FujiFilm NXT Setup Manual

Fuji Scalable Placement Platform

NXT

Setup Manual

QD002-07

R

Consult Fuji beforehand if you are considering selling this

equipment to a third party after it has been installed.

Fuji Scalable Placement Platform

NXT

Setup Manual

The manuals listed below are shipped with the NXT machine.

NXT Setup Manual

NXT System Reference

NXT Mechanical Reference

FUJI Intelligent Feeder Manual

NXT Programming Manual

In order to operate this machine in the safest and most efficient

manner, please read the provided manuals thoroughly and

observe all instructions and warnings.

Keep these manuals in an accessible location near the machine.

QD002-07

R

Copyrights

All rights regarding this manual are reserved by Fuji Machine Manufacturing Co., Ltd. This manual may

not, in whole or in part, be reproduced by any means (electronic, mechanical or otherwise), or reused in

any way, without the prior written permission of Fuji Machine Manufacturing Co., Ltd.

Trademark Rights

R

is a trademark of Fuji Machine Manufacturing Co., Ltd., and registered in the following

countries: Austria, Belgium, Denmark, Finland, France, Germany, Greece, Indonesia, Ireland, Italy, Jap an,

Korea, Luxembourg, the Netherlands, Portugal, Spain, Sweden, the U.K., and the U.S.A.

W arranty and Liability

Fuji Machine Manufacturing Co., Ltd. accepts no responsibility for situations that may arise due to any of

the following:

• The use of third party parts.

• The use of non-genuine Fuji parts.

• Incorrect settings made by the customer.

• Improper use of Fuji equipment.

Notice

Fuji Machine Manufacturing Co., Ltd. reserves the right to change the content of this manual without

notice.

Every effort has been made to ensure that this manual is correct in every detail. However, please contact

Fuji in the unlikely event that errors or omissions are detected.

Fuji Machine Manufacturing Co., Ltd. accepts no liability whatsoever for damages that may arise as a

result of this manual, with the exception of problems that originate in our products.

QD002-07 Contents

Contents

1. Safety Guideline................................................... 1

1.1 About Symbols ................................................. 1

1.1.1 Degree of Hazards ................................................. 1

1.1.2 Examples of the Symbols....................................... 1

1.2 Safety Rules for All Machine Types.................. 2

1.3 Safety Rules for NXT........................................ 6

1.3.1 Main Unit ................................................................ 6

1.3.2 Tray Unit-L............................................................ 10

1.3.3 Tray Unit-M........................................................... 11

1.4 Safety Labels.................................................. 12

1.4.1 NXT Safety Label Explanations............................ 15

1.5 The EMERGENCY STOP Button................... 16

1.6 Locking System.............................................. 17

1.6.1 Lockout Procedure ............................................... 17

1.6.2 Unlocking Procedure............................................ 19

2. Setting Up the NXT............................................. 21

2.1 Introduction..................................................... 21

3. Machine Set Up.................................................. 23

3.1 Moving a Machine .......................................... 23

3.1.1 Precautions when moving the machine................ 23

3.1.2 Transport Procedure............................................. 24

3.2 Removing Fixing Brackets.............................. 28

3.2.1 Procedure............................................................. 28

3.3 Removing the Linear Motor Shaft Protective

Covers .............................................................. 31

3.3.1 Procedure............................................................. 31

3.4 Making Basic Connections............................. 32

3.4.1 Electric power supply............................................ 32

3.4.2 Network Cable...................................................... 34

3.4.3 Air supply.............................................................. 35

3.5 Leveling the Machine...................................... 36

NXT Setup Manual i

Contents QD002-07

3.5.1 Procedure............................................................. 36

3.6 Making Network Settings ............................... 39

3.6.1 Procedure............................................................. 39

3.7 Connecting NXT Bases.................................. 40

3.7.1 Connecting Method............................................... 41

3.7.2 Signal Cable Connecting Diagram

(NXT - NXT - NXT)................................................ 43

3.8 Installing Additional Dependent Bases........... 44

3.8.1 Extension Patterns................................................ 44

3.8.2 Pneumatic Connections........................................ 45

3.8.3 Using One 2M Base.............................................. 46

3.8.4 Using Two 2M Bases............................................ 51

3.8.5 Using Three 2M Bases......................................... 57

3.8.6 Using Four 2M Bases........................................... 63

3.8.7 Using One 2M Base and an Independent

4M Base (1)............................................................ 68

3.8.8 Using Two 2M Bases and an Independent

4M Base (1)............................................................ 75

3.8.9 Using One 2M Base and an Independent

4M Base (2)............................................................ 84

3.8.10 Using Two 2M Bases and an Independent

4M Base (2)............................................................ 91

3.8.11 Using One 4M Base and an Independent

4M Base (1).......................................................... 100

3.8.12 Using One 4M Base and an Independent

4M Base (2).......................................................... 106

3.8.13 Fastening Extensions ....................................... 112

3.9 Connecting an NXT Base to Other Machine Types

....................................................................... 114

3.9.1 Procedure........................................................... 115

3.9.2 Signal Cable Connecting Diagram

(Other machine type - NXT - Other machine type) 116

3.10 Tray Unit-L ................................................. 117

3.10.1 Adjusting the Height and the Levelness ........... 117

4. Setting Up NXT Machines in Flexa.................. 121

4.1 Introduction .................................................. 121

4.2 General Procedures..................................... 121

ii NXT Setup Manual

QD002-07 Contents

4.2.1 Creating a factory............................................... 121

4.2.2 Creating a line .................................................... 121

4.2.3 Creating a machine ............................................ 122

5. Accessory Software Installation........................ 125

5.1 Introduction................................................... 125

5.1.1 Installation outline............................................... 125

5.2 Required Items............................................. 126

5.2.1 Required hardware............................................. 126

5.3 Installing Fuji Flexa....................................... 128

5.4 Installing the NXT Accessory Software Server 136

5.5 Installing the Realtime Workingrate Buffer

Service........................................................... 145

6. Setting Up Fujitrax Verifier ................................ 147

6.1 Introduction................................................... 147

6.2 Required Items............................................. 147

6.2.1 Setting up and running the Central Server......... 147

6.2.2 Adding the NXT to the Fujitrax line configuration 148

6.2.3 Setting the NXT Fujitrax configuration settings .. 150

6.2.4 Registering users for Kit Handy access.............. 151

NXT Setup Manual iii

Contents QD002-07

MEMO:

iv NXT Setup Manual

QD002-07 1. Safety Guideline

1. Safety Guideline

Fuji machines are designed and produced with safety as one of our main considerations.

However, even a perfectly designed machine can be damaged, or someone can still be

injured if the user does not follow the safety rules. It is the responsibility of the user to make

sure all safety rules are followed during operation and maintenance.

Be sure to read these safety rules before operating the machine. Keep this manual close

at hand when operating the machine.

1.1 About Symbols

To avoid injury to persons and damage to the machine, Fuji employs a number of messages

and symbols that are used in manuals and on the machines. Be sure you understand the

meanings of these symbols before reading the manual.

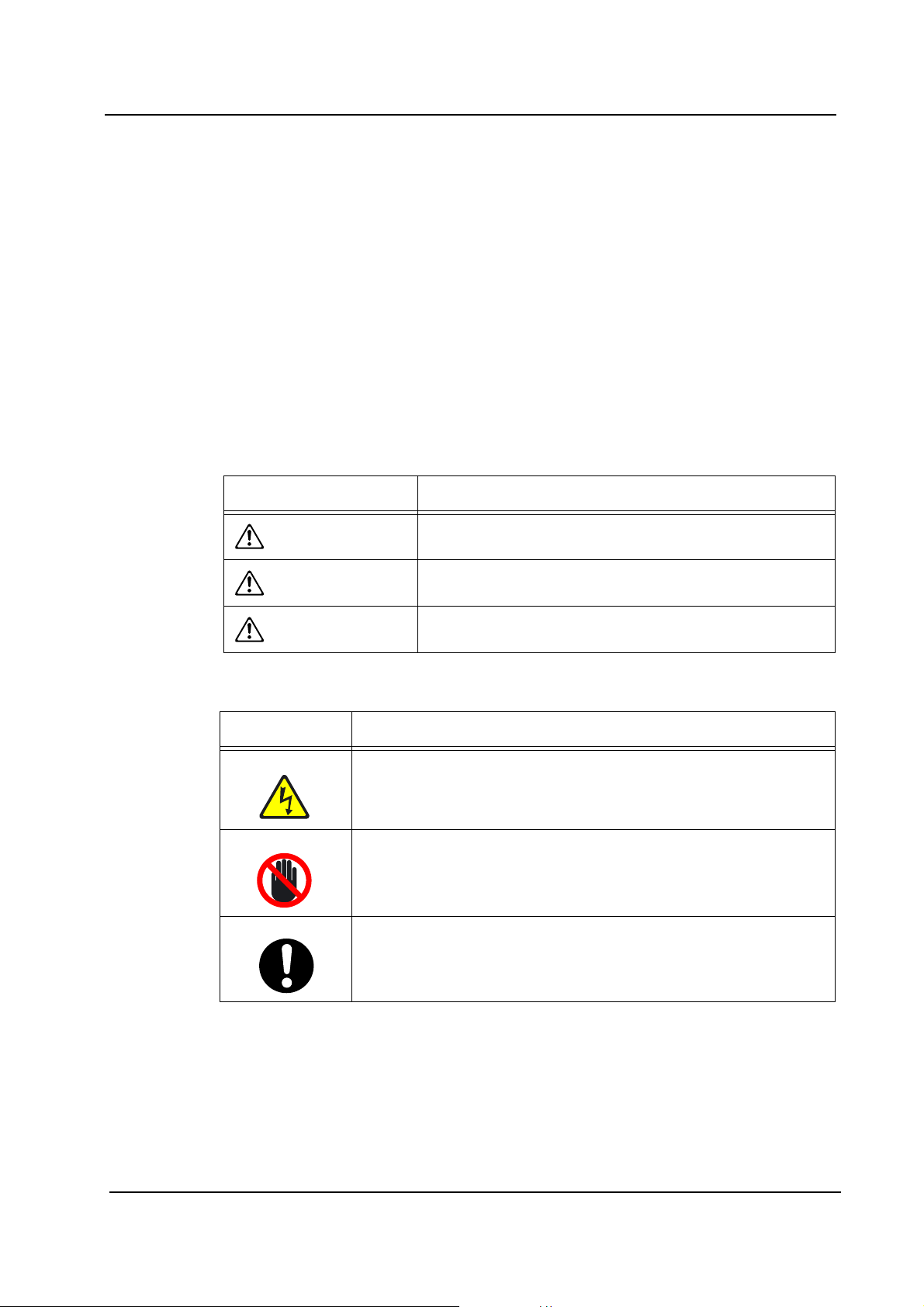

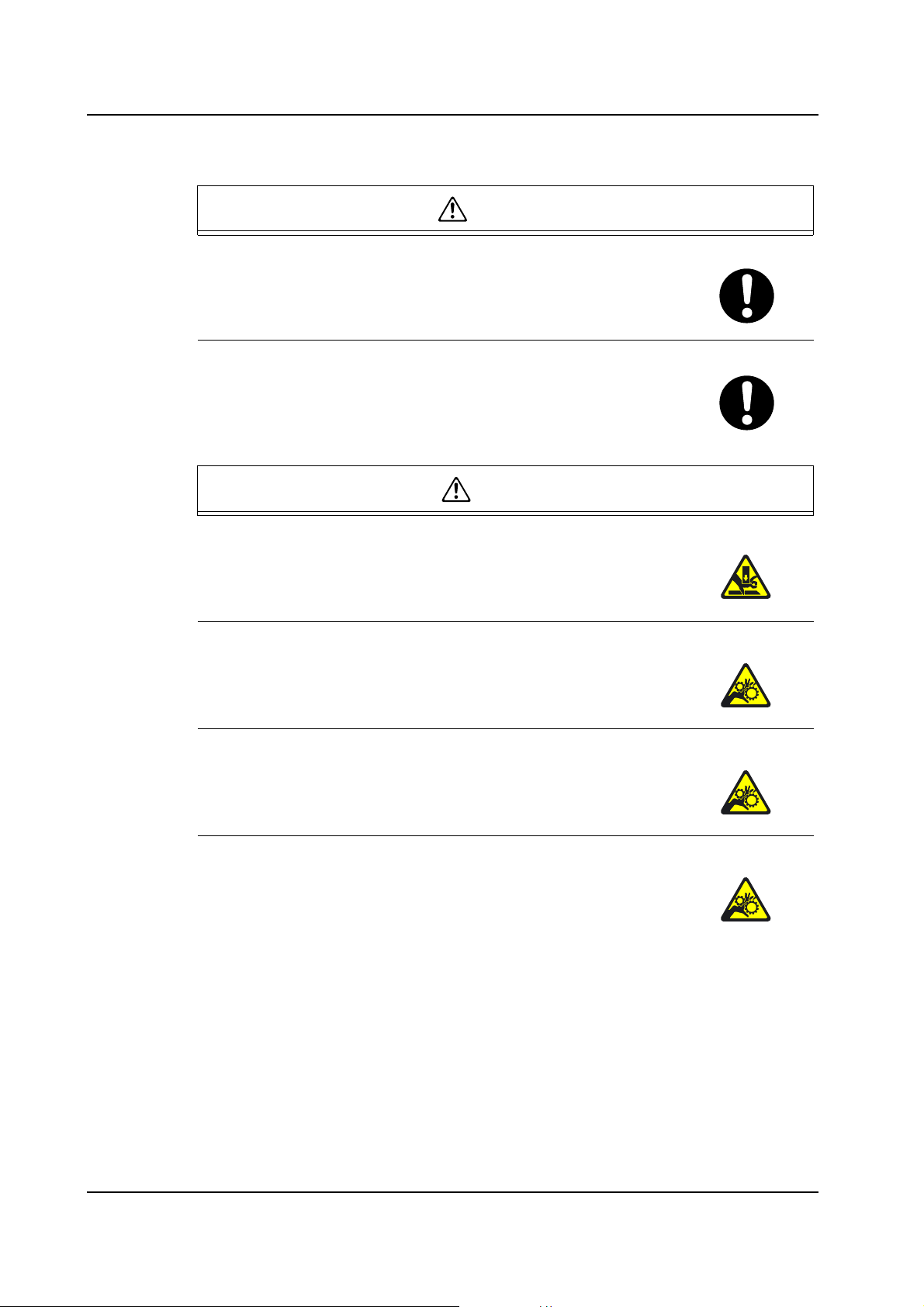

1.1.1 Degree of Hazards Symbol Definition

DANGER

WARNING

CAUTION

Failure to observe this hazard warning will lead to severe

injury or death.

Failure to observe this hazard warning may lead to severe

injury or death.

Failure to observe this hazard warning may lead to

personal injury or damage to the machine.

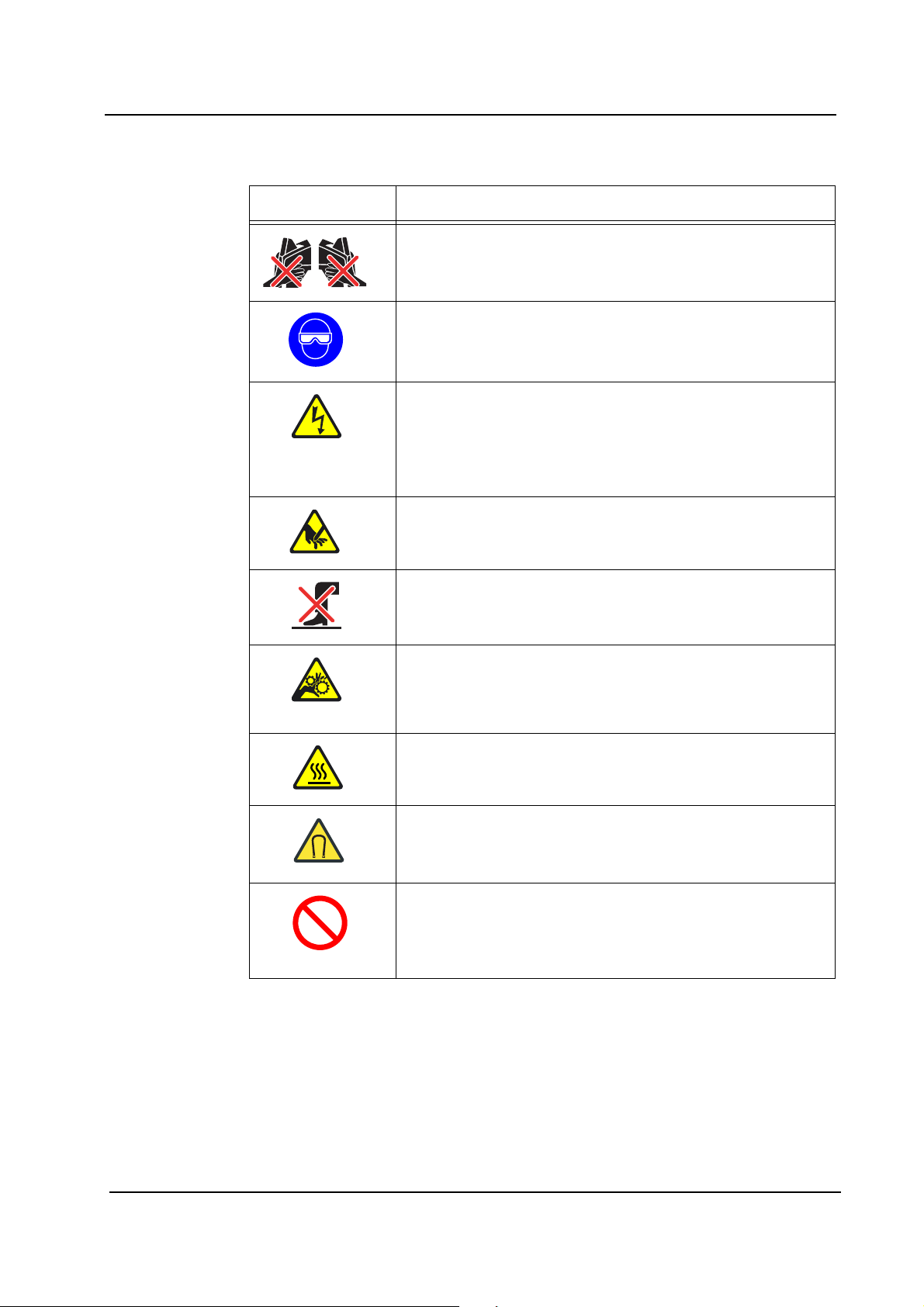

1.1.2 Examples of the Symbols

Symbol Explanation

Hazard

A triangle is used to draw your attention to a hazard. The symbol

inside the triangle indicates the nature of the hazard (in this case,

electrical shock).

Prohibition

A circle with a diagonal line is used to draw your attention to an

operation that is prohibited. The symbol inside the circle indicates

the nature of the operation (in this case, disassembly).

A circle with an exclamation mark is used to draw your attention to to

a mandatory action. In other words, you are required to carefully

carry out the given instructions.

NXT Setup Manual 1

1. Safety Guideline QD002-07

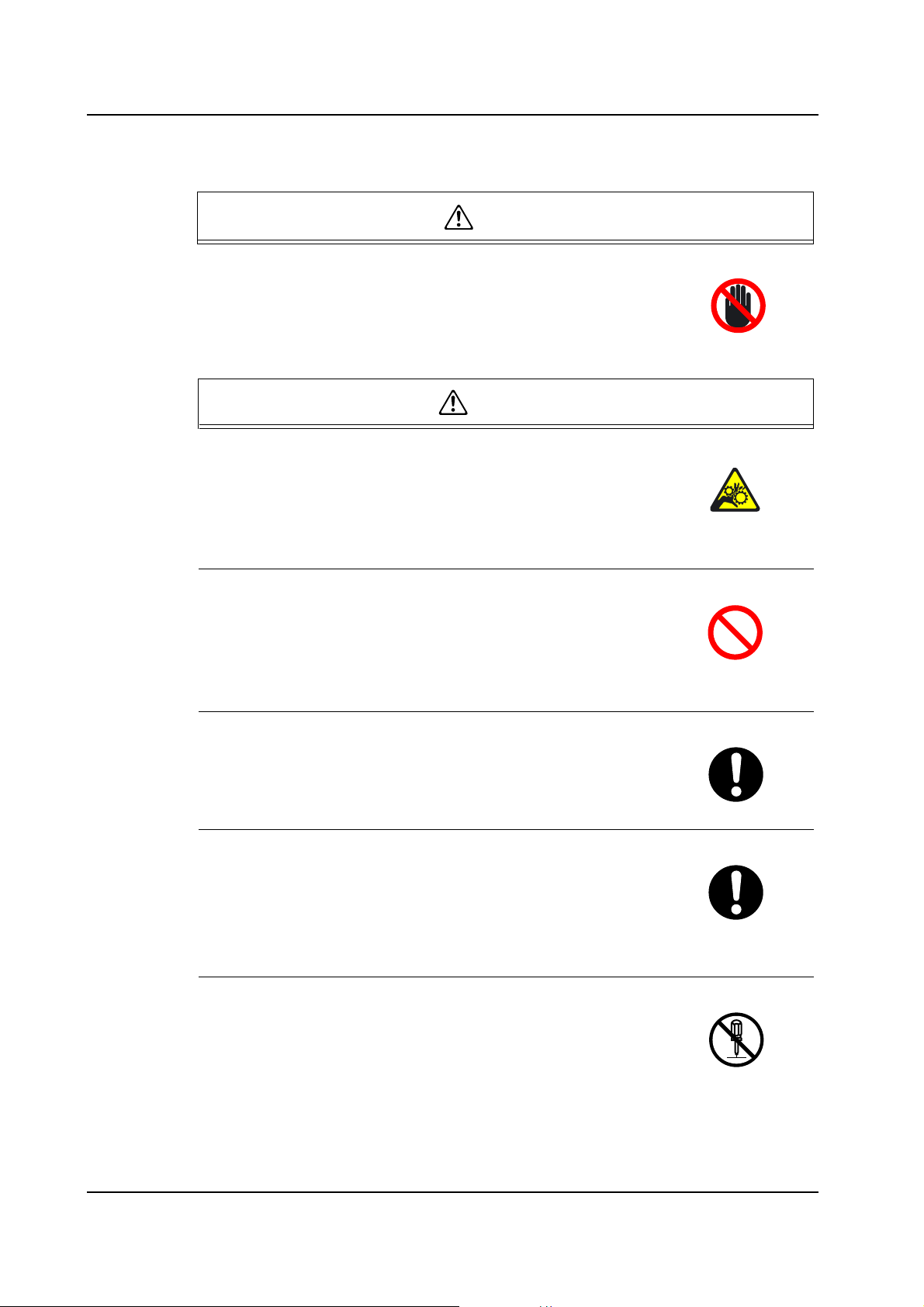

1.2 Safety Rules for All Machine Types

DANGER

Do not approach moving parts during automatic or manual

operation

• Do not place hands or other body parts inside the machine

during automatic operation or positioning. Body parts or

clothing may be caught in the machine causing personal injury.

WARNING

Do not insert hands or other body parts into the conveyor

inlets

• Body parts may get caught in the machine resulting in injury.

• If using a single machine independently, install safety covers or

interlock sensors at the conveyor openings, in accordance with

your local safety regulations, to prevent injuries at the conveyor.

Do not operate the machine with the safety covers or doors

open

• When safety covers or doors are removed, body parts or

clothing may be caught in the machine causing personal injury.

• When maintenance works are completed, return the safety

covers and doors to their original (closed) position.

Always verify the position of the EMERGENCY STOP

buttons before operating the machine

• Always be aware of the positions of the EMERGENCY STOP

buttons so that they can be pressed quickly in case of an

emergency.

Check the safety functions before starting operation

• Before starting the machine check the operation of the

EMERGENCY STOP button, the safety switches on the covers,

doors and all other machine safety feature s.

• Contact a Fuji serviceman immediately if any of the safety

functions fails.

Do not remove safety switches or disarm the safety

functions

• Do not short or remove the machine’s safety switches. Persons

working on the machine may be seriously injured if operation

commands are issued by mistake.

2 NXT Setup Manual

QD002-07 1. Safety Guideline

WARNING

Check that there is nobody inside the machine when

working on the machine with two persons or more

• Verify that nobody is within or near the machine before

operating the machine. Operating the machine may cause

injury to the person who is carrying out maintenance.

Do not approach a machine that has stopped moving

• There are times during automatic operation when the machine

may appear to have stopped while it is waiting for a board,

waiting for the next machine, reading marks, transmitting data,

etc. In such cases, once certain conditions are fulfilled, the

machine will begin moving again automatically, so care should

be taken. Only approach the machine after the EMERGENCY

STOP button has been pressed.

• When the message "Ready" displays at the machine display,

the machine will begin to move once certain conditions are

satisfied. Keep in mind that the machine will begin to move

regardless of whether these conditions are satisfied

intentionally or inadvertently.

Do not place hands near the main conveyor

• Hands or other body parts may be caught in the machine.

Always perform maintenance work after turning OFF the

machine power supply.

• Failure to observe this may result in sudden machine

movements or electric shock, and is therefore extremely

dangerous.

Do not insert or remove connectors while power is being

supplied to the machine

• Removing or inserting connectors while power is supplied to the

machine may not only cause damage to the machine, but may

also cause electrical shock.

Stay clear from the machine when it is being lifted

• Never put hands or feet under the machine when the machine

is being raised by means of a jack or other device for leveling o r

transport.

NXT Setup Manual 3

1. Safety Guideline QD002-07

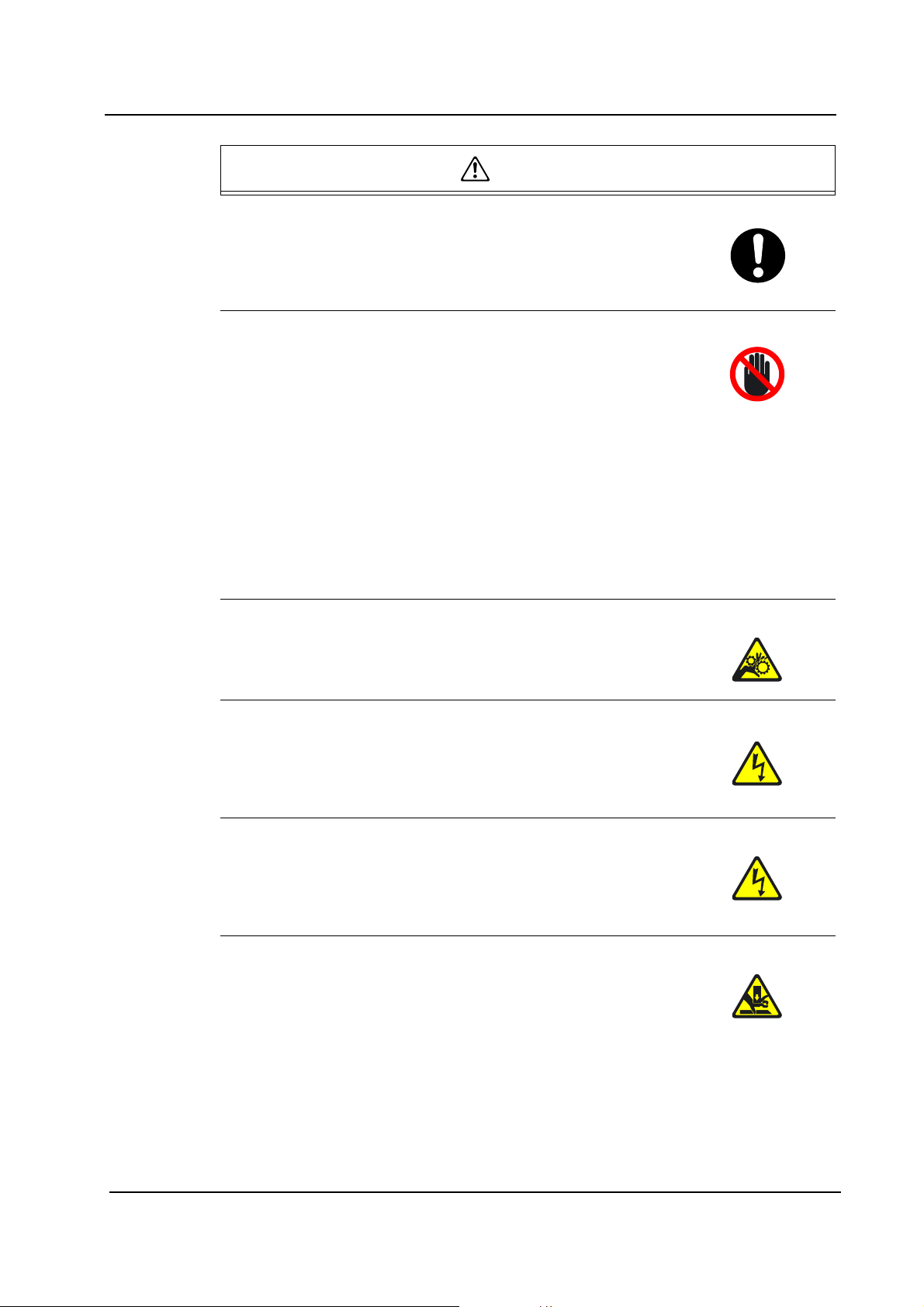

WARNING

Do not wear gloves made of cloth when operating the

machine

• Rubber gloves will tear when caught by the machine and

prevent hands from being drawn into the machine. Gloves

made of cotton or similarly strong material may cause hands to

be drawn into the machine.

Long hair should be tied back

• Long hair may get caught in running machines.

Hair should be kept short or tied back so that it does not get

caught in the machine.

Turn off the air supply when carrying out maintenance on

cylinders, valves, and filters

• Removing cylinders, valves, or filters without turning the air

supply off, may cause parts or particles to be propelled into the

eyes.

• Be sure to turn off the air supply when carrying out maintenance

on cylinders, valves, and filters.

Be sure to wear protective glasses when removing parts

from the machine

• Be sure to wear protective glasses when removing or

disassembling parts.

Check the machine monitor and the target axes while

manually operating the machine

• When operating the machine, carefully follow the instructions

that are displayed at the machine display.

• Operating the machine without looking at the machine display

may lead to operating errors or result in damage to the mach ine

or products.

Do not touch the servo amp power terminal for at least five

minutes after turning off the power

• The servo amp retains a high voltage even after the power has

been turned off.

• Always wait at least five minutes, and ensure that the CHARGE

lamp is off, before undertaking any work that may result in

contact with the servo amp terminal.

4 NXT Setup Manual

QD002-07 1. Safety Guideline

CAUTION

Do not operate the machine after removing or disabling

sensors

• Removing or disabling sensors will disarm the interlock, leading

to collisions and damage to the machine.

Confirm the operational status at the machine messages for

machines that support automatic changeover

• On machines equipped with an automatic changeover system,

it is difficult to ascertain the changeover sta tus fr om th e fr ont o f

the machine during operation in production mode. Follow the

instructions that display at the machine monitor

Ensure to use the handle when opening or closing the safety

doors, fences or covers

• Opening or closing the safety doors, fences or covers without

using the handle may result in injury to the hand.

• Opening or closing the safety doors, fences or covers with force,

without using the handle may result in damage to the machine.

NXT Setup Manual 5

1. Safety Guideline QD002-07

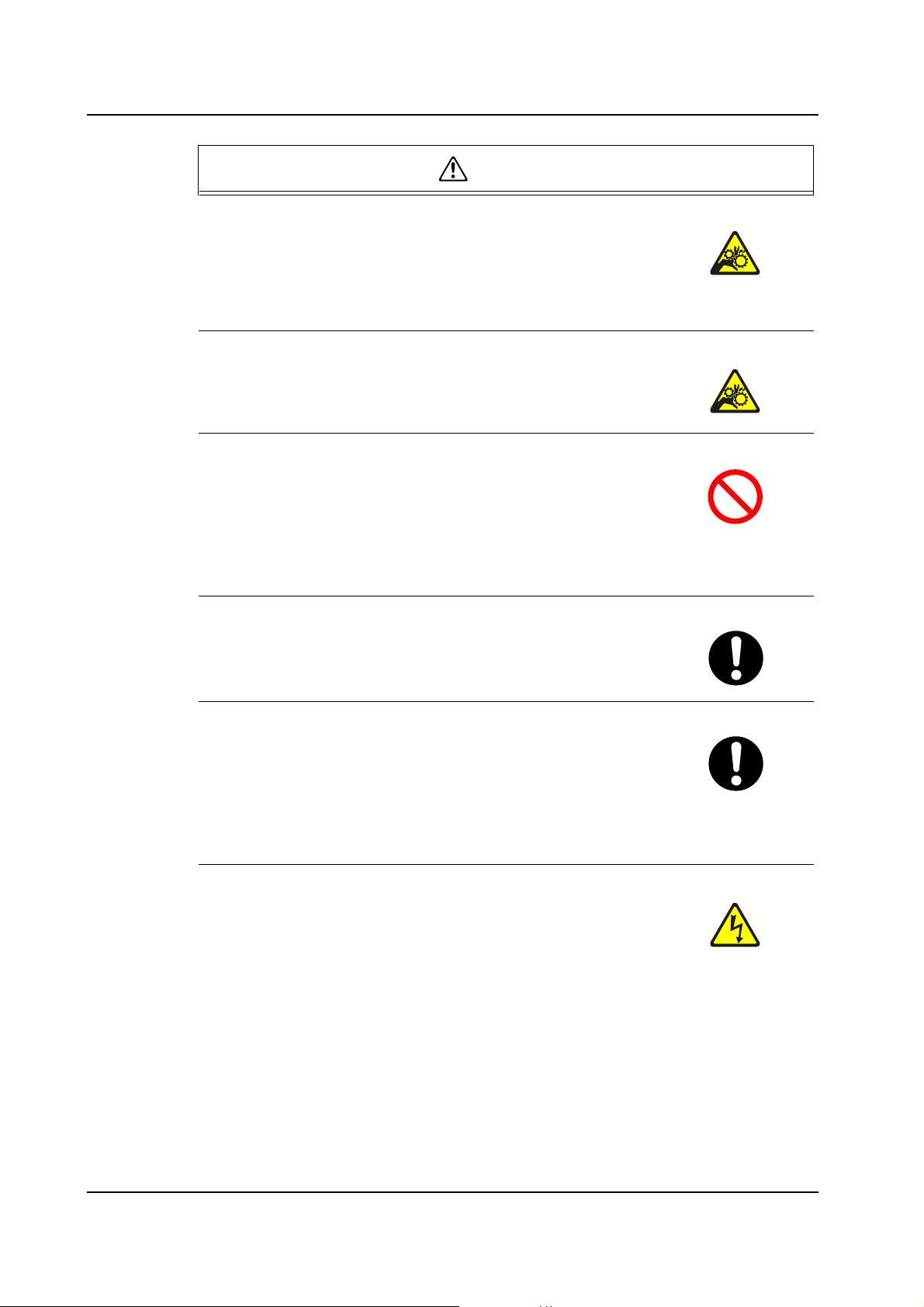

1.3 Safety Rules for NXT

1.3.1 Main Unit

WARNING

Do not insert hands or other body parts into t he mach in e in t he

area between feeders especially when there are only a few

feeders present on the feeder pallet.

• Failure to do so could result in injury due to contact with the body

part and the head during movement.

When changing the conveyor width with the module retracted,

do not insert hands in the area near the conveyor

• Fing e rs may be pi nc ed or caug ht in the m ova b le co nve yo r ra il,

resulting in serious injury.

When mounting the MCU, ensure that no one is between the

MCU and machine base

• A person could be crushed to death if caught between the MCU and

base.

When pushing a module onto the base, check that no one is

behind the module

• A person could be crushed between the base and module, resulting

in serious injury.

When pushing in a module, do not insert hands between the

module cover support and module

• Fingers may be pinced or caught, resulting in serious injury.

When pushing in a module, do not insert hands between the

module lower front cover and base

• Fingers may be pinced or caught, resulting in serious injury.

When pulling out or pushing in a module, do not insert hands or

other body parts in between modules

• If caught between modules, fingers or other body parts could be cut

or severed.

When working on the module in an opening with the cover off,

ensure that no one pushes or pulls out in the module

• The module may punch, sever, or cause serious injury.

6 NXT Setup Manual

QD002-07 1. Safety Guideline

WARNING

When working on the base in the opening above the waste tape

box, ensure that no one pulls out a module

• The module may pinch, sever, or cause serious injury.

When working on the base in an opening with the cover off,

ensure that no one pushes or pulls out in the module

• The module may pinch, sever, or cause serious injury.

Do not rotate the module lock knob to [UNL OCK] when a module

is loaded on the MCU.

• If the module moves on the MCU, it could pinch and sever fingers,

and if it falls from the MCU it could cause severe injury or death.

There is a limit to the number of modules that can be pulled out

safely at the same time. (Maximum: Four M3 modules on an 8M

base, or two M3 modules on a 4M base.)

• If the maximum is exceeded, the entire machine may fall over to the

front, possibly resulting in serious physical harm. This is especially

true when the front leveling bolts have not been adjusted.

Do not modify the module stopper mechanism on the base and

remove the module without mounting the MCU first.

• The module could fall from the base causing severe injury or death.

Do not stare at the vision process light sources with naked eye s.

Wear protective glasses.

• Ey e da m ag e ma y be cau se d by the ligh t.

Stay off of the base.

• Failure to do so could result in injury.

When handling the MCU, watch out for corners and protrusions.

• Failure to do so could result in injury.

Always be ready to apply the caster brake when handling the

MCU.

• Always use the caster brake when stopping an MCU loaded with a

module.

NXT Setup Manual 7

1. Safety Guideline QD002-07

WARNING

When lifting a backup plate, be careful to not put your hands in

the areas between the plate, width-changing ball screw, and

hexagonal shaft. Also, be careful to not cut your hands on the

corners of the conveyor rails.

• Failure to do so could result in injury.

Do not lift a backup plate if you are not strong enough, and

maintain correct lifting posture if you do lift a backup plate.

• Because the backup plates are very heavy, lifting them incorrectly

could result in back or other injuries.

Never insert hands or other body parts into the duct of the waste

tape disposal unit.

• There is a very sharp cutter blade. Exercise extreme caution

especially when carrying the unit.

Two or more people should carry the waste tape disposal unit.

• Maintenance of the waste tape disposal unit is usually accompanied

by removing the unit from the machine. Two or more people should

carry the unit because it is very heavy.

Ensure that the work bench where the waste tape disposal unit

is placed is flat.

• The unit may fall to the ground if the work bench is tilted, causing

personnel injury and the machine damages.

Do not touch the Y-axis linear motor in a M6S module

immediately after production is stopped.

• Contact with the shaft or coil section could cause burns. The shaft

and coil section of the Y-axis linear motor remain at high

temperatures even after production is stopped.

People with a heart pacemaker should stay clear of the Y-axis.

• A heart pacemaker could malfunction due to the strong magnetic

field generated by the linear motor for the Y-axis in M6S modules.

Do not disassemble the linear motor used for the Y-axis in the

M6S module.

• Absolutely do not disassemble the linear motor coil and shaft parts.

Injury and/or machine damage may occur by magnetic parts

shooting out due to the strong force of the magnets.

8 NXT Setup Manual

QD002-07 1. Safety Guideline

CAUTION

Be careful to not pinch your hands when opening and closing

the front or side covers.

• Failure to do so could result in injury.

Do not insert fingers or other body parts into the gap between

the machine side cover and base.

• Failure to do so could result in injury.

When working in front of the base, ensure th at clothing or arms

are not caught on the guide pins on the top of the base to

prevent the risk of injury.

• Failure to do so could result in injury.

When there is no module on the b ase, do not block t he modu le

position confirmation sensor or module seating confirmation

sensor to activate the air cylinder.

• Air cylinder may activate to move lever or clamper causing

personnel injury.

Do not push the mark camera unit by hand when moving the

placing head.

• The position of the mark camera may be shifted, which negatively

affects the placing accuracy of the machine.

Be careful to not put your hands underneath the nozzle st ation

when loading it in the machine.

• Failure to do so could result in injury.

Ensure to place the waste tape disposal unit with the duct

upside on the work bench.

• The duct of the unit may creep by its own weight.

Be careful of the magnetic attraction when using a jig near the

linear motor of the M6S.

• Injury could result by a jig being drawn towards the linear motor.

Keep magnetic cards, wristwatches and other precision

machines away from the linear motor of a M6S module.

• Damage to items may occur due to the magnetic field generated by

a linear motor.

NXT Setup Manual 9

1. Safety Guideline QD002-07

1.3.2 Tray Unit-L

WARNING

When pushing the tray unit-L into the machine, ensure that no

one is between the tray unit-L and machine base.

• A person could be seriously injured or crushed to death if caught

between the tray unit-L and machine.

Lock the caster brake whenever the tra y unit-L is removed from

the machine.

• Depending on the slope and condition of the floor, the tray unit-L

could roll unexpectedly, possibly resulting in injury.

CAUTION

Be careful to not pinch your fingers when opening or closing

the tray unit-L covers (upper cover, front cover, lower cover,

etc.). Do not leave the doors open while the tray unit-L is

unattended.

• Failure to do so could result in injury.

When operating the handle for adjusting the tray unit-L height,

make sure that hands are not caught between the handle and

cover.

• Failure to do so could result in injury.

When removing or replacing the empty tray box, be careful to

not pinch your hands between the tray unit-L and empty tray

box.

• Failure to do so could result in injury.

Do not insert your hand through the bottom of the tray unit-L

into the inner section where the mechanical parts are.

• Failure to do so could result in injury.

10 NXT Setup Manual

QD002-07 1. Safety Guideline

1.3.3 Tray Unit-M

WARNING

Do not insert hands or other body parts in the space between

the tray unit-M and the feeder pallet when at taching or removing

the tray unit-M.

• Failure to do so could result in injury.

Use two or more people to lift, carry and position t he tray unit-M.

• The tray unit-M is extremely heavy and injury could result if

dropped.

Do not insert hands or other body parts in the side spaces

between the machine and the tray unit-M during automatic

operation.

• Body parts may be pinched or caught, resulting in injury.

CAUTION

Be careful to not pinch or get body parts caught on the tray unitM door when opening and closing it. Ensure that the door is

never left open.

• Body parts may be pinched or caught, resulting in injury.

NXT Setup Manual 11

1. Safety Guideline QD002-07

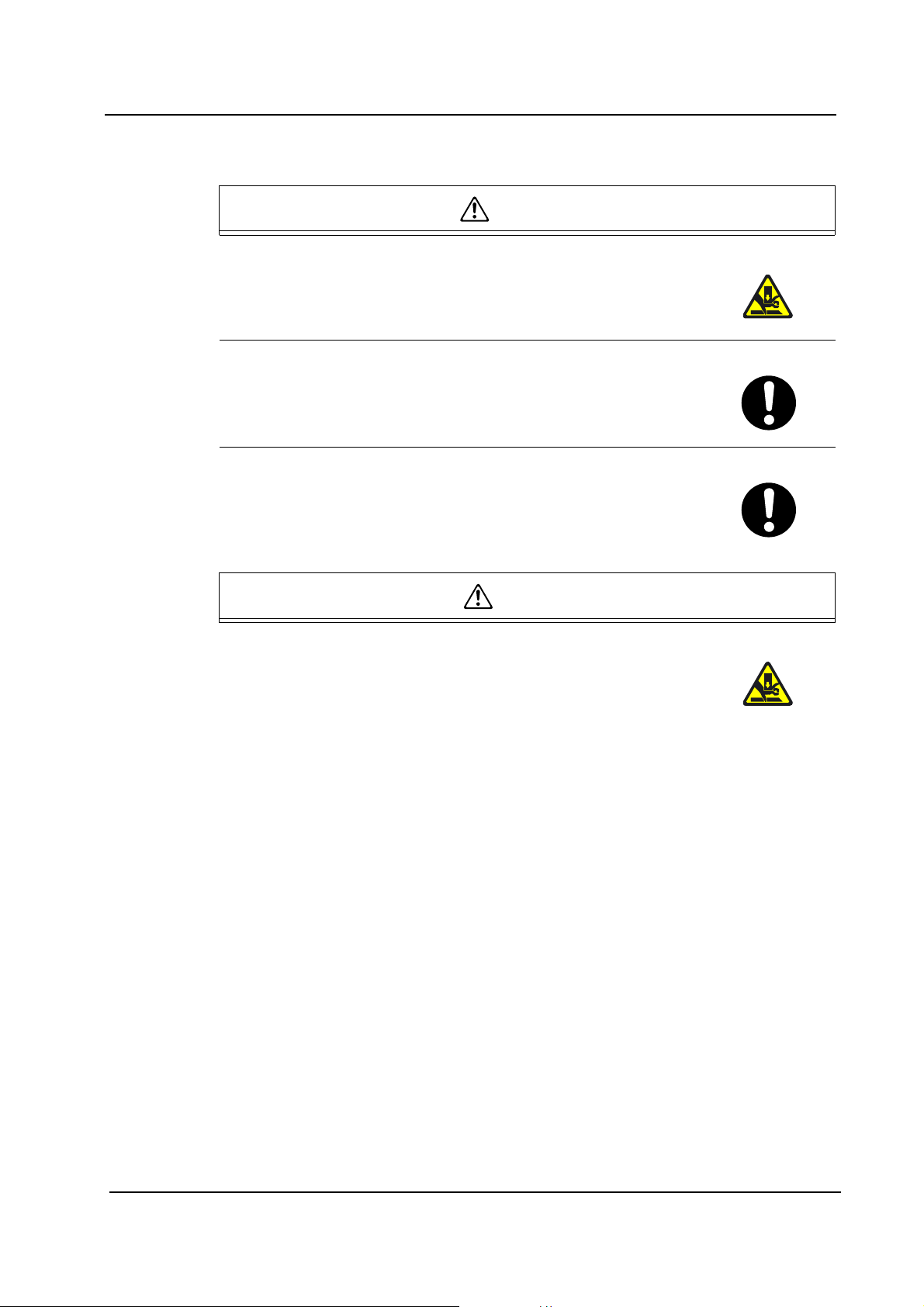

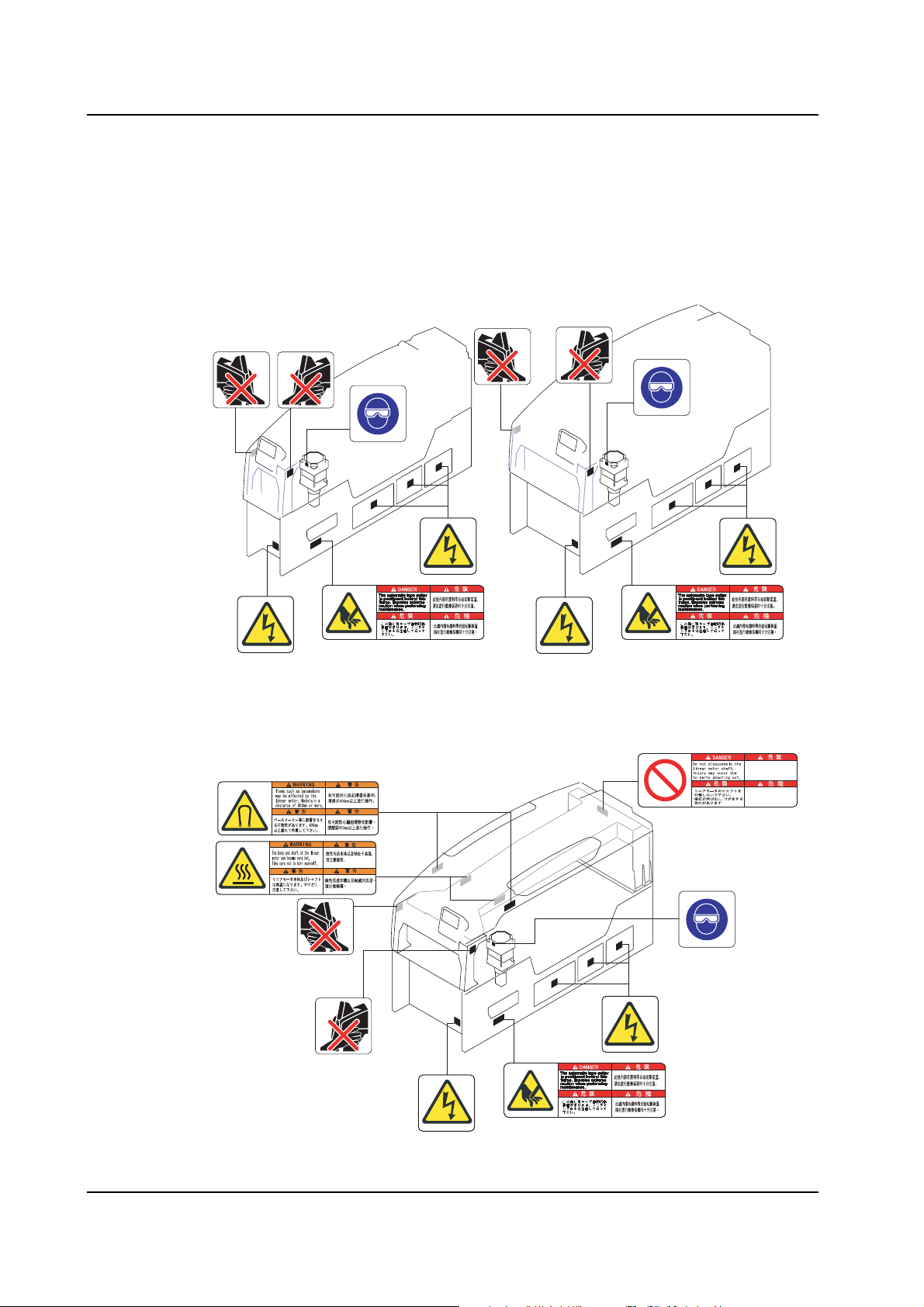

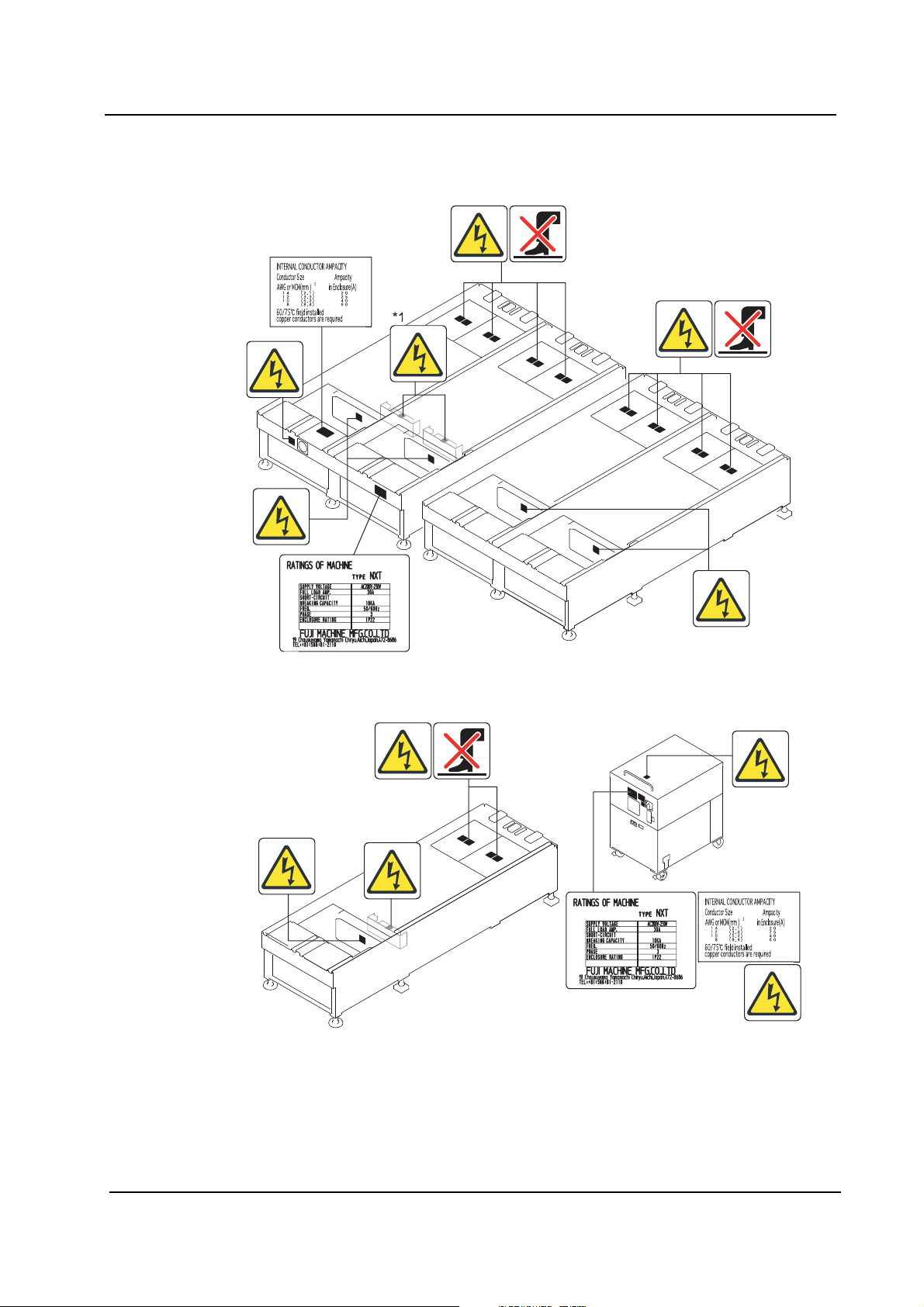

1.4 Safety Labels

To warn the operator of hazards, safety labels are attach ed to the machine at the positions

indicated in the figure below.

Familiarize yourself with each label and its message before operating the machine.

M3(S) Module M6 Module

*1

M6S Module

*1

*1

*1

Зл²»Тª½шРРПЯРФµз¶¯»ъµДЦбµД·Ц½в¡£

´жФЪ´ЕК¯·Й³ц£ ¬µ¼ЦВКЬЙ ЛµДО£ПХ ¡£

½Ð¤£-n¶ i¦æ½u©Ê¹q˚ ʾ÷ªº¶bªº¤À¸ Ñ¡C

¦s¦bºÏ¥Û-¸¥X¡A¾É-P¨ü¶Ëªº¦MÀI¡C

*1

*1

NXTSAF010Eb

12 NXT Setup Manual

QD002-07 1. Safety Guideline

4M base

*

*1

*1

*1

*1

2M base

*1

*1

*1

Dependent 4M base

*1

*2

NXTSAF011E

NXT Setup Manual 13

1. Safety Guideline QD002-07

MSU

WARNING

⼊ ๔

Engineering panel stand

Tray unit-M

Tray unit-L

*1

Side cover

*1

NXTSAF012Ea

14 NXT Setup Manual

QD002-07 1. Safety Guideline

1.4.1 NXT Safety Label Explanations Symbol Explanation

Warning: Pinching danger

Do not insert hands or other body parts in the spa ce betwee n

adjacent modules.

Mandatory action, Direction: Eye protection

Direct exposure to the lighting unit may result in damage to the

eyes. Ensure to use light protection eyewear when necessary.

Caution, Warning: Shock danger

*1: High voltage! Contact may cause electric shock. Turn off

the power prior to servicing.

*2: Connect a 200 - 230V AC +/-10% 50/60Hz primar y po wer

supply to the machine.

Caution, Warning: Cutting danger

An automatic tape cutter is positioned behind this frame.

Exercise extreme caution when performing maintenance.

Warning: Do not step

Do not step or stand on this area.

Caution, Warning: Moving parts

Do not insert hands or other body parts.

Moving parts may cause injury. Turn off the power before

inserting any body parts.

Warning: High Temperature

Contacting with the main body and shaft of the linear motor

could result in burns. They are high temperature.

Warning: Magnetic Field

Heart pacemakers and other precision equipment could be

affected by the magnetic field. Always keep a distance of 400

mm or more.

Warning: Disassembly prohibited

Do not disassemble the linear motor shaft. Injury may occur

by parts shooting out due to the strong force of the magnets.

NXT Setup Manual 15

1. Safety Guideline QD002-07

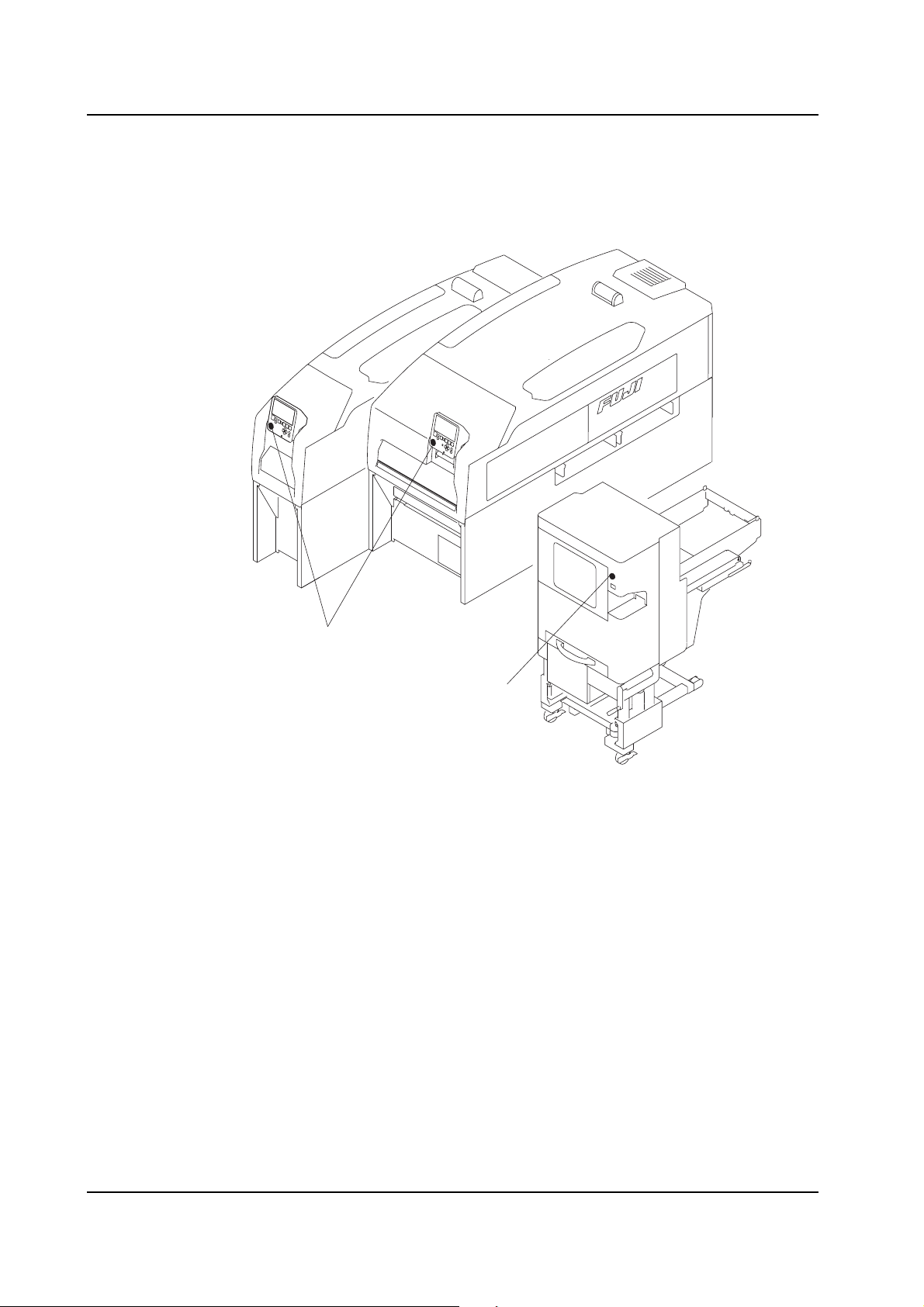

1.5 The EMERGENCY STOP Button

In the event of an emergency, press any of the red EMERGENCY STOP buttons located

on the machine at the positions indicated in the figure below.

EMERGENCY STOP buttons

EMERGENCY STOP button

NXTSAF001Eb

16 NXT Setup Manual

QD002-07 1. Safety Guideline

1.6 Locking System

When performing maintenance or service on the machine, all personnel who service the

machine should use locks to prevent others from turning on the machine power or air. This

procedure is referred to as a lockout.

To prevent accidents, especially those caused by mistakes when multiple operators are

present, all related personnel should have thorough knowledge of lockout procedures.

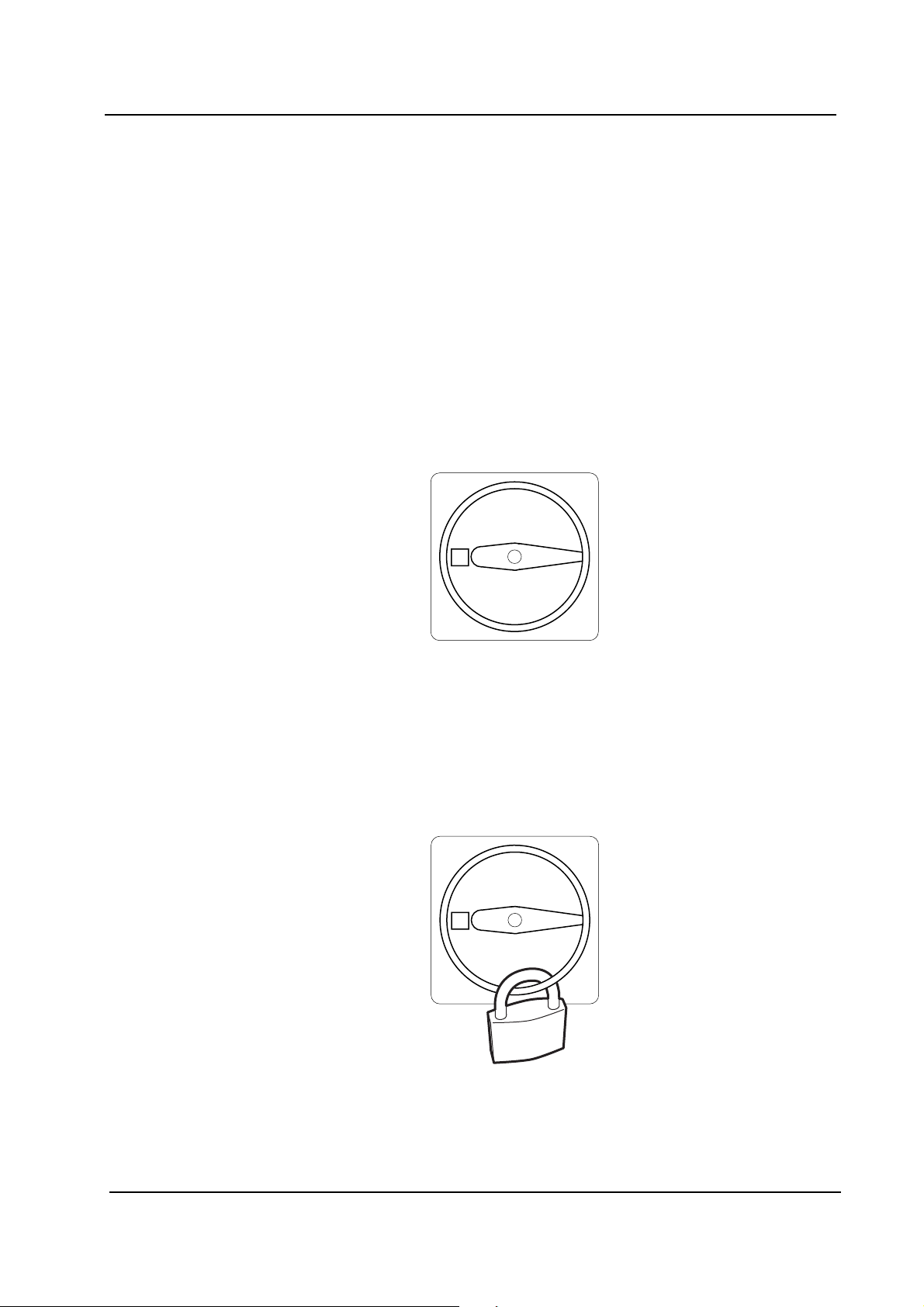

1.6.1 Lockout Procedure

Prepare 2 commercially available padlocks, and require all service personnel to carry

lockout nametags.

1. Switch off the machine power.

2. Rotate the main switch on the base to the OFF position.

0

NXTSAF004

3. Lock the main switch with a padlock.

All personnel working on the machine should attach their lockout nametags to the

padlock.

Note: Note:The presence of a nametag on the padlock signals that the machine is being serviced and that the

lock is not to be removed.

0

NXTSAF006

NXT Setup Manual 17

1. Safety Guideline QD002-07

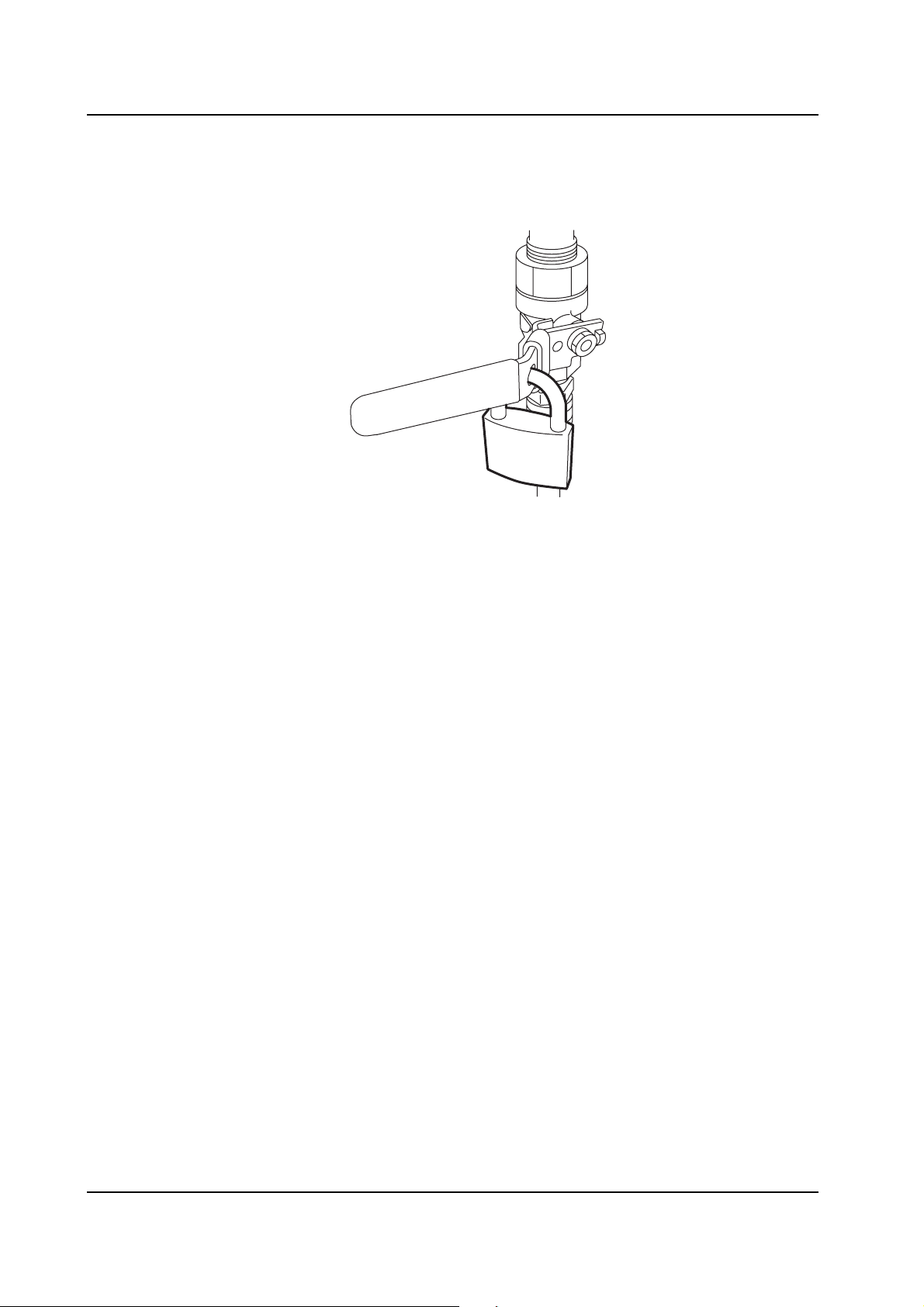

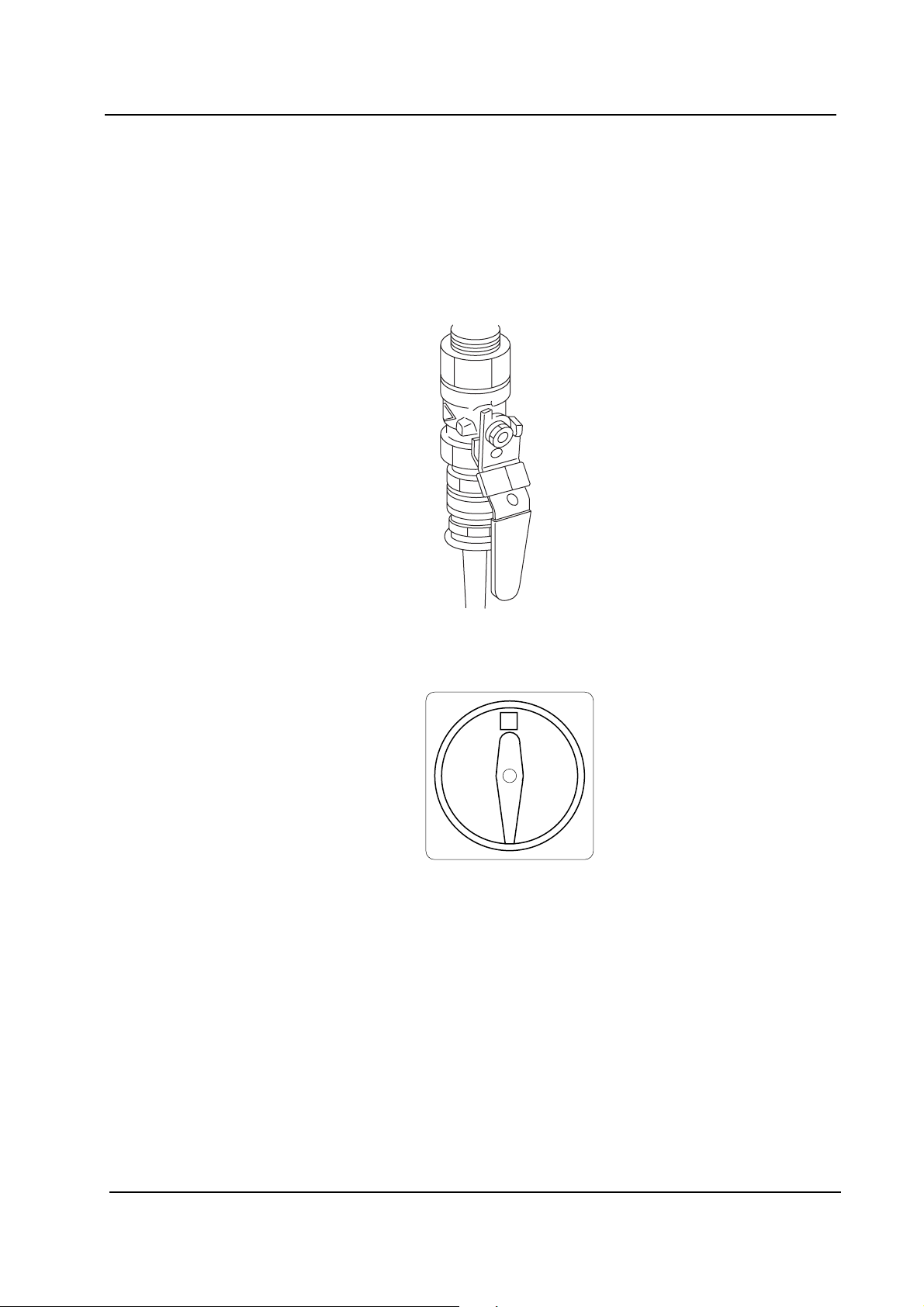

4. In the same manner, rotate the air valve handle to the OFF position and lock with the

second padlock.

All personnel working on the machine should attach their nametags to the padlock.

NXTSAF005

5. The lockout is complete.

18 NXT Setup Manual

QD002-07 1. Safety Guideline

1.6.2 Unlocking Procedure

When finished servicing the machine, all personnel should r emove their lo ckout nametags

from the padlocks.

1. Confirm that all personnel are clear of the mac hin e.

2. Confirm that the machine is in a safe condition. Remove the padlock from the air valve

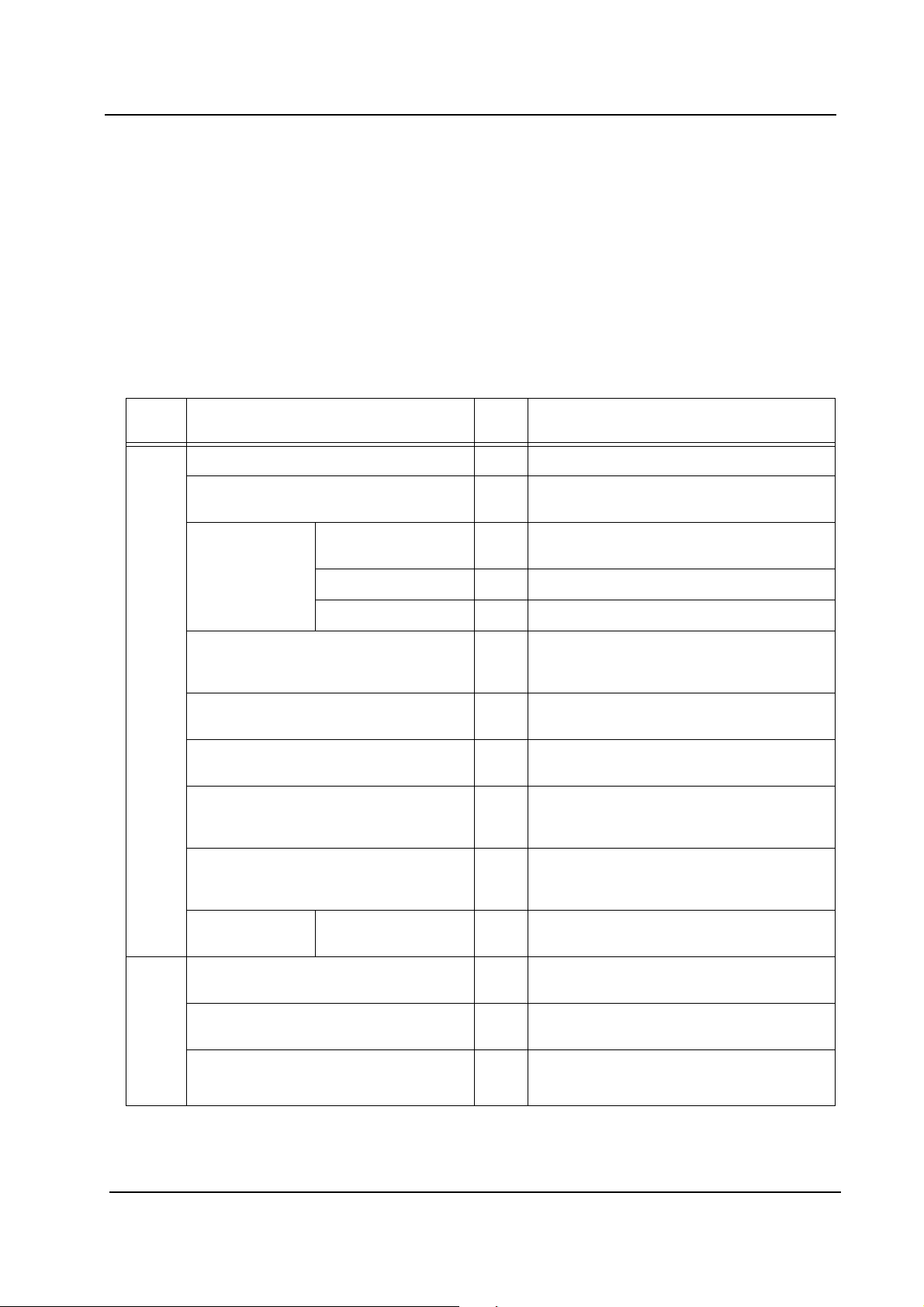

and rotate the handle to the ON position.

NXTSAF007

3. Remove the padlock from the main switch and rotate it to the ON position.

1

NXTSAF008

4. This concludes the unlocking procedure.

NXT Setup Manual 19

1. Safety Guideline QD002-07

MEMO:

20 NXT Setup Manual

QD002-07 2. Setting Up the NXT

2. Setting Up the NXT

2.1 Introduction

The aim of this manual is to provide procedural explanations of how set up the NXT

machine. The procedures outlined are to help an NXT user perform the various

mechanical, and software related operations necessary to set up the NXT for use.

The order of the procedures in this manual are basically in the order that they should be

performed for the easiest set up. In all cases, not all procedures (such as setting the IP

address of the base) need to be performed, especially when just moving the machine/base

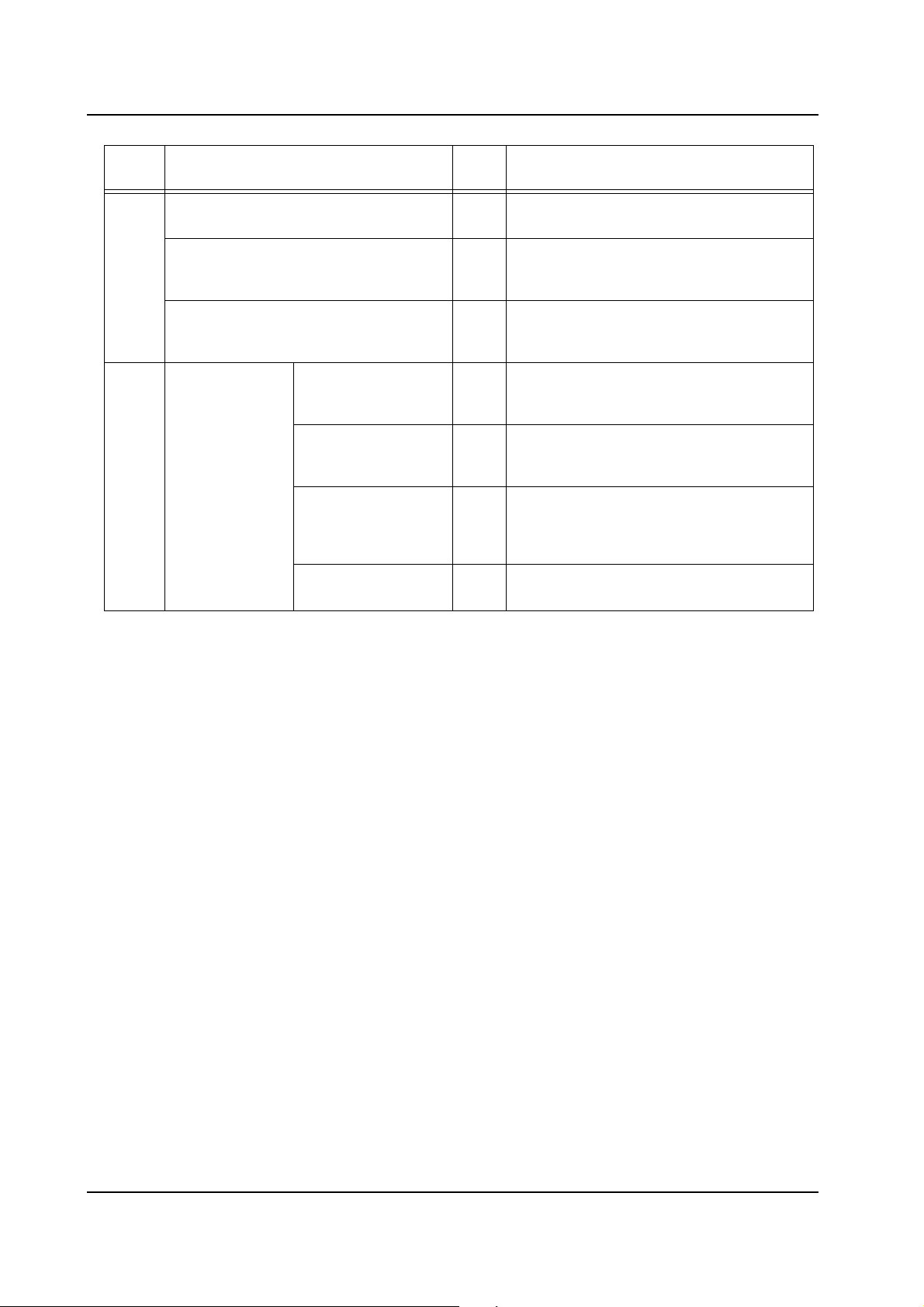

within the factory. Refer to the table below for an outline of the setup process.

Chap

ter

3. Machine Set Up

Section Ord. Step

Moving a Machine 1 Move the machine to the desired location.

Removing Fixing Brackets 2 Remove the brackets used to fixed the

axes during transport.

Making Basic

Connections

Leveling the Machine 6 Level the machine and ensure that the

Making Network Settings 7 Specify the IP address and other network

Connecting NXT Bases 8* Connect the communication cables

Installing Additional Dependent Bases 8* Connect the communication cables and

Electric Power

Supply

Network Cable 4 Connect the network cable to the base.

Air Supply 5 Connect the air supply to the base.

3 Connect the power cable to the base.

conveyor height matches that of the other

machines in the line.

related settings for the set up base.

between the NXT bases.

the pneumatic tubes between the NXT

bases. Fix the bases with brackets.

Connecting an NXT Base to Other

Machine Types

Tray Unit-L Adjusting the height

Creating a factory 10 Create a factory in the Fuji Flexa line

Creating a line 11 Create a line in the Fuji Flexa line

Creating a machine 12 Create the NXT machine in the desired

4. Setting Up NXT

Machines in Flexa

and levelness

8* Connect the communication cables

between the NXT base and neighboring

machines other than NXT bases.

9 Use a level gauge to adjust the height and

levelness.

configuration, if necessary.

configuration, if necessary.

line in the Fuji Flexa line configuration.

NXT Setup Manual 21

2. Setting Up the NXT QD002-07

Chap

ter

Software

5. Accessory

6. Setting Up Fujitrax Verifier

Section Ord. Step

Required Items 13 Ensure that the necessary items to install

Installing Fuji Flexa 14 Install Fuji Flexa on the computer that

Installation

Installing NXT Accessory Software 15 Install the Accessory Software on the

Required Items Installing and

running the Central

Server

Adding the NXT to

the Fujitrax line

configuration

Setting the NXT

Fujitrax

configuration

settings

Registering users

for Kit Handy access

16** Ensure that the Central Server for Fujitrax

17** Add the NXT machine to the line

18** Change the Fujitrax configuration settings

19** Register the ID for the users that are to

Accessory Software are available.

Accessory Software is to be installed, if it is

not already installed.

computer that is to act as the Accessory

Software server.

Verifier has been installed and is running.

configuration for the Kit Server that is to be

used for the NXT.

on the NXT.

access NXT data through Kit Handy.

Note: * Perform the items required based on the line composition.

** These steps are only necessary if Fujitrax Verifier is to be used.

22 NXT Setup Manual

Loading...

Loading...