Page 1

INP-TN514450c-E

Page 2

Introduction

Thank you for purchasing the Fuji Digital Temperature Controller.

This document describes how to connect the Micro controller PXG Series (referred to below as "Micro controller") to the personal

computer or programmable controller. It also describes communication specifications for controlling and monitoring the

communications with the micro controller, MODBUS protocol, and address map for the micro controller.

In addition to this document, please make sure to read the Instruction Manual (which comes with the product) and the Operations

Manual (packaged separately).

NOTE

■ Exclusions

The contents of this document may change without prior notice.

Although great care has been taken in the accuracy of this document, Fuji Electric takes no responsibility for loss or indirect

damages caused by mistakes, missing information, or use of information in this document.

– 1 –

Page 3

Contents

1. Communication Functions

Overview................................................................................4

Connecting to a programmable controller..........................5

Connecting to a personal computer...................................5

2. Specifications

Communication Specifications ..............................................8

RS-485...............................................................................8

PC Loader Interface...........................................................8

3. Connection

Communication Terminal Configuration...............................10

Wiring ..................................................................................11

4. Setting Communication Parameters

List of Setting Parameters...................................................16

Parameter Setting Procedure ..............................................17

5. MODBUS Communication Protocol

Overview..............................................................................20

Message Composition.........................................................21

Station No. .......................................................................21

Function Code..................................................................21

Data Part..........................................................................21

Error Check Code ............................................................21

Slave Response...............................................................22

Function Code..................................................................23

Calculating Error Check Code (CRC-16).............................24

Transmission Control Steps.................................................25

Master Communication Method.......................................25

Explanation ......................................................................25

Precautions when Writing Data...........................................26

7. Address Map and Data Format

Data Format.........................................................................40

Sent Data Format.............................................................40

Internal Calculation Value and Engineering Unit ..............40

Managing the Decimal Point.............................................40

Data during Input Error.....................................................41

Written Data .....................................................................41

Addresses Not Written......................................................41

Internal Calculation Value Data Address Map .....................42

Bit Data (read only): function code [02 (H)]......................42

Word Data (read/write): function code

[03 (H), 06 (H), 10 (H)]......................................................43

Word Data (read only): function code [04 (H)]..................63

8. Sample Program

Sample Program..................................................................68

9. T roubleshooting

Troubleshooting....................................................................78

6.

Command and Transmission Frame Details

Reading Data ......................................................................28

Reading Read-Only Bit Data (Function Code: 02H) ........28

Reading Word Data (Function Code: 03H).......................30

Reading Read-Only Word Data (Function Code: 04H)....32

Writing Data.........................................................................34

Writing Word Data (1 word, function code: 06H)..............34

Writing Continuous Word Data (Function code: 10H) ...... 36

– 2 –

Page 4

Chapter 1

Communication Functions

Overview – 4

Chapter

1

– 3 –

Page 5

Overview

Chapter

1

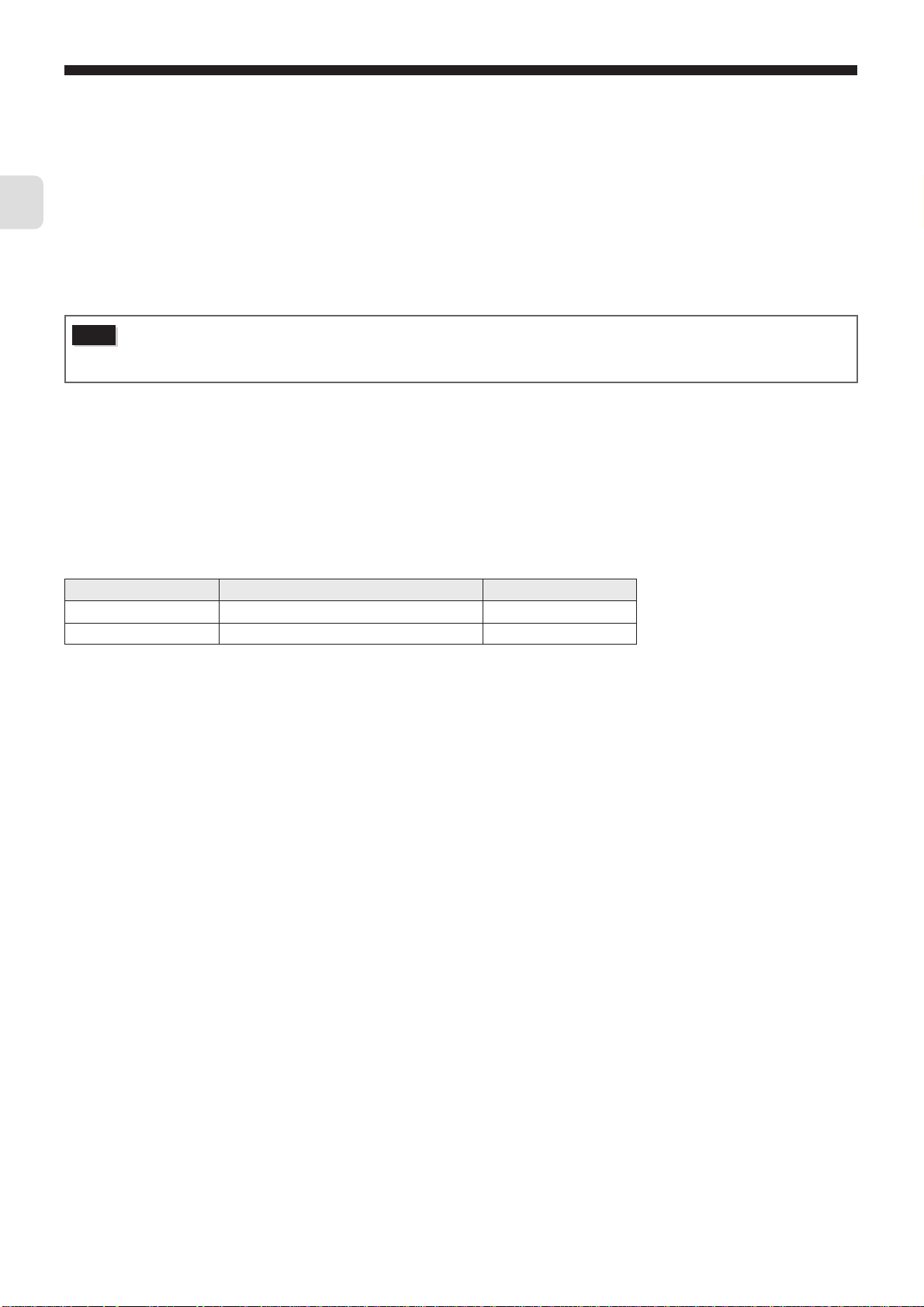

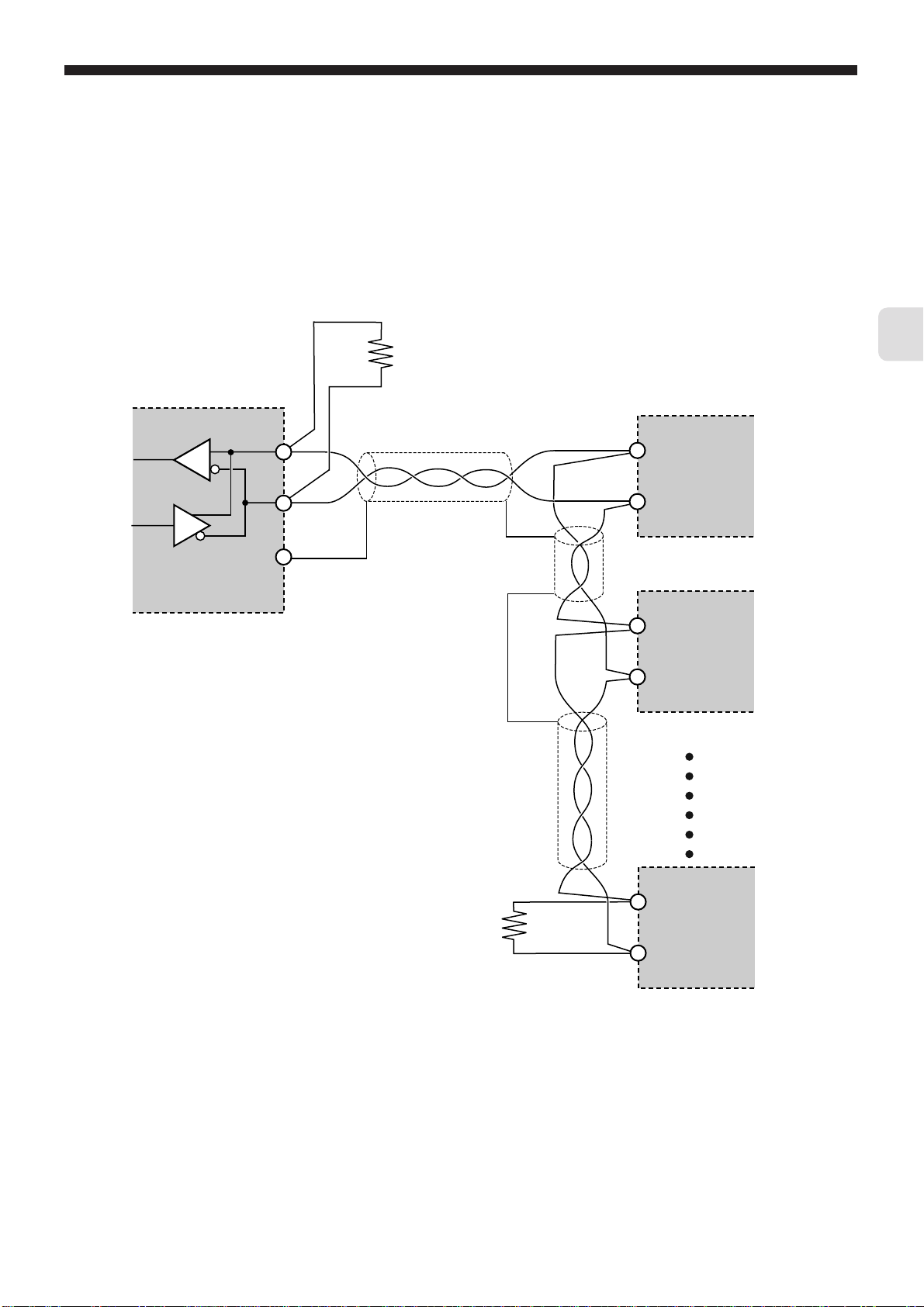

• The micro controller is equipped with communication functions from the RS-485 interface and PC loader interface, which

enables the transmission and reception of data between such devices as the personal computer, programmable controller,

and graphic panel.

• The communication system is composed of a master and slave relationship. Up to thirty-one slaves (micro controllers) may

be connected to one master (such as a personal computer) based on a “single master/multiple slave” method.

• However, the master can only communicate with one slave at a time. Therefore, each slave is specified by the "Station No."

setting.With PC loader communication, only one slave can be connected to one master.

Caution

• In order to have proper communication between master and slave, the transmission data must be in the same format. This

• When using equipment with an RS-232C interface, such as a personal computer, as the master, make sure to use an RS-

• When using PC loader communication, you can use RS-232C communication with the personal computer by connecting the

[RS-232C to RS-485 converter] (Recommended)

Model number/Type Contact URL

KS3C-10 (insulating type) Made by Omron Corporation http://www.omron.co.jp

RC-77 (insulating type) Made by RA Systems Corporation http://www.ras.co.jp

• Systems constructed with the micro controller as slaves do not respond to messages issued by the master

with broadcast queries where the station number is "0".

• PC loader communication is not compatible with the multiple slave method.

document explains how to transmit data using the MODBUS protocol format.

232C to RS-485 converter.

PC loader interface on the bottom of this unit with the PC loader communication cable (RS-232C, model:

ZZPPXH1

TK4H4563) sold separately.

*

– 4 –

Page 6

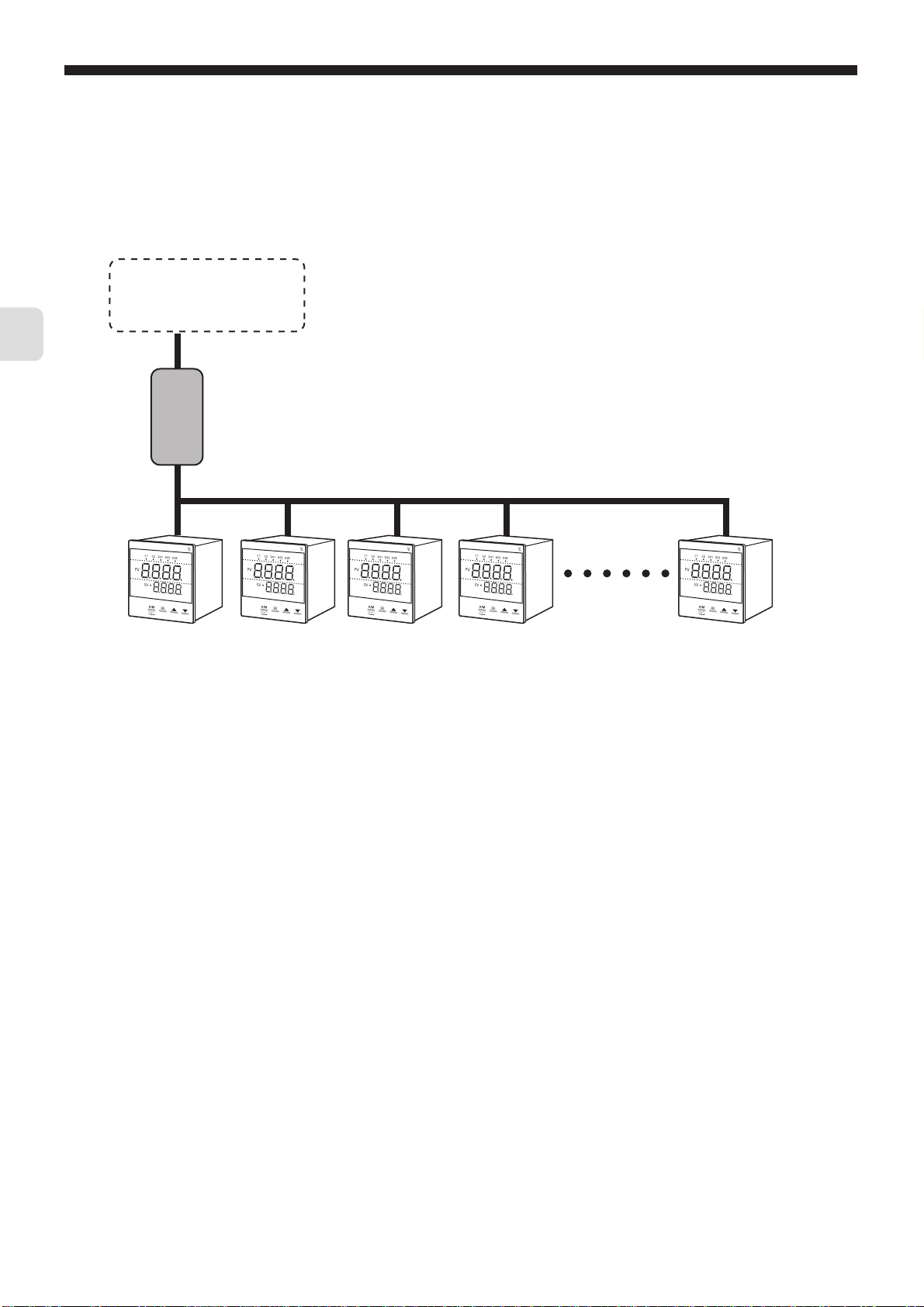

Connecting to a programmable controller

Programmable

controller

RS-485

PXG Series

Connecting to a personal computer

Chapter

1

Caution

Personal

computer

RS-232C

RS-232C to RS-485 converter

RS-485

PXG Series

RS-232C

PC loader communication cable

When using the RS-232C to RS-485 converter, check to make sure that the cable is properly connected between the

converter and master. Communication will not work properly if the connection is incorrect.

Also be sure to correctly set the communication settings (such as communication speed and parity) on the RS-232C

to RS-485 converter. Communication will not work properly if the settings are incorrect.

– 5 –

Page 7

Chapter

1

MEMO

– 6 –

Page 8

Chapter 2

Specifications

Communication Specifications – 8

Chapter

2

– 7 –

Page 9

Chapter

2

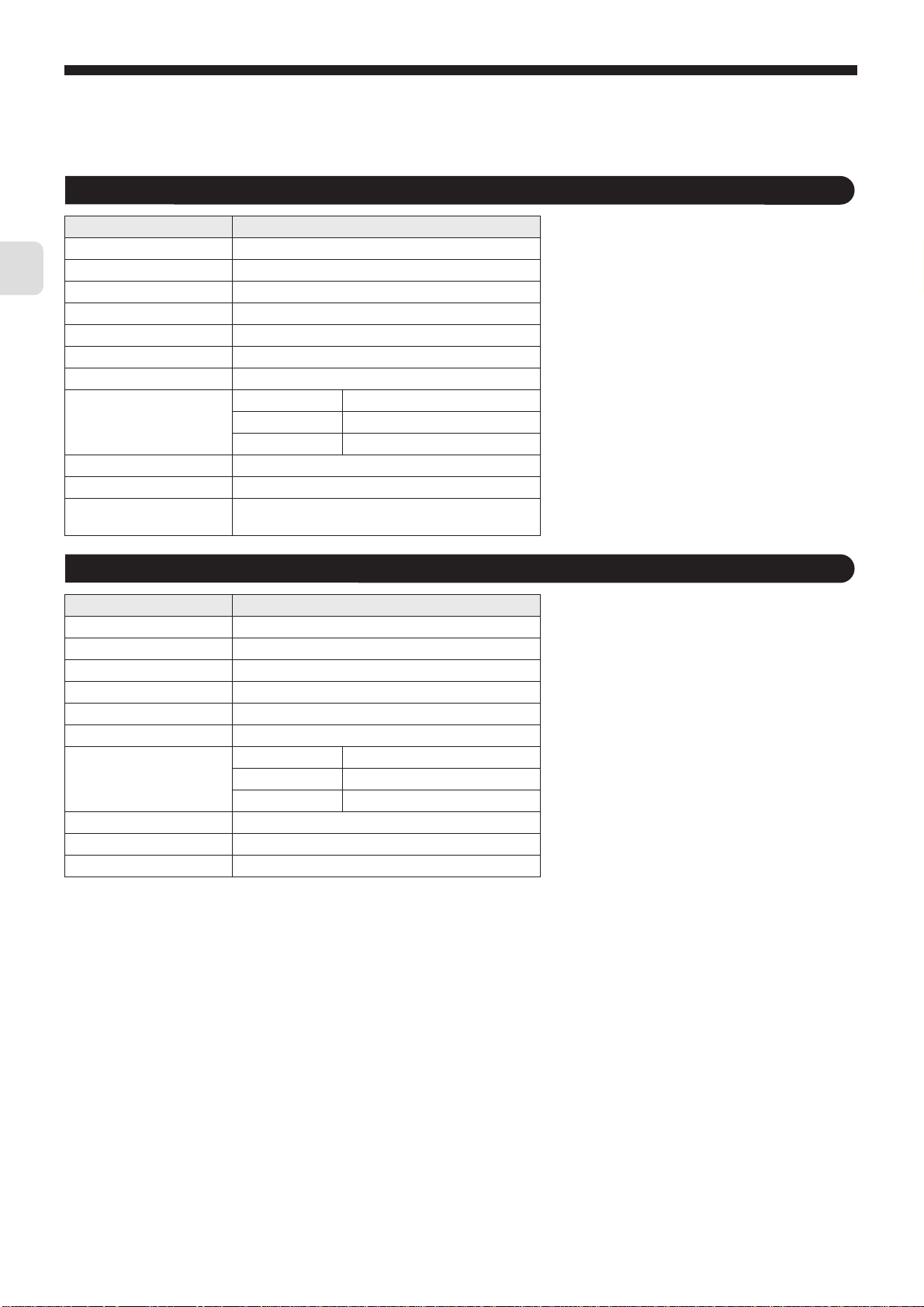

Communication Specifications

RS-485

Item Specifications

Electrical specifications EIA RS-485 compliant

Communication method Two wire system, half double-bit serial

Synchronous method Asynchronous

Connection status 1:N

Max. no. of connections 31 units

Communication distance Max 500m (total length)

Communication speed 9600bps, 19200 bps

Data format Data length 8 bits

Stop bit 1 bit

Parity None/Even/Odd (Selectable)

Transmission code HEX value (MODBUS RTU mode)

Error detection CRC-16

Insulation Functional insulation for the transmission area and

other areas (withstanding AC 500V)

PC Loader Interface

Item Specifications

Electrical specifications EIA RS232 C

Communication method 3wire system, half double-bit serial

Synchronous method Asynchronous

Connection status 1:1

Station No. 1 (Not to be changed)

Communication speed 9600 bps (Not to be changed)

Data format Data length 8 bits

Stop bit 1 bit

Parity none (Not to be changed)

Transmission code HEX value (MODBUS RTU mode)

Error detection CRC-16

Insulation Non-insulated internal circuit

– 8 –

Page 10

Chapter 3

Connection

Communication Terminal Configuration – 10

●

Wiring – 11

Chapter

3

– 9 –

Page 11

Chapter

3

Warning

Do not turn on power until all of the wiring is completely finished.

There is a risk of electrical shock or damage.

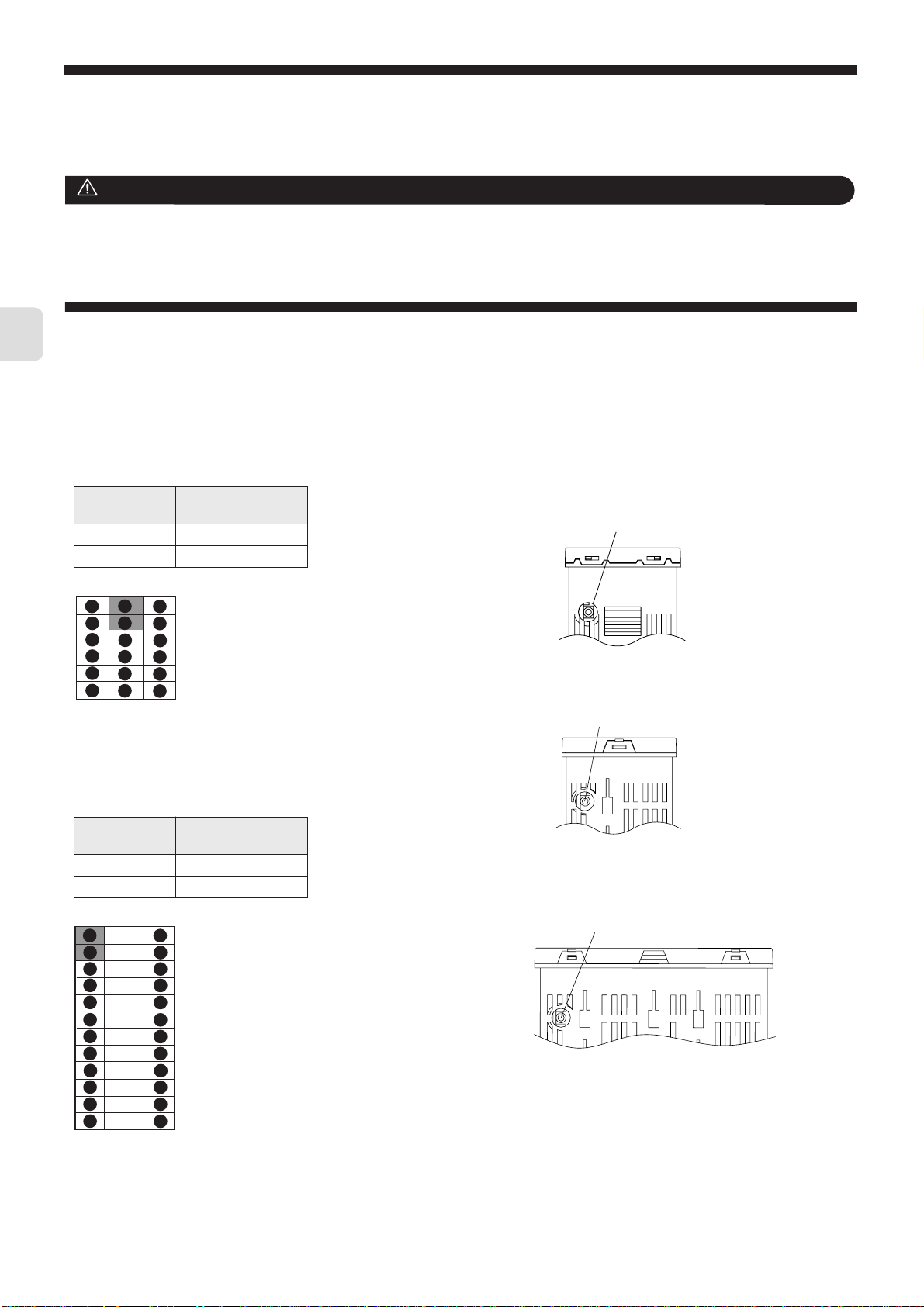

Communication T erminal Configuration

■ RS-485 (rear terminal)

PXG4

Terminal

Number

7 RS-485 +

8 RS-485 -

1

7

13

2

8

14

3

9

15

4

10

16

5

11

17

12

6

18

Signal Name

PXG5, PXG9

Terminal

Number

1 RS-485 +

2 RS-485 -

Signal Name

■ PC Loader Interface

(Bottom, φ2.5, three prong miniature jack)

PXG4

PC Loader Interface

PXG5

PC Loader Interface

PXG9

1

2

3

4

5

6

7

8

9

10

11

12

25

26

27

28

29

30

31

32

33

34

35

36

PC Loader Interface

– 10 –

Page 12

Wiring

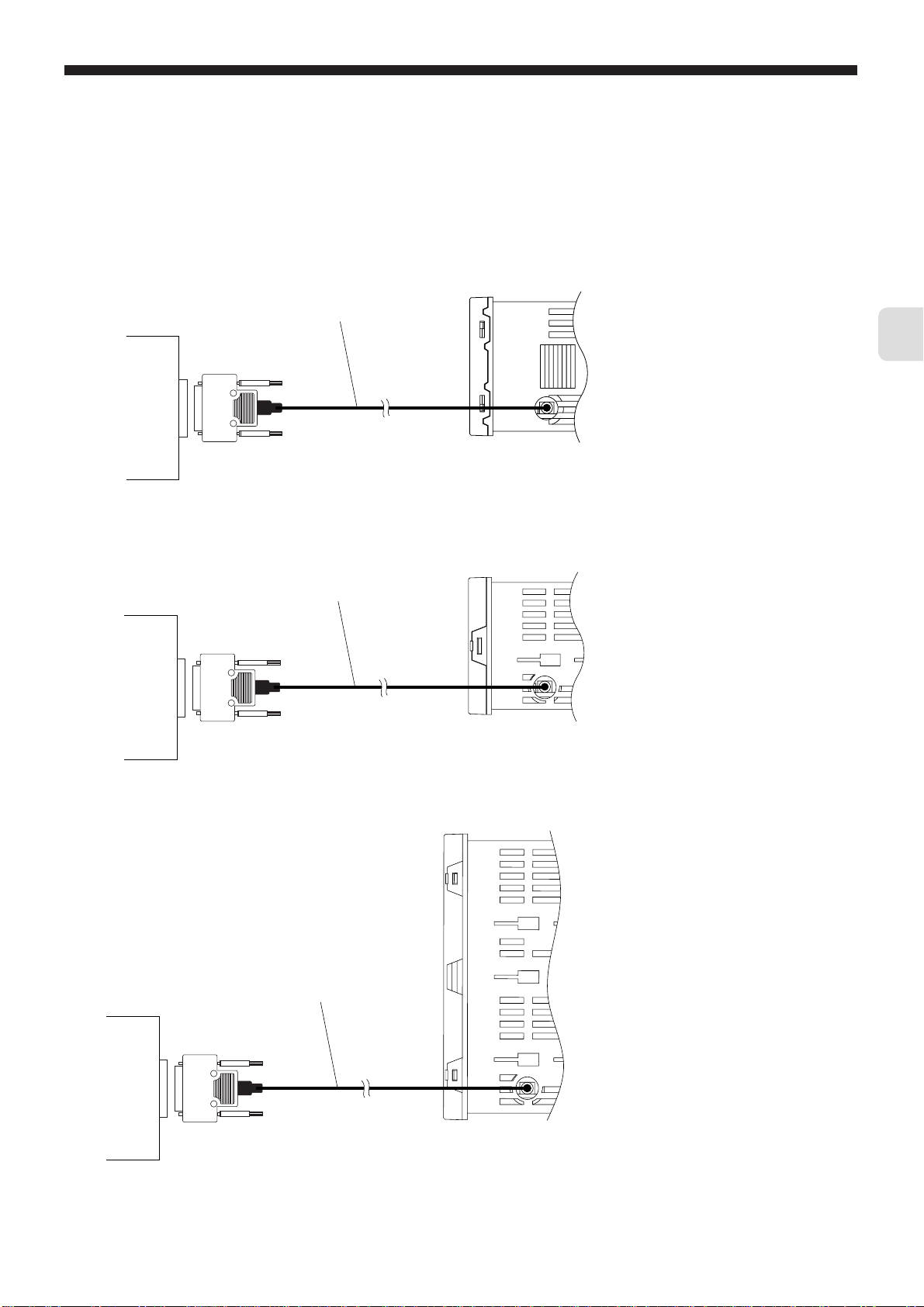

■ RS-485

• Please use a shielded twist pair cable. (Recommended cable: KPEV-SB (made by The Furukawa Electric Co., Ltd.))

• The maximum cable length should be 500m. One master and up to thirty-one micro controllers (slaves) can be connected per

circuit.

• Terminate both ends of the circuit with a terminating resistance of 100

• Ground the shielded cable once towards the master side.

Ω (1/2W or more).

Chapter

Master

RS-485 interface

or

RS-485 side of

RS-232C to RS-485 converter

+

–

SG

Terminating resistance

100W (1/2W)

Shielded twist pair cable

3

Slave

+

–

PXG Series

+

–

PXG Series

+

Terminating resistance

100W (1/2W)

• SG does not have to be connected, but it can be used as an effective countermeasure against communication errors due to

noise.

– 11 –

–

PXG Series

Page 13

•

When using the micro controller in an area where the imposed noise level is expected to exceed 1000V, we recommend using

a noise filter on the master side as seen in the figure below .

[Noise filter] (recommended): ZRAC2203-11 (made by TDK Corporation)

Chapter

3

Programmable controller

or

Personal computer

+ RS-232C to RS-485 converter

Noise filter

RS-485

PXG Series

• If there are problems with EMC during communication, the noise level can be reduced by using a communication cable with a

ferrite core.

Ferrite core (recommended): ZCAT series (made by TDK Corporation)

MSFC series (made by Morimiya Electric Co., Ltd.)

– 12 –

Page 14

■ PC Loader Interface

• Use the PC loader communication cable (RS-232C) sold separately.

PXG4

PC loader communication cable (RS-232C)

Master side

Personal

computer

etc.

ZZPPXH1

RS-232C

TK4H4563

*

Chapter

3

PXG5

PXG9

Master side

Personal

computer

etc.

D-Sub 9 pin

PC loader communication cable (RS-232C)

ZZPPXH1

RS-232C

D-Sub 9 pin

TK4H4563

*

PXG4 Bottom view

PXG5 Bottom view

Master side

Personal

computer

etc.

PC loader communication cable (RS-232C)

ZZPPXH1

RS-232C

D-Sub 9 pin

TK4H4563

*

PXG9 Bottom view

– 13 –

Page 15

Chapter

3

MEMO

– 14 –

Page 16

Chapter 4

Setting Communication Parameters

Chapter

List of Setting Parameters – 16

●

Parameter Setting Procedure – 17

4

– 15 –

Page 17

Chapter

4

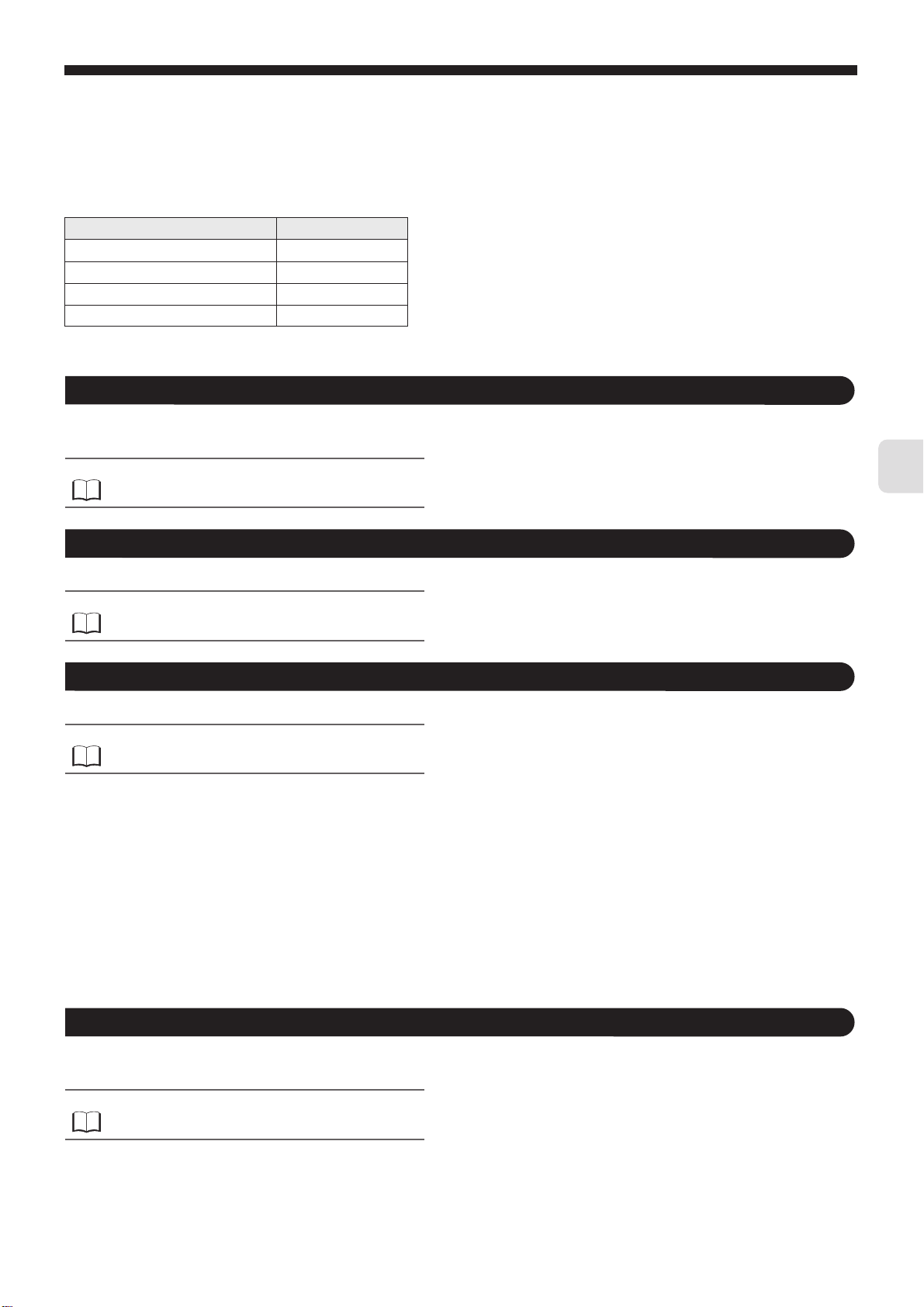

The following settings are required for proper communication between the master and micro controller units.

•

The communication parameters for the master and all of the units must be set the same.

•

During RS-485 communication, all of the micro controllers on a circuit must be set with different "Station No. (STno)" other

than "0 (zero)". (Multiple micro controllers must not have the same "Station No.".)

When using the PC loader interface, settings are not necessary on the main unit (the micro controller).

•

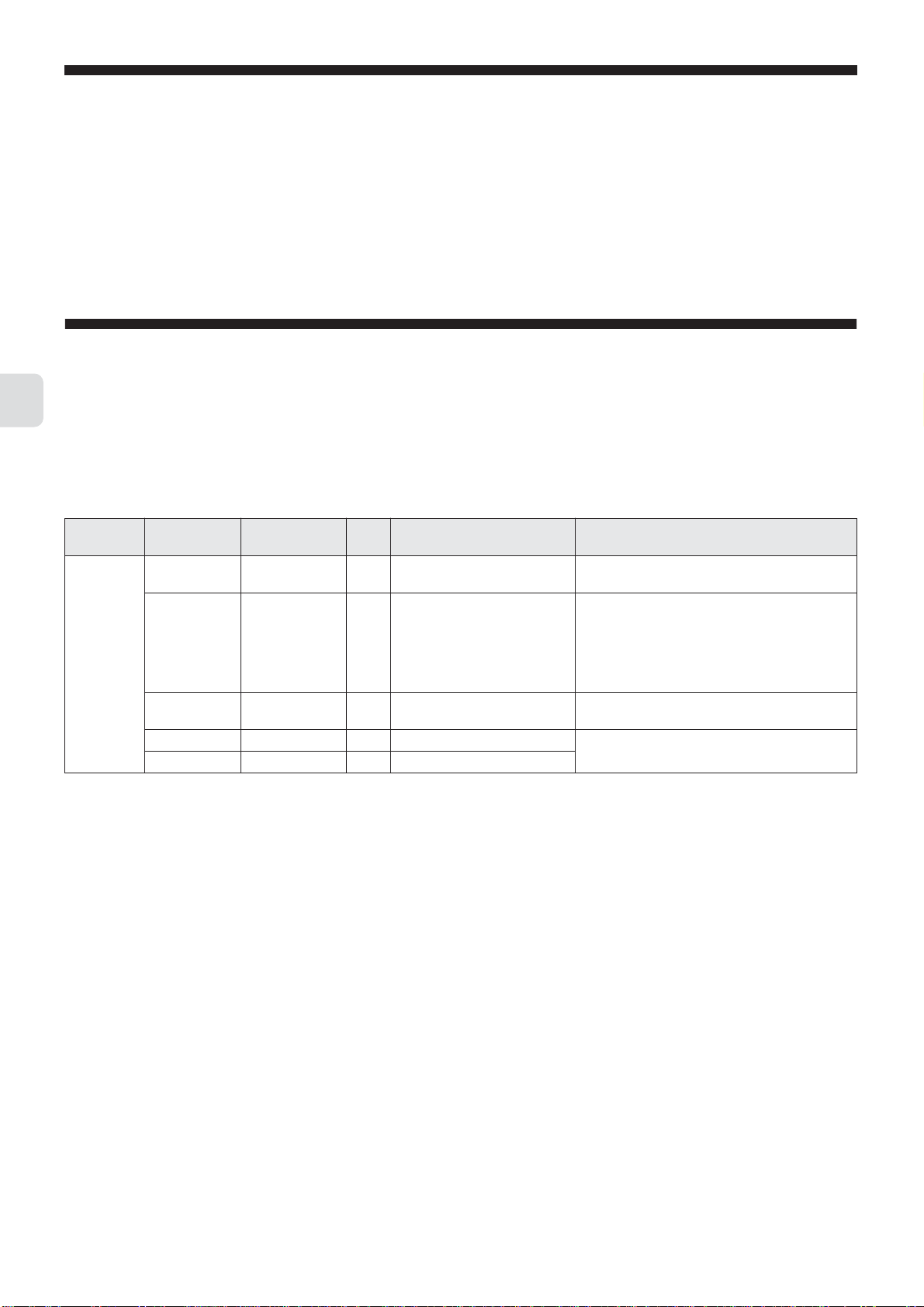

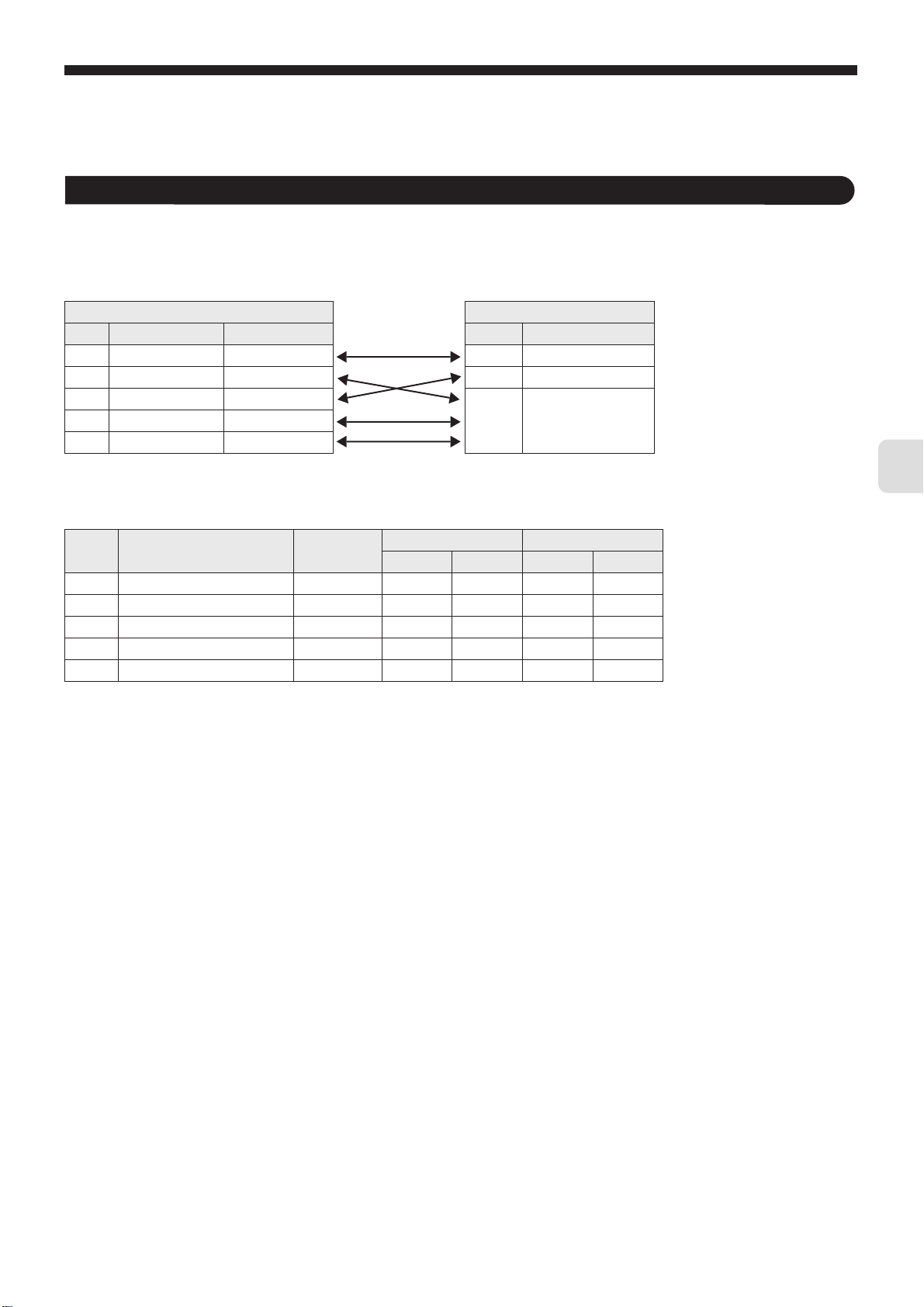

List of Setting Parameters

The setting parameters are shown in the chart shown below. Change the settings using the keys on the front of the micro

controller.

■

RS-485 (main unit side)

Parameter

channel

CoM Ch9

"

(CoM Ch9)

■

Loader interface (main unit side)

Parameter

display symbol

"

STno

"

CoM

"

"

SCC

Parameter name

" (STno)

" (CoM)

" (SCC)

– Data length 8 bits Fixed (cannot be changed) Set the master and all of the slaves with the

– Stop bit 1 bit Fixed (cannot be changed)

Station No. 1 0 to 255 Unit does not respond to communication when 0

baud rate/parity

settings

Communication

permissions

Initial

value

96od 96od (9600 bps/odd)

96Ev (9600 bps/even)

96no (9600 bps/none)

19od (19200 bps/odd)

19Ev (19200 bps/even)

19no (19200 bps/none)

rW r (read only)

rW (read and writable)

Setting range Remarks

is set.

This is the procedure to specify communications

speed and parity check.

Set the master and all of the slaves with the

same settings.

same settings.

The parameters do not need to be set. Set the loader software (master) with the following settings.

•

Communication speed: 9600 bps

•

Parity: none

– 16 –

Page 18

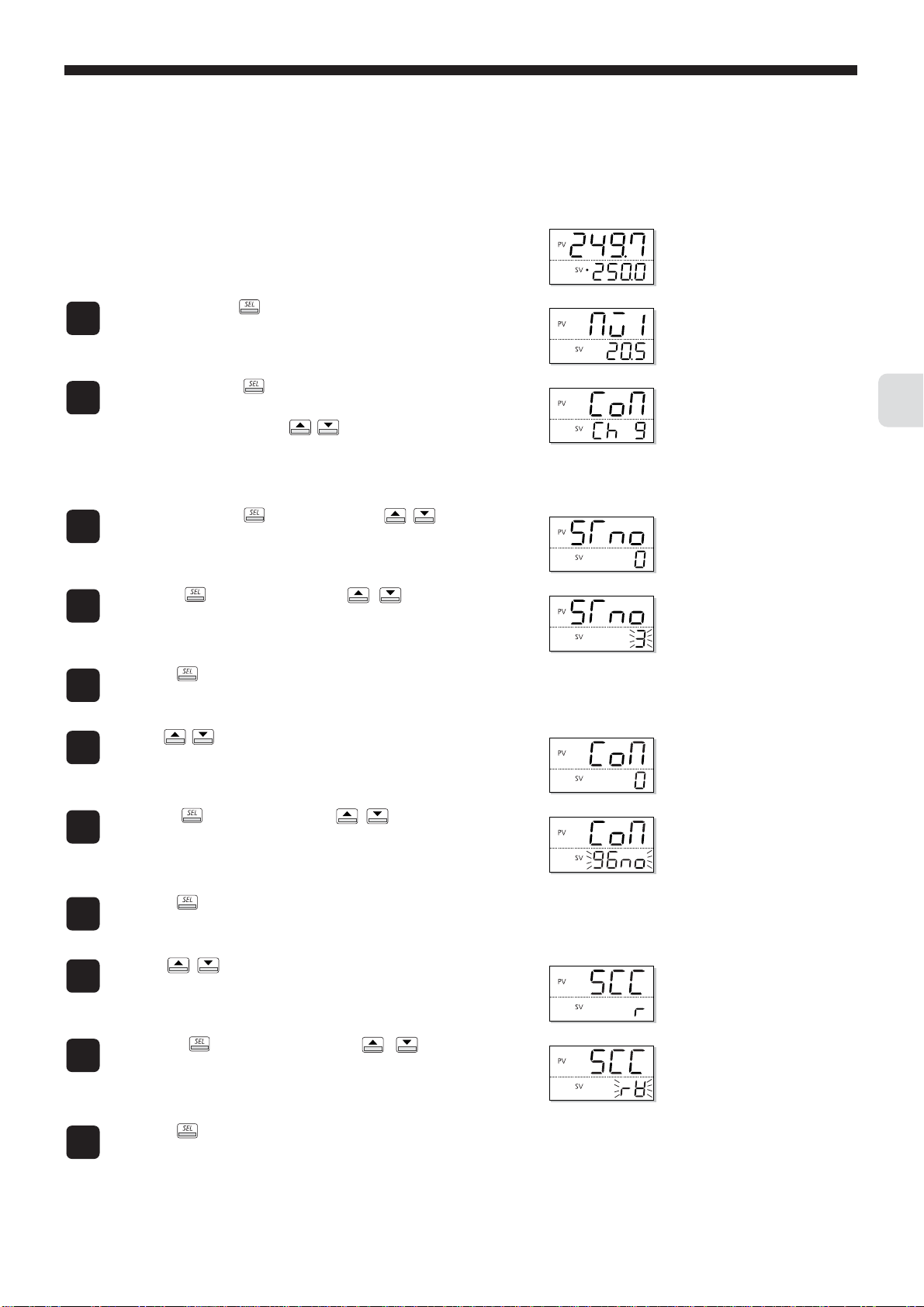

Parameter Setting Procedure

The following steps explain how to change the settings to station number "3", parity setting "9600bps/none", and communication

permissions "read and writable" as an example.

Press and hold the key to display " Mv1 ".

1

The MV1 of the monitoring screen is displayed.

Press and hold the key to display the setup mode operation

2

menu

("

oPE Ch 1

The communication menu is displayed.

(Note) If your micro controller does not have a communication function, "

model.

Press and hold the key, the use the keys to display

3

" STno ."

The station number is displayed.

Press the key, then use the keys to set station

4

number to "3" when the bottom part of the display begins to blink.

This sets the parameter to "3".

Press the key to confirm the setting.

"), then use the keys to display "

CoM Ch 9

5

Use the keys to select the parity setting (" CoM ").

6

Press the key, then use the keys to set the parity

7

setting to "96no" when the bottom part of the display begins to

blink.

The baud rate/parity setting is set to "9600 bps/none".

".

CoM Ch 9

Chapter

4

" will not be displayed. Please check with your

Press the key to confirm the setting.

8

Use the keys to select the communication permissions

9

(" SCC ").

Press the key, then use the keys to set the

10

communication permissions to "rW" when the bottom part of the

display begins to blink.

"read/write" is selected.

Press the key to confirm the setting.

11

– 17 –

Page 19

Chapter

4

Press the key to return to the operation mode PV/SV display.

12

Turn the power to the micro controller off and on again.

13

The changes to the communication parameters become effective after

the power turns off and on again.

– 18 –

Page 20

Chapter 5

MODBUS Communication Protocol

Overview – 20

●

Message Composition – 21

●

Calculating Error Check Code (CRC-16) – 24

●

Transmission Control Steps – 25

●

Precautions when Writing Data – 26

Chapter

5

– 19 –

Page 21

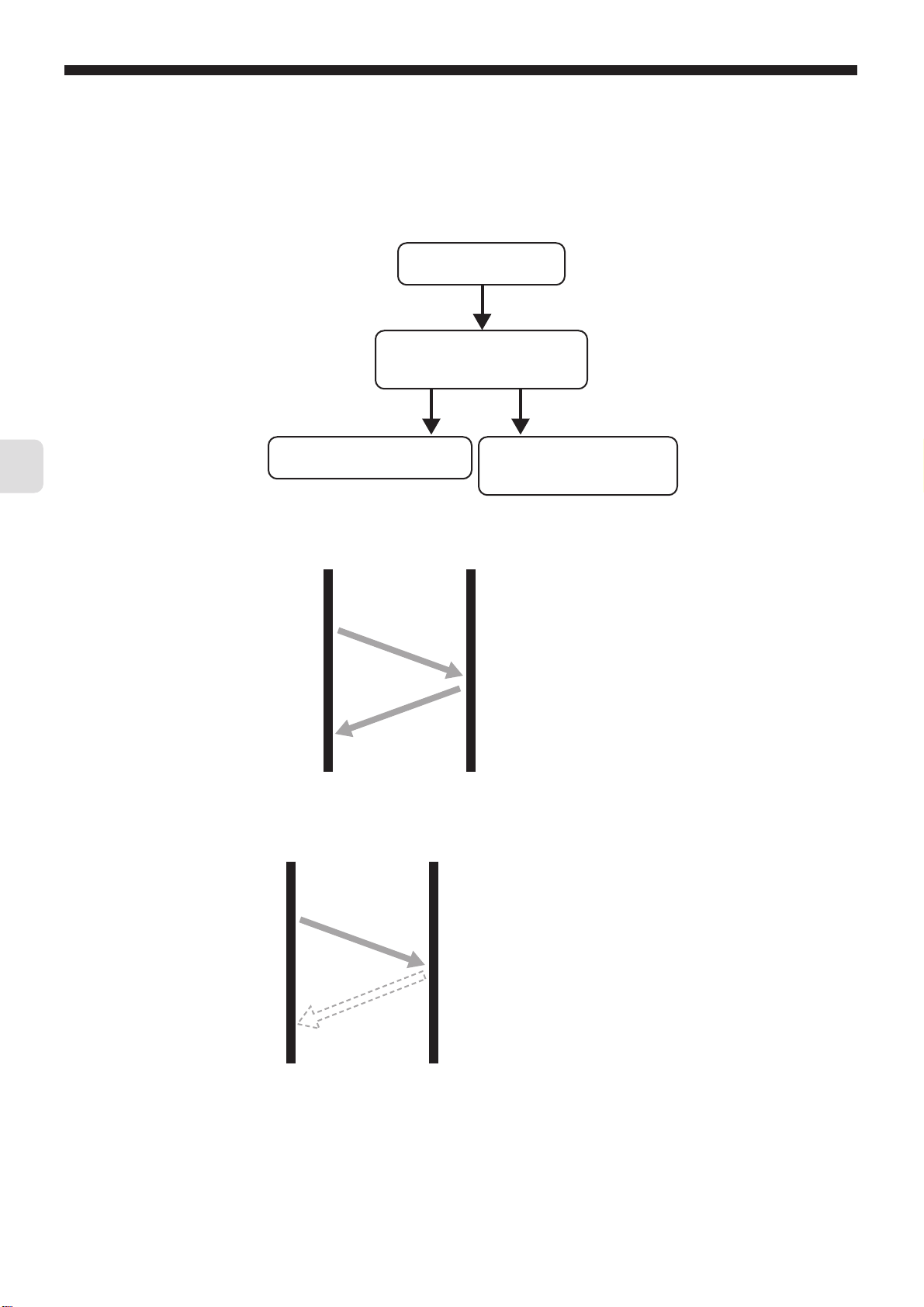

Overview

The communication system with the MODBUS protocol always operates using a method where the master first sends a command

message and the applicable slave replys with a response message .

The following describes the communication steps.

Master sends the command

message for the slave.

The slave checks whether the station

number in the received message is

the same as its own station number.

When it’s the same When it’s not the same

Chapter

5

The slave runs the command and

sends a response message.

The slave throws out the received

message and waits for the next

command message. (No reply.)

● When the station number in the command message is the same as the unit’s station number

Master Slave

Command Message

Station number is the same

Response Message

● When the station number in the command message is not the same as the unit’s station number

Master Slave

Command Message

Station number is not the same

The master can communicate with an individual slave when multiple slaves are connected on the same circuit by the station

number specified in the master’s command message.

– 20 –

Page 22

Message Composition

The command message and response message are composed of four parts: the station number, function code, data part, and

error check code. These four parts are sent in that order.

Field name No. of bytes

Station No. 1 byte

Function Code 1 byte

Data Part 2 to 125 bytes

Error Check Code (CRC-16) 2 bytes

The following describes each part of the message.

Station No.

This is the number specifying the slave. Commands can only be processed by slaves that have the same value set in the "STno"

parameter.

Refer to

For more about setting the "STno" parameter, see "Chapter 4,

Setting Communication Parameters" (p. 15).

Function Code

Chapter

5

This code specifies the function for the slave to perform.

Refer to

For more about function codes, see "Function Code" (p. 23).

Data Part

This data is required to run the function code. The composition of the data part is different depending on the function code.

Refer to

See "Chapter 6, Command and Transmission Frame Details"

(p. 27).

The data in the micro controller is assigned a coil number or resistor number. This coil number or resistor number is specified

when the data is read or written through communication.

The coil number or resistor number used by the message employs a relative address.

The relative address is calculated using the following formula.

Relative address = (last four digits of the coil number or resistor number) – 1

(Ex.) When a function code specifies resistor number "40003"

Relative address= (the last four digits of 40003) – 1

= 0002

is used in the message.

Error Check Code

This code detects whether there are errors (changes in the bits) during the signal transmission processes. MODBUS protocol

(RTU mode) uses CRC-16 (Cyclic Redundancy Check).

Refer to

For more about calculating CRC, see Section 5,

"Calculating Error Check Code (CRC-16)" (p. 24).

– 21 –

Page 23

Chapter

5

Slave Response

■ Normal Slave Response

The slave creates and replies with a response message for each command message. The response message has the same

format as the command message.

The contents of the data part are different depending on the function code.

Refer to

See "Chapter 6, Command and Transmission Frame Details".

■ Irregular Slave Response

If there are problems (such as specification of a nonexistent function code) with the contents of the command message other than

transmission error, the slave creates and replies with an error response message without following the command.

The composition of the error response message uses the value of the function code in the command message plus 80

below.

Field name No. of bytes

Station No. 1 byte

Function Code

+80

H

1 byte

Error Code 1 byte

Error Check Code (CRC-16) 2 bytes

The error code is shown as follows.

Error Code Contents Explanation

01

02

03

H

H

H

Faulty function code A nonexistent function code was specified. Please check the function code.

Faulty address for coil or resistor The specified relative address for the coil number or resistor number cannot be

used by the specified function code.

Faulty coil or resistor number The specified number is too large and specifies a range that does not contain

coil numbers or resistor numbers.

H, as seen

■ No Response

In the following situations, the slave will ignore the command message and not send a response message.

• The station number specified by the command message is not the same as the slave’s specified station number.

• The error check code does not correspond, or a transmission error (such as parity error) is detected.

• The interval between the data comprising the message is empty for more than 24 bit time.

Refer to

See Section 5 "Transmission Control Steps" (p. 25).

• The slave station number is set to "0".

– 22 –

Page 24

Function Code

For MODBUS protocol, coil numbers or resistor numbers are assigned by the function code, and each function code

only works for the assigned coil number or resistor number.

The correspondence between the function code and the coil number or resistor number is as follows.

Function Code

Coil Number, Resistor Number

Code Function Target Number Contents

Read (continuous) Input relay 1xxxx Read bit data

02

H

03

Read (continuous) Hold resistor 3xxxx Read word data

H

04

Read (continuous) Input resistor

H

Write Hold resistor

H

10

Write (continuous) Retention resistor

H

4xxxx Read/write word data06

The message length for each function is as follows.

[unit: byte]

*

*

*

*

*

Code Contents

02

03

04

06

10

Read bit data (read-only) 8 bit

H

Read word data 60 words

H

Read word data (read-only) 37 words

H

Write word data 1 word 8888

H

Continuously write word data 60 words

H

Assignable

Data Number

1

Command Message Response Message

Minimum Maximum Minimum Maximum

8866

1

1

1

887125

88779

11 129 8 8

1: "Assignable Data Number" above is limited by the data number that the micro controller assigned to the coil number or

address number.

(Excluding function code 06

H

).

Chapter

5

– 23 –

Page 25

Chapter

5

Calculating Error Check Code (CRC-16)

CRC-16 is a 2-byte (16-bit) error check code. The calculation r ange extends from the start of the message (station number) to the

end of the data part.

The slave calculates the CRC of the received message and ignores the message if this value is not the same as the received

CRC code.

CRC-16 is calculated as follows.

Start

* Description of Variables

Set CR to FFFF

Exclusive-or (XOR) runs on each character of J (one byte) for CR

and the specified message, and sets that result to CR.

H (hexadecimal)

Set J = 1

Set K = 1

CR : CRC error check data (2 byte)

J:Command message calculation

character digit

K:No. of times to check CR calculation

Is the right-hand

bit for CR 1?

YES

After CR has been adjusted one bit to the right, A001

run and set that result to CR.

Add 1 to K

NO

NO

Has calculation

finished 8 times ?

J > 8

YES

Add 1 to J

Has every character

been calculated ?

J > Number of characters

NO

H and XOR

(Calculations occur in the order

command message station number,

function code, and data.)

Adjust CR one bit

to the right.

YES

Complete

The CR calculation result is added

onto the end of the command

message in LOW or HIGH order.

– 24 –

Page 26

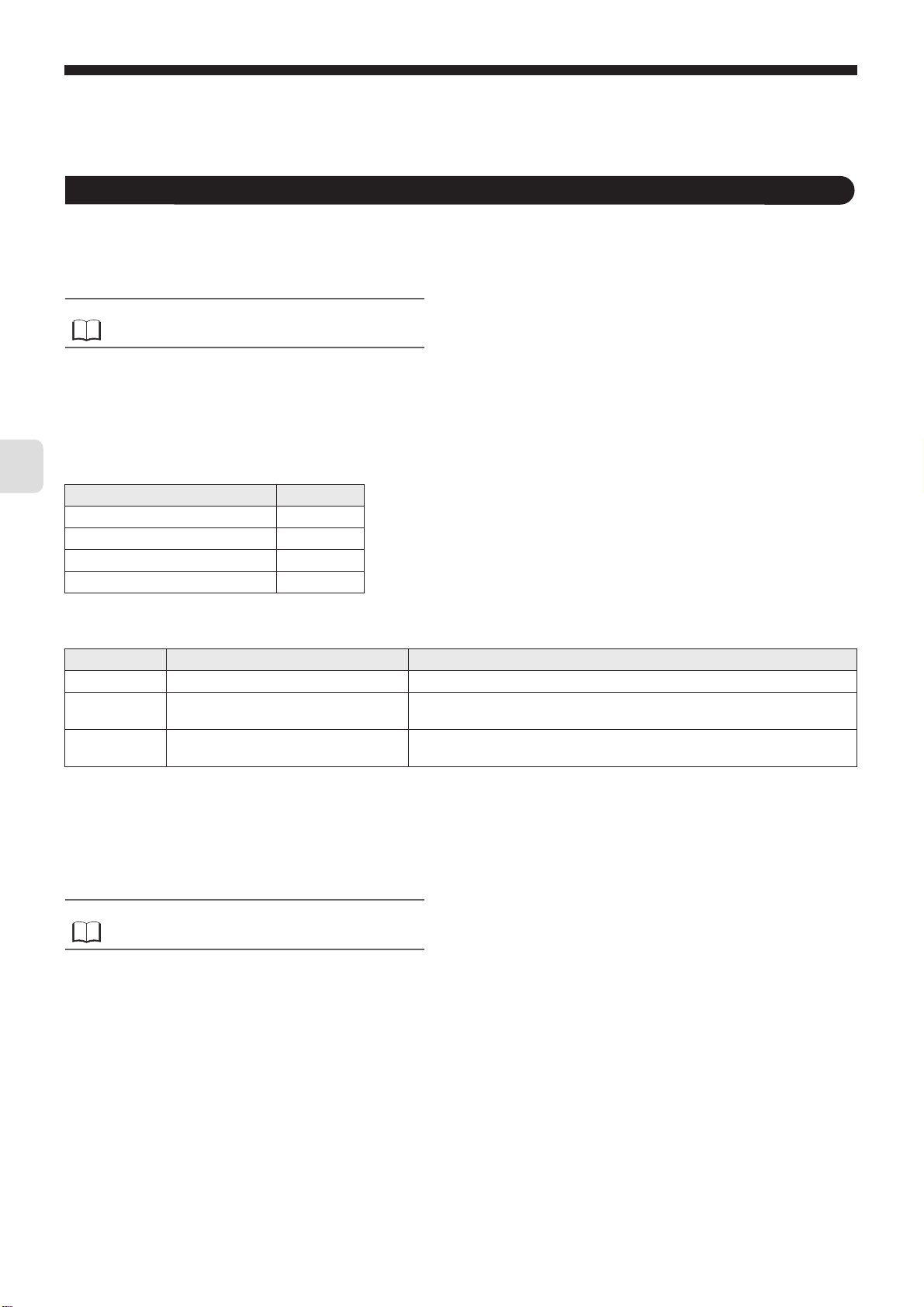

Transmission Control Steps

Master Communication Method

Start communication from the master while following the rules below.

1. The command message, must be sent after an empty space of at least 48 bit time.

2. The interval between each byte in a command message should be less than 24 bit time.

3. After sending a command message, for less than 24 bit time the master will enter receiving standby.

4. After receiving the response message, the next command message must be sent after at least 48 bit time. (Similar to #1.)

5. For safety reasons, create a framework where the master checks the response message, and if there is no response or an

error occurs, retry at least three times.

Caution

The definitions written above are for the minimum required value. For safety reasons, we recommend creating a

master side program that keeps margins two to three times as large. For a concrete example, with 9600 bps, we

recommend programming a blank state (#1 above) of at least 10ms, and the interval between bytes (#2 above) and

switching time from sending to receiving (#3 above) within 1 ms.

Explanation

■

Frame Detection

This communication system uses a two-wire RS-485 interface, and the circuit can therefore enter one of the following two states.

Empty state (no data on the circuit)

•

•

Communication state (data running on the circuit)

The units connected on the circuit start in receiving state and monitor the circuit. When a blank state appears on the circuit for at least

24 bit time, the unit detects the end of the previous frame, and within the next 24 bit time, enters receiving standby. When data

appears on the circuit, the unit begins receiving data, and once another blank state of at least 24 bit time is detected, that frame is

ended. In other words, the data on the circuit from the first time that a 24 bit time blank state appears to the second time one appears

is loaded as one frame (a bundle of data). Therefore, one frame (command message) must be sent while following the rules below.

Before sending the command message, leave an empty space of at least 48 bit time.

•

•

The interval between each byte in a command message should be less than 24 bit time.

■

Micro controller Response

After the micro controller detects the frame (detects blank states at least 24 bit time long), that frame is used to send a command

message. When a command message is sent locally, the response message is returned, but the processing time is about 1 to 30

ms. (The time may change depending on the contents of the command message. ) Therefore, one frame (command message)

must be sent while following the rules below.

•

After sending a command message, for less than 24 seconds the master will enter receiving standby.

Master

POL1

Slave

Chapter

5

Interval of at least 5ms required

(at least 10ms recommended)

1 to 30ms

POL1 response data

POL2

1 to 30ms

POL2 response data

– 25 –

Page 27

Chapter

5

Precautions when Writing Data

PXG contains internal nonvolatile memory (EEPROM) that is used to save the setting parameters. The data written to the

nonvolatile memory (EEPROM) remains even after the power for PXG is turned off. Parameters that are written via

communication are automatically saved in the internal nonvolatile memory (EEPROM). However, please note that there are two

limitations as follows.

Caution

1. There is a limit to the number of times that data can be transferred to the nonvolatile memory (EEPROM)

(100,000 times). Data cannot be guaranteed if written more than 100,000 times.

Be careful not to transfer unnecessary data when writing data via communication.

In particular, when constructing a communication system with master POD (such as a touch panel), make sure

that the POD writing and trigger settings are appropriate.

Avoid writing at fixed cycles.

2. Writing to the nonvolatile memory (EEPROM) takes several milliseconds. If the power for PXG is turned off

during this operation, the data saved to the nonvolatile memory (EEPROM) may be corrupted.

Wait several seconds after writing data before turning off the power.

In particular, when writing data in a cycle from master device, there is a greater danger of the writing timing and

power shutoff timing coinciding.

Avoid writing at fixed cycles.

– 26 –

Page 28

Chapter 6

Command and Transmission Frame

Details

Reading Data – 28

●

Writing Data – 34

Chapter

6

– 27 –

Page 29

Reading Data

Reading Read-Only Bit Data (Function Code: 02H)

The unit reads bit data continuously for the specified number of bits from the first number to start reading from.

The slaves systematically send the read data in 8-bit units.

Caution

Function Code 02H

Max. No. of Bits to Read in One Message 8 bits

Relative Address 0000H to 000CH

Coil Number 10001H to 10013H

Message Composition

When the number of bits to be read is not a multiple of eight, unrelated bits (on the MSB side) all become "0".

Chapter

6

Command Message (bytes)

Station No.

Function Code

Number to Start Reading

(Relative Address)

No. of Bits to Read

CRC Data

■

Bit Data to Read List

MSB LSB

00000000

State of last 1 bit

Upper

Lower

00H

Lower

Upper

Lower

Master Slave

State of first 1 bit

Reply Message Composition (bytes)

Station No.

Function Code

No. of Bytes to Read (01H)

State of first 8 bits

CRC Data

Upper

Lower

– 28 –

Page 30

Example of Transmitting a Message

This following example explains how to read ALM1 and ALM2 on station number 31.

• ALM1 detection data bit Relative address: 0000H Data number: 2H

• ALM2 detection data bit Relative address: 0001H

Command Message (bytes)

Station No. 1FH

Function Code 02H

No. to Start Reading

(Relative Address)

No. of Bits to Read Upper 00H

CRC Data Upper FAH

■

Meaning of Read Data

Upper 00H

Lower 00H

Lower 02H

Lower 75H

MSB LSB

00000001

ALM2 OFF state

Master Slave

ALM1 ON state

Response Message (bytes)

Station No. 1FH

Function Code 02H

No. of Bytes to Read 01H

State of first 8 bits 01H

CRC Data Upper 66H

Lower 60H

Chapter

6

– 29 –

Page 31

Reading Word Data (Function Code: 03H)

The unit reads word data continuously for the specified number of words from the first number to start reading from.

The slave forwards the read word data from the upper number of bytes to the lower number.

Function Code 03H

Max. No. of Words to Read in One Message 60 words

Relative Address 0000H to 0276H 03E8H to 065EH

Resistor Number 40001 to 40628 41001 to 41628

Contents

Message Composition

Internal Calculation

Value

Engineering Unit

Chapter

6

Command Message Composition

(bytes)

Station No.

Function Code

No. to Start Reading

(Relative Address)

No. of Words to Read

(1 to 60 words)

CRC Data

Upper

Lower

Upper

Lower

Upper

Lower

Master Slave

Reply Message Composition (bytes)

Station No.

Function Code

No. of Bytes to Read

(No. of Words to Read x 2)

First Word Data

Contents

Next Word Data

Contents

Last Word Data

Contents

CRC Data

Upper

Lower

Upper

Lower

Upper

Lower

Upper

Lower

■

Meaning of Read Word Data

MSB LSB

First Word Data upper byte

First Word Data lower byte

Next Word Data upper byte

Next Word Data lower byte

Last Word Data upper byte

Last Word Data lower byte

– 30 –

Page 32

Example of Transmitting a Message (For Engineering Unit)

The message is composed as follows when reading the PV input lower limit and PV input upper limit from station number 2.

• PV Lower Limit Relative Address: 03F9H

Master Slave

Command Message (bytes)

Station No. 02H

Function Code 03H

No. to Start Reading

(Relative Address)

No. of Words to Read

CRC Data

■

Meaning of Read Data

Upper 03H

Lower F9H

Upper 00H

Lower 02H

Upper 14H

Lower 4DH

PV Input Lower Limit 00 00H = 0

PV Input Upper Limit 01 90H = 400

Response Message (bytes)

Station No. 02H

Function Code 03H

No. of Bytes to Read 04H

First Word Data

Contents

Next Word

Data Contents

CRC Data

Upper 00H

Lower 00H

Upper 01H

Lower 90H

Upper C8H

Lower CFH

Chapter

6

If Decimal Point Position = 0, then the PV input upper limit and lower limit are as follows.

PV Lower Limit = 0°C

PV Upper Limit = 400°C

For more about the internal calculation value, engineering unit,

Refer to

and decimal point see

"Chapter 7, Address Map and Data Format" (p. 39).

– 31 –

Page 33

Reading Read-Only Word Data (Function Code: 04H)

The unit reads word data continuously for the specified number of words from the first number to start reading from.

The slave forwards the read word data from the upper number of bytes to the lower number.

Function Code 04H

Max. No. of Words to Read in One Message 37 bytes

Relative Address 0000H to 0064H 03E8H to 044CH

Resistor Number 30001 to 30100 31001 to 31100

Contents Internal Calculation Value Engineering Unit

Message Composition

Chapter

6

Command Message Composition

(bytes)

Station No.

Function Code

No. to Start Reading

(Relative Address)

No. of Words to Read

(1 to 15 words)

CRC Data

Upper

Lower

Upper

Lower

Upper

Lower

Master Slave

Reply Message Composition (bytes)

Station No.

Function Code

No. of Bytes to Read

(No. of Words to Read x 2)

First Word Data

Contents

Next Word Data

Contents

Last Word Data

Contents

CRC Data

Upper

Lower

Upper

Lower

Upper

Lower

Upper

Lower

■ Meaning of Read Word Data

MSB LSB

First Word Data upper byte

First Word Data lower byte

Next Word Data upper byte

Next Word Data lower byte

Last Word Data upper byte

Last Word Data lower byte

– 32 –

Page 34

Example of Transmitting a Message (Internal Calculation Data)

The message is composed as follows when reading the PV input value from station number 1.

• PV value relative address: 0000H Number of data: 01H

Command Message (bytes)

Station No. 01H

Function Code 04H

No. to Start Reading

(Relative Address)

No. of Bits to Read

CRC Data

Upper 00H

Lower 00H

Upper 00H

Lower 01H

Upper 31H

Lower CAH

Master Slave

■ Meaning of Read Data

Word Data Contents 03 46H = 838 (8.38% FS)

When the input range is 0 to 400°C

PV = 33.5°C (= 8.38% FS x 400 (input range width))

For more about the internal calculation value, engineering unit,

Refer to

and decimal point see

"Chapter 7, Address Map and Data Format" (p. 39).

Example of Transmitting a Message (For Engineering Unit)

Response Message (bytes)

Station No. 01H

Function Code 04H

No. of Bytes to Read 02H

First Word Data

Contents

CRC Data

Upper 03H

Lower 46H

Upper 38H

Lower 32H

Chapter

6

The message is composed as follows when reading the PV value from station number 1.

• PV value relative address: 03E8H Number of data: 01H

Command Message (bytes)

Station No. 01H

Function Code 04H

No. to Start Reading

(Relative Address)

No. of Words to Read

CRC Data

Upper 03H

Lower E8H

Upper 00H

Lower 01H

Upper B1H

Lower BAH

Master Slave

Response Message (bytes)

Station No. 01H

Function Code 04H

No. of Bytes to Read 02H

First Word Data

Contents

CRC Data

■ Meaning of Read Data

Word Data Contents 01 4FH = 335

When the decimal point position = 1

PV = 33.5°C

For more about the internal calculation value, engineering unit,

Refer to

and decimal point see

"Chapter 7, Address Map and Data Format" (p. 39).

Upper 01H

Lower 4FH

Upper F9H

Lower 54H

– 33 –

Page 35

Chapter

6

Writing Data

Writing Word Data (1 word, function code: 06H)

This writes the specified data to the specified number for word data. The master sends the data to be written from the upper

number of bytes to the lower number.

Function Code 06H

Max. No. of Bits to Read in One Message 1 words

Relative Address 0001H to 0274H 03E9H to 065CH

Resistor Number 40002 to 40628 41002 to 41628

Contents Internal Calculation

Value

Message Composition

Master Slave

Command Message Composition

(bytes)

Station No.

Function Code

Specified Write Number

(Relative Address)

Word Data to Write

CRC Data

Upper

Lower

Upper

Lower

Upper

Lower

Engineering Unit

Response Message Composition

(bytes)

Station No.

Function Code

Specified Write

Number

(Relative Address)

Word Data to

Write

CRC Data

Upper

Lower

Upper

Lower

Upper

Lower

– 34 –

Page 36

Example of Transmitting a Message

This example explains how to set PID parameter "P" to 100.0 (1000D = 03E8H) on station number 1.

Parameter "P" relative address: 0005H (internal calculation value table)

03EDH (initial value table)

Master Slave

Command Message (bytes)

Station No. 01H

Function Code 06H

Specified Write

Number

(Relative Address)

Word Data to Write

CRC Data

Upper 00H

Lower 05H

Upper 03H

Lower E8H

Upper 99H

Lower 75H

Response Message (bytes)

Station No. 01H

Function Code 06H

Specified Write

Number

(Relative Address)

Write Specification

State

CRC Data

Upper 00H

Lower 05H

Upper 03H

Lower E8H

Upper 99H

Lower 75H

Chapter

6

Point

For more about the internal calculation value, engineering unit, and decimal point see "Sent Data Format" (p. 40).

– 35 –

Page 37

Chapter

Writing Continuous Word Data (Function code: 10H)

This writes continuous word information for a number of written words from the first number for writing.

The master sends the data to be written from the upper number of bytes to the lower number.

Function Code 10H

Max. No. of Bits to Read in One Message 60 words

Relative Address 0000H to 0077H 03E8H to 045FH

Resistor Number 40001 to 40120 41001 to 41120

Contents Internal Calculation

Value

Message Composition

Master Slave

Engineering Unit

6

Command Message Composition (bytes)

Station No.

Function Code

Specified Write

Number (Relative

Address)

No. of Words to Write Upper

No. of Bytes to Write

First Word Data to

Write

Next Word Data to

Write

Last Word Data to

Write

CRC Data Upper

Upper

Lower

Lower

Upper

Lower

Upper

Lower

Upper

Lower

Lower

}

1 to 60

} No. of Words

to Write x 2

Reply Message Composition (bytes)

Station No.

Function Code

Specified Write

Number (Relative

Address)

No. of Words to

Write

CRC Data Upper

Upper

Lower

Upper

Lower

Lower

■ Meaning of Read Word Data

MSB LSB

First Word Data upper byte

First Word Data lower byte

Next Word Data upper byte

Next Word Data lower byte

Last Word Data upper byte

Last Word Data lower byte

– 36 –

Page 38

Example of Transmitting a Message (Internal Calculation Data)

The message is composed as follows when writing the following PID parameters to station number 1.

P = 100.0 (= 1000D = 03E8H)

I = 10 (= 100D = 0064)

D = 5.0 (= 50D = 0032H)

•Parameter “PPPP” relative address: 0005H, Data number: 03H

Command Message (bytes)

Station No. 01H

Function Code 10H

Specified Write

Number (Relative

Address)

No. of Words to

Write

No. of Bytes to Write 06H

First Word Data to

Write

Next W ord Data to

Write

Last Word Data to

Write

CRC Data Upper 56H

Upper 00H

Lower 05H

Upper 00H

Lower 03H

Upper 03H

Lower E8H

Upper 00H

Lower 64H

Upper 00H

Lower 32H

Lower BEH

Master Slave

Response Message (bytes)

Station No. 01H

Function Code 10H

Specified Write

Number

(Relative Address)

Write Specification

State

CRC Data

Upper 00H

Lower 05H

Upper 00H

Lower 03H

Upper 90H

Lower 09H

Chapter

6

Point

Refer to

The decimal point cannot be included in the sent data, so data such as “100.0” above is sent as “1000”.

For each type of send data format, see “Chapter 7, Address

Map and Data Format” (p. 39).

– 37 –

Page 39

Chapter

6

MEMO

– 38 –

Page 40

Chapter 7

Address Map and Data Format

Data Format – 40

●

Internal Calculation Value Data Address Map – 42

Chapter

7

– 39 –

Page 41

Data Format

Sent Data Format

The MODBUS protocol used by this equipment employs RTU (Remote Terminal Unit) mode. The data is sent as "numerical

value", not as ASCII code.

Internal Calculation Value and Engineering Unit

In this unit, parameter data and data dependent on an input range can handle the following two types of data.

Internal Calculation Value: Values listed as percentages of the input range (0.00 to 100.00, without decimal point)

Engineering Unit: Values subjected to scaling to actual values depending on the input range

"Engineering Unit" data is handled as the address (resister number) of 1000 added to the address (resister number) for "Internal

Calculation Value".

(Ex.) The value is calculated as follows when the full scale is 400°C and the PV value is "150".

Class Resistor Number Data (HEX) Data

Internal Calculation Value 30001 0EA6 (H)

Engineering unit 31001 0096 (H) 150

→

3750 (37.5%)

Chapter

7

The PV value is received as follows.

37.50 (%) x 400 (full scale °C) = 150 °C

Data not dependent on an input range the same data in both addresses.

Also, bit data cannot be handled in this manner. (Not effective for addresses with 1,000 added.)

Refer to

For more about data dependent on an input range, see

"Chapter 7 Address Map and Data Format" (page 39).

Caution

(Ex.) When changing the input range from 0 to 400 to 0.0 to 400.0

■ Operating the keys on the front of the equipment

Change the position of the decimal point ("PP

PPvvvvdddd

"PP

■ Changing by communication

Set the decimal position parameter ("PP

upper limit ("PP

PPvvvvdddd

"PP

PPvvvvbbbb

"PP

PPvvvvFFFF

"PP

Pay attention to the position of the decimal point when changing the input range by writing with communication. When

changing the position of the decimal point by writing with communication, change the lower limit and upper limit of the

input range at the same time.

" = 0 → 1 (or 2)

PPvvvvFFFF

").

" = 0 → 1

" = 0 → 0

" = 400 → 4000

PPvvvvdddd

") in the setup menu ("SS

PPvvvvdddd

"), as well as the corresponding values for PF input lower limit ("PP

SSEEEETTTT CCCChhhh 6666

").

PPvvvvbbbb

") and PV input

Managing the Decimal Point

Some of the internally stored data may contain may digits lower than the decimal point on the front displa y. Also, the decimal point

is not added to sent data.

Carry out processes for the decimal point position (erasing the decimal point when sending data and adding the decimal point

when receiving data).

Attention must be paid to the position of the decimal point for data where the parameters are dependent on a range in "Chapter 7

Address Map and Data Format". Refer to Address Map.

– 40 –

Page 42

Data during Input Error

For situations such as overrange, underrange, and input breaks where "UU

becomes 105% or -5% of the input range.

Input errors can be detected via communication using "resistor number 30008 (or 31008): Input/Unit Error Status".

UUUUUUUUUUUUUU

" or "LL

LLLLLLLLLLLLLL

" display on the front, read PV value

Written Data

When writing data to each parameter, set that written data within the range for the data. PXG can accept written data outside of

the range, but do so with care as correct operations are not guaranteed.

Addresses Not Written

Do not write to addresses that are not public. Doing so may cause damage.

Chapter

7

– 41 –

Page 43

Internal Calculation Value Data Address Map

Handles data dependent on an input range as an internal value before scaling (0.00 to 100.00%).

See "Operation Manual" for more details about individual parameter functions and settings ranges.

Bit Data (read only): function code [02 (H)]

Chapter

7

Relative

address

0000H 10001 bit DO1 OUTPUT

00001H 10002 bit DO2 OUTPUT

00002H 10003 bit DO3 OUTPUT

00003H 10004 bit DO4 OUTPUT

00004H 10005 bit DO5 OUTPUT

00008H 10009 bit DO1 Lamp

00009H 10010 bit DO2 Lamp

0000AH 10011 bit DO3 Lamp

0000BH 10012 bit DO4 Lamp

H 10013 bit DO5 Lamp

0000C

Coil

Number

Type

Memory

contents

ON/OFF

ON/OFF

ON/OFF

ON/OFF

ON/OFF

ON/OFF

ON/OFF

ON/OFF

ON/OFF

ON/OFF

Read data

0: DO1 OFF

1: DO1 ON

0: DO2 OFF

1: DO2 ON

0: DO3 OFF

1: DO3 ON

0: DO4 OFF

1: DO4 ON

0: DO5 OFF

1: DO5 ON

0: DO1 Lamp OFF

1: DO1 Lamp ON

0: DO2 Lamp OFF

1: DO2 Lamp ON

0: DO3 Lamp OFF

1: DO3 Lamp ON

0: DO4 Lamp OFF

1: DO4 Lamp ON

0: DO5 Lamp OFF

1: DO5 Lamp ON

Dependent

on range

Remarks/

related

parameters

– 42 –

Page 44

Word Data (read/write): function code [03 (H), 06 (H), 10 (H)]

Operation (Ch1)

Parameter

display

nn

MMMMaaaann

"

"

YY

SSSSTTTTbbbbYY

"

MM

rrrrEEEEMM

"

"

GG

PPPPrrrrGG

"

"

tt

AAAAtt

"

"

Parameter

name

MAn Switches to manual mode 0084

STbY Switches between RUN

"

Contents

and standby

rEM Switches to remote mode 0074

PrG Ramp/soak controls

Command

AT Auto-tuning

run command

Relative

address

0003

0051

0004

Resistor Number

Internal

H

40121 41121 Word 0: oFF (during auto)

Engineering

Type Read data

unit

1: on (during manual)

H

40004 41004 Word 0: oFF (during RUN)

1: on (during standby)

H

40117 41117 Word

0: LoCL (during Local)

1: rEM (during Remote)

H

40082 41082 Word 0: oFF (during stop)

1: rUn (during run)

2: hLd (during hold)

H

40005 41005 Word 0: oFF

1: rUn

Written data

range

0: oFF (auto)

1: on (manual)

0: LoCL (Local)

1: rEM (Remote)

0: oFF (stop)

1: rUn (run)

2: hLd (hold)

Factory

Setting

oFF

oFF

LoCL

oFF

oFF

Dependent

on range

2: Low

hh

LLLLAAAACCCChh

"

nn

SSSSvvvvnn

"

"

(note 1)

LACh Cancels the DO output

"

latch Command

Svn

Selectable SV numbers

00A0

00DC

H

40161 41161 Word 0: oFF

1: rST (latch reset)

H

40221 41221 Word 0: Sv0 (Local SV)

1: Sv1 (SV = SV-1)

2: Sv2 (SV = SV-2)

oFF

Sv0

3: Sv3 (SV = SV-3)

4: Sv4 (SV = SV-4)

5: Sv5 (SV = SV-5)

6: Sv6 (SV = SV-6)

7: Sv7 (SV = SV-7)

8: di : SV = choose Di

PPPPLLLLnnnn11

"

PLn1

11

"

Currently selected PID No.

00DD

H

40222 41222 Word 0: Pid0 (PID group local)

Pid0

1: Pid1 (PID group No. 1)

2: Pid2 (PID group No. 2)

3: Pid3 (PID group No. 3)

4: Pid4 (PID group No. 4)

5: Pid5 (PID group No. 5)

6: Pid6 (PID group No. 6)

7: Pid7 (PID group No. 7)

8: di (PID group Di selection)

AAAALLLL11

"

AAAALLLL1111LL

"

AL1 ALM1 set value or A1-L 00A2

11

"

AL1L AL1L set value Word 0% to 100% FS (absolute alarm)

LL

"

H

40163 41163 Word 0% to 100% FS 10°C

-100% to 100 % FS (deviation alarm)

AAAALLLL1111hh

"

AL1h AL1h set value 00A3

hh

"

H

40164 41164 Word 0% to 100% FS (absolute alarm)

-100% to 100 % FS (deviation alarm)

AAAALLLL22

"

AAAALLLL2222LL

"

AL2 ALM2 set value or A2-L 00A9

22

"

AL2L AL2L set value Word 0% to 100% FS (absolute alarm)

LL

"

H

40170 41170 Word 0% to 100% FS 10°C

-100% to 100 % FS (deviation alarm)

AAAALLLL2222hh

"

AL2h AL2h set value 00AA

hh

"

H

40171 41171 Word 0% to 100% FS (absolute alarm)

-100% to 100 % FS (deviation alarm)

AAAALLLL33

"

AAAALLLL3333LL

"

AL3 ALM3 set value or A3-L 00B0

33

"

AL3L AL3L set value Word 0% to 100% FS (absolute alarm)

LL

"

H

40177 41177 Word 0% to 100% FS 10°C

-100% to 100 % FS (deviation alarm)

AAAALLLL3333hh

"

AL3h AL3h set value 00B1

hh

"

H

40178 41178 Word 0% to 100% FS (absolute alarm)

-100% to 100 % FS (deviation alarm)

Note 1: If SV is changed using the front keys of the equipment and “SVn” is changed via communication at the same time, the SV set from the

front panel may be reflected to the SV number changed via communication.

Chapter

7

– 43 –

Page 45

Parameter

display

"

"

44

AAAALLLL44

"

LL

AAAALLLL4444LL

Parameter

name

AL4 ALM4 set value or A4-L 00B7

AL4L AL4L set value Word 0% to 100% FS (absolute alarm)

"

Contents

Relative

address

Resistor Number

Internal

H

40184 41184 Word 0% to 100% FS 10°C

Engineering

Type

unit

Read data

Written data

range

Factory

Setting

Dependent

on range

-100% to 100 % FS (deviation alarm)

"

AAAALLLL44

AL4h AL4h set value 00B8

"

44

h

H

40185 41185 Word 0% to 100% FS (absolute alarm)

-100% to 100 % FS (deviation alarm)

"

AAAALLLL55

"

AAAALLLL5555LL

AL5 ALM5 set value or A5-L 00BE

"

55

AL5L AL5L set value Word 0% to 100% FS (absolute alarm)

"

LL

H

40191 41191 Word 0% to 100% FS 10°C

-100% to 100 % FS (deviation alarm)

"

AAAALLLL5555hh

AL5h AL5h set value 00BF

"

hh

H

40192 41192 Word 0% to 100% FS (absolute alarm)

-100% to 100 % FS (deviation alarm)

"

LLLLooooCC

LoC Key lock 0027

"

CC

H

40040 41040 Word 0 : no lock

1 : all lock

2 : All but SV locked

Note 1: If SV is changed using the front keys of the equipment and “SVn” is changed via communication at the same time, the SV set from the

front panel may be reflected to the SV number changed via communication.

PID (Ch2)

Chapter

7

Parameter

display

PP

PP

"

"

II

II

"

"

dd

dd

"

"

SS

hhhhYYYYSS

"

"

LL

CCCCooooLL

"

"

bb

ddddbb

"

"

LL

bbbbAAAALL

"

"

rr

AAAArr

"

"

vv

rrrrEEEEvv

"

"

LL

SSSSvvvvLL

"

"

hh

SSSSvvvvhh

"

"

11

TTTTCCCC11

"

"

22

TTTTCCCC22

"

"

11

PPPPLLLLCCCC11

"

11

PPPPhhhhCCCC11

"

22

PPPPLLLLCCCC22

"

22

PPPPhhhhCCCC22

"

TT

PPPPCCCCUUUUTT

"

Parameter

name

Contents

P Proportional band 0005

i Integration time 0006

d Derivation time 0007

hYS

CoL Cooling proportional

ON/OFF control hysteresis

band coefficient

db Dead band 000A

bAL Output convergence

value

Ar Anti-reset windup 000B

rEv Sets normal/reverse

operations

SvL SV limit (lower) 001E

Svh SV limit (upper) 001F

TC1 OUT1 proportion cycle 0058

TC2 OUT2 proportion cycle 0059

PLC1 OUT1 lower limit 0018

"

PhC1 OUT1 upper limit 0019

"

PLC2 OUT2 lower limit 001A

"

PhC2 OUT2 upper limit 001B

"

"

PCUT

Selects the output limiter type

Relative

address

0008

0009

000C

0057

0017

Resistor Number

Internal

40006 41006 Word 0 to 9999 (0.0% to 999.9%) 5.0%

H

40007 41007 Word 0 to 32000 (0 to 3200 sec) 240 sec

H

40008 41008 Word 0 to 9999 (0.0 to 999.9sec) 60.0 sec

H

40009 41009 Word 0% to 50% FS 1°C

H

40010 41010 Word 0 to 1000 (0.0 to 100.0) 1.0

H

40011 41011 Word -5000 to 5000 (-50 to 50%) 0%

H

40013 41013 Word -10000 to 10000

H

Engineering

Type

unit

Read data

Written data

range

(-100 to 100%)

40012 41012 Word 0% to 100% FS 100%

H

40088 41088 Word 0: rv-- (heat (reverse)

H

/ cool (none))

1: no-- (heat (normal)

/ cool (none))

2: rvno (heat (reverse)

/ cool (normal))

3: norv (heat (normal)

/ cool (reverse))

4: rvrv (heat (reverse)

/ cool (reverse))

5: nono (heat (normal)

/ cool (normal))

40031 41031 Word 0% to 100% FS 0% FS

H

40032 41032 Word 0% to 100% FS 100% FS

H

40089 41089 Word 1 sec to 150 sec 30 or 2 sec

H

40090 41090 Word 1 sec to 150 sec 30 or 3 sec

H

40025 41025 Word -300 to 10300 (-3.0 to 103.0%) -3.0%

H

40026 41026 Word -300 to 10300 (-3.0 to 103.0%) 103.0%

H

40027 41027 Word -300 to 10300 (-3.0 to 103.0%) -3.0%

H

40028 41028 Word -300 to 10300 (-3.0 to 103.0%) 103.0%

H

40024 41024 Word 0 to 15 0

H

Factory Setting

Dependent

on range

0/50 (single/dual)

rv--/rvno (single/ dual)

– 44 –

Page 46

PID Palette (Ch3)

Parameter

display

11

SSSSvvvv11

"

"

11

PPPP11

"

"

11

iiii11

"

"

11

dddd11

"

"

11

hhhhYYYYSSSS11

"

11

CCCCooooLLLL11

"

11

ddddbbbb11

"

"

11

bbbbAAAALLLL11

"

11

AAAArrrr11

"

"

11

rrrrEEEEvvvv11

"

22

SSSSvvvv22

"

"

22

PPPP22

"

"

22

iiii22

"

"

22

dddd22

"

"

22

hhhhYYYYSSSS22

"

22

CCCCooooLLLL22

"

22

ddddbbbb22

"

"

22

BBBBaaaaLLLL22

"

22

AAAArrrr22

"

"

22

rrrrEEEEvvvv22

"

33

SSSSVVVV33

"

"

33

PPPP33

"

"

name

Parameter

Contents

Sv1 SV set value 1 00F0

P1 Proportional band 1 00F1

i1 Integration time 1 00F2

d1 Derivation time 1 00F3

hYS1 ON/OFF Control

"

hysteresis 1

CoL1

"

db1 Dead band 1 00F6

bAL1

"

Ar1 Anti-reset windup 1 00F8

rEv1 Normal/Reverse setting 1 00F9

"

Sv2 SV set value 2 00FA

Cooling proportional band 1

Output convergence value 1

P2 Proportional band 2 00FB

i2 Integration time 2

d2 Derivation time

hYS2 ON/OFF control

"

hysteresis 2

CoL2 Cooling proportional

"

band 2

db2 Dead band 2 0100

bAL2 Output convergence

"

value 2

Ar2 Anti-reset windup 2 0102

rEv2 Normal/Reverse setting 2 0103

"

Sv3 SV set value 3 0104

P3 Proportional band 3 0105

Relative

address

H

H

H

H

00F4

H

00F5

H

H

00F7

H

H

H

H

H

00FC

H

00FD

H

00FE

H

00FF

H

H

0101

H

H

H

H

H

Resistor Number

Internal

Engineering

unit

Type

Read data

Written data

range

Factory

Setting

40241 41241 Word 0% to 100% FS 0% FS

40242 41242 Word 0 to 9999 (0.0 to 999.9%) 5.0%

40243 41243 Word 0 to 32000 (0 to 3200sec) 240 sec

40244 41244 Word 0 to 9999 (0.0 to 999.9sec) 60.0sec

40245 41245 Word 0% to 50% FS 1°C

40246 41246 Word 0 to 1000 (0.0 to 100.0) 1.0

40247 41247 Word -5000 to 5000

0%

(-50.0 to 50.0%)

40248 41248 Word -10000 to 10000

(-100.0 to 100.0%)

0/50

(single/dual)

40249 41249 Word 0% to 100% FS 100% FS

40250 41250 Word 0: rv-- (heat (reverse)

/ cool (none))

rv--/rvno

(single/dual)

1: no-- (heat (normal)

/ cool (none))

2: rvno (heat (reverse)

/ cool (normal))

3: norv (heat (normal)

/ cool (reverse))

4: rvrv (heat (reverse)

/ cool (reverse))

5: nono (heat (normal)

/ cool (normal))

40251 41251 Word 0% to 100% FS 0% FS

40252 41252 Word 0 to 9999 (0.0 to 999.9%) 5.0%

40253 41253 Word 0 to 32000 (0 to 3200sec) 240 sec

40254 41254 Word 0 to 9999 (0.0 to 999.9sec) 60.0sec

40255 41255 Word 0% to 50% FS 1°C

40256 41256 Word 0 to 1000 (0.0 to 100.0) 1.0

40257 41257 Word -5000 to 5000

0%

(-50.0 to 50.0%)

40258 41258 Word -10000 to 10000

(-100.0 to 100.0%)

0/50

(single/dual)

40259 41259 Word 0% to 100% FS 100% FS

40260 41260 Word 0: rv-- (heat (reverse)

/ cool (none))

rv--/rvno

(single/dual)

1: no-- (heat (normal)

/ cool (none))

2: rvno (heat (reverse)

/ cool (normal))

3: norv (heat (normal)

/ cool (reverse))

4: rvrv (heat (reverse)

/ cool (reverse))

5: nono (heat (normal)

/ cool (normal))

40261 41261 Word 0% to 100% FS 0% FS

40262 41262 Word 0 to 9999 (0.0 to 999.9%) 5.0%

Dependent

on range

Chapter

7

– 45 –

Page 47

Chapter

7

Parameter

display

"

"

44

iiii44

"

"

33

dddd33

"

33

hhhhYYYYSSSS33

"

33

CCCCooooLLLL33

"

"

33

ddddbbbb33

"

33

bbbbAAAALLLL33

"

"

33

AAAArrrr33

"

33

rrrrEEEEvvvv33

"

"

44

SSSSvvvv44

"

"

44

PPPP44

"

"

44

iiii44

"

"

44

dddd44

"

44

hhhhYYYYSSSS44

"

44

CCCCooooLLLL44

"

"

44

ddddbbbb44

"

44

bbbbAAAALLLL44

"

"

44

AAAArrrr44

"

44

rrrrEEEEvvvv44

"

"

55

SSSSvvvv55

"

"

55

PPPP55

"

"

55

iiii55

"

"

55

dddd55

"

55

hhhhYYYYSSSS55

"

55

CCCCooooLLLL55

"

"

55

ddddbbbb55

Parameter

name

Contents

i3 Integration time 3 0106

d3 Derivation time 3 0107

hYS3

"

CoL3

"

db3 Dead band 3 010A

bAL3 Output convergence

"

ON/OFF control hysteresis 3

Cooling proportional band 3

value 3

Ar3 Anti-reset windup 3 010C

rEv3 Normal/Reverse setting 3 010D

"

Sv4 SV set value 4 010E

P4 Proportional band 4 010F

i4 Integration time 4 0110

d4 Derivation time 4 0111

hYS4

"

CoL4

"

db4 Dead band 4 0114

bAL4 Output convergence

"

ON/OFF control hysteresis 4

Cooling proportional band 4

value 4

Ar4 Anti-reset windup 4 0116

rEv4 Normal/Reverse setting 4 0117

"

Sv5 SV set value 5 0118

P5 Proportional band 5 0119

i5 Integration time 5 011A

d5 Derivation time 5 011B

hYS5

"

CoL5

"

db5 Dead band 5 011E

ON/OFF control hysteresis 5

Cooling proportional band 5

Relative

address

H

H

H

0108

H

0109

H

H

010B

H

H

H

H

H

H

H

0112

H

0113

H

H

0115

H

H

H

H

H

H

H

011C

H

011D

H

Resistor Number

Internal

Engineering

unit

Type

Read data

Written data

range

Factory

Setting

40263 41263 Word 0 to 32000 (0 to 3200sec) 240 sec

40264 41264 Word 0 to 9999 (0.0 to 999.9sec) 60.0 sec

40265 41265 Word 0% to 50% FS 1°C

40266 41266 Word 0 to 1000 (0.0 to 100.0) 1.0

40267 41267 Word -5000 to 5000

0%

(-50.0 to 50.0%)

40268 41268 Word -10000 to 10000

(-100.0 to 100.0%)

0/50

(single/dual)

40269 41269 Word 0% to 100% FS 100% FS

40270 41270 Word 0: rv-- (heat (reverse)

/ cool (none))

rv--/rvno

(single/dual)

1: no-- (heat (normal)

/ cool (none))

2: rvno (heat (reverse)

/ cool (normal))

3: norv (heat (normal)

/ cool (reverse))

4: rvrv (heat (reverse)

/ cool (reverse))

5: nono (heat (normal)

/ cool (normal))

40271 41271 Word 0% to 100% FS 0% FS

40272 41272 Word 0 to 9999 (0.0 to 999.9%) 5.0%

40273 41273 Word 0 to 32000 (0 to 3200sec) 240 sec

40274 41274 Word 0 to 9999 (0.0 to 999.9sec) 60.0sec

40275 41275 Word 0% to 50% FS 1°C

40276 41276 Word 0 to 1000 (0.0 to 100.0) 1.0

40277 41277 Word -5000 to 5000

0%

(-50.0 to 50.0%)

40278 41278 Word -10000 to 10000

(-100.0 to 100.0%)

0/50

(single/dual)

40279 41279 Word 0% to 100% FS 100% FS

40280 41280 Word 0: rv-- (heat (reverse)

/ cool (none))

rv--/rvno

(single/dual)

1: no-- (heat (normal)

/ cool (none))

2: rvno (heat (reverse)

/ cool (normal))

3: norv (heat (normal)

/ cool (reverse))

4: rvrv (heat (reverse)

/ cool (reverse))

5: nono (heat (normal)

/ cool (normal))

40281 41281 Word 0% to 100% FS 0% FS

40282 41282 Word 0 to 9999 (0.0 to 999.9%) 5.0%

40283 41283 Word 0 to 32000 (0 to 3200sec) 240 sec

40284 41284 Word 0 to 9999 (0.0 to 999.9sec) 60.0sec

40285 41285 Word 0% to 50% FS 1°C

40286 41286 Word 0 to 1000 (0.0 to 100.0) 1.0

40287 41287 Word -5000 to 5000

0%

(-50.0 to 50.0%)

Dependent

on range

– 46 –

Page 48

Parameter

display

"

55

bbbbAAAALLLL55

"

"

55

AAAArrrr55

"

55

rrrrEEEEvvvv55

"

"

66

SSSSvvvv66

"

"

66

PPPP66

"

"

66

iiii66

"

"

66

dddd66

"

66

hhhhYYYYSSSS66

"

66

CCCCooooLLLL66

"

"

66

ddddbbbb66

"

66

bbbbAAAALLLL66

"

"

66

AAAArrrr66

"

66

rrrrEEEEvvvv66

"

"

77

SSSSvvvv77

"

"

77

PPPP77

"

"

77

iiii77

"

"

77

dddd77

"

77

hhhhYYYYSSSS77

"

"

LL

CCCCooooLL

"

"

77

ddddbbbb77

"

77

bbbbAAAALLLL77

"

"

77

AAAArrrr77

Parameter

name

bAL5 Output convergence

"

Contents

value 5

Ar5 Anti-reset windup 5 0120

rEv5 Normal/Reverse setting 5 0121

"

Sv6 SV set value 6 0122

P6 Proportional band 6 0123

i6 Integration time 6 0124

D6 Derivation time 6 0125

hYS6

"

CoL6 Cooling proportional

"

ON/OFF control hysteresis 6

band 6

db6 Dead band 6 0128

bAL6 Output convergence

"

value 6

Ar6 Anti-reset windup 6 012A

rEv6 Normal/Reverse setting 6 012B

"

Sv7 SV set value 7 012C

P7 Proportional band 7 012D

i7 Integration time 7 012E

d7 Derivation time 7 012F

hYS7

"

CoL7 Cooling proportional

ON/OFF control hysteresis7

band 7

db7 Dead band 7 0132

bAL7 Output convergence

"

value 7

Ar7 Anti-reset windup 7 0134

Relative

address

H

011F

H

H

H

H

H

H

H

0126

H

0127

H

H

0129

H

H

H

H

H

H

H

0130

H

0131

H

H

0133

H

Resistor Number

Internal

Engineering

unit

Type

Read data

40288 41288 Word -10000 to 10000

(-100.0 to 100.0%)

40289 41289 Word

0% to 100% FS

40290 41290 Word 0: rv-- (heat (reverse)

Written data

range

/ cool (none))

Factory

Setting

0/50

(single/dual)

100% FS

rv--/rvno

(single/dual)

1: no-- (heat (normal)

/ cool (none))

2: rvno (heat (reverse)

/ cool (normal))

3: norv (heat (normal)

/ cool (reverse))

4: rvrv (heat (reverse)

/ cool (reverse))

5: nono (heat (normal)

/ cool (normal))

40291 41291 Word 0% to 100% FS 0% FS

40292 41292 Word 0 to 9999 (0.0 to 999.9%) 5.0%

40293 41293 Word 0 to 32000 (0 to 3200sec) 240 sec

40294 41294 Word 0 to 9999 (0.0 to 999.9sec) 60.0sec

40295 41295 Word 0% to 50% FS 1°C

40296 41296 Word 0 to 1000 (0.0 to 100.0) 1.0

40297 41297 Word -5000 to 5000

0%

(-50.0 to 50.0%)

40298 41298 Word -10000 to 10000

(-100.0 to 100.0%)

0/50

(single/

dual)

40299 41299 Word 0% to 100% FS 100% FS

40300 41300 Word 0: rv-- (heat (reverse)

/ cool (none))

rv--/rvno

(single/dual)

1: no-- (heat (normal)

/ cool (none))

2: rvno (heat (reverse)

/ cool (normal))

3: norv (heat (normal)

/ cool (reverse))

4: rvrv (heat (reverse)

/ cool (reverse))

5: nono (heat (normal)

/ cool (normal))

40301 41301 Word 0% to 100% FS 0% FS

40302 41302 Word 0 to 9999 (0.0 to 999.9%) 5.0%

40303 41303 Word 0 to 32000 (0 to 3200sec) 240 sec

40304 41304 Word 0 to 9999 (0.0 to 999.9sec) 60.0sec

40305 41305 Word 0% to 50% FS 1°C

40306 41306 Word 0 to 1000 (0.0 to 100.0) 1.0

40307 41307 Word -5000 to 5000

0%

(-50.0 to 50.0%)

40308 41308 Word -10000 to 10000

(-100.0 to 100.0%)

0/50

(single/dual)

40309 41309 Word 0% to 100% FS 100% FS

Dependent

on range

Chapter

7

– 47 –

Page 49

Chapter

7

Parameter

display

"

77

rrrrEEEEvvvv77

"

XX

SSSSvvvvMMMMXX

"

MM

PPPPLLLL1111MM

Parameter

name

rEv7 Normal/Reverse setting 7 0135

"

SvMX

"

Contents

Selectable SV numbers

maximum

PL1M Selectable PID group

"

maximum

Relative

address

H

00DF

H

H

00E0

Resistor Number

Internal

Engineering

unit

Type

Read data

Written data

range

40310 41310 Word 0: rv-- (heat (reverse)

/ cool (none))

1: no-- (heat (normal)

/ cool (none))

2: rvno (heat (reverse)

/ cool (normal))

3: norv (heat (normal)

/ cool (reverse))

4: rvrv (heat (reverse)

/ cool (reverse))

5: nono (heat (normal)

/ cool (normal))

40224 41224 Word 0: Sv0 (Local SV)

1: Sv1 (SV = SV-1)

2: Sv2 (SV = SV-2)

3: Sv3 (SV = SV-3)

4: Sv4 (SV = SV-4)

5: Sv5 (SV = SV-5)

6: Sv6 (SV = SV-6)

7: Sv7 (SV = SV-7)

8: di : SV = choose Di

40225 41225 Word 0: Pid0 (PID group local)

1: Pid1 (PID group No. 1)

2: Pid2 (PID group No. 2)

3: Pid3 (PID group No. 3)

4: Pid4 (PID group No. 4)

5: Pid5 (PID group No. 5)

6: Pid6 (PID group No. 6)

7: Pid7 (PID group No. 7)

8: di (PID group Di

selection)

Factory

Setting

rv--/rvno

(single/dual)

Sv7

Pid7

Dependent

on range

– 48 –

Page 50

Ramp/Soak (Ch4)

Parameter

display

nn

PPPPTTTTnn

"

"

UU

TTTTiiiiMMMMUU

"

11

SSSSvvvv----11

"

rr

TTTTMMMM1111rr

"

SS

TTTTMMMM1111SS

"

22

SSSSvvvv----22

"

rr

TTTTMMMM2222rr

"

SS

TTTTMMMM2222SS

"

33

SSSSvvvv----33

"

rr

TTTTMMMM3333rr

"

SS

TTTTMMMM3333SS

"

44

SSSSvvvv----44

"

rr

TTTTMMMM4444rr

"

SS

TTTTMMMM4444SS

"

55

SSSSvvvv----55

"

rr

TTTTMMMM5555rr

"

SS

TTTTMMMM5555SS

"

66

SSSSvvvv----66

"

rr

TTTTMMMM6666rr

"

SS

TTTTMMMM6666SS

"

77

SSSSvvvv----77

"

rr

TTTTMMMM7777rr

"

SS

TTTTMMMM7777SS

"

Parameter

name

PTn Ramp/Soak Activation

Contents

Pattern

TiMU Ramp/soak time units 0231

"

Sv-1 Ramp/Soak

"

1 seg/SV Set Value

TM1r Ramp/Soak

"

1 seg ramp time

TM1S Ramp/Soak

"

1 seg soak time

Sv-2 Ramp/Soak

"

2 seg/SV Set Value

TM2r Ramp/Soak

"

2 seg ramp time

TM2S Ramp/Soak

"

2 seg soak time

Sv-3 Ramp/Soak

"

3 seg/SV Set Value

TM3r Ramp/Soak

"

3 seg ramp time

TM3S Ramp/Soak

"

3 seg soak time

Sv-4 Ramp/Soak

"

4 seg/SV Set Value

TM4r Ramp/Soak

"

4 seg ramp time

TM4S Ramp/Soak

"

4 seg soak time

Sv-5 Ramp/Soak

"

5 seg/SV Set Value

TM5r Ramp/Soak

"

5 seg ramp time

TM5S Ramp/Soak

"

5 seg soak time

Sv-6 Ramp/Soak

"

6 seg/SV Set Value

TM6r Ramp/Soak

"

6 seg ramp time

TM6S Ramp/Soak

"

6 seg soak time

Sv-7 Ramp/Soak

"

7 seg/SV Set Value

TM7r Ramp/Soak

"

7 seg ramp time

TM7S Ramp/Soak

"

7 seg soak time

Relative

address

0230

0244

0245

0246

0247

0248

0249

024A

024B

024C

024D

024E

024F

0250

0251

0252

0253

0254

0255

0256

0257

0258

Resistor Number

Internal

40561 41561 Word 0 (uses steps 1 to 4)

H

Engineering

Type

unit

Read data

Written data

range

1 (uses steps 5 to 8)

2 (uses steps 1 to 8)

3 (uses steps 9 to 12)

4 (uses steps 13 to 16)

5 (uses steps 9 to 16)

6 (uses steps 1 to 16)

7 (according to DI)

40562 41562 Word 0 : hh.MM ( hour: min)

H

1 : MM.SS (min: sec)

40581 41581 Word 0% to 100% FS 0% FS

H

40582 41582 Word 00.00-99.59

H

(hour:min/min: sec)

40583 41583 Word 00.00-99.59

H

(hour:min/min: sec)

40584 41584 Word 0% to 100% FS 0% FS

H

40585 41585 Word 00.00-99.59

H

(hour:min/min: sec)

40586 41586 Word 00.00-99.59

H

(hour:min/min: sec)

40587 41587 Word 0% to 100% FS 0% FS

H

40588 41588 Word 00.00-99.59

H

(hour:min/min: sec)

40589 41589 Word 00.00-99.59

H

(hour:min/min: sec)

40590 41590 Word 0% to 100% FS 0% FS

H

40591 41591 Word 00.00-99.59

H

(hour:min/min: sec)

40592 41592 Word 00.00-99.59

H

(hour:min/min: sec)

40593 41593 Word 0% to 100% FS 0% FS

H

40594 41594 Word 00.00-99.59

H

(hour:min/min: sec)

40595 41595 Word 00.00-99.59

H

(hour:min/min: sec)

40596 41596 Word 0% to 100% FS 0% FS

H

40597 41597 Word 00.00-99.59

H

(hour:min/min: sec)

H

40598 41598 Word 00.00-99.59

(hour:min/min: sec)

H

40599 41599 Word 0% to 100% FS 0% FS

H

40600 41600 Word 00.00-99.59

(hour:min/min: sec)

H

40601 41601 Word 00.00-99.59

(hour:min/min: sec)

Factory Setting

6

hh.MM