Page 1

TechNotes V1.0

Industrial Mainboard Series

Mini-ITX

D3433-S

D3434-S

Page 2

a

Content

1

2

2.1

2.2

2.3

2.4

2.5

2.6

2.7

3

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

3.10 LAN Connector 20

3.11 DVI-D Connector 20

3.12 DisplayPort V1.2 Connector 21

3.13 Embedded DisplayPort Connector 22

3.14 Serial ATA Connector 23

3.15 mSATA Pinout / Mini-PCIe Pinout – Fullsize 24

3.16 mSATA / Mini-PCIe BIOS Setup Options 25

3.17 m-SATA / Mini-PCIe Socket Assembly Note 26

3.18 M.2 (Key M) – 2242 & 2260 27

Safety Instructions 6

Feature Overview 7

Summary: Feature overview D343x-S 7

Basic Layout & External Connectors D3433-S 9

Basic Layout & External Connectors D3434-S 10

Block Diagram D3433-S 11

Block Diagram D3434-S 12

Onboard components D3433-S & D3434-S 13

I/O-Shield 14

Interfaces & Connectors 15

Frontpanel Connector 15

Internal Serial (COM) Port Connector 16

External Serial (COM) Port Connector 16

Internal USB2.0 Connector (2 Ports) 17

Internal USB3.0 Pin Connector (2 Ports) 17

Internal USB3.0 Stick Socket 18

External USB3.0 Connector 18

PS/2 Keyboard Port 19

PS/2 Mouse Port 19

Page 3

a

3.19 M.2 Socket Assembly Note 28

3.20 Possible configurations for M.2 & Minicard –Modules 29

3.21 PCIe x16 Slot Configuration for Riser cards (only supported for D3433-S) 30

3.22 Fan Connectors 31

3.23 Rear Audio / Frontpanel Audio Connector 32

3.24 S/PDIF Connector 34

3.25 GPIO (Feature Connector) 35

3.26 Power Supply Connector (Multirail) 36

3.27 Additional Power Supply Connector (12V for Processor) 36

3.28 Power Supply Connectors (ATX Multirail or Single 12V Operation) 37

3.28.1

3.28.2

3.28.3

3.29 Chassis Intrusion 40

4

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

5

5.1

5.2

6

6.1

6.2

7

7.1

7.2

7.3

System Monitoring 41

D343x-S: Temperature Sensors and Fan Connectors (preliminary) 42

SystemGuard 43

SystemGuard - Details 44

SilentFanConfigManager – Customize System Monitoring Settings 45

Components for continous 24/7 operation @ +60°C 46

Capacitor Endurance Time Comparison 47

Temperature Reference Points D343x-S 48

Temperature Reference Points D343x-S (rear) 49

BMC – BIOS Default Settings D343x-S 50

Power Supply 51

ATX Power Supply 51

Typcial Power Consumption (to be added soon) 52

USB Implementation 53

USB Ports & USB Power Fuses (D3433-S) 53

USB Ports & USB Power Fuses (D3434-S) 55

Display Options 57

Summary: Video Output Options D343x-S 57

LVDS Display & Backlight Inverter 59

LVDS Connector Details 60

ATX Multirail Operation

Single 12V Operation

Single 12V Operation – Config

37

38

39

Page 4

a

7.4

7.5

7.6

7.7

7.8

7.9

7.10 Embedded DisplayPort (prelim.) 69

7.11 Embedded Display Port Power 70

8

8.1

8.2

9

Common Mainboard Tools 74

9.1

9.2

9.3

9.4

Industrial Tools 76

9.5

9.6

9.7

10

10.1 USB 2.0 / MS Windows 7 78

10.2 TPM2.0 / MS Windows 7 78

11

11.1 Battery Lifetime 79

11.2 RealTime Clock (RTC) Accuracy 80

11.3 System Watchdog (WD) 81

11.4 BIOS Update / BIOS Recovery 84

11.5 BIOS/CMOS: Reset Defaults 85

11.6 BIOS integrated HW Diagnostic Tool 86

11.7 BIOS integrated Erase Disk Tool 86

11.8 Power indicator 87

Backlight Inverter Connector Details 61

LVDS Timing & Screen Resolution 62

LVDS Tool 65

LVDS – Influence on Graphics Output (prelim.) 66

LVDS Cabling Reference 67

LVDS Sample Cabling for AuO-G150 68

Operating System Support 71

Support for Windows 7 / Windows 8.1 / Windows 10 72

Linux Support (to be added soon) 73

Mainboard Tools 74

BIOS Boot Logo Tool 74

EditCMOS 74

OEMIDENT 74

SystemGuard 75

SilentFanConfig-Manager 76

Windows System-Monitoring API (BMCAPI) 77

Linux System-Monitoring Driver (“LM-Sensors”) To be added soon 77

Known Issues & Important Notes 78

Miscellaneous 79

Page 5

a

Revision History:

V1.0 First Version 22.02.2016

Technical data are subject to change without prior notice. Fujitsu accepts no

responsibility with regards to technical or editorial mistakes or omissions.

Page 6

a

Safety Instructions

Do not connect or disconnect any cables or modules to or from any onboard connectors (except

for the rear I/O connectors) until the mainboard is completely powered down.

Any damage caused to the mainboard by misuse of the onboard connectors is excluded from the

standard warranty. Fujitsu Technology Solutions cannot be held liable for any damage that results

from incorrect use of any onboard connectors.

The system integrator is fully responsible for the usage of appropriate connectors and cables in

order to fulfill the technical requirements (electrical contact, durability, power/current levels,

signal integrity etc.)

1 Safety Instructions

Page 7

a

Feature

D3433-S

D3434-S

Note

Chipset (PCH)

Q170

H110

incl. heatsink

Memory Sockets / max. RAM / ECC Support

2 / 32GB DDR4-2133

/ Non-ECC

2 / 32GB DDR4-2133

/ Non-ECC

SO-DIMM

Intel® Core™ i7 / i5 / i3 – (6th gen.) processor series (max. 65W TDP)

x

x

K-Series not supported!

Intel® Pentium® / Celeron® processor series (max. 65W TDP)

x

x

TPM V1.2 / TPM V2.0

-- / Infineon

-- / Intel integrated

mSATA Socket 1) / Mini-PCIe Socket 1) / 8 Bit GPIO

x / x / x

-- / x / x

halfsize / fullsize possible,

incl. USB2.0

M.2 Socket

PCIe x2 & SATA based M.2

modules supported

SATA based M.2

modules supported

Mechanical support for

42mm and 60mm modules;

Key M

USB2.0 Ports internal / external

2 / 4

2 / 3

USB3.0 Ports internal / external / USB 3.0 Stick Socket onboard

2 / 4 / x

2 / 2 / -

Fan 1 /2 / 3 / 4

x / -- / x / --

x / -- / x / --

FAN3: PWM or 3Pin

x

x

BIOS Setup option

Onboard LVDS 24bit / eDP (2 lanes)

x / x

x / x

Simultaneous use possible

SATA3 / RAID Support (0/1/5/10)

4 / x

2 / --

S/P-DIF / Intrusion

x / x

x / x

2 Feature Overview

2.1 Summary: Feature overview D343x-S

1) Shared socket mSATA / Mini-PCIe

Page 8

a

Feature

D3433-S

D3434-S

Notes

Slot #1: PCIe x16 (PEG Slot)

Gen3; Support for lane split

Riser: 2x PCIe x8 or 1x

PCIe8 and 2x PCIe4

Gen3

No lane split support

COM-Port external / COM-Port internal / Parallel Port internal

1 / 1 / --

1 / 1 / --

DVI-I / DVI-D / DisplayPort 1 / DisplayPort 2 / LVDS / Emb. DisplayPort

-- / x / x / x / x / x

-- / x / x / -- / x / x

Up to 3 independent displays

(D3434 / H110: max. 2)

Dual LAN / Intel iAMT 11 - vPro 2015 Manageability 1)

x / x

x / --

Incl. Teaming Support;

BIOS-POST / BIOS-Boot / OS – HW Watchdog onboard

x / x / x

x / x / x

8 Layer PCB x x

Improved electrical signal

quality &

improved durability

Approved for 24/7 operation @ 60°C / full load

x

x

UL/CSA 60950-1 certification

planned

planned

FCC/B approval

planned

planned

EraseDisk (BIOS Feature) included

x

x

Feature Overview

Summary: Feature overview D343x-S (continued)

1) iAMT (Q170) requires appropriate Core i5 / Core i7 processor;

Page 9

a

Feature Overview

2.2 Basic Layout & External Connectors D3433-S

Mouse 4x USB2.0 COM1 LAN2 LAN1 (iAMT)

Kbd 2x DisplayPort V1.2 DVI-D 4x USB 3.0 Audio

Page 10

a

Feature Overview

2.3 Basic Layout & External Connectors D3434-S

Mouse 1x USB2.0 COM1 LAN2 LAN1

Kbd 1x DisplayPort V1.2 DVI-D 2x USB 2.0 2x USB 3.0 Audio

Page 11

a

Feature Overview

2.4 Block Diagram D3433-S

Page 12

a

Feature Overview

2.5 Block Diagram D3434-S

Page 13

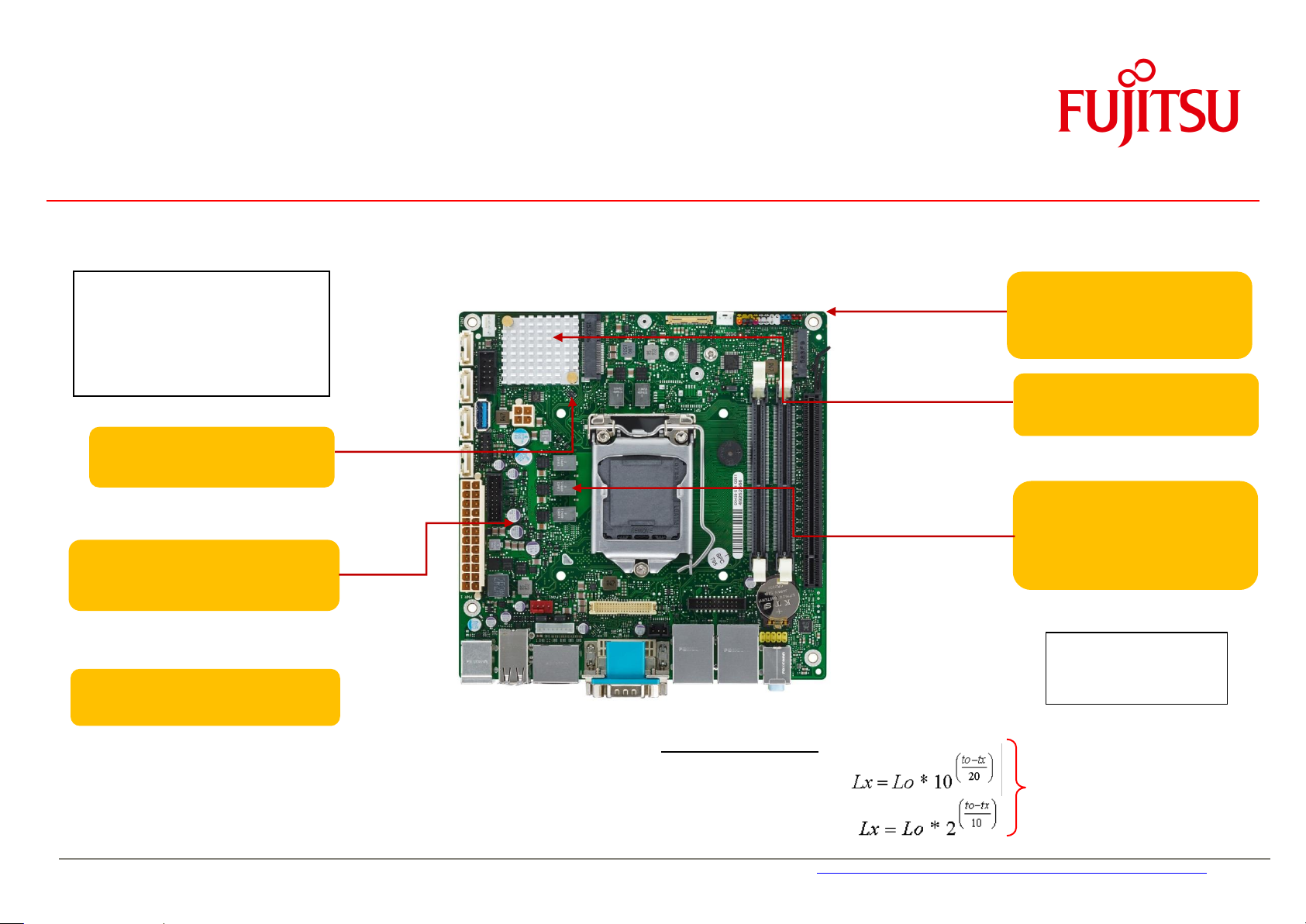

a

Frontpanel

12V Supply (Processor)

Backlight LVDS

24bit dual channel LVDS

2x USB 3.0 (Frontpanel)

2 x USB 2.0 (Internal)

Frontpanel Audio

GPIO Port

CPU LGA1151 max. 65W

COM2 Port

24 pin ATX PSU / 12V DC Supply

2 x SATA-III = D3434-S

S/PDIF Output

Intrusion

Fan3 (4 pin PWM / 3 pin)

Processor Fan (4 Pin)

mSATA(D3433-S only) / Mini-PCIe

8 Layer PCB

4 x SATA-III = D3433-S

USB 3.0 Socket (D3433-S only)

eDP (2Lanes)

M.2 - SATA / PCIe (D3433-S only)

PCIe x16 (16 Lanes, Gen3)

D3433-S only: Lane split

supported

Feature Overview

2.6 Onboard components D3433-S & D3434-S

Page 14

a

Spring Steel Sheet

Enforcement Sheet

Rear Side: EMI Gasket

(Foam with Copper Nickel

fabric)

Nominal force: ~ 75 N

for specified ATX IO “letterbox”

Note: ATX Chassis “letterbox” for I/O shield:

Nom. size = 158.75 x 44.45mm

Tolerance = +/- 0.2mm

USB/DP-cover to be removed for D3433-S

Feature Overview

2.7 I/O-Shield

Page 15

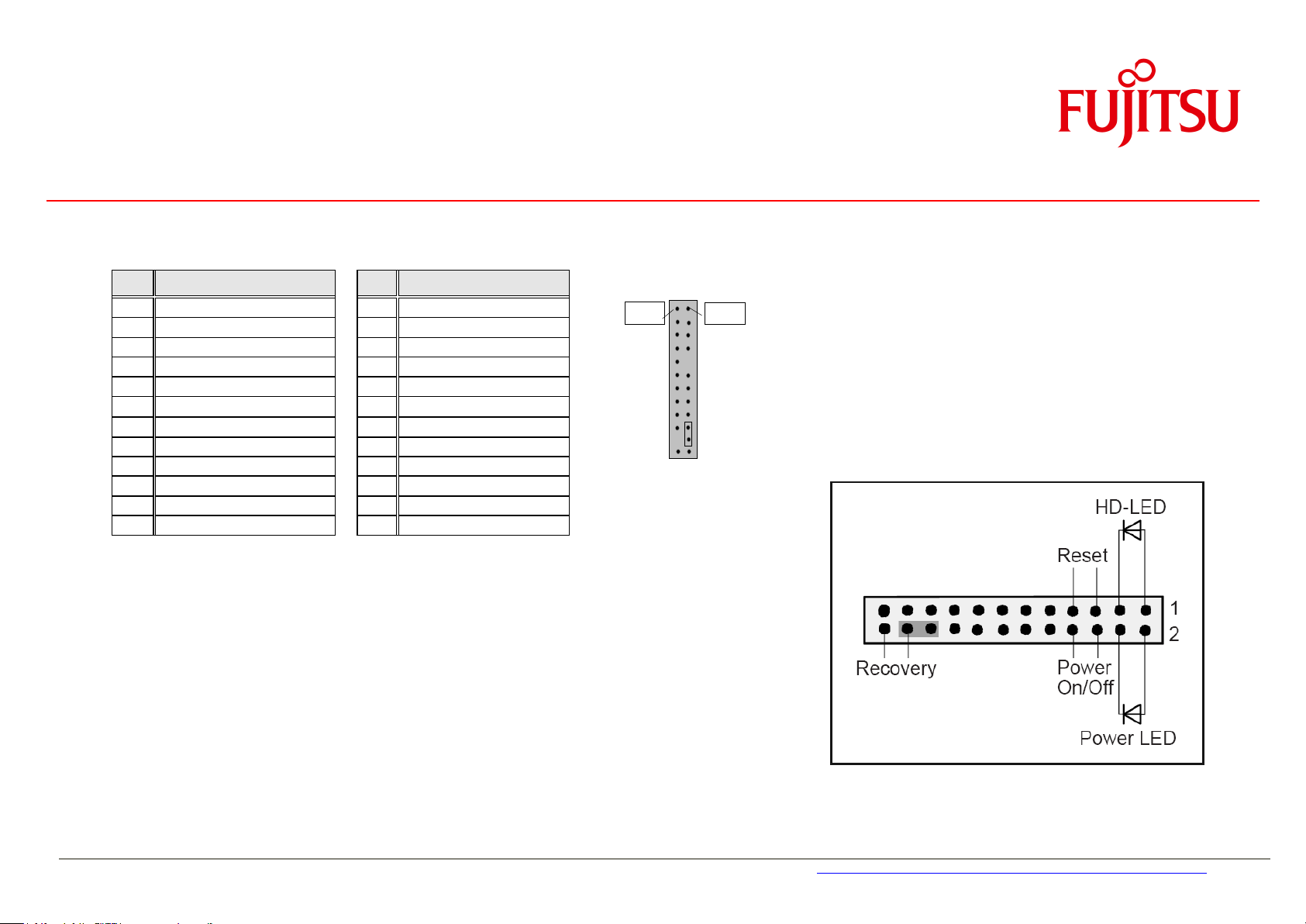

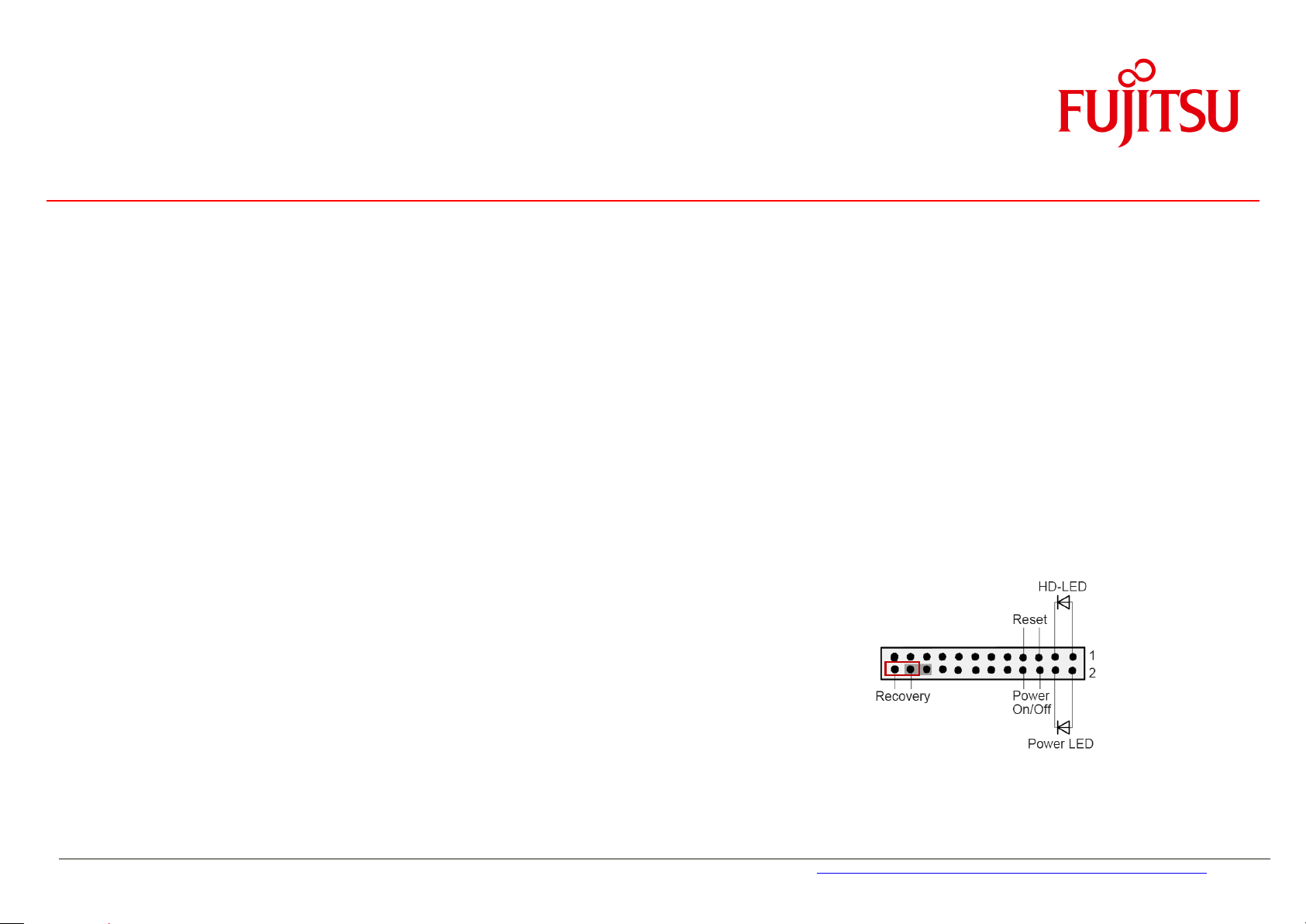

a

Pin

Signal

Pin

Signal

1

HD-LED +

2 Power LED +

3

HD-LED -

4 Power LED -

5

GND 6

Power_Button

7

RST_L

8 GND

9

reserved

10

Key

11

reserved

12

GND

13

BMC Alert LED +

14

BMC Alert LED -

15

reserved

16

reserved

17

Speaker +

18

BIOS Testmode (reserved)

19

GND 20

GND (0,1K)

21

Key 22

GND (0,1K)

23

Speaker -

24

Recover BIOS

Power LED:

Anode: Pin 2 – current source 3mA up to 4V

Cathode: Pin 4 (suitable for various LED colors)

HDD LED:

Anode: Pin 1 – current source 3mA up to 4V

Cathode: Pin 3 (suitable for various LED colors)

Internal Speaker Output:

Differential audio signal; mono, max. 2W RMS / 4Ohm

Note: System Beeps are audible via the internal speaker output only,

even if a device is connected to the external audio ports (rear/front) .

Pin 2

Pin 1

3 Interfaces & Connectors

3.1 Frontpanel Connector

Page 16

a

Pin

Signal

Pin

Signal

1

DCD 1

6 DSR 1

2

SIN 1

7 RTS 1

3

SOUT 1

8 CTS 1

4

DTR 1

9 RI 1

5

GND

Pin

Signal

Pin

Signal

1

DCD 2

2 DSR 2

3

SIN 2

4 RTS 2

5

SOUT 2

6 CTS 2

7

DTR 2

8 RI 2

9

GND 10

Key

Pin 1

Pin 2

Pin 1

Pin 6

Interfaces & Connectors

3.2 Internal Serial (COM) Port Connector

Note: D3433/34: The internal COM-Port is COM2

3.3 External Serial (COM) Port Connector

Page 17

a

Pin

Signal

Pin

Signal

1

VCC AUX (fuse protected)

2 VCC AUX (fuse protected)

3

Data negative Port X

4 Data negative Port Y

5

Data positive Port X

6 Data positive Port Y

7

GND

8 GND

9

Key 10

Not connected

Pin

Signal

Pin

Signal

1

VCC AUX (polyswitch fused and power

supervision with over current detection)

2 USB3_RX negative (P2)

3

USB3_RX positive (P2)

4 GND

5

USB3_TX negative (P2)

6 USB3_TX positive (P2)

7

GND 8

Data negative (P2) [USB2.0]

9

Data positive (P2) [USB2.0]

10

FP Detect

11

Data positive (P3) [USB2.0]

12

Data negative (P3) [USB2.0]

13

GND 14

USB3_TX positive (P3)

15

USB3_TX negative (P3)

16

GND

17

USB3_RX positive (P3)

18

USB3_RX negative (P3)

19

VCC AUX (polyswitch fused and power

supervision with over current detection)

Pin 1

Pin 2

Pin 19

Pin 1

Note:

All USB3 connectors provide separate signal

lines for USB3.0 and USB2.0!

All “fused” ports provide max. 500mA

(USB2.0) resp. . 900mA (USB3.0) for each

port

Interfaces & Connectors

3.4 Internal USB2.0 Connector (2 Ports)

3.5 Internal USB3.0 Pin Connector (2 Ports)

Page 18

a

Pin

Signal

1

VCC auxiliary

(polyswitch fused and power supervision with over current detection)

2

Data negative [USB2.0]

3

Data positive [USB2.0]

4

GND

5

USB3_RX negative

6

USB3_RX positive

7

GND 8 USB3_TX negative

9

USB3_TX positive

Pin

Signal

1

VCC auxiliary

(polyswitch fused and power supervision with over current detection)

2

Data negative [USB2.0]

3

Data positive [USB2.0]

4

GND 5 USB3_RX negative

6

USB3_RX positive

7

GND

8

USB3_TX negative

9

USB3_TX positive

Pin 9

Pin 1

Note:

All USB3 connectors provide separate signal

lines for USB3.0 and USB2.0!

All “fused” ports provide max. 500mA (USB2.0) resp. .

900mA (USB3.0) for each port

Pin 9

Pin 1

Interfaces & Connectors

3.6 Internal USB3.0 Stick Socket

3.7 External USB3.0 Connector

Page 19

a

Pin

Signal

1

KBD Data

2

Not connected

3

GND

4

VCC (polyswitch fused)

5

KBD CLK

6

Keyboard_On (low asserted pulse)

Pin

Signal

1

MOUSE Data

2

Not connected

3

GND 4 VCC (polyswitch fused)

5

MOUSE CLK

6

Not connected

Pin 2

Pin 1

Pin 5

Pin 3

Pin 6

Pin 4

Pin 2

Pin 1

Pin 5

Pin 3

Pin 6

Pin 4

Interfaces & Connectors

3.8 PS/2 Keyboard Port

3.9 PS/2 Mouse Port

Page 20

a

Pin

Signal with 10/100/1000

Signal with 10/100

1

MX1 +

TX +

2

MX1 -

TX -

3

MX2 +

RX +

4

MX3 +

TERMPLANE

5

MX3 -

TERMPLANE

6

MX2 -

RX - 7 MX4 +

TERMPLANE

8

MX4 -

TERMPLANE

Pin

Signal

Pin

Signal

1

Data2+

13

NC 2 Data2-

14

Vcc (fused)

3

GND 15

ND

4

NC 16

Hot_Plug_detect

5

NC 17

Data0-

6

DDC_CLK

18

Data0+

7

DDC_DAT

19

GND 8 NC 20

NC

9

Data1-

21

NC

10

Data1+

22

GND

11

GND 23

CLK+

12

NC 24

CLK-

C5

GND C3

Blue (DVI-I)

C1

Red (DVI-I)

C4

H-Sync (DVI-I)

C2

Green (DVI-I)

Pin 1

C5

Note: Supports Single-Link only!

Interfaces & Connectors

3.10 LAN Connector

3.11 DVI-D Connector

Page 21

a

Pin

Signal

Pin

Signal

1

Link0+

11

GND

2

Link0-

12

Link1+

3

GND

13

Link1-

4

Link2+

14

GND

5

Link2-

15

Link3+

6

GND

16

Link3-

7

DVI dongle detect / (GND

(N/A))

17

GND / (CEC for HDMI (N/A))

8

AUX+

18

GND

9

AUX-

19

Hotplug detect

10

GND (Return)

20

P3V3P

1

19 2 20

Interfaces & Connectors

3.12 DisplayPort V1.2 Connector

Page 22

a

Pi

Signal Assignment

Comment

PiSignal Assignment

Comment

1

NC

16

LCD GND

2

GND

17

Hotplug detect

3

Link1-

18

Backl. GND

4

Link1+

19

Backl. GND

5

GND

20

Backl. GND

6

Link0-

21

Backl. GND

7

Link0+

22

Backl enable

activ high 8 GND

23

Backl PWM / Dimm

9

AUX+

24

NC

10

AUX-

25

NC

11

GND

26

Backl 12V

12

LCD VCC

3,3V or 5V

27

Backl 12V

13

LCD VCC

28

Backl 12V

14

NC

29

Backl 12V

15

LCD GND

30

NC

Pin 1

Pin 30

Interfaces & Connectors

3.13 Embedded DisplayPort Connector

Note: Connector type:

Onboard: I-PEX: 20455-030E-12 (or compatible)

eDP Cable (mating housing): I-PEX: 20453-030T-11 (or compatible)

Cable requires 1:30 connection (pin 1 to pin 30, pin2 to pin29 etc.)

Page 23

a

Pin

Signal

Pin

Signal

1

GND 2

Transmit data positive

3

Transmit data negative

4 GND

5

Receive data negative

6 Receive data positive

7

GND

1

Interfaces & Connectors

3.14 Serial ATA Connector

Page 24

a

Pin

Signal Assignment

Comment

Pin

Signal Assignment

Comment

mSATA

Mini PCIe

mSATA

Mini PCIe

1 NC

WAKE#

27

GND 2

+3.3V

+3.3V STBY

28

+1.5V

3

NC

29

GND 4

GND

30

NC 5

NC

31

SATA RX-

PCIe RX-

6

+1.5V

32

NC

7

NC

33

SATA RX+

PCIe RX+

8

NC

34

GND

9

GND

35

GND 10

NC

36

USB Data negative

selectable by BIOS

11

RSVD

REFCLK-

37

GND 12

NC

38

USB Data positive

selectable by BIOS

13

RSVD

REFCLK+

39

+3.3V

+3.3V STBY

14

NC

40

GND 15

GND

41

+3.3V

+3.3V STBY

16

RSVD

42

NC

17

NC

43

GND 18

GND

44

NC 19

NC

45

NC

20

EN_WLAN

for PCIe miniCard

46

NC 21

GND

47

NC 22

NC

PERST#

48

+1.5V

23

SATA TX+

PCIe TX+

49

NC 24

+3.3V

+3.3V STBY

50

GND 25

SATA TX-

PCIe TX-

51

MSATA Present low

26

GND

52

+3.3V

+3.3V STBY

Interfaces & Connectors

3.15

mSATA Pinout / Mini-PCIe Pinout – Fullsize

Fullsize socket can be used for mSATA (D3433 only!)

or Mini-PCIe (D3433 and D3434) and supports auto

detection mode.

(D3433: Mode also selectable via BIOS Setup)

NC: pin not connected to mainboard

RSVD: pin reserved, connected on mainboard

Page 25

a

fInterfaces & Connectors

3.16 mSATA / Mini-PCIe BIOS Setup Options

Mini-PCIe Card Mode (only for D3433-S):

The Halsize / Fullsize socket always supports

Mini-PCI Express, mSATA and USB 2.0.

The socket can be configured as:

- Standard SATA mode - [Disabled]

- MiniCard auto detection – [Auto]

- Mini SATA mode – [mSATA]

- Mini PCIe mode – [mPCIe]

(BIOS Setup option; default = auto).

Note: BIOS Setup option “WLAN” (for D3433-S and D3434)

This option can be used to enable/disable Mini-PCIe WLAN modules.

(BIOS Setup option; default = Enabled).

Page 26

a

Mandatory torque for mounting

screws: 0.25Nm +/- 0.05Nm

Max. torque must never be exceeded,

otherwise the mainboard (solder

nuts) may be damaged.

Note: Damaged solder nuts are not

covered by any warranty!

Module Assembly Kit (included in

mainboard shipment) contains

1metal spacers and 1 mounting

screws.

(spacer)

(mounting screw)

Solder nut for

Fullsize

Minicard

Solder nut for

Halfsize

Minicard

Interfaces & Connectors

3.17 m-SATA / Mini-PCIe Socket Assembly Note

Page 27

a

Interfaces & Connectors

3.18 M.2 (Key M) – 2242 & 2260

D3433-S: M.2 cards with SATA or PCIe are supported. PCIe is connected via 2lanes.

D3434-S: M.2 SATA only supported.

Page 28

a

Mandatory torque for mounting

M3 screw: 0.4Nm +/- 0.05Nm

Mandatory torque for mounting

spacer nut: 0.6Nm +/- 0.05Nm

Max. torque must never be exceeded,

otherwise the mainboard (solder

nuts) may be damaged.

Note: Damaged solder nuts are not

covered by any warranty!

Module Assembly Kit

(included in mainboard shipment)

contains 1metal spacer nut

and 1 mounting screw

(M3 x 3.5mm ,bolt head ø = 4.5mm).

(spacer nut)

(mounting screw)

Solder nut for

M.2

2242

Solder nut for

M.2

2260

Interfaces & Connectors

3.19 M.2 Socket Assembly Note

Page 29

a

Solder nut for

M.2

2242

Solder nut for

M.2

2260

Solder nut for

Minicard

Halfsize

Solder nut for

Minicard

Fullfsize

M.2 2242 Module

Minicard

Fullfsize

Configuration

example:

Interfaces & Connectors

3.20 Possible configurations for M.2 & Minicard –Modules

Important Note:

Possible configurations: 1. Minicard fullsize + M.2 - 2242, 2. Minicard Halfsize + M.2 – 2260, 3. Minicard Halfsize + M.2 – 2242;

Minicard Fullsize + M.2 – 2260: Not supported!

Page 30

a

Interfaces & Connectors

3.21 PCIe x16 Slot Configuration for Riser cards (only supported for D3433-S)

The PCIe x16 Slot (PEG) is compatible for

riser cards up to 3 PCIe slots.

The PCIe x16 Slot (PEG) can be configured for:

- Single PCIe x16 Slot usage - [PEG]

- Riser card with 2x PCIe x8 Slot usage – [Riser]

- Riser card with 1x PCIe x8 and 2x PCIe x4 Slot usage – [Riser]

(BIOS Setup option; default = PEG).

Page 31

a

Pin

Signal

1

GND

2

12V

3

FAN Sense

4

FAN PWM

Note:

Fans must never be attached or

removed while the system is

powered. Mainboard may be

damaged!

Pin 1

Interfaces & Connectors

3.22 Fan Connectors

Fan speed control is supported for 4 pin (PWM) fans.

Fan3 can be changed from 4-pin mode to 3-pin controlled mode via BIOS Setup.

3-pin fans (voltage controlled) connected to Fan3 connector will always operate at full speed resp. 12V supply voltage!

Fan1 current: max. 2A continuous / 4A peak

Fan3 current: max. 1,2A

Page 32

a

Pin

Signal

Pin

Signal

1

HDA Port 1 Left

2 Analog GND

3

HDA Port 1 Right

4 FP Presence Detect

5

HDA Port 2 Right

6 Jack Sense Port 1

7

Jack Sense common

8 Key 9 HDA Port 2 Left

10

Jack Sense Port 2

Pin

Signal

Pin

Signal

1

Mic Left

2 Analog GND

3

Mic Right

4 reserved

5

Headphone out Right

6 reserved

7

Analog GND

8 Key 9 Headphone out Left

10

reserved

Note: Front audio operating

mode (High Definition Audio

or Legacy Audio) selectable in

BIOS Setup

Interfaces & Connectors

3.23 Rear Audio / Frontpanel Audio Connector

Frontpanel Audio: High Definition Mode

Frontpanel Audio: Legacy Mode (AC97)

Note: In case of using this connector in AC97 = Legacy mode (BIOS Setting) take care for pin 7.

This pin is tied to GND. HP_ON# signaling on this pin is not supported.

Page 33

a

Pin

Signal

A

Line input

Pin

Signal

A

Headphone output

Line IN (light blue)

Pin A

Headphone OUT (lime)

Pin A

Interfaces & Connectors

Rear Audio / Frontpanel Audio Connector

Rear Audio Connectors

Electrical input characteristics

Line: Stereo max. 1,2Vrms (Gain=0dB) input voltage

Electrical output characteristics

Headphone: Stereo max. 1,2 Vrms output voltage at 32Ohm load

System Speaker (via frontpanel connector): Mono, typ. 2W (RMS) at 4Ohm load

Mute Topology

When an outPut device (HeadPhone, HifiAmp...) is attached to an output jack, the following mute topology is required:

FrontOut mutes RearOut and MonoOut RearOut mutes MonoOut (frontpanel system speaker)

Remark: System beeps are only audible via the internal (frontpanel) system speaker. System beeps are also audible on the internal speaker if an external

device is plugged in.

Page 34

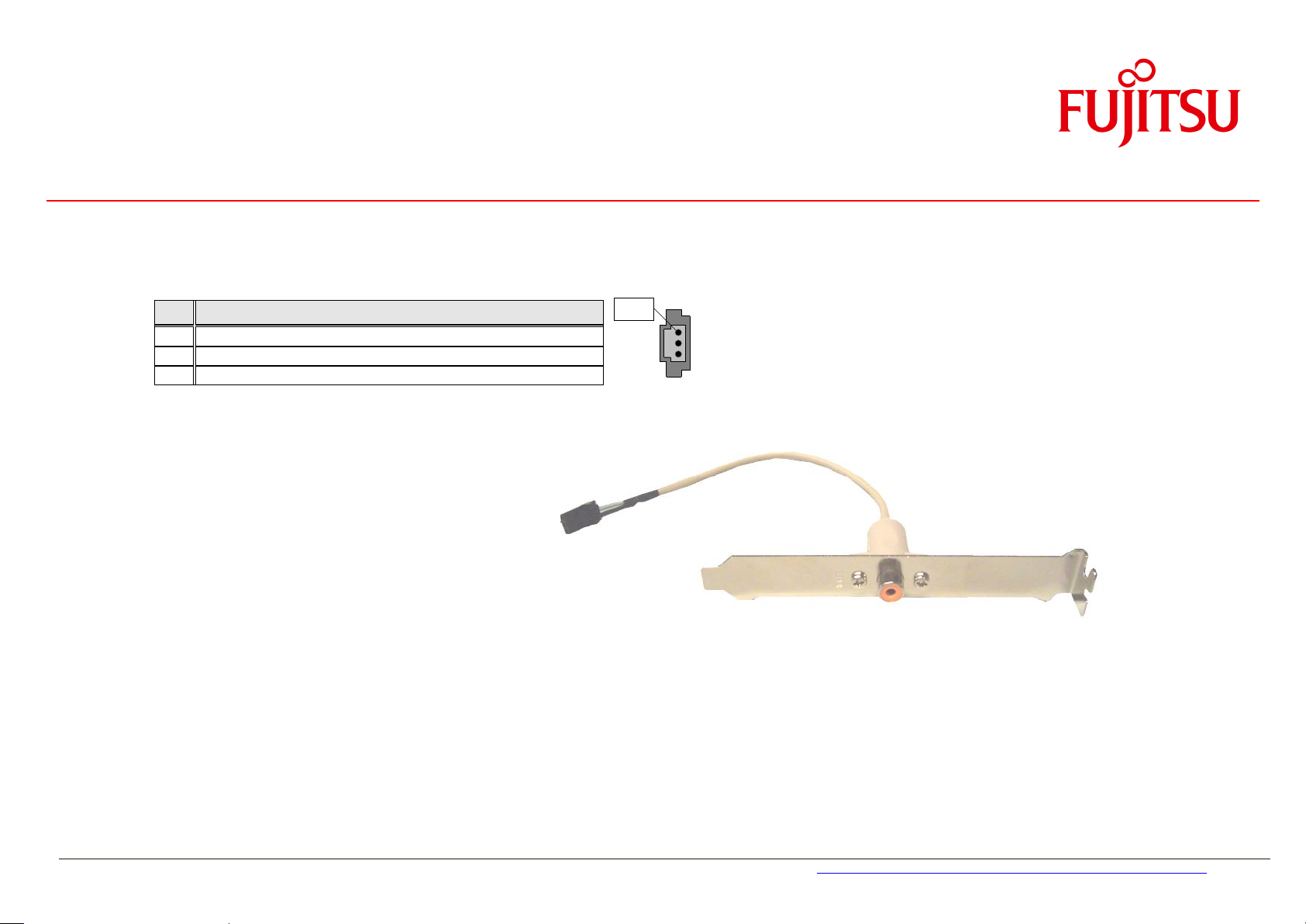

a

Pin

Signal

1

VCC

2

SPDIF out

3

GND

Pin 1

Interfaces & Connectors

3.24 S/PDIF Connector

Note:

Standard connector bracket should directly

connect to SPDIF out and GND pins

(no signal converter required)

(Sample S/PDIF connector bracket)

Page 35

a

Feature Connector: CompuPack R-DRK2-20-S3-SMT

(Note: Any 2mm pitch ribbon cable standard parts can be used)

1

GPI/O_0

GPI/O_1

2

3

GPI/O_2

GPI/O_3

4

5

GPI/O_4

GPI/O_5

6

7

GPI/O_6

GPI/O_7

8

9

VCC_3.3V

GND

10

11

VCC_3.3V

VCC_5Vaux

12

13

EN WLAN H (Input)

GND

14

15

WLAN LED+ (Output ~5mA)

GND

16

17

GND

VCC_5V

18

19

VCC_12V

VCC_12V

20

Note: Current max. 1.5 A per power pin!

Parameter

Range

GPI/O Input Low Voltage

-0.5V … 0.8V

GPI/O Input High Voltage

2V … 3.3V

GPI/O Output Low Voltage

max. 0.7V

GPI/O Output High Voltage

min. 2.5V

Note: max. load per GPI/O pin: 10mA

(overall current for all GPI/O pins must be < 85mA)

Each GPI/O pin has an integrated serial resistor of 150 Ohm

GPIO access is provided via the SM-Bus controller PCA9554A

ftp://ftp.ts.fujitsu.com/pub/Mainboard-OEM-Sales/Products/Mainboards/Industrial&ExtendedLifetime/

D343x-S_Mini-ITX/Documentation/Specification/GPIO_Chip_PCA9554a.pdf

Note: SM-Bus address: 0x78h (8-bit)

For Windows OS, the FTS BMC API provides easy access to the GPIO:

ftp://ftp.ts.fujitsu.com/pub/Mainboard-OEM-Sales/Products/Mainboards/Industrial&ExtendedLifetime/

D343x-S_Mini-ITX/IndustrialTools_D343x-S/

2

1

(preliminary)

Interfaces & Connectors

3.25 GPIO (Feature Connector)

Page 36

a

Pin

Signal

Pin

Signal

13

+ 3.3V (P3V3P)

1 + 3.3V (P3V3P)

14

- 12V (P12VN)

2 + 3.3V (P3V3P)

15

GND 3

GND

16

PS on (low asserted)

4 + 5V (VCC)

17

GND 5

GND

18

GND 6

+ 5V (VCC)

19

GND 7

GND

20

NC 8

Powergood (high asserted)

21

+ 5V (VCC)

9 + 5V Auxiliary (VCC Aux)

22

+ 5V (VCC)

10

+ 12V (P12VP)

23

+ 5V (VCC)

11

+ 12V (P12VP)

24

GND 12

+ 3.3V (P3V3P)

Pin

Signal

Pin

Signal

3

+ 12V

1 GND

4

+ 12V

2 GND

Pin 13

Pin 1

Pin 1

Pin 3

Interfaces & Connectors

3.26 Power Supply Connector (Multirail)

3.27 Additional Power Supply Connector (12V for Processor)

Page 37

a

Important Note:

If the Power Supply is changed from Multirail to

single 12V or vice versa, make sure to

disconnect the mainboard from any power at

least for 10 minutes!

2)Requirement for ATX Multirail operation:

Operational state from the main PSU is off.

The mainboard checks

if

PIN10 and PIN11 = 0V

&

PIN 9 = 5V

only then the main PSU starts and the

mainboard is in ATX Multirail operating mode.

Interfaces & Connectors

3.28 Power Supply Connectors (ATX Multirail or Single 12V Operation)

3.28.1

(24 pin ATX connector)

(4 pin 12V connector for CPU power)

24 pin ATX connector:

1) Pin 14 (-12V) and pin 20 (-5V) are not required

2) Pin 9, Pin 10 & Pin11 are responsible for operational state

ATX Multirail Operation

Page 38

a

Important Note (Single 12V mode):

The “output” pins (3.3V

out

, 5V

out

, 12V

out

)

provide power for drives or extra devices.

Maximum “output” power ratings:

+3.3V

out

: max. 4A

= combined output current of 3.3V

PCIe x16 and 3.3V

out

pins (1, 2, 12, 13)

+5V

out

: max. 9A

= combined output current of all USB

ports and +5V

out

pins (4, 6, 21, 22, 23)

+12V

out

: max. 6A

depends on output power of single

12V PSU! (12V

out

= pin 20)

2)Requirement for Single 12V operation:

IF

PIN10 and PIN11 = 12V

&

PIN 9 = 0V

only then the mainboard is in Single 12V

operating mode.

Interfaces & Connectors

3.28.2

Single 12V Operation

(24 pin ATX connector)

(4 pin 12V connector for CPU power)

For single 12V operation both connectors 24 pin and 4 pin are required!

24 pin ATX connector:

1) Pin 8, 9, 14, 16 (NC) must NOT be used in single 12V mode!

2) Pin 9, Pin 10 & Pin 11 are responsible for the operating mode

Page 39

a

Important Note:

The switching / mode detection between ATX-

and single 12V- operating mode is different to

the mainboard D3243-S!!!

All four +12Vin pins must be

connected to the +12V supply

source.

Both GND pins (4-pin conn.) &

two GND pins (24-pin

connector) must be connected

to the supply source.

Interfaces & Connectors

3.28.3

Sample supply cabling for single 12V configuration:

e.g. processor 65W, additional graphics card, several SATA drives

+12V

GND

(Single 12V PSU)

Note: Each single pin of both connectors is capable of max. 8A!

All pins of the 4-pin connector must

be used due to peak current in Turbo Mode.

Single 12V Operation – Config

Page 40

a

Pin

Signal

1

GND

2

Case open (low asserted)

3

Intrusion switch present (low asserted)

Note:

The intrusion supervision feature needs to be enabled in BIOS Setup first (Menu „Security“ „Cabinet

Monitoring“).

This BIOS option is only available if pin 3 („Intrusion Switch Present“) is connected to GND!

Note:

Chassis intrusion is active even if the system is switched off (S5 state) or

disconnected from mains power.

The intrusion event is monitored by the chipset (PCH) and stored in the BIOS

Eventlog during the next Boot.

A timestamp (Boot date/time) will be added then.

Note: This timestamp does not represent date/time of the intrusion event!

If a Supervisor Password is enabled in BIOS Setup, the system will stop

during BIOS POST if an intrusion event has been detected. In order to

continue, the Supervisor Password must be entered to confirm the intrusion

event.

The intrusion status can be easily monitored by using the BMCAPI (Windows):

ftp://ftp.ts.fujitsu.com/pub/Mainboard-OEM-Sales/Products/Mainboards/Industrial&ExtendedLifetime/D343x-S_Mini-ITX/IndustrialTools_D343x-S/

Pin 1

Interfaces & Connectors

3.29 Chassis Intrusion

Page 41

a

4 System Monitoring

- Temperature Sensors and Fans

- SystemGuard: Fan / Temperature Monitor

- SilentFanConfig-Manager

- Temperature Reference Points

- BMC – BIOS Default Settings

Page 42

a

1) 2A continuous / 4A peak current

2) 1,2A continuous

3) FAN 3:

PWM or 3-Wire

Selectable via BIOS Setup

Default = PWM)

Processor

(Fan1; PWM) 1)

Sensor “Memory”

Sensor “PCIe Graphics”

Note: Do not attach more than one fan per connector!

Remove or connect fans only when unit is powered off!

Sensor “Processor”

Sensor “PCH”

Fan 3 (PWM or 3-pin)

2) 3)

Sensor “CoreRegulator”

Sensor “Ambient”

System Monitoring

4.1 D343x-S: Temperature Sensors and Fan Connectors (preliminary)

Page 43

a

System Monitoring Tool:

• Visualize processor and sensor

temperature data

• Display current speed for all

attached fans

• User can configure fan aging control

(menu “Special”)

• User can configure system watchdog

(menu “Special”)

User can adjust system behaviour via

“Silent PC / Performance PC” slider by

forced processor throttling

System Monitoring

4.2 SystemGuard

Page 44

a

Temperature Sensors

Processor Sensor

1)

Sensor PCIe Graphics

Ambient Temperature

Core Voltage Regualtor Sensor

Memory Sensor

PCH Sensor

Sensor / Fan Matrix

Indicates which sensor influences the specific fan speed

Note: Characteristics for FAN1 is always dependent on the CPU

temperature – fully controlled by the system BIOS.

Due to safety reasons the influence of the CPU sensor for FAN1

cannot be disabled!

1) Note: The temperature value shown for the processor (digital „PECI“ measurement =Platform Environment Control

Interface) does NOT provide the absolute processor temperature, but it is a calculated value based on the relative PECI data.

(Note: Sample screenshot only; data may differ for specific mainboard model)

System Monitoring

4.3 SystemGuard - Details

Page 45

a

System Monitoring

4.4 SilentFanConfigManager – Customize System Monitoring Settings

Windows-based System Management Configuration Tool

ftp://ftp.ts.fujitsu.com/pub/Mainboard-OEM-Sales/Products/Mainboards/Industrial&ExtendedLifetime/D343x-S_Mini-ITX/IndustrialTools_D343x-S/SilentFanConfig-Manager/

1. Windows-based configuration tool (SilentFanConfig) to create customized system monitoring settings like minimum fan speed and

temperature sensor influence. These customized settings are stored in a specific “SMCO” flash file.

2. DOS-based tool “SMCO” to flash the customized system monitoring settings (SMCO file) to the system BIOS of the target unit.

SilentFanConfig-Tool: SMCO-Tool SilentFanConfig-Tool +

Create specific system SMCO Flash File Flash SMCO file to SMCO-Tool =

monitoring settings mainboard BIOS SilentFanConfigManager

(any Windows-based PC) (each unit in production)

Note: New settings are written permanently to system BIOS.

Any BIOS update will not reset the new settings

SilentFanConfig V1.82.0 or higher required for D343x-S

Please see documentation in ZIP file (link below) for further details.

ftp://ftp.ts.fujitsu.com/pub/Mainboard-OEM-Sales/Products/Mainboards/Industrial&ExtendedLifetime/D343x-S_Mini-ITX/IndustrialTools_D343x-S/

Page 46

a

Capacitor Endurance Time

Solid Electrolyte:

Fluid Electrolyte:

Operating Conditions:

Circulating air

(mainboard) max. 60°C

Usage 24h / 7 days

All onboard electrolyte

capacitors: Polymer type only

(= solid electrolyte)

Lx = effective endurance time

Lo = endurance time @ 105°C

(e.g. 2.000hrs)

to = 105°C

tx = capacitor surface temperature

(e.g. 68°C)

High Efficiency Processor

Core Voltage Regulator

for reduced thermal

dissipation loss

Note: Power Consumption

PCH P max ~ 4.1W

P idle ~ 0.7W

Extra Heatsink

on PCH

COM Driver with enhanced

operating temperature range

8-layer PCB for improved

signal quality within full

operating temperature range

Oscillator with enhanced

operating temperature range

System Monitoring

4.5 Components for continous 24/7 operation @ +60°C

Page 47

a

System Monitoring

4.6 Capacitor Endurance Time Comparison

Page 48

a

Battery max. 60/70°C 1)

PCH max. 95°C

(chip surface)

All capacitors max. 70°C

1) Note: Battery operation is specified in

temperature range up to 60°C. Operation

between 60°C and 70°C may result in:

- Higher self discharge rate

- Decline of specified characteristics

- Danger of leakage increases

Qscillator max. 70°C

Audio Codec max. 75°C

Reference Point Limit Temperatures (Component Surface) must not be exceeded!

Power MOS-FETs / MOS-FET

Drivers max. 100°C

Operating Conditions:

Circulating air

(mainboard) max. 60°C

Usage 24h / 7 days

TPM max. 70°C

Inductor max. 100°C

System Monitoring

4.7 Temperature Reference Points D343x-S

Page 49

a

Super I/O max. 70°C

LAN max. 85°C

Reference Point Limit Temperatures (Component Surface) must not be exceeded!

Operating Conditions:

Circulating air

(mainboard) max. 60°C

Usage 24h / 7 days

LVDS Converter max. 85°C

COM Driver max. 70°C

COM Driver max. 70°C

Quartz max. 70°C

Quartz max. 70°C

SP-Caps max. 95°C

Note: Humidity should not

exceed 75% at 60°C

System Monitoring

4.8 Temperature Reference Points D343x-S (rear)

Page 50

a

Sensors

PECI (Processor)

PCIe Graphics

Ambient

Core regulator

Memory

PCH

Fan1 (CPU)

X

X

Fan3

X

X X X

X

X

StartUp 1)

FullSpeed 2)

Alert 3)

Note

PECI (Processor)

n.a.

n.a.

n.a.

These settings are fixed by the BIOS (depends on the

individual installed processor) and cannot be changed via

SilentFanConfig-Manager.

Ambient

45°C

60°C

68°C

These settings are implemented for the current

BIOS version and may be changed for upcoming

BIOS versions!

Default minimum fan speed = 30% (all fans).

Core Regulator

50°C

75°C

80°C

Memory

40°C

60°C

65°C

PCH

50°C

60°C

70°C

PCIe Graphics

40°C

60°C

65°C

System Monitoring

4.9 BMC – BIOS Default Settings D343x-S

The default system monitoring settings like fan speed, sensor influence, and Alert temperatures are fixed by the system BIOS.

All relevant settings can be customized by system builders via the SilentFanConfig-Manager tool kit.

“X” indicates that this specific sensor influences the speed of this specific fan

1) If the sensor temperature is below “StartUp” the fan rotates a its defined minimum fan speed

2) Between “StartUp” and “FullSpeed” the fan speed increases linear

3) If the sensor temperature achieves “Alert”, the system can provide a warning (e.g. via SystemGuard tool)

Page 51

a

Connectors for ATX (Multirail) Power Supply

(1) 24 pin connector (ATX layout)

(2) 4 pin connector (+12V, GND)

Note: The +12V supply (up to 12A) for processor and chipset is provided via the 4 pin

connector! Onboard voltage regulators convert the +12V input power to the appropriate

processor / chipset supply voltages.

(3) Processor Core Voltage Regulator: High Efficiency design for enhanced

power saving and less thermal dissipation loss.

Power Supply Requirements

for onboard components (worst case incl. processor & memory; w/o USB devices;

w/o PCIe cards, w/o M.2 / mSATA / SATA drives)

Source 1)

Voltage

Min. PS

Load

Max.Voltage

Tolerance

Mainboard

Capacitive

Load

Max. Mainboard

Current

ATX Power

Supply

+ 12V

0.05A

± 5 %

1.300µF

8A/12A 2)

- 12V

0A --

not used

+ 5V

0.2A

± 5 %

900µF

3A

+ 3.3V

0A

± 5 %

350µF

0.5A

+ 5Vaux

0A

+5 % / -3%

330µF

0.5A

12V only PSU

+12V

0A

± 5 %

1.300µF

8A/12A 2)

1) ATX PSU or 12V only DC Supply

2) Max. Cont. Current = 8A; max. Surge Current = 10A (< 100sec) / 12A (< 10ms)

The power supply must support the minimum load

conditions as mentioned in the left chart.

(3)

(2)

(1)

5 Power Supply

5.1 ATX Power Supply

Page 52

a

Power Supply

5.2 Typcial Power Consumption (to be added soon)

Page 53

a

Description

USB Port #

Common Fuse

Max. Current

per Port

Note

USB 3.0

Frontpanel

#2 / #3

2A

900mA

USB 2.0

Internal

#6 / #7

2A

500mA

for internal

devices 1)

USB 3.0

Stick Socket 1)

#13

900mA

for internal

devices 1)

USB 3.0 Rear

(right)

(USB/USB/LAN)

#0 / #1

2A

900mA

USB 3.0 Rear

(left)

(USB/USB/LAN)

#4 / #5

2A

900mA

USB 2.0 Rear

#9 / #10 / #12 / #11

2A

500mA

USB 2.0

mSATA / mPCIe 1)

#8

(not fused)

500mA

for internal

devices

1)

#2 / #3

USB Ports:

#13

#6 / #7

#8

6 USB Implementation

6.1 USB Ports & USB Power Fuses (D3433-S)

D3433-S: There is one USB controller (xHCI) for all USB ports

1) Note: These “internal” ports do not provide “Windows Device Eject”

Page 54

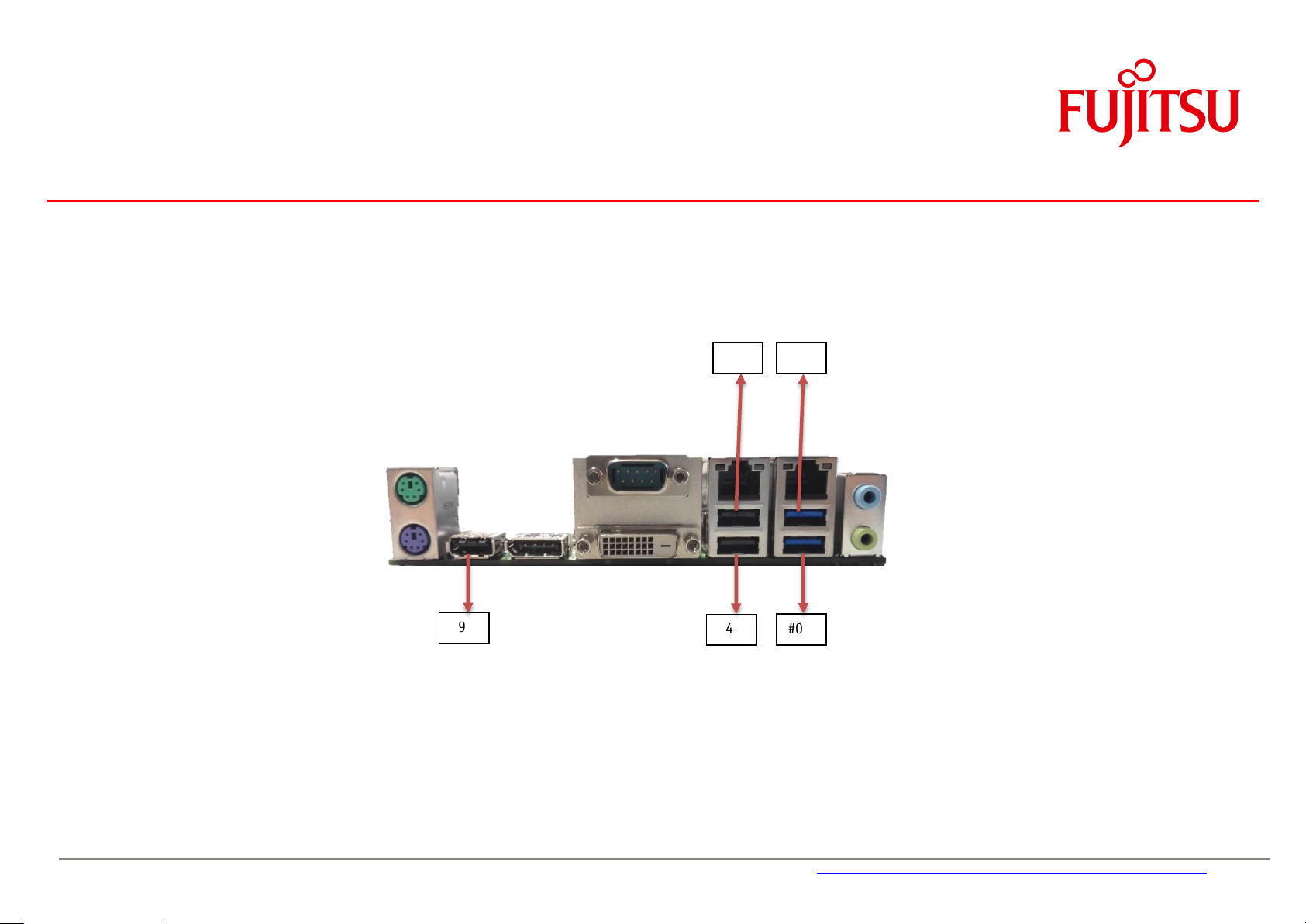

a

#11

#12

#10

#9

#5

#4

#1

#0

USB Implementation

Rear USB Ports for D3433-S:

Page 55

a

Description

USB Port #

Common Fuse

Max. Current

per Port

Note

USB 3.0

Frontpanel

#2 / #3

2A

900mA

USB 2.0

Internal

#6 / #7

2A

500mA

for internal

devices 1)

USB 3.0 Rear

(right)

(USB/USB/LAN)

#0 / #1

2A

900mA

USB 2.0 Rear

(left)

(USB/USB/LAN)

#4 / #5

2A

500mA

USB 2.0 Rear

#9

2A

500mA

USB 2.0

mPCIe 1)

#8

(not fused)

500mA

for internal

devices

1)

USB Ports:

#2 / #3

#6 / #7

#8

USB Implementation

6.2 USB Ports & USB Power Fuses (D3434-S)

D3434-S: There is one USB controller (xHCI) for all USB ports

1) Note: These “internal” ports do not provide “Windows Device Eject”

Page 56

a

#1

#5

#0

#4

#9

USB Implementation

Rear USB Ports for D3434-S:

Page 57

a

7 Display Options

7.1 Summary: Video Output Options D343x-S

Up to three independent displays supported (D3434-S: max. two displays)

Supports Clone Mode, Extended Desktop and Collage Mode (combine 2 or 3 displays to one screen)

Support of 4K display technology via DisplayPort output

DisplayPort is compatible with

DVI-D is compatible with

DVI to HDMI

DP to HDMI

– adapter and (active) DVI to VGA - adapter

– adapter,

DP to DVI

– adapter and

DP to VGA

Second DisplayPort can be used as DP, eDP or LVDS (via onboard DP to LVDS converter)

eDP and LVDS can be used simultanously

– adapter

Page 58

a

1 x or 2 x Displayport V1.2

DVI-D

eDP (2 lanes)

DP: max. 4096 x 2304 @ 60 Hz

DVI-D: max. 1920 x 1200 @ 60Hz

eDP: max. 1920 x 1200 @ 60Hz (18, 24-bit)

LVDS 24bit 8max. 1920 x 1200)

Display Options

Page 59

a

Integrated Backlight, powered by Inverter

Backlight

Inverter

Display Options

7.2 LVDS Display & Backlight Inverter

Page 60

a

PIN SIGNAL SIGNAL PIN

2 Ground Ground 1

4 LVDS_H3+ (EVEN_3+) LVDS_L3+ (ODD_3+) 3

6 LVDS_H3- (EVEN_3-) LVDS_L3- (ODD_3-) 5

8 Ground Ground 7

10 LVDS_H2+ (EVEN_2+) LVDS_L2+ (ODD_2+) 9

12 LVDS_H2- (EVEN_2-) LVDS_L2- (ODD_2-) 11

14 Ground Ground 13

16 LVDS_H1+ (EVEN_1+) LVDS_L1+ (ODD_1+) 15

18 LVDS_H1- (EVEN_1-) LVDS_L1- (ODD_1-) 17

20 Ground Ground 19

22 LVDS_H0+ (EVEN_0+) LVDS_L0+ (ODD_0+) 21

24 LVDS_H0- (EVEN_0-) LVDS_L0- (ODD_0-) 23

26 Ground Ground 25

28 LVDS_CLK_H+ (CLK_EVEN+) LVDS_CLK_L+ (CLK_ODD+) 27

30 LVDS_CLKH- (CLK_EVEN-) LVDS_CLK_L- (CLK_ODD-) 29

32 Ground Ground 31

34 DDC-Data DDC-Clock 33

36

LCD-Power

1)

LCD-Power

1)

35

38 Ground

LCD-Power

1)

37

40 LCD_Power_Enable Ground 39

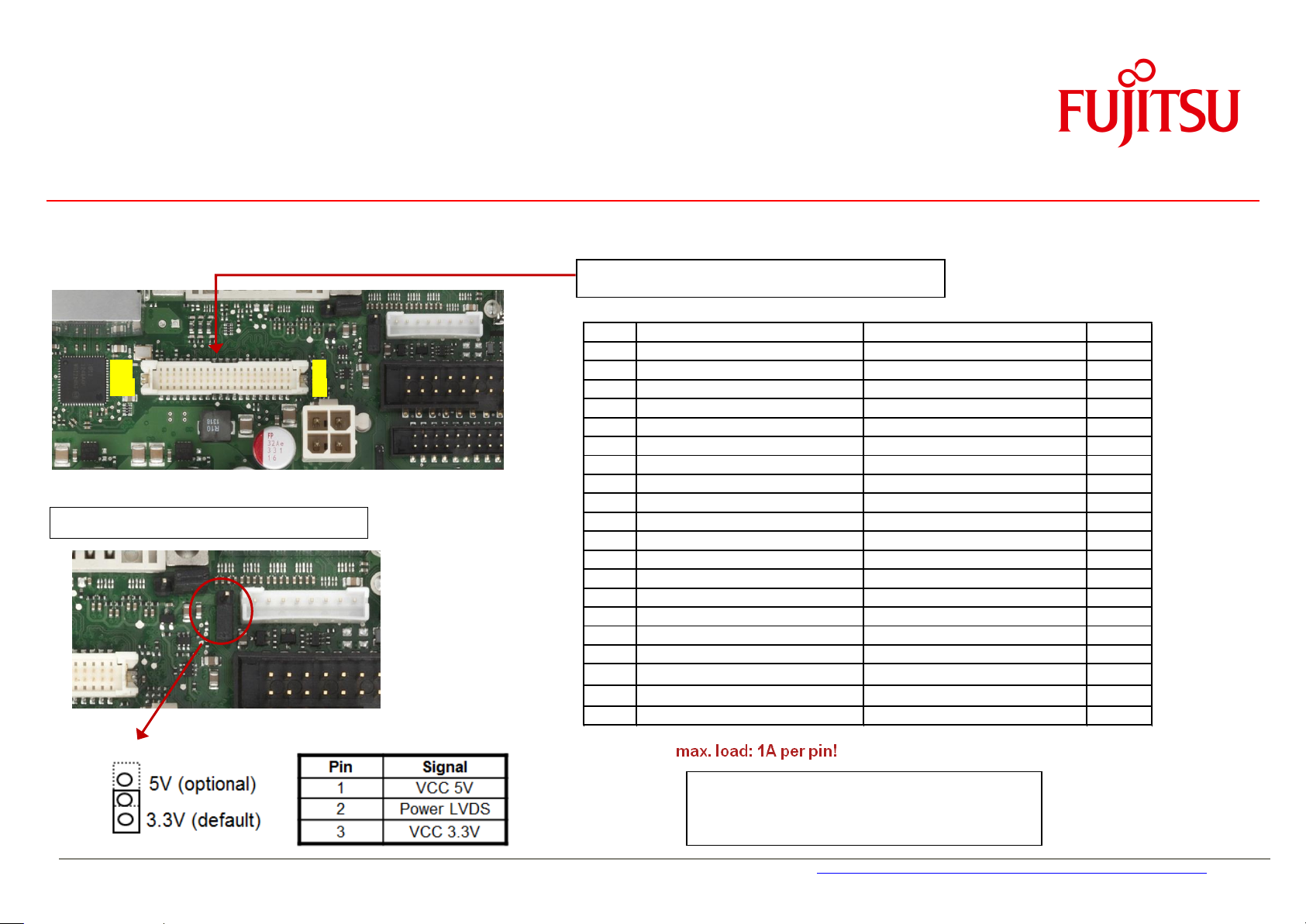

1) selectable via Jumper

LVDS Connector: Hirose DF13-40 (or compatible)

LVDS operating voltage selector jumper

2.

1.

Note: LVDS pinning is compatible to D2703-S /

D2963-S / D3003-S / D3313-S / D3243-S

D3433-S / D3434-S

40.

39.

Display Options

7.3 LVDS Connector Details

Page 61

a

Backlight Inverter Connector: JST PHR-8

Backlight Brightness Control:

Provides a variable DC voltage between 0V and 4V via an RC filter (10kOhm / 20uF; buffered output).

Alternatively a PWM control is available, please see related jumper setting.

Basically the brightness level can be selected by BIOS Setup, but it is also accessible

from Windows OS.

If this control signal is used, the system integrator is responsible for the implementation of a backlight

converter that fits to the control output voltage range.

Backlight On/Off Control:

Active High, 3.3V Note: Polarity can be changed via BIOS Setup

LVDS Backlight Brightness Control Jumper

(Select analog or PWM output)

1. 8.

Display Options

7.4 Backlight Inverter Connector Details

Page 62

a

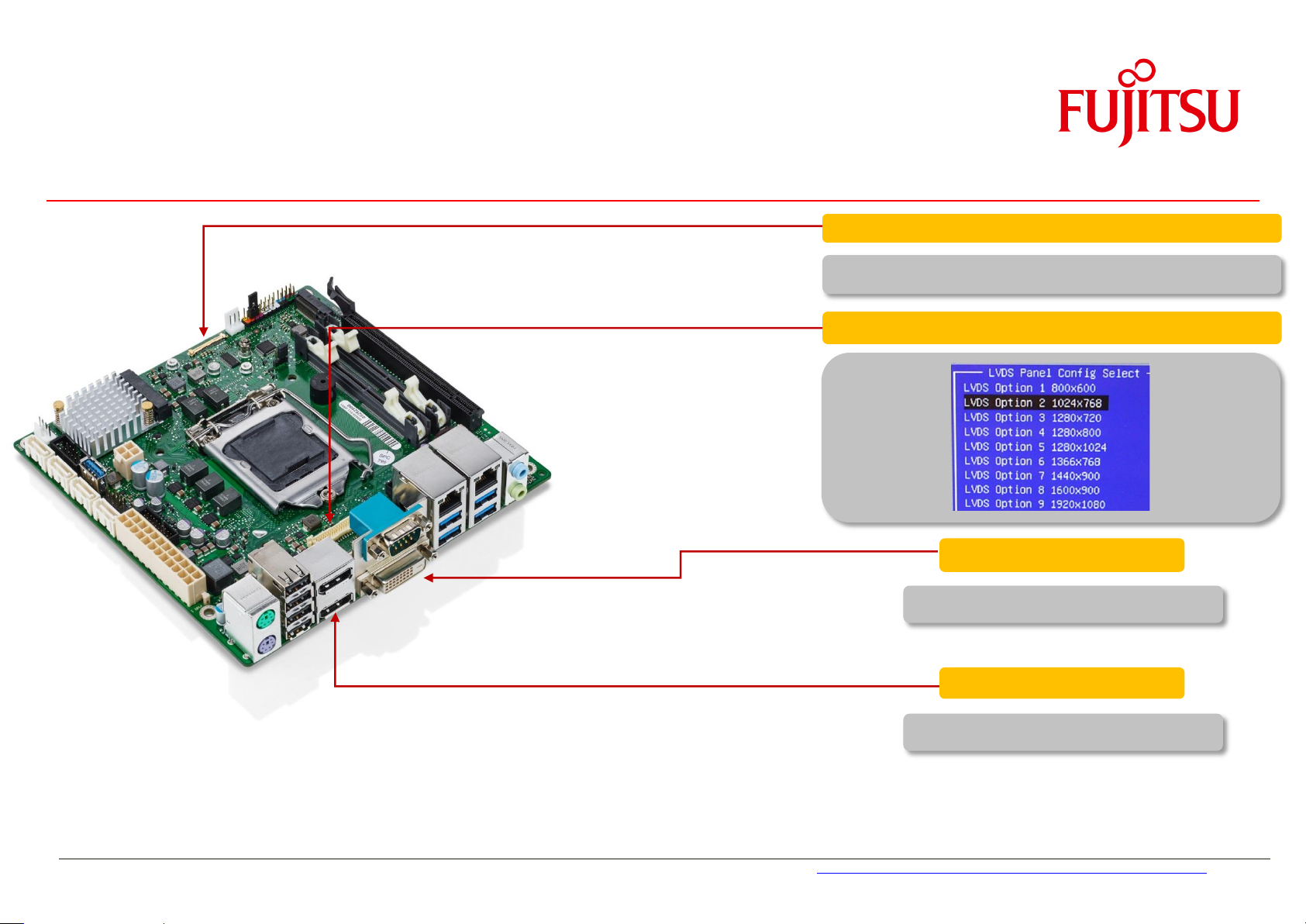

There are 9 default LVDS settings available

BIOS Setup – Advanced –LVDS Config Select

Note: Option 10 (LVDS adjusted Parameters)

becomes visible after running the “LVDS Tool”

for implementing customized LVDS settings

once.

Important note:

“Non-EDID Support” must be set to

<Enabled> for standard LVDS displays

w/o DDC (EDID) interface!

Display Options

7.5 LVDS Timing & Screen Resolution

Page 63

a

LVDS Mode:

The correct mode must be set for the attached LVDS panel.

Note: This setting is also required if customized LVDS timings are

implemented (LVDS tool)!

LVDS Brightness:

Set the level for the „Backlight Brightness Pin“.

Typical voltage level (analog mode) resp. PWM level:

BIOS-Setting Voltage Level / PWM Level (prelim.)

0 0.1V / 0.4%

255 4.1V / 100%

Preliminary (not yet implemented):

The LVDS brightness level can be adjusted in BIOS Setup or via

Windows 7 / Windows 8.1 Mobility Center (<Windows key> + <X>)

Display Options

LVDS Timing & Screen Resolution

Page 64

a

POST Screen Mode:

Default setting = Graphic Mode (800 x 600).

For panels < 800 x 600 mode could be changed to <Text Mode> in

order to enable full BIOS POST screen resp. full BIOS Setup screen

(otherwise some portion of the screen may be cut off)

Display Options

LVDS Timing & Screen Resolution

Page 65

a

The LVDS tool (DOS-based) allows to flash specific

LVDS settings to the system BIOS of D343x-S.

The LVDS tool needs a panel-specific

EDID configuration file based on the spec data

of the LVDS panel.

Note: Sample configuration EDID files

are available in the LVDS Tool kit.

For adjusting EDID files the “Phoenix EDID tool”

Is required (see link below).

(Sample screen message after running LVDS tool)

Download-Link for LVDS Tool:

ftp://ftp.ts.fujitsu.com/pub/Mainboard-OEM-Sales/Products/Mainboards/Industrial&ExtendedLifetime/D343x-S_Mini-ITX/IndustrialTools_D343x-S/LVDS-Tool/

LVDS tool ≥ V2.2.1 must be used to implement customized LVDS settings

Note:

The onboard LVDS converter switches automatically between single channel and dual channel mode.

The reference resolution is 1366 x 800 pixels. If H > 1366 or V > 800, the scaler switches to dual channel mode.

Otherwise, LVDS will operate in single channel mode.

The scaler supports clock rates up to 105Mhz; LVDS displays with clock rates > 105Mhz are not supported

Display Options

7.6 LVDS Tool

Page 66

a

Display Options

7.7 LVDS – Influence on Graphics Output (prelim.)

When LVDS support is enabled in BIOS Setup, this has some effect on the support of the other graphics output ports (DVI-D, DisplayPort).

Furthermore, the setting “Secure Boot” also influences the supported graphics output modes.

Page 67

a

Display Size TFT Pixel Inverter

10.4" NEC NL6448BC33-63D 640 x 480 NEC 104PW201

12.1" AUO G121SN01-V0 800 x 600 Green-C&C GH093A-ROHS

12.1" LG-Philips LB121S03-TL01 800 x 600 Green-C&C GH001HB-ROHS

15" Sharp LQ150X1LW71N 1024 x 768 TDK CXA-0349

15" AUO G150XG01V0 1024 x 768 Green-C&C GH001A-ROHS

17" AUO M170EG01-VD 1280 x 1024 Green-C&C GH053A-ROHS

19" Sharp LQ190E1LW01 1280 x 1024 Power Systems PS-DA0412-05

19" AUO M190EG01 1280 x 1024 GH053(A1)-ROHS

Sample cabling diagrams for following LVDS displays & related inverters are available:

ftp://ftp.ts.fujitsu.com/pub/Mainboard-OEM-Sales/Products/Mainboards/Industrial&ExtendedLifetime/D343x-S_Mini-ITX/Documentation/LVDS_Cabling-Samples/

Display Options

7.8 LVDS Cabling Reference

Page 68

a

Display Options

7.9 LVDS Sample Cabling for AuO-G150

Page 69

a

Cable requires 1:30 connection

(pin 1 to pin 30, pin2 to pin29 etc.)

Pin 1

Pin 30

Pin 1

Pin 30

Display Options

7.10 Embedded DisplayPort (prelim.)

Page 70

a

eDP-Power Jumper

Pin

Signal

Pin

Signal

1

P5VP

2

VCC 3 P3V3P

Pin 1

Display Options

7.11 Embedded Display Port Power

With this jumper you can select the level of the power for embedded display port connector.

Note: The default state is VCC = 3,3V

Page 71

a

8 Operating System Support

- Windows® 7

- Windows® 8.1

- Windows® 10

- Linux

Page 72

a

Operating System Support

8.1 Support for Windows 7 / Windows 8.1 / Windows 10

• Mainboards D343x-S are designed according to the

Microsoft Guidelines for Windows 7, Windows 8.1 and Windows 10

• MS certified drivers are available via OEM DU-DVD

and OEM FTP Server

ftp://ftp.ts.fujitsu.com/pub/Mainboard-OEM-Sales/Products/Mainboards/Industrial&ExtendedLifetime/D343x-S_Mini-ITX/Drivers_D343x-S/

Page 73

a

Operating System Support

8.2 Linux Support (to be added soon)

Page 74

a

9 Mainboard Tools

Common Mainboard Tools

Note: Make sure to not use any DOS memory manager like

himem.sys

oder

emm386!

9.1 BIOS Boot Logo Tool

- Tool to integrate a customized boot logo

ftp://ftp.ts.fujitsu.com/pub/Mainboard-OEM-Sales/Services/Software&Tools/Common-Mainboard-Tools/BootLogo_4_UEFI/

9.2 EditCMOS

- DOS-based production tool to change BIOS settings

and freeze customized BIOS settings (= customized default settings)

ftp://ftp.ts.fujitsu.com/pub/Mainboard-OEM-Sales/Services/Software&Tools/Common-Mainboard-Tools/EditCMOS_UEFI/

9.3 OEMIDENT

- Production tool to add MS OEM licence data (SLP1 / SLP2.x / OA3.0)

- Add an individual customer serial no / add a chassis asset tag and patch several DMI data

- Disable and hide TPM feature in BIOS Setup

ftp://ftp.ts.fujitsu.com/pub/Mainboard-OEM-Sales/Services/Software&Tools/Common-Mainboard-Tools/OEM-Ident/

Page 75

a

Mainboard Tools

9.4 SystemGuard

- Windows-based tool to monitor temperatures and fan speed of FTS mainboards

- Option to configure automatic fan ageing supervision

- Provides access to the System Watchdog

ftp://ftp.ts.fujitsu.com/pub/Mainboard-OEM-Sales/Services/Software&Tools/Common-Mainboard-Tools/SystemGuard/

Note: SystemGuard V4.07 (or higher) required for D3433-S, D3434-S

Page 76

a

Mainboard Tools

Industrial Tools

9.5 SilentFanConfig-Manager

- Windows-based configuration tool to implement customized fan

characteristics and temperature parameters. Includes DOS-based

tool "SMCO" to flash the configuration file permanently into the system BIOS.

ftp://ftp.ts.fujitsu.com/pub/Mainboard-OEM-Sales/Products/Mainboards/Industrial&ExtendedLifetime/D343x-S_Mini-ITX/IndustrialTools_D343x-S/Silent

FanConfig-Manager/

Page 77

a

Mainboard Tools

9.6 Windows System-Monitoring API (BMCAPI)

- BMC-Management-Controller to access and adjust System Monitoring parameters like

fan speed and temperatures. This API also provides access to the mainboard watchdog, the 8Bit GPIO interface and

the intrusion feature of the mainboard.

ftp://ftp.ts.fujitsu.com/pub/Mainboard-OEM-Sales/Products/Mainboards/Industrial&ExtendedLifetime/D343x-S_Mini-ITX/IndustrialTools_D343x-S/BMC_

Management-Controller-API/

9.7 Linux System-Monitoring Driver (“LM-Sensors”) To be added soon

- BMC-Management-Controller to access and adjust System Monitoring parameters like

fan speed and temperatures. This driver also provides access to the mainboard watchdog.

Page 78

a

Win7 (x32/x64)

legacy

Win7 (x32)

UEFI

Win7 (x64)

UEFI

Win8.x (x32/x64)

Legacy

Win8.x (x32/x64)

UEFI

Win10 (x32/x64)

Legacy

Win10 (x32/x64)

UEFI

TPM 2.0 Support

No

No

YES 1)

No

YES

No

YES

10 Known Issues & Important Notes

10.1 USB 2.0 / MS Windows 7

Skylake provides no longer native USB 2.0 support for MS Windows 7 --> PS/2 keyboard/mouse for OS setup recommended

Note:

Intel removed the EHCI USB controller, which is replaced by the xHCI USB controller.

MS Windows 7 only provides inbox driver support for EHCI; the xHCI USB device driver must be installed first before any USB port can be used when running

MS Windows 7.

A BIOS workaround for this USB issue is available from BIOS R1.10.0.

10.2 TPM2.0 / MS Windows 7

All Fujitsu Skylake-based mainboards provide TPM V2.0. as recommended for MS Windows 10.

1) MS Hotfix required: Update to add support for TPM 2.0 in Windows 7 and Windows Server 2008: https://support.microsoft.com/en-us/kb/2920188

As TPM 2.0 is not supported by MS Windows 7 (except for 64Bit/UEFI), TPM should be disabled in BIOS Setup then

Page 79

a

11 Miscellaneous

11.1 Battery Lifetime

The typical battery lifetime is designed for 5 years.

This is based on following usage profile:

G3 28% / two days per week

(System Off, Power disconnected)

Deep S5/S4/S3 48% / 17 hrs per working day

(System Off, Power connected)

S0 24% / 8 hrs per working day

(System Working)

On-Temperature (S0): 70°C

Off-Temperature (G3, S5/S4/S3): 23°C

Note: If the system is never in G3 mode or if the S0 “working” temperature is lower than 70°C, this may result

in much higher battery lifetime.

If the mainboard is just stored (no operating voltage attached), the typical battery lifetime is also 5 years.

Due to tolerances of the installed battery, the effective battery lifetime may be in the range of 4.5 years – 6 years

Page 80

a

Miscellaneous

11.2

The onboard realtime clock is approved for an accuracy

of +/-30ppm (= max. 75sec deviation per month).

The RTC crystal itself is specified with +/-10ppm

(= max. 26 seconds deviation per month).

Each year of ageing adds around +/-3ppm on top of this.

RealTime Clock (RTC) Accuracy

Page 81

a

Miscellaneous

11.3 System Watchdog (WD)

Mainboards provide full BIOS POST-, Operating System Boot-, and Operating System-Runtime watchdog supervision.

Power On Init BIOS POST OS Boot OS running

“BIOS POST Watchdog

1)

” “BIOS Boot Watchdog 1)” “OS Watchdog”

1) 2)

POST-WD-timeout = 120sec. BOOT-WD-timeout OS-WD-timeout (max. 255 minutes)

(fix defined by BMC firmware) (according to BIOS Setup) (according to specific WD software agent)

OS started. If the watchdog has been enabled by BIOS (timeout

set to xy minutes in BIOS Setup) it must be switched off or

retriggered (continuously) by a specific OS application (=WD software

agent), otherwise the system will be reset after xy minutes (= BOOT WD-timeout) respectively after nn minutes (repetitive OS-WD-timeout).

If the watchdog is enabled in BIOS Setup (timeout set to xy minutes) and the

system hangs during OS boot, the system will be reset after xy minutes.

BIOS checks at the end of POST if the watchdog must be switched off (timeout set to 0

in BIOS Setup) or retriggered according to the timeout setting in BIOS Setup (1 - 255 minutes)

BMC initializes watchdog (fixed timeout = 2 minutes; no user setting possible). If the operator runs BIOS Setup

the watchdog is set on hold. Additional PCI/PCEe extensions cards that provide an Option ROM may cause

a system reset due to BIOS POST watchdog timeout, if the user activates any menu within the Option ROM

for more than 2 minutes!

1) Note: All three watchdogs are physical identical, but they are handled from different application levels

2) As the SystemGuard tool offers access to the watchdog it can be used as “WD software agent” to retrigger the watchdog during OS runtime

Page 82

a

Miscellaneous

System Watchdog (WD)

How to handle the different watchdog levels

BIOS POST Watchdog

o No user interaction possible – POST Watchdog is always enabled!

BIOS Boot Watchdog

o Set Watchdog in BIOS Setup

0 = WD disabled

1 – 255 = WD enabled (timeout = 1 – 255 minutes)

Page 83

a

Miscellaneous

System Watchdog (WD)

OS Watchdog

o Use “WD software agent” to stop or retrigger the watchdog during OS runtime

Note: This “agent” needs to be provided by the customer, dependent on his needs.

For easy access to the watchdog functions, the Windows API (BMCAPI) or the related Linux driver (lm-sensors) can be used:

ftp://ftp.ts.fujitsu.com/pub/Mainboard-OEM-Sales/Products/Mainboards/Industrial&ExtendedLifetime/D343x-S_Mini-ITX/IndustrialTools_D343x-S/

o For easy testing, the SystemGuard tool provides access to the OS Watchdog. After enabling the Watchdog, SystemGuard retriggers the WD

continuously. In case the system freezes, SystemGuard does no longer provide the retrigger signal and the watchdog resets the system after the timeout.

Note: When SystemGuard is closed, the WD is stopped in order to avoid a unwanted system reset!

Menu “Special”:

--> Enable WD

--> Set timeout to 1 – 8 minutes

Page 84

a

Miscellaneous

11.4 BIOS Update / BIOS Recovery

BIOS update options

Link to related BIOS files (OEM FTP Server):

ftp://ftp.ts.fujitsu.com/pub/Mainboard-OEM-Sales/Products/Mainboards/Industrial&ExtendedLifetime/D343x-S_Mini-ITX/BIOS_D343x-S/

DOS-based BIOS update (DOS-bootable USB stick)

Required BIOS files:

o EfiFlash.exe (DOS flash tool)

o DosFlash.bat (batch file)

o Dxxx-y.upd (flash file)

Copy unzipped files to a DOS-bootable USB stick, boot system from stick and run

Note: In order to easily create a Free-DOS bootable stick, the Fujitsu

ftp://ftp.ts.fujitsu.com/pub/Mainboard-OEM-Sales/Services/Software&Tools/Common-Mainboard-Tools/USB-FreeDOS-Bootstick/

Note: Make sure not to use any DOS memory manager like

himem.sys

BootStick

or

DosFlash.bat

tool can be used:

emm386!

Page 85

a

Miscellaneous

BIOS Update / BIOS Recovery

Windows-based BIOS update (Deskflash tool)

Required BIOS file:

o Dxxxx-Sx.R1.x.y.DFI.exe (Windows executable flash tool)

Copy file from FTP (link see above), rename

Doubleclick to start BIOS update and follow instructions on the screen.

DOS-based BIOS Recovery (DOS-bootable USB stick)

Required BIOS files:

o EfiFlash.exe (DOS flash tool)

o DosFlash.bat (batch file)

o Dxxxx-S1.upd (flash file)

o Dxxxx-S1.rom --> Important: These files must be located in the root directory of the USB stick!

Copy the *.ROM file (included in the ZIP file) to the root directory of a FAT32 formatted bootable USB stick.

Power off the mainboard, insert the USB stick, set the jumper to Recovery Mode (see picture), then turn on

the mainboard.

You will hear short beeps while the BIOS is recovered. Wait until you hear a series of "long-long-short-short"

beeps. Then turn off the mainboard and move the jumper back to the standard position.

The Recovery process can take a few minutes.

Note: BIOS Recovery should only be used to repair a corrupted BIOS.

All customized data except for OEM SLP data will be reset.

filename.$xe

to

filename.exe

and copy to target system (e.g. Windows desktop).

11.5 BIOS/CMOS: Reset Defaults

Set BIOS Setup to Defaults (“Clear CMOS”): Power off system, set Jumper to “Recovery”, power on system and wait until picture appears on screen.

Power off again and set jumper to previous position. CMOS settings should now be reset to default mode. (For this procedure no BIOS update/ USB stick is required!).

Page 86

a

Miscellaneous

11.6 BIOS integrated HW Diagnostic Tool

Starting with the D323x mainboards, there is a hardware test module integrated in the system BIOS.

In order to run the tool, please select “Diagnostic Program” as boot device and follow the instructions on the screen.

This test module analyzes CPU, Memory and HDD.

11.7 BIOS integrated Erase Disk Tool

All Industrial Mainboard include the BIOS tool “EraseDisk” for easy and secure deletion of any data on the harddisk

Detailed information about Erase Disk is available here:

ftp://ftp.ts.fujitsu.com/pub/Mainboard-OEM-Sales/Products/Mainboards/Industrial&ExtendedLifetime/D343x-S_Mini-ITX/Documentation/PF_EraseDisk_e.pdf

Page 87

a

Miscellaneous

11.8 Power indicator

Page 88

a

54

Copyright 2011 FUJITSU

TechNotes D307x-S V1.1

Loading...

Loading...