FujiFilm GTX User Manual

CONTENTS

Contents . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Precautions . . . . . . . . . . . . . . . . . 2

Air Control Valve & Diaphragm . . . . . . . 3

Spray p attern . . . . . . . . . . . . . . . . . . . . . . 4

Fan size . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Spraying techniques . . . . . . . . . . . . . . . . 6

Aircap selection . . . . . . . . . . . . . . . . . . . 7

Latex & Viscosity . . . . . . . . . . . . . . . .8 - 9

Viscosity guide . . . . . . . . . . . . . . . . . . . . 9

Cleaning . . . . . . . . . . . . . . . . . . . . . . . 9 -10

Pressure pot use . . . . . . . . . . . . . . . . . .10

Finish Problems . . . . . . . . . . . . . . . . . . 11

Spray Gun Problems . . . . . . . . . . . . . 12 -13

Needle Packing & Seals. . . . . . . . . . . . 14

Parts disassembly . .. . . . . . . . . . . . . . . 15

Turbine problems . . . . . . . . . . . . . . . . . 15

Parts diagrams. . . . . . . . . . . . . . . . . . 16 -18

Gravity Spray Gun. . . . . . . . . . . . . . 18

Service information. . . . . . . . . . . . . . . . 19

Warranty information . . . . . . . . . . . . . . 20

CE Declaration . . . . . . . . . . . Back Cover

20

1

Limited 2 Y ear W arranty

Fuji Industrial Spray Equipment Ltd. issues a 24

month limited warranty to the purchaser effective from

the date of purchase against defects in materials or

workmanship. This warranty does not cover abuse,

accidental damage, misuse, normal wear parts, motor

brush replacement, or spray gun maintenance and

clean-up. W arranty is void if repairs are made or

attempted by unauthorized persons. At our option,

Fuji Spray will repair or replace defective parts

without charge provided the purchaser return parts

prepaid to the nearest authorized service center or to

the factory.

Factory returns must first receive a Return Material

Authorization. In North America, please call 800650-0930 to obtain an authorization number. In other

countries, please call the company where you purchased the product.

This unit is designed to be used for spray painting and

similar operations only. Fuji will not be held liable if

equipment is not used solely for the purpose it was

designed. W arranty will become void through improper installation or operation. Any modifications to

the equipment or deviations from recommended

procedures, accidental damage or any related action

that impairs or abuses normal wear and care of Fuji

spray equipment will also void warranty and liability .

19

Please read these instructions carefully before using the equipment

ELECTRICAL

The turbine is powered by a 3-stage or 4-stage (depending on the model)

single speed, bypass, air turbine. This turbine must be connected to the

correct voltage. Please check the label on the base for voltage rating.

ELECTRICAL CONNECTION

For your safety and protection, we have equipped your Fuji turbine with a

three-pronged grounding plug on the service cord. This must be plugged

into a properly grounded 3-pronged receptacle. (For some countries this

may be a 2-pin grounded plug).

SAFETY WARNINGS:

THE TURBINE MUST NOT BE USED IN AN AREA CONTAMINA TED BY

VOLATILE OR FLAMMABLE MA TERIALS SINCE SP ARKING CAN BE

EXPECTED IN THE NORMAL OPERATION OF THE MOT OR. THIS COULD

IGNITE THE CONTAMINANTS CAUSING A DANGEROUS EXPLOSION. KEEP

THE TURBINE A T LEAST 18 FEET (5.5 METERS) A WA Y FROM THE SPRA Y ING AREA. FOR HEALTH REASONS, ALWA YS WEAR A RESPIRATOR.

PLEASE CHECK WITH THE LOCAL JURISDICTION.

THE SPRAYGUN MUST NEVER BE POINTED A T SOMEONE’S FACE.

THE OPERATOR MUST WEAR SHOES AND THE FLOOR MUST NOT BE

WET.

FILTER(S)

The Q-PRO Series turbines use just ONE large filter. The turbine case

does not need to be taken apart to replace the filter. To remove, simply

turn the turbine on its side and pull the filter out. Wash in solvent and dry

before replacing. All Fuji filters are a friction fit. When replacing, push the

filter in by hand and finish up by using a screwdriver through the square

holes to lever the filter into position. The filter must fill the entire filter

enclosure and always be FLUSH with the base of the turbine case.The

Mini-Mite Turbines use 2 filters, one fine and one coarse. Looking from the

front of the turbine please insert the fine filter to the left side (near the ‘F’ of

Fuji) and the coarse to the right side. It is important to keep the turbine as

far away as possible from the spraying area (and workshop dust). If the

filters become badly clogged, cooling air will be restricted - this may cause

serious damage to the motor. THE TURBINE MUST BE PLACED ON THE

FLOOR - NOT UP HIGH. THIS IS BECAUSE THE BEND IN THE HOSE CAUSES

BACK PRESSURE INTO THE MOTOR.

2

For SERVICE & PARTS

USA

Fuji Spray

Phone: 800-650-0930 Online: www.hvlp.net

Phelps Refinishing

Phone: 800-377-5662 Online: www.phelpsrefinishing.net

UNITED KINGDOM

Axminster Power Tool Centre. Axminster, Devon, England

Phone: 01297 33656

Rutlands Limited. Bakewell, Derbyshire, England

Phone: 01629 815518

EUROPE

Larius SRL. (Lecco), Italy

Phone: 0341-621152

Aerometal. S.A. Spain/Portugal

Phone: 34-935620212

AUSTRALIA & NZ

apSM Tecni Pty Ltd. Campbellfield, Victoria 3061

Phone: 3-9359-5000

PUERTO RICO

Eagle Tools Mfg. Corp San Lorenzo, Puerto Rico, 00754

Phone: 787-736-0444

SOUTH KOREA

E-Woo Painting Technology . Seoul, Korea

Phone: 82-2-2103-1477 Fax: 82-2-2103-1488

Copyright © 2008 Fuji Industrial Spray Equipment Ltd. T oronto. Canada

3

18

AIR CONTROL VA LVE

The air control valve 2032 is located on the hose next to the brass quickconnect. It provides you with a means of controlling the air flow through the

gun. It offers you fingertip control when you need it to reduce bounceback

and overspray. There is one thing to remember about the air control valve - it

is the ‘last in the chain’ of operations after...

1) Thinning the paint

2) Adjusting the shape and size of the spray pattern

3) Adjusting the flow of paint through the gun.

After performing these operations, you should spray a few passes onto a

scrap piece of plywood or cardboard. This will allow you to determine if the

paint (generic word for any type of coating) levels nicely. If there is ‘orangepeel’ then you must thin the product more. Once the gun is producing a

perfect finish with full air, you may then experiment with turning the air down

until bounceback is reduced to a mininum. However, if orange-peel results,

you have no option but to turn the air up again a slight amount. With heavier

paints (such as latex) spraying may be done with the valve fully open (or even

removed). When excessive ‘bounceback’ or overspray is a problem, turn the

lever to reduce the amount of air.

PLASTIC DIAPHRAGM - XT-2 MODEL

The XT 1 Quart pressurized cup (not found in the Gravity Spraygun) has a

plastic diaphragm 2038. This diaphragm prevents paint from entering the

pressure tube 2024. The small air hole in the diaphragm should not be

placed directy below the air hole in the nipple. Position the diaphragm hole

to the rear of the cup. The spraygun can be turned to different angles when

spraying, however the cup should never be higher than the gun (above

horizontal). To remove the diaphragm for cleaning, grab the small tab and

slide it gently down the metal fluid tube. The diaphragm can be washed in

thinner. Note: There is no diaphragm on the Fuji GT-X Gravity Spraygun.

GETTING STARTED

Your Fuji Spraygun has been adjusted at the factory and is ready for spraying.

To clean out any impurities that may have accumulated during assembly or

shipping, we recommend spraying a small quantity of clean paint thinner

through the gun. Before tackling any serious spraying, experiment using

plain water until you become familiar with all the controls.

HOSE CONNECTION

Connect the end of the hose (female connector) to the turbine air outlet.

ALW A YS TURN OFF THE TURBINE BEFORE DISCONNECTING THE GUN FROM

THE HOSE. This prevents unequal pressure in the cup forcing paint up the

pressure tube.

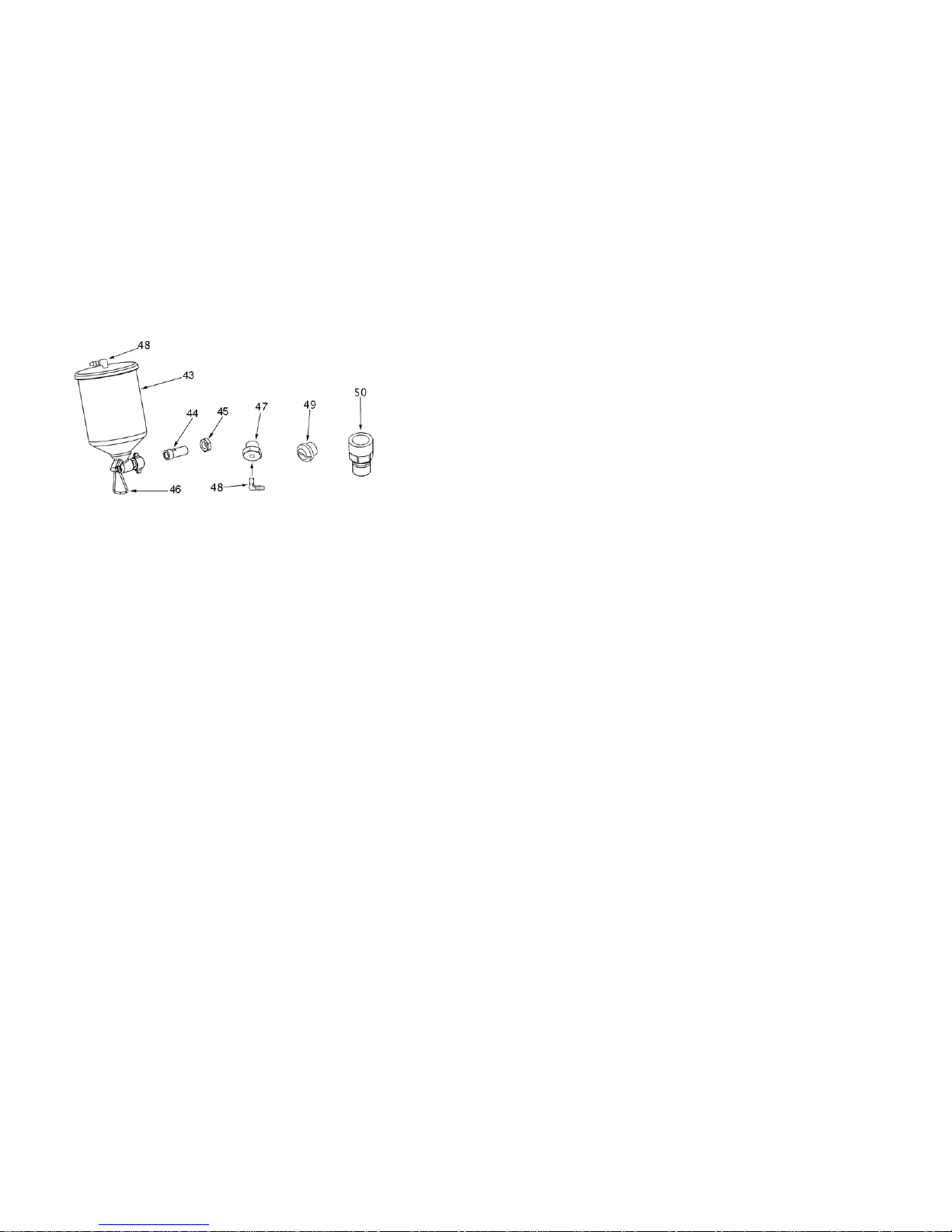

GTX Gravity Gun (Accessory)

ITEM PART NAME ITEM PART NUMBER

43 9850 Gravity Cup 47 2020 Nipple Adaptor

44 9051 Fluid Coupler 48 2021 Nipple

45 8067 Jamb Nut 49 8010 Air Plug

46 0000 Stand 50 8065 Hose Connector

The new GT-X Gravity Gun now offers the choice between pressurized or

non-pressurized use – here’s how…

PRESSURIZED CUP

The GTX spraygun is already setup to spray using the pressurized Gravity

Cup. This is more suited to heavier paints such as Latex House Paint

(Emulsion) and will also provide for faster coverage. But for a softer spray,

you may want to try experimenting with a ‘non-pressurized cup’.

Non-Pressurized Cup:

1) Remove the Pressure Tube from the 2021 Nipple on the Lid of

the Cup

2) Unscrew the 2020 Nipple Adaptor (located under the front barrel

of the gun).

3) Replace the 2020 Nipple Adaptor wiht thethe 8010 Air Plug

(Supplied) to block the hole.

You can now spray with a non-pressurized Gravity Cup. This is more

suited to thinner (less viscous) liquids. Coverage will be slower than with

the pressurized cup.

Loading...

Loading...