Page 1

5

1

;4"

M255XK

Mini-Flexible

Disk

Drive

Customer

Engineering

Manual

TS021-013087

FUJITSU

...

01

70221

Rev.

A

Page 2

Page 3

REVISION RECORD

Edition

01

Direct

your

Date

Published Revised

April 1987

comments

on

Initial

this

publication

Contents

Fujitsu

America

Release

to:

FUJITSU AMERICA,

3055 Orchard Drive

San

Jose,

CA

95134 USA

INC.

TEL: (408) 432-1300

FAX: (408) 432-1318

TLX: 230-176207

TWX:

(910) 338-2193

The

contents

of

this

manual

are

subject

to

change

without

Copyright 1987 FUJITSU AMERICA, INC.

All

Rights

Reserved

ii

prior

notice.

TS-021-013087

•••

01

70221

Rev.

A

Page 4

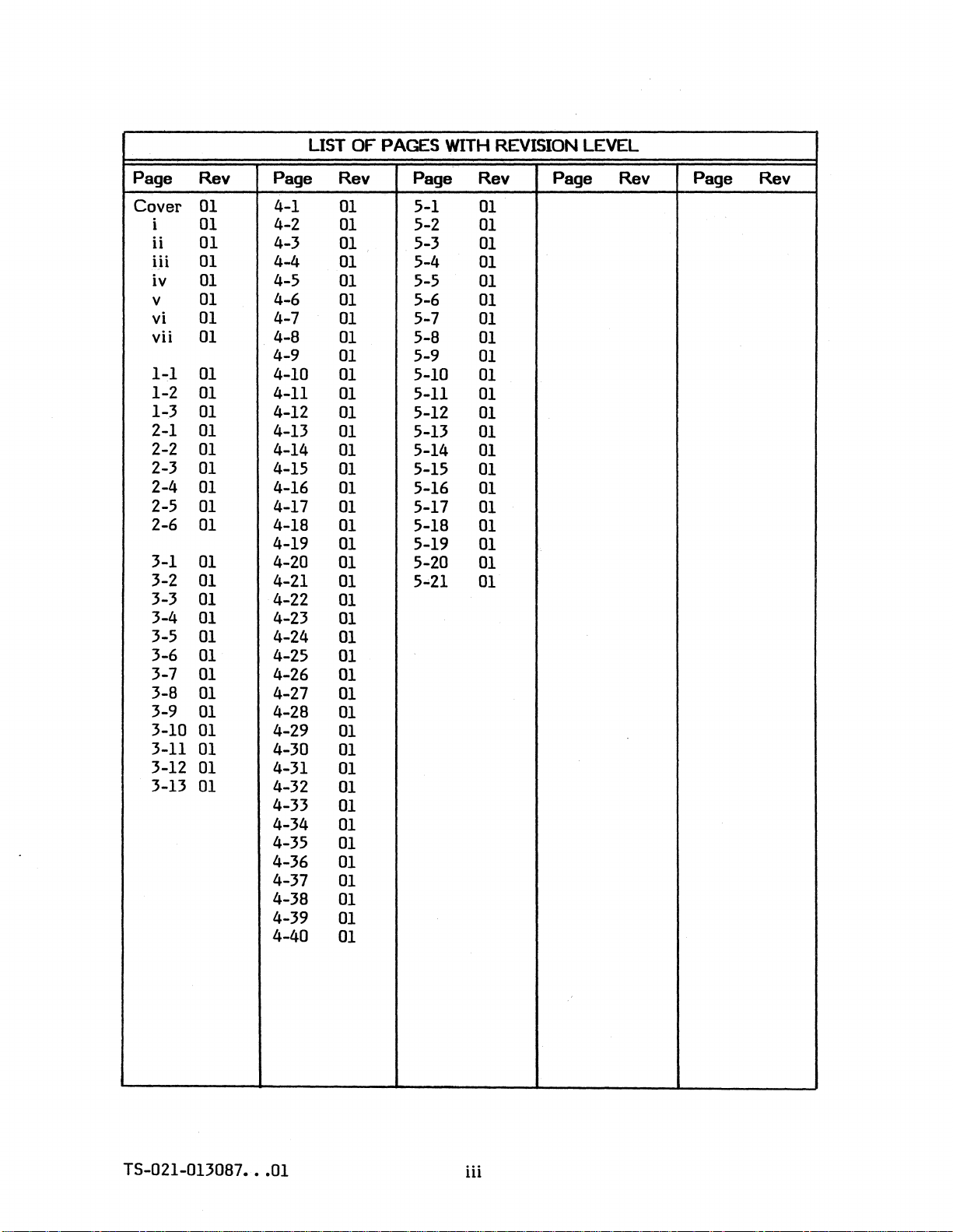

LIST

OF PAGES

WITH

REVISION

LEVEL

Page

Cover

i

ii

iJi

iv 01

v

vi

vii

1-1

1-2 01

1-3

2-1 01

2-2

2-3

2-4

2-5

2-6

3-1

3-2

3-3

3-4

3-5

3-6 01

3-7 01

3-8

3-9

3-10

3-11

3-12

3-13

Rev

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

Page

4-1

Rev

01

4-2 01

4-3

4-4

01

01

4-5 01

4-6 01

4-7 01

4-8

4-9

4-10

4-11

4-12

4-13

4-14

4-15

4-16

01

01

01

01

01

01

01

01

01

4-17 01

4-18 01

4-19 01

4-20

4-21

4-22

4-23

4-24

01

01

01

01

01

4-25 01

4-26

01

4-27 01

4-28

01

4-29 01

4-30 01

4-31 01

4-32

4-33

4-34

4-35

4-36

4-37

4-38

4-39

4-40

01

01

01

01

01

01

01

01

01

Page

5-1

5-2

5-3

5-4

Rev

01

01

01

01

5-5 01

5-6 01

5-7

5-8

5-9

5-10

5-11

5-12

5-13

5-14

5-15

01

01

01

01

01

01

01

01

01

5-16 01

5-17

5-18

01

01

5-19 01

5-20 01

5-21

01

Page

Rev

Page

Rev

TS-021-013087

•••

01

iii

Page 5

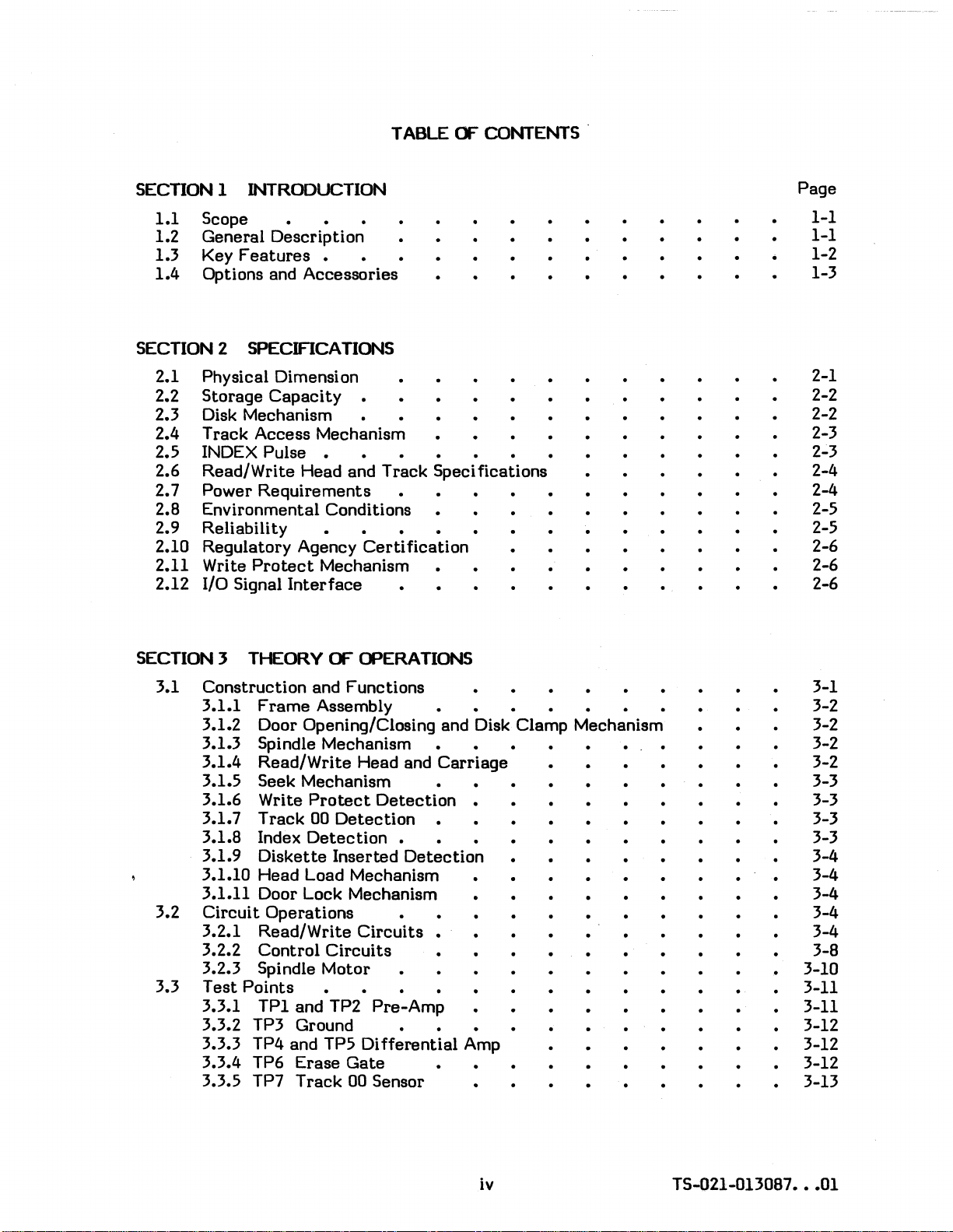

TABLE OF CONTENTS

SECTION 1 INTRODUCTION

1.1 Scope

1.2 General Description

1.3 Key

1.4

Features

Options and Accessories

•

SECTION 2 SPECIFlCATIONS

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

2.10

2.11

2.12

Physical Dimension

Storage

Disk Mechanism

Track Access Mechanism

INDEX

Read/Write

Power

Environmental Conditions

Reliability

Regulatory Agency

Write

I/o Signal

Capacity

Pulse.

Head and Track Specifications

Requirements

Protect

Mechanism

Interface

•

• • • • •

Certification

..

Page

1-1

1-1

1-2

1-3

2-1

2-2

2-2

2-3

2~3

2-4

2-4

2-5

2-5

2-6

2-6

2-6

SECTION 3 Tl-EORV

3.1

3.2

3.3

Construction

3.1.1

3.1.2 Door Opening/Closing and Disk Clamp Mechanism

3.1.3 Spindle Mechanism • •

3.1.4

3.1.5 Seek Mechanism

3.1.6 Write

3.1. 7

3.1.8 Index

3.1.9

3.1.10 Head Load Mechanism

3.1.11 Door Lock Mechanism

Circuit

3.2.1

3.2.2

3.2.3 Spindle Motor

Test

3.3.1 TP1 and TP2

3.3.2 TP3 Ground •

3.3.3 TP4 and TP5 Di

3.3.4 TP6

3.3.5 TP7

Frame

Read/Write

Track

Diskette

Read/Write

Control

Points

and Functions

Protect

00

Detection

Operations

Erase

Track

OF

OPERATIONS

Assembly • • • • • • •

Head and

Detection

Detection

Inserted

Circuits

Circuits

Pre-Amp

fferential

Gate

00 Sensor

Carriage

•

•

Detection

•

•

•

Amp

3-1

3-2

3-2

3-2

3-2

3-3

3-3

3-3

3-3

3-4

3-4

3-4

3-4

3-4

3-8

3-10

3-11

3-11

3-12

3-12

3-12

3-13

iv

TS-DZI-OIJ087

•••

01

Page 6

TABLE OF CONTENTS

SECTION 4 MAINTENANCE

4.1 Periodic Maintenance

4.1.1 Inspection and Adjustment

4.1.2 Field Replaceable Items

for

4.1.3 Tools Required

4.2 Maintenance

4.2.1 Screw Torque

4.2.2 Screw Lock

4.2.3 Handling Connectors

4.2.4 Additional Maintenance

4.3 -Head

4.4 Inspection and Adjustment Procedures

4.5 Removal and

Cleaning.

4.4.1

4.4.2 Bail Inspection and Adjustment

4.4.3 Disk-in Sensor Inspection

4.4.4 Write

4.4.5 Disk

4.4.6 Head

4.4.7 Asymmetry

4.4.B Read Level

4.4.9 Resolution

4.4.10 T

4.4.11 Track 00 Sensor Inspection and Adjustment

4.4.12 Index Burst Timing Inspection and Adjustment •

4.4.13 Head Load Inspection and Adjustment •

4.4.14 Door Lock Inspection

4.5.1 Head

4.5.2 Stepping Motor and

4.5.3 Spindle Motor

4.5.4

4.5.5 Sensor Block

4.5.6 Main

4.5.7 Write

4.5.8 Bezel

4.5.9

4.5.10 Clamp

4.5.11 Head Load

4.5.12 Door Lock Solenoid

Precautions

Collet

Protect

Rotational

Contact

rack

Alignment

Replacement

Carriage

Collet

Circuit

Protect

Replacement

Front

Lever

Assembly

Assembly

Replacement

Card

Replacement

Cam

Replacement

Replacement

Maintenance

Precautions

Centering

Sensor

Speed

Inspection and Adjustment

Procedures

Replacement

Steel

Replacement

Replacement

Replacement

Sensor

Replacement

•

Replacement

Items

Adjustment

Band

•

•

Replacement

•

•

'.

Page

4-1

4-1

4-1

4-2

4-3

4-3

4-3

4-4

4-4

4-8

4:"9

4-9

4-10

4-11

4-12

4-13

4-13

4-15

4-16

4-17

4-18

4-20

4-22

4-24

4-26

4-27

4-27

4-31

4-32

4-33

4-33

4-34

4-35

4-35

4-35

4-36

4-37

4-38

SECTION 5 MAINTENANCE DRAWINGS AND PARTS

5.1 Construction •

5.2

TS-017-082786

Structural

5.3 Screws and Washers

5.4 Main

5-5

Circuit

Parts

Circuit

Card

•••

01

Listing

Card

Components •

Layout and Schematic Diagrams •

v

LISTS

5-1

5-7

5-9

5-10

5-14

Page 7

LIST

OF

ILLUSTRATIONS

FIGURE

2-1

3-1

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-9

3-10

3-11

3-12

4-1A

4-1B

4-1C

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

4-10

4-11

4-12

4-13

4-14

4-15

4-16

4-17

4-18

4-19

4-20

4-21

4-22

4-23

4-24

4-25

4-26

4-27

External Outline Drawing of Disk Drive

Overall Block Diagram • • •

Tunnel Erase Type Read/Write Head

Read/Write

Typical Read

Typical Write

Control Circui

Typical Stepping Motor Control

Location

TP1/TP2 Typical Pre-Amp Waveform • •

TP4/TP5 Typical

TP6 Typical Erase

TP7 Track 00

M2553K/54K Revision 2

M2553K Revision 3

M2552K Revision 1

Disk Drive

Collet

Bail Height Adjustment

Bail Adjustment

Write

Head

Asymmetry Measurement • •

Average Read Level Measurement (2F)

Resolution Measurement •

Lobe

Track Alignment Adjustment •

Track 00 Sensor Adjustment

Index Burst Timing

Index Sensor Adjustment •

Head Load SignalllAII

Head Load Signal

Head Load Adjustment Screw

Head Unload Signal

Head Unload Signal

Door Lock Solenoid

Door Lock Solenoid

Head

Head Cable Routing •

Clamp

Head Load Height Adjustment

Door Lock Solenoid

Protect

Contact

Pattern

Carriage

Circuits

Circuit

Circuit

ts

of

Connectors and

Detect

Orientation

Shaft

Cam

Adjustment •

Sensor

Inspection •

for

Assembly

Assembly

•

Waveforms

Waveforms •

•

Circuit

Test

Differential

Gate

Waveform

Circuit

Circuit

During Maintenance

Track Alignment

IIBII

II

All

liB"

Activated

Deactivated

Amp Waveform

Waveform

Circuit

Replacement

Card -Jumper

Card -Jumper

Card -Jumper

Waveforms

Points

Locations

Locations

Locations

.

Page

.2-1

3-1

3-2

3-5

3-6

3-7

3-9

3-10

3-11

3-12

3-12

3-12

3-13

4-4

4-6

4-7

4-8

4-9

4-10

4-11

4-12

4-14

4-15

4-16

4-17

4-18

4-19

4-21

4-22

4-23

4-24

4-24

4-25

4-25

4-25

4-26

4-26

4-28

4-29

4-36

4-37

4-38

vi TS-017-082786

•••

01

Page 8

LIST

OF

ILLUSTRATIONS (Continued)

FIGURE

5-1

5-2

5-3

5-4

5-5

5-6

5-7

5-8

5-9

5-10

5-9

5-10

TABLE

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

Top View

Top View

Bottom

Rear

Exploded View Drawing

M2552K Revision 1

M2553/54K Revision 2

M2553 Revision 3

Interconnec t Diagram

M2552K Revision 1

M2553/54K Revision 2

M2553K Revision 3

MFM

Recording

Disk Mechanism

Track

INDEX

Read/Write

Power

Environmental

Reliabili

Regulatory

Interface

of

Disk Drive (View 1)

of

Disk Drive (View

View

of

Disk Drive

View

of

M255XK

Storage

Access

Pulse.

Supply

Mechanism

• • • • •

Head and

Requirements

Conditions

ty

Agency

Signal - Pin Designation

Certification

Circuit

Circuit

Circuit

Schematic

Schematic

Schematic

UST

Capacity

Track

2)

Card

Layout

Card

Layout

Card

Layout

Drawing

Drawing

Drawing

OF

TABLES

Specifications

Page

5-2

5-3

5-4

5-5

5-6

5-15

•

•

5-16

5-17

5-18

5-17

5-19

5-21

Page

2-2

2-2

2-3

2-3

2-4

2-4

2-5

2-5

2-6

2-6

4-1

4-2

4-3

4-4

4-5A M2553K/54K Revision 2

4-5B M2553K Revision 3

4-5C

5-1 M255XK Assembly

5-2

5-3

5-4

TS-017-082786

Inspection and

Field

Replaceable

Maintenance

Screw

M2552K Revision 1

Listing

Listing

Listing

Size and Torque

of

of

of

•••

Adjustment

Tools

Structural

Screws and Washers • •

Main

Circuit

01

Items

Circuit

Circuit

Circuit

Chart

Parts

Card

Items

•••••••

Card

Card

Jumper

Card

Jumper

•

Components

vii

Jumper

Definitions

Definitions

Definitions

4-1

4-2

4-2

4-3

4-5

4-6

4-7

5-1

5-7

5-9

5-10

Page 9

1.1

SCOPE

This manual explains

51"

Mini Flexible Disk Drives.

the

service

SECTION 1

INTRODUCTION

procedures

for

the

FUJITSU M255XK Family of

This Section gives

Section 2 provides

Section 3 explains

Section 4

Section 5 contains

1.2

GEI\ERAL DESCRIPTION

M255XK disk drives

Half-Height

Industry

drives have an independently addressed Read/Write head

diskette.

FM (Frequency Modulation)

methods

There

standard

are

are

details

5i" Flexible Disk Drive technology.

acceptable.

three

Models in

an

overview

specifications.

the

maintenance

parts

offer

51"

(130mm)

the

of

the

Disk Drives.

drive's operations

procedures

lists

and mechanical and

superior

or

M255XK Family:

performance,

diskettes

MFM

(Modified Frequency Modulation) recording

are

used

schematic

reliability

as

the

drawings.

and

storage

for

construction

medium. These

each

side

of

in

the

M2552K - This model

unformatted

Kbytes with

With a 16

double density/double sided, 96

disk drive.

M255JK - This model

unformatted

802 Kbytes with FM'Encording.

With a 15

double density/double sided, 96

standard

M2554K - This model

allows

TS-021-013087

•••

51" disk drive.

operation

01

records

storage

FM

sector

records

storage

sector

has

5,922 flux transitions

capacity

Encoding.

format

format

a host

at

either

(256

9,646 flux transitions

capacity

of

bytes

of

(512

bytes

system

300 RPM,

1-1

per

il1ch

1 Mbyte

per

track

1.604 Mbytes with

per

track

controlled

or

with

sector),

per

inch

per

sector)

per

inch (1.2 MByte) industry

interface

360 RPM.

MFM

the

51"

inch and has a

the

and has a

Encoding

M2552K

industry

MFM

M2553K

Encording

emulates

line (pin-2)

per

disk

or

500

emulates

standard

per

disk

that

a

or

a

Page 10

M2554K (Continued)

When

inch (similar

capacity

Encording.

When

inch (similar

capacity

Encoding.

set

of

set

of

at

300 RPM

to

a M2552K) and

1 Mbyte with

at

360 RPM,

to

the

M2553K). and

1.604

Mbytes

the

the

with

M2554K

has a per

MFM

M2554K

MFM

records

Encording

records

has a per

Encording

5,922 flux

disk

unformatted

or

500

9646 flux

disk

unformatted

or

802

transistions

Kbytes

transitions

Kbytes

with

with

per

storage

FM

per

storage

FM

MFM

With

M2552K - 250 Kbi

M2553K - 500 Kbi

M2554K - 250

Spindle

M2552K 300 RPM

M2553K - 360 RPM

M2554K - Host

On all Models,

disk.

time.

Except

Refer

M2553K, and M2554K Mini

1.3

KEY FEATURES

recording

- 500

motor

Track

Average

for

to

the

the

to

M255XK

ts

ts

Kbits

Kbits

speed

system

Track

track

access

di

fferences

methods,

per

per

per

per

is:

selected

density is 96 TPI and

access

time,

Product

the

data

second

second

second

second

.listedabove,

Flexible

at

at

(via an

time

including

Description Manual

transfer

300 RPM

360 RPM

interface

is 3 milliseconds, plus a 15 millisecond

settling

performance

Disk Drives.

rate

signal line)

there

time,

is 94 milliseconds.

for

is:

for

ere

80 cylinders/160

of

the

units

an

overview

300

or

is

identical.

of

360 RPM

the

tracks

settling

M2552K,

per

o

Half-Height

o Industry

o Industry

o

Vertical

Up

to

o

o The M2554K may be

or

products)

o High quality and

o FUJITSU AMERICA

1.604 Mbytes

1.0

(1.625 inches)

standard

standard

clamping mechanism

Mbyte

flexible disk drive mounting

flexible disk drive

of

capacity

reliability

unformatted

set

by

disk drive (allowing a single

support

the

host

1-2

interface

storage

computer

capacity

to

function

as a 1.6

source

TS-021-013087

Mbyte

for two

•••

01

Page 11

1.4

OPTIONS AND ACCESSORIES

o

Automatic

Diskette

Eject

Ejects

The disk drive is

ejected).

o Head Load Solenoid

Allows

drive via an

Auto-Rezero

o

Rotates

Track

o Door Lock

Allows

drive is

o Door Switch

Allows

regardless

the

diskettes

the

host

system

interface

the

diskette

00, whenever power is turned-on.

the

door

lever

selected

the

of

or

Ready signal

Drive

from

set

when

Selection.

the

disk drive, when

to

the

Not

to

Load/Unload

signal line.

(to full speed) and

to be locked,

In

Use is

to

selected.

be

Ready

the

retracts

to

prevent

active

the

door

State

Read/Write

whenever

(when

the

media

lever

heads

Read/Write

removal,

the

is

the

diskette

in

door is closd

released.

the

disk

heads

when

to

the

is

TS-021-0l3087

•••

01

1-3

Page 12

Page 13

SECTION 2

SPECIFICATIONS

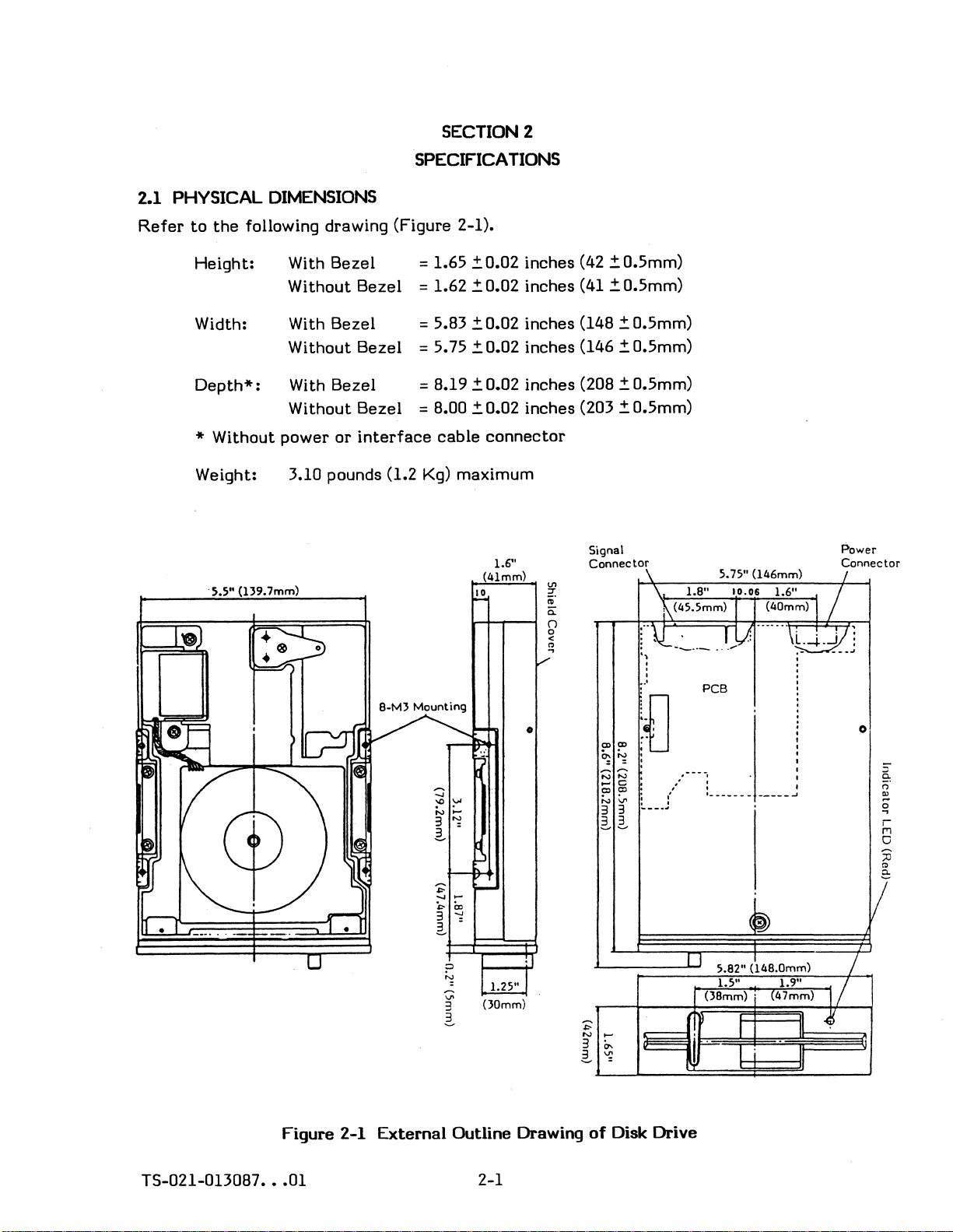

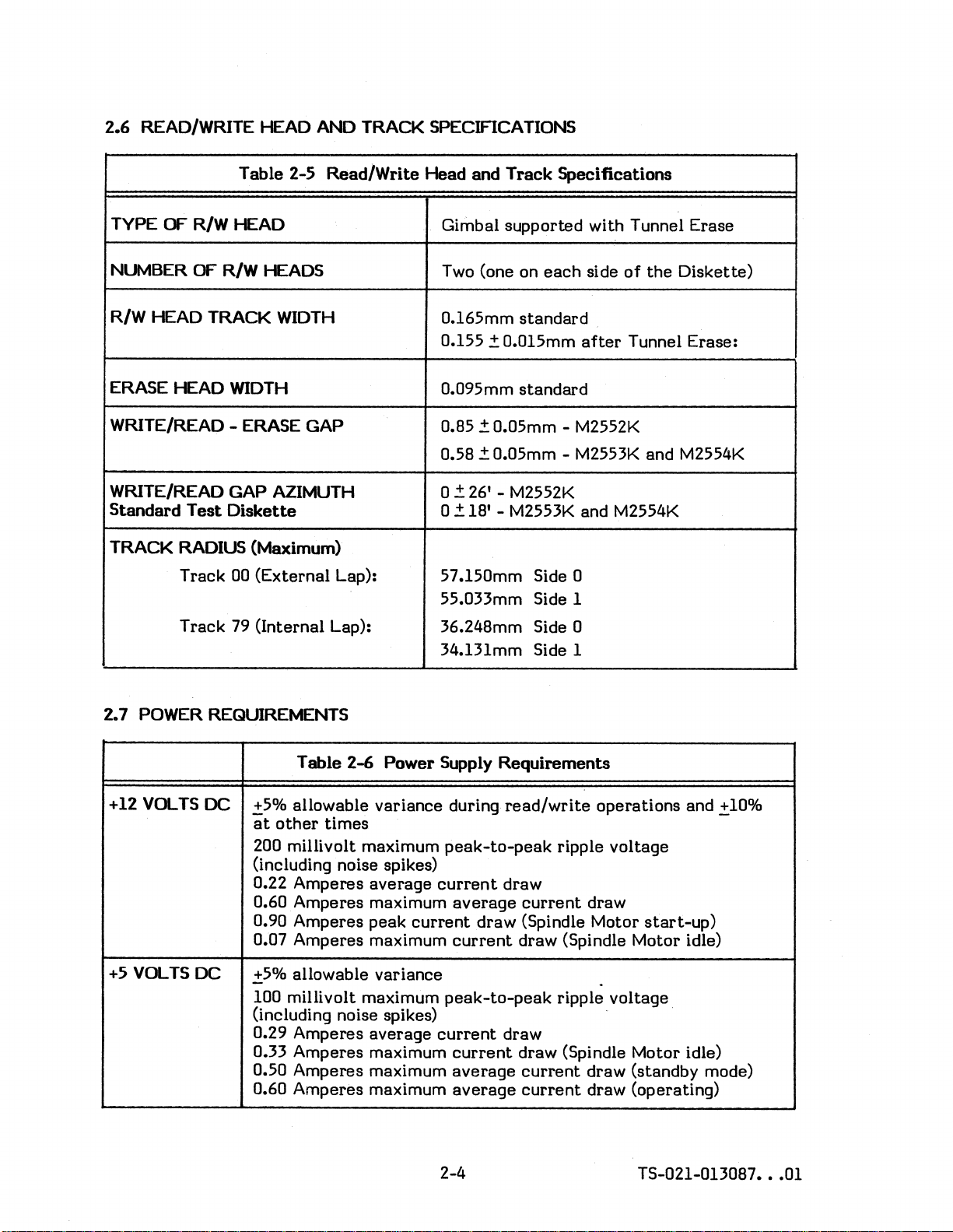

2.1 PHYSICAL

Refer

to

the

following drawing (Figure 2-1).

Height:

Width: With Bezel

Depth*:

* Without

Weight:

. 5.5" (139.7mm)

DIMENSIONS

With

Bezel

Without

Without

Bezel

Bezel

With Bezel = B.19

Without

power

Bezel = B.OO

or

interface

= 1.65

= 1.62

=

5.B3

= 5.75

cable

~0.02

~

0.02 inches (41 ~ 0.5mm)

~0.02

~0.02

~0.02

~0.02

connector

3.10 pounds (1.2 Kg) maximum

(41mm)

10

inches (42

inches (l4B

inches (146

inches

inches (203

1.6"

~0.5mm)

~0.5mm)

~0.5mm)

(20B

~0.5mm)

~0.5mm)

Signal

Connector

\ S.7S"

\ 1.8"

r·\L_~

,

, .

.

, .

,

..

'

(l46mm)

10.06

...

V:

1.6" /

......

\L.-l.J/]

'~

1\

(45.5mm) (40mm) I

..

_ }

PCB

.

Power

Connector

I

..

•

(JOmm)

Figure 2-1 External Outline Drawing

0>0>

"'N

= = : ·

NN

....

c

ClCl

NV,

3 3

3 3

~~

of

Disk Drive

....

_;

,

....

• I

:.--"'~

• I

11

r

(J8mm)'

___________

5.82"

(~48.0mm)

1.S"

·

I

·

•

I

:

..J

1.9"

(47mm) I /

'/

/

o

II

::

~

II)

o

-

...

2:

TS-021-0130B7

•••

01

2-1

Page 14

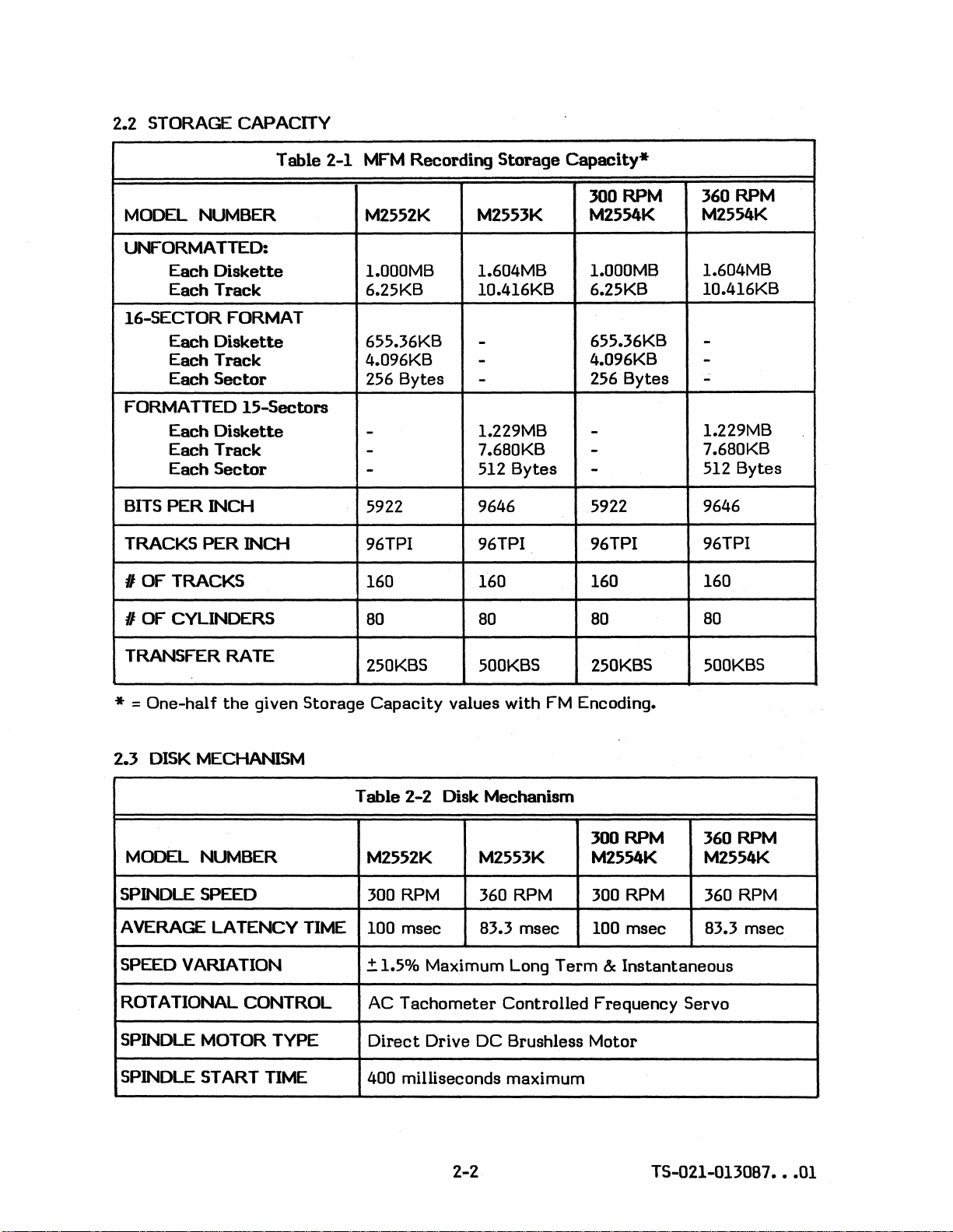

2.2 STORAGE CAPACITY

Table 2-1

MODEL NUMBER

UNFORMATTED:

Diskette

Each

Track

Each

16-SECTOR FORMAT

Diskette

Each

Each

Track

Each

Sector

FORMATTED

Each

Each

Each

BITS

PER

TRACKS

I OF TRACKS 160 160 160

15-Sectors

Diskette

Track

Sector

INCH

PER

INCH 96TPI 96TPI

MFM

Recording

M2552K

1.000MB 1.604MB

6.25KB

655.36KB

4.096KB

256 Bytes

-

-

-

5922 9646

Storage

M2553K M2554K

1O.416KB 6.25KB

-

-

-

1.229MB

7.680KB

512 Bytes

Capacity*

300 RPM

1.000MB

655.36KB

4.096KB

256·

-

-

-

5922 9646

96TPI

Bytes

360 RPM

M2554K

1.604MB

10.416KB

-

-

-

1.229MB

7.680KB

512 Bytes

96TPI

160

I OF CYLINDERS

TRANSFER RATE

*

= One-half

2.3 DISK MECHANISM

MODEL NUMBER

SPINDLE SPEED

AVERAGE LATENCY

SPEED VARIATION

ROTATIONAL CONTROL

SPINDLE MOTOR TYPE

the

given Storage

TIME

80

250KBS 500KBS 250KBS

Capacity

Table 2-2 Disk Mechanism

M2552K

300

RPM

100 msec 83.3 msec 100 msec 83.3 msec

='1.5% Maximum Long

AC

Tachometer

Direct

Drive DC Brushless Motor

80

values with

M2553K

360 RPM 300 RPM 360 RPM

Controlled Frequency Servo

80

FM

Encoding.

300 RPM 360 RPM

M2554K

Term

& Instantaneous

80

500KBS

M2554K

SPINDLE START

TIME

400 milliseconds maximum

TS"()21-D1JOB7

•••

01

Page 15

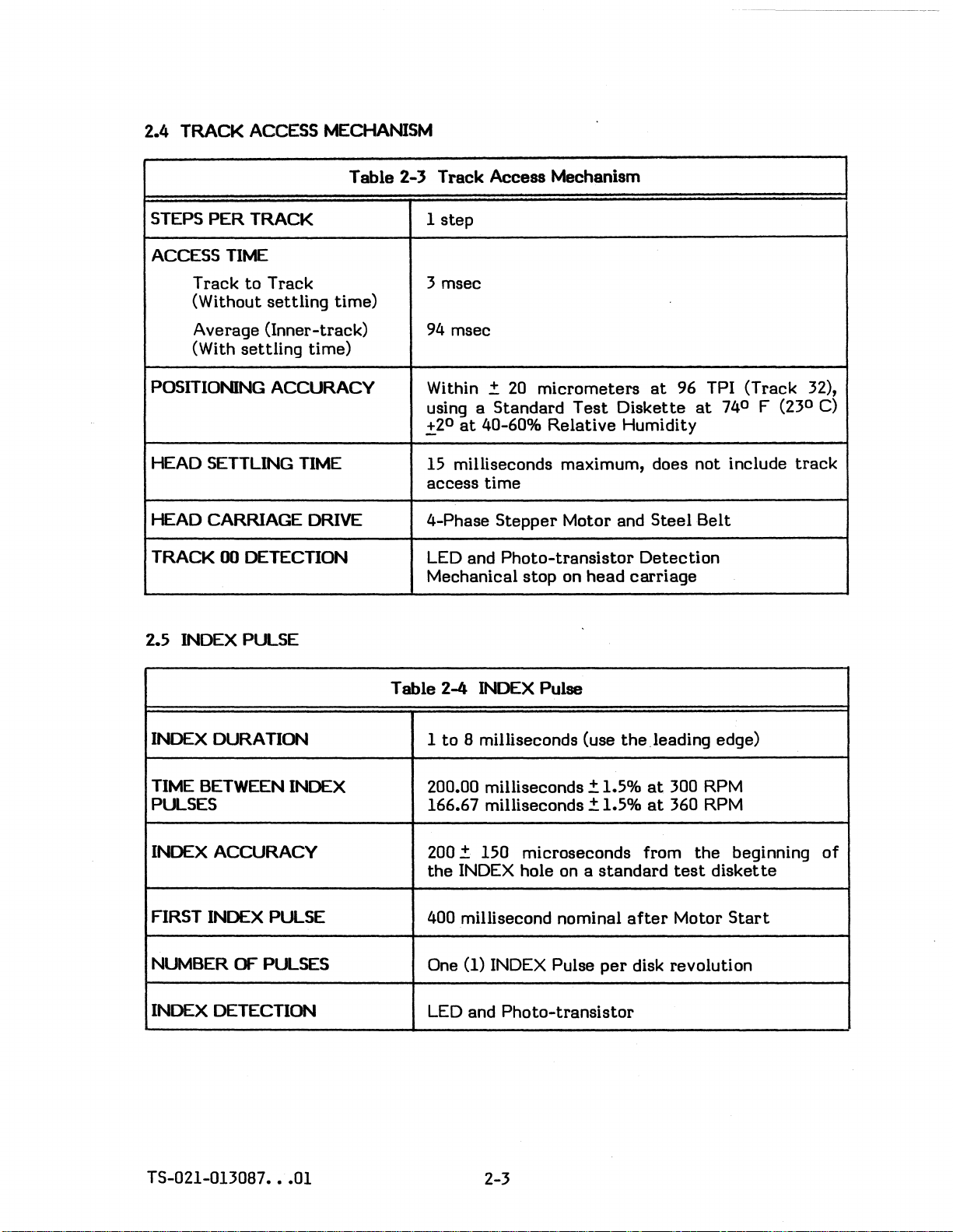

2.4 TRACK ACCESS MECHANISM

Table 2-3 Track Access Mechanism

PER

STEPS

TRACK

1

step

ACCESS

TIME

Track

to

(Without

Track 3 msec

settling

time)

Average (Inner-track)

(With

settling

time)

POSITIONING ACCURACY

HEAD SETTLING

HEAD CARRIAGE

TIME

DRIVE

TRACK 00 DETECTION

2.5 INDEX PULSE

94

msec

Within

using a Standard

.:t20

.:t

20

micrometers

Test

Diskette

at

40-60% Relative Humidity

at

96 TPI (Track 32),

at

15 milliseconds maximum, does not include

access

4-Phase

LED and

Mechanical stop on

time

Stepper

Motor and

Photo-transistor

head

Steel

Detection

carriage

Belt

Table 2-4 INDEX Pulse

740 F (230 C)

track

INDEX DURATION

TIME

BETWEEN INDEX 200.00 milliseconds

PULSES

INDEX ACCURACY

FIRST INDEX PULSE

NUMBER

OF

PULSES

INDEX DETECTION

TS-021-013087

•••

01

1

to

8 milliseconds (use

166.67 milliseconds

.:t

1.5%

.:t

1.5%

the

leading edge)

at

300 RPM

at

360 RPM

200.:t 150 microseconds from

the

INDEX hole on a

400 millisecond nominal

(1) INDEX Pulse

One

LED

and

Photo-transistor

standard

after

per

disk revolution

2-3

the

test

disket

Motor

beginning

te

Start

of

Page 16

2.6

READ/WRITE .-EAD AND TRACK SPECIFICA

nONS

Table 2-5 Read/Write Head and

TYPE OF R/W HEAD

OF

NUv1BER

R/W HEAD TRACK

ERASE HEAD

WRITE/READ - ERASE GAP 0.85 !: 0.05mm - M2552K

WRITE/READ GAP AZIMUTH O!: 26' - M2552K

Standard

TRACK RADIUS (Maximum)

R/W HEADS

WIDTH

WIDTH

Test

Diskette

Track 00 (External Lap): 57.150mm Side 0

Gimbal supported with Tunnel Erase

Two

0.165mm

0.155 !:

0.095mm

0.58 !: 0.05mm - M2553K and M2554K

o !: 18' - M2553K and M2554K

55.033mm Side 1

Track

(one on

standard

0.0l5mm

standard

Specifications

each

side

of

after

Tunnel Erase:

the

Diskette)

Track 79 (Internal Lap): 36.248mm Side 0

2.7 POWER REQUIREMENTS

Table

+12

+5

VOLTS

VOLTS

DC

DC

!:5% allowable variance during

at

other

200 millivolt maximum

(including noise spikes)

0.22 Amperes average

0.60

0.90 Amperes peak

0.07 Amperes maximum

!:5% allowable variance

100 millivolt maximum

(including noise spikes) -

0.29 Amperes average

0.33 Amperes maximum

0.50 Amperes maximum

0.60 Amperes maximum

times

Amperes

2-6

Power

maximum

34.131mm Side 1

Supply Requirements

read/write

peak-to-peak

current

average

current

current

peak-to-peak

current

current

average

average

draw

current

draw (Spindle Motor

draw (Spindle Motor idle)

draw

draw (Spindle Motor idle)

current

current

operations and !:10%

ripple voltage

draw

start-up)

.

ripple voltage.

draw (standby mode)

draw (operating)

2-4

TS-021-013087

•••

01

Page 17

2.8 ENVIRONMENTAL CONDITIONS

Table

2-7 Environmental Conditions

OPERATING STORAGE TRANSPORT*

39

to

Ambient

Non-condensi

Temperature

Temperature

ng

Gradients

(Maximum)

Relative

Humidity

(Maximum Wet-Bulb)

Non-condensing

1150 F

to

46

0

(4

590 F/Hour

(150 C/Hour)

20

to

80%

840 F

(290 C)

Vibration Tolerance 0.50G 55Hz

(Maximum)

Shock Tolerance

0.25G

lOG 10msec

55

(Maximum)

* Packed in designated

for

Correctly

When

ship)

transport

the

Packed

takes

Storage Environmental Conditions apply.

crates

Freight

place over an extended period (such as

with conditions conforming to JIS-Z0200 - Provisions

Testing Methods; Level

C)

Max. 10

to 150HZ

to

-7.6

(-22

1400 F -40

to

600 C) (-40

Not speci fied

to

1490 F

to

650 C)

860 F/Hour

(300 C/Hour)

to

90% Max. 5 to 95% Max.

1040 F

1130F

(400 C) (450 C)

Not Speci fied

2.0G 100Hz

Not Speci fied 40G 10msec

II.

trans-oceanic

by

2.9 RELIABILITY

Table 2-8 Reliability

MEAN

TIME

BETWEEN FAILURES

(MTBF)

MEAN

TIME

TO REPAIR

(MTTR)

PERIODIC MAINTENANCE

PRODUCT LIFE 5

DISK LIFE

DISKETTE INSERTIONS

DATA ERROR RATES:

Soft

Read

Error

Hard Read

Error

Rate

Rate

SEEK ERROR RATE

11,000 Power-on hours, with

30

Minutes Maximum

Not required.

Head Cleaning

to

subassembly level

years

Three

One

One

One

One

times

times

per

per

per

106 passes/track

104 insertions minimum

109 bits

12

10

(with

bits

(with more

up

to

106 seeks

25%

duty

cycle

if

necessary

minimum

2 re-reads)

than 2 re-reads)

TS-021-013087

•••

01

2-5

Page 18

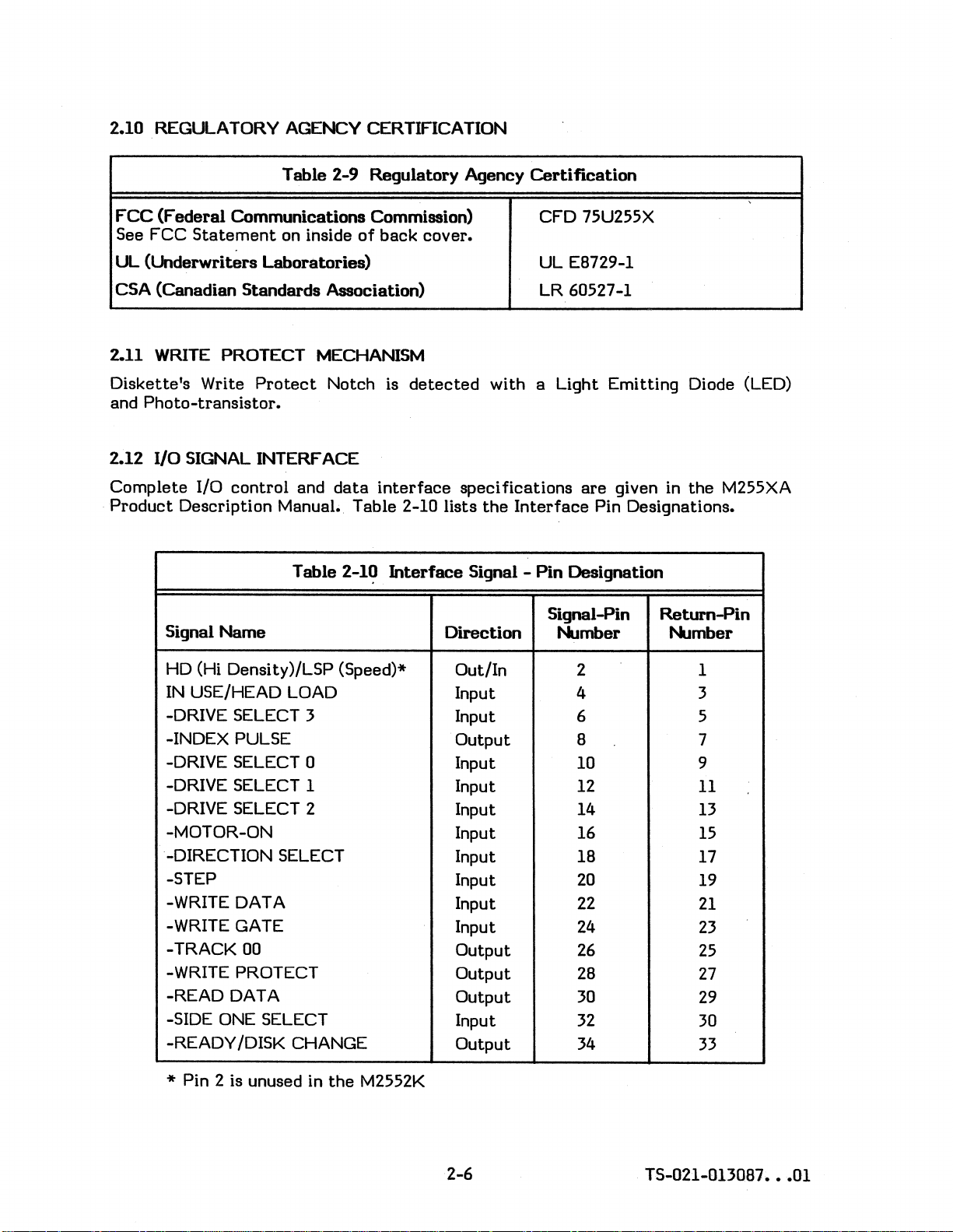

2.10 REGULATORY AGENCY CERTIFICATION

Table 2-9 Regulatory Agency

FCC

(Federal

See FCC

Communications Commission) CFD 75U255X

Statement

on inside

of

back

UL (Underwriters Laboratories)

CSA (Canadian Standards Association)

2.11 WRITE PROTECT MECHANISM

Diskette's Write

and

Photo-transistor.

Protect

Notch is

detected

2.12 I/O SIGNAL INTERFACE

Complete

Product

I/o

control

and

data

interface

Description Manual. Table 2-10 lists

Table 2-10

Interface

Signal Name

cover.

with a Light Emitting Diode (LED)

specifications

the

Signal -

Direction

Certification

UL

EB729-1

LR 60527-1

are

given in

Interface

Pin

Pin Designations.

Designation

Signal-Pin

Number Number

the

M255XA

Return-Pin

HD

(Hi Density)/LSP (Speed)*

IN

USE/HEAD LOAD

-DRIVE SELECT 3

-INDEX PULSE

-DRIVE SELECT 0

-DRIVE SELECT 1

-DRIVE SELECT 2

-MOTOR-ON

-DIRECTION SELECT

-STEP

-WRITE DATA

-WRITE GATE

-TRACK 00

-WRITE PROTECT

-READ DATA

-SIDE ONE SELECT

-READY /DISK CHANGE

* Pin 2 is unused in

the

M2552K

Out/In

2 1

Input 4 3

Input

Output

6

B

5

7

Input 10 9

Input 12

Input 14

Input 16

Input IB

Input

Input

Input

Output

Output

Output

20

22

24

26

2B

30

11

13

15

17

19

21

23

25

27

29

Input 32 30

Output 34

33

2-6

TS-021-0130B7

•••

01

Page 19

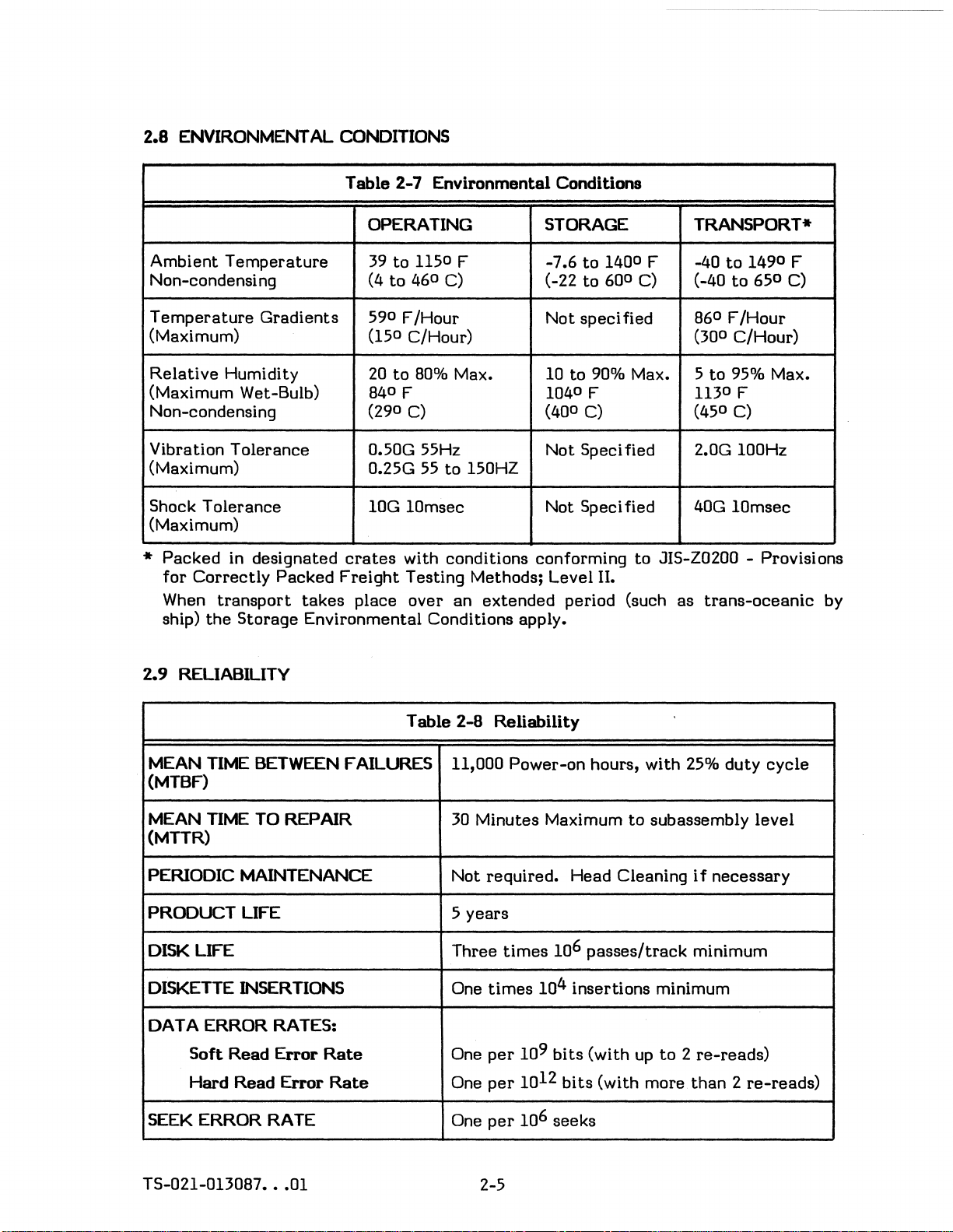

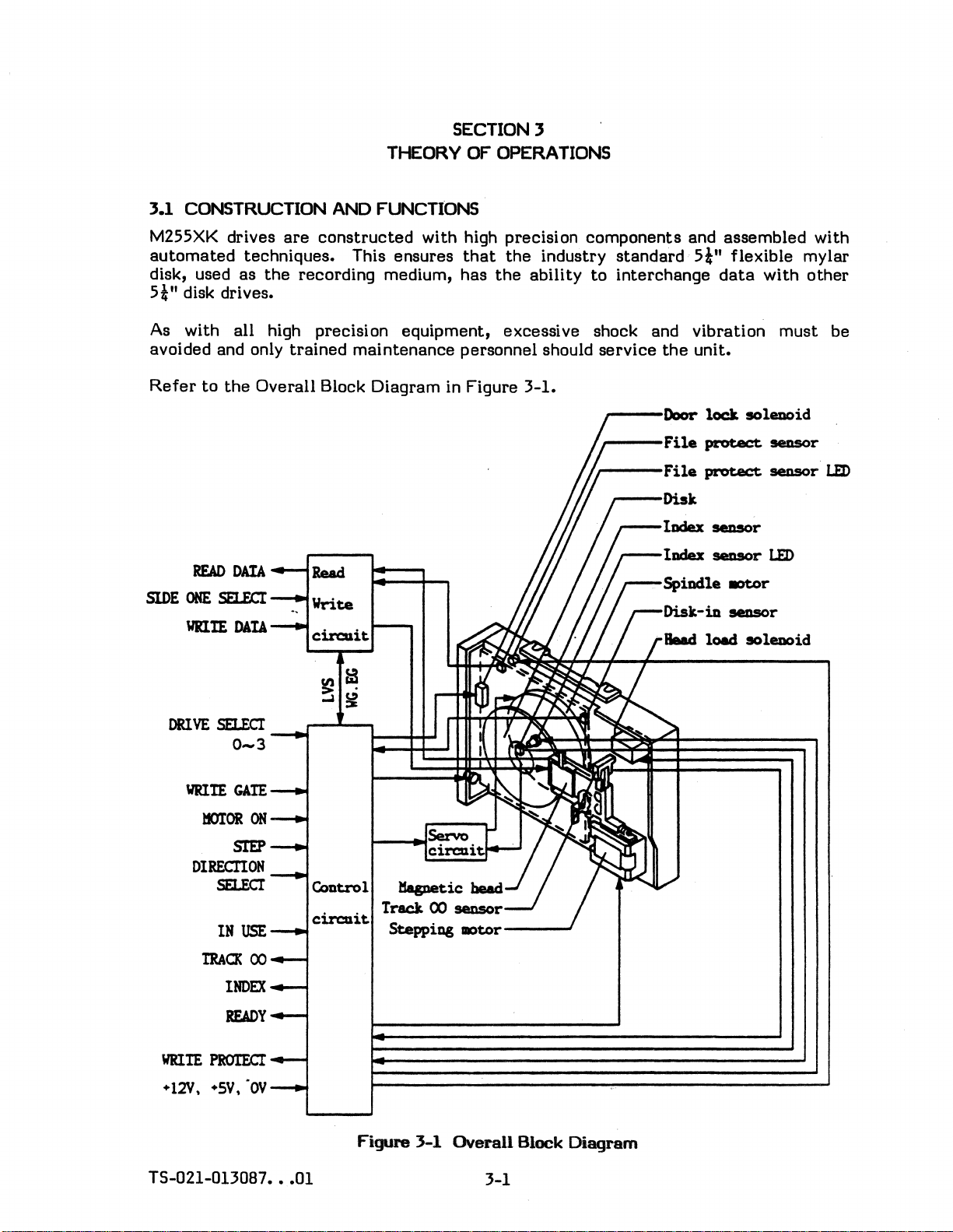

THEORY OF OPERATIONS

3.1

CONSTRUCTION AND FUNCTIONS

SECTION 3

M255XK drives

automated

disk, used

5i"

disk drives.

are

constructed

with high precision

techniques. This ensures

as

the

recording medium,

that

has

the

the

industry

ability

components

standard

to

interchange

As with all high precision equipment, excessive shock and

avoided and only

Refer

to

the

trained

Overall

maintenance

personnel should

Block Diagram in Figure

3-1.

service

the

,---Door

,---File

r----File

,--Disk

IDdex

and assembled with

5i"

flexible

data

vibration

with

must

mylar

other

be

unit.

lock

soleuoid

protect

protect

seasor

sensor

sensor

LFD

LED

T5-021-013087

•••

01

!fapetic

Track 00

~wi~~r---J

Figure

J-1

bead

sensor

OveraD Block

3-1

Diagram

Page 20

3.1.1

The

are

accuracy

Frame

frame

Assembly

assembly is

the

skeleton on which

mounted. This aluminum die

and expansion

ratio

required

cast

chassis ensures

for

stable

the

mechanisms and

the

disk drive operations.

3.1.2 Door Opening/Closing and Disk Clamping Mechanism

drive has

circuit

the

strength,

boards

The door opening/closing mechanism includes

lever,

the

the

spindle

and

end

of

collet

to

set

arm.

the

enters

ensure

set

the

The disk clamp mechanism (Collet) is moved

arm.

the

When a

opening in

disk is

accurately

diskette

the

is

center

clamped into posi tion.

3.1.3 Spindle Mechanism

The disk

spindle

rotating

motor

a service life

rotates

temperature

into

the

at

300 or 360 RPM and maintains a

fluctuations, by using feedback signals from an AC

motor.

The spindle and

the

disk and

to

and disk come into

3.1.4

The

the

obtain

Read/Write

flat

shaped

disk and

are

maximum playback from

system

is a

direct

of

20,000

collet

allow

contact

Head

read/write

mounted on

is comprised

spindle coupled

or

more hours

are

precisely aligned

accurate

and

centering

at

exactly

Carriage

heads

the

of

outer

of

continuous operation. The spindle

of

the

correct

are

supported by a gimbal. The heads

carriage.

the

disk, with minimum head

pressure.

the

clamp spring

inserted

of

the

rotor

constant

and

the

the

disk, and presses

spindle and spindle motor. The

type

DC brushless

speed, even with load and

(flat

front

spring),

up

and down by

lever

against

motor

tachometer

to

prevent

the

disk. This also ensures

injury

to

the

center

location.

The

read/write

heads

are

to

designed

disk

front

is closed,

the

with

motor

built

hole

of

the

heads

straddle

to

contact

Refer

record

to

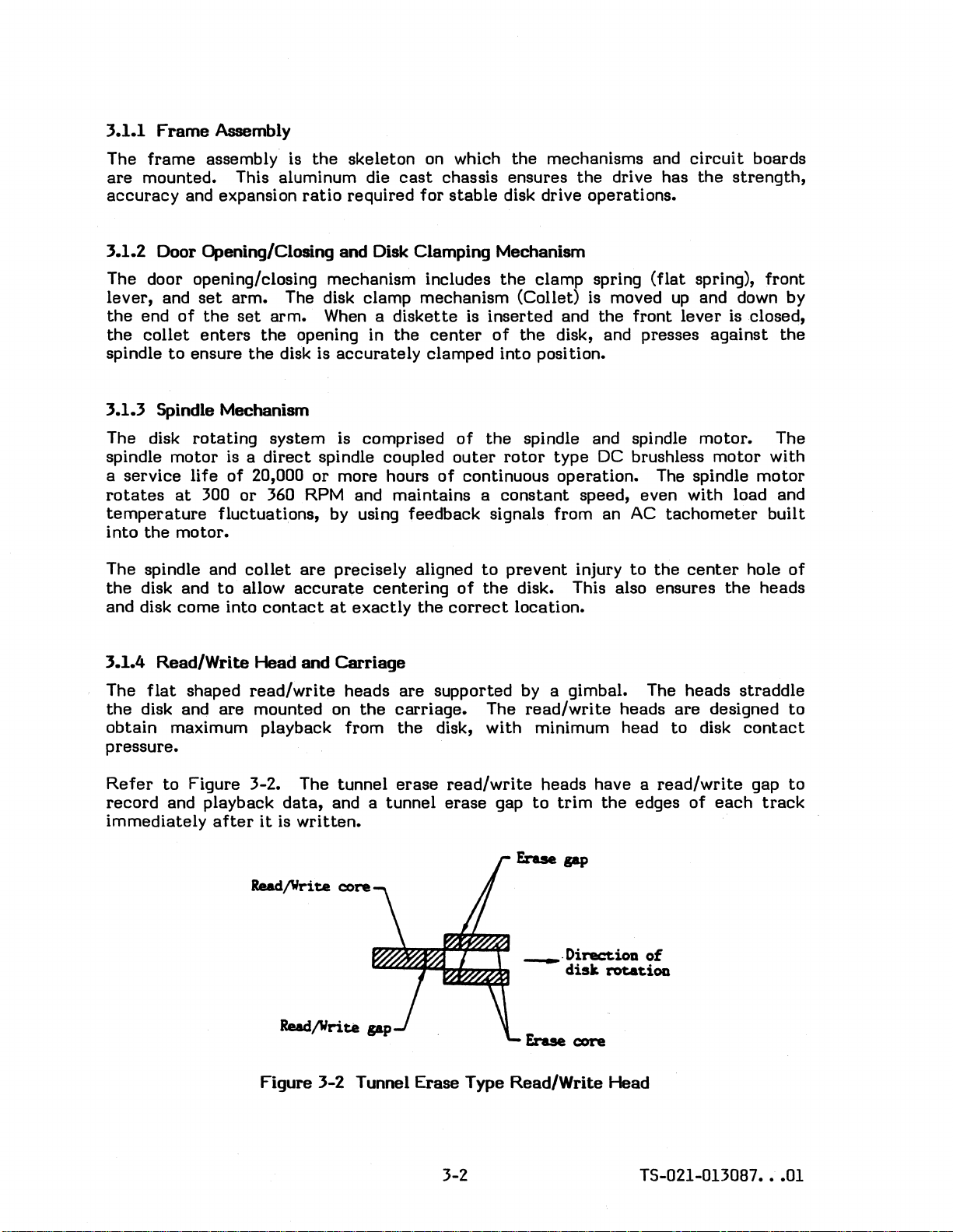

Figure 3-2. The tunnel

and playback

immediately

data,

after

it

is

Rea.d/Write core

erase

and a tunnel

written.

read/write

erase

gap

heads have a

to

_.Direc:tioa

Erase

Figure 3-2 Tunnel Erase Type Read/Write Head

3-2 T5-021-013087

trim

disk

core

the

edges of

of

rotation

read/write

each

gap

track

•••

to

01

Page 21

3.1.5 Seek Mechanism

The seek mechanism is

mechanism includes a

carriage

stepping

The stepping

by single-phase

slides along two guide

motor

via

motor

the

utilizes

excitation

built

steel

steel

around a stepping

band, guide

shafts

band.

a 4-phase

and

it

rotates

track.

Parallelism

shaft

the

and

chassis,

and designed

3.1.6 Write

This

detector

They

detect

and

distance

capstan,

steel

to

counteract

Protect

is comprised

the

presence

are

assembled

band,

carriage,

Detection

between

the

expansion

of

a Light

or

absence

the

to

and

When a disk with a covered notch is

operation

protected,

The LED is mounted on

sensor is mounted on

of

the

even

write

if a write

the

circuits

is

prevented.

command is given.

the

spindle

write

protect

motor

shaft

and

and is

construction.

one

step

shaft

close

and disk

tolerances.

associated

of

the

disk.

Emitting

of

a wri

te

inserted,

Previously

motor

circuit

circuit

card

with a

read/write

connected

capstan

head

to

the

This stepping

0

(1.8

to

)

center

move

lines,

Temperature

items

have

been

Diode (LED) and

enable

the

light

notch

path

on

is broken and any

written

card

and

the

assembly.

(pulley). This

carriage.

capstan

motor

the

carriage

as

well as

The

of

the

is driven

one

the

expansion

carefully

studied

photo-transistor.

the

disk

jacket.

data

is

thereby

photo-transistor

of

3.1.7 Track 00

The Track 00

(photo-interrupter)

to

the

drive's

Detection

detector

is comprised

and a mechanical

circuitry

whenever

position (Track 00). The mechanical

beyond Track 00 during a

If

the

head

carriage

received,

the

edge

calibrate

To

move

there

of

the

several

is enough margin provided

opening in

the

head

steps

seek

is

at

carriage

beyond

operation

its

the

disk.

the

innermost

(return

maximum

M255XK, which has 80 cylinders,

calibrate

3.1.8 Index

An

LED and

the

spindle

disk

at

track

Detection

each

motor

00.

photo-transistor

time

circuit

the

hole passes

board and

are

mounted in

the

assembly.

of

an LED and photo

stop.

the

stop

to

the

The

photo-interrupter

head

carriage

prevents

or

when power is initially

track

it

track

position, and a

to

ensure

to

Track 00), command

number.

move outward 84

the

drive

detector.

photo-transistor

transistor

provides a signal

is

at

the

outermost

the

head

that

to

carriage

the

For

to

detect

example,

turned

step-in

heads will

86

from moving

on.

command is

not

the

carriage

command a

steps

the

to

Index hole in

The LED is mounted on

is mounted on

the

sensor

assembly

track

reach

to

have

it

the

block

TS-021-013087

•••

01

3-3

Page 22

3.1.9 Diskette Inserted Detection

The

diskette

the

disk drive.

The

diskette

assembly (photo-interrupter). This

drive's circuitry whenever a

3.1.10 Head Load Mechanism

inserted mechanism

inserted

detector

diskette

detects

is comprised

the

presence

of

photo-interrupter

is

inserted

into

or

absence

an LED and photo

provides a signal

the

drive.

of a diskette

in

transistor

to

the

The head load mechanism extends

diskettes

when necessary.

The head load mechanism is comprised

assembly, and associated

3.1.11 Door Lock Mechanism

The door lock mechanism locks

to

prevent

The door lock mechanism is comprised

and associated

3.2 CIRCUIT CPERATIONS

The drive's

by

allowing them

the

door from being opened, and causing damage

parts.

electronic

Read/Write

Control

Circuits

to

parts.

circuitry

Circuits

- explained in paragraph 3.2.2.

is comprised

- explained in paragraph 3.2.1.

the

come into uniform

the

front lever during

of

service life

of

the

head load solenoid,

the

door lock solenoid,

of

three

of

the

read/write

contact

major sections:

all

read

or

with each

or

the

lost

write

of

data.

eject

heads and

other,

arm

operations

only

lifter

assembly,

Spindle Motor Servo

The Read/Write, and Control

the

Servo

3.2.1

The Read/Write

circuits,

LSI

Figure 3-3.

circuits

are mounted on

Read/Write Circuits

circuits

and associated sections. These various

control

circuit.

Circuits

include

A

partial

- explained in paragraph 3.2.3.

circuits

the

read

are

mounted on

spindle motor board.

circuits,

diagram

of

write

sections

this

circuits,

LSI

control

the

are

main

circuit

low voltage

accommodated in one

circuit

T5-021-013087

board and

detection

is

shown in

••.•

01

Page 23

Rud,lVrite coil

Erase

coil

eo.on

(center

tap)

TPI

TP2

IP4

IPS

tP'3

J

GIlD

-----------AO

l....I'lrn....t.....L..I Oiode

SIDE

1

1'-r-r"T"T"""'1"T'-r-'

I.

Iwitch

~:f:ii

~:

I

I

I

I

L

____________

The read

detector,

circuits

drop

detector

includes a pre-amp, low pass .filter,

Al

At

F'-----1

UD

0.1

and

Urite

driver

VD

_

Figure 3-3

read

output

AO-

Read/Write

driver.

VGSO

-

Circuits

Low

YOltap

cletectioo

circuit

---------~

differential

LYS

amp, peak

I

I I

I

I

I I

I

I

LJ

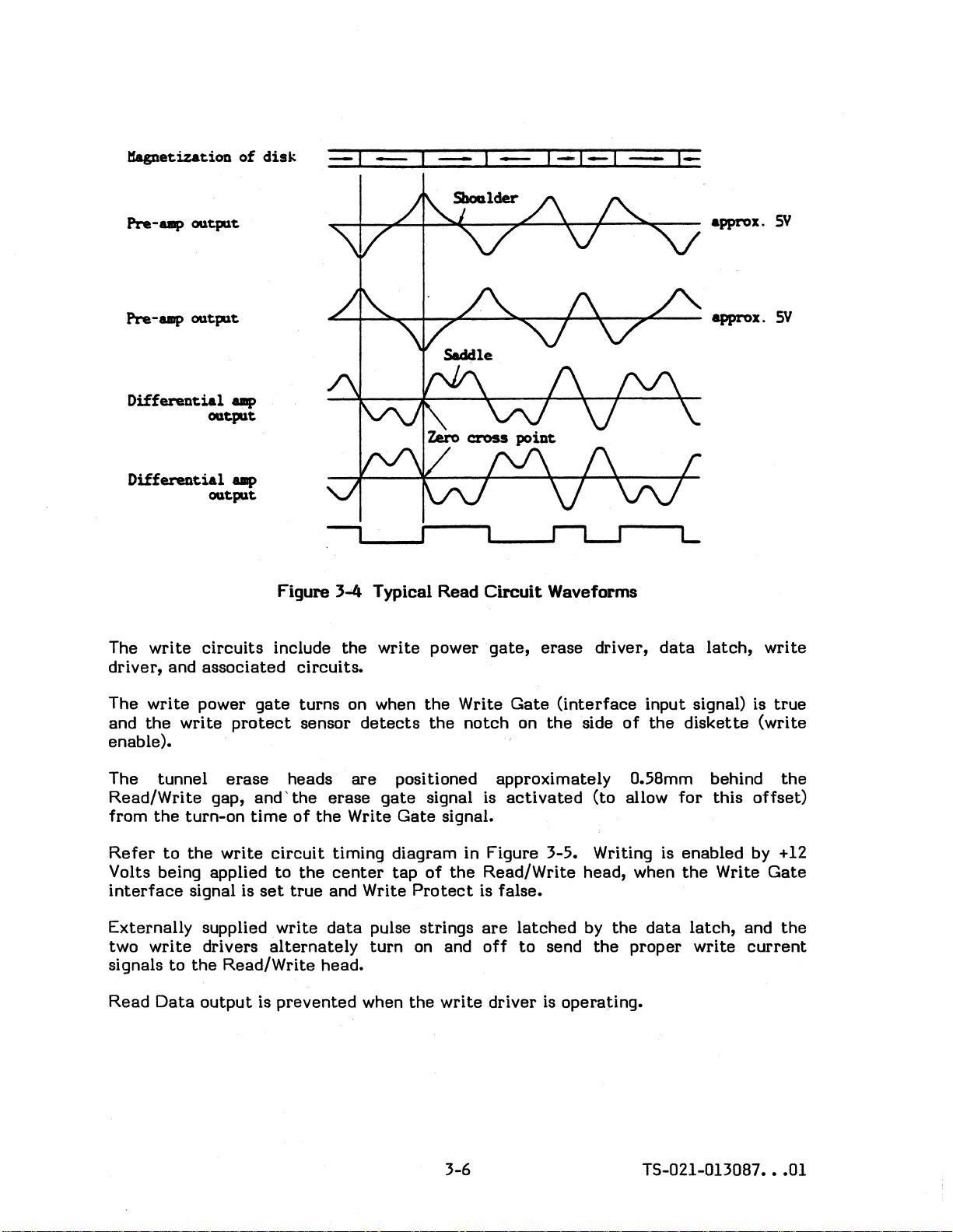

Refer

signals induced into

amp (a

pass

The

simultaneously applies

difference

The

detector,

to

the

read

subtraction

filter.

The amplified signal then goes

differential

in

the

output

from

the

bad influence

circuit

the

timing

chart

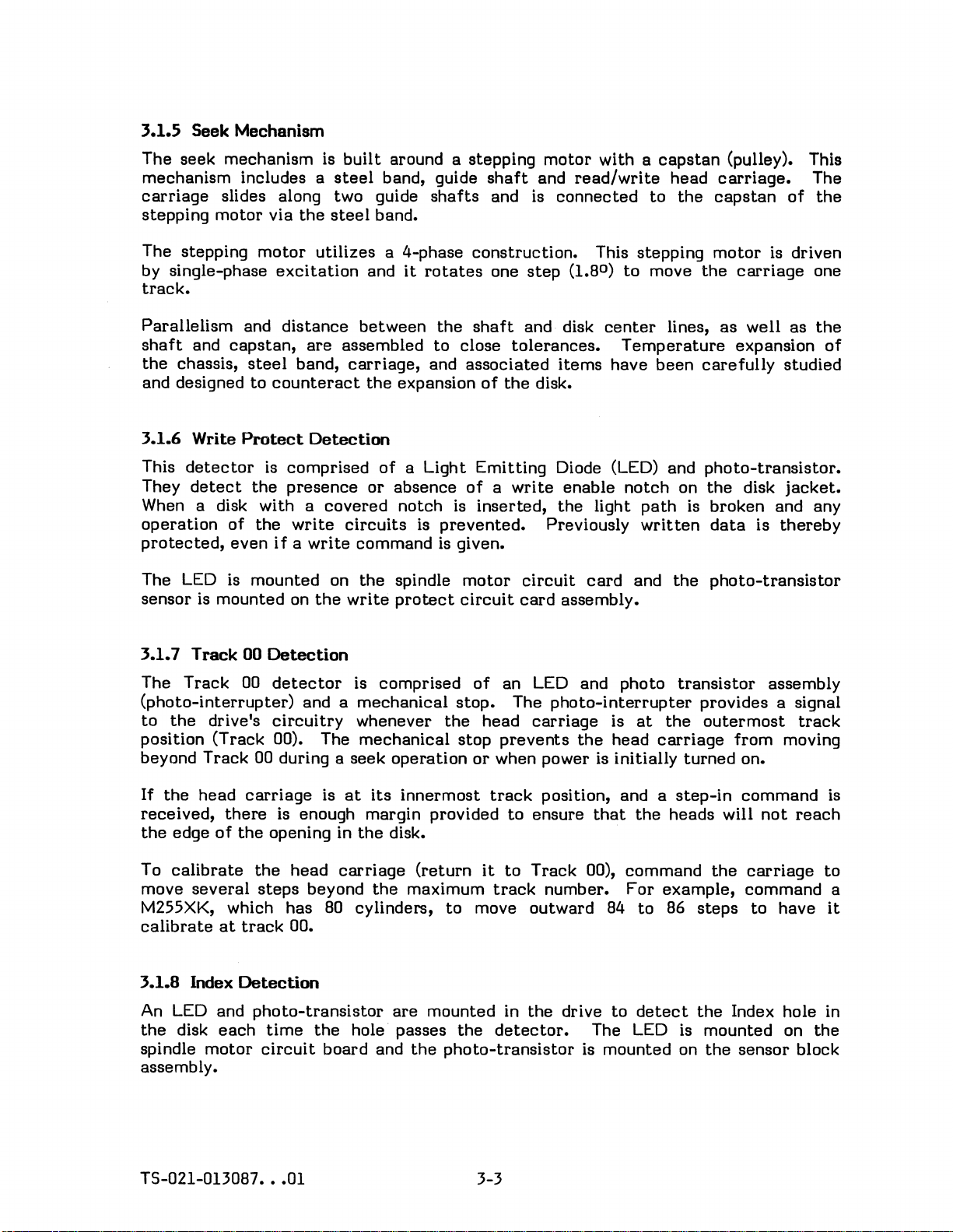

in Figure 3-4. The micro-voltage level

Read/Write head during playback is amplified by a

amplifier) and spurious noise components

to

the

differential

amp

shifts

frequency components. The signal is

the

differential

the

the

proper amount

of

the

playback signal

of

compensation in

amp is

converted

saddle (which

to

the

further

into a square wave by

occurs

zero

during playback

frequency signal component approximately 125k Hertz) is

detector.

The

read

data

when Read

Gate

TS-021-013087

signal is driven

is

true.

•••

01

out

of

the

3-5

drive by

the

read

pre-

are

removed by a low

amp.

crossover position and

accordance

with

the

amplified.

the

peak

of

the

low-

eliminated

output

by

driver

the

drop

circuit,

Page 24

tfagnetizatiou

of

disk

-I

~

1

......

1--1

1--

Pre-up

Pre-up

Differential

Differential

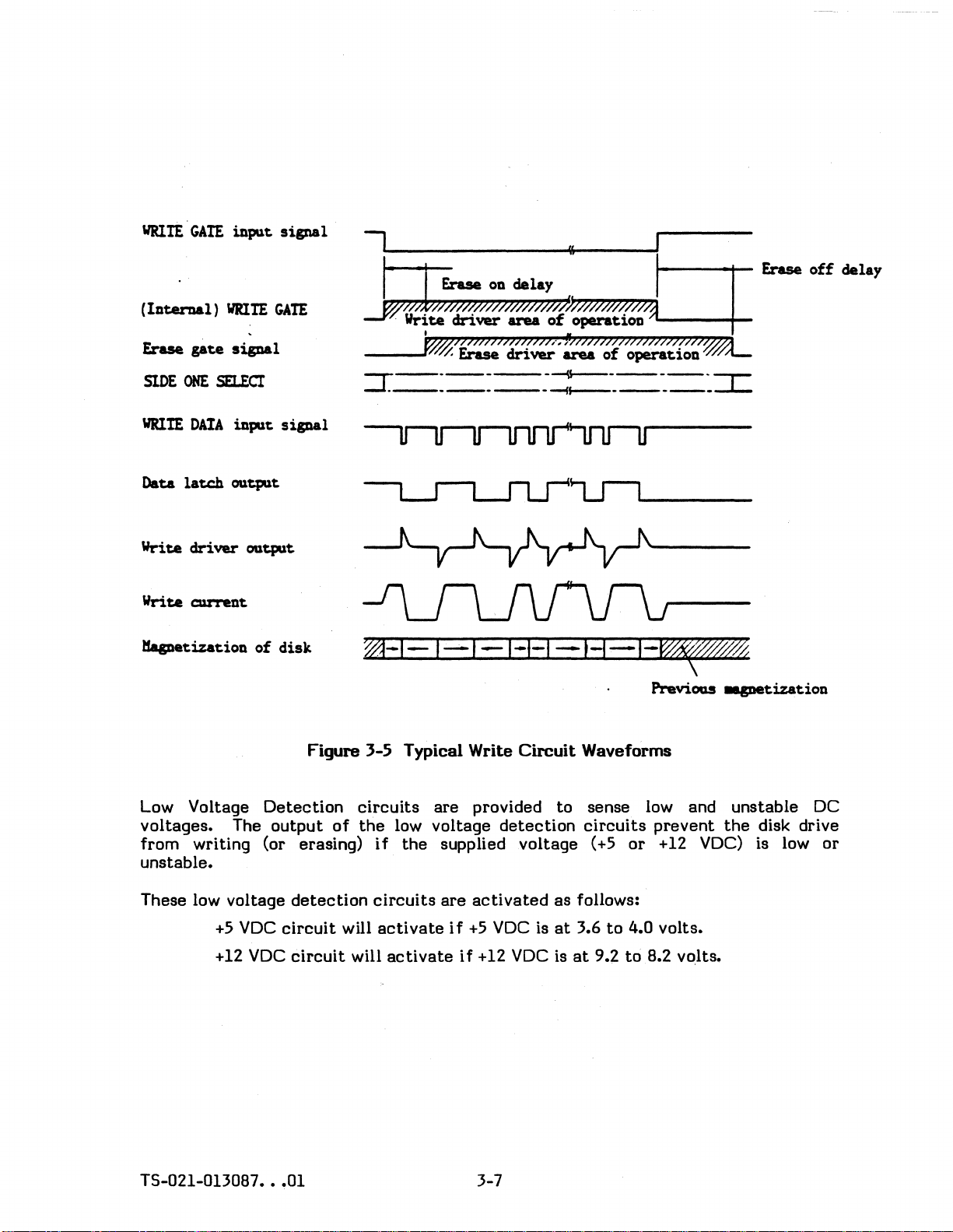

The

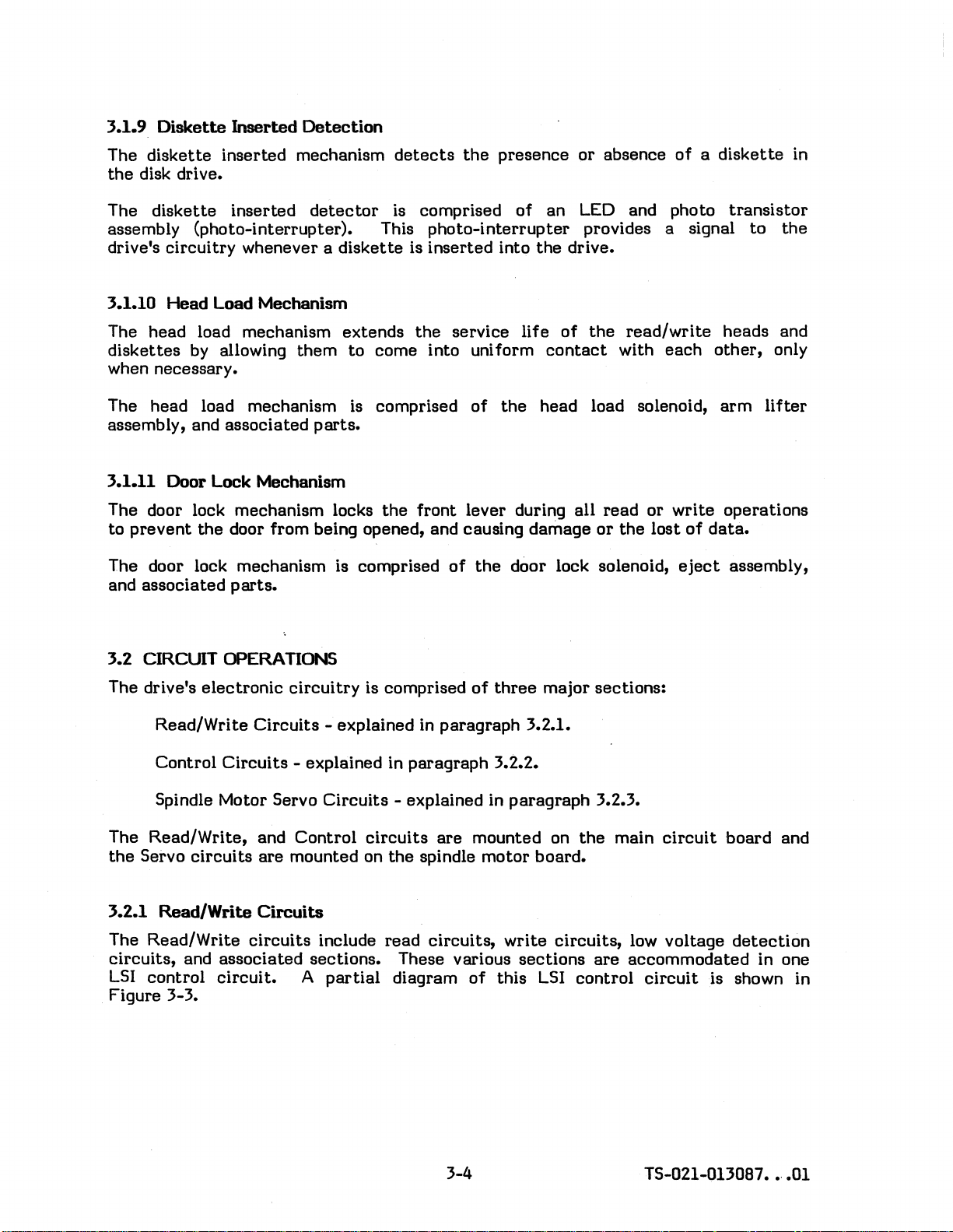

write

driver,

and

OQtpllt

OQtpllt

amp

OQtp1t

up

OQtpllt

circuits

associated

Figure

include

circuits.

,L..-_

3.04

the

....

Typical

write

Read

power

Circuit

gate,

Waveforms

erase

driver,

L

data

latch,

write

The

write

and

the

enable).

The tunnel

Read/Write

from

Refer

Volts being applied

interface

Externally

two

write

signals

Read

write

the

to

to

Data

power

protect

erase

gap,

turn-on

the

write

signal is

supplied

drivers

the

Read/Write

output

gate

and'the

time

turns

sensor

heads

of

the

circuit

to

the

set

true

write

alternately

head.

is

prevented

on when

detects

are

erase

Write

timing diagram in Figure 3-5. Writing is

center

and Write

data

pulse

turn

when

the

the

positioned

gate

signal is

Gate

signal.

tap

of

Protect

strings

on and

the

write

Write

the

Gate

notch

approximately

activated

Read/Write

is

false.

are

off

driver

(interface

on

the

latched

to

send

is

operating.

input signal) is

side

of

the

0.58mm behind

(to

allow

head, when

by

the

data

the

proper

diskette

for

this

enabled

the

Write

latch,

write

true

(write

the

offset)

by

+12

Gate

and

the

current

3-6

TS-021-013087

•••

01

Page 25

WRIIE

GAIE

input

signal

--,

i

(lDterDal)

Erase

SIDE

WRItE

Data

Write

Hagoatization

gate

ONE

DAtA

latch

driver

WRITE

sigaal

SELECI

input

output

GATE

sigDal

outplt

of

disk

J;J/7~~:=I//J/////#ql/jt-----+-r-

.

Wrlte

__

-JV///'

-.-----

--.1.--------II------------L-

driver

iw»n»»,""",""

Erase

area

driver

of

operatlOD . .

b»»m;m;mmm%VZ1

area

--+-------,-

of

operation

'///.11..-

Erase

off

delay

%I-I-I~I-I-I-I-t3-1-~

Previous

-.petization

Figure 3-5 Typical Write

Low Voltage

voltages. The

Detection

output

of

from writing (or erasing)

unstable.

VDC

•••

detection

circuit

circuit

01

will

will

These low voltage

+5

VDC

+12

TS-021-013087

circuits

the

low voltage

if

the

circuits

activate

activate

Circuit

are

provided to sense low and unstable DC

detection

supplied

are

if

+5

if

voltage

activated

VDC

+12

VDC

Waveforms

circuits

(+5

as follows:

is

at

3.6

is

at

to

9.2

to

prevent

or

+12

4.0 volts.

8.2 volts.

the

VDC)

3-7

disk drive

is low or

Page 26

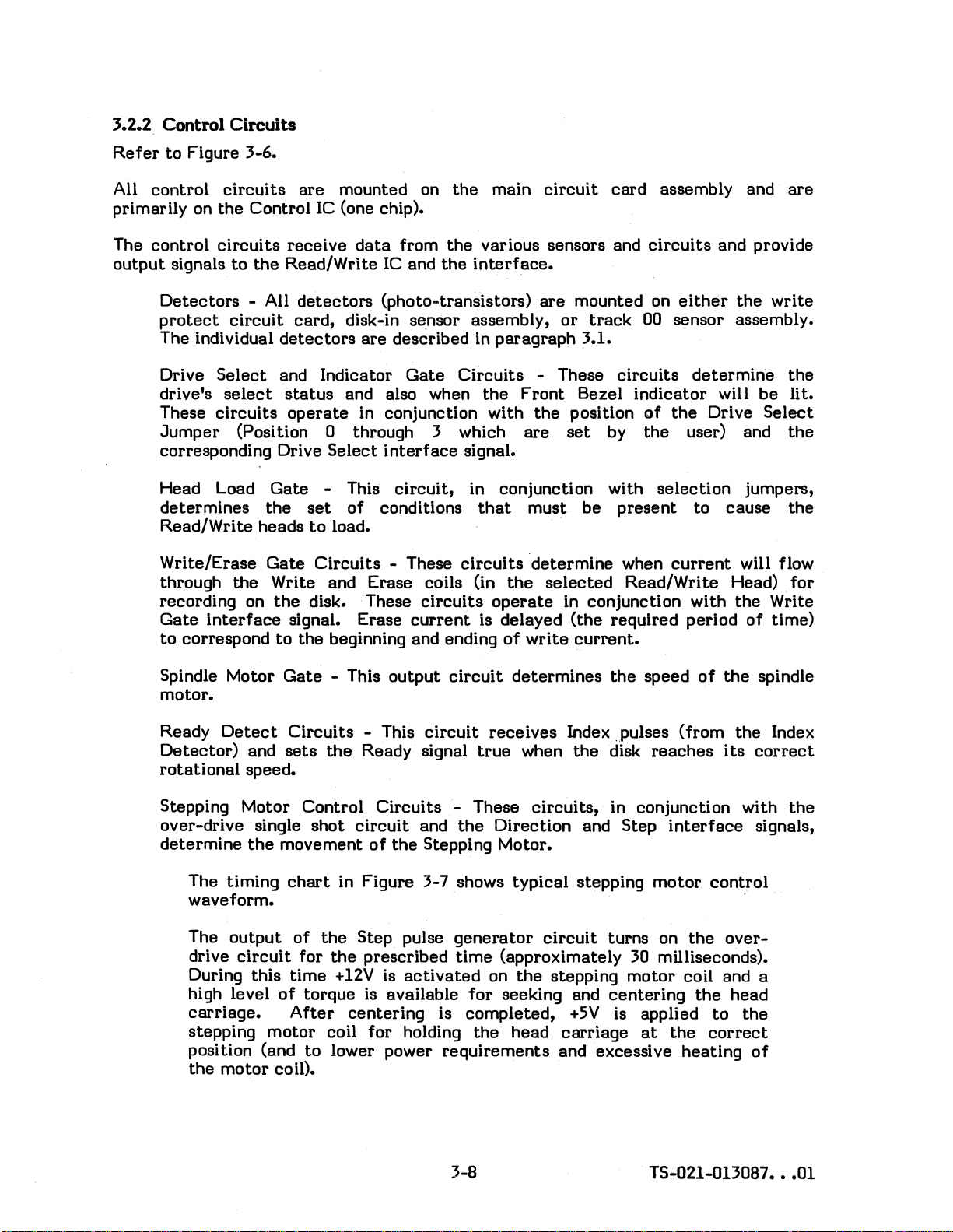

3.2.2

Control

Circuits

Refer

All

primarily on

The

output

to

Figure

control

control

signals

the

circuits

Detectors·

protect

The individual

Drive

Select

drive's

These

circuits

Jumper

corresponding Drive

Head Load

determines

Read/Write heads

Write/Erase

through

recording on

Gate

to

interface

correspond

3·6.

circuits

are

mounted on

the

Control IC (one chip).

to

the

circuit

select

receive

Read/Write IC and

All

detectors

card,

detectors

and Indicator

status

operate

data

from

the

the

(photo-transistors)

disk-in senSor assembly,

are

described in paragraph 3.1.

Gate

Circuits

and also when

in conjunction with

(Position 0 through 3 which

Select

Gate

the

Gate

the

Write and Erase coils (in

the

- This

set

to

load. . .

Circuits

disk. . These

signal. Erase

to

the

beginning and ending

interface

of

conditions

circuit,

- These

circuits

current

signal.

circuits

main

circuit

card

various sensors and

interface.

are

mounted on

or

track

the

- These

Front

the

are

position

set

Bezel

by

circuits

indicator

in conjunction with

that

is delayed

must be

determine

the

operate

of

write

present

when

selected

Read/Write Head) for

in conjunction with

(the

required period

current.

assembly and

circuits

and provide

either

the

are

write

00 sensor assembly.

determine

of

the

the

user) and

selection

to

current

will

Drive

cause

will flow

the

the

be

lit.

Select

the

jumpers,

the

Write

of

time)

Spindle Motor

Gate

- This

motor.

Ready

Detector)

rotational

Detect

and

speed.

Circuits

sets

the

Stepping Motor Control

over-drive single

determine

the

The timing

shot

circuit

movement

chart

in Figure 3-7 shows

waveform.

output

The

drive

circuit

During this

high level

carriage.

stepping

position (and

the

motor

of

the

for

the

time

+12V

of

torque is available

After

motor

centering

coil for holding

to

lower power

coil).

output

- This

circuit

circuit

Ready signal

Circuits

and

of

the

Stepping Motor.

Step pulse

prescribed

is

activated

is

requirements

determines

receives

true

when

- These

the

circuits,

Direction and Step

typical

generator

time

on

for

circuit

(approximately 30 milliseconds).

the

stepping

seeking and

completed,

the

head

carriage

and excessive heating

the

speed

of

Index .pulses (from

the

disk

reaches

in conjunction with

interface

stepping

motor

control

'.

turnQ

centering

+5V

on

the

motor

coil and a

is applied

at

the

the

to

correct

the

the

its

over-

head

the

of

spindle

Index

correct

the

signals,

.

3-8

TS~21-013087

•••

01

Page 27

....---4

Door

l.ocJt

drive

cinait

t----

Door

lock

IOleooid

Read

Write

IC

lDdu

File

detector

track

Write

...

Erue

Write

I

Side 1 select

l5V

detector

protect

00

detector

data

gate

gate

(Floppy

tfechaoisll

FDMC

Disk Drive

Q)otrol

Fl'ODt

bezel

LSl)

iadicator

Buffer

Buffer

r--e'

~--1IMd

IDPUt

si&Dal

OIltplt

si&Da1

load soleDOid

.

IDterface

Read

date

..

TS-021-013087

•••

01

I-----1Over-drive

Stepping

driver

Figure

3-6

Control

3-9

circuit

mtor

Circuits

1---

Spindle

.

.

IIOtor

Stepping

.

IDOtor

Page 28

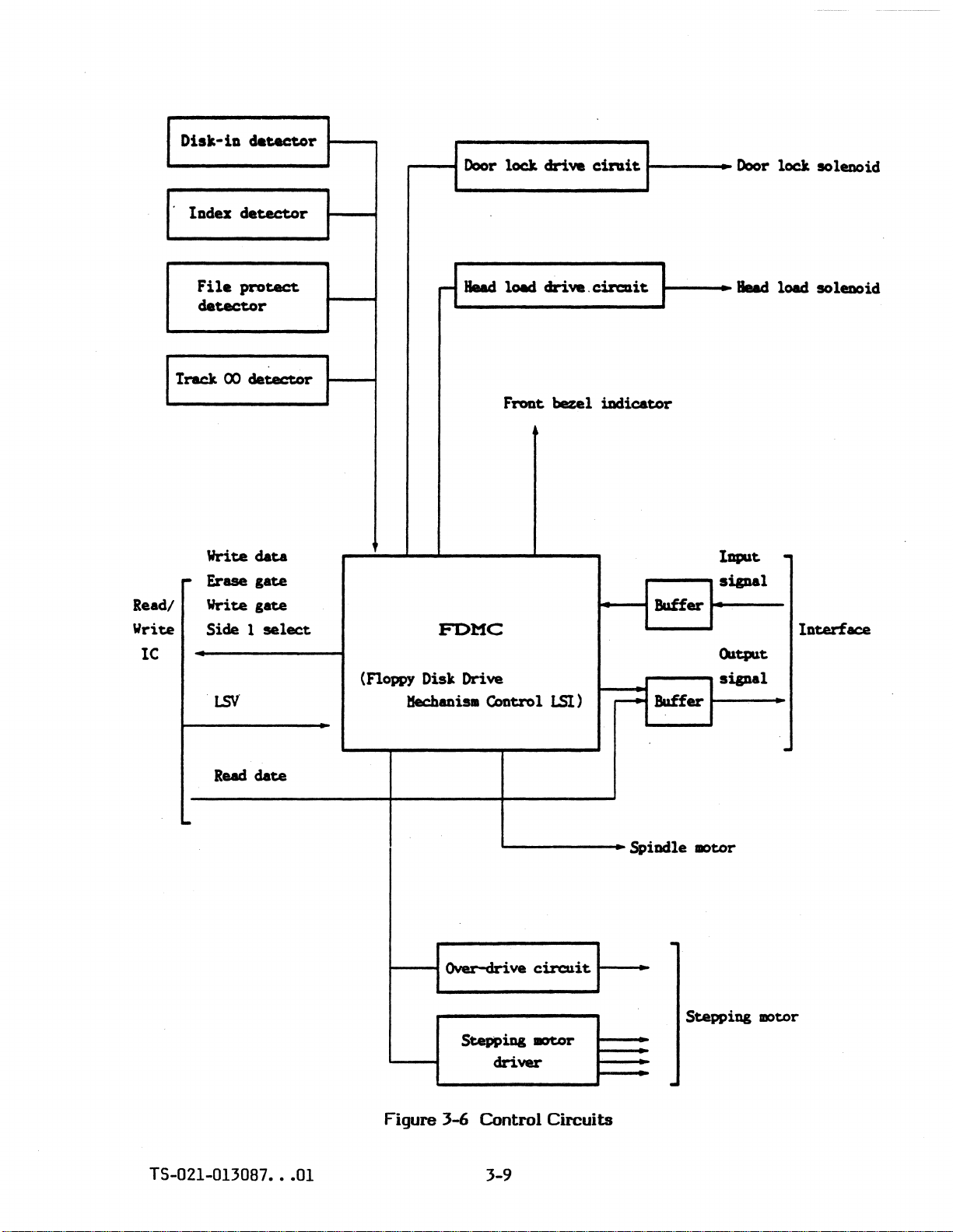

DlRECIlON

STEP

Direction

SELECI

input signal

input signal

latch

----------~------~

output-

Step

out

Step

in

~--------~:~~----

,...---...,';i-------

Over-drive

Motor

circuit

driver

PHASE

PHASE

PHASE

PHASE!"

Figl.lre 3-7 Typical Stepping Motor

3.2.3 Spindle Motor

The Spindle Motor is

The spindle

special

excitation,

card

on

direction

motor

3-phase driver IC. The flow

is

performed

the

outer

of

periphery

excitation

rotation.

input

~--~---~---+------~--~--4-----1~

input

A

8

I

__

started

is an AC, long Ii

by signals from

controlled so they switch

~

and stopped by

fe,

of

of

the

motor's

Control

the

"Motor On"

Circuit

brushless 3-phase motor driven with a

current,

the

rotor,

Hall

and

the

element

with

the

to

the

; approx.3

Omsec.

"

Waveforms

interface

switching

mounted on

sequential drive coil and

prescribed direction

signal.

of

direction

the

circuit

of

of

Rotational

voltage

on

the

circuit

conversion

feedback

speed is

to

the

of

card

voltage

accurately

maintained,

a feedback signal

inside

the

control

motor's

section

at

the

desired value, by frequency

received

rotor.

of

the

3-phase driver IC.

from an AC

tachometer

Another servo IC is used

to

3-10 TS-021-013087

to

etched

apply this

•••

01

Page 29

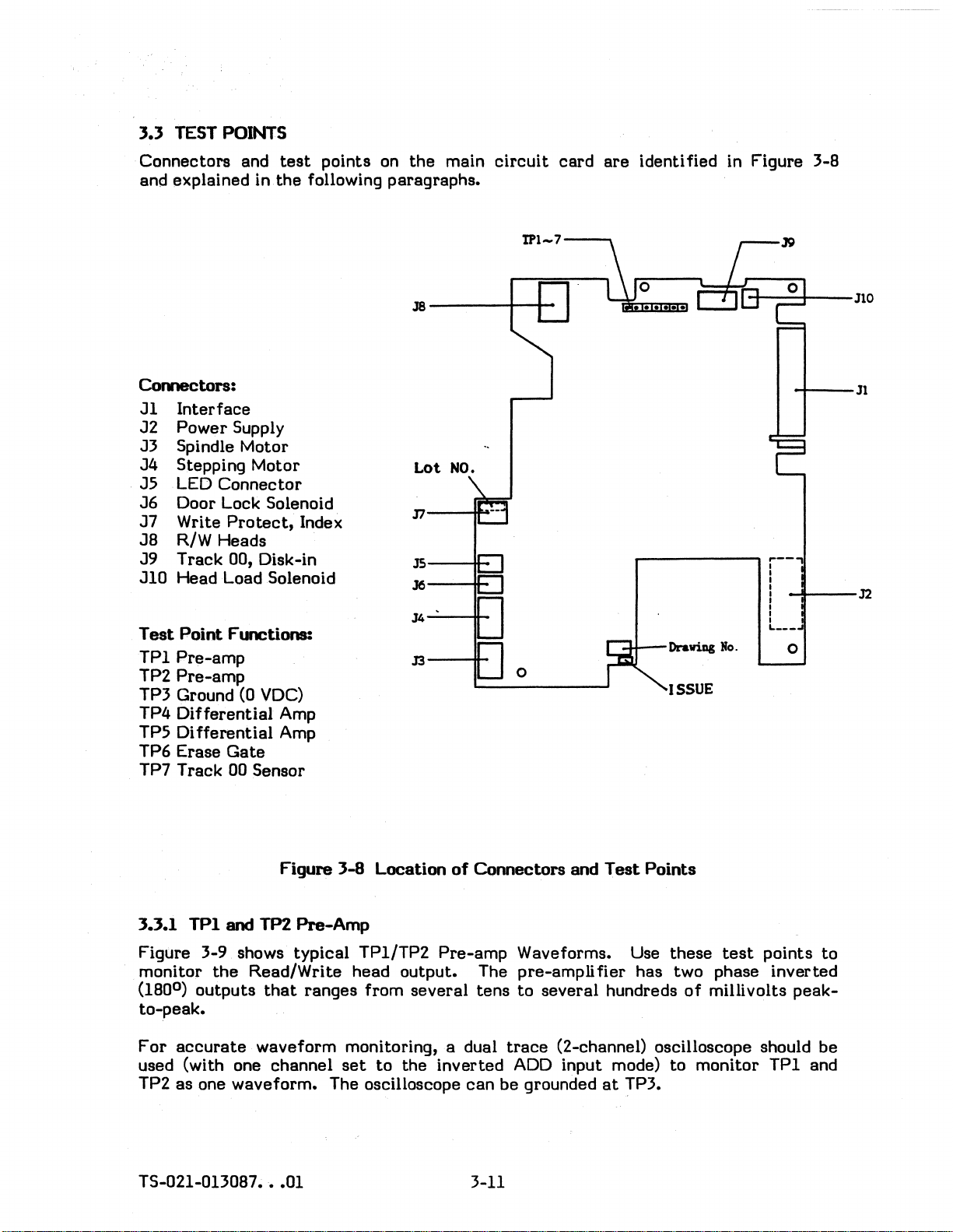

3.3 TEST POINTS

Connectors and

and explained in

test

the

Con1ectors:

Jl

Interface

J2

Power

Supply

J3 Spindle Motor

J4

Stepping Motor

J5

LED

Connector

J6

Door Lock Solenoid

J7

Write

J8

R/W Heads

J9

Track 00, Disk-in

JI0

Head Load Solenoid

Test

Point

TPI

Pre-amp

TP2

Pre-amp

TP3 Ground (0

TP4

Differential

Di

TP5

TP6 Erase

Protect,

FlD!tions:

VDC)

fferential

Gate

Amp

Amp

TP7 Track 00 Sensor

points

on

the

main

following paragraphs.

J8---~-+-

Lot

NO.

Index

circuit

card

are

identified in Figure 3-8

-t---+--Jl0

,..---------,

Draviag

ISSUE

No.

-+---Jl

r--"

I

I

I

I

-+--32

I

I

L

__

_

I

o

Figure

3.3.1

Figure 3-9 shows

monitor

(180

TPI

0

)

outputs

and TP2

Pre-Amp

typical

the

Read/Write head output. The pre-ampll

that

ranges

to-peak.

For

accurate

waveform monitoring, a dual

used (with one channel

as

TP2

TS-021-0n087

one waveform. The oscilloscope

•••

01

3-8

Location

TP1/TP2

from

set

to

Pre-amp

several

the

inverted

of

Connectors

tens

trace

ADD

can

be

3-11

and

Test

Points

Waveforms. Use

fier

to

several

hundreds

these

test

has two phase

of

mUll volts

(2-channel) oscilloscope should

input mode)

grounded

at

TP3.

to

monitor

points

inverted

peak-

TPI

and

to

be

Page 30

3.3.1

TPI

and TP2 Pre-Amp (Continued)

TP1 and TP2

signal.

3.3.2 TP3

Used for grounding

prevent

3.3.3 TP4 and TP5

These

The

(180

to-peak.

shorting nearby

test

Differential

0

outputs

)

are

Ground

points

Amp (like

that

Figure 3-10 shows

~

available for checking

Figure

Differential

are

3-9

TPl/TP2

test

instruments. Use

test

points.

Amp

used

to

monitor

the

Pre-Amp and 2nd Amp) also has two 'phase inverted

ranges from

typical

Typical Pre-Amp Waveform

several

TP1/TP2

/\

the

characteristics

care

the

output

tens

to

several

Differential

/"f\

of

the

Read/Write

when connecting a probe

from

the

Differential

hundreds

Amp Waveforms!

./\

A

of

millivolts

head

to

TP3

to

Amplifier.

peak-

Figure 3-10 TP4/TP5 Typical

For

accurate

used (with one channel

TP5 as one waveform. The oscilloscope can be grounded

TP4 and TP5

head and amplifiers, and for checking

3.3.4 TP6

Figure 3-10 shows a typical TP6 Waveform.

at

the

low level. TP6

On

Delay

Off

Delay

WRIIE

GAIE

waveform monitoring, a dual

set

to

the

are

available for checking

Erase

time

time

Gate

is

used

to

check

= 262 ±24 microseconds

= 776 ±24 microseconds

input signal

Erase

gate

On

delay

inverted

track

Differential

the

alignment.

Erase

at

1MB

at

1MB

trace

Gate

(2-channeI) oscilloscope should

ADD

input mode)

overall

Current

to

Write

(194 ±24 microseconds

(524 ±24 microseconds

Off

deJ..y

Amp Waveform

to

monitor TP4 and

at

TP3.

operation

is flowing

Gate

of

'in

delay

the

the

read/write

erase

a,t

1.6MB)

at

1~6MB).

head

..

be

Figure

3;..11

TP6 Typical

}-12

Eraae

Gate

Waveform

TS-021.013087

•••

01

Page 31

3.3.5

TP7

Track

00

Sensor

Figure

detects

this

Note:

3-12 shows a

when

signal is Low only when

Track

phase

waveform

the

00

for

Track

00

typical

head

carriage

the

output

the

variation

signal

stepping Motor is

is

not

sensor

track

Figure

3-12 TP7

Track

00

is

at

Track

head

is

becomes

constant.

02--J

Track

waveform.

00. Like

at

or

near

True (low level) while

excited.

The

track

Because

'------

the

00.

~track

00

Detect

Waveforms

Track

Track

of

this,

00

photo-transistor

00

interface

the

basic

the

timing

(m

level)

00

signal,

excitation

of

the

TS-021-0130B7

•••

01

3-13

Page 32

Page 33

4.1 PERIODIC MAINTENANCE

SECTION 4

MAINTENANCE

When used

replacing

provides additional information on cleaning

4.Ll

Table 4-1

The paragraph number, listed under

additional information

The

minutes, with

about 10 minutes

Inspection and Adjustment

time

at

a normal

parts,

lists

required

Item

Collet

Bail - Inspection and Adjustment

Disk-in Sensor - Inspection

Write

and lubricating should

the

items

to

the

exception

to

perform.

Table 4-1 Inspection and Adjustment

Assembly - Centering Adjustment

Protect

rate,

that

or a step-by-step

perform

Senor -Inspection

periodic maintenance such as cleaning, adjusting,

Items

may require inspection,

the

of

each

the

item

Track Inspection and Adjustment - which

not

removal and

be

required

the

read/write

"Refer

To" column in Table 4-1, provides

listed in Table 4-1 is approximately 5

for

5 years.

heads.

replacement

replacement

Items

Paragraph

or

adjustment.

procedure.

Refer

4.4.1

4.4.2

4.4.3

4.4.4

To

4.3

takes

Disk Speed - Inspection and Adjustment

Head

Asymmetry - Inspection and Adjustment

Read Level - Inspection

Resolution - Inspection

Track

Track 00 Sensor - Inspection and Adjustment

Index Burst - Timing, Inspection and Adjustment 4.4.12

Head Load - Inspection and Adjustment 4.4.13

Door Lock Insp,:,ction 4.4.14

4.1.2 Field

Table 4-2

wear

or

Table 4-2, provides a

Refer

item

in

to

the

Contact

- Inspection and Adjustment 4.4.10

Replaceable

lists

the

breakage.

the

Maintenance

disk drive.

- Inspection and Adjustment

Items

field

The paragraph number,

replaceable

step-by-step

Precautions

items

listed

removal and

given in paragraph 4.2 prior

that

may require

under

replacement

replacement

the

"Refer

procedure.

4.4.5

4.4.6

4.4.7

4.4.8

4.4.9

4.4.11

due

To" column in

to

replacing any

to

TS-021-013087

•••

01

4-1

Page 34

Table 4-2 Field Replaceable

Items

Item

Head

Carriage

Stepping Motor

Steel

Band Assembly JA4-5674

Part

Number

Replacement

Interval

Assembly JA3-5321 7,000 Operating Hours

or

5 X 106 Seeks

J3-5295

5

5

X 10

X 10

6

Seeks 4.5.2

6

Seeks

Refer

4~5.1

4.5.2

Spindle Motor J3-5294 20,000 Operating Hours 4.5.3

Collet

Sensor

Main

Write

Front

Front

Clamp

LED

Note

Note

Assembly JA3-5265

Card

Assembly JA4-5717

Circuit

Protect

Bezel Assembly

Lever Assembly

Cam

Circuit

1: Obtain

2:

Card

Card

Note 1

JA4-5715 If

JA4-5207 If

JA4-5708

Assembly JA4-5698

Card

Front

order

replacement

Bezel and

other

colors with a color drawing number.

JA4-5716 If

part

Front

If

If

If

If

If

number from

Lever

Assembly

defective

defective

defective

defective

defective

defective

defective

defective

the

old

part

Circuit

numbers

Card.

are

4.5.4

4.5.5

4.5.6

4.5.7

4.4.8

4.4.9

4.4.10

4.4.11

black

To

items,

for

4.1.3 Tools Required

Table 4-3

mentor

list

the

adjustment

Measuring Instruments: Exerciser

Maintenance

tools

that

procedure.

Table

may

be

4-3

Trace

Dual

34-pin

AP

Intraconnector

Products

Relative

required to

perform

Maintenance Tools

(AVA

409

or

equivalent)

Oscilloscope

Adaptor

Part

Number 922576-34-1

Humidity Gauge

Hand Tools: Phillips Screwdrivers (M2.6 and

Flat

Blade Screwdriver (small and medium)

Set

Allen Wrench

(1.5mm

Tweezers, Needle Nose

flat)

Pliers

Soldering Iron and Solder

Fine Cleaning Brush

an inspection,

M3)

and Wire

Cutters

replace-

TS-021-013087

•••

01

4-2

Page 35

Table

4-3 Maintenance Tools (Continued)

D;.skettes:

(Recommended)

Maintenance Supplies:

Special

4.2 MAINTENANCE PRECAUTIONS

Ensure

Jig:

the

following precautions

Commercially available Work/Scratch

(M2552K

Commercially available Cleaning

(Dysan = 802944)

Read Level

Alignment

(M2552K = Dysan 206-31, M2553/54K = Dysan 206-34)

Anhydrous Alcohol (Ethyl Alcohol)

Cotton

Screw Lock Liquid

Epoxy Adhesive

Lubricating Oil (Kanto Kasel 946P, or equivalent)

Light Oil (Nippon Koyu HH-17,

MAX

Media Jig (Jig

are

Diskette

= Dysan 802067, M2553/54K = Dysan 802914)

Diskette

Diskette

Diskette

Gauze

or

equivalent)

D)

observed whenever working on

the

disk drive.

4.2.1 Screw Torque

Unless otherwise specified,

torque values listed in Table 4-4.

Screw Size

M3

4.2.2 Screw Lock

Use screw lock

1.

When

lock liquid

2. Before replacing a

three

as

speci fied below:

making an

off

the

threads.

adjustment,

setscrew

all

Table

M2

M2.6

M3

setscrew

setscrew

screws

4-4 Screw Size and Torque

and hole

are

tightened, according

Torque

11 Inch Pounds

24

Inch Pounds

33

Inch Pounds

24

Inch Pounds (4.5 Kilograms cm)

remove

(or any screw), apply screw lock liquid

the

holding

as

completely

(2

Kilograms cm)

(4.5

(6

Kilograms cm)

setscrew

as

possible.

to

their

Kilograms cm)

and

clean

size,

old

to

the

to

the

screw

first

3.

When

TS-021-013087

replacing a screw or

•••

01

setscrew,

tighten

4-3

it

to

the

designated torque.

Page 36

4.2.3. Handling Connectors

Handle connectors as speci fied below:

Off

Always turn power

Do not apply excessive

Remove/insert each connector

before inserting

force

to

the

by

or

removing a connector.

cable

pulling/pushing in a

or

post pin.

straight

manner.

4.2.4

Overall

Diskette

Set

Additional

Error

Perform

when inspecting, adjusting

not include

perform a window margin

Never use a

Jumper Selections

Set Drive

ble with

OSRSTR

.

MS

Ii

.

MM

Maintenance

Test

the Inspection and Adjustment procedures given in paragraph 4.4

data

Read/Write checks,

defective

Select

the

(DSO

test

system, as given below:

Precautions

or

replacing

test

to

work,

or

through

PC/AT

ensure

test

diskette

DS3)

and

CONfIGURATION

parts.

connect

data

Procedures in paragraph 4.4

the

drive

integrity.

during a maintenance

all

jumper selections

(MOVEABLE)

to a test

action.

to

system and

be

compati-

do

0--

JP3

.,4·1

OK1OK2

r:lIR

L:JIl:J

OM20M1

••

JP1

JP2

TS-021"{)13087

__

MOD

RI

~"

01

Figure 4-1A M2553K/5ltK Revision 2

++

-+--+-.J

~

______________

•••

01

J

Circuit

Card -Jumper

Locations

Page 37

Table

4-5A

M255JK/54K Revision 2

Circuit

Card

Jumper

Definitions

M255JK

and

M2554K M2554K M2554K M2554K

High

Density

Install

Open

Install

Open

Low

Density

Open Open Install

Install

Open

Open

Dual

Speed

Install

Open Open

Install

** ** **

(X)

Install

Install

(*) (*)

(*) (*)

DSO

Install

Install

(X) (X)

Install

Install

DSO

Install

Install

Install

Install

Install

Install

(*) (*)

(*)

DSO

** ** **

** ** **

Open

Open Open

Open Open

Install

(*)

Install

Install

(*)

(*) (*)

Install

Open Open

Install

Open Open

Open

Open

Install

Install Install

Install

Open Open

Open Open 300 Low

**

**

Install

(*)

(*)

Install

Open Open

Open

Install

** ** **

(*) (*)

Open Open

Open

Open

Open Open Open

Open Open Open

** **

Install

Install Install

** **

(*)

Open Open

**

**

** ** **

**

Install

Open

Open Open Open

**

Install

Open

**

Install

Open

M255JK

and

IBM

PC/AT

Open

Install LSP Density

Open In Use

Open

Install

Open

Open

DS1

Install

Open RY Ready

Open

Install

Open

Install

Open DSR Disk

Install

Open

Install

Install

Open DK2 Disk-in Sensor and Dynamic

Open

Install

Open

Open

Install

Open

Open

Open

Open

Install

Open DL1

Open DL2

Jumper

1 SP

2 SP

HD

HL

TD

MR

HM

HS

DSO-3

TM

DO

DC Disk

SM1

SM2

STR

MS

MM

JP3

DK1 Disk-in Sensor Enabled

DM2

DM1

MOD

DL Door Lock

JP4

JP1

JP2

RI

DI

LD

LC

LB

LA

Definition

360 RPM Only

Motor

in

High Density

LED

Head Load

Terminator

Pin 34

Head Load

Head Load

Drive

Terminator

Door Switch Ready

Densi

Densi

Disk

Motor on

Motor on wi

Motor always

Disabled

FWS3

FWS2

Motor-Off

Undefined

No

No

Index

Index

LED

LED

LED

LED

LED

and Head Load Ready

LED

In-use

speed

tandem

controlled

Lit

with

with

for

gated

with

with

Select

for

to

pi n 34

Change

Density

ty

and Speed

ty

and Speed

change

change

Active

Active

Index during

Read

gated

Gated

Lit

Lit

Lit

Lit

Lit

Lit

reset

reset

with

th

Delay

with

Data

with

with

with

with

with

with

with

with

Latch

and R/W

sense

pin 4

pin 4

Drive

with Drive

Motor-on

Drive

input

to

pin 34

300 RPM always

with

with

Drive

pin 16

on'

LD, LC,

Step

during

Pre

Drive

DL1

Drive

LED 0

Drive

Drive

Drive

and

Head

circuits

output

by

pin

Select

Select

Select

signal

to

pin 34

Control

Control

Drive

step

Select

LB

Step

Ready

Select

or

DL2

Select

Select

Select

Select

Load

changed

2

lines

Latched

Unlatched

Select

Clamping

or

LA

and

Ready'

or

Ready

TS-021·013087

•••

01

4-5

Page 38

DM1DM2

~

I

.•

OSRSTR

,

PCI

AT

CONFIGURATION

~K

• •

HS

HM

CFDCED)

0

0

0

0

~

i:

i=

D

i

c:=:J

i~

'

RI

FG

OS3

OS2

DS1

OSO

TM

Table

M2553K

IBM

PC/AT

Open

Shorted

DS1

Install

Shorted

Open

Open

Shorted DC Disk Change

Shorted RI Index

Open