Page 1

M2488 CARTRIDGE TAPE DRIVE

PRODUCT GUIDE

C144-E019-03EN

Page 2

Please complete the comment from at the back of this manual and send it by mail or facsimile to the

indicated address.

The contents of this manual may be revised without prior notice.

The contents of this manual shall not be disclosed in any way or reproduced in any media without the

express written permission of Fujitsu Limited.

All Rights Reserved, Copyright © FUJITSU LIMITED 1996, 1997

C144-E019-03EN

Page 3

M2488 USER’S GUIDE PREFACE

PREFACE

The M2488 User’s Guide provides the information necessary for the user to operate the M2488 Cartridge Tape Drive.

Chapter 1 Introduction

This chapter provides an overview of the M2488 Cartridge Tape Drive and its optional equipment.

Chapter 2 Installation Instructions

This chapter provides procedures for the preparation and assembly of the M2488 Cartridge Tape

Drive.

Chapter 3 Controls and Indicators

This chapter describes the controls, indicators and connectors for the M2488 Cartridge Tape Drive

and its optional equipment.

Chapter 4 Configuration

This chapter describes the configuration menus of the M2488 Cartridge Tape Drive.

Chapter 5 Operating Instructions

This chapter provides procedures for operating the M2488 Cartridge Tape Drive and its optional

equipment.

Chapter 6 Maintenance and Servicing

This chapter describes the user maintenance and servicing of the M2488 Cartridge Tape Drive.

Chapter 7 Parts List

This chapter describes the M2488 models and optional equipment available.

The ANSI X3.131-199x SCSI specification may be purchased from:

American National Standard Institute, Inc.

1430 Broadway, New York, N.Y. 10018

Tel. (212) 642-4900

SCSI-2 unreleased documentation X3B5/87-099 may be obtained from:

Global Engineering Documents

2805 McGaw

Irvine, CA 92714

CONVENTION

Hexadecimal numbers are denoted by an “h” following the number (e.g. 23h) or 0xNN.

Binary numbers are denoted by a “b” following the number (e.g. 001b).

C144-E019-03EN i

Page 4

Page 5

M2488 PRODUCT GUIDE TABLE OF CONTENTS

TABLE OF CONTENTS

CHAPTER TITLE PAGE

REVISION RECORD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

DIRECTORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

AGENCY STATEMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

PREFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

INFORMATION LOCATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

TABLE OF CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

LIST OF FIGURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

LIST OF TABLES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

1

INSTALLATION INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-2 PREPARING THE M2488 AND ITS OPTIONAL EQUIPMENT . . . . . . . . . . . . . . 1-1

1-3 CONFIGURATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-3.1 Rack-mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-3.2 Desktop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

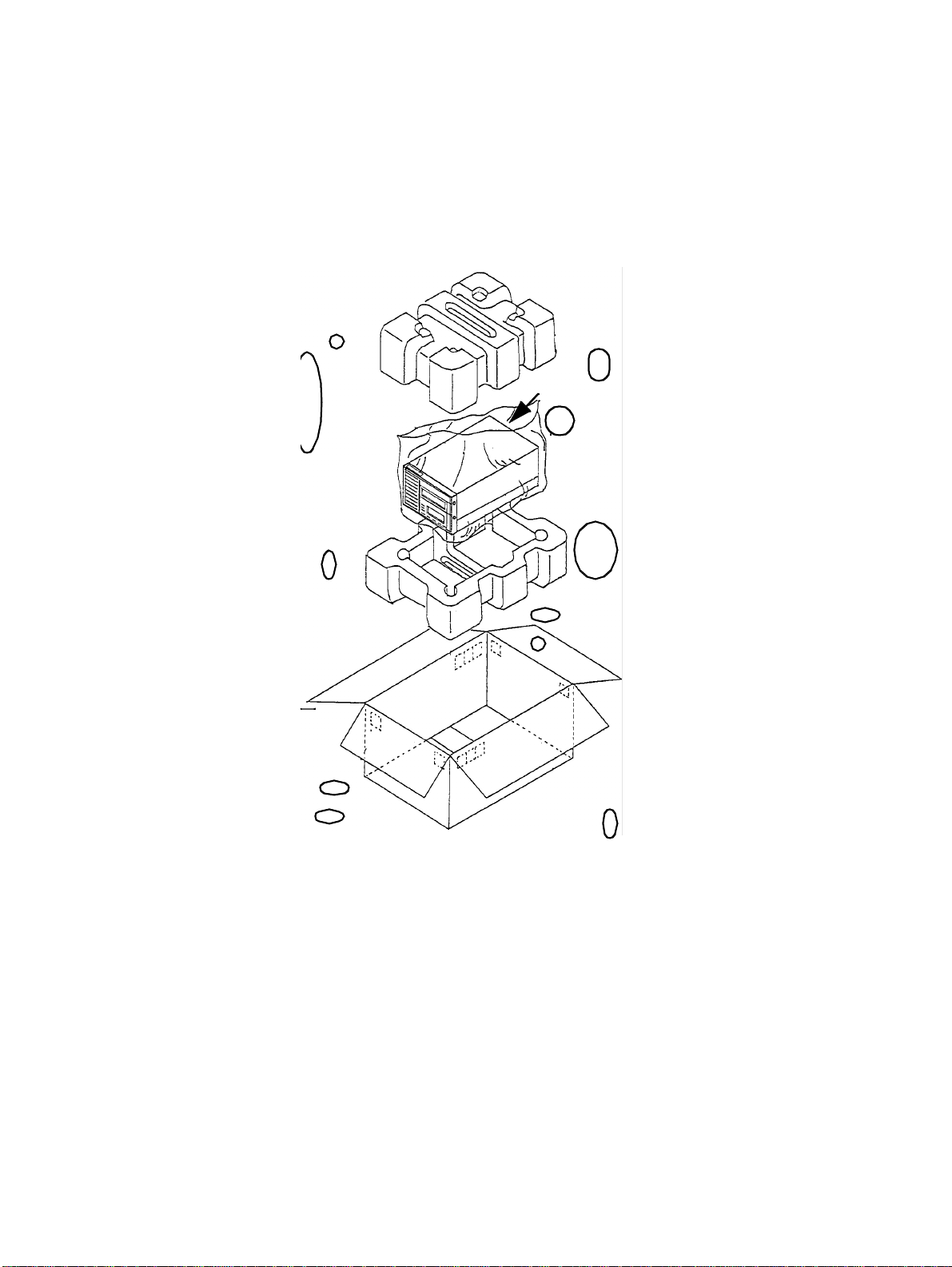

1-4 UNPACKING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-4.1 Unpack the M2488 Tape Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-4.2 Unpack the Automatic Cartridge Loader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-4.3 Unpack the Flush-mounted Automatic Cartridge Loader . . . . . . . . . . . . . . . . 1-6

1-5 EQUIPMENT INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-5.1 Inspect the M2488 Tape Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-5.2 Inspect the ACL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-5.3 Inspect the FACL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-6 ASSEMBLY INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1-6.1 General Installation and Assembly Instructions. . . . . . . . . . . . . . . . . . . . . . . . 1-9

1-6.1.1 Air Flow and Service Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1-6.2 Interface Personality Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1-6.3 Cable and Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1-6.4 Desktop Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1-6.4.1 Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1-6.4.2 Tape Drive Only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1-6.4.3 Drive with ACL Attached (5-Cartridge Magazine) . . . . . . . . . . . . . 1-11

1-6.4.4 Drive with ACL Attached (10-Cartridge Magazine) . . . . . . . . . . . . 1-12

1-6.4.5 Drive with FACL Attached . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1-6.5 Rack-Mount Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

1-6.5.1 Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

1-6.5.2 Adjust the Guide Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

1-6.5.2.1 Inner Cover Mounted to Mounting Tray. . . . . . . . . . . . 1-19

1-6.5.2.2 Inner Cover NOT Mounted to Mounting Tray . . . . . . . 1-19

1-6.5.3 Screw Plate Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

C144-E019-03EN iii

Page 6

TABLE OF CONTENTS M2488 PRODUCT GUIDE

TABLE OF CONTENTS - CONTINUED

CHAPTER TITLE PAGE

1-6.5.4 Attach Mounting Tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-20

1-6.5.5 Adjust the Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-22

1-6.5.6 Install the M2488 or M2488 with Medium Changer on the

Mounting Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-23

1-6.6 Installation of the Automatic Cartridge Loader. . . . . . . . . . . . . . . . . . . . . . . . .1-26

1-6.6.1 Prepare the M2488 Tape Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-27

1-6.6.2 Prepare the ACL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-28

1-6.6.3 Connect the M2488 and the ACL . . . . . . . . . . . . . . . . . . . . . . . . . . .1-29

1-6.7 Installation of the Flush-mount Automatic Cartridge Loader. . . . . . . . . . . . . .1-32

1-6.7.1 Prepare the M2488 Tape Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-33

1-6.7.2 Prepare the FACL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-34

1-6.7.3 Connect the M2488 and the FACL . . . . . . . . . . . . . . . . . . . . . . . . . .1-35

1-7 PREPARATION FOR USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-37

2

DESIGN ARCHITECTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2-1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2-2 OPERATION OF THE M2488. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2-3 OPERATION OF THE MAGNETIC TAPE CONTROLLER (MTC). . . . . . . . . . . . .2-2

2-3.1 Data Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2-3.2 Data Buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2-3.3 ERDC Compression Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2-3.4 Microprocessor Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2-3.5 Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2-4 OPERATION OF THE MAGNETIC TAPE UNIT (MTU) . . . . . . . . . . . . . . . . . . . . .2-4

2-4.1 Airless Tape Path. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2-4.2 Read and Write Electronics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

3

SCSI MESSAGES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3-1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3-2 M2488 TAPE AND MEDIUM CHANGER SCSI MESSAGES. . . . . . . . . . . . . . . . .3-1

3-2.1 ABORT code 06h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3-2.2 BUS DEVICE RESET code 0Ch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3-2.3 COMMAND COMPLETE code 00h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3-2.4 DISCONNECT code 04h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3-2.5 EXTENDED MESSAGE FORMAT code 01h. . . . . . . . . . . . . . . . . . . . . . . . .3-3

3-2.5.1 Synchronous Data Transfer Request (SDTR) . . . . . . . . . . . . . . . . . .3-3

3-2.5.2 Wide Data Transfer Request (WDTR) . . . . . . . . . . . . . . . . . . . . . . .3-5

3-2.6 IDENTIFY code 80h-FFh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

3-2.7 IGNORE WIDE RESIDUE code 23h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

3-2.8 INITIATOR DETECTED ERROR code 05h . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

3-2.9 LINKED COMMAND COMPLETE code 0Ah . . . . . . . . . . . . . . . . . . . . . . . .3-8

iv C144-E019-03EN

Page 7

M2488 PRODUCT GUIDE TABLE OF CONTENTS

TABLE OF CONTENTS - CONTINUED

CHAPTER TITLE PAGE

3-2.10 LINKED COMMAND COMPLETE (WITH FLAG) code 0Bh. . . . . . . . . . 3-8

3-2.11 MESSAGE PARITY ERROR code 09h . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3-2.12 MESSAGE REJECT code 07h. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3-2.13 NO OPERATION code 08h. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3-2.14 RESTORE POINTERS code 03h. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3-2.15 SAVE DATA POINTER code 02h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3-3 SCSI BUS STATUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3-3.1 Good Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3-3.2 Check Condition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3-3.3 Busy Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3-3.4 Intermediate Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3-3.5 Reservation Conflict Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

4

TAPE UNIT SCSI COMMANDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2 LOGICAL UNITS AND SCSI IDS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2.1 Target ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2.2 Initiator ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2.3 Tape LUN 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2.4 Media Changer LUN 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2.5 LUN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-3 M2488 TAPE SCSI COMMANDS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4-3.1 Command Description Block Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4-3.2 CHANGE DEFINITION command 40h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4-3.2.1 CHANGE DEFINITION CDB Description. . . . . . . . . . . . . . . . . . . 4-5

4-3.2.2 CHANGE DEFINITION Changes. . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4-3.2.3 CHANGE DEFINITION CHECK CONDITION Status . . . . . . . . . 4-7

4-3.2.4 CHANGE DEFINITION Sense Keys . . . . . . . . . . . . . . . . . . . . . . . 4-7

4-3.3 DISPLAY command CFh (11h). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4-3.3.1 DISPLAY CDB Description (11h). . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4-3.3.2 Display Data (11h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4-3.3.3 DISPLAY Sense Keys (11h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4-3.4 DISPLAY command CFh (10h). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4-3.4.1 DISPLAY CDB Description (10h). . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4-3.4.2 Display Data (10h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4-3.4.3 DISPLAY Sense Keys (10h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4-3.5 ERASE command 19h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4-3.5.1 ERASE CDB Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4-3.5.2 ERASE Sense Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4-3.6 INQUIRY command 12h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

4-3.6.1 INQUIRY CDB Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

4-3.6.2 INQUIRY CHECK CONDITION Status. . . . . . . . . . . . . . . . . . . . . 4-19

C144-E019-03EN v

Page 8

TABLE OF CONTENTS M2488 PRODUCT GUIDE

TABLE OF CONTENTS - CONTINUED

CHAPTER TITLE PAGE

4-3.6.3 Inquiry Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

4-3.6.4 INQUIRY Sense Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-24

4-3.7 LOAD UNLOAD command 1Bh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

4-3.7.1 LOAD UNLOAD CDB Description . . . . . . . . . . . . . . . . . . . . . . . . .4-25

4-3.7.2 LOAD UNLOAD CHECK CONDITION Status . . . . . . . . . . . . . . .4-26

4-3.7.3 LOAD UNLOAD Sense Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

4-3.8 LOCATE command 2Bh. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-28

4-3.8.1 LOCATE CDB Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-28

4-3.8.2 LOCATE CHECK CONDITION Status. . . . . . . . . . . . . . . . . . . . . .4-31

4-3.8.3 LOCATE Sense Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-31

4-3.9 LOG SELECT command 4Ch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-32

4-3.9.1 LOG SELECT CDB Description. . . . . . . . . . . . . . . . . . . . . . . . . . . .4-32

4-3.9.2 LOG SELECT CHECK CONDITION Status. . . . . . . . . . . . . . . . . .4-32

4-3.10 LOG SENSE command 4Dh. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-33

4-3.10.1 LOG SENSE CDB Description. . . . . . . . . . . . . . . . . . . . . . . . . . . .4-33

4-3.10.2 LOG SENSE Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-34

4-3.10.3 LOG SENSE Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-35

4-3.10.3.1 Log Sense Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-37

4-3.10.4 LOG SENSE Sense Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-48

4-3.11 LOOP WRITE TO READ command C1h. . . . . . . . . . . . . . . . . . . . . . . . . . . .4-49

4-3.11.1 LOOP WRITE TO READ CDB Description . . . . . . . . . . . . . . . . .4-49

4-3.11.2 LOOP WRITE TO READ CHECK CONDITION Status . . . . . . .4-50

4-3.11.3 LOOP WRITE TO READ Sense Keys . . . . . . . . . . . . . . . . . . . . . .4-50

4-3.12 MODE SELECT command 15h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-51

4-3.12.1 MODE SELECT CDB Description. . . . . . . . . . . . . . . . . . . . . . . . .4-51

4-3.12.2 Mode Select Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-52

4-3.12.3 MODE SELECT Sense Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-55

4-3.13 MODE SENSE command 1Ah . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-56

4-3.13.1 MODE SENSE CDB Description . . . . . . . . . . . . . . . . . . . . . . . . . .4-56

4-3.13.2 Mode Sense Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-57

4-3.13.3 Mode Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-60

4-3.13.4 Initiator Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-60

4-3.13.5 MODE SENSE Sense Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-62

4-3.14 READ command 08h. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-63

4-3.14.1 READ CDB Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-63

4-3.14.2 READ CHECK CONDITION Status . . . . . . . . . . . . . . . . . . . . . . .4-64

4-3.14.3 READ Sense Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-66

4-3.15 READ BLOCK LIMITS command 05h . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-68

4-3.15.1 READ BLOCK LIMITS CDB Description. . . . . . . . . . . . . . . . . . .4-68

4-3.15.2 READ BLOCK LIMITS Sense Keys . . . . . . . . . . . . . . . . . . . . . . .4-69

4-3.16 READ BUFFER command 3Ch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-70

4-3.16.1 READ BUFFER CDB Description . . . . . . . . . . . . . . . . . . . . . . . . .4-70

vi C144-E019-03EN

Page 9

M2488 PRODUCT GUIDE TABLE OF CONTENTS

TABLE OF CONTENTS - CONTINUED

CHAPTER TITLE PAGE

4-3.16.2 READ BUFFER Sense Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-74

4-3.17 READ POSITION command 34h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-75

4-3.17.1 READ POSITION CDB Description. . . . . . . . . . . . . . . . . . . . . . . 4-75

4-3.17.2 READ POSITION Return Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-76

4-3.17.3 Description of Block ID Format. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-78

4-3.17.4 READ POSITION Sense Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-79

4-3.18 READ REVERSE command 0Fh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-80

4-3.18.1 READ REVERSE CDB Description . . . . . . . . . . . . . . . . . . . . . . . 4-80

4-3.18.2 READ REVERSE CHECK CONDITION Status . . . . . . . . . . . . . 4-81

4-3.18.3 READ REVERSE Sense Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-82

4-3.19 RECEIVE DIAGNOSTIC RESULTS command 1Ch. . . . . . . . . . . . . . . . . . 4-83

4-3.19.1 RECEIVE DIAGNOSTIC RESULTS CDB Description. . . . . . . . 4-83

4-3.19.2 Diagnostic Page Codes (PF=1 in SEND DIAGNOSTIC

command CDB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-85

4-3.19.3 Diagnostic Parameter List (PF=0 in SEND DIAGNOSTIC

command CDB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-87

4-3.19.4 RECEIVE DIAGNOSTIC RESULTS CHECK CONDITION

Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-87

4-3.19.5 RECEIVE DIAGNOSTIC RESULTS Sense Keys . . . . . . . . . . . . 4-88

4-3.20 RECEIVE DIAGNOSTIC RESULTS (FACTORY MODE) command 1Ch 4-89

4-3.20.1 RECEIVE DIAGNOSTIC RESULTS (FACTORY MODE)

CDB Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-89

4-3.20.2 Diagnostic Page Codes (PF=1 in SEND DIAGNOSTIC

command CDB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-91

4-3.20.3 Diagnostic Parameter List (PF=0 in SEND DIAGNOSTIC

command CDB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-96

4-3.20.4 RECEIVE DIAGNOSTIC RESULTS CHECK CONDITION

Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-96

4-3.20.5 RECEIVE DIAGNOSTIC RESULTS Sense Keys . . . . . . . . . . . . 4-97

4-3.21 RECOVER BUFFERED DATA command 14h . . . . . . . . . . . . . . . . . . . . . . 4-98

4-3.21.1 RECOVER BUFFERED DATA CDB Description. . . . . . . . . . . . 4-98

4-3.21.2 RECOVER BUFFERED DATA Operation. . . . . . . . . . . . . . . . . . 4-99

4-3.21.3 RECOVER BUFFERED DATA CHECK CONDITION Status . . 4-99

4-3.21.4 RECOVER BUFFERED DATA Sense Keys . . . . . . . . . . . . . . . . 4-100

4-3.22 RELEASE UNIT command 17h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-101

4-3.22.1 RELEASE UNIT CDB Description. . . . . . . . . . . . . . . . . . . . . . . . 4-101

4-3.22.2 RELEASE UNIT Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-102

4-3.22.3 RELEASE UNIT Sense Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-102

4-3.23 REQUEST SENSE command 03h. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-103

4-3.23.1 REQUEST SENSE CDB Description . . . . . . . . . . . . . . . . . . . . . . 4-103

4-3.23.2 REQUEST SENSE CHECK CONDITION Status . . . . . . . . . . . . 4-103

4-3.23.3 REQUEST SENSE Sense Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-104

4-3.24 Report Density Support command 44h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-105

C144-E019-03EN vii

Page 10

TABLE OF CONTENTS M2488 PRODUCT GUIDE

TABLE OF CONTENTS - CONTINUED

CHAPTER TITLE PAGE

4-3.24.1 REPORT DENSITY SUPPORT CDB Description . . . . . . . . . . . .4-105

4-3.24.2 REPORT DENSITY SUPPORT Data. . . . . . . . . . . . . . . . . . . . . . .4-106

4-3.24.3 REPORT DENSITY SUPPORT Sense Keys . . . . . . . . . . . . . . . . .4-111

4-3.25 RESERVE UNIT command 16h. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-112

4-3.25.1 RESERVE UNIT CDB Description . . . . . . . . . . . . . . . . . . . . . . . .4-112

4-3.25.2 RESERVE UNIT Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-113

4-3.25.3 RESERVE UNIT Sense Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-114

4-3.26 REWIND command 01h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-115

4-3.26.1 REWIND CDB Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-115

4-3.26.2 REWIND CHECK CONDITION Status. . . . . . . . . . . . . . . . . . . . .4-115

4-3.26.3 REWIND Sense Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-116

4-3.27 SEND DIAGNOSTIC command 1Dh. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-117

4-3.27.1 SEND DIAGNOSTIC CDB Description. . . . . . . . . . . . . . . . . . . . .4-117

4-3.27.2 SEND DIAGNOSTIC CHECK CONDITION Status. . . . . . . . . . .4-119

4-3.27.3 Diagnostic Pages (PF=1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-119

4-3.27.4 Diagnostic Parameter List (PF=0). . . . . . . . . . . . . . . . . . . . . . . . . .4-122

4-3.27.5 SEND DIAGNOSTIC Sense Keys . . . . . . . . . . . . . . . . . . . . . . . . .4-123

4-3.28 SEND DIAGNOSTIC (FACTORY MODE) command 1Dh . . . . . . . . . . . . .4-124

4-3.28.1 SEND DIAGNOSTIC CDB Description. . . . . . . . . . . . . . . . . . . . .4-124

4-3.28.2 SEND DIAGNOSTIC (FACTORY MODE) CHECK

CONDITION Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-126

4-3.28.3 Diagnostic Pages (PF=1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-126

4-3.28.4 Diagnostic Parameter List (PF=0). . . . . . . . . . . . . . . . . . . . . . . . . .4-132

4-3.28.5 SEND DIAGNOSTIC Sense Keys . . . . . . . . . . . . . . . . . . . . . . . . .4-134

4-3.29 SPACE command 11h. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-135

4-3.29.1 SPACE CDB Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-135

4-3.29.2 SPACE CHECK CONDITION Status . . . . . . . . . . . . . . . . . . . . . .4-136

4-3.29.3 SPACE Sense Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-137

4-3.30 TEST UNIT READY command 00h. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-138

4-3.30.1 TEST UNIT READY CDB Description . . . . . . . . . . . . . . . . . . . . .4-138

4-3.30.2 TEST UNIT READY CHECK CONDITION Status . . . . . . . . . . .4-138

4-3.30.3 TEST UNIT READY Sense Keys. . . . . . . . . . . . . . . . . . . . . . . . . .4-139

4-3.31 WRITE command 0Ah . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-140

4-3.31.1 WRITE CDB Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-140

4-3.31.2 WRITE CHECK CONDITION Status . . . . . . . . . . . . . . . . . . . . . .4-140

4-3.31.3 WRITE Sense Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-143

4-3.32 WRITE BUFFER command 3Bh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-144

4-3.32.1 WRITE BUFFER CDB Description . . . . . . . . . . . . . . . . . . . . . . . .4-144

4-3.32.2 WRITE BUFFER CHECK CONDITION Status . . . . . . . . . . . . . .4-148

4-3.32.3 WRITE BUFFER Sense Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-149

4-3.33 WRITE FILEMARKS command 10h. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-150

4-3.33.1 WRITE FILEMARKS CDB Description . . . . . . . . . . . . . . . . . . . .4-150

viii C144-E019-03EN

Page 11

M2488 PRODUCT GUIDE TABLE OF CONTENTS

TABLE OF CONTENTS - CONTINUED

CHAPTER TITLE PAGE

4-3.33.2 WRITE FILEMARKS CHECK CONDITION Status. . . . . . . . . . 4-151

4-3.33.3 WRITE FILEMARKS Sense Keys . . . . . . . . . . . . . . . . . . . . . . . . 4-152

4-4 COMMAND DISCONNECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-153

4-5 SCSI RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-153

5

TAPE UNIT PARAMETERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2 ADDITIONAL COMMAND INFORMATION ON MTU MODE SELECT AND

MODE SENSE COMMANDS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2.1 The Parameters Savable Bit (All pages). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2.2 Vendor Unique Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-2.3 Error Recovery and Reporting Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5-2.4 Disconnect/Reconnect Control Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5-2.5 Common Device-Type Control Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5-2.6 Device Configuration Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5-2.7 Density Code 28h. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

5-2.7.1 M2488 Operation When Density Code 28h Is Not Configured. . . . 5-15

5-2.7.2 M2488 Operation When Density Code 28h Is Configured . . . . . . . 5-15

5-3 MTU INQUIRY/CHANGE DEFINITION VITAL PRODUCT DATA PAGES. . . . 5-17

5-3.1 General VPD Page Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5-3.2 Supported VPD Pages - Page 00h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5-3.3 Unit Serial Number Page - Page 80h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5-3.4 Implemented Operating Definition Page - Page 81h . . . . . . . . . . . . . . . . . . . . 5-20

5-3.5 ASCII Implemented Operating Definition Page - Page 82h . . . . . . . . . . . . . . 5-21

5-3.6 Unit Usage Page - Page C0h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5-3.7 Configuration Page - Page C1h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

5-3.8 Product Identification Page - Page C2h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

6

MEDIA CHANGER SCSI COMMANDS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-2 MEDIA CHANGER COMMANDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-2.1 EXCHANGE MEDIUM MC command A6h. . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-2.1.1 EXCHANGE MEDIUM CDB Description . . . . . . . . . . . . . . . . . . . 6-2

6-2.1.2 Exchange Medium Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6-2.1.3 EXCHANGE MEDIUM Sense Keys. . . . . . . . . . . . . . . . . . . . . . . . 6-4

6-2.2 MODE SELECT MC command 15h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6-2.2.1 MODE SELECT CDB Description . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6-2.2.2 MODE SELECT CHECK CONDITION Status . . . . . . . . . . . . . . . 6-8

6-2.2.3 MODE SELECT Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6-2.2.4 MODE SELECT MC Sense Keys . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

6-2.3 MODE SENSE MC command 1Ah. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

C144-E019-03EN ix

Page 12

TABLE OF CONTENTS M2488 PRODUCT GUIDE

TABLE OF CONTENTS - CONTINUED

CHAPTER TITLE PAGE

6-2.3.1 MODE SENSE CDB Description . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

6-2.3.2 MODE SENSE Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

6-2.3.3 MODE SENSE MC Sense Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

6-2.4 MOVE MEDIUM MC command A5h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

6-2.4.1 MOVE MEDIUM CDB Description. . . . . . . . . . . . . . . . . . . . . . . . .6-16

6-2.4.2 ACL/FACL Tables of Allowed Moves. . . . . . . . . . . . . . . . . . . . . . .6-17

6-2.4.3 MOVE MEDIUM Sense Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-18

6-2.5 READ ELEMENT STATUS MC command B8h. . . . . . . . . . . . . . . . . . . . . . .6-19

6-2.5.1 READ ELEMENT STATUS CDB Description . . . . . . . . . . . . . . . .6-19

6-2.5.2 READ ELEMENT STATUS Data . . . . . . . . . . . . . . . . . . . . . . . . . .6-21

6-2.5.2.1 Element Status Data . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22

6-2.5.2.2 Element Status Page . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-23

6-2.5.2.3 Element Descriptors . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-24

6-2.5.3 Source and Destination Elements . . . . . . . . . . . . . . . . . . . . . . . . . . .6-29

6-2.5.4 READ ELEMENT STATUS Sense Keys. . . . . . . . . . . . . . . . . . . . .6-29

6-2.6 TEST UNIT READY MC command 00h . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-30

6-2.6.1 TEST UNIT READY CDB Description . . . . . . . . . . . . . . . . . . . . . .6-30

6-2.6.2 TEST UNIT READY CHECK CONDITION Status . . . . . . . . . . . .6-30

6-2.6.3 TEST UNIT READY Sense Keys. . . . . . . . . . . . . . . . . . . . . . . . . . .6-31

6-3 ADDITIONAL COMMAND INFORMATION ON MEDIUM CHANGER

MODE SELECT AND MODE SENSE COMMANDS . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-32

6-3.1 Page Code 00h, Device Unique Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . .6-32

6-3.2 Page Code 1Dh, Element Address Assignments. . . . . . . . . . . . . . . . . . . . . . . .6-35

6-3.3 Page Code 1Eh, Transport Geometry Parameters. . . . . . . . . . . . . . . . . . . . . . .6-37

6-3.4 Page Code 1Fh, Device Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-38

6-4 MC (MEDIUM CHANGER) INQUIRY/CHANGE DEFINITION

VITAL PRODUCT DATA PAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-41

6-4.1 General VPD Page Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-41

6-4.2 Supported VPD Pages - Page 00h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-42

6-4.3 Implemented Operating Definition Page 81h . . . . . . . . . . . . . . . . . . . . . . . . . .6-43

6-4.4 ASCII Implemented Operating Definition Page 82h. . . . . . . . . . . . . . . . . . . . .6-44

6-4.5 Product Identification Page C2h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-45

7

TAPE PROCESSING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7-1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7-2 CHANGING MODE PARAMETERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7-2.1 Initiator Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7-3 PERMANENT ERROR HANDLING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7-3.1 PERMANENT WRITE ERROR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7-3.2 PERMANENT READ ERROR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

x C144-E019-03EN

Page 13

M2488 PRODUCT GUIDE TABLE OF CONTENTS

TABLE OF CONTENTS - CONTINUED

CHAPTER TITLE PAGE

8

MAINTENANCE AND SERVICING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8-1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8-2 OPERATOR PANEL DISPLAYED ERROR MESSAGES. . . . . . . . . . . . . . . . . . . . 8-1

8-2.1 OZONE:xxxxyyyy <text> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8-2.2 NVRAM Initialization Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8-2.3 CHK XX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8-2.4 Diagnostic Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8-2.4.1 Operator Panel Error Code Display . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8-2.4.2 Maintenance Terminal Error Code Display . . . . . . . . . . . . . . . . . . . 8-3

8-3 SENSE DATA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8-3.1 Error Code Sense Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8-3.2 Sense Information Bytes 20-43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

8-3.2.1 Format 0 Sense Information Description for SIC. . . . . . . . . . . . . . . 8-9

8-3.2.2 Format 01h Sense Information for FMT . . . . . . . . . . . . . . . . . . . . . 8-9

8-3.2.3 Description of Format 01h Sense Information for Drive. . . . . . . . . 8-11

8-3.2.4 Format 2 and 3 Sense Information, Hardware Registers . . . . . . . . . 8-13

8-3.2.5 Format 4 Sense Information for Diagnostic Errors . . . . . . . . . . . . . 8-15

8-4 DIAGNOSTICS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

8-4.1 Go/No-Go Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

8-4.2 Off-Line Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

8-4.3 MTU Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

8-4.3.1 Off-Line Diagnostic Menu on the Operator Panel. . . . . . . . . . . . . . 8-19

8-4.3.2 Off-Line Diagnostic Menu through the Remote Maintenance

(RS-232) Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

8-4.4 Types of Diagnostic Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

8-4.4.1 Tasked Go/No-Go Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

8-4.4.2 Off-Line Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-25

8-4.4.3 In-line Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-25

8-4.5 Diagnostic Test Registry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-27

8-4.6 Diagnostic Microcode Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-27

8-5 FACTORY SETTINGS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28

8-6 ERROR RECOVERY PROCEDURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-30

8-6.1 EDRC Error Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-30

8-6.2 Retry Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-30

8-7 MAINTENANCE TERMINAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-33

8-7.1 Maintenance Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-33

8-7.2 Remote Debug for JDB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-34

8-7.2.1 M2488 Side (Remote) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-34

8-7.2.1.1 Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-34

8-7.2.1.2 Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-34

8-8 PREVENTIVE MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-35

C144-E019-03EN xi

Page 14

TABLE OF CONTENTS M2488 PRODUCT GUIDE

TABLE OF CONTENTS - CONTINUED

CHAPTER TITLE PAGE

8-9 TAPE PATH CLEANING PROCEDURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-35

8-10 MANUAL TAPE REMOVAL PROCEDURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-36

8-10.1 Cartridge Tape Stopped During Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-36

8-10.2 Tape Stopped During Threading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-37

8-10.3 Tape Wound on Take-up Reel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-37

8-11 REMOVE AND REPLACE PROCEDURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-38

8-11.1 Air Filter Remove and Replace Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . .8-43

8-11.1.1 Air Filter Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-43

8-11.1.2 Air Filter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-43

8-11.2 Fan Assembly Remove and Replace Procedures. . . . . . . . . . . . . . . . . . . . . . .8-44

8-11.2.1 Fan Assembly Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-44

8-11.2.2 Fan Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-44

8-11.3 IPM Remove and Replace Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-45

8-11.3.1 IPM Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-45

8-11.3.2 IPM Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-45

8-11.4 Top Cover Remove and Replace Procedures . . . . . . . . . . . . . . . . . . . . . . . . .8-46

8-11.4.1 Top Cover Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-46

8-11.4.2 Top Cover Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-46

8-11.5 Bottom Cover Remove and Replace Procedures. . . . . . . . . . . . . . . . . . . . . . .8-47

8-11.5.1 Bottom Cover Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-47

8-11.5.2 Bottom Cover Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-47

8-11.6 DTC PCBA Remove and Replace Procedures . . . . . . . . . . . . . . . . . . . . . . . .8-48

8-11.6.1 DTC PCBA Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-48

8-11.6.2 DTC PCBA Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-48

8-11.7 Threader Assembly Remove and Replace Procedures . . . . . . . . . . . . . . . . . .8-50

8-11.7.1 Threader Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-50

8-11.7.2 Threader Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . . . .8-50

8-11.8 Loader Assembly Remove and Replace Procedures. . . . . . . . . . . . . . . . . . . .8-51

8-11.8.1 Loader Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-51

8-11.8.2 Loader Assembly Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . .8-51

8-11.9 OP PCA Remove and Replace Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . .8-52

8-11.9.1 OP PCA Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-52

8-11.9.2 OP PCA Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-52

8-11.10 Power Supply (PSU) Remove and Replace Procedures.. . . . . . . . . . . . . . . .8-53

8-11.10.1 Power Supply Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-53

8-11.10.2 Power Supply Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-53

8-11.11 SVL PCBA Remove and Replace Procedures. . . . . . . . . . . . . . . . . . . . . . . .8-54

8-11.11.1 SVL PCBA Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-54

8-11.11.2 SVL PCBA Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-54

8-11.12 RDL PCBA Remove and Replace Procedures . . . . . . . . . . . . . . . . . . . . . . .8-54

8-11.12.1 RDL PCBA Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-54

8-11.12.2 RDL PCBA Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-54

xii C144-E019-03EN

Page 15

M2488 PRODUCT GUIDE TABLE OF CONTENTS

TABLE OF CONTENTS - CONTINUED

CHAPTER TITLE PAGE

8-11.13 WTL PCBA Remove and Replace Procedures . . . . . . . . . . . . . . . . . . . . . . 8-55

8-11.13.1 WTL PCBA Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-55

8-11.13.2 WTL PCBA Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-55

9

PARTS REPLACEMENT CATALOG. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9-1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9-2 FIELD REPLACEABLE UNITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

A

SENSE KEYS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

B

ASC/ASCQ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

C

ERPA CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

D

FAULT SYMPTOM CODES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

E

CHK XX ERROR CODES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

E-1 CHK XX ERROR CODE DESCRIPTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

E-2 CHK XX ERROR CODE REPLACEMENT ACTIONS . . . . . . . . . . . . . . . . . . . . . . E-7

F

DIAGNOSTIC TESTS AND ERROR CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

G

SUPPORTED SCSI TRANSFER RATES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-1

H

MTU DIAGNOSTIC SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-1

H-1 OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-1

H-2 HOW TO EXECUTE THE DIAG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-1

H-2.1 SCSI interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-1

H-2.2 RS-232C interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-1

H-2.3 How to execute the DIAG for the MTU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-1

H-3 M2488 DIAG STRUCTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-1

H-4 MTU DIAG PARAMETER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-3

H-4.1 DIAG activation parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-3

H-4.2 Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-3

H-4.3 DIAG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-4

H-4.3.1 READ/WRITE: Ten diagnostic tests to check read and write. . . . H-4

C144-E019-03EN xiii

Page 16

TABLE OF CONTENTS M2488 PRODUCT GUIDE

TABLE OF CONTENTS - CONTINUED

CHAPTER TITLE PAGE

H-4.3.2 LOAD/UNLOAD: Two diagnostic tests to check loading and

unloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-5

H-4.3.3 ACL TEST: Two diagnostic tests to check the autoloader . . . . . . .H-6

H-4.3.4 TESTMODE: Diagnostic test to measure operations . . . . . . . . . . .H-6

H-4.3.4.1 M1:LOAD: Cartridge loading time measurement . . . .H-7

H-4.3.4.2 M2:TPPFM: Measure the tape acceleration/

deceleration time.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-7

H-4.3.4.3 M3:AC/PS: Measure the tape access/positioning time.H-7

H-4.3.4.4 M4:MODCH: Mode change time measurement. . . . . .H-7

H-4.3.4.5 M5:LOCAT: Tape locating time measurement . . . . . .H-8

H-4.3.4.6 M6:REWND: Tape rewinding time measurement . . . .H-8

H-4.3.4.7 M7:D.S.E: DSE time measurement . . . . . . . . . . . . . . .H-8

H-4.3.4.8 M8:UNLD: Cartridge unloading time measurement . .H-8

H-4.3.4.9 M9:CLEAN: Cleaning time measurement . . . . . . . . . .H-8

H-4.4 COMBINATION : Running test by combining up to ten commands . . . . . . .H-9

H-4.5 Error reset command ------- CMD CD : 0x70 or 0xF0 . . . . . . . .H-9

H-5 PARAMETER LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-10

H-6 DIAG RESULT DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-21

I

FLOWCHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-1

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Index-1

xiv C1 44-E019- 03EN

Page 17

M2488 PRODUCT GUIDE LIST OF FIGURES

LIST OF FIGURES

FIGURE TITLE PAGE

Figure 1-1. IPM Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Figure 1-2. Cable and Power Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Figure 1-3. Drive with ACL (5-cartridge) Desktop Configuration . . . . . . . . . . . . . . . . . . . . . 1-11

Figure 1-4. Attaching Bases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Figure 1-5. Stability Brackets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Figure 1-6. Drive Placement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Figure 1-7. Drive Positioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Figure 1-8. Rear Bracket Attachment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Figure 1-9. M2488 with FACL in Desktop Model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Figure 1-10. Attach to Bottom Base. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Figure 1-11. Desktop Model Top Covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Figure 1-12. Desktop Model Rear Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Figure 1-13. Guide Plate Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Figure 1-14. 19-inch Rack-mount Kit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Figure 1-15. Bracket Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Figure 1-16. M2488 Tray Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Figure 1-17. M2488 with ACL Tray Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Figure 1-18. Mount FACL to Inner Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Figure 1-19. FACL Face Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Figure 1-20. Prepare the M2488 Tape Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

Figure 1-21. Prepare the ACL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

Figure 1-22. Connect the M2488 and the ACL Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

Figure 1-23. Attach Operator Panel Cable to ACL Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

Figure 1-24. Attach the ACL Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

Figure 1-25. Replace Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

Figure 1-26. Prepare the M2488 Tape Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

Figure 1-27. Prepare the FACL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-34

Figure 1-28. FACL Rear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

Figure 1-29. Connect the M2488 and the FACL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

Figure 1-30. Cable Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

Figure 1-31. Replace Top Covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-37

Figure 2-1. M2488 Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Figure 2-2. DTC PCA Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-3. DVL PCA Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Figure 8-1. Help Information Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

Figure 8-2. EDRC Retry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-32

Figure 8-3. Maintenance Connector (M2488) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-33

Figure 8-1. Tape Path Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-35

Figure 8-2. Interconnect Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-41

Figure 8-3. Air Filter Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-43

Figure 8-4. Fan Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-44

Figure 8-5. IPM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-45

C144-E019-03EN xv

Page 18

LIST OF FIGURES M2488 PRODUCT GUIDE

LIST OF FIGURES - CONTINUED

FIGURE TI TLE PAGE

Figure 8-6. Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-46

Figure 8-7. Bottom Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-47

Figure 8-8. DTC PCBA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-49

Figure 8-9. Threader Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-50

Figure 8-10. Loader Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-51

Figure 8-11. OP PCBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-52

Figure 8-12. PSU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-53

Figure 8-13. WTL PCBA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-55

Figure 9-1. M2488 Tape Drive FRUs (Top Side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-2

Figure 9-2. M2488 Tape Drive FRUs (Bottom Side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-3

Figure 9-3. DTC PCBA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-4

Figure 9-4. IPM PCBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-4

Figure 9-5. RDL PCBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-5

Figure 9-6. SVL PCBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-5

Figure 9-7. WTL PCBA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-6

Figure 9-8. DVL PCBA (Reference Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-6

Figure I-1. Operator Panel Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-2

Figure I-2. RUN COMB Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-3

Figure I-3. RUN ACL Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-3

Figure I-4. LIST ERROR Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-4

Figure I-5. RS-232 Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-4

Figure I-6. SETTING Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-5

Figure I-7. LOAD CODE Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-6

Figure I-8. INQUIRY Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-6

Figure I-9. MODE PAGES Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-7

Figure I-10. FACTORY Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-8

Figure I-11. 81:FSGRP Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-8

xvi C144-E019-03EN

Page 19

M2488 PRODUCT GUIDE LIST OF TABLES

LIST OF TABLES

TABLE TITLE PAGE

Table 1-1. Rack-mount Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Table 1-2. Desktop Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Table 1-3. Equipment and Tools Required for ACL Installation . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Table 1-4. Equipment and Tools Required for FACL Installation. . . . . . . . . . . . . . . . . . . . . . . 1-32

Table 3-1. M2488 SCSI Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Table 3-2. Ignore Field Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Table 3-3. Status Byte. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Table 3-4. Status Byte Code Bit Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Table 4-1. M2488 SCSI Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Table 4-2. CDB Field Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Table 4-3. CHANGE DEFINITION Field Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Table 4-4. Definition Parameter Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Table 4-5. DISPLAY Field Description (11h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Table 4-6. DISPLAY Parameter (11h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Table 4-7. Display Parameter Field Description (11h). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Table 4-8. Display Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Table 4-9. Display Mode Selection Bits (11h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Table 4-10. DISPLAY Field Description (10h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Table 4-11. Display Format Control Byte Description (10h). . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Table 4-12. DISPLAY Parameter (10h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Table 4-13. Display Mode Selection Bits (10h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Table 4-14. ERASE Field Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Table 4-15. INQUIRY Field Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Table 4-16. EVPD Bit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Table 4-17. Supported VPD Page Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Table 4-18. INQUIRY Data Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Table 4-19. INQUIRY Data Format Field Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Table 4-20. Peripheral Qualifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Table 4-21. Peripheral Device Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Table 4-22. Possible Peripheral Qualifier and Device Types Generated . . . . . . . . . . . . . . . . . . . 4-23

Table 4-23. Default Vendor and Product Identification Fields. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Table 4-24. LOAD UNLOAD Field Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Table 4-25. LOCATE Field Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Table 4-26. Block ID Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Table 4-27. Block ID Format Field Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Table 4-28. Format Mode Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Table 4-29. LOG SELECT Field Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Table 4-30. LOG SENSE Field Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Table 4-31. Page Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Table 4-32. Log Page Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Table 4-33. Log Parameter Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Table 4-34. LOG Parameter Field Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

C144-E019-03EN xvii

Page 20

LIST OF TABLES M2488 PRODUCT GUIDE

LIST OF TABLES -CONTINUED

TABLE TITLE PAGE

Table 4-35. Log Sense Page 00h, Supported Log Pages (default). . . . . . . . . . . . . . . . . . . . . . . . .4-37

Table 4-36. Log Sense Page 00h, Supported Log Pages *. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-37

Table 4-37. Log Sense Page 02h, Error Counter Page - Write . . . . . . . . . . . . . . . . . . . . . . . . . . .4-38

Table 4-38. Log Sense Page 03h, Error Counter Page - Read. . . . . . . . . . . . . . . . . . . . . . . . . . . .4-40

Table 4-39. Log Sense Page 0Ch, Sequential-Access Device Page. . . . . . . . . . . . . . . . . . . . . . . .4-43

Table 4-40. Log Sense Page 31h, Track Error Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-44

Table 4-41. LOOP WRITE TO READ Field Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-49

Table 4-42. MODE SELECT Field Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-51

Table 4-43. MODE SELECT Parameter List Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-52

Table 4-44. MODE SELECT Parameter Header. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-52

Table 4-45. MODE SELECT Parameter Header Field Description . . . . . . . . . . . . . . . . . . . . . . .4-52

Table 4-46. Buffered Mode Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-53

Table 4-47. Block Descriptor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-53

Table 4-48. Block Descriptor Field Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-53

Table 4-49. Page Descriptors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-54

Table 4-50. Page Descriptor Field Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-54

Table 4-51. MODE SENSE Field Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-56

Table 4-52. PC Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-57

Table 4-53. MODE SENSE Data Header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-57

Table 4-54. MODE SENSE Data Header Field Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-58

Table 4-55. Buffered Mode Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-58

Table 4-56. Block Descriptor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-59

Table 4-57. MODE SELECT Parameter Header Field Description . . . . . . . . . . . . . . . . . . . . . . .4-59

Table 4-58. Page Descriptors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-59

Table 4-59. Page Descriptor Field Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-60

Table 4-60. READ Field Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-63

Table 4-61. READ BLOCK LIMITS Field Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-68

Table 4-62. READ BLOCK LIMITS Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-68

Table 4-63. READ BUFFER Field Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-70

Table 4-64. READ BUFFER Command Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-71

Table 4-65. Supported Buffer ID Values for Read Data Mode . . . . . . . . . . . . . . . . . . . . . . . . . . .4-71

Table 4-66. Read/Write Data Buffer Descriptor (buffer ID 0) . . . . . . . . . . . . . . . . . . . . . . . . . . .4-72

Table 4-67. Read/Write NVRAM Descriptor (buffer ID 1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-72

Table 4-68. Descriptor Mode Field Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-72

Table 4-69. Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-73

Table 4-70. READ POSITION Field Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-75

Table 4-71. READ POSITION Return Data Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-77

Table 4-72. Block ID Field Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-78

Table 4-73. Format Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-78

Table 4-74. READ REVERSE Field Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-80

Table 4-75. RECEIVE DIAGNOSTIC RESULTS Field Description. . . . . . . . . . . . . . . . . . . . . .4-83

Table 4-76. RECEIVE DIAGNOSTIC Parameter List Length Field . . . . . . . . . . . . . . . . . . . . . .4-84

xviii C144-E019-03EN

Page 21

M2488 PRODUCT GUIDE LIST OF TABLES

LIST OF TABLES -CONTINUED

TABLE TITLE PAGE

Table 4-77. Diagnostic Page Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-85

Table 4-78. Receive Diagnostic Results Page, General Form . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-85

Table 4-79. Page 00h - Supported Diagnostic Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-85

Table 4-80. Page 80h - Online Diagnostic Test Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-86

Table 4-81. Page 80h Field Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-86

Table 4-82. Online Diagnostic Results data Parameter List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-87

Table 4-83. Parameter List Field Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-87

Table 4-84. RECEIVE DIAGNOSTIC RESULTS Field Description . . . . . . . . . . . . . . . . . . . . . 4-89

Table 4-85. RECEIVE DIAGNOSTIC (FACTORY MODE) Parameter List Length Field . . . . 4-90

Table 4-86. Diagnostic Page Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-91

Table 4-87. Receive Diagnostic Results Page, General Form . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-91

Table 4-88. Page 00h - Supported Diagnostic Pages (FACTORY MODE). . . . . . . . . . . . . . . . . 4-91

Table 4-89. Page 80h - Online Diagnostic Test Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-92

Table 4-90. Page 80h Field Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-93

Table 4-91. Page 81h - Online Manufacturing Diagnostic Test Page. . . . . . . . . . . . . . . . . . . . . . 4-93

Table 4-92. Page 81h Field Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-94

Table 4-93. Page 90-9Fh - Online Diagnostic Test Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-94

Table 4-94. Page Code 90-9Fh Field Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-95

Table 4-95. Online Diagnostic Results data Parameter List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-96

Table 4-96. Parameter List Field Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-96

Table 4-97. RECOVER BUFFERED DATA Field Description . . . . . . . . . . . . . . . . . . . . . . . . . 4-98

Table 4-98. RELEASE UNIT Field Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-101

Table 4-99. REQUEST SENSE Field Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-103

Table 4-100. REPORT DENSITY SUPPORT Field Description . . . . . . . . . . . . . . . . . . . . . . . . . 4-106

Table 4-101. REPORT DENSITY SUPPORT Header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-107

Table 4-102. DENSITY SUPPORT Data Block for density 09h (18-track, standard length tape) 4-107

Table 4-103. DENSITY SUPPORT Data Block for density 28h (36-track, standard or extended

length tape) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-108

Table 4-104. REPORT DENSITY SUPPORT Data Block Field Description. . . . . . . . . . . . . . . . 4-109

Table 4-105. RESERVE UNIT Field Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-112

Table 4-106. REWIND Field Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-115

Table 4-107. SEND DIAGNOSTIC Field Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-117

Table 4-108. SEND DIAGNOSTIC CDB Field Description Overview . . . . . . . . . . . . . . . . . . . . 4-118

Table 4-109. Send Diagnostic Page, General Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-120

Table 4-110. Diagnostic Page Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-120

Table 4-111. Page 00h - Supported Diagnostic Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-120

Table 4-112. Page 80h - Online Diagnostic Test Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-121

Table 4-113. Diagnostic Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-122

Table 4-114. SEND DIAGNOSTIC (FACTORY MODE) Field Description . . . . . . . . . . . . . . . . 4-124

Table 4-115. SEND DIAGNOSTIC (FACTORY MODE) CDB Field Description Overview . . . 4-125

Table 4-116. Send Diagnostic Page, General Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-127

Table 4-117. Diagnostic Page Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-127

C144-E019-03EN xix

Page 22

LIST OF TABLES M2488 PRODUCT GUIDE

LIST OF TABLES -CONTINUED

TABLE TITLE PAGE

Table 4-118. Page 00h - Supported Diagnostic Pages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-127

Table 4-119. Page 80h - Online Diagnostic Test Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-128

Table 4-120. Page 81h - Manufacturing Online Diagnostic Test Page . . . . . . . . . . . . . . . . . . . . . .4-129

Table 4-121. Page Code 81h Field Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-129

Table 4-122. Page 90-9Fh - MTU Online Diagnostic Test Page. . . . . . . . . . . . . . . . . . . . . . . . . . .4-131

Table 4-123. Page Code 90-9Fh Field Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-131

Table 4-124. Diagnostic Parameter List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-133

Table 4-125. SPACE Field Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-135