Fujitsu AW*Z24LBC, AO*Z24LBT Service Instruction

SPLIT TYPE

ROOM AIR CONDITIONER

CEILING WALL

type

Models Indoor unit Outdoor unit

AW Z24LBC

AO Z24LBT

INVERTER

SERVICE

INSTRUCTION

R410A

CONTENTS

1. SPECIFICATION

AW *Z24LBC, AO*Z24LBT.............................................................................................

2. DIMENSIONS

AW *Z24LBC, AO*Z24LBT.............................................................................................

3. REFRIGERANT SYSTEM DIAGRAM

AW *Z24LBC, AO*Z24LBT.............................................................................................

4. CIRCUIT DIAGRAM

AW *Z24LBC, AO*Z24LBT.............................................................................................

5. DESCRIPTION OF EACH CONTROL OPERATION

1. COOLING OPERATION..............................................................................................

3. DRY OPERATION......................................................................................................

2. HEATING OPERATION..............................................................................................

5. INDOOR FAN CONTROL...........................................................................................

4. AUTO CHANGEOVER OPERATION.........................................................................

7. LOUVER CONTROL...................................................................................................

6. OUTDOOR FAN CONTROL.......................................................................................

9. TIMER OPERATION CONTROL................................................................................

8. COMPRESSOR CONTROL........................................................................................

11. TEST OPERATION CONTROL..................................................................................

10. ELECTRONIC EXPANSION VALVE CONTROL........................................................

13. FOUR-WAY VALVE EXTENSION SELECT...............................................................

12. PREVENT TO RESTART FOR 3 MINUTES ( 3 MINUTES ST )................................

15. MANUAL AUTO OPERATION ( Indoor unit body operation ).....................................

14. AUTO RESTART........................................................................................................

16. FORCED COOLING OPERATION.............................................................................

18. COIL DRY OPERATION CONTROL..........................................................................

17. COMPRESSOR PREHEATING..................................................................................

20. DEFROST OPERATION CONTROL..........................................................................

22. VARIOUS PROTECTIONS.........................................................................................

21. OFF DEFROST OPERATION CONTROL..................................................................

01-01

02-01

03-01

04-01

05-01

05-02

05-03

05-04

05-05

05-07

05-08

05-09

05-10

05-12

05-12

05-12

05-12

05-13

05-13

05-13

05-13

19. UV FILTER CLEANING CONTROL............................................................................ 05-14

05-16

05-18

05-19

05-12

6. REFRIGERANT CAUTION -R410A-

1. R410A TOOLS............................................................................................................

3. PRECAUTION FOR SERVICING...............................................................................

2. PRECAUTION FOR INSTALLATION.........................................................................

5. DEFFERENCE FROM CONVENTIONAL MODEL(R22) AND PRECAUTIONS........

4. NEW REFRIGERANT R410A.....................................................................................

7. TROUBLE SHOOTING

1. WHEN THE UNIT DOES NOT OPERATE AT ALL....................................................

3. TROUBLE SHOOTING METHOD

2. SELF DIAGNOSIS FUNCTION..................................................................................

1. EXPLODED VIEW......................................................................................................

2. INVERTER ASSEMBLY SPECIFICATION.................................................................

8. APPENDING DATA

1. JUMPER SETTING OF INDOOR UNIT AND OUTDOOR UNIT................................

3. CAPACITY/INPUT DATA............................................................................................

4. THERMISTOR RESISTANCE VALUES............................................... .....................

2. OUTDOOR UNIT PRESSURE VALUE AND TOTAL ELECTRIC

CURRENT CURVE...................................................................................................

9. REPLACEMENT PARTS

10. INSTALLATION MANUAL

4. SELF-DIAGNOSIS FUNCTION AND CHECKING POINTS.......................................

5. SERIAL SIGNAL DIAGNOSIS....................................................................................

6. IPM PROTECTION.....................................................................................................

8. TROUBLE SHOOTING OF REFRIGERANT CYCLE.................................................

06-01

06-02

06-04

06-05

06-08

07-01

07-02

07-03

07-07

07-08

7. ACTIVE FILTER FAILURE..........................................................................................07-09

08-01

08-02

08-04

08-06

09-01

09-18

07-10

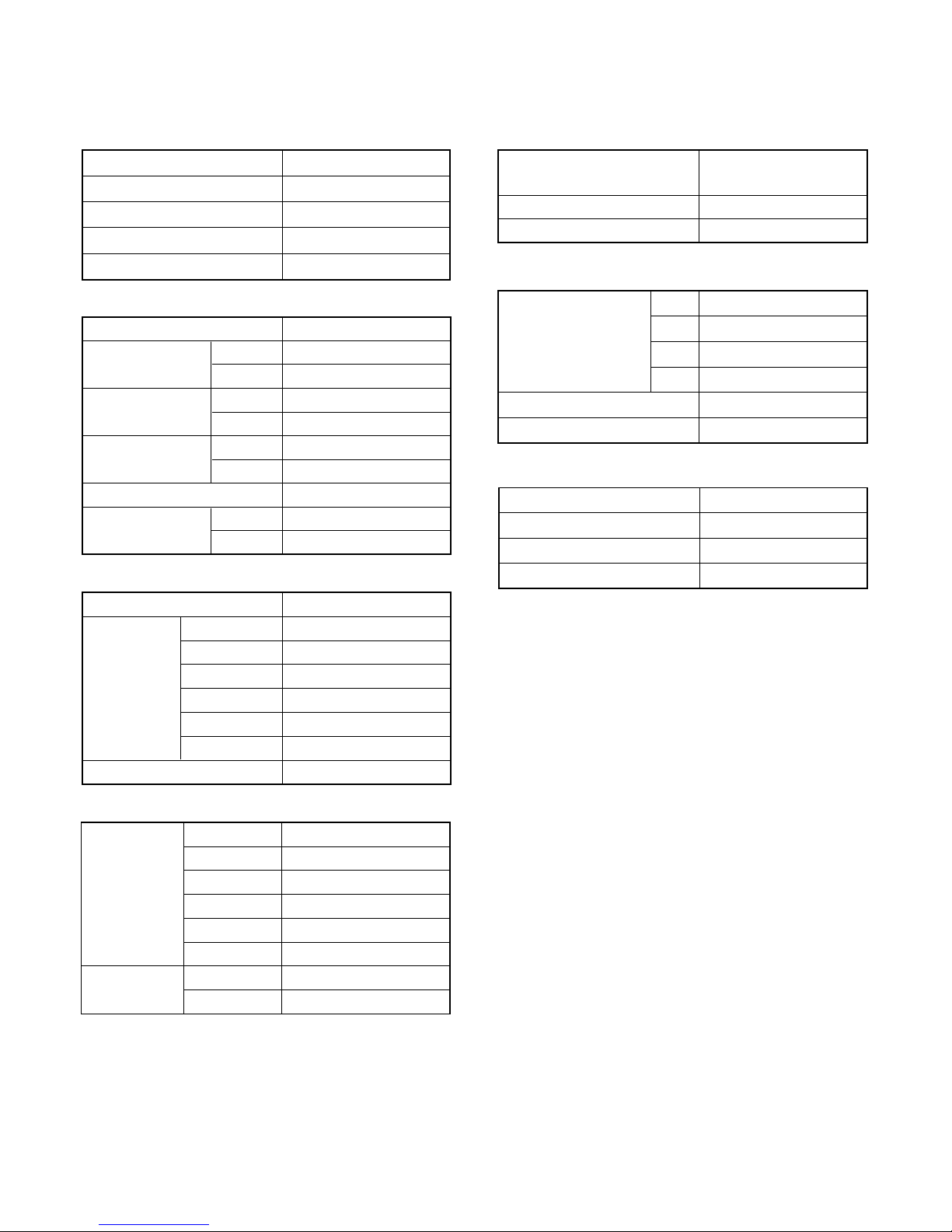

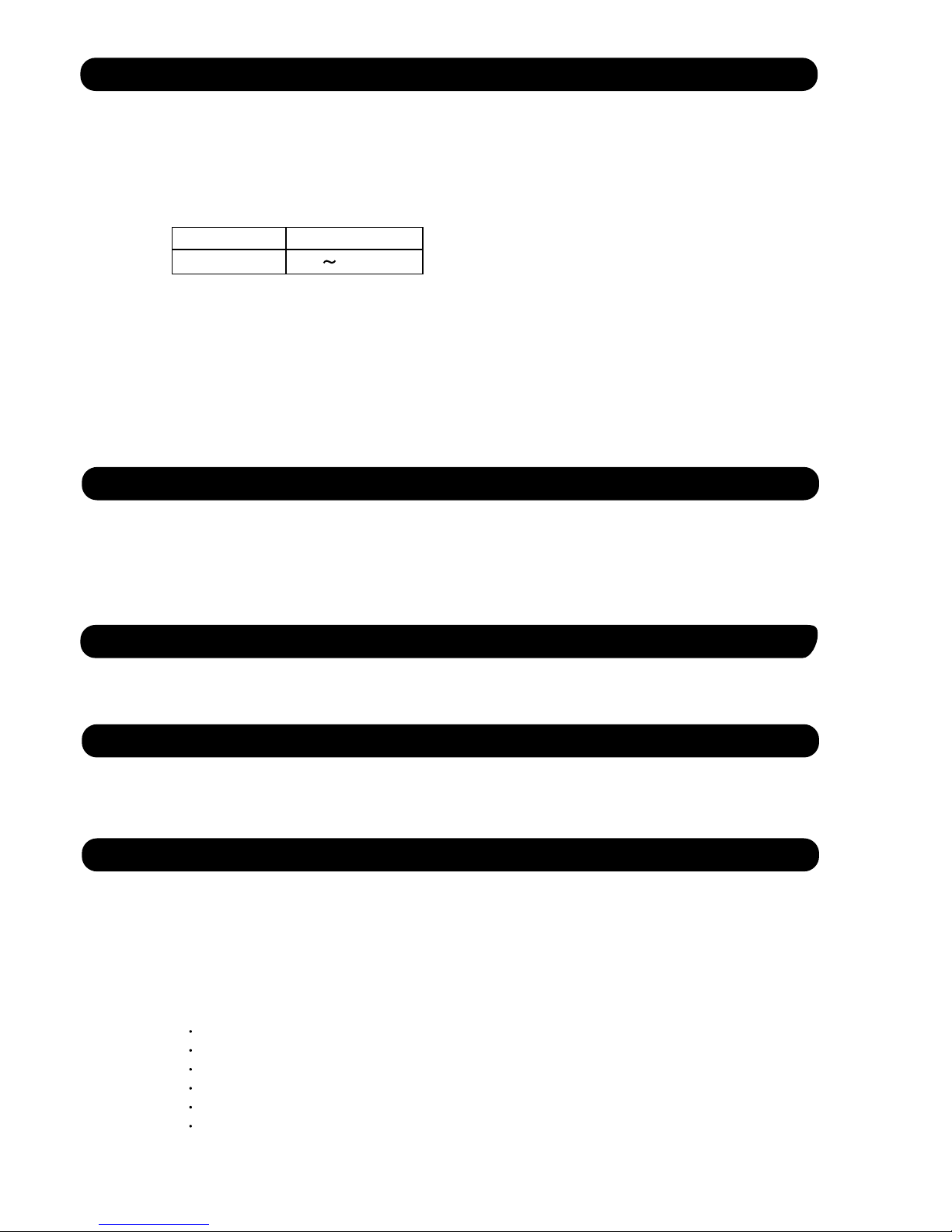

1 . SPECIFICATIONS

R410A

CEILING WALL type

INVERTER

HEATING CAPACITY

POWER SUPPLY

RUNNING

CURRENT

COOLING

HEATING

10.3 A

INPUT WATTS

COOLING

HEATING

2.35 kW

E.E.R.

COOLING

HEATING

COOLING

HEATING

3.62 kW/kW

MOISTURE REMOVAL

AIR CIRCULATION

HIGH

Cooling and heating inverter

AW *Z24LBC

AO*Z24LBT

7.1 kW

8.5 kW

TYPE

INDOOR UNIT

OUTDOOR UNIT

COOLING CAPACITY

230 V 50 Hz

9.7 A

2.21 kW

3.0 L/hr

3.21 kW/kW

ELECTRICAL DATA

POWER SOURCE 230 V

HIGH SPEED

1,500 r.p.m. / 1,700 r.p.m.

HIGH2 1,700 r.p.m. / 1,850 r.p.m.

INDOOR UNIT

( cool / heat )

MED SPEED

1,370 r.p.m. / 1,540 r.p.m.

SUPER QUIET

1,030 r.p.m. / 1,120 r.p.m.

QUIET

1,130 r.p.m. / 1,260 r.p.m.

LOW SPEED

1,250 r.p.m. / 1,390 r.p.m.

OUTDOOR UNIT ( cool / heat )

850 r.p.m. / 900 r.p.m.

FAN MOTOR

DIMENSIONS and WEIGHT

INDOOR UNIT

H x W x D

OUTDOOR UNIT

830 x 900 x 330 mm

250 x 899 x 298 mm

INDOOR UNIT Gross / Net

H x W x D

Gross / NetOUTDOOR UNIT 70 kg / 62 kg

17.5 kg / 14 kg

REFRIGERANT CHARGE (R410A)

FULL CHARGE

2,100 g

15 m

20 m

25 m

30 m

Pipe Length

2,200 g

1,900 g

2,000 g

ADDITIONAL CHARGE

20 g/m

MAX PIPE LENGTH

30 m

COMPRESSOR

TYPE

DISCRIMINATION

REFRIGERANT

R410A 1,900 g

5KD240XAD21

Hermetic type, DC Inverter,

Twin rotary

SPECIFICATIONS

HIGH SPEED

HIGH SPEED

880 m3/hr

980 m

3

/hr

47 dB / 47 dB

43 dB / 43 dB

40 dB / 40 dB

36 dB / 36 dB

32 dB / 32 dB

53 dB / 54 dB

HIGH2 49 dB / 49 dB

HIGH2 53 dB / 54 dB

INDOOR UNIT

( cool / heat )

MED SPEED

LOW SPEED

SUPER QUIET

QUIET

OUTDOOR UNIT

( cool / heat )

NOISE LEVEL

Note :

Noise was measured in accordance with JIS standards, Japan.

"HIGH2" means when ability measurement.

01-01

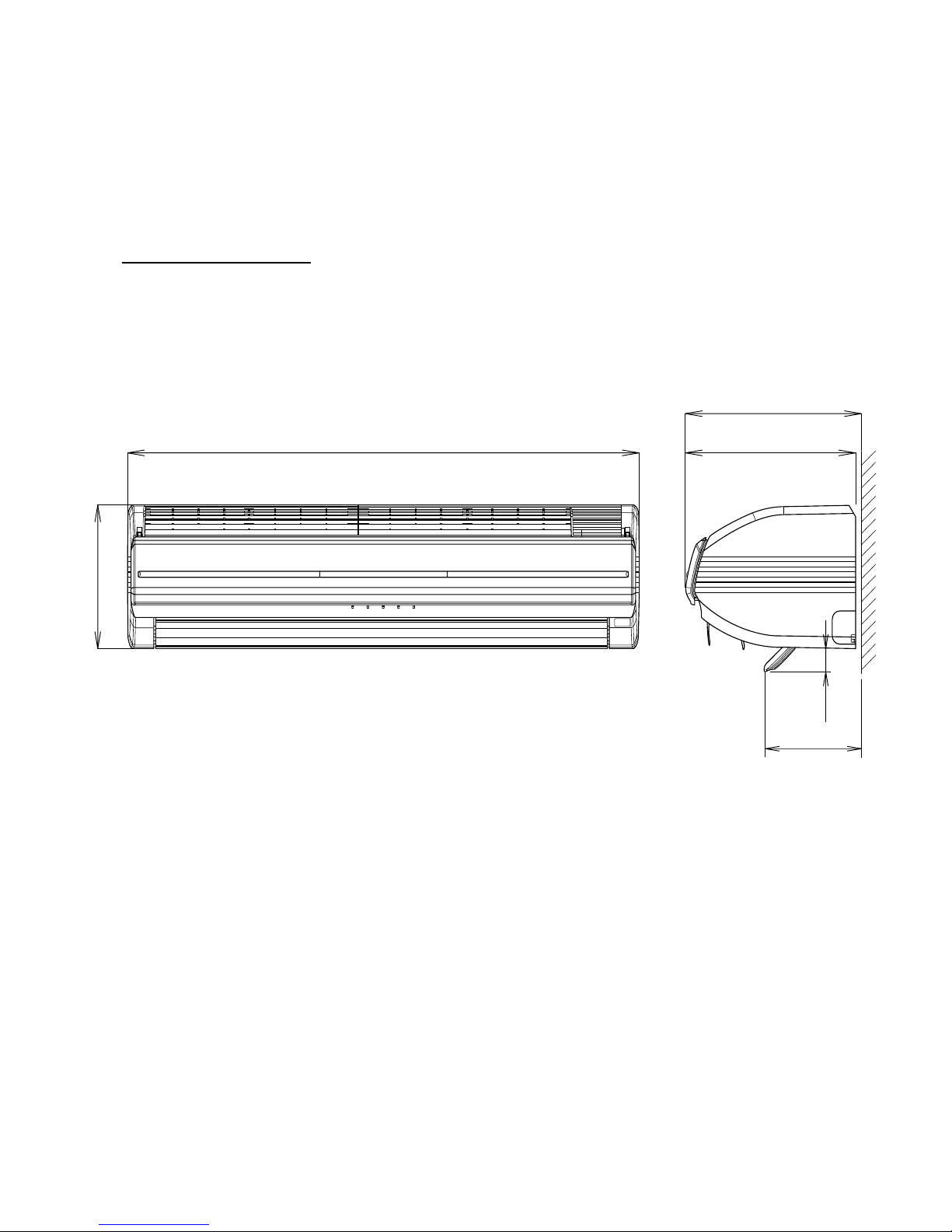

2 . DIMENSIONS

R410A

CEILING WALL type

INVERTER

(Unit : mm)

DIMENSIONS

INDOOR UNIT

02-01

Models :

AW * Z24LBC

300

298

899

250

170

40

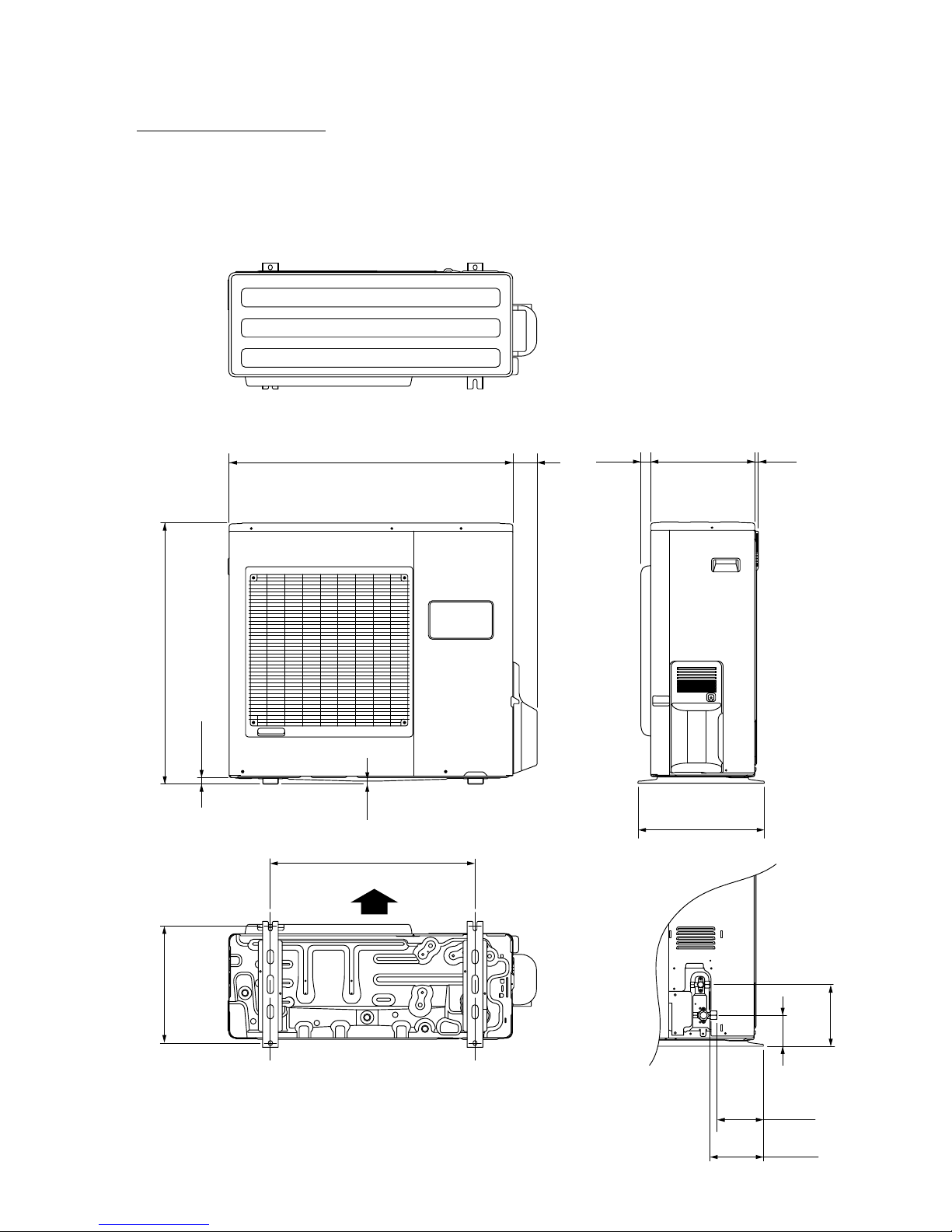

OUTDOOR UNIT

(unit : mm)

77900

830

21

9

400

33031 12

196

147

170

99

370

650

Air Flow

02-02

Models :

AO * Z24LBT

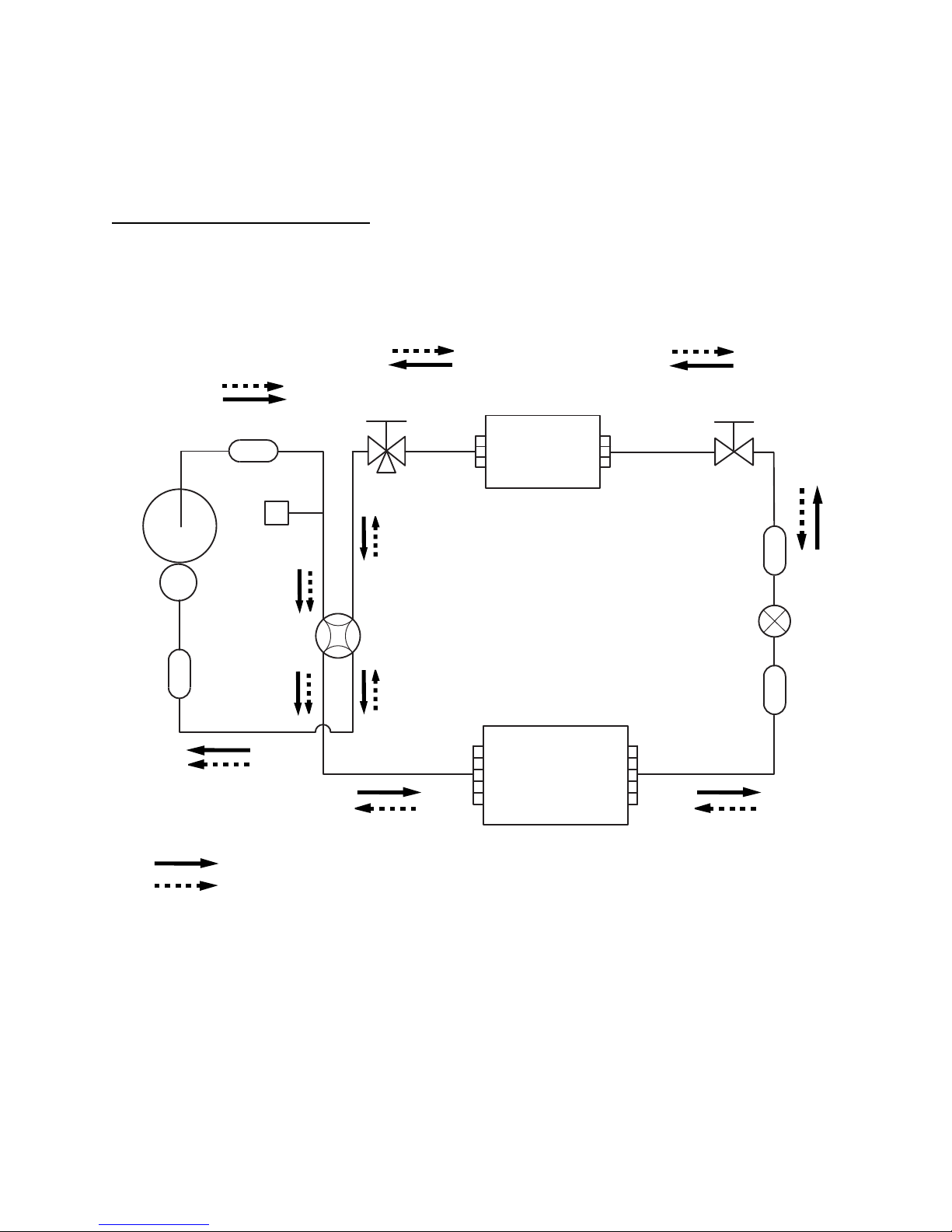

3 . REFRIGERANT SYSTEM DIAGRAM

R410A

CEILING WALL type

INVERTER

REFRIGERANT SYSTEM DIAGRAM

2-Way valve

(Small)

3-Way valve

(Large)

Strainer

Strainer

Muffler

Pressure

switch

4-Way valve

Expansion valve

Heat exchanger

( INDOOR )

Heat exchanger

( OUTDOOR )

Sub-accumulator

Compressor

Refrigerant pipe diameter

Liquid : 1/4" (6.35 mm)

Gas : 5/8" (15.88 mm)

Cooling

Heating

03-01

Models : AW * Z24LBC / AO * Z24LBT

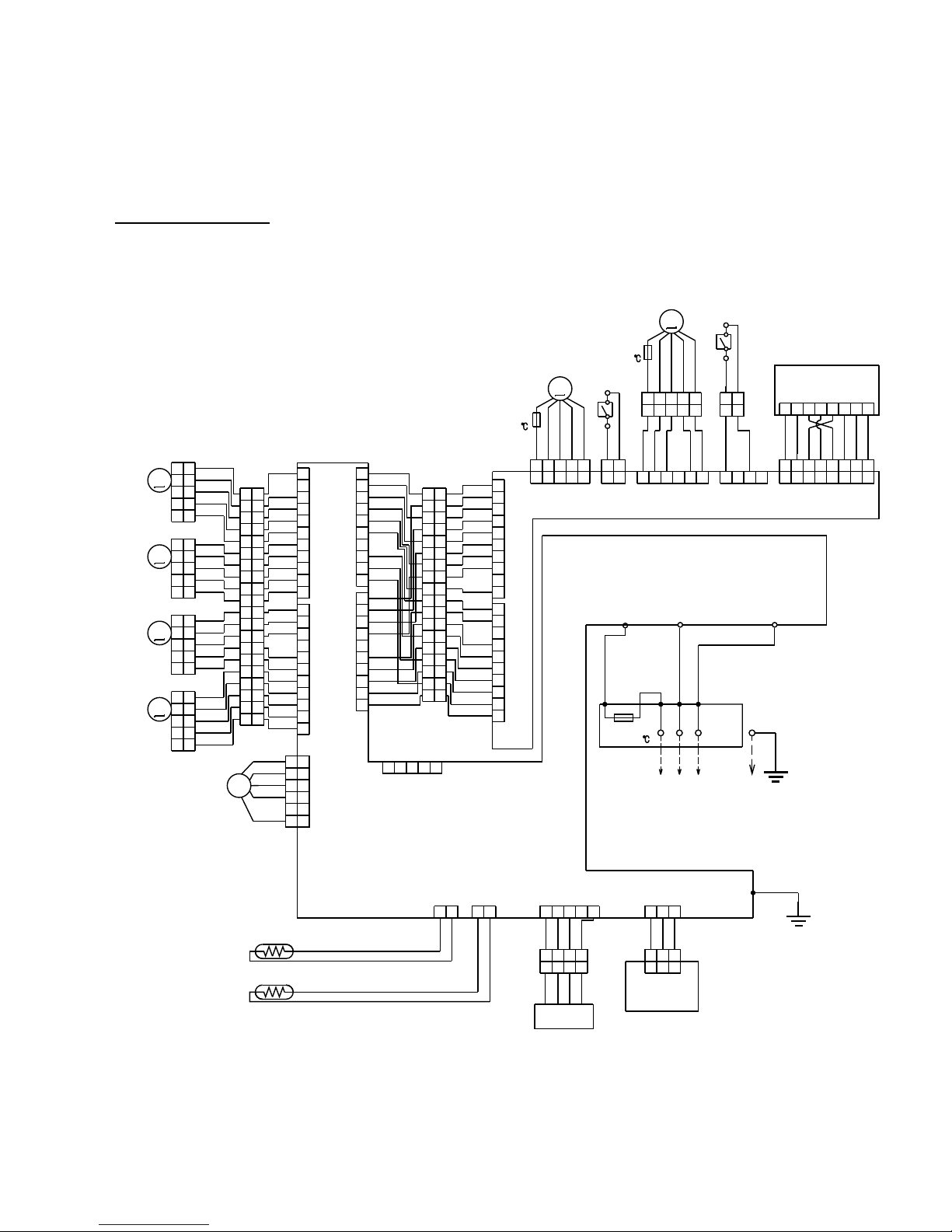

4 . CIRCUIT DIAGRAM

R410A

CEILING WALL type

INVERTER

INDOOR UNIT

CIRCUIT DIAGRAM

04-01

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

RED

RED

RED

RED

RED

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

BROWN

ORANGE

YELLOW

GREEN

BLUE

PURPLE

GRAY

WHITE

BLACK

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

RED

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

RED

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

RED

RED

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

BLUE

YELLOW

WHITE

BLACK

RED

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

RED

RED

WHITE

RED

WHITE

WHITE

WHITE

WHITE

RED

WHITE

RED

WHITE

WHITE

BROWN

RED

ORANGE

YELLOW

BROWN

RED

ORANGE

YELLOW

WHITE

WHITE

WHITE

WHITE

WHITE

RED

RED

BLUE

WHITE

BLACK

RED

BLACK

BLACK

BLACK

BLACK

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

11

10

9

8

7

6

5

4

3

2

1

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

11

10

9

8

7

6

5

4

3

2

1

10

9

8

7

6

5

4

3

2

1

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

5

4

3

2

1

5

4

3

2

1

5

4

3

2

1

5

4

3

2

1

5

4

3

2

1

5

4

3

2

1

5

4

3

2

1

5

4

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

10

9

8

7

6

5

4

3

2

1

10

9

8

7

6

5

4

3

2

1

10

9

8

7

6

5

4

3

2

1

1234567

8

1234567

8

1234561234

1

2

1

212345

12345

12345

12345 12

12

12

345

678

12345

12345

1234

1234

123

12

3

123

12 12

CN205

TEST

CN12CN17

CN7

CN6

CN3

CN4

CN16

CN9

CN206

CN15

CN11

CN201

CN200

CN203

CN202 CN204

CN208

CN210

3

3

1

1

SW (LEFT)

SW (RIGHT)

THERMAL

FUSE 102

AIR FILTER (LEFT)

AIR FILTER (RIGHT)

THERMAL

FUSE 102

TM1

TM2

LOUVER U

LOUVER Z

LOUVER

(RIGHT-LEFT)

DIFFUSER

FAN MOTOR

CONNECTOR (WHITE)

CONNECTOR (WHITE)

CONNECTOR (RED)

CONNECTOR (RED)

ROOM TEMP. THERMISTOR

PIPE TEMP. THERMISTOR

RECEIVER PCB

UV-LED UNIT

W3

CONTROLLER PCB

F M

M

M

CONNECTOR PCB

INDICATOR PCB

M

M

M

M

TM4

WHITE

BLACK

RED

THERMAL

FUSE 102

TERMINAL

N

L

3

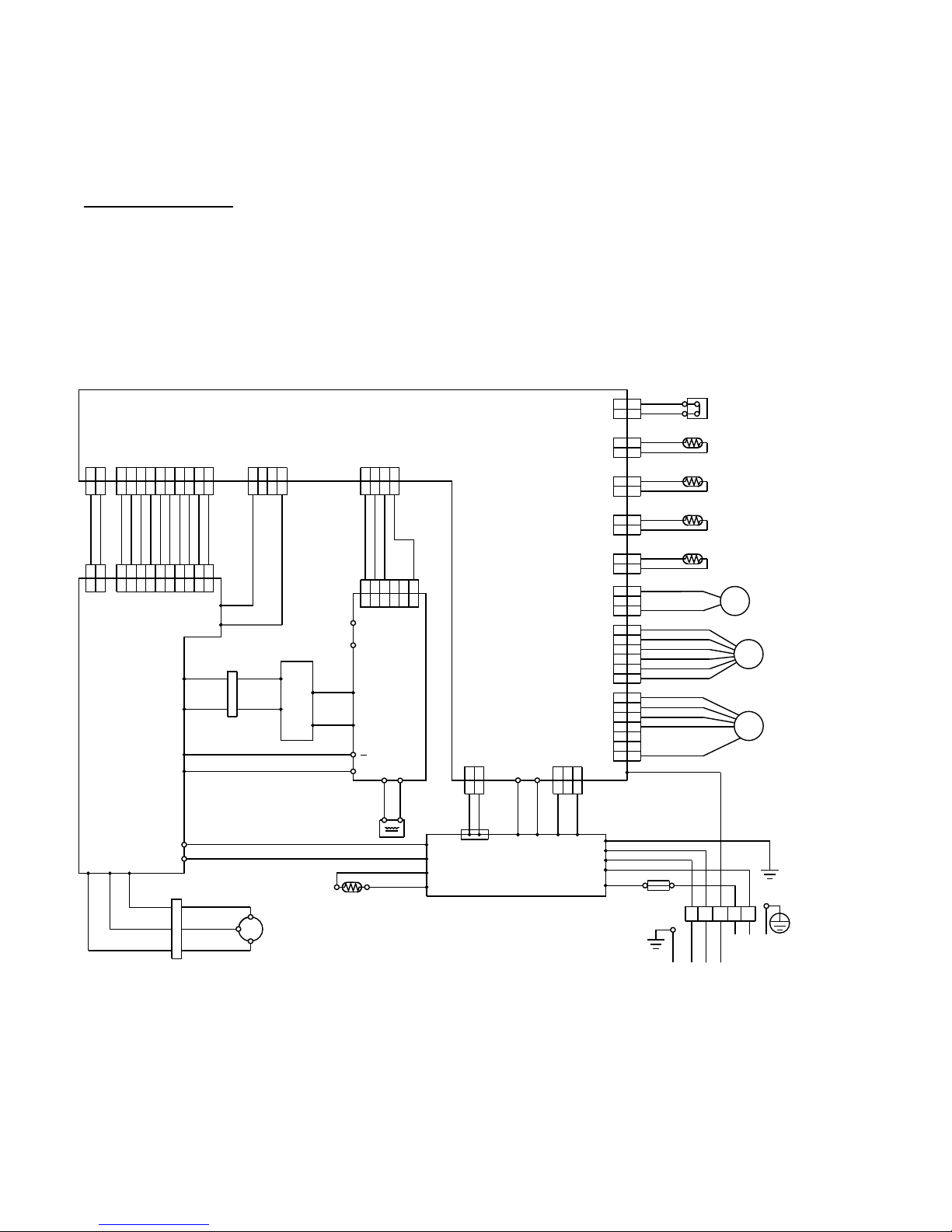

OUTDOOR UNIT

Models : AW * Z24LBC

OUTDOOR UNIT

04-02

RED

RED

BROWN

BROWN

BLUE

BLUE

BLACK

BLACK

BROWN

BROWN

BLACK

BLACK

WHITE

YELLOW

ORANGE

BLUE

BROWN

RED

BROWN

YELLOW

WHITE

BLACK

RED

RED

BLACK

GREEN

BLACK

WHITE

WHITE

BLACK

PURPLE

WHITE

YELLOW

YELLOW

BLUE

BLUE

BLACK

RED

BROWN

ORANGE

BLACK BLACK

WHITE

WHITE

RED RED

ORANGE

ORANGE

BLACK

WHITE

BROWN

RED

BROWN

RED

ORANGE

YELLOW

GREEN

BLUE

PURPLE

GRAY

BLACK

WHITE

BROWN

RED

ORANGE

YELLOW

BLACK

BLACK

WHITE

GRAY

WHITE

WHITE

109

87654

321

109

87654

321

21

109

87654

321

109

87654

321

654

321

654

321

4

321

4

321

4

321

4

321

321

321

21

21

21

7

6

5

4

3

21

21

2

1

6

5

4

3

2

1

7

6

5

4

3

2

1

6

5

4

3

2

1

3

2

1

3

2

1

2

1

2

121

212

1

2

1

2

1

212

1

2

1

CN700

CN801

CN500

CN110CN1

CN400

CN200

CN11

CN60

CN61

CN62

CN64

CN90

CN40CN42

CN303 CN301

W306

W307

W302

W301

W17

W16

TM102

TM101

W303

W

W304

V

W305

U

W8

W7

W13

W12

L2 L1

+

P

N1

N2

I O

TM600

TM601

W4

R

C

S

CN100

12

W29

W28

W25

W26

W21 W20

W9

W17

W3

W18

W2

W1

W19

WHITE

WHITE

TERMINAL

FUSE 250V 25A

123LN

POWER SOURCE

TO INDOOR UNIT

FAN MOTOR

EXPANSION VALVE

4-WAY VALVE

F M

PMV

4WV

DISCHARGE TEMP. THERMISTOR

PIPE TEMP. THERMISTOR

OUTDOOR TEMP. THERMISTOR

COMPRESSOR TEMP. THERMISTOR

HIGH PRESSURE SWITCH

CHOKE COIL

POSISTOR

COMPRESSOR

C M

CONNECTOR

CONNECTOR

CAPACITOR PCB

ACTPM

I P M PCB

POWER SUPPLY PCB

CONTROLLER PCB

( MAIN PCB )

Models : AO * Z24LBT

5 . DESCRIPTION OF EACH

CONTROL OPERATION

R410A

CEILING WALL type

INVERTER

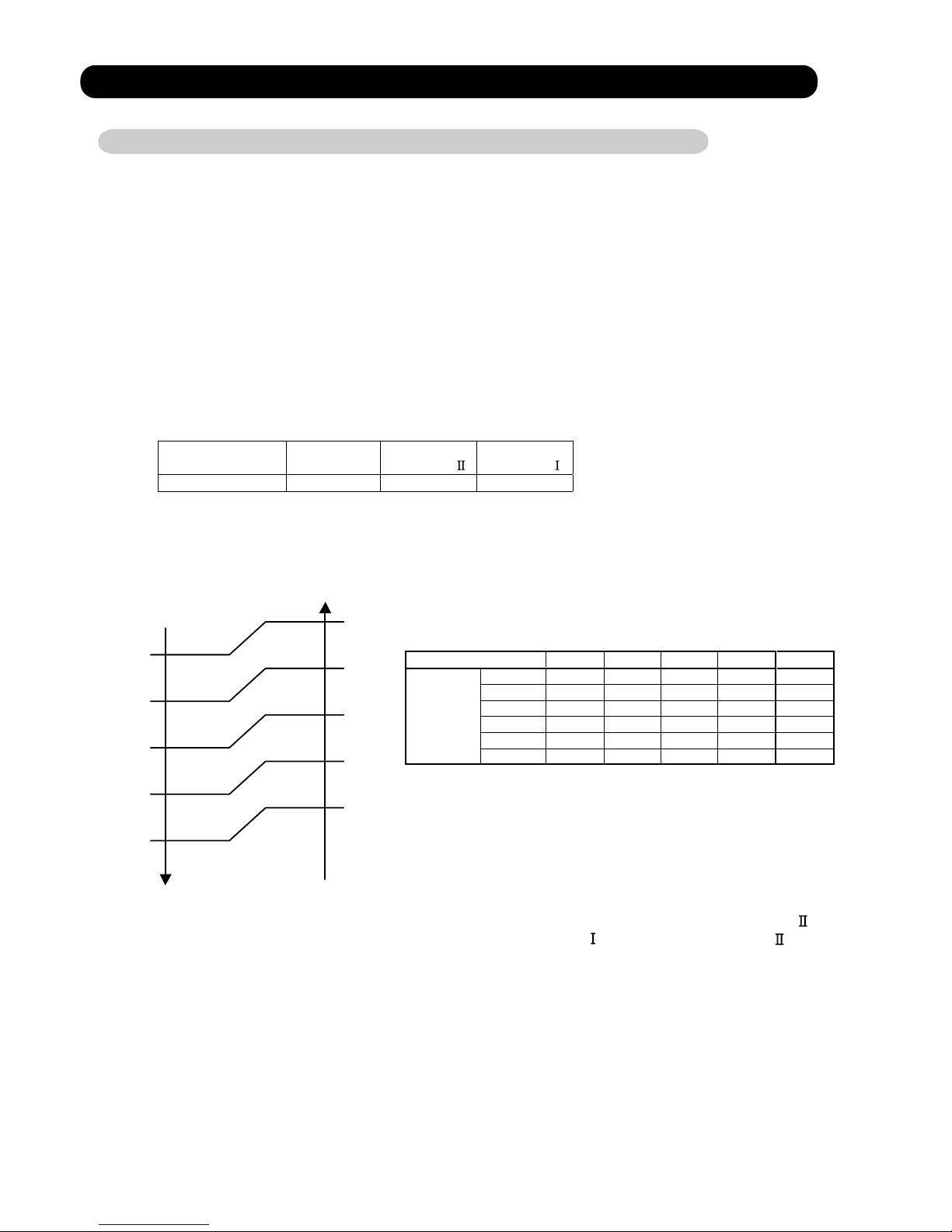

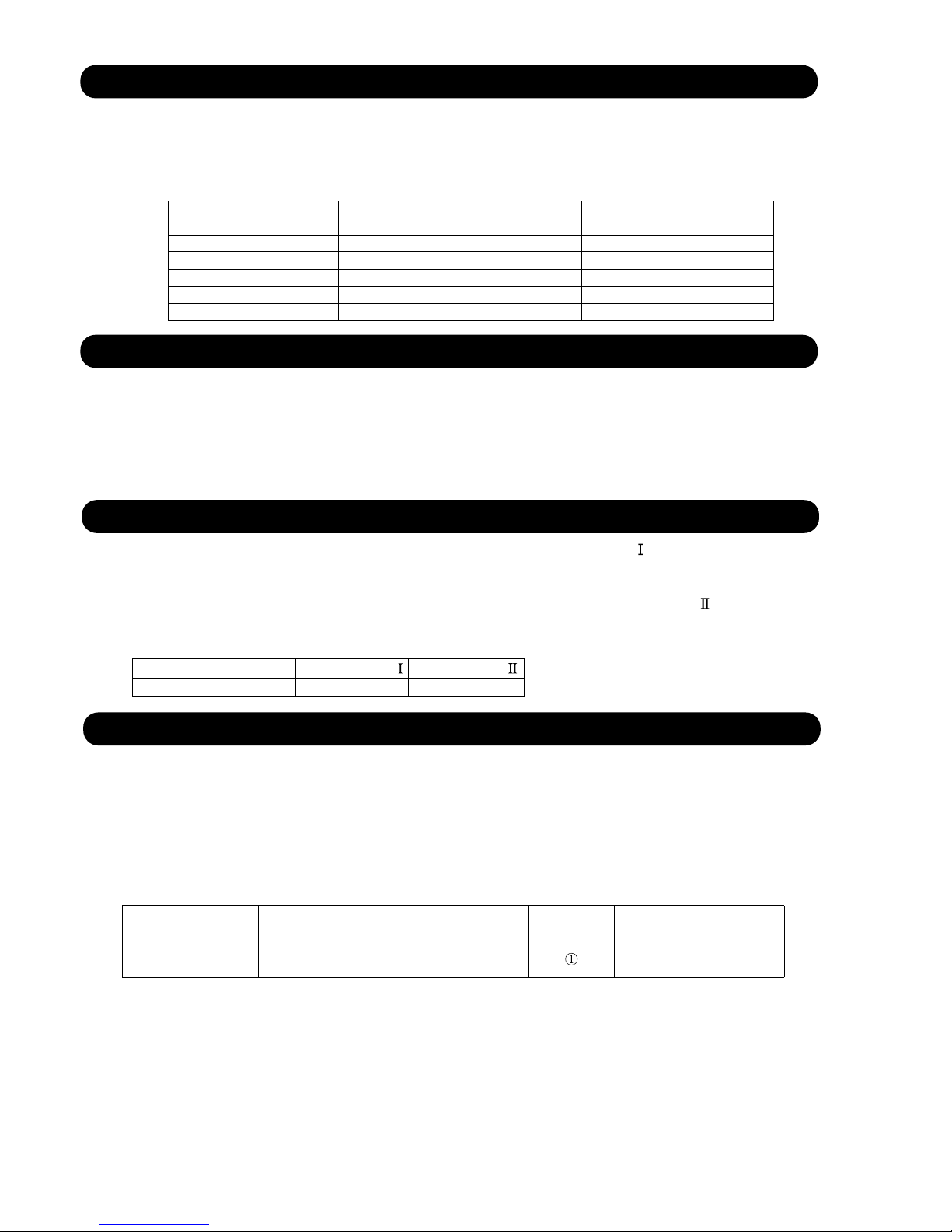

1. COOLING OPERATION

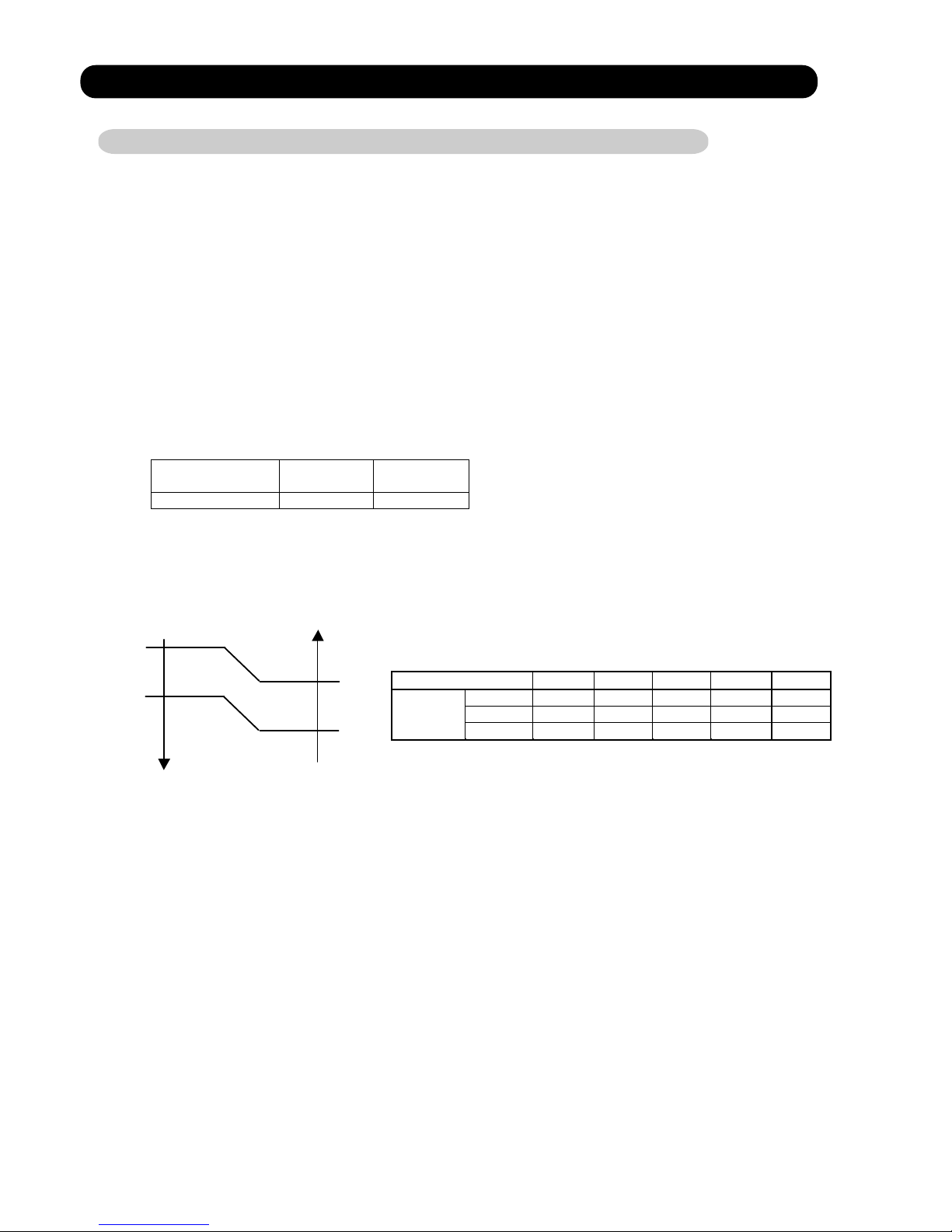

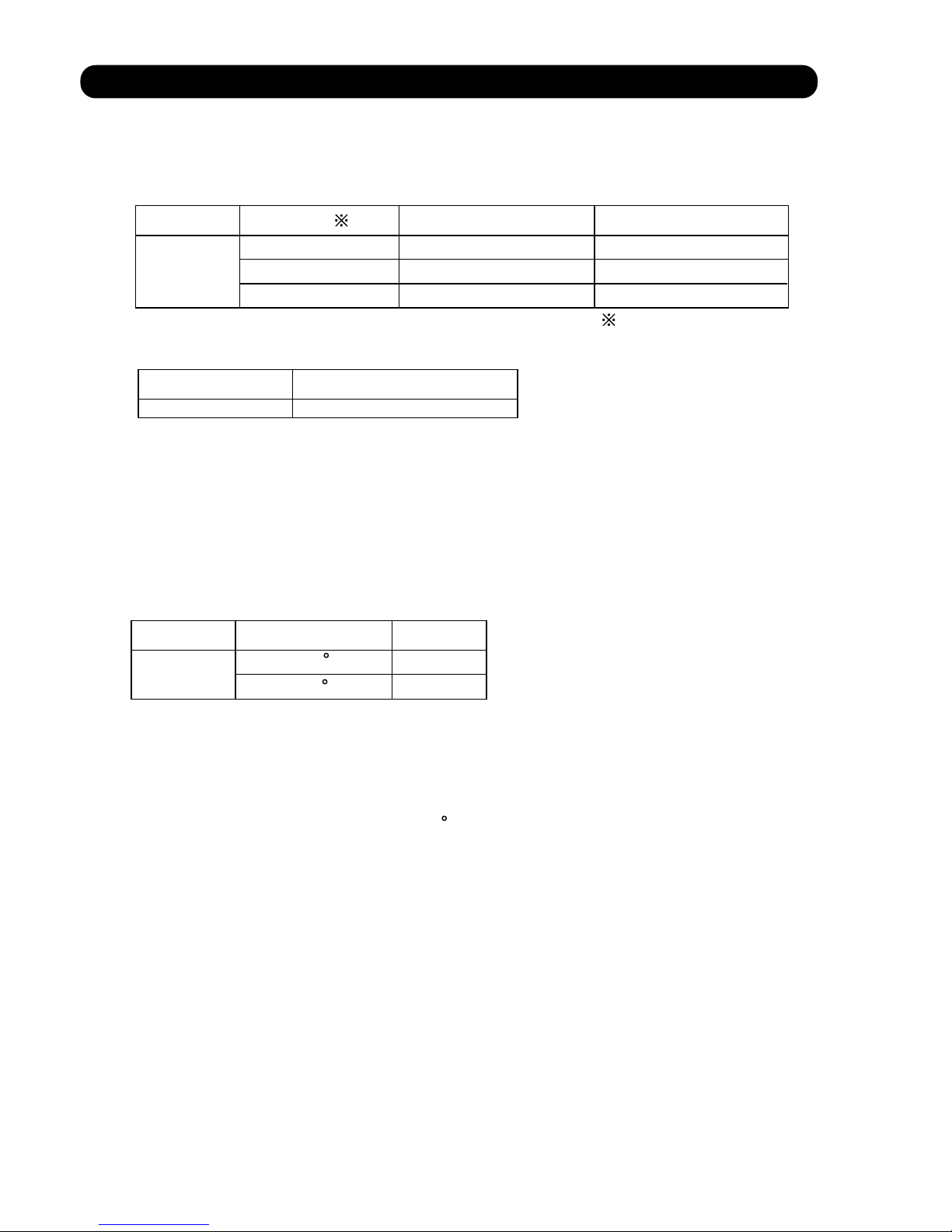

1-1 COOLING CAPACITY CONTROL

A sensor (room temperature thermistor) built in the indoor unit body will usually perceive

difference or variation between a set temperature and present room temperature, and

controls the operation frequency of the compressor.

* If the room temperature is 2°C higher than a set temperature, the compressor operation

frequency will attain to maximum performance.

minimum

frequency

maximum

frequency

maximum

frequency

AW * Z24LBC 21Hz 47Hz 63Hz

Outside air Outside air

temperature temperature

36°C

A zone

34°C

32°C

B zone

30°C

21°C

C zone

19°C

D zone

Hi Me Lo Quiet

A zone 63Hz 43Hz 37Hz 27Hz

B zone 63Hz 43Hz 37Hz 27Hz

C zone 57Hz 39Hz 33Hz 23Hz

24LBC

D zone 39Hz 31Hz 27Hz 21Hz

E zone 39Hz 31Hz 27Hz 21Hz

F zone 39Hz 31Hz 27Hz 21Hz

S-Quiet

25Hz

25Hz

21Hz

21Hz

21Hz

21Hz

( Table 1 : Compressor Frequency Range )

When the compressor operates for 30 minutes continuously at over the maximum frequency ,

the maximum frequency is changed from Maximum Frequency to Maximum Frequency .

The room temperature is controlled 1°C lower than the setting temperature for 40 minutes

after starting the operation.

After 40 minutes, it is controlled based on the normal setting temperature.

05-01

E zone

F zone

10°C

0°C

12°C

2°C

* When the room temperature is between +2°C to -2.5°C of the setting temperature,

the compressor frequency is controlled within the range shown in Table1.

However, the maximum frequency is limited in the range shown in Figure 1 based on the

fan speed mode and the outdoor temperature.

* If the room temperature is 2.5°C lower than a set temperature, the compressor will be

stopped.

( Fig.1 : Limit of Maximum Frequency based on Outdoor Temperature )

2. HEATING OPERATION

2-1 HEATING CAPACITY CONTROL

A sensor (room temperature thermistor) built in the indoor unit body will usually perceive

difference or variation between a set temperature and present room temperature, and

controls the operation frequency of the compressor.

* If the room temperature is lower by 3°C than a set temperature, the compressor operation

frequency will attain to maximum performance.

* If the room temperature is higher 2.5°C than a set temperatire, the compressor will be

stopped.

minimum

frequency

maximum

frequency

AW * Z24LBC 21Hz 87Hz

Outside air Outside air

temperature temperature

19°C

C zone

17°C

14°C

B zone

12°C

A zone

Hi Me Lo Quiet

A zone 87Hz 63Hz 51Hz 49Hz

B zone 87Hz 63Hz 51Hz 47Hz

24LBC

C zone 87Hz 63Hz 51Hz 43Hz

S-Quiet

47Hz

43Hz

39Hz

* When the room temperature is between +2°C to -3°C of the setting temperature,

the compressor frequency is controlled within the range shown in Table2.

However, the maximum frequency is limited in the range shown in Figure 2 based on the

fan speed mode and the outdoor temperature.

( Table 2 : Compressor Frequency Range )

( Fig.2 : Limit of Maximum Frequency based on Outdoor Temperature )

* The room temperature is controlled 2°C higher than the setting temperature for 60 minutes

after starting the operation.

After 60 minutes, it is controlled based on the normal setting temperature.

05-02

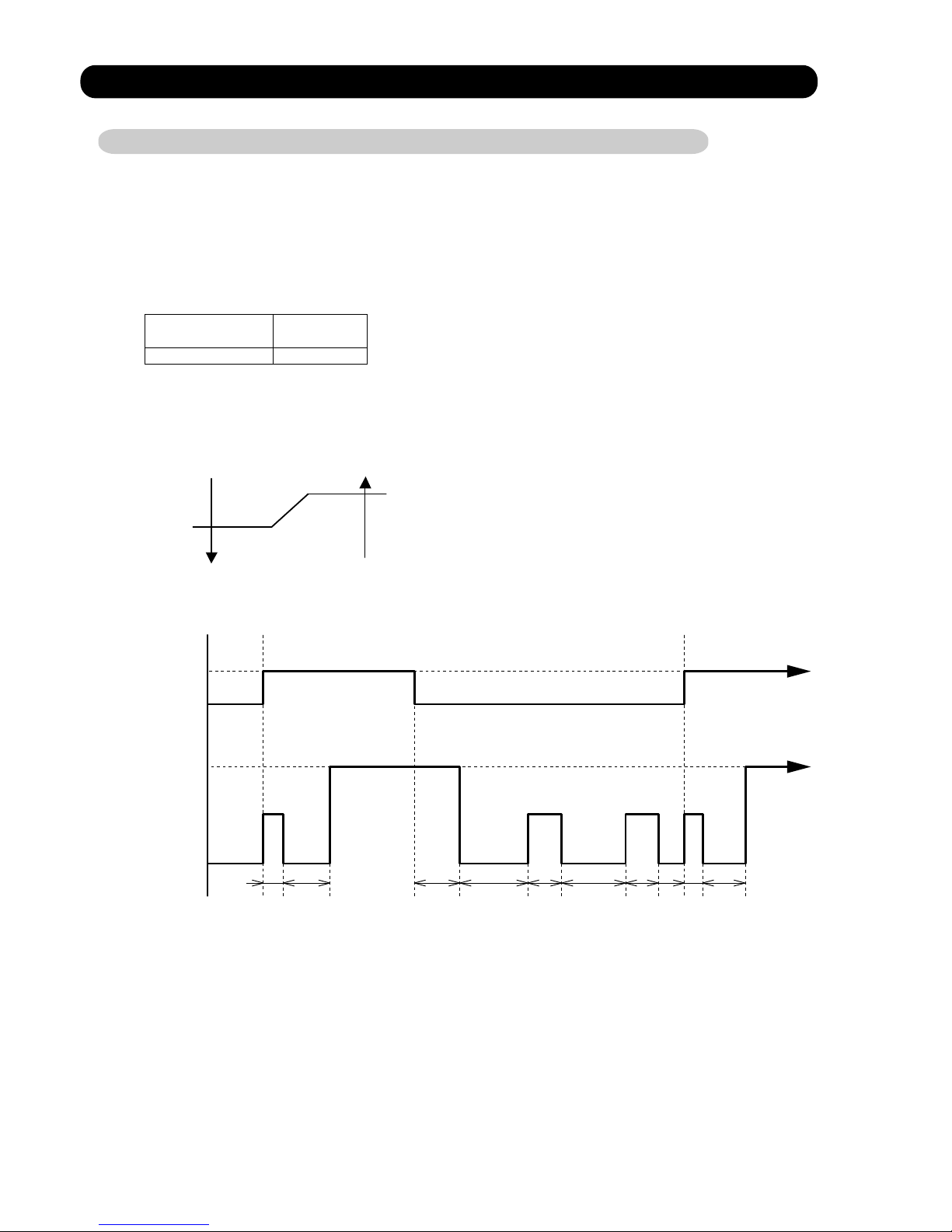

3. DRY OPERATION

3-1 INDOOR UNIT CONTROL

The compressor rotation frequency shall change according to the temperature, set temperature,

and room temperature variation which the room temperature sensor of the indoor unit body has

detected as shown in the Table 3. However, after the compressor is driven, the indoor unit shall

run at operation frequency of 58Hz, for a minute.

Operating

frequency

AW * Z24LBC 23Hz

room room

temperature temperature

compressor ON

Ts+1.5°C

Ts+0.5°C

compressor OFF

Compressor

ON

OFF

Indoor fan

Dry air flow

S-Lo

OFF

( Table 3 : Compressor frequency )

( Fig.3 : Compressor Control based on Room Temperature )

( Fig.4 : Indoor Fan Control )

05-03

10 30 60 180 60 180 60 10 30

(SEC)

4. AUTO CHANGEOVER OPERATION

When the air conditioner is set to the AUTO mode by remote control, operation starts in the optimum

mode from among the HEATING, COOLING, DRY and MONITORING modes. During operation, the

optimum mode is automatically switched in accordance with temperature changes. The temperature

can be set between 18°C and 30°C in 1°C steps.

.When operation starts, only the indoor and outdoor fans are operated for 1 minute. After 1 minute,

the room temperature and outside air temperature are sensed and the operation mode is

selected in accordance with the table below.

C zone

32°C

B zone

-10°C

A zone

( Table.4 Operation mode selection table)

Outside air temperature (To)

Room temperature (Tb)

A zone B zone C zone

Tb > Ts+2°C

Tb < Ts - 2°C

Monitoring

Cooling

(automatic dry)

Cooling

(automatic dry)

Ts+2°C Tb Ts - 2°C

Monitoring Monitoring Monitoring

Heating Heating Monitoring

.When COOING was selected at , the air conditioner operates as follow:

The same operation as COOLING OPERATION of item 1 above is performed.

When the room temperature has remained at (set temperature -1°C) for 8 minutes, operation is

automatically switched to DRY and the same operation as DRY OPERATION of item 3 above

is performed.

If the room temperature reaches (set temperature +2°C during DRY operation, operation returns to

COOLING operation.

.When HEATING was selected at , the same operation as HEATING OPERATION of item 2

above is performed.

When the compressor was stopped for 6 consecutive minutes by the temperature control function

after the COOLING or HEATING operation mode was selected at above, operation is switched

to MONITORING and the operation mode is selected again.

1

1

2

3

1

4

1

( Fig.5 : Outside air temperature zone selection )

05-04

5. INDOOR FAN CONTROL

(1).Fan speed

( Table 5 : Indoor Fan Speed )

Except S-Quiet

(2).FAN OPERATION

The airflow can be switched in 5 steps such as AUTO, QUIET, LOW, MED, HIGH, while the indoor

fan only runs.

When Fan mode is set at (Auto), it operates on (MED) Fan Speed.

AW * Z24LBC

Operation mode Air flow mode Speed (rpm)

Hi 1,700

Me+ 1,610

Me 1,510

Lo 1,390

Quiet 1,260

S-Quiet

S-Quiet

S-Quiet

1,120

Cool air

prevention

850

Heating

S-Lo 480

Hi 1,500

Me 1,370

Lo 1,250

Cooling

Fan

Quiet

1,030

1,130

Dry

1,030

05-05

1,130

(3).COOLING OPERATION

Switch the airflow [AUTO], and the (Fig.6)

indoor fan motor will run according

airflow change - over ( Cooling:AUTO )

to a room temperature, as shown in

When the room

Figure 6.

temperature rises

On the other hand, if switched in

[HIGH]

[QUIET], the indoor motor

+2.5°C

will run at a constant airflow of [COOL]

operation modes QUIET, LOW, MED,

HIGH, as shown in Table 5.

+1.5°C

+1°C

LOW mode

When the room

temperature lowers

(Room temperature) D (Setting temperature)

(4).DRY OPERATION

(5).HEATING OPERATION

Switch the airflow [AUTO], and the (Fig.7)

indoor fan motor will run according

airflow change - over ( Heating:AUTO)

to a room temperature, as shown in

When the room

Figure 7. temperature rises

On the other hand, if switched

LOW mode

[HIGH]

[QUIET], the indoor motor -1°C

will run at a constant airflow of [HEAT]

-1.5°C

operation modes QUIET, LOW, MED,

HIGH, as shown in Table 5.

-2°C

-2.5°C

MED + mode

When the room

temperature lowers

(Room temperature) D (Setting temperature)

(6).COOL AIR PREVENTION CONTROL (Heating mode)

Indoor heat exchanger Indoor heat exchanger

temperature temperature

47°C

Hi

40°C

Me+

37°C

Lo

Cool air prevention

30°C

S-Lo

Refer to the table 4.

Durring the dry mode operation, the fan speed

setting can not be changed.

The maximum value of the indoor fan speed is set as shown in Figure 8, based on the detected

temperature by the indoor heat exchanger sensor on heating mode.

(Fig.8 : Cool Air Prevention Control)

05-06

40°C

28°C

32°C

34°C

HIGH mode

MED mode

+2°C

MED mode

6. OUTDOOR FAN CONTROL

(1). Fan speed

Zone

AW * Z24LBC

Heating

AW * Z24LBC

900/780/700/550/450rpm

Table 6 : Fan speed (Cooling, Dry)

Table 7 : Fan speed (Heating)

The outdoor fan speed is changed in the range of the speed shown in the above table,

based on the frequency of the compressor.

(When the compressor frequency increases, the outdoor fan speed is also changed to

higher speed. If the compressor frequency decreases, the outdoor fan speed is changed

to the lower speed as well.)

After starting up the outdoor fan, it operates with the following speed for initial 20 seconds.

*

Table 8 : Fan speed when starting up Outdoor fan

*

After operating the defrost control function on heating mode, its speed becomes 1,000rpm

regardless of the compressor frequency.

However, it returns to the normal speed control when the defrosting operation does not function

for 240 minutes after releasing the defrost operation or when the outdoor temperature sensor

detection value becomes higher than 5 C.

05-07

A to D

Cooling

850/780/700/500rpm

500/250/200rpm

320/250/200rpm

Dry

550/450rpm

500/250/200rpm

320/250/200rpm

Outdoor temperature

AW * Z24LBC

Speed

500rpm

200rpm

Over than 12 C

Less than 12 C

E

F

Refer to Fig.1

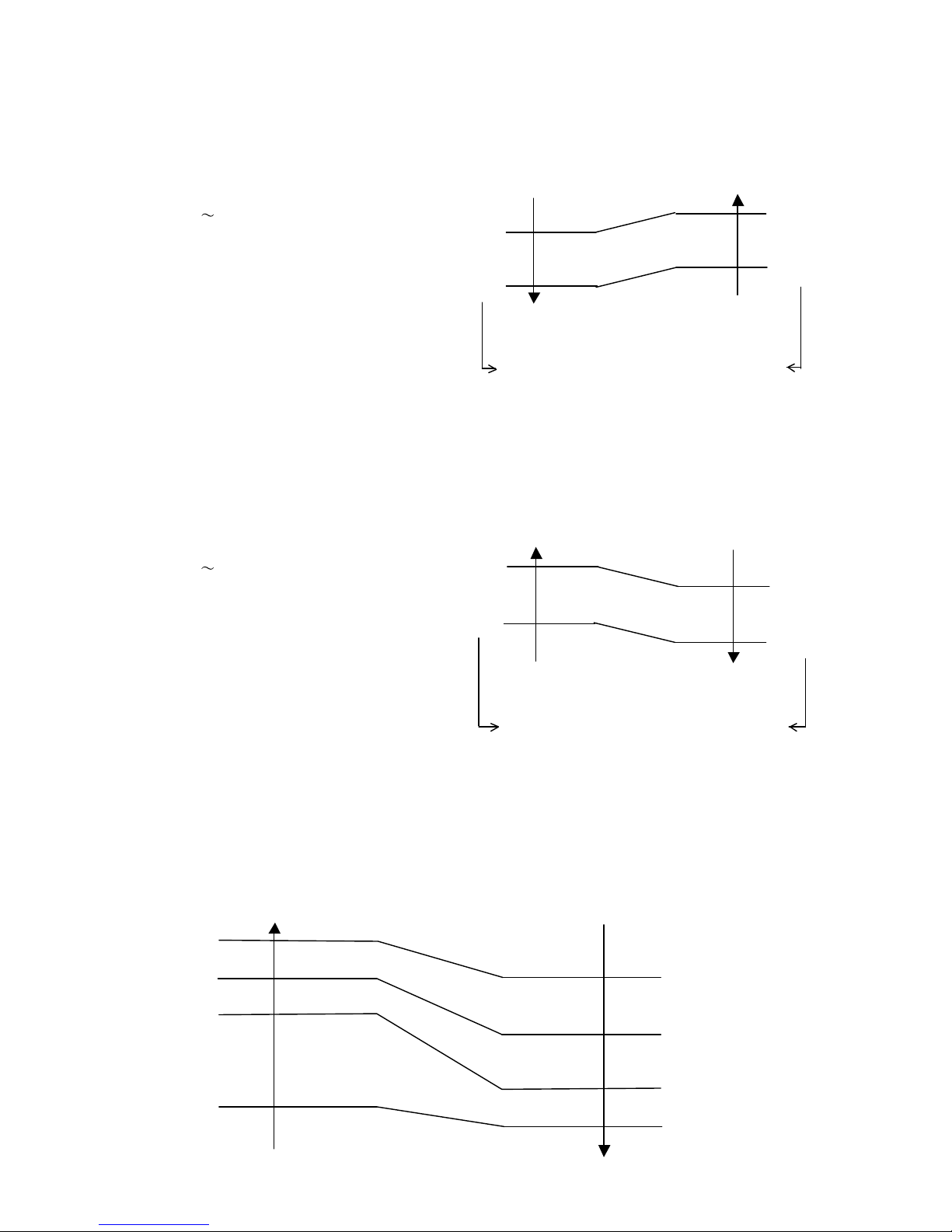

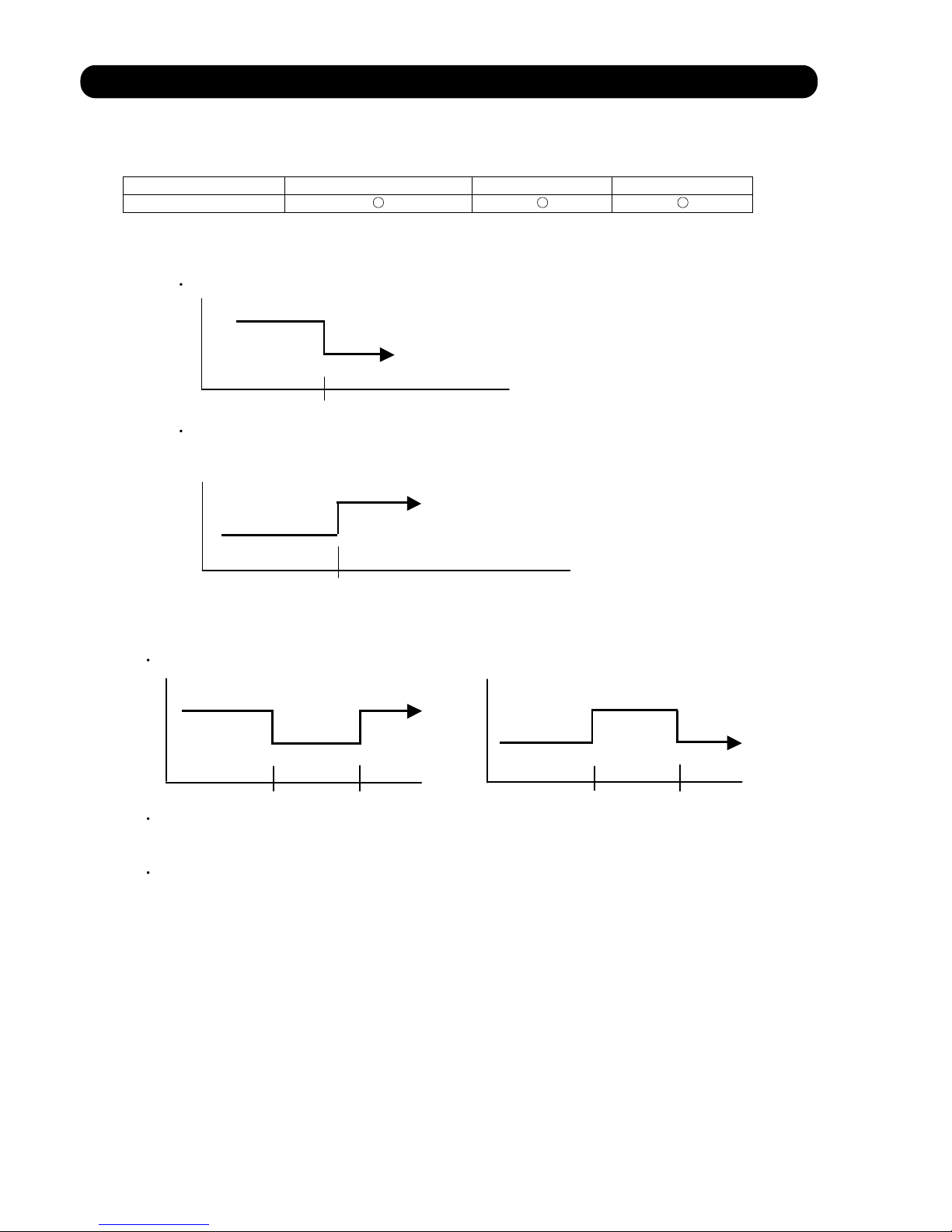

7. LOUVER CONTROL

05-08

(1). LOUVER CONTROL

Each time the button is pressed, the air direction range will change as follow:

Cooling / Dry mode

Heating mode

Fan mode

Use the air direction adjustments within the ranges shown above.

The vertical airflow direction is set automatically as shown, in accordance with the type of operation

selected.

Cooling / Dry mode

Horizontal flow

Heating mode

Downward flow

When the temperature of the air being blown out is low at the start of heating operation or during

defrosting, the airflow direction temporarily becomes

to prevent cold air being blown onto the body.

During Monitor operation in AUTO CHANGEOVER mode, the airflow direction automatically

becomes

.

(Function Range)

(Fig 9: Air Direction Range)

(Operation Range)

When the indoor control interface device receives a control signal light from the remote control,

it will actuate, the step motor according to the control signal, and set the louver to each position.

In addition, if the air conditioner is stopped, vertical louver will be closed automatically.

Vertical Air Direction Adjustment

6

Each time the button is pressed, the air direction range will change as follow:

(Function Range)

Horizontal Air Direction Adjustment

7

1

8

778

8

5

6

Cooling mode / Dry mode / Fan mode( )

Heating mode / Fan mode(

)

(2). SWING OPERATION

When the swing signal is received from the remote controller, the vertical louver starts to swing.

(Swinging Range)

When the indoor fan is at S-Lo or Stop mode, the swinging operation is interrupted

and it stops at either right end or left end.

14

1

4

5

8

88

To select Vertical Airflow Swing Operation

To select Horizontal Airflow Swing Operation

When the swing signal is received from the remote controller, the horizontal louver starts to swing.

All mode :

(Swinging Range)

3

1

When the indoor fan is S-Lo or Stop mode, the swinging operation is interrupted

and it stops at either upper end or bottom end.

To select Vertical and Horizontal Airflow Swing Operation

When the horizontal swing signal is input from remote control, the combination of the vertical

and horizontal swing operation is performed.

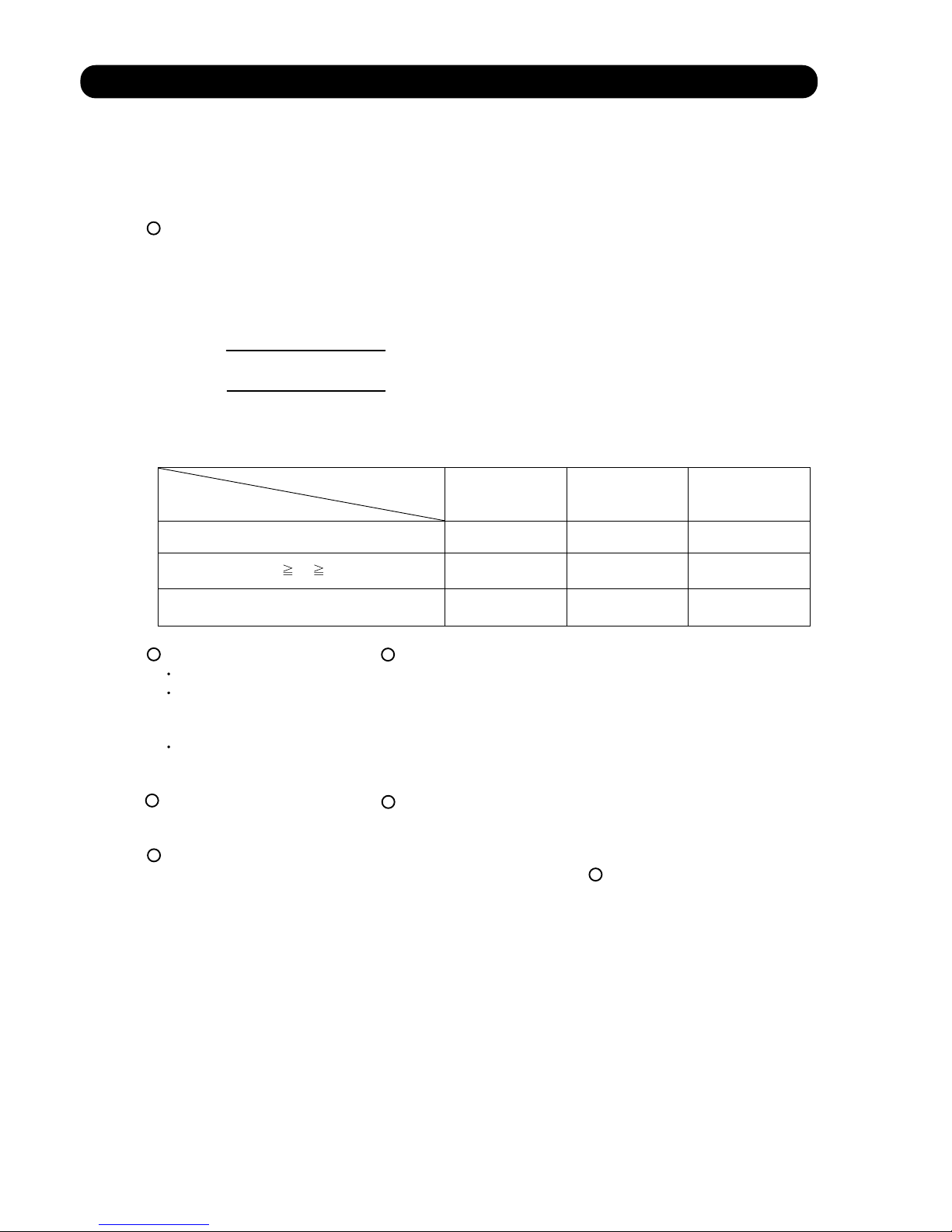

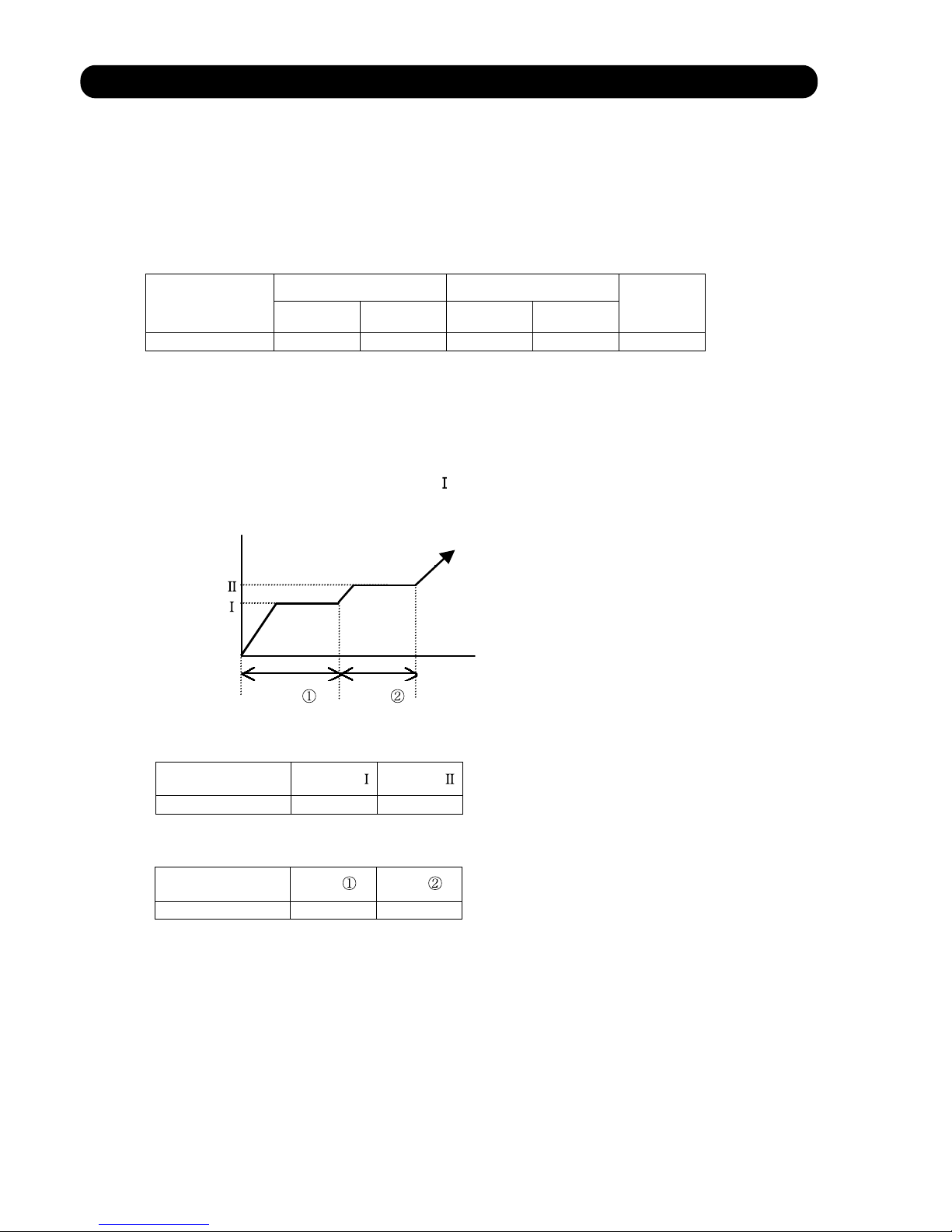

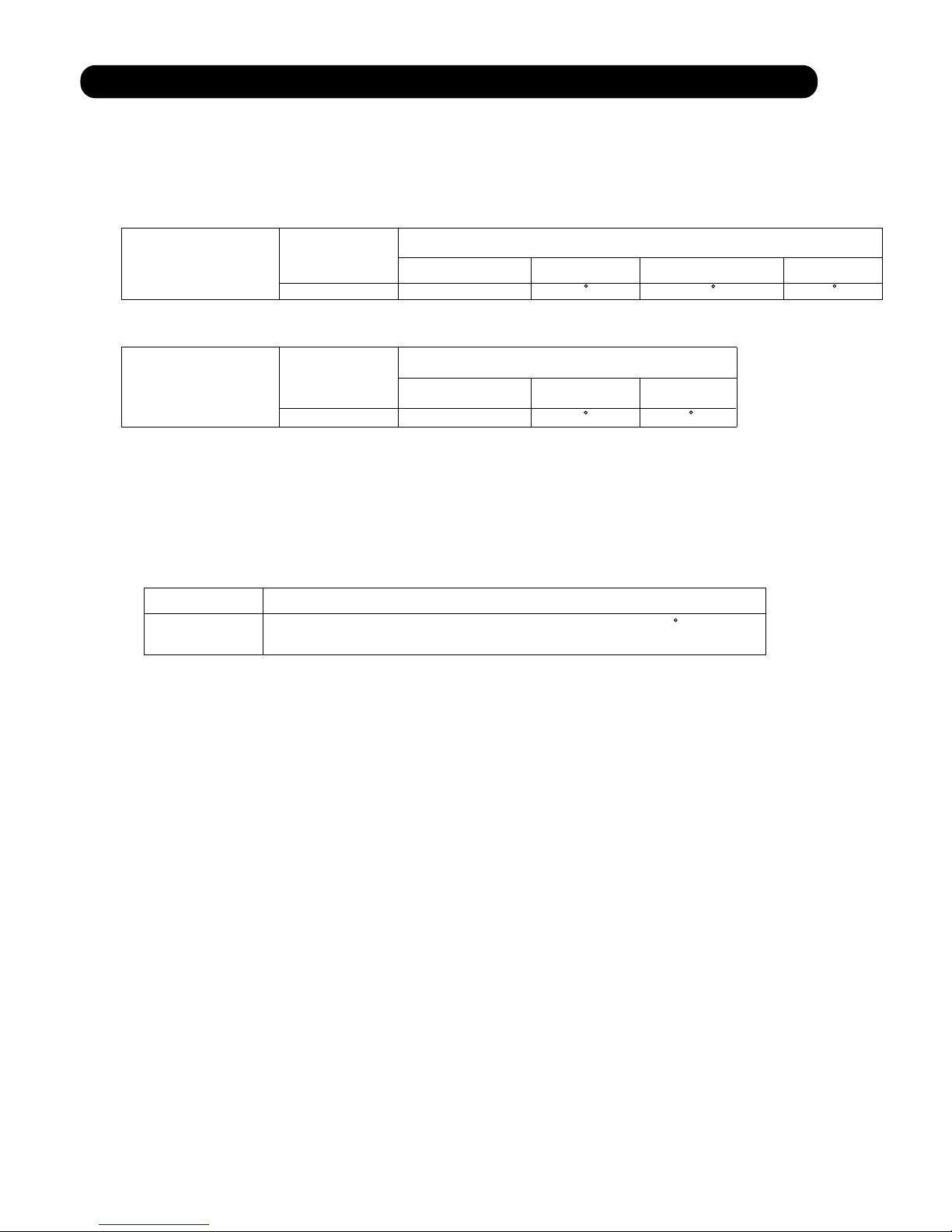

8. COMPRESSOR CONTROL

(1). OPEARTION FREQUENCY RANGE

The operation frequency of the compressor is different based on the operation mode as

shown in the table 9.

Cooling Heating

Min Max Min Max

Dry

AW * Z24LBC 21Hz 75Hz 21Hz 87Hz 23Hz

AW * Z24LBC 40Hz 59Hz

(Table 9 : Compressor Operation Frequency Range)

(2). OPEARTION FREQUENCY CONTROL AT START UP

The compressor frequency soon after the start-up is controlled as shown in the figure 10.

(Fig.10 : Compressor Control at Start-up )

Time

Time

(Frequency)

(Time)

Frequency

Frequency

Time Time

Frequency

Frequency

05-09

AW * Z24LBC

60sec 40sec

AW * Z24LBC

9. TIMER OPEARTION CONTROL

(1). OPEARTION FREQUENCY RANGE

The table 9 shows the available timer setting based on the product model.

ON TIMER / OFF TIMER PROGRAM TIMER SLEEP TIMER

AW * Z24LBC

OFF timer : When the clock reaches the set time, the air conditioner will be turned off.

Operation mode

Stop mode

Set time of timer

ON timer : When the clock reaches the set time, the air conditioner will be turned on.

Operation mode

Stop mode

Set time of timer

The program timer allows the OFF timer and ON timer to be used in combination one time.

Operation mode

Operation will start from the timer setting (either OFF timer or ON timer) whichever is closest

to the clock's current timer setting. The order of operations is indicated by the arrow in the remote

control unit's display.

SLEEP timer operation cannot be combined with ON timer operation.

(Table 9 : Timer Setting)

(2). PROGRAM TIMER

Stop mode

Stop mode

Stop mode

Operation mode

Operation mode

Set time

Set time Set time Set time

05-10

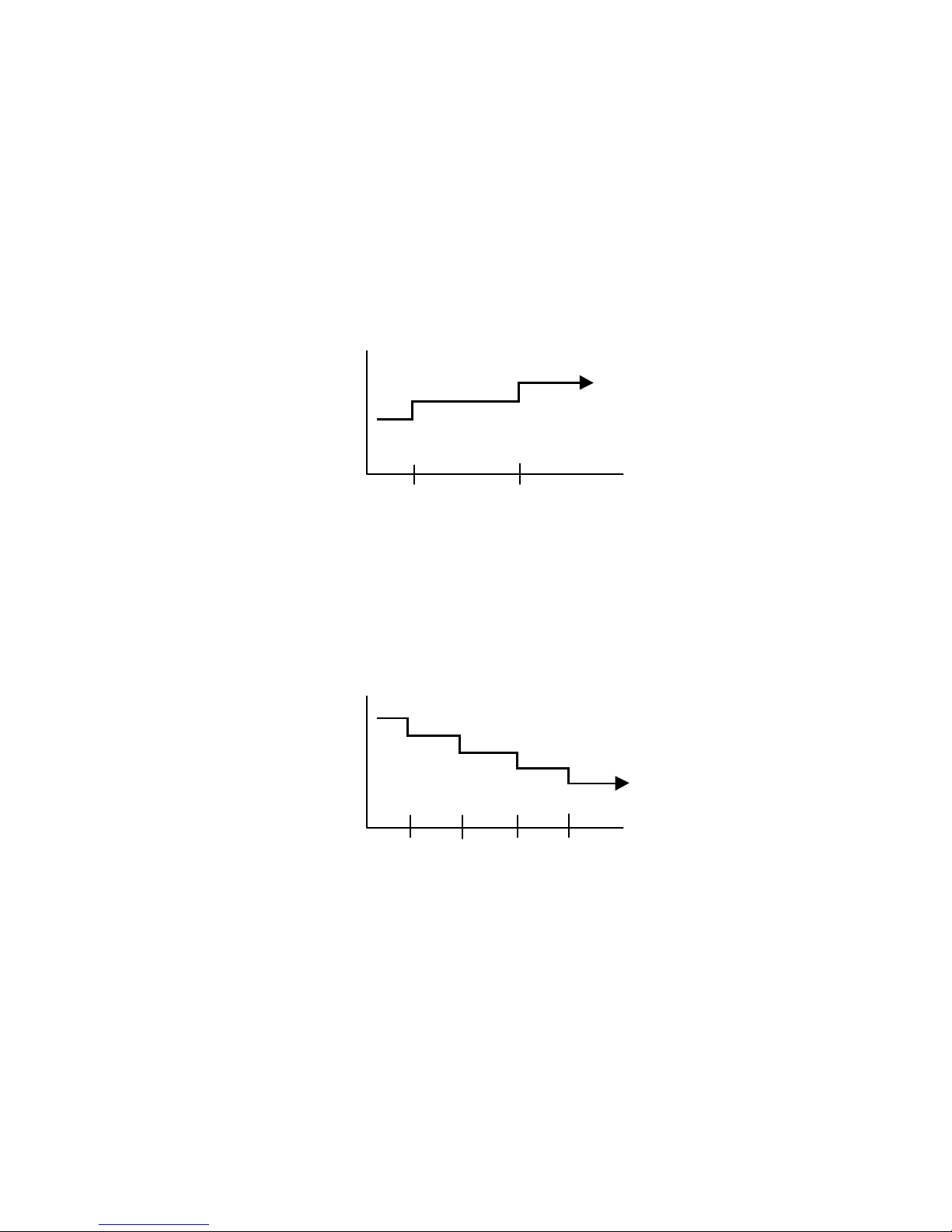

(3). SLEEP TIMER

If the sleep is set, the room temperature is monitored and the operation is stopped automatically.

If the operation mode or the set temperature is change after the sleep timer is set, the operation is

continued according to the changed setting of the sleep timer from that time ON.

Set temperature rises

( Ts : Set temperature )

Stop of operation

Set temperature lowers

( Ts : Set temperature )

Ts

Stop of operation

In the cooling operation mode

When the sleep timer is set, the setting temperature is increased 1°C.

It increases the setting temperature another 1°C after 1 hour.

After that, the setting temperature is not changed and the operation is stopped at the time

of timer setting.

Ts

+1°C

+2°C

Set

60min

In the heating operation mode

When the sleep timer is set, the setting temperature is decreased 1°C.

It decreases the setting temperature another 1°C every 30 minutes.

Upon lowering 4°C, the setting temperature is not changed and the operation stops at

the time of timer setting.

-4°C

-3°C

-2°C

-1°C

Set

30min

30min

30min

05-11

10. ELECTRONIC EXPANSION VALVE CONTROL

The most proper opening of the electronic expansion valve is calculated and controlled under the

present operating condition based on the following values.

The compressor frequency, the temperatures detected by the discharge temperature sensor, the

indoor heat exchanger sensor, the outdoor heat exchanger sensor, and the outdoor temperature

sensor.

11. TEST OPERATION CONTROL

Under the condition where the air conditioner runs, press the test operation button of the remote

control, and the test operation control mode will appear. During test running, the operation lamp

and timer lamp of the air conditioner body twinkle simultaneously. Set the test operation mode,

and the compressor will continue to run regardless of whether the room temperature sensor detects.

The compressor won't enter operation status for 3 minutes after the compressor is stopped,

even if any operation is given.

At the time when the air conditioner is switched from the cooling mode to heating mode, the

compressor is stopped, and the four-way valve is switched in 3 minutes later after the compressor

stopped.

When the power was interrupted by a power failure, etc. during operation, the operation contents

at that time are memorized and when power is recovered, operation is automatically started with

the memorized operation contents.

When the power is interrupted and recovered during timer operation, since the timer operation time

is shifted by the time the power was interrupted, an alarm is given by blinking (7 sec ON/2 sec OFF)

the indoor unit body timer lamp.

[Operation contents memorized when the power is interrupted]

Operation mode

Set temperature

Set air flow

Timer mode and timer time

Set air flow Direction

Swing

The test operation mode is released if 60 minutes have passed after setting up the test operation.

12. PREVENT TO RESTART FOR 3 MINUTES ( 3 MINUTES ST )

13. FOUR-WAY VALVE EXTENSION SELECT

14. AUTO RESTART

05-12

AW * Z24LBC

Pulse range

40 480 pulse

(1) Pulse range of EEV

(2) The EEV is set up at 480 pulses when the compressor is stopped.

(3) Intialization (Input of 528 pulses toward closing direction) is operated under the

following condition.

* When the power is turned on.

* 3 hours has passed since the last initialization, and 3 minutes has passed after

the compressor stop.

(If 12 hours has passed since the last initialization, the compressor is compulsorily

stopped.)

15. MANUAL AUTO OPERATION (Indoor unit body operation)

If MANUAL AUTO Button is set (Push a MANUAL AUTO button for 3~10 seconds), the operation

If the remote control is lost or battery power dissipated, this function will work without the remote

control.

is controlled as shown in Table 10.

OPERATION MODE Auto changeover

FAN CONT. MODE Auto

TIMER MODE Continuous

SETTING TEMP. 24°C

SETTING LOUVER Standard

SWING OFF

When the outdoor heat exchanger temperature is lower than temperature and the heating operation has

been stopped for 30 minutes, power is applied to the compressor and the compressor is heated.

(By heating the compressor, warm air is quickly discharged when operation is started.)

When operation was started, and when the outdoor temperature rises to temperature or greater, preheating

is ended.

Filter Clean is operated after a coil dry operation end.

FIlter Clean function performs disinfection and deodorization of a filter with UV lamp during filter

movement.

Unit is stopped after Filter Clean operation.

AW * Z24LBC

AW * Z24LBC

1100rpm 29Hz

(Table 10)

(No timer setting available)

17. COMPRESSOR PREHEATING

(Table 11 : Preheating Operation / Release Temperature)

Temperature

Temperature

5°C

7°C

18. COIL DRY AND CLEAN OPERATION CONTROL

The coil-dry operation functions by pressing COIL DRY button on the remote controller.

The coil-dry operation is consisted of 3 cycles of [Fan operation 3 minutes / Heating operation

2 minutes], and Fan operates for 3 minutes at last before ending the air conditioner operation.

(It takes 18 minutes to complete the coil-dry operation.)

(Table 12 : COIL-DRY Operating Functions)

Indoor Fan Speed

Compressor

Frequency

Louver

Position

Main Unit

Indication

COIL-DRY indication : ON

Other indication : OFF

05-13

Forced cooling operation

Cooling

16. FORCED COOLING OPERATION

Forced cooling operation is started when pressing MANUAL AUTO button for 10 seconds or more.

During the forced cooling operation, it operates regardless of room temperature sensor.

Operation LED and timer LED blink during the forced cooling operation. They blink for 1 second ON

and 1 second OFF on both operation LED and timer LED (same as test operation).

Forced cooling operation is released after 60 minutes of starting operation.

The FORCED COOLING OPERATION will start as shown in Table10.

COIL DRY OPERATION CONTROL

Hi

Horizontal

OFF

Room Temp is not controlled

Manual auto operation

-

19. UV FILTER CLEANING CONTROL

1. SETTING METHOD

(1) Manual filter cleaning function

- Press [FILTER] button on remote controller to start filter cleaning.

(2) Automatic cleaning function

- Filter maintenance interval can be set at either 50 hours or 100 hours

with the remote controller ([SET TIME] button is kept pressed - refer to

the operation manual).

- When the accumulated operating time reached to the set up interval

time, the filter cleaning function automatically starts at the stop mode.

2. MAIN UNIT INDICATION

* Type of [MAINTENANCE SIGN] lamp (Red) indications on main unit.

- During the filter cleaning function

[MAINTENANCE SIGN] lamp (Red) is ON.

(It lights up only when the filter is functioning. Upon filter

function is completed, it goes off.)

- When the filter cleaning function is abnormal

[MAINTENANCE SIGN] lamp (Red) blinks (1 sec. ON / 1 sec. OFF)

- Notification of Dust box maintenance

[MAINTENANCE SIGN] lamp (Red) will light up.

It notifies the timing of Dust box maintenance. It lights up after 2,000

or 4,000 hours of operation by setting up with the auto cleaning

function time.

The red lamp will keep lighting until resetting the accumulated time,

regardless of air conditioner's operating mode.

3. REMOTE CONTROLLER CONDITION

The LCD indication does not change with [FILTER] button.

4. LIMIT SWITCH CONDITION FOR THE FILTER LOCATION DETECTION.

- Limit switch ON - On filter function, the filter is stopped on the way.

- Limit switch OFF - The filter is correctly installed, or The filter is not installed.

05-14

MAINTENANCE SIGN

TIMER OPERATION HI-POWER

SUPER QUIET

5. OPERATING FUNCTION

- UV filter cleaning function

UV LED is turned on during the filter cleaning operation to remove bacteria or to deodorize.

< Condition to light up UV-LED >

UV-LED is lighted up after 5 seconds of starting the filter cleaning operation.

If error is occurred during the filter operation, it is turned off.

6. PROTECTING FUNCTIONS

(1) Automatic filter retracting function

Under following conditions, the filter moves toward retracting direction until the limit switch

turns OFF.

- The limit switch is kept ON for 2 seconds when the power is turned on.

- The limit switch turns ON from OFF and it is kept ON for 2 seconds when the air conditioner

is in operating or stop mode.

> If the air conditioner is in operating mode, it does not stop the operation and functions the

filter.

(2) Filter mounting error protection

(a) Filter come out mounting error

(b) Filter retract mounting error

If above error occurs, it is memorized in EEPROM (Error history).

Error is indicated with blinking [MAINTENANCE SIGN] lamp (Red) for 1 sec. ON / 1 sec. OFF.

(3) Filter cleaning forced stop function when Dust box maintenance notification is in operation.

* When [MAINTENANCE SIGN] LED (Red) is ON, following functions do not work until reset

button will be pressed.

- Auto cleaning / Manual filter cleaning function

- Filter auto retract function

- Forced filter cleaning function, Off timer operating time auto cleaning.

* This protecting function can be released by pressing [MAINTENANCE/MANUAL AUTO]

button.

(4) Filter cleaning stepping motor temperature rise protection

Filter cleaning can be operated continuously up to 3 times.

(If it is operated 3 times continuously, it stops filter cleaning function for 3 minutes.)

(5) Forced filter cleaning protection for the continuous operation

When the operation time of air conditioner reaches to 200 hours, the operation is temporarily

stopped, and the filter cleaning is performed. Upon completion of the filter cleaning, it resumes

operation.

(6) Auto cleaning function protection for OFF Timer operating time

If the filter cleaning does not operate after 100 hours of air conditioner operating time and it is

reached to 150 hours, the filter cleaning function starts to operate at the time of stopping

operation by OFF Timer time up

05-15

20. DEFROST OPERATION CONTROL

(1). CONDITION OF STARTING THE DEFROST OPERATION

The defrost operation starts when the outdoor heat exchanger temperature sensor detects

the temperature lower than the values shown in Table 15.

(Table 15 : Condition of starting Defrost Operation)

AW * Z24LBC

AW * Z24LBC

AW * Z24LBC

1 time defrosting

after starting

operation

ST

Defrosting after 2

time upon starting

operation

ND

Compressor operating time

Less than 17 minutes 17 to 60 minutes

60 minutes to 4 hours

After 4 hours

Does not operate

- 9 C

- 5 C

- 3 C

Less than 35 minutes

35 minutes to

4 hours

Does not operate

Compressor operating time

After 4 hours

- 3 C

- 6 C

(2). CONDITION OF THE DEFROST OPERATION COMPLETION

Defrost operation is released when the conditions become as shown in Table 16.

(Table 16 : Defrost Release Condition)

Release Condition

Outdoor heat exchanger temperature sensor value is higher than 13 C or

Compressor operation time has passed 15 minutes.

05-16

Loading...

Loading...