Page 1

CO

FUJITSU

FUJITSU AMERICA, INC.

M2266S/H

Intelligent Disk Drive

Technical Handbook

FS810125-01.. . B

Page 2

Disk Manager® is a registered trademark of Ontrack Systems, Inc.

SpeedStor® is a registered trademark of Storage Dimensions, Inc.

VFeature® is a registered trademark of Golden Bow Systems.

Copyright 1990, Fujitsu America, Inc.

Printed in the U.S.A.

Page 3

Edition

A

B

Date published

August, 1990

REVISION RECORD

Revised contents

First Printing

Editing

Specification No.: FS810125.01

FB104961

FUJITSU LIMITED

International Marketing

Marunouchi 1-6-1, Chiyoda-ku,

Tokyo 100 JAPAN

TEL: 03-216-3211

FAX: 03-213-7174, 03-216-9353

TLX: J22833

Cable: "FUJITSU LIMITED TOKYO"

FUJITSU AMERICA INC.

3055 Orchard Drive

San Jose, California 95134-2022, U.S.A.

TEL:

(1-408) 432-1300

FAX: 408-432-1318, 1319

TLX: 230-176207

TWX: 910-338-2193

FUJITSU CANADA INC.

6280 Northwest Drive

Mississauga, Toronto, Ontario, CANADA

TEL: (1-416) 673-8666

FAX: 416-673-8677

TLX: 968132

FUJITSU EUROPE LIMITED

2, Longwalk Road, Stockly Park,

West Drayton,

Middlesex UB11 lAB, ENGLAND

TEL: (44-81) 573-4444

FAX: 81-573-2643

TLX: 263871FEL5PG

FUJITSU DEUTSCHLAND GmbH

Rosen heimerstra6e 145,

D-8000 MUnchen 80, F.R. GERMANY

TEL:

(49-89) 32378142

FAX: 89-32378102 or 3

TLX: 897106 FDG D

Fujitsu America, Inc.

FUJITSU NORDIC AB

Torggatan 8, 171 54, Solna, SWEDEN

TEL: (46) 8-764-76-90

FAX: 8-28-03-45

TLX: 13411 FNABS

FUJITSU ITALIA S.p.A.

Via Melchiorre Gioia, 8, 20124 Milano, ITALY

TEL: (39-2) 6572741

FAX: 2-6572257

TLX: 350142 FJITLY I

FUJITSU AUSTRALIA LIMITED

475 Victoria Avenue,

Chatswood, N.S.W. 2067, AUSTRALIA

TEL: (61-2) 410-4555

FAX: 2-411-8603, 8362

TLX: 25233

FUJITSU HONG KONG LIMITED

R.M. 1831, Sur Hung Kai Centre,

30 Harbour Road,

HONG KONG

TEL: (852-5) 8915780

FAX: 5-742917

TLX: 62667

FUJITSU ESPANA, S.A.

Edificio Torre Europa,

Paseo de la Castellana 95,

Madrid 28046, SPAIN

TEL:

(34-1) 581-8000

FAX: 1-581-8300

TLX: 23887

The contents of this manual are subject to

change without prior notice.

All Rights Reserved,

FAI Copyright 01990 FUJITSU LIMITED.

FS810125-01 . . . B

Page 4

Page 5

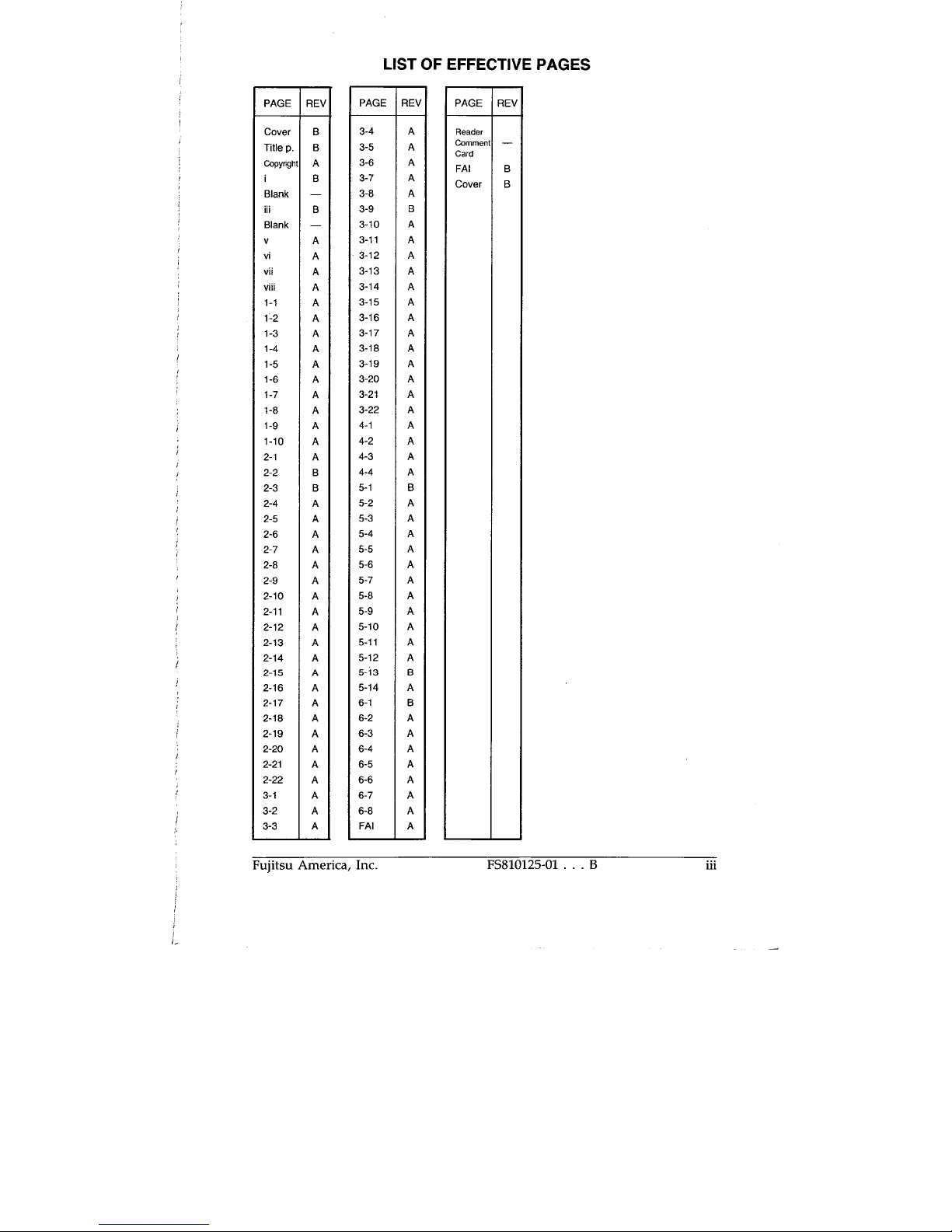

PAGE

REV

PAGE

LIST

REV

OF

EFFECTIVE

PAGE

PAGES

REV

Cover

Title p.

Copyright

Blank

iii

Blank

v

vi

vii

viii

1-1

1-2

1-3

1-4

1-5

1-6

1-7

1-8

1-9

1-10

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

2-11

2-12

2-13

2-14

2-15

2-16

2-17

2-18

2-19

2-20

2-21

2-22

3-1

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-9

3-10

3-11

3-12

3-13

3-14

3-15

3-16

3-17

3-18

3-19

3-20

3-21

3-22

4-1

4-2

4-3

4-4

5-1

5-2

5-3

5-4

5-5

5-6

5-7

5-8

5-9

5-10

5-11

5-12

5-13

5-14

6-1

6-2

6-3

6-4

6-5

6-6

6-7

6-8

FAI

Reader

Comment

Card

FAI

Cover

B

B

Fujitsu America, Inc.

FS810125-01 B

iii

Page 6

Page 7

Technical Handbook

Table of Contents

M2266S/l-1

List of Tables

List of Figures

Section 1. General Description

Section

Standard Features

Hardware Structure

System Configuration

Model/Part Number Cross References

2. Installation

Introduction

Outer Dimensions

Mounting

Power Supply Requirements

Power Supply to SCSI Terminating Resistor

Connectors

Connection Requirements

Environmental Requirements

Mounting Frame Structure

Service Clearance Area

Allowable Input Voltage and Current

Current Waveform

Power On/Off Sequence

Sequential Starting of Spindle Motors

Power Supply Connector

SCSI Connector

SG Terminal

Connectors for External Operator Panel

SCSI Cable

Power Cable

DC Ground

External Operator Panel

Requirements

ii

iii

1-1

1-2

1-5

1-7

1-8

2-1

2-1

2-1

2-6

2-6

2-7

2-7

2-7

2-7

2-8

2-10

2-10

2-11

2-13

2-13

2-14

2-14

2-16

2-16

2-19

2-20

2-20

2-22

Fujitsu America, Inc.

FS810125-01 . . . A

v

Page 8

M2266S/H

Technical Handbook

Section 3. Hardware Installation

Notes on Handling Drives

Connections

Setting Terminals

Setting Terminals CN3 and CN9

Setting Terminals CNHI, CNH2, CNH3, and CNH4

SCSI Terminating Resistor

Mounting Drives

Mounting Procedures

Connecting Cables

Confirming Operations after Installation

Initializing the drive

Section 4. Software Installation

Introduction

Preparation of the Hard Disk for DOS Applications

Definition of Drive Type

Drive Partitioning

Basic Steps for Software Installation

Section 5. Specifications

Section 6. Troubleshooting

Troubleshooting checklist

Diagnostics

Self-Diagnostics

Test Programs

Maintenance Information

Revision Numbers

Spare Parts

SCSI Bus Signal Assignments

3-1

3-1

3-2

3-4

3-6

3-9

3-12

3-15

3-15

3-15

3-16

3-18

4-1

4-1

4-1

4-1

4-1

4-2

5-1

6-1

6-1

6-2

6-2

6-4

6-5

6-6

6-6

6-7

vi

FS810125-01 . . A

Fujitsu America, Inc.

Page 9

List of Tables

Technical Handbook

M2266S/H

Table ii

Table 3.1

Table 5.1

Table 5.2

Table 5.3

Table 6.1

Table 6.2

Table 6.3

Table 6.4

Figure 1.1

Figure 1.2

Figure 2.1

Figure 2.2

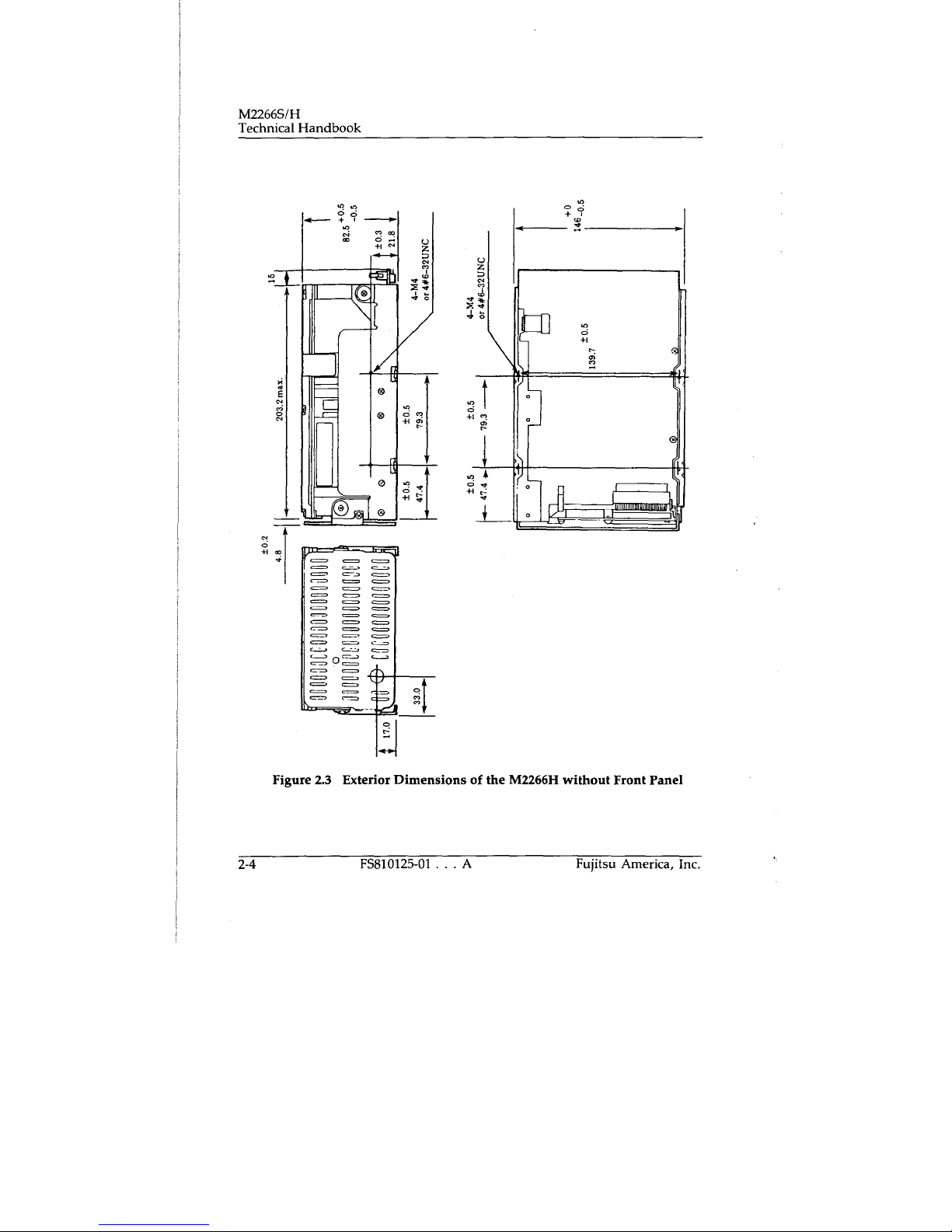

Figure 2.3

Figure 2.4

IDD Models and Part Numbers

Setting Checklist

Drive Functional Specifications

SCSI Functional Specifications

Environmental Specifications

Self-Diagnostic Functions

Spare Parts

SCSI Connector Signal Assignments

(Single-Ended Type: M2266S)

SCSI Connector Signal Assignments

(Differential Type: M2266H)

List of Figures

M2266S Outer View

System Configuration

Exterior Dimensions of the M2266S

without Front Panel

Exterior Dimensions of the M2266S

with Front Panel

Exterior Dimensions of the M2266H

without Front Panel

Exterior Dimensions of the M2266H

with Front Panel

1-9

3-14

5-1

5-3

5-13

6-2

6-7

6-7

6-8

1-5

1-7

2-2

2-3

2-4

2-5

Fujitsu America, Inc.

FS810125-01 . . . A

vii

Page 10

M2266S/H

Technical Handbook

Figure 2.5

Figure 2.6

Figure 2.7

Figure 2.8

Figure 2.9

Figure 2.10

Figure 2.11

Figure 2.12

IDD Orientation

Mounting Frame Structure

Service Clearance Area

Current Waveform (+12 VDC)

Power On/Off Sequence (1)

Power On/Off Sequence (2)

Power On/Off Sequence (3)

Supplying Power to the Terminating

Resistor

Figure 2.13

Figure 2.14

Figure 2.15

Figure 2.16

Figure 2.17

Figure 2.18

Figure 2.19

Figure 2.20

Figure 2.21

Positions of M2266S Connectors

Positions of M2266H Connectors

Power Supply Connector

SCSI Connector

SC Terminal

External Operator Panel Connector

SCSI Cable Connector

Connection of the SCSI Cable

Example of External Operator

Panel Circuit

Figure 2.22

DE Surface Temperature Measurement

Point

Figure 3.1

Figure 3.2

SCSI Bus Connections

The Setting Terminals and Terminating 3-5

Resistor (M2266S)

Figure 3.3

The Setting Terminals and Terminating

Resistor (M2266H)

Figure 3.4 Setting Terminals CN3/CN9

Figure 3.5

Setting Terminals CNHI, CNH2, CNH3,

and CNH4

Figure 3.6

SCSI Terminating Resistor Module

(M2266S)

Figure 3.7

SCSI Terminating Resistor Module

(M2266H)

Figure 3.8

MODE SELECT Command for

Reformatting

2-6

2-6

2-7

2-8

2-8

2-9

2-9

2-11

2-12

2-12

2-13

2-13

2-14

2-15

2-17

2-19

2-21

2-22

3-3

3-6

3-7

3-9

3-13

3-13

3-18

Figure 6.1

viii

Revision Label

FS810125-01 . . . A

6-6

Fujitsu America, Inc.

Page 11

Technical Handbook

M2266S/H

Section 1. General Description

This

is the preliminary manual for the M2266 manual and is subject to

change without notice.

This section describes the features and configuration of the M2266S/H

intelligent disk drive. This drive is a high-performance, large-capacity, 5

1/4-inch fixed disk drive with an embedded SCSI controller.

The interface between the IDD (Intelligent Disk Drive) and host system is

based on the Small Computer System Interface (SCSI) ANSI standard

(X3.131, 1986.)

The flexibility and expandability of the SCSI, as well as the powerful

command set of the IDD, allow the user to construct a high-performance,

reliable disk subsystem with large storage capacity.

The IDD is available with two different kinds of SCSI bus, based upon

electrical requirements:

M2266S

Single-Ended SCSI

•

M2266H

Also, the IDD is available with the following models based upon data format

at factory shipment. The drives are preformatted at 512 bytes per sector, but

may easily be reformatted in the field to any sector size from 180 to 4128

bytes per sector, in 2-byte increments.

Differential SCSI

Note: Some earlier revisions of the drive have a maximum bytes per sector

of 3808 bytes.

M2266S

M2266H

M2266SA

M2266HA

M2266SB

M2266HB

Fujitsu America, Inc.

256 bytes (data block length)

256 bytes (data block length)

512 bytes (data block length)

512 bytes (data block length)

1024 bytes (data block length)

1024 bytes (data block length)

FS810125-01 . . . A

1-1

Page 12

M2266S1H

Technical Handbook

Standard Features

Compactness

Since the SCSI controller circuit is inside the IDD PCA in the standard 5 1/4-

inch fixed disk drive form factor, the IDD is extremely compact. The IDD

can be connected directly to the SCSI bus of the host system.

SCSI/CCS Standard

The IDD provides not only SCSI basic functions but also the following

features:

•

Arbitration

•

Disconnection/Reselection

Data Bus Parity

•

Command set which meets the logical specification of the SCSI CCS

•

(Common Command Set for Direct Access Device) Requirements

(Rev. 4B).

The SCSI commands can manipulate data through logical block addressing

regardless of the physical characteristics of the disk drive. This allows

software to accommodate future expansion of system functions.

High-Speed Data Transfer

The data transfer rate on the SCSI bus is 2.00MB/s maximum, in

asynchronous mode and 4.8 MB/s maximum in synchronous mode. Such a

high data transfer rate on the SCSI bus can be useful with the large capacity

buffer in the IDD.

Notes:

1.

2.

1-2

The maximum data transfer rate in asynchronous mode may be

limited by the response time of the initiator and by the SCSI bus

length.

The maximum data transfer rate in synchronous mode on the

single-ended SCSI bus may be limited by the cable length and

transmission characteristics of the SCSI bus.

FS810125-01 . . . A

Fujitsu America, Inc.

Page 13

Technical Handbook

M2266S1 H

Continuous Block Processing

The addressing method of data blocks is logical block address. The initiator

can access data by specifying the block number in a logically continuous data

space without regard to the physical structure of the track or of cylinder

boundaries.

The continuous processing of up to 64K blocks in a command can be

achieved, aid the IDD can perform continuous read/write operations when

processing data blocks across track or cylinder boundaries.

256KB Data Buffer

Data is transferred between the SCSI bus and the disk media through the

embedded 256KB data buffer in the IDD.

Since the initiator can control the disconnect/ reconnect timing on the SCSI

bus by specifying the condition of stored data to the data buffer or empty

condition of the data buffer, the initiator can perform the effective

input/output operations by utilizing the high data-transfer capability of the

SCSI bus, regardless of the actual data transfer rate of the disk drive.

Read-Ahead Cache Feature

After executing the READ command, the IDD reads automatically and stores

(prefetches) the subsequent data blocks into the data buffer (Read-Ahead

caching.) This function may be programmed to prefetch data in amounts

from one sector's worth to 256 Kbytes of data.

The high-speed sequential data access can be achieved by transferring the

data from the data buffer without reaccessing the disk in case the subsequent

command requests the prefetched data blocks.

Command Stack Feature

The command stack feature of the IDD corresponds to up to seven initiators.

Therefore, the IDD can accept and stack the input/output command issued

by another initiator even if the IDD is executing another command. The

stacked command is retrieved and executed in stacked order after the

present command has completed execution.

Reserve and Release Functions

The IDD can be accessed exclusively in the multi-host or multi-initiator

environment by using the reserve and release functions.

Fujitsu America, Inc.

FS810125-01 . . . A

1-3

Page 14

M2266S/H

Technical Handbook

Error Recovery

The IDD can try to recover from errors in the SCSI bus or the disk drive

using its powerful retry processing. If a recoverable data check occurs, error-

free data can be transferred to the initiator after being corrected in the data

buffer. The initiator software is released from the complicated error

recovery processing by these error recovery functions of the IDD.

Automatic Alternate Block Reassignment

If a defective data block is detected during read or write, the IDD can

automatically reassign its alternate data block.

Programmable Data Block Length

Data can be accessed with a fixed block-length unit. Data block length is

programmable, and can be set during formatting to the most suitable length,

from 180 to 4,128 bytes, with a 2-byte boundary.

Defective Block Slipping

A logical data block can be reallocated in a physical sequence by slipping the

defective data block during formatting. This results in high speed

contiguous data-block processing without a revolution delay due to a

defective data block.

High-Speed Positioning

A rotary voice coil motor achieves fast positioning.

Large Capacity

The unformatted capacity is 1266 MB. Typically, at 512 bytes per sector the

formatted capacity is 1079 MB. A disk subsystem with large capacity can be

constructed that uses space efficiently.

Start/Stop of Spindle Motor

Using the SCSI command, the host system can start and stop the spindle

motor.

Diagnosis

The IDD has a diagnostic capability that checks internal controller functions

and drive operations to facilitate testing and repair.

1-4

FS810125-01 . . . A

Fujitsu America, Inc.

Page 15

Technical Handbook

M2266S/H

Low Power Consumption

By using highly-integrated LSI components, the power consumption of the

IDD is very low, enabling use of the unit in a wide range of ambient

temperatures between 5°C and 45°C.

Low Noise and Low Vibration

The IDD is quiet, running at approximately 45 dB (A-scale weighting) even

during seek, making it ideal for office use. The IDD has rubber vibration

isolators, which minimize the transfer of vibration.

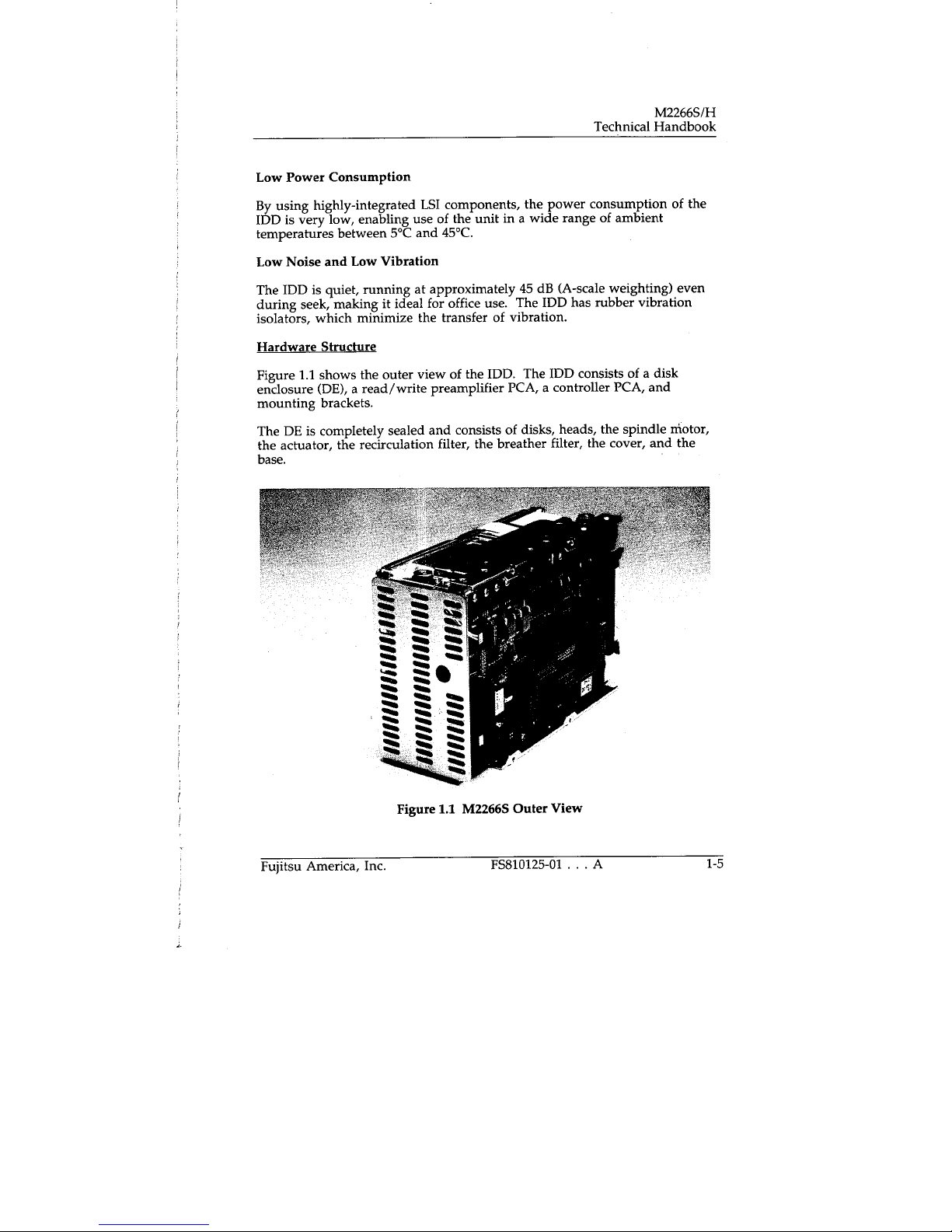

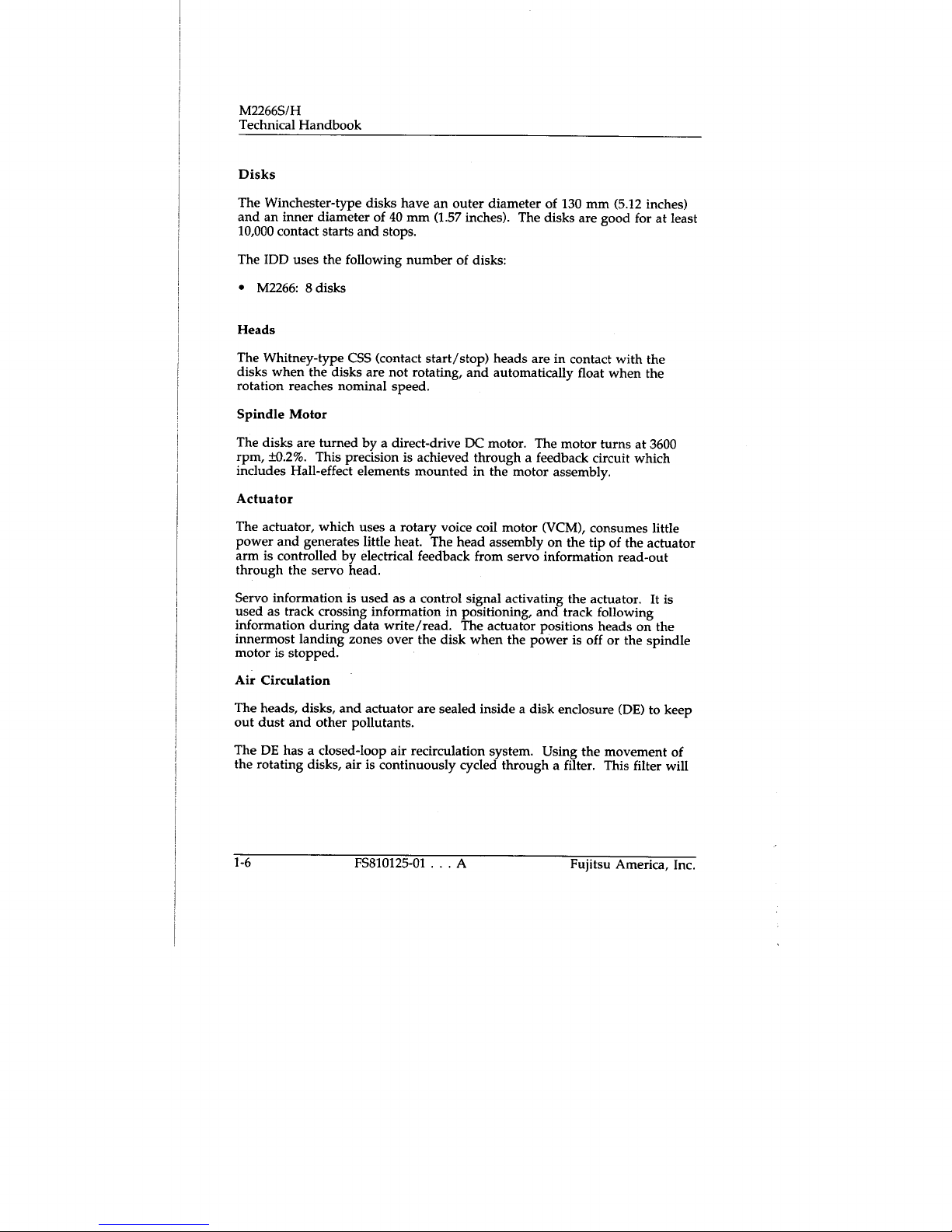

Hardware Structure

Figure 1.1 shows the outer view of the IDD. The IDD consists of a disk

enclosure (DE), a read/write preamplifier PCA, a controller PCA, and

mounting brackets.

The DE is completely sealed and consists of disks, heads, the spindle motor,

the actuator, the recirculation filter, the breather filter, the cover, and the

base.

Fujitsu America, Inc.

Figure 1.1 M2266S Outer View

FS810125-01 . . . A

1-5

Page 16

M2266S/H

Technical Handbook

Disks

The Winchester-type disks have an outer diameter of 130 mm (5.12 inches)

and an inner diameter of 40 mm (1.57 inches). The disks are good for at least

10,000 contact starts and stops.

The IDD uses the following number of disks:

M2266: 8 disks

Heads

The Whitney-type CSS (contact start/stop) heads are in contact with the

disks when the disks are not rotating, and automatically float when the

rotation reaches nominal speed.

Spindle Motor

The disks are turned by a direct-drive DC motor. The motor turns at 3600

rpm, ±0.2%. This precision is achieved through a feedback circuit which

includes Hall-effect elements mounted in the motor assembly.

Actuator

The actuator, which uses a rotary voice coil motor (VCM), consumes little

power and generates little heat. The head assembly on the tip of the actuator

arm is controlled by electrical feedback from servo information read-out

through the servo head.

Servo information is used as a control signal activating the actuator. It is

used as track crossing information in positioning, and track following

information during data write/read. The actuator positions heads on the

innermost landing zones over the disk when the power is off or the spindle

motor is stopped.

Air Circulation

The heads, disks, and actuator are sealed inside a disk enclosure (DE) to keep

out dust and other pollutants.

The DE has a closed-loop air recirculation system. Using the movement of

the rotating disks, air is continuously cycled through a filter. This filter will

1-6

F5810125-01 . . . A

Fujitsu America, Inc.

Page 17

Technical Handbook

M2266S/H

trap any dust generated inside the enclosure and keep the air inside the DE

contaminant-free. To prevent negative pressure in the vicinity of the

spindle when the disks begin rotating, a breather filter is attached. The

breather filter also equalizes the internal air pressure with the atmospheric

pressure due to surrounding temperature changes.

Read/Write Circuit

The read/write circuit uses LSIs and head ICs to prevent errors caused by

external noise, thus increasing reliability.

Controller Circuit

The controller circuit uses LSIs to increase reliability and uses a high-speed

Micro-Processing Unit (MPU) to increase the performance of the SCSI

controller.

System Configuration

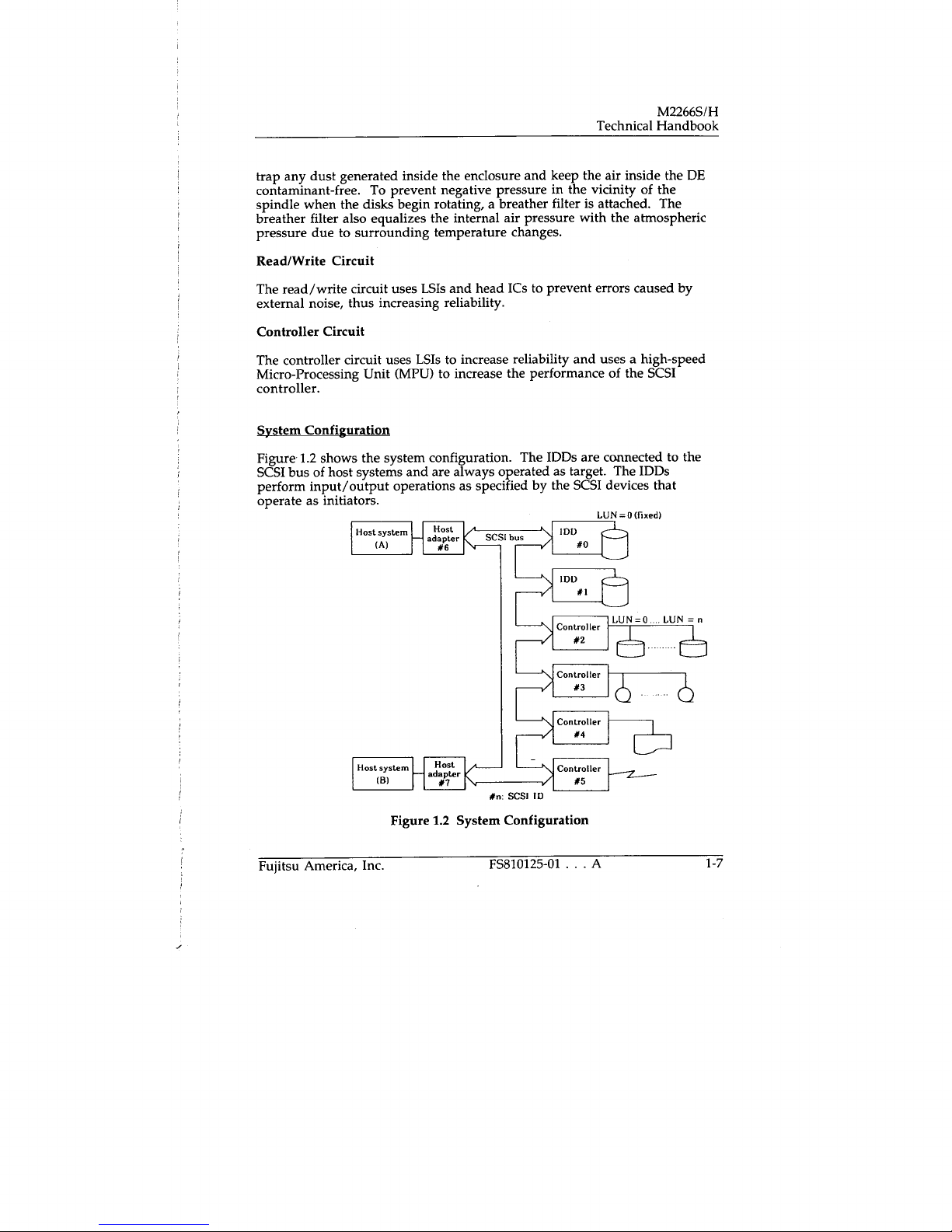

Figure 1.2 shows the system configuration. The IDDs are connected to the

SCSI bus of host systems and are always operated as target. The IDDs

perform input/output operations as specified by the SCSI devices that

operate as initiators.

LUN =

A

0 (hoed)

1-7

Host system

(A)

lost system - aHost

I

-

(B)

adapter

Figure

Fujitsu America, Inc.

Host

#6

( SCSI bus

I DI)

IDD

>

Controller LUN=0 LUN=n

Controller

>

Controller

N,

/ #4

dapter

#7

(

System Configuration

1.2

SCSI 10

FS810125-01

Controlle

)

...

#0

#1

#2

#3

#5

Page 18

M2266S/H

Technical Handbook

SCSI Bus Configuration

Up to eight SCSI devices can be connected to the SCSI bus, with any

combination of the SCSI devices operating as initiators and operating as

targets.

For example, the system can be configured as a multi-host system on which

multiple host computers that operate as initiators are connected through the

SCSI bus.

Using the disconnect/reconnect function, concurrent input/output

processing is possible on multi-SCSI devices.

Peripheral Device Addressing

Each SCSI device on the bus has its own unique address (the SCSI ID

number shown in Figure 1.2). For input/output operations, a peripheral

device attached to the SCSI bus and operating as the target is addressed as the

logical unit. A unique address or logical unit number (LUN) is assigned to

each logical unit.

The initiator selects one SCSI device by specifying the SCSI ID, and then

specifies the LUN to select the peripheral device for input/output

operations.

When the IDD is constructed so that the whole volume of disk drives is a

single logical unit, the selectable SCSI ID and LUN are as follows:

•

SCSI ID: Jumper selectable from 0 to 7

•

LUN: 0 (fixed)

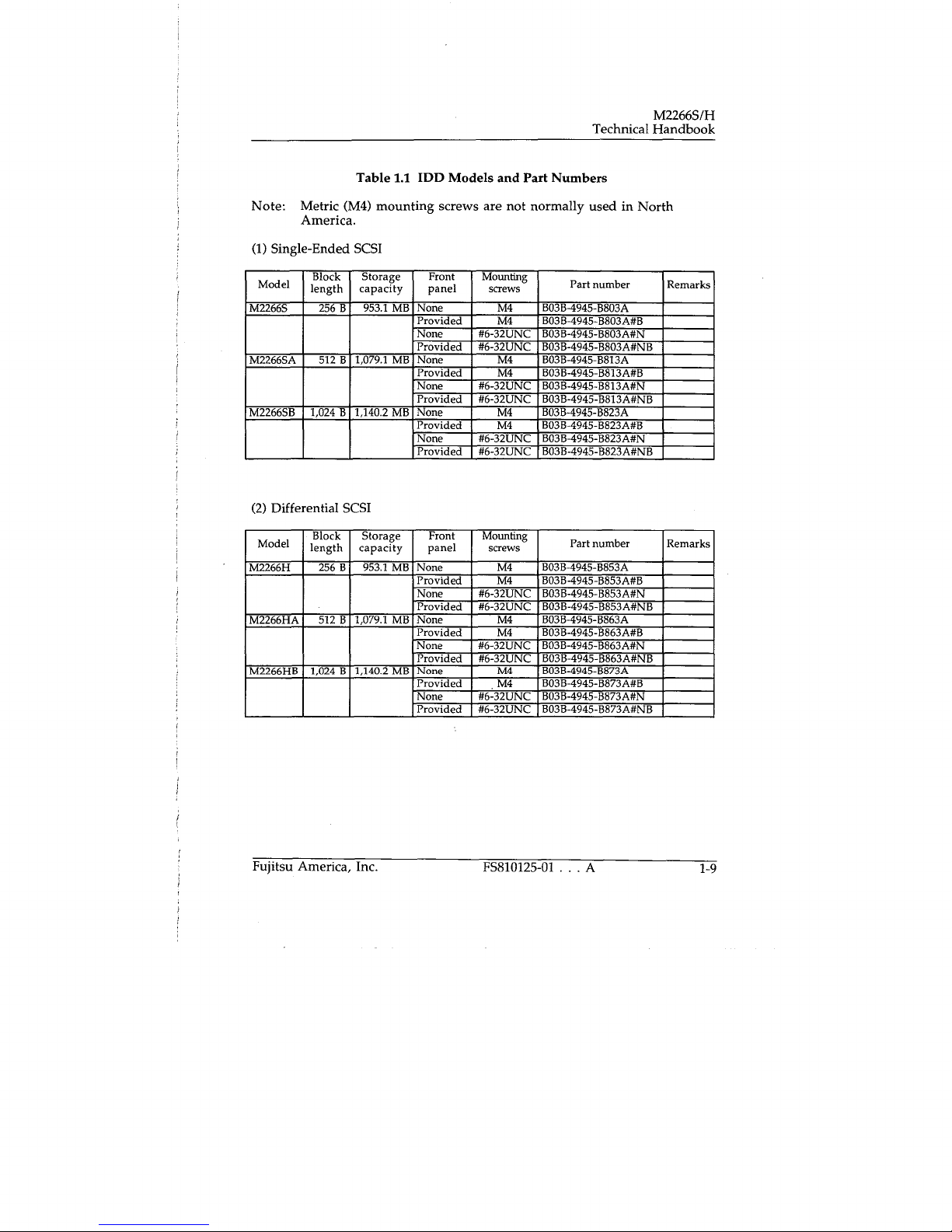

Model/Part Number Cross References

Each model has a different data format, front panel, and mounting-screw

type. Table 1.1 shows the IDD model names and part numbers. To change

the data format, reinitialize the drive on your system.

1-8

FS810125-01

...

A

Fujitsu America, Inc.

Page 19

Technical Handbook

M2266S/H

Table 1.1 IDD Models and Part Numbers

Note: Metric (M4) mounting screws are not normally used in North

America.

Single-Ended SCSI

(1)

Model

M22665

M2266SA

M2266SB

(2)

Model

M2266H

M2266HA

M2266HB

Block

length

1,024 B

Differential SCSI

Block

length

1,024 B

256 B

512 B

256 B

512 B

Storage

capacity

953.1 MB

1,079.1 MB

1,140.2 MB

Storage

capacity

953.1 MB

1,079.1 MB

1,140.2 MB

Front

panel

None

Provided

None

Provided

None

Provided

None

Provided

None

Provided

None

Provided

Front

panel

None

Provided

None

Provided

None

Provided

None

Provided

None

Provided

None

Provided

Mounting

screws

M4

M4

#6-32UNC

#6-32UNC

M4

M4

#6-32UNC

#6-32UNC

M4

M4

#6-32UNC

#6-32UNC

Mounting

screws

M4

M4

#6-32UNC

#6-32UNC

M4

M4

#6-32UNC

#6-32UNC

M4

M4

#6-32UNC

#6-32UNC

Part number

B03B-4945-B803A

B03B-4945-B803A#B

B03B-4945-U803A#N

B03B-4945-B803A#NB

B03B-4945-B813A

B03B-4945-B813A#B

B03B-4945-B813A#N

B03B-4945-B813A#NB

B03B-4945-B823A

B03B-4945-B823A#B

B03B-4945-B823A#N

B03B-4945-B823A#NB

Part number

B03B-4945-B853A

B03B-4945-B853A#B

B03B-4945-B853A#N

B03B-4945-B853A#NB

B03B-4945-B863A

B03B-4945-B863A#B

B03B-4945-B863A#N

B03B-4945-B863A#NB

B03B-4945-B873A

B03B-4945-B873A#B

B03B-4945-B873A#N

B03B-4945-B873A#NB

Remarks

Remarks

Fujitsu America, Inc.

FS810125-01 . . . A

1-9

Page 20

M2266S/H

Technical Handbook

1-10

FS810125-01

A

Fujitsu America, Inc.

Page 21

Technical Handbook

M2266S/H

Section 2. Installation Requirements

Introduction

Installation of the M2266S/H disk drive is a two-part process:

•

Mechanical and electrical installation of the hardware

•

Performance of the software procedures needed to bring the device to

operational readiness.

This section contains information on the requirements for hardware

installation, including the physical dimensions that assist in mounting the

device, the cabling schemes, and information on how to set the jumpers.

For specific information on installing the drives, see section 3. For

information on software installation of the drive in a Personal Computer

environment, see section 4.

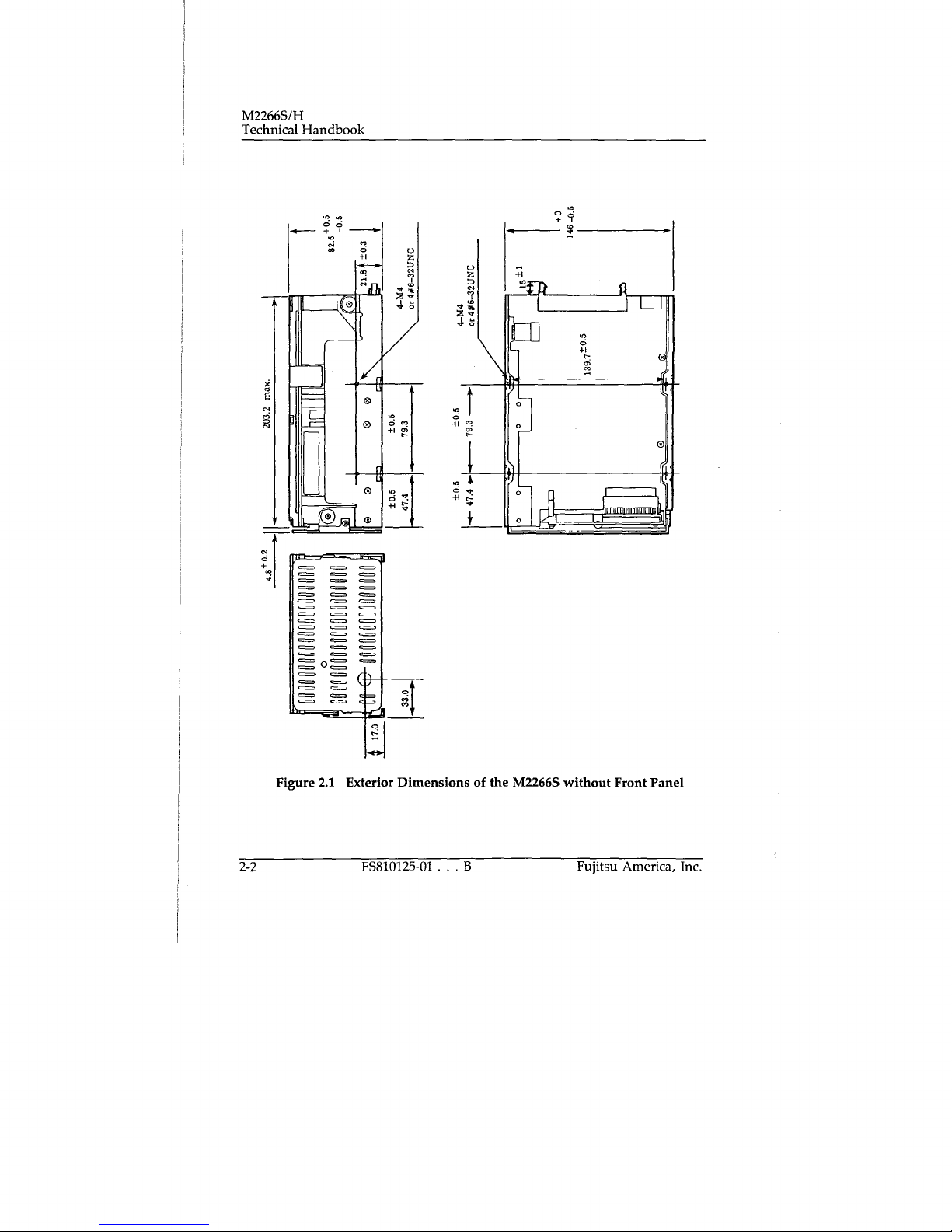

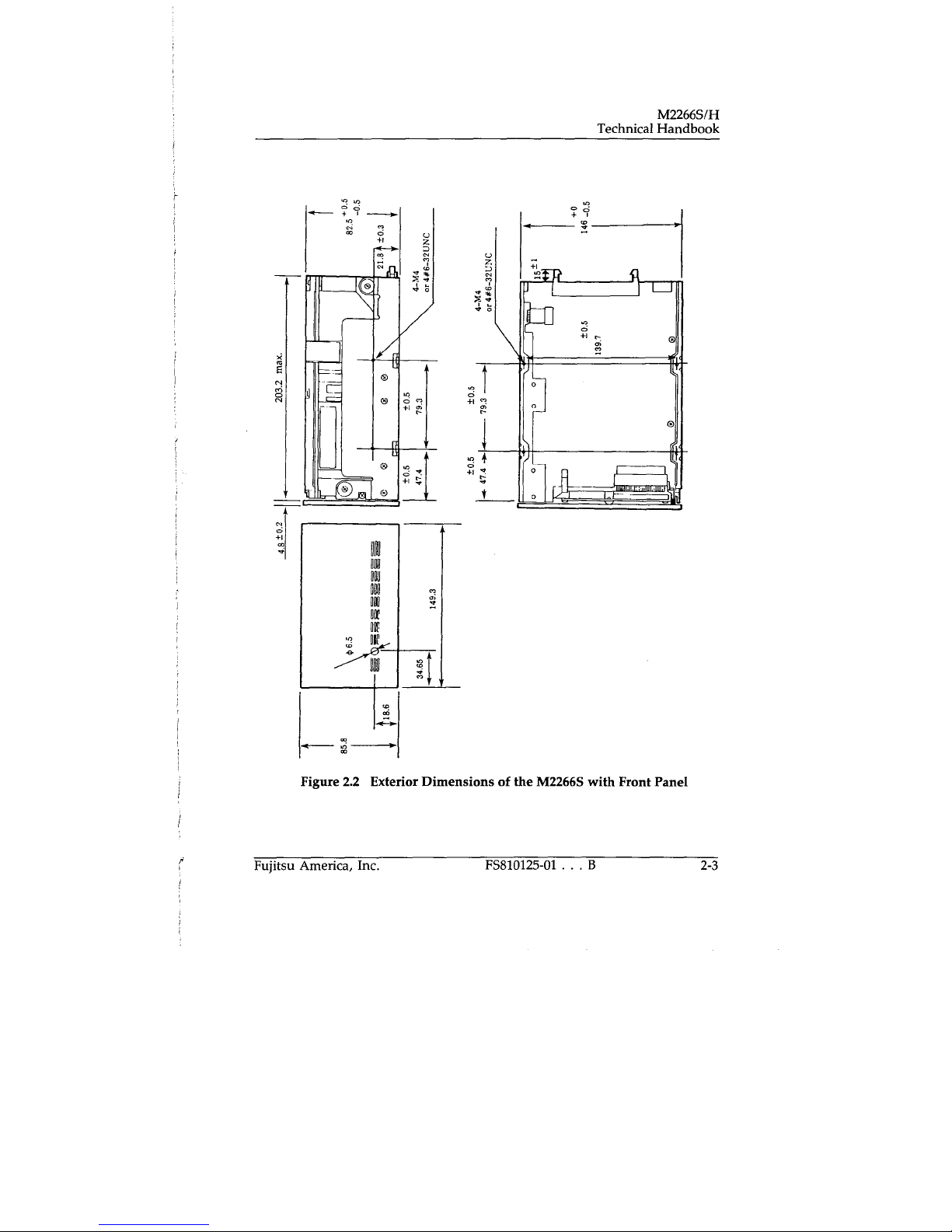

Outer Dimensions

Figures 2.1 to 2.4 show the exterior dimensions of the IDD and the positions

of the holes for the IDD mounting screws.

Notes:

1.

Dimensions are in mm.

2.

The depth does not include the dimension of the hook for mounting

the cable on the interface connector.

Fujitsu America, Inc.

FS810125-01 . . . A

2-1

Page 22

M2266S/H

Technical Handbook

IIIIIIIIfIIIIIIIIIIIINII l

Figure 2.1 Exterior Dimensions of the M2266S without Front Panel

2-2

FS810125-01 B

Fujitsu America, Inc.

Page 23

Technical Handbook

M2266S/H

Figure 2.2 Exterior Dimensions of the M2266S with Front Panel

Fujitsu America, Inc.

FS810125-01 . B

2-3

Page 24

M2266S/H

Technical Handbook

U

z

Figure 2.3 Extenor Dimensions of the M2266H without Front Panel

2-4

FS810125-01

A

Fujitsu America, Inc.

Page 25

Oh

ON

Ito

fill

lID

ItOh

Technical Handbook

M2266S/H

gI

IR

Figure 2.4 Exterior Dimensions of the M2266H with Front Panel

Fujitsu America, Inc.

FS810125-01 A

2-5

Page 26

M2266S/H

Technical Handbook

Mounting

Figure 2.5 shows the permissible orientations of the IDD. The tolerance of

the angle is ±5° from the horizontal plane.

Direction

of gravity

(n) Horizontal

(b) Vertical

(ci Vortical

Figure 2.5 IDD Orientation

Mounting Frame Structure

The disk enclosure (DE) of the IDD serves as a signal ground (SC) and is

insulated from the mounting frame. As this insulation is maintained after

the IDD is mounted in the system, the following precautions must be

followed:

Note:

Generally, SC and FG (frame ground) are connected at one point in the

system enclosure. To maintain insulation when mounting the IDD:

Use the frame with an embossed structure to avoid contact between

(a)

the DE base and FG.

As shown in Figure 2.6, the inward projection of the screw from the

(b)

IDD frame wall at the corner must be 4 mm or less.

4 or lens

2-6

4 or lens

(Unit mm)

Figure 2.6 Mounting Frame Structure

FS810125-01 . . . A

Fujitsu America, Inc.

Page 27

Technical Handbook

M2266S/H

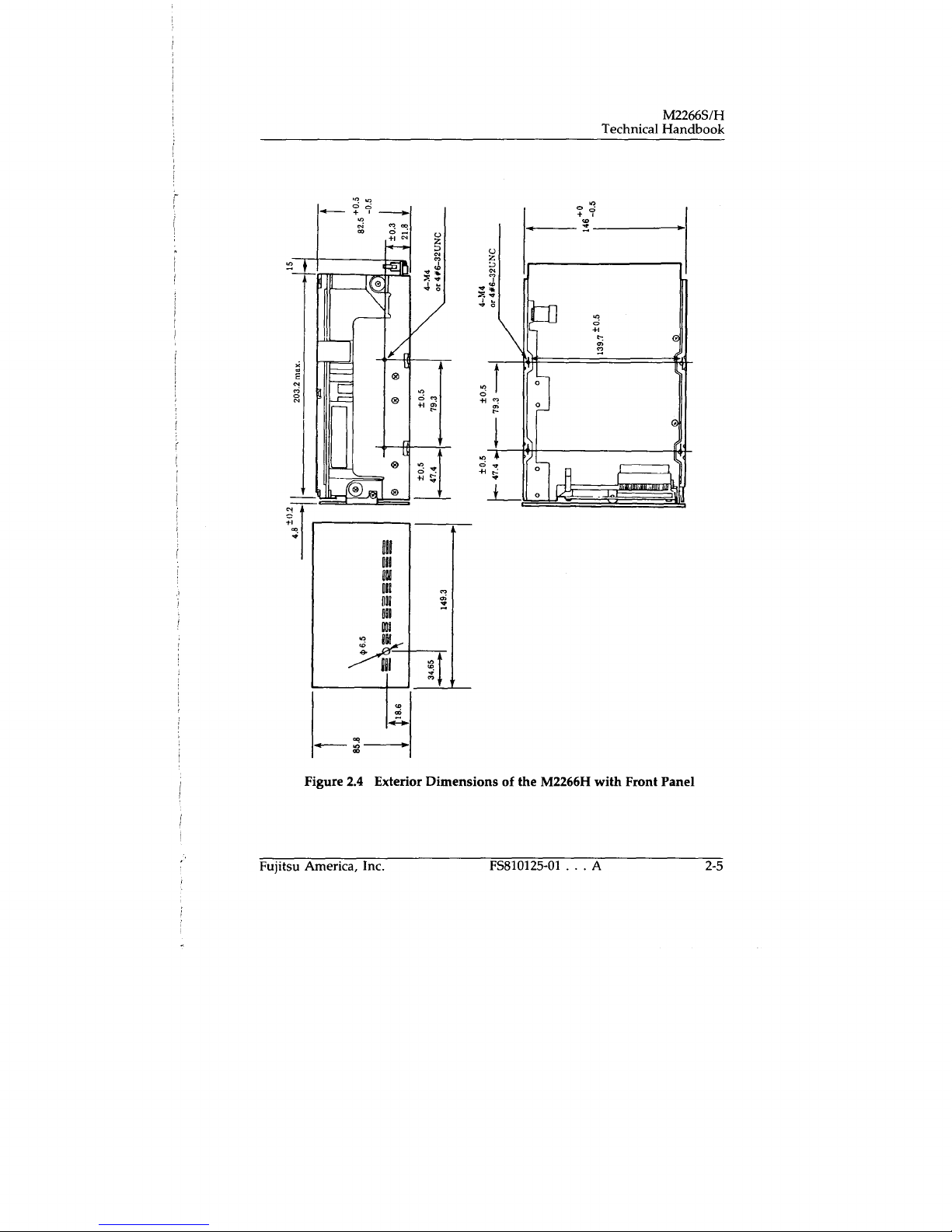

Service Clearance Area

Figure 2.7 shows the service clearance area, which must be accessible during

IDD installation or maintenance.

[Surface SI

•

Cable connection (M2266H)

[Surface P1

Cable connection (M2266S)

•

SG pin

•

Setting terminal

•

External operator panel

connection

[Surface RI

•

[Surface TI

•

External operator [Surface Qi

panel connection

• SCSI terminating resistor

•

•

Hole for mounting screw

Setting terminal, test pin

Hole for mounting screw

Figure 2.7 Service Clearance Area

Power Supply Requirements

Allowable Input Voltage and Current

The power supply input voltage measured at the power supply connector

pin at the receiving end of the IDD must satisfy the requirement given in

Table 5.3.

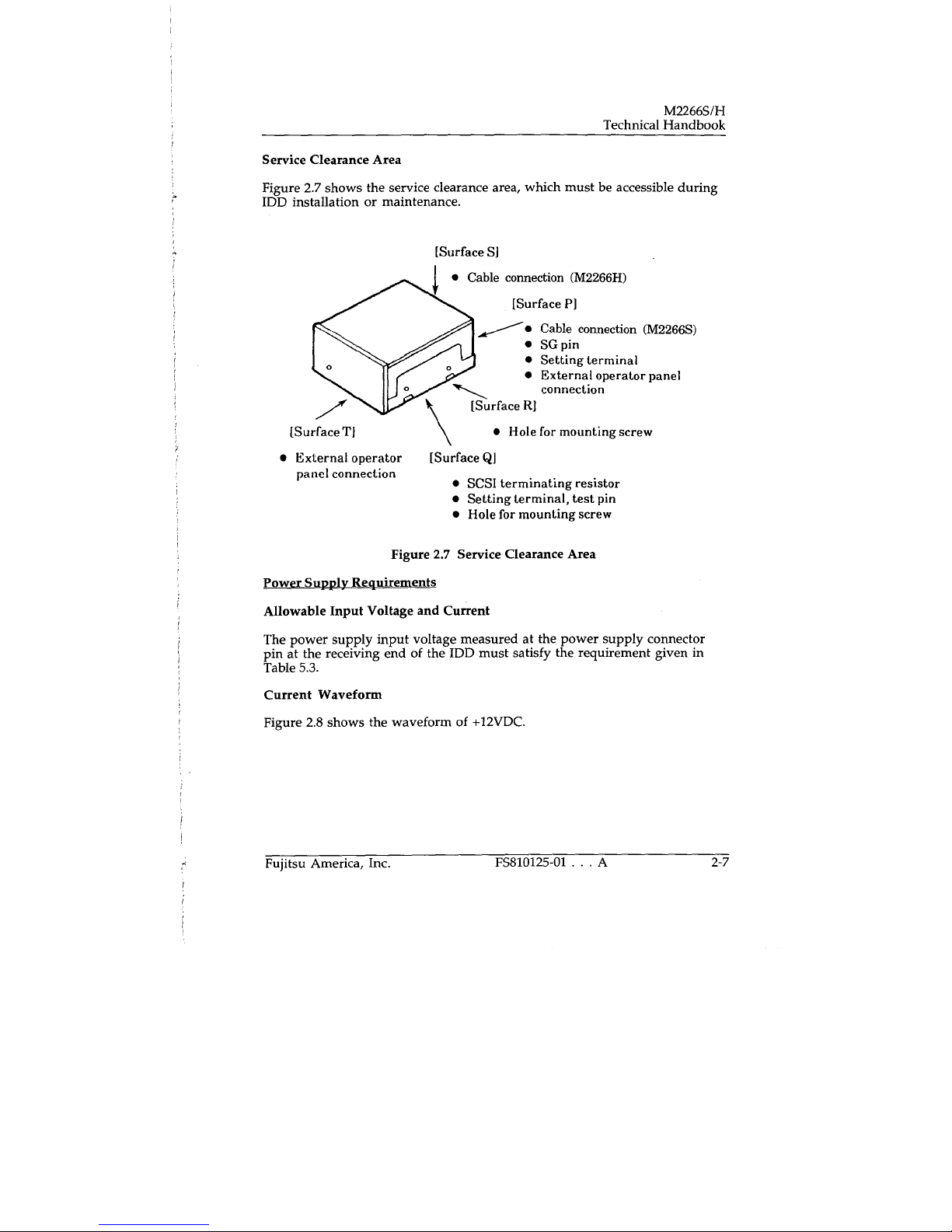

Current Waveform

Figure 2.8 shows the waveform of +I2VDC.

Fujitsu America, Inc.

FS810125-01 ... A

2-7

Page 28

M2266S/H

Technical Handbook

At start of spindle motor

(a)

rotation

(A)

5

4

'Iu

•

1

3

2

I

5 10 15 20 25 (s)

Seek, read, and seek

(b)

(0--> 500 CYL)

(A)

5

4

3

2

?%M~~

1

10

20

44

30 (ms)

Figure 2.8 Current Waveform (+12 VDC)

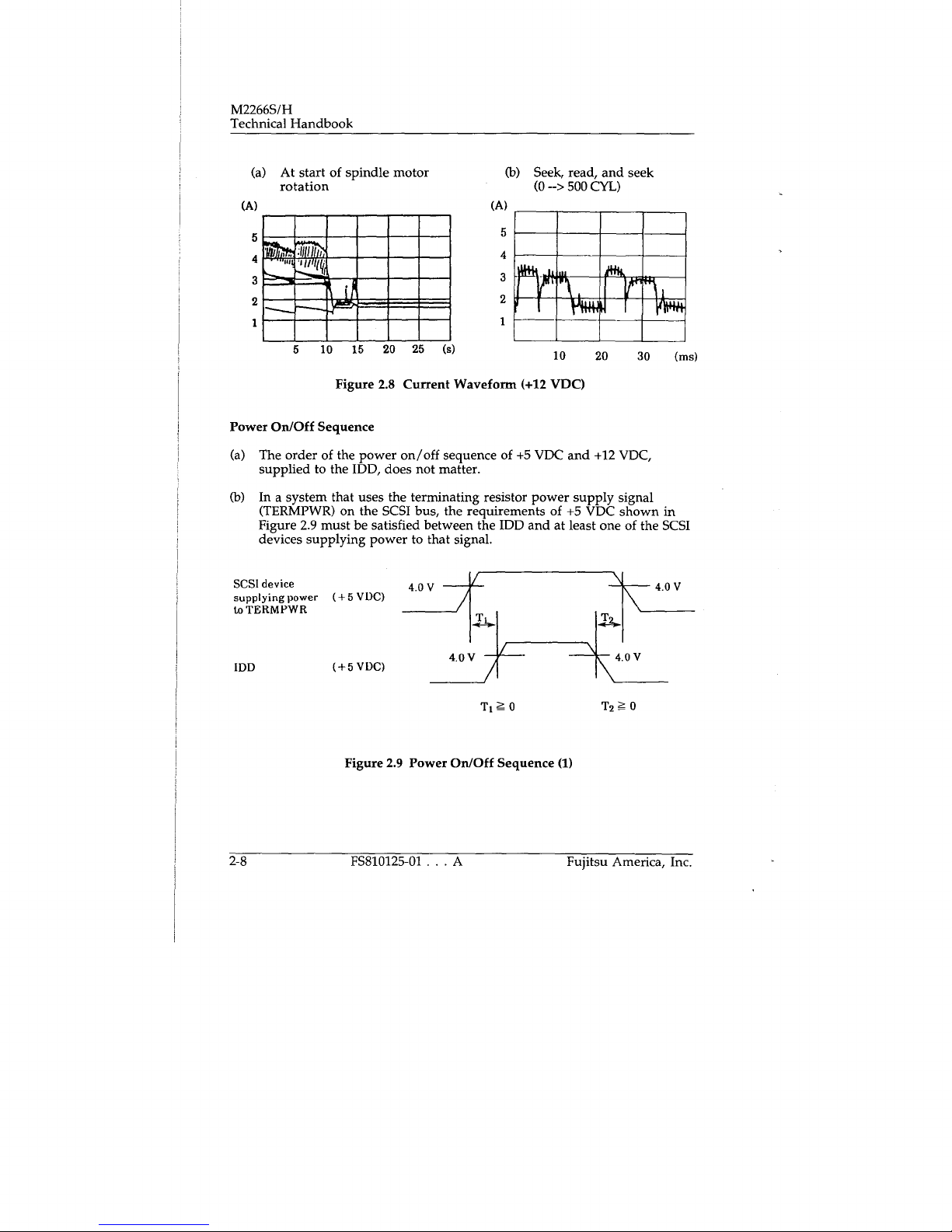

Power On/Off Sequence

The order of the power on/off sequence of +5 VDC and +12 VDC,

(a)

supplied to the IDD, does not matter.

In a system that uses the terminating resistor power supply signal

(b)

(TERMPWR) on the SCSI bus, the requirements of +5 VDC shown in

Figure 2.9 must be satisfied between the IDD and at least one of the SCSI

devices supplying power to that signal.

SCSI device

supplying power (+ 5 VDC)

TERMPWR

to

4.0 V

IDD

2-8

(+5 VDC)

4.0 V

/

Tj0

\4 0 V

T20

Figure 2.9 Power On/Off Sequence (1)

FS810125-01

. . .

A

Fujitsu America, Inc.

Page 29

Technical Handbook

M2266S/H

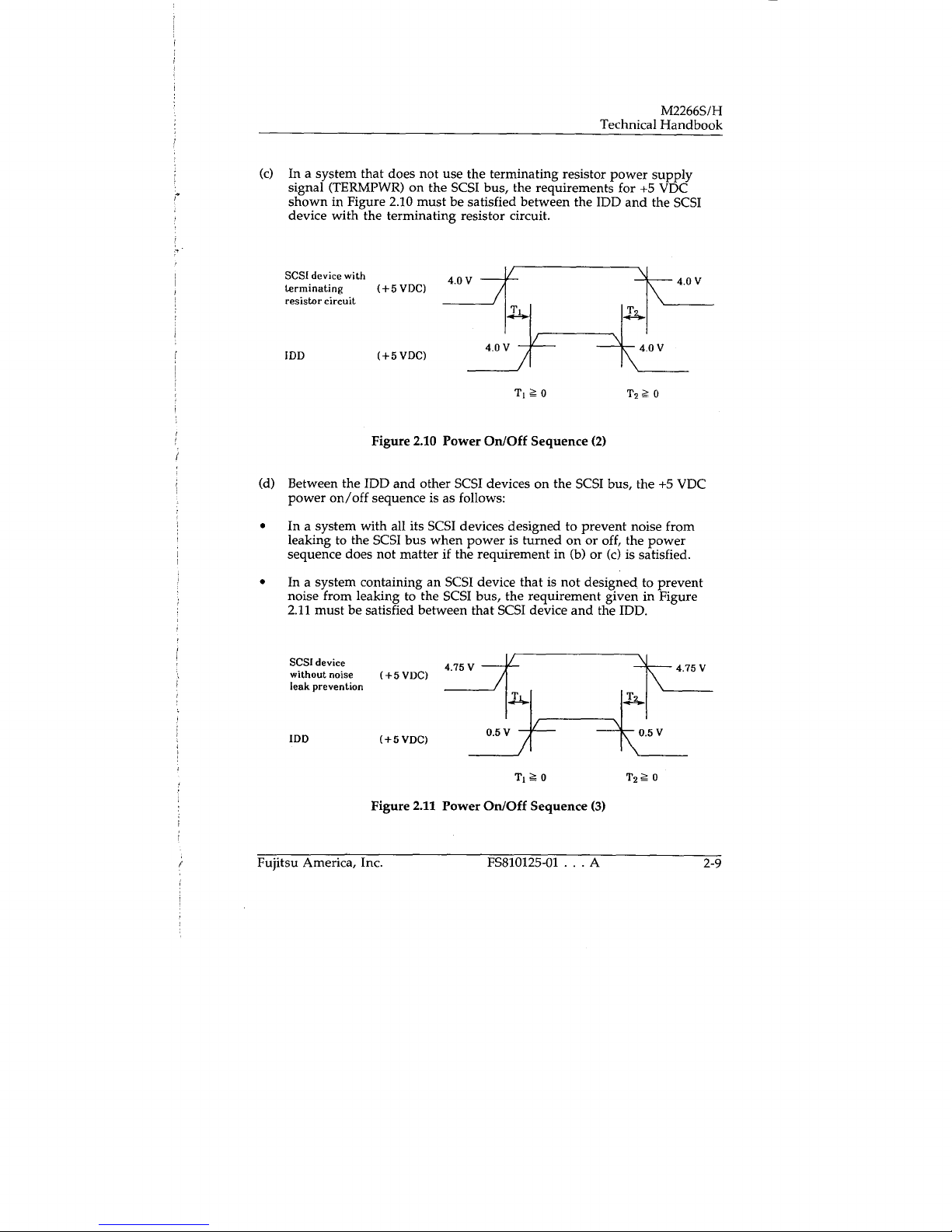

In a system that does not use the terminating resistor power supply

(c)

signal (TERMPWR) on the SCSI bus, the requirements for +5 VDC

shown in Figure 2.10 must be satisfied between the IDD and the SCSI

device with the terminating resistor circuit.

SCSI

device with

terminating

resistor circuit

IDD

(+5 VDC)

(+5VDC)

4.OV

4.0

V

T10

T20

4.0 V

40V

Figure 2.10 Power On/Off Sequence (2)

Between the IDD and other SCSI devices on the SCSI bus, the +5 VDC

(d)

power on/off sequence is as follows:

•

In a system with all its SCSI devices designed to prevent noise from

leaking to the SCSI bus when power is turned on or off, the power

sequence does not matter if the requirement in (b) or (c) is satisfied.

•

In a system containing an SCSI device that is not designed, to prevent

noise from leaking to the SCSI bus, the requirement given in Figure

2.11 must be satisfied between that SCSI device and the IDD.

SCSI device

without noise

leak prevention

IDD

(+5 VDC)

(+SVDC)

4.75 V

0.5V

T10

4.75 V

05V

T20

Figure 2.11 Power On/Off Sequence (3)

Fujitsu America, Inc.

FS810125-01 . . . A

2-9

Page 30

M2266S/H

Technical Handbook

Sequential Starting of Spindle Motors

After power is turned on to the IDD, a large amount of current flows in the

+12 VDC line as the spindle motor rotation starts. Therefore, if more than

one IDD is used, the spindle motors should be started sequentially using one

of the following procedures to prevent overload of the power supply unit.

For information on setting spindle motor start control mode, see Setting

Terminals" in section 3.

Issue START commands at 20-second intervals to start the spindle

a.

motors.

b.

Turn on the +12 VDC power in the power supply unit at 20-second

intervals to start the spindle motors sequentially.

Power Supply to SCSI Terminating Resistor

If power for the terminating resistor is supplied from the IDD to other SCSI

devices through the SCSI bus, the current-carrying capacity of the +5 VDC

power supply line to the IDD must be designed with consideration given to

an increase of up to 900 mA for the M2266S or up to 600

mA

for the

M2266H.

The method of supplying power to the terminating resistor is shown in

Figure 2.12.

2-10

FS810125-01 . . . A

Fujitsu America, Inc.

Page 31

M2266S/H

Technical Handbook

Section 4. Software Installation

Introduction

Due to the vast array of computer types, controllers, device configurations,

and software utilities in use within small business systems, it is impossible

to give specific installation instructions for each computer type in which the

drive may be installed. There is no generic installation description that

would apply in all cases.

Instead, this section presents basic principles for installing the M2266S/H

disk drive into the most frequently used system: an IBM Personal

Computer or PC-clone, using the PC DOS or MS DOS operating system.

Preparation of the Hard Disk for DOS Applications

Definition of Drive Type

First define the hard drive as "zero",or, "not installed".

Basic Steps for Software Installation

Software installation on the M2266S/H drive involves partitioning, and

high-level formatting. It requires the following steps:

Step 1: Boot DOS, and then run the DEBUG program. At the DEBUG

prompt (" — "), type g=c800:5 to access the BIOS-level formatter.

(Note: The manufacturer of the controller may specify a different

segment and offset location to access the low-level formatter, or

may provide standalone installation software.)

Drive Partitioning

With a DOS version of 3.3 or lower, the maximum drive capacity is 32 MB.

Therefore, multiple drive partitions (C:, D:, E:, . . Z:) of 32 MB or less must

be created. (See step 3 below.) Definition of larger partition size requires

either DOS 4.0x or a third-party software package such as Disk Manager®

from Ontrack Systems, Inc.

Fujitsu America, Inc.

FS810125-01 . . . A

4-1

Page 32

M2266S/H

Technical Handbook

Step 2: Run the software to create the partitions required by your unique

configuration. (This software is either the FDISK program or one

of the third-party software packages mentioned above.) Then boot

the system again to save the partitions.

Step 3: To perform high-level (or DOS-level) formatting of the partitions,

use the DOS FORMAT command or follow the on-screen

instructions for a third-party software package. If using the

FORMAT command, enter it at the A: prompt as follows:

FORMAT d:/s

d

where

drive. The

is the drive letter (typically C) assigned by DOS to the hard

Is

flag automatically copies the system files required to

boot the system from the hard drive.

The flow chart on the following page summarizes the steps for partitioning

the drive and preparing the drive to receive data.

4-2

FS810125-01 . . . A

Fujitsu America, Inc.

Page 33

Technical Handbook

Partitioning and High-Level Formatting

Start

I

Partition

Hard disk

M2266S/H

Use Compaq

tX)S 3.31 or

MS/PC DOS

4.01 or

Greater

I

(Run Fdisk*)

Use DOS

3.3 Run

Fdjsk

Create

Partitions

Reboot the

System to write

the partition

table on the

disk

Format the

Partitions. Use

/5 Option on

Boot Partition.

Transfer System

files on Boot

Drive or

Partition

Use Host

Adapter

Mfr's Standalone

Software or

Disk Manager

4.0 and Above.

Create

Partitions

Scan or

Verify the

Partitions.

Fujitsu America, Inc.

I

/ Hard

Disk'\

Prepa ation

Complete.

FS810125-01 A

4-3

Page 34

M2266S/H

Technical Handbook

4-4

FS810125-01 . . . A

Fujitsu America, Inc.

Page 35

Technical Handbook

Section 5. Specifications

This section describes the functional and environmental specifications of

the M2266S/H disk drives.

Table 5.1 Drive Functional Specifications (1 of 2)

M2266S/H

Unformatted capacity of the

drive (*1)

Number of disks

Number of heads

(read/write + servo)

Number of cylinders

(user + CE + SA) (*2)

Unformatted Capacity / Track

(*1)

Rotational Speed

Average Latency Time

Positioning Time

Start/Stop Time

(*3)

Recording Code

Recording Density

Track Density

Dimension

(W x H x D) (*4)

Items

Minimum

Average

Maximum

Start Time

Stop Time

M2266S

M2266H

Specifications

M2266

1266MB

8

15+1

1,658 + 1 + 2

50,910 Bytes

3,600 rpm 0.2%

8.3 ms

4 ms

14.5 ms

30 ins

20 seconds, maximum

15 seconds, maximum

1/7 RLL

46,635 BPI

1,634 TPI

5.7 in (146 mm) x 3.3 in. (83 mm) x 8.0 in (203 mm)

Front Protector Installed: 5.7 in x 3.3 in x 8.2 in

Front Panel Installed: 5.9 in x 3.4 in x 8.2 in

5.7 in (146 mm) x 3.3 in. (83 mm) x 8.6 in. (218mm)

Front Protector Installed: 5.7 in. x 3.3 in. x 8.8 in.

Front Panel Installed: 5.9 in x 3.4 in. x 8.8 in.

Fujitsu America, Inc.

FS810125-01 . . . B

5-1

Page 36

C

S

TEMPWR

SIGNAL

Setting terminal (CNH4)

CD

FUSE -.

(Inserted in a socket)

3

Termi-

resistor

Technical Handbook

M2266S/H

+5VDC

nating

circuit

IDD

TERMPWR

Power supply to terminal resistor circuit on IDD

Power is supplied from both IDD and

Power is supplied from 100 only

Power is supplied from

(100

power

supply is not used)

The

setting mode

(TERMPWR

TERMPWR

TERMPWR

TERMPWR

pin only

pin is also supplied with power from IDD

pin (°)

Pin is not used)

- GND

Setting erminal

(CNH4)

1-2

Strap Strap

Open

Strap

3-4

Strap

Open

Figure 2.12 Supplying Power to the Terminating Resistor

Connectors

Connectors and terminals for connection to the outside are installed on the

IDD. Their positions are shown in Figures 2.13 and 2.14.

•

Power supply connector

•

SCSI connector

•

SC (signal ground) connector

•

Connector for external operator panel

Fujitsu America, Inc.

FS810125-01 . . . A

2-11

Page 37

M2266S/H

Technical Handbook

Power supply

connector

SO

terminal

SCSI

ccnnector(CNI)

Setting terminal (CN9)

(External operator panel connector)

Figure 2.13 Positions of M2266S Connectors

Read/write

preamplifier

PCA

Read/write

preamplifier

connector

External operator

panel connector

(CNT)

VCM

connector

Control printed

circuit board

Spindle motor

connector

Setting terminal ICN3(

(External operator panel connector)

axoenbly(PCA)

2-12

Setting Ler.oimn1lCN9)

(External operator panel connector)

Setting tocminnllCN3

(External operator panel connector)

Figure 2.14 Positions of M2266H Connectors

A

FS810125-01

Fujitsu America, Inc.

Page 38

Technical Handbook

M2266S1H

Power Supply Connector

Figure 2.15 shows the shape and pin configuration of the DC power supply

connector.

1M226xSI

01

+I2VDC

+ 12 VUC Return (GND)

+5 VDC Return (GND)

3

+5VDC

(M226x11 J

D

0 3

2.15 Power Supply Connector

Figure

/

SCSI Connector

The connector for the SCSI bus is an unshielded standard connector which

has two rows of 25 pins spaced 2.54 mm (0.1 inch) apart. Figure 2.16 shows

several views of the connector and gives the physical specifications. See

Table 6.3 for the signal assignments on the connector for the single-ended

type SCSI bus (M2266S) and the differential-type bus (M2266H).

IMZZS,SI

0

Symbol

DI

D2

D3

D4

rrin

2.54

2.54

4.19+102

-0.25

6.09

Figure 2.16 SCSI Connector

Fujitsu America, Inc.

1M226.IIi

I

Inches

0.1

0.1

0.165+0.04

-0.01

0.24

FS810125-01 . . . A

Remarks

2-13

Page 39

M2266S/H

Technical Handbook

SG Terminal

For DC ground, an SG terminal (Fastin-Faston tab) is mounted as shown in

Figure 2.17.

Controller PCA

SCSI connector

Note: This figure shows the M22668

Figure 2.17 SG Terminal

Connectors for External Operator Panel

Two types of connectors for the external operator panel are provided on the

IDD as shown in Figure 2.18. They allow connection of an external write

protect switch, an LED on the front panel, and an SCSI ID setting switch. For

the recommended circuit of the external operator panel, see Figure 2.21.

2-14

FS810125-01 . . . A

Fujitsu America, Inc.

Page 40

Pin 13

2.54 nun

2.54 mm

Pin I

(CN9)

Pa2 Pin

,D

(CN3

\-

2.54 mm

Technical Handbook

M2266S/H

CN3/CN9

Pin 13

Pin

Pin 14

2.54mm

2.54 mm

Note: This figure shows the M22868s.

CN7

Signal Signal

01

+DIAG

03

(Reserved)

05

—RAC

07

—STM

09

—104

Ii

—11)2

13

—101

In M2266H, the setting terminal

(CNR4) exists between CN9 and CN3,

but pin assignments of CN9 and CN3

GNU

GND

GNU

GNU

GNU

GNU

GNU

are the same as M2266Ss.

Pin

01

03

Signal

LED (V)

—WPR

Signal

WPR(G)

—LED

Pin

02

04

06

08

10

12

14

Pin

02

04

Pin 1

Pin 3

Pin 2

Pin 4

Figure 2.18 External Operator Panel Connector

Fujitsu America, Inc.

Note: Pins 04 to 10 are connected to the cable

connector for internal connection.

Only pins 01 to 04 are used for

connection of the operator panel.

2.54 aim

FS810125-01

A

2-15

Page 41

M2266S/H

Technical Handbook

Notes:

I. Some signals are assigned on both pins CN3 and CN9.

When no external operator panel is connected to the IDD, CN3 and

2.

CN9 are used for setting the terminal of the SCSI ID, etc. (see Setting

Terminals' in section 3) When the IDD is shipped from the factory,

the short plugs are mounted between all even numbered and odd

numbered pins of CN9 and no short plug is mounted on CN3.

When the external operator panel is connected to CN3 or CN9, pay

3.

attention to the following items.

CN3 and CN9 are physically interchangeable. The external

•

operator panel can be connected to either one.

When the external operator panel is connected to CN9, all short

•

plugs on CN9 must be removed. However, pins on CN3

corresponding to the signal set on the external operator panel

must be opened. When there is a signal not set on the external

operator panel, the state of that signal must be set on CN3 using

the short plug. The removed short plug from CN9 can be used for

setting the state.

When the external operator panel is connected to CN3, the short

•

plug on CN9 corresponding to the signal set on the external

operator panel must be removed. When there is a signal not set

on the external operator panel, the state of that signal must be set

on CN9 using the short plug.

Connection Requirements

This section discusses the connections required when installing the drive.

SCSI Cable

All SCSI devices on one bus are daisy-chained with an SCSI cable. A

terminating resistor must be mounted in the SCSI device at each end of the

SCSI cable.

2-16

FS810125-0I . . . A

Fujitsu America, Inc.

Page 42

Technical Handbook

M2266S1H

Since an SCSI terminating resistor module is mounted in the IDD on

shipment, it must be removed when the IDD is not connected at either end

of the SCSI cable. Also, a method for supplying power to the terminating

resistor must be selected with the setting terminal on the IDD. For further

details, see "Setting Terminals" in section 3.

The maximum number of SCSI devices that can be connected to the SCSI

bus is 8, including the host adaptor, IDD, and other SCSI equipment.

The connector socket for the SCSI cable must be an unshielded 50-contact

socket which has two rows of 25 contacts spaced at 2.54 mm (0.1 inch) apart.

It should also have a key way to prevent insertion in the wrong direction

(bump type connector). (See Figure 2.16).

Pi. 50\

i—Cl

Pi.

C8—

C3

I

.Pial

lu

000000 JO 00000

L19

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0J

"Pin2

Synhol

nn

CI

2.540

CS

60.960

2,540

C3

Ca

3.302

CS

32.385

68.072

C6

Cl

6,096

7.620

CO

Notn: The Lolnroncnin ± 0.127 mm (0.805 inch) onlnnn oLhnrc inn npnciflnd,

Figure 2.19 SCSI Cable Connector

Fujitsu America, Inc.

Li

—I 1—

C4

CS

nhllinnhlu

R

CO

CO

Inch

0.100

2.400

0.100

0.130

1.275

2.680

0.240

0.300

Mon.

FS810125-01 . . . A

00000000

Remark

Pio49._

P50"

rn

ci

I

{

2-17

Page 43

M2266S/H

Technical Handbook

The maximum length of the SCSI cable is as follows. If more than one SCSI

device is connected, the total cable length must not exceed the following:

•

6 m for single-ended type SCSI

25 m for differential type SCSI

•

The use of a 25-pair twisted cable satisfying the following requirements is

recommended.

Single-Ended Type

Conductor Size: 28 AWG (American Wire Guage) or bigger

Characteristics impedance: 100 to 132

Differential Type

Conductor Size: 28 AWG or bigger

Characteristic impedance: 100 to 122 0

Each pair of wires in the 25-pair twisted cable must be connected to pins n

and n+1 (where n is an odd number) on the interface connector. Cables

having an identical impedance must be used on the same SCSI bus to reduce

signal reflection and maintain transmission characteristics.

When an SCSI device is connected to the SCSI cable (except at either end of

the cable), connection to the SCSI connector must be at a branch point of the

cable. If an SCSI device is connected to one end of the SCSI bus, no cable

should be connected after the last SCSI device, except when the cable has a

terminating resistor. (See Figure 2.20.)

2-18

F5810125-01 . . . A

Fujitsu America, Inc.

Page 44

Technical Handbook

(A) Connection to a Middle Point of the Cable.

M2266S/H

Correct connection (1) Correct connection (2)

SCSI cable

Link connector

SCSI cable

(B) SCSI Cable Termination

Correct connection (1) Correct connection (2)

SCSI cable

SCSI

connector

TRM: SCSI terminating resistor

TRM

Incorrect connection

Incorrect connection

SCSI cable

Figure 2.20 Connection of SCSI Cable

Power Cable

The IDDs must be star-connected to the DC power supply in a one-to-one

connection to reduce the influence of load variations.

Fujitsu America, Inc.

FS810125-01 . . . A

2-19

Page 45

M2266S/H

Technical Handbook

DC Ground

A DC ground cable may or may be installed depending on the system

requirements (system installation environment, cabinet structure, power

supply system). This cable is generally connected to the ground of the power

supply unit. Connection between more than one IDD may be in a daisy

chain.

External Operator Panel

The external operator panel is installed only when required for the system.

If it is unnecessary, pins 1 to 4 of CN7 connector for the external operator

panel on the IDD must be opened. Also, necessary features must be set on

CN3 or CN9 using the short plug. (See 'Setting Terminals in section 3.)

Figure 2.21 shows a recommended circuit for the external operator panel.

Since the external operator panel is not provided as an option, the user

must fabricate this panel, referring to the recommendation if necessary.

Note:

Necessary switches and LEDs for the system can be provided on the

external operator panel by referring to the recommended circuit shown

in Figure 2.21.

When there is no signal set for the external operator panel, the signal

must be set on CN3 (or on CN9) using the short plug. The CN3 or CN9

pins corresponding to the signal must be opened. For details, see

"Connectors" in this section and Setting Terminals" in section 3.

2-20

FS810125-01 . . . A

Fujitsu America, Inc.

Page 46

(IDD)

C

N

9

or

C

N

3

S9

>

2

)

3

>-

4

>

5

>-

6

>

7

>-

8

>

9

>-

10

>

11

>-

12

>

13

>-

14

-1-DIAG

GND

GND

- RAC

GND

— STM

GND

- 1D4

GND

—ID2

GND

—ID1

GND

Technical Handbook

(ON)

(ON)

(ON)

$Y0

(ON)

-

a o—.

(ON)

0'_ID1

(ON)

M2266S/H

DIAG

CACHE

SCSI

TIMER

-41D4

ID2

S7

(V)

LED

C

2

3

4

WPR(G)

—

WPR

—

LED

N

>-

>

Figure. 2.21 Example of External Operator Panel Circuit

Fujitsu America, Inc.

FS810125-01

(ON)

0—

K

(LED)

A

WRITE

PROTECT

2-21

Page 47

M2266S/H

Technical Handbook

Environmental Requirements

The IDD must conform to the environmental requirements listed in section

5. When the IDD is operating, the ambient temperature measured 3 cm

from the disk enclosure (DE) surface and from the PCA surface must satisfy

the specified requirement. At the DE surface during operation, the contact

temperature at the measurement point shown in Figure 2.22 must satisfy

the specified requirement.

Measurement point

(Rear-center of DE)

2-22

Figure 2.22 DE Surface Temperature Measurement Point

FS810125-01 . . . A

Fujitsu America, Inc.

Page 48

Technical Handbook

M2266S1H

Section 3. Hardware Installation

This section describes how to handle the drives, make connections, set

switches and plugs, mount drives, connect cables, confirm drive operations

after installation, prepare the drives for use, and remove the drives.

Notes on Handling Drives

General Notes

To avoid damage to the drive, do not allow vibration or shocks

•

exceeding the values defined in the standard. Be especially careful

during unpacking.

Do not leave the drive in a dirty or contaminated environment.

•

Since static discharge may destroy the CMOS semiconductors in the

•

drive, use an antistatic mat after unpacking, and ground yourself when

handling the drive.

Hold the DE. or mounting frame when handling the drive. Do not touch

•

PCAs, except when setting switches.

Unpacking

Use a flat work area. Be sure that the "This Side Up" sign is up. Handle

•

the drive of soft material such as a rubber mat, not on hard material such

as a desk. Handle the drive gently at all times.

Do not remove the sealing label or cover of the DE and screws.

•

Installation

While power is turned on, do not connect or disconnect connectors or

•

change terminals except CN3 and CN9.

Do not move the drive when power is turned on or until the drive has

•

been completely stopped for 15 seconds after the power is turned off.

Fujitsu America, Inc.

FS810125-01 . . . A

3-1

Page 49

M2266S/H

Technical Handbook

Packing

Store the drive in an antistatic vinyl bag with a dessicant (silica gel).

•

It is recommended that you use the same cushions and packages as those

•

used at delivery. If those cannot be used, use a package with shock

absorption so that the drive is free from direct shocks. In this case, fully

protect the PCAs and interface connectors so that they are not damaged.

Indicate "This Side Up' and "Handle With Care" on the outside of the

•

package so that it is not turned over.

Storage

Provide vapor-proof packaging for storage.

•

The storage environment must satisfy the requirements specified in

•

Table 5.3 (Environmental Specifications).

To avoid condensation, avoid rapid changes in temperature.

Connections

Figure 3 1 shows examples of connections between the host system and the

IDD. Up to eight devices, including the host adapter, IDD, and other SCSI

devices can be connected to the SCSI bus in arbitrary combinations. Install a

terminating resistor on the host adaptor and on either the last device in the

chain or at the end of the cable.

See Connectors' in section 2 for the cable connection requirements and

power-cable connections.

3-2

FS810125-01 . . . A

Fujitsu America, Inc.

Page 50

Connecting One IDD

(1)

Technical Handbook

M2266S1H

Host

system

Connecting More than One IDD (Single Host)

(2)

Host

system

TRM

Host

adapter

TRM

Host

adapter

TRM

SCSI terminating resister

SCSI cable

SCSI cable

C

N

TRM

I TRM

IDD

N

C

N

IDD

IDD

Other SCSI device

Figure 3.1 SCSI Bus Connections

Fujitsu America, Inc.

of

(1

2)

FS810125-01 . . . A

3-3

Page 51

M2266S/H

Technical Handbook

(3) Connecting More Than One IDD (Multi-Host)

SCSI

Host

system

#1

Host

adapter

TRM

cable

N

C

N

IDD

IDD

Host

system

#2

TRM: SCSI terminating resistor

Host

adapter

TRM

Figure 3.1 SCSI Bus Connections

(2 of 2)

Other SCSI device

Setting Terminals

You must set the following terminals and SCSI terminating-resistors before

installing the IDD in the system.

•

Setting Terminal:

CN3/CN9 (These pins are commonly used with a

connector for the external operator panel.) (See

Figure 3.4.)

•

Setting Terminal:

•

SCSI Terminating Resistor

CNH1, CNH2, CNH3, CNH4

Figures 3.2 and 3.3 show the terminal settings and the position of the SCSI

terminating resistor module.

3-4

FS810125-01 . . . A

Fujitsu America, Inc.

Page 52

Technical Handbook

M2266S/H

Notes:

The user must not change the setting of terminals not described in this

1.

section. Do not change factory settings for terminals not described.

Do not change the setting of terminals other than CN3 and CN9, and

2

do not connect or disconnect the SCSI terminating resistor module

when power is on.

You can change the CN3 or CN9 settings when power is on. The SCSI

3.

ID setting is valid after power is turned on again or the SCSI bus is

reset.

To short the setting terminal, use the short plug attached when the

4.

device is shipped from the factory.

CNHI

15

I

CNI-12

16

CN7

n

P

..- Power connector (CN2)

SCSI connector (CN1)

SCSI

terminating

resistor

CNH4

Io42

CNH3

15 I

IS

14 13

13

C

N

15 I

16 2

2

3.2 The Setting Terminals and Terminating Resistor (M2266S)

Figure

Fujitsu America, Inc.

FS810125-01 . . . A

3-5

Page 53

M2266S/H

Technical Handbook

Power connector (CN2)

L_J

SCSI terminating

resistor

L_J

SCSI connector

(CND

''

6i

14 13

CNH4

I o2

3 4

2

C

N

3

CNH3

I

2

15

16

CNHI

15

jl

2

CNH2

16

CNI

Figure 3.3 The Setting Terminals and Terminating Resistor (M2266H)

Setting Terminals CN3 and CN9

Figure 3.4 shows setting terminals CN3 and CN9. Either of these terminals

can be used as a connector for the external operator panel. Following the

figure are explanations of the factory default settings.

3-6

FS810125-01 . . . A

Fujitsu America, Inc.

Page 54

13 11 9 7 5 3 1

DD000DD

EJ DO DUD U

14 12 10 8 6 4 2

Technical Handbook

M2266S/H

CN3

CN9

rT TITITi

Note: This figure showas M2266Ss. In

13 11 9 7 5 3 1

n n n n n n n

42

14 12 10

Notes:

The same functions are assigned on the same pins of both CN3 and

1.

CN9.

To set features for an external operator panel, use CN3 or CN9. For

2.

details, see 'Connectors for External Operator Panel" in section 2.

86

Startlstop offline self-diagnostics

(User setting inhibited)

Enable/disable Read-Ahead cashe feature

Enable/disable SCSI time monitoring feature

SCSI ID

Figure 3.4 Setting Terminals CN3/CN9

M2266H, the setting terminal

(CNII4) exists between CN9 and

CN3. Pin assignments of CN9 and

CN3 are the same as M2266Ss.

Fujitsu America, Inc.

FS810125-01 . . . A

3-7

Page 55

M2266S/H

Technical Handbook

Factory Terminal Settings

The following paragraphs list the terminal settings at factory shipment. The

terms "short" and "open" have the following meaning:

Short: The short plug is mounted between specified pins on either

CN3 or CN9 as indicated.

Open:

The short plug is removed from between specified pins on

both CN3 and CN9.

Table 3.1 Setting Terminal: CN3/CN9

Setting item

SCSI ID

SCSI time monitoring

(RESELECTION, ACK response)

Read-Ahead caching

Diagnostic switch

•

Pin position

9-10

Open

Open

Open

Open

Short

Short

Short

Short

7-8

5

3-4

1-2

11-12

Open

Open

Short

Short

Open

Open

Short

Short

13-14

Open

Short

Open

Short

Open

Short

Open

Short

Open

Short

Open

Short

O

p

en

Short

0pei

Short

Setting contents

SCSI ID

0

2

3

4

5

6

7

Time monitoring is disabled.

Time monitoring is enabled.

Disabled

Enabled

(Reserved, do not remove)

Diagnostics are executed

(diagnostic mode).

Diagnostics stops (normal

operation mode).

Setting at factory shipment (CN9)

3-8

F5810125-01 . . . A

Fujitsu America, Inc.

Page 56

Technical Handbook

M2266S/H

Setting Terminals CN111, CNH2, CNH3, and CNH4

Figure 3.5 shows the plug types and settings at factory shipment. Following

the figure are explanations of each setting.

CNH1

2 4 6 8 10 12 14 16

0 0 0 0 0 0 0

0 0 0 0 0 0 0

3579

LED display requirement

2 4 6 8 10 12 14 16

11 13 15

I

I

I

I

L

I

I

I

LUNIT mode

ATTENTION

report mode

User setting disabled *

CNM3

000000

00000000

3 5 7 9 11 13 15

Drive type (user change disabled)

L

(Setting at shipment differs

depending on the mD model type.

M2266S1H are indicated in this figure.)

- User setting disabled

CNH2

2 4 6 8 10 12 14 16

0 0 00 0 0 0

0 0 0 0 0 0 0

3 5 7 9 11 13 15

I SCSltirne

monitoring

- Message mode

INQUIRY data

CNII4

24

0 0

0 0

L

User setting disabled

i Synchro-

L_ nous mode

transfer

3to4MB/s

L

I

transfer

- SCSI bus parity

Motor start mode

PER default value

MODE SELECT parameter rounding

irrocess report

13

L scsi

terminating

resistor Power

* Factory settings may vary.

Figure 3.5 Setting Terminals CNH1, CNH2, CNH3, and CNH4

Fujitsu America, Inc.

FS810125-01 . . . B

3-9

Page 57

M2266S/H

Technical Handbook

Factory Terminal Settings

The following paragraphs list the factory default settings for CNHI, CNH2,

CNH3, and CNH4. 'Short' means that a short plug is set between the two

terminal pins; "open" means that there is no short plug.

SCSI Terminating Resistor Power Supply

Table

3.2 Setting Terminal: CNH4

Pin position

Setting item

1-2

Connecting

TERMPWR

34

pin and

terminating

Setting contents

Connecting

power to

TERMPWR

pin

Connecting

power to IDD

terminating

resistor

resistor

SCSI

terminating

resistor power

Open

Short

Short

Short

Open

Yes

No

Yes

Yes

No

No

Yes

Yes

No

Short

*: Setting at factory shipment

Drive Types

Table 3.3 Setting Terminal: CNH3

Setting item

Device type

Pin position

1-2

3-4

5-6

7-8

9-10

11-12

Device type (User must not change the setting).

Open

Open

M2266S/H

13-14

15-16

J

Setting contents

The user must not change the setting

(setting at factory shipment depends on

the model).

The user must not change the setting

(should be open).

Note: The user must not change the setting of CNH3.

3-10

FS810125-01 . . . A

Fujitsu America, Inc.

Page 58

Technical Handbook

M2266S/H

Table 3.4 Setting Terminal: CNH2

Setting item

SCSI level

Pin position

Short

1-2

Open

Short

Message mode

34

Open

Error report at

MODE SELECT

parameter rounding

PER default value

5-6

7-8

Short

Open

Short

Open

Short

Motor start mode

9-10

Open

Short

SCSI bus parity

11-12

Open

Synchronous mode

transfer rate

Synchronous mode

data transfer request

Short

13-14

Open

Short

15-16

Open

Setting contents

Corresponds to SCSI-2

Corresponds to SCSI-1 /CCS

SAVE DATA POINTER is issued for

disconnection after data transfer.

SAVE DATA POINTER is not issued for

disconnection after data transfer.

CHECK CONDITION status is not posted.

CHECK CONDITION status

(RECOVERED ERROR) is posted.

0

1

Started when power is turned on.

Started with the START/STOP UNIT

command.

A parity check is executed.

No parity check is executed.

0.96 to 4.8 MB/s

0.96 to 2.67 MB/s

Enabled

Disabled

Setting at factory shipment

Refer to synchronous mode data transfer request explanation.

(1)

Refer to SCSI level explanation.

(2)

Fujitsu America, Inc.

FS810125-01 . . . A

3-11

Page 59

M2266S/H

Technical Handbook

Synchronous mode data transfer request

Set whether synchronous mode data transfer request is used according to

Table 3.5. The user can set the allowable scope of the maximum transfer rate

in synchronous mode according to Table 3.5.

Table 3.5 Synchronous Mode Data Transfer Request Setting (CNH2)

Synchronous mode transfer request

Enabled

Disabled

15-16

Short

Open

* 1 Set at factory shipment

Table 3.6 Scope of Transfer Rate in Synchronous Mode Setting (CNH2)

3 to 4.8 MB/s

synchronous mode transfer

Enabled (max. 4.80 MB/s)

Disabled (max. 2.67 MB/s)

13-14

Short

Open

*1 Set at factory shipment

Notes:

1.

This setting does not affect asynchronous mode transfer.

When synchronous mode transfer request is disabled, the IDD

2.

operates as follows.

•

When the SYNCHRONOUS DATA TRANSFER REQUEST

message is sent from the INIT, the IDD replys to that message and

the DATA IN and the DATA OUT phases of the SCSI bus can be

executed in synchronous mode.

•

The IDD does not send the SYNCHRONOUS DATA TRANSFER

REQUEST message to the INIT.

3. The maximum data transfer rate in synchronous mode is determined

when the SYNCHRONOUS DATA TRANSFER REQUEST message is

exchanged between the IDD and INIT.

3-12

P5810125-01 . . . A

Fujitsu America, Inc.

Page 60

Technical Handbook

M2266S/H

The INIT must determine the parameter sent to the IDD when the

message is exchanged in consideration of the signal transfer

characteristics of the system SCSI bus and the data reception capacity

of the INIT.

The IDD can transfer up to 4.8 MB/s in synchronous mode. However,

since the configuration of the SCSI bus and its transfer characteristics

differ depending on the system, the maximun transfer rate in which

data can be transferred in a stable condition must be determined for

each system.

4.

When 3 to 4.8 MB/s synchronous mode transfer is disabled with this

terminal, the IDD suppresses the data transfer rate to 2.67 MB/s or less

when the SYNCHRONOUS DATA TRANSFER REQUEST message is

exchanged. When 3 to 4.8 MB/s synchronous mode transfer is

enabled, up to 4.8 MB/s of data can be transferred.

At any rate, the maximum data transfer rate determined when the

message is exchanged does not exceed the value in the parameter of

the SYNCHRONOUS DATA TRANSFER REQUEST message

declared by the initiator. Therefore, when the initiator declares the

parameter within the allowable scope of the system, 3 to 4.8 MB/s

synchronous mode transfer is enabled with this plug.

For reference, the IDD data transfer rate in synchronous mode and the

5.

restrictions on the system configuration of the SCSI bus are shown

below.

Remarks:

The following values are rough standards. The values must be

evaluated for each system.

•

Single-ended SCSI bus

Maximum transfer rate

Maximum length of the

of the IDD (MB/s)

3.00 to 4.80

2.67 or less

SCSI cable (m)

*

6.0

Number of connectable

SCSI devices

5

*

8

* The maximum SCSI cable length and the number of connectable SCSI

devices must be determined for each system.

•

Differential SCSI bus

Generally, the restrictions on the system configuration need

not be considered. When up to eight SCSI devices connect to

the SCSI cable (up to 25 m), data can be transferred at 4.8 MB/s.

Fujitsu America, Inc.

FS810125-01 . . . A

3-13

Page 61

M2266S/H

Technical Handbook

SCSI level

I) Set the display contents of data posted to the initiator from the IDD

with the INQUIRY command according to Table 3.7. Select one of the

modes depending on the system software requirements.

2) When the SCSI/CCS mode is selected, parameters transferred by the

MODE SENSE command are as follows.

Page code 3F (all pages equipped in the IDD are transferred.)

a)

(D Page 7 and page 8 are not transferred.

© Page 1, page 2 and page 4 are transferred with the specified

length of CCS.

When the page 1, page 2 or page 4 is specified individually, it is

b)

transferred with the specified length of CCS.

When the page 7 or page 8 is specified individually, it is

c)

transferred with the specified length of SCSI-2.

For the recovery parameter of the VERIFY, the recovery parameter

d)

in page 1 is used.

3) When the SCSI-1/CCS mode is selected and the REQUEST SENSE

command is issued with specifying the transfer byte length to 0, the

IDD transfers the 4-byte sense data.

Table 3.7 SCSI Level Setting (CNH2)

INQUIRY data

Mode

SCSI-2

mode

l

SCSI-1

CCS

mode

Byte 2, bits 2

to 0

(ANSI

version)

'0,1,0' (SCSI-2)

'O,O,l'

=

ANSIX3.131=

1986

(SCSI-1)

Byte 3, bits 3

to 0

(Response data

format)

'0,0,1,0'

'0,0,0,1'

=ANSIX3T9.2/

85-52

-

(CCS)

* Set at factory shipment

3-14

FS810125-01 . , . A

(SCSI-2)

Byte 7

(Provided

function)

Indicates the

function

of the

IDD for each bit.

All bits '0'

INQUIRY

information

Fujitsu America, Inc.

VPD

Valid

Invalid

1-2

(1)

Short

Open

Page 62

Technical Handbook

M2266S/H

Table 3.8

Setting item

LED display

requirements

(1)

UNIT

ATTENTION

report mode

SCSI time

monitoring mode

*: Setting at factory shipment

(1) Refer to unit attention report mode explanation.

Pin position

1-2

11-12

13-14

Short Short

Short

Open

Open

Setting Terminal: CNH1

Setting contents

Operating with the SCSI bus

Short

Open

READY (seek completion) status

3-4

5-6

7-8

9-10

Short

Open

15-16

Open

Short

Open

The user cannot change the setting

}

Responds with CHECK CONDITION

status

Does not respond with CHECK

CONDITION status

ACK signal wait

monitoring time

oo

(unlimited)

-

60 sec

30

30 60 sec

1

-

2 sec

SELECTION

monitoring time and

number of retries

250 ms, 128 retries

250 ms, 10 retries

250 ms, unlimited

retries

1 ms, 10 retries

Fujitsu America, Inc.

FS810125-01 . . . A

3-15

Page 63

M2266S/H

Technical Handbook

UNIT ATTENTION Report Mode

Sets the response method against the received command when the IDD

keeps the UNIT ATTENTION condition (see Table 3.9). This mode is set for

system requirement, however, it is recommended to use the SCSI standard

setting (setting at factory shipment).

Table 3.9 UNIT ATTENTION Report Mode Setting (CNH1)

IDD response under the UNIT ATTENTION condition

11-12

For a command other than INQUIRY, REQUEST SENSE, or

PRIORITY RESERVE the IDD responsed with the CHECK

CONDITION status.

Short

(SCSI standard)

All received commands are executed normally.

(The CHECK CONDITION status caused by the UNIT

Open

ATTENTION condition is not reported.)

*1

Set at factory shipment

SCSI Terminating Resistor

The SCSI terminating resistor module is installed in the IDD when the IDD

is shipped from the factory. See Figure 3.2 and 3.3 for installation positions.

The terminating resistor module is mounted in a socket and must be

processed in one of the following ways:

•

When connecting the IDD to either end of the SCSI cable, do not remove

the terminating resistor module.

When connecting the IDD to a position not at the end of the SCSI cable,

•

remove the terminating resistor modules. For the M22665, there is one

module. For the M2266H, there are three modules.

Notes:

When removing the terminating resistor module, be careful not to

1.

damage the resistor-module pins, mount socket, and contiguous parts.

When mounting the terminating resistor module, check the mounting

2.

direction and whether the module is fixed. See Figures 3.6 and 3.7.

3-16

FS810125-01 . . . A

Fujitsu America, Inc.

Page 64

Technical Handbook

M2266S/H

Demounting the resistor module

DEIDDDDDDEJD

0

DJDDDDDDDD

S

shows pin No. 1 of the resistor module.

1

Figure 3.6 SCSI Terminating Resistor Module (M2266S)

Dismounting the resistor module

DDEJDDDEID

0

DDUDDEJDD

000DDDEID

0

00000000

Mounting the resistor module

Mounting the resistor module

nnnnrinnnnn

)..

uuuuuuuuuu

0000000,0

0

00000000

)

•

*

La L La La La La La La

*1 *shows pin No. I of the resistor module.

Figure 3.7 SCSI Terminating Resistor Module (M2266H)

Fujitsu America, Inc.

La La La La La La La Li

FS810125-01 ... A

La La La La La La La La

3-17

Page 65

M2266S/H

Technical Handbook

Table 3.10 Setting Checklist

Setting group

Terminals

Item

SCSI ID

SCSI time monitoring

2

Read-ahead caching

Setting

Location

CN3/CN9 13-14

CN3/CN9

CN3/CN9

11-12

9-10

7-8

5-6

Checkoff

-

SCSI ID=

-

Short

- Open

-

Short _Open

Terminals

Diagnostic switch

SCSI terminating

resistor power

Synchronous mode

6

transfer

3 to 4MB/sec

synchronous mode

transfer

SCSI bus parity

8

Motor start mode

PER default value

10

MODE SELECT

11

parameter rounding

process report mode

SAVE DATA

12

POINTER message

mode

INQUIRY data

13

SCSI time monitoring

14

mode

UNIT ATTENTION

15

report mode

LED display

16

requirement

CN3/CN9

CNH4

2

3-4

CNH2 15-16

CNH2

CNH2

CNH2 9-10 - Short

CNH2 7-8 - Short

CNH2 5-6

CNH2

CNH2 1-2 - Short _Open

CNHI 13-14

CNHI 11-12

CNI-I1 1-2

1-2

-

Short _Open

1-

-

Short _Open

-

Short

-

Short Open

13-14

-

Short

11-12

-

Short Open

Short

3-4 - Short _Open

-

Short

15-16

-

Short _Open

-

Short _Open

-

Short _Open

-

-

-

-

-

-

Open

Open

Open

Open

Open

Open

Terminal

resistor

3-18