Page 1

AJYA72LALH

TM

INSTALLATION MANUAL

OUTDOOR UNIT

For authorized service personnel only.

INSTALLATIONSANLEITUNG

AUßENGERÄT

Nur für autorisiertes Fachpersonal.

MANUEL D’INSTALLATION

UNITÉ EXTÉRIEURE

Pour le personnel agréé uniquement.

English

Deutsch

FrançaisEspañol

AJYA90LALH

AJY108LALH

AJY126LALH

AJY144LALH

AJHA72LALH

AJHA90LALH

AJH108LALH

AJH126LALH

AJH144LALH

MANUAL DE INSTALACIÓN

UNIDAD EXTERIOR

Únicamente para personal de servicio autorizado.

MANUALE DI INSTALLAZIONE

UNITÀ ESTERNA

A uso esclusivo del personale tecnico autorizzato.

ΕΓΧΕΙΡΙΔΙΟ ΕΓΚΑΤΑΣΤΑΣΗΣ

ΕΞΩΤΕΡΙΚΉ ΜΟΝΆΔΑ

Μόνο για εξουσιοδοτημένο τεχνικό προσωπικό.

MANUAL DE INSTALAÇÃO

UNIDADE EXTERIOR

Apenas para técnicos autorizados.

РУКОВОДСТВО ПО УСТАНОВКЕ

ВНЕШНИЙ МОДУЛЬ

Только для авторизованного обслуживающего персонала.

Italiano

ΕλληνικάPortuguês

РусскийTürkçe

MONTAJ KILAVUZU

DIŞ ÜNİTE

Yalnızca yetkili servis personeli için.

安装说明书

室外机

仅针对授权的专业维修人员。

PART NO. 9378945104

中 文

Page 2

INSTALLATION MANUAL

PART NO. 9378945104

VRF system outdoor unit

CONTENTS

1. SAFETY PRECAUTIONS ........................................................................................ 1

2. ABOUT THE UNIT ...................................................................................................2

2. 1. Precautions for using the R410A refrigerant .................................................2

2. 2. Special tools for R410A .................................................................................2

2. 3. Accessories ..................................................................................................2

2. 4. Combinations ................................................................................................ 2

2. 5. Optional parts................................................................................................3

3. INSTALLATION WORK ............................................................................................ 3

3. 1. Selecting an installation location ................................................................... 3

3. 2. Drain processing ........................................................................................... 3

3. 3. Installation dimensions .................................................................................. 3

3. 4. Transportation the outdoor unit .....................................................................5

3. 5. Installation the unit ........................................................................................ 6

4. SYSTEM CONFIGURATION ...................................................................................6

4. 1. System confi guration .................................................................................... 6

4. 2. Pipe selection................................................................................................7

4. 3. Protection of pipes ........................................................................................ 8

5. PIPE INSTALLATION ............................................................................................... 8

5. 1. Brazing .......................................................................................................... 8

5. 2. Indoor unit pipe connections ......................................................................... 8

5. 3. Piping method ............................................................................................... 8

5. 4. Multiple connections .....................................................................................9

6. ELECTRICAL WIRING ........................................................................................... 11

6. 1. The precautions of electrical wiring ............................................................. 11

6. 2. Wiring method ............................................................................................. 11

6. 3. Knockout hole ............................................................................................. 11

6. 4. Selecting power supply cable and breaker ................................................. 12

6. 5. Transmission line ........................................................................................12

6. 6. Wiring procedure......................................................................................... 13

6. 7. External input and external output .............................................................. 14

7. FIELD SETTING ....................................................................................................15

7. 1. Field setting switches .................................................................................. 15

7. 2. DIP switch setting ....................................................................................... 15

7. 3. Rotary switch setting ................................................................................... 16

7. 4. Push button setting ..................................................................................... 17

7. 5. Signal amplifi er address setting .................................................................. 19

7. 6. Indoor unit address setting .......................................................................... 19

7. 7. Resistance measurement of transmission cable

(Measure with breaker OFF) ....................................................................... 20

8. PIPE INSTALLATION II .......................................................................................... 20

8. 1. Sealing test ................................................................................................. 20

8. 2. Vacuum process .........................................................................................20

8. 3. Additional charging .....................................................................................21

8. 4. Installing insulation ...................................................................................... 22

9. TEST RUN .............................................................................................................22

9. 1. Pre-test run check items ............................................................................. 22

9. 2. Test operation method ................................................................................ 22

9. 3. Checklist ..................................................................................................... 23

10. LED Status ............................................................................................................. 23

10. 1. Normal operation mode .............................................................................. 23

10. 2. Error codes ................................................................................................. 23

11. INFORMATION ...................................................................................................... 24

SAFETY PRECAUTIONS1.

Be sure to read this Installation manual thoroughly before installation•

The warnings and precautions indicated in this Installation manual contain impor-•

tant information pertaining to your safety. Be sure to observe them.

After installing the unit, perform a test run to make sure the unit operates normally. •

Then, explain to the customer how to operate and maintain the unit.

Please pass this Installation manual together with the Operating manual to the cus-•

tomer.

Please ask the customer to keep the Operating manual and Installation manual at

hand for future reference during the moving or repair of the main unit.

This mark indicates procedures which, if improperly

WARNING

For installation purposes, be sure to use the parts supplied by the manufacturer or

other prescribed parts.

Using non-specifi ed parts will cause serious accidents such as falling unit, refriger-

ant leakage, water leakage, electric shock, and fi re.

performed, might lead to the death or serious injury of the

user.

.

To in st all a u nit th at us es the R410A refrigerant, use dedicated tools and piping

materials that have been manufactured specifi cally for R410A use.

Because the pressure of the R410A refrigerant is approximately 1.6 times higher

than the R22, failure to use dedicated piping material or improper installation can

cause rupture or injury.

It will also cause serious accidents such as refrigerant leakage, water leakage,

electric shock, and fi re.

Do not use this equipment with air or any other unspecifi ed refrigerant in the refrig-

erant lines.

Excess pressure can cause a rupture.

Be sure to install the unit as prescribed, so that it can withstand earthquakes and

typhoons or other strong winds.

Improper installation can cause the unit to topple or fall, or other accidents

Ensure that the outdoor unit is securely installed at a place that can withstand the

weight of the unit.

Improper installation will cause injuries caused by falling unit.

If there is a refrigerant leakage, make sure that it does not exceed the concentration limit.

If a refrigerant leakage exceeds the concentration limit, it can lead to accidents

such as oxygen starvation.

If a refrigerant leakage occurs during operation, immediately vacate the premises

and thoroughly ventilate the area.

If the refrigerant is exposed to fi re, it will create a hazardous gas.

Electrical work must be performed in accordance with this Installation manual by a

person certifi ed under the national or regional regulations. Be sure to use a dedi-

cated circuit for the unit.

An insuffi cient power supply circuit or improperly performed electrical work can

cause serious accidents such as electric shock or fi re.

For wiring, use the prescribed type of cables, connect them securely, making sure

that there are no external forces of the cables applied to the terminal connections.

Improperly connected or secured cables can cause serious accidents such as

overheating the terminals, electric shock, or fi re.

Do not turn ON the power until all work has been completed.

Turning ON the power before the work is completed can cause serious accidents

such as electric shock or fi re.

After the installation, make sure there is no refrigerant leakage.

If the refrigerant leaks into the room and becomes exposed to a source of fi re such

as a fan heater, stove, or burner, it will create a hazardous gas.

Use a wall hole pipe. Otherwise, it may cause a short circuit.

Do not place the outdoor unit near the handrail of the balcony.

Children may climb onto the outdoor unit, lean over the handrail and fall over.

Use only a specifi ed power cable. Poor connection, poor insulation, and exceeding the

allowable current will lead to electric shock and fi re

Attach the connecting cables securely to the terminal. Or secure it fi rmly with a "wir-

ing suppressor".

Loose connection will lead to malfunction, electric shock, and fi re.

Install a breaker to cut off all AC main current at the same time.

If you do not install a breaker, it may cause electric shock and fi re.

During installation, make sure that the refrigerant pipe is attached fi rmly before you

run the compressor.

Do not operate the compressor under the condition of refrigerant piping not

attached properly with 2-way or 3-way valve open. This may cause abnormal pressure in the refrigeration cycle that leads to rupture and even injury.

During the pump-down operation, make sure that the compressor is turned off

before you remove the refrigerant piping. Do not remove the connection pipe while

the compressor is in operation with 2-way or 3-way valve open. This may cause

abnormal pressure in the refrigeration cycle that leads to breakage and even injury.

If there is a possibility of touching the fan during maintenance, make sure to turn

OFF the power before implementing the maintenance. Even if operations are

suspended, the fan of outdoor unit sometimes rotates, so if the fan rotates suddenly

while in contact with you may cause serious injury.

This mark indicates procedures which, if improperly

CAUTION

This unit must be installed by qualifi ed personnel with a capacity certifi cate for

handling refrigerant fl uids. Refer to regulation and laws in use on installation place.

The installation must be carried out in compliance with regulations in force in the

place of installation and the installation instructions of the manufacturer.

This unit is part of a set constituting an air conditioner. It must not be installed alone

or with non-authorized by the manufacturer.

This unit contains no user-serviceable parts. Always consult authorized service

personnel to repairs.

When moving, consult authorized service personnel for disconnection and installation of the unit.

Obtain the distribution network operator's agreement about the power capacity •

of the power supply system, specifi cation of the cable and the harmonic current,

and etc. when you connect the outdoor unit with the power supply.

This unit must be connected to a power supply with impedance of 0.33 ohm and •

below. If the power supply does not satisfy this requirement, please consult the

power supplier.

This product is intended for professional use.•

Be sure to use a dedicated power circuit.

Never use a power supply shared by another appliance.

performed, might possibly result in personal harm to the

user, or damage to property.

.

.

En-1

Page 3

Do not install the unit in the following areas:

Area with high salt content, such as at the seaside. •

It will deteriorate metal parts, causing the parts to fall or the unit to leak water.

Area fi lled with mineral oil or containing a large amount of splashed oil or •

steam, such as a kitchen.

It will deteriorate plastic parts, causing the parts to fall or the unit to leak

water.

Area that generates substances that adversely affect the equipment, such as •

sulfuric gas, chlorine gas, acid, or alkali.

It will cause the copper pipes and brazed joints to corrode, which can cause

refrigerant leakage.

Area containing equipment that generates electromagnetic interference. •

It will cause the control system to malfunction, preventing the unit from operating normally.

Area that can cause combustible gas to leak, contains suspended carbon •

fi bers or fl ammable dust, or volatile infl ammables such as paint thinner or

gasoline.

If gas leaks and settles around the unit, it can cause a fi re.

Avoid installing the unit at places where it will come into contact with animals’ •

urine or ammonia.

The units are not explosion proof and therefore should not be installed in explosive

atmosphere.

Do not use the unit for special purposes, such as storing food, raising animals,

growing plants, or preserving precision devices or art objects. It can degrade the

quality of the preserved or stored objects.

Ground the unit. Do not connect the ground wire to a gas pipe, water pipe, lightning

rod, or a telephone ground wire. Improper grounding may cause electric shock.

Perform draining for the unit according to the Installation manual. Check that the

water is properly drained.

If the drain processing is improperly installed, water may drip down from the unit,

wetting the furniture.

Do not touch the fi ns with bare hands.

Be sure not to start or stop the operation of air conditioning with power breaker.

Otherwise, it may cause malfunction or water leakage.

When setting it up near the equipment that generates electromagnetic waves and

the equipment that generates the higher harmonics wave, be sure to take measures

against noise. Otherwise, it may cause malfunction or failure.

When energizing to the crankcase heater, please turn on the power 12 hours or

earlier before operation begins. When the energizing time is short, it may cause

failure. Besides, please do not turn off power during the busy season.

Children should be monitored to ensure they do not play with the device.

This product is not intended to be used by people (including children) with physical,

sensory or mental disability, or persons lacking experience or knowledge unless

they have been given by the through a person responsible for their safety, supervision or instruction concerning the use of the device.

Tool name Contents of change for R22 tool

A conventional (R22) vacuum pump can be used by installing a vacuum pump adapter.

Vac uu m p um p

Gas leakage detector

A conventional vacuum pump can be used by installing a •

vacuum pump adapter.

Be sure that the pump oil does not back fl ow into the sys-•

tem. Use one capable for vacuum suction of -100.7kPa (5

Ton, -755mmHg).

Special gas leakage detector for HFC refrigerant R410A.

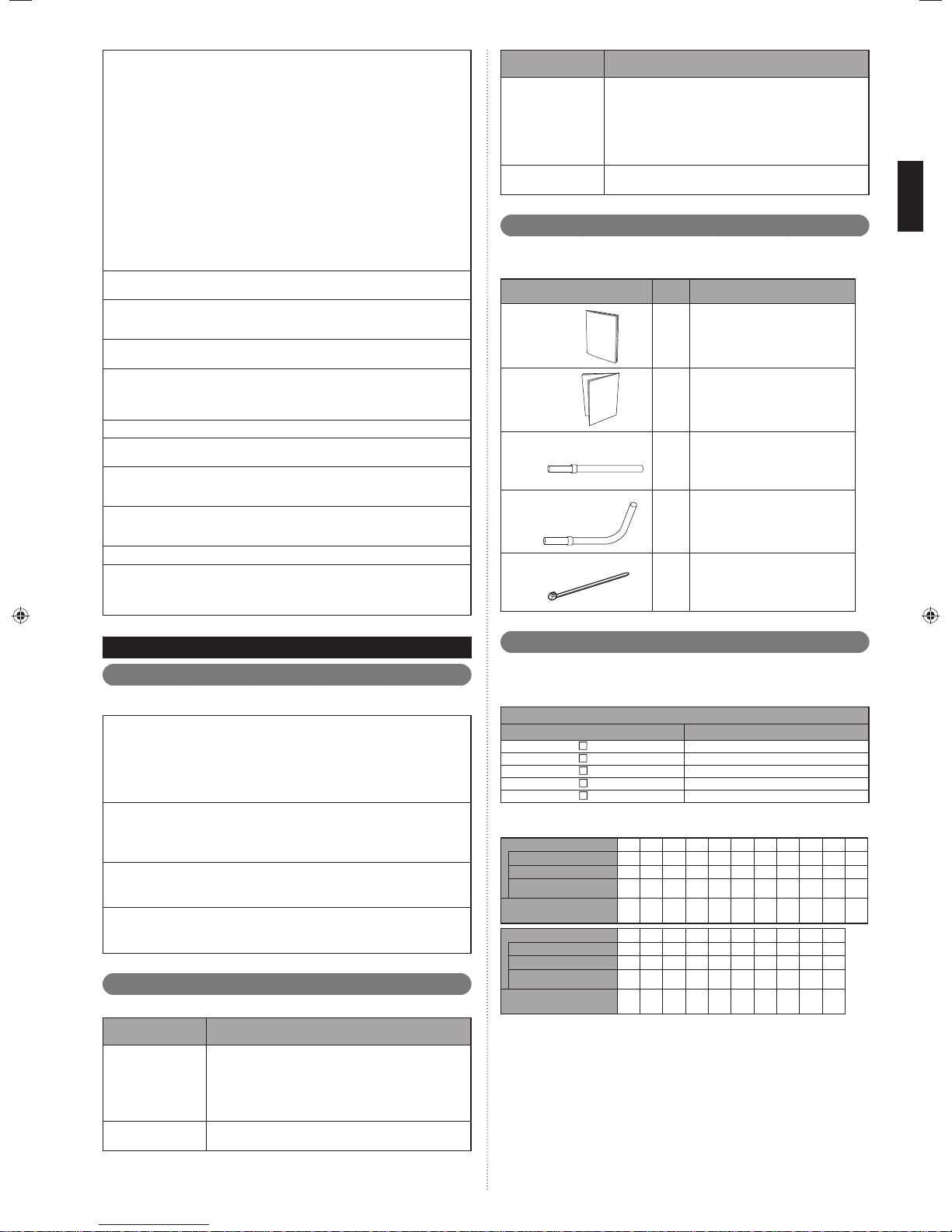

Accessories2. 3.

Use connecting parts as required.

Do not throw away the connecting parts until the installation has been complete.

Name and shape Q’ty Application

Specifi cations

manual

Installation

manual

Joint pipe A

Joint pipe B

Cable tie

—

1

(This book)

1

For connecting gas pipe

(Straight type)

1

For connecting gas pipe

(L type)

1

For binding power cable and transmission cable

4

ABOUT THE UNIT2.

Precautions for using the R410A refrigerant2. 1.

Pay careful attention to the following points :

Since the working pressure is 1.6 times higher than that of R22 models, some of the

piping and installation and service tools are special. (See the table in the SPECIAL

TOOLS FOR R410A section.)

Especially, when replacing a conventional refrigerant (other than R410A) model

with a new refrigerant R410A model, always replace the conventional piping and

fl are nuts with the R410A piping and fl are nuts.

Models that use refrigerant R410A have a different charging port thread diameter

to prevent erroneous charging with R22, R407C and for safety. Therefore, check

beforehand. [The charging port thread diameter for R410A is 1/2 UNF 20 threads

per inch.]

Be more careful than the installation of the refrigerant (other than R410A) models,

not to enter foreign matters (oil, water, etc.) and other refrigerant into the piping.

Also, when storing the piping, securely seal the openings by pinching, taping, etc.

When charging the refrigerant, take into account the slight change in the composition of the gas and liquid phases, and always charge from the liquid phase side

whose composition is stable.

Special tools for R410A2. 2.

Tool name Contents of change for R22 tool

Pressure is huge and cannot be measured with a conventional (R22) gauge. To prevent erroneous mixing of other

Gauge manifold

Charging hose

refrigerants, the diameter of each port has been changed.

It is recommended to use a gauge manifold with a high

pressure display range -0.1 to 5.3 MPa and a low pressure

display range -0.1 to 3.8 MPa.

To increase pressure resistance, the hose material and

base size were changed.

Combinations2. 4.

A maximum of 3 outdoor units can be connected to 1 refrigerant system.

The combination of outdoor units per refrigerant system and the number of indoor units

that can be connected are as follows:

Outdoor Unit

Model Name Nominal System Capacity (HP)

A72LALH 8

AJ

AJ

A90LALH 10

AJ

108LALH 12

AJ

126LALH 14

144LALH 16

AJ

Installation space combination

Combination (HP) 8 10121416182022242628

Outdoor Unit 1 (HP) 8 10121416101212121416

Outdoor Unit 2 (HP) –––––8810121212

Outdoor Unit 3 (HP) –––––––––––

Maximum Connectable

Indoor Unit

Combination (HP) 30 32 34 36 38 40 42 44 46 48

Outdoor Unit 1 (HP) 16 16 12 12 14 16 16 16 16 16

Outdoor Unit 2 (HP) 14 16 12 12 12 12 14 16 16 16

Outdoor Unit 3 (HP) – – 10 12 12 12 12 12 14 16

Maximum Connectable

Indoor Unit

When connecting outdoor units, install the outdoor unit with the largest nominal system capacity nearest to the refrigerant pipe and indoor unit, followed by those with lesser nominal system

capacities. (Outdoor unit 1 ≥ Outdoor unit 2 ≥ Outdoor unit 3)

15 16 17 21 24 32 32 32 35 39 42

45 48 48 48 48 48 48 48 48 48

En-2

Page 4

Energy-saving combination

Combination (HP) 8 10121416182022242628

Outdoor Unit 1 (HP) ––––8––1481012

Outdoor Unit 2 (HP) ––––8––8888

Outdoor Unit 3 (HP) ––––––––888

Maximum Connectable

Indoor Unit

Combination (HP) 30 32 34 36 38 40 42 44 46 48

Outdoor Unit 1 (HP) 14 12 14 14 – 14 14 16 – –

Outdoor Unit 2 (HP) 8 12 12 14 – 14 14 14 – –

Outdoor Unit 3 (HP) 8888–121414––

Maximum Connectable

Indoor Unit

* Means that the energy-saving combination is unavailable.

When connecting outdoor units, install the outdoor unit with the largest nominal system capacity nearest to the refrigerant pipe and indoor unit, followed by those with lesser nominal system

capacities. (Outdoor unit 1 ≥ Outdoor unit 2 ≥ Outdoor unit 3)

* * * * 30 * * 33 36 39 42

45 48 48 48 * 48 48 48 * *

Optional parts2. 5.

CAUTION

The following parts are optional parts specifi c to R410A refrigerant.

Do not use parts other than those listed below.

Outdoor unit branch kit2. 5. 1.

Model Total cooling capacity of indoor unit (kW)

UTP-CX567A, UTR-CP567X ALL

CAUTION

Install the unit in an area that has no heat sources, vapors, or the risk of the leakage

of fl ammable gas in the vicinity.

Install the unit in an area that is away from the exhaust or vent ports that discharge

vapor, soot, dust, or debris.

Install the indoor unit, outdoor unit, power supply cable, transmission cable and

remote control cable at least 1 meter away from a television or radio.

The purpose of this is to prevent TV reception interference or radio noise. (Even if

they are installed more than 1 meter apart, you could still receive noise under some

signal conditions.)

Keep the length of the piping of the indoor and outdoor units within the allowable

range.

For maintenance purposes, do not bury the piping.

Drain processing3. 2.

The drain water is discharged from the bottom of the equipment. Construct a drain •

ditch around the base and discharge the drain water properly.

When installing on a roof, perform fl oor waterproofi ng properly.•

Drain processing:

The drain water from the base of the outdoor unit may generate during operations.•

Perform drain processing, as necessary.

When you want to prevent the drain water from leaking at the perimeter, construct •

a ditch for the drain water as shown in the fi gure.

Provide a central drain pan, as necessary.•

Outdoor unit

50mm or

more

Separation tube2. 5. 2.

Model Total cooling capacity of indoor unit (kW)

UTP-AX090A , UTR-BP090X 28.0 or less

UTP-AX180A , UTR-BP180X 28.1 to 56.0

UTP-AX567A , UTR-BP567X 56.1 or more

Header2. 5. 3.

3-6 branches 3-8 branches Total cooling capacity of indoor unit (kW)

UTR-H0906L UTR-H0908L 28.0 or less

UTR-H1806L UTR-H1808L 28.1 to 56.0

INSTALLATION WORK3.

Please obtain the approval of the customer when selecting the location of installation

and installing the main unit.

Selecting an installation location3. 1.

WARNING

Install the unit in a location that can withstand its weight, and where it will not topple

or fall.

Calculate the proper refrigerant concentration if you will be installing it in an enclosed location.

Total amount of replenished refrigerant in refrigerant facility (kg)

Capacity of smallest room where unit is installed (m3)

If the results of the calculation exceed the concentration limit, increase the room

surface area or install a ventilation duct.

≤

Refrigerant concentration (kg/m3)

(0.3kg/m3)

CAUTION

Select an installation location by observing the following precautions:

Install the unit level. (Within 3 degrees)

Install this unit in a location with good ventilation.

If the unit must be installed in an area within easy reach of the general public, install

as necessary a protective fence or the like to prevent their access.

Install the unit in an area that would not inconvenience your neighbors, as they could

be affected by the airfl ow coming out from the outlet, noise, or vibration.

If it must be installed in proximity to your neighbors, be sure to obtain their approval.

If the unit is installed in a cold region that is affected by snow accumulation, snow fall,

or freezing, take appropriate measures to protect it from those elements.

To ensure a stable operation, install inlet and outlet ducts.

Install the unit in an area that would not cause problems even if the drain water is

discharged from the unit. Otherwise, provide drainage that would not affect people or

objects.

10mm or more

Installation dimensions3. 3.

CAUTION

When installing the outdoor unit, pay attention to the following items.

Provide suffi cient installation space, such as transportation route, maintenance

space, ventilation space, refrigerant piping space, and passageways.

Pay attention to the specifi cations of the installation space as shown in the fi gure.

If the unit is not installed according to specifi cations, it may cause short circuit or

poor performance. The unit may be prone to lapse into non-operation due to high

pressure protection.

Do not place obstructions in the air fl ow outlet direction. If there is an obstruction in

the outlet direction, install an outlet duct.

When there is a wall in front of the unit, provide a space of 500mm or more as

maintenance space.

When there is a wall at the left side of the unit, provide a space of 30mm or more

as maintenance space.

An outdoor temperature of 35 degrees in air-conditioned operation is assumed for

the installation space in this item. If the outdoor temperature exceeds 35 degrees

and the outdoor unit is operating at a load exceeding its rated ability, provide a

larger inlet space.

If you are installing more outdoor units than indicated here, please ensure suffi cient

space or consult your distributing agent as it may affect the performance due to

short circuit and other problems.

When install near by limited height wall3. 3. 1.

Single and multiple installations(1)

There are no restrictions on the height of the side wall.•

Provide installation spaces L1 and L2 in accordance with the table below according •

to the wall height (front side, rear side) conditions.

Provide installation spaces other than L1 and L2 in accordance with the conditions •

shown in the fi gure below.

Ventilation resistance can be ignorable when the distance from a wall or product, •

etc. is larger than 2m.

Wall height condition Necessary installation space

When H1 is 1500 (mm) or less L1 ≥ 500 (mm)

When H1 is 1500 (mm) or more L1 ≥ 500+h1÷2 (mm)

When H2 is 500 (mm) or less L2 ≥ 100 (mm)

When H2 is 500 (mm) or more L2 ≥ 100+h2÷2 (mm)

En-3

Page 5

1Fig.

<Front> <Rear>

<Side view>

J

6 Fig.

<Top view>

L4

*

Wall

2 Single installationFig.

<Front>

3 Multiple installationsFig.

<Rear>

<Front>

30mm or

more

Concentrated installation(2)

Provide installation spaces L3, L4, and L5 in accordance with the table below ac-•

cording to the wall height (front side, rear side) conditions.

Provide installation spaces other than L3, L4, and L5 in accordance with the condi-•

tions shown in the fi gure below.

Ventilation resistance can be ignorable when the distance from a wall or product, •

etc. is larger than 2m.

Wall height condition Necessary installation space

When H3 is 1500 (mm) or less L3 ≥ 500 (mm)

When H3 is 1500 (mm) or more L3 ≥ 500+h3÷2 (mm)

When H4 is 500 (mm) or less L4 ≥ 200 (mm)

When H4 is 500 (mm) or more L4 ≥ 200+h4÷2 (mm)

When H5 is 500 (mm) or less L5 ≥ 200 (mm)

When H5 is 500 (mm) or more L5 ≥ 200+h5÷2 (mm)

4Fig.

<Front>

.

<Top view>

<Rear>

30mm or more 10mm or more

.

.

<Top view>

20mm or

more

<Side view>

.

.

.

20mm or

more

J

Wall

<Rear>

*

10mm or

more

J

*

.

Wall

5 Fig.

<Front view>

J

*

.

Wall

800mm

or more

800mm

or more

L3

20mm or

more

7 Fig.

20mm or

L5

more

20mm or

more

<Top view>

20mm or

more

L5L5

L4

500mm

or more

1000mm

or more

L3

L5

When install near unlimited height wall3. 3. 2.

Single and multiple installations(1)

There are no restrictions on the height of the wall.•

The wall (without height restrictions) must not exist on the both sides (left / right) •

of outdoor unit. Also, must not exist on the both sides (front / rear) of outdoor

unit.

Provide installation spaces other than L6 in accordance with the conditions •

shown in the fi gure below.

Ventilation resistance can be ignorable when the distance from a wall or prod-•

uct, etc. is larger than 2 m.

When installing with the REAR of the outdoor unit facing the wall side

Condition Necessary installation space

When B ≥ 400 (mm) L6 ≥ 200 (mm)

When 20 ≤ B < 400 (mm) L6 ≥ 200 + (400-B) ×3 (mm)

8 Single installationFig.

<Rear>

<Front>

9 MFig. ultiple installations

<Rear>

200mm

or more

<Top view>

<Top view>

100mm

or more

L6

h5

H5

500

Wall Wall

L5

L5

h5

500

<Front>

H5

200mm

or more

B

B

En-4

Page 6

800mm

or more

200mm

or more

When installing with the FRONT of the outdoor unit facing the wall side

10 Fig.

11 Fig.

Wall

200mm

or more

Concentrated Installation(2)

The wall (without height restrictions) must not exist on the both sides (left / right) of •

outdoor unit. Also, must not exist on the both sides (front / rear) of outdoor unit.

Ventilation resistance can be ignorable when the distance from a wall or product, •

etc. is larger than 2m.

12 Fig.

200mm 200mm

Example :

When B is made 200mm

L6 ≥ 200+(400-200)×3=800mm

<Top view>

Wall

200mm or more

20mm or

more

<Top view>

<Top view>

20mm or

more

Wall

500mm

or more

Wall

500mm

or more

400mm

or more

800mm

or more

When there are obstacles above the product3. 3. 3.

When there are obstacles above the product, keep the

minimum installation height as shown in the fi gure and

install the outlet duct.

When installing the outlet duct, you must set the high

static pressure mode with the push-button switch.

(Similar when installing anti-snow hood)

Setting high static pressure mode

Follow the instructions in the table below to set the high

static pressure mode.

Condition

Static Pressure (SP) *1 :

0 ≤ SP ≤ 30 (Pa)

Static Pressure (SP)

30 < SP ≤ 80 (Pa)

Static pressure is the air fl ow resistance that includes *1.

the discharge duct resistance & the other additional resistance like discharge grill

and so on.

Refer to the section on Push Switch Setting in “Chapter 7 Field Setting”.*2.

High static pressure mode

setting

Set to Mode 1

*1

:

Set to Mode 2

*2

Outlet duct

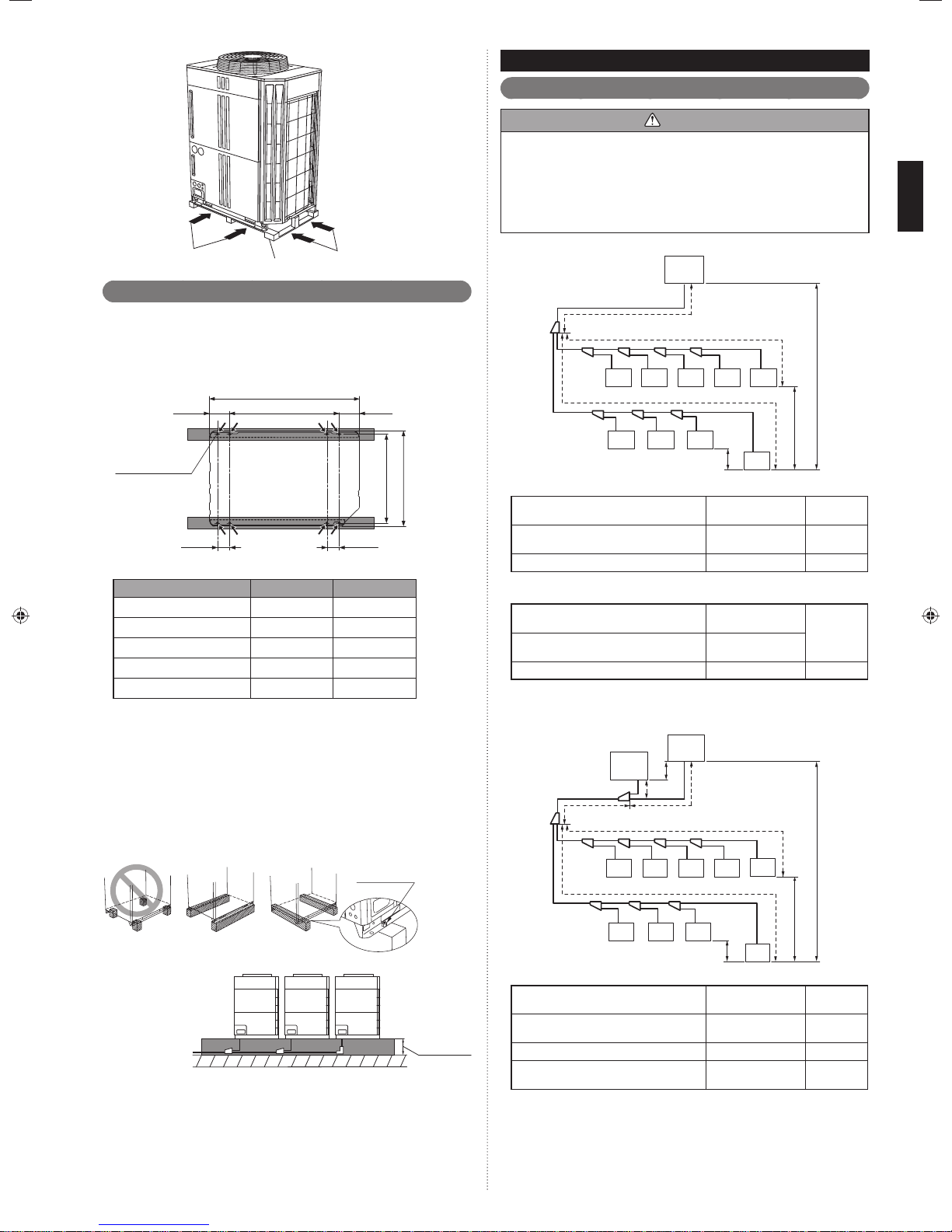

Transportation the outdoor unit3. 4.

Product mass (kg)

A72LALH 220

AJ

□

A90LALH 220

AJ

□

AJ

108LALH 275

□

AJ

126LALH 303

□

AJ

144LALH 303

□

Hoisting method

When hanging the outdoor unit and conveying it to installation location, hang the •

unit with rope by passing through the 4 opening holes on bottom of front and rear

side as shown in fi gure.

Use 2 ropes at least 8m long. If used shorter length, it may cause to damage to the •

unit

.

Use the suffi ciently strong rope to bear the unit’s weight.•

Place the protective board or fi ller cloth at the place where the cabinet may come •

into contact with rope to prevent from damages. Without using them, cabinet may

cause to damage or deform.

During the hanging unit, make sure to keep the unit level to prevent from falling.•

To prevent an unit swing accident or falling down of the unit, do not apply any •

impact to the unit when it is hanging.

500mm

or more

1000mm

or more

13Fig.

1000mm

or more

400mm

or more

400mm

or more

400mm

or more

<Top view>

400mm

or more

800mm

or more

400mm

or more

500mm

or more

1000mm

or more

protective boards

opening space

Lifting by forklift

When using the forklift to lift the unit, pass the forklift arms through the opening •

space as shown in below.

Front : Bottom of the wooden delivery pallet.

Side : Space between pallet and cabinet.

(Enable to remove the pallet from cabinet.)

Be careful not to damaged.•

Lifting by forklift (Manual forklift: hand-fork)

When using the manual forklift to lift the unit, pass the forklift arms through to the •

opening space between pallet and cabinet from side.

En-5

Page 7

SYSTEM CONFIGURATION4.

System confi guration4. 1.

<Front>

Fork (Forklift)

Delivery pallet

<Side>

Fork (Forklift) or

Fork (Manual forklift)

Installation the unit3. 5.

Install the unit level. (within 3 degrees).•

Install 4 or more anchor bolts at the 8 locations indicated by arrows (Fig. A).•

Place the left and right anchor bolts at a distance further away than the dimensions •

of A in the Table A.

(Excluding the case where anchor bolts are installed at 8 places.)

AFig.

Hole: 12 × 17

(8 places)

80

Table.A

Model name A B

AJ

A72LALH 610 930

□

A90LALH 610 930

AJ

□

108LALH 610 930

AJ

□

126LALH 920 1240

AJ

□

144LALH 920 1240

AJ

□

To minimize vibration, do not install the outdoor unit directly on the ground.•

Instead, install it on top of a fi rm platform (such as concrete block). (Fig. B)

The foundation base should be able to support the product and the foot width of •

the product should be more than 46.5mm.

Depending on the installation condition, vibration during the operation of the unit •

may cause noise and vibration.

Install vibration-proofi ng materials (such as rubber pads).

Consider the removal space of the connection piping when installing the founda-•

tion.

Secure the equipment fi rmly with anchor bolts, washers, and nuts.•

BFig.

GOODPROHIBITED GOOD

B

A

Bottom view

(Unit: mm)

160160

732

80

Bolt (M10)

765

CAUTION

When connecting multiple outdoor units, set the nearest outdoor unit to the indoor •

unit on the refrigerant pipe as the master unit.

When connecting multiple outdoor units, install the outdoor unit with the largest •

nominal system capacity nearest to the indoor unit on the refrigerant pipe, followed by those with less nominal system capacities.

[Capacity: Master ≥ Slave]

Always keep to the limit on the total amount of refrigerant. Exceeding the limit •

on the total amount of refrigerant when charging will lead to malfunction.

In case of 1 outdoor unit connected A)

A Fig.

f

I.U.

I.U. I.U. I.U.

Allowable pip length (actual pipe length)•

Between master outdoor unit and the

farthest indoor unit

Between the fi rst separation tube and the

farthest indoor unit

Total pipe length 700 m or less Total

Allowable height difference•

Between outdoor unit and indoor unit (When

indoor unit is installed below)

Between outdoor unit and indoor unit (When

outdoor unit is installed below)

Between indoor units 15 m or less H2, H3

Total refrigerant amount : 31.5 kg or less•

In case of 2 outdoor units connected B)

B Fig.

O.U.-1

(Master)

e

I.U.

O.U.

(Master)

O.U. :Outdoor unit

f

O.U.-2

(Slave)

p

I.U. :Indoor unit

H3

O.U. :Outdoor unit

I.U. :Indoor unit

b

I.U.

I.U. I.U.

150 m or less

60 m or less f, p

50 m or less

40 m or less

a

I.U. I.U. I.U. I.U.

H4

a

I.U.

H1

H2

I.U.

a+p

H1

a+f

H1

*Do not use a four-corner support foundation.

CFig.

When installing piping from the bottom

of the outdoor units,

the required space

under the outdoor

unit ≥ 200mm.

* Install the branch

kit horizontally.

More than

200mm

I.U.

H2

a+e+f

a+e+p

I.U.

I.U.

I.U.

H3

Allowable pip length (actual pipe length)•

Between master outdoor unit and the

farthest indoor unit

Between the fi rst separation tube and the

farthest indoor unit

Total pipe length 1000 m or less Total

Between outdoor unit and outdoor unit

branch kit

150 m or less

60 m or less f, p

3 m or less a, b

En-6

Page 8

Allowable height difference•

Between outdoor unit and indoor unit (When

indoor unit is installed below)

Between outdoor unit and indoor unit (When

outdoor unit is installed below)

50 m or less

40 m or less

Between indoor units 15 m or less H2, H3

Between outdoor units 0.5 m or less H4

Total refrigerant amount : 63 kg or less•

Outdoor unit capacity : Master ≥ Slave•

In the case of 3 outdoor units connected C)

CFig.

O.U.-3

O.U.-1

(Master)

O.U.-2

(Slave1)

a

d

e

H4

b

c

(Slave2)

f

O.U. :Outdoor unit

I.U. :Indoor unit

H1

p

H2

H3

Allowable pip length (actual pipe length)•

Between master outdoor unit and the

farthest indoor unit

Between the fi rst separation tube and the

farthest indoor unit

150 m or less

60 m or less f, p

a+e+f

a+e+p

Total pipe length 1000 m or less Total

Between outdoor unit and outdoor unit

branch kit

Between the farthest outdoor unit and the

fi rst outdoor unit branch kit

3 m or less a, b, c

12 m or less

b+d

c+d

Allowable height difference•

Between outdoor unit and indoor unit (When

indoor unit is installed below)

Between outdoor unit and indoor unit (When

outdoor unit is installed below)

50 m or less

40 m or less

Between indoor units 15 m or less H2, H3

Between outdoor units 0.5 m or less H4

Total refrigerant amount : 94.5 kg or less•

Outdoor unit capacity : Master ≥ Slave 1 ≥ Slave 2•

If the outdoor temperature during cooling operation is expected to be –5 °C

• NOTE)

or less, do not install the outdoor unit lower than the indoor unit

• Please refer to “8.3.2. Checking total amount of refrigerant and calculating the amount of refrigerant charge to be added” for the total amount of

refrigerant.

.

(Wall thickness and pipe material for each diameter)

Outside Diameter mm 6.35 9.52 12.70 15.88 19.05 22.22 28.58 34.92 41.27

H1

Wall Thick ness*3mm 0.8 0.8 0.8 1.0 1.2 1.0 1.0 1.2 1.43

Material

Allowable tensile stress ≥ 33 (N/mm*1.

Allowable tensile stress ≥ 61 (N/mm*2.

Endurance pressure of the pipes 4.2MPa*3.

Please select the pipe size in accordance with local rules.

JIS H3300 C1220T-O or equiva-

COPPER

lent

2

)

2

)

*1

JIS H3300 C1220T-H or

COPPER

equivalent

*2

A (Between outdoor unit and outdoor unit branch kit)Tab le.

Outdoor unit cooling

HP

capacity (kW)

8

10

12

14

16

22.4 12.70 (1/2") 22.22 (7/8")

28.0 12.70 (1/2") 22.22 (7/8")

33.5 12.70 (1/2") 28.58 (1-1/8")

40.0 12.70 (1/2") 28.58 (1-1/8")

45.0 12.70 (1/2") 28.58 (1-1/8")

Outside diameter (mm)

Liquid pipe Gas pipe

*4

Branch kit

UTP-DX567A,

UTR-CP567X

For the installation method, refer to “5.4. Multiple connections”.*4.

B (Between outdoor unit branch kits or outdoor unit branch kit and Table.

fi rst separation tube)

Tot al co oling ca pa ci ty

of outdoor unit (kW)

Outside diameter (mm)

Liquid pipe Gas pipe

22.4 to 28.0 12.70 (1/2") 22.22 (7/8")

28.1 to 45.0 12.70 (1/2") 28.58 (1-1/8")

45.1 to 56.0 15.88 (5/8") 28.58 (1-1/8")

56.1 to 80.0 15.88 (5/8") 34.92 (1-3/8")

80.1 to 96.0 19.05 (3/4") 34.92 (1-3/8")

96.1 or more 19.05 (3/4") 41.27 (1-5/8")

C (Between separation tubes)Tab le.

Total cooling capacity

of indoor unit (kW)

Outside diameter (mm)

Liquid pipe Gas pipe

4.4 to 11.1 9.52 (3/8") 15.88 (5/8")

11.2 to 13.9 9.52 (3/8") 19.05 (3/4")

14.0 to 28.0 12.70 (1/2") 22.22 (7/8")

H1

28.1 to 44.7 12.70 (1/2") 28.58 (1-1/8")

44.8 to 56.0 15.88 (5/8") 28.58 (1-1/8")

56.1 to 80.0 15.88 (5/8") 34.92 (1-3/8")

80.1 to 95.0 19.05 (3/4") 34.92 (1-3/8")

95.1 or more 19.05 (3/4") 41.27 (1-5/8")

* If the selected pipe diameter between separation tubes (based on table "C") becomes

larger than the pipe diameter between outdoor unit branch kit and the fi rst separation

tube (based on table "B"), please select the pipe whose diameter is equal to the one

between outdoor unit branch kit and the fi rst separation tube.

(If pipe diameter C > B, select pipe size from table B)

* Total cooling capacity of indoor unit" is the total value for the cooling capacity of indoor

unit connected downstream.

Pipe selection4. 2.

CAUTION

This unit is designed specifi cally for use with the R410A refrigerant. Pipes for

R407C or R22 may not be used with this unit. Do not use existing pipes. Improper

pipe selection will degrade performance.

unit

Slave

unit1

Indoor

unit

Slave

unit2

Separation tube

(optional)

Indoor

unit

Indoor

unit

Master

First separation

tube (optional)

Indoor

Indoor

unit

unit

unit

Outdoor unit

branch kit

(optional)

Indoor

En-7

Pipe size

(table A)

Pipe size

(table B)

Pipe size

(table C)

Pipe size

(table D)

D (Between separation tube to indoor unitTab le.

Model code

Cooling capacity of

indoor unit (kW)

)

Outside diameter mm (in)

Liquid pipe Gas pipe

07, 09, 12, 14 2.2, 2.8, 3.6, 4.0, 4.5 6.35 (1/4") 12.70 (1/2")

18, 24, 30 5.6, 7.1, 8.0, 9.0 9.52 (3/8") 15.88 (5/8")

36, 45, 54, 60 11.2, 12.5, 14.0, 18.0 9.52 (3/8") 19.05 (3/4")

72, 90 22.4, 25.0 12.70 (1/2") 22.22 (7/8")

Use a standard separation tube for pipe branching. Do not use a T tube as it does not

separate the refrigerant evenly.

E (Separation tube / Header)Tabl e.

Separation tube•

Total cooling capacity of indoor unit (kW) Separation tube

*5

28.0 or less UTP-AX090A or UTR-BP090X

28.1 to 56.0 UTP-AX180A or UTR-BP180X

56.1 or more UTP-AX567A or UTR-BP567X

Page 9

Header•

*5

Total cooling capacity of indoor unit (kW)

Header

3-6 Branches 3-8 Branches

28.0 or less UTR-H0906L UTR-H0908L

28.1 to 56.0 UTR-H1806L UTR-H1808L

For the installation method, refer to the section on "Indoor unit pipe connections" *5.

below.

Protection of pipes4. 3.

Protect the pipes to prevent the entry of moisture and dust.•

Especially pay attention when passing the pipes through a hole or connecting the •

end of a pipe to the outdoor unit.

Location Working period

Outdoor

Indoor

1 month or more Pinch pipes

Less than 1 month Pinch or tape pipes

—

Protection method

Pinch or tape pipes

PIPE INSTALLATION5.

Brazing5. 1.

CAUTION

If air or different type of refrigerant enters

the refrigeration cycle, the internal pressure in the refrigeration cycle will become

abnormally high and prevent the unit from

exerting its full performance.

Apply nitrogen gas while brazing the

pipes.

Nitrogen gas pressure: 0.02 MPa (= suffi cient pressure to be felt on the back of

your hand or more)

If a pipe is brazed without applying nitrogen gas, it will create an oxidation fi lm.

This can degrade performance or damage the parts in the unit (such as the compressor or valves).

Do not use fl ux to braze pipes. If the fl ux is the chlorine type, it will cause the pipes

to corrode.

In addition, if the fl ux contains fl uoride, it will affect the refrigerant piping system due to

deterioration of refrigerant oil.

For brazing material, use phosphor copper that does not require fl ux.

Fig.

Pressure regulating valve

Cap

Nitrogen gas

Brazing area

Header

Gas pipe

Outdoor

unit side

Liquid pipe

Outdoor

unit side

H

= 0 to 10 mm

1

(α1: 0° to 1°)

β1: -10° to 10°

= 0 to 10 mm

H

2

(α2: 0° to 1°)

β2: -10° to 10°

C

D

Horizontal line

A

1

H

1

Vertical line

2

GOOD

Horizontal line

A

2

H

PROHIBITED PROHIBITED

CAUTION

Do not connect a separation tube after a header.

Leave the distance 0.5 m or more for straight part to branch tube and

header.

Main pipe

Main pipe

0.5 m or more

0.5 m or more

To in do or u ni t

0.5 m or more

To in do or u ni t

0.5 m or more

Separation tube

or

Header

To in do or u ni t

Separation tube

or

Header

To in do or

unit

B

1

VIEW C

B2

VIEW D

To in do or

unit

Horizontal

line

Indoor unit pipe connections5. 2.

CAUTION

For details, refer to the Installation Instruction Sheet of each part.

Separation tube

Horizontal

A

± 15°

B

Horizontal line

GOOD

A : Outdoor unit or Refrigerant branch kit

B : Indoor unit or Refrigerant branch kit

PROHIBITED

A

Vertic al

B

To in do or u ni t

Piping method5. 3.

Opening the knockout hole5. 3. 1.

B

Be careful to prevent panel deformation or damaged while opening the knockout

hole.

or

A

To prevent cutting of the wiring after the knockout hole was opened, remove the

burrs along the edge.

In addition, to prevent rusting, painting the edge with rust preventive paint is recom-

mended.

The piping can be connected from 2 directions; the front or the bottom.

(Knockout holes are provided so that the piping can be connected from 2 different

directions.)

Use the front knockout hole, as required.

A Knockout positionFig.

CAUTION

En-8

Page 10

B Detail of knockout position (bottom)Fig.

(Unit: mm)

Knockout hole

After all the gas is vented, melt the brazing fi ller metal on connecting part using a 3)

torch and remove the pinch pipe.

C Detail of knockout position (front)Fig.

95

75

10

100

(Unit: mm)

Knockout

hole

125

4373199

Removing the pinch pipe5. 3. 2.

WARNING

Remove the pinch pipe only when the internal gas is completely drained as shown

on the below instructions.

If gas still remains inside, the piping may crack if you melt the brazing fi ller metal of

the junction area with a burner.

Before connecting the piping, remove the pinch pipe in accordance with the following

instructions:

Verify that the liquid side and gas side 3-way valves are closed. 1)

3-way valve

Pinch pipe

Pipe connection5. 3. 3.

CAUTION

Seal the pipe route hole with putty (fi eld supply) such that there are no gaps.

Small insects or animals that are trapped in the outdoor unit may cause a short circuit

in the electrical component box.

To prevent pipe damage; do not make sharp bends.

Bend the pipe at a radius of 70mm or greater.

Do not bent pipe many times at same part to prevent break.

After completing all the pipe connection by brazing, perform the indoor unit pipe connection with a fl are joint.

When removing the pinch pipe or brazing the joint pipe, carry out the work while

cooling down the 3-way valve suffi ciently.

Braze the joint pipe onto the 3-way valves at the liquid and gas side.•

Install the joint pipe appropriately so that it can be connected easily with the main

pipe.

Braze the joint pipe at the liquid and gas side with the main pipe.•

* Be sure to supply nitrogen when brazing.

AFig.

Joint pipe

(Accessory)

Joint pipe

(Field supply)

Liquid pipe

(Field supply)

BFig.

Knockout

hole

Gas pipe (Field

supply)

To in do or u ni t

Cut the end of the liquid side and gas side pinch pipe and vent the gas inside the 2)

pinch pipe.

End of pinch pipe

En-9

Joint pipe

(Field supply)

Multiple connections5. 4.

CAUTION

When connecting multiple (maximum 3) units, be sure to install the unit with the •

largest capacity nearest to the indoor unit.

For example) AJ

When connecting multiple units, set the unit with the largest capacity as the master •

unit, and the rest as the slave units.

(Refer to 7. Field Setting)

When connecting multiple units, use the optional outdoor unit branch kit.•

126LALH (Outdoor Unit1) + AJ 126LALH (Outdoor Unit2) +

AJ

A90LALH (Outdoor Unit3)

Joint pipe

(Accessory)

Knockout

hole

Page 11

To in do or u ni t

Outdoor unit 1

(Master unit)

Outdoor Capacity

2 Units : Unit 1 ≥ Unit 2

3 Units : Unit 1 ≥ Unit 2 ≥ Unit 3

Outdoor unit 2

(Slave unit 1)

Outdoor unit 3

(Slave unit 2)

CAUTION

To prevent the oil from settling in the stopped unit, install the pipes between the

outdoor units so that they are level or are tilted upward to the outdoor units.

Examples of multiple unit installation are shown below.(1)

Installable patterns a)

GOOD

Master

unit

Slave

unit 1

Slave

unit 2

Outdoor unit branch kit

(Optional)

To in do or u ni t

(To main pipe)

To ou td oor un it

To ou td oor un it

Branch kit restriction when install

Be sure following restriction.

Installation angle 1)

Outdoor unit branch kit

Horizontal

A

To in do or u ni t

PROHIBITED

GOOD:

0° to -10°

PROHIBITED

Vert ical

PROHIBITED PROHIBITED PROHIBITED

Install the outdoor unit branch kit horizontally level, within 0° to -10°, so that the •

refrigerant separates evenly.

Do not install the outdoor unit branch kit vertically.•

Straight pipe length 2)

To in do or u ni t

(To main pipe)

To indoor unit (To main pipe)

Leave the distance 0.5 m or more for straight part to outdoor unit branch kit.•

For details, refer to the Installation Instruction Sheet of the outdoor unit branch kit. 3)

Examples of multiple unit installationFig.

(Example 1)

Master unit Slave unit1 Slave unit2

(Example 2)

Master unit Slave unit1 Slave unit2

A

0.5 m or more

0.5 m or more

Liquid pipe

(Field supply)

C

To ou td oor un it

To ou td oor un it

B

To outdoor unit or

C

next branch kit

C

B

To ou td oor un it

(Example 3)

Master

unit

Slave

unit1

Slave

unit2

Joint pipe

(Accessory)

Gas pipe

(Field supply)

PROHIBITED

GOOD:

0° to -10°

PROHIBITED

To ou td oor un it

To ou td oor un it

To ou td oor

unit

To in do or u ni t

GOOD

To in do or u ni t

GOOD

To in do or u ni t

Non-installable patterns b)

PROHIBITED

To in do or u ni t

PROHIBITED

To in do or u ni t

PROHIBITED

To in do or u ni t

If the pipe length between outdoor unit branch kit and outdoor unit branch kit (2)

(or slave unit) is longer than 2 m, or a lower pipe line exists between outdoor

units, rise for gas pipe should be arranged to eliminate oil from entering into and

remaining at pipes and the stopped outdoor unit. However, there is no need to

provide a rise on the pipe connecting between the master unit and the indoor unit

even if the length exceeds 2m.

To in do or u ni t

To in do or u ni t

To in do or u ni t

Master

unit

Master

unit

Master

unit

Master

unit

Master

unit

Master

unit

Master

unit

Master

unit

Slave

unit 1

2 m or less 2 m or less

2 m or more 2 m or more

Slave

unit 1

Slave

unit 1

Slave

unit 1

2 m or less2 m or less

Slave

unit1

Slave

unit 1

Slave

unit 1

Slave

unit1

Rise

lower pipe

Slave

unit 2

Slave

unit 2

Slave

unit 2

Slave

unit 2

Slave

unit 2

Slave

unit 2

Gas pipe

Rise

(200 mm or more)

Slave

unit2

500 mm or less

Gas pipe

Slave

unit2

Gas pipe

En-10

Page 12

ELECTRICAL WIRING6.

The precautions of electrical wiring6. 1.

WARNING

Wiring connections must be performed by a qualifi ed person in accordance with

specifi cations.

The rated supply of this product is 50Hz, 400V of 3-phase, 4-wire. Use a voltage

within the range of 342-456V.

Make sure to perform earthing (grounding) work. Improper earthing (grounding) work

can cause electric shocks.

Before connecting the cables, make sure the power supply is OFF.

Be sure to install an earth (ground) leakage breaker. Otherwise, it will cause electric

shock or fi re.

Be sure to install a breaker of the specifi ed capacity. When selecting breaker, please

comply with the laws and the regulations of each country. One breaker must be

installed on the power supply of the outdoor unit. Wrong selection and setup of the

breaker will cause electric shock or fi re.

Do not connect AC power supply to the transmission line terminal board.

Improper wiring can damage the entire system.

Connect the connector cord securely to the terminal.

Faulty installation can cause a fi re.

Do not modify power cable, use extension cable or branch wiring. Improper use may

cause electric shock or fi re by poor connection, insuffi cient insulation or over current.

Make sure to secure the insulation portion of the connector cable with the cord

clamp. A damaged insulation can cause a short circuit.

Never install a power factor improvement condenser. Instead of improving the power factor,

the condenser may overheat.

Before servicing the unit, turn the power supply switch OFF. Then, do not touch electric parts for 10 minutes due to the risk of electric shock.

Always use a separate power supply line protected by a circuit breaker operating on

all cables with a distance between contact of 3 mm for this unit.

Use crimp-type terminals and tighten the terminal screws to the specifi ed torques,

otherwise, abnormal overheating may be produced and possibly cause serious damage inside the unit.

Securely install the electrical box cover on the unit. An improperly installed service

panel can cause serious accidents such as electric shock or fi re through exposure to

dust or water.

If the supply cable is damaged, it must be replaced by the manufacturer, its service

agent or similarly qualifi ed persons in order to avoid a hazard.

CAUTION

The primary power supply capacity is for the air conditioner itself, and does not include the

concurrent use of other devices.

Connect the power cables in positive phase sequence. If they are connected in

negative phase sequence, an error will be displayed. If there is a missing phase connection, the unit will not operate normally. Do not connect a N phase (neutral phase)

cable to other phases (misconnection). Wrong wiring will lead to parts damage.

Do not use crossover power supply wiring for the outdoor unit.

If the electrical power is inadequate, contact your electric power company.

Install a breaker (Included with earth leakage circuit breaker) in a location that is not

exposed to high temperatures.

If the temperature surrounding the breaker is too high, the amperage at which the

breaker cuts out may decrease.

Use a breaker (Included with earth leakage circuit breaker) that is capable of handling

high frequencies. Because the outdoor unit is inverter controlled, a high-frequency

breaker is necessary to prevent a malfunction of the breaker itself.

When the electrical switchboard is installed outdoors, place it under lock and key so

that it is not easily accessible.

Never bundle the power supply cable and transmission cable, remote control cable

together. Separate these cable by 50 mm or more. Bundling these cables together

will cause miss operation or breakdown.

Always keep to the maximum length of the transmission cable. Exceeding the maximum length may lead to erroneous operation.

The static electricity that is charged to the human body can damage the control PC

board when handling the control PC board for address setting, etc.

Please keep caution to the following points.

Provide the earthing (grounding) of Indoor unit, Outdoor unit and Option equipment.

Cut off the power supply (breaker).

Touch the metal section (such as the unpainted control box section) of the indoor or

outdoor unit for more than 10 seconds. Discharge the static electricity in your body.

Never touch the component terminal or pattern on the PC board.

Wiring method6. 2.

The wiring example for outdoor units and indoor units is shown in the fi gure.

To other refrigerant cricuit

outdoor unit

Power supply

400V 3Ø 50Hz

Outdoor unit 1

(Master unit)

Transmission Transmission Transmission

Power supply

*1

Breaker Breaker Breaker

Power supply

230V 1Ø 50Hz

*1: The number of power supply terminals is different depending on the indoor unit

model. For the wiring, refer to the indoor unit installation manual.

*2: Earth (Ground) the remote controller if it has an earth (ground) cable.

There are two types of remote controller: the 2-wire type and the 3-wire type. For •

details, see the relevant remote controller installation manual. (When connecting the

2-wire type remote controller, Y3 is not used.)

Remote control Remote control Remote control

*2 *2 *2

Remote

controller

Power supply

400V 3Ø 50Hz

Power supplyPower supply

Outdoor unit 2

(Slave unit 1)

Power supply Power supply

*1 *1

Remote

Power supply

230V 1Ø 50Hz

controller

Power supply

400V 3Ø 50Hz

Breaker Breaker Breaker

Power supply

Outdoor unit 3

(Slave unit 1)

TransmissionTransmissionTransmission

Indoor unitIndoor unitIndoor unit

Power supply

230V 1Ø 50Hz

Remote

controller

Knockout hole6. 3.

CAUTION

Seal the wiring route hole with putty (fi eld supply) such that there are no gaps.

Small insects or animals that are trapped in the outdoor unit may cause a short circuit

in the electrical component box.

Be careful not to deform or scratch the panel while opening the knockout holes.

After opening the knockout hole, remove the burr on the edges to prevent snapping

of cables.

It is recommended to apply rust proof paint on the edges to prevent rust.

Electric wires can be connected from the front or from the left.

(Knockout holes are prepared so that wiring can be made from 2 different directions.)

Use the knockout holes on the front and the left separately when necessary.

En-11

Page 13

In case of connected 3 outdoor unitFig.

GOOD

Sub

Main

breaker

400 V 3ø

50 Hz

breaker

< Left view >

Ø 50

Ø 34.5

Ø 43.7

Ø 22.2

< Front view >

Ø 50

Ø 34.5

Ø 22.2

Ø 43.7

(Unit: mm)

Selecting power supply cable and breaker6. 4.

CAUTION

Obtain the distribution network operator's agreement about the power capacity of

the power supply system, specifi cation of the cable and the harmonic current, and

etc. when you connect the outdoor unit with the power supply.

Regulation of wire size and circuit breaker differs from each locality, please refer in

accordance with local rules.

Refer to the table for the wiring and breaker specifi cations of each installation condition

Selecting power supply cable and breaker when connecting 1 outdoor unit(1)

MODEL

AJ

A72LALH 30

A90LALH 30

AJ

AJ

108LALH 50

126LALH 50

AJ

144LALH 50

AJ

MODEL

A72LALH 4 4 30

AJ

AJ

A90LALH 4 4 30

108LALH 10 6 42

AJ

126LALH 10 6 42

AJ

144LALH 10 6 42

AJ

These values are recommended data. 1)

Specifi cation: Use conformed cord with Type 60245 IEC66 2)

Max. wire length: Set a length so that the voltage drop is less than 2%. Increase 3)

the wire diameter when the wire length is long.

In case of connected outdoor unitFig.

Transmission cable

GOOD

400 V 3ø 50 Hz

Breaker

Outdoor unit

Power supply cable

Selecting main breaker and main power supply cable when connecting multiple (2)

outdoor units

Main breaker: Main breaker ≥ Total Sub breaker

sub breaker capacity)

Breaker (Time delay fuse or circuit capacity)

Fuse capacity (A) Leakage current

100mA

0.1sec or less

Outdoor unit power supply cable

Power supply

cable (mm

Ground wire (mm2)

2

)

230 V 1ø 50 Hz

(Refer to the table in item (1) for the

Critical wiring

Indoor unit

Power supply cable

Breaker

Remote controller cable

length (m)

Outdoor unit power supply cable

Example of bad breaker wiring(3)

PROHIBITED

400 V 3ø

50 Hz

Outdoor unit

Breaker

PROHIBITED: install a

breaker for each outdoor unit

Power supply cable

PROHIBITED: crossover

power supply wiring prohibited

Transmission line6. 5.

CAUTION

Caution when wiring cable•

.

When stripping off the coating of lead wire, always use the exclusive tool such as

a wire stripper. If there is no exclusive tool available necessarily, carefully strip the

coating by a cutter etc. so that the conductive wire is not damaged.

If it is damaged, it may lead to an open circuit and a communication error.

Pay attention to the following points while attaching wires on the terminal board.•

Do not attach 2 wires on one side.

Do not twist wires.

Do not cross the wires.

Do not shorted at edge at root.

2pcs at one side

PROHIBITED

Shorted at edge

PROHIBITED PROHIBITED

Wires twisted

PROHIBITED

Shorted at root

Transmission wiring specifi cations6. 5. 1.

Follow the specifi cations below for the transmission cable.

Use Size Wire type Remarks

Transmission

cable

0.33mm

22AWG LEVEL 4 (NEMA)

2

non-polar 2core, twisted pair

solid core diameter 0.65mm

Wiring rules6. 5. 2.

(1) Total length of transmission cable

Total transmission line length : Max. 3,600 m

EF + EG + GH + HJ + HK + KL < 3,600 m (Fig.2)

In the following cases , Signal Amplifi er is required.

When the total length of the transmission line exceeded 500 m.

①

AB + BC + BD > 500 m (Fig.1)

When the total number of units* is over 64.

②

Transmission line length between each unit* ≥

③

(2) Length of transmission cable between 1 network segment (NS)

EF + EG + GH + HJ + HK ≤ 500 m (Fig.2)

KL ≤ 400 m (Fig.2)

(3) Length of transmission cable between outdoor units in a refrigerant system

MN ≤ 18 m

NP ≤ 18 m

400m

1 wire

GOOD

2 wires

GOOD

LONWORKS

patible cable

®

com-

En-12

Page 14

1Fig.

Terminal

resistor

2Fig.

Outdoor unit

B

A

Indoor unit

When AB + BC + BD > 500 m :

Signal Amplifi er is required.

Outdoor unit

E

Terminal resistor

M

N

Transmission line

Indoor unit

F

Wiring procedure6. 6.

System

Controller

C

D

Tou c h

Panel

Controller

NS 1

P

• Remove the cover of the electrical compartment and follow the terminal plate to connect the electric cables to the terminal.

• After connecting the cables, secure them with the cable ties.

• Connect the cables without applying excessive tension.

Cable routing

Secure with a binder as shown in the fi gure below.

Connecting the

power supply

cable

Connecting the

transmission

cable

G

Transmission line

H

K

Signal Amplifi er

NOTE)

Unit* means indoor unit, outdoor unit, Touch Panel Controller and System Controller,

Signal Amplifi er, single split adaptor, Network Convertor etc..

Do not use loop wiring. This may lead to parts damage and erroneous operation.

Terminal resistor

J

NS 2

Tou c h

Panel

Controller

System

L

Controller

Enabling/Disabling automatic address setting6. 5. 3.

You can enable/disable automatic address setting for the indoor unit and the signal

amplifi er.

To enable automatic address setting for the indoor unit, connect the indoor unit to

outdoor units under the same refrigerant system.(Fig.4)

Example : Disable Automatic Address setting

Refrigerant

system 1

Refrigerant

system 2

Refrigerant

system 3

Example : Enable Automatic Address setting

Refrigerant

system 1

Transmission line

Transmission line

Transmission line

Transmission line

Cable tie

(Accessory)

Cable guide

Cable clip

Cable tie *

(Accessory)

Power supply

cable routing

* Tighten the cable tie fi rmly so that pulling force does not propagate to the terminal

connection even if force of 100N is applied to the cable.

Transmission cable routing

Connecting cables to the terminals

WARNING

Use ring terminals and tighten the terminal screws to the specifi ed torques, other-

wise, abnormal overheating may be produced and possibly cause heavy damage

inside the unit.

Be sure fi ll the holes of power supply cable and transmission cable with putty (fi eld

supply).

If small animals such as insects enter the electrical component box, a short circuit

may be caused.

Tight ening to rque

M3 screw 0.5 to 0.6 N·m (5 to 6 kgf·cm)

M8 screw 5.0 to 7.0 N·m (50 to 70 kgf·cm)

Refrigerant

system 2

Refrigerant

system 3

En-13

Transmission line

Transmission line

Page 15

(1) Connecting the power supply cable

Caution when wiring cable

1) Use crimp-type terminals with insulating sleeves as shown in the fi gure to con-

nect to the terminal block.

2) Securely clamp the crimp-type terminals to the cables using an appropriate tool

so that the cables do not come loose.

3) Use the specifi ed cables, connect them securely, and fasten them so that there

is no stress placed on the terminals.

4) Use an appropriate screwdriver to tighten the terminal screws. Do not use a

screwdriver that is too small, otherwise, the screw heads may be damaged and

prevent the screws from being properly tightened.

5) Do not tighten the terminal screws too much, otherwise, the screws may break.

6) See the table for the terminal screw tightening torques.

Strip 10 mm

Ring terminal

Sleeve

Cable

Screw with

special washer

Ring terminal

Screw with

special washer

Ring terminal

Terminal block

Cable

External input and external output6. 7.

Terminal position6. 7. 1.

Base heater

(CN115: Black)

Output 1

(CN136: Black)

Output 2

(CN137: Blue)

Input 4

(CN134: Red)

Input 3

(CN133: White)

Input 2

(CN132: Green)

Input 1

(CN131: Yellow)

Input 5

(CN135: Orange)

Ring terminal: M8

Earth (Ground)

cable

Cable clamp

90 to 100 mm

70 to 80 mm

Use a ring terminal to connect the electric cables to the power supply terminal *

board.

(2) Connecting the transmission cable

Sealing transmission cable

Connect both ends of the sealed wires of the transmission cable to the earth terminal

of the equipment or to the earth screw near the terminal.

Be very careful that the screws are not overly tightened as the wires may snap and

the terminal may be damaged.

Wind with insulation tape to

prevent short circuit

Use one side of the

twisted-pair cable

Be sure to use one side of a twisted-pair cable when using transmission cable with 2

sets of twisted-pair cables.

8 to 10 mm

Connect both ends of sealed

cable to earth.

IN

RB

Outdoor unit PC board

CAUTION

Do not bundle the cable for base heater with other cables.

(Example)

In case of Outdoor unit

Insert the connector to CN136 (Black) and CN137 (Blue) of control PC board. (1)

Fix it to the wire with the attached cable tie.(2)

CN136

(Black)

CN115

(Black)

Clamp

Wire

▪ Do not clamp the base heater cable.

External input terminal6. 7. 2.

Service parts: EXTERNAL INPUT WIRE A (9368777005)

Setting to low noise mode, outdoor unit operation peak control setting, emergency/•

batch stop and electricity meter pulse are possible from the outside.

Except for wattmeter pulse reception (CN135) among external input terminals, only •

the Master unit is effective.

Clamp

CN137

(Blue)

Cable tie

(Accessory)

40 mm or more

Cable clip

Cable tie

(Accessory)

Wiring method and specifi cations

A twisted pair cable (0.33 mm*

cable is 150 m.

Use an external input and output cable with appropriate external dimension, de-*

pending on the number of cables to be installed

For each input, pin No.1 is of positive polarity and pin No.2 is of ground level.*

2

(22AWG)) should be used. Maximum length of

En-14

Page 16

Input 1

CN131

(Yellow)

P. C .B

connected unit connected unit

Operation behavior

Each input terminal works as follows.

Connector Input signal Status

Input 1

CN131 (Yellow)

Input 2

CN132 (Green) *1

Input 3

CN133 (White)

Input 4

CN134 (Red)

Input 5

CN135 (Orange) *4

Slave unit can connect only input5 (CN135).

The operations of each input terminal and the selection of function are set with the

push button on the PC board of outdoor unit. About the setting, please refer to 7.4.

Push button setting.

Note :

*1: The "external input priority mode" must be set by pressing push button on PC

board of outdoor unit.

*2: Batch stop or Emergency stop pattern can be selected by outdoor unit PC

board push button.

*3: The emergency stop function mounted in the V-II does not guarantee the

regulations of each country. For this reason, suffi cient checking is necessary

regarding use.

Especially, since the fact that the equipment may not be emergency-stopped

in the case of breaking of the wiring to the external input terminals and communication line, communication error due to noise, VRF external input circuit

trouble, etc. must be considered, the provision of double measures that add

direct interruption of the power supply by switch, etc. is recommended as a

precaution.

*4: Pulse input to CN135 must be width 50ms or more, and must be interval 50ms

or more.

CN132

(Green)

OFF Normal operation

ON Low noise mode operation

OFF Cooling priority

ON Heating priority

OFF Normal operation

ON

OFF Normal operation

ON

No pulse

Pulse

Input 3Input 2

CN133

(White)

connected unit connected unit connected unit

Outdoor unit operation peak

control

Batch stop or Emergency stop

operation *2, *3

No information from electricity

meter

Power usage information from

electricity meter

Input 4

CN134

(Red)

Input 5

CN135

(Orange)

Outdoor unit

Master Slave

O

O

O

O

OO

External output terminal6. 7. 3.

Service parts : EXTERNAL INPUT WIRE A (9368777005)

You can detect the operation condition of outdoor unit and the abnormal situation •

of both indoor and outdoor unit.

The external output terminal is only valid for Master Unit.•

Wiring method and specifi cations

Error status (Master unit only)

This output indicates the outdoor unit and connected indoor unit's "Normal" or "Error"

status.

Operation status (Master unit only)

This output indicates the outdoor unit's "Operation" status.

Connector Output voltage Status

CN136 (Black)

CN137 (Blue)

0 V Normal

DC 12 to 24 V Error

0 V Stop

DC 12 to 24 V Operation

P. C .B

CN136

(Black)

or CN137

(Blue)

5: Provide a DC12 to 24 V power supply. *

Select a power supply capacity with an ample surplus for the connected load.

6: The allowable current is 30 mA or less. *

Provide a load resistance such that the current becomes 30 mA or less.

7: Polarity is [+] for pin 1 and [-] for pin 2. Connect correctly.*