Fujitsu AB*30LBAG series, AB*36LBAG series, AO*45LJBYL series, AB*45LBAG series, AO*30LMBWL series Service Instruction

...Page 1

SPLIT TYPE

ROOM AIR CONDITIONER

Large Ceiling

type

Models Indoor unit Outdoor unit

AB*30LBAG

AB*36LBAG

AB*45LBAG

AO*30LMBWL

AO*36LMBWL

AO*45LJBYL

INVERTER

SERVICE

INSTRUCTION

R410A

Page 2

CONTENTS

1. SPECIFICATIONS

SPECIFICATIONS.......................................................................................................... 01-01

2. DIMENSIONS

DIMENSIONS.................................................................................................................. 02-01

3. REFRIGERANT SYSTEM DIAGRAM

REFRIGERANT CIRCUIT............................................................................................... 03-01

4. CIRCUIT DIAGRAM

CIRCUIT DIAGRAM........................................................................................................ 04-01

5. DESCRIPTION OF EACH CONTROL OPERATION

5-1-1 COOLING CAPACITY CONTROL......................................................................

5-1 COOLING OPERATION............................................................................................

5-4 AUTO CHANGEOVER OPERATION........................................................................

5-5 INDOOR FAN CONTROL.........................................................................................

5-6 OUTDOOR FAN CONTROL......................................................................................

5-7 LOUVER CONTROL.................................................................................................

05-01

05-01

5-2-1 HEATING CAPACITY CONTROL......................................................................

5-2 HEATING OPERATION.............................................................................................

05-02

05-02

5-3-1 INDOOR UNIT CONTROL.................................................................................

5-3 DRY OPERATION......................................................................................................

05-03

05-03

05-04

05-05

05-07

05-08

5-8 COMPRESSOR CONTROL......................................................................................

05-10

5-9 TIMER OPERATION CONTROL...............................................................................

05-11

5-10 ELECTRONIC EXPANSION VALVE CONTROL....................................................

05-13

5-11 TEST OPERATION CONTROL...............................................................................

05-13

5-12 PREVENT TO START FOR 3 MINUTES (3 MINUTES ST)....................................

05-13

5-13 4-WAY VALVE EXTENSION SELECT....................................................................

05-13

5-14 AUTO RESTART.....................................................................................................

05-13

5-15 PUMP DOWN (Refrigerant collecting operation).................................................

05-14

5-16 COMPRESSOR PREHEATING...............................................................................

05-14

5-17 DEFROST OPERATION CONTROL.......................................................................

05-14

5-19 VARIOUS PROTECTIONS......................................................................................

05-16

5-18 MANUAL AUTO OPERATION................................................................................

05-16

Page 3

6. REFRIGERANT CAUTION -R410A-

6-1 R410A TOOLS............................................................................................................ 06-01

6-2 PRECAUTION FOR INSTALLATION.........................................................................

06-02

6-3 PRECAUTION FOR SERVICING...............................................................................

06-04

6-4 NEW REFRIGERANT R410A.....................................................................................

06-05

6-5 DEFFERENCE FROM CONVENTIONAL MODEL (R22) AND PRECAUTIONS.......

06-08

8. APPENDING DATA

9. INSTALLATION MANUAL

8-1 CAPACITY TABLE..................................................................................................... 08-01

8-2 OPERATION RANGE.................................................................................................

08-02

8-3 ELECTRIC CHARACTERISTICS...............................................................................

08-03

8-4 SAFETY DEVICE........................................................................................................

08-04

8-5 FUNCTION SETTING.................................................................................................

08-05

7-1-2 OUTDOOR UNIT DISPLAY................................................................................

7-1-1 INDOOR UNIT DISPLAY....................................................................................

7-1 ERROR DISPLAY......................................................................................................

7. TROUBLE SHOOTING

7-2 TROUBLE SHOOTING WITH ERROR CODE..........................................................

7-3 TROUBLE SHOOTING WITH NO ERROR CODE....................................................

7-4 SERVICE PARTS INFORMATION............................................................................

07-01

07-01

8-5-1 INDOOR UNIT....................................................................................................

08-05

8-5-2 OUTDOOR UNIT (AO*30/ 36LMBWL)................................................................

08-07

8-5-3 OUTDOOR UNIT (AO*45LJBYL)........................................................................

08-09

07-02

07-21

07-03

07-26

Page 4

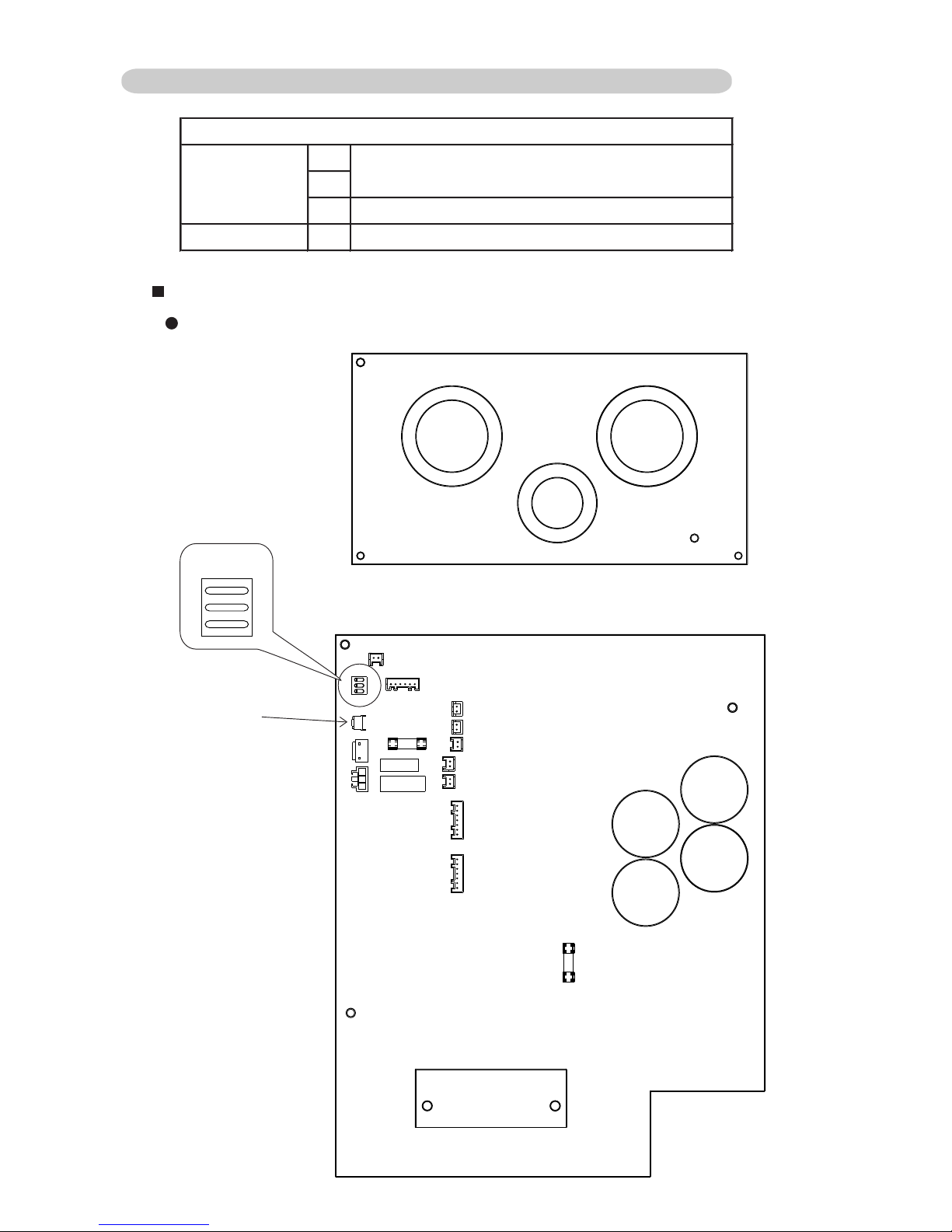

1-1-1 PARTS LAYOUT DRAWING...............................................................................

1-1-2 WIRING................................................................................................................

1-1-3 DISASSEMBLY PROCESS.................................................................................

1-1 For AO*30/ 36LMBWL.............................................................................................

1 REPLACEMENT PARTS ( For OUTDOOR UNIT ).......................................................

10. REPLACEMENT PARTS

10-01

10-01

10-01

10-04

10-03

2-1 PARTS LAYOUT DRAWING...................................................................................

2 REPLACEMENT PARTS ( For INDOOR UNIT )........................................................... 10-29

10-29

1-1-4 ASSEMBLY PROCESS of INVERTER UNIT.......................................................

10-09

1-2-1 PARTS LAYOUT DRAWING...............................................................................

1-2-2 WIRING................................................................................................................

1-2-3 DISASSEMBLY PROCESS.................................................................................

1-2-4 ASSEMBLY PROCESS of INVERTER UNIT......................................................

1-2 For AO*45LJBYL.....................................................................................................

10-14

10-14

10-18

10-16

10-24

Page 5

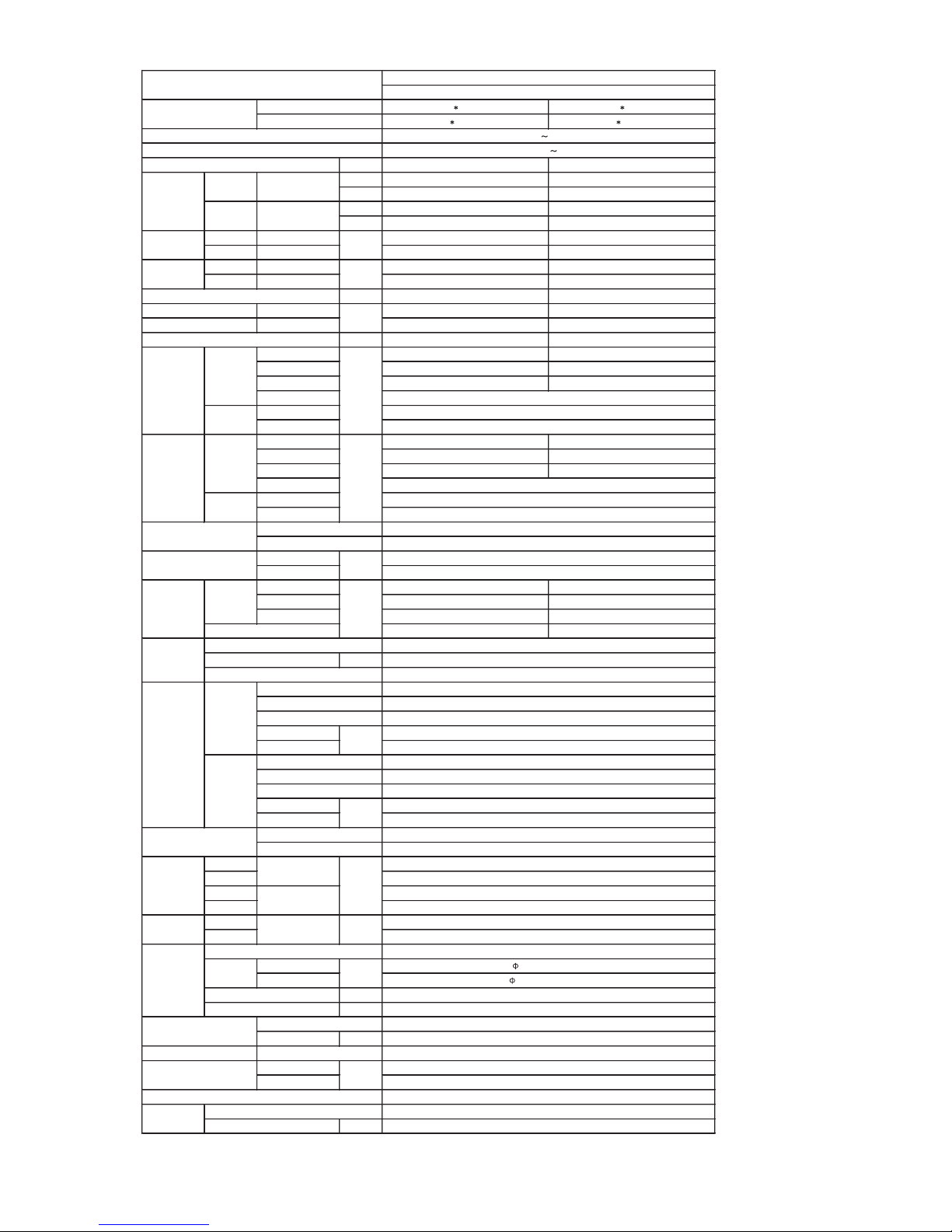

1 . SPECIFICATIONS

R410A

INVERTER

Large Ceiling type

Page 6

01-01

1. SPECIFICATIONS

AB 30LBAG AB 36LBAG

AO 30LMBW L AO 36LMBW L

EUROPEAN ENERGY LABEL COOLING C E

kW 8.50/10.00 10.0/11.20

BTU/h 29000/34100 34100/38200

kW 10.00/11.20 10.8/12.77

BTU/h 34100/38200 36900/43600

COOLING RATED/MAX 3.00/3.45 4.12/4.35

HEATING RATED/MAX 2.90/3.50 3.26/4.15

COOLING RATED/MAX 13.1/15.2 18.0/18.4

HEATING RATED/MAX 12.7/15.3 14.2/18.8

A 10 10

EER COOLING 2.83 2.43

COP HEATING 3.45 3.31

l/h (pints/h) 2.5 ( 5.3 ) 3.0 ( 6.3 )

High 1660 / 1660 1850 / 1850

Med 1500 / 1450 1660 / 1500

Low 1270 / 1150 1430 / 1270

Quiet

High

Low

High 1000 / 1000 1100 / 1100

Med 900 / 850 1000 / 900

Low 750 / 650 850 / 750

Quiet

High

Low

INDOOR

OUTDOOR

INDOOR

OUTDOOR

High 45.0 / 45.0 48.0 / 48.0

Med 42.0 / 42.0 45.0 / 45.0

Low 37.0 / 37.0 41.0 / 41.0

53.0 / 55.0 54.0 / 55.0

OUTPUT W

Rows × Stages

Fin Pitch

Coil Dimensions

Rows × Stages

Fin Pitch

Coil Dimensions

INDOOR

OUTDOOR

INDOOR

OUTDOOR

INDOOR

OUTDOOR

INDOOR

OUTDOOR

LIQUID

GAS

m

m

CHARGE g

COOLING

HEATING

mm

Note: Specifications are based on the following conditions.

Cooling: Indoor temperature of 27 °CDB / 19 °CWB,and outdoor temperature of 35 °CDB/24 °CWB.

Heating: Indoor temperature of 20 °CDB / 15 °CWB,and outdoor temperature of 7 °CDB/6 °CWB.

Pipe length : 7.5 m, Height difference : 0 m.(Outdoor unit - Indoor unit)

CEILING MODELS

INVERTER HEAT PUMP

230V 50Hz

STARTING METHOD

FAN TYPE x Q'ty

FAN MOTOR OUTPUT

W

COMPRESSOR

TYPE

FAN SPEED

COOL/HEAT

DRAIN PIPE

kg(lbs)

MATERIAL

SIZE

CONNECTION METHOD

SIZE

mm

WEIGHT

NET /

GROSS

MAX HEIGHT

HEAT

EXCHANGER

TYPE

INDOOR

Coil

OUTDOOR

Coil

Fin

mm

mm

PIPE

REFRIGERANT

REMOTE CONTROLLER TYPE

OPERATION(OUTDOOR)

°C

REFRIGERANT OIL

TYPE

TYPE

MAX LENGTH

CASING COLOR

DIMENSIONS

H × W × D

NET

dB(A)

OUTDOOR

mm

GROSS

NOISE LEVEL

(SOUND

PRESSURE)

COOL/HEAT

INDOOR

Fin

INDOOR

r.p.m

OUTDOOR

STARTING CURRENT

kW/kW

MOISTURE REMOVAL

AIR

CIRCULATION

COOL/HEAT

INDOOR

m3/h

OUTDOOR

INPUT POWER

kW

CURRENT

A

POWER SOURCE

AVAILABLE VOLTAGE RANGE

CAPACITY

COOLING

RATED/MAX

HEATING

RATED/MAX

TYPE

MODEL NAME

INDOOR

OUTDOOR

-

198-264V 50Hz

-

3600 / 3800

-

850 / 900

-

SIROCCO × 4

PROPELLER × 1

160

103

DC TWIN ROTARY (INVERTER)

1300

Inverter

Copper tube

Aluminium

3 × 12

1.45

252 × 1350 × 39.9

Copper tube

Aluminium

2 × 38

1.3

798 × 900 × 36.38

White (5Y9/0.5NN)

Beige (10YR7.5/1.0NN)

240 × 1660 × 700

830 × 900 × 330

318 × 1800 × 790

970 × 1050 × 445

48 / 61 ( 106 / 134 )

64 / 70 ( 141 / 154 )

FLARE

9.52 ( 3 / 8 inc.)

15.88 ( 5 / 8 inc.)

50 (chargeless:15)

30

R410A

2200

ABS

Outer diameter 25.6 / Inner diameter 22.0

POE

-10 to 43

-10 to 24

WIRELESS

Page 7

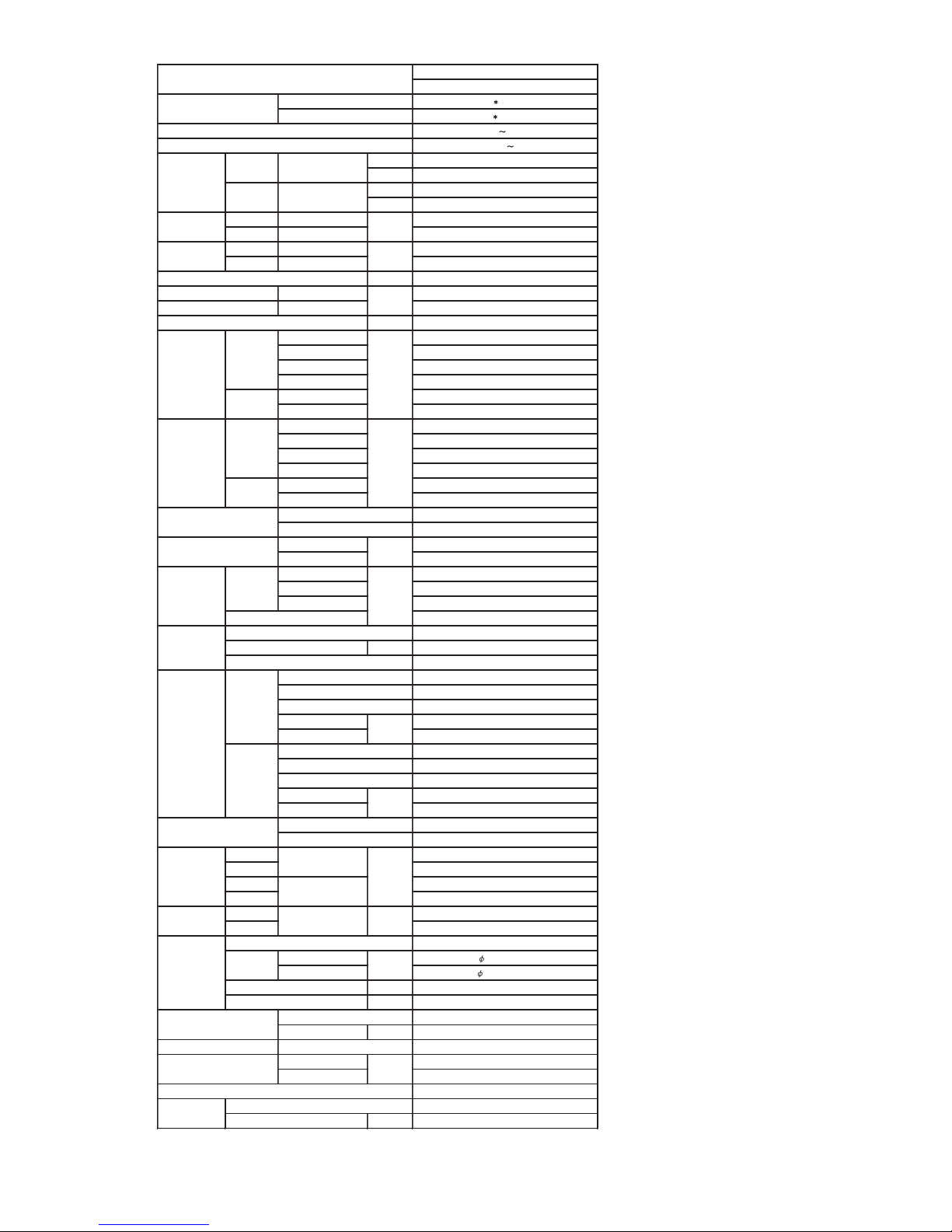

01-02

CEILING MODELS

INVERTER HEAT PUMP TYPE

AB 45LBAG

AO 45LJBYL

230V 50Hz

198-264V 50Hz

kW 12.5/14.0

BTU/h 42700/47800

kW 14.0/16.0

BTU/h 47800/54600

COOLING RATED/MAX 4.45/5.15

HEATING RATED/MAX 4.25/4.60

COOLING RATED/MAX 19.5/22.6

HEATING RATED/MAX 18.5/20.0

A 15

COOLING 2.81

HEATING 3.29

l/h (pints/h) 4.0(8.5)

High 2000/2000

Med 1850/1850

Low 1590/1590

Quiet -

High 6600/6600

Low -

High 1200/1200

Med 1100/1100

Low 950/950

Quiet -

High Upper fan : 850 , Lower fan : 750

Low -

INDOOR Sirocco × 4

OUTDOOR Propeller × 2

INDOOR 160

OUTDOOR 103 × 2

High 50/50

Med 47/47

Low 43/43

52/53

DC SCROLL(INVERTER)

OUTPUT W 2500

Inverter

Copper tube

Aluminium

3 × 12

Fin Pitch

1.45

Coil Dimensions

252 × 1350 × 39.9

Copper tube

Aluminium

2 × 60

Fin Pitch

1.3

Coil Dimensions

1260 × 900 × 36.38

INDOOR White(5Y9/0.5NN)

OUTDOOR Beige(10YR7.5/1.0NN)

INDOOR 240 × 1660 × 700

OUTDOOR 1290 × 900 × 330

INDOOR 318 × 1800 × 790

OUTDOOR 1430 × 1050 × 445

INDOOR 48/61 (106/134)

OUTDOOR 105/112 (231/247)

FLARE

LIQUID

9.52(3/8 inc.)

GAS

15.88(5/8 inc.)

m 70 (chargeless:20)

m 30

R410A

CHARGE g 3400

POE

COOLING

-15 to 43

HEATING

-15 to 24

WIRELESS

ABS

mm

Outer diameter 25.6 / Inner diameter 22.0

Note:

Specifications are based on the following conditions.

Cooling: Indoor temperature of 27 °CDB / 19 °CWB,and outdoor temperature of 35 °CDB/24 °CWB.

Heating: Indoor temperature of 20 °CDB / 15 °CWB,and outdoor temperature of 7 °CDB/6 °CW B.

Pipe length : 7.5 m, Height difference : 0 m.(Outdoor unit - Indoor unit)

DRAIN PIPE

MATERIAL

SIZE

WEIGHT

AIR

CIRCULATION

COOL/HEAT

m3/h

dB(A)

INDOOR

OUTDOOR

r.p.m

COMPRESSOR

FAN TYPE x Q'ty

Rows x Stages

PIPE

SIZE

mm

CONNECTION METHOD

MAX HEIGHT

MAX LENGTH

OUTDOOR

FAN MOTOR OUTPUT

W

STARTING METHOD

FAN SPEED

COOL/HEAT

NOISE LEVEL

(SOUND

PRESSURE)

COOL/HEAT

OUTDOOR

INDOOR

Coil

CURRENT

MOISTURE REMOVAL

INDOOR

TYPE

INDOOR

kW/kW

A

EER

COP

STARTING CURRENT

INDOOR

OUTDOOR

HEATING

kW

INPUT POWER

TYPE

MODEL NAME

POWER SOURCE

COOLING

RATED/MAX

AVAILABLE VOLTAGE RANGE

CAPACITY

RATED/MAX

DIMENSIONS

H × W × D

OUTDOOR

Coil

Fin

HEAT

EXCHANGER

TYPE

Fin

mm

Rows x Stages

mm

CASING COLOR

NET

GROSS

mm

kg(lbs)

NET /

GROSS

REMOTE CONTROLLER TYPE

TYPE

REFRIGERANT OIL

REFRIGERANT

TYPE

OPERATION(OUTDOOR)

°C

Page 8

2 . DIMENSIONS

R410A

INVERTER

Large Ceiling type

Page 9

02-01

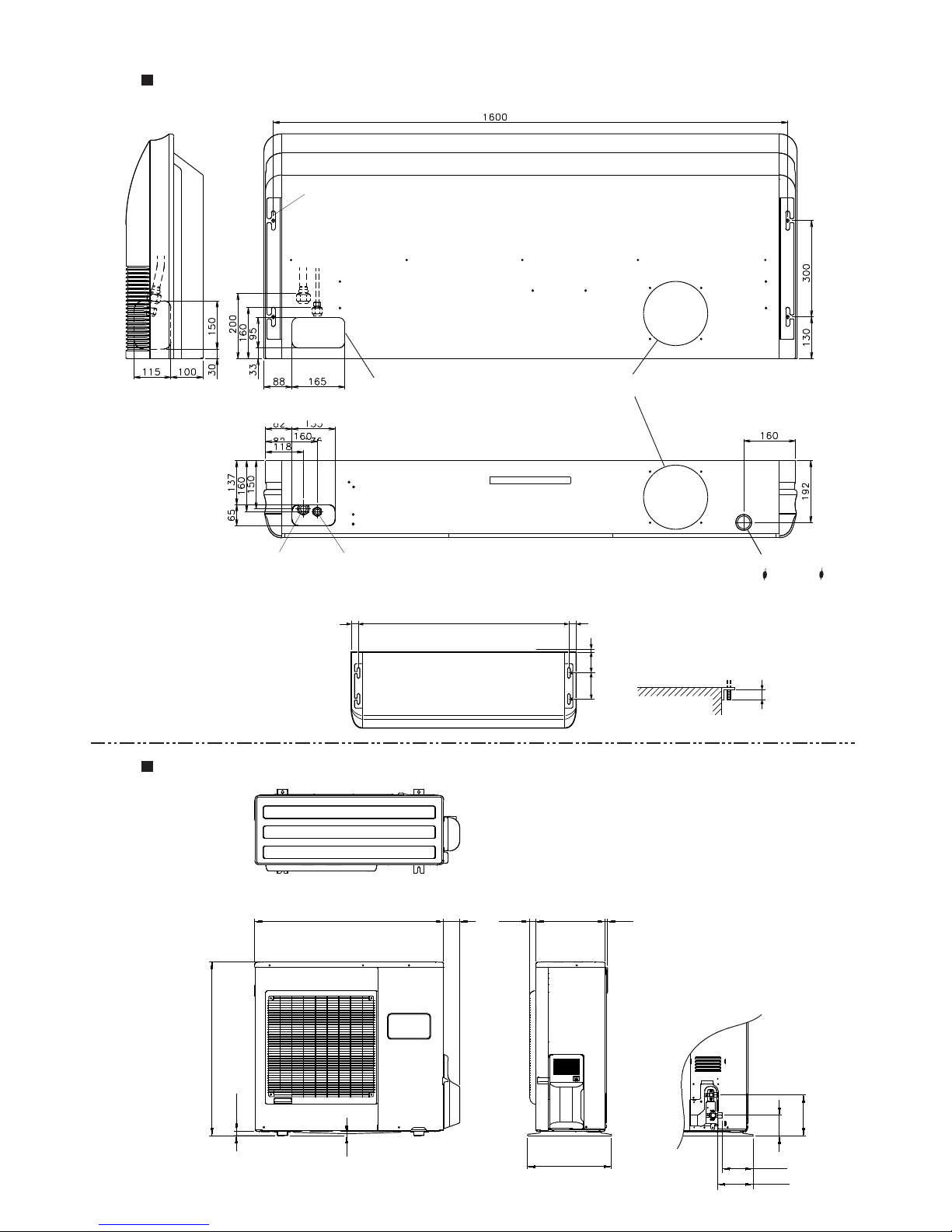

MODEL : AB*30/ 36LBAG

MODEL : AO*30/ 36LMBWL

(Unit : mm)

900

830

99

196

21

9

77

31 330

400

170

147

12

Top view

Front view

Side view

2. DIMENSIONS

Rear view

Side view

Bottom view

(Unit : mm)

30 30

Suspension bolt pitch

1,600

INDOOR UNIT (TOP VIEW)

10

155

300

INDOOR UNIT

Suspension bolt

should extend

outward 30 to 75.

Refrigerant piping

flare connection (Gas)

Refrigerant piping

flare connection (Liquid)

Drain piping connection

(Drain pipe : I.D. 22 O.D. 25.6)

Knock out hole for fresh air

Knock out hole for refrigerant piping

Hole for lifting bolt

(Use M10 screw bolt)

Page 10

02-02

MODEL : AB*45LBAG

MODEL : AO*45LJBYL

(Unit : mm)

900

1290

77 31

21

9

400

151

99

196

170

12

330

Top view

Side view

Front view

Rear view

Side view

Bottom view

(Unit : mm)

30 30

Suspension bolt pitch

1,600

INDOOR UNIT (TOP VIEW)

10

155

300

INDOOR UNIT

Suspension bolt

should extend

outward 30 to 75.

Refrigerant piping

flare connection (Gas)

Refrigerant piping

flare connection (Liquid)

Drain piping connection

(Drain pipe : I.D. 22 O.D. 25.6)

Knock out hole for fresh air

Knock out hole for refrigerant piping

Hole for lifting bolt

(Use M10 screw bolt)

Page 11

3 . REFRIGERANT SYSTEM DIAGRAM

R410A

INVERTER

Large Ceiling type

Page 12

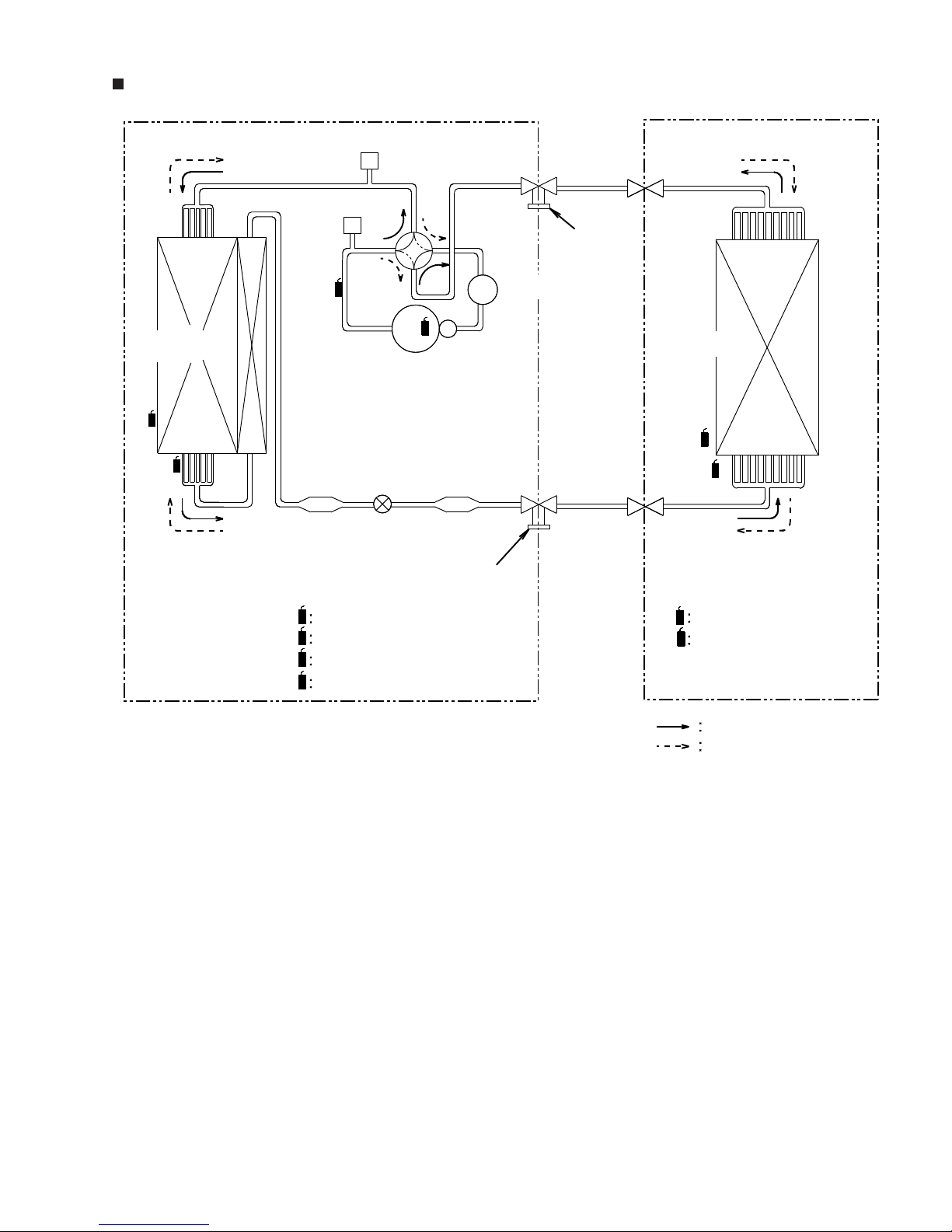

03-01

Ø15.88mm(5/8")

Ø9.52mm(3/8")

MODEL : AB*30/ 36LBAG / AO*30/ 36LMBWL

Outdoor Unit Indoor Unit

CONDENSER

HIGH PRESSURE

SWITCH

PRESSURE

CHECK VALVE

THO

THO

THC

THPO

THD

THR

THR

THPI

THPI

THD

THC

THPO

COMPRESSOR

ACCUMULATOR

EXPANSION

VALVE

STRAINERSTRAINER

4-Way

valve

THERMISTOR(DISCHARGE TEMP.)

THERMISTOR(ROOM TEMP.)

THERMISTOR(PIPE TEMP.)

THERMISTOR(OUTDOOR TEMP.)

THERMISTOR(PIPE TEMP.)

THERMISTOR(COMP TOP TEMP.)

Refrigerant Pipe

Refrigerant Pipe

COOL

HEAT

EVAPOLATOR

Charging Valve

Charging Valve

3. REFRIGERANT CIRCUIT

Page 13

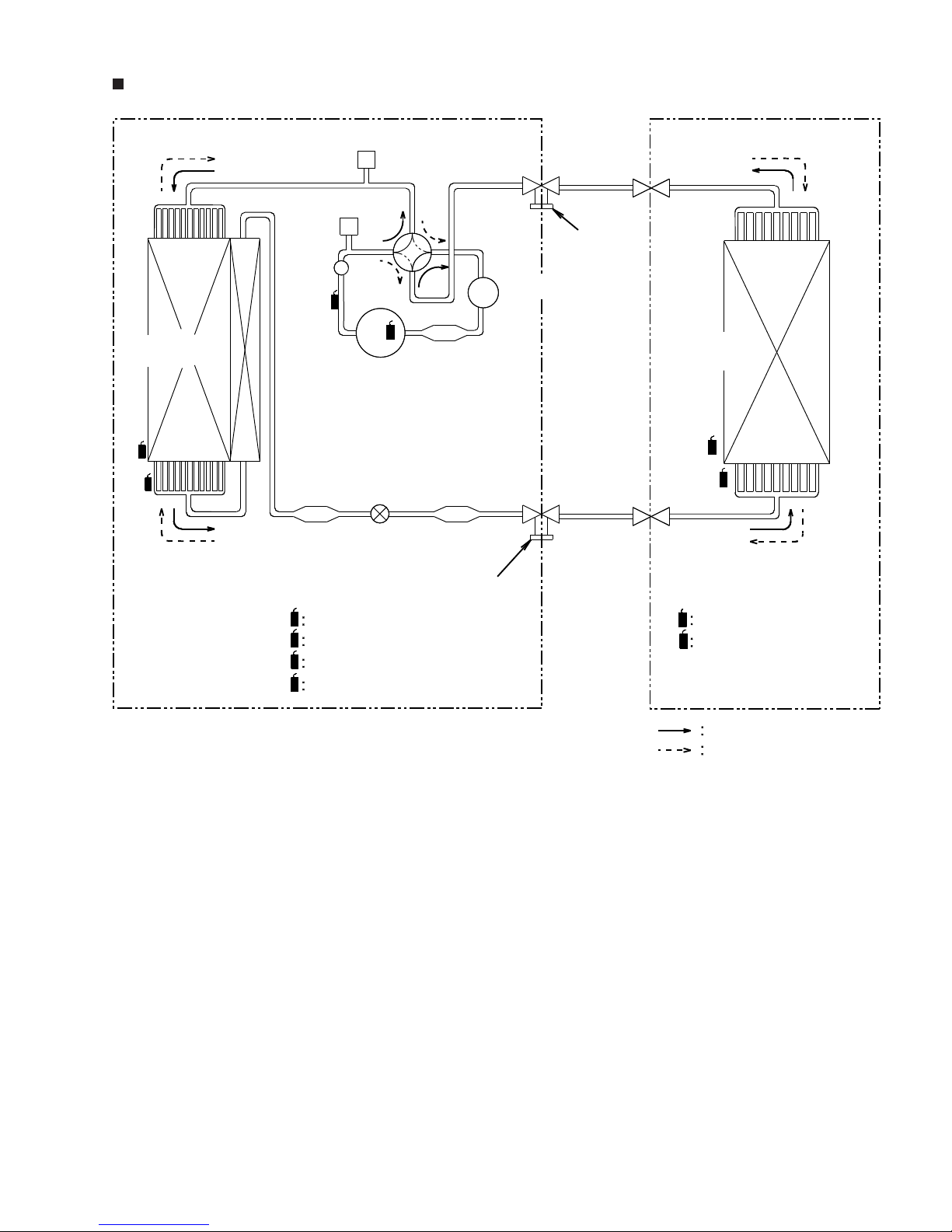

03-02

Ø15.88mm(5/8")

Ø9.52mm(3/8")

MODEL : AB*45LBAG / AO*45LJBYL

Outdoor Unit Indoor Unit

CONDENSER

HIGH PRESSURE

SWITCH

PRESSURE

CHECK VALVE

THO

THO

THC

THPO

THD

THR

THPI

THR

THPI

THD

THC

THPO

COMPRESSOR

ACCUMULATOR

EXPANSION

VALVE

STRAINER

STRAINER STRAINER

4-Way

valve

THERMISTOR(DISCHARGE TEMP.)

THERMISTOR(ROOM TEMP.)

THERMISTOR(PIPE TEMP.)

THERMISTOR(OUTDOOR TEMP.)

THERMISTOR(PIPE TEMP.)

THERMISTOR(COMP TOP TEMP.)

Refrigerant Pipe

Refrigerant Pipe

COOL

HEAT

EVAPOLATOR

Charging Valve

Charging Valve

MUFFLER

Page 14

4 . CIRCUIT DIAGRAM

R410A

INVERTER

Large Ceiling type

Page 15

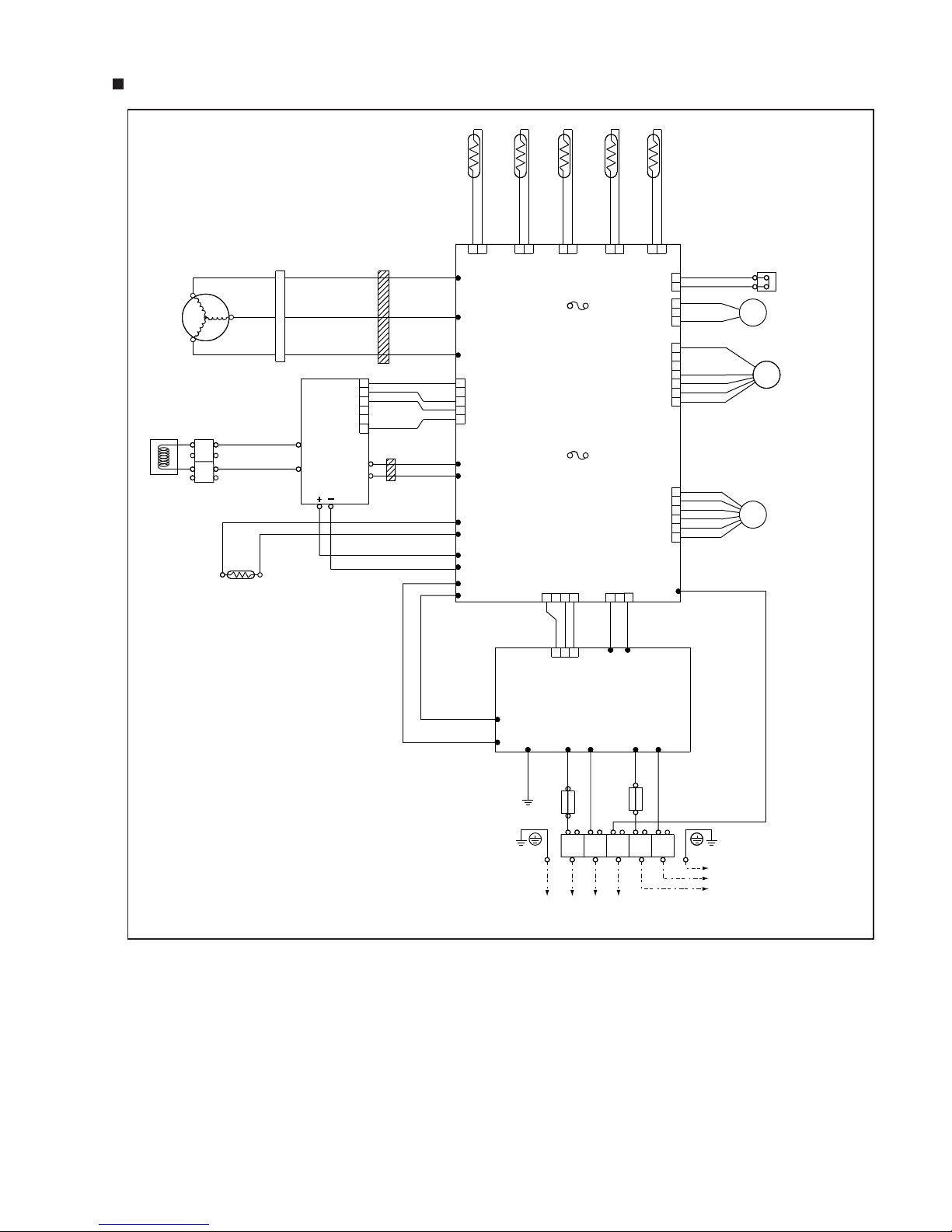

04-01

MODEL : AB*30/ 36/ 45LBAG

THERMISTOR(PIPE TEMP.)

THERMISTOR(ROOM TEMP.)

FAN MOTOR

CAPACITOR

FAN MOTOR

STEP MOTOR

(UP / DOWN)

STEP MOTOR

(LEFT / RIGHT)

BROWN

RED

GRAY

GRAY

BLACK

WHITE

WHITE

RED

BLACKBLACK

BLACK

ORANGE

YELLOW

WHITE

BROWN

RED

RED

ORANGE

YELLOW

WHITE

WHITE

BLACK

BLUE

BLUE

PURPLE

PURPLE

GRAY

GRAY

BROWN

RED

ORANGE

YELLOW

WHITE

GREEN

WHITE

WHITE

1

2

3

4

5

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

1

2

1

2

3

4

5

1

2

3

1

2

3

1

2

3

2

1

3

1

2

3

4

5

1

2

3

4

5

1 2

1 2 1 2

3 2 1

1 2

CN4

CN10

CN15CN13CN16CN5

CN11

CN7CN6

CN1

CN201

CN8

CONTROL BOARD

DISPLAY BOARD

N

L

FILTER

BOARD

Use T 3.15A 250V

Fuse on F101

4. CIRCUIT DIAGRAM

TO OUTDOOR UNIT

TERMINAL

3 2 1

Page 16

04-02

MODEL : AO*30/ 36LMBWL

CN21

U

W305

V

W304

W

W303

CN22 CN23 CN26 CN25

CN37

CN30

CN800

CN27

CN1

CN1

TM102

TM101

CN34

W9

W6W3 W7 W4 W5

W8

CN407

W12

W13

W21

W22

W200

W16

W17

W10

W11

1 2

1 2 3 4 1 2 3

1 2 3

1 2 1 2 1 2 1 2

BLACK

BLACK

WHITE

WHITE

GREEN

1 2(N) 3 L N

TO INDOOR UNIT

TO POWER SUPPLY

1

2

1

2

3

1

2

3

4

5

6

7

1

2

3

4

5

6

1

2

3

4

5

1

2

3

4

5

6

FUSE

F4 T 5A 250V

FUSE

F2 T 3.15A 250V

PRINTED

CIRCUIT

BOARD

(MAIN)

RED

BLACK

BLACK

BROWN

BLUE

BLACK

BROWN

BLACK

BLACK

WHITE

WHITE

YELLOW

YELLOW

BROWN

BROWN

BLUE

ORANGE

RED

RED

RED

RED

BLACK

WHITE

WHITE

BLACK

BLACK

ORANGE

BROWN

RED

REDRED

WHITEWHITE

BLACKBLACK

ORANGE

YELLOW

YELLOW

BLUE

WHITE

BROWN

ORANGE

RED

BLACK

BROWN

RED

4WV

FM

EV

HIGH PRESSURE SW

SOLENOID

COIL

EXPANSION

VALVE COIL

FAN MOTOR

THERMISTOR

(HEAT SINK)

THERMISTOR

(DISCHARGE)

THERMISTOR

(PIPE)

THERMISTOR

(OUTDOOR)

THERMISTOR

(COMPRESSOR)

PRINTED CIRCUIT

BOARD (FILTER)

EARTH

FUSE

10A

FUSE

25A

POSISTOR

TERMINAL

CHOKE

COIL

ACTIVE

FILTER

MODULE

L1

L2

P

N

EMI FILTER

2T

EMI FILTER

1T

CONNECTOR

COMPRESSOR

U

W

V

Page 17

04-03

MODEL : AO*45LJBYL

CN21

U

W305

V

W304

W

W303

CN22 CN23 CN26 CN25

CN37

CN30

CN800

CN801

CN27

CN1

CN1

TM102

TM101

CN34

W9

W6W3 W7 W1 W2

W8

CN407

W14

W15

W107

W108

W200

1 2

1 2 3 4 1 2 3

1 2 3

1 2 1 2 1 2 1 2

BLACK

BLACK

GRAY

RED

BLACK

GRAY

BLACK

WHITE

WHITE

GREEN

1 2(N) 3 L N

1

2

1

2

3

1

2

3

4

5

6

7

1

2

3

4

5

6

7

1

2

3

4

5

6

1

2

3

4

5

1

2

3

4

5

6

F4 T 5A 250V

F2 T 3.15A 250V

PRINTED

CIRCUIT

BOARD

(MAIN)

RED

BLACK

BLACK

BROWN

BLUE

BLACK

BROWN

BLACK

BLACK

WHITE

WHITE

YELLOW

YELLOW

BROWN

BROWN

BLUE

ORANGE

RED

RED

BLACK

WHITE

YELLOW

BROWN

RED

RED

RED

BLACK

WHITE

WHITE

WHITE

WHITE

BROWN

YELLOW

BLUE

VIOLET

BLACK

ORANGE

BROWN

RED

REDRED

WHITEWHITE

BLACKBLACK

ORANGE

YELLOW

ORANGE

BLACK

BROWN

RED

4WV

FM

FM

EV

HIGH PRESSURE SW

SOLENOID

COIL

EXPANSION

VALVE COIL

FAN MOTOR 1

FAN MOTOR 2

THERMISTOR

(HEAT SINK)

THERMISTOR

(DISCHARGE)

THERMISTOR

(PIPE)

THERMISTOR

(OUTDOOR)

THERMISTOR

(COMPRESSOR)

PRINTED CIRCUIT

BOARD (FILTER)

EARTH

FUSE

10A

POSISTOR

CHOKE

COIL

ACTIVE

FILTER

MODULE

L1

L2

P

N

EMI FILTER

1T

EMI FILTER

2T

EMI FILTER

2T

EMI FILTER

2T

EMI FILTER

3T

EMI FILTER

1T

CONNECTOR

COMPRESSOR

U

W

V

TERMINAL

TERMINAL

DIODE BRIDGE

RELAY

FUSE

TO INDOOR UNIT

TO POWER SUPPLY

Page 18

5 . DESCRIPTION OF EACH

CONTROL OPERATION

R410A

Large Ceiling type

INVERTER

Page 19

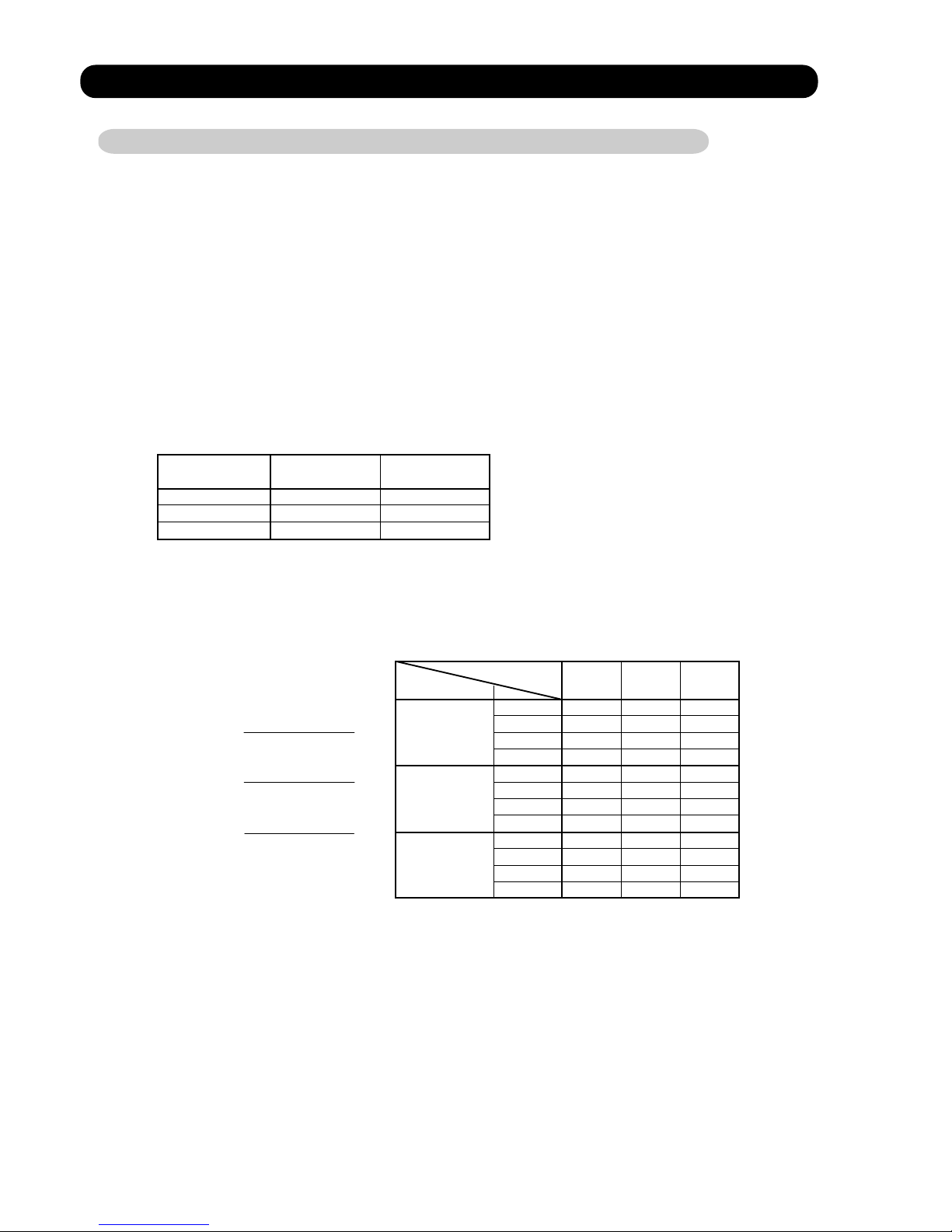

5-1. COOLING OPERATION

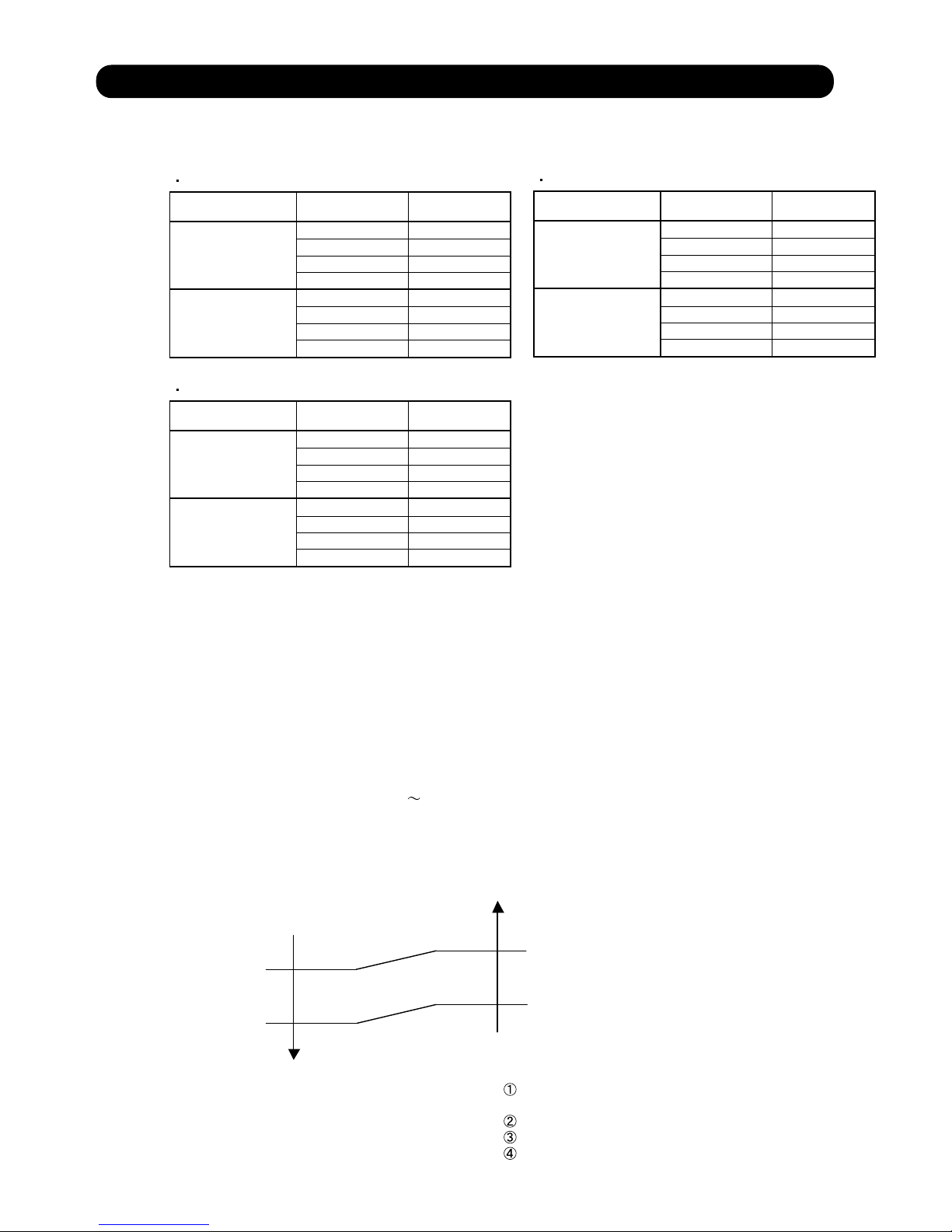

5-1-1 COOLING CAPACITY CONTROL

A sensor (room temperature thermistor) built in the indoor unit will usually perceive

difference or variation between a set temperature and present room temperature, and

controls the operation frequency of the compressor.

* If the room temperature is 2 degC higher than a set temperature,

the compressor operation frequency will attain to maximum performance.

* If the room temperature is 2 degC lower than a set temperature, the compressor

will be stopped.

* When the room temperature is between +2 degC to -2 degC of the setting temperature,

the compressor frequency is controlled within the range shown in Table1.

However, the maximum frequency is limited in the range shown in Figure 1 based on the

fan speed mode and the outdoor temperature.

minimum

frequency

maximum

frequency

20Hz

20Hz

20Hz

90Hz

90Hz

92Hz

AB*30LBAG

AB*36LBAG

AB*45LBAG

Outdoor air

temperature

A zone

31°C

B zone

C zone

D zone

Hi Me Lo

A zone

90Hz

70Hz

65Hz

55Hz

90Hz

92Hz

72Hz

60Hz

60Hz

75Hz

70Hz

65Hz

45Hz

75Hz

70Hz

65Hz

55Hz

72Hz

60Hz

45Hz

75Hz

70Hz

60Hz

60Hz

53Hz

53Hz

65Hz

70Hz

65Hz

70Hz

55Hz

72Hz

60Hz

65Hz

55Hz

55Hz

B zone

C zone

D zone

A zone

B zone

C zone

AB*30LBAG

D zone

A zone

B zone

C zone

AB*36LBAG

D zone

AB*45LBAG

19°C

11°C

( Table 1 : Compressor Frequency Range )

( Fig. 1 : Limit of Maximum Frequency based on Outdoor Temperature )

05-01

Fan speed mode

Page 20

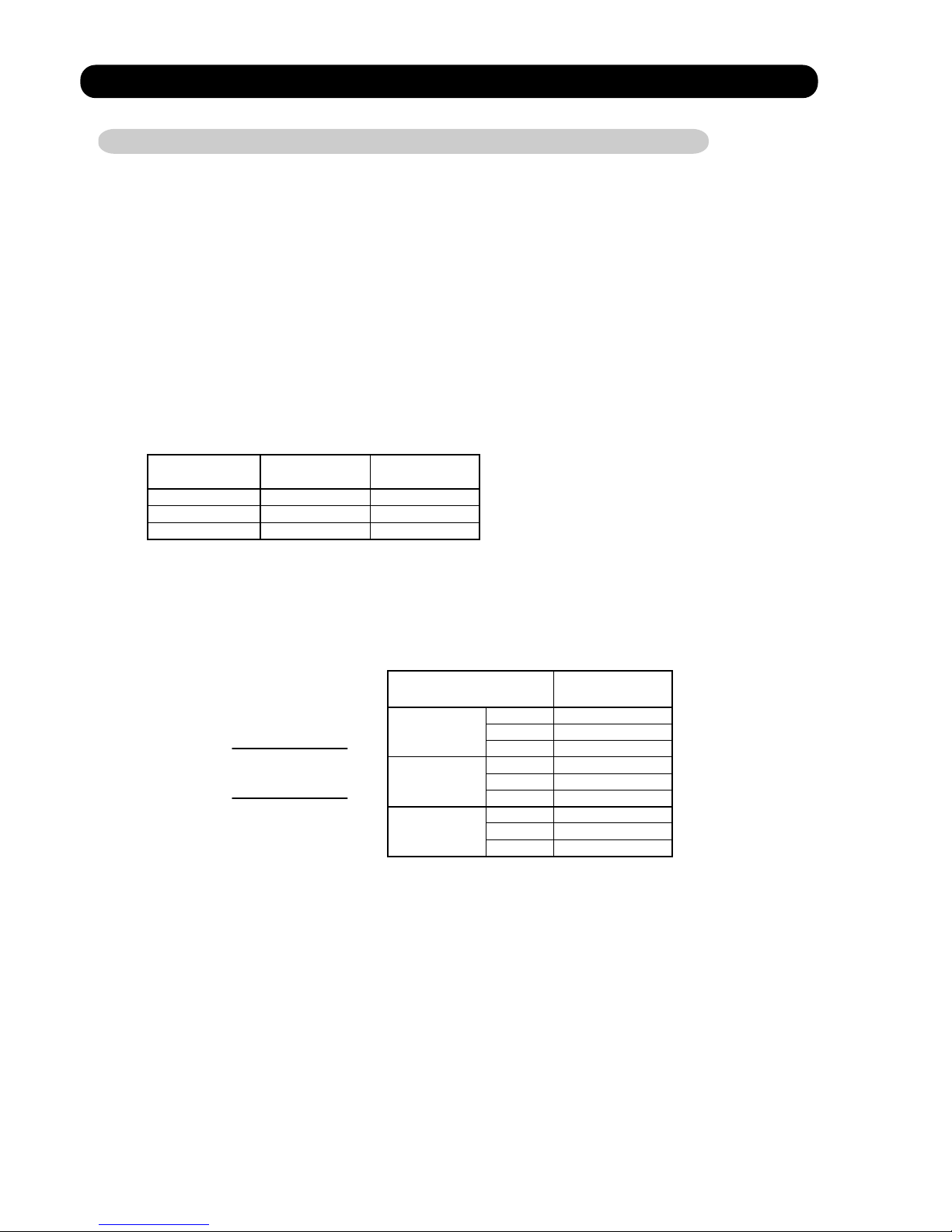

5-2. HEATING OPERATION

5-2-1 HEATING CAPACITY CONTROL

A sensor (room temperature thermistor) built in the indoor unit will usually perceive

difference or variation between a set temperature and present room temperature, and

controls the operation frequency of the compressor.

* If the room temperature is lower 3 degC than a set temperature,

the compressor operation frequency will attain to maximum performance.

* If the room temperature is higher 2 degC than a set temperature, the compressor

will be stopped.

* When the room temperature is between +2 degC to -3 degC of the setting temperature,

the compressor frequency is controlled within the range shown in Table2.

However, the maximum frequency is limited in the range shown in Figure 2 based on

the outdoor temperature.

( Table 2 : Compressor Frequency Range )

( Fig.2 : Limit of Maximum Frequency based on Outdoor Temperature )

05-02

Outdoor air

temperature

C zone

B zone

A zone

A zone

95Hz

90Hz

80Hz

95Hz

90Hz

80Hz

92Hz

90Hz

80Hz

B zone

C zone

A zone

B zone

C zone

A zone

B zone

C zone

AB*30LBAG

AB*36LBAG

AB*45LBAG

16°C

12°C

Limit of Maximum

Frequency

minimum

frequency

maximum

frequency

20Hz

20Hz

20Hz

95Hz

95Hz

92Hz

AB*30LBAG

AB*36LBAG

AB*45LBAG

Page 21

5-3. DRY OPERATION

5-3-1 INDOOR UNIT CONTROL

The compressor rotation frequency shall change according to set temperature and room

temperature variation which the room temperature sensor of the indoor unit has detected

as shown in the Table 3.

Room

temperature

Room

temperature

Compressor ON

Ts+1.5 degC

Ts+1 degC

Compressor OFF

Compressor

ON

ON

OFF

Indoor fan

air flow mode

Air flow mode : Lo

OFF

30 5 30 120 5 (sec)

180 180

( Table 3 : Compressor frequency )

( Fig.3 : Compressor Control based on Room Temperature )

( Fig.4 : Indoor Fan Control )

05-03

Operating frequency

45Hz

45Hz

30Hz

AB*30LBAG

AB*36LBAG

AB*45LBAG

Ts : Setting temperature

Page 22

5-4. AUTO CHANGEOVER OPERATION

When the air conditioner is set to the AUTO mode by remote control, operation starts in the optimum

mode from among the HEATING, COOLING and MONITORING modes. During operation, the

optimum mode is automatically swiched in accordance with temperature changes. The temperature

can be set between 18°C and 30°C in 1 degC steps.

When operation starts, only the indoor fan is operated for 1 minute. (Air flow mode: S- Lo)

After 1 minute, depends on the room temperature and outdoor unit's operarion mode,

the operation mode is selected in accordance with the table below.

( Table 4 : Operation mode selection table )

When COOLING was selected at , the same operation as COOLING OPERATION is performed.

When HEATING was selected at , the same operation as HEATING OPERATION is performed.

When the compressor was stopped for 6 consecutive minutes by the temperature control function

after the COOLING or HEATING operation mode was selected at above, operation is switched

to MONITORING and the operation mode is selected again.

1

1

2

3

1

4

1

05-04

Room temperature :TR

Operation mode

TR > Ts +2 degC

Ts +2 degC > TR

=

=

Ts +2 degC > TR > Ts -2 degC

Cooling

Monitoring

Heating

Ts : Setting temperature

Page 23

5-5. INDOOR FAN CONTROL

1. Fan speed

( Table 5 : Indoor Fan Speed )

Operation mode Air flow mode Speed (rpm)

Hi 1000

850

650

200

Me

Lo

Heating

S-Lo

2. FAN OPERATION

The airflow can be switched in 4 steps such as AUTO, LOW, MED, HIGH, while the indoor

fan only runs.

05-05

Hi 1000

850

650

200

Me

Lo

Cooling

S-Lo

Operation mode Air flow mode Speed (rpm)

Hi 1100

750

900

900

200

Me

Lo

Heating

S-Lo

Hi 1100

750

200

Me

Lo

Cooling

S-Lo

Operation mode Air flow mode Speed (rpm)

Hi 1200

1100

950

200

Me

Lo

Heating

S-Lo

Hi 1200

1100

950

200

Me

Lo

Cooling

S-Lo

3. COOLING OPERATION

Switch the airflow [AUTO], and the indoor fan motor will run according to a room temperature,

as shown in Figure 5.

On the other hand, if switched in [HIGH] [LOW], the indoor motor will run at a constant airflow of [COOL]

operation modes LOW, MED, HIGH,as shown in Table 5.

( Fig.5 : Airflow change - over ( Cooling : AUTO ) )

When the room

temperature rises

When the room

temperature drops

TR : Room temperature

Ts : Setting temperature

TR-Ts > 2 degC

=

1 degC > TR-Ts

2 degC > TR-Ts > 1 degC

=

TR-Ts > 3 degC

=

2 degC > TR-Ts

3 degC > TR-Ts > 2 degC

=

HIGH mode

MED mode

LOW mode

*1

*1 : Contains a condition to the following

When the operation mode is set to AUTO mode

at the start of operation.

When the setting temperature was changed.

When the operation mode was changed to COOLING mode.

When the airflow mode was changed to AUTO mode.

When [AUTO] is selected, the indoor fan motor runs LO and OFF at 1 minute intervals.

AB*30LBAG

AB*36LBAG

AB*45LBAG

Page 24

05-06

4. HEATING OPERATION

When the airflow is set to [AUTO], the indoor fan

motor operates [MED] mode.

Then the indoor fan motor will run according

to a room temperature, as shown in Figure 6.

On the other hand, if switched in [HIGH] [LOW],

the indoor motor will run at a constant airflow

of [COOL] operation modes LOW, MED, HIGH,

as shown in Table 5.

5. COOL AIR PREVENTION CONTROL (Heating mode)

6. DRY OPERATION

Refer to the Figure 4.

During the dry mode operation, the fan speed setting can not be changed.

47°C

41°C

SETTING

FAN MODE

LO mode

S-LOW mode

33°C

30°C

30°C

Indoor heat exchanger

temperature

Indoor heat exchanger

temperature

Indoor heat exchanger

temperature

The maximum value of the indoor fan speed is set as shown in Figure 7, based on the detected

temperature by the indoor heat exchanger sensor on heating mode.

( Fig.6 : Airflow change - over ( Heating : AUTO ) )

( Fig.7 : Cool Air Prevention Control )

Hold

Go down one-step

Go up one-step

Page 25

5-6. OUTDOOR FAN CONTROL

1. Outdoor Fan Motor

Following table shows the fan speed of the outdoor unit.

*

The outdoor fan speed changs in the range mentioned avobe depending on the compressor

frequency and outdoor temperature.

(When the compressor frequency and outdoor temperature increase, the outdoor fan speed

also changes to the higher speed.

When the compressor frequency and outdoor temperature decrease, the outdoor fan

speed also changes to the lower speed.)

*

AB*45LBAG has two fan motors.

*

For AB*30/ 36LBAG

It runs at 500rpm for 20 seconds after starting up the outdoor fan.

When the outdoor heat exchanger tenperature is lower than 2°C,

the fan speed switches to 900rpm on heating mode.

For AB*45LBAG

It runs at 500rpm for 20 seconds after starting up the outdoor fan.

When the outdoor heat exchanger tenperature is lower than 2°C,

the fan speed switches to 850rpm(Upper fan) and 750rpm(Lower fan) on heating mode.

*

05-07

( Table 6 : Fan speed of the outdoor unit )

850/ 780/ 400/ 250/ 170 rpm

850/ 780/ 400/ 350/ 300 rpm

780/ 750/ 350/ 0 rpm

900/ 780/ 400/ 250/ 170 rpm

850/ 780/ 350/ 200/ 150 rpm

780/ 750/ 350/ 200/ 150 rpm

Cooling

Heating

AB*36LBAG

AB*30LBAG

AB*45LBAG

Upper fan

Lower fan

Page 26

5-7. LOUVER CONTROL

1. VERTICAL LOUVER CONTROL

Each time the button is pressed, the air direction range will

change as follows:

Use the air direction adjustments within the ranges shown above.

The vertical airflow direction is set automatically as shown, in accordance with the type of operation selected.

Cooling / Dry / Fan mode Horizontal flow

Heating mode Downward flow

(Function Range)

(Fig.8 : Air Direction Range)

(Operation Range)

1-2. SWING OPERATION

When the swing signal is received from the remote controller, the vertical louver starts to swing.

The range of swing depends on the set airflow direction.

When the indoor fan is either at S-Lo or Stop mode, the swinging operation is interrupted

and the louver stops at the memorized position.

05-08

The indoor fan motor starts after the louver reaches to the setting position.

At the start of operation if the setting louver position is or ,the setting position is set to or

after the louver moves from totally-enclosed position to . (Positioning Control)

( Stop mode means Operation stop.)

1

2

3

4

1 2 3 4

1

2

3

4

1

4

Cooling / Dry mode

Heating mode

Fan mode

1 2 3

1

1

2

2

3

4

(Swinging Range)

Airflow direction set

Range of swing

1

1

2

2

3

4

4

4

to

to

to

to

Page 27

2. HORIZONTAL LOUVER CONTROL

Each time the button is pressed, the air direction range will

change as follows:

Cooling / Dry mode

Heating mode

Fan mode

Use the air direction adjustments within the ranges shown above.

The horizontal airflow direction is set automatically on after initialization.

(Function Range)

(Fig.9 : Air Direction Range)

(Operation Range)

2-1. SWING OPERATION

When the swing signal is received from the remote controller, the horizontal louver starts to swing.

The range of swing depends on the set airflow direction.

When the indoor fan is either at S-Lo or Stop mode, the swinging operation is interrupted

and the louver stops at the memorized position.

05-09

( Stop mode means Operation stop.)

1 2 3 4 5

1 2 334 5

1

3

4

5

2

1

2

1

3

1

2

5

5

3

4

3

4

5

(Swinging Range)

Airflow direction set

Range of swing

to

to

to

to

1 5

to

Page 28

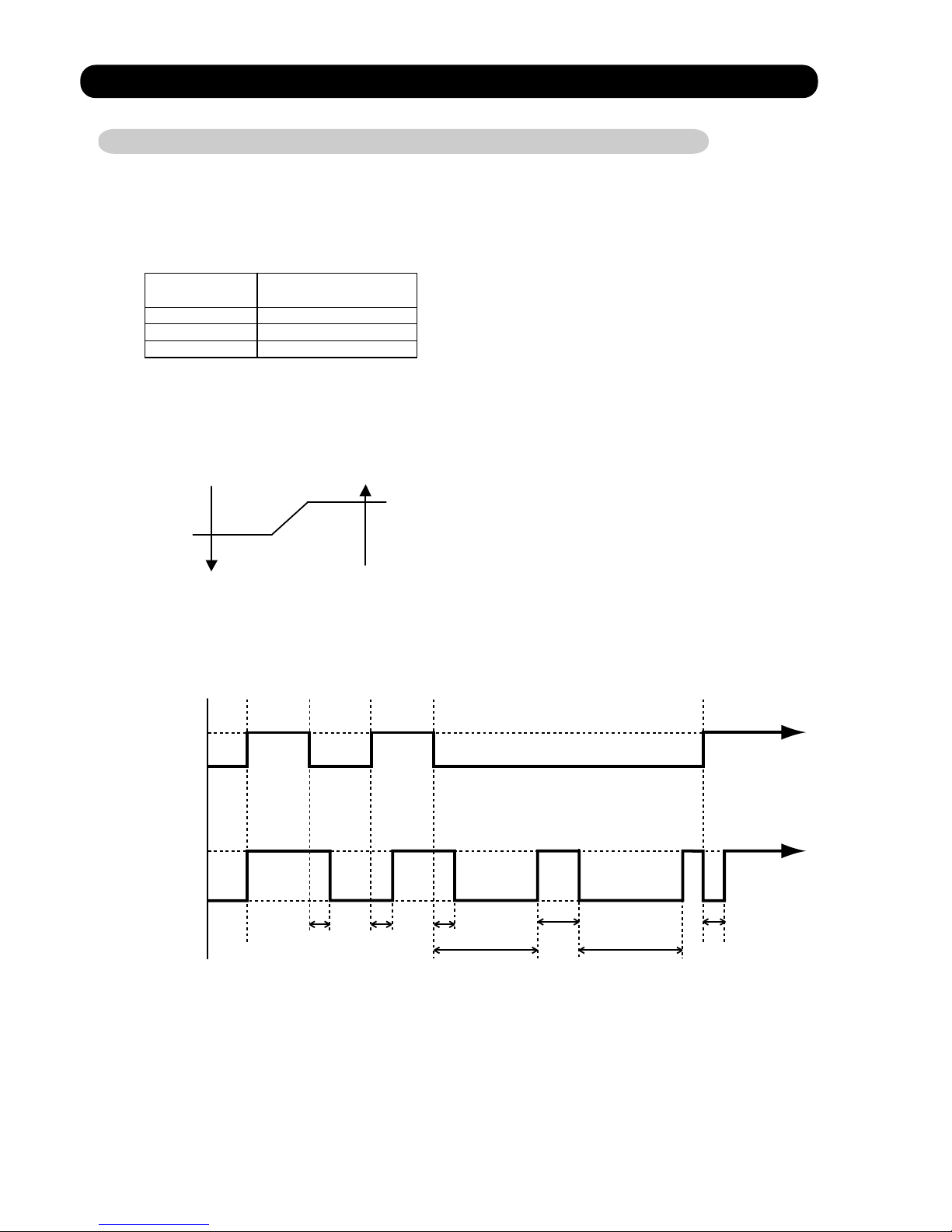

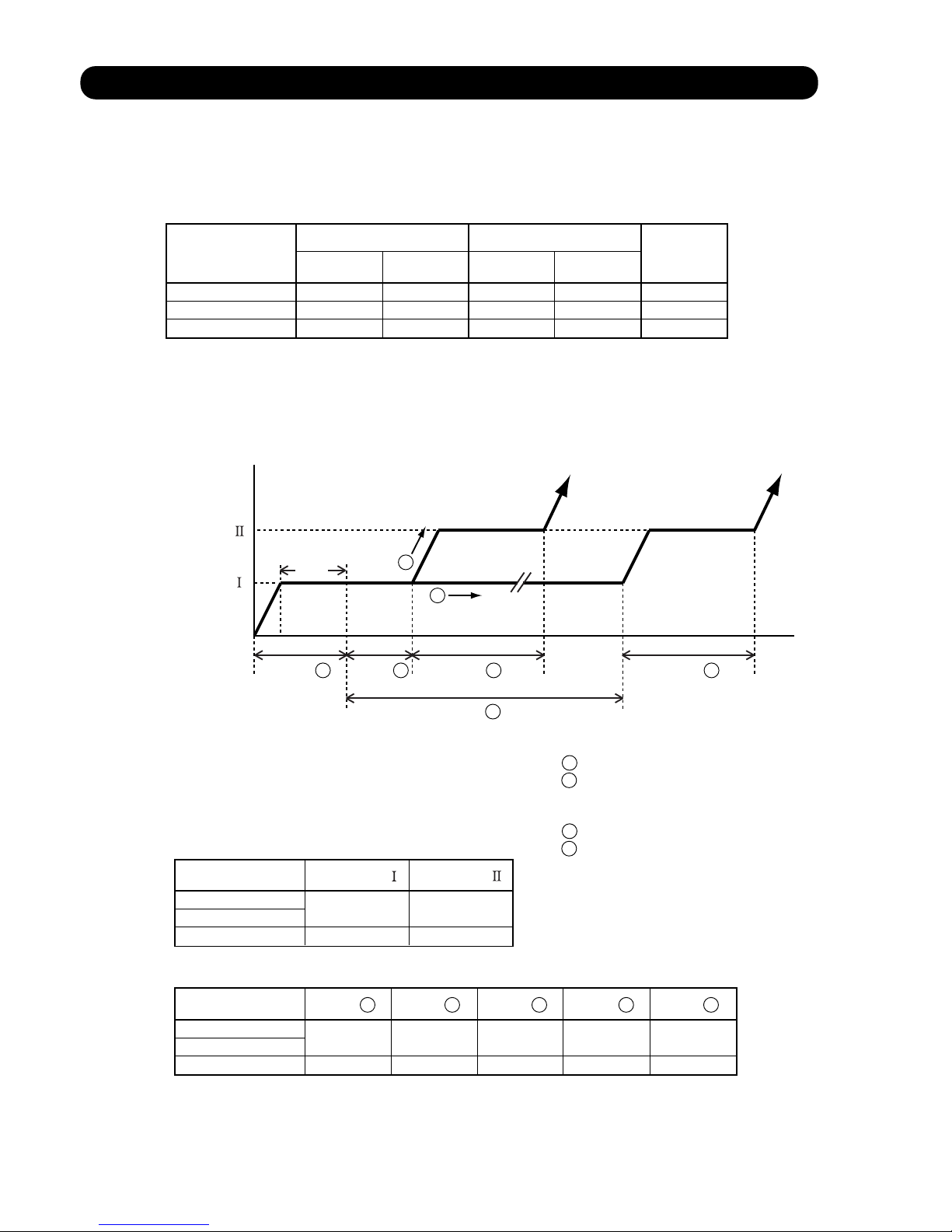

5-8. COMPRESSOR CONTROL

1. OPERATION FREQUENCY RANGE

The operation frequency of the compressor is different based on the operation mode as

shown in Table 7.

Cooling Heating

Min Max Min Max

Dry

(Table 7 : Compressor Operation Frequency Range)

2. OPERATION FREQUENCY CONTROL AT START UP

The compressor frequency soon after the start-up is controlled as shown in Figure 10.

(Fig.10 : Compressor Control at Start-up)

Frequency

Frequency

05-10

AB*30LBAG

20Hz

20Hz

20Hz

90Hz

90Hz

92Hz

AB*36LBAG

AB*45LBAG

20Hz

20Hz

20Hz

95Hz

95Hz

92Hz

45Hz

45Hz

30Hz

Time A Time B Time C

Time E

Time D

Hold

1

2

(Frequency)

(Time)

Frequency

Frequency

AB*30LBAG

AB*36LBAG

AB*45LBAG

180sec

60sec

120sec

120sec

720sec

180sec

80sec

180sec

180sec

720sec

40Hz

56Hz

56Hz

70Hz

AB*30LBAG

AB*36LBAG

AB*45LBAG

Time A Time B Time C Time D Time E

1 Discharge pipe temp. > 30°C

2 Discharge pipe temp. < 30°C

1 Discharge pipe temp. > 35°C

2 Discharge pipe temp. < 35°C

=

=

For AB*30/ 36LBAG

For AB*45LBAG

Page 29

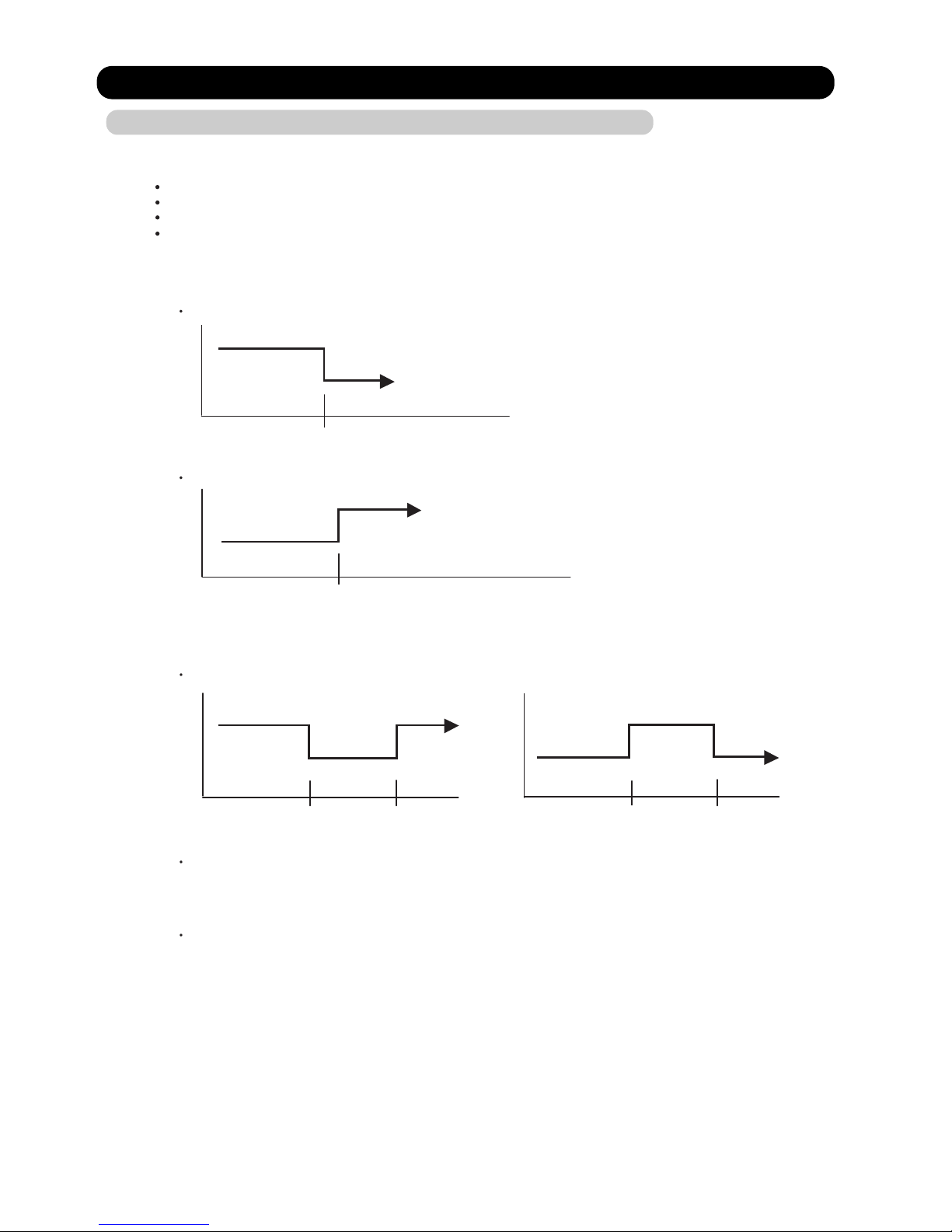

5-9. TIMER OPERATION CONTROL

1. ON / OFF TIMER

OFF timer : When the clock reaches the set time, the air conditioner will be turned off.

Operation mode

Stop mode

Set time of timer

ON timer : When the clock reaches the set time, the air conditioner will be turned on.

Operation mode

Stop mode

Set time of timer

2. PROGRAM TIMER

05-11

AR- JW1

5-9-1 Wireless Remote Controller

ON / TIMER

OFF / TIMER

PROGRAM TIMER

SLEEP TIMER

The program timer allows the OFF timer and ON timer to be used in combination one time.

Operation mode

Operation will start from the timer setting (either OFF timer or ON timer)

whichever is closest to the clock's current timer setting.

The order of operations is indicated by the arrow in the remote control unit's display.

SLEEP timer operation cannot be combined with ON timer operation.

Stop mode

Stop mode

Stop mode

Operation mode

Operation mode

Set time

Set time Set time Set time

Page 30

05-12

3. SLEEP TIMER

If the sleep timer is set, the room temperature is monitored and the operation is stopped automatically.

If the operation mode or the set temperature is change after the sleep timer is set, the operation is

continued according to the changed setting of the sleep timer from that time ON.

Set temperature rises

( Ts : Set temperature )

Stop of operation

Set temperature lowers

( Ts : Set temperature )

Ts

Stop of operation

In the cooling operation mode

When the sleep timer is set, the setting temperature is increased 1 degC.

It increases the setting temperature another 1 degC after 1 hour.

After that, the setting temperature is not changed and the operation is stopped at the time

of timer setting.

Ts

+1degC

+2degC

-2degC

-1degC

-4degC

-3degC

Set

60min

In the heating operation mode

When the sleep timer is set, the setting temperature is decreased 1 degC.

It decreases the setting temperature another 1 degC every 30 minutes.

Upon lowering 4 degC, the setting temperature is not changed and the operation stops

at the time of timer setting.

Set

30min

30min

30min

Page 31

5-10. ELECTRONIC EXPANSION VALVE CONTROL

The most proper opening of the electronic expansion valve is calculated and controlled under the

present operating condition based on the following values.

The compressor frequency, the temperatures detected by the discharge temperature sensor

and the outdoor temperature sensor.

The pulse range of the electronic expansion valve control is between 50 to 480 pulses.

At the time of supplying the power to the outdoor unit, the initialization of the electronic

expansion valve is operated (1000 pulses are input to the closing direction).

5-11. TEST OPERATION CONTROL

The compressor won't enter operation status for 3 minutes after the compressor is stopped,

even if any operation is given.

At the time when the air conditioner is switched from the cooling mode to heating mode,

the compressor is stopped, and the 4-way valve is switched in 3 minutes later

after the compressor stopped.

When the power was interrupted by a power failure, etc. during operation, the operation contents

at that time are memorized and when power is recovered, operation is automatically resumed with

the memorized operation contents.

When the power is interrupted and recovered during timer operation, timer operation is canceled,

but only setting time is memorized.

[Operation contents memorized when the power is interrupted]

Operation mode

Set temperature

Set air flow

Timer mode and timer time

Air flow Direction

Swing

Thermistor detected position

5-12. PREVENT TO RESTART FOR 3 MINUTES ( 3 MINUTES ST )

5-13. 4-WAY VALVE EXTENSION SELECT

5-14. AUTO RESTART

05-13

Under the condition where the air conditioner runs, short two metal contacts under the battery

compartment lid, and the test operation control mode will appear.

During test running, the operation lamp and timer lamp of the air conditioner body twinkle simultaneously.

Set the test operation mode, and the compressor will continue to run regardless of whether the room

temperature sensor detects.

The test operation mode is released if 60 minutes have passed after setting up the test operation.

With Wireless Remote Controller

Page 32

05-14

AB*30LBAG

AB*36LBAG

AB*45LBAG

5-17. DEFROST OPERATION CONTROL

1. CONDITION OF STARTING THE DEFROST OPERATION

2. CONDITION OF THE DEFROST OPERATION COMPLETION

Defrost operation is released when the conditions become as shown in Table 10.

(Table 10 : Defrost Release Condition)

Release Condition

Outdoor heat exchanger temperature sensor value is higher than 12°C or

Compressor operation time has passed 15 minutes.

5-15. PUMP DOWN ( Refrigerant collecting operation )

When the product is stopped:

1. Press the PUMP DOWN switch (SW2) on the outdoor unit.

(The LED on the outdoor unit circuit board flickers every 1second.)

2. The pump down operation (cooling operation) begins right away.

After operation starts, close the 3-way valve (liquid).

3. After 2-3minutes, operation stops. Close the 3-way valve (gas) within 1minute after operations stops.

4. The LED will go out 3minutes after it stops. Disconnect the power supply after confirming that the LED has gone out.

When the product is operating:

1. Press the PUMP DOWN switch (SW2) on the outdoor unit. The LED on the outdoor unit circuit board flickers

every 1second, and operation stops.

At this point, recovery has not been completed, so do not close the 2 and 3-way valves.

2. The pump down operation (cooling operation) begins after 3minutes.

Close the 3-way valve (liquid) after operation starts.

3. After 2-3minutes, operation stops. Close the 3-way valve (gas) within 1minute after operations stops.

4. The LED will go out 3minutes after it stops. Disconnect the power supply after confirming that the LED has gone out.

Perform the following procedures to collect the refrigerant when moving the indoor unit or the outdoor unit.

When the outdoor heat exchanger temperature is lower than Operation temperature (Refer to Table 8) and the heating

operation has

been stopped for 3 hours, power is applied to the compressor and the compressor is heated.

(By heating the compressor, warm air is quickly discharged when operation is started.)

When operation was started, and when the outdoor temperature rises to Release temperature or greater,

preheating

is over.

5-16. COMPRESSOR PREHEATING

(Table 8 : Preheating Operation / Release Temperature)

Before 24 hour After 24 hour

Operation

temperature

Operation

temperature

Release

temperature

Release

temperature

3°C 7°C 0°C 4°C

The defrost operation starts when the outdoor heat exchanger temperature sensor detects

the temperature lower than the values shown in Table 9.

(Table 9 : Condition of starting Defrost Operation)

Less than 6 min. *1

or 10min. *2

AB*30LBAG

AB*36LBAG

AB*45LBAG

*3. Outdoor temp. > -1°C

*4. Outdoor temp. < -1°C

*2. Compressor stop time: Below 20min. Select 6min.

Above 20min. Select 10min.

After 6 min. *1

or 10min. *2

Compressor integrating

operation :Less than 45min.

Compressor integrating

operation :45min and over

-8°C *3

-10°C *4

-8°C *3

-10°C *4

Does not operate

Does not operate

=

Outdoor temp. Outdoor heat exchanger

temp.

Outdoor heat

exchanger temp.

12 degC

-20°C

*1. It means contiguous operation time.

Page 33

3. Defrost Flow Chart

The defrosting shall proceed by the integrating operation time and

outdoor heat exchanger temperature as follows.

05-15

(Not defrosted for 6 or 10 minutes)

3 sec later Compressor OFF

3 sec later Outdoor fan motor OFF

28 sec later 4-way valve OFF

34 sec later compressor ON

(Frequency : 92 Hz)

Outdoor fan motor : Low

Compressor : 30 Hz

4-way valve OFF

Outdoor fan motor OFF

Compressor ON

(Frequency : 92 Hz)

Heating operation start : Compressor ON

Defrost start

Defrost Indicator:

[Operation lamp]

9 sec ON / 1 sec OFF

Outdoor heat exchanger temperature: Over 12°C

or

Compressor ON time: Over 15 minutes

Defrost end

Compressor integrating

operation:

45 minutes and over

Outdoor heat exchanger

temperarure:

Below -10°C

Outdoor heat exchanger

temperarure:

Below -8°C

Outdoor temp. > -1°C

=

Outdoor temp. < -1°C

Compressor integrating

operation:

45 minutes and over

Outdoor temp Outdoor heat exchanger

temperature:

Above 12 degC

Outdoor heat exchanger

temperarure:

Below -10°C

Outdoor heat exchanger

temperarure:

Below -20°C

Outdoor heat exchanger

temperarure:

Below -8°C

Outdoor temp. > -1°C

=

Outdoor temp. < -1°C

AB*30/ 36LBAG

AB*45LBAG

Defrost start

Defrost Indicator:

[Operation lamp]

9 sec ON / 1 sec OFF

5

Page 34

05-16

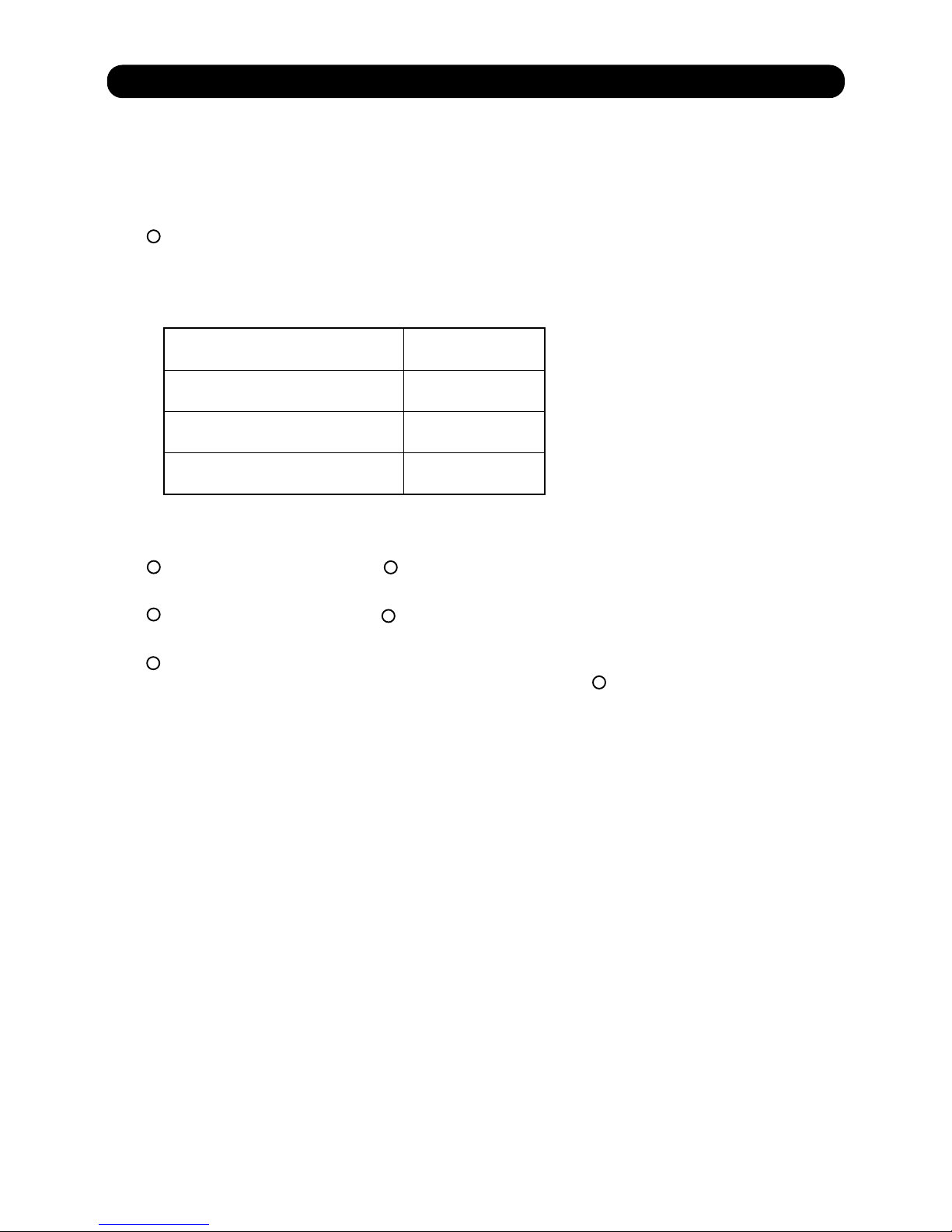

5-18. MANUAL AUTO OPERATION

If MANUAL AUTO Button is set, the operation is controlled as shown in Table 11.

If the remote control is lost or battery power dissipated, this function will work without the remote control.

OPERATION MODE

Auto changeover

FAN CONT. MODE

Auto

TIMER MODE

Continuous (No timer setting available)

SETTING TEMP.

23°C

SETTING LOUVER

Standard

SWING

OFF

(Table 11 : Manual auto operation )

5-19. VARIOUS PROTECTIONS

1. DISCHARGE GAS TEMPERATURE OVER RISE PREVENTION CONTROL

The discharge gas thermosensor (discharge thermistor : Outdoor side) will detect discharge gas

temperature.

When the discharge temperature becomes higher than Temperature ,the compressor frequency

is decreased 10 Hz, and it continues to decrease the frequency for 10 Hz every 120 seconds until

the temperature becomes lower than Temperature .

When the discharge temperature becomes lower than Temperature ,the control of the compressor

frequency is released.

When the discharge temperature becomes higher than Temperature ,the compressor stops.

When the discharge temperature becomes lower than Temperature ,the compressor operates.

(Table 12 : Discharge Temperature Over Rise Prevention Control / Release Temperature)

Temperature Temperature Temperature Temperature

AB*30LBAG

AB*36LBAG

AB*45LBAG

110°C 105°C 120°C 80°C

Page 35

2. CURRENT RELEASE CONTROL

05-17

[ Heating ]

AB*45LBAG

T0 > 12°C

T0 < 12°C

=

T0: Outdoor temperature

780 rpm850 rpm 350 rpm 200 rpm 150 rpm

23.5A / 23.0A 20.0A / 19.5A

23.5A / 23.0A 23.5A / 23.0A 23.5A / 23.0A 23.5A / 23.0A

20.0A / 19.5A 15.0A / 14.5A 12.0A / 11.5A

Outdoor unit fan speed

[ Cooling ]

AB*45LBAG

T0 > 45°C

=

T0: Outdoor temperature

780 rpm850 rpm 400 rpm 350 rpm 300 rpm

12.0A / 11.5A

20.0A / 19.5A 20.0A / 19.5A

23.5A / 23.0A

12.0A / 11.5A 12.0A / 11.5A

18.0A / 17.5A

20.0A / 19.5A

12.0A / 11.5A

18.0A / 17.5A

12.0A / 11.5A

15.0A / 14.5A

18.0A / 17.5A

Outdoor unit fan speed

[ Cooling ]

AB*30LBAG

AB*36LBAG

T0 > 45°C

T0 < 0°C

T0 < 13°C

45°C > T0 > 38°C

=

=

45°C > T0 > 38°C

=

38°C > T0 > 31°C

=

31°C > T0 > 25°C

=

25°C > T0 > 19°C

=

19°C > T0 > 13°C

=

13°C > T0 > 0°C

=

19°C > T0 > 13°C

=

38°C > T0 > 19°C

=

T0: Outdoor temperature

780 rpm850 rpm 400 rpm 250 rpm 170 rpm

10.0A / 9.5A

14.0A / 13.5A 14.0A / 13.5A

15.0A / 14.5A

18.0A / 17.5A

10.0A / 9.5A 10.0A / 9.5A

15.0A / 14.5A

7.0A / 6.5A

12.0A / 11.5A

5.5A / 5.0A

7.0A / 6.5A

9.5A / 9.0A

Outdoor unit fan speed

The compressor frequency is controlled so that the outdoor unit input current does not exceeds

the current limit value that was set up with the outdoor temperature.

The compressor frequency returns to the designated frequency of the indoor unit at the time

when the frequency becomes lower than the release value.

(Table 13 : Current Release Operation Value / Release Value)

[ Heating ]

AB*30LBAG

AB*36LBAG

T0 > 16°C

T0 < 5°C

16°C > T0 > 5°C

=

=

T0: Outdoor temperature

780 rpm900 rpm 400 rpm 250 rpm 170 rpm

15.0A / 14.5A 15.0A / 14.5A

18.0A / 17.5A 18.0A / 17.5A 18.0A / 17.5A18.0A / 17.5A

13.0A / 12.5A 10.0A / 9.5A 8.0A / 7.5A

18.0A / 17.5A

Outdoor unit fan speed

Page 36

3. ANTI-FREEZING CONTROL (Cooling mode)

The compressor frequency decreases on cooling mode when the indoor heat exchanger

temperature sensor detects the temperature lower than 3°C.

Then, the anti-freezing control is released when it becomes higher than 6°C.

(Fig.11 : Anti-freezing Protection Operation / Release Temperature)

4. COOLING PRESSURE OVER RISE PROTECTION

When the outdoor unit heat exchange sensor temperature rises to 70.5°C or greater,

the compressor is stopped and error display is indicated.

Indoor heat exchange

temperature

5. HIGH TEMPERATURE RELEASE CONTROL ( HEATING MODE )

On heating mode, the compressor frequency is controlled as following based on the

detection value of the indoor heat exchanger temperature sensor.

(Fig.12 : Heating Overload Protection Control)

05-18

63°C

54°C

50°C

Compressor is OFF

The compressor frequency is

decreased 10Hz every 60seconds.

Compressor OFF :

Release of protection

Compressor ON :

The compressor frequency is

increased 10Hz every 60seconds.

Hold

Indoor heat exchange

temperature

3°C

6°C

12°C

The compressor frequency is

decreased 10Hz every 120seconds.

Compressor OFF : Hold

Compressor ON : Release of protection

Hold

Release of protection

When the compressor frequency becomes lower than minimum frequency,

the compressor operates at minimum frequency.

If the indoor heat exchanger temperature sensor detects the temperature lower than

3°C after 2minutes upon operating the compressor at minimum frequency,

the compressor stops.

Page 37

6 . REFRIGERANT CAUTION -R410A-

R410A

INVERTER

Large Ceiling type

Page 38

6-1. R410A TOOLS

Gauge manifold . . . . . . . . . . . . . . . . . . . . . (Fig.4-1)

Since the normal pressure is high, the connection pipe size

is also different.

Charge hose . . . . . . . . . . . . . . . . . . . . . . . (Fig.4-2)

Refrigerant cylinder . . . . . . . . . . . . . . . . . (Fig.4-3)

Confirm the refrigerant type before charging. Always

charge liquid-phase refrigerant.

Electronic balance for refrigerant

charging . . . . . . . . . . . . . . . . . . . . . . . . . . . (Fig.4-4)

Electronic balance is recommended as in the case of

R410A.

Vacuum pump with adapter to prevent

reverse flow . . . . . . . . . . . . . . . . . . . . . . . .(Fig.4-5)

Conventional pump can be used.

Vacuum holder . . . . . . . . . . . . . . . . . . . . . (Fig.4-6)

Conventional pump can be used if adapter for preventing

vacuum pump oil from flowing back is used.

Gas leakage tester . . . . . . . . . . . . . . . . . . (Fig.4-7)

Exclusive for HFC

Refrigerant cleaner . . . . . . . . . . . . . . . . . . (Fig.4-8)

Brown paint as designated by the ARI, USA

Flare tool . . . . . . . . . . . . . . . . . . . . . . . . . . (Fig.4-9)

Torque wrench . . . . . . . . . . . . . . . . . . . . (Fig.4-10)

Refrigerant recovering

equipment (Collector) . . . . . . . . . . . . . . (Fig.4-11)

The type which can be used for any refrigerant is available

Nitrogen cylinder . . . . . . . . . . . . . . . . . . . (Fig.4-12)

This prevents an oxide film from forming in the pipe silveralloy brazing work by turning the air out of the pipe and

preventing the inside combustion.

Safety charger . . . . . . . . . . . . . . . . . . . . . (Fig.4-13)

It is always compulsory to change the liquid, because

R410A is a mixed refrigerant and there is some fear that a

mixing ratio changes. In order to avoid the refrigerant from

returning to the compressor in a liquid state, the refrigerant

can be charged instead of giving a load to the compressor

with a safety charger.

Control valve . . . . . . . . . . . . . . . . . . . . . . (Fig.4-14)

The control valve prevents the refrigerant from spouting

when it is removed, as the charging hose side and the service port side are possible to open and close at the same

time.

Thermistor vacuum gauge . . . . . . . . . . . (Fig.4-15)

To remove moisture from the refrigerating cycle completely, it is necessary to perform appropriate vacuum drying.

For that reason, vacuum conditions can be confirmed certainly.

Vacuum valve . . . . . . . . . . . . . . . . . . . . . (Fig.4-16)

This valve builts in a check valve, and it is easily possible

to vacuum a refrigerating cycle or check for degree of vacuum with it.

TOOLS AND EQUIPMENT (R410A)

Gauge Manifold

R410A

R22, R407C

High

pressure

gauge

Compond

gauge

Port size

-0.1 5.3

Mpa

-0.1 3.8

Mpa

1/2UNF

5/16"

-0.1 3.5

Mpa

-0.1 1.7

Mpa

7/16UNF

1/4"

*

1

Charge hose

R410A

R22, R407C

Normal

pressure

Port size

5.1 Mpa

27.4 Mpa

1/2UNF

3.4 Mpa

17.2 Mpa

7/16UNF

*

2

Breaking

pressure

This air conditioner used R410A.

For installation and servicing, it is necessary to prepare the

tools and machines that are different from the previous

refrigerant.

Mark shows the exclusive use for R410A.

The specification of the gauge is different due

to higher pressure.

The size of connection pipe is also different to

prevent mis-use.

The shape of flare is different for

high pressure condition.

06-01

Gas charging

Vacuuming

Piping work

Pressure control and

Circuit switching

Charge hose

Fig.4-2

Outdoor unit

Electronic charging

scale Fig.4-4

Vacuum pump Fig.4-5

Thermistor vacuum gauge Fig.4-15

Vacuum

Valve Fig.4-16

Safety charger Fig.4-13

Control Valve

Fig.4-14

Vacuum holder Fig.4-6

Leakage tester Fig.4-7

Cleaner Fig.4-8

Collector Fig.4-11

Nitrogen Cylinder

Fig.4-12

Torque wrench

Fig.4-10

Flare tool

Fig.4-9

Gauge manifold

Fig.4-1

Fig.4-3

Refrigerant cylinder

Vacuum control

Low pressure

High pressure

side

side

6. REFRIGERANT CAUTION -R410A-

Page 39

6-2. PRECAUTION FOR INSTALLATION

06-02

Precaution for installation

The pipe must be properly pressure rated for R410A

The pipe must be an air-conditioning refrigerant pipe.

Flare and flare nuts

Diameter 1/4 ” (6.35mm) 3/8 ” (9.52mm) 1/2” (12.7mm)

Refrigerant

R410A

R22

/R407C

R410A R410A

A 9.1 9.0 13.2 13.0 16.6

16.2

B 13 12 20 15 13 20

C 12 11 16 12.5 19 16

Nut width 17 22 26 24

Always use the flare nut that is packed

with the product.

Do not use existing (for R22) pipes

•

Be sure to use new pipes when replacing

conventional (R22) model with HFC

(R407C, R410A) model.

•

If you use existing pipes, it may cause

resolution of compressor oil by remaining

mineral oil.

3/8” (15.88mm)

R410A

22

29

19.7

25

R22

/R407C

R22

/R407C

R22

/R407C

19.4

23

20

27

3/4” (19.05mm)

R410A

24

36

24

29

R22

/R407C

23.7

29

24

Material

Nominal diameter

(in)

1/4" 3/8" 1/2" 5/8" 3/4" 7/8" 1 1/8" 1 1/4" 1 1/2"1 3/8"1"

6.35 9.52 12.70 15.88 19.05 22.22 28.58 31.75 38.1034.9225.40

Outside diameter

(mm)

Wall thickness

(mm)

0.8 0.8 0.8 1.0 1.2 1.0 1.0 1.1 1.31.21.0

1) Allowable tensile stress 33 (N/mm );

>

=

2

2) Allowable tensile stress 61 (N/mm ); 3) Design pressure 4.2MPa.

>

=

2

JIS H3300-C1220T-H or equivalent

2)

COPPER

JIS H3300-C1220T-O or equivalent

1)

COPPER

3)

Pipe diameter, recommended material and wall thickness

A

C

B

Page 40

Be careful not to mix moisture and

contamination into the pipe

Moisture and contamination

in the pipe is a cause of

trouble.

Air purge

Always use a

vacuum pump

to purge air.

Refrigerant charge

Do it always from the liquid phase

side.

Don't charge from the gas phase side.

Compressor oil is changed

Be careful to handle synthetic oil, since it

resolves easily by moisture and

contamination.

Don't mix new synthetic oil and mineral oil.

It may cause trouble.

We developed new synthetic oil, since HFC

refrigerant doesn't dissolve in mineral (for R22)oil.

06-03

Page 41

6-3. PRECAUTION FOR SERVICING

Feature 1 Refrigerant oil is different from before.

Refrigerant oil for

New Refrigerant

Synthetic oil

Ether

Esther

Different point from

previous one

Previously it was

mineral oil.

Absorbent character

is high.

Contamination occurs

when mixed withe other

kind of oil.

Use the gauge manifold and charge hose

for New Refrigerant(HFC), which shall

be segregated from those of R22.

Attach the stop valve on the vacuum pump

and avoid the oil from reverse frow.

It is necessary to use the vacuum pump

which can obtain the high vacuum condition.

Precaution on Tools

Feature 2 New Refrigerant has Approx 1.6 times higher pressure than previous refrigerant.

R410A

High Pressure

Different point from

previous one

Diameter of Service port

has been changed from

1/4 Flare to 5/16 Flare.

It requires the gauge manifold and charge

hose exclusively for R410A.

It requires the flare tool and torque wrench

that satisfies New JIS standard.

Precaution on Tools

R410A R22

1.6 times of R22.

JIS standard of flare

process It became lager

To keep thethickness of

copper tube.

(1/4,3/3=more than 0.8mm)

Previous flare tool + flare adapter can be used as well.

06-04

Page 42

6-4. NEW REFRIGERANT R410A

What is HFC ?

Phase-out schedule of HCFC

according to Montreal protocol

1996 20102000 2004 2015 2020 2030

60

40

20

100

(Year)

(%)

80

(HCFC consumption of 1989) +

(CFC consumption of 1989) x 2.8%

65%

35%

10%

0.5%

started control

only service use

total abolition

100% =

0

*

06-05

Page 43

Ozone Layer depleting mechanism

CFC

CFCl

2

Cl Ozone

(O3)

O

2

ClO

Cl

sunbeam

What is CFC and HCFC?

CFC : Chloro-Fluoro-Carbon

High ODP( ozone depletion potential ) chemical compound, including chlorine. (ODP:0.6-1.0)

For example : R12 (for refrigerator and car air-conditioner)

Low ODP chemical compound, including chlorine and hydrogen. (ODP:0.02-01)

HCFC : Hydro-Chloro-Fluoro-Carbon

For example : R22 (for air-conditioner)

R134a (for Car air conditioner)

HFC3 : Hydro-Fluoro-Carbon

R407C (for air conditioner)

Refrigerant characteristics

R22

Composition

(wt%)

R22

(100)

Boiling Point

- 40.8

Behavior ---

Pressure at 54.5

C

(kPa)

2,151

Temperature Glide

(deg)

0

ODP 0.055

R407C

R32/R125/R134a

(23/25/52)

- 43.6

zeotrope

2,262

5.4

0

R410A

R32/R125

(50/50)

- 51.4

near azeotrope

3,406

0.11

0

06-06

Page 44

Summary of R407C and R410A characteristics

Pressure (Mpa) Temp ( C)

2.20 37.9

2.25 38.7

2.30 39.6

2.35 40.5

2.40 41.3

2.45 42.1

2.55 43.8

2.60 44.6

2.65 45.3

2.70 46.1

2.75 46.8

2.80 47.6

2.85 48.3

2.90 49.0

2.95 49.8

3.00 50.5

3.05 51.2

3.10 51.9

3.15 52.6

3.20 53.2

3.25 53.9

3.30 54.6

3.35 55.3

3.40 55.9

3.45 56.5

3.50 57.1

2.55 57.8

3.60 58.4

3.65 59.0

3.70 59.6

3.75 60.2

3.80 60.8

3.85 61.4

3.90 52.0

3.95 62.5

4.00 63.1

4.05 63.6

4.10 64.2

4.15 64.8

Temp ( C) Pressure (Mpa)

39 2.27

40 2.32

41 2.38

42 2.44

44 2.57

45 2.63

46 2.69

47 2.76

48 2.83

49 2.90

51 3.04

52 3.11

53 3.18

54 3.26

56 3.41

57 3.49

58 3.57

59 3.65

61 3.82

62 3.90

63 3.99

64 4.08

Desighed pressure of R410A refrigerant

< Pressure Temp >

Relation between R410A condensing temperature and saturated pressure.

< Temp Pressure >

Advantage

Disadvantage

Suitable for

R410A

higher system

performance

Near-Azeotropic

refrigerant

1.6 times higher

(difficult to design against

pressure resistance)

Small Air-Conditioners

pressure than R22

R407C

similar pressure as R22

(possible to design

large equipment)

Zeotropic refrigerant

(handle with care)

Large Air-Conditioners

*

05-07

Page 45

OIL

• Use new synthetic oils such as ester because HFC series refrigerant has less solubility with mineral oils

conventionally used for R22.

• As these new synthetic oils are easily influenced by moisture and dusts, they must be treated more care-

fully than the conventional lubricating oils.

CAUTION

For installation/servicing, take more precautions than the case of conventional refrigerants to avoid moisture

and dusts entering the refrigerant circuit. Also, for storing parts, more precautions must be taken.

2, 3-WAY VALVE

• Review material O-ring, valve core seal for securing suitability with oil.

CAUTION

Check if the valve is suitable for the refrigerant (model) when replacing.

CAUTION

Check if the compressor is suitable for the refrigerant (model) when replacing. Complete welding within 15minutes

after opening the cap when replacing.

COMPRESSOR

• Use better grade of material for sliding parts for securing good lubrication of sliding part as HFC

refrigerant does not contain chloride.

• Review insulating materials

• Increase pressure resistance strength

CAUTION

During storage, due care must be taken so that foreign matters such as dust and water do not enter.

HEAT EXCHANGER

• Review the water,contaminants controlling level

• Use thinner tube to increase pressure Increase capacity for resistance strength (only outdoor unit)

improving performance

CAUTION

Check if the valve is suitable for the refrigerant (model) when replacing.

4-WAY VALVE

• Review materials

6-5. DEFFERENCE FROM CONVENTIONAL MODEL (R22) AND PRECAUTIONS

06-08

Check Valve

Other Piping

CAUTION

Check if the valve is suitable for the refrigerant (model) when replacing.

• Review materials

Change shape of pipe ends to increase pressure resistance strength.

•

•

Review the water, contaminants controlling level.

Review thickness of pipes.

•

CAUTION

During storage, due care must be taken so that foreign matters such as dust and water do not enter.

Page 46

7 . TROUBLE SHOOTING

R410A

INVERTER

Large Ceiling type

Page 47

7. TROUBLESHOOTING

07-01

7-1 ERROR DISPLAY

7-1-1 INDOOR UNIT DISPLAY

Communication error

(Serial reverse transfer error)

Room temperature sensor open

Room temperature sensor short-circuited

Indoor heat exchanger temperature

sensor open

Indoor heat exchanger temperature

sensor short-circuited

Outdoor heat exchanger temperature

sensor error

Outdoor temperature sensor error

Outdoor discharge pipe temperature

sensor error

Indoor EEPROM abnormal (Model No.)

Indoor fan motor abnormal

Outdoor unit fan motor error

Outdoor communication signal error

(Forward transfer signal error)

Pressure switch error

Active filter module (AFM) error

CT error

IPM error

Compressor rotor location cannot detect

(permanent stop)

Compressor temperature sensor error

8

3

4

2

5

6

7

9

10

11

12

13

14

15

16

17

0.5sec0.5sec

5sec

ON

OFF

0.1sec 0.1sec

ON

OFF

1. ERROR DISPLAY

2. ERROR DISPLAY METHOD

Error Contents

2 times blink

2 times blink

3 times blink

3 times blink

5 times blink

6 times blink

5 times blink

3 times blink

4 times blink

5 times blink

8 times blink

9 times blink

10 times blink

11 times blink

12 times blink

13 times blink

14 times blink

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

Trouble

shooting

Vertical

Swing LED

Timer LED

Operation

LED

Please refer the blinking pattern as follows.

Continuous

blink

Continuous

blink

Continuous

blink

Continuous

blink

Continuous

blink

Continuous

blink

Continuous

blink

Continuous

blink

Continuous

blink

Continuous

blink

Continuous

blink

Continuous

blink

Continuous

blink

Continuous

blink

Continuous

blink

Continuous

blink

Continuous

blink

Continuous

blink

Continuous

blink

Continuous

blink

Continuous

blink

Continuous

blink

LED Continuous Blink : 0.1sec ON / 0.1sec OFF blinking

LED Blink (2 to 14 times) : 0.5sec ON / 0.5sec OFF blinking

(RED) (GREEN) (ORANGE)

Page 48

07-02

Operation LED Blinking Pattern

Normal operation Continuously lighting

5sec ON / 1sec OFF

Protected operation

1sec ON / 1sec OFF

Pump down operation

0.5sec 0.5sec 2sec

ON

OFF

1. ERROR DISPLAY

3. NORMAL OPERATION DISPLAY

2. ERROR DISPLAY METHOD

Outdoor LED Blink (1 to 16 times) 0.5sec ON / 0.5sec OFF blinking

7-1-2 OUTDOOR UNIT DISPLAY

Error contents

LED Flashing

Pattern

Display

priority

Trouble

shooting

Outdoor communication signal error

(Forward transfer signal error)

1 time blink

2 times blink

3 times blink

4 times blink

7 times blink

8 times blink

9 times blink

12 times blink

13 times blink

14 times blink

15 times blink

1

2

3

4

5

6

7

8

9

10

11

Outdoor heat exchanger temperature sensor error

Outdoor temperature sensor error

Outdoor discharge pipe temperature sensor error

Outdoor unit fan motor error (upper fan)

Pressure switch abnormal

IPM error

Compressor rotor location cannot detect

Compressor Start-up error

Compressor temperature sensor error

Heat sink temperature sensor error

10

7

5

6

11

18

12

13

16

19

17

16 times blink

12

Outdoor unit fan motor error (lower fan)

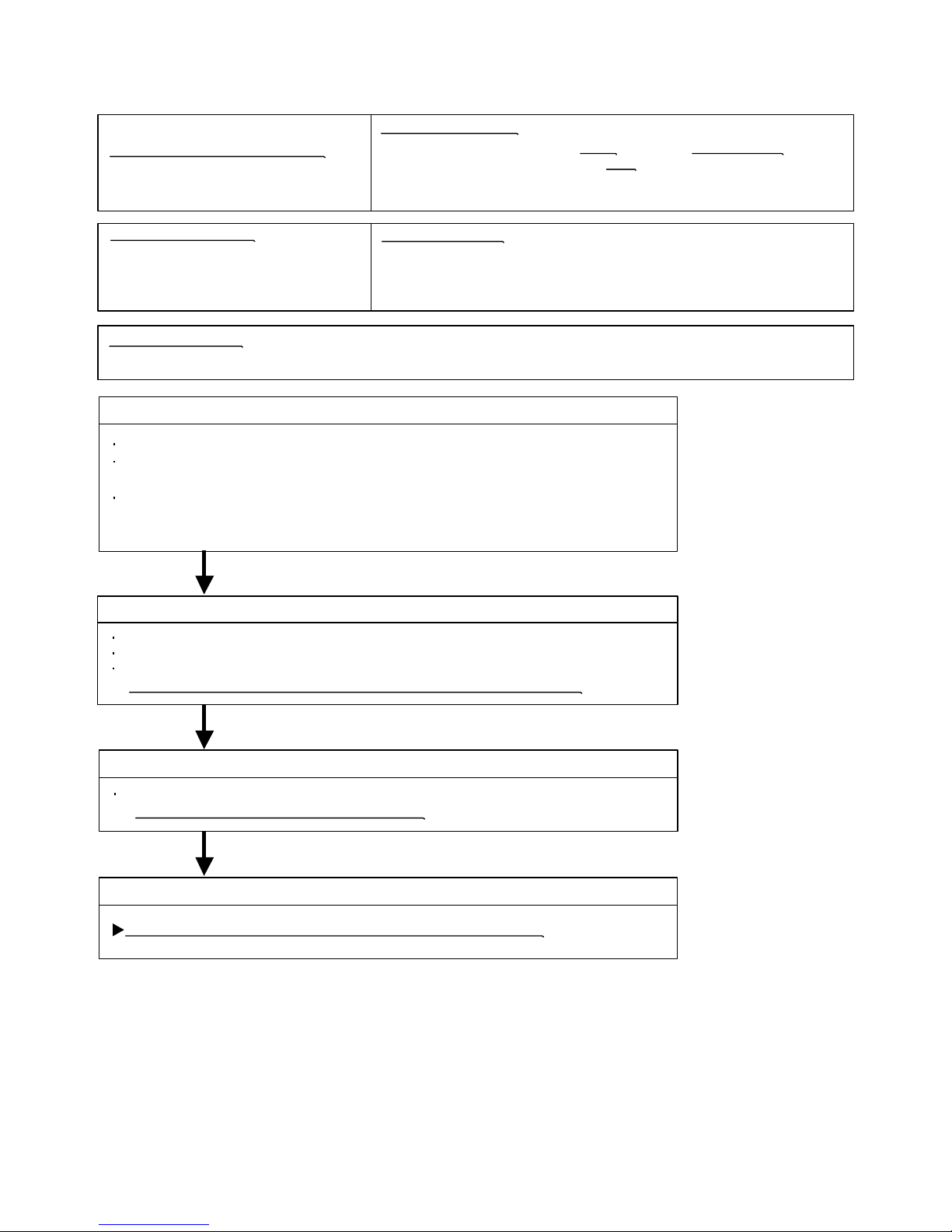

Page 49

Trouble shooting 2

OUTDOOR UNIT Error Method:

Detective Actuators:

Detective details:

Forecast of Cause:

OK

Indicate or Display:Indicate or Display:

Outdoor Unit : No indication

YESYES

NO

N

L

3

2

1

WHITE

BLACK

RED

WHITE

BLACK

+

-

OK

Communication Error

(Serial Reverse Transfer Error)

Outdoor Unit Main PCB Circuit

1. Connection failure 2. External cause 3. Main PCB failure 4. Active Filter Module failure

Check Point 1-1 : Reset the power and operate

Does Error indication show again?

Check Point 1-2:

Check external cause such as noise

Check the complete insulation of the grounding.

Check if there is any equipment that causes harmonic wave

near the power cable (Neon light bulb or any electronic

equipment which causes harmonic wave).

Check Point 2 : Check Connection

Check any loose or removed connection line of

Indoor unit and Outdoor unit.

>> If there is an abnormal condition, correct it by

referring to Installation Manual or Data &

Technical Manual.

Check connection between Outdoor Unit Main PCB

and Filter PCB.

(If there is loose connector or open cable)

Check Point 3 : Check the voltage of power supply

Check the voltage of power supply

>> Check if AC198 - 264V appears at Outdoor Unit Terminal L - N.

Check Point 4 : Check Serial Signal (Reverse Transfer Signal)

Check Serial Signal (Reverse Transfer Signal)

>> Check if Indicated value swings between AC70V and AC130V at Outdoor Unit Terminal 1 - 3.

>> If it is abnormal, Check Active Filter Module. (PARTS INFORMATION 3)

When the indoor unit cannot receive the serial signal from Outdoor unit

more than 10seconds.

>>If Active Filter Module is abnormal, replace it.

>>If Active Filter Module is normal, replace Main PCB.

07-03

Indoor Unit : Operation LED: 5 times blink, Timer LED: Blink,

Vertical swing LED: OFF

7-2 TROUBLE SHOOTING WITH ERROR CODE

Page 50

Trouble shooting 3

INDOOR UNIT

INDOOR UNIT Error Method:

Indicate or Display:

Outdoor Unit : No indication

Detective Actuators:

Detective details:

Forecast of Cause :

Check Point 2 : Check Point 2 : Remove connector and check Thermistor resistance value

Check Point 1 : Check connection of Connector

Check Point 3 : Check Point 3 : Check voltage of Controller PCB (DC5.0V)

6.51

35°C

8.04

30°C

10.012.515.820.225.933.6Resistance Value (k )

25°C20°C15°C10°C5°C0°C

Temperature

OK

OK

3.594.355.30Resistance Value (k )

50°C45°C40°C

Temperature

THERMISTOR

(PIPE TEMP.)

THERMISTOR

(ROOM TEMP.)

GRAY

GRAY

BLACK

BLACK

CN7 CN8

1 2 1 2

Room Temperature Sensor Error

Indoor Unit Controller PCB Circuit

Room Temperature Thermistor

When Room Temperature Thermistor open or short-circuit is

detected at power ON.

1. Connector connection failure 2.Thermistor failure 3. Controller PCB failure

Check if connector is removed.

Check erroneous connection.

Check if thermistor cable is open.

>>Upon correcting the removed connector or mis-wiring, reset the power.

Thermistor Characteristics (Approx. value)

If Thermistor is either open or shorted, replace it and reset the power.

Make sure circuit diagram of indoor unit and check terminal voltage at Thermistor (DC5.0V)

If the voltage does not appear, replace Controller PCB.

07-04

1 2

Indoor Unit : Operation LED: 2 times blink, Timer LED: Blink,

Vertical swing LED: OFF / Blink

Page 51

Trouble shooting 4

INDOOR UNIT

INDOOR UNIT Error Method:

Indicate or Display:

Outdoor Unit : No indication

Detective Actuators:

Detective details:

Forecast of Cause :

Check Point 2 :

31.7

35°C

39.6

30°C

49.762.980.3103134176Resistance Value (k )

25°C20°C15°C10°C5°C0°C

Temperature

OKOK

OK

17.120.825.6Resistance Value (k )

50°C45°C40°C

Temperature

Indoor Heat Exchanger Temperature