Page 1

DIGITAL CAMERA

FinePix V10

TROUBLESHOOTING GUIDE

CAUTION

BECAUSE THIS PRODUCTIS RoHS LEAD-FREE COMPLIANT, USE THE

DESIGNATED AFTER-SELES PARTS AND THE DESIGNATED LEAD-FREE SOLDER

WHEN PERFORMING REPAIRS. (Refer to page 3 to page 5)

WARNING

THE COMPONENTS IDENTIFIED WITH THE MARK “ ” ON THE SCHEMATIC

DIAGRAM AND IN THE PARTS LIST ARE CRITICAL FOR SAFETY.

PLEASE REPLACE ONLY WITH THE COMPONENTS SPECIFIED ON THE SCHEMATIC

DIAGRAM AND IN THE PARTS LIST.

IF YOU USE PARTS NOT SPECIFIED, IT MAY RESULT IN A FIRE AND AN

ELECTRICAL SHOCK.

FUJI PHOTO FILM CO., LTD.

Ref.No.:ZM00621-400

Printed in Japan 2006.03

Page 2

FinePix V10 TROUBLESHOOTING GUIDE

SAFETY CHECK-OUT

After correcting the original problem, perform the following

safety check before return the product to the customer.

1. Check the area of your repair for unsoldered or poorly

soldered connections. Check the entire board surface

for solder splasher and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair.

Point them out to the customer and recommend their

replacement.

4. Look for parts which, though functioning, show obvious

signs of deterioration. Point them out to the customer

and recommend their replacement.

5. Check the B + voltage to see it is at the values

specified.

6. Make leakage - current measurements to determine

that exposed parts are acceptably insulated from the

supply circuit before returning the product to the

customer.

7. CAUTION: FOR CONTINUED

PROTECTION AGAINST FIRE

HAZARD, REPLACE ONLY WITH

SAME TYPE 2.5 AMPERES 125V

FUSE.

2.5A 125V

2.5A 125V

8. WARNING:

RISK OF FIREREPLACE FUSE

AS MARKED

ATTENTION: AFIN D'ASSURER

UNE PROTECTION

PERMANENTE CONTRE LES

RISQUES D'INCENDIE,

REMPLACER UNIQUEMENT

PAR UN FUSIBLE DE MEME,

TYPE 2.5 AMPERES, 125 VOLTS.

TO REDUCE THE ELECTRIC

SHOCK, BE CAREFUL TO

TOUCH THE PARTS.

WARNING!

HIGH VOLTAGE

2

Page 3

FinePix V10 TROUBLESHOOTING GUIDE

RoHS lead-free compliance

Because this product is RoHS lead-free compliant, use the designated after-sales parts and the designated lead-free solder

when performing repairs.

<Background & Overview>

With the exception of parts and materials expressly excluded from the RoHS directive (*1), all the internal connections and

component parts and materials used in this product are lead-free compliant (*2) under the European RoHS directive.

*1: Excluded items (list of the main lead-related items)

• Lead included in glass used in fluorescent tubes, electronic components and cathode-ray tubes

• Lead in high-melting-point solder (i.e. tin-lead solder alloys that contain 85% lead or more)

• Lead in ceramic electronic parts (piezo-electronic devices)

• Mercury contained in fluorescent tubes is also excluded.

*2: Definition of lead-free

A lead content ratio of 0.1 wt% or less in the applicable locations (solder, terminals, electronic components, etc.)

<Reference>

RoHS: The name of a directive issued by the European Parliament aimed at restricting the use of

certain designated hazardous substances included in electrical and electronic equipment.

Designated substances (6): Lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBBs) and

polybrominated diphenyl ether (PBDE)

<Lead-free soldering>

When carrying out repairs, use a designated lead-free solder, bearing in mind the differing work practices for conventional

solder (eutectic) and lead-free solder.

Differences in the soldering work for lead-free and eutectic solder

When the soldering work practices for eutectic solder and lead-free solder are compared, the main differences are as shown

below. In particular, when lead-free solder is used, the solder tends to be less workable than when eutectic solder is used.

Accordingly, the soldering techniques used must take that into account.

Difference

The solder starts melting later.

1

Poor wetting

2

Solder feed rate is difficult to control.

3

Wetting the insides of through holes is especially

4

difficult.

5

During repairs (or modifications) removing solder

from inside through holes is difficult.

6

There is serious carbonization of the soldering iron.

The surface is not glossy.

7

The initial melting point of lead-free solder is high, so you

have to get used to it.

Move the tip of the soldering iron around to heat the entire

connection to the melting temperature and assist wetting.

Use the solder (wire) diameter and soldering iron that are

best suited to connection being soldered.

First apply solder to the area immediately around the

through hold and then feed the solder into the hole.

Use a suitable wicking wire (with a suitable method and

heating) and a suction tool.

Either put solder onto the soldering iron tip after completing

the work, or turn the iron off frequently.

Learn to recognize the appearance of the surface.

Countermeasure

3

Page 4

FinePix V10 TROUBLESHOOTING GUIDE

Setting temperature during lead-free soldering

• Lead-free solder melting temperature

The melting point of eutectic (Sn-Pb) solder is 183°C, while the melting point of lead-free solder (Sn-Ag-Cu) is 30°C higher

at 220°C.

• Soldering iron tip temperature

The temperature setting for the soldering iron used should be such that the tip of the soldering iron is at the correct

bonding temperature for the connection. This temperature is normally set at around 100°C higher than the melting point of

the solder.

However, the actual temperature should take into account the shape and size of the soldering iron tip, the heat tolerance

of the connection and the workability of that temperature.

• Correct bonding temperature

The correct bonding temperature refers not to the temperature of the heat source, but to the bonding temperature that will

give the best bond strength.

Precautions when soldering with lead-free solder

• Soldering iron maintenance

Because of the high soldering iron temperature in lead-free soldering, there is rapid carbonization of the flux adhering to

the tip of the soldering iron.

(1) Always cover the tip of the soldering iron with solder when it is not being used.

(2) If the tip is black from carbonization, wipe it gently with a paper towel soaked in alcohol until the solder will wet.

• Uniform heating of the board and components

To ensure that the lead-free solder wets the entire surface of the pattern and the lands despite its poor wetting

characteristics, you must move the tip of the soldering iron over a wide area to raise the temperature of the entire

connection.

Soldering iron

A soldering iron with a temperature control is best.

4

Page 5

FinePix V10 TROUBLESHOOTING GUIDE

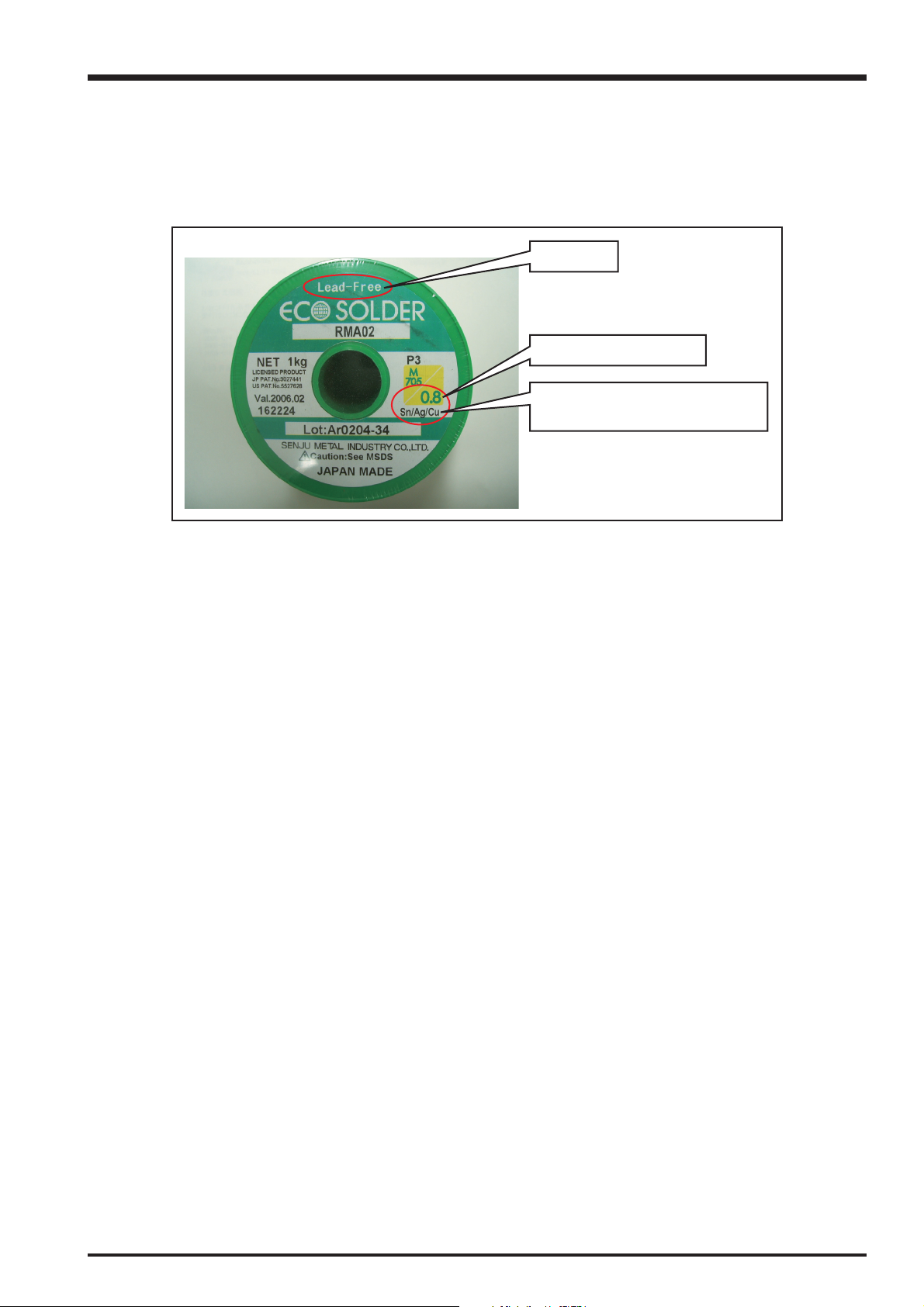

Solder wire (thread)

Use the lead-free solders specified below.

Solder type: Sn96.5Ag3Cu0.5 (Displayed symbol: SnAgCu)

Wire diameter: 0.6, 0.8 or 1.0 mm

Sample:

lead-free

Wire diameter 0.8mm

Solder type (Displayed symbol)

SnAgCu

Flux

Conventional flux can be used.

Solder application wires (mesh, wicking wire, etc.)

Conventional application wires can be used.

5

Page 6

MEMO

FinePix V10 TROUBLESHOOTING GUIDE

6

Page 7

FinePix V10 TROUBLESHOOTING GUIDE

CONTENTS

CONTENTS

1. Names of internal Components .................................................................................. 8

2. Overall connection Diagram........................................................................................ 9

3. Mounted Parts Diagrams (MAIN PWB ASSY) .......................................................... 10

4. Mounted Parts Diagrams (SUB PWB ASSY) ............................................................ 11

5. Information on problems identified in production during inspection.......................... 13

6. Information on problems arising in production during adjustment ............................ 17

7

Page 8

FinePix V10 TROUBLESHOOTING GUIDE

1. Names of internal Components

R PANEL CONST

SUB PWB ASSY

F PANEL CONST

FLASH CONST

MIC ASSY

MAIN PWB ASSY

LENS ASSY

SPEAKER ASSY

BOTTOM CASE CONST

8

Page 9

FinePix V10 TROUBLESHOOTING GUIDE

2. Overall connection Diagram

9

Page 10

3. Mounted Parts Diagrams (MAIN PWB ASSY)

A

B

FinePix V10 TROUBLESHOOTING GUIDE

C

D

E

10

F

1

23456789

Page 11

FinePix V10 TROUBLESHOOTING GUIDE

A

B

4. Mounted Parts Diagrams (SUB PWB ASSY)

C

D

E

1

23456789

11

Page 12

MEMO

FinePix V10 TROUBLESHOOTING GUIDE

12

Page 13

FinePix V10 TROUBLESHOOTING GUIDE

5. Information on problems identified in production

during inspection

Main category Problem details Cause

LCD

Sounds/Beeps

LCD image white.

LCD image white.

LCD image white.

LCD image white.

LCD image (solarized).

LCD image too dark.

LCD image not displayed.

LCD image not displayed.

Vertical lines on the LCD.

LCD backlight fails to light.

Bright points on the LCD.

W BEEP does not sound.

W BEEP does not sound.

W BEEP does not sound.

W BEEP does not sound.

W BEEP does not sound.

No movie sound.

No movie sound.

Cannot record sound.

MAIN PWB R209 (LCDCLK) soldering defect.

Solder bridging in MAIN

PWB Q303.

SUB PWB R454 dislodged.

SUB PWB CN451 inserted

at an angle.

MAIN PWB FB205

soldering defect.

Part defective.

SUB PWB IC602 defective.

SUB PWB CN801

soldering defect.

Part defective.

Part defective.

Part defective.

MAIN PWB IC205 part

defective.

SUB PWB IC701 part

defective.

Speaker part defective.

SUB PWB CN702 not

inserted fully.

Connection error between

SUB PWB CN701 and

CN702.

MAIN PWB IC205 part

defective.

MAIN PWB CN551

damaged.

Microphone part defective.

Repair location ref. no

M221: Resolder the

MAIN PWB R209.

M221: Resolder the

MAIN PWB Q303.

M226: Re-fit the

SUB PWB R454.

M226: Re-insert the

SUB PWB CN451.

M221: Resolder the

MAIN PWB FB205.

M304: Replace the

LCD CONST.

M226: Replace the SUB PWB.

M226: Resolder the

SUB PWB CN801.

M304: Replace the

LCD CONST.

M304: Replace the

LCD CONST.

M304: Replace the

LCD CONST.

M221: Replace the MAIN PWB.

M226: Replace the SUB PWB.

M217: Replace the SPEAKER.

M226: Re-insert the

SUB PWB CN702.

M226: Re-insert SUB PWB

CN701 and CN702.

M221: Replace the MAIN PWB.

M221: Replace the

MAIN PWB CN551.

M216: Replace the MIC.

PWB

diagram

B-8

B-3

C-1

---

C-8

---

---

B-2

---

---

---

---

---

---

E-2

E-2

---

B-7

---

13

Page 14

FinePix V10 TROUBLESHOOTING GUIDE

Main category Problem details Cause

Image quality

Functions

Operation

Black smearing on the

CCD.

Live image quality coarse.

Live image quality defective

(reddish).

Live image quality defective

(solarized).

Live image quality defective

(appears pink).

Vertical lines on the live

image.

Horizontal lines on the live

image.

Resolution blurred or

shifted.

Quality problems in

recorded images.

LED lighting defect.

LED lighting defect

(self-timer).

No TV monitor output.

No TV monitor output.

USB communication fails.

USB communication fails.

USB communication fails.

USB communication fails

(red LED does not light).

Battery fails to lock.

Read error.

Battery difficult to load.

Shutter button operation

defect.

Mode switch setting cannot

be changed.

Mode switch setting cannot

be changed.

Mode switch setting cannot

be changed.

Soiling on the CCD

surface.

SUB PWB CN451 inserted

incompletely or at an angle.

MAIN PWB CN551

damaged.

SUB PWB IC602 defective.

Part defective.

Part defective.

Part defective.

Part defective.

Part defective.

Assembly error.

MAIN PWB IC205 part

defective.

Soldering defect in MAIN

PWB CN151 or FB151.

MAIN PWB C221 soldering

defect.

MAIN PWB IC205 part

defective.

MAIN PWB FB151

soldering defect.

MAIN PWB CN151

soldering defect.

MAIN PWB D407 soldering

defect.

Part defective.

Card connector soldering

defect.

Assembly error.

Part defective.

Switch defective (SW201).

Switch defective (SW202).

Part defective.

Repair location ref. no

M227: Replace the LENS ASSY.

M226: Re-insert the

SUB PWB CN451.

M221: Replace the

MAIN PWB CN551.

M226: Replace the SUB PWB.

M227: Replace the LENS ASSY.

M227: Replace the LENS ASSY.

M227: Replace the LENS ASSY.

M227: Replace the LENS ASSY.

M227: Replace the LENS ASSY.

M221: Re-assemble the

MAIN PWB.

M221: Replace the MAIN PWB.

M221: Resolder the MAIN PWB

CN151 or FB151.

M221: Resolder the

MAIN PWB C221.

M221: Replace the MAIN PWB.

M221: Resolder the

MAIN PWB FB151.

M221: Resolder the

MAIN PWB CN151.

M221: Resolder the

MAIN PWB D405.

M209: Replace the

BATTERY LOCK.

M221: Resolder the

MAIN PWB CN251.

M210: Re-assemble the

BATTERY FRAME.

M227: Replace the LENS ASSY.

M212: Replace the

RELEASE KEY UNIT.

M212: Replace the

RELEASE KEY UNIT.

M212: Replace the

RELEASE KEY UNIT.

PWB

diagram

---

C-8

B-7

---

---

---

---

---

---

---

---

A-8

C-8

---

A-8

A-8

C-7

---

B-1

---

---

---

---

---

14

Page 15

FinePix V10 TROUBLESHOOTING GUIDE

Main category Problem details Cause

Power supply

Camera will not turn on in

Camera mode.

Camera power cuts out.

Camera power cuts out

(current: 0.84 A).

The camera does not turn

on.

The camera does not turn

on.

The camera does not turn on

(no USB communication).

The camera does not turn on

(no USB communication).

The camera does not turn

on (current: 0 A).

The camera does not turn

on (current: 0 A).

The camera does not turn

on (current: 0 A).

The camera does not turn

on (current: 0 A).

The camera does not turn

on (current: 0 A).

The camera does not turn

on (current: 0 A).

The camera does not turn

on (current: 0 A).

The camera does not turn

on (current: 0 A).

The camera does not turn

on (current: 0 A).

Battery charge depletion

defect.

Operation freezes.

The camera does not turn

on (0.19 A current flows

continuously).

The camera does not turn

on (current short-circuits).

The camera does not turn

on (current short-circuits).

The camera does not turn

on under battery power.

The camera does not turn

on under battery power.

SUB PWB CN751 inserted

incompletely or at an angle.

Camera assembly error.

MAIN PWB part defective.

MAIN PWB D154

damaged.

Wire breakage in the MAIN

PWB F304.

MAIN PWB IC205 part

defective.

MAIN PWB CN151

soldering defect.

MAIN PWB X201 part

defective.

MAIN PWB F152 soldering

defect or wire breakage.

MAIN PWB FB154

soldering defect.

MAIN PWB CN551

soldering defect.

Assembly error.

Assembly error.

MAIN PWB X401 part

defective.

SUB PWB CN751 inserted

incompletely or at an angle.

Wire breakage in MAIN

PWB F351.

Part defective.

MAIN PWB IC206 part

defective.

MAIN PWB IC204 part

defective.

MAIN PWB part defective.

Solder short-circuit in the

MAIN PWB R341-C522.

BATTERY FRAME

assembly error.

MAIN PWB assembly error.

Repair location ref. no

M226: Re-insert

SUB PWB CN751.

Completely disassemble and

then re-assemble.

M221: Replace the MAIN PWB.

M221: Replace the

MAIN PWB D154.

M221: Replace the

MAIN PWB F304.

M221: Replace the MAIN PWB.

M221: Resolder the

MAIN PWB CN151.

M221: Replace the

MAIN PWB X201.

M221: Resolder or replace the

MAIN PWB F152.

M221: Resolder the

MAIN PWB FB154.

M221: Resolder the

MAIN PWB CN551.

M217: Re-assemble the

SPEAKER.

M216: Re-assemble the MIC.

M221: Replace the

MAIN PWB X401.

M226: Re-insert the

SUB PWB CN751.

M221: Replace the

MAIN PWB F351.

M227: Replace the LENS ASSY.

M222: Replace the MAIN PWB.

M221: Replace the MAIN PWB.

M221: Replace the MAIN PWB.

M221: Resolder the

MAIN PWB R341-C522.

M210: Re-assemble the

BATTERY FRAME.

M221: Re-assemble the

MAIN PWB.

PWB

diagram

A-7

---

---

A-8

B-2

---

A-8

C-8

E-1

F-9

B-7

---

---

C-8

A-7

A-7

---

---

---

---

B-4

---

---

15

Page 16

FinePix V10 TROUBLESHOOTING GUIDE

Main category Problem details Cause

Lens

Shutter operation defect.

Zoom error.

Zoom error.

Abnormal noise during

zoom operation.

Focusing error.

Focusing error.

Lens barrier operation

defect (lower side fails to

open).

Lens barrier operation

defect (fails to open).

Part defective.

MAIN PWB CN551

damaged.

Part defective.

Part defective.

Part defective.

SUB PWB IC602 defective.

Part defective.

Part defective.

Repair location ref. no

M227: Replace the LENS ASSY.

M221: Replace the

MAIN PWB CN551.

M227: Replace the LENS ASSY.

M227: Replace the LENS ASSY.

M227: Replace the LENS ASSY.

M226: Replace the SUB PWB.

M227: Replace the LENS ASSY.

M227: Replace the LENS ASSY.

PWB

diagram

---

B-7

---

---

---

---

---

---

16

Page 17

FinePix V10 TROUBLESHOOTING GUIDE

6. Information on problems arising in production during

adjustment

Adjustment Problem details Cause

AF Adj.

CAM Adj.

STEP655 (ZBL error)

STEP660 (ZRP error)

STEP802 (AF search NG)

STEP806

(AF peak detect NG)

STEP1643

(Sensitivity OFD G NG)

STEP1644

(Sensitivity OFD R/G NG)

STEP1644

(Sensitivity OFD R/G NG)

STEP1645

(Sensitivity OFD B/G NG)

STEP1713 (WB-Hi[no] NG)

STEP307

(Shutter ADJ [OPEN] NG)

STEP3100

(Zoom Control NG)

STEP331 (Smear [S] NG

(h0180~h0300))

STEP331 (Smear [S] NG

(h0180~h0300))

STEP337 (Measure [E] NG

(h0400~h2000))

STEP337 (Measure [E] NG

(h0400~h2000))

STEP337 (Measure [E] NG

(h0400~h2000))

STEP337 (Measure [E] NG

(h0400~h2000))

STEP337 (Measure [E] NG

(h0400~h2000))

STEP337 (Measure [E] NG

(h0400~h2000))

STEP339 (Value [B] NG

(h0180~h0300))

STEP339 (Value [B] NG

(h0180~h0300))

STEP342 (Shutter ADJ

[small aperture] NG)

STEP3884

(delta C NG POS:1)

STEP3884

(delta C NG POS:1)

STEP3885

(color NG POS:1)

STEP3888

(delta C NG POS:5)

Lens-related.

Lens-related.

Lens-related.

Lens-related.

SUB PWB IC602 defective.

SUB PWB IC602 defective.

Lens-related.

Lens-related.

Lens-related.

SUB PWB IC602 defective.

Lens-related.

SUB PWB IC602 defective.

Lens-related.

Solder bridging in the MAIN

PWB CN551.

MAIN PWB CN551

damaged.

SUB PWB CN601 not

locked or incompletely

locked.

SUB PWB FB601 soldering

defect.

SUB PWB IC602 defective.

Lens-related.

SUB PWB assembly error.

Lens-related.

SUB PWB R651 damaged.

SUB PWB IC602 defective.

Lens-related.

Lens-related.

Lens-related.

Repair location ref. no

M227: Replace the LENS ASSY.

M227: Replace the LENS ASSY.

M227: Replace the LENS ASSY.

M227: Replace the LENS ASSY.

M226: Replace the SUB PWB.

M226: Replace the SUB PWB.

M228: Replace the LENS ASSY.

M228: Replace the LENS ASSY.

M228: Replace the LENS ASSY.

M226: Replace the SUB PWB.

M228: Replace the LENS ASSY.

M226: Replace the SUB PWB.

M228: Replace the LENS ASSY.

M221: Repair the solder on the

MAIN PWB CN551.

M221: Replace the

MAIN PWB CN551.

M226: Re-insert the

SUB PWB CN601.

M226: Resolder the

SUB PWB FB601.

M226: Replace the SUB PWB.

M228: Replace the LENS ASSY.

Re-assemble the SUB PWB.

M228: Replace the LENS ASSY.

M226: Replace the

SUB PWB R651.

M226: Replace the SUB PWB.

M228: Replace the LENS ASSY.

M228: Replace the LENS ASSY.

M227: Replace the LENS ASSY.

PWB

diagram

---

---

---

---

---

---

---

---

---

---

---

---

---

B-7

B-7

C-7

D-4

---

---

---

---

D-3

---

---

---

---

17

Page 18

FinePix V10 TROUBLESHOOTING GUIDE

Adjustment Problem details Cause

CAM Adj.

CCD Data

Input

CCD L.D. Adj.

STEP411

(ISO sensitivity adjustment

NG (h014F~h021D))

STEP411 (ISO sensitivity

adjustment NG

(h014F~h021D))

STEP453 (WB[LB145]

adjustment NG)

STEP252 (OFD adjustment

NG (GreenLine))

STEP252 (OFD adjustment

NG (GreenLine))

STEP252 (OFD adjustment

NG (GreenLine))

STEP252 (OFD adjustment

NG (GreenLine))

STEP252 (OFD adjustment

NG (GreenLine))

STEP252 (OFD adjustment

NG (GreenLine))

STEP252 (OFD adjustment

NG (GreenLine))

STEP252 (OFD adjustment

NG (GreenLine))

STEP252 (OFD adjustment

NG (GreenLine))

STEP252 (OFD adjustment

NG (GreenLine))

STEP252 (OFD adjustment

NG (GreenLine))

STEP255

(REC OFD Adjustment NG)

STEP255

(REC OFD Adjustment NG)

STEP255

(REC OFD Adjustment NG)

STEP265

(MV OFD adjustment NG)

STEP4562 (Line defect

data NG (h00~h40)

STEP4562 (Line defect

data NG (h00~h40)

STEP4562 (Line defect

data NG (h00~h40)

STEP4562 (Line defect

data NG (h00~h40)

STEP4652

(Noise inspection NG)

SUB PWB IC602 defective.

Lens-related.

Lens-related.

MAIN PWB CN551 not

inserted fully.

MAIN PWB CN551

soldering defect.

SUB PWB CN601 not

locked or incompletely

locked.

SUB PWB CN601 not

inserted fully.

Wire breakage in MAIN

PWB F304.

MAIN PWB FB201

damaged.

MAIN PWB IC205 part

defective.

SUB PWB IC602 defective.

MIC assembly error.

SUB PWB R626 damaged.

Lens-related.

Solder bridging in the MAIN

PWB CN551.

SUB PWB D602 damaged.

Lens-related.

Lens-related.

SUB PWB CN601 inserted

at an angle.

MAIN PWB CN551

damaged.

SUB PWB IC602 defective.

Lens-related.

Lens-related.

Repair location ref. no

M226: Replace the SUB PWB.

M227: Replace the LENS ASSY.

M227: Replace the LENS ASSY.

M221: Re-insert the

MAIN PWB CN551.

M221: Repair the solder on

MAIN PWB CN551.

M226: Re-insert the

SUB PWB CN601.

M221: Re-insert the

MAIN PWB CN601.

M221: Replace the

MAIN PWB F304.

M221: Replace the

MAIN PWB FB201.

M221: Replace the MAIN PWB.

M226: Replace the SUB PWB.

M216 Re-assemble the MIC.

M226: Replace the

SUB PWB R626.

M228: Replace the LENS ASSY.

M221: Repair the solder on the

MAIN PWB CN551.

M226: Replace the

SUB PWB D602.

M228: Replace the LENS ASSY.

M228: Replace the LENS ASSY.

M226: Re-insert the

SUB PWB CN601.

M221: Replace the

MAIN PWB CN551.

M226: Replace the SUB PWB.

M227: Replace the LENS ASSY.

M227: Replace the LENS ASSY.

PWB

diagram

---

---

---

B-7

B-7

C-7

E-7

B-2

A-7

---

---

---

C-6

---

B-7

D-4

---

---

C-7

B-7

---

---

---

18

Page 19

FinePix V10 TROUBLESHOOTING GUIDE

Adjustment Problem details Cause

Flash Adj. STEP1240

(Flash CHARGE 1 NG)

STEP1240

(Flash CHARGE 1 NG)

STEP1240

(Flash CHARGE 1 NG)

STEP1241

(Flash luminescence 1 NG)

STEP1241

(Flash luminescence 1 NG)

STEP1241

(Flash luminescence 1 NG)

STEP1241

(Flash luminescence 1 NG)

STEP1241

(Flash luminescence 1 NG)

STEP1241

(Flash luminescence 1 NG)

STEP1241

(Flash luminescence 1 NG)

STEP1241

(Flash luminescence 1 NG)

STEP1243

(Flash luminescence 2 NG)

STEP1245

(Flash luminescence 3 NG)

STEP1245

(Flash luminescence 3 NG)

STEP1249

(Flash luminescence 5 NG)

STEP1251

(Flash luminescence 6 NG)

STEP1253 (Flash

luminescence average NG)

STEP1253 (Flash

luminescence average NG)

STEP1253 (Flash

luminescence average NG)

MAIN PWB IC205 part

defective.

MAIN PWB T401 soldering

defect.

Main capacitor polarity

reversed.

MAIN PWB IC205 part

defective.

SUB PWB IC602 defective.

Battery terminal soldering

defect.

FLASH CONST damaged.

MAIN PWB T401 part

defective.

Xenon tube defective.

Xenon tube soldering

defect.

Trigger coil damaged.

Xenon tube soldering

defect.

C852 in the FLASH

CONST damaged.

FLASH CONST damaged.

Trigger coil damaged.

FLASH CONST damaged.

FLASH CONST damaged.

Xenon tube defective.

Xenon tube soldering

defect.

Repair location ref. no

M221: Replace the MAIN PWB.

Resolder the MAIN PWB T401.

Correct the polarity and then

resolder.

M221: Replace the MAIN PWB.

M226: Replace the SUB PWB.

Resolder the battery terminals.

M218: Replace the

FLASH CONST.

MAIN PWB T401 damaged.

M219: Replace the Xe-LIGHT.

M219: Resolder the Xe-LIGHT.

M218: Replace the

FLASH CONST.

M219: Resolder the Xe-LIGHT.

Replace C852 in the

FLASH CONST.

M218: Replace the

FLASH CONST.

M218: Replace the

FLASH CONST.

M218: Replace the

FLASH CONST.

M218: Replace the

FLASH CONST.

M219: Replace the Xe-LIGHT

M219: Resolder the Xe-LIGHT.

PWB

diagram

---

---

---

---

---

B-4

---

C-6

---

---

---

---

---

---

---

---

---

---

---

19

Page 20

FinePix V10 TROUBLESHOOTING GUIDE

Adjustment Problem details Cause

Video Adj. STEP2702

(PLAY mode NG)

STEP2702

(PLAY mode NG)

STEP2702

(PLAY mode NG)

STEP2711

(NTSC BLK level NG)

STEP2711

(NTSC BLK level NG)

STEP2721

(NTSC Y gain NG)

STEP2721

(NTSC Y gain NG)

STEP2884

(PAL R HUE NG)

STEP2931

(STB Y gain NG)

STEP2931

(STB Y gain NG)

STEP2940

(STB WB R-Y NG)

MAIN PWB CN551

soldering defect.

MAIN PWB FB202

damaged.

MAIN PWB part defective.

MAIN PWB C104

damaged.

MAIN PWB X201 part

defective.

MAIN PWB C103

damaged.

MAIN PWB FB152

soldering defect.

Lens-related.

MAIN PWB IC205 part

defective.

SUB PWB IC602 defective.

SUB PWB IC602 defective.

Repair location ref. no

M221: Resolder the

MAIN PWB CN551.

M221: Replace the

MAIN PWB FB202.

M221: Replace the MAIN PWB.

M221: Replace the

MAIN PWB C104.

M221: Replace the

MAIN PWB X201.

M221: Replace the

MAIN PWB C103.

M221: Resolder the

MAIN PWB FB152.

M228: Replace the LENS ASSY.

M221: Replace the MAIN PWB.

M226: Replace the SUB PWB.

M226: Replace the SUB PWB.

PWB

diagram

---

B-7

---

D-9

C-8

C-9

A-8

---

---

---

---

20

Page 21

FUJI PHOTO FILM CO., LTD.

26-30, Nishiazabu 2-chome, Minato-ku, Tokyo 106-8620, Japan.

Loading...

Loading...