Page 1

IP-920E/DC

Hardware User’s Guide

Page 2

(This page is intentionally left blank)

Page 3

USING IP-920E/DC SAFELY

The following notice is for USA users only.

has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

eration of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

The following notice is for Canada users only.

The following notice is for EU (European Union) users only.

ct may cause radio interference in which case the user may be required to make adequate

measures.

This manual includes technology controlled under the Foreign Exchange and Foreign Trade Control

exported) without

authorization from the appropriate governmental authorities in accordance with the above law.

is designed and manufactured for use in standard applications such as office work,

appliances. The product is not intended for special uses (such as

reactor control in atomic energy facilities, aeronautic and space systems, air traffic control,

sile firing controls in

weapons facilities) where particularly high reliability requirements exist, where the pertinent levels of

safety are not guaranteed, or where a failure or operational error could threaten a life or cause physical

assurance measures in place beforehand. Moreover,

Handling of This Manual

The manual contains important information regarding the safe use of IP-920E/DC. Read it thoroughly

before operating this device. Make sure that users of this equipment read and understand thoroughly all

safety precautions contained in the manual. Keep this manual in a safe and convenient location for

quick reference.

Fujitsu makes every effort to prevent users and bystanders from injury and to prevent property damage.

To ensure no harm to you and bystanders, and to prevent damage to this equipment itself, be sure to use

this equipment in accordance with instructions

IP-920E/DC

harmful interference when the equipment is operated in a commercial environment. This equipment

the instruction manual, may cause harmful interference to radio communications. Op

required to correct the interference at his own expense.

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment

Regulations.

in the manual.

This is Class A product of Electromagnetic Interference (EMI) standard. In a domestic environment

this produ

Law of Japan. The manual or a portion thereof must not be exported (or re-

IP-920E/DC

personal devices, and household

nuclearoperation control in mass transit systems, medical devices for life support, and mis

injury (hereafter referred to as "mission-critical" use). Customers considering use of this product for

mission-critical applications must have safetythey are requested to consult our sales representative before embarking on such specialized use.

i

IP-920E/DC

Page 4

Copying of and disassembly, decompilation and other forms of reverse engineering of any program

included with this device is prohibited.

ation in the

Definition Multimedia Interface are trademarks or registered trademarks

contained in this

contained herein; including any

Windows, Internet Explorer are registered trademarks or trademarks of Microsoft Corpor

United States and/or other countries.

HDMI, HDMI Logo and High-

of HDMI Licensing LLC.

IMPORTANT NOTE TO USERS

READ THE ENTIRE MANUAL CAREFULLY BEFORE USING THIS PRODUCT.

INCORRECT USE OF THE PRODUCT MAY RESULT IN INJURY OR DAMAGE TO

USERS, BYSTANDERS OR PROPERTY.

While FUJITSU has sought to ensure the accuracy of all information in this manual, FUJITSU

assumes no liability to any party for any damage caused by any error or omission

manual, its updates or supplements, whether such errors or omissions result from negligence, accident,

or any other cause. In addition, FUJITSU assumes no liability with respect to the application or use of

any product or system in accordance with descriptions or instructions

liability for incidental or consequential damages arising therefrom.

FUJITSU DISCLAIMS ALL WARRANTIES REGARDING THE INFORMATION

CONTAINED HEREIN, WHETHER EXPRESSED, IMPLIED, OR STATUTORY.

FUJITSU reserves the right to make changes to any products described herein without

and without obligation.

No part of this manual shall be reproduced in any way or form without the permission of Fujitsu Limited.

All Rights Reserved. Copyright

©

FUJITSU LIMITED 2011-2016

further notice

IP-920E/DC

ii

Page 5

PREFACE

Thank you for purchasing the IP-920E/DC.

IP-920E/DC is the video transmission unit with the H.264 encoding technology which performs the high

compression ratio, and transmits the SD (Standard Definition) /HD (High Definition) video and audio signals

in real time through even the optical IP network like FTTH. (*1) IP-920E has functions that encodes SD/HD

video signals from a SD/HD camera or similar device and distributes it across the network in real-time.

This manual is intended for system designers and system managers who use IP-920E/DC. Readers are

assumed to have a basic knowledge of networks and video distribution.

*1: IP-920E/DC supports only SD video. By adding optional software, IP-920E/DC will be upgraded to

support HD video.

Edition 8

June 2016

Product operating environment

• Designed for use in real-time audio/video transmission systems and in the transmission system of

monitoring systems, IP-920E/DC is intended for indoor use.

Note:

The contents of this manual are subject to change without notice.

IP-920E/DC

iii

Page 6

ORGANIZATION AND CONTENTS OF THIS MANUAL

The manual consists of five chapters, an appendix, a glossary and an index.

Read Chapters 1 and 2 first for information on installing and connecting this equipment. Read Chapter

3 for operating instructions, and Chapter 4 and subsequent chapters can be read as required.

Chapter 1 Preparations

This chapter describes the checks that are required before the start of IP-920E/DC operation.

Chapter 2 Installation and Connection

This chapter describes conditions for IP-920E/DC installation and explains how to connect it to

peripheral this equipments.

Chapter 3 Operating Instructions

This chapter explains how to power on/off, set up and operate this equipment.

Chapter 4 Connection Cable Specifications

This chapter contains a classification of how work is implemented, cable connection system diagrams

and cable connector details.

Chapter 5 Troubleshooting

This chapter describes actions to be taken if this equipment does not operate normally or if an alarm LED

turns on.

Appendix

The appendix contains views of this equipment and its basic specifications. Installation work and

on-site adjustment preparations are also covered in this section.

Glossary

The glossary defines the technical terms used in this manual.

Index

The index lists keywords and corresponding pages on which the words appear, so necessary items can be

looked up immediately.

IP-920E/DC

iv

Page 7

WARNING INDICATIONS

Left and right indents are set for warning messages to differentiate them from ordinary text.

!

CAUTION

This manual uses warning indications to warn of conditions in order to prevent serious injury and

property damage. Warning indications consist of warning markings of specific levels and warning

messages. The warning markings are shown below along with their definitions.

WARNING indicates a situation that could lead to serious injury

or loss of life if procedures are not followed correctly.

CAUTION indicates a situation that could lead to minor or

moderate injury and/or damage to this equipment itself if

procedures are not followed correctly.

Warning indications within text

Warning markings are followed by warning messages. Every warning marking is centered on a line.

Furthermore, the lines immediately before and after warning indications are left blank.

(Example)

Possibility of electric shock, fire and damage to this equipment

Always observe the precautions given below.

This indicates a hazardous situation that could lead to electric shock, fire or

damage to this equipment.

• When using

between this equipment and an external power-supply unit or at an

output part of an external power-supply unit. Also, ensure to use a

breaker that cuts off both terminals at the same time. Observe the

conditions below and select a proper breaker.

- Service voltage: DC12 to 24V±10%

- Steady current: 3.3A (maximum in case of 12V)

- Inrush current: up to 10A

Important warning indications are summarized below in “Safety Precautions.”

IP-920E/DC, ensure to set a breaker at an internal wiring

IP-920E/DC

v

Page 8

SAFETY PRECAUTIONS

Normal use

Possibility of electric shock and fire

this

, immediately set its power switch to OFF and remove the power cord plug

, immediately

tacle.

has been dropped or otherwise damaged, immediately set its power

ch to OFF and remove the power cord plug from the power receptacle. Then,

that drink containers and metal objects are not placed

creates a hazardous

creates a hazardous

If the power cord has a heavy object is placed on it, pulled at, bent, or becomes entangled, it

o heat,

Indicates a situation that could lead to serious injury or loss of life if procedures

are not followed correctly.

List of important warnings

The table below contains a list of important warning indications.

Work type Warning

If an excessive heat, smoke, an abnormal odor or an unusual noise is coming from

equipment

from the power receptacle. Then, contact a Fujitsu Service Center.

This indicates a hazardous situation that could lead to fire and electric shock.

Possibility of electric shock and fire

If foreign matter (e.g., water, bits of metal, fluid) gets inside this equipment

set its power switch to OFF and remove the power cord plug from the power recep

Then, contact a Fujitsu Service Center.

This indicates a hazardous situation that could lead to fire and electric shock.

Possibility of electric shock and fire

If this equipment

swit

contact a Fujitsu Service Center.

This indicates a hazardous situation that could lead to electric shock.

Possibility of electric shock and fire

To keep foreign matter out, ensure

on or near this equipment.

The presence of foreign matter such as water inside this equipment

situation that could lead to electric shock.

Possibility of electric shock and fire

Ensure that no liquid is splashed on this equipment, making it wet.

The presence of foreign matter such as water inside this equipment

situation that could lead to fire and electric shock.

Possibility of electric shock and fire

Ensure that the power cord does not become damaged, and avoid tampering with it.

could be damaged as a result. Also, the power cord could be damaged if subjected t

creating a hazardous situation that could lead to fire and electric shock.

IP-920E/DC

vi

Page 9

Installation

to

Using a power supply

this

may cause a

is exposed to direct sunlight or

. If the attached cable is not

and

ut part of an external

at the

- Inrush current: up to 10A

Work type

Warning

Possibility of electric shock and fire

Always observe the precautions given below.

This indicates a hazardous situation that could lead to electric shock, fire and damage

this equipment.

• Ensure to use a DC power supply with SELV safety status.

with another safety status could lead to electric shock, fire or damage to

equipment.

Possibility of electric shock and fire

Do not install this equipment in the following places because using it there

fire:

• Extremely dusty or dirty place

• Wet or humid location

• Hot location, such as a place where this equipment

is near heating equipment

• Near products (e.g., speakers) that generate a strong magnetic field

• Location where the temperature is too hot or cold

• In an environment with sharp temperature fluctuations

• Area with poor ventilation

• Near a fire

Possibility of electric shock, fire, and damage to this equipment

Always observe the precautions given below.

This indicates a hazardous situation that could lead to fire and damage to this equipment.

• Choose a power supply that meets the nominal voltage of IP-920E/DC.

• Use the power cable (DC) attached to IP-920E/DC

usable, use a cable adapted to current capacity of more than 5A.

• When using IP-920E/DC, ensure to set an internal wiring between IP-920E/DC

an external power-supply unit or a breaker at an outp

power-supply unit. Also, ensure to use a breaker that cuts off both terminals

same time. Observe the conditions below and select a proper breaker.

- Service voltage: DC12 to 24V±10%

- Steady current: 3.2A (maximum in case of 12V)

vii

IP-920E/DC

Page 10

Installation

in places where it is exposed to shock and strong vibrations,

ct against

Set the power switch to OFF, and disconnect all connected cables. Take care to

cial care

Clean

Possibility of fire, serious injury and damage to this equipment

fire,

, please wipe off with the cloth squeezing water (or

switches or the spaces.

Work type Warning

Possibility of serious injury and damage to this equipment

and

relocation

Do not install this equipment

on an incline or in unstable locations.

This indicates a hazardous situation that could lead to serious injury or damage to this

equipment.

Possibility of serious injury and damage to this equipment

When relocating this equipment, observe the following precautions to prote

serious injury and damage to this equipment:

•

avoid getting your feet entangled in the cables.

• To prevent serious personal injury when moving this equipment, take spe

to pay attention to your surroundings.

When cleaning this equipment, observe the following precautions to protect against

serious injury and damage to this equipment:

• When cleaning this equipment, please do not use cleaning spray that is including

combustible material. Also, please do not use it around this equipment.

• When cleaning this equipment

neutral detergent thinned by water).

• When wiping off, please be careful not to put water into this equipment from

IP-920E/DC

viii

Page 11

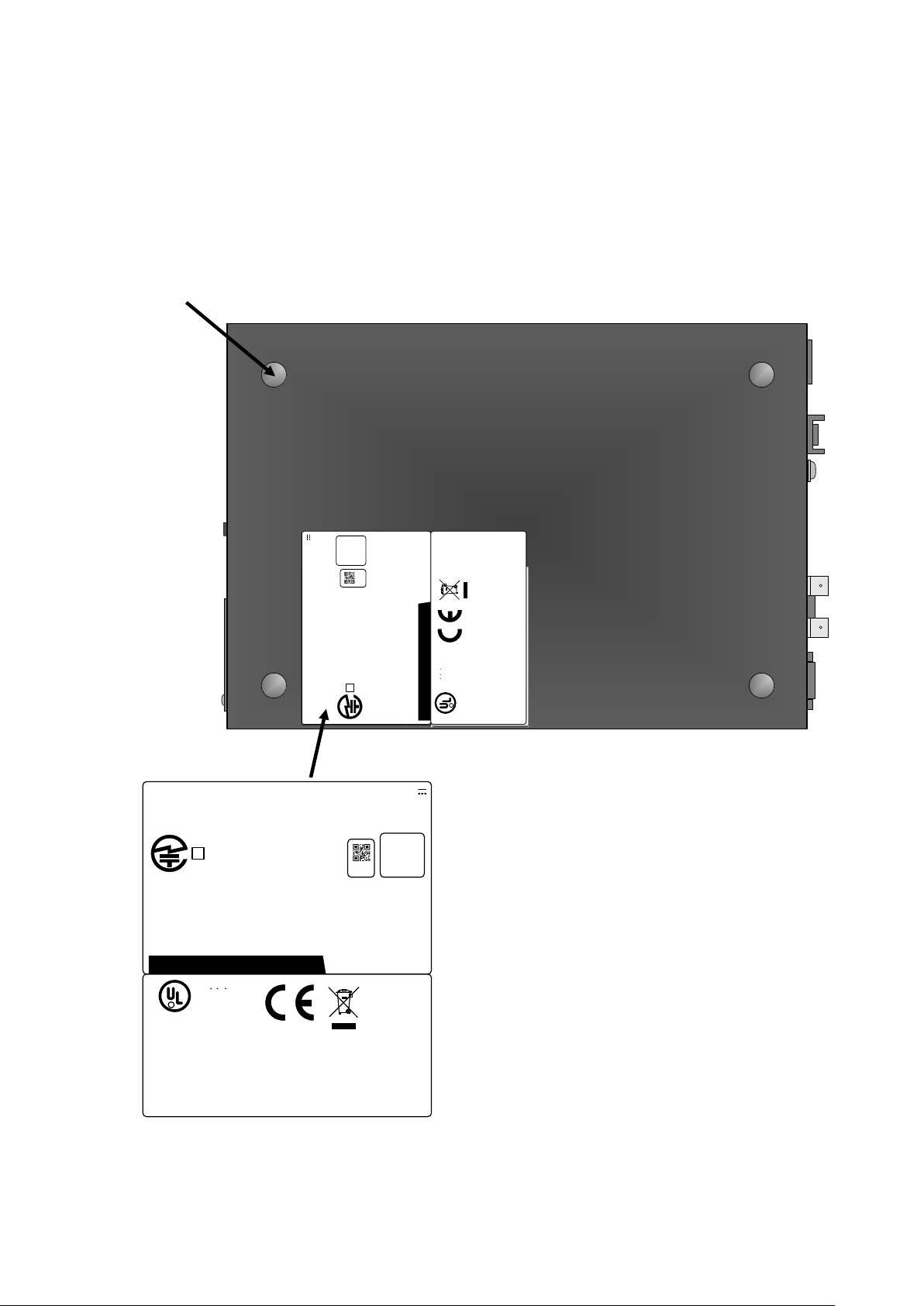

LABEL

Label:IP-9

20E/DC

LISTED

R

C

US

1K

91

I T E

E136004

Manufacture

Fujitsu Limited

Address: 1-1, Kamikodanaka 4

-Chome, Nakahara-

Ku, Kawasaki 211-8588, Japan

Authorised representati ve

Fujitsu Services Limited

Address: 22 Baker Street, London

, W1U

3BW, United Kingdom

CAN ICES-3 (A) / NMB

-3 (A)

MODEL

PART NO.

IP-920E/DC

TA

23742-

B7

XX

This device complies with Part 15 of the FCC Rules.

operation is subject to the following two conditions:

(1)

This device may not cause harmful interference. and

(

2) this device must accept any i nterference received

,

including i nterference that may cause undesired operation

.

MADE IN JAPAN

3.

2A

-

1.

6A

+12V

-24V

2.3

kg

FUJITSU LIMITED

T

認証番号

01

A

11

-03

00001

D08

-0454001

12345

ACCESSORY

MODEL

PART NO.

IP-920E/DC

TA23742-B72X

This device complies with Part 15 of the FCC Rules.

operation is subject to the f ollowing two conditions:

(1) This device may not cause harmful interference. and

(2) this device must accept any interference received,

including interfer ence that may cause undesired operation.

MADE IN JAPAN

3.2

A-1.6A

+12V-24V

2.3kg

FUJITSU LIMITED

T

認証番号

01A

11-03

00001

D08-0454001

00001

I T E

ACCESSORY

LISTED

R

C

US

1K91

E136004

MODEL

PART NO.

IP-920E/DC

TA23742-B72X

This device complies with Part 15 of the FCC Rules.

operation is subject to the following two conditions:

(1) This device may not cause harmful int erference. and

(2) this device must accept any inter ference received,

including inter ference that may cause undesired operation.

MADE IN JAPAN

3

.2A

-1.6

A

+12V-

24V

2.3kg

FUJITSU LIMITED

T

認証番号

01A

11

-03

00001

D08

-0454001

12345

LISTED

R

C US

1K91

I T E

E136004

Manufacture

Fujitsu Limited

Address: 1-1, Kamikodanaka 4-Chome, Nakahara-Ku, Kawasaki 211-8588, Japan

Authorised representative

Fujitsu Services Limited

Address: 22 Baker Street, London, W1U 3BW, United Kingdom

CAN ICES-3 (A) / NMB-3 (A)

MODEL

PART NO.

IP-920E/DC

TA23742-B7XX

This device complies with Part 15 of the FCC Rules.

operation is subject t o the following two conditions:

(1) This device may not cause harmful int erference. and

(2) this device must accept any inter ference received,

including inter ference that may cause undesired operation.

MADE IN JAPAN

3.2A-1.6A

+12V-24V

2.3kg

FUJITSU LIMITED

T

認証番号

01A

11-03

00001

D08-0454001

12345

ACCESSORY

The warning label shown below is affixed to

・ Never remove the label.

・ Be sure to check the label at the bottom of this device before coming to the power supply.

・ The following label is intended for users of this equipments.

Mark for rubber feet

this equipment.

IP-920E/DC

ix

Page 12

PRODUCT HANDLING PRECAUTIONS

WARNING

CAUTION

Maintenance

Do not try to repair this equipment yourself. Contact a Fujitsu Service

Center.

Read this manual thoroughly before attempting to operate this equipment.

If you have any questions, contact a Fujitsu Service Center.

If a problem occurs, contact a Fujitsu Service Center.

The Fujitsu Service Center will ask you to describe the problem, the lamp display status of

alarm LEDs and other details. Check the system for this information.

Connectable devices

Only devices that conform to this equipment interface specifications (see Appendix 2.3, "Device

Specifications") can be connected. Otherwise, if incompatible devices are connected, the result

may be personal injury and property damage.

CF card consideration

Please note that you need to remove the CF card or take the backup of its recorded data in case of

requesting the repair of the main unit that the CF card is installed, since Fujitsu does not guarantee

the recorded content during the repair work.

Please also note that the recorded content might be deleted by the process of the diagnostic and

the repair work after Fujitsu starts the work even if you already cancel the repair request

Disposal

To dispose of this equipment, contact a Fujitsu Service Center, or request a specialist to take care

its disposal.

Modification and restoration

Do not use any device that has been modified or rebuilt with refurbished used parts. Doing so

may result in personal injury and property damage.

IP-920E/DC

x

Page 13

CONTENTS

Chapter 1 Preparations .......................................................................... 1

1.1 Main Features ......................................................................................... 3

1.2 Components ........................................................................................... 4

1.3 Basic Application Examples ................................................................... 5

1.4 Part Names ............................................................................................. 6

Chapter 2 Installation and Connection ................................................. 9

2.1 Installation Conditions .......................................................................... 11

2.1.1 Environment conditions ........................................................... 11

2.1.2 Installation environment ........................................................... 11

2.1.3 Air supply and exhaust of the equipment ................................ 30

2.1.4 Open space required around this equipment .......................... 31

2.2 Power Supply System Connections ........................................................ 32

2.2.1 Connection to ground .............................................................. 32

2.2.2 Connection to power source .................................................... 33

2.3 Audio and Video Device Connections .......................................................... 35

2.4 Connection to Network ......................................................................... 36

2.5 Connection to RS-232C Device ........................................................... 37

2.6 CF Card Insertion and Removal ........................................................... 38

Chapter 3 Operation Instructions........................................................ 41

3.1 Turn ON/OFF IP-920E/DC ................................................................... 43

3.1.1 Turn on IP-920E/DC .................................................................. 43

3.1.2 Turn off IP-920E/DC .................................................................. 43

3.2 Device Settings and Operation ............................................................ 44

3.2.1 Reboot ....................................................................................... 45

3.3 Special Use of MNT Button .................................................................. 46

Chapter 4 Cable Specifications ........................................................... 47

4.1 Installation Preparations ....................................................................... 49

4.2 Cable and Connector Details ............................................................... 50

Chapter 5 Troubleshooting .................................................................. 59

5.1 Help Information ................................................................................... 61

5.2 Alarm LED Lamp Is On ........................................................................ 65

5.3 Maintenance ......................................................................................... 67

5.3.1 Maintenance space ................................................................... 67

5.3.2 Change equipment (Only for CE) .............................................. 68

IP-920E/DC

I

Page 14

Appendix ................................................................................................. 69

A.1 Appearance .......................................................................................... 71

A.2 Basic Specifications .............................................................................. 73

A.2.1 External specifications ............................................................... 73

A.2.2 Environment specifications........................................................ 73

A.2.3 Function specifications .............................................................. 74

A.3 Preparations for Installation Work ........................................................ 79

A.3.1 Scope of installation work .......................................................... 79

A.3.2 Unpacking and device check..................................................... 79

A.3.3 Installation conditions ................................................................ 79

A.3.4 Connecting external cables ....................................................... 79

A.4 Preparations for On-site Turn-up .......................................................... 80

Glossary and Index ................................................................................ 83

Glossary ......................................................................................................... 85

Index .............................................................................................................. 88

CE Conformity Information ............................................................................ 90

IP-920E/DC

II

Page 15

CHAPTER 1

Chapter 1 Preparations

This chapter describes the checks that are required before the start of IP-920E/DC

operation.

PREPARATIONS

1.1 Main Features .............................................................................................. 3

1.2 Components ................................................................................................. 4

1.3 Basic Application Examples ......................................................................... 5

1.4 Part Names .................................................................................................. 6

Page 16

(This page is intentionally left blank)

Page 17

Chapter 1 Preparations

HD-SDI / SD-SDI

1ch

[BNC]

HDMI 1.2a (*2)

1ch

[HDMI]

Analog Composite

1ch

[BNC]NTSC/PAL

HD/SD-SDI embedded

2ch

[BNC], 1 stereo pairs

HDMI 1.2a (*2)

2ch

[HDMI]

Analog balanced

2ch

[D-sub9-pin], female connector, 1 stereo pair

[RJ45],

10BASE-T / 100BASE-TX

Data input/output

RS-232C

1ch

[D-sub9-pin], male connector

CF CARD slot

CF CARD

1

Data storage application

Installation conditions

Indoor: On a desk, mounted in a rack

Dimensions

W: 210 H: 42 D: 300 (mm) Note: Excluding protrusions (i.e., not including feet)

Cooling system

Forced air cooling

Power supply

+12-24VDC

Weight

Maximum 2.3kg

Power consumption

38.4W or less

Temperature

Humidity

-10 to 55°C (No low temperature startup: -10 to -1°C)

20 to 90%RH (No condensing)

Safety Standard

Approved as Class III device of IEC60950-1, UL60950-1, EN60950-1

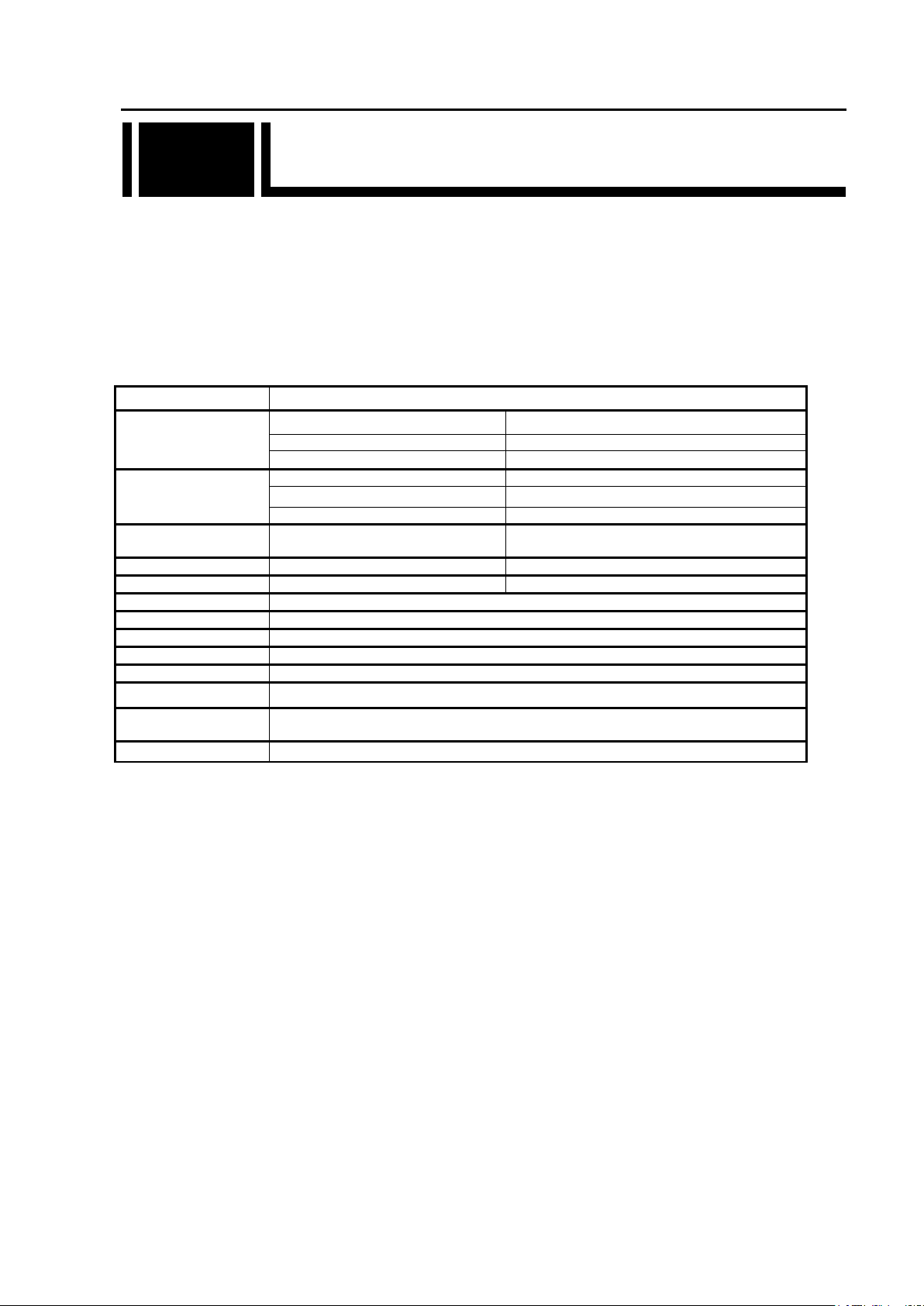

1.1 Main Features

1.1

IP-920E/DC is the video transmission unit with the H.264 encoding technology which performs the

high compression ratio, and transmits the SD (Standard Definition) /HD (High Definition) video and

audio signals in real time through even the optical IP network like FTTH.

IP-920E has functions that encodes SD/HD video signals from a SD/HD camera or similar device and

distributes it across the network in real-time.

Main Features

Item Specifications

Video input

Audio input

Network LAN 1ch

*1: IP-920E supports only SD video. By adding optional software, IP-920E will be upgraded to support HD video.

*2: DVI isn't supported.

3

IP-920E/DC

Page 18

Chapter 1 Preparations

・

・

・

CF CARD

/ACT

RDY

PWR ALM

IN

DWN

OPT

100M

LINK

E

A-IN (L)

A

I

N

L

(

)

A

I

N

R

(

)

1.2 Components

1.2

The IP-920E/DC product package consists of the following components.

Attachments for all series consist of same contents.

・

IP-920E/DC: 1 pc (cables separate order)

Safety manual: 1pc ・ User’s Guide: 1pc

Feet: 4 pcs ・DC Power cable: 1 pc

Audio adapter cable (type 1) : 1 pc

IP-920E/IP-920D

4

Page 19

Chapter 1 Preparations

CF CARD

/ACT

RDY

PWRALM

IN

DWN

OPT

100M

LINK

E

IP-920E

/DC

CF CARD

/

ACT

RDY

PWR

ALM

IN

DWN

OPT

100M

LINK

E

IP

-920E/DC

CF CARD

/ACT

RDY

PWR

ALM

IN

DWN

OPT

100M

LINK

E

RDY

PWRALM

DEC

MNT

FG

/ACT

100M

LINK

10/100BASE RS-232C

ANALOG

VIDEO OUT

100-240V

SDI

D

ANALOG AUDIO OUT

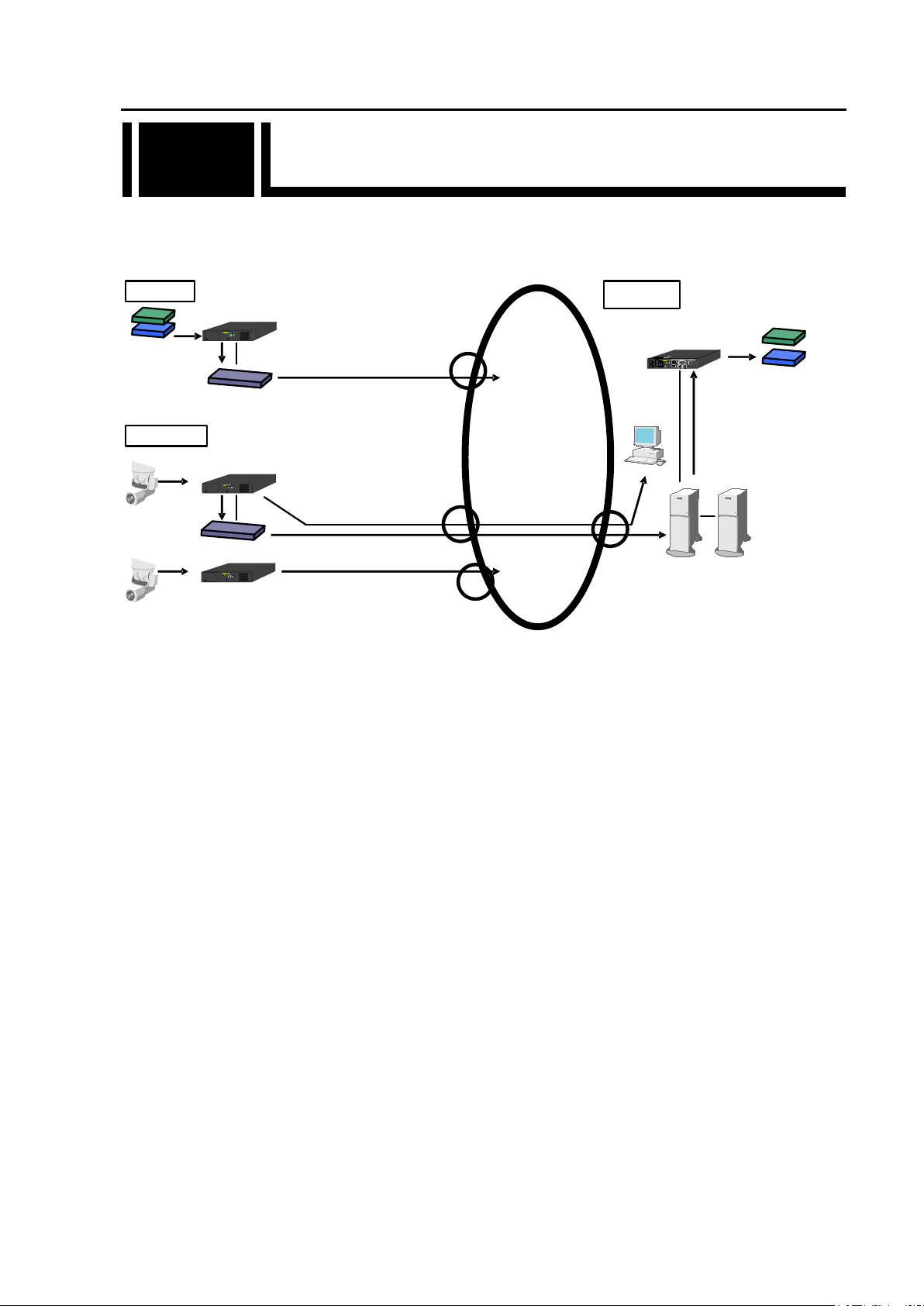

IP Network

FTTB

/ FTTH

Dart Fiber

AP

AP

HD

VTR

HD Camera

AP

Encoder Site

Live Coverage

IP

-920

E

/DC

Monitoring

Control

HD Archive Server

Strage(NR)

AP

Dual Encoding (

SD

)

File Transfer by Flow Control

HD VTR

Video Editing

Equipment

On demand file transfer

From affiliates

Decoder Site

1

U サーバー

Live Coverage

IP-920

D

HD Camera

1.3 Basic Application Examples

1.3

Examples (sys tem configuration) of use of IP-920E/DC are shown below.

5

IP-920E/DC

Page 20

Chapter 1 Preparations

By using a DC power cable attached to IP-920E/DC, it enables to connect to a

connection information.

(2)

Power button

Turns this equipment on and off.

(3)

Power LED (PWR)

Turns on when this equipment is powered on.

Status LED

(RDY)

Turn on when IP-920E power is on. For more information, see Table 5.3,

“Details of LED Indications,” in Section 5.2.

Alarm LED

(ALM)

Turns on when IP-920E operation is abnormal. For more information, see

Table 5.3, “Details of LED Indications,” in Section 5.2.

Audio/Video input setting status indicator and LED that indicates the input off

LED Indications,” in Section 5.2.

Option LED

(OPT)

Turn on when option license is installed. For more information, see Software

guide.

RDY

PWR ALM

IN

DWN

OPT

MNT

FG

/

ACT

100M

LINK

10

/

100BASE

RS

-

232C

ANALOG

VIDEO IN

SDI

ANALOG AUDIO IN

12

-

24

V

E

(

2)

(

7

)

(

8)

(

9)

(10

) (

11

)

(12

)

(13

)

(

14)

(15

)

(

16)

(

17

)

(1

)

(

3)

(

4

)

(

5

)

(

6

)

E

/

ACT

RDY

PWR

ALM

IN

DWN

OPT

100M

LINK

11

CF CARD

AUX

(18

)

(19

)

(20

)

(3) (4) (5) (6) (7)

(9

)

(10)

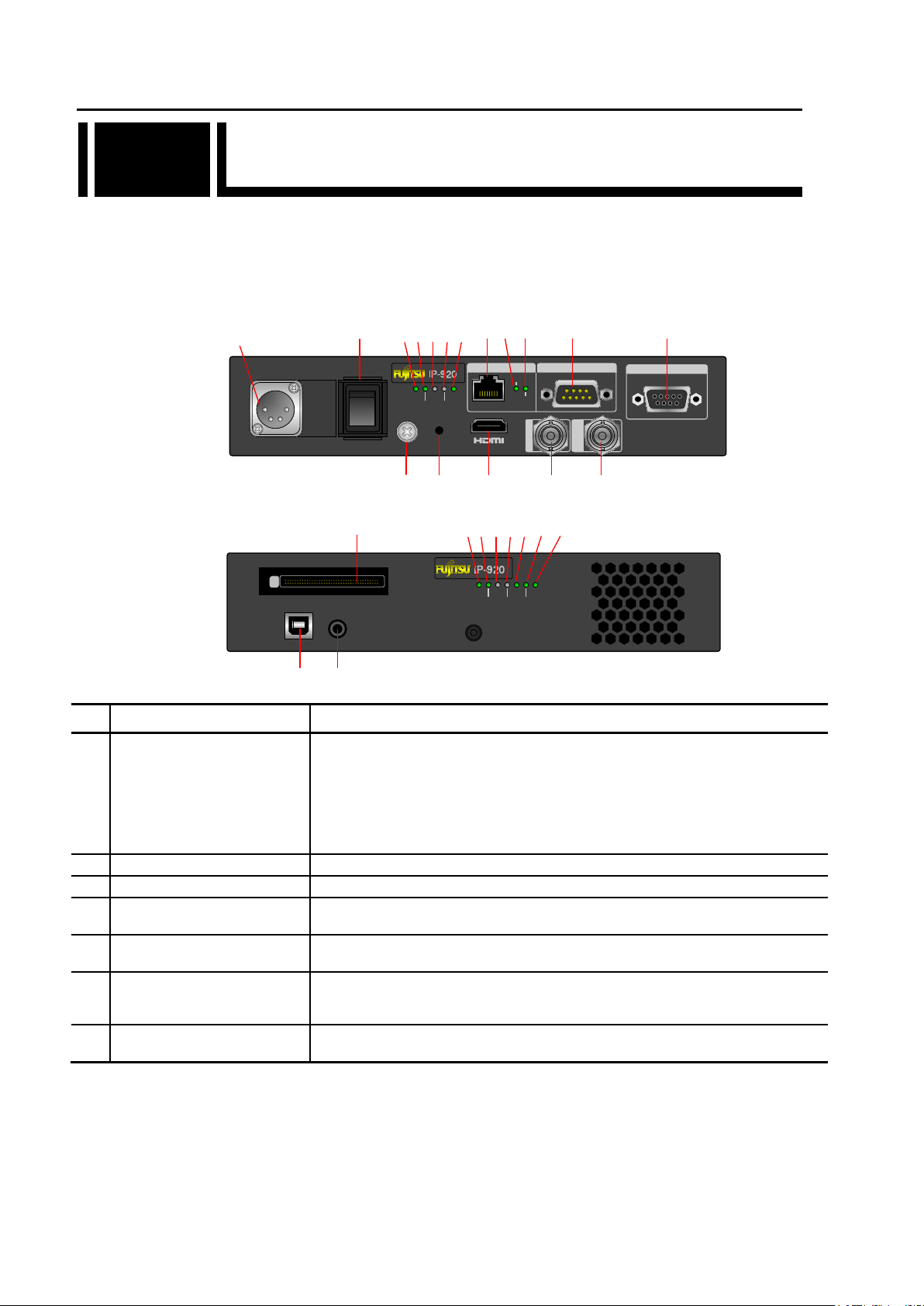

1.4 Part Names

1.4

This section gives the name and describes the function of individual parts of IP-920E/DC.

The diagrams below show the layout of parts on the outside of this equipment, and the table below

lists the name and describes t he function of individual parts.

- IP-920E/DC

Figure Front panel

Figure Rear panel

Part names

No. Name Description

power supply of DC12-24V.

Power inlet connector

(1)

(DC +12-24V)

However, a connectable power-source equipment needs to be SELV (*) safety

status.

See Section 2.2.2, “Connection to a Power Source,” for an explanation on using

this connector. See Section 4.2, “Cable and Connector Details,” for cable

(4)

(5)

AV input status LED

(6)

(INDWN)

status during input setting. For more information, see Table 5.3, “Details of

(7)

* SELV is a secondary circuit protected in the structure that electrical potential difference between any two

touchable points is not dangerous under the normal condition or even under the condition that any one point is

broken. It indicates up to 60V in case of DC voltage.

IP-920E/IP-920D

6

Page 21

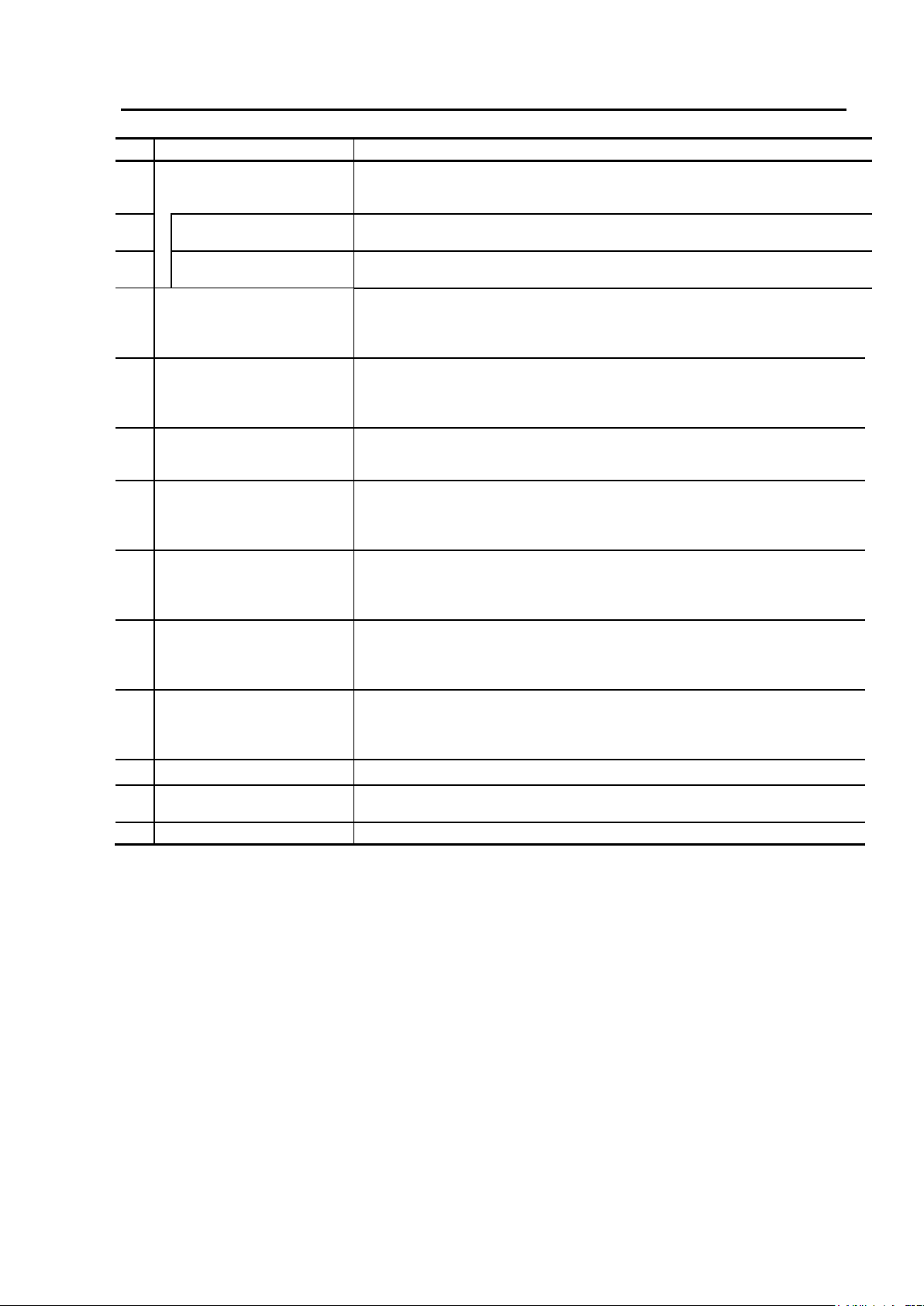

Names

Description

Ethernet 10BASE-T/100BASE-TX communication port. See Section 2.4,

4.2, “Cable and Connector Details,” for cable connection information.

Speed LED

(100M)

Indicates the status of LAN port. For more information, see Table 5.3, “Details

of LED Indications,” in Section 5.2.

Status LED

(LINK/ACT)

Indicates the speed of LAN port. For more information, see Table 5.3, “Details

of LED Indications,” in Section 5.2.

RS-232C data communication port.

connection information.

Audio input terminal. 600Ω balanced.

connection information.

Use for an FG connection to this equipment.

terminal.

IP-920E start mode selector switch. when the IP-920E is powered on with this

switch.

Digital HDMI video input terminal. 50Ω unbalanced.

connection information.

Digital HD-SDI video input terminal. 75Ω unbalanced.

connection information.

Analog video input terminal. 75Ω unbalanced.

connection information.

AUX port

(AUX)

(20)

Test port

Factory test port.

No.

Chapter 1 Preparations

LAN port

(8)

(10/100BASE)

(9)

(10)

RS-232C port

(11)

(RS-232C)

Audio input

(12)

(ANALOG AUDIO IN)

FG terminal

(13)

(14)

(15)

)

(FG

Maintenance mode switch

(MNT)

HDMI input

(HDMI)

“Connection to a Network,” for an explanation on using this port. See Section

See Section 2.5, “Connection to an RS-232C Device,” for an explanation on

using this pin. See Section 4.2, “Cable and Connector Details,” for cable

See Section 2.3, “Audio and Video Device Connections,” for an explanation on

using this terminal. See Section 4.2, “Cable and Connector Details,” for cable

See Section 2.2.1, “Connection to ground,” for an explanation on using this

switch held down, it starts in initial start mode.

See section 3.3, “Special Use of MNT Button,” for an explanation on using this

See Section 2.3, “Audio and Video Device Connections,” for an explanation on

using this terminal. See Section 4.2, “Cable and Connector Details,” for cable

SDI video input

(16)

(SDI)

Video input

(17)

(ANALOG VIDEO IN)

CF CARD slot

(18)

(19)

See Section 2.3, “Audio and Video Device Connections,” for an explanation on

using this terminal. See Section 4.2, “Cable and Connector Details,” for cable

See section 2.3, “Audio and Video Device Connections,” for an explanation on

using this terminal. See Section 4.2, “Cable and Connector Details,” for cable

Slot in which a CompactFlash@ card is inserted.

Auxiliary port.

7

IP-920E/DC

Page 22

(This page is intentionally left blank)

Page 23

CHAPTER 2

Chapter 2 Installation and Connection

INSTALLATION AND

CONNECTION

This chapter describes conditions for IP-920E/DC installation and explains how to

connect it to peripheral devices.

2.1 Installation Conditions ................................................................................ 11

2.2 Power Supply System Connections .............................................................. 32

2.3 Audio and Video Device Connections ................................................................ 35

2.4 Connection to Network ............................................................................... 36

2.5 Connection to RS-232C Device ................................................................. 37

2.6 CF Card Insertion and Removal ................................................................ 38

Page 24

Possibility of serious injury

The power cord and other cables connected to IP-920E/DC may become

entangled with someone walking close to them, possibly leading to serious

injury and property damage. Clamp the cables to the rack or floor.

Page 25

Chapter 2 Installation and Connection

2.1 Installation Conditions

2.1

This section describes the installation environment, space and air supply and exhaust of the

equipment.

2.1.1 Environment conditions

Please use this equipment in the air supply and ambient temperature which is not exceeded 55

degrees C. If the condition above is observed, you may install plural equipment as piling on a shelf.

In case of using this equipment under unsupported conditions, the equipment cannot be supported

by Fujitsu and it might be the cause of failure and shortening the product life remarkably.

Use this Equipment in the environment which airborne dust is under 0.15mg/m3. (In case of being

over 0.15mg/m3, use dust-proofing rack.) In addition, clean up around this equipment because

remarkably amount of dust is the cause of equipment errors and failures if it is attached to the

equipment.

Use this Equipment in the environment which gaseous contamination is under “IEC 60721-3-3

Class 3C1”.(Refer to “Appendix 2.2 Environment Specifications - Gaseous contamination”).

2.1.2 Installation environment

1. 19” rack mounting

Mount this equipment to 19” rack of EIA standard using the 19” rack mounting kit. We have 2

types of mounting kits; 1 unit per 1 U and 2 units per 1U.

(19” rack mounting kit is an optional product.)

If you would like to mount different way from the descriptions in this document, please

consult Fujitsu Service Center or your system administrator.

5 types of rack mounting kit are available. (Type A1, A2, B1, B2 and C2)

Use attached mounting kit and screws for installing equipment. Fix the

equipment tightly with the attached rack using attached screws. In case of

loosening the screws or not being fixed tightly with the equipment, it may be

a cause of serious accident.

11

IP-920E/DC

Page 26

Chapter 2 Installation and Connection

C

B A D

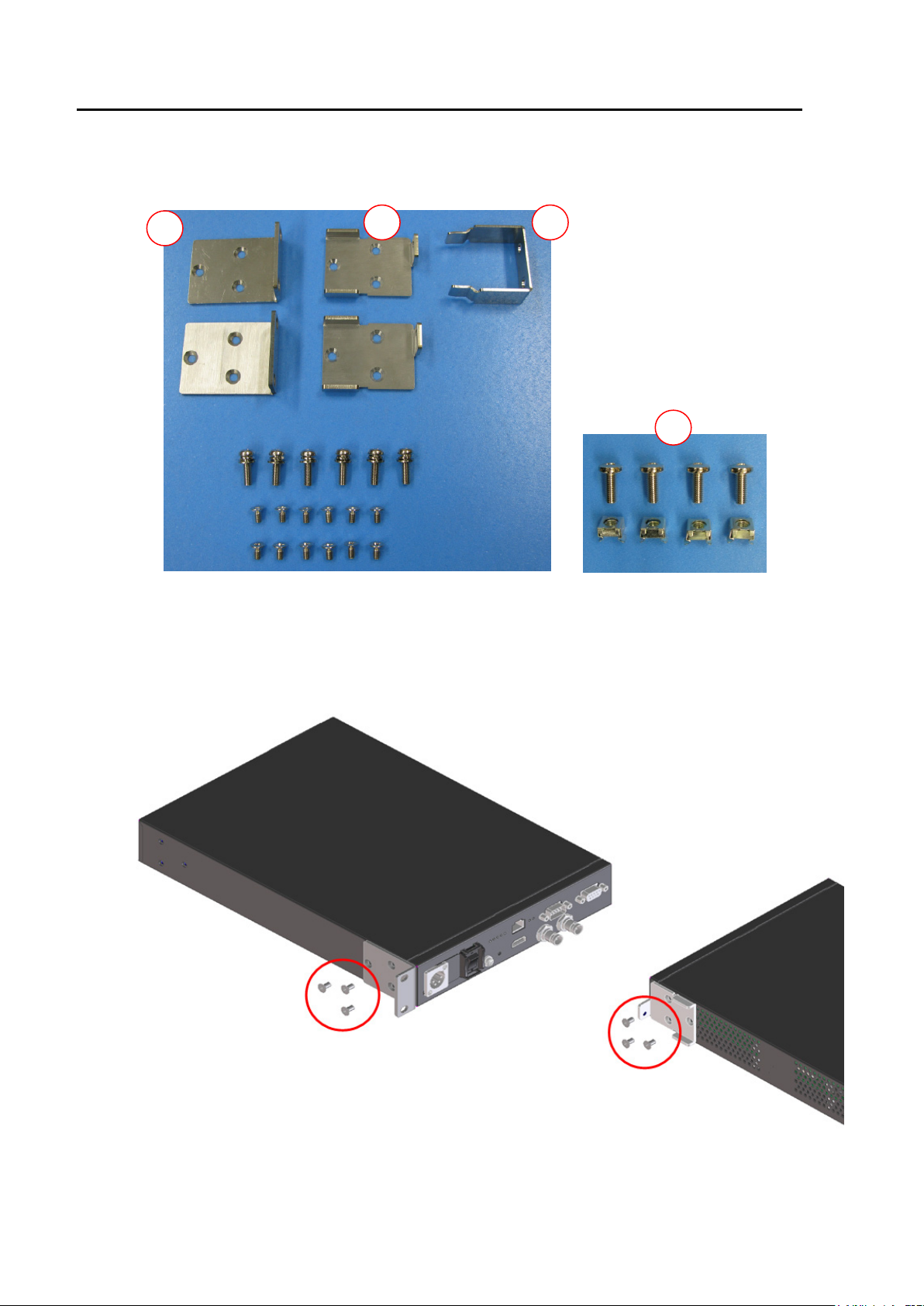

- Two IP-920 per 1U (Type C2)

(1) Check contents of the rack mounting kit.

(2) Check all cables disconnected.

(3) Connect the first device with the rack mounting kit “A” and “B” on IP-920 using six same

screws (M4).

IP-920E/DC

12

Page 27

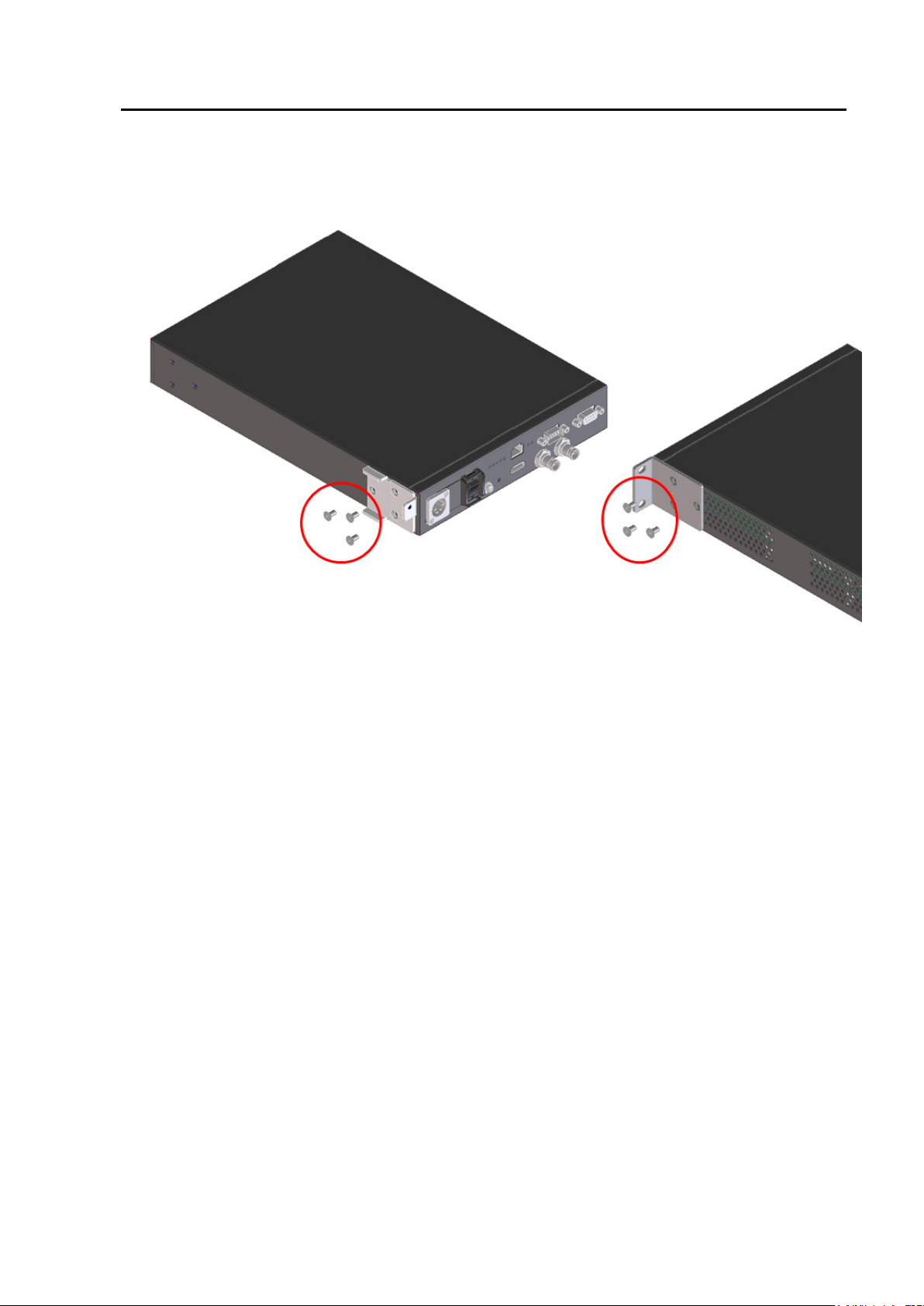

Chapter 2 Installation and Connection

(4) Connect the second device with the rack mounting kit “A” and “B” on IP-920 using six same

screws (M4).

13

IP-920E/DC

Page 28

Chapter 2 Installation and Connection

(5) Install the mounting kit C on IP-920 using two pan head screws (M5).

IP-920E/DC

14

Page 29

Chapter 2 Installation and Connection

(6) Align the main unit at the desired height on the 19" rack, and firmly secure the unit in position

with the screws supplied with this product. Use four pan head screws (M5) to fix the product in

position.

To secure the unit to a server rack, use the cage nuts (D) and bind head screws (M6) supplied with

this product.

15

IP-920E/DC

Page 30

Chapter 2 Installation and Connection

- Removing the device

(1) When removing two devices at the same time

Remove them by reversing the installation procedure for two devices.

(2) When removing only one device

Remove the four screws shown in the figure below.

Remove the mounting brackets (C), and then remove the device.

IP-920E/DC

16

Page 31

Chapter 2 Installation and Connection

B

A

- 1 unit per 1U (Type A1)

(1) Check components of the rack mounting kit.

(2) Check all cables are disconnected.

(3) Install the rack mounting kit “A” on IP-920 using three same screws (M4).

IP-920E/DC

17

Page 32

Chapter 2 Installation and Connection

(4) Install the rack mounting kit “B” on IP-920 series using three same screws (M4).

(5) Install IP-920 on 19” rack using four pan head screws (M5).

- Removing the device

Remove the device by reversing the installation procedure.

IP-920E/DC

18

Page 33

Chapter 2 Installation and Connection

C B A

- 2 units per 1U (Type A2)

(1) Check components of the rack mounting kit.

(2) Check all cables are disconnected.

(3) Connect the first device with the rack mounting kit “A” and “B” on IP-920 using six same

screws (M4).

IP-920E/DC

19

Page 34

Chapter 2 Installation and Connection

(4) Install IP-920 on 19” rack using two pan head screws (M5).

(5) Connect the second device with the rack mounting kit “A” and “B” on IP-920 using six same

screws (M4).

IP-920E/DC

20

Page 35

Chapter 2 Installation and Connection

(6) Install IP-920 on 19” rack using two pan head screws (M5).

21

IP-920E/DC

Page 36

Chapter 2 Installation and Connection

(7) Install the mounting kit C on IP-920 using two pan head screws (M5).

- Removing the device

Remove the device by reversing the installation procedure.

IP-920E/DC

22

Page 37

Chapter 2 Installation and Connection

B

A

C

- 1 unit per 1U(Type B1)

(1) Check components of the rack mounting kit.

(2) Check all cables disconnected.

(3) Install the rack mounting kit A on IP-920 using three same screws (M4).

IP-920E/DC

23

Page 38

Chapter 2 Installation and Connection

(4) Install the rack mounting kit B on IP-920 using three same screws (M4).

(5) Install the rack mounting kit C on IP-920 and rack mounting kit B using four screws (M4).

IP-920E/DC

24

Page 39

Chapter 2 Installation and Connection

(6) Install IP-920 on 19” rack using four pan head screws (M5).

- Removing the device

Remove the device by reversing the installation procedure.

25

IP-920E/DC

Page 40

Chapter 2 Installation and Connection

Coupling fittings

Mounting fittings

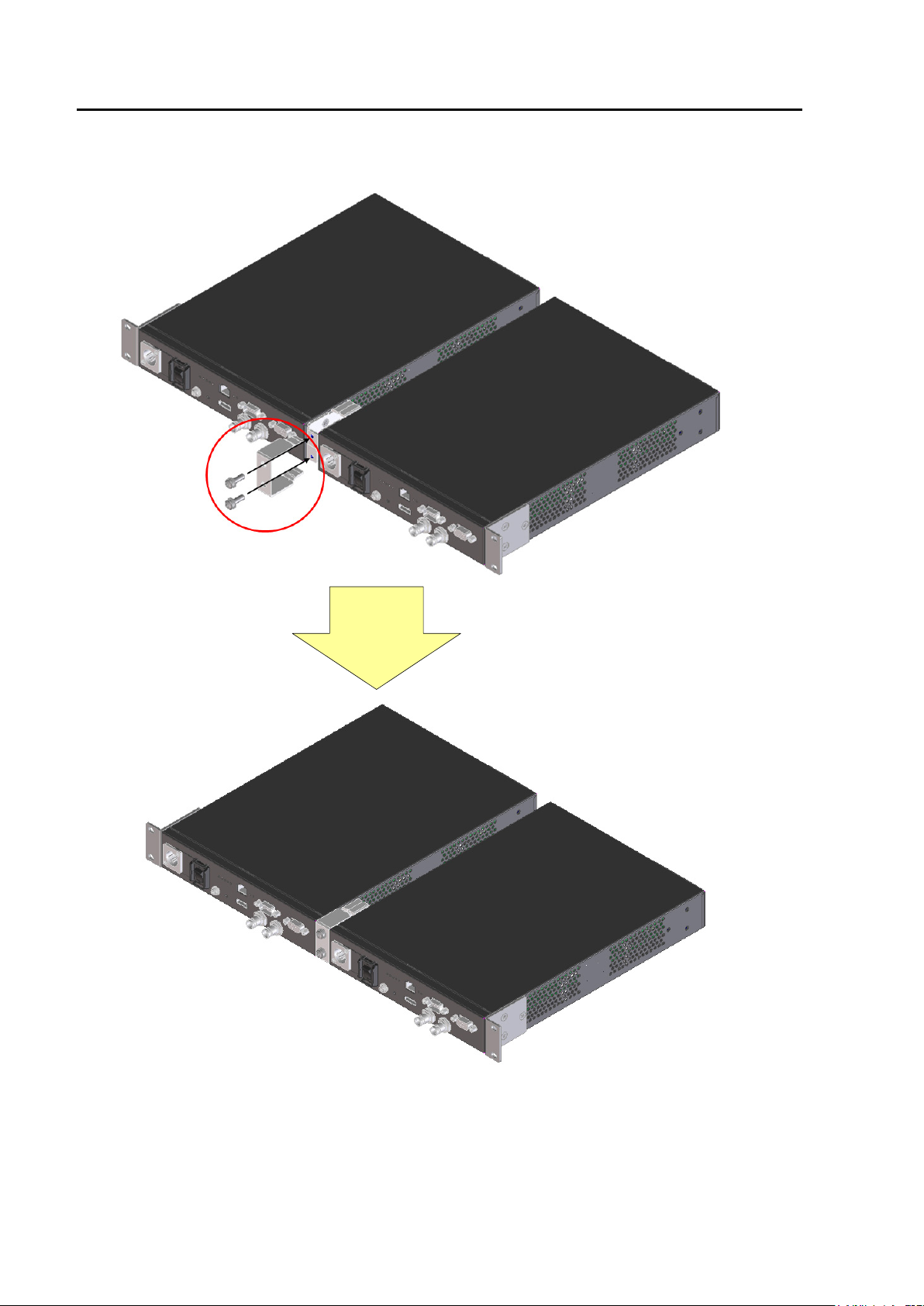

- - 2 units per 1U(Type B2)

(1) Check contents of the rack mounting kit.

(2) Check all cables disconnected.

(3) Connect the first device with the connecting kit using six same screws (M4).

(4) Connect the second device with the connecting kit using six same screws (M4).

IP-920E/DC

26

Page 41

Chapter 2 Installation and Connection

(5) Rotate the connecting kit, and fix with twelve screws (M4).

(Bottom view)

(Top view)

27

IP-920E/DC

Page 42

Chapter 2 Installation and Connection

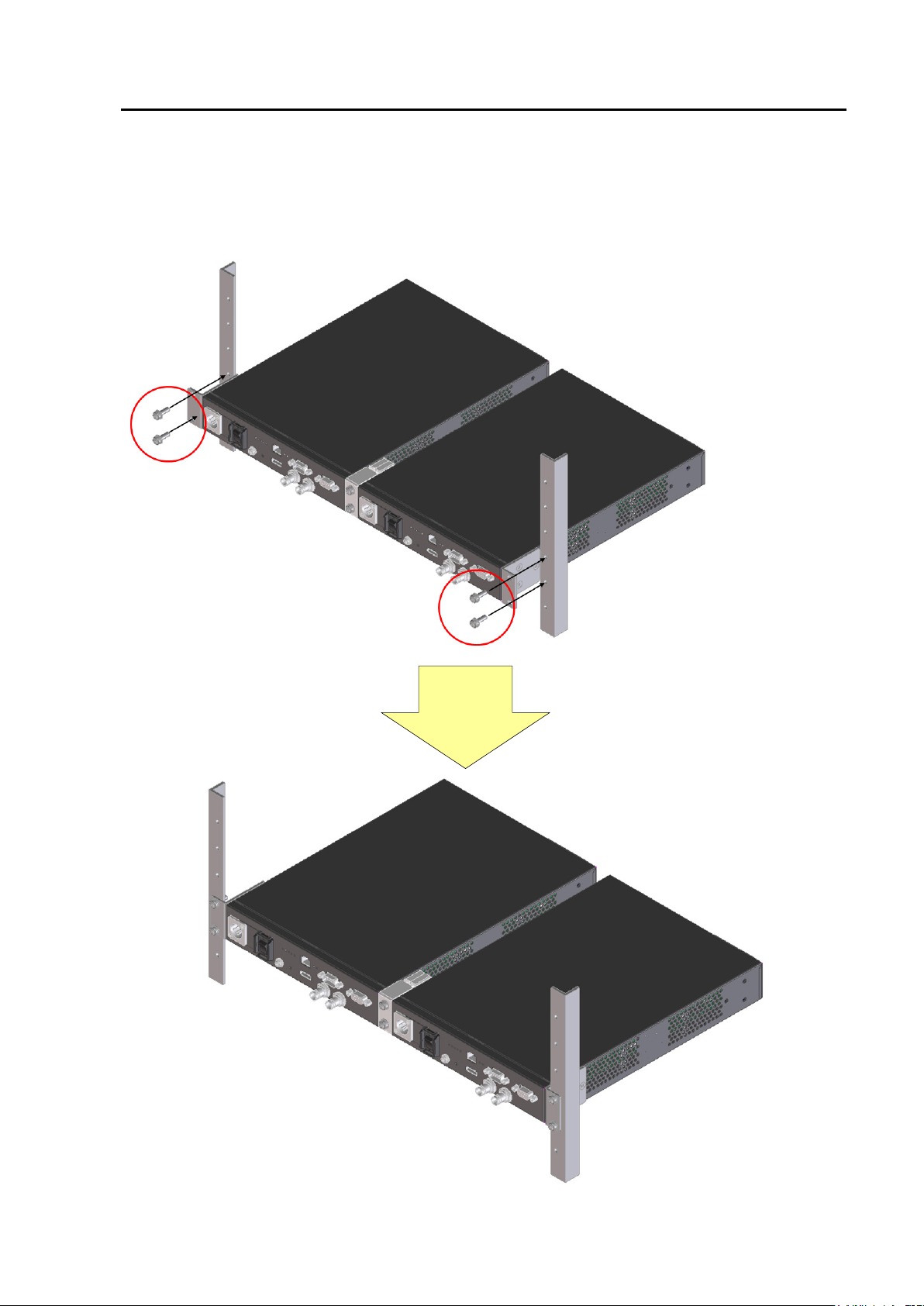

(6) Install the mounting kit on 2 units using six same screws(M4).

(7) Install 2 units on 19” rack using four pan head screws (M5).

- Removing the device

Remove the device by reversing the installation procedure.

IP-920E/DC

28

Page 43

MODEL

PART NO.

IP-920E/DC

TA23742-B72X

This device complies with Part 15 of the FCC Rules.

operation is subject to the f ollowing two conditions:

(1) This device may not cause harmful interference. and

(2) this device must accept any interference received,

including interfer ence that may cause undesired operation.

MADE IN JAPAN

3.2A-1.6A

+12V-24V

2.3kg

FUJITSU LIMITED

T

認証番号

01A

11-03

00001

D08-0454001

00001

I T E

ACCESSORY

LISTED

R

C

US

1K91

E136004

MODEL

PART NO.

IP-920E/DC

TA23742-B72

X

This device complies with Part 15 of the FCC Rules.

operation is subject t o the following two conditions:

(1) This device may not cause harmful int erference. and

(2) this device must accept any inter ference received,

including inter ference that may cause undesired operation.

MADE IN JAPAN

3.2A-

1.6

A

+12V-24V

2.3kg

FUJITSU LIMITED

T

認証番号

01A

11-03

00001

D08-0454001

12345

Chapter 2 Installation and Connection

2. Place the equipment to a Table

Attach 4 rubber feet on the parts marked on the bottom of this equipment as below. Refer to

“Open space required around this equipment” before deciding the place for this equipment.

Mark for rubber feet

Safety installation instruction:

1) Multiple pile

The maximum 5 IP-920E/DC can be piled under the environment condition

specified. Please install considering the maintenance-ability. When

IP-920E/DC is piled, please fix them to avoid falling (do not cover the air

intake.). See Section 2.1.4, “Open space required around this equipment”

for the installation space.

2) rack mounting

a) When IP-920E/DC is installed in a closed or multi-unit rack, the

operating ambient temperature inside of the rack environment may be

greater than room ambient. Therefore, the consideration should be

given to operate in the environment compatible with the specifications

in Appendix 2.2 “Environment Specifications.”

- The consideration for adjustment of the air condition like air

circulation should be given to prevent the internal rack ambient

from exceeding the maximum operating ambient temperature of

IP-920E/DC.

- The maximum operating ambient temperature for IP-920E/DC:

55°C.

IP-920E/DC

29

Page 44

Chapter 2 Installation and Connection

–

b) The installation of IP-920E/DC in a rack should be such that the

amount of airflow required for safe operation of IP-920E/DC is not

compromised.

- IP-920E/DC has ventilation opening at the right and rear side.

- Do not cover or close these ventilation openings to prevent

overheating.

c) The mounting of IP-920E/DC in a rack should be such that a hazardous

condition in not archived due to uneven mechanical loading. To keep

stability of the entire rack, please fix the rack to wall or floor by

suitable means.

- Be careful about injury during installation of IP-920E/DC into

rack.

- Do not install IP-920E/DC into your rack where IP-920E/DC may

make the entire rack unstable.

- The weight of IP-920E/DC with the maximum configuration: 2.3

kg

d) When using a bracket for mounting two products and you remove one

product, do not leave the remaining one that is fixed at one end only

unattended. If you apply pressure to a product that is supported at

one end only, it may deform the mounting bracket.

e) Confirm that power supplying capacity of power tap is larger than the

total nominal power of all devices connected in the rack.

The nominal power of IP-920E/DC is DC +12-24V, 3.2

1.6 A.

2.1.3 Air supply and exhaust of the equipment

IP-920E/DC is forced air cooled equipment. Be sure not to block the air intake/exhaust vents.

Provide an adequate amount of space around the vents.

IP-920E/DC

30

Page 45

Chapter 2 Installation and Connection

2.1.4 Open space required around this equipment

Provide the indicated (parts with hatched area) below, cable forming space, operation space and

air intake/exhaust.

For the information of maintenance space, see Section 5.3.1, “Maintenance space.”

31

IP-920E/DC

Page 46

Chapter 2 Installation and Connection

RDY

PWR ALM

IN

DWN

OPT

MNT

FG

/ACT

100M

LINK

10/100BASE

RS-232C

ANALOG

VIDEO IN

SDI

ANALOG AUDIO IN

12 - 24V

E

2.2 Power Supply System Connections

2.2

This section explains ground and power-source connections.

2.2.1 Connection to ground

When the exogenous noise influences IP-920E/DC, connect the FG terminal to an external ground.

FG terminal (M4)

Figure Connection to ground

IP-920E/DC

32

Page 47

2.2.2 Connection to power source

RDY

PWR ALM

IN

DWN

OPT

MNT

FG

/ACT

100M

LINK

10/100BASE RS-232C

ANALOG

VIDEO IN

SDI

ANALOG AUDIO IN

12 -

24V

E

Power connector

To connect a cable, insert it until

it clicks into place.

To remove a cable, unplug it

while holding down the button.

DC power output equipment

(SELV safety status)

PUSH

IP-920E/DC is safety-approved Class III devices of IEC60950-1, UL60950-1 and EN60950-1.

Therefore, IP-920E/DC needs power source from SELV. Also, in case of using this device in the

United States, it needs to be a UL60950-1 approved power-supply unit.

Prepare a power-supply unit outputting DC12-24V with a power consumption of more than 40W

and connect to this equipment by using the attached DC power cable.

* In case of using non-attached power cable, select a power cable referring to (9) in “4.2 Cable

Connector Details.”

Also, power cable can be ordered separately with your suitable length.

<Reference>

・DC power cable (3m) : TA77057-3000 (normally attached)

・DC power cable (length specification) : TA77057-xxxx (Maximum length : 3m)

(TA77057-0500 is 0.5m, TA7 7057-2000 is 2m)

Chapter 2 Installation and Connection

Figure Power cord connection

IP-920E/DC

33

Page 48

Chapter 2 Installation and Connection

Possibility of electric shock, fire, and damage to this equipment

Always observe the precautions given below.

This indicates a hazardous situation that could lead to electric shock, fire, or

damage to this equipment.

Use a DC power cable attached to IP-920E/DC. If the attached power cable

is unusable, select a power cable referring to (9) in “4.2 Cable and Connector

Details.”

Use a power-supply unit outputting DC12-24V with a power consumption of

more than 40W.

IP-920E/DC

34

Page 49

Chapter 2 Installation and Connection

RDY

PWR ALM

IN

DWN

OPT

MNT

FG

/ACT

100M

LINK

10

/100BASE RS

-232C

ANALOG

VIDEO IN

SDI

ANALOG AUDIO IN

12 - 24V

E

Audio adapter cable#1

or

Audio adapter cable

#3

PUSH

or

PUSH

A

-

I

N

R

(

)

A-IN (L)

A

-

I

N

L

(

)

or

Video & Audio Output Device

NOT E:

2.3 Audio and Video Device Connections

2.3

2 Digital and 1analog video input connectors are equipped for connecting with video output equipment.

- SDI Video Input (Digital Video)

Connect to SDI IN connector using BNC cable. Input digital HD-SDI or SD-SDI signal.

The signal is terminated with 75Ω impedance.

- HDMI Input (Digital Video)

Connect to HDMI connector on front panel of IP-920E/DC using the HDMI cable.

Input digital signal of HDMI. The signal is terminated with 50Ω.

- Analog Video Input

Connect to ANALOG VIDEO IN connector using

BNC cable with NTSC or PAL signal.

2 Digital and 1analog audio input connectors are equipped for connecting with audio output equipment.

- Digital Audio Input

SDI Embedded Audio and HDMI audio are supported.

- Analog Audio Input

Connect to ANALOG AUDIO IN connector of IP-920E using the audio adaptor cable.

The figure of cable connections are shown below.

For details about connectors and cables, see Section 4.2, “Cable and Connector Details.”

For electrical specifications, see Appendix 2.3, “Function Specifications.”

Figure Audio and video output device connections

35

IP-920E/DC

Page 50

Chapter 2 Installation and Connection

RDY

PWR ALM

IN

DWN

OPT

MNT

FG

/ACT

100M

LINK

10/100BASE RS-232C

ANALOG

VIDEO IN

SDI

ANALOG AUDIO IN

12 - 24V

E

Hub, Router, PC, etc.

CAUTION

NOT E:

2.4 Connection to Network

2.4

To connect IP-920E/DC to a LAN device, connect the LAN device to the LAN communication port

of IP-920E/DC using a LAN cable (UTP cable). The LAN communication port specification of

IP-920E/DC is 10BASE-T/100BASE-TX.

The figure below shows the connection method.

For details

about connectors and cables, see Section 4.2, “Cable and Connector Details.”

For electrical specifications, see Appendix 2.3, “Function Specifications.”

Figure Connection to a network

IP-920E/DC

Please do not provision the IP address below.

・ IP address commonly unused(0.0.0.0,255.255.255.255,etc…)

・ Loop back address (127.xxx.xxx.xxx)

・ Class D and Class E addresses

・ IP address already used

For more information, see IP-920E/DC Software User’s Guide.

36

Page 51

Chapter 2 Installation and Connection

RDY

PWR ALM

IN

DWN

OPT

MNT

FG

/

ACT

100M

LINK

10

/

100BASE

RS-232C

ANALOG

VIDEO IN

SDI

ANALOG AUDIO IN

12

-

24

V

E

Data communication

device

D

-sub

9pin(female

)

NOT E:

2.5 Connection to RS-232C Device

2.5

The [RS-232C] connector of IP-920E/DC is the RS-232C communication terminal. The terminal of

IP-920E/DC is the D-sub 9 pins (male) and the specification is DTE. Use a cross connection or straight

cable corresponding to the connected device. See Section 4.2, “Cable and Connector Details.”

The figure below shows the connection method.

For details about connectors and cables, see Section 4.2, “Cable and Connector Details.”

For electrical specifications, see Appendix 2.3, “Function Specifications.”

Figure Connection to RS-232C input/output device

IP-920E/DC

37

Page 52

Chapter 2 Installation and Connection

(1) Check if the power is OFF.

(2) Screw out.

Eject button

CF card

(4) Press the eject button and remove the CF card.

※CF card is unequipped initially (Separate order).

(5) Replace CF card and cover it.

(3) Remove the cover.

2.6 CF Card Insertion and Removal

2.6

In order to insert the CF card, the front cover of IP-920E/DC must be opened by screwing out the cover.

No storage card is supplied with IP-920E/DC. It can be procured separately, depending on the system.

The CF card removal procedure is shown below.

Please turn off the power to insert or remove the CF card.

Please contact Fujitsu office what type of CF card is available to use.

IP-920E/DC

38

Page 53

Chapter 2 Installation and Connection

Updating the Software

The CF card is formatted when upgrading from before V02L002 to after V02L010. Please back up

necessary data of the CF card before it upgrades.

CF card consideration

Please note that you need to remove the CF card or take the backup of its recorded data in case of

requesting the repair of the main unit that the CF card is installed, since Fujitsu does not guarantee

the recorded content during the repair work.

Please also note that the recorded content might be deleted by the process of the diagnostic and

the repair work after Fujitsu starts the work even if you already cancel the repair request

39

IP-920E/DC

Page 54

Page 55

Chapter 3 Operation Instructions

OPERATION INSTRUCTIONS

This section explains how to power on/off, setup and operate this equipment.

CHAPTER 3

3.1 Turn ON/OFF IP-920E/DC ......................................................................... 43

3.2 Device Settings and Operation .................................................................. 44

3.3 Special Use of MNT Button ........................................................................ 46

Page 56

(This page is intentionally left blank)

Page 57

Chapter 3 Operation Instructions

RDY

PWR ALM

IN

DWN

OPT

MNT

FG

/ACT

100M

LINK

10/100BASE

RS-232C

ANALOG

VIDEO IN

SDI

ANALOG AUDIO IN

12 - 24V

E

RDY

PWR ALM

IN

DWN

OPT

MNT

FG

/ACT

100M

LINK

10/100BASE

RS-232C

ANALOG

VIDEO IN

SDI

ANALOG AUDIO IN

12 - 24V

E

Power button

Power(PWR) LED

Status(RDY) LED

3.1 Turn ON/OFF IP-920E/DC

3.1

This section explains how to power on/off the IP-920E/DC.

3.1.1 Turn on IP-920E/DC

When the power button on the front panel is set to the [ | ] position, the PWR LED turns on.

When IP-920E/DC completes preparations for operation, the RDY LED turns on.

This indicates the on switch, which is used to supply power to the IP-920E/DC.

|

This indicates the off switch, which is used to disconnect power from the IP-920E/DC.

○

3.1.2 Turn off IP-920E/DC

When the power button on the front panel is set to the [O] position, this equipment is turned off

and the PWR LED turns off.

IP-920E/DC

43

Page 58

Chapter 3 Operation Instructions

Connect IP-920E/DC and PC

using UTP cable

- Check if IP-920E/DC is disconnected to user’s network.

- Connect using UTP cable.

- When connect through LAN port, the default IP address and subnet

mask are 10.0.0.1 and 255.0.0.0 respectively. Assign 10.xxx.xxx.xxx for

PC.

(ex. IP address: 10.0.0.2, Subnet mask: 255.0.0.0)

for PC.

For details, please refer to the Software User's Guide.

Turn ON IP-920E/DC

- Execute the Network setting from WEB GUI after the device starts.

For details, please refer to the Software User's Guide.

Change network settings

(Refer the software user’s guide)

Connect user’s network

Start settings and operations

(Refer the software user’s guide)

3.2 Device Settings and Operation

3.2

■Setup Procedure

The setup procedure is shown below.

See Software User’s Guide for the procedure of the software installation and the each setting.

■Web browser recommended

The recommended web browser is as follow.

- Internet Explorer 6.0 SP2 or later

IP-920E/DC

44

Page 59

This section briefly explains the basic functions of the setup pages.

3.2.1 Reboot

Clicking the button displayed in the left frame of the browser reboots this equipment.

When you click the button, the following dialog box shown below appears for confirmation. Click

OK to reboot.

Chapter 3 Operation Instructions

45

IP-920E/DC

Page 60

Chapter 3 Operation Instructions

3.3 Special Use of MNT Button

3.3

You can start IP-920E/DC by turning on the power while holding down the [MNT] Button (for

about 10 seconds) until the RDY LED begins blinking in orange. Doing so starts the IP-920E/DC

with the initial IP address and subnet mask with which the IP-920E/DC is shipped from the factory

(IP address 10.0.0.1, Subnet mask: 255.0.0.0).

Use this function when making initial settings for IP-920E/DC from a control terminal (such as a

PC having a LAN interface) (*1).

*1 When you operate the IP-920E/DC with the default IP address, connect this equipment to a

control terminal and make setting from the terminal with this equipment disconnected from

your network.

After making settings according to the requirements for your network, connect this

equipment to the network. If this equipment with the default settings made at the factory is

connected to the network, an unexpected problem may occur with your network.

If you start IP-920E/DC while holding the [MNT] button, set the IP addresses and subnet

masks of the control terminal to connect as follows:

- IP address : 10.xxx.xxx.xxx

(xxx is any number from 0 to 255, excluding 10.0.0.0, 10.0.0.1, and 10.255.255.255.)

- Subnet mask : 255.0.0.0

IP-920E/DC

46

Page 61

Chapter 4 Cable Specifications

CABLE SPECIFICATIONS

CHAPTER 4

This chapter contains a type of how work is implemented, cable connection system

diagrams, and cable connector details.

4.1 Installation Preparations ............................................................................. 49

4.2 Cable and Connector Details ..................................................................... 50

Page 62

(This page is intentionally left blank)

Page 63

Chapter 4 Cable specifications

(8) DC Power cable

IP-920E/DC External device

D-sub9

(1) XLR cable

(2) XLR cable

232C

INPUT DC +12-24V

(5) RS-232C cable

SDI

ANALOG AUDIO

Analog audio output device

(mic, etc)

IN

(3) Coaxial cable

BNC

IN

IN

ANALOG VIDEO

(4) Coaxial cable

BNC

IN

HDMI

(6) HDMI cable

HDMI

RJ45

(7) LAN cable

LAN

10/100BASE

Power source DC+12-24V

(SELV Output)

Device with RS-232C interface

Digital video (HD/SD-SDI) output device

(incld embedded audio)

(Camera, etc)

Analog video output device

(Camera, etc)

Digital video (HDMI) output device

(Camera, etc)

Device with LAN interface (HUB, etc)

D-sub9

(separate order)

XLR

XLR

Audio adapter cable#1

(Attached or separate order)

or

Audio adapter cable#3

(separate order)

4.1 Installation Preparations

4.1

A type of IP-920E/DC installation work is shown below.

When constructing a system that uses IP-920E/DC, consideration must be given so that its boundary

between IP-920E/DC and other devices is similar to that shown in the above figure. Since the type of

work may change depending on the system, procure equipment and perform work based on

consultations with a system designer.

(IP-920E/DC)

49

IP-920E/DC

Page 64

Chapter 4 Cable specifications

Coaxial cable 75Ω

(3C-2V or more)

1

2

BNC BNC

SIGNAL

SG

SIGNAL

SG

①

②

①

②

Coaxial cable with BNC connector

Product code: TBD

<IP-920E/DC> <External device>

Front view

NTSC

Connector

Order

Pin assignment

Maximum length

200m (Coaxial cable 75Ω 3C-2T)

:

30m (Coaxial cable 75Ω 3C-2T)

:

Color

Mono

Coaxial cable 75Ω

5C-FB or more

BNC BNC

SIGNAL

SG

SIGNAL

SG

①

②

①

②

HD-SDI 100m (Coaxial cable 75Ω 5C-FB or more)

1

2

Front view

Connector

Order

Pin assignment

Maximum length

Coaxial cable with BNC connector

Product code

: TBD

<IP

-920

E

/DC>

<External device>

SD-SDI 100m (Coaxial cable 75Ω 5C-FB or more)

4.2 Cable and Connector Details

4.2

(1) SD I VIDEO cable

(2) Analog VIDEO cable

IP-920E/DC

50

Page 65

(3) Analog AUDIO cable

Front view

①

③

②

Audio cable

1

2

XLR (Male)

①

②

20m

Front view

Connector

Order

Pin assignment

Maximum length

OR

3

③

①

②

③

<IP-920E/DC> <External device>

XLR (Male)

XLR (Female)

XLR (Male)

XLR (Female)XLR (Female)

XLR(Female)

XLR(Male)

OR

Audio cable with XLR (male) connector

Product code: TBD

Chapter 4 Cable specifications

IP-920E/DC

51

Page 66

Chapter 4 Cable specifications

(4) AUDIO Adapter cable (#1, #3)

IP-920E/DC

52

Page 67

Connector

<

IP-920E/DC>

Pin assignment

①

Front view

HDMI

<External device side>

HDMI

TMDS DATA2 +

②

③

④

⑤

⑥

⑦

⑧

⑨

⑩

⑪

⑫

⑬

⑭

⑮

⑯

⑰

⑱

⑲

①

②

③

④

⑤

⑥

⑦

⑧

⑨

⑩

⑪

⑫

⑬

⑭

⑮

⑯

⑰

⑱

⑲

TMDS DATA2 SHIELD

TMDS DATA2 TMDS DATA1 +

TMDS DATA

1 SHIELD

TMDS DATA

1 -

TMDS DATA

0 +

TMDS DATA0 SHIELD

TMDS DATA0 -

TMDS CLOCK

+

TMDS CLOCK SHIELD

TMDS CLOCK -

CEC

RESERVE(N.C.)

SCL

SDA

DDC/CEC GROUND

+5V POWER

HOT PLUG DETECT

TMDS DATA2 +

TMDS DATA2 SHIELD

TMDS DATA2 TMDS DATA1 +

TMDS

DATA1 SHIELD

TMDS

DATA1 -

TMDS

DATA0 +

TMDS

DATA0

SHIELD

TMDS DATA

0 -

TMDS CLOCK

+

TMDS CLOCK

SHIELD

TMDS CLOCK

-

CEC

RESERVE(N.C.)

SCL

SDA

DDC/CEC GROUND

+5V POWER

HOT PLUG DETECT

Length of the attested HDMI cable is pretermission.

The unattested cable can't be used.

HDMI cable with HDMI connector

Order

Maximum length

(5) HDMI cable

Chapter 4 Cable specifications

53

IP-920E/DC

Page 68

Chapter 4 Cable specifications

○

○

○

○

○

○

○

○

<External device side>

Front view

<IP-920E/DC>

(DTE)

RS-232C DTE

○

<External device>

(DTE)

D-sub 9 pin

(female)

01

02

03

04

05

06

07

08

09

○

○

○

○

○

○

○

○

○

D-sub 9 pin (Female)

D-sub9 (Female)

#4-40 retainer screw

SG

DSR(DR)

RTS(RS)

CTS(CS)

CD

RD

SD

DTR(ER)

RI

SG

DSR(DR)

RTS(RS)

CTS(CS)

CD

RD

SD

DTR(ER)

RI

○

○

○

○

○

○

○

○

<IP-920E/DC>

(DTE)

RS-232C DCE

○

<External device>

(DCE)

D-sub 9 pin

(female)

01

02

03

04

05

06

07

08

09

○

○

○

○

○

○

○

○

○

SG

DSR(DR)

RTS(RS)

CTS(CS)

CD

RD

SD

DTR(ER)

RI

SG

DSR(DR)

RTS(RS)

CTS(CS)

CD

RD

SD

DTR(ER)

RI

15 m (Twisted pair cable with shield 24AWG)

Connector

Pin assignment

Maximum length

Pin assignment

<IP-920E/DC>

①②③④⑤

⑥⑦⑧⑨

(6) RS-232C cable

IP-920E/DC

54

Page 69

12345678

:100m UTP cable(Category 5 or more)10/100BASE

order

Connector

Pin assignment

Max length

Front view <IP-920E/DC> <External device>

RJ45 RJ45

<IP-920E/DC> <External device>

5m : TPCBL-B005

10m : TPCBL-B010

50m : TPCBL-B050

100m : TPCBL-B100

<IP-920E/DC> <External device>

②

①

④

③

⑥

⑤

⑧

⑦

②

①

④

③

⑥

⑤

⑧

⑦

②

①

④

③

⑥

⑤

⑧

⑦

②

①

④

③

⑥

⑤

⑧

⑦

TD+

TDRD+

RD-

TD+

TDRD+

RD-

TD+

TDRD+

RD-

TD+

TDRD+

RD-

10/100BASE

<Straight connection>

(7) LAN cable

Chapter 4 Cable specifications

IP-920E/DC

55

Page 70

Chapter 4 Cable specifications

Order

Connector

Pin assignment

Front view

①

②

③

④

XLR (Male)

<IP-920E/DC> <

External device

>

XLR

(

Female)

①

②

③

④

①

②

③

④

-

+

N.

C

N

.C

-

+

N.

C

N

.C

・DC Power cord (normally attached)

3m

:

TA77057

-3000

・DC Power cord (

length specified) Maximum length 3

m:

TA

77057-xxxx

Order example:

TA77057-0500(

0.5m

),TA

77057-2000

(2.

0m)

Manufacturer

FUJITSU LIMITED

(8) DC power cable (attached to IP-920E/DC)

(9) In case of using non-attached DC power cable

Use a connector, cable and plug that meet the following conditions.

[IP-920E/DC Connector] Equivalent to HA216P-4S(72) / Allowable current: 5A and above /

Nominal voltage: 60V and above

[Cable] Size: 0.5 square millimeter and above / Allowable current: 5A and above /

Nominal voltage: 60V and above

[Plug] Although it depends on the opposite device, select a plug of more than 5A-allowable

current and more than 60V-nominal voltage. If you need a specialized tool when

making a cable, ensure to use the matching item from the same maker as the plug’s

maker.

Please refer to the next page for the method of wire connection with IP-920E/DC connector.

IP-920E/DC

56

Page 71

5~

6mm

(

1

) Remove the insulation about 5-6 mm.

(2) Put the shell and the bushing together

.

(3) Pass the cable through the hole.

(4) Solder the pin.

Pin

#1 : (

-)

Pin #2

: N.C

Pin

#3 :

N.C

Pin #

4 : (+)

(

5)

Build it into the shell

.

(

6)

Screw down the barrel.

(7

) Screw down the clamp.

The bigger bore is

for IP-920 side

Screw clamp (x 2)

IP-920E/DC side Cable side

How to connect wiring with IP-920E/DC connector (DC power cable)

In case of using HA216P-4S(72)

Chapter 4 Cable specifications

57

IP-920E/DC

Page 72

(This page is intentionally left blank)

Page 73

CHAPTER 5

Chapter 5 Troubleshooting

TROUBLESHOOTING

This section explains how to power on/off, setup and operate this equipment.

This chapter describes actions to be taken if this equipment does not operate

normally or if an alarm LED turns on.

5.1 Help Information ......................................................................................... 61

5.2 Alarm LED Lamp Is On .............................................................................. 65

5.3 Maintenance ............................................................................................... 67

Page 74

(This page is intentionally left blank)

Page 75

Chapter 5 Troubleshooting

Check the power cable is properly connected

to the outlet.

Measure the voltage with a tester and check

performance.

Contact to CE in Fujitsu Service Center. CE

contact to us.

Settings/ Performances of the

shown.

Check alarm code using log information

are shown.

Check whether the condition is satisfied with

In case of having problems in the conditions

In case of not having any problems, contact

be failed.

CF card or this equipment might be

replacement.

L009 DHCP connection

failure

Is the ambient temperature of this

of specification?

If yes, adjust the temperature within the

Refer to “2.1.1 Environment Conditions”.

Do you secure indicated space in

exhaust opening?

If no, secure the space.

the equipment”.

5.1 Help Information

5.1

If a problem is found in device operation, take recommended action described in the table below,

according to the applicable conditions. If the action does not solve the problem, contact a service

representative.

Possibility of electric shock

Contact your system administrator before checking the voltage of a power

outlet. Otherwise, electric shock may occur.

Table 5.1.1 Problem descriptions and recommended actions

No. Class Status Description Recommended action

1.

2.

3.

4.

Power cannot be

turned on.

Power

The ALM LED

is on.

The ALM LED

is blinking.

Device

Is the power cable connected?

Is the outlet voltage normal?

Equipment error is occurred.

equipment and each error is

E013 Temperature warning

E084 CF card access error

E085 CF card power error

the voltage is normal.

When another device is connected to the

same outlet, check the other device’s

may ask the alarm code for checking your

status. Check each alarm code using log

information screen of Web GUI before you

screen of Web GUI. The countermeasures

“2.1 Installation Conditions” or not.

- Do you secure certain space for air supply

and exhaust opening?

-Is ambient temperature within the

condition?

above, reboot the equipment after excluding

the all problems.

to Fujitsu CE because the equipment might

abnormal.

In case that you have the spare CF card,

please check whether the problem is

recovered after replacing the failed card to

the spare.

Contact CE in Fujitsu Service Center in

case that you do not have the spare or the

problem is not recovered even after the

5.

The LEDs

excluding LAN

are on.

failure

L00A PPPoE connection

equipment within the condition

the condition for air supply and

61

Please refer to 43 of this table.

condition of specification.

⇒

⇒Refer to “2.1.3 Air supply and exhaust of

IP-920E/DC

Page 76

Chapter 5 Troubleshooting

Check the data input-output port settings.

⇒Refer to Software User’s Guide.

Is the data input/output device

Check the operation of the data input/ output

Is the power to the video/audio

selected for input turned on?

Check the selected power supply of

performance.

Is this equipment correctly

mistake.)

Check the connection between this

Are the specified input

by mistake.)

Are the specified input

the output

device was set as 50Hz by

mistake.)

Is the monitor which connects to

normally?

Is the receiving device working

Check the power and operation of the

Is the receiving device and

monitor connected correctly?

Check connections between the receiving

device and the monitor.

Does alarm occur on the

receiving device?

If yes, refer to the user’s guide of receiving

device and follow the instructions.

Does a color bar or gray screen

conducting this test.)

The hardware system is operating while the

remains on.

This equipment is started in the maintenance

Reboot this equipment.

ALM LED blinks when IP address obtaining

Software User’s Guide).

No. Class Status Description Recommended action

6.

7.

8.

9.

10.

11.

Data

communication

Data

is disabled.

The INDWN

lamp lights in

orange.

The INDWN

lamp blinks in

orange.

Is the port setting correct?

operating normally?

Are this equipment and the