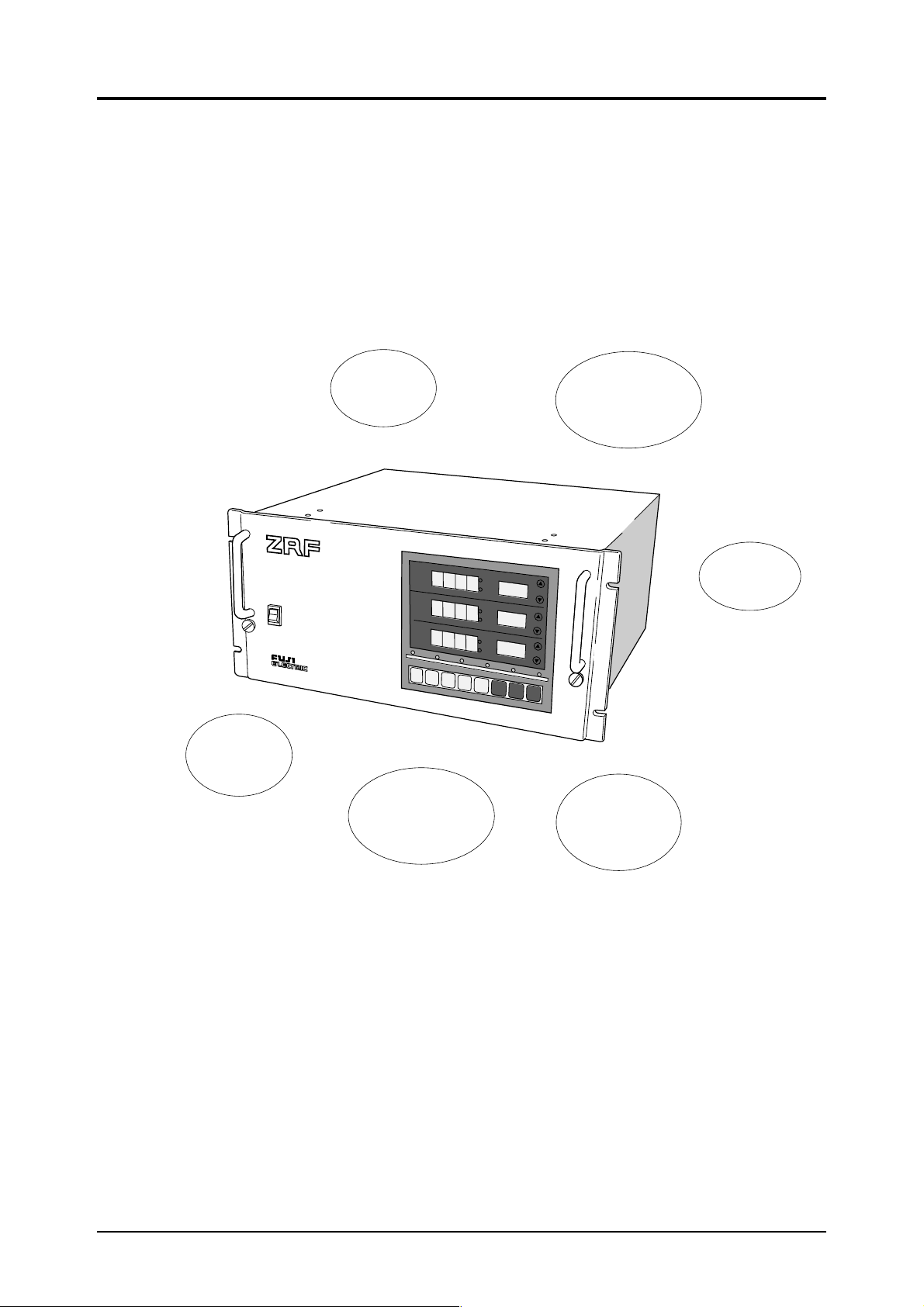

Page 1

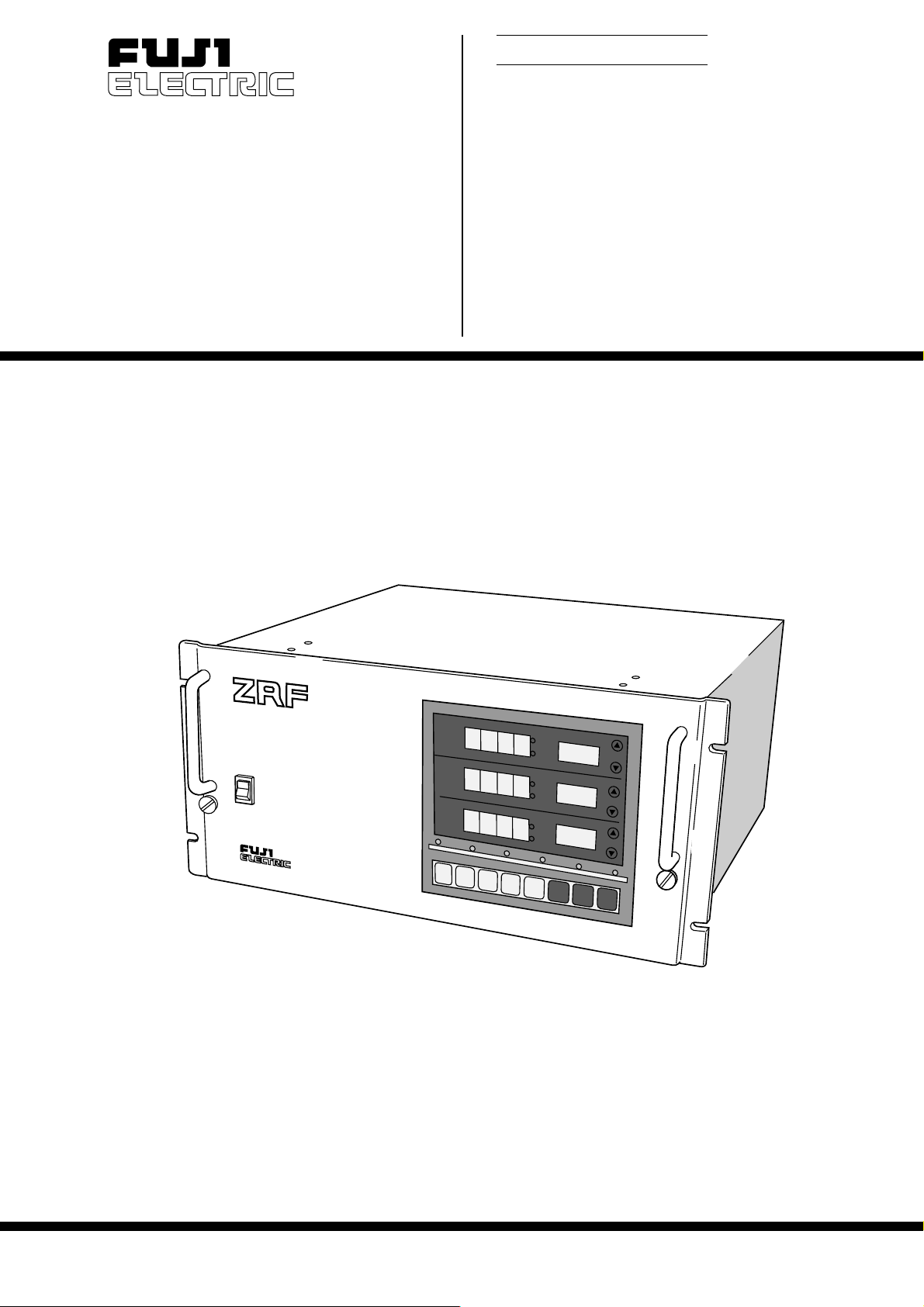

Instruction Manual

NON-DISPERSION TYPE

INFRARED GAS ANALYZER

TYPE: ZRF

IN

FR

AR

ED

G

AS

AN

ALY

ZER

NO

PO

W

ER

O

N

O

FF

SO

O

MEAS

FUNC

2

2

COMP

MEAS

>

SPAN

∧

ENT

vol%

ppm

vol%

ppm

vol%

ppm

HOLD

ZERO

R

M

T

R

A

N

SPAN

RANG

E

RANG

E

RANG

E

G

E

AUTO CAL

CAL

Fuji Electric Co.,Ltd. INZ-TN1ZRFb-E

Page 2

PREFACE

Congratulations on your purchase of Fuji’s Infrared Gas Analyzer (Type: ZRF).

• Before using, be sure to read this instruction manual carefully to ensure correct installation,

operation and maintenance of the infrared gas analyzer. Note that incorrect handling may lead

to trouble or personal injury.

• The specifications of this infrared gas analyzer are subject to change for improvement without

prior notice.

• Do not attempt to modify the infrared gas analyzer without permission. Fuji is not responsible

for any trouble caused by modification without permission.

• This instruction manual should always be kept on hand by the user.

After reading, be sure to keep this manual in a place where it can easily be seen by the operator.

•

• Make sure that this manual is presented to the final user.

Manufacturer : Fuji Electric Co., Ltd.

Type : Described in Fuji Electric’s company nameplate on main frame

Date of manufacture : Described in Fuji Electric’s company nameplate on main frame

Product nationality : Japan

Delivered items

Analyzer main frame .................................................... 1

Fuse (2A) ......................................................................2

Cell assembling tool (only for block cell) .................... 1

Instruction manual ........................................................1

Test report ..................................................................... 1

Mounting fixture (in case of panel flush mount) .......... 4

NOTICE

• It is prohibited to transfer part or all of this manual without Fuji

Electric’s permission in written format.

• Description in this manual will be changed without prior notice

for further improvement.

i

© Fuji Electric Co., Ltd., 1990

Issued in Sept., 1990

Rev. 1st ed. in July, 1993

Rev. 2nd ed. in Apr., 1997

Page 3

SAFETY PRECAUTION

First of all, read this “Safety Precaution” carefully, and then use the analyzer in the correct way.

• The cautionary descriptions listed here contain important information about safety, so they should

always be observed. Those safety precautions are ranked 2 levels; “DANGER” and “CAUTION”.

Warning & Symbol

DANGER:

CAUTION:

Caution on installation and transport of gas analyzer

DANGER: This unit is not an explosion-proof type. Do not use it in a place

CAUTION: • For installation, observe the rule on it given in the instruction

Meaning

Wrong handling may cause a dangerous situation, in which there

is a risk of death or heavy injury.

Wrong handling may invite a dangerous situation, in which there is

a possibility of medium-level trouble or slight injury or only physical

damage is predictable. .

with explosive gases to prevent explosion, fire or other serious

accidents.

manual and select a place where the weight of gas analyzer can

be endured.

Installation at an unsuited place may cause turnover or fall and

there is a risk of injury.

• For lifting the gas analyzer, be sure to wear protective gloves.

Bare hands may invite an injury. .

• Before transport, fix the casing so that it will not open. Otherwise, the casing may be separated and fall to cause an injury.

• The gas analyzer is heavy. It should be transported carefully.

Otherwise, body may be damaged or injured.

• During installation work, care should be taken to keep the unit

free from entry of cable chips or other foreign objects. Otherwise, it may cause fire, trouble or malfunction of the unit.

ii

Page 4

Caution on piping

DANGER: In piping, the following precautions should be observed. Wrong

piping may cause gas leakage.

If the leaking gas contains a toxic component, there is a risk of

serious accident being induced.

Also, if combustible gas is contained, there is a danger of explosion, fire or the like occurring.

• Connect pipes correctly referring to the instruction manual.

• Exhaust should be led outdoors so that it will not remain in the

locker and installation room.

• Exhaust from the analyzer should be relieved in the atmospheric

air in order that an unnecessary pressure will not be applied to

the analyzer. Otherwise, any pipe in the analyzer may be disconnected to cause gas leakage.

• For piping, use a pipe and a pressure reducing valve to which oil

and grease are not adhering. If such a material is adhering, a

fire or the like accident may be caused.

Caution on wiring

CAUTION: • Wiring is allowed only when all power supplies are turned off.

This is required for preventing a shock hazard.

• Enforce construction of specified grounding wire by all means. If

the specified grounding construction is neglected, a shock hazard or fault may be caused.

• Wires should be the proper one meeting the ratings of this instrument. If using a wire which cannot endure the ratings, a fire may

occur.

• Use power source that matches the rating of the unit. Use of

power source out of rating may cause fire.

Caution on use

DANGER: • When handling the standard gas such as calibration gas, read

the instruction manual of the standard gas carefully and use the

gas correctly.

CAUTION: • Avoid continuous operation with the casing drawn out.

• During operation, avoid opening the casing and touching the

internal parts. Otherwise, you may suffer a burn or shock hazard.

iii

Page 5

Caution on maintenance and check

DANGER: • When doors are open during maintenance or inspection for

adjusting the optical system, etc., be sure to purge sufficiently

the inside of the gas analyzer as well as the measuring gas line

with nitrogen or air, in order to prevent poisoning, fire or explosion due to gas leaks.

CAUTION: • Before working, take off a wrist watch, finger ring or the like

metallic accessories. And never touch the instrument with a wet

hand, Otherwise, you will have a shock hazard.

• If the fuse is blown, eliminate the cause, and then replace it with

the one of the same capacity and type as before. Otherwise,

shock hazard or fault may be caused.

Others

CAUTION: • If the cause of any fault cannot be determined despite reference

to the instruction manual, be sure to contact your dealer or Fuji

Electric’s technician in charge of adjustment. If the instrument is

disassembled carelessly, you may have a shock hazard or injury.

• Do not use a replacement part other than specified by the instrument maker. Otherwise, adequate performance will not be

provided. Besides, an accident or fault may be caused.

• Replacement parts such as a maintenance part should be disposed of as incombustibles.

iv

Page 6

CAUTIONS ON USE

Select a suitable installation place.

Install the unit in a place with normal temperature and humidity, free from excessive change in

temperature and from heat radiation and direct sunlight.

This unit is designed for indoor installation. When it is installed outdoors, choose a place where it

is not exposed to wind and rain. Be sure to use a proper case cover.

Do not install the unit in a place with vibrations.

Cleaning of instrument

Do not use solvents such as benzine, thinner, etc., as it damages the case.

Use the unit in a place with good environment.

The unit should be used in a place free from corrosive or combustible gases.

Be careful with electric shocks.

The unit should be earthed to avoid electric shocks.

Key operation

Do not use any object with a sharp tip when operating the function keys on the instrument panel.

v

Page 7

CONTENTS

PREFACE........................................................................................................................................ i

SAFETY PRECAUTION...............................................................................................................ii

CAUTIONS ON USE..................................................................................................................... v

1. OUTLINE ............................................................................................................................... 1

2. NAME AND DESCRIPTION OF EACH COMPONENT .................................................... 2

2.1 Name and description of each component on case .................................................................... 2

2.2 Name and description of components on indication/operation panel........................................ 4

3. INSTALLATION ................................................................................................................... 6

3.1 Mounting method....................................................................................................................... 6

3.2 Piping method ............................................................................................................................ 7

3.3 Sampling .................................................................................................................................... 8

3.4 Wiring method ......................................................................................................................... 10

4. OPERATION ........................................................................................................................ 15

4.1 Operation procedure................................................................................................................. 15

4.2 Preparation for operation ......................................................................................................... 16

4.3 Start of measurement ............................................................................................................... 17

4.4 Shutdown ................................................................................................................................. 17

5. OPERATION OF INDICATION/OPERATION PANEL.................................................... 18

5.1 Outline of indication/operation panel ...................................................................................... 18

5.2 General operation..................................................................................................................... 20

① Calibration concentration setting (when not using Zirconia O

② Calibration concentration setting (when using Zirconia O

③ Alarm value setting (option) .............................................................................................. 27

④ Hold setting........................................................................................................................ 29

⑤ Remote range setting (option)............................................................................................ 31

⑥ Auto calibration (option) ................................................................................................... 32

⑦ Key lock ON/OFF Setting ................................................................................................. 40

⑧ Zero calibration.................................................................................................................. 41

⑨ Span calibration ................................................................................................................. 42

analyzer)......................... 22

2

analyzer)............................... 24

2

6. MAINTENANCE MODE .................................................................................................... 43

6.1 Response time setting .............................................................................................................. 44

6.2 O

6.3 Optical balance adjustment...................................................................................................... 45

6.4 Interference compensation coefficient setting ......................................................................... 46

6.5 Indication and clearing of integrated drift value...................................................................... 47

conversion reference value setting...................................................................................... 44

2

7. MAINTENANCE ................................................................................................................. 48

7.1 Routine maintenance................................................................................................................ 48

7.2 Periodical inspection................................................................................................................ 49

8. ERROR CODES AND REMEDIES .................................................................................... 56

vi

Page 8

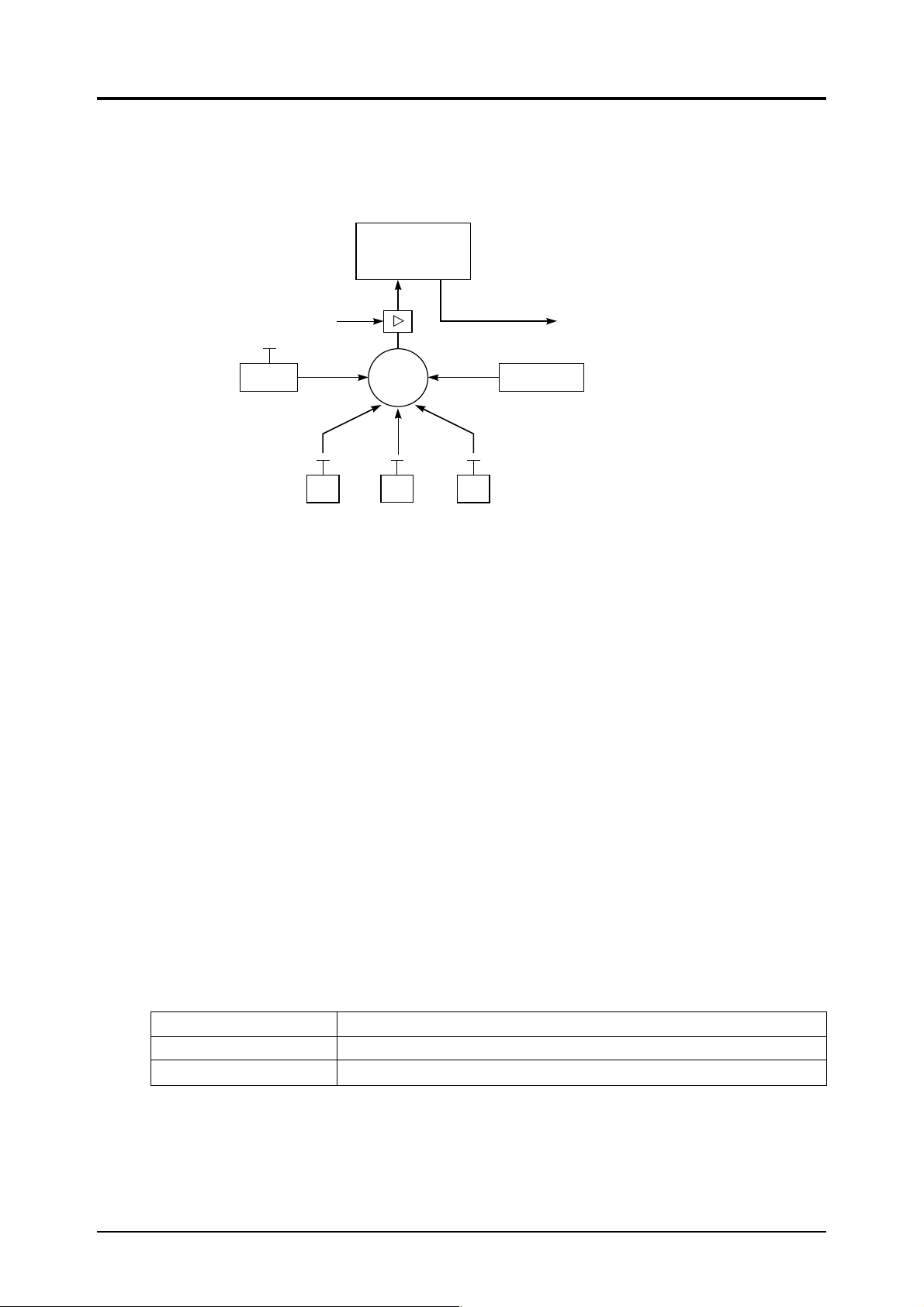

1. OUTLINE

This is a multi-function, easy-to-operate non-dispersion type infrared gas analyzer for measuring the

concentration of gases such as NO, SO

featuring high sensitivity and reliability, plus a microprocessor for easy operation.

, CO2 and CO. It utilizes a highly reputed mass flow type detector

2

INFRARED GAS ANALYZER

PO

Auto

calibration

function

(option)

Self diagnosis

function

Zero point

and span easily

adjustable by

key operation

NO

W

ER

ON

OFF

MEAS

FUNC

SO

O

2

2

MEAS

COMP

Remote range,

range detect

function

(option)

v

o

l%

p

p

m

R

A

N

G

E

v

o

l%

p

p

m

R

A

N

G

E

vol%

ppm

R

A

N

G

SPAN

HOLD

>

∧

E

N

T

Z

E

R

M

T

R

A

N

G

E

AUTO CAL

E

R

O

S

P

A

N

C

A

L

Upper/lower

limit alarm

function

(option)

Output hold

function

1

Page 9

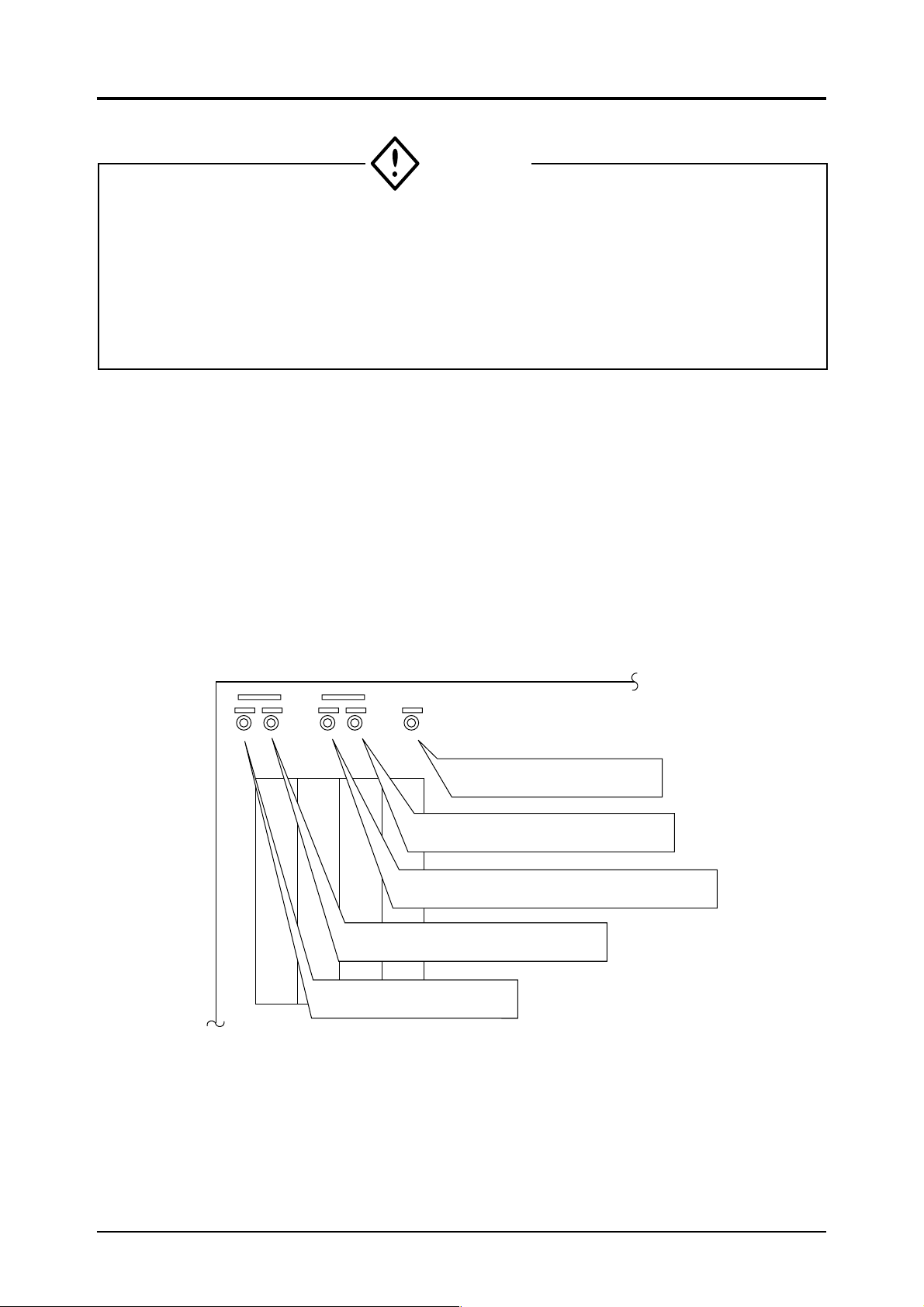

2. NAME AND DESCRIPTION OF EACH COMPONENT

2.1 Name and description of each component on case

INFRARED GAS ANALYZER

① Grip

② Knurled knob

POWER

ON

OFF

NO

SO

O

2

MEAS

F

U

N

C

③ Power switch

④ Indication/operation panel

* *

⑧ Reference gas inlet

⑦ Sample gas outlet

⑥ Sample gas inlet

2

MEAS

C

O

M

P

>

v

o

l%

p

p

m

v

o

l%

p

p

m

v

o

l%

p

p

m

SPAN

HOLD

RMT RANGE

∧

ENT

ZERO

Front panel

SPAN

R

A

N

G

E

R

A

N

G

E

R

A

N

G

E

AUTO CAL

CAL

⑨ Reference gas outlet

⑩ Purge gas inlet

*Used for differential

flow system only.

⑪ COMP1 (1st component)

input/output terminal

⑫ COMP2 (2nd component)

input/output terminal

⑬ O2 input/output terminal

(option)

SUMPLE GAS

INLET

OUTLET

COMP1 COMP2 O2 AUTO CAL

PLUG

Infrared

Gas Analyzer

Type

Range

Output

DC mA

Power Supply AC v 50/60Hz

Mid

Ser No.

Fuji Electric Co., Ltd

Rear panel

⑮ Power terminal

Japan

⑭ AUTO CAL input/output

terminal (option)

2

Page 10

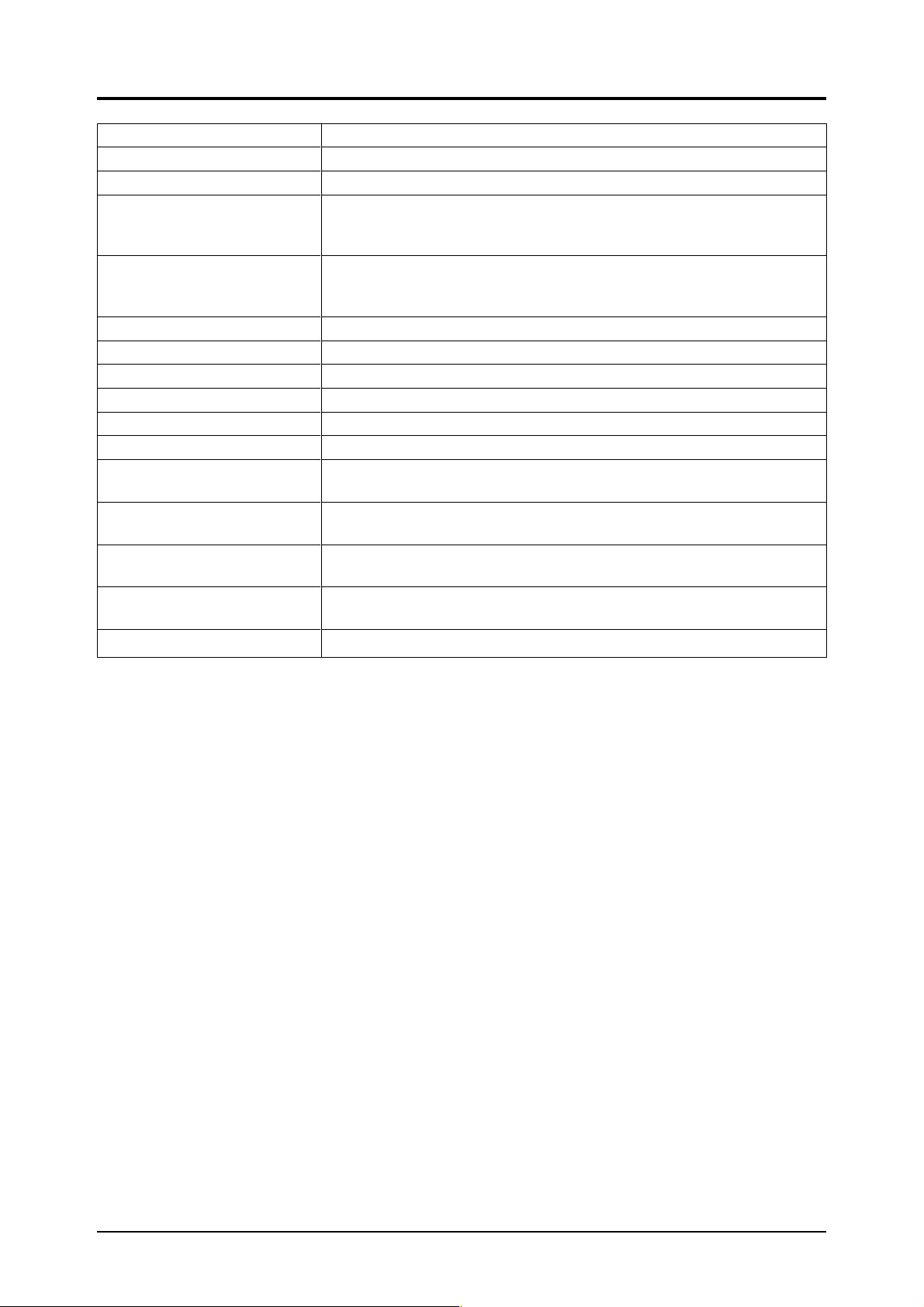

Part name

① Grip

② Knurled knob

③ Power switch

④ Indication/operation panel

⑤ Flowmeter (option)

⑥ Sample gas inlet

⑦ Sample gas outlet

⑧ Reference gas inlet

⑨ Reference gas outlet

⑩ Purge gas inlet

⑪ COMP1 (1st component)

input/output terminal

⑫ COMP2 (2nd component)

input/output terminal

⑬ O2 input/output terminal

(option)

⑭ AUTO CAL input/output

terminal (option)

⑮ Power terminals

Description

Used to pull out the interior (base).

Used to fasten the instrument and case.

Turn ON to supply power to the internal components (excluding the pump).

After 3 or 4 seconds the LED indicator lights up. (Refer to 4.2 for pump

power supply.)

Indicates gas concentration, measuring range, etc., and contains keys necessary for routine operation and settings. Refer to section 5 for operating

method.

Used to check sample gas flow rate. Float rises when sample gas flows.

Connect gas to be measured here.

Connect pipe for discharging measured gas here.

Connect reference gas here in case of differential flow system.

Connect pipe here for discharging reference gas.

Connect pipe for purge gas here.

Used for 1st component of standard type and sample switching type or flow

differential type.

Input/output terminal for 2nd component of two-component analyzer.

Input/output terminal for O2 analyzer.

Input/output terminal for auto calibration function.

Supply power to the analyzer.

3

Page 11

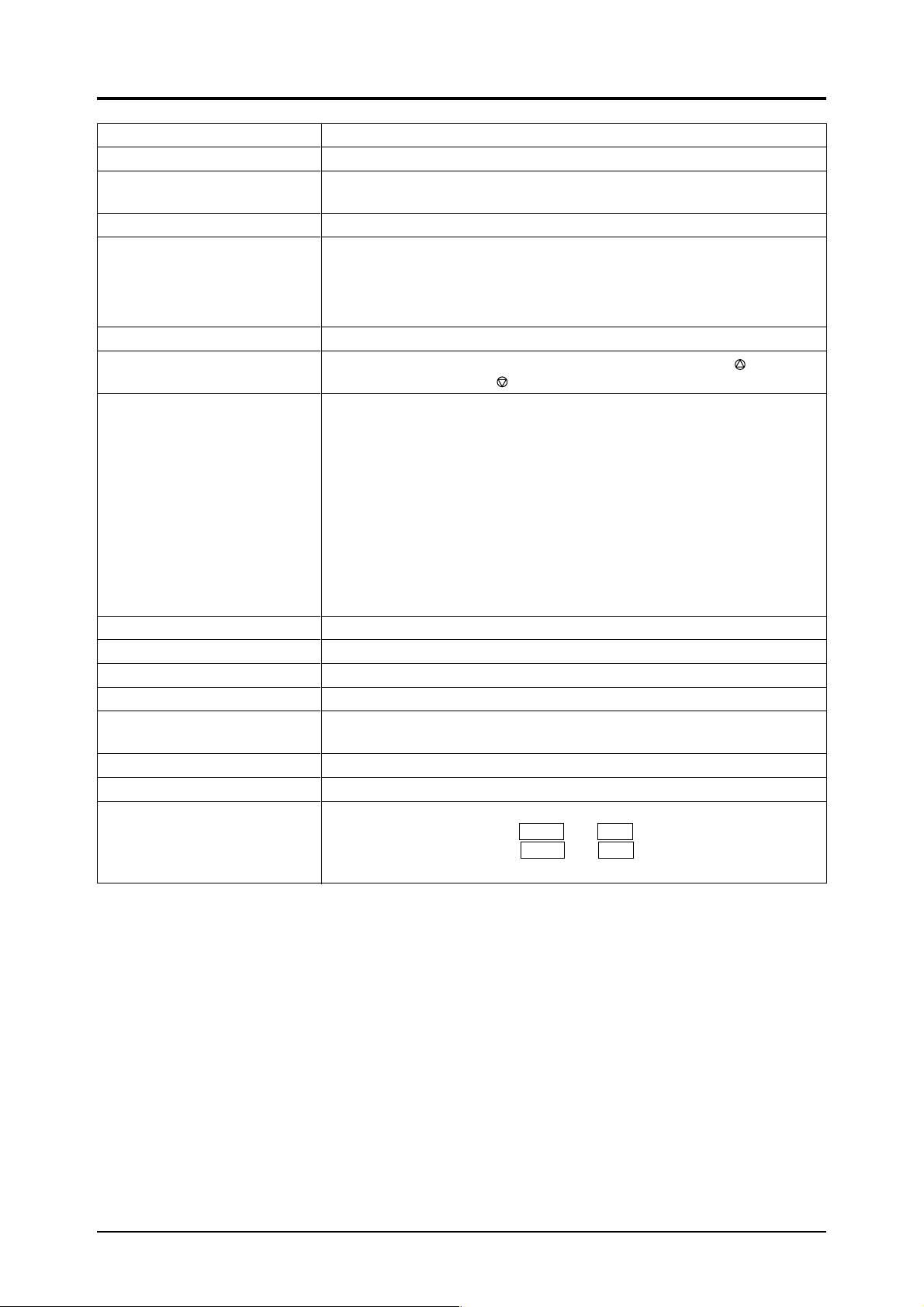

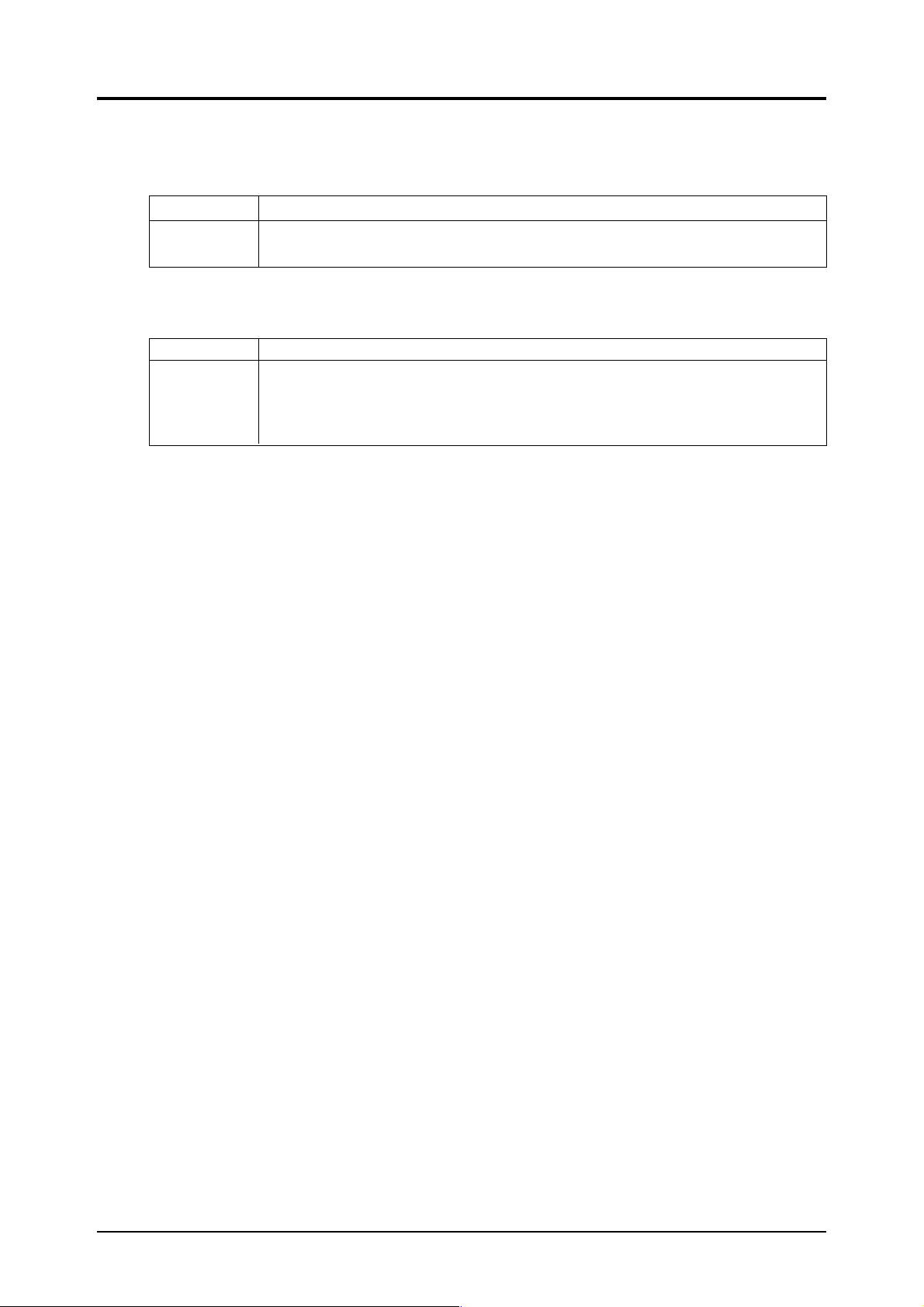

2.2 Name and description of components on indication/operation panel

3 Unit indication lamp

2 Main indication

1 Component indication

7 Function indicator lamp

9 Component selector key

10

Digit shift key

11

Numeric input key

8 Function key

SU

TU TH

NO

SO

2

O

2

MEAS CAL SET ALH SET HOLD RMT RANGE AUTO CAL

COMP

FUNC

> ∧

vol%

ppm

MO WE FR

vol%

ppm

vol%

ENT ZERO SPAN CAL

SA

RANGE

RANGE

RANGE

(Three components of NO, SO2 and O2 are

indicated in this figure.)

4 Day indication

5 Sub indication

6 Range changeover key

15

Calibration start key

14

Span calibration key

13

Zero calibration key

12

ENT key

4

Page 12

Part name

① Component indication

② Main indication

③ Unit indication lamp

④ Day indication

⑤ Sub indication

⑥ Range changeover key

⑦ Function indicator lamp

⑧ Function key

⑨ Component selector key

⑩ Digit shift key

⑪ Numeric input key

⑫ ENT key

⑬ Zero calibration key

⑭ Span calibration key

⑮ Calibration start key

Description

Indicates kind of gas measured.

Indicates measured concentration. Also indicates various setpoints for alarm

function, auto calibration function (option), etc.

Indicates unit of measured gas concentration.

Indicates current day or day of starting by means of bar in auto calibration

(option) setting mode.

Indication SU MO TU WE TH FR SA

Day Sun Mon Tue Wed Thu Fri Sat

Indicates measuring range, error code, various setpoints, etc.

Used when changing the range. High range is set when pressing and low

range is set when pressing .

Relevant lamp lights up when following functions are set.

MEAS : Lights up in measuring status.

CAL SET : Flashes in calibration concentration setting mode.

ALM SET : Flashes in alarm setting mode.

HOLD : Flashes in hold setting mode or lights steadily while hold

function is activated.

RMT RANGE : Flashes in remote range setting mode or lights steadily while

remote range function is activated.

AUTO CAL : Flashes in auto calibration setting mode or lights steadily

while auto calibration function is activated.

Setting mode is changed at each press of this key. (Refer to section 5.)

Set component is changed for each setting mode or span adjustment.

Shift is made from highest toward lowest digit at each press of this key.

Selected digit is incremented at each press of this key.

By pressing this key after setting, the set contents are memorized and become

valid.

Used for zero point calibration. (Lamp flashes in zero calibration mode.)

Used for span calibration. (Lamp flashes in span calibration mode.)

Start key for manual calibration.

Zero is calibrated by pressing ZERO and CAL keys.

Span is calibrated by pressing SPAN and CAL keys. (CAL lamp lights

steadily during calibration.)

5

Page 13

3. INSTALLATION

• This unit is not explosion-proof type. Do not use it in a place with explosive gases to

prevent explosion, fire or other serious accidents.

• This unit is heavy and should be mounted securely to prevent it from falling.

Before mounting the unit, make sure that all the knobs on the front of the unit are fixed firmly.

•

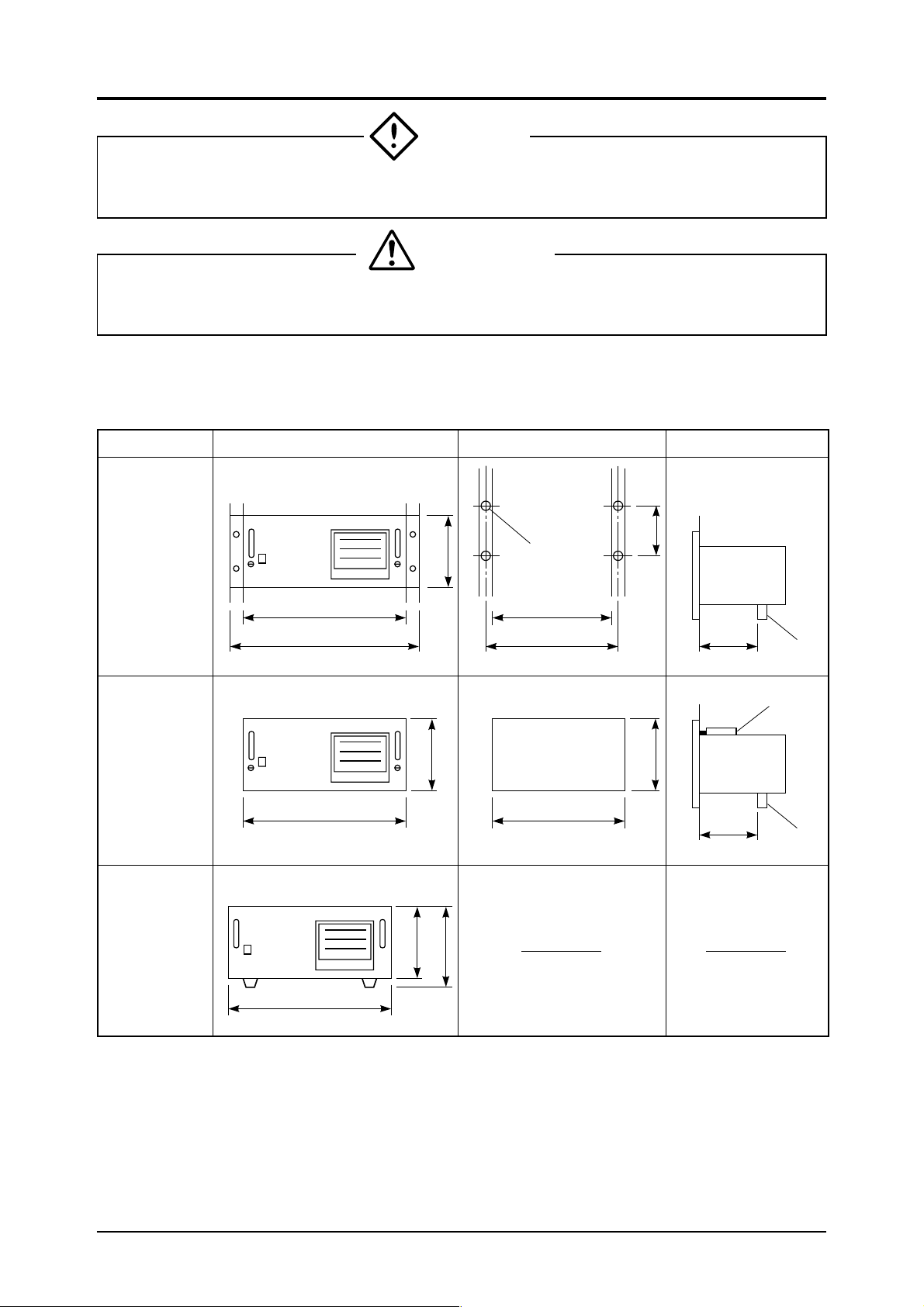

3.1 Mounting method

DANGER

CAUTIONS

The following three methods are usable for mounting the analyzer.

Type Outer dimensions of analyzer Mounting dimensions Mounting method

19 inch

rack

mounting

Panel

mounting

ZRF

ZRF

443

483

443

220

<Panel output dimensions>

220

M6

438 or more

465

436

+2

–0

146

+2

213

240 or

more

–0

240 or

more

(Unit: mm)

Support

Mounting

bracket

Support

ZRF

Desk top

type

443

220

233

(1) Mounting method

Mount so that the front panel is vertical.

(2) Caution on installation

70% or more of the instrument weight should be supported by the case bottom.

(When mounting on a panel or 19 inch rack, attach a support under the rear of the case.)

6

Page 14

3.2 Piping method

DANGER

• Use clean pipes of which inside should not be stained with deposits of oil or fat.

• Piping joints must be tightened firmly to avoid gas leakage.

• Exhaust gas should be discharged to an outdoor safe place to prevent it from staying in the

sampling device and indoors.

• Exhaust from the analyzer should be relieved at the atmospheric pressure in order that an

unnecessary pressure will not be applied to the analyzer. Otherwise, any pipe in the

analyzer may be disconnected to cause gas leakage.

(1) Piping procedure

Connect pipes to the gas inlets and outlets located at the top left on the analyzer rear.

Use anticorrosive tubes made of Teflon, stainless steel, polyethylene or the like for connecting the

analyzer and sampling system. Avoid using rubber or soft vinyl tubes even if there is no worry about

corrosion. Improper piping material may cause inaccurate indication due to adsorption of gas.

The pipe connections are Rc1/4 (PT1/4) internal thread. And the pipes should be kept as short as

possible to quicken the response. A suitable inner diameter is about 4mm. Note that dust entering

the analyzer may cause a malfunction, so be sure to use clean pipes and joints.

Carry out gas piping as follows.

Purge gas inlet :

Connect purge gas pipe here.

Reference gas outlet :

Connect pipe here for discharging reference gas.

Reference gas inlet :

Connect reference gas here in case of flow differential system.

Sample gas outlet :

Connect pipe here for discharging measured gas.

Sample gas inlet :

Connect gas to be measured here.

7

Page 15

(2) Piping diagram

e

Shown next is an example of the configuration for measuring three components. (When using

Zirconia O

analyzer)

2

Gas analyzer

(ZRF)

Sample gas inlet

Flow meter

Air

(Zero calibration gas)

NO

Change

-over

valve

SO

(Span calibration gas)

Sample gas outlet

2

O

Arrange so that sample ga

outlet is at atmospheric pr

Sample gas

2

3.3 Sampling

3.3.1 Sample gas condition

(1) Remove all dust included in sample gas by means of a filter. Use a filter capable of eliminating

dust particles of 0.3µ at the final stage.

(2) The dew point of sample gas must be lower than the ambient temperature to prevent accumula-

tion of drain inside the analyzer. If water vapor is included in the sample gas, then feed the gas

through a dehumidifier to lower the dew point to around 0°C.

(3) If SO

(4) Note that if strongly corrosive gas such as Cl

(5) The sample gas temperature should range from 0 to 50°C. Be careful not to introduce a high

mist is included in sample gas, then use a mist filter, cooler etc. to exclude the mist. The

3

same applies if other kinds of mist are included.

, F2 or HCr is included in sample gas in a large

2

amount, it will shorten the service life of the analyzer.

temperature gas directly into the analyzer.

3.3.2 Sample gas flow rate

The sample gas flow rate should be as follows.

Provide a flowmeter as shown in the preceding diagram to measure the flow rate.

Standard type 0.5r±0.25r/minute

Sample switching type (1r+1r)±0.1r/minute (sample gas+reference gas)

Flow differential type (0.5r+ 0.5r)±0.25r/minute (sample gas +reference gas)

8

Page 16

3.3.3 Preparation of standard gas

Prepare standard gas for zero point and span point calibration.

Zero gas N2 gas

Span gas Gas with concentration of 80% or more of full scale for each component

(Span gas in measuring method is gas with concentration of 90% or more of full scale.)

When using a Zirconia O2 analyzer, use air for zero gas.

Zero gas Air (O2 analyser span gas in measuring method) Note)

Span gas 1 to 2% O2 (O2 analyser span gas in measuring method)

Gas with concentration of 80% or more of full scale for other than Zirconia O2 analyzer.

(Span gas in measuring method is gas with concentration of 90% or more of full scale.)

Note: When calibrating the low and high ranges of Zirconia type O2 analyzer, use 9 to 10% O2/N

for the low range, and air for the high range.

3.3.4 Analyzer interior purging

Although purging of the analyzer interior is normally unnecessary, it should be considered in the

following cases.

(1) When combustible gas is included in the measured gas

(2) When corrosive gas is included in the atmosphere at the installation site.

(3) When the same gas as the measured components is included in the atmosphere at the installa-

tion site.

In such cases, purge the analyzer interior with instrumentation air or N

should be about 1r/minute.

And dust or mist should be completely eliminated from the gas for purging.

3.3.5 Pressure at sample gas outlet

Arrange so that the sample gas outlet is at atmospheric pressure.

. The flow rate for purging

2

2

9

Page 17

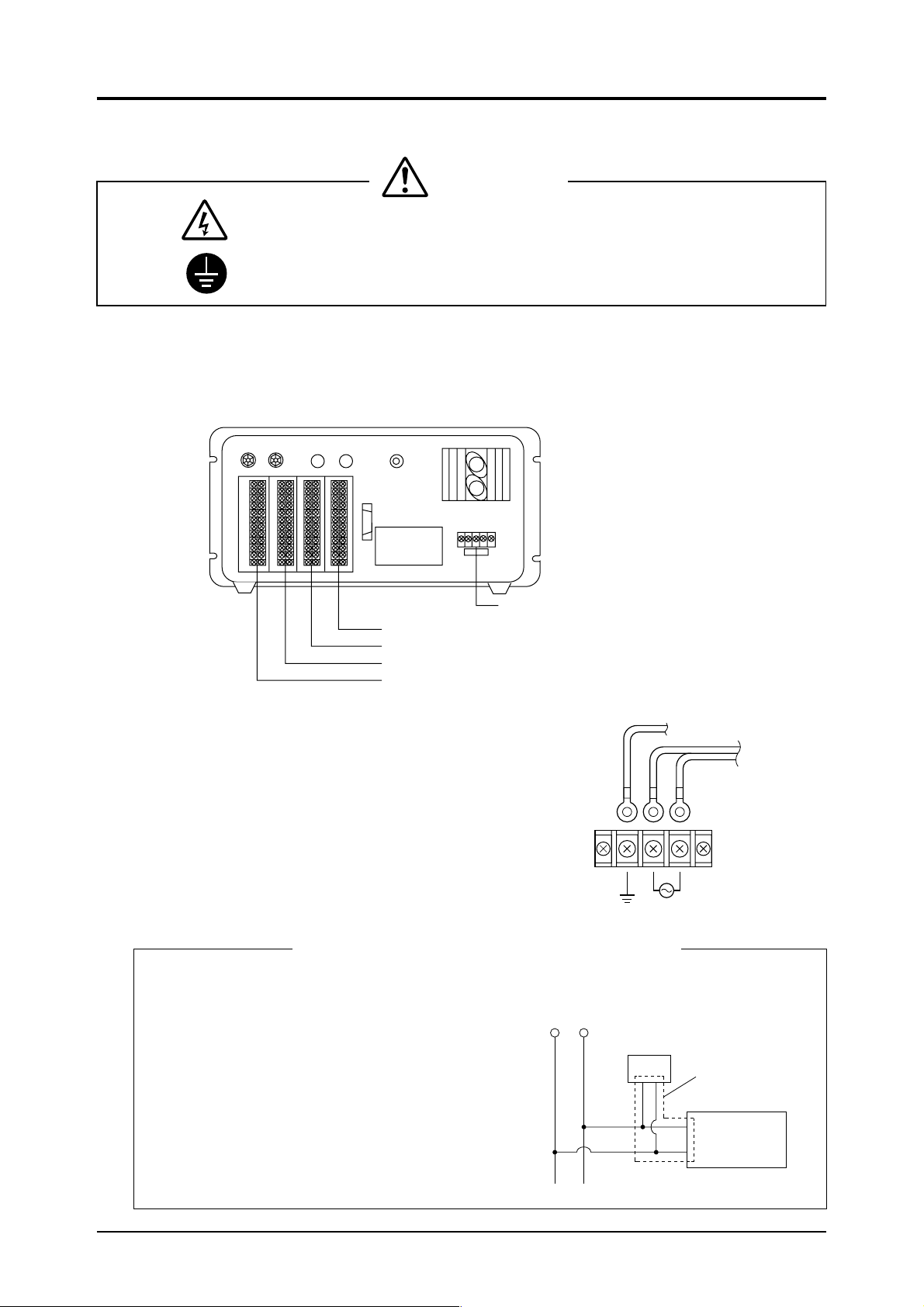

3.4 Wiring method

CAUTIONS

: Turn OFF all the power before starting a wiring work to prevent a risk of electric

shocks.

: Be sure to enforce construction of specified grounding.

The external terminals are provided on the rear of the instrument.

Carry out wiring to each terminal according to the figure. Terminal screws are M3.5 (but power

terminals are M4).

Use shielded wires for the output signals to suppress the influence of external noise.

3.4.1 Power terminals

The power terminals are arranged as shown in the figure.

Connect the specified power supply to the terminals and

connect a grounding wire to the ground terminal.

The grounding should be made securely.

Use solderless terminals (for M4) for connection to the

terminals.

Avoid installing this analyzer near an electrical apparatus which produces power source noise. (Such as

high frequency furnace, electric welder, etc.) If use of

the analyzer near such an apparatus is unavoidable,

then keep the power lines separate to avoid noise.

If noise from a relay, solenoid valve or the like enters

the power source, then attach a varistor or a spark

killer to the noise source as shown in the figure.

Note that attaching the varistor or spark killer away

from the noise source will be ineffective.

Power terminals (see 3.4.1)

Auto CAL input /output terminal (option) (see 3.4.5)

O

2

input/output terminal (option) (see 3.4.4)

COMP2 (2nd component) input/output terminal (see 3.4.3)

COMP1 (1st component) input/output terminal (see 3.4.2)

Source

E

When noise generating source is located nearby

ZRF

power supply

Varister or spark killer

Grounding wire

Power supply

Close connection

Noise

generating

source

10

Page 18

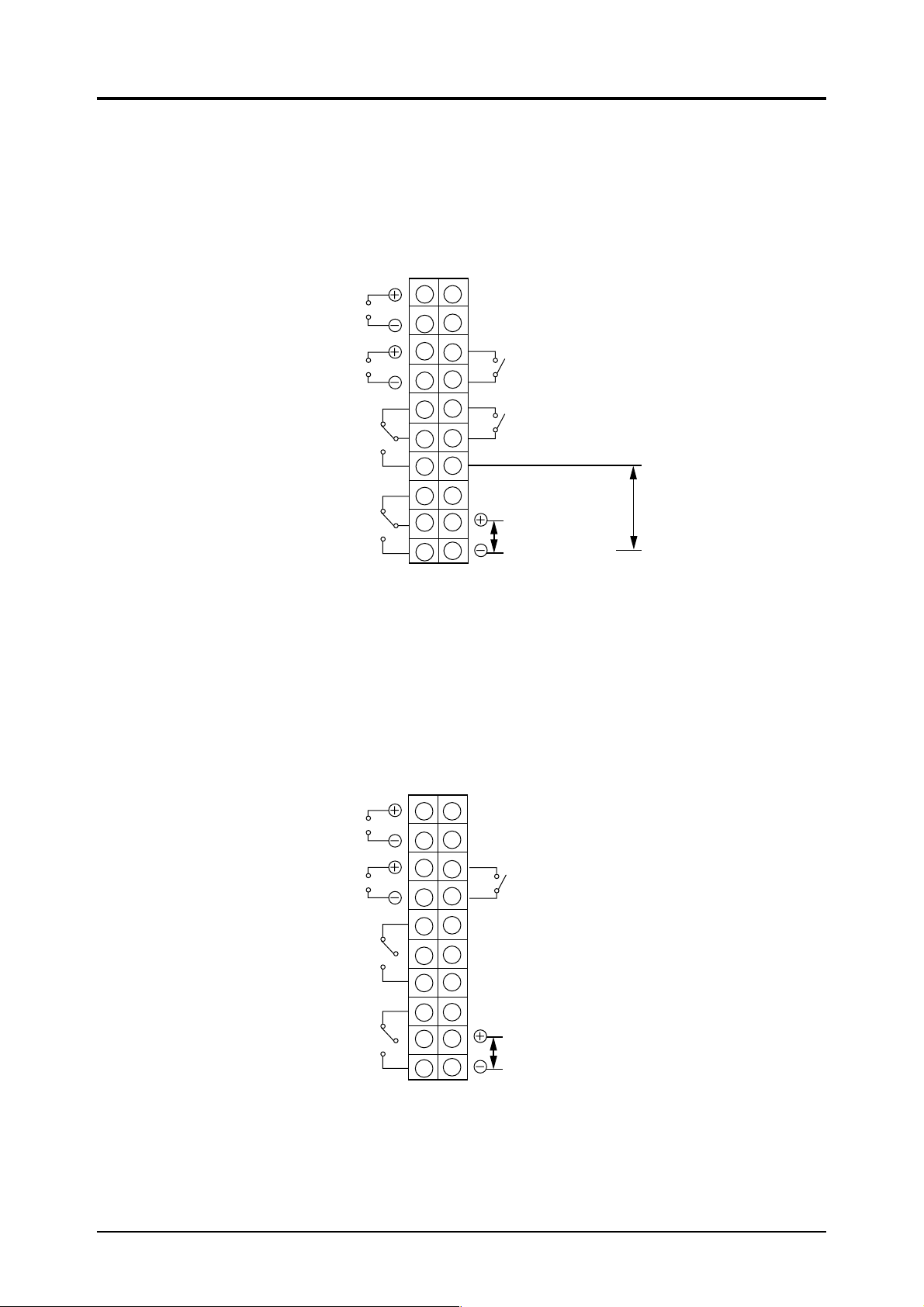

3.4.2 COMP 1 (1st component) input/output terminal

This output terminal is used with the standard single-component type, sample switching type or

flow differential type.

The wiring method is as follows.

Instantantaneous value

output signal

0 to 1V DC or

4 to 20mA DC

1

11

12

2

10

3

13

14

4

15

5

16

6

17

7

18

8

19

9

20

Range identification

contact output (option)

Fault

External hold input

(option)

Remote range

changeover signal

input (option)

Average value

output signal

0 to 1V DC or

4 to 20mA DC

(option)

Upper limit alarm

contact output

(option)

Lower limit alarm

contact output

(option)

3.4.3 COMP2 (2nd component) input/output terminal

This output terminal is for the 2nd component of the standard type.

The wiring method is as follows

Instantantaneous value

output signal

0 to 1V DC or

4 to 20mA DC

1

11

12

2

Average value

output signal

0 to 1V DC or

4 to 20mA DC

(option)

Upper limit alarm

contact output

(option)

Lower limit alarm

contact output

(option)

10

3

13

14

4

15

5

16

6

17

7

18

8

19

9

20

Range identification

contact output (option)

Remote range

input (option)

11

Page 19

COMP1, COMP 2 input/output terminal block

<Instantaneous value output>

Instantaneous value of 0 to 1V DC or 4 to 20mA DC is outputted.

<Moving average output> (option)

Specified 1 or 4 moving average value of 0 to 1V DC or 4 to 20mA DC is outputted.

<Upper limit alarm contact output> (option)

When signal exceeds upper limit, terminals ⑤ and ⑥ turn from ON to OFF and ⑥ and ⑦ turn from OFF

to ON.

1c contact 250V AC, 2A (resistive load)

<Lower limit alarm contact output> (option)

When signal is below lower limit, terminals ⑧ and ⑨ turn from ON to OFF and ⑨ ⑩ turn from OFF to

ON.

1c contact 250V AC, 2A (resistive load)

<Range identification signal output> (option)

Terminals ⑬ and ⑭ are conductive when 1st range is selected: ⑬ and ⑭ are open when 2nd range is

selected.

1a contact 250V AC, 2A (resistive load)

<Remote range input> (option)

1st range is selected when 5V DC is inputted to terminals ⑲ and ⑳ ; 2nd range is selected when there is

no input to terminals ⑲ and ⑳ .

<External hold input> (Input to COMP1 terminal) (option)

Hold setting component is outputted and held with 5V DC inputted between ⑲ and ⑳ .

<Fault> (Input to COMP1 terminal)

Contact output when analyzer incurs an abnormality.

1a contact 250V AC, 2A (resistive load)

12

Page 20

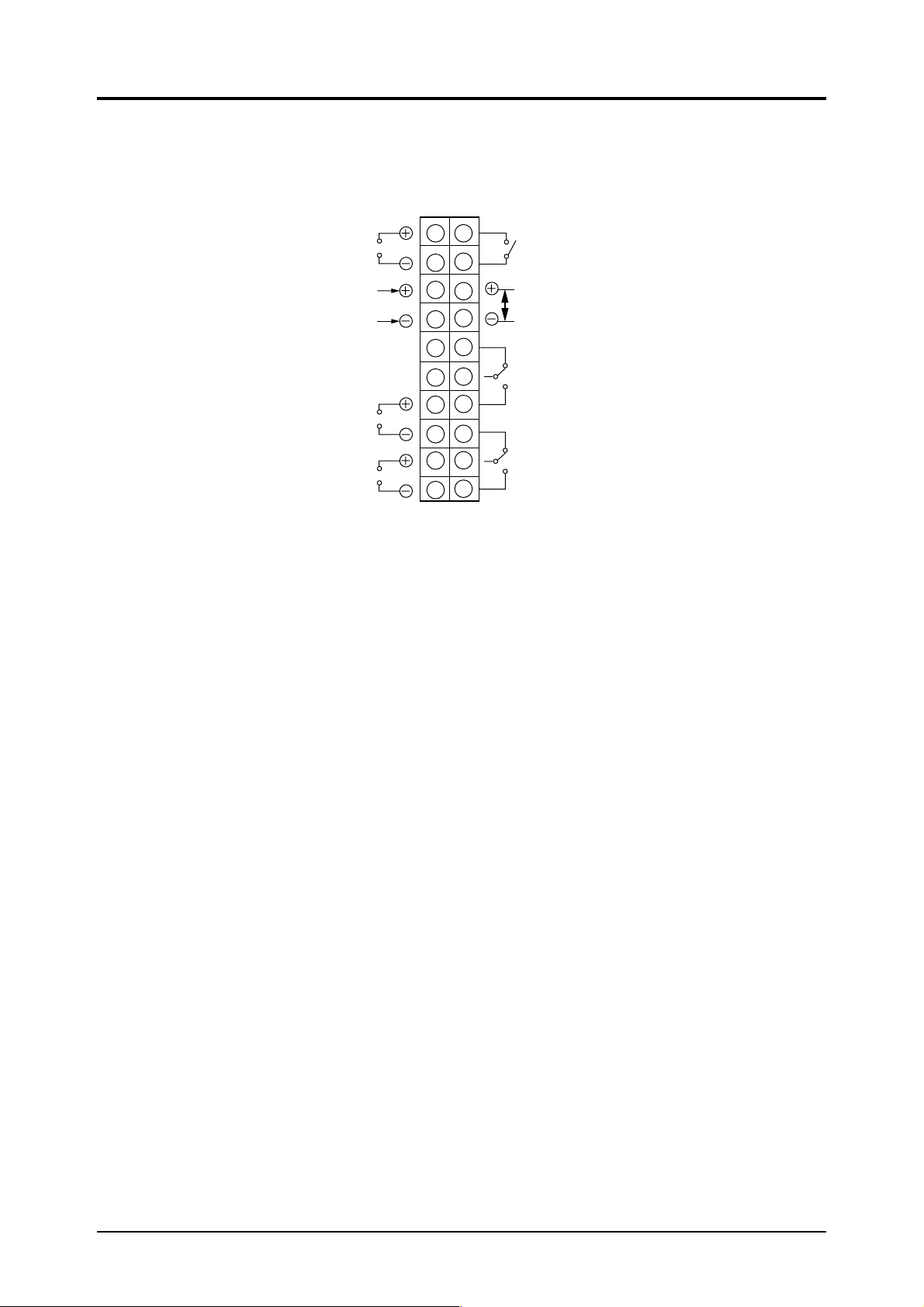

3.4.4 O2 input/output terminals (option)

This is the input/output terminal for the standard type O

2

The wiring method is as follows.

Instantantaneous value

output signal

0 to 1V DC or

4 to 20mA DC

O2 analyzer input

signal

0 to 1V DC

O

2

converted value

output signal

(1st component)

0 to 1V DC or

4 to 20mA DC

O

2

converted value

output signal

(2nd component)

0 to 1V DC or

4 to 20mA DC

input/output terminal block

O

2

1 11

2

3

4

5

6

7

8

9

10

12

13

14

15

16

17

18

19

20

Range identification

contact output (option)

Remote range

input (option)

Upper limit alarm

contact output

(option)

Lower limit alarm

contact output

(option)

<Instantaneous value output>

Instantaneous value of 0 to 1V DC or 4 to 20mA DC is outputted.

analyzer.

analyzer input signal>

<O

2

analyzer signal of 0 to linear 1V DC is inputted.

O

2

conversion output>

<O

2

conversion instantaneous value is outputted with preset conversion reference value.

O

2

<Upper limit alarm contact output> (option)

When upper limit is exceeded, terminals ⑮ and ⑯ turn from ON to off and ⑯ and ⑰ turn from OFF to

ON .

1c contact 250V AC, 2A (resistive load)

<Lower limit alarm contact output> (option)

When signal is below lower limit, terminals ⑱ and ⑲ turn from ON to OFF and ⑲ and ⑳ turn from OFF

to ON .

1c contact 250V AC, 2A (resistive load)

<Range identification contact output> (option)

Terminals ⑪ and ⑫ are conductive when 1st range is selected: ⑪ and ⑫ are open when 2nd range is

selected.

1a contact 250V AC, 2A (resistive load)

<Remote range input> (option)

1st range is selected when 5V DC is inputted to terminals ⑬ and ⑭ ; 2nd range is selected when there is

no input to terminals ⑬ and ⑭ .

13

Page 21

3.4.5 AUTO CAL input/output terminal (option)

This is the output terminal for the auto calibration function.

The wiring method is as follows.

1

10

11

12

2

3

13

14

4

15

5

16

6

17

7

18

8

19

9

20

Auto calibration

contact output

Zero gas contact

output

Span gas 1

contact output

Span gas 2

contact output

Span gas 3

contact output

AUTO CAL input/output terminal block (option)

<Contact output during auto calibration>

Contact between ① and ② is ON during auto calibration.

1a contact, 250V AC, 2A (resistive load)

Auto calibration

abnormal contact output

Remote start input

<Zero gas contact output>

Contact output for driving solenoid valve for flowing zero gas.

1a contact 250V AC, 2A (resistive load)

<Span gas 1 contact output>

Contact output for driving solenoid valve for flowing 1st component span gas.

1a contact 250V AC, 2A (resistive load)

<Span gas 2 contact output>

Contact output for driving solenoid valve for flowing 2nd component span gas.

1a contact 250V AC, 2A (resistive load)

<Span gas 3 contact output>

Contact output for driving solenoid valve for flowing O

analyzer span gas.

2

1a contact 250V AC, 2A (resistive load)

<Auto calibration abnormal contact output>

Contact output when abnormality occurs during auto calibration.

<Remote start input>

Input for starting auto calibration via external signal. Calibration started by inputting 5V DC between

terminals ⑬ and ⑭ .

14

Page 22

4. OPERATION

DANGER

• When handling the standard gas such as calibration gas, read the instruction manual of the

standard gas carefully and use the gas correctly.

CAUTIONS

• Avoid continuous operation with the casing drawn out.

• During operation, avoid opening the casing and touching the internal parts. Otherwise,

you may suffer a burn or shock hazard.

4.1 Operation procedure

Set up the operational status by the following procedure.

Operation is started by using the keys on the front panel of the analyzer. Before use, please read

through the instruction manual for the analyzer.

Mounting

Piping

Wiring

Check of piping

Purging inside alanyzer

Power switch on

Warming up

General Operation

Alarm value setting

Hold setting

Remote range setting

Automatic calibration setting

Concentration setting of

zero (air) point and span

calibration gas

Refer to Item 3.1.

Refer to Item 3.2.

Refer to Item 3.4.

Refer to Item 4.2 (1).

Refer to Item 4.2 (2).

Refer to Item 4.2 (3).

Refer to Item 4.2 (4).

Refer to Item 5.2 3).

Refer to Item 5.2 4).

Refer to Item 5.2 5).

Refer to Item 5.2 6).

Refer to Item 5.2 1)

to 2).

Carry out if needed.

Carry out if needed.

Zero/span calibration

Key lock ON/OFF setting

Intruduction of sample gas

(Start of measuring)

Refer to Item 5.2 8)

to 9).

Refer to Item 5.2 7).

Refer to Item 4.3.

15

Carry out if needed.

Page 23

4.2 Preparation for operation

(1) Check of piping

Check that piping has been made correctly.

(2) Purging of analyzer interior

When purging is necessary, then flow purge gas for about 3 hours before turning on power.

Purge gas

SAMPLE GAS

INLET INLETOUTLET OUTLET PURGE

(3) Turning on power

Turn on the power switch and indication will appear in a few seconds.

INFRARED GAS ANALYZER

POW

NO

ER

ON

OFF

O

M

E

FUNC

SO

A

S

2

2

COMP

M

E

A

S

vol%

ppm

vol%

ppm

vol%

ppm

S

P

A

N

H

O

L

D

RM

T RAN

ENT

ZERO

GE

SPAN

>

∧

(4) Turn on pump power supply

When the optional pump is provided, then pull out the base and turn on the pump power supply.

(5) Warmup

Flow the zero gas and warm up the instrument. The warmup is completed when the zero point

stabilizes (about 4 hours).

16

Page 24

(6) Concentration setting for calibration gas

Next set the concentration for the calibration gas.

Refer to 5.2 ① , ② for the procedure.

(7) Zero calibration

Flow zero calibration gas and calibrate the zero point. Refer to 5.2 ⑧ for the key operation for zero

calibration.

(8) Span calibration

Flow span calibration gas and calibrate the span.

Refer to 5.2 ⑨ for the key operation for span calibration.

4.3 Start of measurement

Flow the sample gas to start measurement.

4.4 Shutdown

Stop the flow of sample gas, and flow zero gas to purge the interior of the measuring cell.

Then turn off the power switch of the instrument.

When a pump is equipped, also turn off the pump power supply.

* The set values are retained in the memory even when power is turned off. But note that

with the clock function of the auto calibration function, the backup fails to work after 48

hours has elapsed, so when the power is turned on again, the correct time must be re-inputted.

CAUTIONS

Density below zero (indicated by a minus symbol) is displayed as zero.

When ZERO or SPAN key is pressed, this function is released to display minus value.

17

Page 25

5. OPERATION OF INDICATION/OPERATION PANEL

5.1 Outline of indication/operation panel

This panel consists of the following functions.

Function and key operation Main indication Sub indication Function lamp Page

(Option)

Measurement mode

FUNC

Setting of

calibration density

(O

2

zero setting mode)

and CAL>

Span setting mode

and CAL>

(Setting of single

zero calibration)

and CAL>

All/single range setting

FUNC

Alarm setting

and CAL>

Measured value

Zero point calibration density (with

zirconia O2)

Span point calibration density

(with O2 meter)

Range

Range

Range

Set value

Set value

Alarm value

MEAS lamp

ON

CAL SET

lamp ON

CAL SET

lamp ON

CAL SET

lamp ON

CAL SET

lamp ON

ALM SET

lamp flickers

20

22

22

23

23

27

Hysteresis setting

FUNC

Hold setting

(Option)

Remote range setting

FUNC

FUNC

To be continued to the next page.

Hysteresis

value

ON or OFF

ON or OFF

ALM SET

lamp flickers

Hold lamp

flickers.

RMT RANGE

lamp flickers.

28

29

31

18

Page 26

Function and key operation Main indication Sub indication Function lamp Page

(Option)

Auto calibration

Present time setting

FUNC

Auto calibration

start time setting

FUNC

Auto calibration

cycle setting

FUNC

Calibration gas

flow time setting

FUNC

Calibration gas

flow mode setting

FUNC

Auto calibration

selection

Hour & minute

Hour & minute

Day of week

Day of week

Time

Time

Mode No.

ON or OFF

AUTO CAL

flickers.

AUTO CAL

lamp flickers.

AUTO CAL

lamp flickers.

AUTO CAL

lamp flickers.

AUTO CAL

lamp flickers.

AUTO CAL

lamp flickers.

34

35

36

37

38

39

FUNC

Key lock selection

FUNC

Zero calibration ZERO CAL

Measured value

ON or OFF

Range

—

ZERO/CAL

40

key lamp

flickers.

Span calibration SPAN CAL

Measured value

Range

SPAN/CAL

key lamp

flickers.

• When the setting mode is assumed, the analog output signal is held at the value just before entering this

mode.

• When optional functions are not provided, the contents of these functions are not indicated.

19

Page 27

5.2 General operation

The measuring mode is assumed when power is turned ON.

The gas concentration appears on the main indication, while the range being used appears on the

sub indication.

NO

Gas concentration indication

• When selecting the range

In the setting status, as shown in

the figure at the right, the high

range is selected when

key is

pressed, while the low range is

selected when

When selecting the gas component.

•

key is pressed.

In the setting status, as shown in

the figure at the right, the gas

component can be set by pressing

COMP key.

Example:

When COMP key is pressed

while the 1st component is flashing, the flashing moves to the 2nd

component (Figure at the right).

The setting for the 2nd component

is now chageable.

COMP key is not provided for

*

single-component analyzer.

Advice on Operation

COMP

>

∧

By pressing this key, gas component to be set is selected.

Range indication

High range is selected by pressing this key.

Low range is selected by pressing this key.

No. 1 component

No. 2 component

No. 3 component

CAL

SPANZEROENT

20

Page 28

• For releasing zero or span

If a mistake has been made in zero

or span calibration, then perform a

reset in the following way.

The figure at the right shows an

example.

If SPAN key has been pressed

mistakenly instead of ZERO key,

press SPAN key again.

Calibration is cleared.

If ZERO key has been pressed

mistakenly instead of SPAN key,

press ZERO key again.

Calibration is cleared.

To clear moving average value,

press the

pressing the

key 3 times while

key in measure-

ment mode.

The data of each moving average

value is cleared.

SPANZERO

Key was pressed by mistake.

SPANZERO

Lamp flickers.

SPANZERO

Press the same key once again and the lamp will go off.

In this way, calibration is released, press Zero key.

21

Page 29

qq

q Calibration concentration setting (when not using Zirconia O2 analyzer)

qq

When not using a Zirconia O

analyzer, then set a span value for the calibration concentration

2

setting. (Zero point calibration concentration is fixed at zero.)

Set the calibration gas concentration (span value).

When FUNC key is pressed in the measuring status, the

previously set span value will appear on the main indication.

The CAL SET LED of the function indicating lamps will

flash.

By pressing the

key, the highest digit of the main

indication for the 1st component will flash, and the span

value can now be set.

Select a range with the

keys.

After selecting the range, set a span value in this status.

Then numeric value will be incremented by pressing

key.

The digit to be set can be selected by pressing

key.

For selecting the 2nd and subsequent components and

the range, press the

key and while the main

indication for the 1st component is flashing, press the

COMP

component to be set will flash. Now press the

key and then the main indication for the

keys to select the range to be set.

NO

FUNC

NO

CAL SET

>

NO

∧ >

NO

ENT

When the span value has been set, press the ENT key.

Setting operation is now completed.

Setting of single zero calibration:

This setting operation is used to select a zero calibration

component.

This function is invalid when O

component is not in-

2

cluded.

Press the

key in span setting mode.

The first digit in the main indication flickers.

NO

NO

>

NO

CAL

22

Page 30

Press the CAL key. “ ” appears in the main indication and “

At each press of the

order of “

” appears in the sub indication.

key, the setting is changed in the

→ → → ”.

After selecting, press the ENT key. The data is stored in

memory.

CAL

NO

∧

NO

= Meaning of set value =

Select

code

0 Calibration of all components Calibration of all components

1 Calibration of components other than O

2 Calibration of O

Manual calibration Auto calibration

2

Zero calibration

Calibration of components other than O

2

Note 1: This mode is invalid when O2 component is not included.

Note 2:

The main indication flickers when zero calibration ( ZERO + CAL ) is made on

selected components.

Setting of single calibration of all or each range:

This setting operation is used for calibration of all or each

NO

range during zero/span calibration.

Perform setting in the following way.

By pressing CAL key while the highest digit of the main

indication for the 1st component is flashing, then “

will appear on the main indication and “

” will appear on

”

NO

the sub indication.

Press

key and “ “ will change to “ ”.

ENT

2

CAL

∧

= Meaning of set value =

:The calibration is valid only for the selected range, and

zero and span calibration can be made independently

for each range.

: By conducting zero and span calibration for one range,

the calibration will be done automatically for the other

ranges as well.

Note 3: S.CAL “1” is interlocked with the range ratio

calibrated by “0” on each range.

Note 4: When a 1-range meter is used, be sure to set

S.CAL to “0”. If “1” is set, the result is the

same as “0”.

When the selection has been finished, press the ENT key.

23

NO

ENT

NO

Page 31

ww

w Calibration concentration setting (when using Zirconia O2 analyzer)

ww

When a Zirconia O

tion for each components of the O

analyzer is provided, set the zero (air) point and the span calibration concentra-

2

analyzer. Refer to 3.3.3. Preparation of standard gas for the

2

concentration of calibration gas to be used.

• Setting of calibration concentration for zero (air) point

The zero (air) point calibration concentration is settable

for the O

concentration for components other than for the O

analyzer alone. The zero point calibration

2

2

analyzer is fixed at zero.

By pressing the FUNC key in the measuring status, the

calibration concentration previously set for the zero (air)

point will appear on the main indication.

The CAL SET LED of the function indicating lamps will

flash.

By pressing the

main indication of the O

keys, the 2nd highest digit of the

analyzer will flash, and zero

2

point setting is enabled.

Press the

keys to select a range.

The numeric value will be incremented by pressing

key.

The digit to be set is selected by pressing

key.

Set the same air concentration for both high and low

range.

Press the ENT key after setting the zero point. Setting

operation is now completed.

O2

O2

O2

O2

FUNC

CAL SET

>

∧

ENT

>

Note: When using air for the high range and 9-10 vol % O

value of concentration for each range.

O2

for the low range, be sure to set the

2/N2

24

Page 32

• Setting of span calibration concentration

= Setting for each components =

Press the CAL key in the status where the digit of the O

analyzer main indication is flashing via the zero (air)

point calibration concentration setting.

The previously set span value will now appear on the

main indication.

The CAL SET LED of the function indicating lamps will

flash.

The highest digit of the 1st component main indication

will flash and the span value is now settable.

Press the

keys to select a range.

When the range has been selected, set a span value in this

status.

The numeric value will be incremented by pressing

key.

Press the

key and the digit to be set can be selected.

For selecting the 2nd and subsequent components and

the range, press the

key and in the status where

the 1st component main indication is flashing, press

the COMP key and the main indication for the component to be set will flash. Press the

keys to

select the range to be set.

2

O2

CAL

NO

∧

>

NO

ENT

NO

= Setting of O

analyzer =

2

NO

COMP

Press the ENT key after setting the span value. Setting

operation is now completed.

Setting of single zero calibration:

This setting operation is used to select a zero calibration

component.

This function is invalid when O

component is not in-

2

cluded.

Press the

key in span setting mode.

The first digit in the main indication flickers.

O

2

O

2

O

2

NO

NO

ENT

>

∧

>

25

Page 33

Press the CAL key. “ ” appears in the main indication and “

At each press of the

“ appears in the sub indication.

key, the setting is changed in the

CAL

NO

order of “

After selecting, press the ENT key. The data is stored in

→ → → ”.

∧

memory.

NO

= Meaning of set value =

Select

code

0 Calibration of all components Calibration of all components

1 Calibration of components other than O

2 Calibration of O

Manual calibration Auto calibration

2

Zero calibration

Calibration of components other than O

2

ENT

2

Note 1: This mode is invalid when O2 component is not included.

Note 2: The main indication flickers when zero calibration

( ZERO + CAL ) is made on selected components.

Setting of single calibration of all or each range:

This setting operation is used for calibration of all or each range during zero/span calibration.

Carry out the setting as follows.

By pressing CAL key while the highest digit of the 1st

components main indication is flashing, “

appear on the main indication and “

” will appear on the

” will

sub indication.

NO

CAL

Press key and “ ” will change to “ ”.

= Meaning of set values =

: The calibration is valid only for the selected range,

and zero and span calibration can be made independently for each range.

: By conducting zero and span calibration for one

range, the calibration will be done automatically for

the other ranges as well.

Note 3: S.CAL “1” is interlocked with the range ratio

calibrated by “0” on each range.

Note 4: When a 1-range meter is used, be sure to set

S.CAL to “0”. If “1” is set, the result is the

same as “0”.

Press the ENT key when the selection is finished.

Note: When using air for the high range and 9-10 vol % O

value of concentration for each range.

NO

∧

NO

ENT

NO

for the low range, be sure to set the

2/N2

26

Page 34

ee

e Alarm value setting (option)

ee

Set the upper and lower limit alarms and output an alarm.

Setting can be made for each component and each range.

Press FUNC key in the measuring status and “ ”

will be indicated.

The ALM SET LED of the function indicating lamps will

flash.

Press the

key and then alarm values are settable. The

highest two digits of the main indication will flash.

Contents of alarm value

setting indication

NO

:Upper limit

:Lower limit

:Lower range

:Upper range

FUNC

Setting value

:Plus

:Minus

Press the COMP key and select the gas component

for which alarms will be set.

Press

Press the

keys and select the range.

key to select either the upper or lower limit

alarm.

” indication appears when lower limit alarm is to

“

be set and “

” indication appears when upper limit

alarm is to be set.

Press the

key and the lowest digit flashes, so press the

key to select either plus “ ”or minus “ ”for the set

value.

A minus value should be set after releasing the alarm

function referring to the next page.

Press the

key and the highest digit of the main indication flashes, so set an alarm value. The numeric value is

incremented by pressing

Press the

key and the digit can be selected.

key.

NO

NO

NO

NO

NO

ALM SET

COMP

>

∧

>

∧

>

∧

ENT

>

)(

)(

When the alarm setting is finished, press the ENT key.

Setting operation is now completed.

NO

CAUTIONS

Alarm values are settable within the selected range. Setting is performed with the concentration

value.

Note that the upper limit alarm cannot be set below the lower limit alarm.

And if the lower limit alarm is set above the already memorized upper limit alarm, then the

upper limit alarm will become the same value as the newly set lower limit alarm.

27

Page 35

To make the alarm function invalid

For making the alarm function invalid, then set the upper limit alarm value to “

the lower limit alarm value to “

” for each component and each range.

NO

NO

Note: Use the following hysteresis setting as a reference when setting the hysteresis for the

alarm value.

Hysteresis setting

Set a hysteresis versus the alarm value.

Setting range of ±20% max.

ON

OFF

▲

Upper limit set value

Setting range of ±20% max.

ON

OFF

▲

Lower limit set value

” and

When CAL key is pressed in the alarm setting status, “

will appear on the main indication.

This is the mode for setting the hysteresis for the alarm value.

Change the hysteresis value on the sub indication by pressing

the

key.

The hysteresis is settable in 1% steps in a range of

±0 to ±20% versus the measuring range.

→

→

The indication changes from

→

→

→...........

..............

Press the ENT key when the setting is finished.

”

NO

CAL

NO

∧

NO

ENT

NO

28

Page 36

rr

r Hold setting

rr

This is used when calibrating for holding the output signal

at the value just before entering calibration. (The indication is not held.)

The hold function is settable for each component.

Set to OFF when not using.

Press the FUNC key in the measuring status and

“

” will be indicated.

The HOLD LED of the function indicating lamps will

flash.

Press the

key and the hold function will be settable.

The sub indication will flash.

Press the COMP key and select a setting

component.

Select hold “

” or “ ” by pressing the key.

Press the ENT key after setting the hold function. Setting operation is now completed.

At hold ON, the HOLD of the function indicating lamp

will light steadily while the hold functon is activated.

The unit indicating lamp flickers only for components

which have been set. This lamp goes off at hold OFF.

NO

NO

NO

NO

FUNC

HOLD

> ( )

∧

ENT

COMP

Note: Only the output will be held when this function is “

”, the indication is not held.

29

Page 37

Hold function

<Output hold functions after manual calibration>

The following shows the output hold function after manual calibration (zero or span).

The hold function is cleared automatically after 30 minutes or it can be cleared by key operation

(manual).

1. Operation

ZERO

Calibration

operation

Output hold

CAL keykey

30 min.

2. Clear operation

1) Auto clear

Press the ZERO key or SPAN key after hold setting (ON/OFF).

Output hold is started and calibration is completed with CAL key.

Then, the hold function is automatically cleared after 30 minutes.

2) Manual clear

The hold function is cleared manually by pressing the ENT key and CAL key at the same time.

Note 1: During auto calibration, the contact output between terminals ① and ② does not

operate when it is under manual calibration.

Note 2: Output hold is effective only for preset components.

<Output hold function under auto calibration>

Output hold function under auto calibration and replacement time. For operation, refer to Item ⑥ .

<External hold function> (option)

The following operation is used for output hold with external signals.

1. Operation

ON OFF

External signal

Output hold

2. Operation method

By putting 5V DC between the 1st component input/output terminals 17 and 20 (“+” and “-”),

only the component preset by the front key will be operated.

Note 1: The indication during operation is the same as that of hold calibration.

Note 2: This function is effective only when alarm, remote range or range detect function is

used as an option. (When using the supplied function, be sure to contact Fuji because

the hardware is different.)

Note 3: This function is effective only for the standard type No. 1 and 2 range analyzers and

flow differential type.

30

Page 38

tt

t Remote range setting (option)

tt

This is used for selecting the range via an external signal.

This setting should be OFF when remote range is not

used.

Press the FUNC key in the measuring status and

“

” will be indicated.

The RMT RANGE LED of the function indicating lamp

will flash.

Press the

key and the remote range function is

settable.

The sub indication will flash.

Select the remote range “

” or “ ” by pressing the

key.

The setting is valid for all the components.

Press the ENT key when the remote range setting is

finished. Setting operation is now completed.

FUNC

NO

RMT RANGE

>

NO

∧

NO

When the remote range function is set ON, the RMT

RANGE LED of the function indicating lamps will

remain lit, and the

keys will be unusable for range

selection.

• By inputting 5V DC between the remote input

terminals ⑬ and ⑭ , the No. 1 range is selected.

• No. 2 range is selected when 5V DC input is not

applied to the remote input terminals ⑬ and ⑭ .

ENT

NO

31

Page 39

;

;

;

;

;

;

;

;;;;;;;;;;;;

;

;

;

;

;

;

;

;

;;;;;;;;;;;;

;

;

yy

y Auto calibration (option)

yy

As an option with this analyzer, the signals from the input/output terminals on the rear panel can be

used for driving an external solenoid valve and introducing standard gas, whereby zero point and

span can be calibrated automatically.

The auto calibration is done according to ⑥ -1 current time setting, ⑥ -2 Auto calibration start

time, ⑥ -3 Auto calibration cycle, ⑥ -4 Calibration gas flow time, ⑥ -5 Calibration gas flow

mode, and ⑥ -6 Auto calibration ON/OFF setting.

Caution on operation

1. When the auto calibration start time is reached during key operation, the auto calibration is given

priority and is started. All key operation will be invalid until the auto calibration is finished.

To forcibly interrupt the auto calibration in progress, press both the ENT and CAL keys

2.

simultaneously. After the forcible interrupt, the measuring mode is resumed and all the keys are

operable. Although the current auto calibration will be passed over, it will be started from the

initially set cycle from the next time onward.

Example: When auto calibration is set for 3 hour intervals

starting from 8:00 a.m.

8:00

;;;;;;;;;;

11:00 14:00 17:00

;;;;;;;;;;;

;;;;;;;;;;;

;;;;;;;;;;

;;;;;;;

;;;;;;;

: Under auto

calibration

8:00

;;;;;;;;;;

;;;;;;;;;;

11:00 14:00 17:00

;;;

;;;

;;;;;;;;;;;

;;;;;;;;;;;

;;;;;;;;;;

;;;;;;;;;;

Manual interruption

3. Key operation is possible while calibration is not under way with the auto calibration function

set. Therefore all settings (of span, hold, remote range, time, etc.) including manual calibration

can be made. But note that if the wrong time is set on the clock, the auto calibration will not be

started at the correct time.

4. Auto calibration is able to start by applying remote start signal, 5V DC longer than 100m sec, to

remote start input terminals. In this case, auto calibration will start independent of its ON/OFF

setting.

32

Page 40

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

Gas flow time

;

Auto calibration

gas flow time

Example where auto calibration gas flow mode 5 is set

Auto calibration start time Auto calibration end time

Under

Under

mesurement

Under auto calibration

Zero gas

Span

gas 1

Span

gas 2

Span

gas 3

Substitution

TTTTT

T: Settable from 100 to 599 sec

mesurement

Next process

;;;;;;;;;;;;;;;;;;;;;

Gases introduced:

Sample gas

Zero gas

Span gas 1

Span gas 2

Span gas 3

Indicator lamps

AUTO CAL.

ZERO

SPAN

CAL

HOLD

(At HOLD ON)

;;;;;;;;;;;;;;;;;;;;

Auto calibration cycle

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;

Flashes

;

Lights

;

;

Lights

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

Flashes

;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

Lights Lights Lights

;

Lights

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

Auto calibration abnormality:

If an abnormality occurs during auto calibration, a contact signal for auto calibration abnormality

will be outputted from the input/output terminals on the rear of the analyzer. The gas which incurred the abnormality will not be calibrated, and the next component will be calibrated instead .

33

Page 41

yy

y-1 Current time setting

yy

Set the current time and day of the week.

Press the FUNC key in the measuring status.

The AUTO CAL LED of the function indicating lamps

will flash.

NO

FUNC

SU TU TH

MO WE FR

SA

The main indication shows the hour and minute via

a 24-hour indication and the decimal point flashes.

bar lights up at the relevant weekday on the

A

sub indication.

Indication SU MO TU WE TH FR SA

Day Sun Mon Tue Wed Thu Fri Sat

Press the

key and the time is now settable. The

highest two digits of the main indication will flash.

The numeric value is incremented by pressing the

key.

Press the

After the time setting, press

key and the digit can be selected.

key and the day is

settable on the sub indication.

The bar indication will flash.

Press the

key and the bar will shift.

Press the ENT key when the time and day setting is

finished. The data is stored in memory.

Flashes

NO

NO

NO

>

>

ENT

∧

SU TU TH

MO WE FR

)(

∧

SU TU TH

MO WE FR

SU TU TH

MO WE FR

>

)(

AUTO CAL

SA

SA

SA

Time starts from the point where ENT key is

pressed.

34

Page 42

yy

A

y-2 Auto calibration start time setting

yy

When FUNC key is pressed at the current time indication, the auto calibration start time and day will appear on

the main and sub indications. The AUTO CAL LED of

the function indicating lamps will flash. In the case of

start time, the decimal point on the main indication will

light steadily.

Press the

key and the auto calibration start time is

settable, so set a start time on the main indication.

The numeric value is incremented by pressing the

key.

Press the

After setting the calibration start time, press the

key and the digit can be selected.

key

and the calibration start day can be set on the sub indication. The bar indication will flash.

Press the

key and the bar will shift.

The auto calibration start time is settable up to one

week ahead.

When the auto calibration start time and day have been

set, press the ENT key.

The data is stored in memory.

NO

Flashes

NO

NO

NO

NO

FUNC

>

>

ENT

SU TU TH

MO WE FR

SU TU TH

MO WE FR

∧

SU TU TH

MO WE FR

)(

∧

SU TU TH

MO WE FR

SU TU TH

MO WE FR

>

SA

SA

AUTO C

)(

SA

SA

SA

When the auto calibration at the set time is finished,

the next auto calibration start time will be set

automatically.

To confirm the next auto calibration start time, then

carry out this operation and check the indication.

Note: When the auto calibration start time has been set, then set the auto calibration cycle.

35

Page 43

yy

y-3 Auto calibration cycle setting

yy

The calibration cycle is settable in either ‘days’ or ‘hours’.

Press the FUNC key at the calibration start time indica-

tion and “

” will appear.

The AUTO CAL LED of the function indicating lamps

will flash.

Press the

key and the auto calibration cycle is

settable. The highest digit on the sub indication will flash.

Select either ‘days’ or ‘hours’ by pressing the

” appears on the sub indication when selecting

“

‘days’ and “

Press the

” appears when selecting ‘hours’.

key and the calibration cycle can be set in

the lower digits of the sub indication.

The numeric value is incremented by pressing the

key.

Press the

key and the digit can be selected.

key.

NO

NO

NO

NO

FUNC

( )

>

> ( )

∧

∧

>

AUTO CAL

Day is settable in a range of 1 to 7 days. Hour is

ENT

settable in a range of 1 to 99 hours.

NO

CAUTIONS

” (hours) is set, it will be automatically set to

If “

” (hour).

“

Press the ENT key when the calibration cycle has been

set. The data is stored in memory.

Note:When the auto calibration start time has been set, then set the auto calibration gas flow time.

36

Page 44

yy

y-4 Calibration gas flow time setting

yy

Press the FUNC key at the calibration cycle indication

and “

” will appear.

The AUTO CAL LED of the function indicating lamps

will flash.

Press the

key and the auto calibration gas flow time

is settable.

Set the flow time on the sub indication.

The numeric value is incremented by pressing the

key.

Press the

key and the digit can be selected.

NO

NO

FUNC

AUTO CAL

> ( )

∧

>

The setting range is 100 to 599 seconds.

NO

Press the ENT key when the calibration gas flow time

has been set. The data is stored in memory.

The times set in this mode is common to all the cali-

NO

ENT

bration gas flow time including replacement time.

Note: When the auto calibration start time has been set, set the auto calibration gas flow mode.

37

Page 45

yy

y-5 Calibration gas flow mode setting

yy

Select a calibration gas flow mode according to the number of components to be calibrated.

Press the FUNC key at the calibration gas flow time

indication and “

” will appear.

The AUTO CAL LED of the function indicating lamps

will flash.

Press the

key and the auto calibration gas flow time is

settable.

Set the calibration gas flow mode No. by pressing the

key.

(See the table below for the meaning of the flow mode

No.)

Press the ENT key when the calibration gas flow mode

has been set. The data is stored in memory.

NO

NO

NO

NO

FUNC

>( )

ENT

∧

AUTO CAL

Meaning of flow modes

Mode no. 1: Zero gas

Mode no. 2: Zero gas — 1st component

span gas

Mode no. 3: Zero gas — 1st component — 2nd component

span gas span gas

Mode no. 4: Zero gas — 1st component — 2nd component

span gas span gas (O

)

2

Mode no. 5: Zero gas — 1st components— 2nd component — 3rd component

span gas span gas span gas (O

)

2

Note: When all the settings for auto calibration have been finished, then select whether or not to

carry out auto calibration.

38

Page 46

yy

y-6 Auto calibration ON/OFF setting

yy

Select whether or not to carry out auto calibration.

Set to “

” when calibration will not be made.

NO

Press the FUNC key at the calibration gas flow mode

indication and “

” will be appear.

The AUTO CAL LED of the function indicating lamps

will flash.

Press the

key and auto calibration ON or OFF can be

set.

Select either “

pressing the

” or “ ” on the sub indication by

key.

When the auto calibration ON/OFF setting is finished,

press the ENT key.

Setting operation is now completed.

FUNC

NO

AUTO CAL

>

NO

∧

NO

ENT

NO

39

Page 47

uu

u Key lock ON/OFF setting

uu

This function is intended to prevent erroneous key operation.

By pressing the key lock at “ ” keys other than the

FUNC key will be inoperable.

To release the function, set at “

”.

NO

FUNC

Press the FUNC key in the measuring status and “ ”

NO

will be indicated.

Now press the

key and the key lock can be set.

>

The sub indication will flash.

NO

Set the key lock ON or OFF by pressing the key.

∧

NO

Press the ENT key when the key lock setting is finished.

Setting operation is now completed.

ENT

NO

Note: When the key lock is set at “ ” keys other than the FUNC key are inoperable.

40

Page 48

ii

i Zero calibration

ii

This is used for adjusting the zero point.

Flow the zero gas and wait until the indication stabilizes.

When the Zirconia O

analyzer is used, use air as the zero

2

gas. Note1)

When the indication has stabilized, select the measuring

range to be calibrated by using the

keys.

NO

ZERO

NO

When using a multi-component analyzer, undergo

zero calibration at the selected range and component.

Note 2)

Press the

ZERO

After the indication is stabilized, press the

key, and

ZERO

key lamp will flash.

CAL

key

NO

and conduct zero calibration.

The

CAL

key lamp lights steadily during calibration.

The calibration is completed when the key lamp goes off.

After the calibration, it is reset in measurement mode.

Calibrate other ranges as necessary.

CAUTIONS

Density below zero (indicated by a minus symbol) is displayed as zero.

This function is released by pressing

ZERO

key.

Flashes

CALSPANZEROENT

CAL

Lights steadily

CALSPANZEROENT

CALSPANZEROENT

(The lamp goes off after calibration)

Note 1: When using gas separately for low and high ranges, apply 9 to 10 vol% O

which has

2/N2

been set for low range.

Note 2: Calibration component should be set in zero calibration select mode.

Note 3: After zero calibration, change the range (2-range meter only) to confirm zero point of both

ranges being calibrated. When the indication of each range is not “Zero”, set S.CAL mode

to “0” and calibrate the zero point once again.

After it is calibrated, set S.CAL mode to “1”.

41

Page 49

oo