Page 1

M304X

SERIES LINE PRINTER

OEM MANUAL

Page 2

Page 3

r

REVISION RECORD

Edition

01

02

03

04

05 Jun., 1986

06

Dam Lwblishd

*ug.,

No”..

.I”“.. 1985

Aug.,

Nov., 1986

1983

1984

1985

f3ewritren

Rer”ped and dePCripti.3”

Pager

440.96

Pager

Cha,xerr 4 to 9.

Pager

: Chacmr9 deleted.

4-3.4-28.4-31

2-3.44

added

pages 2-2.2.3.

Revised Content$

Of. RS-232-C

-4-39.441.

2.6 10 2-8. 2.10 to 2-20 reused.

Chamerand 8 revised.

interfact! and aprionr added.

442, 4.46.

449.6-7.6-8.6.16.9-6

modified

Swcification

N O .: 802P.1500.OOOIA

BOZP-ISOO-OOOlA...06

i

Page 4

FWITS” LlMlTED

In1er”atim.l

Marketing

FUJITSU NORDIC A8

lndunrigatan 2A

MaN”O”di l-s-1. Chiyoda-k”. Tokyo 100.m.PAN TEL: 8.231125

TEL 03.216-3211

FAX: 03-213-7174.03-218-9353 TLX:

TLX:

,229s

Cable: “FUJITSU LlMlTED TOKYO”

FAX: 8.106865

13411

FUJITSU ITALlA

“ia Lalzaro”i. 4. 20124

FUJITSU AMERICA INC. TEL:

3055

Orchard Drive. San

TEL: 408.9468777

,ore.

California

951342017. U.S.A.

FAX: 2-688-6637

TLX: 350142

139.21 607-3601

FAX: 408-945-131*

TLX: 230-176207

TWX:

I9101

338-2193

FUJITSU CANADA INC.

6260 Northwen

TEL:

114161

Drive.

6734666

FAX: 416.673-8677

TLX: 968132

FUJITSSU

Roy., Trurr

EUROPE LlMlTED

House.

54

Misksaqa. Taronro. Ontario. CANADA

Jermyn

Street. London

S.W.1,

ENGLAND TLX:

FUJITSU AUSTRALIA LIMITED

4-l

McLaren

TEL:

Street. North Syd”ey, N.S.W.

161-2,

95943555

FAX: 2-922-2653

TM:

25233

FUJlTS” HONG KONG LIMITED

R.M.

1831.

Sun Hung

(852.51

TEL:

8915780

FAX: 5-742917

62667

TEL: W-1 I4084043

FAX:

1.629-9826

TLX: 263871

Plan 7. 112 46 Sroctholm. SWEDEN

S&A.

rdibano.

ITALY

2060,

AUSTRALIA

Kai

Came. 30 Harbur

Road.

HONG KONG

FVJITS” DEUTSCHLAND

RorenheimetaraBe

TEL:

149.89,

145. D-8000

413010

FAX: 8941301100

TLX: 5213994

ii

GmbH

MCinchsn 80.

F.R. GERMANY

BOZP-1500-OOOlA...06

Page 5

CONTENTS

CHAPTER

1.1

CHAPTER 2

2.1

2.2

2.3

2.4

2.5

2.5.1

2.5.2

2.5.3

2.5.4

2.5.5

2.6

2.6.1

2.6.2

CHAPTER 3

3.1

3.2 Control Unit

CHAPTER 4

4.1

4.2

4.2.1

4.2.2

4.3

4.3.1

4.3.2

4.4

4.4.1

4.4.2

4.4.3

INTRODUCTION ...............................................

1

Introduction

SPECIFICATIONS .............................................

Printer Specifications .........................................

Ribbon Specifications

Installation Conditions

Optional Unit

Forms Specification

General note about forms

Dimensions

Multiple-part forms

Ambient conditions for forms ............................... 2 - 18

Purchase order for forms

Format Control Tape

Medium quality

Dimensions

CONFIGURATION

Mechanical Unit ................................................

DPC-COMPATIBLE INTERFACE

Operation Outline ..............................................

Interface Signals

Interface signal lines

Physical specifications of interface signals

Character and Control Codes

Character codes ............................................

Control codes

Format

control

Definition of the top of forms

of form

Specification of a forms feed format

Skip and Space commands

l-l

...................................................

..........................................

........................................

..................................................

............................................

...................................

.................................................

........................................

...................................

(FCT)

.............................................

.................................................

.............................................. 3 - 1

...................................................

..............................................

..............................................

.................................................

(BOF)

..............................................

......................................

...................................

.....................................

...............

....................................

(TOF)

and the bottom

.......................

....................................

l-l

2-l

2 - 1

2-3

2-3

2-6

2 - 11

2 - 11

2 - 12

2 - 15

2 - 18

2 - 19

2 - 19

2 - 19

3-2

3-3

4-l

4-l

4-2

4-2

4-6

4-a

4 - 10

4 - 10

4 - 11

4 - 11

4- 12

4 - 19

CHAPTER 5

5.1

5.2

5.2.1

5.2.2

5.3

5.3.1

5.3.2

5.4 Format Control

5.4.1

5.4.2

5.4.3

5.5

5.5.1

5.5.2

CENTRONICS-COKPATIBLE

Operation Outline

Interface Signals

Interface signal lines

Physical specifications of interface signals

Character and Control Codes

Character codes

Control codes

Loading from the mainframe to the VFU

Loading from an FCT to the VFU

Format specification from the operator panel

VFU Commands

n-Line Skip command

Skip to Channel-n commands

................................................... 5 - 17

5

INTERFACE

..............................................

..............................................

.....................................

....................................

............................................

..............................................

.................................................

........................................

B02P-1500-OOOlA...05

............................

...............

......................

.............................

,,

..............

.................................

- 1

5-l

5-2

5-2

5-a

5 - 11

5 - 12

5 - 12

5 - 14

5 - 15

5 - 16

5 - 16

5 - 17

5 - 18

.

13.1

Page 6

CHAPTER 6

6.1

6.2

Operation Outline ..............................................

Interface Signals ..............................................

6.2.1

6.2.2

6.3

Character and Control Codes ....................................

6.3.1

6.3.2

6.4

Hessage Protocols ..............................................

6.4.1

6.4.2

6.4.3

6.4.4

6.5

6.6

Commands .......................................................

Printer Status .................................................

RS-232-C INTERFACE .........................................

6-1

6-1

6 - 4

Interface signal lines .....................................

Physical specifications of interface signals

...............

6-4

6-8

6 - 14

Character codes

............................................

6 - 16

Control codes .............................................. 6 - 16

6 - 19

XON/XOFF protocol .......................................... 6 - 19

Reverse Channel line protocol ..............................

DTR line protocol ..........................................

RTS line protocol

..........................................

6 - 19

6 - 20

6 - 20

6 - 21

6 - 28

CHAPTER 7

7.1

7.2

7.3

CRAPTER

8.1

8.2

a.3

a.4

Standard Print Band List .......................................

Standard Character Sets

Type Catalog

8

Print Bands .................................................... 8 - 2

Options ..............................................

Expendable Supplies ............................................

Special Tools ..................................................

PRIYT BAND SPECIFICATIONS

..................................

7-1

7-2

........................................

...................................................

SPECIFICATION LIST .........................................

.

..........

7-2

i-9

a-

8-3

1

8-3

a-3

iv

B02P-1500-OOOlA...06

Page 7

ILLUSTRATIONS

Figure 1.1

Figure 2.1

Figure 2.2

Figure 2.3

Figure

Figure 2.5

Figure 2.6

Figure 2.7

Figure 2.8

Figure 2.9

Figure 2.10

Figure 2.11

Figure 2.12

Lgure

Figure 2.14

Figure 2.15

Figure 2.16

Figure 2.17

Figure 2.18

Figure 2.19

2.L

2.13

M304x series line printer

Outer dimensions (with the forms rack)

Operation and maintenance area (with the forms rack)

Outer dimensions (with the powered stacker)

Operation and maintenance areas (with the

powered stacker)

FCT unit

Paper puller

Forms

Curled

Forms container lids .....................................

Shape of the forms container

Leftmost and rightmost print positions

Dimensions relating to pin feed holes

Protrusion and separation of the outer layer at the

perforation of multiple-part forms

Methods of fastening paper

Allowable incorrect alignment of multiple-pzrt forms

Multi-part forms with layers of different

Carbon paper covering pin feed holes

Self-adhesive

Specifications of FCT

.................................................

....................................................

forms

.........................................

.............................................

............................................. 2 - 11

lable

forms ................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

...................

....

..............

.............................

...................2 -

....................

.......................

............................... 2 - 15

.....2 -

th:ickness

.....................

.................................... 2 - 20

......2 -

1- 2

2-4

2-5

2-7

2-8

2-9

2 - 10

2 - 11

2 - 12

2 - 12

13

2 - 13

2 - 14

16

17

2 - 17

2 - 18

Figure 3.1

Figure 3.2

Figure 4.1

Figure 4.2

Figure 4.3

Figure 4.4

Figure 4.5

Figure 4.6

.igure

Figure 4.8

Figure 4.9

Figure 4.10

Figure 4.11

Figure 4.12

Figure 5.1

Figure 5.2

Figure 5.3

Figure 5.4

Figure 5.5

Figure 5.6

Figure 5.7

Figure 5.8

4.7

Printer configuration ....................................

Control unit

Basic operations .........................................

Print operation

Basic data transfer operation

Timing of signals in data transfer

DPC-compatible interface signal driver and

DPC-compatible interface connector pin

(Alup type)

DPC-compatible interface connector pin assignment

(Winchester type)

Timing of FCB data loading ............................... 4 - 12

Correspondence between FCB data channels and bits

Channels specified for a forms feed format

An example of FCT and forms feed format

An example of format specification from

the operator panel .......................................

Basic operations

Character code transfer timing

Control code receive timing

DC1 code receive timing chart

DC3 code receive timing

Skip-15-Lines command receive timing chart

VFU

data receive timing chart

Centronics-compatible interface signal

.............................................

..........................................

............................

.......................

rseceiver ......4 -

assig:nment

................................................

........................................

........

...............

..................

.........................................

...........................

..............................

............................

..................................

...............5 -

............................

driver/rec.eiver

...

3 - 1

3-4

4-l

4-2

4-5

4-5

6

4-7

4-8

4 - 13

4 - 15

4 - 17

4 - 19

5-l

5 - 5

5-5

5 - 6

5-7

7

5

-8

5 - 9

BOZP-1500-OOOlA...05

"

Page 8

Figure 5.9

Figure 5.10

Centronics-compatible interface connector pin

assignment

Loading the data in the VFU

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . ..*.......................

5 - 10

5 - 15

Figure 6.1

Figure 6.2

Figure 6.3

Figure 6.4

Figure 6.5

Figure 6.6

Figure 6.7

Figure 6.8

Figure 6.9

Figure 6.10

RS-232-C interface circuit

RS-232-C interface signal transmitter and receiver . . . . . . . 6

Reverse channel line-protocol

(Drop DTR in START/STOP mode)

Reverse channel line-protocol (DTR Constant

XON/XOFF protocol (Drop DTR in START/STOP mode and

Half-auplex mode)

XON/XOFF protocol (Drop DTR in START/STOP mode and

Full-auplex

DTR line protocol

RTS line protocol (Drop DTR in START/STOP mode) . . . . . . . . . . 6

Interface cable connector

RS-232-C interface connector pin assignment . . . . . . . . . . . . . . 6

mode)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . ..*.........

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..*............................

. . . . . . . . . . . . . . . . ..*.........

On

mode) . . . . . 6

. . . . . . . ..*......................

6-2

-

8

6 - 10

- 10

6 - 11

6 - 11

6 - 12

-

12

6 - 13

-'14

vi

B02P-1500-OOOlA...O5

Page 9

TABLES

Table 2.1

Table 2.2

Table 2.3

Table 2.4

Table 2.5

Table 2.6

Table 2.7

Table 2.8

Table 4.1

Table 4.2

Table 4.3

Table 4.4

Table 4.5

Table 4.6

Able 4.7

Table 5.1

Table 5.2

Table 5.3

Table 5.4

Table 6.1

Table 6.2

Table 6.3

Table 6.4

stable

Table 6.6

6.5

Printer specifications

Ribbon specifications

Electrical specifications

Environmental conditions

Powered stacker specifications

FCT unit specifications

Perforation dimensions ....................................

Recommended bond weight of forms

DPC-compatible interface signal lines (Positive logic)

Character (ASCII) and control codes

Definition of the start code

VFU data example

Skip commands ............................................. 4 - 20

Space commands

Space commands

Centronics-compatible interface signal lines

Character (ASCII) and control codes

n-line Skip commands

Skip to Channel-n commands ................................

RS-232-C interface signal lines

Operation by the RTS and CTS combination

Printer statuses

Character (ASCII) and control codes

Commands and their control sequences

Printer status

..........................................

(15-line

(63-line

.......................................... 6 -

............................................ 6 - 28

.................................... 2-2

.....................................

.................................

.................................. 2 - 6

............................

...................................

..........................2 - 16

....

.......................4 -

...............................

feed mode)

feed mode)

......................................

........................

........................

.............. 5 - 3

.......................5 -

...........................

..................

.......................6 -

......................6 -

2 - 3

2-3

2 - 6

2-9

2 - 14

4 - 3

4 - 13

4 - 16

4 - 21

4 - 21

5 - 17

6 - 1

6-7

9

11

5 - 18

9

15

21

B02P-1500-OOOlA...05 vii

Page 10

Page 11

CHAPTER 1 INTRODUCTION

1.1 Introduction

The

M304x

series (M3040, M3041, M3042, and M3043) is Fujitsu's latest

introduction of highly cost-effective line printers using a print band and

designed for OKM applications. The printing speeds of

390, 750, 1090, and 1420

1200

The

lpm

for a 64-character set respectively.

M304x series provides the following features:

lpm

for a 48-character set, and

M304:x

3013,

series models are

600, 900, and

Superb Print-quality:

up to six-part forms.

High Reliability_: By using simplified mechanical design, reduced adjustment

requirements,

guaranteed.

compactness:

unit is controlled by microprocessors, operability has be improved and printer

size has been reduced,

Commonality:

in all M304x series models, minimizing parts inventory and reducing maintenance

training costs.

Low Sound Level:

55 dB A (in the

-zlf-diagnosis:

diagnosis is performed immediately after power-on.

automatically indicated, enabling the operator to determine if the error is

operator-correctable or requires customer engineer service.

can also test printers offline.

and self-diagnosis function, high reliability is consistently

Since the mechanical unit is divided into modules and control

Almost all mechanical and electric components are used in common

By using a soundproofing structure, a sound pressure level of

ECM@.

Thanks to the incorporation of microprocessors and sensors,

Improved print hammers assure excellent print quality on

resulting in compact installation space.

condition) has been attained for all models.

Errors during printing are

The microprocessor

Simple Print Band Interchange: Each printer can use up to four print band;

three standard ones,

Wide Variety of Options:

individual customer needs

and one optional one.

M304x

The

B02P-1500-OOOlA...03

series offers

a variety

of

options to meet

l-l

Page 12

Figure

1.1 M304x

series line printer

1-2

Page 13

CHAPTER 2 SPECIFICATIONS

This section describes specifications of the M304x series

ribbons, and forms.

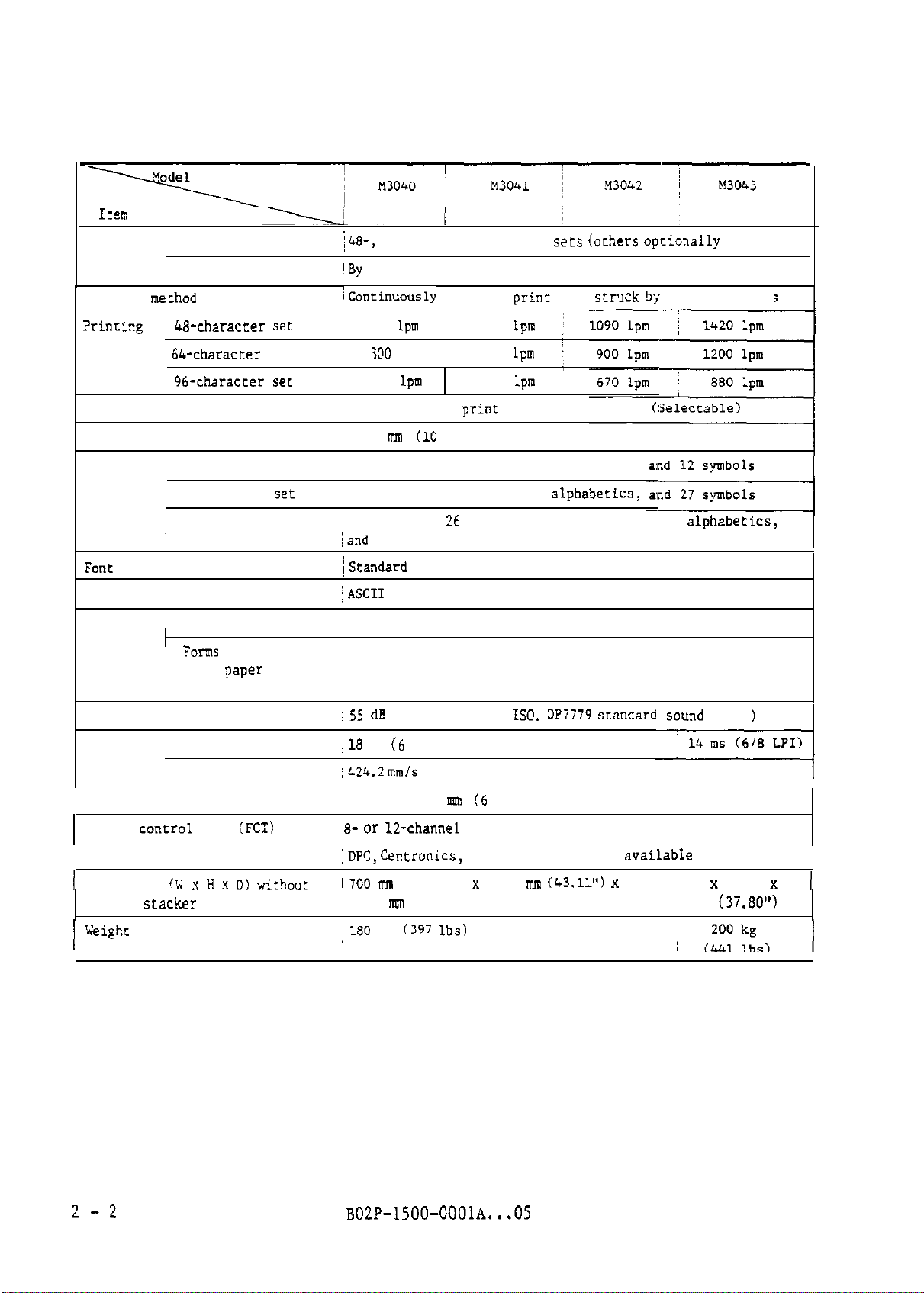

2.1 Printer Specifications

Table 2.1 lists the printer specifications. For electrical specifications and

ambient conditions, see Section 2.3.

DPC, Centronics or RS-232-C interface, see Chapter 4, 5, or 6.

For standard interface specifications,

:Line

printers,

B02P-1500-OOOlA...03

2-l

Page 14

Item

Print band ~ Type

'

Replacement

Table 2.1 Printer specifications

i48-,

64-, and 96-character

my

operator

sets (ochers optionally

available)

Printing mechod

Prinringj 48-character set

speed

~ 64-character

(

96-character set

set

Print positions

Character spacing

~Continuously

390

~

3@0

210

80, 132 or 136

2.54

nrm (10

rotating

Ipm

/

lpm ~

lpm

print positions per inch)

print

band

750

lpm

600

lpm

420

lpm

prinr

positions per line

~

str~xk b:;

rotary hammers

(:Selecrable)

Character ~ 48-character set 10 numerics, 26 upper-case alphabecics,

set

I

Font

type

Character code

Number of I Carbonless copy

copies

j

64-character

(

96-character set

I

set

;

10 numeric*,

26 upper-case

alphabecics,

10 numerics,26 upper-case and 26 lower-case

iand

32 symbols

~Scandard Gothic (others optionally available)

iASCI1 (others optionally available)

paper

~

6 (Including original)

j

Ferns with interleaved! 5 (Including original)

~

carbon

?aper

and

alphabetics,

~ carbonbacked forms

S5 dB

Sound pressure level

A (Conforms to

ISO. UP7779 srandarcl

so"nd level)

Forms feed I Line spacing time

rate

Vertical line spacing

Format

:

Continuous feed i424.2 mm/s

control

tape

(FCT)

option ~ 8- or

Interface

1

Dimensions

powered

11; x ii x D) without 1700 m

stacker

,18

i4.23 or 3.18 m (6 or 8 lines/inch)

:DPC, Centronics,

i

900

1 Weighr I180

ms (6 LPI)

(16.7 inches/s)

12-channel

FCT is available.

RS-232-C, and other

(27.56") x 1095 mm

fmn

05.43")

kg

(I?7 lbs)

(43.11") x

avai.lable

options

700 x 1095

~

960

(37.80")

I

x

I

2-2

BOZP-1500-OOOlA...05

Page 15

2.2 Ribbon Specifications

This printer uses an endless cartridge type or open-type ribbon, which only

moves

in one direction.

specifications are as

The ribbon is replaced by the operator. The ribbon

f0110ws:

Table 2.2 Ribbon specifications

I~ ~~

Item

Parts number ~

I

B87L-0840-0401A

Specification

(black)

B87L-0840-0402A (blue black)

Fabric

Width

Length

Ink

-

.~

Storage life

I ~-~- -

2 years

blue black

_..__~_

2.3 Installation Conditions

This section shows the outer dimensions,

electrical specifications,

and environmental conditions of the printer.

operation and maintenance area,

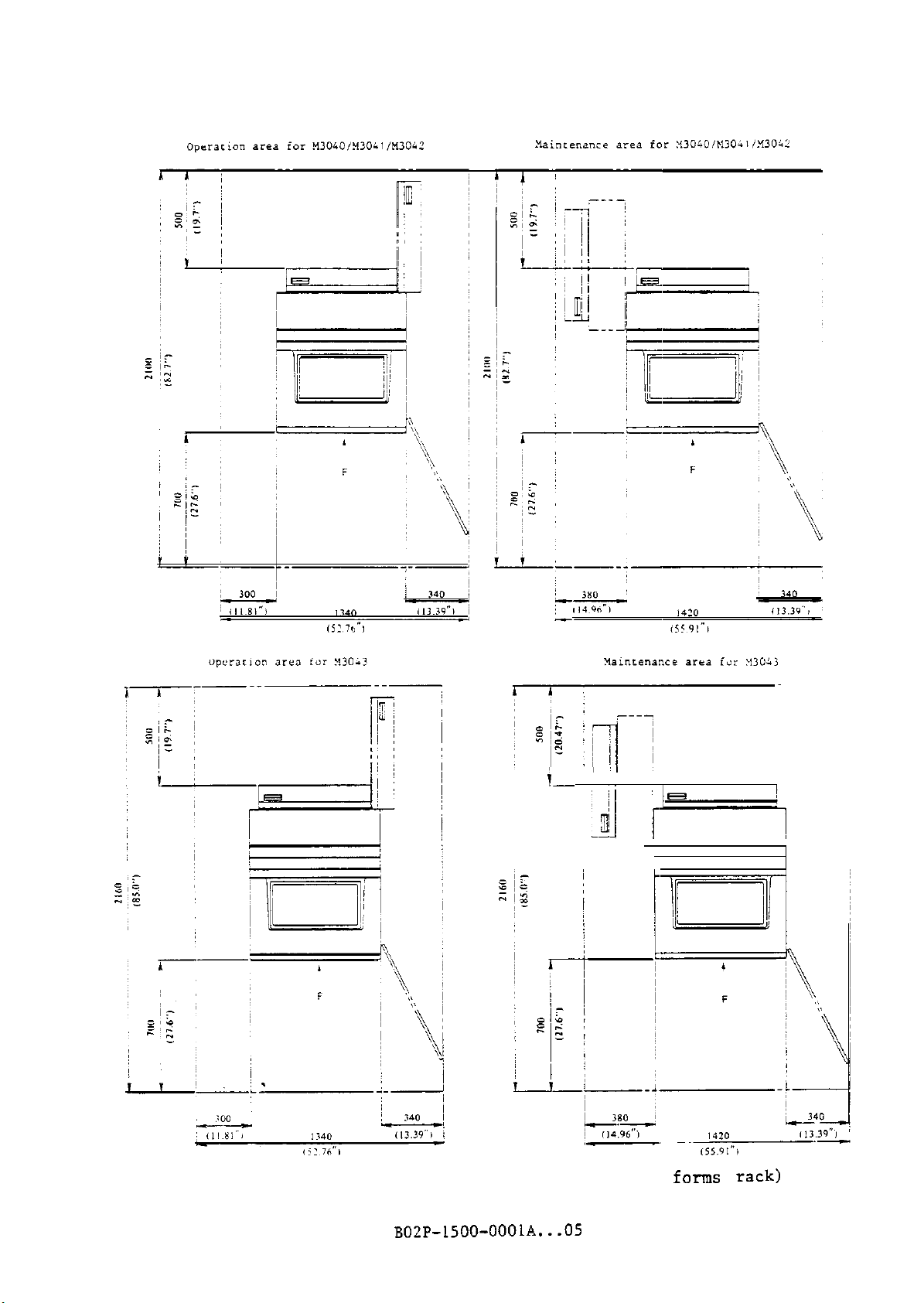

Table 2.3 Electrical specifications

I

M3040 j

I

Primary voltage

Phase

Frequency

POW7

consumption

Starting Surge

men

print- !

ing

When not printing

UL/CSA

version

I VDE

version

I

! LB-character set

136-column

64-character

~

136-column

printing

printing

200/220/2301240

Single phase

50 or 60 Hz

250 VA

50

A or less

+2

4%

VAC

20%

I

B02P-1500-OOOlA...06

2

-3

Page 16

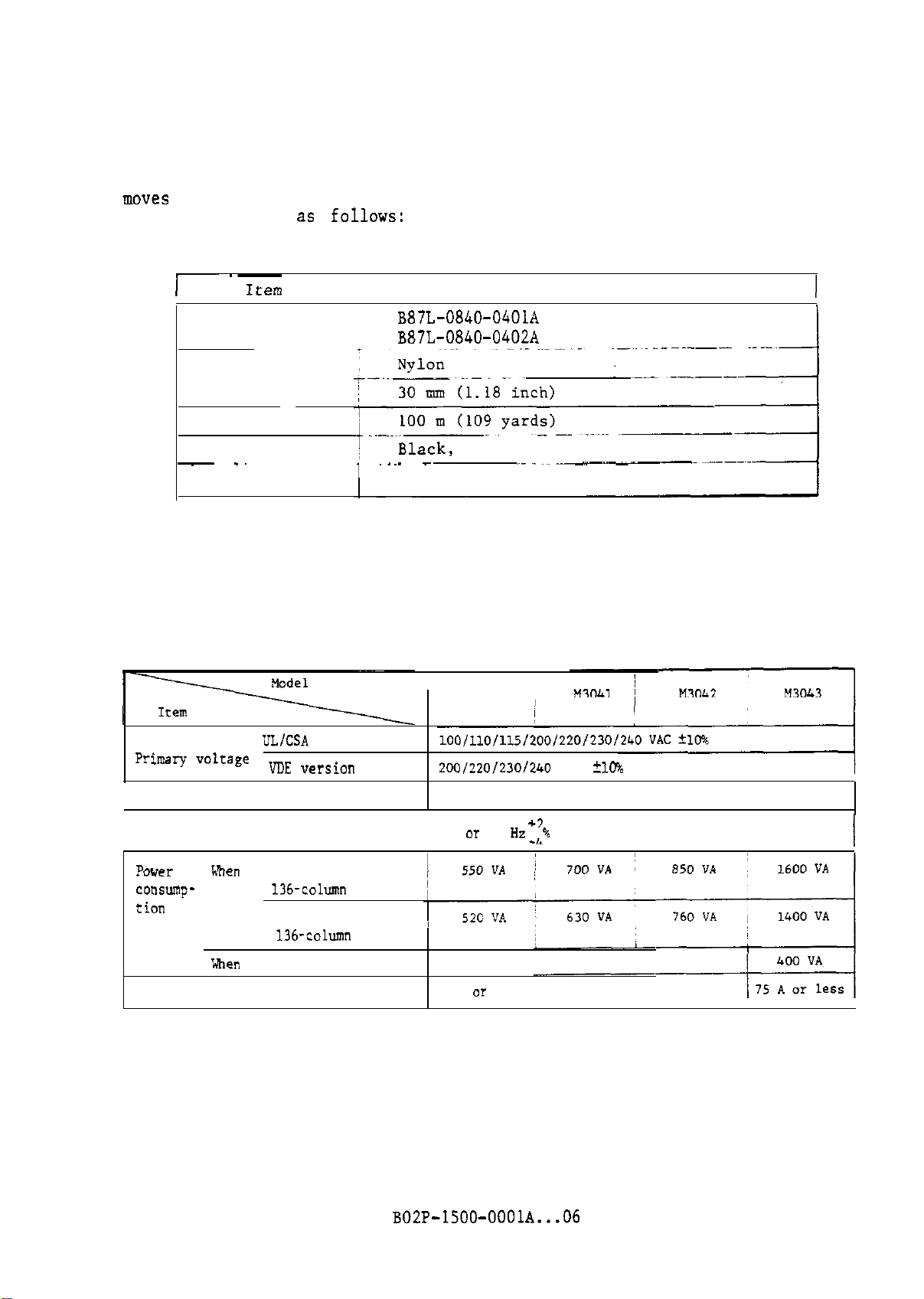

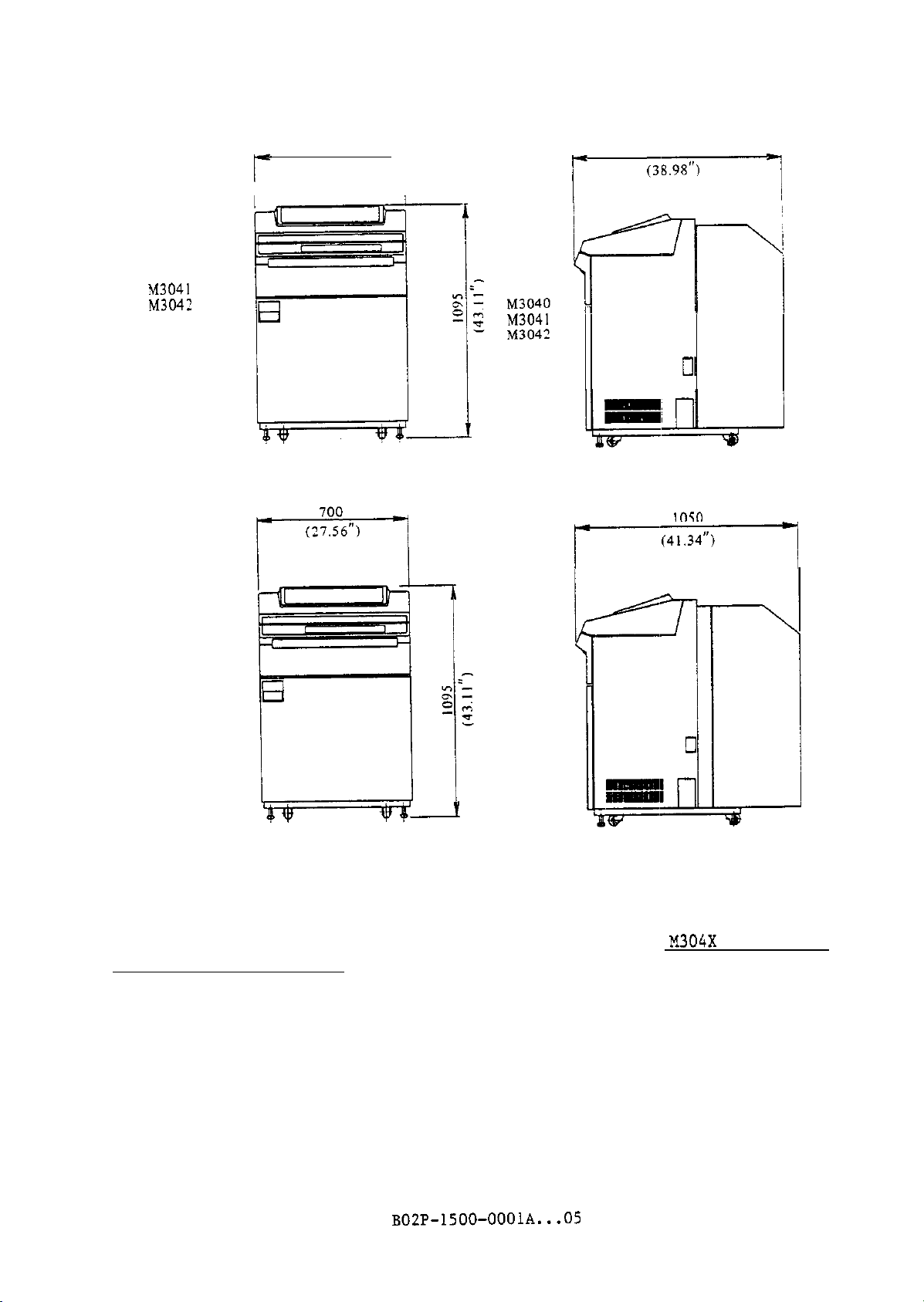

x3040

xi3041

M304?

900

(35.43")

-9

M3043

Figure 2.1 Outer dimensions (with the forms rack)

2-4

B02P-1500-OOOlA...O3

Page 17

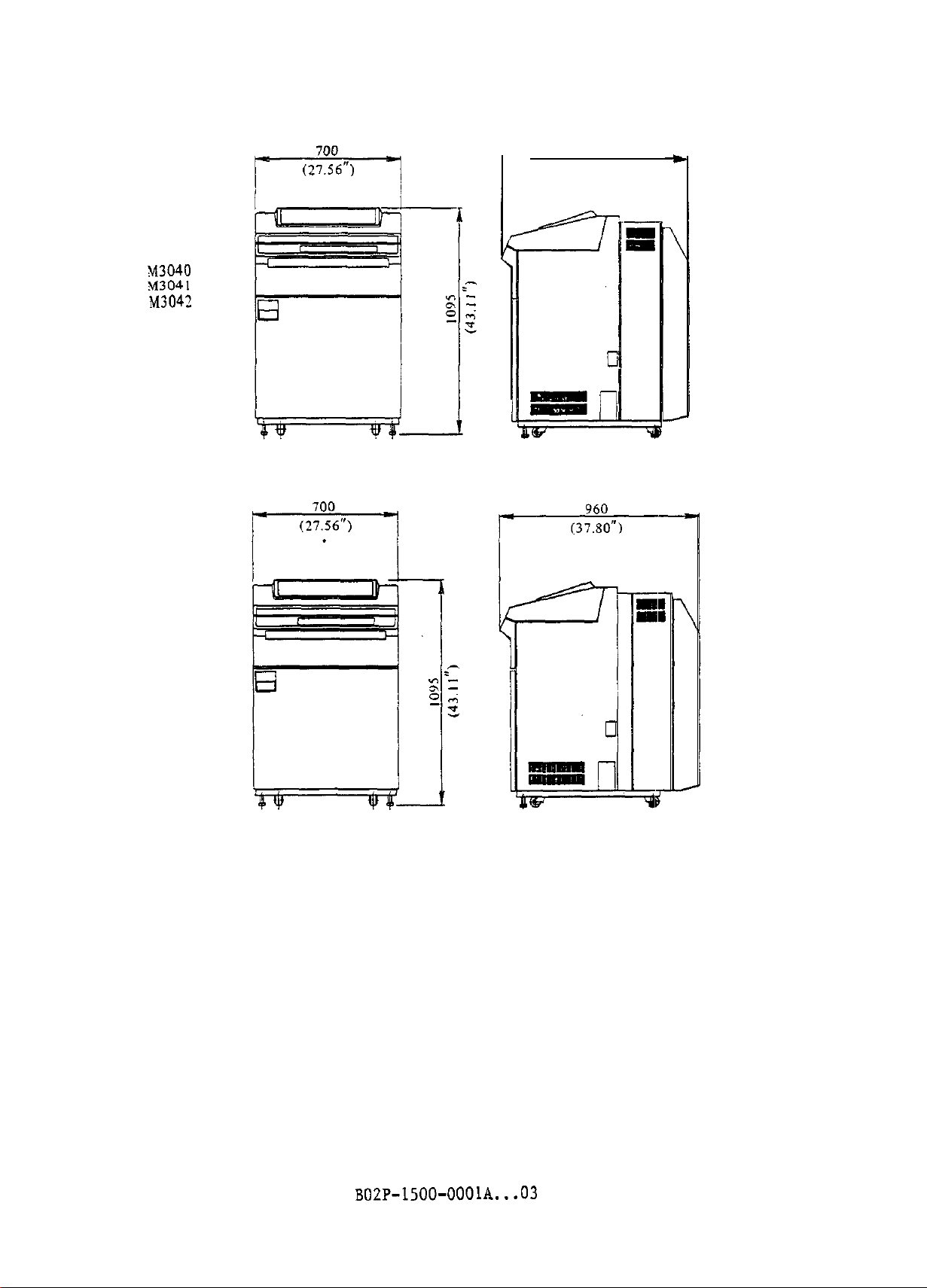

i-

Figure 2.2 Operation and maintenance area (with the

B02P-1500-OOOlA...O5

forms rack)

2-5

Page 18

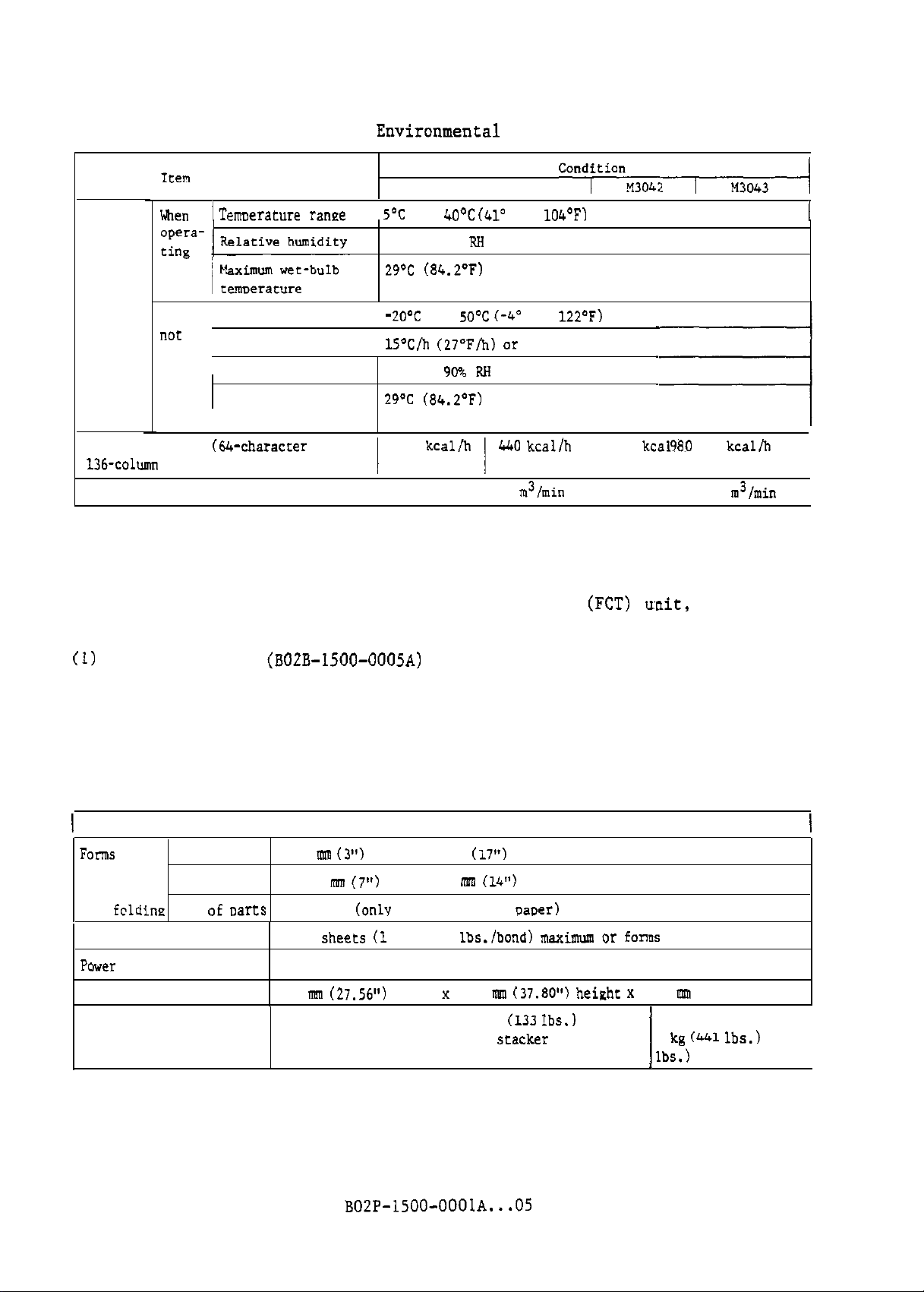

Table 2.4

Environmenral

conditions

Ambient

condi-

tions

When I

when

“CX

ope-

Temoerature

~ Temperature range / -

( Temperature gradient ! lS’C/h (27”F/h) or below

ranee 1

rating Relative 10% to

Maximum wet-bulb ZY’C

I temperature

Heat dissipation (6Lvcharacter set

136-column

printing)

Air flow

M3040

5’C

to 40aC

20% to 80%

290~

(84.20~)

20-Z

to

(84.2’F)

360 kcallh

I

I M3041

(41’

P.8

5O’C C-4’

90% RH

to 104’F)

(Without condensation)

440

5

condftianM304:T-rTA

to 122’F)

kcalfh 1 530 kcailh

I I

m31min

y80

kcal/h I

7

m3/min

I

I

2.4 Optional Unit

This section gives specifications of printer optional units such as the powered

stacker, long-line interface unit, format control tape

(FCT) wit,

line counter,

and paper puller.

(1)

Powered stacker

(BOZB-ISOO-0005A)

The powered stacker enables folding and stacking of forms.

lists the powered stacker specifications. Figure 2.3 and 2.4 show the

outer dimensions,

and the operation and maintenance areas for printers

with the powered stacker attached.

Table 2.5 Powered stacker specifications

I

Forms

available

for

fcldine

Capacity 3000 sheete (1 part, 17

Power

consumption

Dimensions

Weight

Item

I

’ Width 76.2 mm

Length

No. oE carts

177.8

1 to 5. 6 (only for carbonless paoer)

60 VA maximum (powered stacker only)

700

mm

Powered stacker only: 60 kg

M3040 to M3042 with powered stacker attached:

M3043 with powered stacker attached: 220 kg (485

(3”)

to 431.8 mm

mm

(7”)

(27.56”)

co 355.6 m

width

Table 2.5

Specifications

(17”)

(14l’)

lbs./bond) maxirmvn

x

960 mm (37.80”) height x 417 mm (16.42”) width

(133 Ibs.)

or fonos stacked 32 cm high

200 kg

1

(441 lbs.)

lbs.)

I

2-6

B02P-1500-OOOlA...O5

Page 19

M3040

M3041

M3042

700

(27.56")

1

M3041

M3042

'990

r

(,T

1050

r-14134.)

M3043

M3043

Figure 2.3 Outer dimensions (with the powered stacker)

The powered stacker can be operated using switches on the switch panel at the

top of the stacker.

Printer Operator's Guide.

For switch panel operation.

refer to M304X Series Line

BOZP-1500-OOOlA...O5

2-7

Page 20

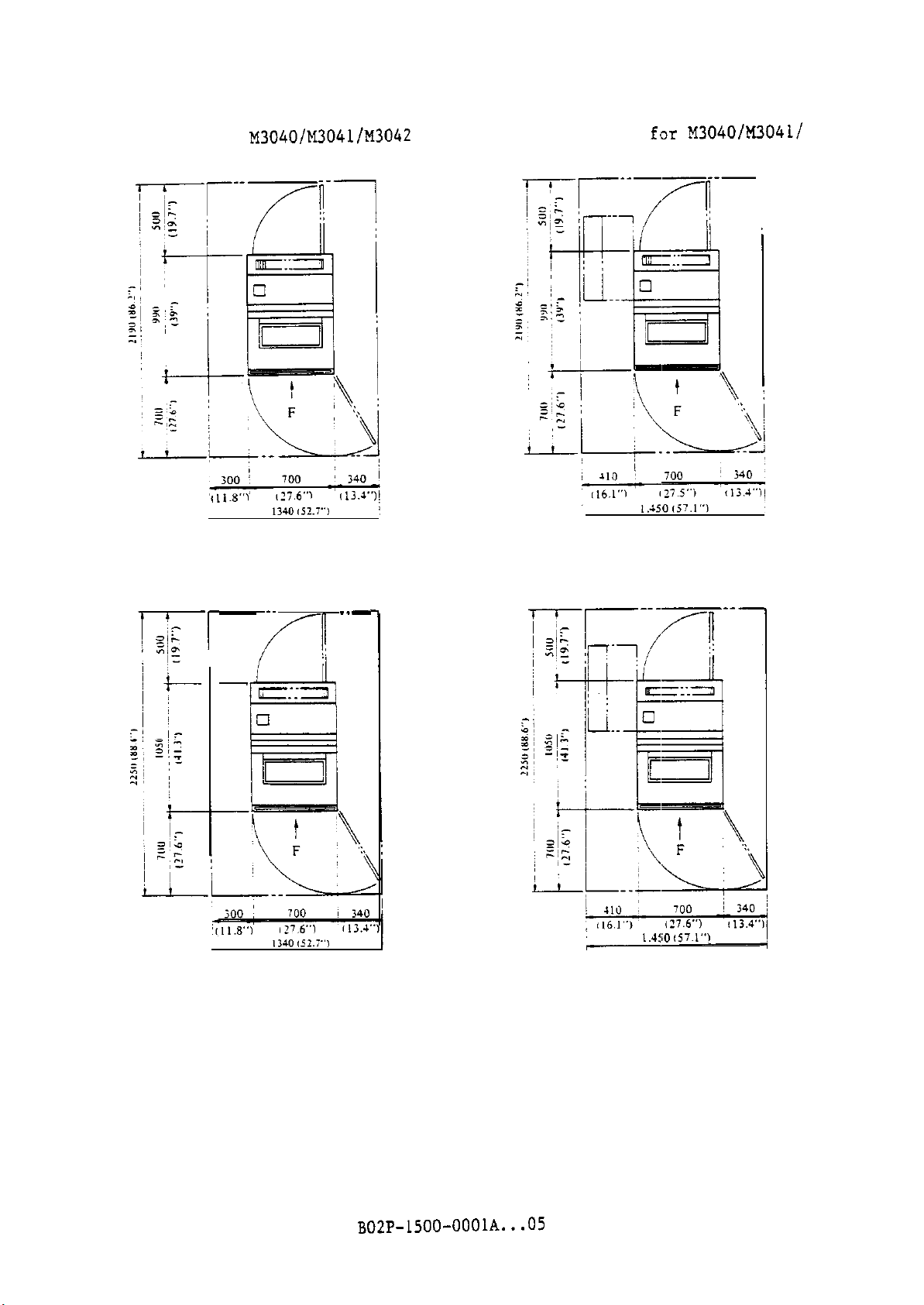

Operation area for M3040/M3041/M3042

with powered stacker attached

Maintenance area

M3042 with powered stacker attached

f'or

M3040/M3041/

1

Operation area for M3043 with

powered stacker attached

-_.

-r

T’

-

[5::3

el

Figure 2.4 Operation and maintenance areas

Maintenance area for M3043 with

powered stacker attached

..-

(with the powered stacker)

2-8 B02P-1500-OOOlA...05

Page 21

(2) Long-line interface unit

The long-line interface unit can transmit and receive differential-mode

interface signals via signal lines which can be up to 150 m in length.

(B02B-1500-0004A)

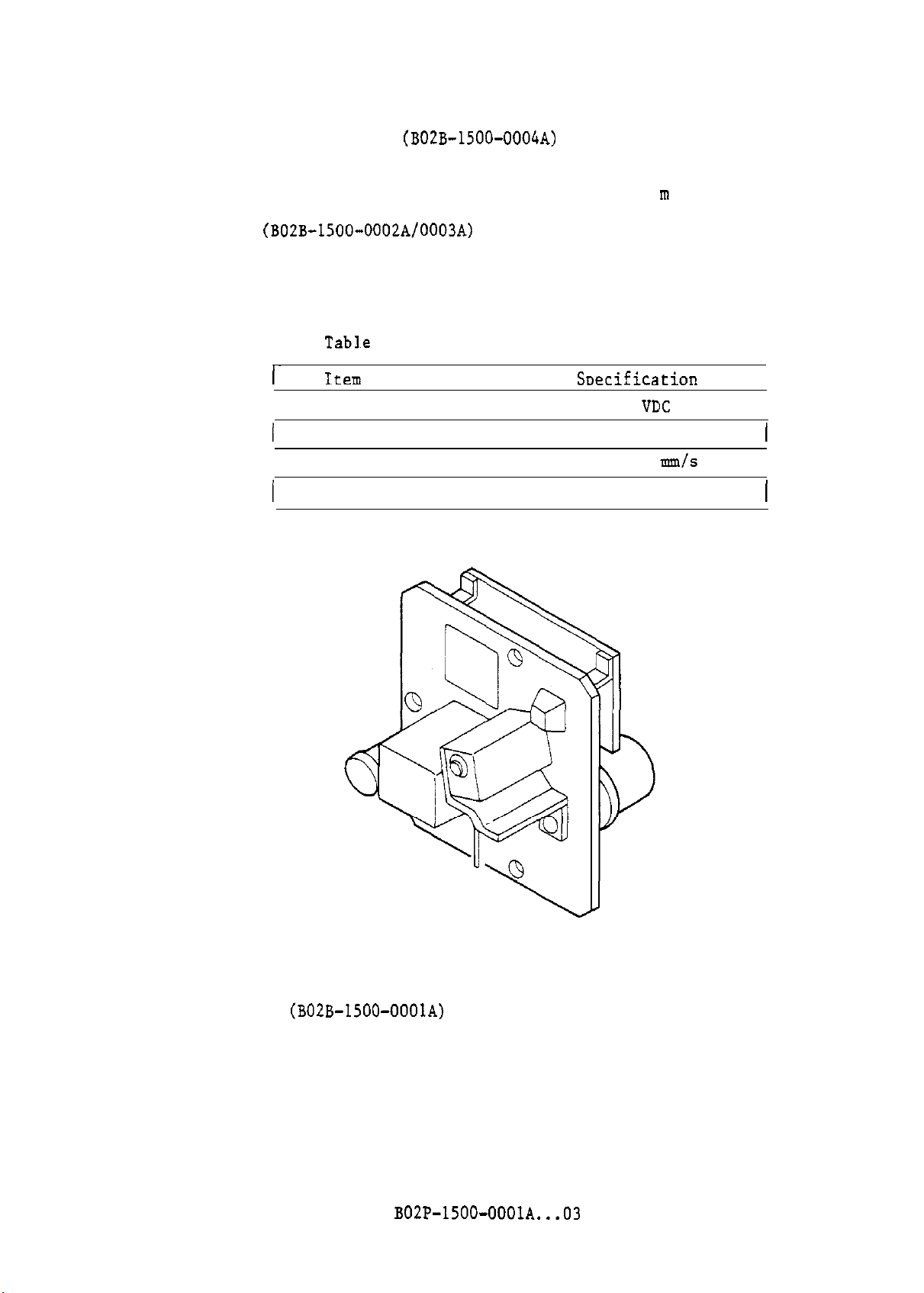

(3) FCT units

The FCT unit reads format control data from the FCT and sends the data to the

printer.

FCT unit.

Table 2.6 lists the FCT unit specifications.

(BO2B-1500-0002A/OOO3A)

Tabl~e

2.6 FCT unit specifications

1~

I

Current

(

Dimensions

Item

Rated voltage

Tape speed

I

/

I

I

I

Figure 2.5 shows the

Soecification

6 to 12

0.4 A maximum

75 to 200 mm/s

To be supplied

VClC

I

I

I

I

I

Figure 2.5 FCT unit

Line counter

(4)

The line counter counts up by one every time 100 lines are printed.

(B02B-1500-OOOlA)

B02P-1500-OOOlA...03

2-9

Page 22

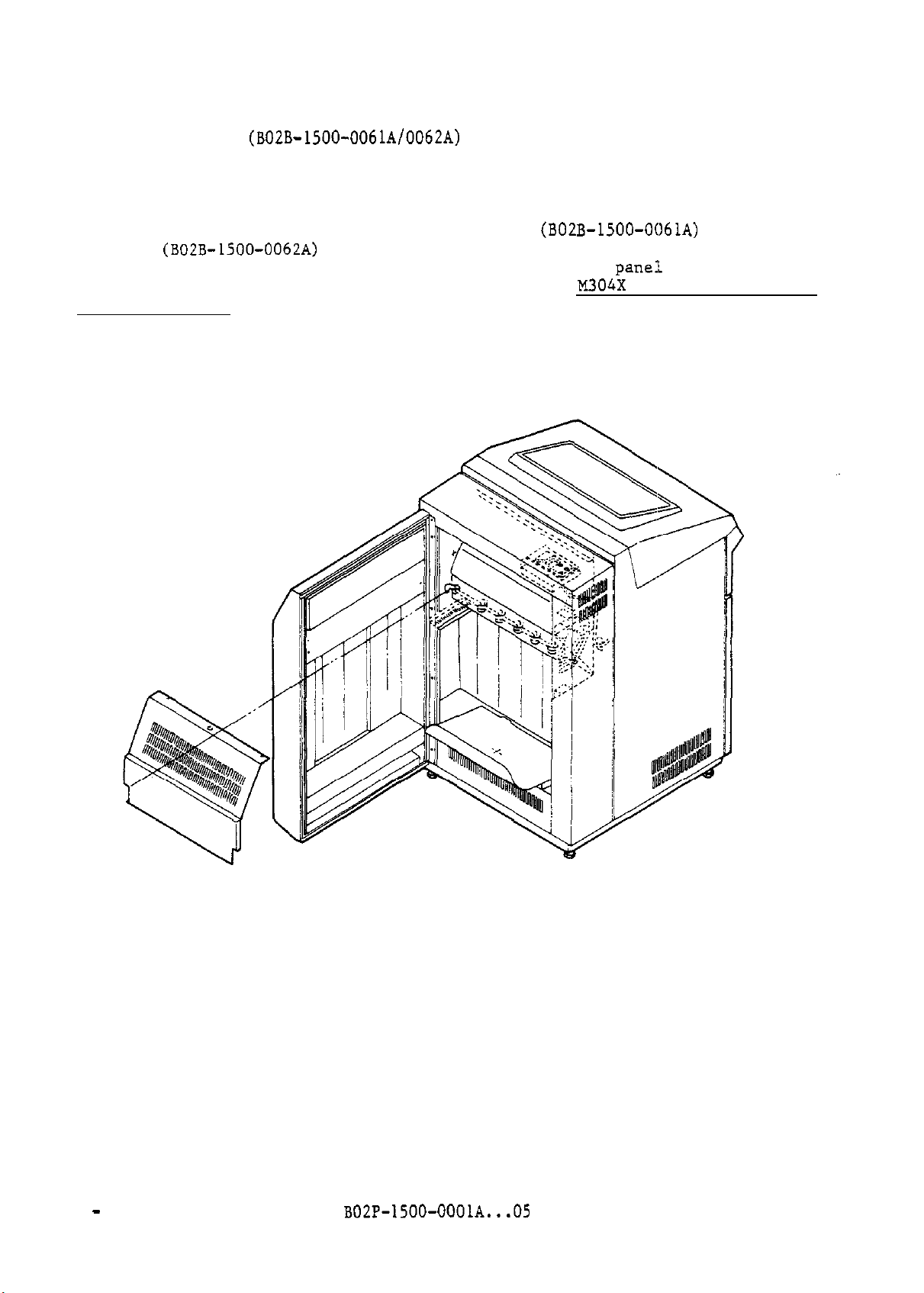

(5) 'Paper puller

(B02B-1500-0061A/0062A)

The paper puller,

forms folding.

The paper puller is supplied only as a parts kit (B02B-1500-0061A) or as an

assembly

the same way as the power stacker, that is, by using the

upper part of the forms rack.

Operator's Guide.

Figure 2.6 shows the paper puller.

(B02B-1500-0062A)

installed in the forms rack, pulls printed forms to improve

with a forms rack.

For details,

The paper puller is operated in

par~e!~

installed at the

refer to M304X Series Line Printer

2 - 10

Figure 2.6 Paper puller

B02P-1500-OOOlA...05

Page 23

2.5

Form

Specification

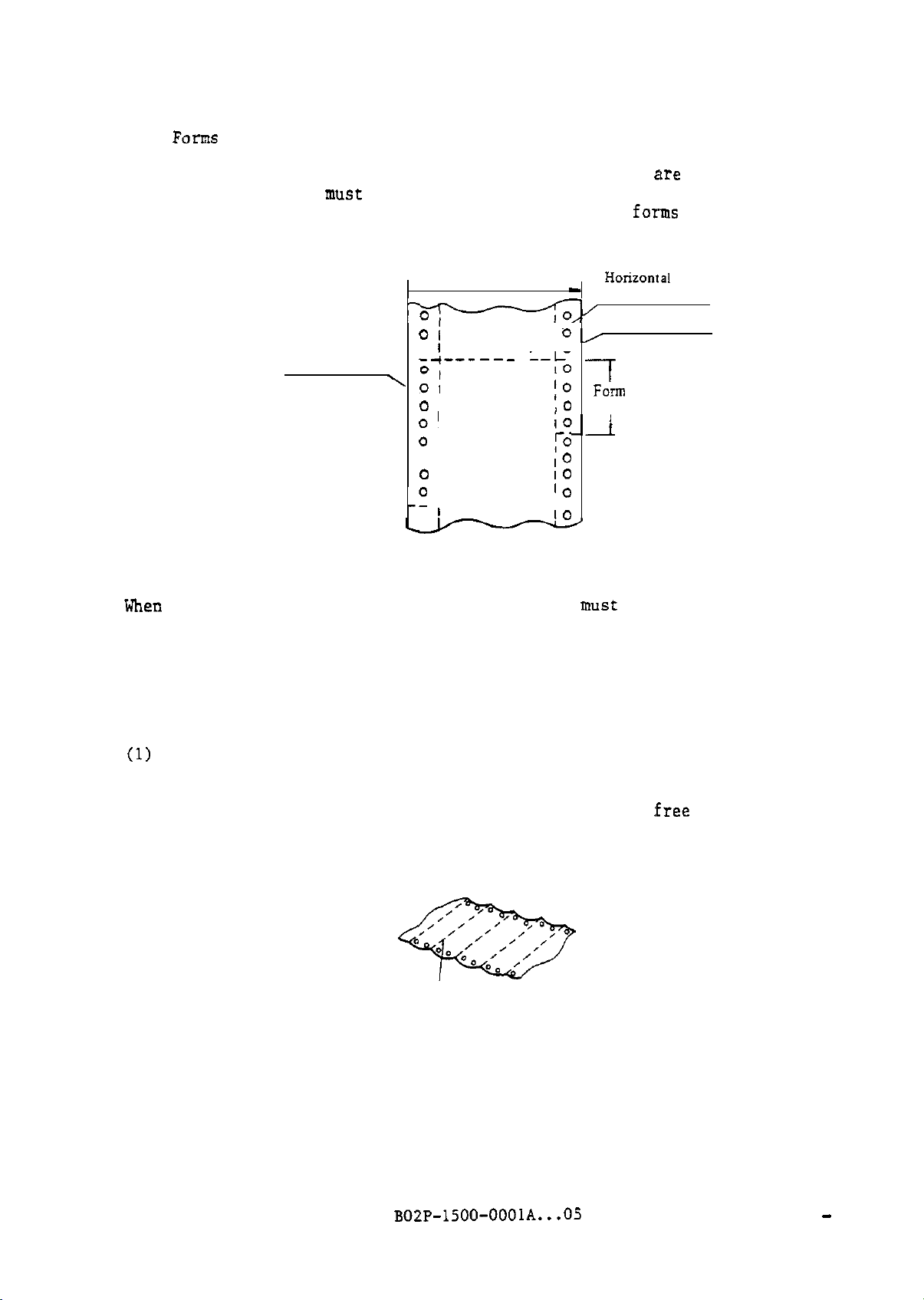

Continuous

printers.

fanfold forms,

The forms

single copy or multiple copy,

must

have pin feed holes evenly lined up on both sides and

horizontal perforations that run perpendicular to the

See Figure

2.7.

Vertical

perforations

'

Forms width

--+---CA

01

01

0

1

o+-----

--ko

01

0

0’

--A---------

fJ

I

0 I

0 1 10

I

-0

I

----------A--

0 1

HoIiZOIXil

-

perforations

0,

I

Pin feed hole

7

FOrIll

lo

length

10

‘O--i

:O

10

‘0

10

Figure 2.7 Forms

When selecting forms for this printer,

the user

must

conform to the following

forms specifications:

are

used for the

forms

feed direction.

2.5.1 General note about forms

This

section describes paper quality and shape of the forms container.

Paper quality

(1)

paper used for forms should be of good quality, opaque, not too elastic,

and suitable for printing. The paper must also be

wrinkles,

and tears.

Torn paper can cause printing trouble.

Curled forms es shown in Figure 2.8 will not be fed or stacked correctly

after printing. Do not use curled forms.

*

Figure 2.8 Curled forms

Perforations

:free

from dirt,

B02P-1500-OOOlA...Of

2

- 11

Page 24

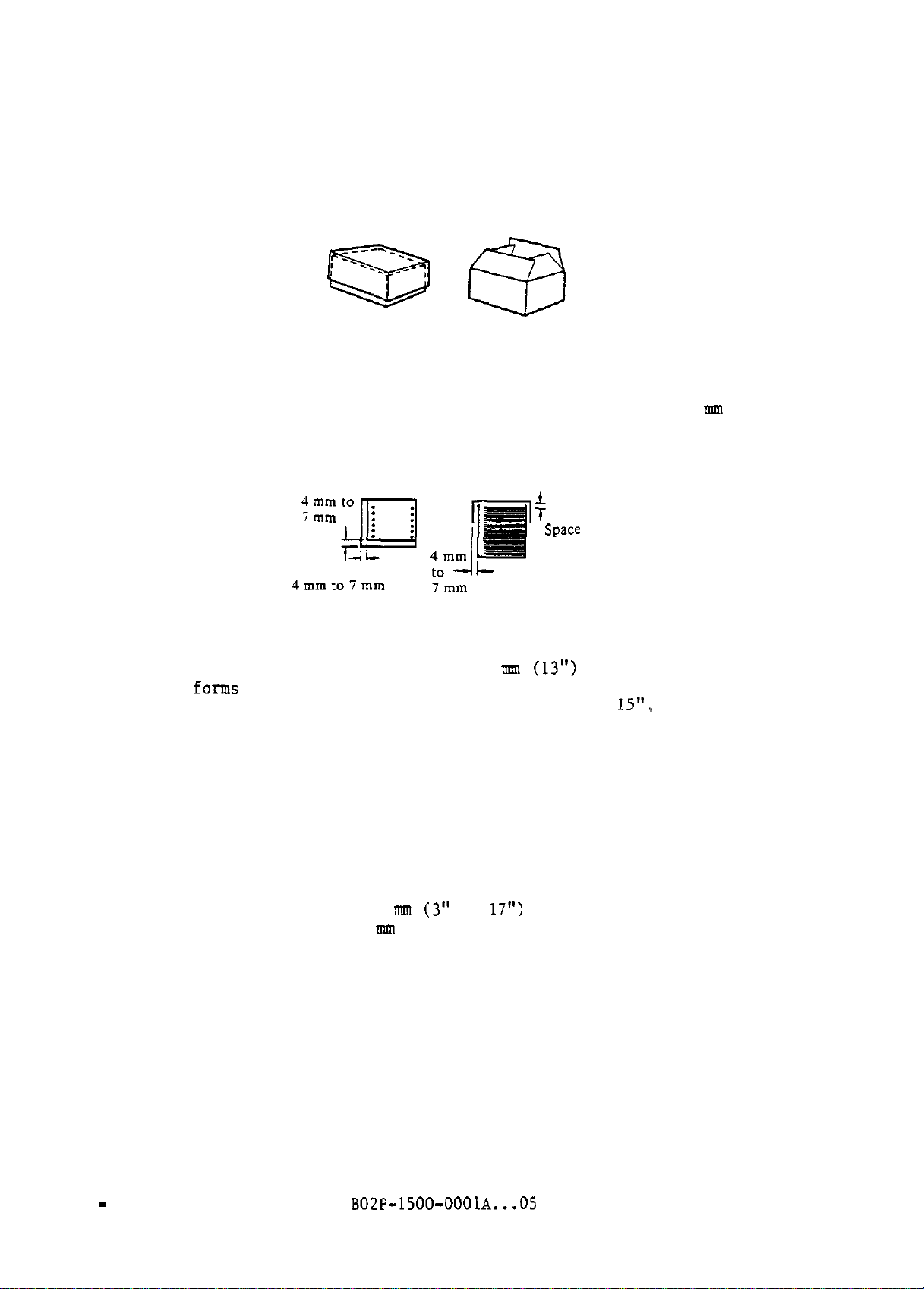

(2) Forms container

If the forms catch on container lids when being fed, feed errors may

occur.

Therefore arrange the lids as shown in Figure 2.9.

Allowable

Figure 2.9 Forms container lids

Inside space between the forms and container should be 4 to 7 mm (0.16" to

0.28").

The bottom of the box must be flat.

(Top view) (Side view)

Unallowable

See Figure 2.10.

f

space

Figure 2.10 Shape of the forms container

The forms container height must be 330.2

in the

If the form length or folding dimension is more than

rear doors must be open during operation.

forms

hopper.

rmn (13")

or less to be installed

IS":,

the front and

2.5.2 Dimensions

This section describes dimensions of the forms, printing area, pin feed holes.

and perforations.

(1) Forms dimensions

Forms width:

Forms length:

2 - 12

76.2 to 431.8 mm

76.2 to 381 m (3" to 15")

B02P-1500-OOOlA...OS

(3"

to

17")

Page 25

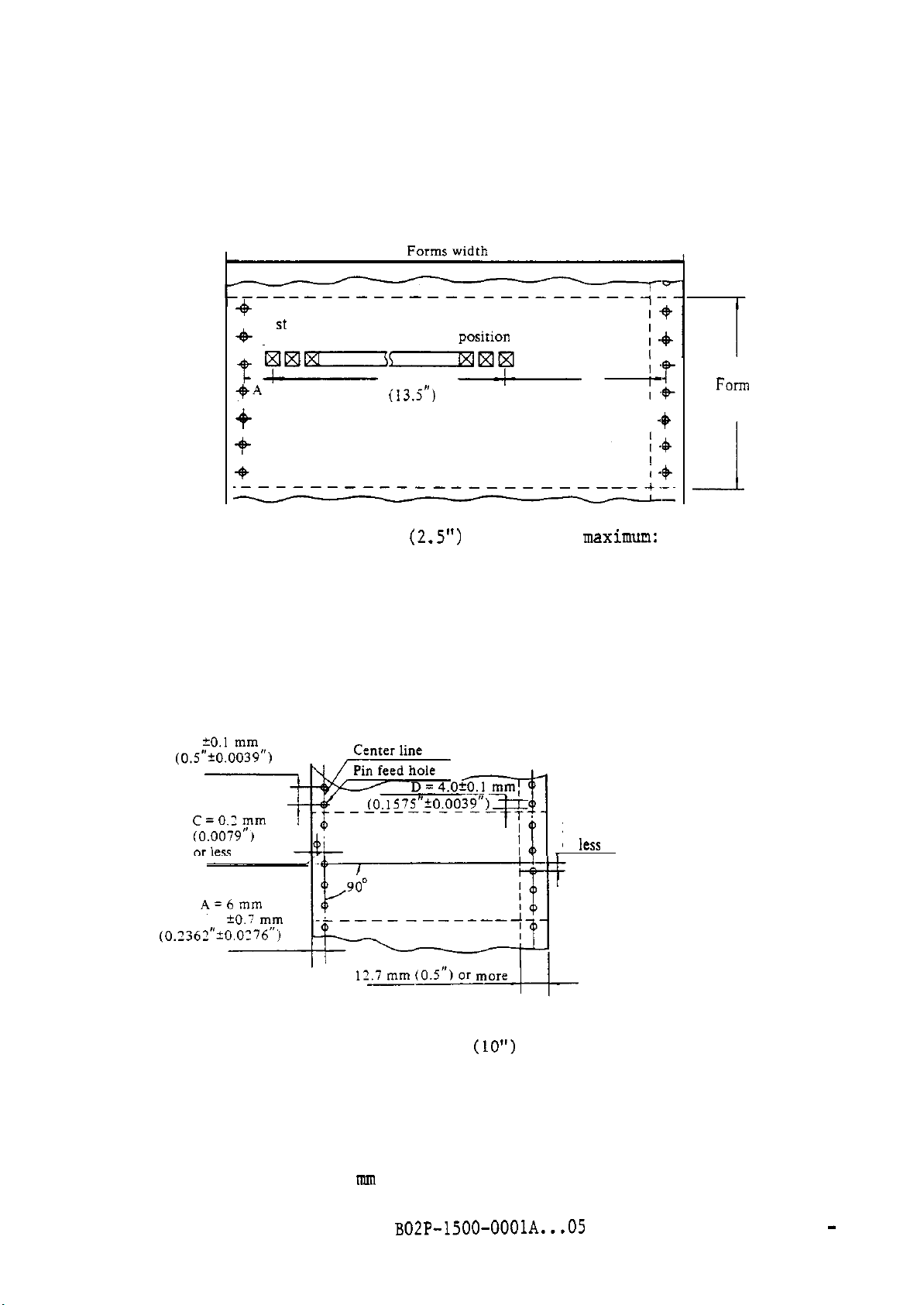

(2) Positions and dimensions of the printing area

Figure 2.11 illustrates the distances between the leftmost and rightmost

print-position centers of the printing area and the pin feed hole center.

+

I st print

+

position

km--wlxlm

-t

-

$A

-+

A- maximum: 63.5 mm

Figure 2.11 Leftmost and rightmost print positions

(3) Pin feed holes

Pin feed holes must be round.

are given in Figure 2.12.

B = 12.7 mm

342.9 mm

(13.5")

136th print

posiiion

-

(2.5")

The dimensions relating to pin feed holes

B

I +

B-

maximun:

E = 0.2 mm

or

less

FOTC

length

--I

68.6 mm (2.7")

A: Distance between

the forms edge and

pin feed holes.

B: Distance between

two consecutive pin

feed holes.

C

: Misalignment of the

pin-feed hole

center with other

holes.

D: Diameter of a pin

feed hole.

E: Misalignment of the

pin feed hole with

a hole on the

opposite side.

Note:

Poorly shapted pin feed holes and misalignment between left and right pin

feed holes may result in inferior paper tensile strength. Misalignment

must be within 0.2 mm (0.0079").

The total misalignment of any two holes on opposite sides of

forms along a 254 mm

(0.0118").

Figure 2.12 Dimensions relating to pin feed holes

B02P-1500-OOOlA...O5

(10")

length must not exceed 0.3 mm

2 - 13

Page 26

Pin feed holes that touch horizontal perforations may damage the paper.

Pin feed holes must not overlap horizontal perforations.

Hanging hole

stick to the printing area,

chad

will likely cause problems with the printer.

resulting in printing cutoff characters. Do

Chad may

not use such forms.

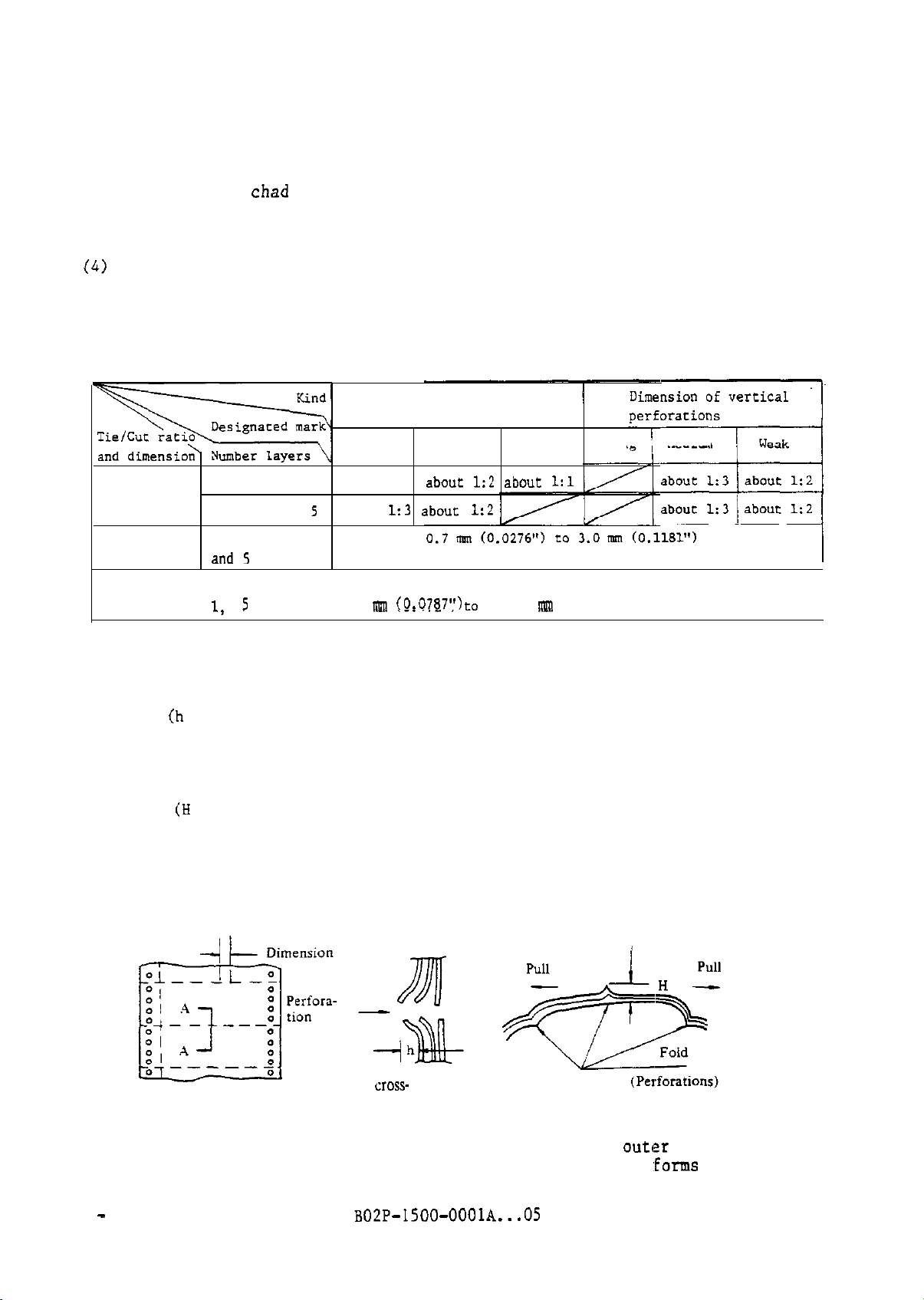

(4)

Perforations

Perforations must be straight. The perforations should be of the size

shown in Table 2.7.

Table 2.7 Perforation dimensions

Dimension of horizontal

perforations

Tie/Cut ratio 1

2,

3, 4, and

Tie dimension 1, 2, 3, 4,

and 5

and

Cur

dimension

1,

2, 3, 4,

5

about 1:3

5

2.0 ml (0.0787")

1.2 mm (0.472")

strong

Medium Weak

abollr 1:2 about 1:l

about 1:2

3.0

to 1.2m(0.0472")

rmn

Strong 1 Medium

/

(0.1181")

co

I

Use weak or medium perforations shown in Table 2.7. The dimensions of

horizontal perforation should be 2 mm (0.0787") or less.

If the

dimensions of horizontal perforations exceed 2 mm, the portion sticking

out (h in Figure 2.13) at the cutting edge becomes large! and feed error or

forms damage may occur.

If separation at the perforations (fold) between each part is too great,

the forms may be damaged or ink stain may result.

The raised part at the

fold (H in Figure 2.13) must be 2 mm or less with the bottom layer kept

flat by force.

Figure 2.13 shows the protrusion and separation of the outer layer at the

perforation of multiple-part forms.

Expended

CIOSS-

sectional view of

A-A'

Figure 2.13 Protrusion and separation of the

at the perforation of multiple-part

2 - 14 B02P-1500-OOOlA...O5

outlzr

layer

~forms

Page 27

2.5.3 Multiple-part forms

This printer utilizes up to 6-part forms. Interleaved carbon paper utilizes

6-part forms and is not included in the number of parts. Forms with

interleaved carbon paper, carbon-backed forms, and forms using carbonless copy

paper are available as multiple-part forms.

must meet the specifications in Subsections 2.5.1 and

the same length and width.

This section describes the fastening, misalignment, and thickness of

multiple-part forms and also how multiple-part forms cause feed defects.

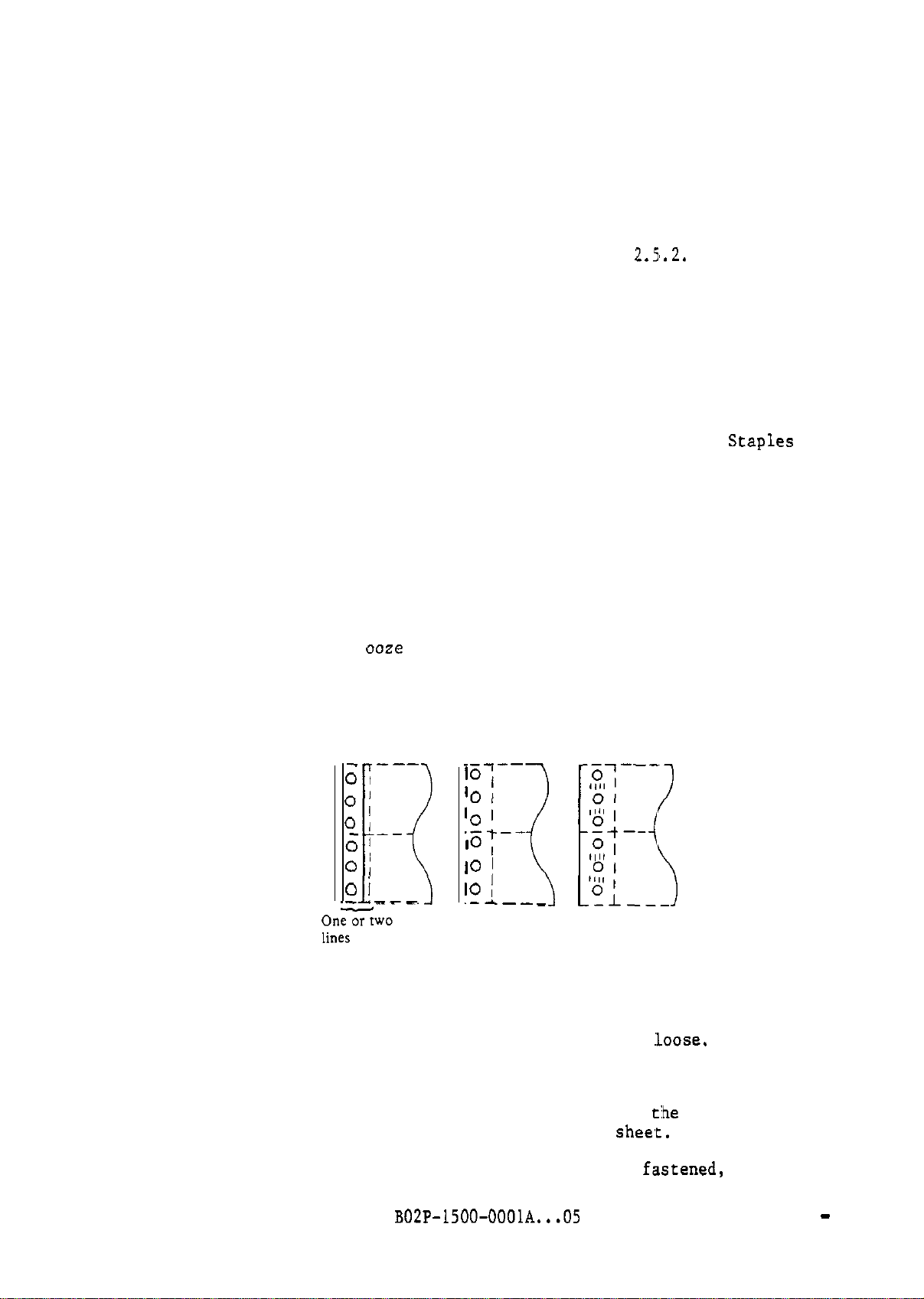

(1) Fastening multiple-parts

Each part of multiple-part forms must be fastened together at one or both

pin feed hole areas by gluing or crimping.

interleaved carbon paper should be fastened on the right.

not be used on forms.

damaged and a feed error will occur.

For gluing, do the following:

. The shape of glued parts should be dots or stripes in the vertical

direction, as shown in Figure 2.14,

. Glue should be applied evenly and must not cause wrinkles or discolor

the paper.

. Do not apply glue to the perforations. If stripe gluing is necessary,

the glue must not

layers.

. Glue cannot be used if forms lose pliability.

If they are used,

ooze

through perforations of the top and bottom

Each part of multiple-part forms

2.5'.2.

Multiple-part forms with

the printer print section will be

They must be of

Staples

must

Stripe

gluing

-

---

0

I

Dotted

gluing

iO7--

Crimps

‘0 I

O/

0

I

0

I--

0 !

0 I

---

It

-5

Figure 2.14 Methods of fastening paper

For crimping, do the following:

. Layers must be firmly fastened and must not come

. There should be no paper tailings or dust.

. Forms should maintain their shape so as not to cause jams.

. Crimps must not overlap horizontal perforations.

horizontal perforations,

. Crimps should not project through the bottom

If layers of multiple-part forms are not properly

likely to peel apart, causing feed defects.

‘0 ’

;Et--

IO

1

10

,

._A___

I<

the forms will tear at

shee,t.

:Loose.

If crimps overlap

t:he

perforation.

f,astened,

the layers are

B02P-1500-OOOlA...05 2 - 15

Page 28

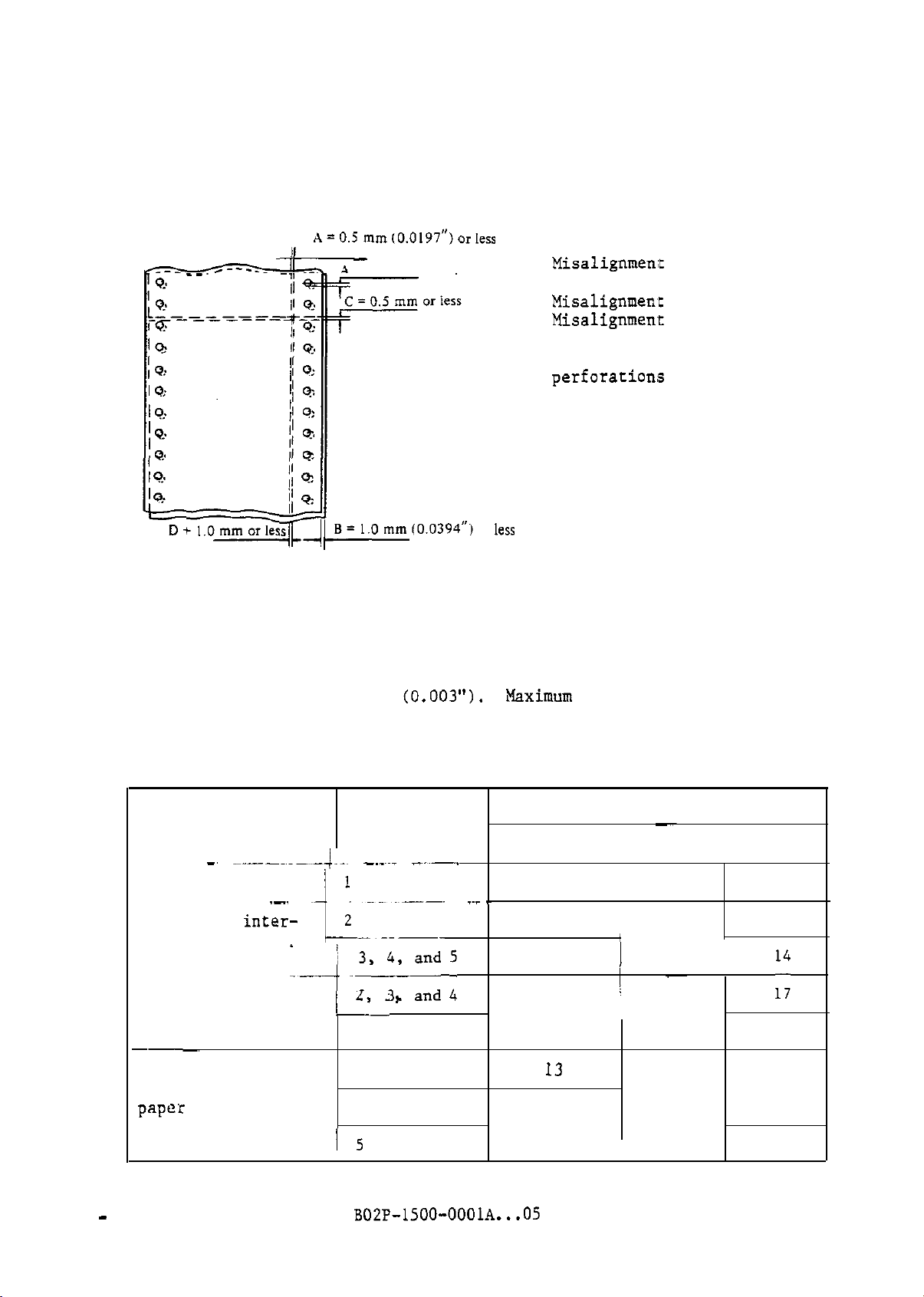

(2) Misalignment of paper

Misalignment between layers should be within the range shown in Figure

2.15.

Misalignmen;t

= 0.5 mm or less

or

Figure 2.15 Allowable incorrect alignment of multiple-part forms

(3) Thickness of parts

Thickness of parts should be uniform.

area must be within 0.076 mm

(including edges) is 0.6 mm (0.0236"). Table 2.8 indicates recommended

bond weight of each layer according to forms type.

(0.003").

A:

holes

B:

Misalignmen,t

c:

MLsa1ignmen.t

perforations

D:

Misalignment of vertical

perforatiom

less

Thickness deviation in the print

Maximum total thickness of forms

of pin feed

of edges

of horizontal

2 - 16

Table 2.8 Recommended bond weight of forms

Forms type

-~ ----...-~~-i.-

Single-part forms

Forms with

leaved carbon paper

Carbon-backed forms

-~

Forms using

carbonless copy

paper

inter-

--. l-r--.

.~-j -=I;;

iL

I5

No. of parts

_..~~. -~.~-.

1

2

1

'

5

2 and 3

4

B02P-1500-OOOlA...O5

Recommended j Minimum I Maximum

-~--

Bond weight (pound/bond)

17 ~

14 I

12.5

11

13

11

-

4

125 /

)

I 11

15

-

:

11

/

28

17

:;

11

17

11

Page 29

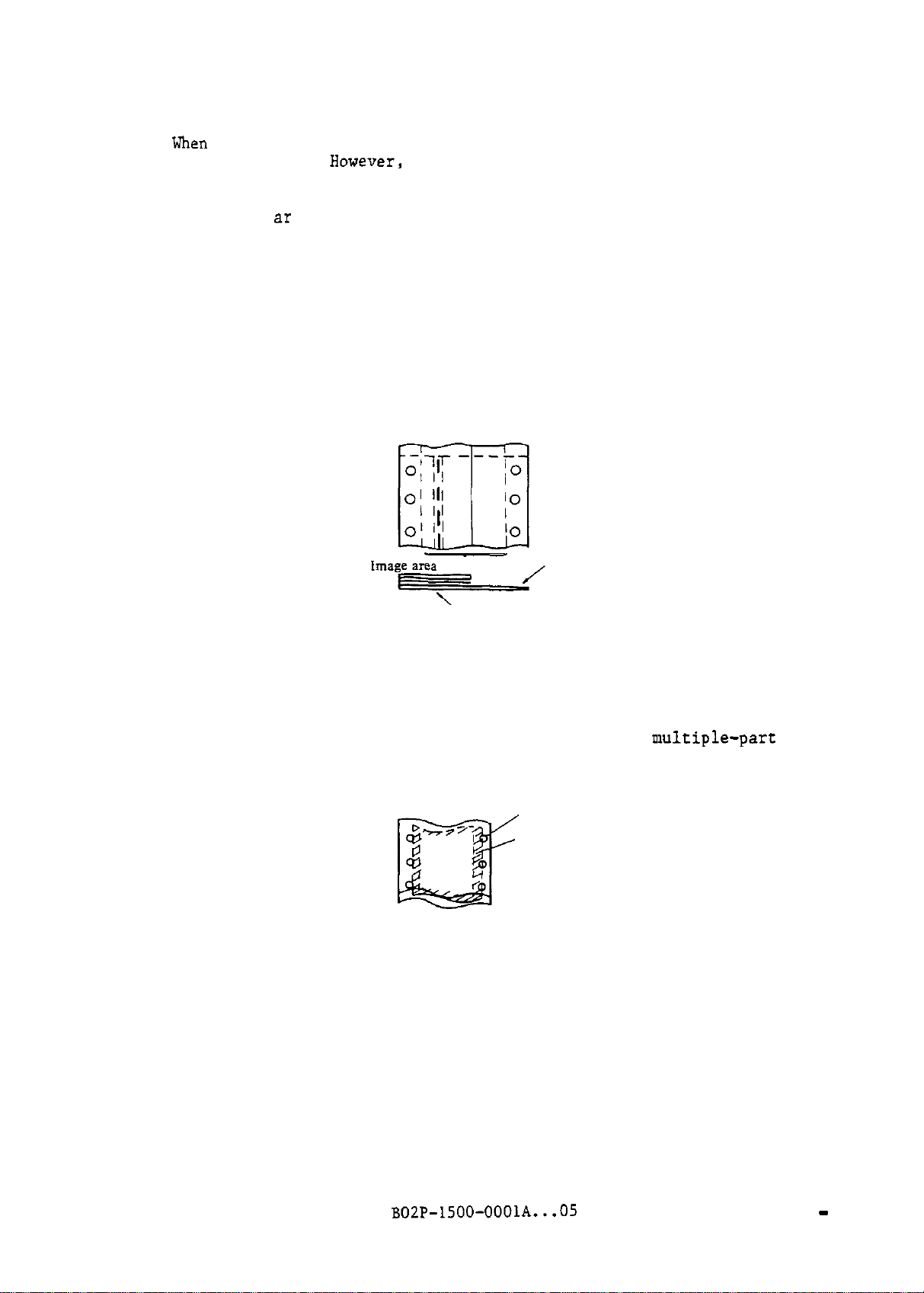

When

multiple-part forms are used,

parts (layers), HOWeVer,

the weight of each part should be that given in

the forms can have different weights of

Table 2.8 according to the number of parts.

When forms ar too thick, density fading between the top and bottom of each

character will occur.

When forms are too thin, they will be damaged and a

feed defect will occur.

(4) Forms causing feed defects

The following forms are likely to cause feed defects, excluding those

described before:

. Multiple-part forms with layers whose thickness or number varies by

section, such as shown in Figure 2.16.

Glued

portions

'Glued portions

Figure 2.16 Multi-part forms with layers of different thickness

. Multiple-part forms with layers glued in the print: area (Printing should

not be done on the glued portions.)

. Carbon paper which is covering pin feed holes of uultiple-part forms

(see Figure 2.17.)

Pin feed hole

Carbon paper

Figure 2.17

Carbon paper covering pin feed holes

. Self-adhesive label form with labels whose all sides are cut (see

Figure 2.18)

Such forms are likely to peel off.

The forms feed 'direction side of every

label must be perforations to prevent peeling.

BOZP-1500-OOOlA...O5

2 - 17

Page 30

Forms

feed direction

allowable Unallowable

Figure 2.18 Self-adhesive label forms

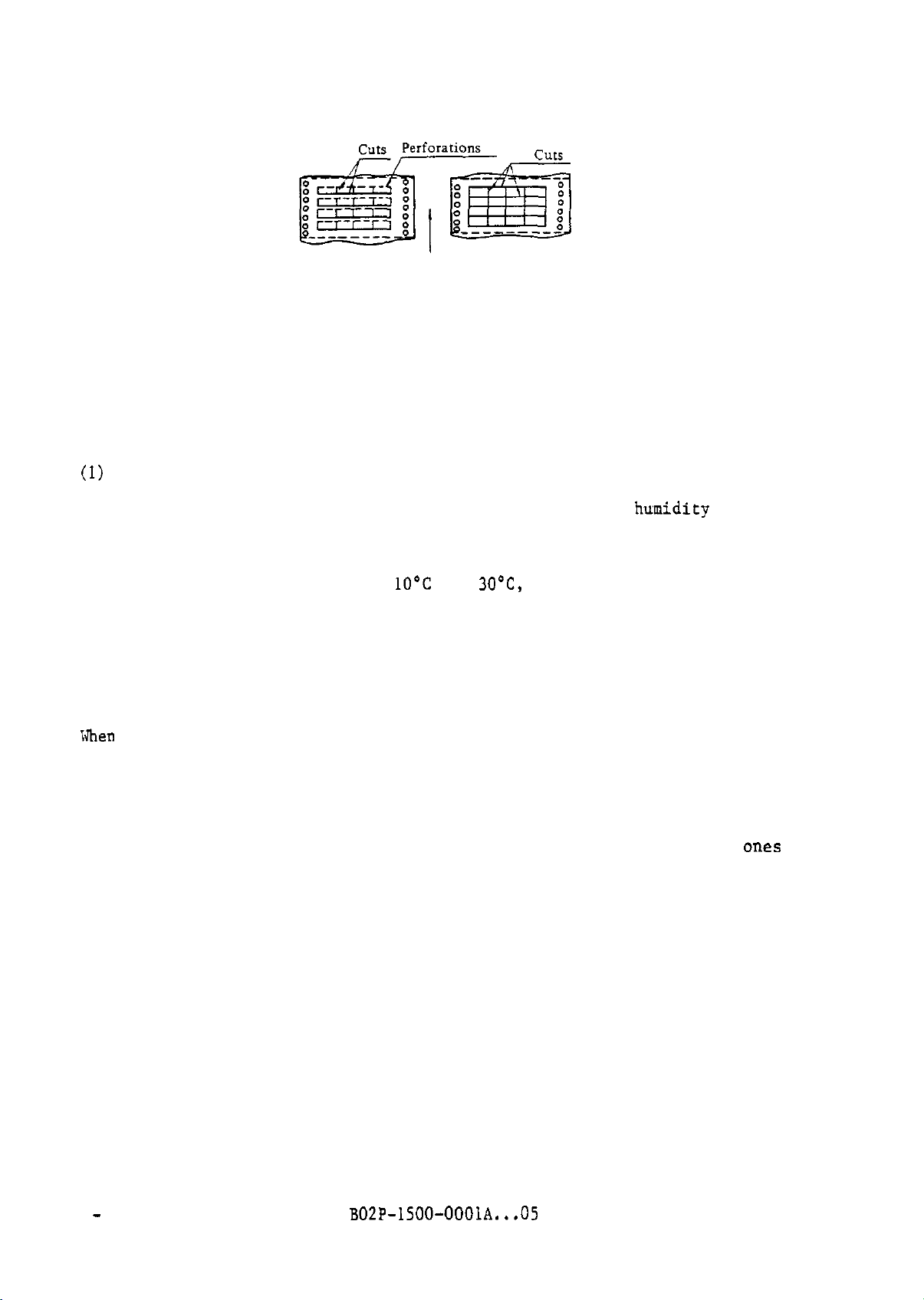

2.5.4 Ambient conditions for forms

The following are the ambient conditions in storage and usage:

(1)

Storage

Temperature should be with 10°C to 30°C and,

(2) Usage

Temperature should be within

70%.

If the conditions where it is stored and used are different, keep

1O'C

to

30°C,

and relative humidity 30% to

the paper for more than 48 hours in the environment where it will be used

before using. it.

2.5.5 Purchase order for forms

ordering forms, specify the following items:

m-K?*

Forms dimensions

The number of parts

Bond weight of each part

Perforation position

Perforation dimensions (tie and cut) for horizontal and vertical

Carbon paper position (If carbon paper is used)

Carbon-backed position (If carbon-backed paper is used)

Fastening method for multiple-part forms

Color of each part

Type of carbon paper (If carbon paper is used)

Carbon color (If carbon paper or carbon-backed paper is used)

Copy color (If carbonless copy paper is used)

Preprint on forms

relative humidity 30% to 70%.

ones

For more detailed specifications, specify as required.

forms, prepare a sample in advance and test it.

Order after confirming that it

When specifying special

will work.

2 - 18

B02P-1500-OOOlA...O5

Page 31

2.6 Format Control Tape

(FCT)

The 8- and 12-channel format control tapes

format

the FCT unit.

2.6.1 Medium quality

Medium used for the FCT should be:

Total thickness:

Light transmittance: 5% or less

The FCT made up of a polyester resin film and paper would be stronger at

tensile, tearing, and folding.

2.6.2

The FCT dimensions vary with the 8- and

as shown in Figure 2.18.

control data into the forms control buffer

FCTs

must conform to the following FCT specifications:

0.100 to 0.110 mm (0.0039" to 0.0043")

Dimensions

(FCT)

are used for loading vertical

(FCB) o:E

i2-channel FCTs.

the printer using

The dimension must be

B02P-1500-OOOlA...05 2 - 19

Page 32

9.96 + 0.05

Refe

-

,3.40

k 0.04

(1.000”‘0.002~)

4~.~04fO,ljO (1.6:22”?0.005”i

.A\:

Total tolerance

0.005 inches

0.013 inches for

for lOsprocket-hole

pitches

pitches

,&channelFCT)

50

sprocket-hole

30.602tO.

-e

-&

+

I i (0.8 I l”f0.004”)

(Channel-l side)

-‘-

-0.03

,n

Inl”+o

-. . - -

,

itI--

(0.0697”‘0.0020*)

-0.001")

.77*0.05

---.

1) The Y-Y' line is a sprocket-hole

center line perpendicular to the

reference line.

2) When diameters of damaged sprocket

holes become 0.005 inches wider

than normal, replace the FCT.

Figure 2.18 Specifications of

2- 20

B02P-15@0-OOOlA...05

Y‘

(I?-channel FCT)

c:

Reference line

FCT

Page 33

CHAPTER 3 CONFIGURATION

The printer consists of the mechanical unit, control unit, forms rack, rear

door and cabinet.

The operator panel,

control unit.

The top cover and front door are included in the cabinet.

control circuit board, and power supply are included in the

Figure 3.1 shows their locations.

Rear door

Powersuppiy

Operator

/

pane1

\ Front

door

Figure 3.1 Printer configuration

BOZP-1500-OOOlA...03

3-l

Page 34

3.1 Mechanical Unit

The mechanical unit consists of the following:

. Base unit (includes the print-band drive section)

. Print unit

. Forms feed unit

. Ribbon unit

(1)

Base unit

The base unit is fixed to the cabinet frame.

motor, a pair of band pulleys,

and a variable-reluctance transducer for

A platen,

a print-band drive

detecting each type location are in the base unit.

The print-band drive section has a simplified structure for easy

print-band replacement by the operator.

(2) Print unit

The print unit is attached to the base unit and consists of four

haPmner

magnet assemblies and a print unit frame.

The print unit can slide horizontally to the base unit by using a lever on

the base unit to make the forms path wider so that an operator can easily

load

forms.

The hammer magnet assemblies consist of magnet assemblies and hammer

assemblies, with hammers for 136 print positions.

quality, rotary-type hammers are employed.

Hammer magnet coils are

To improve print

arranged with sufficient space around them to ensure hammer-unit

compactness.

(3)' Forms feed unit

The

forus

feed unit is fixed to the print unit frame.

A pair of forms

tractors with a lever for adjusting their horizontal position, forms

tractor drive mechanism,

forms feed unit.

The ADVANCE FORMS knob for adjusting the vertical forms

and a stepper motor to drive the unit are in the

position, and the SHIFT FORMS knob for adjusting horizontal forms position

are also provided.

(4) Ribbon unit

The ribbon unit is fixed to the base unit.

KOlbS?CS,

a ribbon

feed,motor,

a ribbon feed sensor,

It consists of ribbon feed

ribb#on

guides, and a

ribbon container.

3-2

B02P-1500-OOOlA...03

Page 35

3.2 Control Unit

The control unit consists of the following (see Figure 3.2):

. Control circuit

. operator panel

. Hammer magnet driver (with the register unit only for

. Power supply

Control circuit

(1)

The control circuit is on one PC board and is installed in the maintenance

which can be accessed by opening the forms rack at the rear of

(2)

section,

the printer.

The control circuit uses 2 microprocessors; one for interface control and

the other for printer control.

The LSI for print control reduces the number of parts and improves

reliability.

Operator panel

The operator panel is located at the upper front of the printer. Control

switches and indicator lamps on the operator panel

M3l343)

ar'e

on a PC board.

Hammer magnet driver

(3)

The hammer magnet driver for the 136 magnets is on one PC board. In

113040,

connected directly to the magnet assembly on the PC board. In M3043, the

hammer magnet driver is installed near the control circuit board and the

lead from the magnet assembly is connected to the hammer magnet driver

through the register unit.

A simple circuit is achieved by using custom

enabling easy detection of faulty columns.

Power supply

(4)

The power supply consists of the supply unit and a transformer.

The transformer is connected to an AC input through a line filter and a

circuit breaker.

switching the appropriate tap on the transformer.

The power supply unit has regulation circuits for logic circuits and

hammer magnet driving,

control relays

M3041, M3042, it is installed on the rear of the print unit and is

ICs

and a transistor array,

Input voltages of 100 to 240 V can be selected by

a forms feed stepper motor drive circuit, and

for the AC motor.

B02P-1500-OOOlA...03 3-3

Page 36

7

(only for

M3043)

Mainframe

.AC

input

Inpuf/outpuf

mterface

--/

L--------J

COllt~Ol

circuit

L

Power supply

Figure 3.2 Control unit

Hammer magnet

Mechanical unit

I

-

3-4

B02P-1500-OOOlA...O3

Page 37

CHAPTER 4 DPC-COMPATIBLE INTERFACE

This chapter describes the DPC-compatible interface used for the I/O interface

connected to the

M304x

series line printer (printer).

4.:

Basic printer operations, data transfer, printing, and forms feed are shown in

Figure 4.1.

I

Operation Outline

/

Dara

transfer cycle

Print

data

Control code or the Skip 01 Space command

with the

Data edition

Paperlnsrruction

signal

Data

rransfer

Print data

c:ycle

F

Print

cycle

Data Request=

I

j

1

Approx.14ms 1

Figure 4.1 Basic operations

The printer starts the print cycle after receiving l-line print data sent from

the mainframe and one of the following:

. Control code (LF, FF, or CR code)

. Skip command (with the Paper Instruction signal =

. Space command

For the control codes and the Paper Instruction signal, see Sections 4.3.2 and

4.4.2.

the control code or with the Paper Instruction signal.

Data Request signal to one 14 ms before terminating forms feed and starts

receiving the next line of data during forms feed.

After l-line printing,

(with

the Paper Instruction signal = 1)

the printer starts the forms feed specified by

B02P-1500-OOOlA...05

1)

The printer sets the

Therefore, unless the next

4-1

Page 38

line data is received within 14 ms,

the print speed of the printer drops and

does not achieve the rated print speed.

If the control code or the Paper Instruction signal is received without print

data,

the printer does not print and only feeds forms.

If the received print

data is more than 132 or 136 bytes (one of them is selectable), data of the

133rd,

than 132 (or

137th or higher byte is ignored. If the received print data is less

136)

bytes,

the remaining data is printed as spaces.

The print operation above is shown in Figure 4.2.

Control code or the Skip or Space command

with thePaper Instruction signal

Data edition

I

Data Request= 1

Print operation for

bytes' fo 136

Fuigure

4.2 Print operation

4.2 Interface Signals

This section explains the interface signal functions and physical

specifications.

4.2.1 Interface signal lines

Table 4.1 explains the OPC-compatible interface signal lines. Figures 4.3 a

4.4 show the timing chart of this interface and the timing specifications in

data transfer respectively.

This printer has a print data buffer

(PDB)

for 136 characters.

While a WMR

signal and Online signal are being generated, print data is received according

to the Figure 4.3. Printing starts after the following control code or Paper

Instruction signal is received.

4-2

BO2P-1500-OOOlA...O5

Page 39

Table 4.1 DPC-compatible interface signal lines (Positive logic)

Signal name

Signal

level

(+)

Direction

COiltfSlltS

kite Machine

Leady mire

Online

Data Request

CDTRQ,

Write Strobe

(WSB)

1 0

5v 0

1 j

'5V

5v 0

5v

0

0

System-Printer

1

This signal is high (logical 1) when the following

conditions are satisfied for

. Power has come on and all voltage levels are

nollna1.

i EE H~~"b,"~~:'i:'~~:",e,.,,ed.

Initlallzatxon process has been completed.

. The hammer drive system is normal.

. An error is nor dececced.

This signal enables information to be transmitted

with the system connected to the printer and goes

high when the following conditions are satisfied:

. Write machine

. The START/STOP switch is pressed.

. The print band is rotaxing normally.

A synchronizing signal for data transferred from

the system, and is high when daEa from the system

can be accepted.

This is a strobe signal for Write Information

the printer. The printer resets its Data Request

signal when the leading edge of this strobe signal

is received.

beady (FMR)

the

printer:

is 1.

to

Write

Information

(WIFl-8)

Buffer Clear

(BCLR)

connect 1

Connect 2 of the interface connector.

Paper

Instruction

l-8

(PI) /

5v

5v

- i-

5v

0

0

0

This is

7-bit codes, WIFE can be ignored by setting.)

The data for one line scored in the buffer of the

printer is cleared by this signal.

This signal is used for confirming the connection

connector is connected, the Connecr 1 and Connect 2

lines are connected.

'Ibis

by the sysrem. When this signal is logical 1, the

input data on the WIF lines is stored in the FCB.

This signal is checked 'by the printer at the timing

of the Write Strobe signal in the same way as WIFl

to

WIFE. For derails, see Section 4.4.2.

the

input data from the system. (For ASCII

When the interface

signal is high when forms control is performed

BOZP-1500-OOOlA...05 4-3

Page 40

Table 4.1 DPC-compatible interface signal lines (Positive logic) - continued

Signal name Direction

System-Printer

Write

Information

Parity

Write Check

(++)

paper

Cc-)

Bottom of Form / 5 V 0

(++)

Top fo Form

(++>

IDENT

IDEw 1

(WIFP)

Moving

0 (++)

l5V oi

5v 0

5v

0

COIltentS

Even parity signal for data from mainframe.

! parity is also available by setting. This signal

can be ignored by setting.

If a parity error occurs in

/

sysrem,

I

When rhe

signal is logical 1.

when

i

this signal is logical 1.

‘Ihis signal indicates the type of print band.

IDENT 1 IDENT 0

this signal is logical 1.

s

signal is logical Lwhen

last line on a page is being printed, this

the first line on a

0 0

1 1

0 1

1 0

Undefined

48-character-set print

64-character-set print band

96-character-set print

!JIF

signals from

rhe

paper

page

is being printed,

the

incwes.

band

bend

+ Signal level 1 Active

Signal level 0

Fake

Negative logic is also available by setting (except for Connect

signals).

+t These signals can always be set 0 by setting.

4

-4

B02P-1500-OOOlA...06

l/2

Page 41

The START/STOP switch is pressed.

DTRQ

WSB

Figure 4.3 Basic data transfer operation

WMR

DTRQ

WSB

WIFl-

PI

BCLR

VIF8,VIF P,

Max

!

Min

\

I

530nS -rSOnS

A

1 Min

Figure 4.4 Timing of signals in data transfer

(

Data stable

4-5

Page 42

4.2.2 Physical specifications of interface signals

The physical specifications of DPC-compatible interface signals consist of

electrical characteristics,

assignment specifications.

(1) Electrical characteristics

Signal levels must be within the following ranges:

Low level 0.0 to +4.0 v

High level

+2.4

interface cable specifications, and connector pin

to

+5.0

V

Note:

The interface signal driver and receiver must be the same as those shown

in Figure 4.5.

. Driver

. Receiver

The signal levels above are at the interface

Incorrect signals may be sent in power-on and

5V

220R

T

Printer

--w-

SW406 01

equivalent

I-

-J-J- To usersys*sm

conn#ector.

pow,er-off.

Figure 4.5 DPC-compatible interface signal driver and receiver

(2)

Interface cable

Twisted pair cables with a shield must be used for the

The cable length must be 50 feet (15 m) or less.

4-6

B02P-1500-OOOlA...05

:interface

cable.

Page 43

(3)

Connectors and pin assignment

Either an Amp-type

car

Winchester-type connector is available for the

interface connector of the printer. Figures 5.6 and 5.7 show Amp-type and

Winchester type connector pin assignment.

NO.

1

2

3

4

5

6

/

Signal name

WIF

3

(WIF 3)

(WIF1)P.TN

(WIF2)RTN 21 Online

(Online) RTN

&MR) RTN

RTN

/ No. 1

I

18 (WIFS)

I

j

19 WIF

20

j

22

23

Signal name

1

WIF 2

WMR

Data Request 39

KTN

( No/

1x1

/ 35 1(WIT 7)

36

'

I

37

/ (Write

38

1

Signal name

WIF5

WIF 7

Write Strobe

RTN

Strobe) FZN

7

(Dan Request)

8

(Top of Form) RTN

I

9

(Bottom of

10

11 (Write Check) RTN

12

13 /

14

I.5

16

17

(Paper Moving) RTN

+5

V hax. 200

(WIF P) RTN Buffer Clear

(Paper

(Buffer Clear) RTK

(IDEhT 1) RTN

Insrruction) RTN

RTN

Form) RTN

mA)

Connector specifications

&np

205740-l

Amp 205212-l.

OIT

equivalent (Printer side)

66506-9, or

24

25

m

1 28 ( WIF 8

/

29 / WIF P

! 30 I

) 32 1 (IDENT O! RTN

33

Top of Form

Bottom of Formj41

Paper Instruction / 46 ~Connect 2

equivalent

i

, 40

j

48

49

50

-lIr

(Cable side)

(WIT 4) RTN

I

1

WIF 4

E:',"' RTN

tWIF 8) RTN

Connect

/

Irma 1

IDENT

I

0

Figure 4.6 DPC-compatible interface connector pin assignment (Amp type)

B02P-1500-OOOlA...OS

4-7

Page 44

Write Check

Ccnnector specifications

MRA50S-D5J made by Winchester (Printer side)

MRAC50P-JTDH8 made by Winchester (Cable side)

Figure 4.7 DPC-compatible interface connector pin assignment (Winchester type)

4.3 Character and Control Codes

Table 4.2 shows character and control codes.

a bold faced line indicate control codes,

character codes (ASCII codes). The table shows character codes of

In ‘i-bit mode,

character codes

X'OO'

to

X'7F'

In the table, areas enclosed with

whereas the other areas indicate

&bit

mode.

are available. Character codes

with an asterisk in the table vary with the print band for each country, as

shorn

in the lower table.

4-8

B02P-1500-OOOlA...O5

Page 45

Table 4.2 Character (ASCII) and control codes

C0llntrJ

U.S.A.

U.K.

FIXI-IC~

Note:

Code

Codes with an asterisk in the table above vary with the print band

for each country as follows:

X’24’

X’23’

<t

E S @

X’f+O’ X’SB’ X’SC’ X’SD’ X’SE’

[

S @

s

e

\ 1

[

O

\

1

c

B02P-1500-OOOlA...05

-

.

^

.

5

-

.

4-9

Page 46

4.3.1 Character codes

The ASCII code is used as the standard character code.

If the printer receives a character code not specified in the character code

table or not included on the print band, the code is changed

(X.20')

X'AO'

(regarded as 0) by setting, and a character corresponding to

X'20'

and no character is printed for the code.

to X'FE' is received in 7-bit mode, the WIF8 signal can be ignored

to

X'7E'

is printed.

For the setting method, refer to

If a character code from

130

the space code

leach

code from

#Operator's

Guide.

When receiving character codes, the printer sequentially

internal buffer (IBF).

are printed after a control code is received. The IBF is

printing.

4.3.2 Control codes

The line feed

codes indicated in the area enclosed with a boldfaced line in Table 4.2.

printer starts an operation, such as printing and forms feed when the control

code is received.

(1)

LF code

When receiving the LF code, the printer starts printing characters

corresponding to the received character codes from column 1. After

printing the characters, the printer spaces. If the number of character

codes received before the LF

characters are treated as spaces. If the LF code is received without

character codes, the printer does not print, it only feeds forms.

(2) FF code

The character code received next is for column 1.

(LF),

(X'OA')

(X'OC')

Characters corresponding to the

form feed

(FF),

and carriage return (CR) codes are control

code,is

less than 132 (or

load,s

them in its

loade'd

character codes

cle,ared

after

136),

the remaining

~~

The

When receiving the FF code, the printer starts printing characters

corresponding to the received character codes from column 1. After

printing the characters, the printer feeds forms to the top-of-form

line,

If there is no channel 1 in the loaded FCB data, the printer feeds forms

to the first line on the next page.

1, see Section 4.4.1.

the FF code is less than 132 or 136, the remaining characters are treated

as spaces.

If the FF code is received without character codes, the printer does not

print,

or channel-l line, the printer feeds forms to the next 'TOF or channel-l

line.

(3) CR code

When receiving the CR code, the printer starts printing

corresponding to the received character codes from column 1. One of the

following modes are available for the operation after printing:

4 - 10

or if FCB data is loaded, to the line with channel I.

For definition of the TOF and channel

If the number of character codes received before

it only feeds forms.

(X'OD')

B02P-1500-OOOlA...05

Even if the forms are positioned at the TOF

ch,zxacters

(TOF)

Page 47

. Mode without forms feed

The printer does not feed forms after printing.

code without character codes, the printer does nothing.

. Automatic spacing mode (IF code mode)

The printer spaces after printing.

character codes, the printer only spaces.

LF

code in this mode.

One

of the modes above is selectable by setting at the operator panel.

For the setting method, refer to Operator's Guide.

(4) Undefined control codes

Control codes undefined in the control code area in Table 4.2 are treated

as space-codes.

4.4 Format Control

To control forms feed, in addition to control codes, the printer uses format

control functions that specify the form (page) length and the page print

format.

These functions are as follows:

When receiving the CR code without

The CR code is treated as the

When receiving the CR

.

Forms

control buffer (FCB)

. Format control tape

. Form length function

The FCB and the form length function are standard

The FCT unit can be incorporated as an option.

When the FCT is not used, format control data is loaded

'system) into the printer in online mode.

data is loaded from the FCT unit into the printer in offline mode.

The format control data is indicated with channels which is used by software to

specify special positions of the form.

4.4.1 Definition of the top of form (TOF) and the bottom of form

The TOF and BOF are used for forms feed control.

(1)

TOF

The TOF is defined as follows:

(FCT)

unit option

feature:5

When the FCT

of this printer.

f,rom

the mainframe

i:s

used, format control

(BOF)

. When the FCB data has been loaded,

1 is first specified in the FCB data.

.

When

the FCB data has not been loaded or when channel 1 is not contained

in the FCB data,

the TOF is the first line on the page.

B02P-1500-OOOlA...05

the TOF is the line to which channel

4 - 11

Page 48

(2)

BOF

The BOF is defined as follows:

. When the FCB data has been loaded,

channel is first specified in the FCB or FCT.

specified with any channel

channel specification method, refer to Operator's

. When the FCB data has not been loaded or when the

contained in the FCB, the BOF is the last line on the form (page)

without the skip-over perforation specification.

of lines skipped to the perforation is specified using the skip-over

perforation feature, the BOF is the last line not skipped. For the

setting method of the skip-over perforation feature, refer to Operator's

Guide.

4.4.2 Specification of a forms feed format

The forms feed information must be loaded into the FCB before forms feed,

except when a control code, LF code, or CR code, is specified.

The FCB data is loaded from the mainframe via the I/O interface or from the

optional FCT unit.

FF code or by the Skip command transferred after print data.

Form (page) length and line spacing

For the setting method, refer to Operator's Guide.

The loaded FCB data is used for forms feed control by the

number at

(6/8

the BOF is the line to which the BOF

(The

the operator

LPI) are set at the operator panel.

BOF

channel can be

pane.L.

Guidq.

SOF

channel is not

That is,

For the

if the number

(1)

Format specification by FCB

The format control data is loaded from the mainframe into the FCB of the

printer in online mode.

WSB

PI

WlFl-

SIF8

Note:

x

star1 code

i)

2)

---vv

-----

t

Y'6C‘

X‘bD'

X'6E‘

The PI signal level indicated by dashed lines can be either high or

low.

The Ln and

L

Format control

data of line I

Iln

Figure 4.8 shows the timing of FCB data loading.

----HI

indicate a low-order byte and a

-_---

-----

L2

Formar ionrrol

data of

line

2 X'6F'

HI

+t

-+t-

>cjW=~

hi;gh-order

-

Stopcode

byte.

4 - 12

Figure 4.8 Timing of FCB data loading

B02P-1500-OOOlA...O5

Page 49

If the data code expressed by

the Paper Instruction signal is 1,

WIFl

to WIF8 is

X'6C', X'6D',

or

X'6E'

the printer treats the data code as the

when

start code for FCB data loading and loads into the FCB the data following

the start code, until the printer receives the stop code

code is

also

sent with the Paper Instruction signal.

X'6F'.

The stop

The transferred data is first loaded into the print data buffer

the IBF.

Then the interface control

(IFC)

microprogram loads the data

(PDB)

in

into the FCB and knows the number of lines per page by counting the loaded

FCB data bytes.

Table 4.3 shows the definition of the start code.

Table 4.3 Definition of the start code

WIF

87654321

01101100 6C

01101101

01101110 6E

Note:

_ Code

oiex)

6D

Line spacing is 6

Line

specing

Ipi.

is 8 lpi.

Forms are fed in 618 lpi when specified

Operation

I

:

1

Six or eight

ehe operaror

I

lpi

specification from

panel ignored.

ac

the operator panel.

WIF8 is ignored and treated as 0 in 7-bit mode.

In Figure 4.8, L1H1L2H2...LnHn (2 _

data.

Each L or H is one byte of data.

control data for one line on the form.

data for line 2, and so forth.

L,H,

_

< n < 2.55)

is the format control FCB

Each pair

LiHl

is data for line 1,

Iof

is data for the last line, and

indicates the total number of lines on a form (page.).

of the 2-byte line format data specifies a channel

the second byte

shows the correspondence between channels and

(H)

specifies a channel number from 7 to 12.

WIFl

Data L

Note:

8765432,

WIF

signals

Specified

channel

I-Ix

L-

0

I I

6

5

4

I I I

3

?

X do not care. (In 8-bit mode)

1

8

7

6 ,5 4 3 2 1

:number

to WIF8.

Data H

an L and H is format

L2H2

is

n

The first byte

(L)

from 1 to 6 and

Figure 4.9

Figure 4.9 Correspondence between FCB data channels and bits

B02P-1500-OOOlA...05

4 - 13

Page 50

Even if FCB data other than

WIF7 is ignored (treated a 0) and WIF6 to

control data and stored in the FCB.

when stop code

X'6F'

is used.

X'6F'

(stop code) is received with WIF7 = 1,

WIFl

are treated as format

However, WIF7 should be 0, except

The total number of bytes contained in the FCB data LlHlL2H2...LnHn must

be

even.

At that time,

If it is odd and the stop code

X’bF’

follows, an error occurs.

the printer feeds forms determining that the Hn byte not

received (data of channel 7 to 12) for the last line is

'1'00'

and that the

total number of lines on a form (page) is n lines.

If n is 1,

an error occurs because there must be 2 or more lines on a

page.

If n is greater than 255 -- that is, more than 255 lines are specified for

a page -- an error occurs and data from the 256th line and after is lost

because the FCB holds only 255 lines. The printer feeds forms for a

maximum of a 255-line page, storing up to L

line 255, in the FCB.

The stop code is required because the printer

255'255'

which corresponds to

continues FCB data loading until it receives this code.

FCB data must be loaded after character codes of a previous line are

received, printed,

and cleared because character codes are destroyed and

data is loaded into the FCB incorrectly if the printer has unprinted

character codes in the PDB before the FCB load start code.

Line 1 must be set to the print line of the printer before or immediately

after FCB data loading because the FCB address counter is reset to 1 after

FCB data is received (that is,

the printer treats line 1 as the print line

after FCB data is loaded).

If the printer receives start codes other than

X'6C', X'6D'

and

X'6E',

it

feeds forms as though it had received a Skip or Space command.

Example of FCB data:

. Line spacing:

6 lines/inch

. Form length: 66 lines

Figure 4.10 shows the channels specified for a forms feed format.

Table 4.4 lists the FCB data.

It is assumed that the BOF is set to

channel 12 in the printer.

4

-

14

BOZP-lSOO-OOOlA...OS

Page 51

Perforation

Line 4: TOF (ch.1)Line 4: TOF (ch.1)Line 4: TOF (ch.1)

--

-

Line 7:

Line 7:

Line 7:

Line 1 1: ch.4, ch.

Line 1 1: ch.4, ch.

Line 1 1: ch.4, ch.

Line 2 1: ch.6Line 2 1: ch.6Line 2 1: ch.6

Line 31: ch.7Line 31: ch.7Line 31: ch.7

Line 42: ch.10Line 42: ch.10Line 42: ch.10

Line 51:

Line 51:

Line 51:

Line 60: BOF (ch.12)Line 60: BOF (ch.12)Line 60: BOF (ch.12)

------------------------------------------------------------

Figure 4.10 Channels specified for a forms feed format

ch.5

ch.5

ch.5

ch.1

ch.1

ch.1

I,

I,

I,

IO

IO

IO

ch.8

ch.8

ch.8

::

BOZP-1500-OOOlA...O5

4 - 15

Page 52

Table 4.4

VPU

data example

Data

seauence

1

2-7

8

9 00

10-13

j

i

Line 12/

cnannel

11l1019/ al 7 I

6/j/4

6C

00 l-3

01 1 I i

00 5-6

i i ! I /

i

I

/

, 1

I

I / / I I

I

I3i21l

Data meaning

4 - 16

B02P-1500-OOOlA...05

Channels 11 and 8

BOF

(Channel 12)

Page 53

(2) Format specification by format control tape (FCT)

The FCT is a looped paper tape with punched holes and sprocket holes for

feeding.

printer to notify it of a forms feed format.

The punched hole data is read by the FCT unit and sent to the

Figure 4.11 is an example of

the FCT and shows the relationship between a forms feed format and punched

holes.

EGLUE

(Perforation)

____ --------------

Channel 1 (TOP of form)

---;-.

I 0

A

!,

Channel3

Channels 5 and 7

Channel number

Channel

1

Channel3

Channel12

______

-------------

(Perforation)

Figure 4.11 An example of FCT and forms feed format

I

I

I0

I

I

IO

i 4

1--

!o

A’

.Sprocketh

, Punched hole

Cut here

s

B02P-1500-OOOlA...O5

4 - 17

Page 54

There are 2 types of FCT: 8-channel and 12-channel. Figure 4.11 shows a

12-channel

the form.

the forms,

same as for 8-channel

FCT must be replaced with one for the new forms feed

The FCT is read automatically when the printer is turned on or when the

RUN switch on the FCT unit is pressed in offline mode. The RUN switch

enables a new FCT to be read.

channel 1 of the FCT is the start position, the FCT unit reads punched

hole data starting from channel 1 to the next channel 1 detected.

FCT, where each FCT sprocket hole corresponds to each line of

Punched holes, called channels,

and are used for forms feed control by software. This is the

FCTs.

When a new forms feed format is used, the old

Because the FCT unit determines that

indicate special positions of

fornLat.

The data from the FCT unit is sent

microprocessor. Then, the IFC microprogram loads the data into the FCB in

the internal buffer.

Make an FCT as follows:

Punch a hole at the first column on the center line of the first

1.

sprocket hole (channel 1 as the top of form), as

4.11.

2.

For subsequent lines, punch holes according to the forms feed format.

Note that columns 1 to 12 (1 to 8 for an a-channel