Page 1

SPLIT TYPE

ROOM AIR CONDITIONER

CEILING TYPE (60Hz)

Indoor unit Outdoor unit

ABU36RSLX AOU36RLX

CONTENTS

SPECIFICATIONS

OUTLINE AND DIMENSIONS

REFRIGERANT SYSTEM DIAGRAM

CIRCUIT DIAGRAM

INDOOR PCB CIRCUIT DIAGRAM

OUTDOOR PCB CIRCUIT DIAGRAM

ERROR DISPLAY

DISASSEMBLY ILLUSTRATION

PARTS LIST

ACCESSORIES

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . .

. . . .

1

2

4

5

7

8

11

13

21

23

Page 2

SPECIFICATIONS

ELECTRICAL DATA

TYPE

INDOOR UNIT

OUTDOOR UNIT

COOLING CAPACITY

HEATING CAPACITY

POWER SOURCE

FREQUENCY

RUNNING CURRENT

INPUT WATTS

E.E.R.

MOISTURE REMOVAL

AIR CIRCULATION

COOLING

HEATING

COOLING

HEATING

COOLING

HEATING

COOLING & HEATING

ABU36RSLX

AOU36RLX

34,100 / 33,500 BTU/h

38,200 / 37,600 BTU/h

230 V / 208 V

1 60Hz

18.3 A / 19.5 A

15.6 A / 17.3 A

4.22 kW / 4.08 kW

3.60 kW / 3.60 kW

2.37 / 2.40 kW/kW

3.11 / 3.06 kW/kW

7.4 Pts/h (3.5 L/hr)

1,088 cfm (1,850 m3/hr)

FAN MOTOR

POWER SOURCE

Discrimination

INDOOR UNIT

OUTDOOR UNIT

High speed

Middle speed

Low speed

Discrimination

High speed

Cool 1,100 r.p.m. / Heat 1,100 r.p.m.

Cool 1,000 r.p.m. / Heat 900 r.p.m.

Cool 850 r.p.m. / Heat 750 r.p.m.

Cool 850 r.p.m. / Heat 900 r.p.m.

COMPRESSOR AND REFRIGERANT

TYPE

DISCRIMINATION

PRECHARGED REFRIGERANT

REFRIGERANT TYPE

Pipe length

FULL CHARGE

ADDITIONAL CHARGE

49 ft. (15 m)

66 ft. (20 m)

98 ft. (30 m)

131 ft. (40 m)

164 ft. (50 m)

4 poles, Inverter, Twin rotary

230 V

MFA-45DZM

MFE-45ROM

Hermetic type,

TNB220FPBM9

4 lb 14 oz (2,200g)

R410A

4 lb 14 oz (2,200 g)

5 lb 5 oz (2,400 g)

6 lb 3 oz (2,800 g)

7 lb 1 oz (3,200 g)

7 lb 15 oz (3,600 g)

0.43 oz / ft. (40 g/m)

DIMENSIONS

INDOOR UNIT

OUTDOOR UNIT

H x W x D

H x W x D

WEIGHT

INDOOR UNIT

OUTDOOR UNIT

Net / Gross

Net / Gross

2009.05.22 1

9-1/2" x 65-1/2" x 27-5/8" inch

240 x 1,660 x 700 mm

32-3/4" x 35-1/2" x 13" inch

830 x 900 x 330 mm

106 lb / 135 lb (48 kg / 61 kg)

141 lb / 154 lb (64 kg / 70 kg)

Page 3

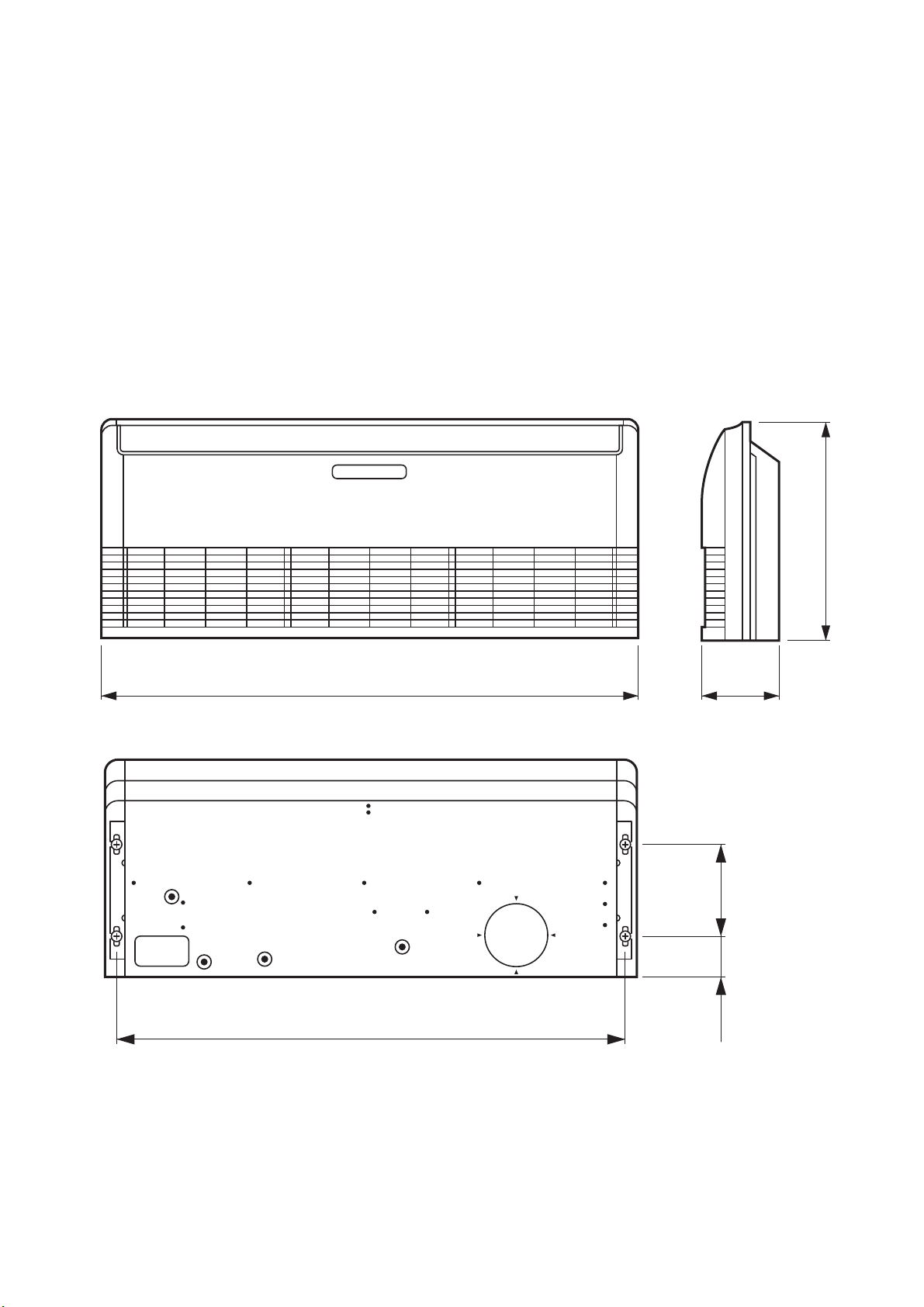

OUTLINE AND DIMENSIONS

INDOOR UNIT

Unit : inch (mm)

65-1/2" (1,660)

27-5/8" (700)

9-1/2"

(240)

63" (1,600)

2005.12.27 2

11-7/8"

(300)

5-1/8" (130)

Page 4

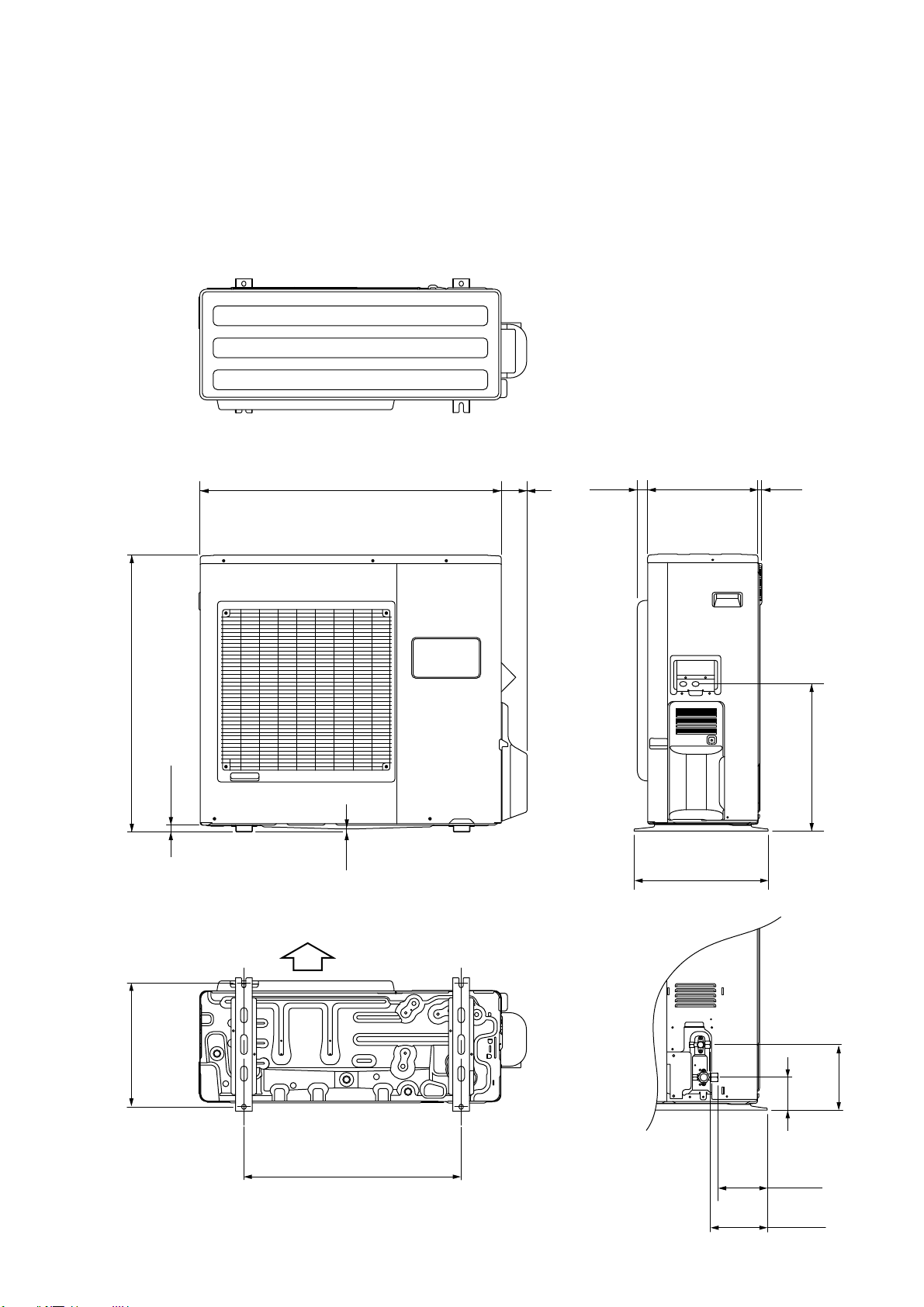

OUTDOOR UNIT

Unit : inch (mm)

35-1/2" (900)

3"(77)

1-1/4"

(31)

13" (330)

1/2"

(12)

32-3/4" (830)

7/8" (21)

3/8"

(9)

15-3/4" (400)

17-3/8" (440)

Air Flow

14-5/8" (370)

25-5/8" (650)

2005.12.27 3

3-7/8"

(99)

5-3/4" (147)

6-3/4" (170)

7-3/4" (196)

Page 5

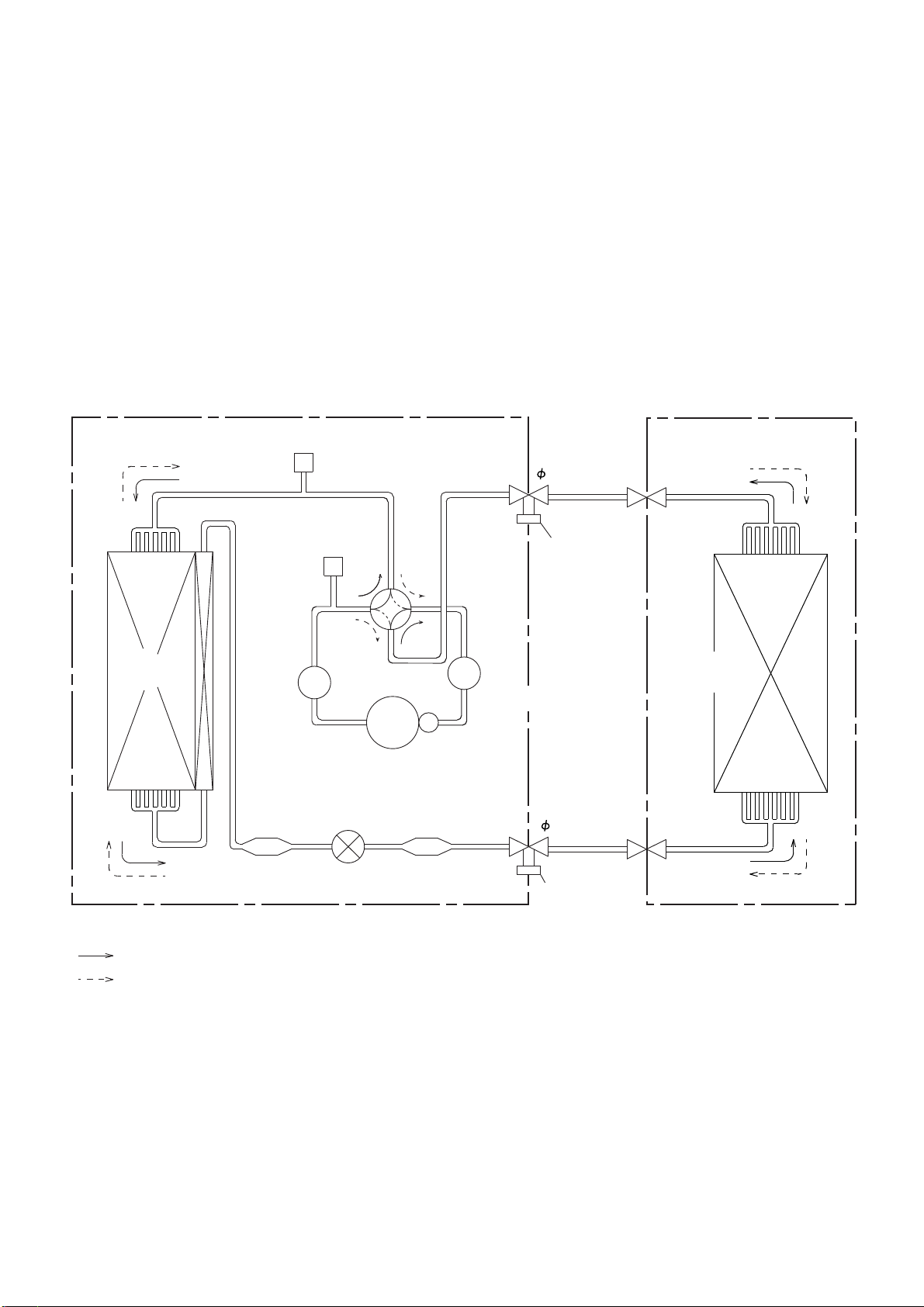

REFRIGERANT

SYSTEM DIAGRAM

OUTDOOR UNIT

Condenser

High Pressure

Switch

Muffler

Pressure

Check Valve

4-way

Valve

Compressor

Expansion

Valve

INDOOR UNIT

Refrigerant Pipe

15.88mm (5/8")

Charging

Valve

Evaporator

Accumulator

Refrigerant Pipe

9.52mm (3/8")

Strainer

Strainer

: COOL

: HEAT

2006.01.23 4

Charging Valve

Page 6

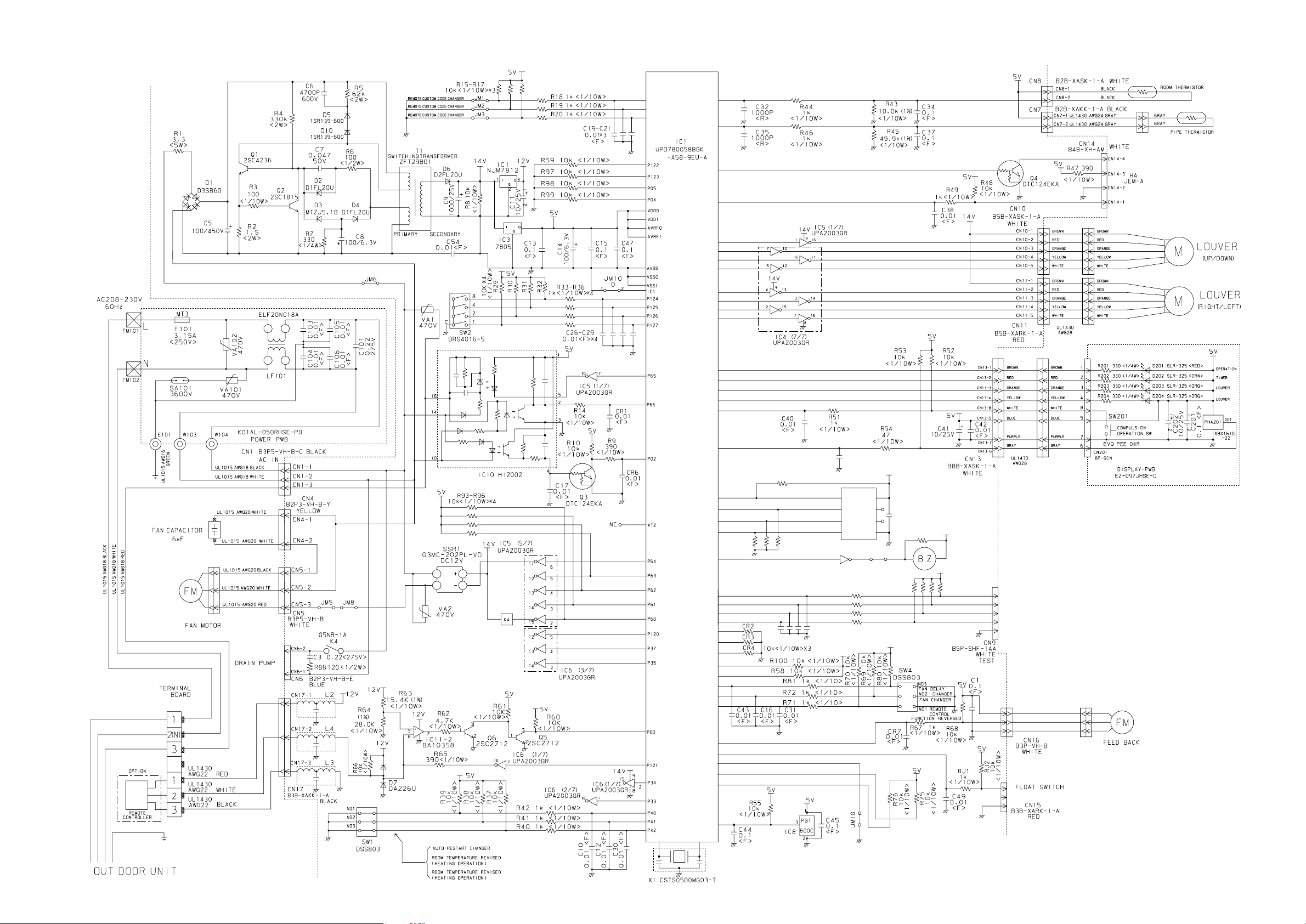

CIRCUIT DIAGRAM

Model : ABU36RSLX

ROOM TEMPERATURE THERMISTOR

PIPE TEMPERATURE THERMISTOR

FAN MOTOR

CN201

INDICATOR PCB

F M

BROWN

1

1

RED

2

2

ORANGE

3

3

YELLOW

4

4

WHITE

5

5

BLUE

6

6

PURPLE

7

7

GRAY

8

8

GRAY

1

PURPLE

2

BLUE

3

BLACK

2

WHITE

1

RED

3

1

2

3

1

2

3

4

5

6

7

8

1

2

3

1

2

3

1 2

CN6 CN7

CN15

CN13

CN16CN5

CN17

23

1

1 2

GRAY

1 2

CN1

3

BLACK

BLACK

GRAY

1 2

CN8

WHITE

1

WHITE

2

BROWN

1

RED

2

ORANGE

3

YELLOW

4

WHITE

5

1

2

3

4

5

FAN MOTOR

CAPACITOR

STEP MOTOR

M

( UP / DOWN )

CONTROLLER PCB

BROWN

1

RED

2

ORANGE

3

YELLOW

CN11 CN10 CN4

4

WHITE

2

5

1

1

2

3

4

5

STEP MOTOR

M

( LEFT / RIGHT )

WHITE

BLACK

N

WHITE

BLACK

RED

WHITE

RED

3 2 1 3 2 1

L

BLACK

TERMINAL

Use T 3.15A-250V

Fuse on F101

POWER SUPPLY PCB

GREEN

G

2005.12.28 5

Page 7

Model : AOU36RLX

PIPE TEMPERATURE

THERMISTOR

DISCHARGE TEMPERATURE

THERMISTOR

COMPRESSOR

U

W

TERMINAL

BLACK

BLACK

CHOKE COIL

POSISTOR

CONNECTOR

ACTIVE

FILTER

MODULE

WHITE

BROWN

REDRED

WHITE WHITE

V

BLACK

BLACK

L1

P

N

L2

+

-

EMI FILTER

1T

BROWN

1

RED

2

ORANGE

3

4

5

YELLOW

6

EMI FILTER

2T

BLACK

BROWN

YELLOW

BLUE

ORANGE

ORANGE

RED

BLACK

1212121

CN21 CN22 CN23

U

W305

V

W304

W

W303

1

2

3

4

5

W12

W13

W21

W22

CN407

FUSE

F4 T 5A-250V

CONTROLLER

PCB ASSY

FUSE

F2 T 3.15A-250V

W16

W17

W10

CN1 CN34

W11

2

1

3 4

2

CN26

BLUE

BROWN

BLACK

1

CN25

CN802

2

1

2

CN37

CN30

CN27

W200

3

OUTDOOR TEMPERATURE

THERMISTOR

COMPRESSOR TEMPERATURE

THERMISTOR

HEAT SINK TEMPERATURE

THERMISTOR

RED

1

RED

2

BLACK

1

2

BLACK

3

RED

1

2

BLACK

3

WHITE

4

YELLOW

5

BLUE

6

RED

1

BROWN

2

BLUE

3

ORANGE

4

YELLOW

5

WHITE

6

HIGH PRESSURE SWITCH

SOLENOID COIL

4WV

FAN MOTOR

F M

EXPANSION VALVE COIL

E V

WHITE

BLACK

TM102

TM101 W3

EARTH EARTH

BLACK

1

CN1

BROWN

2

3

WHITE

RED

BLACK

W9 W8

POWER SUPPLY PCB ASSY

W7 W1 W2

W6

GREEN

G

WHITE

BLACK

3 L N

2(N)1

WHITE

BLACK

RED

G

2005.12.28 6

Page 8

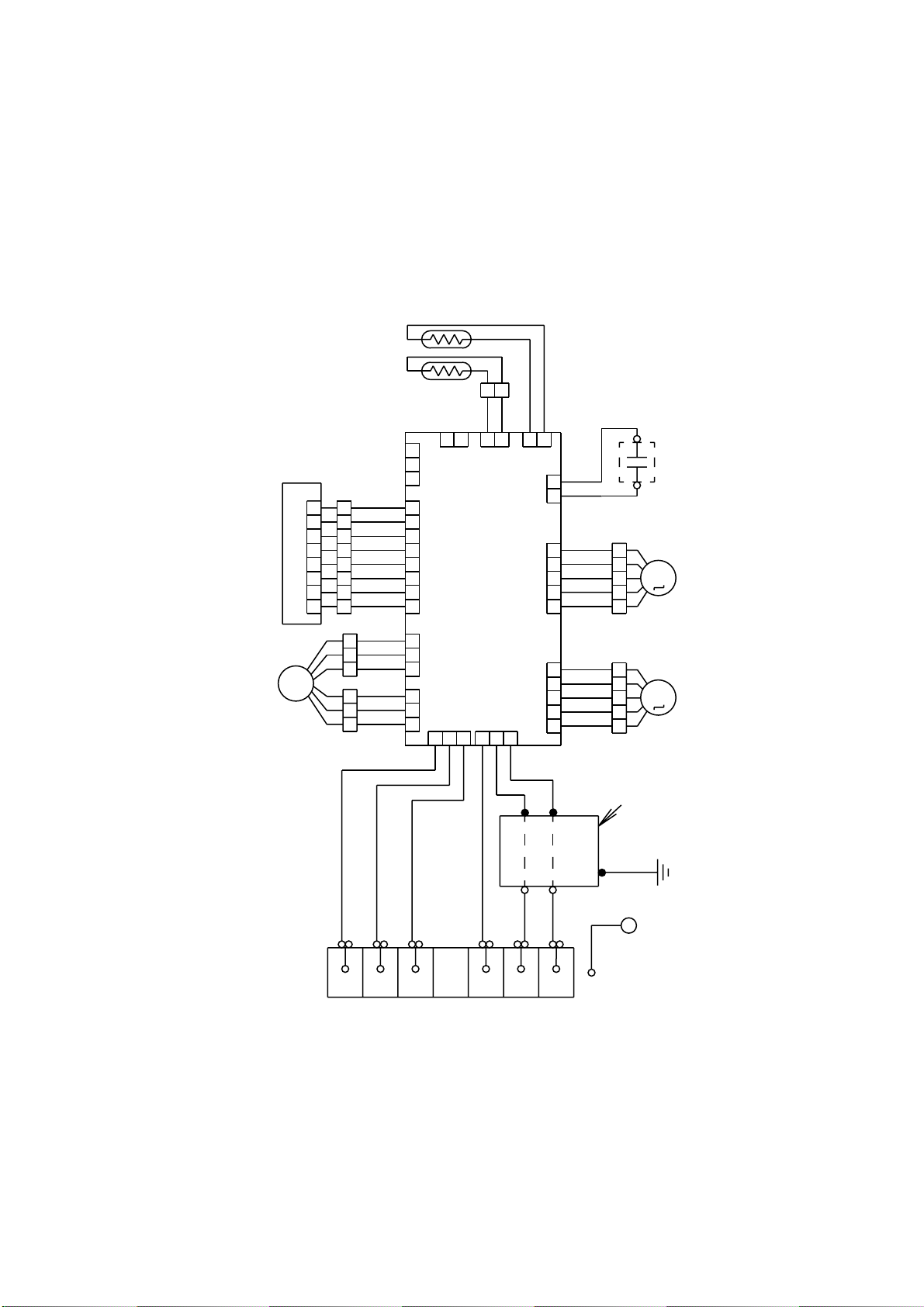

INDOOR PCB CIRCUIT DIAGRAM

Model : ABU36RSLX

CONTROLLER PCB ASSEMBLY ( MAIN PCB )

K01AL-050RHSE-C1

1

P15

2

P16

3

P17

54

55

66

65

74

68

75

7

4

67

33

71

56

57

58

59

41

42

P10

P11

P57

P56

P50

P27

P26

P25

P22

P21

P20

P130

P51

P52

P53

P54

P55

76

77

35

34

27

18

17

16

13

12

11

5

28

29

30

31

32

62

69

P01

P70

P71

P72

P131

P36

P67

P30

P31

P32

P14

P13

P12

P47

P46

P45

P44

P43

P03

XT1

I C

P24

P23

RESET

X2X1

R50 10K

<1/10W>

8

9

10

6

50

43

44

45

46

80

79

78

26

25

24

23

22

64

73

71

15

14

60

3

R77 - R79

10K <1/10W> x 3

C22 - C25

0.01 <F> x 4

63

72

40

39

38

37

36

52

51

49

61

53

48

47

19

20

21

70

1

CR5

1000P

<R>

4

DO

VCC

D I

3

NC

2

SK

NC

CS

GND1

I C7 BR93LC46RF

6

R56

11

I C6 (1/7)

uPA2003GR

R25 - R28

1.0K <1/10W> x 4

5V

5V

8

C39

7

0.1

6

<F>

R57 1.0K

5

<1/10W>

14V

BZ1

PKM13EPY-4000

5V

R21 - R24

10K <1/10W> x 4

CN9-1

CN9-2

CN9-3

CN9-4

CN9-5

5V

CN16-1

UL1430 AWG22 GRAY

CN16-2

UL1430 AWG22 PURPLE

CN16-3

UL1430 AWG22 BLUE

CN15-1

CN15-2

CN15-3

2005.12.28 7

2

Page 9

Model : AOU36RLX

AC230V

60Hz

TERMINAL

HP-T3061-3

INVERTER ASSY

EZ-005HHUE

POWER SUPPLY PCB

K04BA-0501HUE-P0

CONTROLLER PCB ASSY

K04AW-0504HUE-C1

2005.12.28 8

Page 10

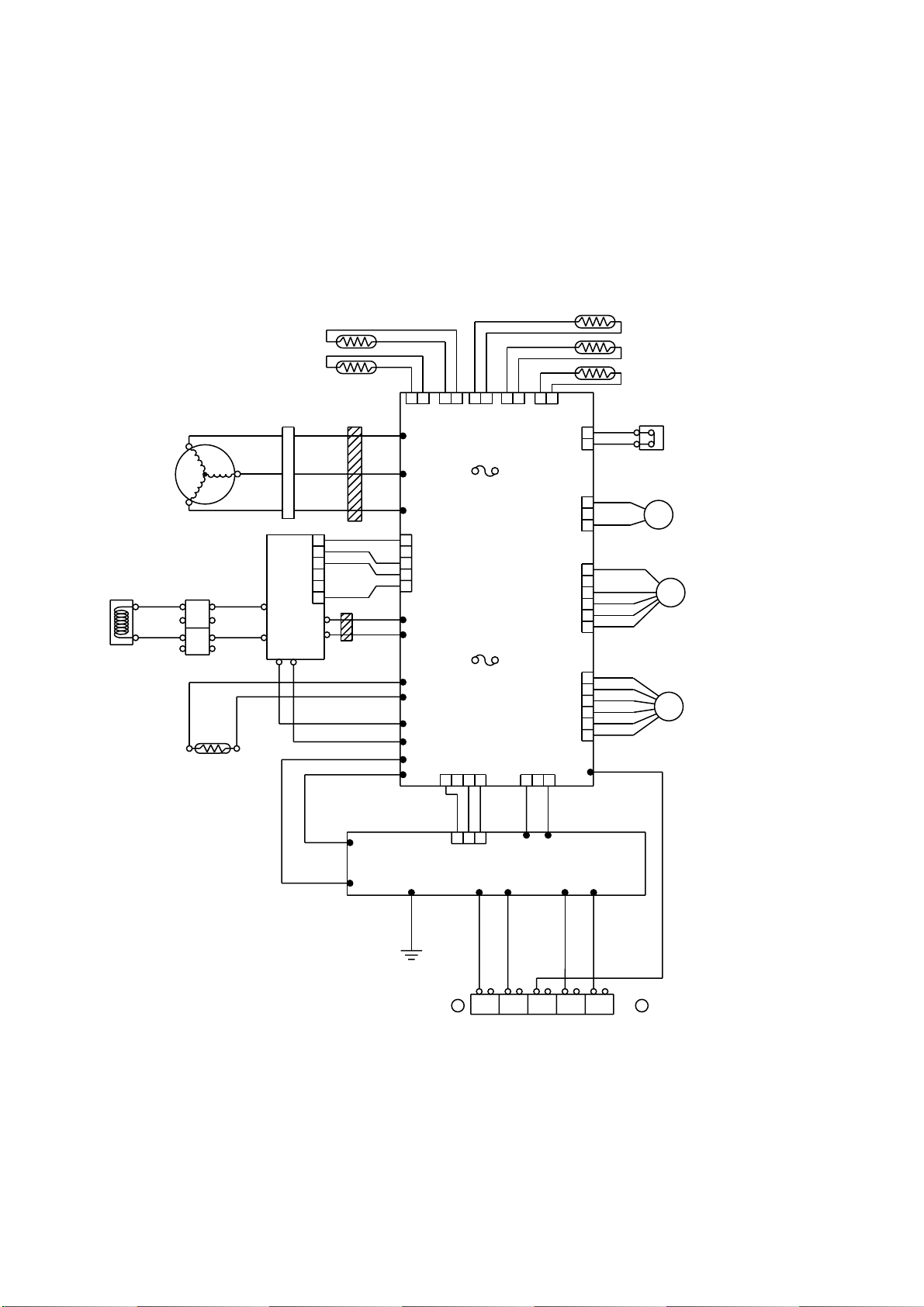

Model : AOU36RLX

CONTROLLER PCB ASSEMBLY ( MAIN PCB )

K04AW-0504HUE-C1

600/450V x 4

2005.12.28 9

Page 11

Model : AOU36RLX

*

AOU18RLX, AOU24RLX : W4 and W5

AOU36RLX, AOU42RLX : W1 and W2

BLACK

POWER SOURCE

230V

60Hz

WHITE

TO INDOOR UNIT

*

W1

or

W4

*

W2

or

W5

W6

BLACK

W7

WHITE

POWER SUPPLY PCB ASSEMBLY

K04BA-0501HUE-P0

TM100

L1

RCH4730-021PF07

VA101

470V

B

<TNR>

VA102

470V

C101

3.3

<LE>

<TNR>

C104

0.033

<YE>

C105

0.033

<YE>

C106

B

SA100

RA-302M

B

B

3.3

<LE>

L2

N200500K1D7C

C107

3.3

<LE>

CT1

CT-1B

L4

RCH4730-021PF07

C111

3.3

<LE>

C112

0.015

<YE>

C113

0.015

<YE>

TM101

TM102

EARTH

AC VOLT OUT

W3

GREEN

BLACK

WHITE

W8

W9

B

B

B

2005.12.28 10

D60

5V

DAN217U

C60

220/16V

<PJ>

R60 1.0K

<1/10W>

(1%)

+

R61 3.74K

<1/10W>

(1%)

VR1

B2K

R68 22K

<1/10W>

C64

0.1

<F>

C65

0.1

<F>

5V

CN1

B3B-XASK-1-A

WHITE

1

2

3

CT OUT

Page 12

ERROR CONTENTS

(Indoor unit)

Operation can be checked by lighting and flashing of the display section OPERATION,

TIMER, and VERTICAL SWING lamps.

Perform judgment in accordance with the following.

VERTICAL SWING lamp (Orange)

TIMER lamp (Green)

OPERATION lamp (Red)

MANUAL

AUTO

SWING SWING TIMER

TEST RUNNING

When the air conditioner is run by pressing the remote control unit test run button, the

OPERATION, TIMER, and VERTICAL SWING lamps flash slowly at the same time.

ERROR

The OPERATION, TIMER, and VERTICAL SWING lamps operate as follows (Table 1)

according to the error contents.

OERATION

OPERATION

lamp (RED)

(2 times)

(2 times)

(3 times)

(3 times)

(4 times)

(5 times)

(5 times)

(6 times)

TIMER lamp

(GREEN)

(2 times)

(3 times)

(3 times)

(4 times)

(4 times)

SWING lamp

(ORANGE)

Error contents

Indoor EEPROM abnormal

Outdoor EEPROM abnormal

Indoor room temperature sensor open

Indoor room temperature sensor shortcircuited

Indoor heat exchanger temperature sensor open

Indoor heat exchanger temperature sensor shortcircuited

Float switch operated

Indoor signal abnormal

Outdoor signal abnormal

Indoor fan abnormal

Outdoor power source connection abnormal

Outdoor heat exchanger temperature sensor open

Outdoor heat exchanger temperature sensor shortcircuited

Outdoor temperature sensor open

Outdoor temperature sensor shortcircuited

(5 times)

(5 times)

(6 times)

(7 times)

: 0.1s ON/0.1s OFF (flash) : OFF

: 0.5s ON/0.5s OFF (flash)

Outdoor discharge pipe temperature sensor or compressor

temperature sensor open

Outdoor discharge pipe temperature sensor or compressor

temperature sensor shortcircuited

Outdoor high pressure abnormal

Outdoor discharge pipe temperature or compressor

temperature sensor abnormal

2005.12.28 11

Page 13

ERROR CONTENTS

(outdoor unit)

1. Make a TEST RUN in accordance with the in stallation instruction sheet for the indoor unit.

2. OUTDOOR UNIT LEDS

When a malfunction occurs in the outdoor unit, the LED on

the circuit board lights to indicate the error. Refer to the following table for the description of each error according to the

LED.

LED

1 flash

2 flash

3 flash

4 flash

7 flash

8 flash

9 flash

12 flash

13 flash

14 flash

15 flash

16 flash

lighting

Communication error

(Indoor unit - Outdoor unit)

Discharg pipe temperature sensor

Outdoor heat exchanger temperature sensor

Outdoor temperature sensor

Compressor temperature sensor

Heat sink temperature sensor

Pressure switch abnormal

IPM error

Compressor rotor position cannot detect

Compressor cannot operate

Outdoor fan abnormal (upper fan)

Outdoor fan abnormal (lower fan)

No error

Error contents

2. When the product is operating:

1

Press the PUMP DOWN switch on the outdoor unit.

The LED on the outdoor unit circuit board lights, and

operation stops. At this point, recovery has not been

completed, so do not close the two- and three-way

valves.

2

The pump down operation (cooling operation) begins after three minutes. Close the three-way valve

(liquid) after operation starts.

3

After 2 - 3 minutes, operation stops. Close the threeway valve (gas) within one minute after operations

stops.

4

The LED will go out three minutes after it stops. Disconnect the power supply after confirming that the

LED has gone out.

*When the pump down operation is repeated, temporarily disconnect

the power supply after opening the closed valves (both liquid and gas).

Reconnect the power supply after 2 - 3 minutes and perform the pump

down operation.

*When the start of the operation after pump down operation has been

completed, temporarily disconnect the power supply after opening the

closed valves (both liquid and gas).

Reconnect the power supply after 2-3 minutes and be sure to perform

a test operation for cooling.

3-way valve

(Liquid)

SPECIAL INSTALLATION

SETTING

PUMP DOWN (Refrigerant collecting operation)

Per form t he following procedures to collect the refri gerant

when moving the indoor unit or the outdoor unit.

1. When the product is stopped:

1

Press the PUMP DOWN switch on the outdoor unit.

(The LED on the outdoor unit circuit board lights.)

The pump down operation (cooling operation) be-

2

gins right away. After oparation starts, close the

three-way valve (liquid).

3

After 2 - 3 minutes, operation stops. Close the threeway valve (gas) within one minute after operations

stops.

4

The LED will go out three minutes after it stops.Disconnect the power supply after confirming that the

LED has gone out.

3-way valve

(Gas)

PUMP DOWN SW

2006.01.25 12

DANGER

This part (Choke coil) generates high voltages.

Never touch this part.

Page 14

DISASSEMBLY ILLUSTRATION

INDOOR UNIT

Model : ABU36RSLX

761

382

403

174

181

122

286

379

109

387

126

12

386

384

56

388

174

383

762

755

223

472

74

164

338-2

338-1

286

122

403

448

345-1

345-2

8

138

684

876-1

435

408

505

580

434

69

228

407

506

321

229

240-2

735

329

361

752

146

396

240-1

160

743

240

868

63

2005.12.28 13

Page 15

Model : ABU36RSLX

69

506

407

505

408

435

434

361

91

321

876-1

386

160

387

91

2005.12.28 14

91

Page 16

Model : ABU36RSLX

321

387

438

876-2

436

424

684

385

868

763

227

2012.10.11 15

Page 17

Model : ABU36RSLX

195

253-2

253-1

875

253-3

34

195

380

253-5

253-4

253-6

253-7

236

234

185-1

815-1

223

381-4

625

187

472

448

2005.12.28 16

Page 18

Model : AOU36RLX

1

6

3

4

7

2

2005.12.28 17

5

Page 19

Model : AOU36RLX

10

13

8

9

15

17

18

14

2006.01.17 18

Page 20

Model : AOU36RLX

26

23

19

22

31

24

25

27

29

28

20

12

12

30

2005.12.28 19

Page 21

Model : AOU36RLX

35

38

37

36

Connector : BLACK

33 34

GREEN

BLUE

RED

YELLOW

2008.03.10 20

63

64

65

66

67

Page 22

PARTS LIST

INDOOR UNIT

Ref. Description DescriptionPart No. Ref. Part No.

8 Air Filter

12 Base Assy

34 Capacitor

56 Sirocco Fan Assy

63 Panel (Front)

69 Louver

74 Intake Grille

91 Hinge

109 Casing

122 Bearing-B Assy

126 Bracket (Motor)

138 Separate Wall

146 Evaporator Assy

160 Drain Pan Sub Assy

164 Fan Motor Assy-IN

174 Hanger

181 Hole Cover

185-1 Rubber Bushing

187 Clamp No.1219

195 Clamp SKB-100

9359739005

9359680000

9900270216

9359701002

9359734000

9359719007

9359738008

9359699002

9359704003

9357921006

9359681007

9359700005

9371073040

9360429018

9360457004

9359742005

9359691006

9357376004

313361271706

313361275805

345-1 Filter Guide-R

345-2 Filter Guide-L

361 Bushing

379 Hinge Plate (Grille)

380

381-4 Spacer

382 Cover (Decoration)-R

383 Cover (Decoration)-L

384 Shaft

385 Indicator PCB Assy

386 Panel Left Assy

387 Kit (Panel Right Assy)

388 Joint Assy

396 Rfm Bracket Metal

403 Fixture (Bearing)

407 Rod (Motor)

408 Link (Louver)

424 Sector Gear

434 Base (Louver)

435 Louver Spring

Locking Spacer KGLS-6S

9359692003

9359693000

9359733003

9359694007

313209391403

0600118075

9359744009

9359745006

9359707004

9705891029

9359685005

9371361017

9359706007

9359697008

9359687009

9359723004

9359726005

9359729006

9359718000

9359720003

223 Control Box Assy

227 Badge "FUJITSU"

228 Insulation (Louver)-R

229 Insulation (Louver)-L

234 Thermistor (Room)

236 Controller PCB Assy

240 Remote Control Unit

240-1 Cover Panel (Pipe)-L

240-2 Cover Panel (Pipe)-R

253-1 Wire Assy (Terminal)

253-2 Wire Assy (Terminal)

253-3 Wire Assembly

253-4 Wire Assy (Connector)

253-5 Wire Assy (Connector)

253-6 Wire Assy (Connector)

253-7 Wire Assy (Connector)

286 Bracket (Bearing)

321 Flap Assy

329 Coupling Pipe Assy

9362025003

9359735014

9359721000

9359722007

9703299025

9705914285

(K01AL-050RHSE-C1)

9371190051

9359690009

9359689003

9702321017

9702322014

9702311018

9702323011

9702319014

9702317010

9702318017

9359686002

9359731009

9373038214

436 Flap Spring

438 Pinion Gear

448 Control Box-B

472 Control Box-A

505 Stopper (Louver)

506 Rod (Louver)

580 Cover (Top)

625 Cord Bushing

684 Motor Base

735 Distributor Assy

743

752 Bracket Panel (Pipe)

755 Cover (Casing)

761 Kit (Cover Side-R)

762 Kit (Cover Side-L)

763 Cover (Receiver)

815-1 Terminal-7P

868 PCB Holder

875 Power Supply PCB Assy

876-1 Motor, Step-H

Remote Control Holder Case

9359730002

9359728009

9359713005

9359712008

9359724001

9359725008

9359737001

9359240006

9359727002

9360455000

9305642014

9359688006

9359705000

9371364018

9371365015

9359714002

9703403019

9359736004

9704561350

9360479013

338-1 Fixture (Motor)

338-2 Fixture (Motor)-B

2006.06.08

9359702009

9359703006

876-2 Motor, Step

--- Thermistor (Pipe)

21

9900362010

9900022020

Page 23

OUTDOOR UNIT

Ref. Description Part Nuber

1 Top Panel Sub Assy

2 Front Panel

3 Fan Guard

4 Grip Side

5 Service Panel Sub Assy

6 Right Panel Sub Assy

7 Emblem Rear

8 Propeller Fan Assy

9 Fan Motor

10 Condenser-A Assy

12 Strainer Assy

13 Separate Wall Assy

14 Cap Foot

15 Base Assy

17 3-Way Valve Assy

18 3-Way Valve Assy

19 Check Joint Assy

20 Compressor Assy

22 4-Way Valve

23 Solenoid

24 Pressure Switch

25 Inlet Pipe Cond A Assy

26 Inlet Pipe Cond B Assy

9374417025

9374094066

9374330010

9374173013

9374415038

9374416073

9351355005

9366378020

9602114016

9374433148

9372524015

9375226015

9374345014

9374166183

9372205044

9372205075

9372802038

9373711018

9900164010

9900165055

9900186012

9373461067

9373463054

27 Outlet Pipe Cond A Assy

28 Expansion Valve Assy

29 Coil (Expansion Valve)

30 Distributor

31 Discharge Pipe A Assy

33 Terminal 2P

34 Terminal 5P

35 ACTPM

36 Holder Thermo

37 Inverter PCB Assy

38 Power PCB Assy

63 Heatsink Thermistor

64 Compressor Thermistor

65 Thermistor (Outdoor Temp.)

66 Heat Exchanger Thermistor

67 Thermistor (Discharge)

-- Thermistor

-- Transformer

-- Varistor

-- Arrester

-- Relay

-- Relay

-- Fuse 3.15A-250V

-- Switch Push

-- Switch Slide

-- Drain Pipe Assy

-- Drain Cap

9374266050

9370947113

9900057039

9369128004

9372264140

9701971015

9900203023

9703457012

9372797013

9705642102

9705647053

9900311018

9900156022

9900378035

9900374013

9704219114

9704265012

9702334024

0000361224

0600280147

9900117016

9900007010

0600239534

9703476013

9701392018

9301102000

313166024302

2008.03.10

22

Page 24

ACCESSORIES

INDOOR UNIT

Name and Shape

Remote

control unit

Q'ty

Use for air conditioner

operation

1

Application

Name and Shape Q'ty Application

Coupler heat insulator (large)

For indoor side pipe joint

(Gas pipe)

2

Battery (penlight)

Remote control

unit holder

Tapping screw

(ø3 x 12)

Drain hose insulation

VT wire

For remote control unit

2

For mounting the remote

control unit

1

For remote control unit

holder installation

2

Adhesive type 70 x 230

1

For fixing the drain hose

L 280 mm

1

Coupler heat insulator (small)

Nylon fastener

Special nut A

(large flange)

Special nut B

(small flange)

Installation

template

Auxiliary pipe assembly

For indoor side pipe joint

(Liquid pipe)

1

Large

For fixing the coupler heat

4

insulator

Small

4

For installing indoor unit

4

For installing indoor unit

4

For positioning the indoor

unit

1

For connecting the piping

1

OUTDOOR UNIT

Name and Shape Q'ty Application

Drain pipe

1

For outdoor unit drain

piping work (May not be

Drain cap

2005.12.28 23

supplied, depending on

the model.)

5

OPTIONAL PARTS

The following options are available.

DRAIN PUMP UNIT : UTR-DPB241 (P/N 9034087001)

WIRED REMOTE CONTROLLER UNIT : UTB-UUB(P/N 9075887004)

Page 25

0512G2981

Loading...

Loading...