Xerox® iGen™ 150 Press

Redefi ned productivity.

So you can redefi ne profi tability.

Xerox® iGen™ 150 Press

Overview

What would you do with more

production time today?

Right now, you currently spend time on

reprinting errors, quality control, job setup and

waiting for the press. More than you need to.

With iGen 150, the time you spend on all of

those is less, so you have more production

time. More time printing jobs that are ready to

go from the press straight into the customers’

hands. More time achieving the color that

meets every quality expectation without trial

and error. More time printing and fi nishing

larger, high-value jobs. More time entering and

dominating markets that might have been

previously out of reach.

And more time to get paid more often.

What would you do with more

production time this year?

Let’s expand our thinking beyond an hour

and consider a week, a month…a year.

When you multiply the added productivity that

iGen 150 makes possible times the number of

hours in a year, it adds up to fi ve more months

of available production time.

What could you do with that increase in

productivity? More jobs. Greater customer

satisfaction. A growing business. iGen 150 can

truly revolutionize your business by enabling

unprecedented effi ciency and higher levels

of profi t.

And no idea is bigger than the one on which iGen™ 150 is built—taking a

fi nite amount of time and making it work harder for you. It’s an idea that

pays bigger and bigger dividends with every tick of the clock.

Think of it this way…your competitors

could make 12 months of profi t in the

next year while you make 17*.

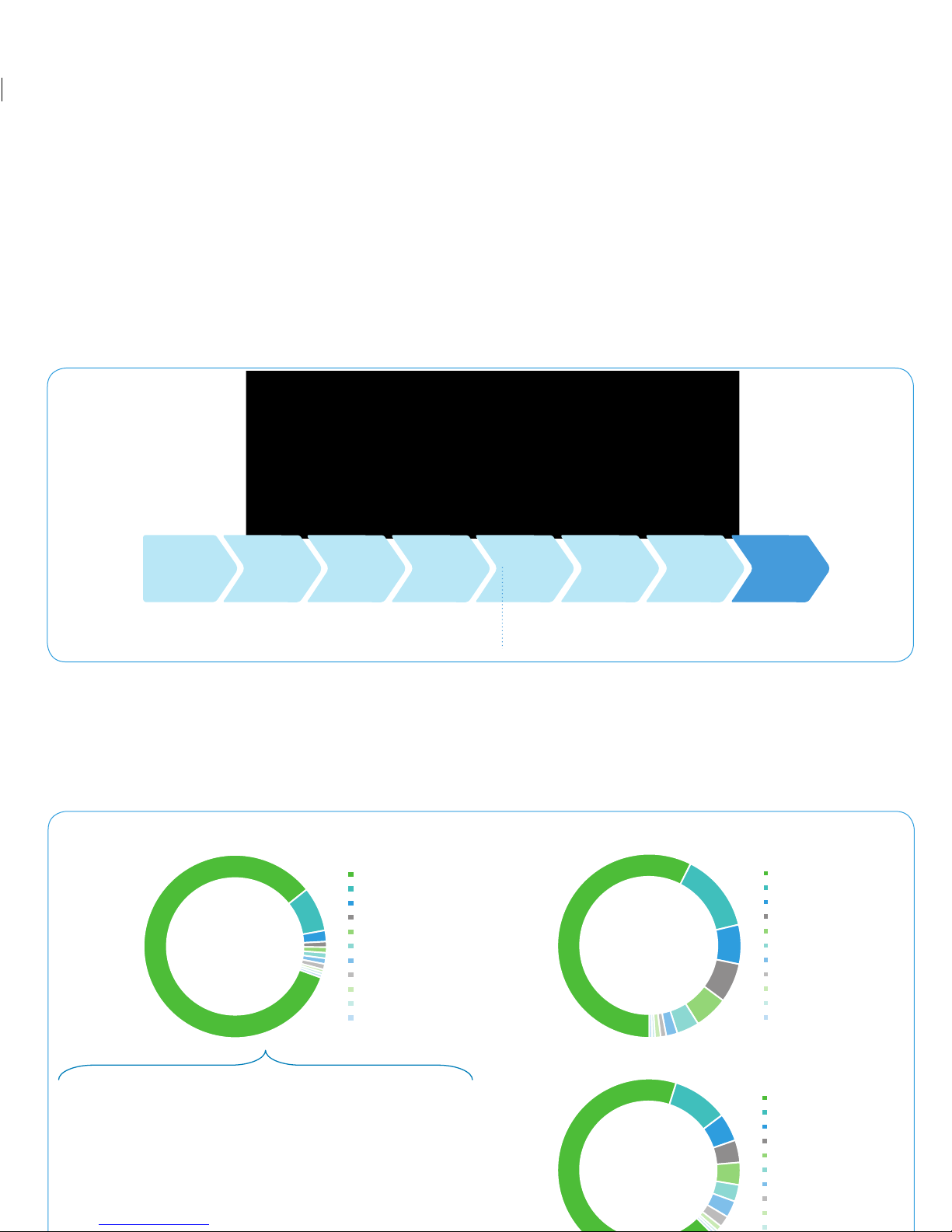

Potential Production Time Greater Than 80% with

iGen 150 Automation

*Assumed iGen 150 with 85% uptime compared to device with same rated speed at 60% uptime.

iGen 150 Production Time

Service

Repair

Quality Control

Waiting for Press

Paper Jam

Planned Maintenance

Consumable Change

Press Error Waste

Job Setup

Morning Routine

To understand the value proposition of the new iGen™ 150, we start

with the value proposition of the iGen4

®

. Since the launch of the iGen3®

in 2002, continued focus on our production customers’ most important

needs have led to innovations and true market differentiating

technology with respect to image quality and productivity.

Xerox® iGen™ Family

A Winning Combination

Innovations like the Color Maintenance Tool, Inline Spectrophotometer

and Auto Density Control are combined with iGen innovations like

maintaining rated speed for all stock weights, multiple feeding pick

points and load while run consumables. These make iGen4 the most

productive press in the industry today as validated by the Spencer

Labs Report.

Auto Density Control

Inline Spectrophotometer

Color Maintenance Tool

iGen 150 Production Time

Service

Repair

Quality Control

Waiting for Press

Paper Jam

Planned Maintenance

Consumable Change

Press Error Waste

Job Setup

Morning Routine

Daily Average Potential Production Time: Xerox® iGen4*

85% 58%

68%

Daily Average Potential Production Time: HP Indigo 7000*

iGen3

®

2002

Carrier

Dispense

Automated

Color Quality

Suite

Auto

Density

Control

iGen4

®

CMT

ILS

iGen4 EXP

Web2Finish

26"/660 mm

Matte

Dry Ink

iGen™ 150

Color Maintenance Tool

Inline Spectrophotometer

HP Indigo 7000 Production Time

Job Setup

Morning Routine

Service

Consumable Change

Repair

Press Error Waste

Planned Maintainence

Quality Control

Paper Jam

Waiting for Press

Daily Average Potential Production Time: HP Indigo 5500*

HP Indigo 5500 Production Time

Job Setup

Morning Routine

Consumable Change

Planned Maintenance

Repair

Service

Waiting for Press

Press Error Waste

Paper Jam

The Xerox® iGen™ 150 Press redefi nes an

hour as one of your most effective tools for

business growth, eliminating the tradeoff

between quality and profi t that printers

have had to make for years.

The press brings together more easily

attained and maintained image quality,

more raw speed and more advanced

automation so every hour becomes a tool

for building a stronger business.

Stronger through delighted

customers.

Impress your customers with outstanding

image quality and you’ve taken a big step

toward gaining valuable loyalty. iGen 150

takes your business to unprecedented levels.

Stronger through greater job

capabilities—including offset

transfer.

Through a powerful mix of capabilities,

iGen 150 is uniquely able to produce a wider

range of jobs. Say yes to short turnarounds.

Match the color from a job produced months

ago. Offer a greater variety of stocks. And

generally knock your customers’ socks off.

Stronger through reduced costs.

iGen 150 reduces your operational costs

in a number of ways. You are able to print

customer-ready output more quickly than ever,

with substantially less time, adjustment and

waste. There’s only so much time. Now more

of it is profi table time.

Stronger through continuous

improvement.

iGen 150 is the culmination of over ten years

of study, innovation and collaboration with

our customers. Virtually every aspect has

been examined to enhance quality, increase

productivity and eliminate costs so that you

can quickly grow your business into something

larger, nimbler and more capable in a

challenging marketplace.

Now every hour can be more profi table,

with fewer tradeoffs.

One hour. It’s a unit for measuring time. Isn’t it? Usually, yes. But in today’s

business world, it’s also a unit of measure for productivity—and ultimately,

success. Every hour of every day is a race against the competition, a contest

for more customers and an opportunity to expand your business—if you have

the right solutions.

What happens in one hour?

The world is one of different cultures,

customs and currencies. But there

are certain things that are universal.

Everywhere, an hour is the measure

of time.

Every hour:

• Lightning strikes the earth

21,600 times.

• 12,671 computers are sold.

• More than 6,100 people are born.

• There are 360 million

Google searches.

• 5,936 cars are produced around the

world— as are 2,283,100 paper clips.

• Business is fueled as we consume

more than 93,000,000 cups

of coffee.

And even with all of those remarkable

facts, an hour just got more productive.

iGen 150 has taken everything that

can happen in 60 minutes and

multiplied it, to make the productivity

you can achieve in an hour—every

hour—eye opening.

You might think of image quality and

productivity separately.

iGen

™

150 thinks differently.

Over the years, there has been one constant in the market—a universal

expectation from your customers that the color you produce will match their unique

requirements, every time. And for years, you had to choose to either deliver that

quality or focus on productivity.

With iGen 150, you can have both. Achieving

outstanding image quality is faster than ever,

thanks to a redesigned imaging system that

takes setup time, waste and guesswork out of

your day.

It starts with a strategy

that builds powerful color

management technologies

right into the press.

Xerox® Confi dent Color is a collection of

the fi nest color management technologies,

designed and refi ned to deliver more

outstanding color and more saleable output.

These built-in technologies are supported by

Xerox’s

®

unique consultation, customization

and business development services so you can

be sure you are ready to meet—or exceed—

the expectations of your customers. Confi dent

Color allows you to emulate a range of

industry standards such as GRACoL and Fogra

and adhere to Pantone standards so you can

accurately match colors, from job to job, shift

to shift and from press to press.

Now digital can pay offset

the ultimate complement.

Xerox® Matte Dry Ink has been developed to

take advantage of the growing opportunity

for digital print with an appearance almost

identical to offset. The combination of Matte

Dry Ink and the imaging system design makes

the iGen 150 Press a perfect complement to

your existing offset business.

You can produce new applications that

integrate seamlessly into your existing

offset workfl ow.

Matte Dry Ink truly expands the power of

iGen 150 and your ability to succeed in

some of the most exciting and fastest

growing markets in our industry. The results

are dramatic…not only in the output you

see on every sheet, but the impact you see

on the most important sheet of all—the

balance sheet.

But this 26"/660 mm sheet is only useful

if you can run it in production quantities.

With the optional 26"/660 mm stacker—

which is compatible with downstream inline

fi nishing—your fi nishing bottlenecks are a

thing of the past.

Automation of the most

complex tasks.

System-wide automation—including critical

color control—eases interaction for operators

with a variety of skill levels and makes everyone

on your staff as productive as possible.

Xerox® IntegratedPLUS

Finishing Solution for Booklets.

Benefi cial as it is, automated fi nishing

used to tie up valuable assets on your shop

fl oor. Prepress and postpress processes

required skilled personnel to set up fi les to

match fi nishing devices at the front end

and then later to set up the actual fi nishing

device to run the job. And you were forced

to dedicate a fi nishing device to just one

printer. If you weren’t running booklets,

for example, that booklet maker sat idle.

Xerox

®

IntegratedPLUS Finishing Solution

for Booklets changes all that. Now prepress

setup and fi nishing setup can be automated,

whether or not the fi nishing device is in-line

with a printer or off-line. You get the best

of both fi nishing worlds—the convenience

of in-line with the fl exibility of off-line, plus

unsurpassed labor savings.

“Hey, if we’re going to increase our business and look towards the future for

our business, we want some kind of new model… That’s the reason that we

got into digital, because when we did the research, we found that’s really

where the future of print and marketing is going to be, a lot of digital print.”

– Buzzy Castonguay

Business Development Manager

Color Web Printers

Loading...

Loading...