Page 1

DIGITAL CONTROLLER PXH

DATA SHEET

PXH9 is a 96 × 96 mm, high-performance digital controller

that assures high-speed and high-accuracy control.

With its abundant and flexible input/output points and powerful math function, it can be used for a wide range of applications, including not only temperature control but also process control of pressure, flow rate, etc.

FEATURES

1. High-speed and high-accuracy control

• High-speed control in sampling cycle of 50 ms

• Highly accurate input indication of ±0.1% FS

•Measurement resolution of 0.01°C (Resistance

bulb input)

2. Multitude of input/output points (including options)

• Universal measurement input: 2 points

(Thermocouple/Resistance bulb/Voltage/Current)

• Auxiliary analog input: 1 point

(DC voltage/Potentiometer)

• Analog output: 2 points

• Digital input: 9 points

•Digital output: 9 points

• Transmitter power supply

3. Substantial communication function

• PC Loader interface (RS232C) equipped as standard

• RS485 (Modbus RTU) communication function

(Option)

4. Strong math function

• Applicable to various applications such as correction processing and input switching based on

mathematical calculations between multiple inputs. Refer to the list of expressions on page 17

for the type of mathematical expressions.

5. Complex setting achieved by easy operation

• Equipped with control template function that allows input/output according to control type and

automatic allocation of calculation blocks.

6. Totalizer function

• Input is selectable from any of measurements or

a result of math operation.

• Seven-digit total display

• Batch control outputs

7. Excellent user-friendliness

• Multi-function, large LED display with the high

level of visibility

• Provision of three function keys whose function

allocation can be changed

•IP66 waterproof front face (NEMA-4X)

• Compact size with the depth of only 81.5 mm

SPECIFICATIONS

1. General specifications

(1) Power supply voltage:

-

100 V (

50/60 Hz

(2) Power consumption:

15 VA or less (100 V AC)

20 VA or less (220 V AC)

(3) Insulation resistance:

20 MΩ or more (500 V DC)

(4) Withstand voltage:

Power supply ↔ All terminals;

Relay output ↔ All terminals;

Others; 500 V AC for 1 minute

(5) Applicable standard:

UL, C-UL, CE Mark

15%) to 240 V (+10%) AC,

1500 V AC for 1 minute

1500 V AC for 1 minute

PXH9

EDS11-157a

Date

Jan. 10, 2006

Page 2

PXH9

2. Input section

2-1 Measurement value input

(1) Number of inputs: 1 or 2 (Option)

(2) Input signal type:

Thermocouple :J, K, R, B, S, T, E, PR40/20, N, PL-II,

WRe5-26

Resistance bulb :Pt100Ω (3-wire)

Voltage :0 to 10 mV DC, 0 to 50 mV DC,

1 to 5 V DC, 0 to 5 V DC, 0 to 10 V DC

Current :4 to 20 mA DC, 0 to 20 mA DC

(3) Measurement range:

Refer to the measurement range table

(page 16).

(4)

Input indication accuracy (Ambient temperature: 23°C):

• Thermocouple:(±0.1%FS±1digit±1°C) or ±1.5°C,

whichever is larger

Thermocouple B: 0°C to 400°C range;

±5%FS±1digit±1°C

Thermocouple R: 0°C to 500°C range;

±1%FS±1digit±1°C

• Resistance bulb input:

(±0.1%FS±1digit) or ±0.25°C, whichever

is larger

• Voltage input, current input:

±0.1%FS±1digit

(5) Input sampling cycle: 50 ms

(6) Input impedance

• Thermocouple, voltage input (mV): 1 MΩ or more

• Voltage input (V): 1MΩ

•Current input: 250 Ω

(7) Influence of source resistance / Permissible wiring

resistance

• Thermocouple, voltage input (mV):0.1%FS per 100 Ω

• Voltage input (V): 0.1%FS per 500 Ω

• Resistance bulb input: 10 Ω or less (per cable)

(8) Permissible input voltage

• Voltage (V) input: +35 V /

•Current input: ±25 mA DC

•

Thermocouple/Resistance bulb/Voltage (mV) input:

(9) Noise reduction ratio

•Normal mode: 40 dB (50/60 Hz)

• Common mode: 120 dB (50/60 Hz)

(10) Input value correction function (Input conditioner)

• User adjustment:

±50%FS both for zero point and span

point

• Square-root extractor:

OFF or cut point from 0.0 to 125.0%

• First-order lag filter: 0.0 to 900.0 sec

• Linearizer: 16 straight lines

2-2 Auxiliary analog input (Option)

(1) Number of inputs: 1

(2) Input signal

1) DC voltage: 1 to 5 V DC / 0 to 5 V DC / 0 to 10 V DC

• Input accuracy: ±0.2%FS

• Sampling cycle: 100 ms

• Input impedance: 1 MΩ

• Influence of source resistance: 0.2%FS per 500 Ω

• Permissible input voltage: +35 V /

•Noise reduction ratio

• Normal mode: 40 dB (50/60 Hz) or more

• Common mode: 120 dB (50/60 Hz) or more

-

10 V DC

-

10 V DC

±5 V DC

2) Valve opening feedback signal (Potentiometer)

• Resistance range: 100 Ω ro 10 kΩ 3-wire

• Resolution: ±0.1%FS

• Input accuracy: ±1.0%FS

(3) Input value correction function

• User adjustment:

±50%FS both for zero point and span

point

• Square-root extractor:

OFF or cut point from 0.0 to 125.0%

• First-order lag filter: 0.0 to 900.0 sec

• Linearizer: 16 straight lines

2-3 Digital input (DI)

(1) Number of points:

Standard: 4 (Di1 to 4)

Expansion: 5 (9 points in total at max.)

(2)

Specifications:

(3) Contact capacity:

(4) Operation pulse width: 200 ms or more

(5) Function: Control mode changeover, EX-MV selec-

2-4 Math function

(1) Kind of formula:

(2)

Operation parameter:

(3) Data type: Engineering unit (with floating point)

3. Output section

3-1 Control output

3-1-1 Control output 1

(1) Number of points: 1

(2) Type: Select one from 1 to 4, as shown below.

1. Relay contact output

• Contact structure: SPDT contact (Do4 used)

• Contact capacity:

• Contact life: 100,000 operations (rated load)

2. SSR/SSC driver output (Voltage pulse)

• Rating: 12 V DC (10 to 15 V DC) / Maximum

• Load resistance:

3. Current output (4 to 20 mA DC)

• Accuracy: ±0.2%FS

• Linearity: ±0.2%FS

• Load resistance:

Contact or transistor input

12 V DC, Approx. 2 mA (per point)

tion, SV changeover, Control standby,

Auto-tuning start, Timer start, Alarm latch

cancel.

24 kinds, selected by the parameter setting. (see page 17.)

Analog input (PV1, PV2, Ai1),

Constant (K1 to K16)

220 V AC / 30 V DC, 3 A (Resistive load)

220 V AC / 30 V DC, 1 A (Inductive load)

current: 20 mA (provided with protection

against short circuit)

600 Ω or more

600 Ω or less

2

Page 3

4. Motorized valve operation pulse output (OPEN,

CLOSE output)

• Contact structure:

SPST contact x 2

(with interlock circuit)

• Contact capacity:

220 V AC / 30 V DC, 1 A

(Resistive load)

220 V AC / 30 V DC, 0.3 A

(Inductive load)

•

Contact life:100,000 times or more (rated load)

3-1-2 Control output 2 (Cooling output)

(1) Number of points: 1

(2) Type: Select one from 1 to 3, as shown below.

1. Relay contact output

• Contact structure: SPST contact (Do3 used)

• Contact capacity:

220 V AC / 30 V DC, 1 A (Resistive load)

220 V AC / 30 V DC, 0.3 A (Inductive load)

• Contact life: 100,000 operations (rated load)

2. SSR/SSC driver output (Voltage pulse)

• Rating: 12 V DC (10 to 15 V DC) / Maximum

current: 20 mA (provided with protection

against short circuit)

• Load resistance:

3. Current output (4 to 20 mA DC)

• Accuracy: ±0.2%FS

• Linearity: ±0.2%FS

• Load resistance:

3-2 Digital output (Do)

(1) Number of points:

(2) Specifications:

• Contact structure:

• Contact capacity:

• Contact life: 100,000 operations (rated load)

(3) Function: Alarm output, timer output, control out-

(4) Restriction: 4 Do points max. for 2-point measure-

(5) Others: Do4 or Do3 becomes control output

600 Ω or more

600 Ω or less

Standard: 2 (Do3, 4)

Expansion: Maximum 7 (9 points in total

at max.)

SPST contact (except for Do4)

SPDT contact (Do4)

220 V AC / 30 V DC, 1A (Resistive load)

put (Do4, Do3)

ment input model.

when relay is selected as control output.

Do4 becomes control output for motorized valve control type.

(4) Restriction: The sum of control output (current or

SSR/SSC drive), analog re-transmission

output and transmitter power supply

output is 2 points at maximum.

3-4 Transmitter power supply output

(1) Number of points: 1 at max.

(2) Rating: 24 V DC (17 to 30 V DC), Maximum cur-

rent; 23 mA (with short circuit protection)

(3) Restriction: The sum of control output (current or

SSR/SSC drive), analog re-transmission

output and transmitter power supply

output is 2 points at maximum.

4. Control function

4-1 Controller type

(1) Control system

• Advanced PID control with Auto-tuning

(2) Controller template

Operation block and I/O definition can be selected by parameter setting from available types according to targets of control.

• Basic type

1-loop basic PID controller (with math function)

1-loop SV selectable PID controller (with math function)

1-loop basic PID controller (without math function)

1-loop SV selectable PID controller (without math function)

1-loop input selectable PID controller (with math function)

• Motorized valve control type

[With or without valve openings feedback input is select-

able]

1-loop motorized valve controller (with math function)

1-loop SV selectable motorized valve controller (with math

function)

1-loop motorized valve controller (without math function)

1-loop SV selectable motorized valve controller (without math

function)

• Heating/cooling control type

1-loop heating/cooling controller (with math function)

1-loop SV selectable heating/cooling controller (with math

function)

1-loop heating/cooling controller (without math function)

1-loop SV selectable heating/cooling controller (without math

function)

Note:

The control template can only be changed within each of

basic type, motorized valve control type, and heating/cooling control type controllers.

3-3 Analog re-transmission output

(1) Number of points: 2 at max.

(2) Type: Current output (4 to 20 mA DC)

• Accuracy: ±0.2%FS

• Linearity: ±0.2%FS

• Load resistance

(3) Output contents:

:

600 Ω or less

PV, SV, MV, DV, AIM (Math operation

result), MVRB (Valve openings), TV

(Totarizer result)

3

Page 4

PXH9

4-2 Control parameter

4-2-1 Basic type, motorized valve control type

• Proportional band (P):

0.0 to 999.9%, ON/OFF (2-position)

operation at P = 0

• Integral time (I):

0.0 to 3200.0 sec, Integral operation OFF

at I = 0

•Derivative time (D):

0.0 to 999.9 sec, Derivative operation

OFF at D = 0

• Anti-reset windup: 0 to 100% of measurement range

• Proportion cycle:

1 to 150 sec, For SSR/SSC drive or relay

output only

• Hysteresis width:

50% of measurement range, for ON/OFF

operation only

• Control cycle: 50 ms

• Number of SV and PID groups: 7 sets

• Method of changing PID groups:

Selected by parameter, SV reference,

PV reference

4-2-2 Heating/cooling control type

• Proportional band on heating side (P): 0.0 to 999.9%

• Integral time on heating side (I):

0.0 to 3200.0 sec, Integral operation OFF

at I = 0

• Derivative time on heating side (D):

0.0 to 999.9 sec, Derivative operation

OFF at D = 0

• Proportional band on cooling side (Pc): 0.0 to 999.9%

• Integral time on cooling side (Ic):

0.0 to 3200.0 sec, Integral operation OFF

at Ic = 0

• Derivative time on cooling side (Dc):

0.0 to 999.9 sec, Derivative operation

OFF at Dc = 0

• Anti-reset windup: 0 to 100% of measurement range

• Proportion cycle:

1 to 150 sec, For SSR/SSC drive or relay

output only

• Hysteresis width:

50% of measurement range, for ON/OFF

operation only

• Control cycle: 50 ms

• Number of SV and PID groups: 7 sets

• Method of changing PID groups:

Selected by parameter, SV reference,

PV reference

4-3 Control mode

Type of mode:

(1)

(2) Changeover: Available via key, Digital input and Com-

Auto/Manual/Remote

munication.

Auto ↔ Manual: With balanceless,

bumpless transfer

Auto/Manual → Remote: With balance,

bumpless transfer

Auto/Manual ← Remote:

With balanceless,

bumpless transfer

5. Alarm function

5-1 Number of alarm points

• 8 points for setting

5-2 Type of alarm

• PV value (upper/lower limit, absolute/deviation, band), PV

variation ratio, SV upper/lower limit, main unit error

<Optional operation>

• Hold (standby) function

• Operation latching

• Excitation/non-excitation

• Operation delay: 0 to 9999 sec, 0 to 9999 min

5-3 Alarm output

• Output to DO1 to DO4 and DO11 to DO15 (Allocation

change available.)

6. Communication function

6-1 PC Loader interface

(1) Number of points: 1

(2) Physical specifications: EIA RS232C

(3) Protocol: Modbus-RTU

(4) Communication method:

3-wire, half-duplex bit serial asynchronous system

(5) Data type, Data length:

8 bits, Parity; Odd/Even/None

(6) Communication speed:

9600 bps, 19200 bps, 38400 bps

(7) Connector: Connected with miniature jack on bottom

face of the main unit (2.5 mm dia., 3-pole)

* Special cable is prepared as option.

6-2 RS-485 interface (option)

(1) Number of points: 1

(2) Physical specifications: EIA RS485

(3) Protocol: Modbus-RTU

(4) Communication method:

2-wire, half-duplex bit serial asynchronous system

(5) Data type, Data length:

8 bits, Parity; Odd/Even/None

(6) Communication speed:

9600 bps, 19200 bps, 38400 bps

(7) Connection topology:

Multi-drop, Up to 32 units can be connected including master device.

(8) Communication distance:

500 m max. (Total length of connection)

4

Page 5

7. Other functions

7-1 Parameter recipe

(1) Number of recipe groups: 7 sets

(2) Number of parameters which can be registered:

10 parameters

(3) Method of changing recipe groups:

Synchronized with the change of PID

groups

7-2 Totalizer

-

(1) Totalized value:

(2) Totalize source: PV1, PV2, Ai1, AiM [MATH result]

(3) Totalize resolution: XXX.XXXX to XXXXXXX

(4) Status: RUN/HOLD/RESET

(5) Totalized value output: via Re-transmission

(6) Alarm/Batch output: 2 points, via Do1 to Do4

(7) Totalized data backup:

8. Operation/display section

8-1 Parameter setting

• Digital setting by UP/DOWN key

• Key-lock function provided

• User function key (3 keys) provided

8-2 Display

(1) Type: LED

(2) Display contents

Measurement value display:

Setting display

Auxiliary display:

Bar graph: 12 segments (orange)

Status display indicator lamp:

9. Processing at power failure

• Memory protection: Non-volatile memory

10. Self diagnosis

• System: Program error monitoring performed by

11. Operation and storage conditions

(1) Ambient operating temperature:

(2) Storage temperature:

(3) Ambient humidity for use/storage:

(4) Warm-up time: 15 min or longer

1999999 to 9999999 (7 digits)

30 seconds interval to EEPROM

7 segments, 5 digits (red), character

height; 20 mm

: 7 segments, 5 digits (orange), character

height; 13 mm

7 segments, 2 digits (orange), character

height; 12 mm

Standby, control mode, output, alarm

watchdog timer

-

10°C to 50°C

-

20°C to 60°C

90% RH or less (non-condensing)

12. Structure

(1) Mounting method: Panel flush mounting

(2) External terminal: M3 screw terminal

(3) Case

• Material: Plastic

(Flame-resistant, UL94V-0)

• Color: Gray

(4) Protection

• Faceplate: IEC IP66, NEMA-4X-equivalent

(When mounted on panel with our genuine packing. Waterproof feature unavailable in side-by-side mounting.)

• Body: IEC IP20 (Provided with slits on top and

bottom faces)

• Terminal section:

IEC IP00. Terminal cover can be mounted

(option).

(5) External dimension:

96 (W) x 96 (H) x 81.5 (D) mm

* “D” is the depth from the front face of

the panel (not including terminal cover).

(6) Mass: Approx. 500 g

13. Range of delivery

• Controller …… 1 piece

• Instruction manual …… 1 piece

• CD-ROM …… 1 piece

Contents: User’s manual

Communication function manual

PC loader software

PC loader software manual

• Mounting bracket …… 2 pieces

• Waterproof packing …… 1 piece

• Terminating resistor …… 1 piece (only for the model

with communication function)

14. PC Loader Software

(1) System requirements

• PC: DoS/V PC (PC-AT compatible PC)

• Operation System:

Confirmed on

Windows 2000 (English)

Windows XP (English)

• RAM: 128MB or more

• HDD capacity (Empty area): 100 MB or more

• CD-ROM drive: Required

• Display resolution: 1024 x 768 dots or more

(2) Connection to the PXH controller

• Via PC Loader interface on bottom face of the main

unit (Optional dedicated cable is required.)

or

Via RS485 communication (RS485 function is necessary for PXH.)

5

Page 6

PXH9

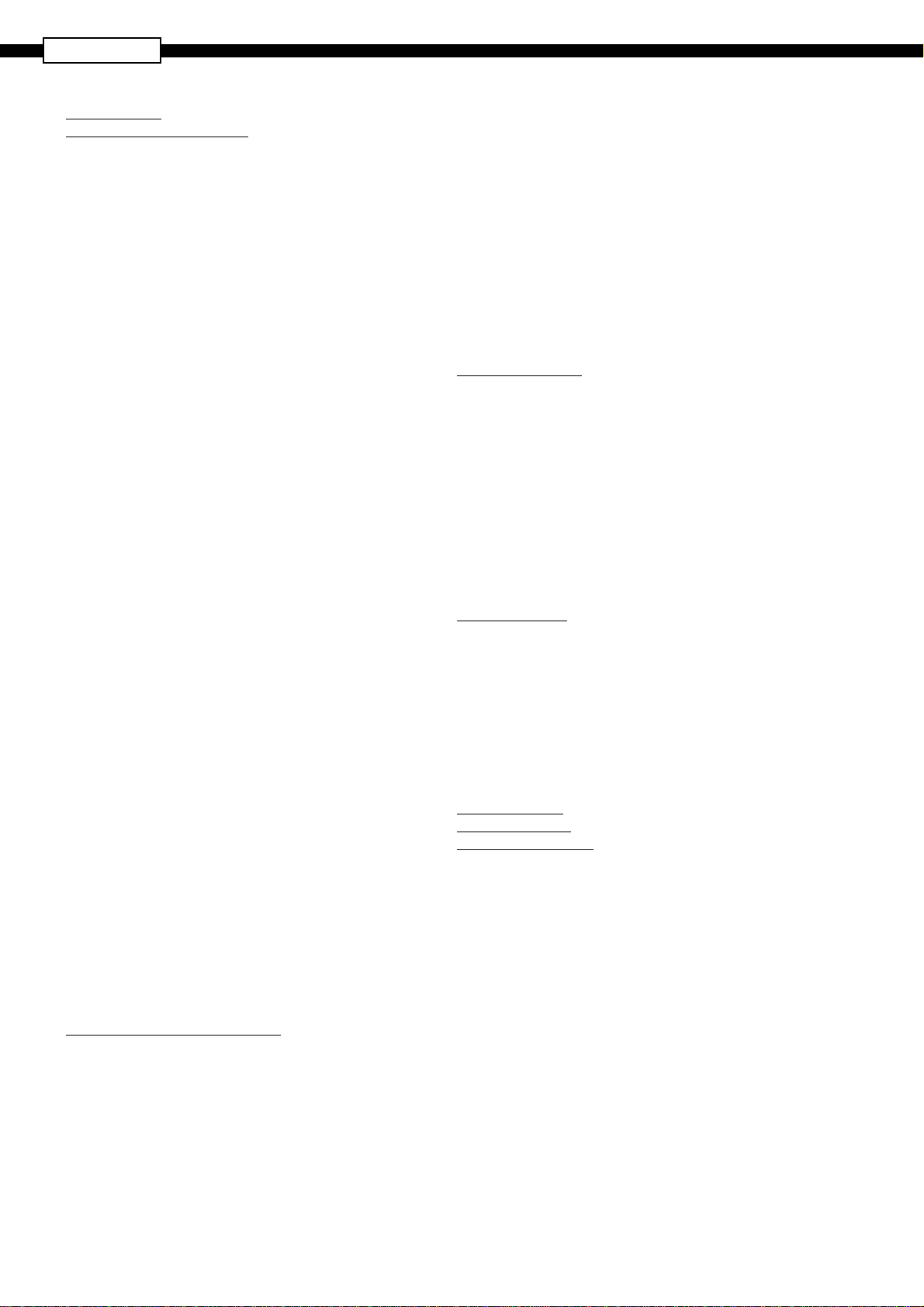

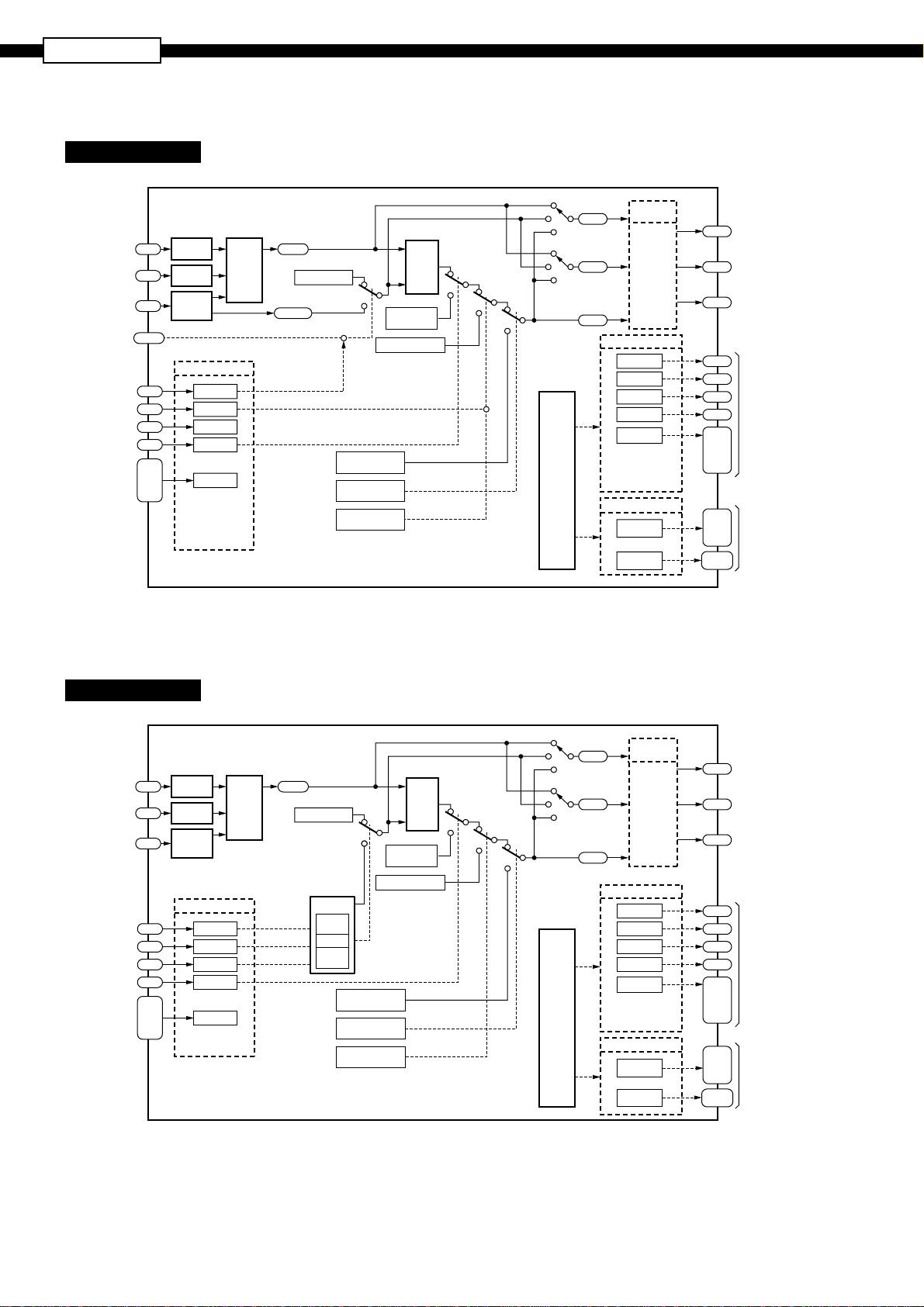

BLOCK DIAGRAMS

Template No. 10

Measurement

value

PV1

input 1

Measurement

value

input 2

Aux. input

/Remote

SV input

Remote

command

Remote

acknowledge

Manual

command

EX-MV

output

command

Conditioner

PV2

Conditioner

Ai1

Conditioner

[REM]

(Parameter setting or key operation)

Di1

Di2

Di3

Di4

Di11

to

Di15

(

CONTROLLER TEMPLATES

1-loop basic PID controller (with math function)

Result of

Math

module

calculation

[AiM]

Local SV

Remote SV

[RSV1]

Remote command

Remote

acknowledge

Input

Input

Input

Di allocation

R-ACK

SMV

No

allocation

EX-MV

command

No

allocation

* Di allocation can be

changed with para meters.

* Since the R-ACK

value is INH at the

time of delivery, set

it to ENA before use.

)

PV

PID

L

R

EX-MV output command

Preset output

value

[STBY] or

Di allocation

Manual

command

operation

SV

EX-MV setting

[EXM1]

Manual MV setting

A/M chargeover

[PMV1]

Stand-by

command

A/M chargeover

[Ao1T]

[Ao2T]

Re-trans-

mission

output 1

RET1

Re-trans-

mission

output 2

RET2

Control

output 1

MV1

* Do allocation can be

* Higher priority is

Output type

setting

Depend on

[OTYP]

setting

DO allocation

ALM1

ALM2

ALM3

ALM4

No

allocation

changed with

parameters.

assigned to designation

of [OTYP] for the

output to Do4.

LED display allocation

ALM

1 to 5

OR of all

the ALMs

AO 1

AO 2

DO 4

OUT1

OUT2

DO4

Do1

Do2

Do3

Do4

Do11

to

Do15

L Do1

to

L Do5

L ALM

Current

output or

SSR driver

output

Current

output or

Transmitter

supply

Relay

output

(Control

output)

Relay

output

(Do)

Indicator

lamp

PV

SV

MV

PV

SV

A

RUN

M

STBY

MV

Alarm

Template No. 11

Measurement

value

input 1

Measurement

value

input 2

Aux. input

SV select

signal 1

SV select

signal 2

SV select

signal 3

EX-MV

output

command

PV1

PV2

Ai1

Di1

Di2

Di3

Di4

Di11

Di15

to

Input

Conditioner

Input

Conditioner

Input

Conditioner

* Di allocation can be

changed with para meters.

1-loop SV selectable PID controller (with math function)

PV

[Ao1T]

SV

SV

MV

PV

MV

Alarm

[Ao2T]

Di allocation

SV select 1

SV select 2

SV select 3

EX-MV

command

No

allocation

Math

module

Result of

calculation

[AiM]

Local SV

SV select

SV1

[SV1]

SV7

[SV7]

to

Preset output

value

[STBY] or

Di allocation

command

PV

L

SV

EX-MV setting

R

Manual MV setting

EX-MV

output command

[PMV1]

Manual

PID

operation

[EXM1]

Stand-by

command

A/M chargeover

A

RUN

M

STBY

Re-trans-

mission

Output type

output 1

mission

output 2

Control

output 1

setting

Depend on

[OTYP]

setting

RET1

Re-trans-

RET2

MV1

DO allocation

ALM1

ALM2

ALM3

ALM4

No

allocation

* Do allocation can be

changed with parameters.

* Higher priority is

assigned to designation

of [OTYP] for the

output to Do4.

LED display allocation

ALM

1 to 5

OR of all

the ALMs

AO 1

AO 2

DO 4

OUT1

OUT2

DO4

Do1

Do2

Do3

Do4

Do11

to

Do15

L Do1

to

L Do5

L ALM

Current

output or

SSR driver

output

Current

output or

Transmitter

supply

Relay

output

(Control

output)

Relay

output

(Do)

Indicator

lamp

6

Page 7

Template No. 13

1-loop basic PID controller (without math function)

Measurement

value

input 1

Remote

SV input

Remote

command

Remote

acknowledge

Manual

command

EX-MV

output

command

PV1

Input Conditioner

Input Conditioner

Ai1

[REM]

(Parameter setting or key operation)

Di allocation

Di1

Di2

Di3

Di4

Di11

Di15

to

R-ACK

SMV

No

allocation

EX-MV

command

No

allocation

* Di allocation can be

changed with para meters.

* Since the R-ACK

value is INH at the

time of delivery, set

it to ENA before use.

Local SV

Remote SV

[RSV1]

Remote command

Remote

acknowledge

PV

L

R

PID

operation

SV

EX-MV setting

[EXM1]

Manual MV setting

A/M chargeover

EX-MV output command

Preset output

value

[PMV1]

Stand-by

command

[STBY] or

Di allocation

Manual

command

A/M chargeover

Alarm

Re-trans-

mission

[Ao1T]

output 1

RET1

Re-trans-

mission

[Ao2T]

output 2

RET2

Control

output 1

MV1

* Do allocation can be

* Higher priority is

LED display allocation

Output type

setting

Depend on

[OTYP]

setting

DO allocation

ALM1

ALM2

ALM3

ALM4

No

allocation

changed with

parameters.

assigned to designation

of [OTYP] for the

output to Do4.

ALM

1 to 5

OR of all

the ALMs

AO 1

AO 2

DO 4

OUT1

OUT2

DO4

Do1

Do2

Do3

Do4

Do11

to

Do15

L Do1

to

L Do5

L ALM

Current

output or

SSR driver

output

Current

output or

Transmitter

supply

Relay

output

(Control

output)

Relay

output

(Do)

Indicator

lamp

PV

SV

MV

PV

SV

A

RUN

M

STBY

MV

Template No. 14

Measurement

PV1

Di1

Di2

Di3

Di4

Di11

Di15

to

Input Conditioner

* Di allocation can be

changed with para meters.

value

input 1

SV select

signal 1

SV select

signal 2

SV select

signal 3

EX-MV

output

command

1-loop SV selectable PID controller (without math function)

[Ao1T]

[Ao2T]

Re-trans-

mission

output 1

RET1

Re-trans-

mission

output 2

RET2

Control

output 1

MV1

* Do allocation can be

* Higher priority is

LED display allocation

Di allocation

SV select 1

SV select 2

SV select 3

EX-MV

command

No

allocation

Local SV

SV select

SV1

[SV1]

to

SV7

[SV7]

L

R

Manual MV setting

EX-MV

output command

Preset output

value

[PMV1]

[STBY] or

Di allocation

Manual

command

PV

PID

operation

SV

EX-MV setting

[EXM1]

Stand-by

command

A/M chargeover

PV

SV

MV

PV

SV

A

RUN

M

STBY

MV

Alarm

Output type

setting

Depend on

[OTYP]

setting

DO allocation

ALM1

ALM2

ALM3

ALM4

No

allocation

changed with parameters.

assigned to designation

of [OTYP] for the

output to Do4.

ALM

1 to 5

OR of all

the ALMs

AO 1

AO 2

DO 4

OUT1

OUT2

DO4

Do1

Do2

Do3

Do4

Do11

to

Do15

L Do1

to

L Do5

L ALM

Current

output or

SSR driver

output

Current

output or

Transmitter

supply

Relay

output

(Control

output)

Relay

output

(Do)

Indicator

lamp

7

Page 8

PXH9

Template No. 16

Measurement

value

input 1

Measurement

value

input 2

Aux. input

Remote

command

PV select

RSV select

EXMV

select

FF select

FF INH

command

Remote

acknowledge

Manual

command

EX-MV

output

command

PV1

PV2

Ai1

key operation)

[REM]

[CN01]

[CN02]

[CN03]

[CN04]

[CN05]

Di1

Di2

Di3

Di4

Di11

to

Di15

(Parameter

setting or

(Parameter

(Parameter

EX-MV setting

(Parameter

(Parameter

(Parameter

Conditioner

Conditioner

Conditioner

setting)

setting)

[EXM1]

setting)

setting)

setting)

* Di allocation can be

changed with para meters.

* Since the R-ACK

value is INH at the

time of delivery, set

it to ENA before use.

1-loop input selectable PID controller (with math function)

Result of

Math

module

Remote

command

calculation

[AiM]

Remote

acknowledge

PV select

[CONST1]

L

Local

SV

R

RSV select

[CONST2]

EXMV select

[CONST3]

FF signal select

[CONST4]

FF

Calculation

Manual MV setting

A/M chargeover

EX-MV output command

PV

SV

AMV1

operation

value

Di allocation

PID

[FFv1]

Feedforward

Preset output

[PMV1]

[STBY] or

A

M

Stand-by

command

STBY

RUN

AIM

PV

SV

PV

SV

MV

AiM

MV

Alarm

Re-trans-

mission

output 1

[Ao1T]

RET1

Re-trans-

mission

[Ao2T]

output 2

RET2

Control

output 1

MV1

* Do allocation can be

changed with parameters.

* Higher priority is

assigned to designation

of [OTYP] for the output

to Do4.

Input

Input

Input

Di allocation

R-ACK

SMV

allocation

EX-MV

allocation

No

No

Output type

setting

Depend

on

[OTYP]

setting

DO allocation

ALM1

ALM2

ALM3

ALM4

No

allocation

LED display allocation

ALM

1 to 5

OR of all

the ALMs

AO 1

AO 2

DO 4

OUT1

OUT2

DO4

Do1

Do2

Do3

Do4

Do11

to

Do15

L Do1

to

L Do5

L ALM

Current

output or

SSR driver

output

Current

output or

Transmitter

supply

Relay

output

(Control

output)

Relay

output

(Do)

Indicator

lamp

8

Page 9

Template No. 30

1-loop motorized valve controller (with math function)

Measurement

value input 1

Measurement

value input 2

/Remote SV

input

Valve openings

feedback

signal

/Aux. input

Remote

command

Remote

acknowledge

Manual

command

EX-MV

output

command

AiM

PV

SV

MV

SV

MV

MVRB

AiM

PV

MVRB

Alarm

PV1

PV2

FB

/Ai1

[REM]

(Parameter setting

or key operation)

Di1

Di2

Di3

Di4

Di11

to

Di15

Input

Conditioner

Input

Conditioner

Input

Conditioner

module

Di allocation

R-ACK

SMV

No

allocation

EX-MV

command

No

allocation

* Di allocation can be

changed with para meters.

* Since the R-ACK

value is INH at the

time of delivery, set

it to ENA before use.

Math

Result of

calculation

[AiM]

Local SV

[RSV1]

Remote command

Remote

acknowledge

PV

L

R

PID

operation

SV

EX-MV setting

[EXM1]

A/M chargeover

EX-MV output command

Preset output

value

[PMV1]

Stand-by

command

[STBY] or

Di allocation

Manual

command

Front key

(during MAN

operation only)

A

RUN

M

STBY

* Valve openings feedback input is used for the type of 5th digit “D” in CODE SYMBOLS.

[Ao1T]

[Ao2T]

Control

output 1

MV1

Re-trans-

mission

output 1

RET1

Re-trans-

mission

output 2

RET2

Output type

setting

Depend on

[OTYP]

setting

PO

DO allocation

ALM1

ALM2

ALM3

No

allocation

* Do allocation can be

changed with

parameters.

* Higher priority is

assigned to designation

of [OTYP] for the

output to Do4.

LED display allocation

ALM

1 to 5

OR of all

the ALMs

AO 1

AO 2

OUT1

OUT2

CLOSE

OPEN

Do1

Do2

Do3

Do11

to

Do15

L Do1

to

L Do5

L ALM

Current

output

Current

output or

Transmitter

supply

Relay output

(Close output)

Relay output

(Open output)

Relay

output

(Do)

Indicator

lamp

Template No. 31

Measurement

value input 1

Measurement

value input 2

Valve openings

feedback

signal

/Aux. input

SV select

signal 1

SV select

signal 2

SV select

signal 3

EX-MV

output

command

PV1

PV2

FB

/Ai1

Di1

Di2

Di3

Di4

Di11

Di15

Conditioner

Conditioner

Conditioner

to

1-loop SV selectable motorized valve controller (with math function)

Input

Input

Input

Math

module

Di allocation

SV select 1

SV select 2

SV select 3

EX-MV

command

No

allocation

* Di allocation can be

changed with para meters.

Result of

calculation

[AiM]

SV select

SV1

[SV1]

to

SV7

[SV7]

Local SV

Remote

command

PV

PID

L

R

operation

SV

EX-MV setting

[EXM1]

EX-MV output command

Preset output

value

[PMV1]

Stand-by

command

[STBY] or

Di allocation

Manual

command

Front key

(during MAN

operation only)

A/M

chargeover

AiM

PV

SV

MV

AiM

PV

A

M

STBY

SV

MV

RUN

MVRB

MVRB

Alarm

[Ao1T]

[Ao2T]

Control

output 1

MV1

Re-trans-

mission

output 1

RET1

Re-trans-

mission

output 2

RET2

* Higher priority is

Output type

setting

Depend on

[OTYP]

setting

PO

DO allocation

ALM1

ALM2

ALM3

No

allocation

* Do allocation can be

changed with parameters.

assigned to designation

of [OTYP] for the

output to Do4.

LED display allocation

ALM

1 to 5

OR of all

the ALMs

AO 1

AO 2

OUT1

OUT2

CLOSE

OPEN

Do1

Do2

Do3

Do11

to

Do15

L Do1

to

L Do5

L ALM

Current

output

Current

output or

Transmitter

supply

Relay output

(Close output)

Relay output

(Open output)

Relay

output

(Do)

Indicator

lamp

* Valve openings feedback input is used for the type of 5th digit “D” in CODE SYMBOLS.

9

Page 10

PXH9

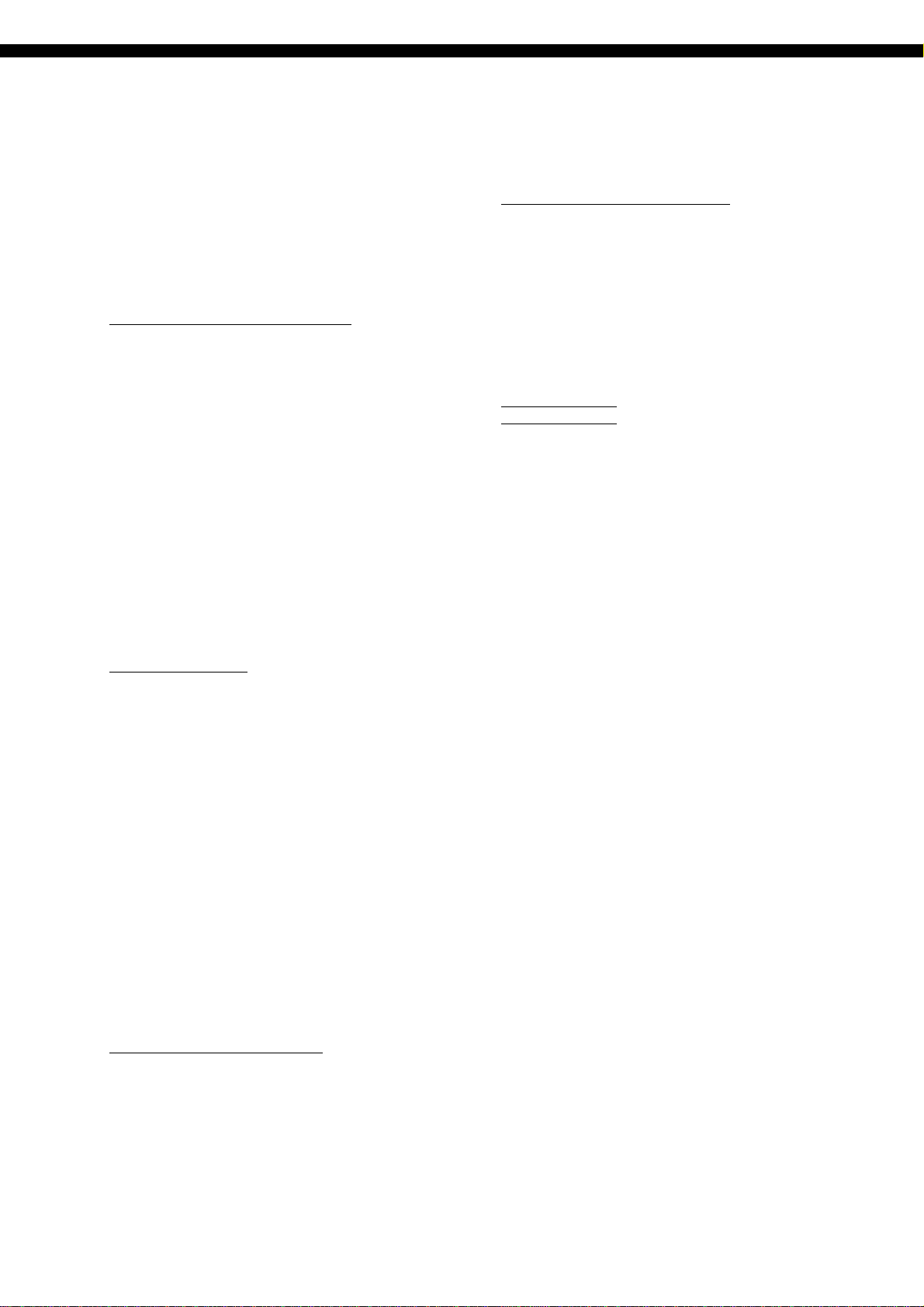

Template No. 33

Measurement

value input 1

Measurement

value input 2

Valve openings

feedback

signal

Remote

command

Remote

acknowledge

Manual

command

EX-MV

output

command

PV1

Conditioner

PV2

Conditioner

FB

Conditioner

〔REM〕

(Parameter setting

or key operation)

Di1

Di2

Di3

Di4

Di11

to

Di15

* Di allocation can be

changed with para meters.

* Since the R-ACK

value is INH at the

time of delivery, set

it to ENA before use.

* Valve openings feedback input is used for the type of 5th digit “D” in CODE SYMBOLS.

1-loop motorized valve controller (without math function)

PV

[Ao1T]

Input

Input

Input

Di allocation

R-ACK

SMV

No

allocation

EX-MV

command

No

allocation

Local SV

[RSV1]

Remote command

Remote

acknowledge

PV

PID

L

R

operation

SV

EX-MV setting

[EXM1]

A/M chargeover

EX-MV output command

Preset output

value

[PMV1]

Stand-by

command

[STBY] or

Di allocation

Manual

command

Front key

(during MAN

operation only)

SV

A

RUN

M

STBY

MV

PV

SV

MV

MVRB

MVRB

Alarm

[Ao2T]

Control

output 1

MV1

RET1

RET2

Re-trans-

mission

Output type

output 1

setting

Re-trans-

Depend on

mission

[OTYP]

output 2

setting

PO

DO allocation

ALM1

ALM2

ALM3

No

allocation

* Do allocation can be

changed with

parameters.

* Higher priority is

assigned to designation

of [OTYP] for the

output to Do4.

LED display allocation

ALM

1 to 5

OR of all

the ALMs

AO 1

AO 2

OUT1

OUT2

CLOSE

OPEN

Do1

Do2

Do3

Do11

to

Do15

L Do1

to

L Do5

L ALM

Current

output

Current

output or

Transmitter

supply

Relay output

(Close output)

Relay output

(Open output)

Relay

output

(Do)

Indicator

lamp

Template No. 34

Measurement

value

input 1

Valve

openings

feedback

signal

SV select

signal 1

SV select

signal 2

SV select

signal 3

EX-MV

output

command

Input

PV1

Conditioner

Input

FB

Conditioner

Di1

Di2

Di3

Di4

Di11

to

Di15

* Di allocation can be

changed with para meters.

* Valve openings feedback input is used for the type of 5th digit “D” in CODE SYMBOLS.

1-loop SV selectable motorized valve controller (without math function)

Re-trans-

[Ao1T]

MVRB

[Ao2T]

MVRB

MV1

mission

output 1

RET1

Re-trans-

mission

output 2

RET2

Control

output 1

PO

DO allocation

* Do allocation can be

changed with parameters.

* Higher priority is

assigned to designation

of [OTYP] for the

output to Do4.

LED display allocation

Output type

setting

Depend on

[OTYP]

setting

ALM1

ALM2

ALM3

No

allocation

ALM

1 to 5

OR of all

the ALMs

AO 1

AO 2

Di allocation

SV select 1

SV select 2

SV select 3

EX-MV

command

No

allocation

SV select

SV1

[SV1]

to

SV7

[SV7]

Local SV

Remote

command

PV

PID

L

R

operation

SV

EX-MV setting

[EXM1]

EX-MV output command

Preset output

value

[PMV1]

Stand-by

command

[STBY] or

Di allocation

Manual

command

Front key

(during MAN

operation only)

A/M

chargeover

PV

SV

MV

PV

A

M

STBY

SV

MV

RUN

Alarm

OUT1

OUT2

CLOSE

OPEN

Do1

Do2

Do3

Do11

to

Do15

L Do1

to

L Do5

L ALM

Current

output

Current

output or

Transmitter

supply

Relay output

(Close output)

Relay output

(Open output)

Relay

output

(Do)

Indicator

lamp

10

Page 11

Template No. 50

Measurement

value

input 1

Measurement

value

input 2

Aux. input

/Remote

SV input

Remote

command

Remote

acknowledge

Manual

command

EX-MV

output

command

Input

PV1

Conditioner

Input

PV2

Conditioner

Input

Ai1

Conditioner

[REM]

(Parameter setting or key operation)

Di allocation

Di1

Di2

Di3

Di4

Di11

to

Di15

* Di allocation can be

changed with para meters.

* Since the R-ACK

value is INH at the

time of delivery, set

it to ENA before use.

1-loop heating/cooling controller (with math function)

PV

[Ao1T]

SV

MV

PV

[Ao2T]

SV

MV

A

RUN

M

Heating

/cooling

operation

Stand-by

command

Heating

output

Cooling

output

RUN

STBY

RUN

STBY

R-ACK

SMV

No

allocation

EX-MV

command

No

allocation

Math

module

Result of

calculation

[AiM]

Local SV

Remote SV

[RSV1]

Remote command

Remote

acknowledge

PV

PID

L

R

operation

SV

EX-MV setting

[EXM1]

Manual MV setting

A/M chargeover

EX-MV output command

Preset output

value

value

Di allocation

[PMV1]

Preset output

[PMC1]

[STBY] or

RET1

RET2

HMV

CMV

Alarm

Re-trans-

mission

output 1

Re-trans-

mission

output 2

Heating

output

Cooling

output

Output type

setting

Depend on

[OTYP]

setting

DO allocation

ALM1

ALM2

ALM3

ALM4

No

allocation

* Do allocation can be

changed with para meters.

* Higher priority is

assigned to designation

of [OTYP] for the output

to Do3 and Do4.

LED display allocation

ALM

1 to 4

OR of all

the ALMs

AO 1

AO 2

DO 3

DO 4

OUT1

OUT2

DO3

DO4

Do1

Do2

Do3

Do4

Do11

to

Do15

L Do1

to

L Do5

L ALM

Current output

or SSR driver

output

Current output

or Transmitter

supply or SSR

driver output

Relay output

(Control output)

Relay output

(Control output)

Relay

output

(Do)

Indicator

lamp

Template No. 51

Measurement

value

input 1

Measurement

value

input 2

Aux. input

SV select

signal 1

SV select

signal 2

SV select

signal 3

EX-MV

output

command

PV1

PV2

Ai1

Di1

Di2

Di3

Di4

Di11

Di15

to

Input

Conditioner

Input

Conditioner

Input

Conditioner

* Di allocation can be

changed with para meters.

1-loop SV selectable heating/cooling controller (with math function)

Re-trans-

RET1

RET2

HMV

CMV

Alarm

mission

output 1

Re-trans-

mission

output 2

Heating

output

Cooling

output

Output type

setting

Depend on

[OTYP]

setting

DO allocation

ALM1

ALM2

ALM3

ALM4

No

allocation

* Do allocation can be

changed with parameters.

* Higher priority is

assigned to designation

of [OTYP] for the output

to Do3 and Do4.

LED display allocation

ALM

1 to 4

OR of all

the ALMs

Di allocation

SV select 1

SV select 2

SV select 3

EX-MV

command

No

allocation

Math

module

Result of

calculation

[AiM]

Local SV

SV select

SV1

[SV1]

to

SV7

[SV7]

PV

L

SV

EX-MV setting

R

Manual MV setting

EX-MV

output command

operation

[EXM1]

PID

A

M

Preset output

[PMV1]

value

Preset output

[PMC1]

value

[STBY] or

Di allocation

PV

SV

MV

PV

SV

MV

Heating

/cooling

operation

Stand-by

command

[Ao1T]

[Ao2T]

Heating

output

Cooling

output

RUN

STBY

RUN

STBY

AO 1

AO 2

DO 3

DO 4

OUT1

OUT2

DO3

DO4

Do1

Do2

Do3

Do4

Do11

to

Do15

L Do1

to

L Do5

L ALM

Current output

or SSR driver

output

Current output

or Transmitter

supply or SSR

driver output

Relay output

(Control output)

Relay output

(Control output)

Relay

output

(Do)

Indicator

lamp

11

Page 12

PXH9

Template No. 53

Measurement

PV1

value

input 1

Remote

SV input

Remote

command

Remote

acknowledge

Manual

command

EX-MV

output

command

Input Conditioner

Ai1

Input Conditioner

[REM]

(Parameter setting or key operation)

Di allocation

Di1

Di2

Di3

Di4

Di11

to

Di15

* Di allocation can be

changed with para meters.

* Since the R-ACK

value is INH at the

time of delivery, set

it to ENA before use.

1-loop heating/cooling controller (without math function)

RET1

RET2

HMV

CMV

Alarm

Re-trans-

output 1

Re-trans-

output 2

R-ACK

SMV

No

allocation

EX-MV

command

No

allocation

Local SV

Remote SV

[RSV1]

Remote

acknowledge

PV

PID

L

R

operation

SV

EX-MV setting

[EXM1]

Manual MV setting

A/M chargeover

EX-MV output command

A

M

Preset output

[PMV1]

value

Preset output

value

[PMC1]

[STBY] or

Di allocation

[Note 1]

Stand-by

command

SV

SV

PV

MV

PV

MV

Heating

/cooling

operation

[Ao1T]

[Ao2T]

Heating

output

Cooling

output

RUN

STBY

RUN

STBY

mission

Output type

setting

mission

Depend on

Heating

[OTYP]

output

setting

Cooling

output

DO allocation

ALM1

ALM2

ALM3

ALM4

allocation

* Do allocation can be

changed with para meters.

* Higher priority is

assigned to designation

of [OTYP] for the output

to Do3 and Do4.

LED display allocation

ALM

OR of all

the ALMs

No

1 to 4

AO 1

AO 2

DO 3

DO 4

OUT1

OUT2

DO3

DO4

Do1

Do2

Do3

Do4

Do11

to

Do15

L Do1

to

L Do5

L ALM

Current output

or SSR driver

output

Current output

or Transmitter

supply or SSR

driver output

Relay output

(Control output)

Relay output

(Control output)

Relay

output

(Do)

Indicator

lamp

Template No. 54

Measurement

PV1

Di1

Di2

Di3

Di4

Di11

to

Di15

Input Conditioner

Di allocation

SV select 2

* Di allocation can be

changed with para meters.

value

input 1

SV select

signal 1

SV select

signal 2

SV select

signal 3

EX-MV

output

command

1-loop SV selectable heating/cooling controller (without math function)

Re-trans-

RET1

RET2

HMV

CMV

Control

output 1

Alarm

mission

output 1

Re-trans-

mission

output 2

Heating

output

Cooling

output

Output type

setting

AO 1

[OTYP]

setting

AO 2

DO 3

DO 4

Depend on

DO allocation

ALM1

ALM2

ALM3

ALM4

No

allocation

* Do allocation can be

changed with parameters.

* Higher priority is

assigned to designation

of [OTYP] for the output

to Do3 and Do4.

LED display allocation

ALM

1 to 4

OR of all

the ALMs

SV select 1

SV select 3

EX-MV

command

No

allocation

Local SV

SV select

SV1

[SV1]

to

SV7

[SV7]

PV

L

SV

EX-MV setting

R

[EXM1]

Manual MV setting

EX-MV

output command

PID

operation

A

M

Preset output

value

[PMV1]

Preset output

value

[PMC1]

[STBY] or

Di allocation

PV

SV

MV

PV

SV

MV

Heating

/cooling

operation

Stand-by

command

[Ao1T]

[Ao2T]

Heating

output

Cooling

output

RUN

STBY

RUN

STBY

Current

output or

SSR driver

output

OUT1

Current output,

Transmitter supply,

OUT2

or

output

Relay output

DO3

(Control output)

Relay output

DO4

(Control output)

Do1

Do2

Do3

Do4

Do11

to

Do15

L Do1

to

L Do5

L ALM

SSR driver

Relay

output

(Do)

Indicator

lamp

12

Page 13

CODE SYMBOLS [Basic type]

Digit

<Dimension of front face H x W>

4

96 x 96 mm

<Number of control loops/Function>

5

1-loop basic controller

<Measurement value input>

6

Universal input: 1 point

Universal input: 2 points

<Auxiliary input>

7

Not fitted

DC voltage: 1 point

<Version No.>

8

<Output>

9

10

11

12

13

OUT1 OUT2

Current Not fitted

Current Current

Current Transmitter supply

SSR/SSC driver Not fitted

SSR/SSC driver Current

<Power supply>

100 to 240 V AC

<Communication interface>

Not fitted

RS-485

<Digital input/output>

Digital input Digital output (Including relay control output)

4 points (Di1 to Di4) 2 points (Do3, Do4)

4 points (Di1 to Di4) 4 points (Do1 to Do4)

9 points (Di1 to Di4, Di11 to Di15) 9 points (Do1 to Do4, Do11 to Do15)

<Additional specifications>

Not fitted.

Description

Notes

*1

*3

*2

*1

12345678

9

A

1

2

0

1

910111213

1V0PXH9A

1

A

B

Digit

1

2

5

V

0

R

0

A

B

0

*1: “2” for the 6th digit and “B” for the 12th digit cannot be specified at the same time.

*2: One digital output (Do4) is occupied when relay is allocated as control output.

*3: Explanation of the 9th digit of type code and output terminal function is below.

Code

9th

digit

Terminal

Output

Kind

Function

*

1

2

5

A

B

Do4

Relay

Control output

or

Digital output

* The selection of “Function” is specified according to the parameter.

(4 to 20 mA)

Control output

Re-transmission

Current

or

output

OUT1

SSR/SSC

driver

Control output

Current

(4 to 20 mA)

Re-transmission

output

Optional Items

Contents Model Notes

Terminal cover ZZP PXR1-B230 Two pieces are necessary per

PC loader interface cable ZZP PXH1*TK4H4563 For RS232C Interface

1 unit.

OUT2

Transmitter

power

supply

: Not fitted

: Fitted

13

Page 14

PXH9

[Motorized valve control type]

Digit

<Dimension of front face H x W>

4

96 x 96 mm

<Number of control loops/Function>

5

1-loop motorized valve controller (with valve openings feedback input)

1-loop motorized valve controller (without valve openings feedback input)

<Measurement value input>

6

Universal input: 1 point

Universal input: 2 points

<Auxiliary input>

7

Not fitted

DC voltage: 1 point

<Version No.>

8

<Output>

9

10

11

12

13

OUT1 OUT2

Current Not fitted

Current Current

Current Transmitter supply

<Power supply>

100 to 240 V AC

<Communication interface>

Not fitted

RS-485

<Digital input/output>

Digital input Digital output (Including valve control output)

4 points (Di1 to Di4) 2 points (Do3, Do4)

4 points (Di1 to Di4) 4 points (Do1 to Do4)

9 points (Di1 to Di4, Di11 to Di15) 9 points (Do1 to Do4, Do11 to Do15)

<Additional specifications>

Not fitted.

Description

Notes

*1

*2

*3

*1

12345678

9

D

S

1

2

0

1

1V0PXH9

1

910111213

1

2

5

V

0

R

0

A

B

Digit

0

*1: Universal input 2 points and “B” for the 12th digit cannot be specified at the same time.

Select “universal input 2 points” when external setting input (RSV) is required.

*2: “D” for the 5th digit and “1” for the 7th digit cannot be specified at the same time.

*3: Do4 is used as control output.

If 2 or 3 Do points are required for event output, specify code A, and if 4 to 8 Do points are required, specify code B.

OUT1

Current

(4 to 20 mA)

Re-transmission

output

OUT2

Current

(4 to 20 mA)

Re-transmission

output

Transmitter

power

supply

: Not fitted

: Fitted

Code

9th

digit

Terminal

Output

kind

Function

*

1

2

5

* The selection of “Function” is specified according to the parameter.

Do4

Relay

Used for

valve

open/close

output.

14

Page 15

[Heating/cooling control type]

9

4

5

6

8

7

9

10

11

12

13

12345678

1V0PXH9F

910111213

F

V

1

2

0

1

0

R

1

0

1

2

3

5

A

B

C

0

A

B

1

2

5

A

B

3

C

Digit

9th

digit

Code

Terminal

Output

kind

Function

*

Do3

Relay

Control output

or

Digital output

OUT1

Current

(4 to 20 mA)

Control output

or

Re-transmission

output

SSR/SSC

driver

Control output

OUT2

: Not fitted

: Fitted

* The selection of “Function” is specified according to the parameter.

<Dimension of front face H x W>

96 x 96 mm

<Number of control loops/Function>

1-loop heating/cooling controller

<Measurement value input>

Universal input: 1 point

Universal input: 2 points

<Auxiliary input>

Not fitted

DC voltage: 1 point

<Version No.>

<Output>

OUT1 OUT2

Current Not fitted

Current Current

Current SSR/SSC drive

Current Transmitter supply

SSR/SSC driver Not fitted

SSR/SSC driver Current

SSR/SSC driver SSR/SSC drive

<Power supply>

100 to 240 V AC

<Communication interface>

Not fitted

RS-485

<Digital input/output>

Digital input Digital output (Including relay control output)

4 points (Di1 to Di4) 2 points (Do3, Do4)

4 points (Di1 to Di4) 4 points (Do1 to Do4)

9 points (Di1 to Di4, Di11 to Di15) 9 points (Do1 to Do4, Do11 to Do15)

<Additional specifications>

Not fitted.

*3

*1

*2

*1

Notes

Digit

Description

*1: “2” for the 6th digit and “B” for the 12th digit cannot be specified at the same time.

*2: One digital output (Do4) or 2 points (Do3 and 4) is occupied when relay is allocated as control output.

*3: Explanation of the 9th digit of type code and output terminal function is below.

Current

(4 to 20 mA)

Control output

Control output

or

Digital output

Control output

or

Re-transmission

output

Relay

Do4

SSR/SSC

driver

Transmitter

power

supply

15

Page 16

PXH9

MEASUREMENT RANGE TABLE

(1) Unit of temperature : ˚C

Input type

Resistance bulb

Thermocouple

DC voltage

DC current

Motorized valve

opening feedback

Pt100Ω

J

K

R

B

S

T

E

PR40/20

N

PL-II

WRe5-26

1 to 5 V

0 to 5 V

0 to 10 V

0 to 10 mV

0 to 50 mV

4 to 20 mA

0 to 20 mA

Potentiometer

Measurement range [˚C]

Max. Min.

-

150 to 850

0 to 1000

0 to 1200

0 to 1600

0 to 1800

0 to 1600

-

200 to 400

-

200 to 800

0 to 1800

0 to 1300

0 to 1300

0 to 2300

-

19999 to 99999

(Range where scaling

is allowed)

100 to 10 kΩ

0 to 150

0 to 400

0 to 400

0 to 1600

0 to 1800

0 to 1600

-

200 to 200

0 to 800

0 to 1800

0 to 1300

0 to 1300

0 to 2300

Reading/setting

resolution (˚C)

0.01

0.1

0.1

0.1

0.1

0.1

0.1

0.1

0.1

0.1

0.1

0.1

1/10000

digit

1/1000

digit

(2) Unit of temperature : ˚F

Input type

Resistance bulb

Thermocouple

DC voltage

Current

Motorized valve

opening feedback

Pt100Ω

J

K

R

B

S

T

E

PR40/20

N

PL-II

WRe5-26

1 to 5V DC

0 to 5V DC

0 to 10V DC

0 to 10mV DC

0 to 50mV DC

4 to 20mA DC

0 to 20mA DC

Potentiometer

Measurement range [˚F]

Max. Min.

-

238 to 1562

32 to 1832

32 to 2192

32 to 932

32 to 3272

32 to 2912

-

328 to 752

-

328 to 1472

32 to 3272

32 to 2372

32 to 2372

32 to 4172

-

19999 to 99999

(Range where scaling is allowed)

100 to 10 kΩ

32 to 302

32 to 752

32 to 752

32 to 932

32 to 3272

32 to 2912

-

328 to 392

32 to 1472

32 to 3272

32 to 2372

32 to 2372

32 to 4172

Reading/setting

resolution (˚F)

0.01

0.1

0.1

0.1

0.1

0.1

0.1

0.1

0.1

0.1

0.1

0.1

1 / 10000

digit

1/1000

digit

16

Page 17

LIST OF MATH FUNCTIONS

CALC

setting

0 No math operation

Mathematical expression 1

(

Flow rate compensation with

1

temperature and pressure

Mathematical expression 2

Flow rate compensation with

(

2

temperature and pressure

Mathematical expression 3

3

Flow rate compensation with

(

temperature and pressure

4

Mathematical expression 4

5

Mathematical expression 5

Mathematical expression 6

6M

7

8

9

10

Input switching (2 points)

11

12

(with Di switching function)

13

(with Di switching function)

Flow rate compensation with

20

temperature and pressure

Flow rate compensation with

temperature and pressure

21

(

without square-root extraction

27

28

29

30

Input switching (2 points)

31

32

(with Di switching function)

33

(with Di switching function)

Input switching (2 points)

34

40

*1: Square-root extraction cut point can be set with k06.

*2: Square-root extraction cut point can be set with k07.

Name

of operation

H selector (2 points)

L selector (2 points)

H selector (3 points)

L selector (3 points)

H/L selector (2 points)

H/L selector (3 points)

[% value operation]

[% value operation]

H selector (2 points)

(with coefficient)

H selector (2 points)

(with coefficient)

H selector (3 points)

(with coefficient)

L selector (3 points)

(with coefficient)

(with coefficient)

H/L selector (2 points)

H/L selector (3 points)

(with coefficient and

interpolation function)

Calorie calculation

M1 = PV1 input

M1 =

)

M1 = k01 X PV1 X

)

M1 = k01 x PV1 x

)

M1 =

M1 =

1

= k01

*1

k01 X PV1 X

PV1: Flow rate (differential pressure), PV2: Temperature, Ai1: Pressure

PV1: Flow rate (differential pressure), PV2: Temperature, Ai1: Pressure

PV1: Flow rate (differential pressure), PV2: Temperature, Ai1: Pressure

(k01 X (k02 X PV1 + k03 X PV2 + k04 X Ai1) + k05)

(k06 X (k07 X PV1 + k08 X PV2 + k09 X Ai1) + k10)

(k01 X ((k02 X PV1 + k03) X (k04 X PV2 + k05) X (k06 X Ai1 + k07)) + k08)

(k09 X ((k10 X PV1 + k11) X (k12 X PV2 + k13) X (k14 X Ai1 + k15)) + k16)

X

PV1

*1

Ai1 + k02

Ai1+k02

k03

X

(k02

Ai1 + k02

k03

X

k03

x

PV2+k05

X

PV2 + k03

*2

M1 = Max (PV1, PV2)

PV1 or PV2, whichever is larger, is selected.

M1 = Min (PV1, PV2)

PV1 or PV2, whichever is smaller, is selected.

M1 = Max (PV1, PV2, Ai1)

PV1, PV2, or Ai1, whichever is largest, is selected.

M1 = Min (PV1, PV2, Ai1)

PV1, PV2, or Ai1, whichever is smallest, is selected.

M1 = PV1 when PV1 ≤ k01, M1 = PV2 when PV1 > k01

Expression 7 or 8 is used by Di switching.

(Specify “140” for Di function for switching.)

Expression 9 or 10 is used by Di switching.

(Specify “140” for Di function for switching.)

1

M

M1 =

All the inputs and constants are of the same specifications as mathematical expression 20.

)

1

M

M

1

1

M

M

1

M

1

M1 = (PV2

Expression 27 or 28 is used by Di switching.

(Specify “140” for Di function for switching.)

Expression 29 or 30 is used by Di switching.

(Specify “140” for Di function for switching.)

When PV1 ≤ k05 : M1 = (PV1 X k01) + k02

When PV2 ≤ k06 : M1 = (PV2 X k03) + k04

When PV1 > k05 and PV2 < k06 : Interpolation shown below, is executed.

M1 =

M

1

(Ai1 + k01) + k02

=

PV

1

(PV2 X k03) + k04

PV1: Differential pressure (flow rate) % value, k01: Pressure compensation constant 1,

k04: Temperature compensation constant 2

PV2: Fluid temperature % value, k03: Temperature compensation constant 1

Ai1: Differential pressure % value, k02: Pressure compensation constant 2,

k05: Square-root extractor cut point

*Input data: % value (0 (0%) to 100000 (100.000%))

(Ai1 X k01) + k02

1

PV

(PV2 X k03) + k04

= max ((PV1

= min ((PV1

= max ((PV1

= min ((PV1

= (PV1

1

* note) k05 : Input switching upper value

= ((PV1

X k01 + k02),

X k01 + k02),

(PV2

X k01 + k02),

X k01 + k02),

(PV2

X k02 + k03) when k

X

k04 + k05) when k01 ≤ (PV1

(PV1

X k01 + k02) - k05

k06 -

k05

k06 : Input switching lower value

X k01 + k02) -

(PV2

Arithmetic expression

k04

X

PV2 + k05

k04

PV2 + k05

k04

X

Ai1) + k04

(PV2

X k03 + k04)

X k03 + k04)

(PV2

X k03 + k04), (Ai X k05 + k06

)

)

X

Ai1 + k05

X k03 + k04), (Ai X k05 + k06

01 > (PV1

X k02 + k03)

X k02 + k03)

(PV1

X k01 + k02) - k05 -

X

X k03 + k04)) X (Ai1 X k05 + k06

))

))

(PV1

X k01 + k02) - k05

k06

))

- k05

(PV2

X

X k03 + k04

)

17

Page 18

PXH9

OUTLINE DIAGRAM

96

PC Loader Interface

(Unit:mm)

96

Waterproof

packing

MTG. bracket

94.5 (With terminal cover)

79.510

2

t

1 ≤ t ≤ 8

Panel

37-48

49-60 61-72 25-3613-24

1-12

91.5

93.7 (Terminal Cover)

Terminal cover

(Available optionally)

107.5

+0.8

6.2

PANEL CUTOUT

+0.8

–0

92

–0

92

100 MIN.

116 MIN.

Terminal screw M3

In some models, a terminal block is not mounted to terminals

those are not being used (terminal Nos. 37 to 60).

(A dummy cover is mounted instead.)

RCJ Module (for PV2)

For PV2 fitted model only.

Remove it for resistance bulb input.

RCJ Module

Remove it for resistance bulb input.

18

Page 19

TERMINAL ALLOCATION

D03/Control output 2 (Relay)

DO3

5

6

37

49

38

50

39

51

40

52

41

53

42

54

43

55

44

56

45

57

46

58

47

59

48

60

OUT1

Current

output

1

2

3

4

5

6

7

8

9

10

11

12

1

2

Output 1

+

1

2

-

SSR/SSC

driver

output

13

14

15

16

17

18

19

20 32

21

22

23

24

+

-

Output 2

+

3

4

-

SSR/SSC

driver

output

+

3

4

-

Transmitter

power supply

[Note 1]

DO4

Di1-4

RS485

Communication

+

14

SG

15

-

16

DO4/

Control output 1 (relay)

NC

25

COM

26

NO

27

Digital inputs

DI1

28

DI2

29

DI3

30

DI4

31

COM

32

Motorized valve

PO

opening/closing output

OPEN

25

COM

26

CLOSE

27

+

-

3

4

Current

output

25

26

27

28

29

30

31

33

34

35

36

OUT2

PV2

+

605760

DC current

DO1, 2

DO-

COM

DO1

DO2

Measurement value input

+

-

58

60

Resistance

bulb

RCJ Module

B

58

A

59

B

60

+

57

-

[mV]

[V]

DC voltage

7

8

9

+

Thermocouple

Power supply

100 to 240 V AC

50/60 Hz

Extended-Di / Do

DI11

49

DI12

50

DI13

51

DI14

52

DI15

53

COM

54

DO11

55

DO12

56

DO13

57

DO14

58

DO15

59

COM

60

FG

10

11

12

49

50

51

52

53

54

55

56

57

58

59

60

The RCJ module must be connected in case of thermocouple input.

Remove it for resistance bulb input.

PV1 Measurement value input 1

+

33

36

-

DC current

+

33

--

[V]

DC voltage Thermo-

+

[mV]

34

3636

RCJ Module

B

34

A

35

B

36

Resistance

bulb

The RCJ module must be connected

in case of thermocouple input.

Remove it for resistance bulb input.

Analog input

AI1

DC voltage

18

+

19

20

Valve opening

FB

feedback input

Potentiometer

I+ (100%)

I

-

(0%)

33

+

34

35

36

-

couple

Io

18

19

20

[Note1] Connection to the transmitter power supply

4 to 20 mA DC

Transmiter

External wiring

needed

OUT2

+

3

Transmitter power supply

-

4

PV1

+

33

Input type code 26 (4 to 20 mA DC)

-

(Input impedance 250Ω)

36

19

Page 20

PXH9

INSULATION BLOCK DIAGRAM

Power source

Digital output (DO) 1, 2

Digital output (DO) 3

Digital output (DO) 4

Digital output (DO) 11 to 15

Basic insulation (1500 V AC)

Functional insulation (500 V AC)

No insulation

Internal Circuit

PC Loader interface

Measurement value input 1 (PV1)

Measurement value input 2 (PV2)

Auxiliary analog Input 1 (Ai1) /

Valve openings feedback input (FB)

Output 1 (Current / SSR driver)

Output 2 (Current / SSR driver)

Digital input (DI) 1 to 4

Digital input (DI) 11 to 15

Transmitter power supply

RS485

Caution on Safety

*Before using this product, be sure to read its instruction manual in advance.

Head Office

Gate City Ohsaki, East Tower, 11-2, Osaki 1-chome,

Shinagawa-ku, Tokyo 141-0032, Japan

http://www.fesys.co.jp/eng

Instrumentation Div.

International Sales Dept.

No.1, Fuji-machi, Hino-city, Tokyo, 191-8502 Japan

Phone: 81-42-585-6201, 6202 Fax: 81-42-585-6187

http://www.fic-net.jp/eng

Information in this catalog is subject to change without notice.

Printed in Japan

Loading...

Loading...