Page 1

SV

C1

C2

AL1

AL2

Micro-contr oller X

SEL

Model: PXR3

Operation Manual

TN5A2704-E

Page 2

Table of Contents

1 Part Names and Functions .................................................................................................... 5

2 Operations ............................................................................................................................. 6

2-1 Parameter list............................................................................................................ 6

2-2 Basic operations ....................................................................................................... 11

2-3 Parameter functions and method of settings ............................................................ 12

① First block parameters ............................................................................................... 13

Standby setting .......................................................................................................... 13

Ramp-soak control..................................................................................................... 14

Canceling the alarm latch .......................................................................................... 15

Auto-tuning function................................................................................................... 16

Displaying ON-delay alarm or the remaining time of timers ...................................... 17

Setting alarm 1 and 2 ................................................................................................ 18

Upper limit of alarm 1 and 2 ...................................................................................... 18

Lower limit of alarm 1 and 2....................................................................................... 18

Key lock ..................................................................................................................... 19

② Second block parameters .......................................................................................... 20

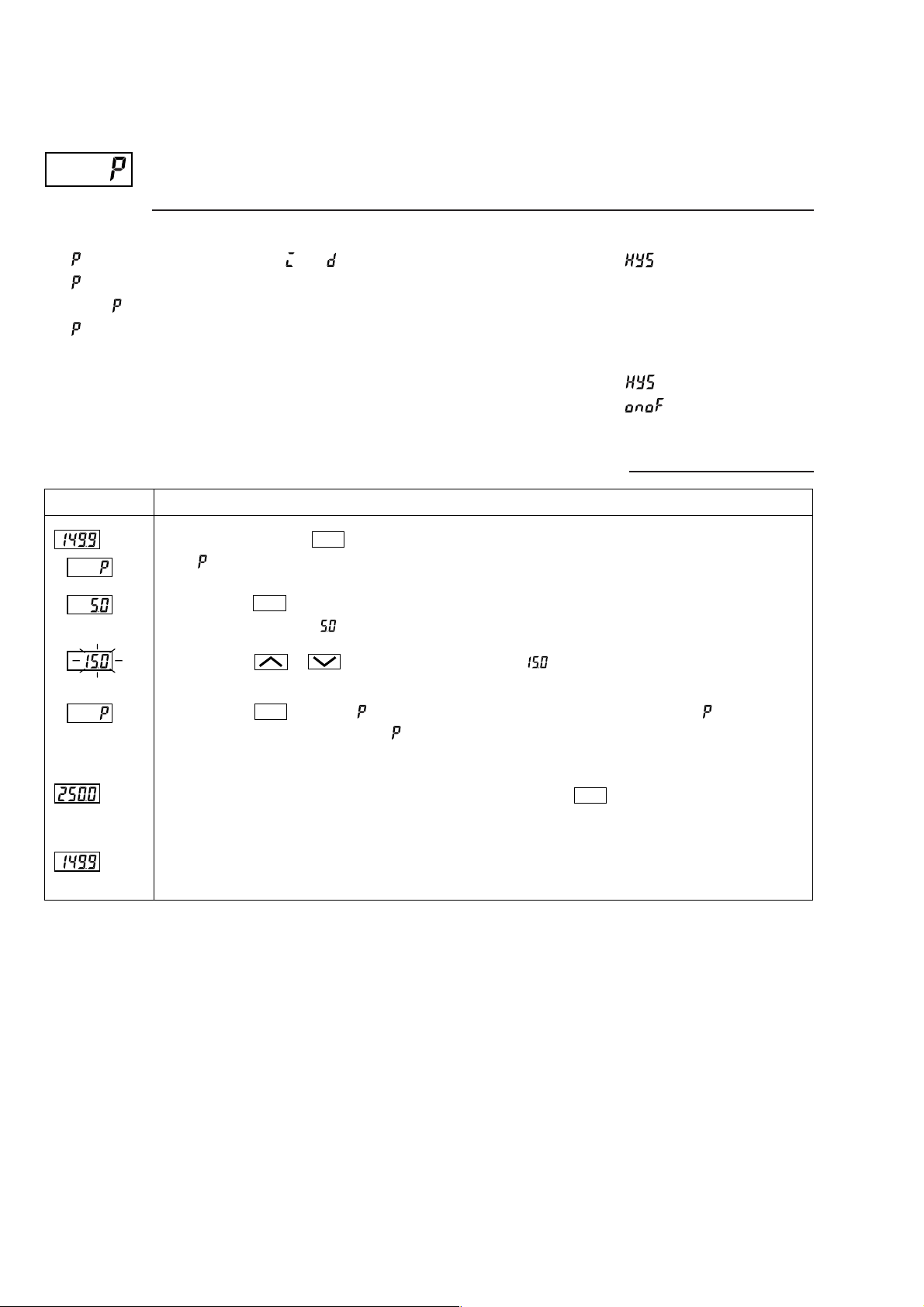

Proportional band ...................................................................................................... 20

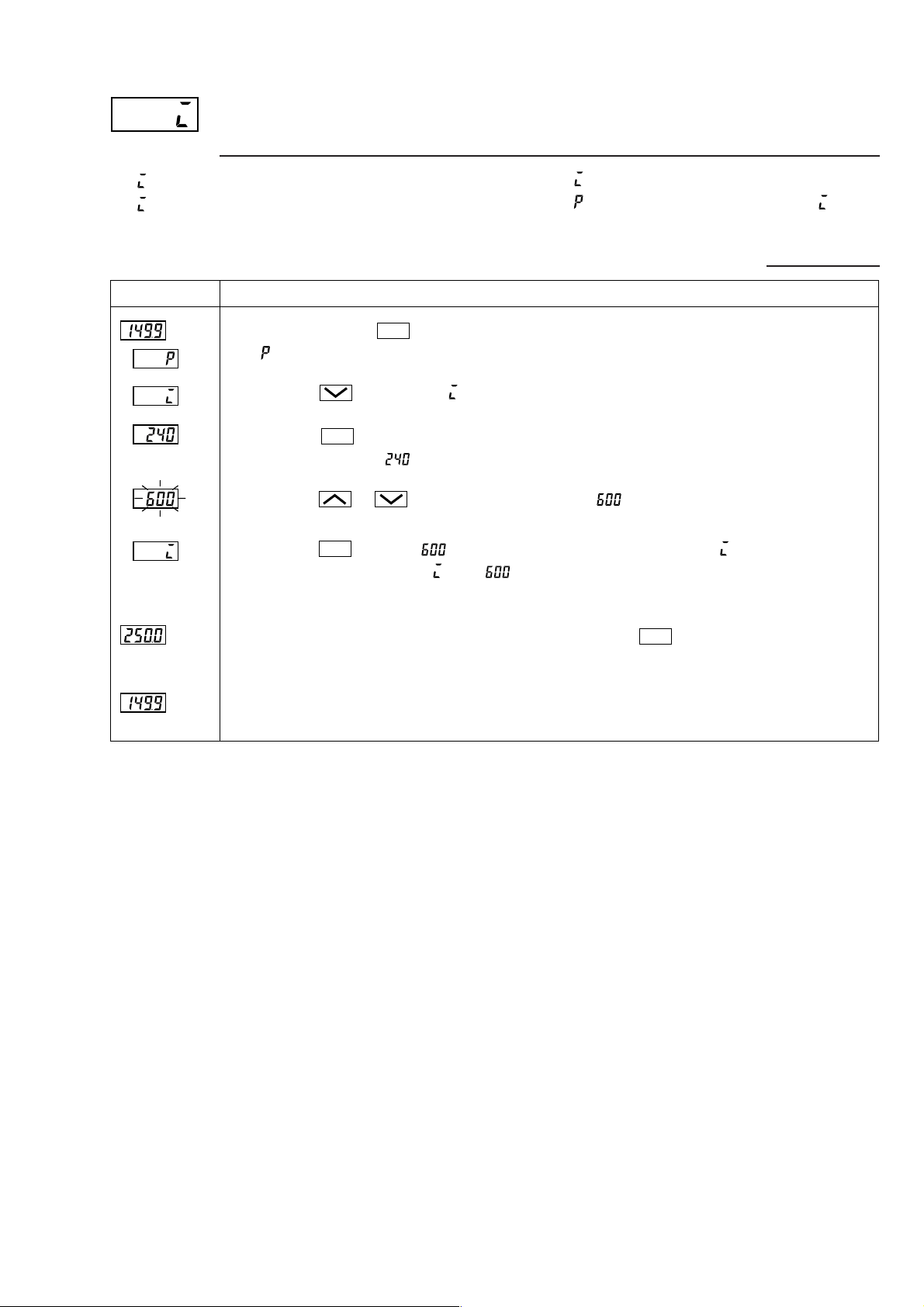

Integral time ............................................................................................................... 21

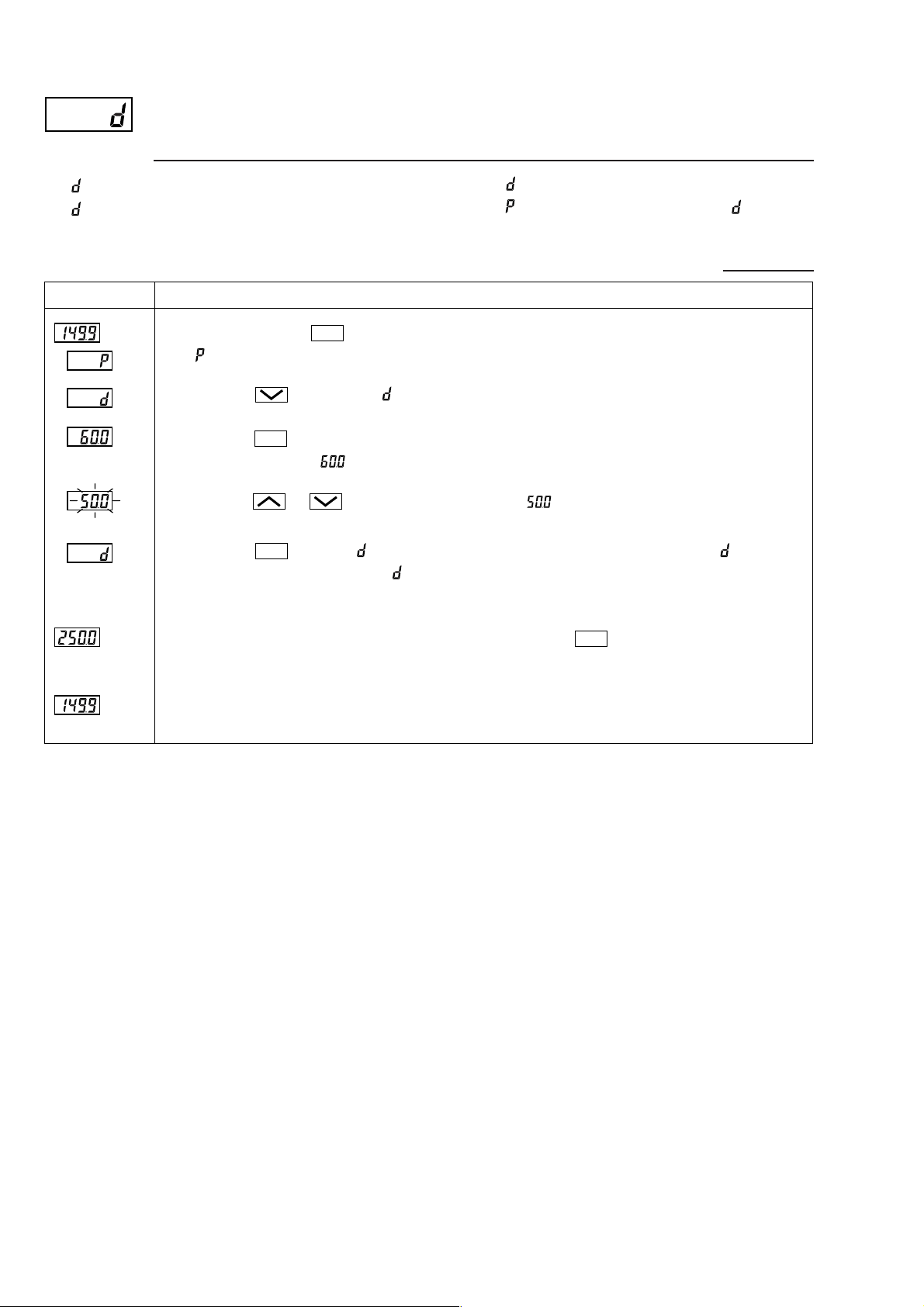

Derivative time ........................................................................................................... 22

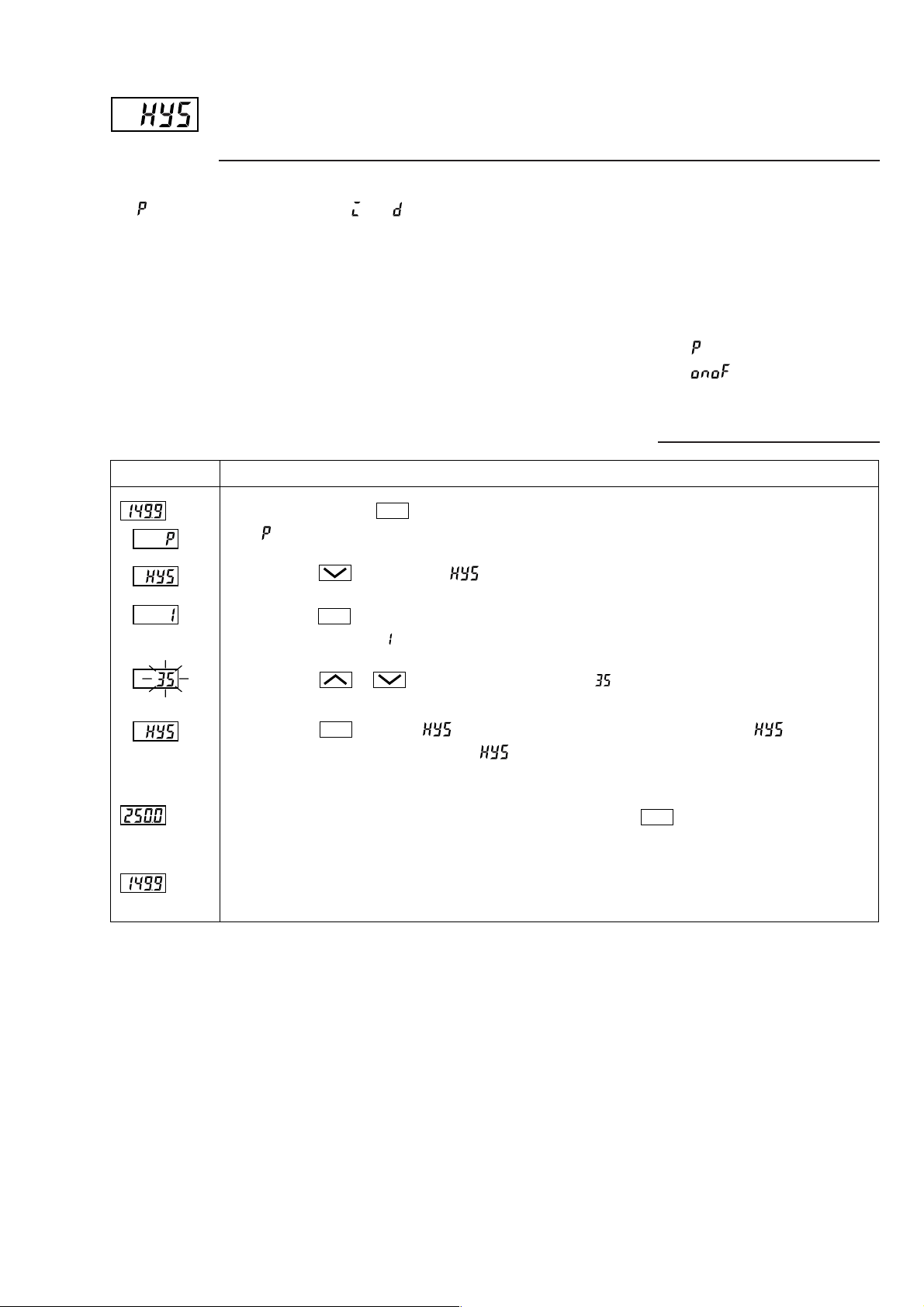

Hysteresis range for ON/OFF control ........................................................................ 23

Cooling-side proportional band coefficient ................................................................ 24

Cooling-side proportional band shift (Dead band/Overlap band) .............................. 25

Output offset value..................................................................................................... 26

Anti-reset windup ....................................................................................................... 26

Control algorithm ....................................................................................................... 27

PV (Measured value) stable range ............................................................................ 31

HYS (Hysteresis) mode at ON/OFF control............................................................... 32

Cycle time of control output 1 .................................................................................... 33

Cycle time of control output 2 (cooling-side).............................................................. 34

Input signal code........................................................................................................ 35

Setting lower limit of the measuring range................................................................. 36

Setting upper limit of the measuring range ................................................................ 36

Decimal point position................................................................................................ 38

PV offset .................................................................................................................... 39

SV offset .................................................................................................................... 40

Time constant of input filter........................................................................................ 41

Alarm types................................................................................................................ 42

Selecting ramp-soak patterns .................................................................................... 45

Ramp-soak status display.......................................................................................... 46

1st to 8th target SV.................................................................................................... 46

1st to 8th ramp segment time .................................................................................... 46

1st to 8th soak segment time..................................................................................... 46

Ramp-soak modes..................................................................................................... 46

2

Page 3

③ Third block parameters .............................................................................................. 49

Specifying control system and action, and output direction at input burn-out............ 49

SV (Setting value) lower limiter.................................................................................. 50

SV (Setting value) upper limiter ................................................................................. 50

The time of ON-delay alarm or timer function............................................................ 51

Hysteresis alarm 1 and 2 ........................................................................................... 53

Options of alarm 1 and 2 ........................................................................................... 54

Upper and lower limits for control output 1 ................................................................ 56

Upper and lower limits for control output 2 ................................................................ 56

Output limit types ....................................................................................................... 57

Output value display .................................................................................................. 58

RCJ (Cold junction compensation) ............................................................................ 59

Adjusting the PV (Measured value) display (0%)....................................................... 60

Adjusting the PV (Measured value) display (100%)................................................... 60

DI operation ............................................................................................................... 61

Station No. for communication ................................................................................... 64

Parity for communication ........................................................................................... 65

Input type for PYP...................................................................................................... 66

Retransmisson output type setting ............................................................................ 67

Retransmisson base scale......................................................................................... 68

Retransmisson span scale......................................................................................... 68

Parameter display mask ............................................................................................ 69

3 T roub leshooting...................................................................................................................... 70

Index ......................................................................................................................................... 72

3

Page 4

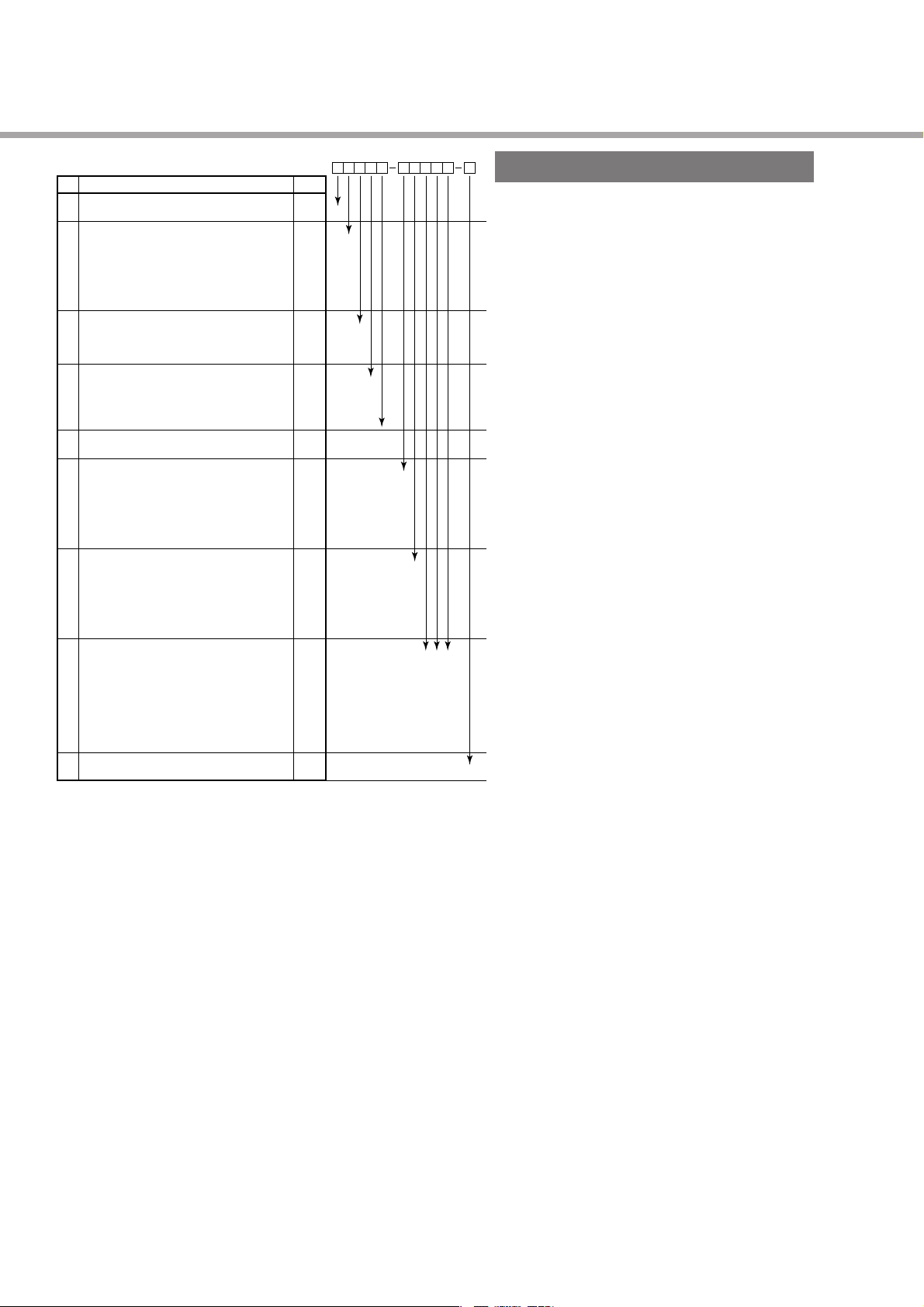

digit

<Size of front H x W>

4

24 × 48 mm

<Input signal>

5

Thermocouple °C

Specification Note

Thermocouple °F

RTD Pt100Ω 3-wire type °C

RTD Pt100Ω 3-wire type °F

1 to 5V DC

4 to 20mA DC

<Control output 1>

6

Relay contact output

SSR/SSC driving output

4 to 20mA DC output

<Control output 2>

7

None

Relay contact output

SSR/SSC driving output

4 to 20mA DC output

<Revision code>

8

<Optional specifications 1>

9

None

Alarm 1 point

8 ramps/soaks

Alarm 1 point + 8 ramps/soaks

Alarm 2 point

Alarm 2 point + 8 ramps/soaks

<Instruction Manual>

10

None 100 to 240V AC

<Power supply voltage>

Japanese 100 to 240V AC

English 100 to 240V AC

None 24V AC/24V DC

Japanese 24V AC/24V DC

English 24V AC/24V DC

<Optional specifications 2>

11

None

12

RS-485 Modbus interface

13

RS-485 Z-ASCLL interface

Retransmission + Digital input 1 point

Retransmission

Digital input 2 points

RS-485 Modbus interface + Digital input 1 point

RS-485 Z-ASCLL interface + Digital input 1 point

<Non-standard specification>

14

Non-standard parameter setting

PXR

Note 1

Note 1

Note 1

Note 2

Note 2

Note 3

Note 3

45678 9

3

T

R

N

S

A

B

A

C

E

Y

A

C

E

1

2

10 11 12 13 14

0

1

4

5

F

G

N

Y

V

C

A

B

0

0

M

0

N

0

Q

0

R

0

T

0

V

0

W

0

Model Specifications

Note 1

Process alarm (2 points) (the codes “ F and G ” in the 9th digit) cannot

be specified.

Note 2

Control output 2 (the codes “ A, C, and E ” in the 7th digit) cannot be

specified.

Note 3

Control output 2, communication digital input (2 points), alarm (2

points), and 24V power supply (the codes “ A, C and E ” in the 7th digit,

“ F and G ” in the 9th digit, and “ A, B, and C ” in the 10th digit) cannot

be specified.

The default settings of input signals, measured ranges, and setting values

are shown below.

Thermocouple specified : Thermocouple K, Measured range: 0 to 400°C,

Resistance bulb specified : Pt, Measured range: 0 to 150°C, Setting value:

Voltage, Current specified : Scaling: 0 to 100%, Setting value: 0%

0

0

0

0

0

0

0

0

In any case other than the description above, specify input signals and

measured range.

The input signals for the thermocouple and the resistance bulb can be

switched with the front panel keys.

The default settings of control action is reverse for control output 1 and direct

for control output 2.

The reverse and direct actions can be switched with keys on the face panel.

F

Setting value: 0°C

0°C

4

Page 5

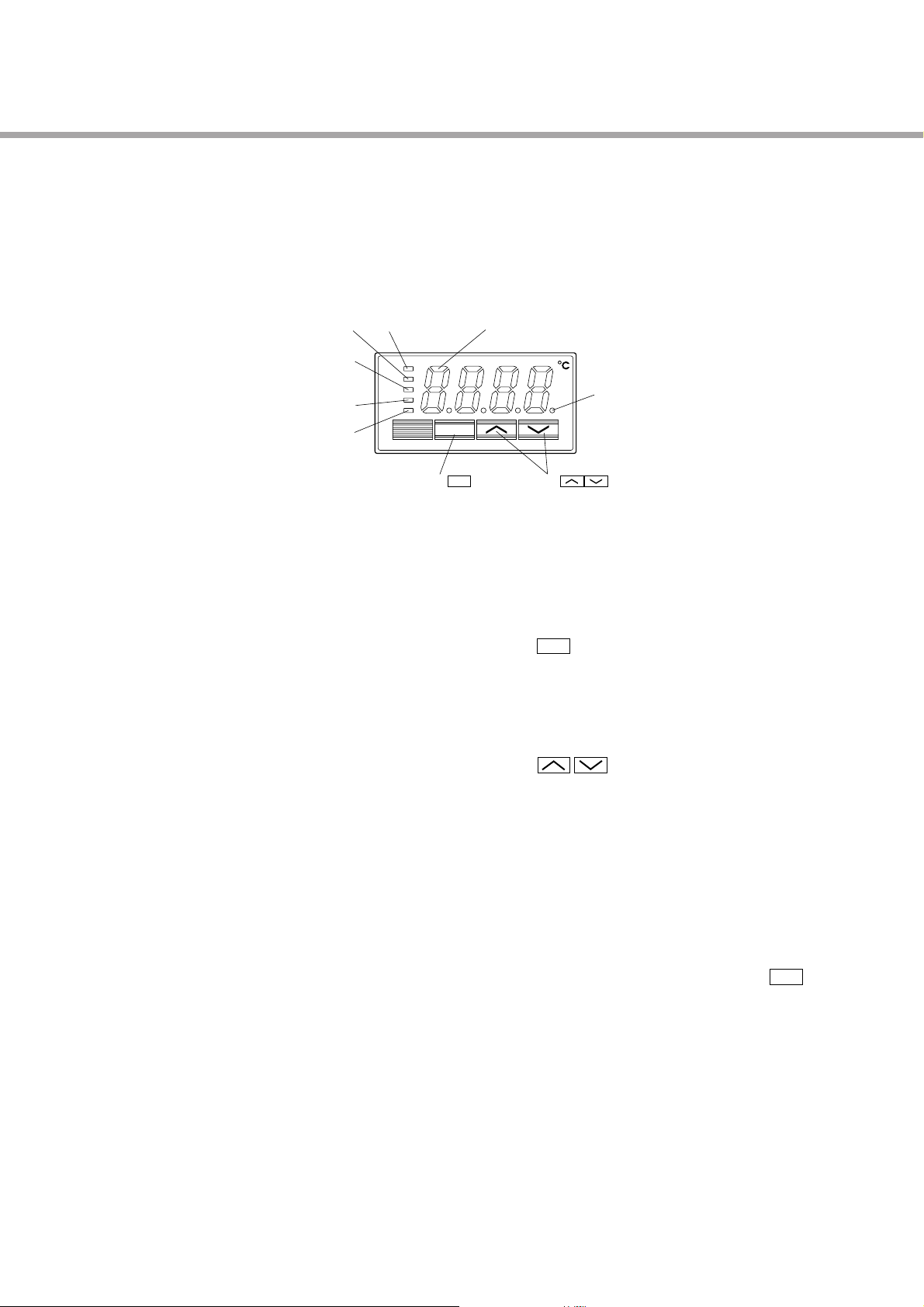

1

This chapter explains the part names and functions on the face panel. The face panel has the PV and SV displays, the status

indicating lamp, and the setting keys, etc. Those functions are explained below. Please read and understand them before

using the PXR. For details about the setting of parameters, see Chapter 2.

Part Names and Functions

Lampforcontroloutput1①

Lampforcontroloutput2②

Lampforalarmoutput1③

Lampforalarmoutput2④

SV

C1

C2

AL1

AL2

⑥ key

Type:PXR3

q Lamp for control output 1

Lights up while control output 1 stays ON.

w Lamp for control output 2

Lights up while control output 2 stays ON.

e Lamp for alarm output 1 (option)

Lights up when alarm output 1 is actuated. Flickers under ON-delay operation.

SEL

SEL

⑤Display⑨SVlamp

⑦ key

y

SEL

Used to switch the PV display to/from the SV display

and select a parameter block and a parameter, and register a set value.

u keys

Used to change the SV, call parameters, and change parameter values.

⑧Auto-tuning/self-tuninglamp

key

r Lamp for alarm output 2 (option)

Lights up when alarm output 2 is actuated. Flickers under ON-delay operation.

t Display

Displays the PV (process value) or SV (set value). When

setting a parameter, its name or its value appears.

i Auto-tuning/self-tuning lamp

Flickers under an auto-tuning or self-tuning operation.

o SV lamp

Displays the PV (process value) in normal condition

(while the lamp stays out). Press the

up the SV lamp and display the SV (set value). Note that

the lamp stays out while parameters and data are displayed.

Flickers while the display shows the PV (process value)

in standby state.

SEL

key to light

5

Page 6

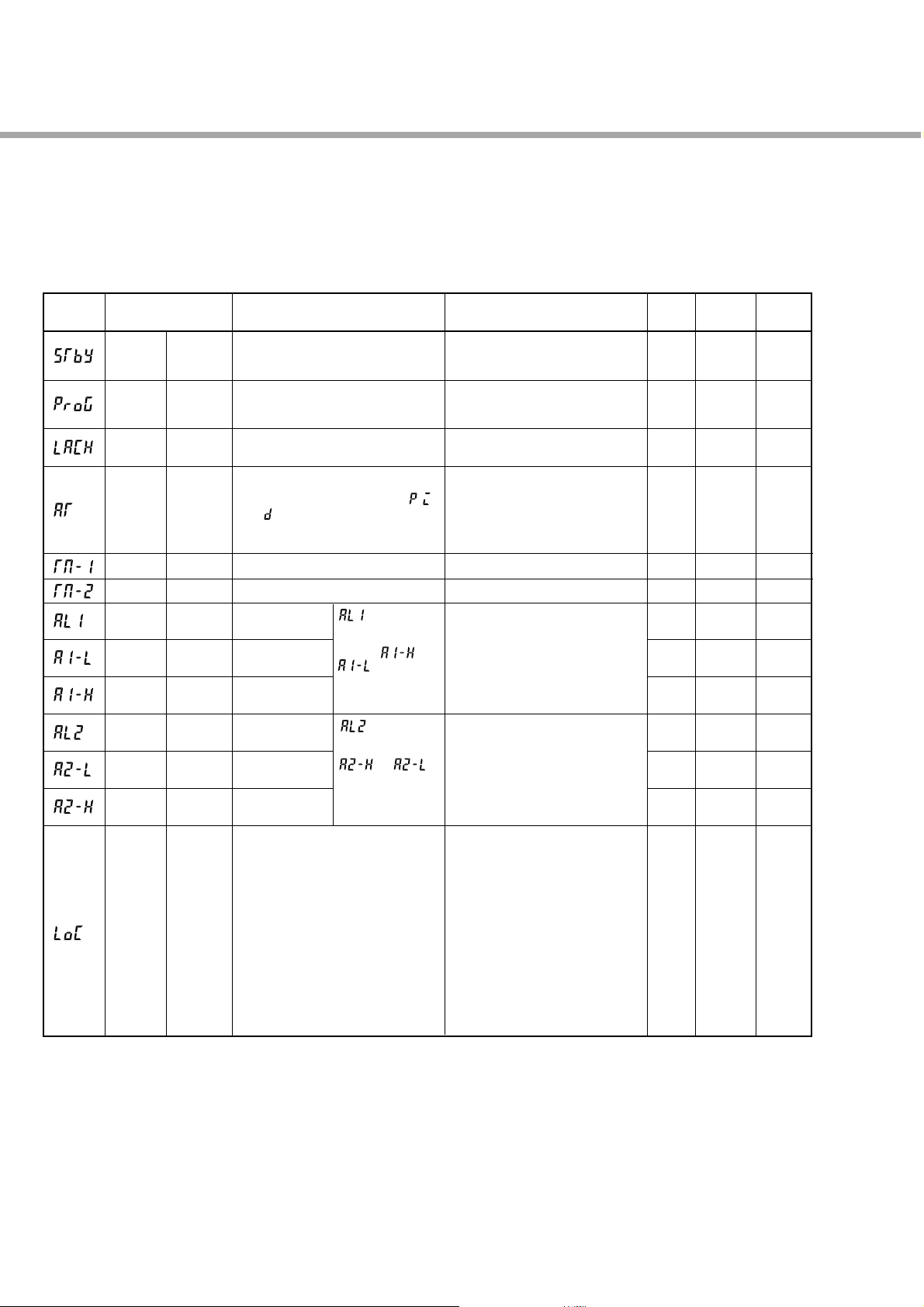

2

Operations

This chapter explains how to set the SV (Setting value) and the parameters for the PXR.

2-1 Parameter list

Parameters for the PXR are classified under three blocks according to the frequency of use. The parameters of the second

and third blocks are used at initialization or when they are of absolute necessity.

Some parameters may not be displayed at the time of delivery depending on the type of the instrument.

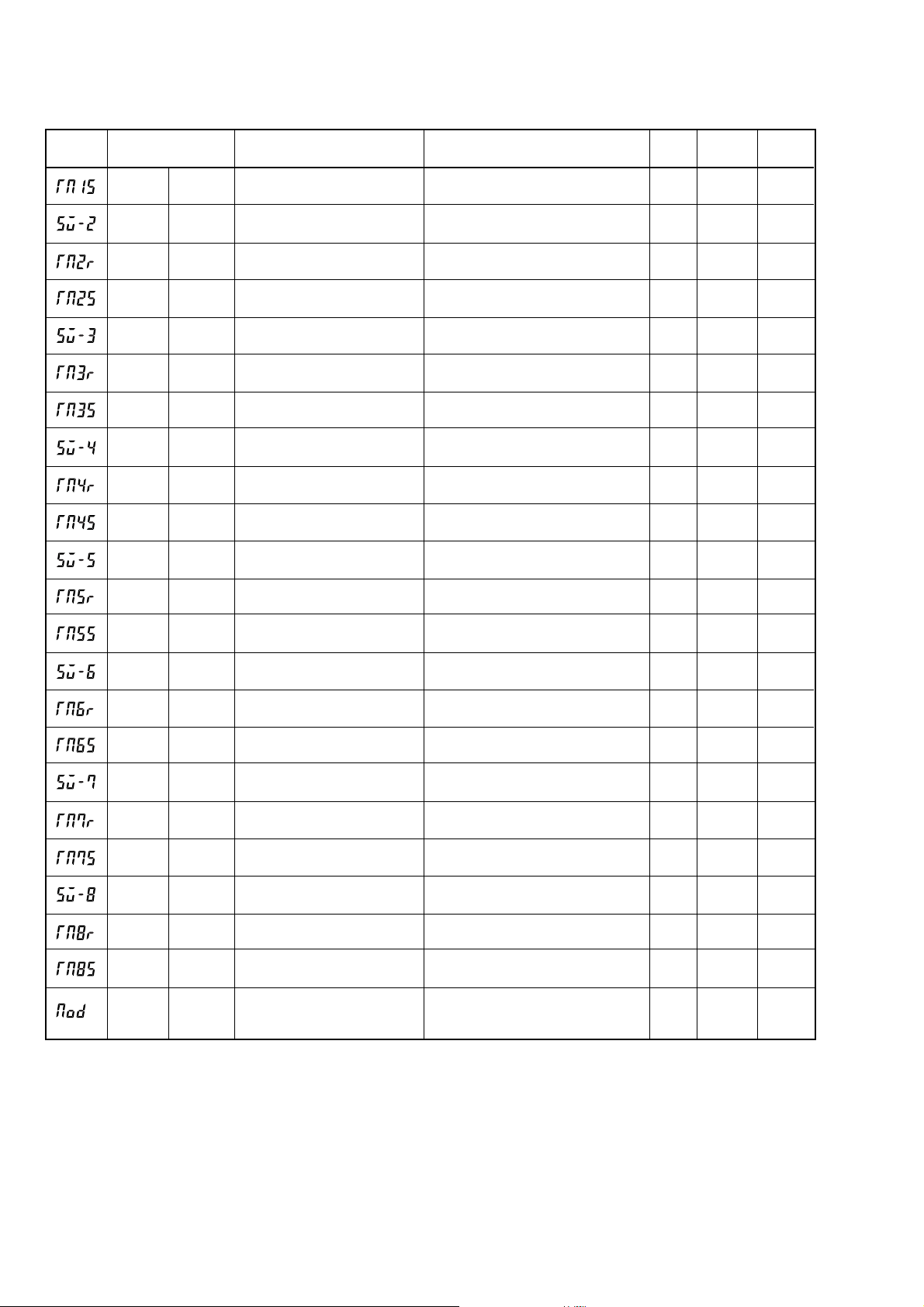

Parameters of the first block

Parameter

display symbol

Parameter name

AT

AL1

AL2

Standby

setting

Ramp-soak

control

Alarm latch

cancel

Auto-tuning

Timer 1 display

Timer 2 display

Set value of

alarm 1

Lower limit

value of

alarm 1

Upper limit

value of

alarm 1

Set value of

alarm 2

Lower limit

value of

alarm 2

Upper limit

value of

alarm 2

Key lock

Stby

ProG

LACH

TM-1

TM-2

A1-L

A1-H

A2-L

A2-H

LoC

Description

Switches between RUN and Standby

for control.

Switches between Start, Stop, and

Hold for ramp-soak control

Cancels the alarm latch.

Used for setting the constants for , ,

and by auto-tuning.

Displays the remaining time of timer 1.

Displays the remaining time of timer 2.

Sets the value at which

alarm 1 is detected.

Sets the lower limit

value at which alarm 1

is detected.

Sets the upper limit

value at which alarm 1

is detected.

Sets the value during

which alarm 2 is

detected.

Sets the lower limit

value at which alarm 2

is detected.

Sets the upper limit

value at which alarm 2

is detected.

Specifies whether or not to allow the

change of parameters.

is displayed

when alarm type 1

is 0 to 15, or 32 to

34, and or

is displayed

when alarm type 1

is 16 to 31.

is displayed

when alarm type 2 is 0

to 15 or 32 to 34, and

or is

displayed when alarm

type 2 is 16 to 31.

Setting range and

factory default setting (*)

oN: Control standby

(Output: OFF, Alarm: OFF)

oFF: Control RUN*

oFF: Stop*

rUn: Start

HLd: Hold

0: Keeps the alarm latch.*

1: Opens up the alarm latch.

0: OFF (Resets the auto-tuning or does

not use it.)*

1: ON (Performs the auto-tuning in the

SV standard type.)

2: ON (Performs the auto-tuning in

low PV type (SV value-10%FS).)

- (Unit: seconds)

- (Unit: seconds)

When the alarm type is absolute value:

0 to 100%FS (*:10)

When the alarm type is deviation:

-100 to 100%FS (*:10)

When the alarm type is absolute value:

0 to 100%FS (*:10)

When the alarm type is deviation:

-100 to 100%FS (*:10)

0: All settings are changeable both from

the face panel and via communication.*

1: All settings are unchangeable from the

face panel, but changeable via

communication.

2: Only the SV is changeable from the

face panel, and all settings are

changeable via communication.

3: All settings are changeable from the

face panel, but unchangeable via

communication.

4:

All settings are unchangeable from the

face

panel or

via

5:

Only the SV is changeable from the

face

panel, but all settings are unchangeable

via

communication.

communication.

User’s

set value

Parameter

mask DSP

dSP1-1

dSP1-2

dSP1-4

dSP1-8

dSP1-16

dSP1-32

dSP1-128

dSP2-1

dSP2-2

dSP2-4

dSP2-8

dSP2-16

dSP3-1

Reference

page

13

14

15

16

17

17

18

18

18

18

18

18

19

*

*

*

*

*

*

6

Note: The parameters for which * is marked with the page number in Reference page are related to Remedies

of “4” on page 70.

Page 7

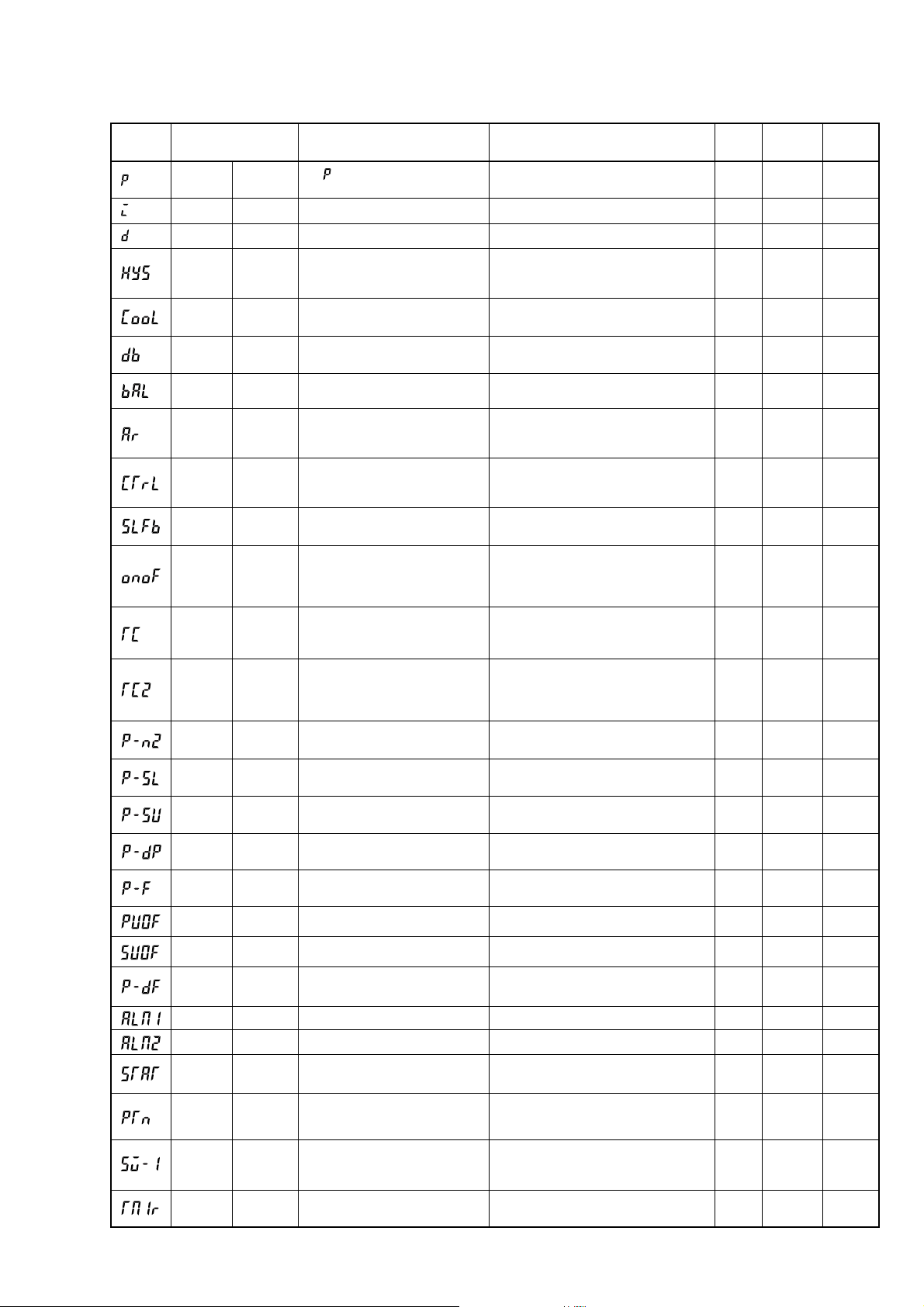

Parameters of the second block

Parameter

display symbol

User’s

set value

Reference

page

Description

Sets the types of alarm operations.

Sets the types of alarm operations.

Selects ramp-soak patterns.

Sets the 1st target SV of ramp-soak

operation. / Selected at switchingSV function for DI1

Sets the first ramp segment time.

Setting range and factory

default setting (*)

0.0 to 999.9% (*: 5.0)

0 to 3200 seconds (*: 240)

0.0 to 999.9 seconds (*: 60.0)

0 to 50%FS (*: equivalent of 1.0°C)

0.0 to 100.0 (*: 1.0)

-50.0 to +50.0 (*: 0.0)

-100 to 100%

(*: single 0.0, dual 50.0)

0 to 100%FS (*: 100%FS)

PID: Runs normal PID control.*

FUZY: Runs PID control with fuzzy logic.

SELF: Runs PID control with self-running.

0 to 100%FS (*: 2%FS)

oFF: Starts the two-position control at the

values of SV+HYS/2 and SV-HYS/2.

on:

Starts the two-position control at the values

of SV and SV+HYS, or SV and SV-HYS.

*

RLY, SSR: 1 to 150 seconds

(*: Contact output = 30,

SSR/SSC-driven output = 2)

RLY, SSR: 1 to 150 seconds

(*: Contact output = 30,

SSR/SSC-driven output = 2)

1 to 16 (*: specified by customer while

ordering)

Note 1

-1999 to 9999 (*: specified by customer

while ordering)

Note 1

-1999 to 9999 (*: specified by customer

while ordering)

Note 1

0 to 2 (*: specified by customer while

ordering)

Note 1

°C / °F

-10 to 10%FS (*: 0)

-50 to 50%FS (*: 0)

0.0 to 900.0 seconds (*: 5.0)

0 to 34 (*: 0/5)

0 to 34 (*: 0/9)

- (*: OFF)

1: Performs 1st to 4th segments.*

2: Performs 5th to 8th segments.

3: Performs 1st to 8th segments.

Within the SV limit. (*: 0%FS)

0 to 99h59m (*: 0.00)

Parameter

mask DSP

dSP3-2

dSP3-4

dSP3-8

dSP3-16

dSP3-32

dSP3-64

dSP3-128

dSP4-1

dSP4-2

dSP4-4

dSP4-8

dSP4-16

dSP4-32

dSP4-64

dSP4-128

dSP5-1

dSP5-2

dSP5-4

dSP5-8

dSP5-16

dSP5-32

dSP5-64

dSP5-128

dSP6-2

dSP6-4

dSP6-8

dSP6-16

Selects the control algorithm.

Sets the PV stable range for the selftuning operation.

Selects the hysteresis operation at

ON/OFF control.

Not shown at 4-20mA DC output

Set this parameter when changing

the types of temperature sensors.

Set to 0.0 to select the ON/OFF

control (Two-position control).

20

21

22

23

24

25

26

26

27

31

32

33

34

35

36

36

38

36

39

40

41

42

42

46

45

46

46

Sets the hysteresis for ON/OFF

control.

*

*

*

*

*

*

P

I

D

HYS

CooL

db

bAL

Ar

CTrL

SLFb

onoF

TC

TC2

P-n2

P-SL

P-SU

P-dP

P-dF

PTn

Sv-1

TM1r

Parameter name

ALM1

ALM2

STAT

P-F

PVOF

SVOF

Proportional

band

Integral time

Derivative time

Hysteresis

range for

ON/OFF

control

Cooling-side

proportional

band coefficient

Cooling-side

proportional

band shift

Output

convergence

value

Anti-reset

windup

Control

algorithm

PV (Measured

value) stable

range

Setting HYS

(Hysteresis)

mode

Cycle time

of control

output 1

Cycle time

of control

output 2

(cooling-side)

Input signal

code

Lower limit of

measuring range

Upper limit of

measuring range

Setting the decimal point position

Time constant

of input filter

Selecting

ramp-soak

execute type

1st target value

/Switching-SV

value

First ramp

segment time

Alarm type 1

Alarm type 2

Status display

of ramp-soak

°C / °F

selection

PV (Measured

value) offset

SV (Setting

value) offset

Shift the display of the PV.

Shift the SV. But the SV display

is not changed.

Note: The pa rameters for which * is marked with the page number in

Reference page are related to Remedies of “4” on page 70.

7

Page 8

Parameter

display symbol

Parameter name Description

TM1S

Sv-2

TM2r

TM2S

Sv-3

TM3r

TM3S

Sv-4

TM4r

TM4S

Sv-5

TM5r

TM5S

Sv-6

TM6r

TM6S

Sv-7

TM7r

TM7S

Sv-8

TM8r

TM8S

Mod

1st soak

segment time

2nd target SV

2nd ramp

segment time

2nd soak

segment time

3rd target SV

3rd ramp

segment time

3rd soak

segment time

4th target SV

4th ramp

segment time

4th soak

segment time

5th target

SV

5th ramp

segment time

5th soak

segment time

6th target SV

6th ramp

segment time

6th soak

segment time

7th target SV

7th ramp

segment time

7th soak

segment time

8th target

SV

8th ramp

segment time

8th soak

segment time

Ramp-soak

mode

Sets the 1st soak segment time.

Sets the 2nd target SV of ramp-soak

operation.

Sets the 2nd ramp segment time.

Sets the 2nd soak segment time.

Sets the 3rd target SV of ramp-soak

operation.

Sets the 3rd ramp segment time.

Sets the 3rd soak segment time.

Sets the 4th target SV of ramp-soak

operation.

Sets the 4th ramp segment time.

Sets the 4th soak segment time.

Sets the 5th target SV of ramp-soak

operation.

Sets the 5th ramp segment time.

Sets the 5th soak segment time.

Sets the 6th target SV of ramp-soak

operation.

Sets the 6th ramp segment time.

Sets the 6th soak segment time.

Sets the 7th target SV of ramp-soak

operation.

Sets the 7th ramp segment time.

Sets the 7th soak segment time.

Sets the 8th target SV of ramp-soak

operation.

Sets the 8th ramp segment time.

Sets the 8th soak segment time.

Selects the power-on start, repeat,

and standby functions for rampsoak operations.

Setting range and factory

default setting (*)

0 to 99h59m (*: 0.00)

Within the SV limit. (*: 0%FS)

0 to 99h59m (*: 0.00)

0 to 99h59m (*: 0.00)

Within the SV limit. (*: 0%FS)

0 to 99h59m (*: 0.00)

0 to 99h59m (*: 0.00)

Within the SV limit. (*: 0%FS)

0 to 99h59m (*: 0.00)

0 to 99h59m (*: 0.00)

Within the SV limit. (*: 0%FS)

0 to 99h59m (*: 0.00)

0 to 99h59m (*: 0.00)

Within the SV limit. (*: 0%FS)

0 to 99h59m (*: 0.00)

0 to 99h59m (*: 0.00)

Within the SV limit. (*: 0%FS)

0 to 99h59m (*: 0.00)

0 to 99h59m (*: 0.00)

Within the SV limit. (*: 0%FS)

0 to 99h59m (*: 0.00)

0 to 99h59m (*: 0.00)

0 to 15 (*: 0)

User’s

set value

Parameter

mask DSP

dSP6-32

dSP6-64

dSP6-128

dSP7-1

dSP7-2

dSP7-4

dSP7-8

dSP7-16

dSP7-32

dSP7-64

dSP7-128

dSP8-1

dSP8-2

dSP8-4

dSP8-8

dSP8-16

dSP8-32

dSP8-64

dSP8-128

dSP9-1

dSP9-2

dSP9-4

dSP9-8

Reference

page

46

*

46

46

46

*

46

46

46

*

46

46

46

*

46

46

46

*

46

46

46

*

46

46

46

*

46

46

46

46

Note 1:When a customer does not specify the settings while ordering, the follo wing settings are selected as f actory defaults.

Thermocouple input: Thermocouple K Measured range: 0 to 400°C

Resistance bulb input: Measured range: 0 to 150°C

Voltage/Current input: Scaling: 0 to 100%

8

Page 9

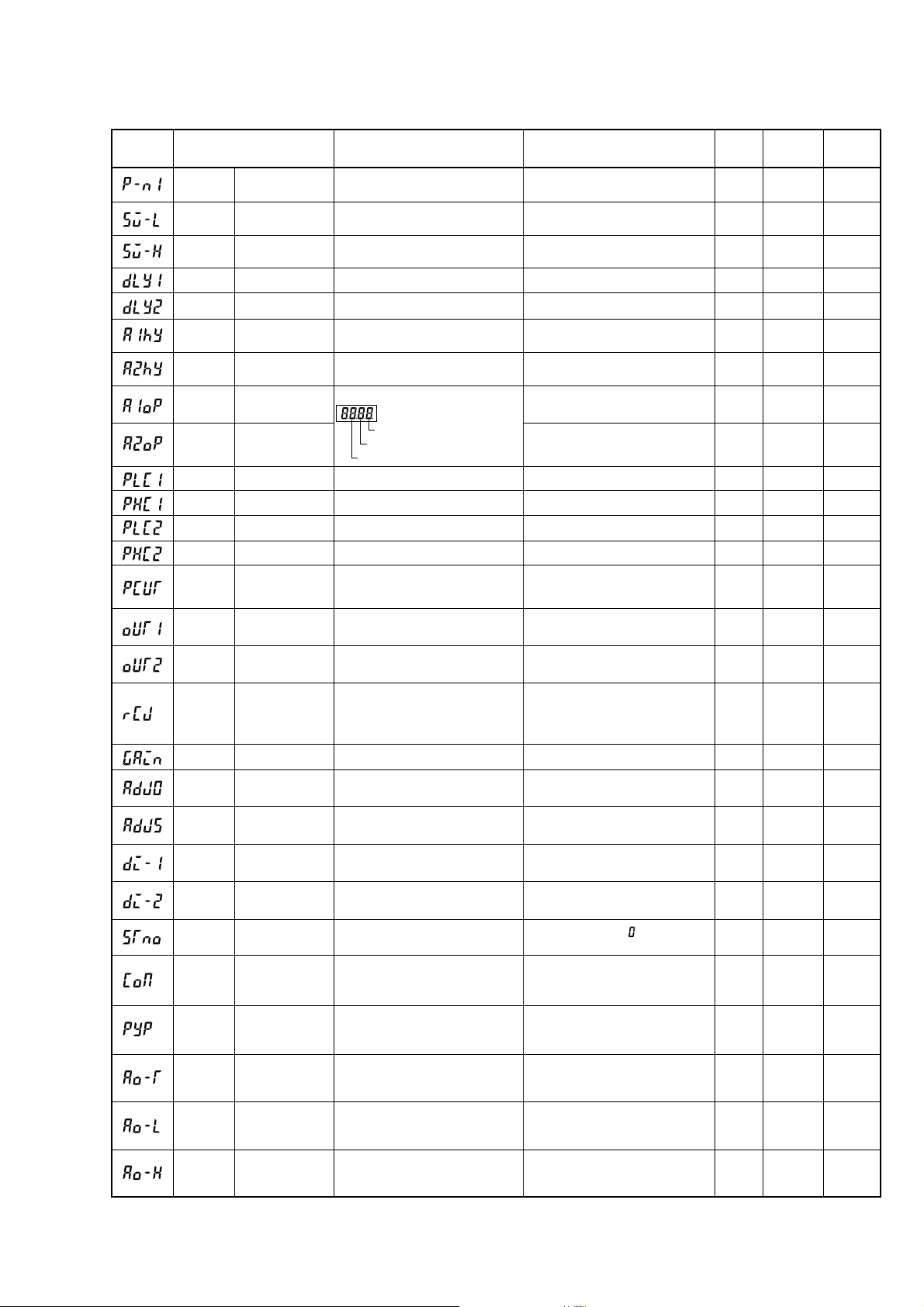

Parameters of the third block

Parameter

display symbol

Parameter name Description

P-n1

Sv-L

Sv-H

dLY1

dLY2

A1hy

A2hy

A1oP

A2oP

PLC1

PHC1

PLC2

PHC2

PCUT

oUT1

oUT2

GAin

AdJ0

AdJS

STno

CoM

PYP

Ao-T

Control action

SV (Setting value)

lower limiter

SV (Setting value)

upper limiter

Delay time 1

Delay time 2

Alarm 1 hysteresis

Alarm 2 hysteresis

Alarm 1 options

Alarm 2 options

Lower limit for output 1

Upper limit for output 1

Lower limit for output 2

Upper limit for output 2

Output limit types

Output value (MV)

display

Output value (MV)

display

RCJ (Cold junction

compensation)

rCJ

setting

PV gradient

User-definable zero

adjustment

User-definable span

adjustment

DI1 (Digital input 1)

di-1

operation

DI2 (Digital input 2)

di-2

operation

Station No.

Parity setting

Input type for PYP

(Color TouchOperation Unit)

Retransmission

output type

Note: The parameters for which * is marked with the page number in

Specifies control action and output at

the input burn-out.

Sets the lower limit of the SV.

Sets the upper limit of the SV.

Delay time or timer value for alarm 1 relay.

Delay time or timer value for alarm 2 relay.

Sets the hysteresis range of ON and

OFF of alarm 1.

Sets the hysteresis range of ON and

OFF of alarm 2.

Sets the optional functions of alarms 1 and 2.

Alarm latch (1: use, 0: not use)

Alarm of error status (1: use, 0: not use)

De-energized output (1: use, 0: not use)

Sets the lower limit for output 1.

Sets the upper limit for output 1.

Sets the lower limit for output 2.

Sets the upper limit for output 2.

Sets the limit types of outputs 1 and

2 (breaking the limit, or maintained

within the limit).

Displays the value of output 1.

Displays the value of output 2.

Sets the cold junction compensation

function to ON/OFF.

Shifts the zero point of input value.

Shifts the span of input value.

Sets the DI1 operations.

Sets the DI2 operations.

Sets the station No. for

communication.

Sets the parity for communication.

(The baud rate is fixed at 9600bps.

Sets the input type for communicating

with PYP.

Selecting retransmission output type.

0 to 19 (*: specified by customer

while ordering)

0 to 100%FS (*: 0%FS)

0 to 100%FS (*: 100%FS)

0 to 9999 seconds (*: 0)

0 to 9999 seconds (*: 0)

0 to 50%FS (*: 1)

0 to 50%FS (*: 1)

000 to 111 (*: 000)

000 to 111 (*: 000)

-3.0 to 103.0% (*: -3.0)

-3.0 to 103.0% (*: 103.0)

-3.0 to 103.0% (*: -3.0)

-3.0 to 103.0% (*: 103.0)

0 to 15 (*: 0)

-

-

ON: Performs the RCJ

compensation).*

OFF: Does not perform the RCJ

(Cold junction compensation).

0.001 to 2.000 (*: 1.000)

-50 to 50%FS (*: 0)

-50 to 50%FS (*: 0)

0 to 12 (*: 0=OFF)

0 to 12 (*: 0=OFF)

0 to 255 (Setting to does not start

the communications function.) (*: 1)

0: Odd parity*

1: Even parity

2: No parity

0 to 255 (*: 34)

0: PV/ 1: Set point/ 2: Output/

3: Error (* : 0)

Reference page are related to Remedies of “4” on page 70.

Setting range and factory

default setting (*)

Note 2

(Cold junction

User’s

set value

Parameter

mask DSP

dSP9-16

dSP9-32

dSP9-64

dSP9-128

dSP10-1

dSP10-16

dSP10-32

dSP10-128

dSP11-1

dSP11-4

dSP11-8

dSP11-16

dSP11-32

dSP11-64

dSP11-128

dSP12-1

dSP12-2

dSP12-4

dSP12-8

dSP12-16

dSP12-32

dSP12-64

dSP12-128

dSP13-1

dSP13-2

dSP13-4

Reference

page

49

50

50

51

51

53

53

54

54

56

56

56

56

57

58

58

59

60

60

61

61

64

65

66

67

*

*

*

*

*

*

Ao-L

Ao-H

Retransmission

base scale

Retransmission

span scale

Setting retransmission base scale.

Setting retransmission span scale.

(Setting range: -100.0 to 100.0%)

(* : 0.0%)

(Setting range: -100.0 to 100.0%)

(* : 100.0%)

Note 2:The following settings are selected as factory defaults depending on the model you order.

Seventh digit = Y model: 0 Seventh digit = A, C, E model: 4

dSP13-8

dSP13-16

68

68

9

Page 10

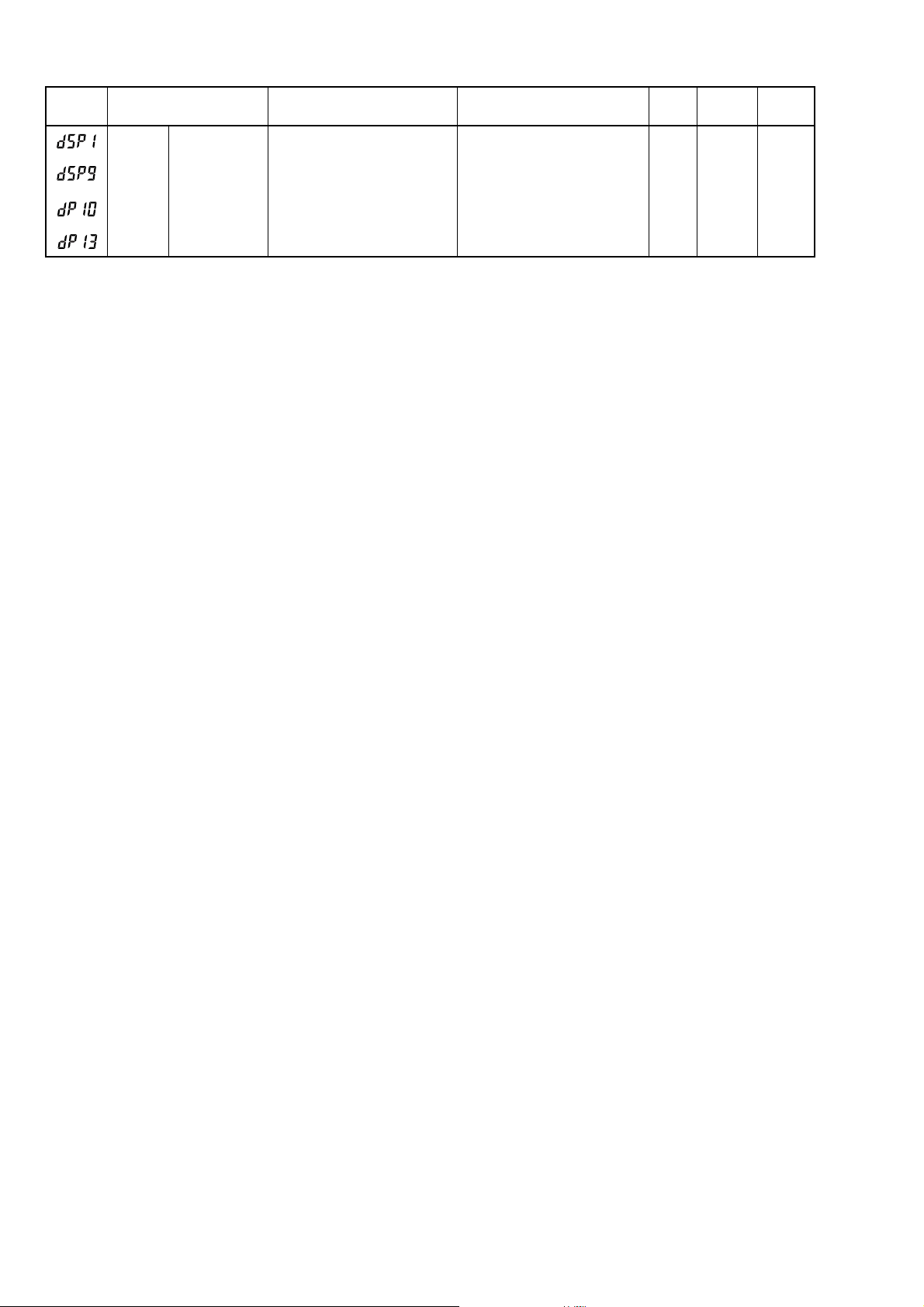

Parameter

display symbol

Parameter name Description

Setting range and factory

default setting (*)

User’s

set value

Parameter

mask DSP

Reference

page

to

to

to

dSP9

dSP10

to

Parameter mask

Sets whether or not to display each

parameter.

0 to 255 (*: specified by customer

while ordering)

–

69

dSP13

dSP1

10

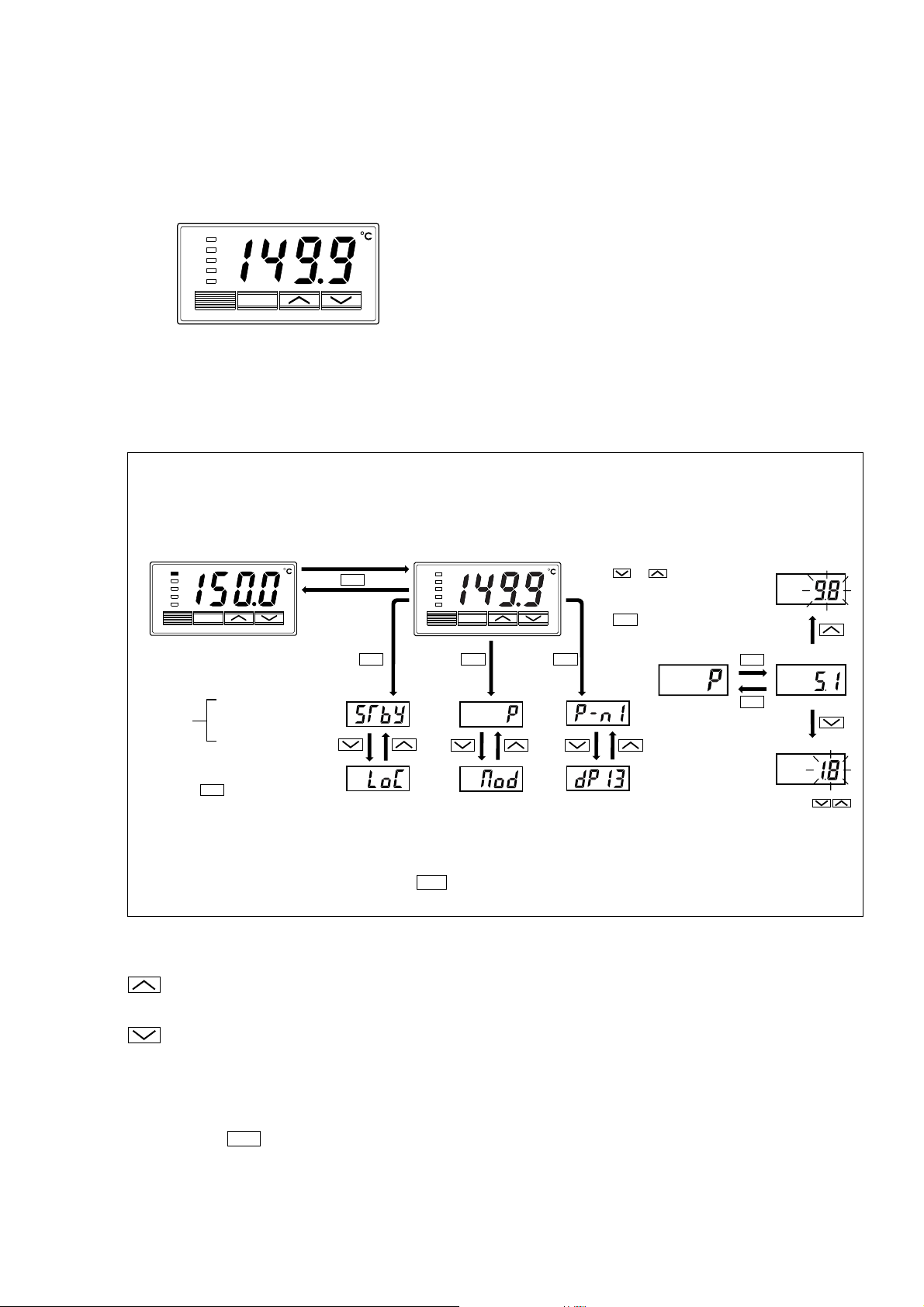

Page 11

2-2 Basic operations

Just after power-on:

The PV (process value) is displayed just after power-on.

SV

C1

C2

AL1

AL2

SEL

How to switch parameters:

The figure below shows the basic operations for the PXR3.

Exp.) In case when the PV (process value)

Basic operations for the PXR3

is 149.9.

SV

C1

C2

AL1

AL2

SEL

Indication switching PV (process value)

to / from SV (set value)

OFF

SV lamp

……indicatingPV

Lit, flickers

……indicatingSV

Press the key to

SEL

switch PV to / from SV.

How to set values:

key: One press increases the value by 1.

Press and hold this key to increase the value.

key: One press decreases the value by 1.

Display state just after power-on

(PV indication)(SV indication)

Parameter setting

Flickers when the set value is

changed by pressing the

SEL

SV

C1

C2

AL1

AL2

SEL

or key.

Stop flickering when the SV

is registered by pressing the

key.

SEL

Set data indication

SEL

(apporox.

1 second)

SEL

(apporox.

3 second)

SEL

(apporox.

5 second)

SEL

SEL

Set data registration

Parameters of

the first block

Parameters of

the second block

Parameters of

the third block

Pressing and holding the

keys makes the value increase

or decrease fast.

If it has not been operated for 30 seconds, the display returns to the PV display.

Pressing the key for 2 second after setting parameters, the indication

SEL

shifts to the SV indication state.

Press and hold this key to decrease the value.

How to register the set data:

By pressing the

Note that the SV (SV0) will be registered in 3 seconds without any operation. (Refer to P.12)

When changed the parameters “P-n2”, “ALM1” or “ALM2”, turn the power OFF and ON.

key, the displayed values are registered.

SEL

11

Page 12

2-3 Parameter functions and method of settings

Method of setting the SV (Setting value)

[Description]

•The SV is a target value for control.

•Any SV that is outside of the range set in the parameters

of (lower limit) and (upper limit) of the

third block cannot be set. (See page 50.)

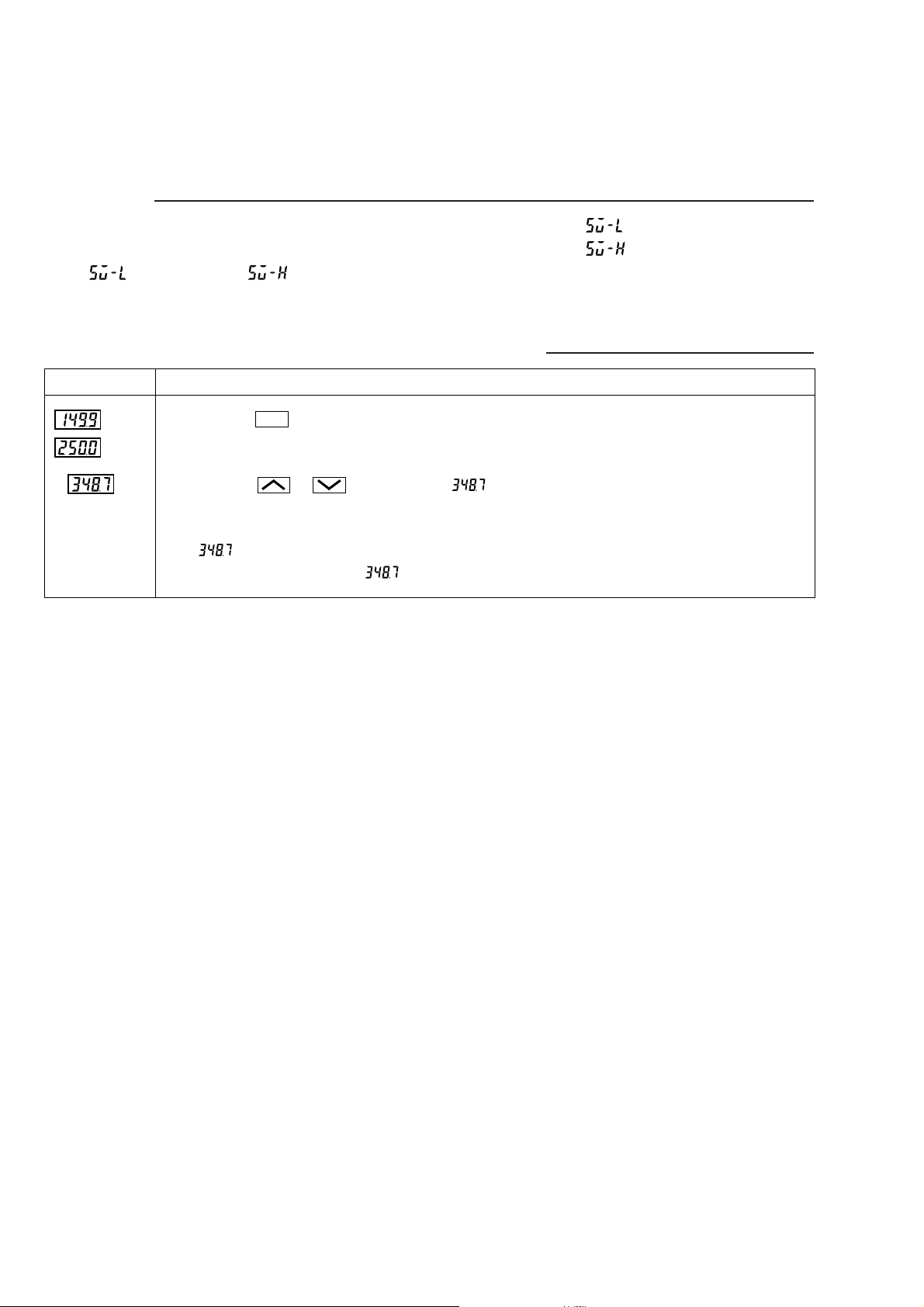

[Setting example] Changing the SV from 250.0°C to 348.7°C

Display Operating procedure

Related parameters: (page 50)

(page 50)

PV indication

SV indication

Press the key to display the SV. (SV lamp is lit.)

1.

Press the or keys to display .

2.

will be registered in the SV (front SV) in three seconds. After that, the controller will

3.

operate with the SV being .

SEL

12

Page 13

q First block parameters

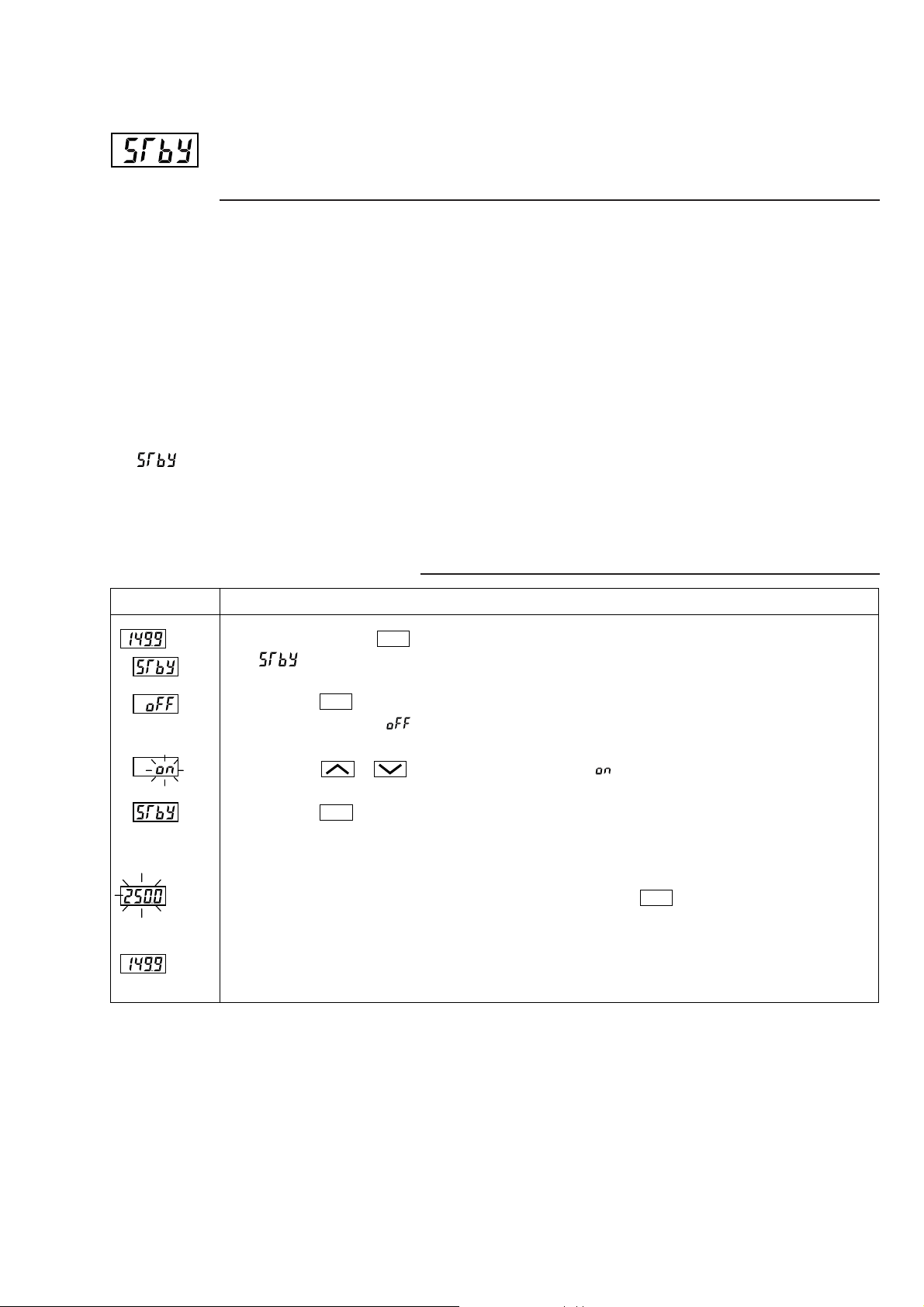

Standby setting (Settings: oFF/on)

[Description]

•This parameter switches the control between RUN and

Standby.

• During standby, the control output and the alarm output

stay OFF, like the standby for ramp-soak operation.

Retransmission output is kept operated. (However, if the

type of retransmission output is set to the MV, it becomes

4mA or lower.)

• While the alarm with a hold is selected, the hold function

takes effect after changing the Standby setting from ON

to OFF.

• is displayed during the standby for ramp-soak

operations or the controller changes to the standby state

in case of the occurrence of errors.

• The other operations are the same as those of the rampsoak standby.

•The setting of ON/OFF for standby is saved after po wer off.

•When the standby is set to ON during the auto-tuning,

self-tuning, and ramp-soak operations, those operations

will stop. (The PID constant will not be renewed.) Even

through it is set to OFF later, the auto-tuning, self-tuning,

and ramp-soak operations will not be re-started.

• During standby, the ON-delay timer is reset. When

returning to RUN from the standby state, the timer will

start from the beginning.

•The SV lamp flickers only when standby state.

[Setting example] Starting the control

Display Operating procedure

PV indication

SV indication

PV indication

Press and hold the key for one second.

1.

will be displayed.

Press the key once.

2.

The current setting ( ) will be displayed.

Press the or keys to flicker and to display .

3.

Press the key once. The standby state for control is selected. (control output and all the alarm

4.

outputs: OFF)

(Repeat the procedure from 2 to 4 to check the set value.)

If you want to display the operation status, press and hold the key for two seconds. The value

5.

on the SV display will flash, indicating the standby status.

If unoperated state continues, the PV will be displayed.

SEL

SEL

SEL

SEL

13

Page 14

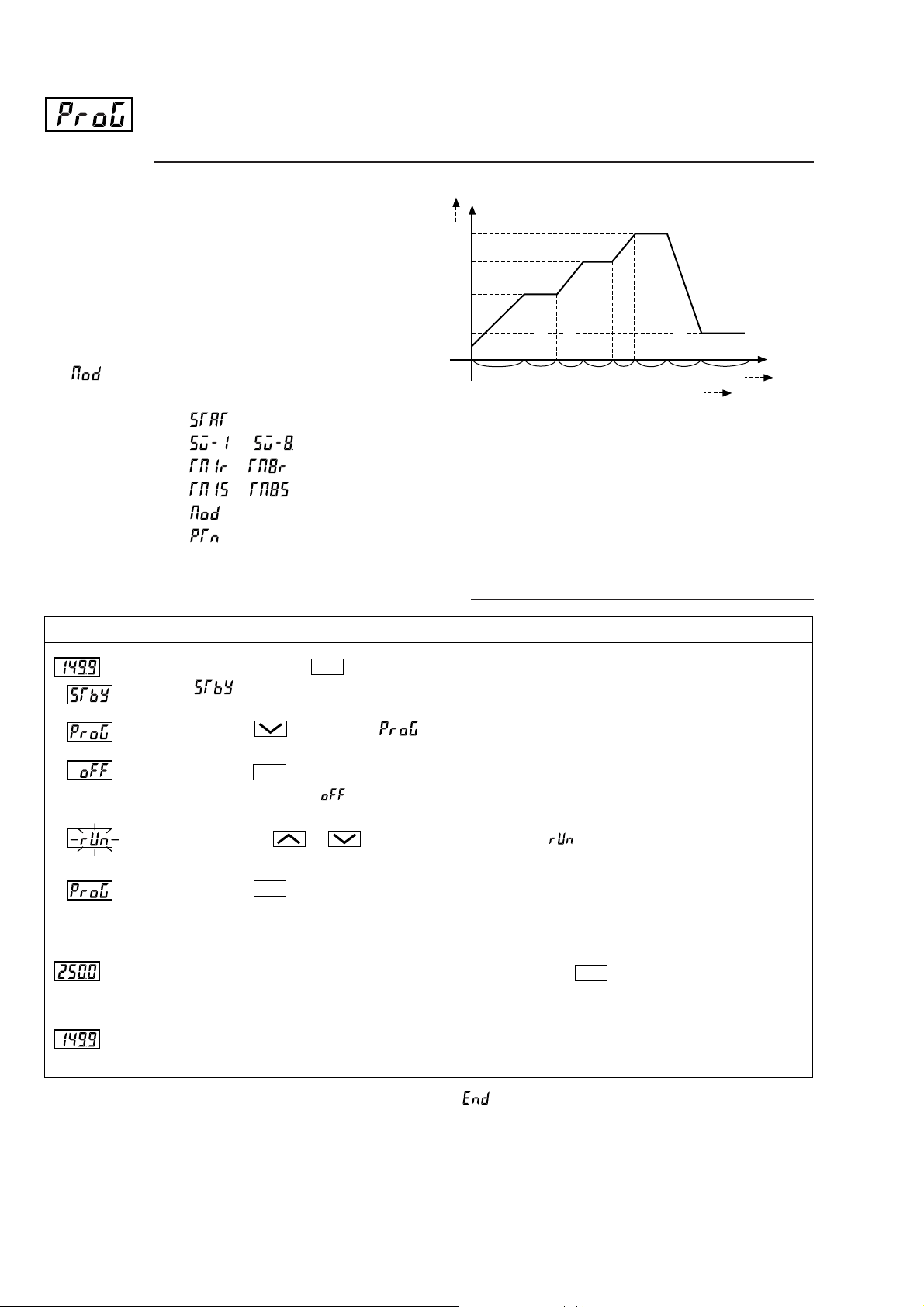

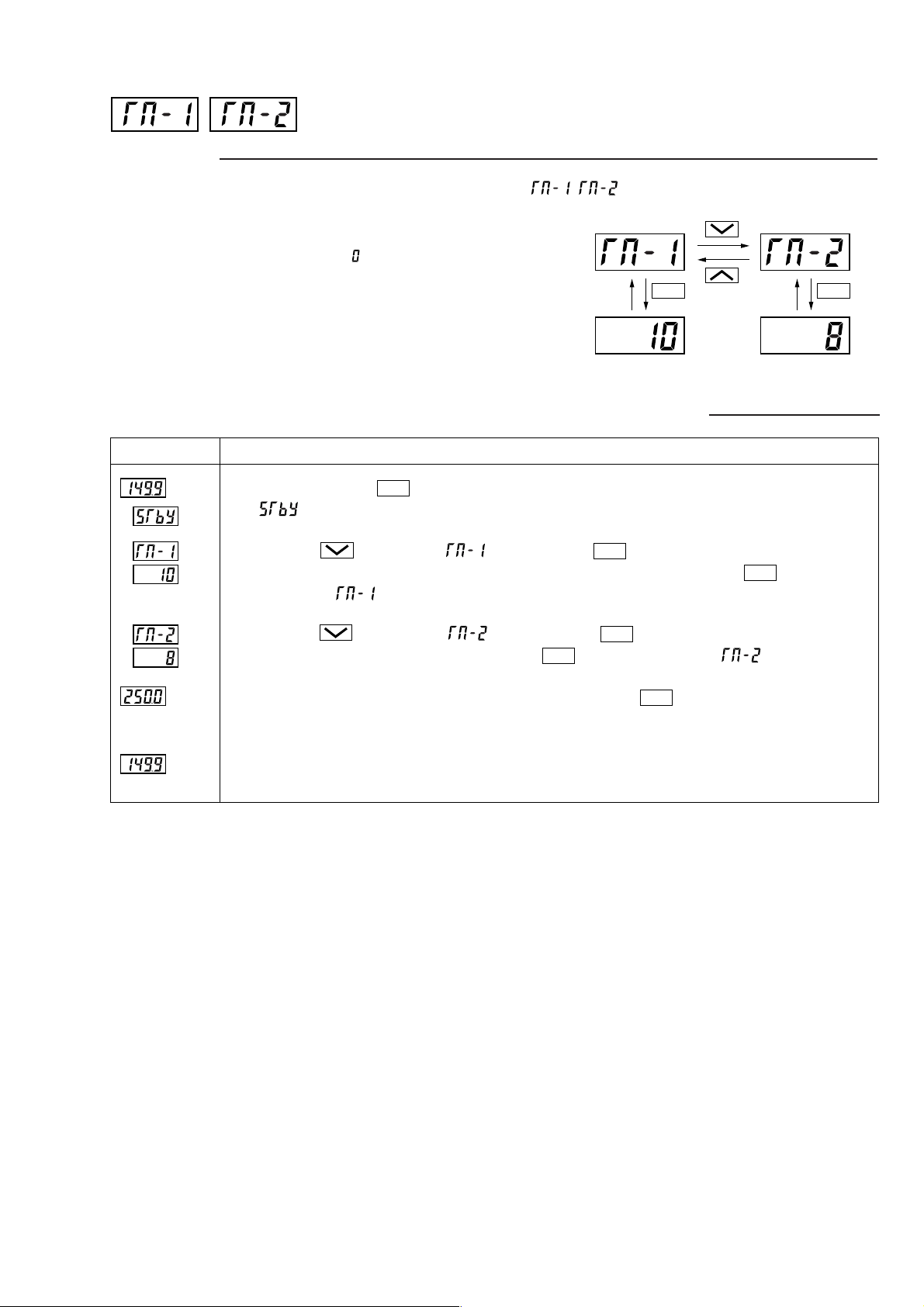

Ramp-soak control (Settings: oFF/rUn/hLd) (Option)

[Description]

• This function automatically changes the SV (Setting

value) according to the program pattern set in advance as

shown in the right line graph. Up to eight pairs of rampsoak operation can be programmed.

•The first ramp starts at the PV (Measured value) that is

the one just before running the program.

•The program can also automatically run at power-on

(Power-on starting function). Refer to the parameter of

(page 46).

Related parameters:

(page 46)

to (page 46)

to (page 46)

to (page 46)

(page 46)

(page 45)

Up to SV-8

SV-3

SV-2

SV-1

SV-4

PV

First ramp

TM1r

Ramp: the section in which the SV changes toward the target value.

Soak: the section in which the SV is the target value, and remains unchanged.

First soak

TM1S

Second soak

Second ramp

TM2S

TM2r

Third soak

Third ramp

Fourth ramp

TM3S

TM3r TM4r

Fourth soak

TM4S

Up to TM8r

Up to TM8s

[Setting example] Starting the ramp-soak operation

Display Operating procedure

PV indication

SV indication

PV indication

Press and hold the key for one second.

1.

will be displayed.

Press the key to display .

2.

Press the key once.

3.

SEL

The current setting ( ) is displayed.

Pressing the or keys, the display flickers and is displayed.

4.

Press the key once. Then, the program will start according to the ramp-soak pattern that is

5.

SEL

set in advance.

(Repeat the procedure from 3 to 5 to check the set value.)

If you want to display the operation status, press and hold the key for two seconds.

6.

The SV is displayed on the display area.

If unoperated state continues, the PV will be displayed.

SEL

*1

SEL

14

*1) When the program was not set, it is turned to .

Page 15

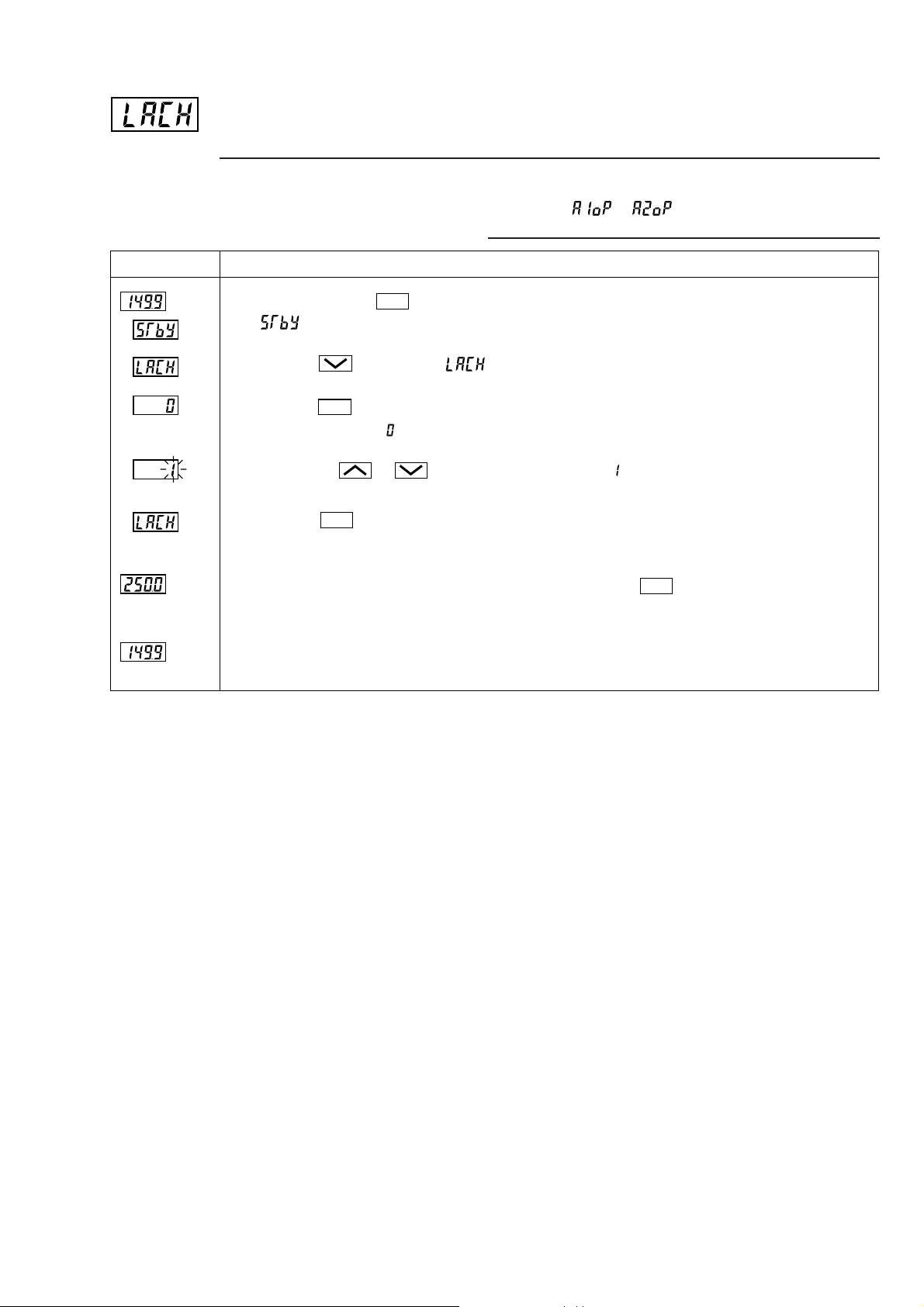

Canceling the alarm latch (Setting range: 0/1) (Option)

[Description]

•This parameter cancels the alarm latch when it is latching.

Related parameters:

[Setting example] Opening up the alarm latch

Display Operating procedure

to (page 54)

PV indication

SV indication

PV indication

Press and hold the key for one second.

1.

will be displayed.

Press the key to display .

2.

Press the key once.

3.

The current setting ( ) is displayed.

Pressing the or keys to flicker and to display .

4.

Press the key once.

5.

(Repeat the procedure from 3 to 5 to check the set value.)

If you want to display the operation status, press and hold the key for two seconds.

6.

The SV is displayed on the display area.

If unoperated state continues, the PV will be displayed.

SEL

SEL

SEL

SEL

15

Page 16

Auto-tuning function (Settings: 0/1/2)

[Description]

[Note]

If the controller is powered off during auto-tuning, this

makes the auto-tuning ineffectiv e with each parameter

of , , and unchanged. To start the auto-tuning

operation, set to “1” or “2” again.

•To suspend the auto-tuning, set to “0”. This makes

the auto-tuning cancel with each parameter of , , and

unchanged.

• Once the parameters of , , and are set automatically

by the auto-tuning, those parameters are stored in the

controller even after it is powered off. Therefore, it is not

necessary to execute the auto-tuning again.

• By setting to “1” or “2” , the auto-tuning operation

starts, and at the end of the tuning, will be displayed

automatically to .

• After the auto-tuning operation, the controller starts to

operate at the automatically set values of , , and .

•A decimal point at the right end of the SV display flashes

during auto-tuning.

•There are two codes for AT:

Setting code [1]: SV standard type

Performs the auto-tuning based on the SV.

Setting code [2]: Low PV type

Performs the auto-tuning based on the

SV-10%FS.

[Note]

Since ON/OFF control is performed during auto-tuning, overshoot against the SV may occur. To reduce

the overshoot, execute the auto-tuning operation with

the setting code [2] (Low PV) selected.

•The auto-tuning can be executed both just after power-on

and in a control or stable status.

Related parameters:

(page 20)

(page 21)

(page 22)

(page 26)

(page 24)

[Setting example] Setting the auto-tuning operation to 1

Display Operating procedure

PV indication

PV indication

SV indication

Press and hold the key for one second.

1.

will be displayed.

Press the key to display .

2.

Press the key once.

3.

The current setting ( ) is displayed.

Press the or keys to flicker the display and to display .

4.

Press the key once. is displayed and the auto-tuning will start. During auto-tuning,

5.

a decimal point at the first digit from the right end of the display flickers.

(Repeat the procedure from 3 to 5 to check the set value.)

When the auto-tuning finishes properly, a decimal point stops flashing, and the set values of , ,

6.

and parameters change. When the auto-tuning finishes abnormally, a decimal point stops flashing, but the set values of , , and parameters remain unchanged.

If you want to display the operation status, press and hold the key for two seconds.

7.

The SV is displayed on the display area.

SEL

SEL

SEL

SEL

16

PV indication

If unoperated state continues, the PV will be displayed.

Page 17

,

Displaying ON-dela y alarm or the remaining time of timers (unit: seconds) (Option)

[Description]

•These parameters display the remaining time of T imers 1

and 2.

• The remaining time of the ON/OFF-delay timer is counted

down. When the counter shows , the alarm relay is

closed.

• During count-down, if the PV changes to the value of the

temperature at which the alarm is set to OFF, or if “DI”

for the timer is set to OFF, the counter is reset, and the

alarm relay is opened.

•

, display parameter

SEL SEL

[Setting example] Displa ying ON-delay alarm or the remaining time of timers

Display Operating procedure

PV indication

SV indication

PV indication

Press and hold the key for one second.

1.

will be displayed.

Press the key to display . By pressing the key,

2.

the remaining time (10 seconds) of the timer 1 will be displayed. Pressing the key again,

it returns to display.

Press the key to display . By pressing the key, the remaining time (8 seconds)

3.

of the timer 2 will be displayed. Pressing the key again, it returns to display.

If you want to display the operation status, press and hold the key for two seconds.

4.

The SV is displayed on the display area.

If unoperated state continues, the PV will be displayed.

SEL

SEL

SEL

SEL

SEL

SEL

17

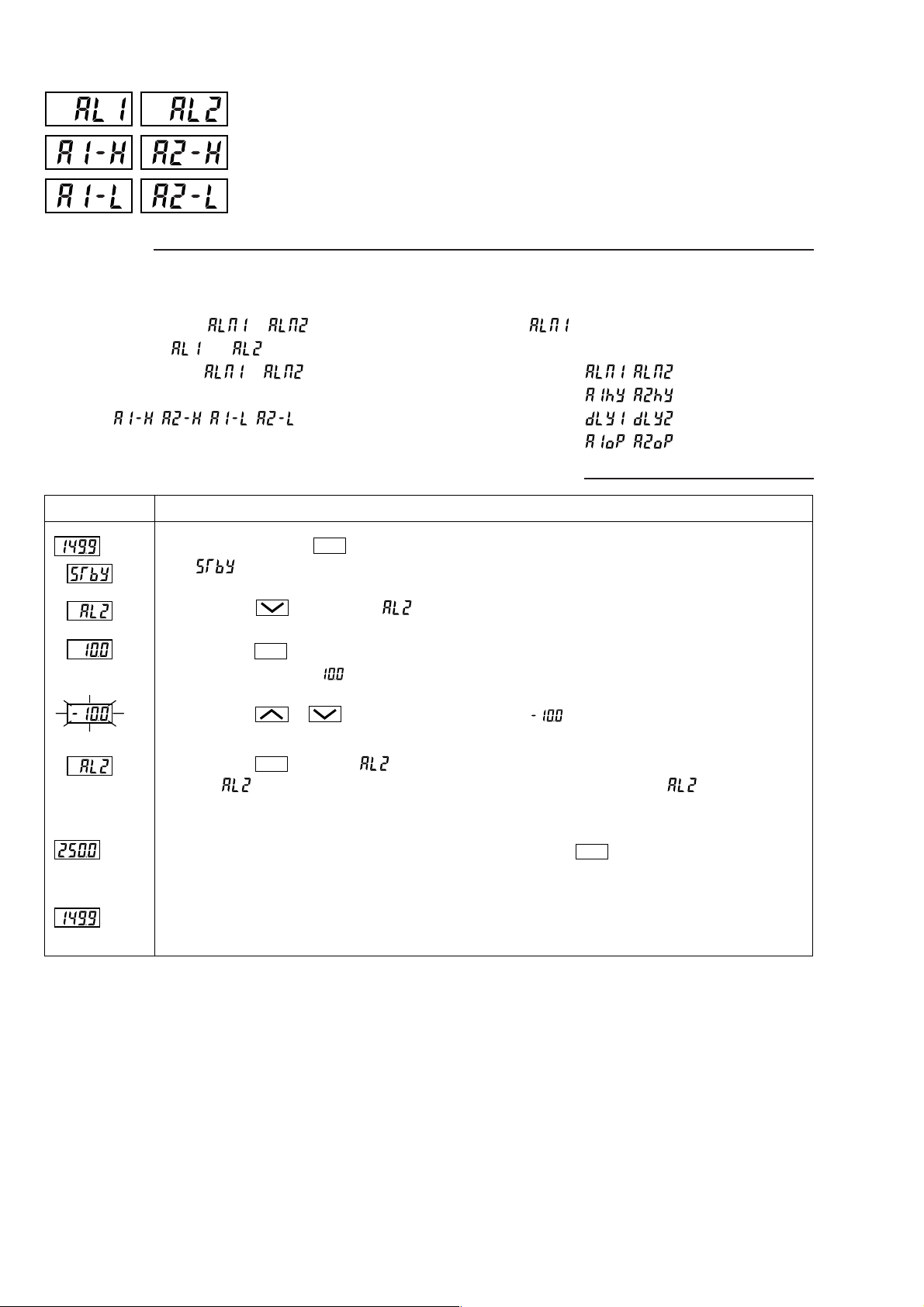

Page 18

[Description]

Setting alarm 1 and 2

Upper limit of alarm 1

and 2

Lower limit of alarm 1

and 2

(Setting range:

Absolute value alarm: 0 to 100%FS

Deviation value alarm: -100 to 100%FS )

}

(Option)

• These parameters are used to for settings of alarm 1

and 2.

• When the alarm type ( or

alarms 1 and 2 ( and ) can be set.

•When the alarm type ( or ) is set to any value

other than 0 to 15, the upper and lower limits of alarm 1

and 2 ( , , , ) can be set.

[Setting example] Setting the operation value of alarm 2 to -10°C

Display Operating procedure

PV indication

Press and hold the key for one second.

1.

will be displayed.

Press the key to display .

2.

Press the key once.

3.

The current setting ( ) will be displayed.

Press the or keys to flicker and to display .

4.

SEL

) is set to 0 to 15,

SEL

[Note]

Setting codes (12 to 15) cannot be selected in alarm

type 1 ( ).

Related parameters: ,

,

,

,

(page 42)

(page 53)

(page 51)

(page 54)

SV indication

PV indication

Press the key once. will be displayed and the operation value -10°C will be registered

5.

for . After that, the controller will operate with the operation value of = -10°C.

(Repeat the procedure from 3 to 5 to check the set value.)

If you want to display the operation status, press and hold the key for two seconds.

6.

The SV will be displayed on the display area.

If unoperated state continues, the PV will be displayed.

SEL

SEL

18

Page 19

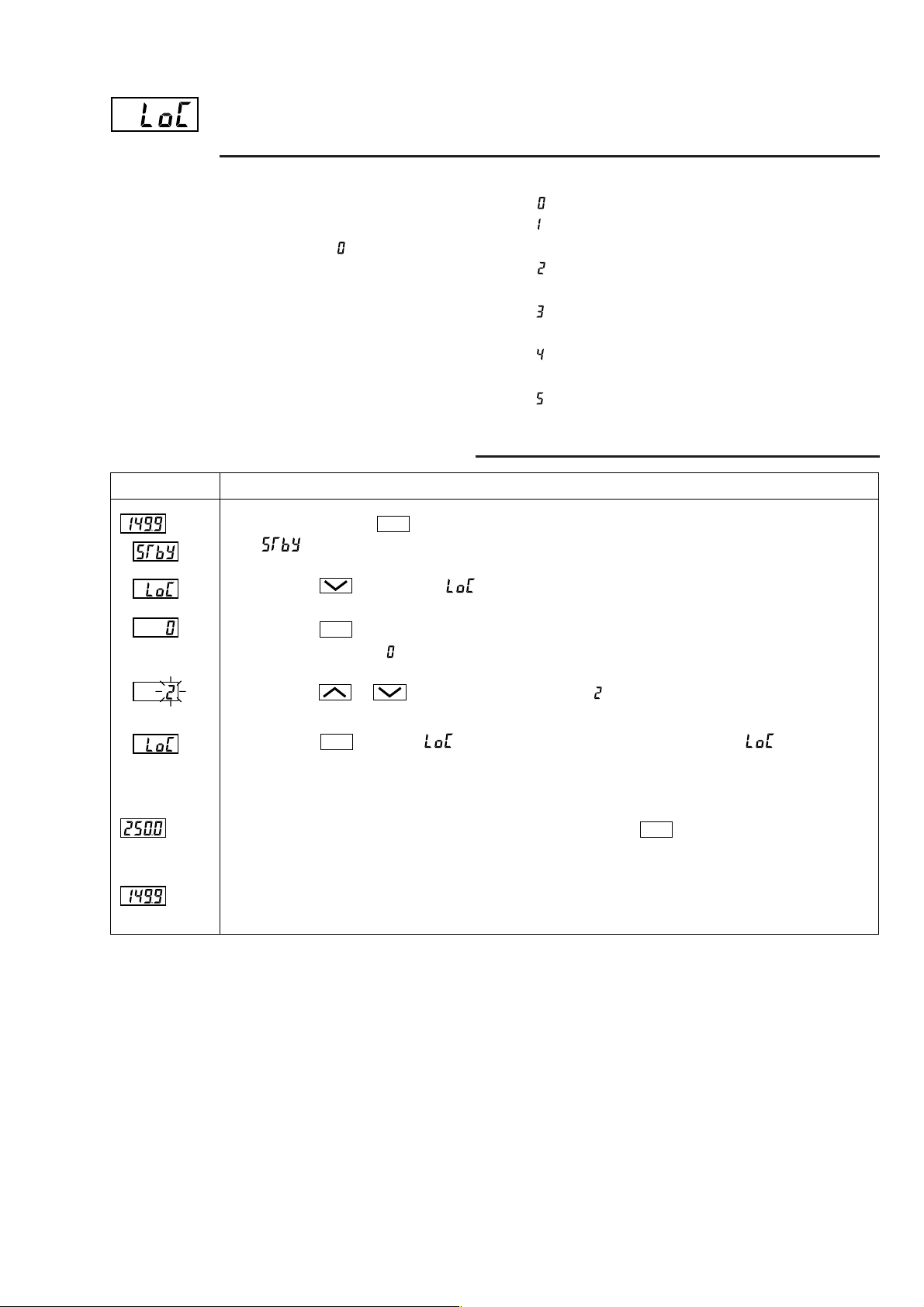

Key lock (Setting range: 0−5)

[Description]

• This parameter makes the set values of parameters

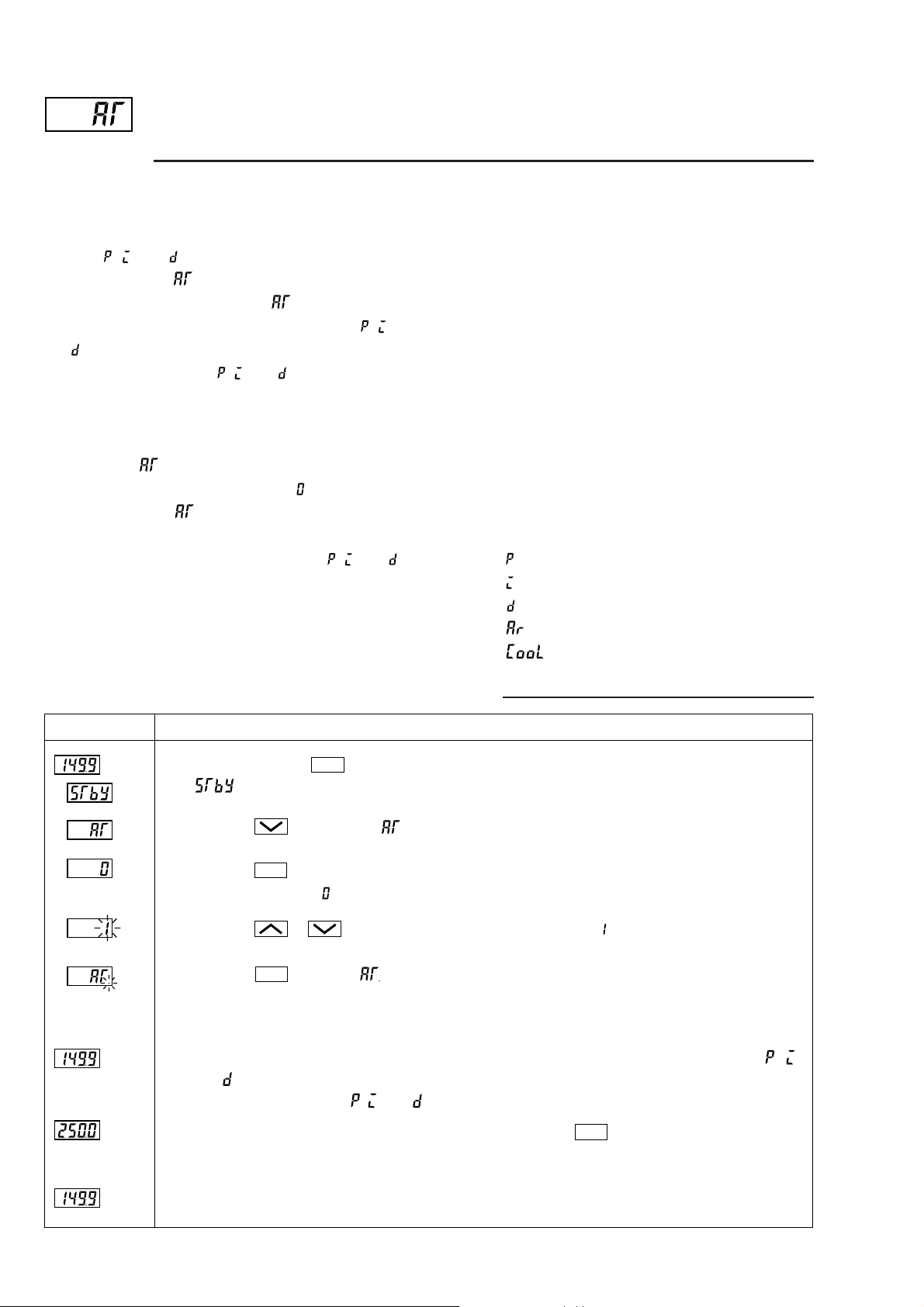

unchangeable. However, the parameter name and the set

values can be displayed.

•To reset the key lock, change to .

• Even when the key lock is set, control and alarm functions

can operate properly.

• There are six levels of the key lock:

[Setting example] Setting the key lock to “2”

Display Operating procedure

: Unlocked (reset)

: All settings are unchangeable from the controller, but

changeable via communication.

: Only the SV is changeable from the controller, and all

settings are changeable via communication.

: All settings are changeable from the controller, but

unchangeable via communication.

:

All settings are unchangeable from the controller or

via communication.

: Only the SV is changeable from the controller, but all

settings are unchangeable via communication.

PV indication

SV indication

PV indication

Press and hold the key for one second.

1.

will be displayed.

Press the key to display .

2.

Press the key once.

3.

The current setting ( ) will be displayed.

Press the or keys to flicker and to display .

4.

Press the key once. will be displayed and "2" will be registered for . After that,

5.

any setting other than the SV cannot be changed from the front panel.

(Repeat the procedure from 3 to 5 to check the set value.)

If you want to display the operation status, press and hold the key for two seconds.

6.

The SV will be displayed on the display area.

If unoperated state continues, the PV will be displayed.

SEL

SEL

SEL

SEL

19

Page 20

w Second block parameters

Proportional band (Setting range: 0.0 to 999.9% of the measured range)

[Description]

•To select the ON/OFF control (two-position control), set

to 0.0. It is not necessary to set and .

• can be automatically set by the auto-tuning operation.

• When is too small, control will be unstable, and when

is too large, the response will be delayed.

[Setting example] Changing the proportional band from 5.0% to 15.0%

Display Operating procedure

• Set the hysteresis of the ON/OFF control (two-position

control) in the parameter

• If auto-tuning is run after the ON/OFF control is selected,

the ON/OFF control changes to the PID control. To keep

the ON/OFF control selected, do not execute the autotuning.

Related parameters: (page 23)

.

(page 32)

PV indication

SV indication

PV indication

Press and hold the key for three seconds.

1.

will be displayed.

Press the key once.

2.

The current setting ( ) will be displayed.

Press the or keys to flicker and to display .

3.

Press the key once. will be displayed and the 15.0% will be registered for . After that,

4.

the controller will operate with being 15.0%.

(Repeat the procedure from 2 to 4 to check the set value.)

If you want to display the operation status, press and hold the key for two seconds.

5.

The SV will be displayed on the display area.

If unoperated state continues, the PV will be displayed.

SEL

SEL

SEL

SEL

20

Page 21

Integral time (Setting range: 0 to 3200 seconds)

[Description]

• can be set automatically by the auto-tuning operation.

• can also be set manually.

•When is set to 0, the integral operation does not start.

•When is set to 0.0, this makes the setting of ineffective.

[Setting example] Changing the integral time from 240 seconds to 600 seconds

Display Operating procedure

PV indication

SV indication

PV indication

Press and hold the key for three seconds.

1.

will be displayed.

Press the key to display .

2.

Press the key once.

3.

The current setting ( ) will be displayed.

Press the or keys to flicker and to display .

4.

Press the key once. will stop flashing and will be registered for . After that, the

5.

controller will operate with being seconds.

(Repeat the procedure from 3 to 5 to check the set value.)

If you want to display the operation status, press and hold the key for two seconds.

6.

The SV will be displayed on the display area.

If unoperated state continues, the PV will be displayed.

SEL

SEL

SEL

SEL

21

Page 22

Derivative time (Setting range: 0.0 to 999.9 seconds)

[Description]

• can be set automatically by the auto-tuning operation.

• can also be set manually.

•When is set to 0, the differential operation does not start.

•When is set to 0.0, this makes the setting of ineffective.

[Setting example] Changing the diff erential time from 60.0 seconds to 50.0 seconds

Display Operating procedure

PV indication

SV indication

PV indication

Press and hold the key for three seconds.

1.

will be displayed.

Press the key to display .

2.

Press the key once.

3.

The current setting ( ) will be displayed.

Press the or keys to flicker and to display .

4.

Press the key once. will be displayed and 50.0 seconds will be registered for . After that,

5.

the controller will operate with being 50.0 seconds.

(Repeat the procedure from 3 to 5 to check the set value.)

If you want to display the operation status, press and hold the key for two seconds.

6.

The SV will be displayed on the display area.

If unoperated state continues, the PV will be displayed.

SEL

SEL

SEL

SEL

22

Page 23

Hysteresis range for ON/OFF control (Setting range: 0 to 50%FS)

[Description]

•To select the ON/OFF control (two-position control), set

to 0.0. It is not necessary to set and .

• When the hysteresis range (Range of ON/OFF control) is

too small, the output may switch the ON/OFF frequently.

(This may affect the life of the device to be controlled,

especially when contact output is selected.)

• The unit of the set value of this parameter is ºC or ºF

(engineering unit). The setting range varies according to

the measured range of input.

[Ex] Input Thermocouple K :At measured range of 0

Resistance bulb :At measured range of 0

Related parameters:

[Setting example] Changing the hysteresis range from 1˚C to 35˚C

Display Operating procedure

to 400 ºC, the setting

range is 0 to 200 ºC.

to 150 ºC, the setting

range is 0 to 75 ºC.

(page 20)

(page 32)

PV indication

SV indication

PV indication

Press and hold the key for three seconds.

1.

will be displayed.

Press the key to display .

2.

Press the key once.

3.

The current setting ( ) will be displayed.

Press the or keys to flicker and to display .

4.

Press the key once. will be displayed and 35˚C will be registered for . After that,

5.

the controller will operate with the being 35˚C.

(Repeat the procedure from 3 to 5 to check the set value.)

If you want to display the operation status, press and hold the key for two seconds.

6.

The SV will be displayed on the display area.

If unoperated state continues, the PV will be displayed.

SEL

SEL

SEL

SEL

23

Page 24

Cooling-side proportional band coefficient (Option: Available for DUAL output only) (Setting range: 0.0 to 100.0)

[Description]

• This parameter is used for setting the cooling-side proportional band. (See the figure below.)

Heating side

Output

Cooling side

Coefficient: 0.5

Coefficient: 1.0

Coefficient: 2.0

• When

is set to 0.0 and

is set to 0.0 in the dual

output type, the cooling output is as shown in the figure

below. The hysteresis is fixed at 0.5%FS.

Heating output (Output 1)

ON 0.5%

Cooling output (Output 2)

0.5% ON

Heating-side

proportional

band

Proportional band (P)

50

Cooling-side

proportional

band

MV

OFF

HYS DB

Related parameters:

SV

(page 20)

(page 23)

OFF

• Before setting the cooling-side proportional band, set the

heating-side proportional band to an optimum value. To

select the two-position control for the cooling side, set

to 0.0.

Cooling-side

proportional band

Ex) When making the proportional band of 10% of the

full scale with the proportional band (P) being 50%:

10% = × Coefficient

Consequently, the coefficient is 0.4.

Proportional band (P)

=

50%

2

2

× Coefficient

[Setting example] Changing the cooling-side proportional band coefficient from 1.0 to 2.5

Display Operating procedure

PV indication

Press and hold the key for three seconds.

1.

will be displayed.

SEL

PV

24

SV indication

PV indication

Press the key to display .

2.

Press the key once.

3.

SEL

The current setting ( ) will be displayed.

Press the or keys to flicker and to display .

4.

Press the key once. will be displayed and 2.5 will be registered for . After that,

5.

SEL

the controller will operate with the being 2.5.

(Repeat the procedure from 3 to 5 to check the set value.)

If you want to display the operation status, press and hold the key for two seconds.

6.

SEL

The SV will be displayed on the display area.

If unoperated state continues, the PV will be displayed.

Page 25

Cooling-side proportional band shift (Dead band/Overlap band)

(Option: Available for DUAL output only) (Setting range: -50.0 to +50.0)

[Description]

• This parameter is used for shifting the cooling-side proportional band from the set value. (See the figure belo w.)

Output

Heating side

MV

Overlap

band

Dead

band

Cooling side

MV

•When is a positive value, it is called the "Dead band",

and when it is a negative value, the "Overlap band".

• Since the unit of is same one used for MV [%], if you

want to set in the unit of deviation [%], must be

converted using the equation below.

DB [%] = Deviation × [%]

Ex) When making a dead band with a deviation of

1.0 [%] from the SV while the proportional

band (P) is 5.0%:

DB [%] = 1.0 × = 20 [%]

100

P

100

5.0

MV=50%

Consequently, set the parameter to 20 [%].

• Related parameter: (page 20)

[Setting example] Shifting the cooling-side proportional band by 2.0

Display Operating procedure

PV indication

Press and hold the key for three seconds.

1.

will be displayed.

Press the key to display .

2.

Press the key once.

3.

The current setting ( ) will be displayed.

Press the or keys to flicker and to display .

4.

Press the key once. will be displayed and 2.0 will be registered for . After that, the

5.

controller will operate with being 2.0 %.

(Repeat the procedure from 3 to 5 to check the set value.)

SEL

SEL

SEL

SV indication

PV indication

If you want to display the operation status, press and hold the key for two seconds.

6.

The SV will be displayed on the display area.

If unoperated state continues, the PV will be displayed.

SEL

25

Page 26

Output offset value (Setting range: -100.0 to 100.0 %)

Anti-reset windup (Setting range: 0 to 100%FS)

[Description]

• The anti-reset windup ( ) is automatically set to an

optimum value by the auto-tuning operation.

By setting , the amount of overshoot can be adjusted.

[Note]

By making use of the fuzzy control system equipped with

PXR, the amount of overshoot can be minimized without

setting and .

SV

PV

AR value

AR value

[Setting example] Changing the anti-reset windup from 60˚C to 80˚C.

Display Operating procedure

In this range, the integral

}

operation is not performed.

In this range, the integral

}

operation is performed.

In this range, the integral

operation is not performed.

}

PV indication

SV indication

PV indication

Press and hold the key for three seconds.

1.

will be displayed.

Press the key to display .

2.

Press the key once.

3.

The current setting ( ) will be displayed.

Press the or keys to flicker and to display .

4.

Press the key once. will be displaed and 80˚C will be registered for . After that, the

5.

controller will operate with the being 80˚C.

(Repeat the procedure from 3 to 5 to check the set value.)

If you want to display the operation status, press and hold the key for two seconds.

6.

The SV will be displayed on the display area.

If unoperated state continues, the PV will be displayed.

SEL

SEL

SEL

SEL

26

Page 27

Control algorithm (Settings: PID/FUZY/SELF)

[Description]

•This parameter is used for selecting PID control, FUZZYPID control, or PID control with self-tuning.

•To select the PID control or FUZZY-PID control, it is

necessary to set the parameters of , , , and

manually or by the auto-tuning in advance.

•For the ON/OFF control (Two-position control), select

the PID control and then set to 0.0. For detailed information, refer to (page 20).

• Refer to the next page for the PID control with self-tuning.

[Setting example] Changing the control system from PID to FUZZY

Display Operating procedure

PV indication

SV indication

PV indication

Press and hold the key for three seconds.

1.

will be displayed.

Press the key to display .

2.

Press the key once.

3.

The current setting ( ) will be displayed.

Press the or keys to flicker and to display .

4.

Press the key once. will be displayed and FUZZY will be registered fo .

5.

After that, the controller will operate with the FUZZY control system activated.

(Repeat the procedure from 3 to 5 to check the set value.)

If you want to display the operation status, press and hold the key for two seconds.

6.

The SV will be displayed on the display area.

If unoperated state continues, the PV will be displayed.

SEL

SEL

SEL

SEL

27

Page 28

[Self-tuning]

1

Function:

With the self-tuning function, PID parameters are automatically re-optimised depending on the actual condition of de vice

to be controlled and the setting temperature (SV).

2

How to execute:

Follow the procedure shown below to set and execute the self-tuning. The self-tuning starts to run at the appropriate

conditions. (See page 27)

q Power on the PXR.

w Set the SV.

e Select in the

parameter of .*

r Power off the PXR.

t Power on the device

to be controlled.

y Power on the PXR.

(Tuning / Control) *

2

1

If the device that is to be

controlled has powered

To re-start the self-tuning:

ON at this point:

Wait until the temperature

of the device that is to be

controlled falls and

Select in the

parameter of .

stabilizes.

The device to be

controlled and the PXR

should be powered ON

at the same time or in

order of the left flowchart.

*1: How to set the parameter of :

SEL

*2: Display during self-tuning is shown below:

28

SEL

This lamp flickers

Page 29

3

Conditions under which the self-tuning runs:

q At power-on:

The self-tuning runs when all of the following conditions are met.

•The SV that appears at power-on is not the same one when the

,

, and set by the self-tuning, auto-tuning, manual setting, and writing by communications tools at

previous time)

•The (SV-PV) at power-on is larger than (the value of × input range) or (the set value of

w When the SV is changed:

The self-tuning runs when all the conditions below are met.

•The changed SV is larger than the SV that was set when the , , , and were selected previously.

•The changed amount of the SV is larger than 0.

•The changed amount of the SV is larger than (the set value of × input range) or (the set value of

e When output becomes unstable:

The self-tuning runs when control becomes unstable and the hunting of the operating output (MV) occurs. (The selftuning runs only once as long as the SV is not changed.)

r When the control standby mode is cancelled:

The self-tuning runs by the same reason as "q At power-on" are met.

* Only when the PXR is set to standby mode at power-on.

4

Conditions under which the self-tuning does not run:

, ,

, and were set previously. (i.e. ,

).

).

q During control standby mode

w During two-position control (Parameter of = 0)

e During auto-tuning operation

r During ramp-soak operation

t Error display ( or is displayed.)

y During dual output (The set value of the parameter of is larger than 4.)

u When setting the parameters of

tools)

5

Conditions under which the self-tuning is suspended:

q At the condition described in

w When the SV is changed during self-tuning operation

e When the self-tuning operation can not be completed within approx. 9 hours

6

Caution

q Once the PID constant is set, the self-tuning does not operate at next power-on as long as the SV is not

changed.

w For an accurate tuning, be sure to power on the device to be controlled before or at the same time as the

PXR is powered on. If the PXR has to be powered on first for reasons of the system configuration, perform

the auto-tuning with the PID or FUZZY control.

e If the device to be controlled is powered on under temperature change (especially when it rises), accurate

tunings can not be performed. Be sure to power on the PYX when the temperature of device to be controlled

is stabilized.

r The self-tuning does not run for cooling system control under Direct Action output (P ar ameter = 2 or 3).

t In case the control is not stable after performing the self-tuning, change the algorithm to the PID or FUZZY

control and perform the auto-tuning.

, ,

4

shown above

, and manually (including the setting written by communications

29

Page 30

7

Reference [About the self-tuning method]

The PID constant is calculated in one of the following two methods.

The method is selected automatically depending on the characteristics of the device to be controlled.

• Step response method

• Limit cycle method

The following figures show the operations at power-on and changing the SV, and under unstable control.

q Operations at power-on

Step response method Limit cycle method

PV

SV

During tuning

w Operations at changing the SV

Step response method Limit cycle method

PV

Changing the SV

SV

During tuning

e Operation under unstable control

Limit cycle method

Time

Time

PV

SV

PV

SV

During tuning

Changing the SV

During tuning

Time

Time

30

SV

100%

Unstable control

PV

MV

During tuning

Time

Page 31

PV (Measured value) stable range (Setting range: 0 to 100%FS)

[Description]

• Self-tuning logic recognizes that control is stable if PV is

staying within the SV ± .

• It is not necessary to set this parameter under normal conditions.

[Setting example] Changing the PV stable range from 2 to 3

Display Operating procedure

PV indication

SV indication

PV indication

Press and hold the key for three seconds.

1.

will be displayed.

Press the key to display .

2.

Press the key once.

3.

The current setting ( ) will be displayed.

Press the or keys to flicker and to display .

4.

Press the key once. will be displayed and 3 will be registered for . After that,

5.

the controller will operate with the PV stable range being 3.

(Repeat the procedure from 3 to 5 to check the set value.)

If you want to display the operation status, press and hold the key for two seconds.

6.

The SV will be displayed on the display area.

If unoperated state continues, the PV will be displayed.

SEL

SEL

SEL

SEL

31

Page 32

HYS (Hysteresis) mode at ON/OFF control (Settings: oFF/on)

[Description]

• This parameter is used for selecting the hysteresis operation mode at ON/OFF control.

:

Starts the ON/OFF control at the values of

HYS

SV+ and SV- .

2

:

Starts the ON/OFF control at the values of

SV and SV+HYS, or SV and SV-HYS.

• Related parameters: (page 20)

HYS

2

Reverse actionDirect action

(page 23)

(page 49)

[Setting example] Setting the hysteresis mode to ON

Display Operating procedure

onoF : OFF onoF : ON

HYS

SV SV

HYS

SV

HYS

HYS

SV

PV indication

SV indication

PV indication

Press and hold the key for three seconds.

1.

will be displayed.

Press the key to display .

2.

Press the key once.

3.

The current setting ( ) will be displayed.

Press the key to flicker and to display .

4.

Press the key once. will be displayed and the hysteresis action ON will be registered

5.

for . After that, the controller will operate with the hysteresis being as shown in the figure

of ON above.

(Repeat the procedure from 3 to 5 to check the set value.)

If you want to display the operation status, press and hold the key for two seconds.

6.

The SV will be displayed on the display area.

If unoperated state continues, the PV will be displayed.

SEL

SEL

SEL

SEL

32

Page 33

Cycle time of control output 1 (Setting range: 1 to 150 seconds)

[Description]

• This parameter is applicable for to the contact output and

SSR-driving output.

• While input is within the proportional band, output

changes between ON and OFF in cycles. These cycles

are called cycle time.

Output: ON

Cycle

time

Cycle

time

• Do not set this parameter to "0".

For contact output:

The higher the frequency of output is, the more precise

the control becomes. However a high frequency of output may shorten the life of the contacts and the device to

be controlled. Be sure to adjust the proportional cycles

considering controllability and the life of the device and

the contacts.

Typical: 30 seconds

For SSR-driving output:

Use in short cycles if there is no problem with the device

to be controlled.

Typical: 1 to 2 seconds

[Setting example] Setting the cycle time from 30 seconds to 20 seconds

Display Operating procedure

PV indication

SV indication

PV indication

Press and hold the key for three seconds.

1.

will be displayed.

Press the key to display .

2.

Press the key once.

3.

The current setting ( ) will be displayed.

Press the or key to flicker and to display .

4.

Press the key once. will be displayed and 20 seconds will be registered for .

5.

After that, the controller will operate with the cycle time being 20 seconds.

(Repeat the procedure from 3 to 5 to check the set value.)

If you want to display the operation status, press and hold the key for two seconds.

6.

The SV will be displayed on the display area.

If unoperated state continues, the PV will be displayed.

SEL

SEL

SEL

SEL

33

Page 34

Cycle time of control output 2 (Cooling-side)

(Setting range: 1 to 150 seconds) (Option: Available for DUAL output only)

[Description]

•By this parameter is set, the cycle time of control output 2.

• While input is within the proportional band, output

changes between ON and OFF in cycles. These cycles

are called cycle time.

Output: ON

Cycle

time

Cycle

time

• Do not set this parameter to "0".

For contact output:

The higher the frequency of output is, the more precise

the control becomes. However a high frequency of output may shorten the life of the contacts and the device to

be controlled. Be sure to adjust the proportional cycles

considering controllability and the life of the device and

the contacts.

Typical: 30 seconds

For SSR-drive output:

Set it to short time if it does not cause any problem on the

operation end.

Typical: 1 to 2 seconds

[Setting example] Setting the cooling-side cycle time from 30 seconds to 20 seconds

Display Operating procedure

PV indication

SV indication

PV indication

Press and hold the key for three seconds.

1.

will be displayed.

Press the key to display .

2.

Press the key once.

3.

The current setting ( ) will be displayed.

Press the or key to flicker and to display .

4.

Press the key once. will be displayed and 20 seconds will be registered for .

5.

After that, the controller will operate with the cooling-side cycle time being 20 seconds.

(Repeat the procedure from 3 to 5 to check the set value.)

If you want to display the operation status, press and hold the key for two seconds.

6.

The SV will be displayed on the display area.

If unoperated state continues, the PV will be displayed.

SEL

SEL

SEL

SEL

34

Page 35

Code

1

2

3

4

5

6

7

8

12

13

16

Input signal

Resistance bulb (RTD)

• Pt 100

Thermocouple

• J

• K

• R

• B

• S

• T

• E

• N

• PL-II

1 to 5 V, 4 to 20mA DC

Type

I

II

Input signal code (Setting range: 0 to 16)

[Description]

• This parameter is used for selecting input signals. Input

signal varies depending on the sensors (2 types below).

Set a code that corresponds to the sensor you use.

Type I : Thermocouples (9 kinds of signals)

Resistance bulbs (1 kind of signal)

Type II : Voltage, current

• Input signals can be selected within the same type. It is

impossible to select input signals of a different type.

• For type II, when changing from the voltage input to the

current input, connect the supplied resistance of 250 Ω

between terminals w and e .

When changing from the current input to the voltage input, remove the resistance of 250 Ω connected to the input terminals.

[Note]

After changing the codes, power off the PXR, and then

power it on again.

• Input signals and codes

q Input signals code table

[Setting example] Changing from thermocouple K to thermocouple T in Type I

Display Operating procedure

SEL

SEL

PV indication

SV indication

PV indication

Press and hold the key for three seconds.

1.

will be displayed.

Press the key to display .

2.

Press the key once.

3.

SEL

The current setting ( ) will be displayed.

Press the or key to flicker and to display .

4.

Press the key once. will be displayed and the thermocouple T will be registered for

5.

. After that, the controller will operate with the kind of input signals being thermocouple T.

SEL

(Repeat the procedure from 3 to 5 to check the set value.)

If you want to display the operation status, press and hold the key for two seconds.

6.

The SV will be displayed on the display area.

If unoperated state continues, the PV will be displayed.

35

Page 36

Setting lower limit of the measuring range (Setting range: -1999 to 9999)

Setting upper limit of the measuring range (Setting range: -1999 to 9999)

Selection ˚C / ˚F (Setting: ˚C or ˚F )

[Description]

•These parameters are used for setting the lower and upper limits of the measured range.

•A decimal point position can be set in the parameter of

.

•For the current and voltage inputs, = , , and for

other inputs, = are valid.

• See the right table for input range.

w Input range table (Standard range)

Input type

Resistance

bulb JIS

(IEC)

Thermocouple

Direct-curren

voltage

t

Pt100Ω

J

J

K

K

K

R

B

S

T

T

E

E

N

PL-II

1 to 5 V DC

Range

(°C)

0

0

0

0

-50

-100

-150

-150

0

0

0

0

0

0

0

0

-150

-150

0

-150

0

0

With / without

a decimal point

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

(°C)

150

O

300

O

500

O

600

O

100

O

200

O

600

O

850

X

400

O

800

O

400

O

800

1200

1600

1800

1600

1300

1300

O

X

X

X

X

200

O

400

O

800

O

800

O

X

X

-1999 to 9999

(Scaling is possible)

* For 4 to 20 mA DC input, connect a resistance of 250Ω between

terminals ② and ③ to change the input to the 1 to 5 V DC input.

[Note]

The input accuracy is ±0.5%FS±1 digit except the cases shown

below.

Thermocouple R at 0 to 400 °C: ±1%FS ± 1 digit ±1˚C

Thermocouple B at 0 to 500 °C: ±5%FS ± 1 digit ±1˚C

Other kinds of thermocouples : ±0.5% FS ± 1 digit ±1˚C

Range

(°F)

*

32

32

32

32

-58

-148