Page 1

Instruction Manual

DIGITAL CONTROLLER

COMMUNICATION

FUNCTIONS (MODBUS)

TYPE: PXH

INP-TN514207-E

Page 2

Note: Windows® is the registered trade mark of Microsoft Corporation.

Note: Visual Basic® is the registered trade mark of Microsoft Corporation.

Note: MODBUS® is the registered trade mark of Gould Modicon.

z Exemption items from responsibility

The contents of this document may be changed in the future without prior notice.

We paid the utmost care for the accuracy of the contents. However, we are not liable for direct

and indirect damages resulting from incorrect descriptions, omission of information, and use of

information in this document.

Notice

Page 3

CONTENTS

CONTENTS....................................................................................................................... i

1. COMMUNICATION FUNCTIONS ......................................................................................1

1.1 Outline..........................................................................................................................1

2. SPECIFICATIONS.................................................................................................................2

2.1 Communication Specifications ....................................................................................2

3. CONNECTION ......................................................................................................................3

3.1 Communication Terminal Allocation...........................................................................3

3.2 Wiring ..........................................................................................................................4

4. SETTING OF COMMUNICATION CONDITION...............................................................6

4.1 Setting items.................................................................................................................6

4.2 Setting Operation Method............................................................................................7

5. MODBUS COMMUNICATION PROTOCOL......................................................................8

5.1 Outline..........................................................................................................................8

5.2 Composition of Message..............................................................................................9

5.3 Response of Slave Station..........................................................................................11

5.4 Function Code ............................................................................................................12

5.5 Calculation of Error Check Code (CRC-16)..............................................................13

5.6 Transmission Control Procedure................................................................................14

5.7 FIX Processing (Cautions in data write) ....................................................................16

6. DETAILS OF MESSAGE....................................................................................................17

6.1 Read-out of Word Data [Function code: 03H]......................................................17

6.2 Read-out of Read-out Only Word Data [Function code: 04H]....................................19

6.3 Write-in of Word Data (1 word) [Function code: 06H]...............................................21

6.4 Write-in of Continuous Word Data [Function code: 10H] ..........................................22

7. ADDRESS MAP AND DATA FORMAT.............................................................................24

7.1 Data Format................................................................................................................24

7.2 Communication Address Map ....................................................................................28

8. SAMPLE PROGRAM .........................................................................................................37

9. TROUBLESHOOTING .......................................................................................................43

INP-TN514207-E

i

Page 4

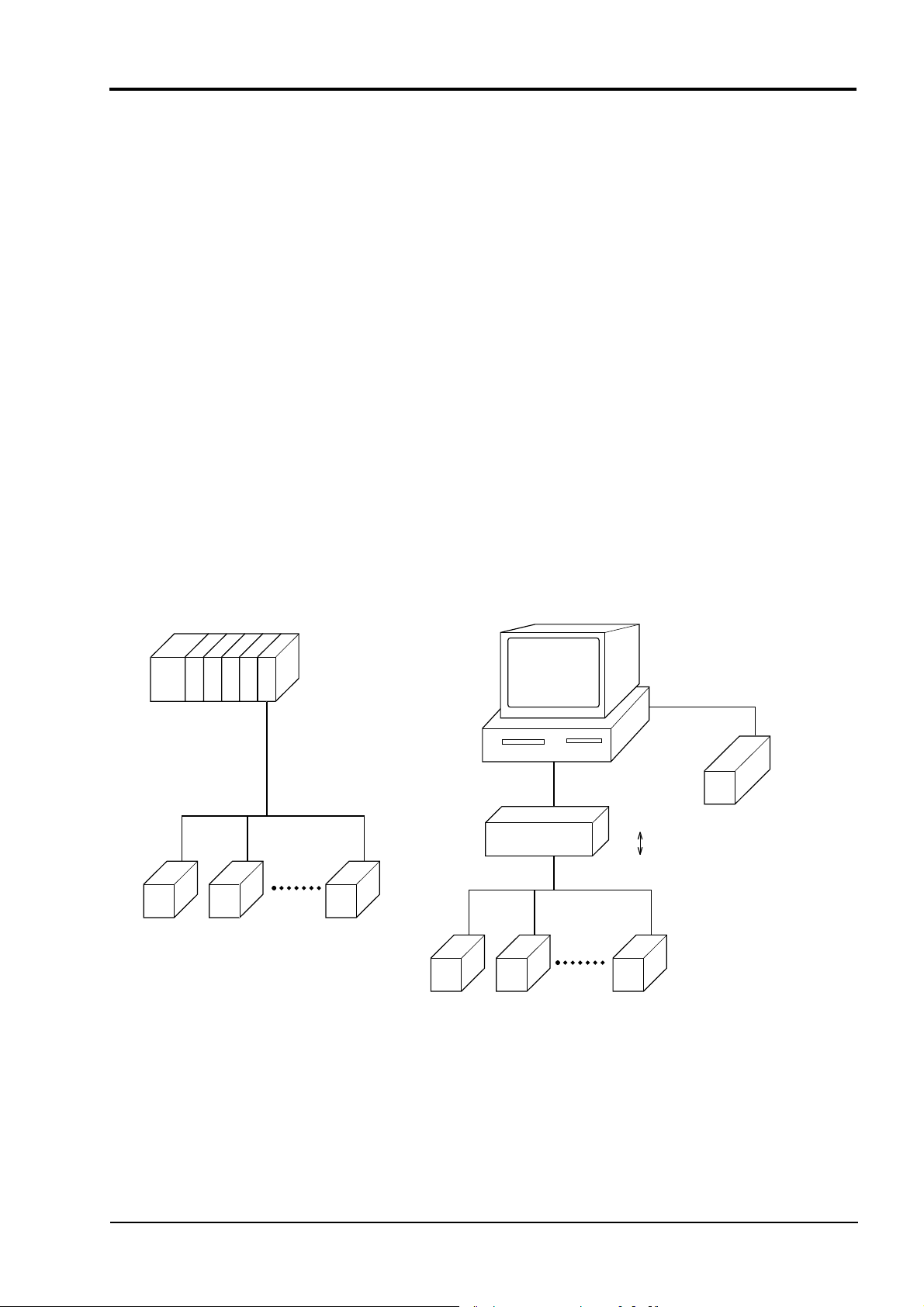

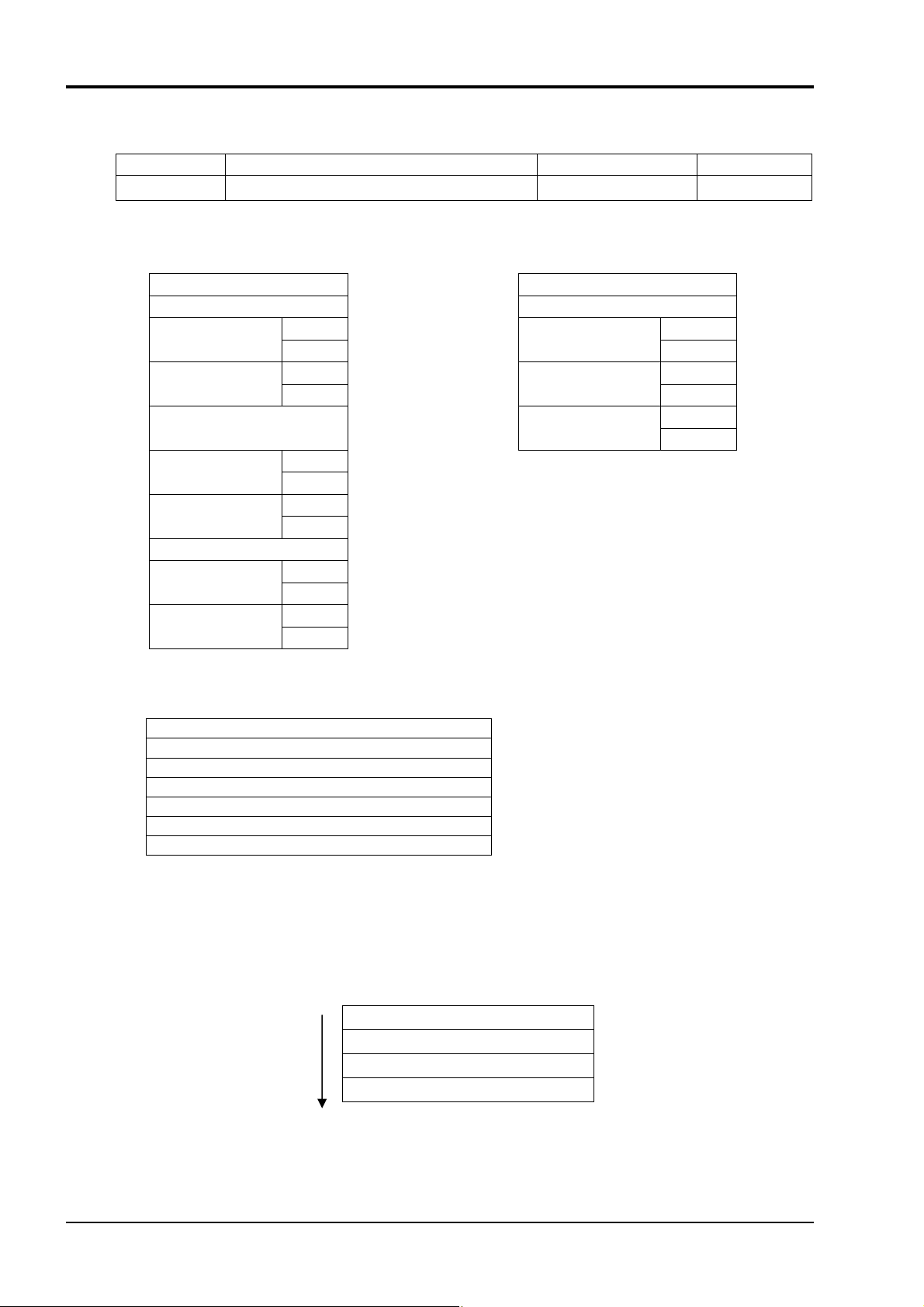

1. COMMUNICATION FUNCTIONS

1.1 Outline

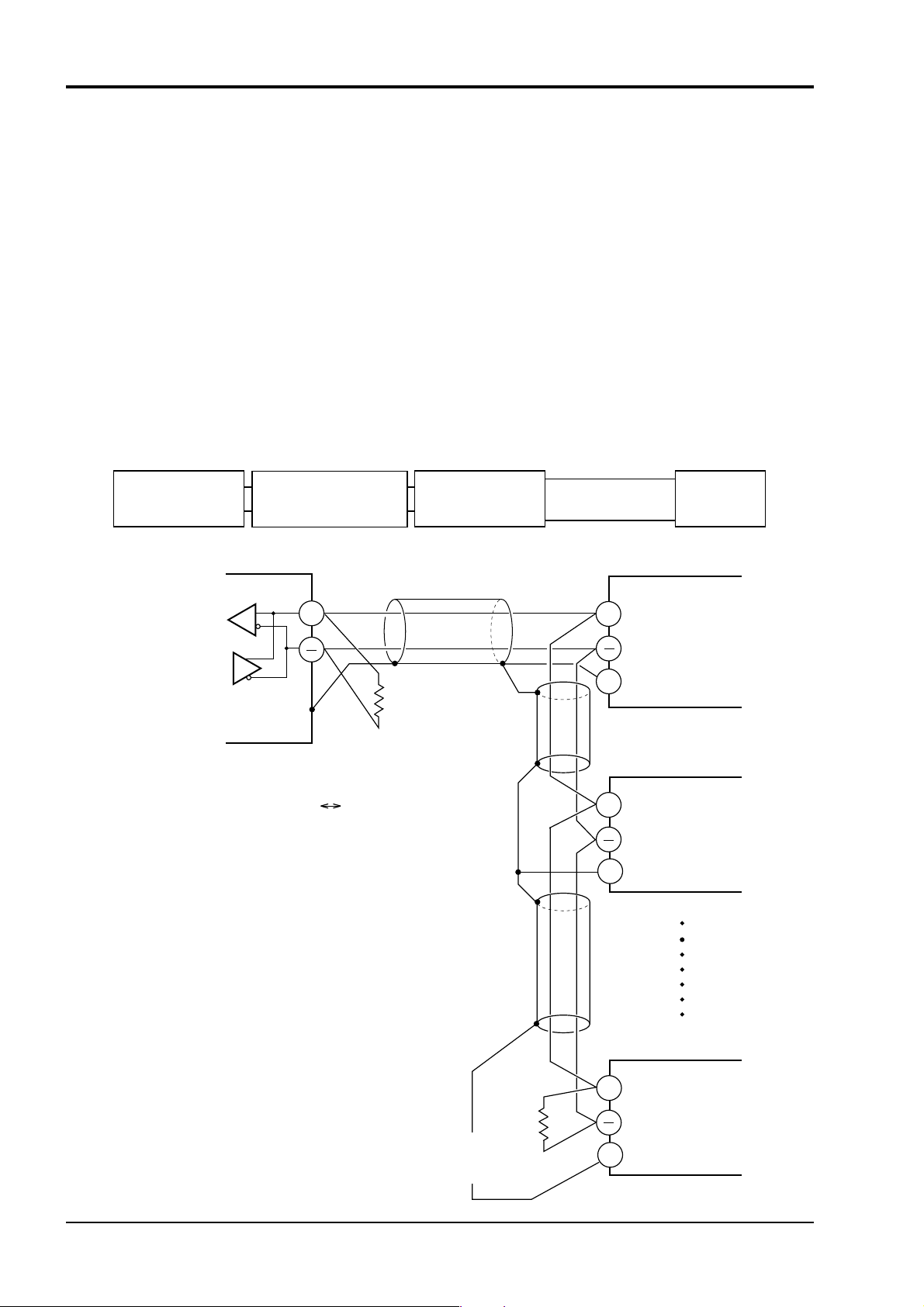

▪ Via RS-485 interface and PC loader interface, PXH provides communication functions of transmit-

ting and receiving data to and from host computer, programmable controller, graphic panel, etc.

▪ The communication system consists of master station and slave stations. For RS-485 communica-

tion, up to 31 slave stations (PXHs) can be connected per master station.

Note that, because the master station can communicate with only one slave station at a time, a party

to communicate with must be specified by the "Station No." set at each slave station.

For loader communication, one slave station (PXH) can be connected per master station.

▪ In order that the master station and slave station can communicate, the format of the trans-

mit/receive data must coincide. For the PXH, the format of the communication data is determined

by the MODBUS protocol.

▪ Please use an RS-232C ⇔ RS-485 converter in case of designating a personal computer or other

devices which have an RS-232C interface as a master station.

[RS-232C ⇔ RS-485 converter] (recommended article)

Type: RC-77 (isolated type)/ RA SYSTEMS make http://www.ras.co.jp

Type: K3SC-10 (isolated type)/ OMRON make http://www.omron.co.jp

RS-232C communication with PC is available upon connecting Type: ZZPPXH1*TK4H4563 to PC

loader interface where PXH is provided in standard.

Programmable

controller

RS-485

RS-232C

RS-485

Personal

computer

RS-232C

D-sub9 pin

RS-232C

RS-485 communication converter

Caution:

When using the RS-232C ⇔ RS-485 converter, pay attention to cable connection between the con-

verter and master station. If the cable is not connected correctly, the master station and slave station

cannot communicate. In addition, be careful about communication settings such as baud rate and

parity set for the converter.

PC loader

interface

INP-TN514207-E

1

Page 5

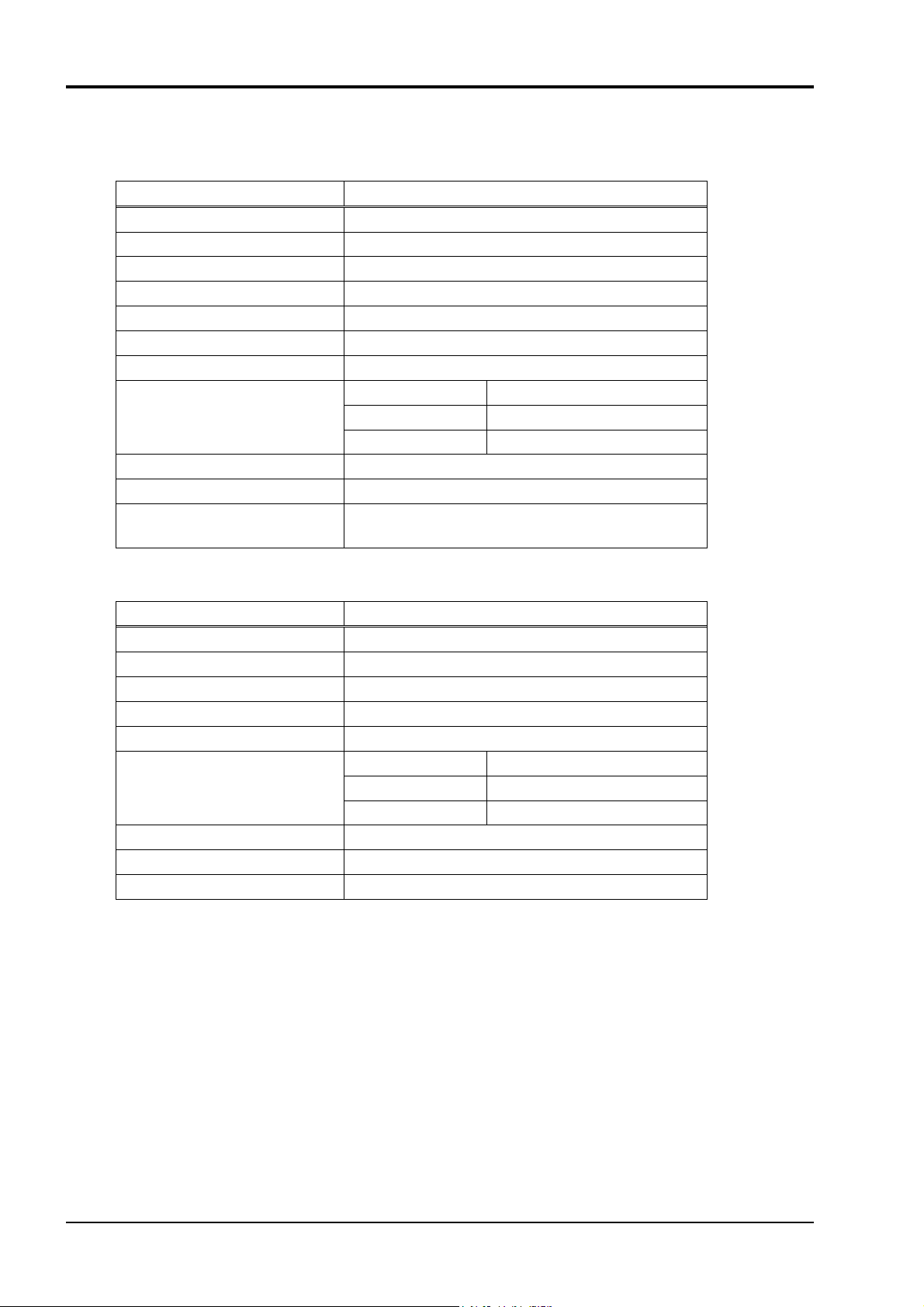

2. SPECIFICATIONS

2.1 Communication Specifications

■ RS-485

Item Specification

Electrical specification Based on EIA RS-485

Transmission method 2-wire, half duplex

Synchronous system Start-stop synchronous system

Connection format 1 : N

Number connectable units Up to 31 units

Transmission distance 500m max. (total extension distance)

Transmission speed 9600bps, 19200bps, 38400bps

Data format Data length 8 bits

Stop bit 1 bit

Parity none, even, odd (selectable)

Transmission code HEX value (MODBUS RTU mode)

Error detection CRC-16

Isolation

■ PC loader interface

Functional isolation between transmission circuit

and others (withstand voltage : 500V AC)

Item Specification

Electrical specification EIA RS232C

Transmission method 3-wire, half duplex, bit-sereal

Synchronous system Start-stop synchronous system

Connection format 1 : 1

Transmission speed 9600bps, 19200bps, 38400bps

Data format Data length 8 bits

Stop bit 1 bit

Parity none, even, odd (selectable)

Transmission code HEX value (MODBUS RTU mode)

Error detection CRC-16

Isolation Non-isolated from internal circuit

INP-TN514207-E

2

Page 6

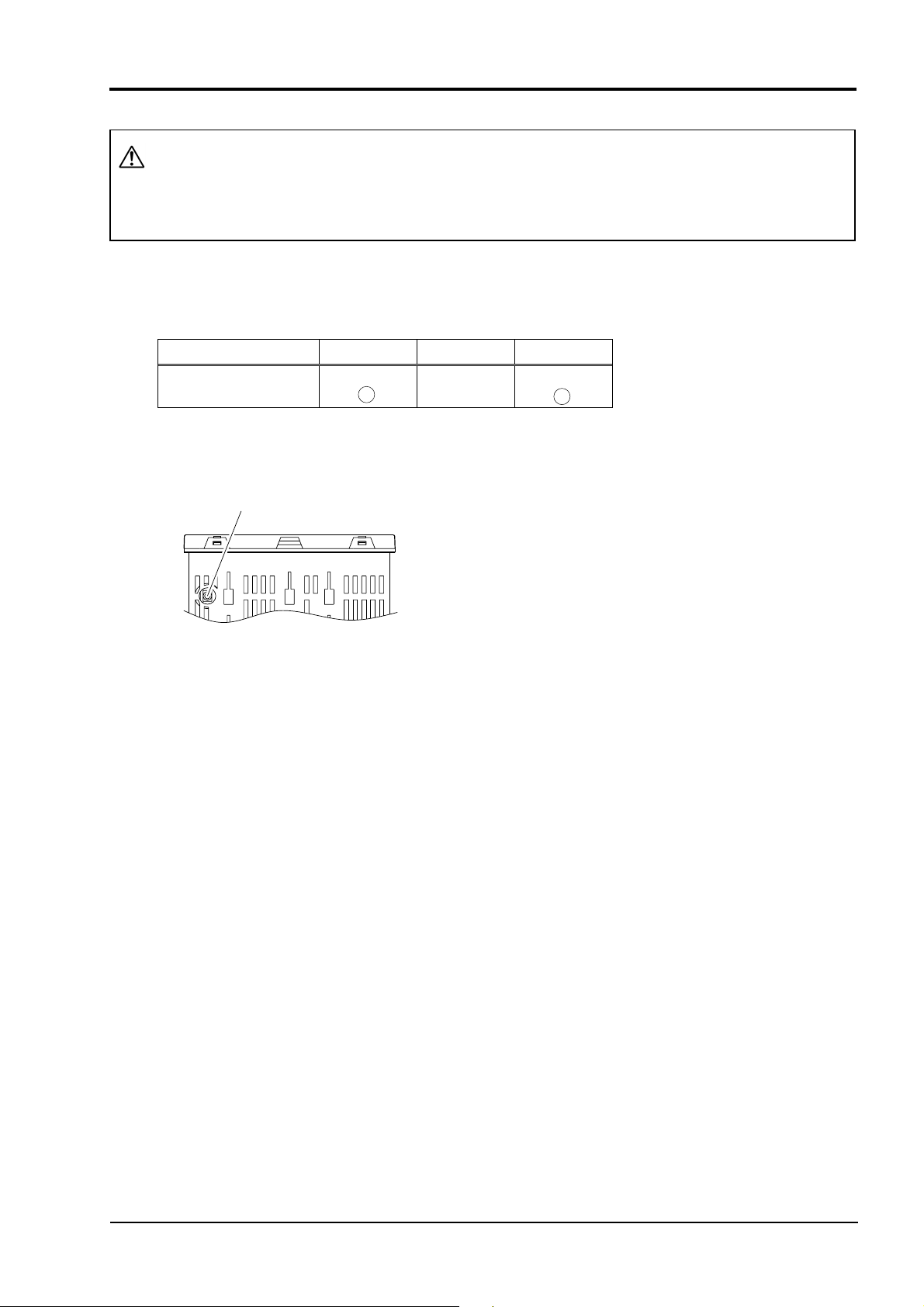

3. CONNECTION

WARNING

For avoiding electric shock and malfunctions, do not turn on the power supply until all wiring is

completed.

3.1 Communication Terminal Allocation

■ PXH9 (RS-485)

Terminal number (14) (15) (16)

Signal name

■ PXH9 (PC loader interface)

PC loader interface

RS485

+

SG

RS485

–

Φ2.5, 3-pole miniature jack

INP-TN514207-E

3

Page 7

3.2 Wiring

■ RS-485

▪ Use twisted pair cables with shield. Recommended: KPEV-SB (Furukawa Electric make)

▪ The total extension length of the cable is up to 500 m. A master station and up to 31 units of the

PXH can be connected per line.

▪ Both ends of the cable should be terminated with terminating resistors 100Ω (1/2W or more).

▪ If the PXH is to be installed where the level of noise applied to the PXH may exceed 1000 V, it is

recommended to install a noise filter in the master station side as below.

Recommended noise filter: ZRAC2203-11 (TDK make)

▪ If problematic in EMC at communication, loading the communication cable with ferrite can lower

the noise level.

Recommended ferrite core: ZCAT series (TDK make)

MSFC series (Morimiya Electric make)

Master station

(PC, etc.)

RS-232C⇔RS-485

Master station side

Twisted pair cable with shield

+

SG

RS-485 interface

or

RS-485 side of the RS-232C RS-485 converter

Terminating resistor

100Ω (1/2W)

Noise filter PXH

Transmission

cable

Slave (PXH)

+

SG

Slave (PXH)

+

SG

Slave (PXH)

▪ SG connection is not mandatory, but is

+

effective for remedying communication

errors attributable to noises.

Terminating

resistor

100Ω (1/2W)

SG

INP-TN514207-E

4

Page 8

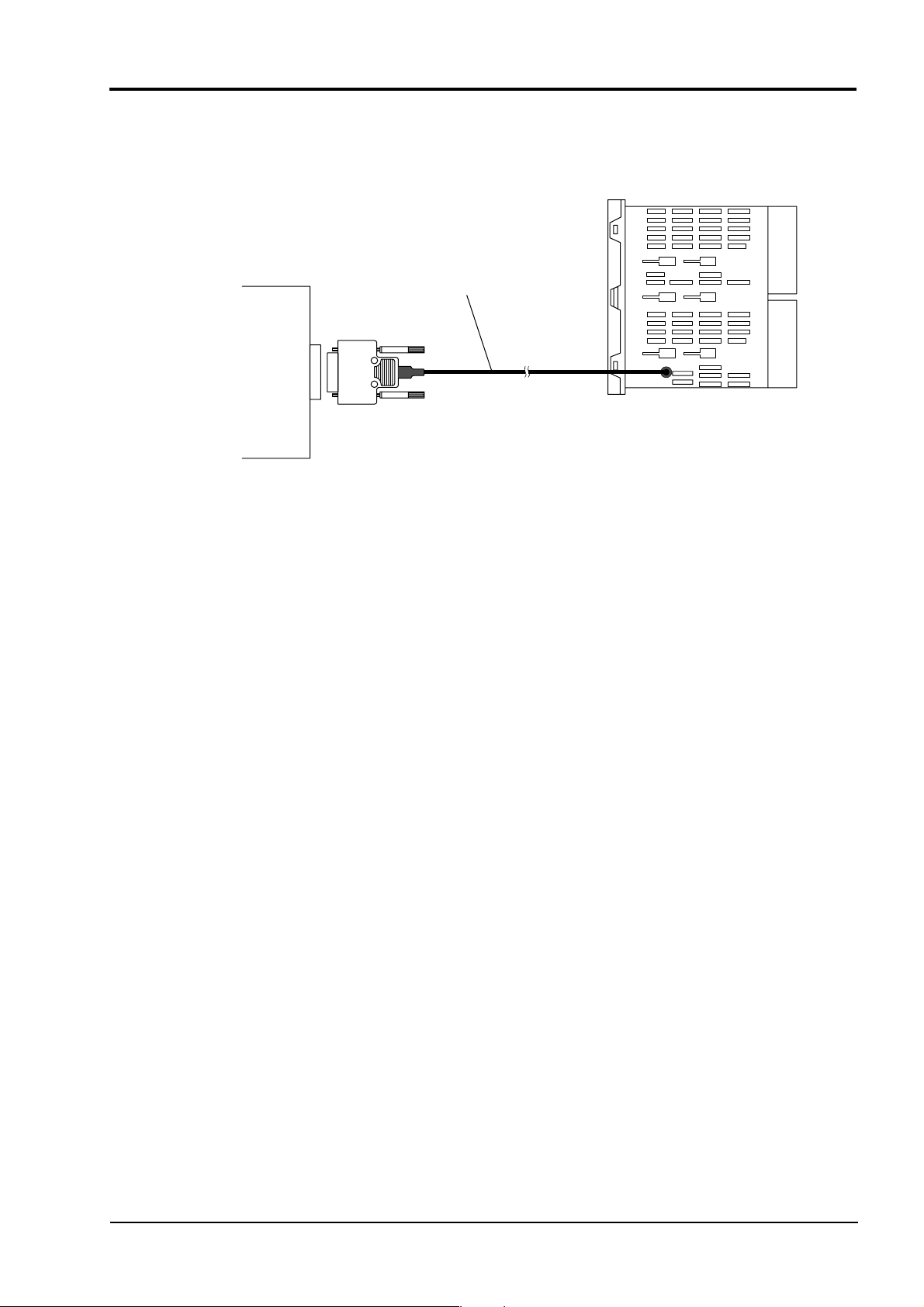

■ PC loader communication

▪ Use an optional PC loader communication cable (RS-232C).

PC loader communication cable

Master station side

(RS232C)

ZZPPXH1 TK4H4563

*

PC or the like

RS232C

D-Sub 9 pins

Bottom of PXH

INP-TN514207-E

5

Page 9

4. SETTING OF COMMUNICATION CONDITION

In order that the master station and instrument (PXH) can correctly communicate, following settings are required.

▪ All communication condition settings of the master station and those of instruments (PXH) are indentical.

▪ For RS-485 communication, different "station numbers (STN4)" are assigned to all PXHs which are con-

nected to a common line. (Any "Station No." is not shared by more than one instrument.)

▪ For PC loader communication, the station No. is fixed at "1".

Both for PC loader communication and RS-485 communication, same station No. "1" may be assigned.

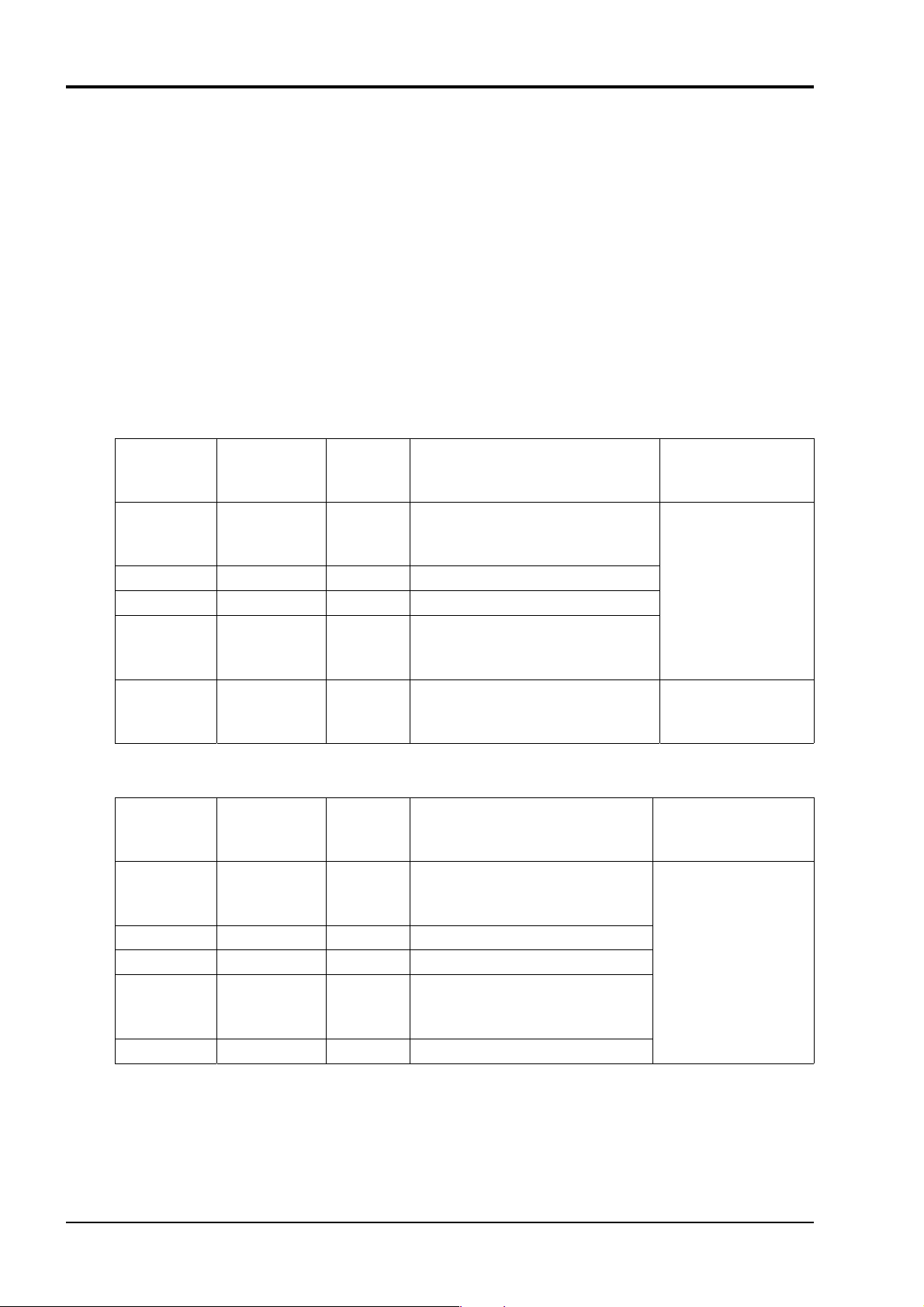

4.1 Setting items

The parameters to be set are shown in the following table. Set them by operating the front panel

keys.

■ RS-485

CH B COM

Parameter

symbol

SPD4

――― Data length 8 bits Fixed (can not be changed)

――― Stop bit 1 bit Fixed (can not be changed)

BIT4 Parity setting odd

STN4 Station No. 1

■ PC loader communication

CH B COM

Parameter

symbol

SPD2

――― Data length 8 bits Fixed (can not be changed)

――― Stop bit 1 bit Fixed (can not be changed)

BIT2 Parity setting odd

――― Station No. 1 Fixed (can not be changed)

Item

Transmission

speed

Item

Transmission

speed

Value at

delivery

38400bps

Value at

delivery

38400bps

Setting range Remarks

96 : 9600bps

192 : 19200bps

384 : 38400bps

8n : none parity

8o : odd parity

8E : even parity

0 to 255

(0: communication function stop)

Setting range Remarks

96 : 9600bps

192 : 19200bps

384 : 38400bps

8n : none parity

8o : odd parity

8E : even parity

Set the same

communication

condition to

the master station

and all slave

stations.

Set a different

number to each

station.

Set the same

conditions as

the master station.

INP-TN514207-E

6

Page 10

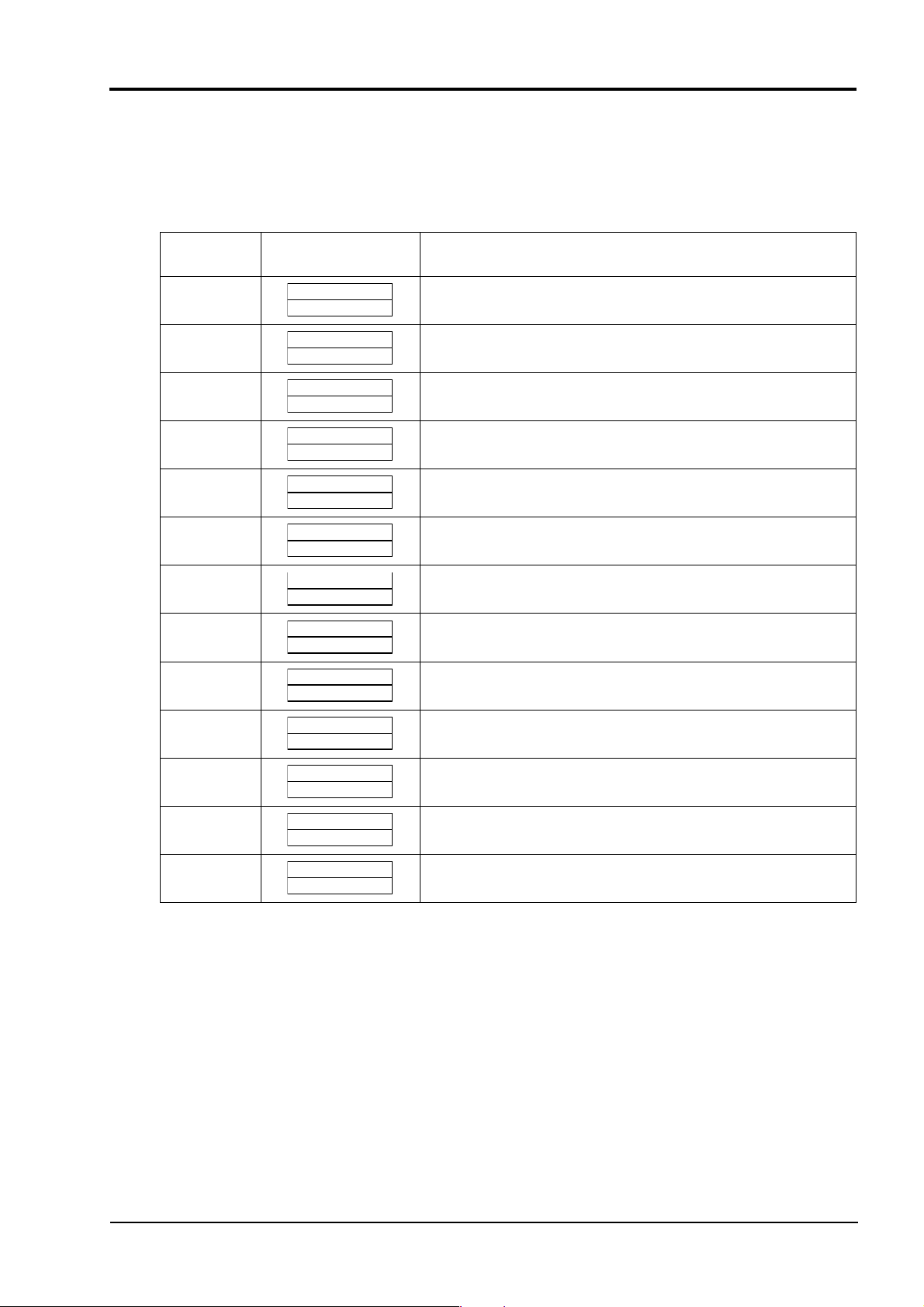

4.2 Setting Operation Method

The following example shows how to set the communication conditions.

Example: For RS-485, set BIT4 parity at even and STN4 at 18.

Key

operation

SEL

∨

SEL

SEL

>∧∨

SEL

∨

SEL

Indication Description

200

LP01SV

200

PS1

0000

b COM

Ch

b. STN4

02 1

b. STN4

02 00001

b. STN4

02 00018

b. STN4

02 18

b. BIT4

04 8o

b. BIT4

04 8o

Operation status (PV/SV indication) or (PV/MV indication)

Press the SEL key to display PS1.

Press the ∨ key repeatedly until b.COM channel appears. (If

past over, press the ∧ key to return.)

Press the SEL key to display STN4 parameter.

Press the SEL key. The numeric value on the lower

indicator blinks and the setting mode is selected.

Press the >, ∧, or ∨ key to change the numeric value to 18.

Press the SEL key again. The numeric value stops blinking

and the setting is registered.

Press the ∨ key to display the BIT4 parameter.

Press the SEL key. The numeric value on the lower

indicator blinks and the setting mode is selected.

∧∨

SEL

DISP

DISP

b. BIT4

04 8E

b. BIT4

04 8E

b COM

Ch

LP01SV

200

200

Press the ∧ or ∨ key until the numeric value changes to 8E

(even parity).

Press the SEL key again. The numeric value stops blinking

and the setting is registered.

Press the DISP key to resume b.COM channel indication.

Press the DISP key to resume the operation status (PV/SV

indication).

* Be sure to turn off and on power so that the communication condition settings will affect the control.

INP-TN514207-E

7

Page 11

5. MODBUS COMMUNICATION PROTOCOL

5.1 Outline

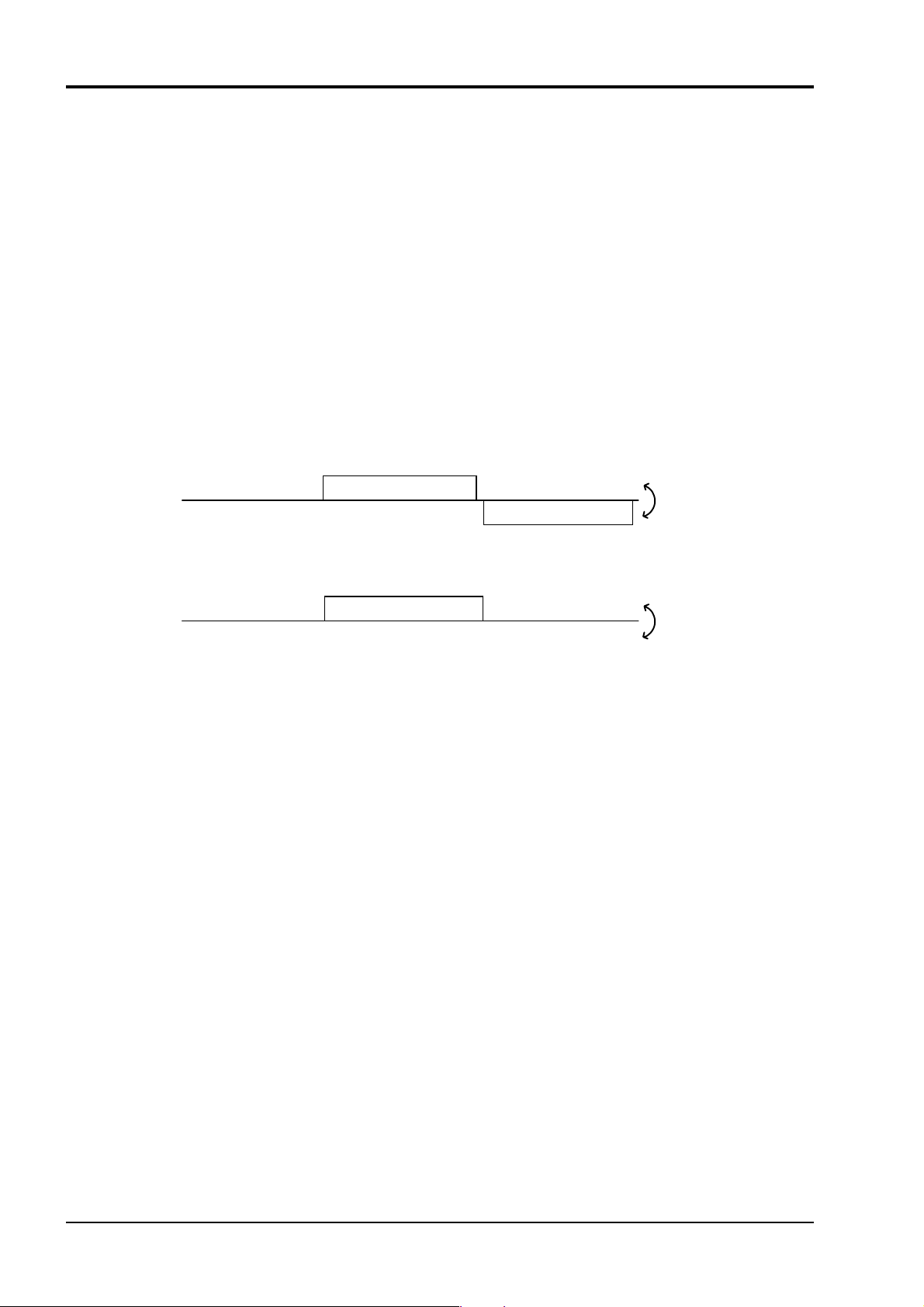

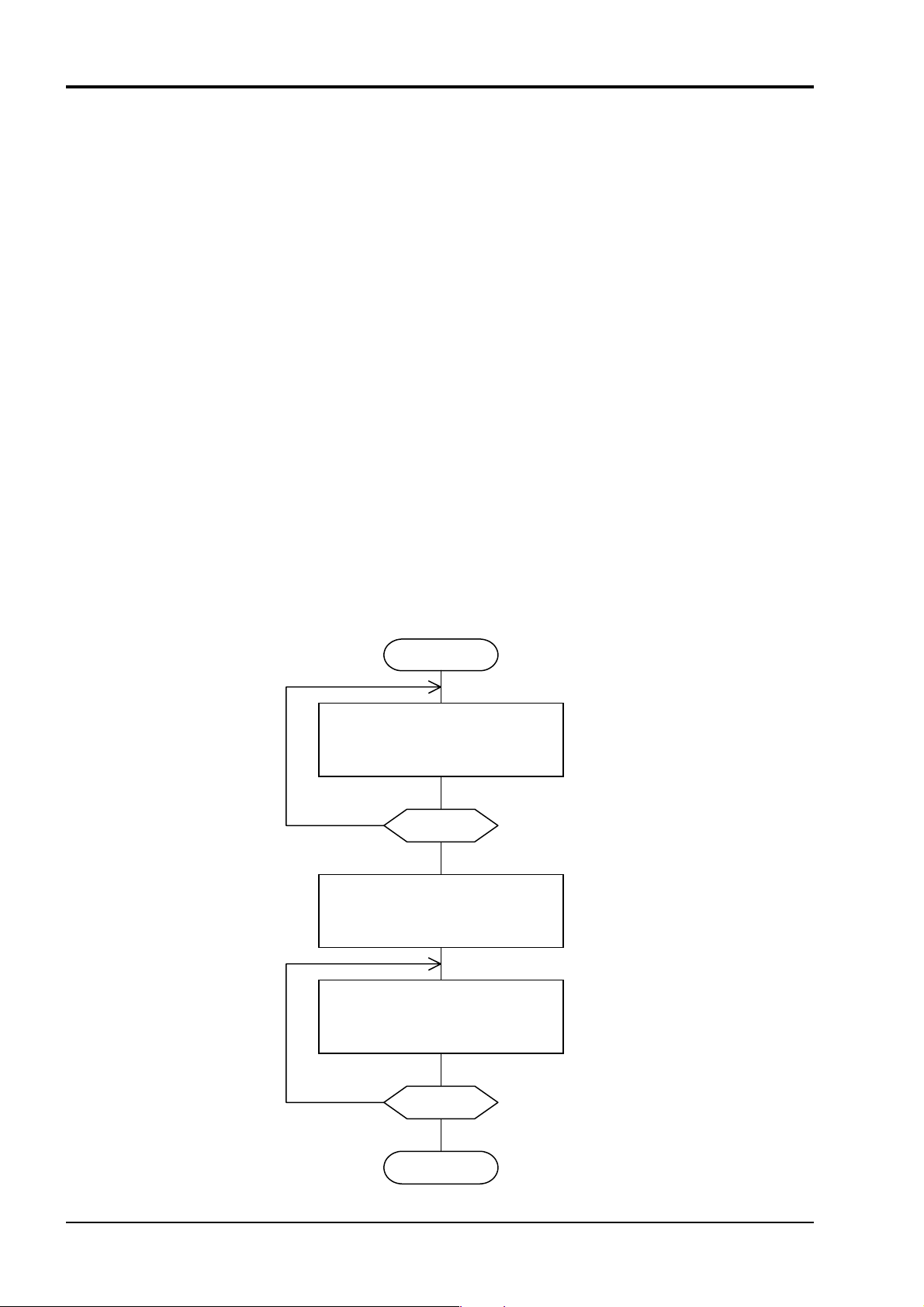

The communication system by the MODBUS protocol is that the communication always starts from

the master station and a slave station responds to the received message.

Transmission procedures is as shown below.

1) The master station sends a command message to a slave station.

2) The slave station checks that the station No. in the received message matches with the own station No.

or not.

3) If matched, the slave station executes the command and sends back the response message.

4) If mismatched, the slave station leaves the command message and wait for the next command

message.

a) In case when the station No. in the received command message matches with the own slave

station No.

Master to slave

Slave to master

b) In case when the station No. in the received command message mismatches with the own

slave station No.

Master to slave

Slave to master

The master station can individually communicate with any one of slave stations connected on the

same line upon setting the station No. in the command message.

Command message

Command message

Response message

(Not respond)

Data on

the line

Data on

the line

INP-TN514207-E

8

Page 12

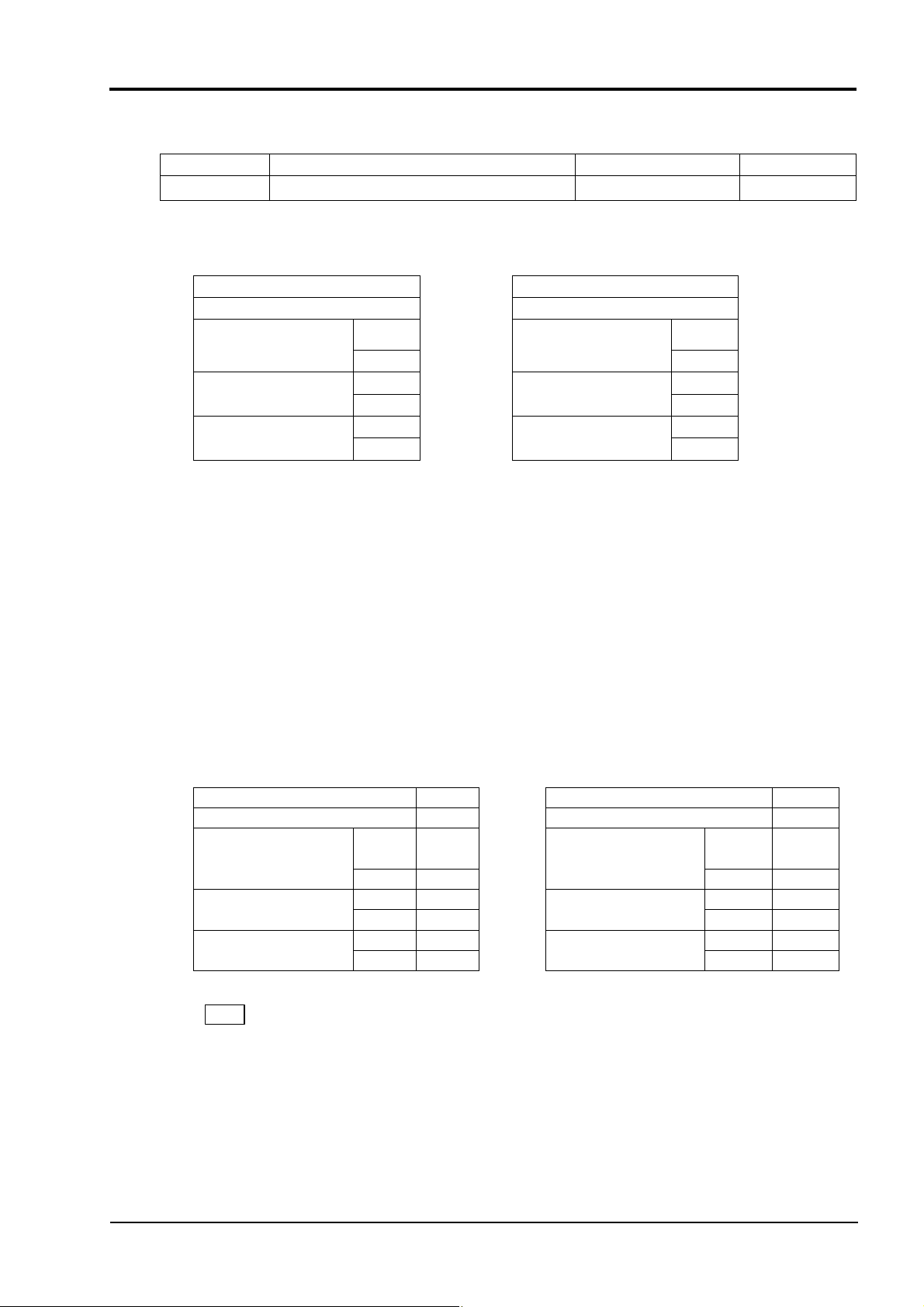

5.2 Composition of Message

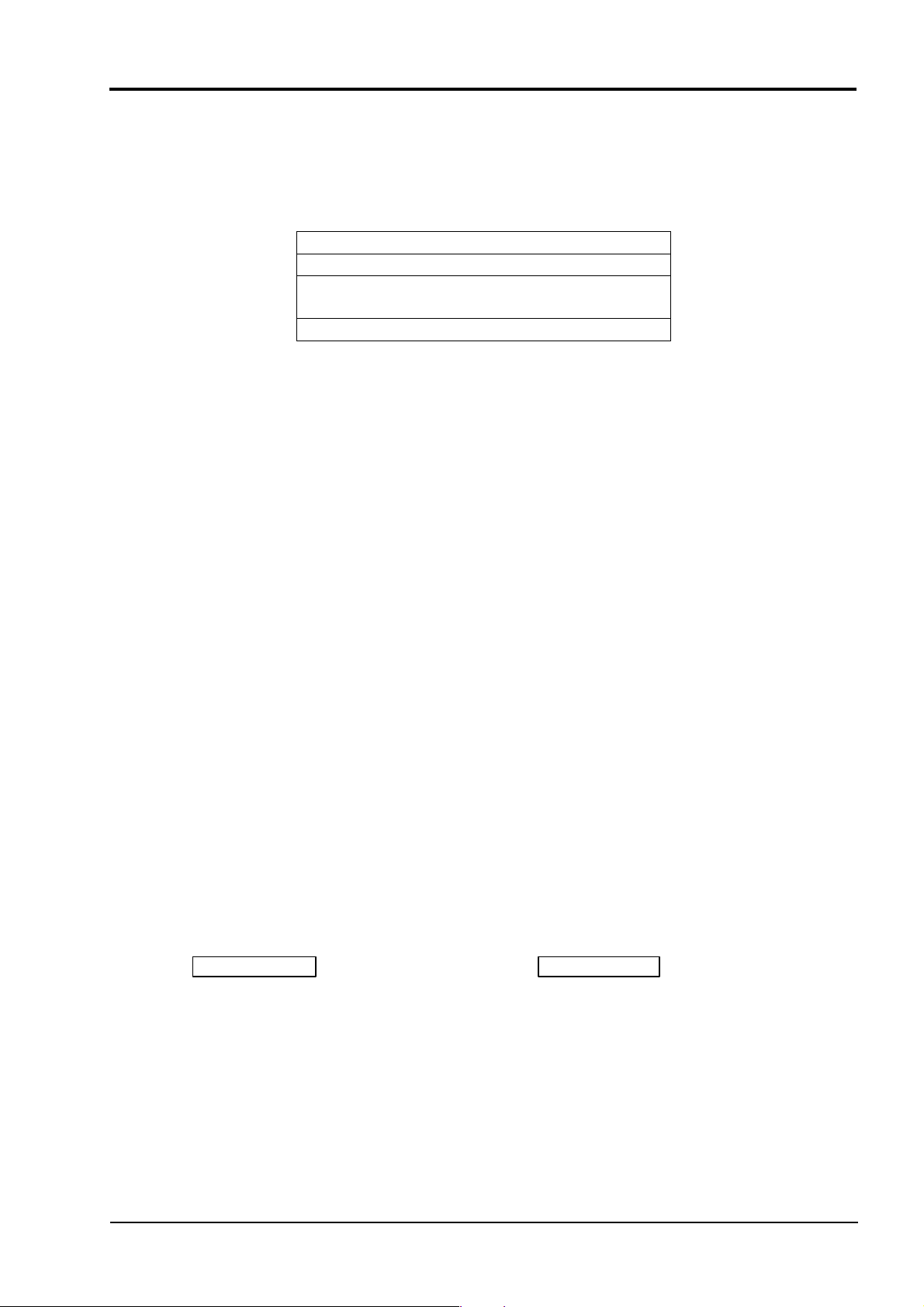

Command message and response message consist of 4 fields; Station No., Function code, Data and

Error check code. And these are sent in the following order.

Station No. (1 byte)

Function code (1 byte)

Data (2 to 69 bytes)

Error check code (CRC-16) (2 bytes)

Fig. 5-1 Composition of message

In the following, each field is explained.

(1) Station No

Station No. is the number specifying a slave station. For RS-485 communication, the command

is processed only by the slave station whose station No. matches with the No. set in the parameter "STN4".

For details of setting the parameter "STN4", refer to chapter 4.

For PC loader communication, the station No. is fixed at "1".

(2) Function code

This is a code to designate the function executed at a slave station.

For details, refer to section 5.4.

(3) Data

Data are the data required for executing function codes. The composition of data varies with

function codes. For details, refer to chapter 6.

A register number is assigned to each data in the indicating controller. For using the data by

communication, designate the register number.

Note that the register number transmitted on message is expressed as its relative address.

The relative address is calculated by the following expression.

Relateve address

The lower 4 digits of the

=

Register number

– 1

For example, when the resister number designated by a function code is 40003,

Relative address = (lower 4 digits of 40003) – 1

= 0002

is used on the message.

INP-TN514207-E

9

Page 13

(4) Error check code

This is the code to detect message errors (change in bit) in the signal transmission.

On the MODBUS protocol (RTU mode), CRC-16 (Cycric Redundancy Check) is applied.

For CRC calculation method, refer to section 5.5.

INP-TN514207-E

10

Page 14

5.3 Response of Slave Station

(1) Response for normal command

To a relevant message, the slave station creates and sends back a response message which corre-

sponds to the command message. The composition of message in this case is the same as in

section 5.2.

Contents of the data field depend on the function code. For details, refer to Chapter 6.

(2) Response for abnormal command

If contents of a command message have an abnormality (for example, non-actual function code is

designated) other than transmission error, the slave station does not execute that command but

creates and sends back a response message at error detection.

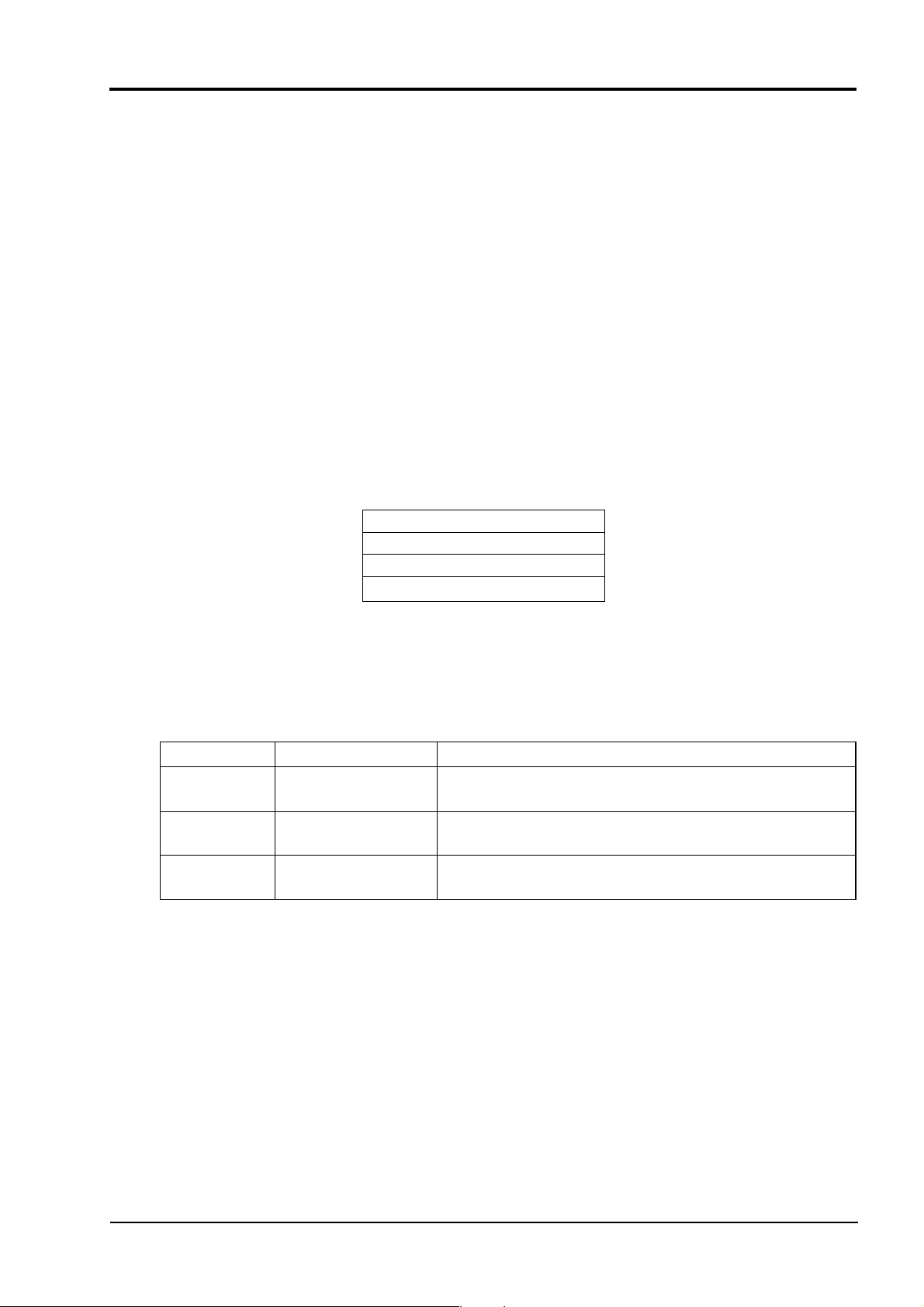

The composition of response message at error detection is as shown in Fig. 5-2. The value used

for function code field is function code of command message plus 80

Table 5-1 gives error codes.

Function code + 80H

Error check(CRC-16)

Station No.

Error code

.

H

Error code Contents Description

01H Illegal function code Non-actual function code is designated.

02H Illegal data address A relative address of resister number to which the

03H Illegal data value Because the designation of number is too much,

(3) No response

Under any of the following items, the slave station takes no action of the command message and

sends back no response.

▪ A station number transmitted in the command message differs from the station number speci-

▪ A error check code is not matched, or a transmission error (parity error, etc.) is detected.

▪ The time interval between the composition data of the message becomes longer than the time

▪ Station No. of a slave station is set as 0.

▪ A write-in command is sent while executing FIX.

Fig. 5-2 Response message at error detection

Table 5-1 Error Code

Check for the function code.

designated function code can not be used.

the area where resister numbers do not exist is designated.

fied to the slave station.

corresponding to 24 bits. (Refer to section 5.6 Transmission Control Procedure.)

INP-TN514207-E

11

Page 15

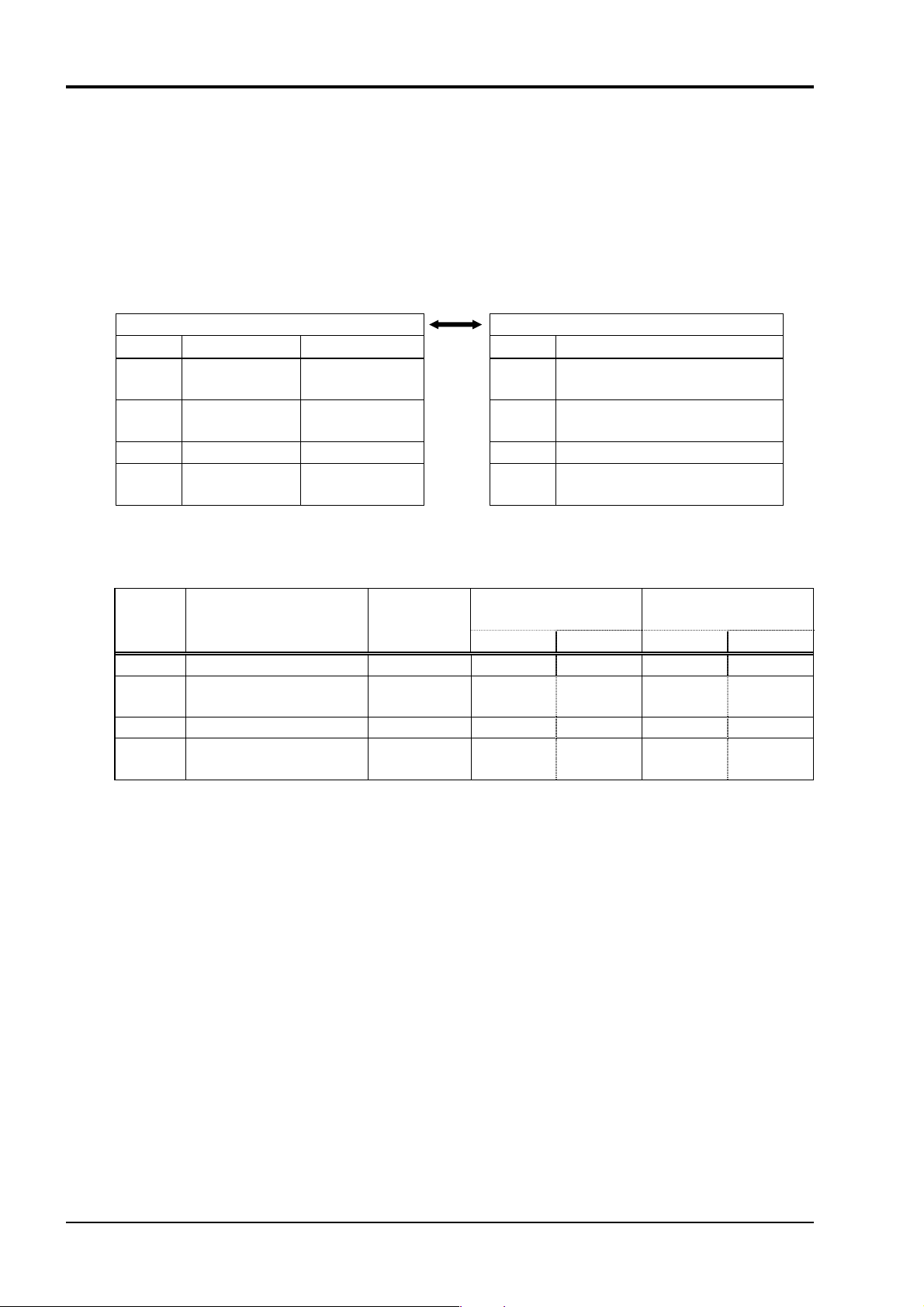

5.4 Function Code

According to MODBUS protocol, register numbers are assigned by function codes.

Each function code acts on specific register number.

This correspondence is shown in Table 5-2, and the message length by function is shown in Table 5-3.

Table 5-2 Correspondence between function codes and objective address

Function code Resister No.

No. Function Object No. Contents

03H

04H

06H Write-in Holding register 4xxxx Read-out/write-in word data

10H

Read-out

(continuously)

Read-out

(continuously)

Write-in

(continuously)

Holding register 4xxxx Read-out/write-in word data

Input register 3xxxx Read-out word data

Holding register 4xxxx Read-out/write-in word data

Table 5-3 Function code and message length

Function

code

03H Read-out of word data 32 words 8 8 7 69

04H

*1

06H Write-in of word data 1 word 8 8 8 8

10H

*1) For PXH, all data is designated by 2 words.

Read-out of word data

(read-out only)

Write-in of continuous

word data

(write-in of word data) is used, only 1 lower word can be written in, and only 1 upper word

If 06

H

cannot.

Contents

Number of

designatable

data

15 words 8 8 7 35

32 words 11 73 8 8

[Unit:byte]

Command message Response message

Minimum Maximum Minimum Maximum

INP-TN514207-E

12

Page 16

5.5 Calculation of Error Check Code (CRC-16)

CRC-16 is the 2-byte (16-bits) error check code. From the top of the message (station No.) to the

end of the data field are calculated.

The slave station calculates the CRC of the received message, and does not respond if the calculated

CRC is different from the contents of the received CRC code.

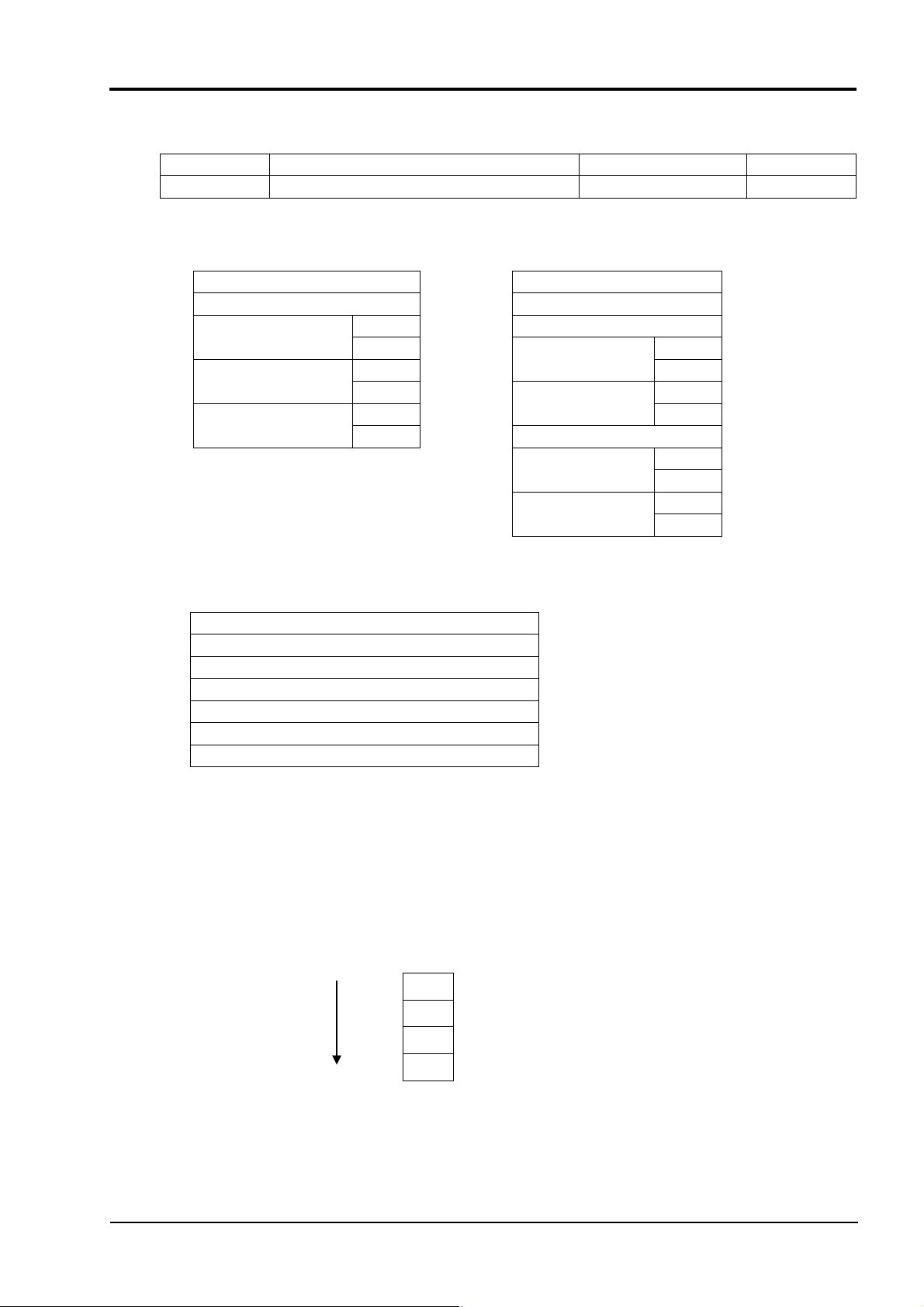

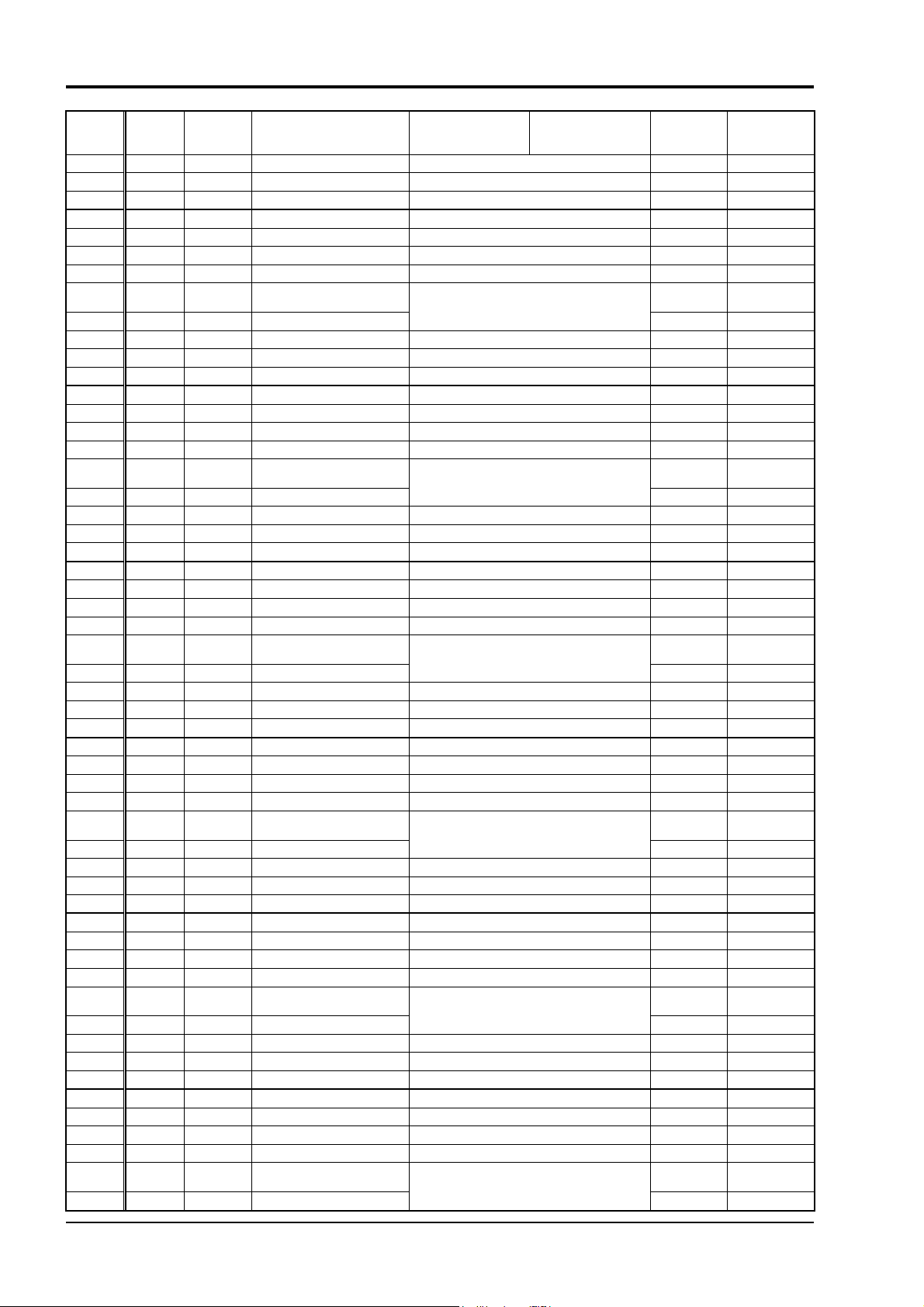

Fig. 5-3 shows the flow of the CRC-16 calculation system.

Set FFFFH (hexadecimal number) in CR.

Exclusive logical sum (XOR) is executed

with CR and one character (1 byte) of the I

characters, and its results is set in CR.

Start

Set 1 in I.

Explanation of variables

CR : CRC error check data (2 bytes)

I : Digits of calculation characters

in command message

J : Check on the number of times

of CR calculation

Set 1 in J.

Bit at right end

of CR is 1?

YES

Shift CR to right by 1 bit, and A001H and

exclusive logical sum (XOR) are executed

and its result is set in CR.

Add 1 to J.

NO

Calculation (8 times)

is finished?

J>8

YES

Add 1 to I.

NO

Shift CR to right by 1 bit.

INP-TN514207-E

NO

Calculation of all characters is

completed?

I>All characters

YES

End

Fig. 5-3 Flow of CRC-16 calculation

13

(Calculation is executed in the order

of command message station No.,

function code and data.)

CR calculation result shall be added

to the last command message in the

order of LOW byte and HIGH byte.

Page 17

5.6 Transmission Control Procedure

(1) Transmission procedure of master station

The master station must proceed to a communication upon conforming to the following items.

(1-1) Before sending a command message, provide 48 bits time or more vacant status.

(1-2) For 1 command message, each field part should be sent below 24 bits time interval.

(1-3) Within 24 bits time after sending a command message, receiving stand-by status

starts.

(1-4) Provide 48 bits time or more vacant status between the end of response message re-

ception and beginning of next command message sending [same as in (1-1)].

(1-5) For ensuring the safety, make a confirmation of the response message and make an

arrangement so as to provide 3 or more retries in case of no response, error occurrence, etc.

Note) The above definition is minimum requirement. For ensuring the safety, it’s recom-

mended the program for the master should be developed with 2 to 3 times margins.

Concretely, it is advised to arrange the program for 9600 bps with 10 ms or more for

vacant status (1-1), and within 1 ms for byte interval (1-2) and changeover from

sending to receiving (1-3).

(2) Description

1) Detection of the message frame

2) Response of this instrument (PXH)

Since the communication system uses the 2-wire RS-485 interface, there may be 2 statuses

on a line below. (The same goes with PC loader communication.)

(a) Vacant status (no data on line)

(b) Communication status (data is existing)

Instruments connected on the line are initially at a receiving status and monitoring the line.

When 24 bits time or more vacant status has appeared on the line, the end of preceding frame

is assumed and, within following 24 bits time, a stand-by status is posted. When data ap-

pears on the line, the instruments enter on receiving, and when 24 bits time or more vacant

status is detected again, and the end of that frame is assumed. I.e., data which appeared on

the line from the first 24 bits time or more vacant status to the next 24 bits time or more vacant status is fetched as one frame.

Therefore, one frame (command message) must be sent upon confirming the following.

(1-1) 48 bits time or more vacant status precedes the command message sending.

(1-2) For 1 command message, each byte should be sent below 24 bits time interval.

After a frame detection (24 bits time or more vacant status is detected), this instrument car-

ries out processing with that frame as a command message. If the command message is ad-

dressed to the own station, a response message is returned. Its processing time is about 10

ms (depends on contents of command message).

After sending a command message, therefore, the master station must observe the following

(1-3) Stand-by status is posted within 24 bits time after sending a command message.

INP-TN514207-E

14

Page 18

Controll

station

Controll

station

→

←

PXH

PXH

POL1

Space of longer than 50msis needed.

(longer than 100ms is recommended.)

POL2

About 10 msec

POL1 response data

Data on line

POL1 POL2 POL1 response data

INP-TN514207-E

15

Page 19

5.7 FIX Processing (Cautions in data write)

The instrument is provided inside with a non-volatile memory (EEPROM) for holding the setting pa-

rameters. Data written in the non-volatile memory is not lost even if turning off the power.

To hold parameters that were written in the internal memory via communication after turning off the

power, the FIX process is effective. It allows parameters to be written in nonvolatile memory.

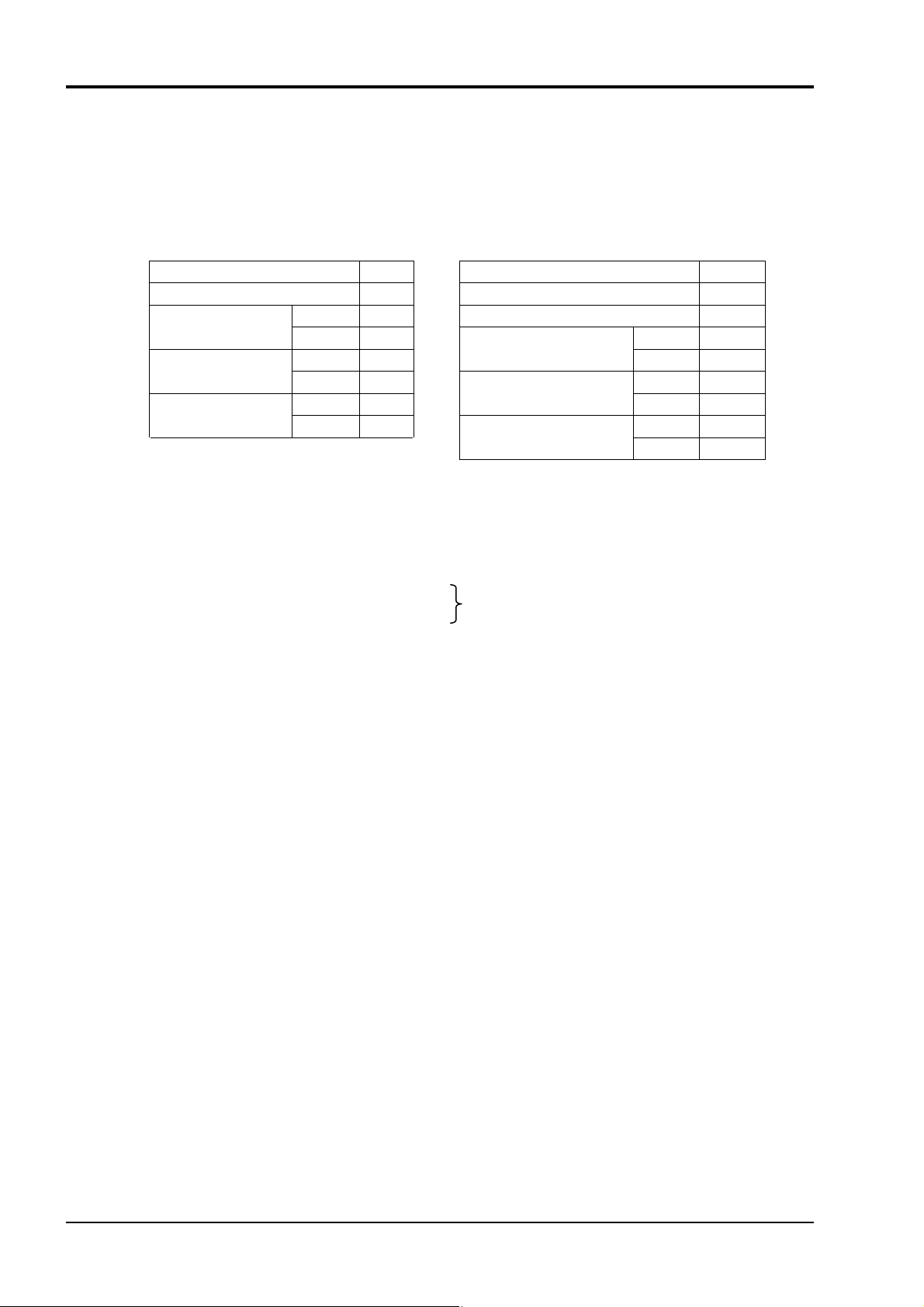

Fig. 5-4 shows the FIX procedure.

Cautions:

▪ FIX processing takes approximately 5 seconds to 3 minutes (depending on how many parameters

were changed).

▪ While writing, do not turn off the power of the PXH. Otherwise, the data in the non-volatile

memory will be destroyed, whereby the PXH could not be used any longer.

▪ Don’t change parameters on the front panel when performing the FIX procedure, or memory error

may result.

▪ The non-volatile memory (EEPROM) is a device where the number of write-in times is limited.

The guaranteed number of write-in times of the non-volatile memory used on the instrument is

100,000 minimum. Therefore, limit the times of FIX processing to bare minimum, like when set-

ting parameters are changed. Refrain from carrying out the FIX processing periodically for example or while such is not absolutely required.

Start FIX

Read the FIX address

with function code : 03

relative address : 0C50

No

FIX=0?

H

H

Yes

Write ‘1’ into FIX address

with function code : 06

relative address : 0C50

Read the FIX

with function code : 03

relative address : 0C50

address

H

H

H

H

No

FIX=0?

Yes

End FIX

Fig. 5-4 FIX procedure

INP-TN514207-E

16

Page 20

6. DETAILS OF MESSAGE

6.1 Read-out of Word Data [Function code: 03H]

Function code Max. word number read-out in one message Relative data address Register No.

03H 32 words 0000H – 0E7F 40001-43712

(1) Message composition

Command message composition (byte) Response message composition (byte)

Station No. Station No.

Function code Function code

Read-out start No.

(relative address)

Read-out

word number

CRC data

Upper

Upper

* Arrangement of read-out word data

Upper Read-out byte number

Lower Upper

Upper

Lower

Upper

Lower

1 to 32

State of the first

word data

State of the next

word data

~

State of the last

word data

CRC data

Lower

Upper

Lower

Lower

Lower

Read-out word

number × 2

~

MSB LSB

Upper byte of contents of the first word data

Lower byte of contents of the first word data

Upper byte of contents of the next word data

Lower byte of contents of the next word data

~

~

Upper byte of contents of the last word data

Lower byte of contents of the last word data

(2) Function explanation

Words data are read-out, starting from read-out start No. until read-out word number. The slave

station transmits the read-out word data in the order of upper and lower bytes.

For PXH for which all data consists of 2 word units, data should be read out by units of 2 words.

Example: Suppose data is 99999 (00 01 86 9F

) Suppose data is 1

H

(1) (2) (3) (4)

(3) 86

(4) 9F

(1) 00

LH(Low word High byte)

LL(Low word Low byte)

HH(High word High byte)

00 LH

01 LL

00 HH

INP-TN514207-E

(2) 01

HL(High word Low byte)

17

00 HL

Page 21

(3) Message transmission

The following shows an example of reading out PV1F (PV1 full scale) from No. 1 station.

Relative address of PV1F (PV1 full scale): 0830

Number of data words: 02

(2 words per data)

H

H

Command message composition (byte) Response message composition (byte)

Station No. 01

Station No. 01H

H

Function code 03H Function code 03H

Read-out start No.

(relative address)

Read-out

word number

CRC data

Upper 08H Read-out byte number 04H

Lower 30

Upper 00H

Lower 02

Upper C6

Lower 64

Upper 0FH

H

H

H

Upper F9H

H

* Meaning of read-out word data Upper data Lower data

PV1F lower data

PV1F upper data

CRC data

Lower A0H

Upper 00H

Lower 00H

Lower 05H

PV1F (PV1 full scale) 00 00 0F A0

= 4000

H

INP-TN514207-E

18

Page 22

6.2 Read-out of Read-out Only Word Data [Function code: 04H]

Function code Max. word number read-out in one message Relative data address Register No.

04H 15 words 0000H – 0563 H 30001-31380

(1) Message composition

Command message composition (byte) Response message composition (byte)

Station No. Station No.

Function code Function code

Read-out start No.

(relative address)

Read-out

word number

CRC data

Upper

Upper

* Arrangement of read-out word data

Upper Read-out byte number

Lower Upper

Upper

Lower

Upper

Lower

1 to 15

State of the first

word data

State of the next

word data

~

State of the last

word data

CRC data

Read-out word

number × 2

Lower

Upper

Lower

~

Lower

Lower

MSB LSB

Upper byte of contents of the first word data

Lower byte of contents of the first word data

Upper byte of contents of the next word data

Lower byte of contents of the next word data

~

~

Upper byte of contents of the last word data

Lower byte of contents of the last word data

(2) Function explanation

Words data are read-out, starting from read-out start No. until read-out word number. The slave

station transmits the read-out word data in the order of upper and lower bytes.

For PXH for which all data consists of 2 word units, data is read out by units of 2 words.

(1) (2) (3) (4)

Example: Suppose data is –2 (FF FF FF FE

)

H

(3) FF LH

(4) FE LL

(1) FF HH

INP-TN514207-E

(2) FF HL

19

Page 23

(3) Message transmission

The following shows an example of reading out PV value from No. 1 station.

Relative address of PV value: 0102

Data number: 02

Command message composition (byte) Response message composition (byte)

Station No. 01

Function code 04H Function code 04H

Read-out start No.

(relative address)

Read-out

word number

CRC data

* Meaning of read-out word data

PV1 measurement data 00 01 38 80

If

decimal point position PV1D = 2

unit

H

(2 words per data)

H

Station No. 01H

H

Upper 01H Read-out byte number 04H

Lower 02

Upper 00H

Lower 02

Upper D1

Lower F7

PV1U = °C

Upper 38H

H

H

H

Upper 36H

H

H

PV1 lower data

PV1 upper data

CRC data

= 80000

800.00°C

Lower 80H

Upper 00H

Lower 01H

Lower CCH

INP-TN514207-E

20

Page 24

6.3 Write-in of Word Data (1 word) [Function code: 06H]

Function code

Max. word number write-in

06H 1 word

(1) Message composition

Command message composition (byte) Response message composition (byte)

Station No. Station No.

Function code Function code

Write-in designate No.

(relative address)

Write-in word

data

CRC data

(2) Function explanation

Designated data is written in word data of write-in designate No. Write-in data are transmitted

from master station in the order of upper and lower bytes.

For PXH, all data consist of 2 word units. If 06H (write-in of word data) is used, only 1 lower

word of 2 word data can be written in, and only 1 upper word of 2 word data cannot.

in one message Relative data address Register No.

40001-43711

0000

Upper Upper

Lower

Upper Upper

Lower

Upper Upper

Lower

Write-in designate No.

(relative address)

Write-in word

data

CRC data

0E7E

-

H

H

Lower

Lower

Lower

(3) Message transmission (example)

The following shows an example of setting 100.0 (1000

slave station.

Parameter "P1" Relative address: 0282

Command message composition (byte) Response message composition (byte)

Station No. 01

Function code 06H Function code 06H

Write-in designate No.

(relative address)

State of write-in

designation

CRC data

Note

When setting is being locked, response is returned normally, but the command is not

executed. Make sure that setting is not locked to send the write-in command.

The setting lock parameter can be written in even if communication setting is invalidated.

If the write-in command message is sent to any slave station during the FIX process,

response is not returned from it.

=03E8H) to the parameter "P1" of No.1

D

H

Station No. 01H

H

Upper 02 H Upper 02H

Lower 82

H

Upper 03H Upper 03H

Lower E8

H

Upper 28H Upper 28H

Lower E4

H

Write-in designate No.

(relative address)

State of write-in

designation

CRC data

Lower 82

Lower E8

Lower E4H

H

H

INP-TN514207-E

21

Page 25

6.4 Write-in of Continuous Word Data [Function code: 10H]

Function code

10H 32 words

Max. word number write-in

in one message Relative data address Register No.

40001-43712

0000

0E7F

-

H

H

(1) Message composition

Command message composition (byte) Response message composition (byte)

Station No. Station No.

Function code Function code

Write-in start No.

(relative address)

Write-in word

number

Write-in byte number

First write-in

word data

Next write-in

word data

~ ~

Last write-in

word data

CRC data

Upper Upper

Lower

Upper Upper

Lower

1 to 32

Write-in word

number × 2

Write-in start No.

(relative address)

Write-in word

number

CRC data

Lower

Lower

Upper

Lower

Upper

Lower

Upper

Lower

Upper

Lower

Upper

Lower

* Arrangement of write-in word data

MSB LSB

Upper byte of contents of the first word data

Lower byte of contents of the first word data

Upper byte of contents of the next word data

Lower byte of contents of the next word data

Upper byte of contents of the last word data

Lower byte of contents of the last word data

~~

(2) Function explanation

Words data are written in, starting from write-in start No. until write-in word number. Write-in

word data are transmitted from master station in the order of upper and lower bytes.

For PXH for which all data consists of 2 word units, write in data by units of 2 words in the order

illustrated below.

Lower word, upper byte (LH)

Lower word, lower byte (LL)

Upper word, upper byte (HH)

Upper word, lower byte (HL)

INP-TN514207-E

22

Page 26

(3) Message transmission (example)

The following shows an example of writing-in P1 = 100.0, I1 = 10, and D1 = 5.0 to No. 1 slave

station.

P1 = 03E8

I1 = 0064

D1 = 0032

(= 1000D)

H

(= 100D)

H

(= 50D)

H

Parameter "P1" Relative address:0282

Command message composition (byte) Response message composition (byte)

Station No. 01

Function code 10H Function code 10H

Write-in start No.

number

Write-in byte number 0CH Upper E1H

P1 lower data

P1 upper data

I1 lower data

I1 upper data

D1 lower data

D1 upper data

CRC data

Point

Since the transmission data can not include a decimal point, data of 100.0 is

transmitted as "1000".

For transmission format of each data, refer to the address map (Chapter 7).

When setting is being locked, response is returned normally. However, the

Caution

command is not executed. If the write-in command message is sent to any slave

station during the FIX process, response is not returned from it.

Data number:06H (2 words per data)

H

Station No. 01H

H

Upper 02H Upper 02H

Lower 82

H

Upper 00H Upper 00H Write-in word

Lower 06

H

Upper 03H

Lower E8

H

Write-in start No.

Write-in

word number

CRC data

Lower 82H

Lower 06

H

Lower 9BH

Upper 00H

Lower 00

H

Upper 00H

Lower 64

H

Upper 00H

Lower 00

H

Upper 00H

Lower 32

H

Upper 00H

Lower 00

H

Upper B6H

Lower D8

H

INP-TN514207-E

23

Page 27

7. ADDRESS MAP AND DATA FORMAT

7.1 Data Format

7.1.1 Transmission data format

The MODBUS protocol used in this instrument (PXH) is RTU (Remote Terminal Unit) mode.

Transmitted data is "numeric value" and not "ASCII code".

7.1.2 Engineering unit

This instrument can handle set value data or other data which are affected by input range as follows.

Engineering unit: Subjected to scaling to match the actual value according to input range

[Example] The value of "PV = 150" (input range: 0º to 400ºC)

Register No. Data (HEX) Data (decimal)

Engineering unit 0102 00000096H

● How to change the input range setting via communication

The input range setting is for full scale, base scale and decimal point position setting.

In order that the change of input range setting will affect the control, power must be turned off and

on, or the reset command must be executed.

Changing the decimal point position automatically changes the full scale and base scale settings.

Example: Changing the input range from 0 to 400, to 0.0 to 400.0

(1) PV1D = 0 → 1 (automatically changes as PV1F = 400 → 400.0, PV1B = 0 → 0.0)

↓

(2) FIX command (see 5.7)

↓

(3) Power OFF-ON or execute reset command (write 1 at relative address 0060H)

● Input range dependent data (see communication address map)

Input range dependent data must be reset after turning off and on power or after transmitting a reset

command subsequent to a change of input range.

(1) Input range setting change

↓

(2) FIX command (see 5.7)

↓

(3) Power off and on or execute reset (write 1 at relative address 0060H)

↓

(4) Reset all data depending upon by input range

→

150

INP-TN514207-E

24

Page 28

7.1.3 Handling of decimal point

No decimal point is added to transmission data.

For data given in the following table, carry out an alignment of decimal point. (Decimal point

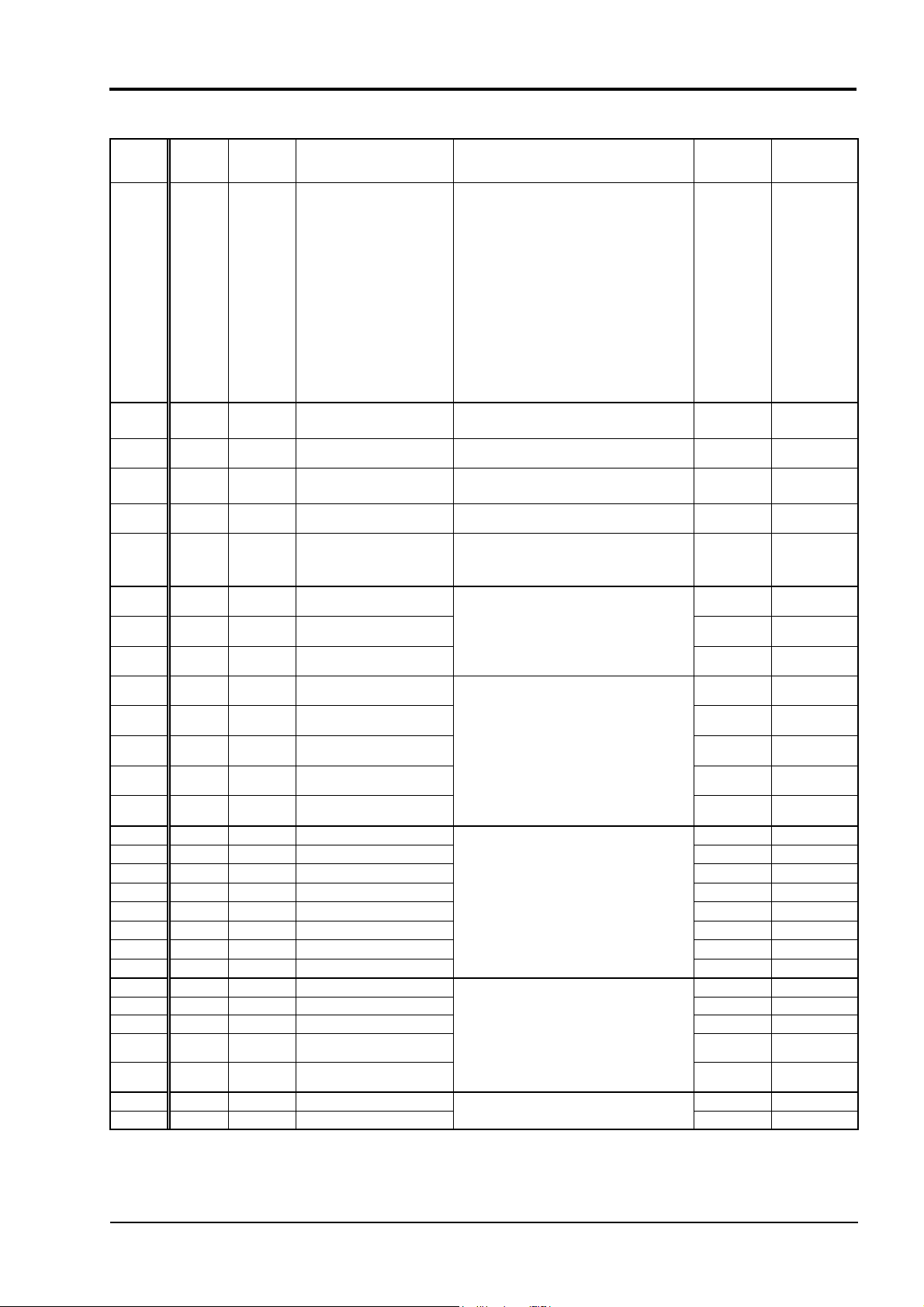

should be removed in transmission, and should be added in receiving data.)

Word data [read-out/write-in]

Digits below

decimal point

Designate by UCD1

if TPLT = 10, 11

(0 to 3)

Designate by PV1D

if TPLT = 13, 14

(0 to 3)

AL3 40289

A3-L 40289

A3-H 40291 AI1F 42193

AL4 40305

A4-L 40305

A4-H 40307

AL5 40321 UCF1 42081

A5-L 40321

A5-H 40323 P1 40643

AL6 40337

A6-L 40337 D1 40647

A6-H 40339 MVH1 40659

AL7 40353 MVL1 40661

A7-L 40353 DMV1 40667

A7-H 40355 BAL1 40677

AL8 40369 PMV1 40685

A8-L 40369 ALP1 40833

A8-H 40371 BET1 40841

1HYS 40265 P-1 41027

2HYS 40281 I-1 41029

3HYS 40297 D-1 41031

4HYS 40313 BL-1 41045

5HYS 40329 P-2 41059

6HYS 40345 I-2 41061

7HYS 40361 D-2 41063

8HYS 40377 BL-2 41077

SV_L1 40641 P-3 41091

ARH1 40651 I-3 41093

ARL1 40653 D-3 41095

SH1 40655 BL-3 41109

SL1 40657 P-4 41123

HS1 40671 I-4 41125

SV1 41025 D-4 41127

ARH1 41035 BL-4 41141

ARL1 41037 P-5 41155

HYS1 41039 I-5 41157

REF1 41047 D-5 41159

SV2 41057 BL-5 41173

ARH2 41067 P-6 41187

ARL2 41069 I-6 41189

HYS2 41071 D-6 41191

REF2 41079 BL-6 41205

SV3 41089 P-7 41219

ARH3 41099 I-7 41221

ARL3 41101 D-7 41223

Kind Register No.

AL1 40257 PV1F 42097

A1-L 40257

A1-H 40259

AL2 40273

A2-L 40273 PV2F 42129

A2-H 40275

Digits below

decimal point

Designate by PV1D

(0 to 3)

Designate by PV2D

(0 to 3)

Designate by AI1D

(0 to 3)

Designate by UCD1

(0 to 3)

1 digit below

decimal point

Kind Register No.

PV1B 42099

PV1Z 42107

PV1S 42109

PV2B 42131

PV2Z 42139

PV2S 42141

AI1B 42195

AI1Z 42203

AI1S 42205

UCB1 42083

I1 40645

INP-TN514207-E

25

Page 29

Digits below

decimal point

Designate by UCD1

if TPLT = 10, 11

(0 to 3)

Designate by PV1D

if TPLT = 13, 14

(0 to 3)

ARH5 41163 AO1H 42437

ARL5 41165 A1LL 42439

HYS5 41167 A1LH 42441

REF5 41175 AO2L 42451

SV6 41185 AO2H 42453

ARH6 41195 A2LL 42455

ARL6 41197 A2LH 42457

HYS6 41199 KF1 40849

REF6 41207 B1F1 40851

SV7 41217 B2F1 40853

ARH7 41227

ARL7 41229

HYS7 41231

REF7 41239

Kind Register No.

HYS3 41103 BL-7 41237

REF3 41111 P1CU 42117

SV4 41121

ARH4 41131

ARL4 41133

HYS4 41135 A1CU 42211

REF4 41143 A1TF 42213

SV5 41153 AO1L 42435

Digits below

decimal point

1 digit below

decimal point

Kind Register No.

P1TF 42119

P2CU 42149

P2TF 42151

Word data [read-out only]

Digits below

decimal point

Designate by UCD1

if TPLT = 10, 11

(0 to 3)

Designate by PV1D

if TPLT = 13, 14

(0 to 3)

AIM 31345

MV1 30265

AO1 31105

AO2 31107

AMV1 31381

RCJ1 31057

Kind Register No.

PV1 30259 PV1 31025

SV1 30261

DV1 30263 PV2 31027

AI1 31031

7.1.4 Data when input is abnormal

When "UUUU" or "LLLL" is displayed on the face panel on account of over-range, under-range or

input burnout for example, PV read-out value (register No. 30259) is 105% or –5% of input range.

Presence of any input abnormality via communication can be detected by:

"Register No. 30269: Input abnormal status"

Digits below

decimal point

Designate by PV1D

(0 to 3)

Designate by PV2D

(0 to 3)

Designate by AI1D

(0 to 3)

Designate by UCD1

(0 to 3)

1 digit below

decimal point

2 digits below

decimal point

Kind Register No.

FFV1 31389

RCJ2 31059

7.1.5 Range of write-in data

When data is written in each parameter, the write-in data should be kept within the setting range.

PXH can accept the write-in data beyond the range, however, be careful since the PXH performance

will not be guaranteed.

INP-TN514207-E

26

Page 30

7.1.6 Floating decimal point type

The mathematical calculation constant uses the floating decimal point type at communication.

Type name Sign Bits

Floating decimal point type Yes 32 (2 words)

(1) Floating decimal point type data format

Floating decimal point (float) data of a binary number is expressed by the data format shown

in [Fig. 7-1].

31

se

s : Sign of mantissa part (1 bit)

e : Exponent part (8 bits)

m : Mantissa part (23 bits)

HH HL LH LL

Decimal point position of mantissa part

2324

16

80

m

Fig. 7-1 Floating decimal point type data format

INP-TN514207-E

27

Page 31

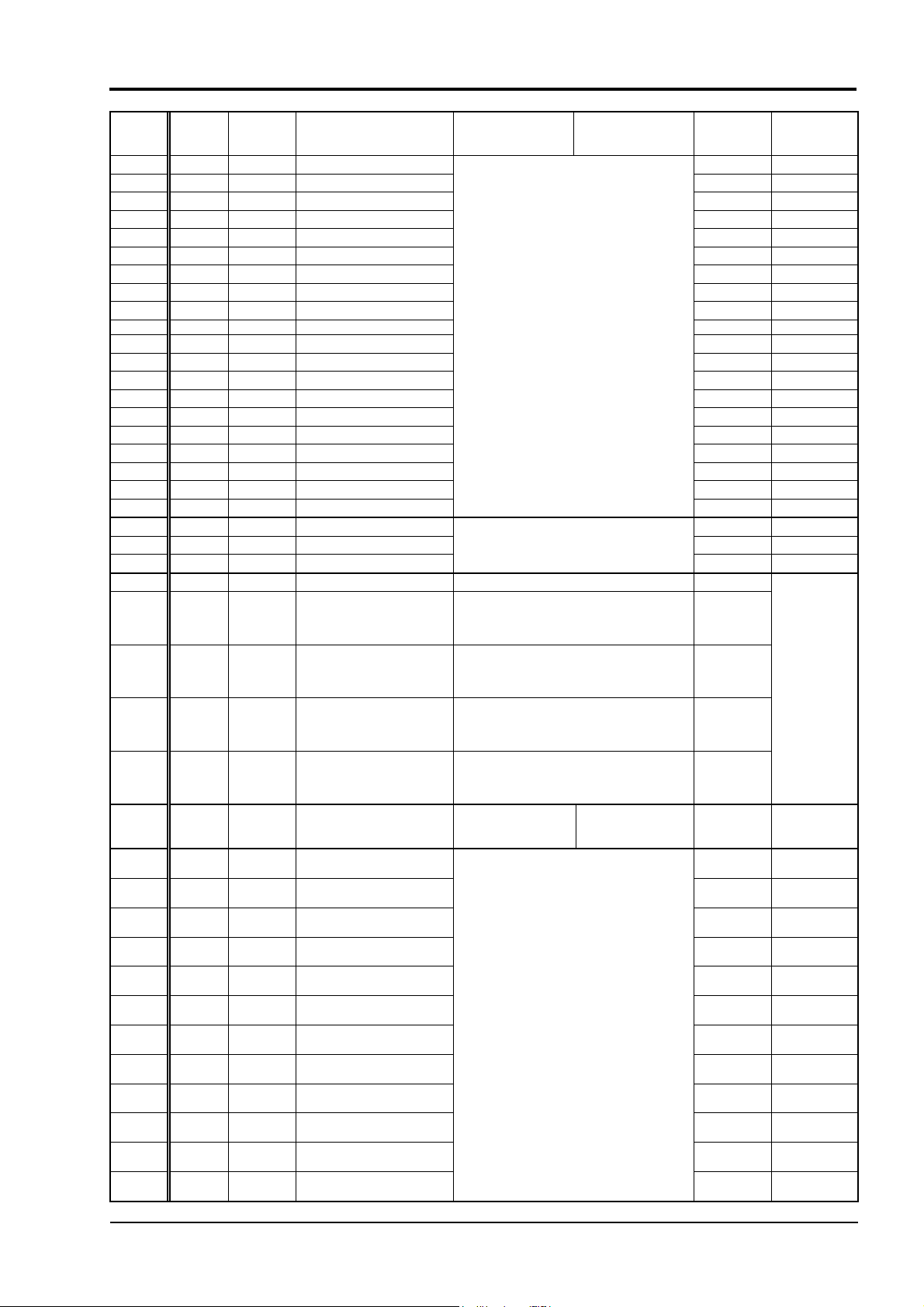

7.2 Communication Address Map

Caution: Never write data into addresses which are not disclosed to users.

Otherwise a failure may be caused.

For detailed contents about individual parameter function or setting range, refer to the user's manual.

Word data [read-out/write-in] : Function code [03

Relative

address

0000H 40001 REM1 Remote mode

0010H 40017 STBY Standby command

0014H 40021 AT Auto tuning command

0020H 40033 LACH Alarm unlatch command

0030H 40049 PLTN Palette signal selection 0 to 7

0040H 40065 LOC Key lock 0 to 5

0060H 40097 RES Reset command

0100H 40257 AL1 Alarm 1 setting

0100H 40257 A1-L Alarm 1 low limit setting Absolute value alarm: 0 to 100%FS *

0102H 40259 A1-H Alarm 1 high limit setting Deviation alarm: –100 to 100%FS *

0104H 40261 1 TP Alarm 1 type 0 to 11, 16 to 32, 35 to 38

0106H 40263 1 OP Alarm 1 option 0 to 15 (0000B to 1111B)

0108H 40265 1HYS Alarm 1 hysteresis ▪ Engineering unit setting (0 to 50%FS) *

010AH 40267 1DLY Alarm 1 delay time 0 to 9999 (sec or min)

0110H 40273 AL2 Alarm 2 setting

0110H 40273 A2-L Alarm 2 low limit setting Absolute value alarm: 0 to 100%FS *

0112H 40275 A2-H Alarm 2 high limit setting Deviation alarm: –100 to 100%FS *

0114H 40277 2 TP Alarm 2 type 0 to 11, 16 to 32, 35 to 38

0116H 40279 2 OP Alarm 2 option 0 to 15 (0000B to 1111B)

0118H 40281 2HYS Alarm 2 hysteresis ▪ Engineering unit setting (0 to 50%FS) *

011AH 40283 2DLY Alarm 2 delay time 0 to 9999 (sec or min)

0120H 40289 AL3 Alarm 3 setting

0120H 40289 A3-L Alarm 3 low limit setting Absolute value alarm: 0 to 100%FS *

0122H 40291 A3-H Alarm 3 high limit setting Deviation alarm: –100 to 100%FS *

0124H 40293 3 TP Alarm 3 type 0 to 11, 16 to 32, 35 to 38

0126H 40295 3 OP Alarm 3 option 0 to 15 (0000B to 1111B)

0128H 40297 3HYS Alarm 3 hysteresis ▪ Engineering unit setting (0 to 50%FS) *

012AH 40299 3DLY Alarm 3 delay time 0 to 9999 (sec or min)

0130H 40305 AL4 Alarm 4 setting

0130H 40305 A4-L Alarm 4 low limit setting Absolute value alarm: 0 to 100%FS *

0132H 40307 A4-H Alarm 4 high limit setting Deviation alarm: –100 to 100%FS *

0134H 40309 4 TP Alarm 4 type 0 to 11, 16 to 32, 35 to 38

0136H 40311 4 OP Alarm 4 option 0 to 15 (0000B to 1111B)

0138H 40313 4HYS Alarm 4 hysteresis ▪ Engineering unit setting (0 to 50%FS) *

013AH 40315 4DLY Alarm 4 delay time 0 to 9999 (sec or min)

0140H 40321 AL5 Alarm 5 setting

0140H 40321 A5-L Alarm 5 low limit setting Absolute value alarm: 0 to 100%FS *

0142H 40323 A5-H Alarm 5 high limit setting Deviation alarm: –100 to 100%FS *

0144H 40325 5 TP Alarm 5 type 0 to 11, 16 to 32, 35 to 38

0146H 40327 5 OP Alarm 5 option 0 to 15 (0000B to 1111B)

0148H 40329 5HYS Alarm 5 hysteresis ▪ Engineering unit setting (0 to 50%FS) *

014AH 40331 5DLY Alarm 5 delay time 0 to 9999 (sec or min)

Register

No.

Parameter

name

Parameter contents Read-out data

, 06H, 10H]

H

0: Auto

1: Remote

0: OFF

1: ON

0: AT Not activated

1: AT Activated

0: Latched

1: Unlatched

0: Operating

normally

1: Being reset

▪ Engineering unit setting

▪ Engineering unit setting

▪ Engineering unit setting

▪ Engineering unit setting

▪ Engineering unit setting

Write-in data

setting range

0: AT Stop

1: AT Execute

0: No effect

1: Unlatch

0: No effect

1: Execute resetting

Affected by

input range

*

*

*

*

*

Remarks or

corresponding

parameter

INP-TN514207-E

28

Page 32

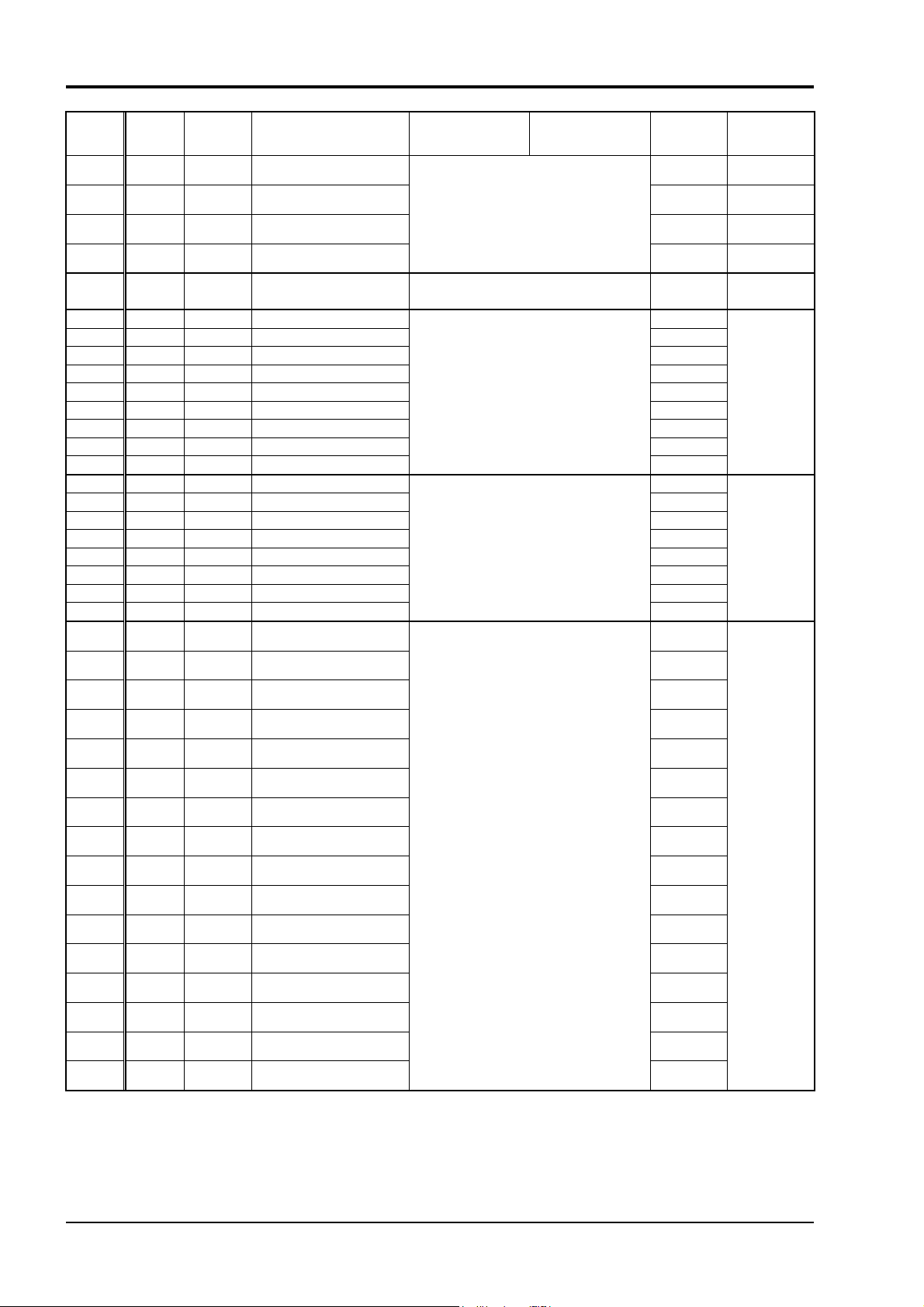

Relative

address

0150H 40337 AL6 Alarm 6 setting

0150H 40337 A6-L Alarm 6 low limit setting Absolute value alarm: 0 to 100%FS *

0152H 40339 A6-H Alarm 6 high limit setting Deviation alarm: –100 to 100%FS *

0154H 40341 6 TP Alarm 6 type 0 to 11, 16 to 32, 35 to 38

0156H 40343 6 OP Alarm 6 option 0 to 15 (0000B to 1111B)

0158H 40345 6HYS Alarm 6 hysteresis ▪ Engineering unit setting (0 to 50%FS) *

015AH 40347 6DLY Alarm 6 delay time 0 to 9999 (sec or min)

0160H 40353 AL7 Alarm 7 setting

0160H 40353 A7-L Alarm 7 low limit setting Absolute value alarm: 0 to 100%FS *

0162H 40355 A7-H Alarm 7 high limit setting Deviation alarm: –100 to 100%FS *

0164H 40357 7 TP Alarm 7 type 0 to 11, 16 to 32, 35 to 38

0166H 40359 7 OP Alarm 7 option 0 to 15 (0000B to 1111B)

0168H 40361 7HYS Alarm 7 hysteresis ▪ Engineering unit setting (0 to 50%FS) *

016AH 40363 7DLY Alarm 7 delay time 0 to 9999 (sec or min)

0170H 40369 AL8 Alarm 8 setting

0170H 40369 A8-L Alarm 8 low limit setting Absolute value alarm: 0 to 100%FS *

0172H 40371 A8-H Alarm 8 high limit setting Deviation alarm: –100 to 100%FS *

0174H 40373 8 TP Alarm 8 type 0 to 11, 16 to 32, 35 to 38

0176H 40375 8 OP Alarm 8 option 0 to 15 (0000B to 1111B)

0178H 40377 8HYS Alarm 8 hysteresis ▪ Engineering unit setting (0 to 50%FS) *

017AH 40379 8DLY Alarm 8 delay time 0 to 9999 (sec or min)

0210H 40529 EXM1

0280H 40641 SV_L1 Local SV ▪ Engineering unit setting (–25 to 125%FS) *

0282H 40643 P1 Proportional band 0 to 9999 (0.0 to 999.9%)

0284H 40645 I1 Integral time 0 to 32000 (0.0 to 3200.0sec)

0286H 40647 D1 Derivative time 0 to 9999 (0.0 to 999.9sec)

028AH 40651 ARH1

028CH 40653 ARL1

028EH 40655 SH1 SV high limit *

0290H 40657 SL1 SV low limit

0292H 40659 MVH1 MV high limit setting

0294H 40661 MVL1 MV low limit setting

029AH 40667 DMV1

029CH 40669 DT1 Sampling rate 5 to 1000 (50 to 10000msec)

029EH 40671 HS1 Hysteresis setting ▪ Engineering unit setting (0 to 50%FS) *

02A4H 40677 BAL1

02A6H 40679 TC1

02A8H 40681 REV1 Control action setting

02ACH 40685 PMV1

0340H 40833 ALP1

0348H 40841 BET1

0350H 40849 KF1

0352H 40851 B1F1

0354H 40853 B2F1

0400H 41025 SV1 Setpoint 1 ▪ Engineering unit setting (–25 to 125%FS) *

0402H 41027 P-1 Proportional band 1 0 to 9999 (0.0 to 999.9%)

0404H 41029 I-1 Integral time 1 0 to 32000 (0.0 to 3200.0sec)

0406H 41031 D-1 Derivative time 1 0 to 9999 (0.0 to 999.9sec)

040AH 41035 ARH1

040CH 41037 ARL1

Register

No.

Parameter

name

Parameter contents Read-out data

▪ Engineering unit setting

▪ Engineering unit setting

▪ Engineering unit setting

External manipulation

variable setting

Anti-reset windup high limit

setting

Anti-reset windup low limit

setting

MV change ratio limit

setting

Manipulating output

convergence value

Control output (MV1)

proportional period

Manipulating output preset

value

2 degrees of freedom

coefficient α

2 degrees of freedom

coefficient β

Sets Feed Forward Gain and

bias 1, bias 2.

[FF=KF1 × (Input − B1F) +

B2F]

Anti-reset windup high limit

1

Anti-reset windup low limit

1

–250 to 1250 (–25.0 to 125.0%)

▪ Engineering unit setting (0 to 100%FS)

▪ Engineering unit setting (–25 to 125%FS)

–250 to 1250 (–25.0 to 125.0%)

0 to 1500 (0.0 to 150.0%)

–1000 to 1000 (–100.0 to 100.0%)

1 to 150sec

0: NRML

1: REV

–250 to 1250 (–25.0 to 125.0%)

–3000 to 3000 (–300.0 to 300.0%)

0 to 9999 (0.0 to 999.9%)

–10000 to 10000

▪ Engineering unit setting (0 to 100%FS)

Write-in data

setting range

Affected by

input range

*

*

*

*

*

*

*

*

Remarks or

corresponding

parameter

Turn off and

on power

INP-TN514207-E

29

Page 33

Relative

address

040EH 41039 HYS1 Hysteresis setting 1 ▪ Engineering unit setting (0 to 50%FS) *

0414H 41045 BL-1 Output convergence value 1 –1000 to 1000 (–100.0 to 100.0%)

0416H 41047 REF1 PID change point 1 ▪ Engineering unit setting (–25 to 125%FS) *

0420H 41057 SV2 Setpoint 2 ▪ Engineering unit setting (–25 to 125%FS) *

0422H 41059 P-2 Proportional band 2 0 to 9999 (0.0 to 999.9%)

0424H 41061 I-2 Integral time 2 0 to 32000 (0.0 to 3200.0sec)

0426H 41063 D-2 Derivative time 2 0 to 9999 (0.0 to 999.9sec)

042AH 41067 ARH2

042CH 41069 ARL2 Anti-reset windup low limit 2

042EH 41071 HYS2 Hysteresis setting 2 ▪ Engineering unit setting (0 to 50%FS) *

0434H 41077 BL-2 Output convergence value 2 –1000 to 1000 (–100.0 to 100.0%)

0436H 41079 REF2 PID change point 2 ▪ Engineering unit setting (–25 to 125%FS) *

0440H 41089 SV3 Setpoint 3 ▪ Engineering unit setting (–25 to 125%FS) *

0442H 41091 P-3 Proportional band 3 0 to 9999 (0.0 to 999.9%)

0444H 41093 I-3 Integral time 3 0 to 32000 (0.0 to 3200.0sec)

0446H 41095 D-3 Derivative time 3 0 to 9999 (0.0 to 999.9sec)

044AH 41099 ARH3

044CH 41101 ARL3 Anti-reset windup low limit 3

044EH 41103 HYS3 Hysteresis setting 3 ▪ Engineering unit setting (0 to 50%FS) *

0454H 41109 BL-3 Output convergence value 3 –1000 to 1000 (–100.0 to 100.0%)

0456H 41111 REF3 PID change point 3 ▪ Engineering unit setting (–25 to 125%FS) *

0460H 41121 SV4 Setpoint 4 ▪ Engineering unit setting (–25 to 125%FS) *

0462H 41123 P-4 Proportional band 4 0 to 9999 (0.0 to 999.9%)

0464H 41125 I-4 Integral time 4 0 to 32000 (0.0 to 3200.0sec)

0466H 41127 D-4 Derivative time 4 0 to 9999 (0.0 to 999.9sec)

046AH 41131 ARH4

046CH 41133 ARL4 Anti-reset windup low limit 4

046EH 41135 HYS4 Hysteresis setting 4 ▪ Engineering unit setting (0 to 50%FS) *

0474H 41141 BL-4 Output convergence value 4 –1000 to 1000 (–100.0 to 100.0%)

0476H 41143 REF4 PID change point 4 ▪ Engineering unit setting (–25 to 125%FS) *

0480H 41153 SV5 Setpoint 5 ▪ Engineering unit setting (–25 to 125%FS) *

0482H 41155 P-5 Proportional band 5 0 to 9999 (0.0 to 999.9%)

0484H 41157 I-5 Integral time 5 0 to 32000 (0.0 to 3200.0sec)

0486H 41159 D-5 Derivative time 5 0 to 9999 (0.0 to 999.9sec)

048AH 41163 ARH5

048CH 41165 ARL5 Anti-reset windup low limit 5

048EH 41167 HYS5 Hysteresis setting 5 ▪ Engineering unit setting (0 to 50%FS) *

0494H 41173 BL-5 Output convergence value 5 –1000 to 1000 (–100.0 to 100.0%)

0496H 41175 REF5 PID change point 5 ▪ Engineering unit setting (–25 to 125%FS) *

04A0H 41185 SV6 Setpoint 6 ▪ Engineering unit setting (–25 to 125%FS) *

04A2H 41187 P-6 Proportional band 6 0 to 9999 (0.0 to 999.9%)

04A4H 41189 I-6 Integral time 6 0 to 32000 (0.0 to 3200.0sec)

04A6H 41191 D-6 Derivative time 6 0 to 9999 (0.0 to 999.9sec)

04AAH 41195 ARH6

04ACH 41197 ARL6 Anti-reset windup low limit 6

04AEH 41199 HYS6 Hysteresis setting 6 ▪ Engineering unit setting (0 to 50%FS) *

04B4H 41205 BL-6 Output convergence value 6 –1000 to 1000 (–100.0 to 100.0%)

04B6H 41207 REF6 PID change point 6 ▪ Engineering unit setting (–25 to 125%FS) *

04C0H 41217 SV7 Setpoint 7 ▪ Engineering unit setting (–25 to 125%FS) *

04C2H 41219 P-7 Proportional band 7 0 to 9999 (0.0 to 999.9%)

04C4H 41221 I-7 Integral time 7 0 to 32000 (0.0 to 3200.0sec)

04C6H 41223 D-7 Derivative time 7 0 to 9999 (0.0 to 999.9sec)

04CAH 41227 ARH7

04CCH 41229 ARL7 Anti-reset windup low limit 7

Register

No.

Parameter

name

Parameter contents Read-out data

Anti-reset windup high limit

2

Anti-reset windup high limit

3

Anti-reset windup high limit

4

Anti-reset windup high limit

5

Anti-reset windup high limit

6

Anti-reset windup high limit

7

▪ Engineering unit setting (0 to 100%FS)

▪ Engineering unit setting (0 to 100%FS)

▪ Engineering unit setting (0 to 100%FS)

▪ Engineering unit setting (0 to 100%FS)

▪ Engineering unit setting (0 to 100%FS)

▪ Engineering unit setting (0 to 100%FS)

Write-in data

setting range

Affected by

input range

*

*

*

*

*

*

*

*

*

*

*

*

Remarks or

corresponding

parameter

INP-TN514207-E

30

Page 34

Relative

address

04CEH 41231 HYS7 Hysteresis setting 7 ▪ Engineering unit setting (0 to 50%FS) *

04D4H 41237 BL-7 Output convergence value 7 –1000 to 1000 (–100.0 to 100.0%)

04D6H 41239 REF7 PID change point 7 ▪ Engineering unit setting (–25 to 125%FS) *

0820H 42081 UCF1

0822H 42083 UCB1

0824H 42085 UCD1

0830H 42097 PV1F PV1 full scale

0832H 42099 PV1B PV1 base scale

0834H 42101 PV1D PV1 decimal point position 0 to 3

0836H 42103 PV1T PV1 input type 0 to 9, 12 to 14, 16 to 20, 26, 27

0838H 42105 PV1U PV1 input unit

083AH 42107 PV1Z PV1 zero adjustment *

083CH 42109 PV1S PV1 span adjustment

0844H 42117 P1CU PV1 input router cut point –1 to 1250 (–0.1 to 125.0%) (–1: OFF)

0846H 42119 P1TF

0850H 42129 PV2F PV2 full scale

0852H 42131 PV2B PV2 base scale

0854H 42133 PV2D PV2 decimal point position 0 to 3

0856H 42135 PV2T PV2 input type 0 to 9, 12 to 14, 16 to 20, 26, 27

0858H 42137 PV2U PV2 input unit

085AH 42139 PV2Z PV2 zero adjustment *

085CH 42141 PV2S PV2 span adjustment

0864H 42149 P2CU PV2 input router cut point –1 to 1250 (–0.1 to 125.0%) (–1: OFF)

0866H 42151 P2TF

0890H 42193 AI1F AI1 full scale

0892H 42195 AI1B AI1 base scale

0894H 42197 AI1D AI1 decimal point position 0 to 3

0896H 42199 AI1T AI1 input unit 16 to 18

089AH 42203 AI1Z AI1 zero adjustment *

089CH 42205 AI1S AI1 span adjustment

08A2H 42211 A1CU AI1 input router cut point –1 to 1250 (–0.1 to 125.0%) (–1: OFF)

08A4H 42213 A1TF

0970H 42417 AO1T AO1 output type

0972H 42419 AO2T AO2 output type

0982H 42435 AO1L AO1 output base scale

0984H 42437 AO1H AO1 output full scale

0986H 42439 A1LL AO1 output low limit

0988H 42441 A1LH AO1 output high limit

0992H 42451 AO2L AO2 output base scale

0994H 42453 AO2H AO2 output full scale

0996H 42455 A2LL AO2 output low limit

0998H 42457 A2LH AO2 output high limit

Register

No.

Parameter

name

Parameter contents Read-out data

Mathematical calculation

full scale

Mathematical calculation

base scale

Mathematical calculation

decimal point position

PV1 input filter time

constant

PV2 input filter time

constant

AI1 input filter time

constant

–19999 to 99999

0 to 3

–19999 to 99999

0: °C

1: °F

2: non

▪ Engineering unit setting (–50 to 50%FS)

0 to 9000 (0.0 to 900.0sec)

–19999 to 99999

0: °C

1: °F

2: non

▪ Engineering unit setting (–50 to 50%FS)

0 to 9000 (0.0 to 900.0sec)

–19999 to 99999

▪ Engineering unit setting (–50 to 50%FS)

0 to 9000 (0.0 to 900.0sec)

1: PV 5: AiM

2: SV 6: S1

3: MV 7: S2

4: DV 8: S3

–1300 to 1300

(–130.0 to 130.0%)

–250 to 1050 (–25.0 to 105.0%)

–1300 to 1300

(–130.0 to 130.0%)

–250 to 1050 (–25.0 to 105.0%)

Write-in data

setting range

Affected by

input range

*

*

*

Remarks or

corresponding

parameter

Turn off and

on power

Turn off and

on power

Turn off and

on power

Turn off and

on power

INP-TN514207-E

31

Page 35

Relative

address

0A00H 42561 CALC Calculation 0 to 11

0A02H 42563 TPLT Template number 10, 11, 13, 14, 16

0A04H 42565 OTYP Output type number 10 to 13

0A30H 42609 RIH1 Remote setting inhibition

0A40H 42625 RAC1

0A50H 42641 A-M1 A/M mode

0A60H 42657 CND1

0A74H 42677 STBO Standby action setting 0, 1

0A80H 42689 TRK1

0A90H 42705 PLTS

0A92H 42707 F1 User assign key 1 (F1)

0A94H 42709 F2 User assign key 2 (F2)

0A96H 42711 F3 User assign key 3 (F3)

0AA0H 42721 BRD1

0AE0H 42785 DI01 DI1 function selection

0AE2H 42787 DI02 DI2 function selection

0AE4H 42789 DI03 DI3 function selection

0AE6H 42791 DI04 DI4 function selection

0AE8H 42793 DI11 DI11 function selection

0AEAH 42795 DI12 DI12 function selection

0AECH 42797 DI13 DI13 function selection

0AEEH 42799 DI14 DI14 function selection

0AF0H 42801 DI15 DI15 function selection

0B50H 42897 DS00 Parameter mask 00

0B52H 42899 DS01 Parameter mask 01

0B54H 42901 DS02 Parameter mask 02

0B56H 42903 DS03 Parameter mask 03

0B58H 42905 DS04 Parameter mask 04

0B5AH 42907 DS05 Parameter mask 05

0B5CH 42909 DS06 Parameter mask 06

0B5EH 42911 DS07 Parameter mask 07

0B60H 42913 DS08 Parameter mask 08

0B62H 42915 DS09 Parameter mask 09

0B64H 42917 DS10 Parameter mask 10

0B66H 42919 DS11 Parameter mask 11

0B68H 42921 DS12 Parameter mask 12

0B6AH 42923 DS13 Parameter mask 13

0B6CH 42925 DS14 Parameter mask 14

0B6EH 42927 DS15 Parameter mask 15

0B70H 42929 DS16 Parameter mask 16

0B72H 42931 DS17 Parameter mask 17

0B74H 42933 DS18 Parameter mask 18

0B76H 42935 DS19 Parameter mask 19

0B78H 42937 DS20 Parameter mask 20

0B7AH 42939 DS21 Parameter mask 21

0B7CH 42941 DS22 Parameter mask 22

0B7EH 42943 DS23 Parameter mask 23

Register

No.

Parameter

name

Parameter contents Read-out data

0: OFF

1: ON

Whether to use R-ACK or

not

Power-ON starting mode

setting

Whether to select tracking

or not

Palette change method

selection

Burnout direction designation (MV1)

0: inhibit

1: enable

0: A–M

1: A

0: Auto

1: Remote

2: Manual

0: OFF

1: ON

0: PLTn

1: SV

2: PV

0 to 27

0: HOLD

1: LO

2: UP

3: EXMV

0 to 255

0 to 65535 (0000H to FFFFH)

Write-in data

setting range

Affected by

input range

Remarks or

corresponding

parameter

Turn off and

on power

INP-TN514207-E

32

Page 36

Relative

address

0B80H 42945 DS24 Parameter mask 24

0B82H 42947 DS25 Parameter mask 25

0B84H 42949 DS26 Parameter mask 26

0B86H 42951 DS27 Parameter mask 27

0B88H 42953 DS28 Parameter mask 28

0B8AH 42955 DS29 Parameter mask 29

0B8CH 42957 DS30 Parameter mask 30

0B8EH 42959 DS31 Parameter mask 31

0B90H 42961 DS32 Parameter mask 32

0B92H 42963 DS33 Parameter mask 33

0B94H 42965 DS34 Parameter mask 34

0B96H 42967 DS35 Parameter mask 35

0B98H 42969 DS36 Parameter mask 36

0B9AH 42971 DS37 Parameter mask 37

0B9CH 42973 DS38 Parameter mask 38

0B9EH 42975 DS39 Parameter mask 39

0BA0H 42977 DS40 Parameter mask 40

0BA2H 42979 DS41 Parameter mask 41

0BA4H 42981 DS42 Parameter mask 42

0BA6H 42983 DS43 Parameter mask 43

0C00H 43073 PAS1 Security setting 1

0C02H 43075 PAS2 Security setting 2

0C04H 43077 PAS3 Security setting 3

0C22H 43107 STN4 RS-485 station No. 0 to 255

0C24H 43109 SPD4

0C26H 43111 BIT4 RS-485 bit format

0C30H 43121 SPD2

0C32H 43123 BIT2 RS-232C bit format

0C50H 43153 - FIX command

0DC0H 43521 K01

0DC2H 43523 K02

0DC4H 43525 K03

0DC6H 43527 K04

0DC8H 43529 K05

0DCAH 43531 K06

0DCCH 43533 K07

0DCEH 43535 K08

0DD0H 43537 K09

0DD2H 43539 K10

0DD4H 43541 K11

0DD6H 43543 K12

Register

No.

Parameter

name

Parameter contents Read-out data

0 to 65535 (0000H to FFFFH)

0 to 65535 (0000H to FFFFH)

RS-485 communication

speed

RS-232C communication

speed

Mathematical calculation

constant 1

Mathematical calculation

constant 2

Mathematical calculation

constant 3

Mathematical calculation

constant 4

Mathematical calculation

constant 5

Mathematical calculation

constant 6

Mathematical calculation

constant 7

Mathematical calculation

constant 8

Mathematical calculation

constant 9

Mathematical calculation

constant 10

Mathematical calculation

constant 11

Mathematical calculation

constant 12

0: 9.6k

1: 19.2k

2: 38.4k

0: 8N

1: 8O

2: 8E

0: 9.6k

1: 19.2k

2: 38.4k

0: 8N

1: 8O

2: 8E

0: Not writing in

1: Now writing in

memory

▪ Floating decimal point type

99999 to 0.0000

–0.001 to –9999

Write-in data

setting range

0: No effect

1: Write-in request

Affected by

input range

Remarks or

corresponding

parameter

Turn off and

on power

INP-TN514207-E

33

Page 37

Relative

address

0DD8H 43545 K13

0DDAH 43547 K14

0DDCH 43549 K15

0DDEH 43551 K16

0E00H 43585 ATP1 Auto tuning type

0E20H 43617 DO1 DO1 output designation

0E22H 43619 DO2 DO2 output designation

0E24H 43621 DO3 DO3 output designation

0E26H 43623 DO4 DO4 output designation

0E30H 43633 DO11 DO11 output designation

0E32H 43635 DO12 DO12 output designation

0E34H 43637 DO13 DO13 output designation

0E36H 43639 DO14 DO14 output designation

0E38H 43641 DO15 DO15 output designation

0E70H 43697 C1 LED C1 assign

0E72H 43699 C2 LED C2 assign

0E74H 43701 LDO1 LED DO1 assign

0E76H 43703 LDO2 LED DO2 assign

0E78H 43705 LDO3 LED DO3 assign

0E7AH 43707 LDO4 LED DO4 assign

0E7CH 43709 LDO5 LED DO5 assign

0E7EH 43711 LALM LED ALM assign

0EA0H 43745 CN01

0EA2H 43747 CN02

0EA4H 43749 CN03

0EA6H 43751 CN04

0EA8H 43753 CN05

0EAAH 43755 CN06

0EACH 43757 CN07

0EAEH 43759 CN08

0EB0H 43761 CN09

0EB2H 43763 CN10

0EB4H 43765 CN11

0EB6H 43767 CN12

0EB8H 43769 CN13

0EBAH 43771 CN14

0EBCH 43773 CN15

0EBEH 43775 CN16

Register

No.

Parameter

name

Parameter contents Read-out data

Mathematical calculation

constant 13

Mathematical calculation

constant 14

Mathematical calculation

constant 15

Mathematical calculation

constant 16

Constant 1 used for template

Constant 2 used for template

Constant 3 used for template

Constant 4 used for template

Constant 5 used for template

Constant 6 used for template

Constant 7 used for template

Constant 8 used for template

Constant 9 used for template

Constant 10 used for template

Constant 11 used for template

Constant 12 used for template

Constant 13 used for template

Constant 14 used for template

Constant 15 used for template

Constant 16 used for template

▪ Floating decimal point type

99999 to 0.0000

–0.001 to –9999

0: NRML

1: LPV

0 to 255

0 to 255

–19999 to 99999

Write-in data

setting range

Affected by

input range

Remarks or

corresponding

parameter

Turn off and

on power

Turn off and

on power

INP-TN514207-E

34

Page 38

Word data [read-out only] : Function code [04H]

Relative

address

0100H 30257

0102H 30259 PV1

0104H 30261 SV1

0106H 30263 DV1

0108H 30265 MV1

010CH 30269 FAULT1

0310H 30785

0312H 30787

0314H 30789

0316H 30791

0318H 30793

031AH 30795

031CH 30797

031EH 30799

0340H 30833 ALM1 Alarm 1 status

0342H 30835 ALM2 Alarm 2 status

0344H 30837 ALM3 Alarm 3 status

0346H 30839 ALM4 Alarm 4 status

0348H 30841 ALM5 Alarm 5 status

034AH 30843 ALM6 Alarm 6 status

034CH 30845 ALM7 Alarm 7 status

034EH 30847 ALM8 Alarm 8 status

0400H 31025 PV1 PV1 measurement value *

0402H 31027 PV2 PV2 measurement value *

0406H 31031 AI1 Ai1 measurement value *

0420H 31057 RCJ1

0422H 31059 RCJ2

0450H 31105 AO1 AO1 output value

0452H 31107 AO2 AO2 output value

Register

No.

Parameter

name

PID

MODE1

ALM1

(RELAY)

ALM2

(RELAY)

ALM3

(RELAY)

ALM4

(RELAY)

ALM5

(RELAY)

ALM6

(RELAY)

ALM7

(RELAY)

ALM8

(RELAY)

Parameter contents Read-out data

0001H: Fault status

0002H: Standby status

0004H: Remote Ack

0008H: Other than auto mode

0010H: Auto mode request

0020H: Remote mode request

Current control mode

Process variable (PV) used

for control currently

Currently used setpoint

(SV)

Currently used deviation

(DV)

Currently used manipulating

value (MV)

Currently used input error

status information

Alarm 1 status (relay status)

Alarm 2 status (relay status)

Alarm 3 status (relay status)

Alarm 4 status (relay status)

Alarm 5 status (relay status)

Alarm 6 status (relay status)

Alarm 7 status (relay status)

Alarm 8 status (relay status)

PV1 RCJ measurement

value

PV2 RCJ measurement

value

0040H: Auto tuning status

0080H: Normal operation status

0100H: PV tracking status

0200H: Local SV status

0400H: Remote SV status

0800H: Local + PV tracking status

1000H: Forced manual mode status

2000H: EX-MV mode status

4000H: Manual mode status

–25999 to 105999

(Input scale: –5 to 105% FS)

–19999 to 99999 (within settable range) *

–125998 to 125998

(Input scale: –105 to 105% FS)

–250 to 1250 (–25.0 to 125.0%)

Normal: 0

Over: 1

Under: 2

Excitation: 1, Non-excitation: 0

Excitation: 1, Non-excitation: 0

ON: 1, OFF: 0

–214783647 to 214783648

–250 to 1250 (–25.0 to 125.0%)

Affected by

input range

*

*

Remarks or

corresponding

parameter

Corresponding bit to

relevant status

is "1".

INP-TN514207-E

35

Page 39

Relative

address

0470H 31137 DI01 DI1 to 4 input status

0472H 31139 DI11 DI11 to 15 input status

04D0H 31233 DO01 DO1 to 4 output status

04D2H 31235 DO11 DO11 to 15 output status

0540H 31345 AIM

0550H 31361

0552H 31363

0554H 31365

0556H 31367

0558H 31369

055AH 31371

055CH 31373

055EH 31375

0564H 31381 AMV1

056CH 31389 FFV1 Feed Forward value –214783647 to 214783648

Register

No.

Parameter

name

ALM

DLY 1

ALM

DLY 2

ALM

DLY 3

ALM

DLY 4

ALM

DLY 5

ALM

DLY 6

ALM

DLY 7

ALM

DLY 8

Parameter contents Read-out data

DI1: 8000H

DI2: 4000H

DI3: 2000H

DI4: 1000H

DI11: 8000H

DI12: 4000H

DI13: 2000H

DI14: 1000H

DI15: 0800H

DO1: 1

DO2: 2

DO3: 4

DO4: 8

DO11: 1

DO12: 2

DO13: 4

DO14: 8

DO15: 16

Mathematical calculation

result

Alarm 1 delay timer remaining time monitor

Alarm 2 delay timer remaining time monitor

Alarm 3 delay timer remaining time monitor

Alarm 4 delay timer remaining time monitor

Alarm 5 delay timer remaining time monitor

Alarm 6 delay timer remaining time monitor

Alarm 7 delay timer remaining time monitor

Alarm 8 delay timer remaining time monitor

EXMV value

(External analog value)

–214783647 to 214783648 *

0 to 9999

–214783647 to 214783648

Affected by

input range

Remarks or

corresponding

parameter

Corresponding bit to ON

is "1".

Corresponding bit to ON

is "1".

Corresponding bit to ON

is "1".

Corresponding bit to ON

is "1".

Mathematical

calculation

scale

INP-TN514207-E

36

Page 40

8. SAMPLE PROGRAM

This section concerns data read-out/write-in sample program by Microsoft Visual Basic 6.0 (SP6) (enclosed

to CD-ROM).

Note that the program shown here is for reference for you to create a program and not for guaranteeing all

actions.

Before executing the program, make sure of the communication conditions in the following procedure.

▪ Parity, communication speed: Must be set in this program to match the instrument.

Precautions for some RS-232C ⇔ RS-485 converter

The transmission data itself may precede the answer data from the slave station. In such a case, discard

as many data as transmission bytes found there, and then process it as answer data.

Applicable OS

Windows 2000 Professional

Windows XP Professional Edition

Fuji Electric Systems Co., Ltd. and Fuji Electric Instruments Co., Ltd. will not be responsible for damages

attributable to use of the sample program nor infringement of rights owned by third parties.

Use the program upon admitting the above.

INP-TN514207-E

37

Page 41

(a) Example of data read-out

Operation: 2 word data of a designated address is read-out and displayed at a time.

Used function code: 03

, 04H

H

Read-out word number: 2

' Variable declaration ***************************************************************************************************************

Dim idx As Integer

Dim Ansdat() As Byte ' For storing answer data

Dim Rxbuff As Variant ' Receive data buffer

Dim PauseTime ' Sets the communication wait time

' Required wait time depends on transmission speed and transmission frame length

Dim Stno As Byte ' Communication station number

Private Sub Form_Load()

' Initializing the variable ************************************************************************************************************

Stno = 1

Main.Visible = True

End Sub

'-----------------------------------------'Read continuous words sample program

'Function code : 03H, 04H

'Number of words : 2

'------------------------------------------

Private Sub TX1_Click()

TX1.Enabled = False