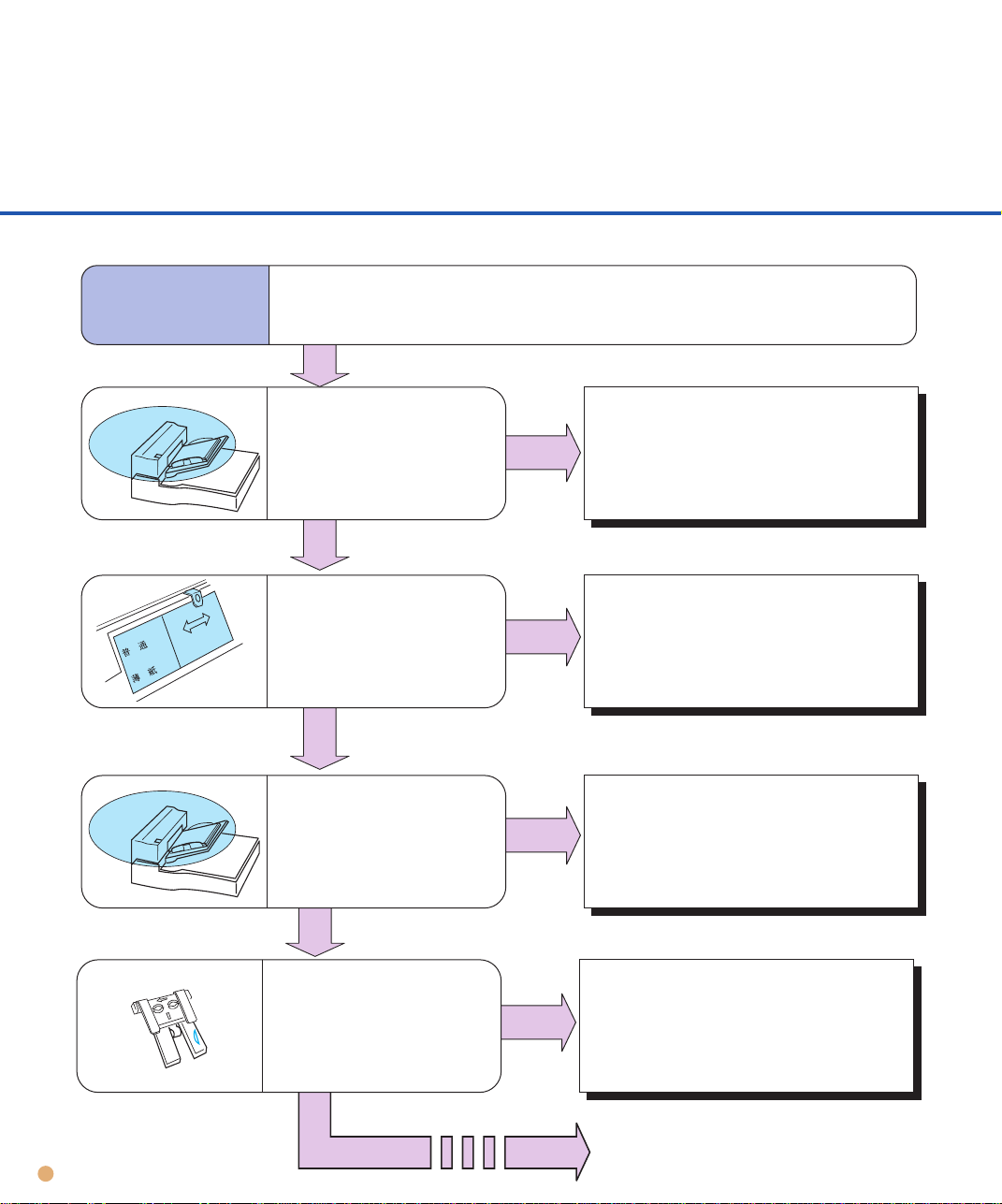

Cleaning the Flatbed

Cleaning the Flatbed with Dry cloth with Cleaner F1

Document cover

Document holding pad

Document bed

NOTE

Window or glass cleaner can be used instead of

cleaner F1.

However do not use organic solvent.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

1

Open the Document cover.

Apply Cleaner F1 to a clean cloth.

2

Wipe the document holding pad and

3

4

NOTE

Be sure to prevent liquid from seeping through the opening

between the document bed and the plastic cover.

document bed.

Allow to dry.

3-9

Page 38

REPLACEMENT

OF PARTS

CHAPTER

4

REPLACEMENT OF PARTS

This chapter describes how to replace the pad ASY, pad and

pick roller.

Pad ASY or Pad

Pick Roller

4-1

Page 39

Pad ASY or Pad

3

ADF lever

Pad ASY (PA02201-0020)

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

NOTE

The life span of the pad ASY is about 100,000

sheets or one year.

The life span may be decreased by half when

carbon-less sheets are used.

Lift up the ADF lever to open

1

the ADF.

Slide the paper select

2

lever to “N”.

Select lever

N:NORMAL

T:THICK

N

T

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Slide the pad ASY to the left and

pull it toward you.

Pad ASY

4-2

Page 40

REPLACEMENT

OF PARTS

If the Pad is attached to the scanner,

5

4

you can replace the Pad according to

Pad holder

the following procedure.

a)Remove the pick spring.

b)Remove the pad from the pad holder.

c)Attach a new pad to the pad

holder and fix it with the pick spring.

NOTE

• Turn the pad upside down so that the pad

holder pin fits with the pad hole.

• Do not alter the shape of the pick spring.

• Attach the pick spring so that both ends of

the pick spring are located on the pad.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Pick spring

Pad

Attach the pad ASY to the ADF

until it clicks in the reverse

sequence of step 3.

NOTE

Fit the pad ASY pin with the larger hole then

slide to the right.

NOTE

Normally, set the select lever to “N”. Return the select

lever if necessary.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Close the ADF.

6

4-3

Page 41

Pick Roller

Pick roller (PA02212-K001)

NOTE

The life span of the pick roller is about 200,000 sheets or one year.

The life span may be decreased by half when carbon-less sheets are used.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

4-4

1

2

Lift up the ADF lever to open the

ADF.

Remove the two thumb screws.

NOTE

Use a Phillips screwdriver when they are tight.

Page 42

REPLACEMENT

OF PARTS

Lift up the Guide A with both of

3

5

6

your hands and disengage the tip

from the right hole.

Then lift the right side of the cover

and remove it.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Hold the retaining spring and

4

slide it to the roller side.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Slide the pick roller to the retaining

spring side until the axis of the

opposite side is disengaged.

Lift and remove it.

Remove the retaining spring.

4-5

Page 43

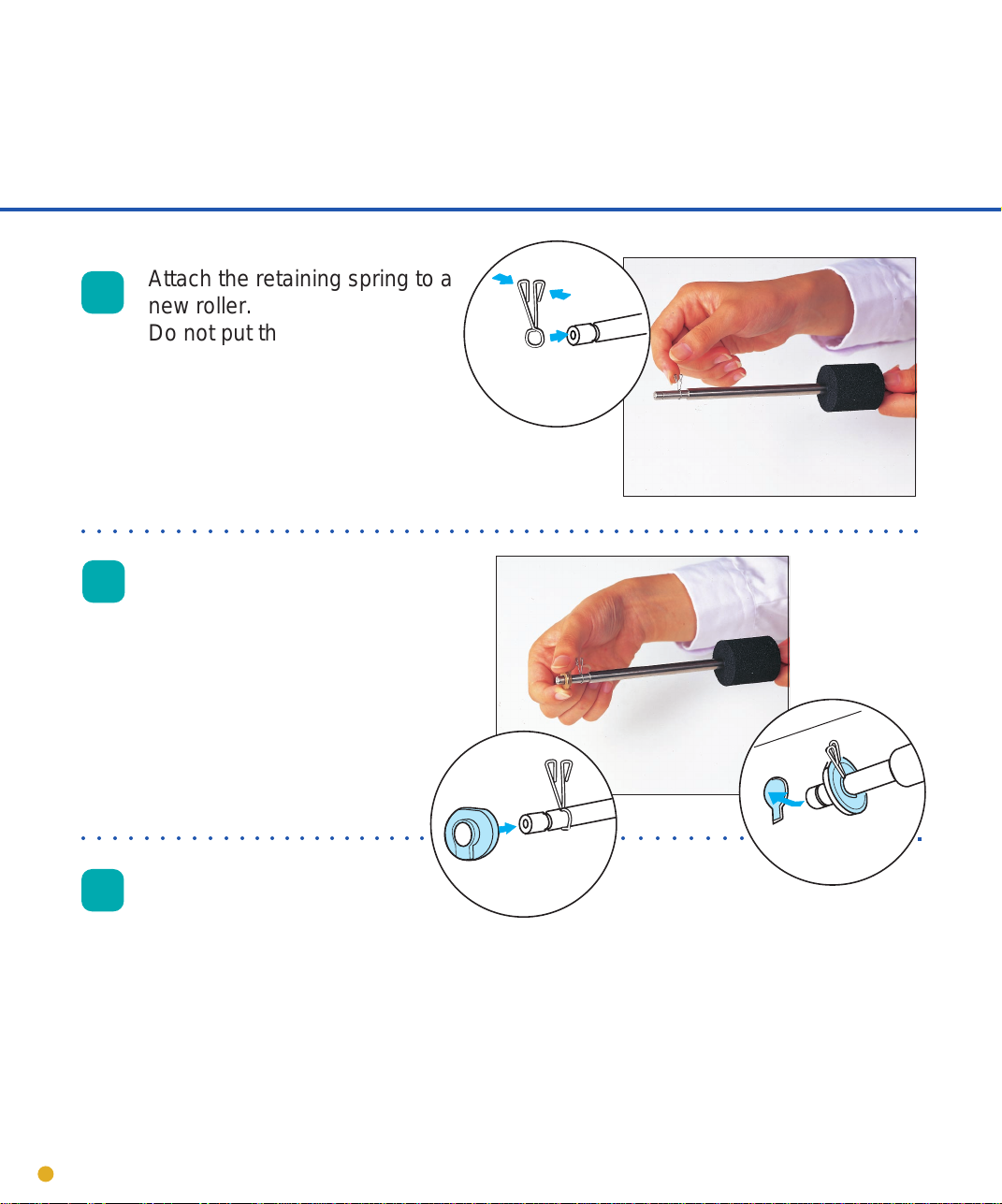

Attach the retaining spring to a

7

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

new roller.

Do not put the spring in the

groove yet. Slide the spring

next to the larger diameter

portion of the shaft.

8

○○○○○○○○○○○○○○○○○○○○○○○ ○○○○○○○○

9

Slide the end of the new pick

roller with the retaining spring

into the bearing, then into the

hole closer to the front of the

scanner. Next, slide the opposite end of the pick roller into

the bearing next to the gears.

Hold the retaining spring,

slide it to the bearing slide

and place it into the groove

to fix it.

4-6

Page 44

REPLACEMENT

OF PARTS

Guide A

Attach the Guide A in the reverse

10

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

sequence of step 3 and align the

screw hole.

Thumb screws

11

12

Tighten the thumb screws.

Close the ADF unit.

4-7

Page 45

Page 46

TROUBLESHOOTING

CHAPTER

5

TROUBLESHOOTING

This chapter describes the paper JAM, initial checks and test mode

for maintenance.

Paper JAM

Initial Checks

Test Mode for Maintenance

Problem Checklist

TROUBLESHOOTING

5-1

Page 47

Paper JAM

Document

ADF

ADF lever

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Remove the documents from

1

the ADF paper chute.

2

3

Inspect the paper and paper path. Make sure no staples,

paper clips or other materials caused the jam. All types of

staples and paper clips should be removed from all

documents bofore scanning.

4

5-2

Lift the ADF lever to open the ADF.

Remove the jammed document.

NOTE

Close the ADF until the ADF lever

locks.

Page 48

TROUBLESHOOTING

Initial Checks

If a problem occurs, check the following items before contacting manufacturer’s authorized

service center.

Symptom1

The power does not go on. Power

Is the power cable

connected correctly?

YES

Is the power switch on?

YES

Contact manufacturer’s authorized

service center.

(No light)

NO

Connect the power

cable correctly.

NO

Press the power switch.

TROUBLESHOOTING

5-3

Page 49

Symptom2

Read operation does not start.

Is the carrier fixing

bracked placed in

operation position?

YES

Are the documents

loaded on the ADF

paper chute correctly?

YES

Is the ADF closed

completely?

YES

Is the interface cable

connected correctly?

NO

NO

NO

NO

Place the carrier fixing

bracket correctly.

(See Operator’s Guide)

Insert the first few pages into

the slot.

Close the ADF completely.

Connect the interface cables

correctly.

5-4

YES

Page 50

TROUBLESHOOTING

Is the terminator connected? Is the SCSI ID

is set correctly?

(M3093DG)

YES

NO

Connect the terminator or

set the SCSI ID correctly.

Is the baud rate of the

system 4800 bps?

(Default is 4800 bps.)

YES

Check

Is the CHECK indicator

lit?

NO

Contact manufacturer’s authorized

service center.

NO

YES

Contact manufacturer’s

authorized service center to

set correct baud rate.

Refer to Symptom 6.

(See p5-9)

TROUBLESHOOTING

5-5

Page 51

Symptom3

Pictures and photographs are not read correctly.

Is the “Photo” mode

selected?

YES

Is halftone or dithering

processing selected?

YES

Is the document bed,

document holding pad,

glass and sheet guide

clean?

YES

NO

NO

NO

Select the “Photo” mode

(White level following off)

through the scanner setting

menu in the software.

Select a halftone or dithering

mode from the host computer.

Clean the dirty parts.

(See p3-5, p3-7, p3-9)

Contact manufacturer’s authorized

service center.

5-6

Page 52

TROUBLESHOOTING

Symptom4

Characters and lines are not read correctly.

NO

Is the “Line Art” mode

selected?

Select a “Line Art” mode from

the host computer.

YES

3mm

Is there printed text on

the first 3mm of the

document?

NO

Is the document bed,

document holding pad,

glass and sheet guide

clean?

YES

Contact manufacturer’s authorized

service center.

YES

NO

Select the “Photo” mode

(White level following off)

via software.

Clean the dirty parts.

(See p3-5, p3-7, p3-9)

TROUBLESHOOTING

5-7

Page 53

Symptom5

Images are distorted or unclear.

missing

Is the document bed,

document holding pad,

glass and sheet guide

clean?

YES

Is the surface of the ADF

pressed or is there

anything heavy on it?

(During rear read operation with ADF)

NO

Is the scanner on

even and flat surface

or any scanner rubber

feet missing?

YES

NO

YES

NO

Clean the dirty parts.

(See p3-5, p3-7, p3-9)

Do not press the surface of

the ADF or do not put anything heavy on it.

Place the scanner on the

even and flat surface.

Or attach the rubber feet.

Contact manufacturer’s authorized

service center.

5-8

Page 54

TROUBLESHOOTING

Symptom6

The check indicator is on.

Check

Is the carrier fixing

bracket placed in

operation position?

YES

Turn off the power once

and try to turn on the

Check

power again.

Is the CHECK lamp

turned on?

YES

Activate the test mode (p5-17) and

inform manufacture’s authorized

service center of the error status.

NO

Place the carrier

fixing bracket correctly.

(See Operator’s Guide)

TROUBLESHOOTING

5-9

Page 55

Symptom7

“Check” lamp blinks at 4 seconds intervals.

YES

Check

Is the pick roller dirty?

NO

Are documents under

specification?

(See p5-11)

YES

Is the Pad ASY dirty or

worn out?

NO

Clean the pick roller.

NO

Flatten the curl or use the

flatbed to read the document.

YES

Clean or replace the Pad ASY.

(See p3-4, p3-5, p4-2)

5-10

Contact manufacturer’s authorized

service center.

Page 56

TROUBLESHOOTING

NOTES

NOTE

• Remove paper clips and staples. Flatten the staple holes.

• Read the following documents using the flatbed.

- Paper with a clip or staple.

- Paper that has ink which is not dry.

- Paper thickness is not constant, such as an envelope.

- Paper that has large rumples or curl.

- Paper that has folds or tears.

- Tracing paper.

- Coating paper.

- Carbon paper.

- Paper that is smaller than A6 size or larger than A4 width.

- Items other than paper, such as clothes, metal sheet, or OHP film.

- Photographic paper.

- Paper that has perforations on its side.

- Paper that has a shape other than square.

- Paper that is very thin.

• Set the paper so that the top of it is curled as shown below.

Less than

3mm

• Do not mix different width documents.

More than 30mm

Top of the paper Read surface

Feed direction

More than 30mm

Less than

5mm

Top of the paper

Feed direction

Read surface

TROUBLESHOOTING

5-11

Page 57

Symptom8

Paper double feed occurs frequently.

N:NORMAL

T:THICK

Does the condition of

the document satisfy

the requirements on

page 5-11.

NO

Flatten the curl or use the

flatbed to read the document.

YES

N

T

Is the plain paper read

with the select lever set

to “T”?

YES

Set the select lever to “N”.

(See p2-3)

NO

Are the documents

fanned and angled before

loading on the ADF paper

chute?

NO

Fan and angle the documents

before loading according to

the procedure on the pages

2-3 and 2-4.

YES

5-12

Is the paper printed by

copier or laser printer

recentry?

NO

YES

Fan 3 or 4 times to remove

the static charge applied on

paper.

Page 58

TROUBLESHOOTING

Is the height of

document less than

0.16” (4mm)?

YES

NO

Reduce the document from

ADF paper chute.

(See p2-6)

YES

Is the pad dirty?

NO

Is the pad worn out?

NO

Contact manufacturer’s authorized

service center.

Clean the pad.

(See p3-4,p3-5)

YES

Replace the pad.

(See p4-2)

TROUBLESHOOTING

5-13

Page 59

Symptom9

Miss pick occurs frequently.

N:NORMAL

T:THICK

Does the condition of

the document satisfy

the requirements on

page 5-11.

NO

Flatten the curl or use the

flatbed to read the document.

YES

YES

N

T

Is the heavy paper read

with the select lever set to

“N”?

Set the select lever to “T”.

(See p2-3)

NO

Are the documents

fanned and angled before

loading on the ADF paper

chute?

NO

Fan and angle the documents

before loading according to

the procedure on the pages

2-3 and 2-4.

YES

5-14

Is the Pad ASY installed

correctly?

YES

NO

Install it correctly.

(See p4-2)

Page 60

TROUBLESHOOTING

YES

Is the pick roller dirty?

NO

Is the pick roller worn

out?

NO

Contact manufacturer’s authorized

service center.

Clean the pick roller.

(See p3-4, p3-6)

YES

Replace the pick roller.

(See p4-4)

TROUBLESHOOTING

5-15

Page 61

Symptom10

Paper jam occurs frequently.

Does the condition of

the document satisfy

the requirements on

page 5-11.

NO

Is there any foreign

particles in the ADF?

NO

Contact manufacturer’s authorized

service center.

YES

Flatten the curl or use the

flatbed to read the document.

YES

Clean the ADF (See p3-4) or

remove the foreign particles.

5-16

Page 62

TROUBLESHOOTING

Test Mode for Maintenance

Power

If the CHECK indicator lights up, activate the test mode and inform your sales or

support agent or Fujitsu service representative of the error status.

CAUTION

If an operation other than described here is performed, the scanner may malfunction.

Activate the test mode and follow the procedure only for the error status.

Activating a test mode

Turn off the power.

Open the ADF.

Try again (*1)

Turn the power on after setting

Empty sensor B5 Size sensor

the empty sensor and B5 size

sensor as shown in the figure.

Up

NO

Does the POWER lamp blinks?

YES

Close the ADF cover.

(The scanner is placed in the maintenance mode.)

*1 Do not perform any other operation this time. Immediately turn the power off when the POWER

lamp does not blink.

Down

TROUBLESHOOTING

5-17

Page 63

Activating the continuous operation test

Open the ADF and close it again. If no document is loaded on the ADF within five seconds after

closing the ADF, the image scanner runs in flatbed mode. If documents are loaded on the ADF

within five seconds after closing the ADF, the image scanner continuously feeds the document

from ADF. Once the image scanner starts reading documents in flatbed mode, it does not feed

documents from ADF even if documents are loaded on the ADF.

Ending the test in flatbed mode

To stop the carrier movement in flatbed mode, open the ADF. If the ADF is opened, the POWER

lamp starts blinking immediately after the carrier returns to the home position.

Ending the test in ADF mode

If the ADF hopper is empty, feeding documents from the ADF ends. To restart feeding, open the

ADF and close it again. Then load documents on the ADF paper chute within five seconds after

closing the ADF.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

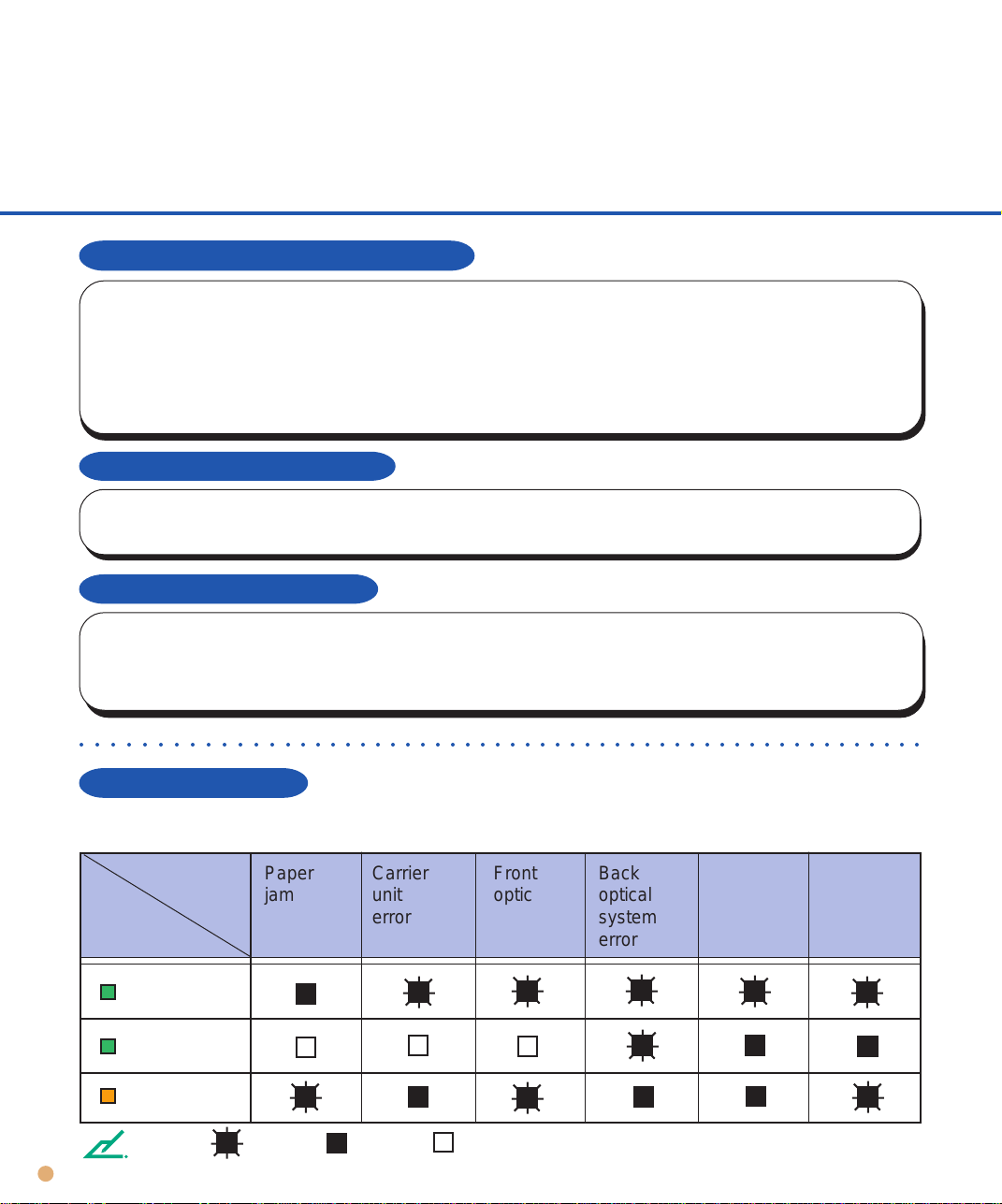

LED status on error

If an error occurs during the test, the LED indicates as shown in the following table.

Motor

fuse

failure

Lamp

fuse

failure

LED

indicates

NOTE

5-18

Power

Read

Check

Errors

Status

Paper

jam

Carrier

unit

error

Blink On Off

Front

optical

system

error

Back

optical

system

error

Page 64

TROUBLESHOOTING

Problem Checklist

Before contacting the manufacture’s authorized service center, please fill in the following items.

General

Model

Part number

Serial number

Manufactured data

Version

A

0

123456789

B

0

123456789

C

0123456789

Date of purchase

Symptoms

Persistent problem?

Serviced before (when and how)?

Error status at test mode. (See p5-18)

Transport error

Type of document.

What is your daily usage?

Date of last cleaning.

Date of the consumable replacement.

(Example) M3093DE

(Example) CA02939-4202

(Example) 900002

(Example) 1996-07

The version is printed on the version label

located at the left of the rear of the equipment.

The version is checked with the double line.

This example is for A2 version.

Image error

Interface controller model

Software/application name

Can you send the original and output of

sheet by facsimile or by mail?

TROUBLESHOOTING

5-19

Page 65

Loading...

Loading...