Page 1

Hardware Specifications

Page 2

Record of Revisions

Reference numbers are shown at the bottom left corner on the back cover of each manual.

Printing Date Reference No. Revised Contents

May, 2014 2023NE0 First edition

February, 2015 2023NE1 Second edition

[Partial amendment]

Revised note regarding when the screen becomes dark in “Notes

on Safe Usage of MONITOUCH”

Revisions for new print

[Additions]

Advanced model (V9101iW)

Notes regarding capacitive touch panels in “Notes on Safe Usage

of MONITOUCH”

Peripheral equipment (DUR-00, CUR-00, CUR-01, CUR-03,

CUR-06, CUR-08, GUR-01, GUR-02, GUR-04, V9-ANT)

Screen configuration environment OS: Windows 8.1

V9120iS, V9071iW

Models produced on order (V9100iSLD, V9100iSRD, V9100iW

series, V9080iSLD, V9080iSRD)

Page 3

Preface

Thank you for selecting the MONITOUCH V9 series.

This manual describes operation procedures and errors of the V9 series in detail.

For correct use of the V9 series, you are requested to read through this manual to understand more about the

product.

The manuals shown below are related manuals for the V9 series. Refer to them as necessary.

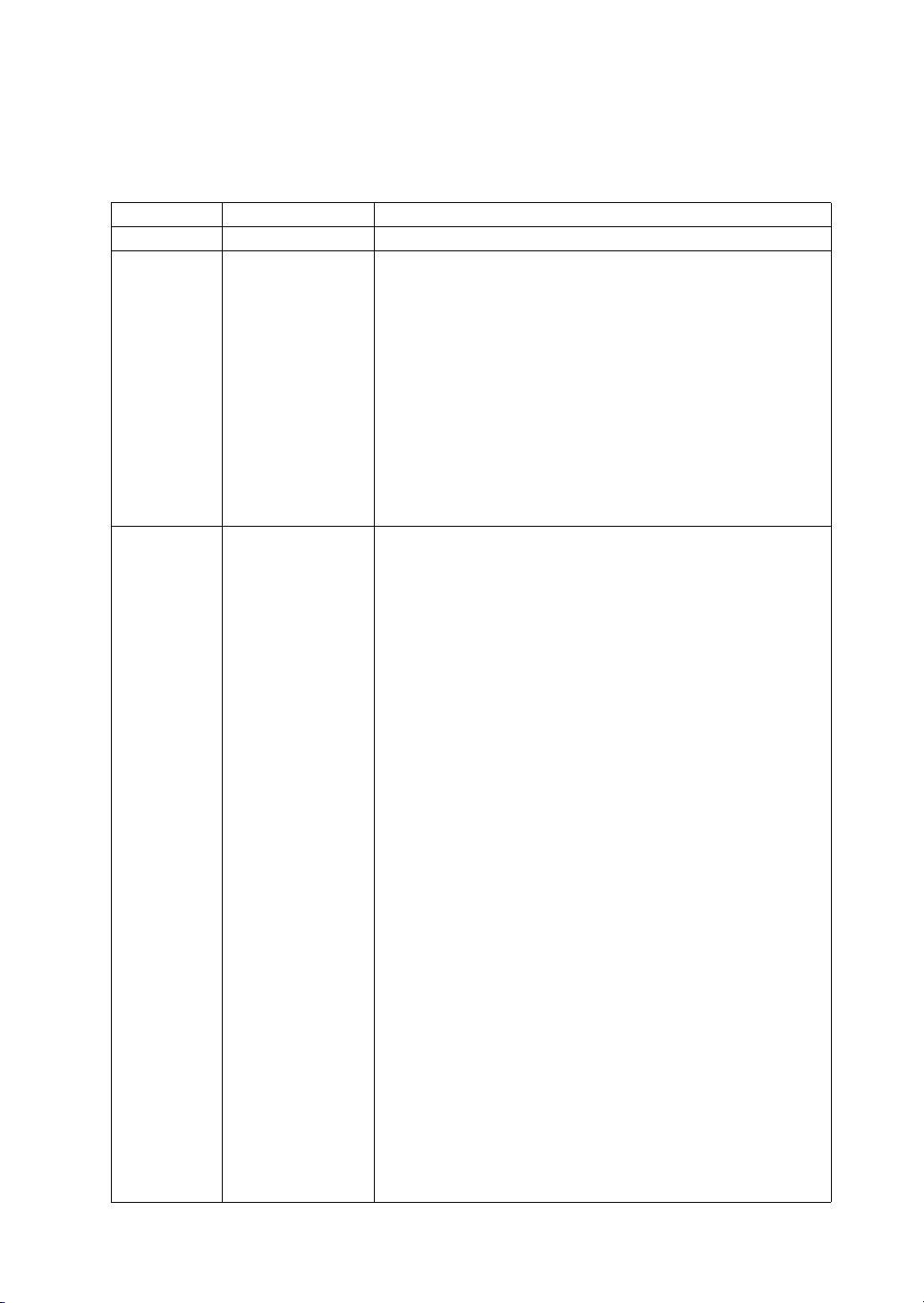

Manual Name Contents Reference No.

V9 Series Reference Manual [1] Explains the functions and operation of the V9

V9 Series Reference Manual [2] 1066NE

V9 Series Setup Manual Explains the installation procedure of V-SFT

V9 Series

Troubleshooting/

Maintenance Manual

V9 Series

Training Manual Beginner’s Guide

V9 Series

Training Manual Practical Guide

V9 Series Macro Reference Provides an overview of macros of V-SFT

V9 Series Operation Manual Explains the configuration of V-SFT version 6,

V9 Series

Connection Manual [1]

V9 Series

Connection Manual [2]

series.

version 6, the creation process of simple screen

programs as well as how to transfer a created

screen program using V-SFT version 6.

Provides an error list and explains the operating

procedures for the V9 series.

Explains the screen creation process using

V-SFT version 6 with examples in detail.

version 6 and explains macro editor operations

and macro command descriptions in detail.

the editing process of each part and limitations

regarding operation in detail.

Explains the connection and communication

parameters for the V9 series and controllers in

detail.

Included Makers

ALLEN BRADLEY, Automationdirect, Azbil,

Baumuller, BECKHOFF, CHINO, CIMON,

DELTA, DELTA TAU DATA SYSTEMS,

EATON Cutler-Hammer, EMERSON,

FANUC, FATEK AUTOMATION, FUFENG,

Fuji Electric, Gammaflux,

GE Fanuc, Hitachi, Hitachi Industrial

Equipment Systems

Explains the connection and communication

parameters for the V9 series and controllers in

detail.

Included Makers

IAI, IDEC, JTEKT, KEYENCE, KOGANEI,

KOYO ELECTRONICS, LS,

MITSUBISHI ELECTRIC, MODICON,

MOELLER, M-SYSTEM, OMRON,

Oriental Motor, Panasonic, RKC, RS

Automation

1065NE

1067NE

1068NE

1069NE

1070NE

1071NE

1072NE

2210NE

2211NE

Page 4

Manual Name Contents Reference No.

V9 Series

Connection Manual [3]

For further details about controllers (PLCs, temperature controllers, etc.), refer to the manual issued by each

controller manufacturer.

Explains the connection and communication

parameters for the V9 series and controllers in

detail.

Included Makers

SAIA, SAMSUNG, SanRex, SANMEI,

SHARP, SHIMADEN, SHINKO TECHNOS,

Siemens, SINFONIA TECHNOLOGY,

TECO, Telemecanique, TOHO, TOSHIBA,

TOSHIBA MACHINE, TURCK, UNIPULSE,

UNITRONICS, VIGOR, WAGO, XINJE,

YAMAHA, Yaskawa Electric, Yokogawa

Electric, MODBUS, Barcode Reader, Slave

Communication Function, Universal Serial

Communication

2212NE

Notes:

1. This manual may not, in whole or in part, be printed or reproduced without the prior written consent of

Hakko Electronics Co., Ltd.

2. The information in this manual is subject to change without prior notice.

3. Windows and Excel are registered trademarks of Microsoft Corporation in the United States and other

countries.

4. All other company names or product names are trademarks or registered trademarks of their

respective holders.

5. This manual is intended to give accurate information about MONITOUCH hardware. If you have any

questions, please contact your local distributor.

Page 5

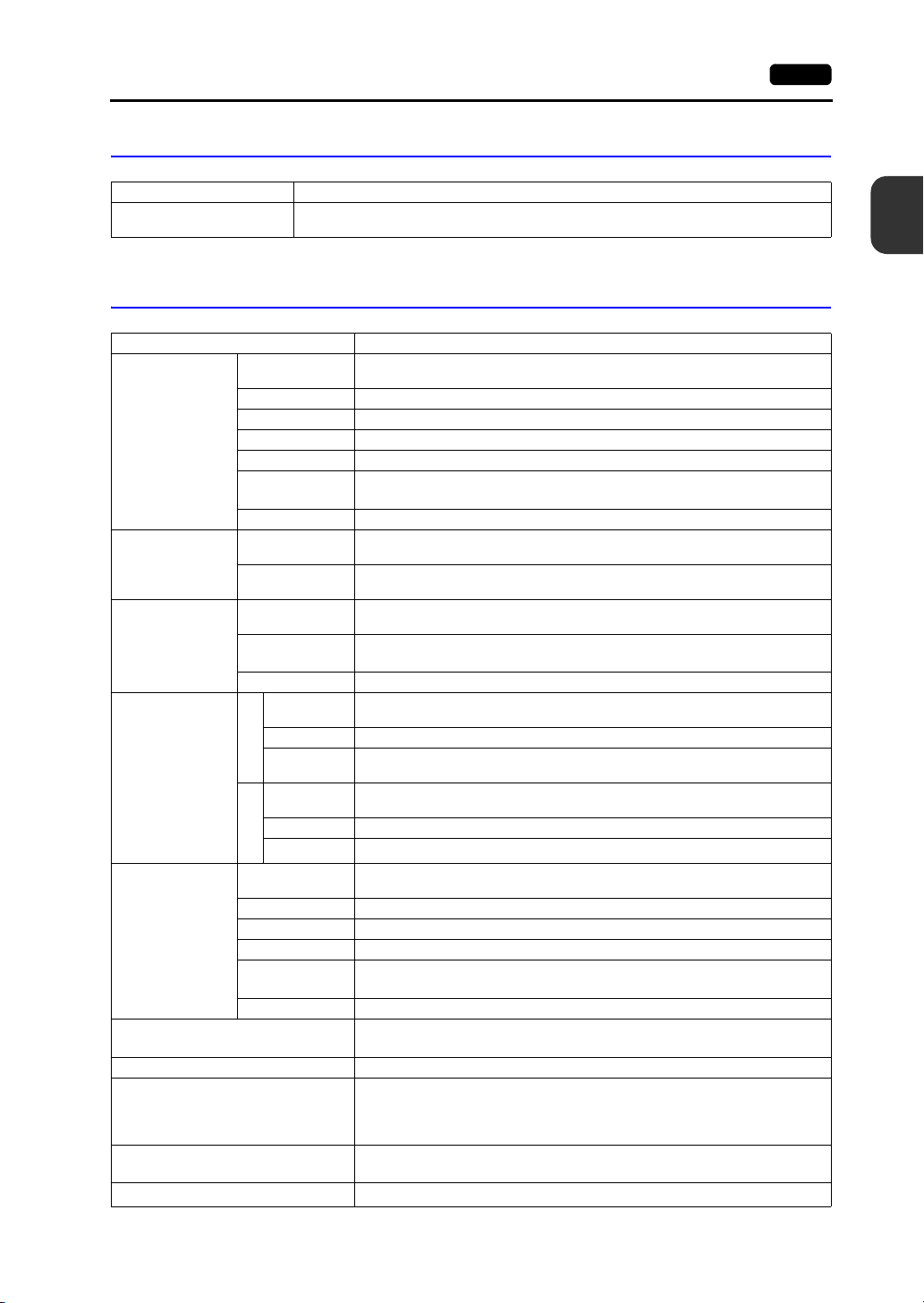

Types and Model Names of the V9 Series

The MONITOUCH V9 series comprises the following types.

General Name Model Classification Model

Advanced model V910xiW, V9071iW

V9 series

General Name Model Classification Model

V9 series

Note that model names are differentiated according to the above descriptions in this manual for operation

explanations.

Standard model V9120iS, V9100iS, V9080iS

Lite model V9100iC, V9080iC

Additional wired LAN I/F model

Wireless LAN I/F model

V9 model name with “L” added

Example: V9101iWLD

V9 model name with “R” added

Example: V9101iWRLD

Page 6

Notes on Safe Usage of MONITOUCH

DANGER

CAUTION

CAUTION

CAUTION

In this manual, you will find various notes categorized under the following levels with the signal words “DANGER”

and “CAUTION”.

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury and could cause property damage.

Note that there is a possibility that items listed with may have serious ramifications.

DANGER

Never use the output signal of the V9 series for operations that may threaten human life or damage the

system, such as signals used in case of emergency. Please design the system so that it can cope with a

touch switch malfunction. A touch switch malfunction may result in machine accidents or damage.

Turn off the power supply when you set up the unit, connect new cables, or perform maintenance or

inspections. Otherwise, electrical shock or damage may occur.

Never touch any terminals while the power is on. Otherwise, electrical shock may occur.

You must cover the terminals on the unit before turning the power on and operating the unit. Otherwise,

electrical shock may occur.

The liquid crystal in the LCD panel is a hazardous substance. If the LCD panel is damaged, do not ingest the

leaked liquid crystal. If leaked liquid crystal makes contact with skin or clothing, wash it away with soap and

water.

Never disassemble, recharge, deform by pressure, short-circuit, reverse the polarity of the lithium battery,

nor dispose of the lithium battery in fire. Failure to follow these conditions will lead to explosion or ignition.

Never use a lithium battery that is deformed, leaking, or shows any other signs of abnormality. Failure to

follow these conditions will lead to explosion or ignition.

Switches on the screen are operable even when the screen has become dark due to a faulty backlight or

when the backlight has reached the end of its service life. If the screen is dark and hard to see, do not touch

the screen. Otherwise, a malfunction may occur resulting in machine accidents or damage.

Check the appearance of the unit when it is unpacked. Do not use the unit if any damage or deformation is

found. Failure to do so may lead to fire, damage, or malfunction.

For use in a facility or as part of a system related to nuclear energy, aerospace, medical, traffic equipment, or

mobile installations, please consult your local distributor.

Operate (or store) the V9 series under the conditions indicated in this manual and related manuals. Failure

to do so could cause fire, malfunction, physical damage, or deterioration.

Observe the following environmental restrictions on use and storage of the unit. Otherwise, fire or damage to

the unit may result.

- Avoid locations where there is a possibility that water, corrosive gas, flammable gas, solvents, grinding

fluids, or cutting oil can come into contact with the unit.

- Avoid high temperatures, high humidity, and outside weather conditions, such as wind, rain, or direct

sunlight.

- Avoid locations where excessive dust, salt, and metallic particles are present.

- Avoid installing the unit in a location where vibrations or physical shocks may be transmitted.

Page 7

Equipment must be correctly mounted so that the main terminal of the V9 series will not be touched

CAUTION

inadvertently. Otherwise, an accident or electric shock may occur.

Tighten the mounting screw on the fixtures of the V9 series to an equal torque of 0.6 N·m.

Excessive tightening may distort the panel surface. Loose mounting screws may cause the unit to fall down,

malfunction, or short-circuit.

Check periodically that terminal screws on the power supply terminal block and fixtures are firmly tightened.

Loosened screws or nuts may result in fire or malfunction.

Tighten the terminal screws on the power supply terminal block of the V9 series to an equal torque of 7.1 to

8.8 inch-lbf (0.8 to 1.0 N·m). Improper tightening of screws may result in fire, malfunction, or other serious

trouble.

The V9 series has a glass screen. Do not drop the unit or impart physical shocks to the unit. Otherwise, the

screen may be damaged.

Correctly connect cables to the terminals of the V9 series in accordance with the specified voltage and

wattage. Overvoltage, overwattage, or incorrect cable connection could cause fire, malfunction, or damage

to the unit.

Always ground the V9 series. The FG terminal must be used exclusively for the V9 series with the level of

grounding resistance less than 100 . Otherwise, you may sustain an electric shock, a fire may occur,

MONITOUCH may not recognize touch operations, and malfunctions may occur.

Prevent any conductive particles from entering the V9 series. Failure to do so may lead to fire, damage, or

malfunction.

After wiring is finished, remove the paper used as a dust cover before starting operation of the V9 series.

Operation with the dust cover attached may result in accidents, fire, malfunction, or other trouble.

Do not attempt to repair the V9 series yourself. Contact Hakko Electronics or the designated contractor for

repairs.

Do not repair, disassemble, or modify the V9 series. Hakko Electronics Co., Ltd. is not responsible for any

damages resulting from repair, disassembly, or modification of the unit that was performed by an

unauthorized person.

Do not use sharp-pointed tools to press touch switches. Doing so may damage the display unit.

Only experts are authorized to set up the unit, connect cables, and perform maintenance and inspection.

Lithium batteries contain combustible material such as lithium and organic solvents. Mishandling may cause

heat, explosion, or ignition resulting in fire or injury. Read the related manuals carefully and correctly handle

the lithium battery as instructed.

Take safety precautions during operations such as changing settings when the unit is running, forced output,

and starting and stopping the unit. Any misoperations may cause unexpected machine movement, resulting

in machine accidents or damage.

In facilities where the failure of the V9 series could lead to accidents that threaten human life or other serious

damage, be sure that such facilities are equipped with adequate safeguards.

When disposing of the V9 series, it must be treated as industrial waste.

Before touching the V9 series, discharge static electricity from your body by touching grounded metal.

Excessive static electricity may cause malfunction or trouble.

Insert an SD card into MONITOUCH in the same orientation as pictured on the unit. Failure to do so may

damage the SD card or the slot on the unit.

The SD card access LED flashes red when the SD card is being accessed. Never remove the SD card or

turn off power to the unit while the LED is flashing. Doing so may destroy the data on the SD card. Check

that the LED has turned off before removing the SD card or turning off the power to the unit.

Be sure to remove the protective sheet that is attached to the touch panel surface at delivery before use.

Using MONITOUCH with the protective sheet attached may result in incorrect touch switch activation.

When using an analog resistive-film type V9 series unit, do not touch two positions on the screen at the

same time. If two or more positions are pressed at the same time, the switch located between the pressed

positions may be activated.

Page 8

When using a V9 series unit of the capacitive type, observe the following points.

CAUTION

- Use a Class 2 power supply for the 24 VDC power unit. Using MONITOUCH with an unstable power

supply may result in incorrect touch switch activation.

- Capacitive touch panel types support two-point touch operations. If a third point is touched, the touch

operation will be cancelled.

- Capacitive touch panel types are prone to the influence of conductive material. Do not place conductive

material such as metals near the touch panel surface and do not use the panel if it is wet. Otherwise,

malfunctions may occur.

[General Notes]

Never bundle control cables or input/output cables with high-voltage and large-current carrying cables such as

power supply cables. Keep control cables and input/output cables at least 200 mm away from high-voltage and

large-current carrying cables. Otherwise, malfunction may occur due to noise.

When using the V9 series in an environment where a source of high-frequency noise is present, it is

recommended that the FG shielded cable (communication cable) be grounded at each end. However, when

communication is unstable, select between grounding one or both ends, as permitted by the usage

environment.

Be sure to plug connectors and sockets of the V9 series in the correct orientation. Failure to do so may lead to

damage or malfunction.

If a LAN cable is inserted into the MJ1 or MJ2 connector, the device on the other end may be damaged. Check

the connector names on the unit and insert cables into the correct connectors.

Do not use thinners for cleaning because it may discolor the V9 series surface. Use commercially available

alcohol.

If a data receive error occurs when the V9 series unit and a counterpart unit (PLC, temperature controller, etc.)

are started at the same time, read the manual of the counterpart unit to correctly resolve the error.

Avoid discharging static electricity on the mounting panel of the V9 series. Static charge can damage the unit

and cause malfunctions. Discharging static electricity on the mounting panel may cause malfunction to occur

due to noise.

Avoid prolonged display of any fixed pattern. Due to the characteristic of liquid crystal displays, an afterimage

may occur. If prolonged display of a fixed pattern is expected, use the backlight’s auto OFF function.

The V9 series is identified as a class-A product in industrial environments. In the case of use in a domestic

environment, the unit is likely to cause electromagnetic interference. Preventive measures should thereby be

taken appropriately.

[Notes on the LCD]

Note that the following conditions may occur under normal circumstances.

The response time, brightness, and colors of the V9 series may be affected by the ambient temperature.

Tiny spots (dark or luminescent) may appear on the display due to the characteristics of liquid crystal.

There are variations in brightness and color between units.

[Notes on Capacitive Touch Panels]

Touch panel operability may not be optimal if used with dry fingers or skin. In such a case, use a capacitive

stylus pen.

Periodically clean the touch panel surface for optimum touch operations.

When cleaning, take note of the following points.

<When cleaning>

- The panel surface is made of glass. Be sure to clean the surface gently with a cloth or sponge. Otherwise,

you may scratch or damage the glass.

- Take care not to let cleaning detergent to seep into the touch panel unit.

Do not directly apply or spray cleaning detergent on the panel surface.

[Notes on Wireless LAN]

For details regarding supported wireless LAN standards, radio law certifications, and countries where wireless LAN

can be used, refer to the “V9 Series About Wirelss LAN” manual and the “V9 Series Hardware Specifications”

manual provided with the V9 series unit at delivery.

Page 9

Preface

Notes on Safe Usage of MONITOUCH

Chapter 1 Product Outline

1. Features ......................................................................................................... 1-1

2. Models and Peripheral Equipment ................................................................. 1-3

MONITOUCH Models ................................................................................................ 1-3

Lineup ........................................................................................................................ 1-3

Peripheral Equipment ................................................................................................ 1-6

3. System Configuration..................................................................................... 1-9

Configuration for Advanced Models ........................................................................... 1-9

Standard Model Configuration ................................................................................. 1-10

Lite Model Configuration .......................................................................................... 1-11

Chapter 2 Specifications

1. Advanced Model............................................................................................. 2-1

General Specifications ............................................................................................... 2-1

Installation Specifications........................................................................................... 2-2

Display Specifications ................................................................................................ 2-2

Touch Switch Specifications ...................................................................................... 2-2

Wireless LAN Specifications (Only for Wireless LAN I/F Models).............................. 2-3

Interface Specifications.............................................................................................. 2-3

Clock and Backup Memory Specifications ................................................................. 2-4

Screen Configuration Environment ............................................................................ 2-4

Display Function Specifications ................................................................................. 2-4

Function Performance Specifications......................................................................... 2-5

V9101iW External Dimensions and Panel Cut-out Dimensions................................. 2-6

V9100iW External Dimensions and Panel Cut-out Dimensions................................. 2-7

V9071iW External Dimensions and Panel Cut-out Dimensions................................. 2-8

V9071iW with DUR-00 External Dimensions and Panel Cut-out Dimensions ........... 2-9

2. Standard Model ............................................................................................ 2-10

General Specifications ............................................................................................. 2-10

Installation Specifications......................................................................................... 2-11

Display Specifications .............................................................................................. 2-11

Touch Switch Specifications .................................................................................... 2-12

Wireless LAN Specifications (Only for Wireless LAN I/F Models)............................ 2-12

Function Switch Specifications................................................................................. 2-12

Interface Specifications............................................................................................ 2-12

Clock and Backup Memory Specifications ............................................................... 2-13

Screen Configuration Environment .......................................................................... 2-13

Display Function Specifications ............................................................................... 2-14

Function Performance Specifications....................................................................... 2-15

V9120iS External Dimensions and Panel Cut-out Dimensions................................ 2-16

V9100iS External Dimensions and Panel Cut-out Dimensions................................ 2-17

Contents

Page 10

V91080iSD External Dimensions and Panel Cut-out Dimensions ........................... 2-18

3. Lite Model..................................................................................................... 2-19

General Specifications ............................................................................................. 2-19

Installation Specifications......................................................................................... 2-20

Display Specifications .............................................................................................. 2-20

Touch Switch Specifications .................................................................................... 2-20

Function Switch Specifications................................................................................. 2-20

Interface Specifications............................................................................................ 2-21

Clock and Backup Memory Specifications ............................................................... 2-22

Screen Configuration Environment .......................................................................... 2-22

Display Function Specifications ............................................................................... 2-22

Function Performance Specifications....................................................................... 2-23

V9100iC External Dimensions and Panel Cut-out Dimensions................................ 2-24

V9080iCD External Dimensions and Panel Cut-out Dimensions ............................. 2-25

Chapter 3 Names and Specifications of Components

1. Names and Functions of Components ........................................................... 3-1

Advanced Model ........................................................................................................ 3-1

Standard Model.......................................................................................................... 3-5

Lite Model .................................................................................................................. 3-8

2. Specifications of Components...................................................................... 3-10

Serial Connector (CN1)............................................................................................ 3-10

Modular Jack (MJ1/MJ2).......................................................................................... 3-11

USB-A (Master Port) ................................................................................................ 3-13

USB mini-B (Slave Port)........................................................................................... 3-17

LAN Connector (LAN) .............................................................................................. 3-18

Additional LAN Connector (LAN2) (Only for Additional Wired LAN I/F Models) ...... 3-19

Connector for Wireless LAN Dipole Antenna (WLAN)

(Only for Wireless LAN I/F Models).......................................................................... 3-20

Communication Interface Unit Connector (EXT1).................................................... 3-23

Optional Unit Connector (EXT2) (V910xiW/Standard Models Only) ........................ 3-24

SD Card Interface (SD) ............................................................................................ 3-25

Audio Output Connector (AUDIO) (V910xiW/Standard Models Only) ..................... 3-27

DIP Switches (DIPSW)............................................................................................. 3-28

Chapter 4 Installation

1. Installation Procedure..................................................................................... 4-1

Installation Procedure ................................................................................................ 4-1

Installation Conditions ................................................................................................ 4-3

2. Power Supply Cable and Grounding Connections ......................................... 4-5

Power Supply Cable Connection ............................................................................... 4-5

Notes on Usage of the 100 to 240 VAC Specification................................................ 4-6

Grounding .................................................................................................................. 4-6

3. Securing USB Cables..................................................................................... 4-7

4. Inserting and Removing SD Cards................................................................. 4-8

SD Card Insertion/Removal Procedure...................................................................... 4-8

Page 11

5. Installing the Battery....................................................................................... 4-9

Role of the Battery ..................................................................................................... 4-9

Battery Replacement Period ...................................................................................... 4-9

Battery Voltage Drop Detection.................................................................................. 4-9

Battery Replacement ................................................................................................. 4-9

Notes on the Battery: EU Directive 2006/66/EC ...................................................... 4-14

Chapter 5 Inspection and Maintenance

1. Inspection and Maintenance .......................................................................... 5-1

Daily Inspection.......................................................................................................... 5-1

Periodical Inspection .................................................................................................. 5-1

2. Warranty Policy .............................................................................................. 5-2

Inquiries about Failure ............................................................................................... 5-2

Warranty Period ......................................................................................................... 5-2

Free-of-charge Repair................................................................................................ 5-2

Chargeable Repair ..................................................................................................... 5-2

Inquiry Form ............................................................................................................... 5-3

Page 12

1

1. Features

2. Models and Peripheral Equipment

3. System Configuration

Product Outline

Page 13

1. Features 1-1

1. Features

The V9 series inherits and improves on the features of the V8 series as described below.

1. A programmable display unit that offers 16.77 million maximum display colors* and an LCD with an

LED backlight.

V9 series units are divided into the following model types.

* Only for displaying “picture” images and 3D parts. All other content is displayed using 65,536 colors.

Advanced model:

A high-definition/resolution and high-performance model standardly equipped with a wide

high-resolution LCD, two wired LAN connectors, and connectors for communication interface

units. Capacitive touch panel types are also available.

Standard model:

A high-performance model equipped with connectors for communication interface units,

connectors for optional units, and an audio output connector as standard.

Lite model:

A basic model that does not include the connectors for optional units or the audio output

connector.

2. Improved performance

High-speed processing and rapid rendering can be achieved through the adoption of a

high-performance processor and significantly increased CPU clock speed.

3. LAN connectors standard on all models

All models are equipped with LAN connectors (10BASE-T/100BASE-TX).

The Advanced model is equipped with two LAN connectors as standard.

4. SD card interface as standard

All models are equipped with an SD/SDHC card interface as standard.

SD cards can be used as storage for saving screen programs and logging/alarm data, and

transferring recipe data.

5. Wireless LAN function as standard

Models are equipped with a wireless LAN function compliant with IEEE802.11b/g/n as standard.

An access point is built-in, allowing direct communication with devices equipped with wireless LAN

function such as tablets.

* Only for wireless LAN I/F models

6. Scrolling function

Single screens can be registered at sizes higher than the resolution of the display unit and the

scrolling function can be used to display each part of such screens.

According to screen configuration, this function can be used to display screens of sizes that extend

in the horizontal and vertical directions.

In addition, navigation display is supported which allows users to instantly check the current

display position.

7. Zoom in/out function

Screens can be zoomed in by a maximum of 200 % using pinch-in and pinch-out gestures.

This enables users to check parts that are small and difficult to see.

* Only for Advanced models. Standard and Lite models can be zoomed in/out by double-tapping.

8. VNC server function

All models can be remotely monitored and operated from a computer or tablet.

Server functions can be limited to remote monitoring as necessary.

9. VPN function

All models are equipped with a VPN function, enabling safe, simple and low-cost VPN

communication.

For 2CH/3CH LAN types, the routing function can be used to establish remote connection to

devices connected to the V9 series unit via Ethernet, such as a PLC and network camera.

1

Product Outline

Page 14

1-2 1. Features

10. Scheduler function

Predetermined operations (turning bits ON, executing macros, etc.) can be executed at a time set

in advance, such as every week, every day, or a specified time. Operations such as periodical

saving of logging/alarm data can be scheduled easily.

11. TrueType font

TrueType fonts enable smoother character expression through anti-aliasing processing.

Page 15

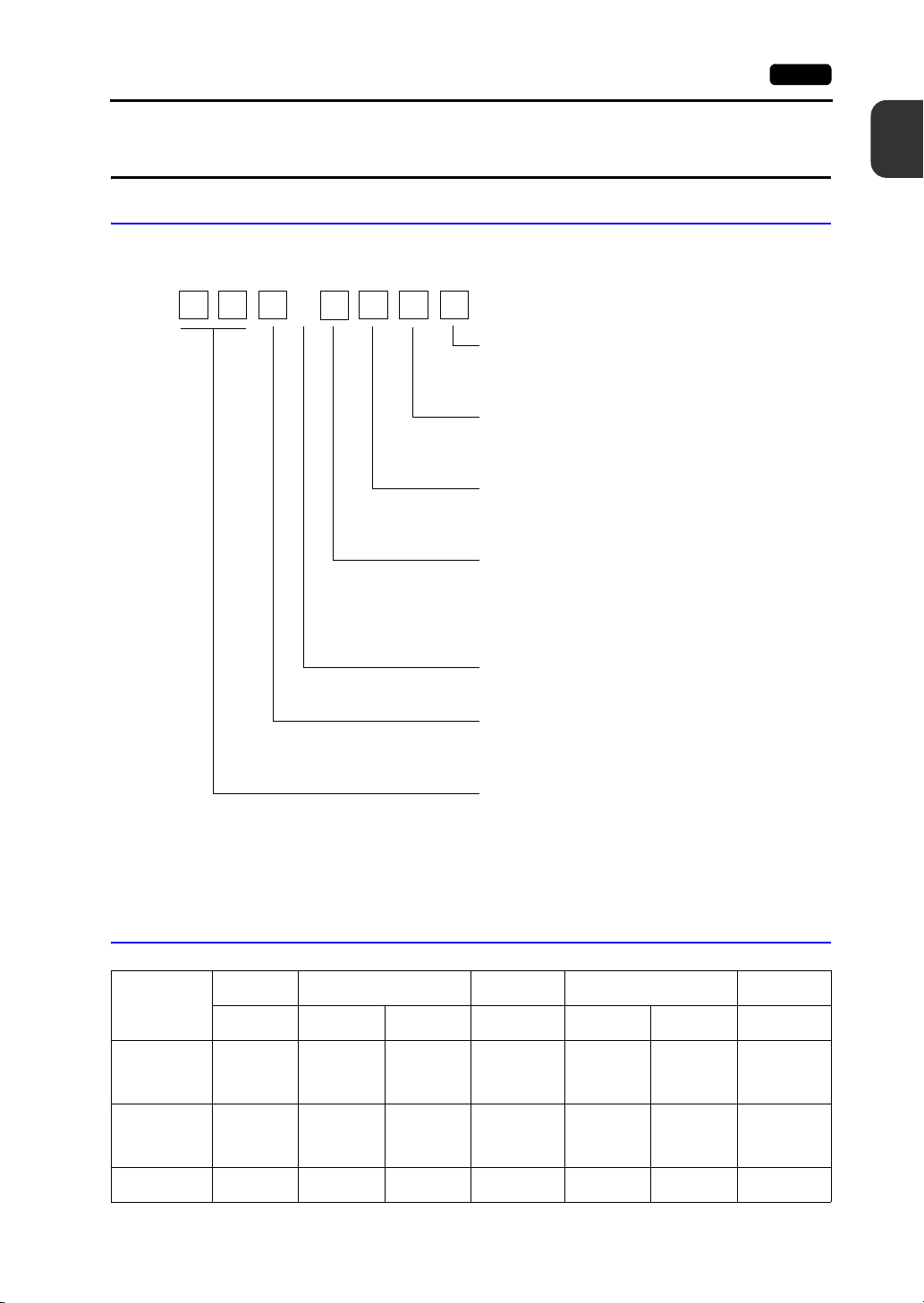

2. Models and Peripheral Equipment 1-3

Power supply specification

None: 100 to 240 VAC type

D: 24 VDC type

Additional wired LAN I/F

None: No additional wired LAN I/F

L: With additional wired LAN I/F

Wireless LAN I/F

None: No wireless LAN I/F

R: With wireless LAN I/F

Device specification

W: TFT color LCD (WSVGA: V910xiW)

(WVGA: V9071iW)

S: TFT color LCD (SVGA)

C: TFT color LCD (VGA)

Functional specification

i: With built-in LAN port

Touch switch specification

0: Analog resistive film type

1: Capacitive type

Screen size

12: 12.1-inch

10: 10.4-inch (Standard/Lite models)

10.1-inch, widescreen (Advance models)

08: 8.4-inch

07: 7.0-inch widescreen

V9 i

2. Models and Peripheral Equipment

MONITOUCH Models

The model name consists of the following information.

1

Product Outline

Lineup

Model

Advanced - - -

Standard

Lite - -

12.1-inch 10.4-inch

SVGA

(800 600)

SVGA

(800 600)

V9120iS

V9120iSD

V9120iSLD

V9120iSRD

V9100iS

V9100iSD

V9100iSLD

V9100iSRD

VGA

(640 480)

--

V9100iC

V9100iCD

10.1-inch

Widescreen

WSVGA

(1024 600)

V9101iWRLD

V9100iWRLD

V9101iWLD

V9100iWLD

SVGA

(800 600)

V9080iSD

V9080iSLD

V9080iSRD

- - V9080iCD -

8.4-inch

VGA

(640 480)

--

--

7.0-inch

Widescreen

(800 480)

V9071iWRLD

V9071iWLD

WVGA

Page 16

1-4 2. Models and Peripheral Equipment

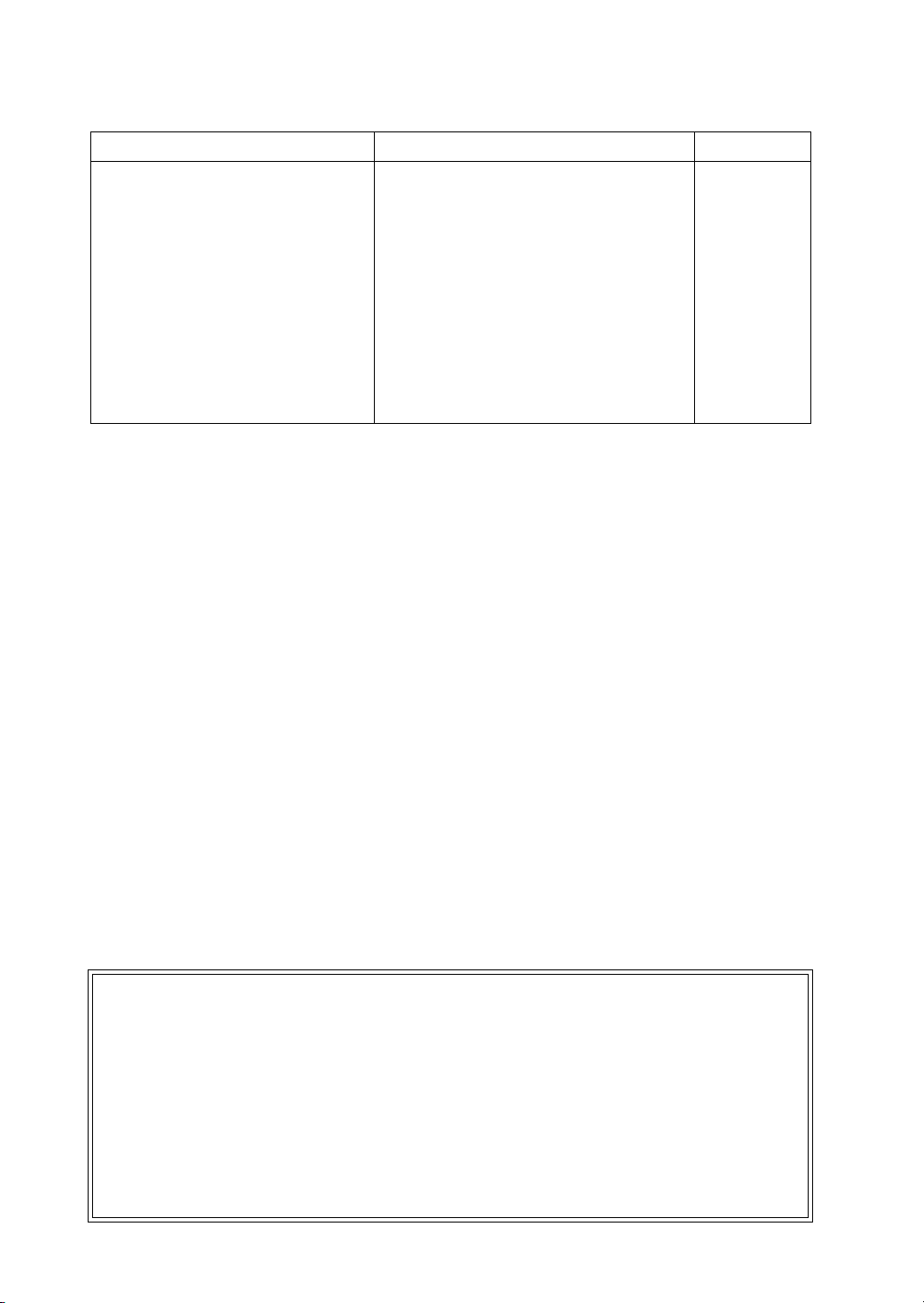

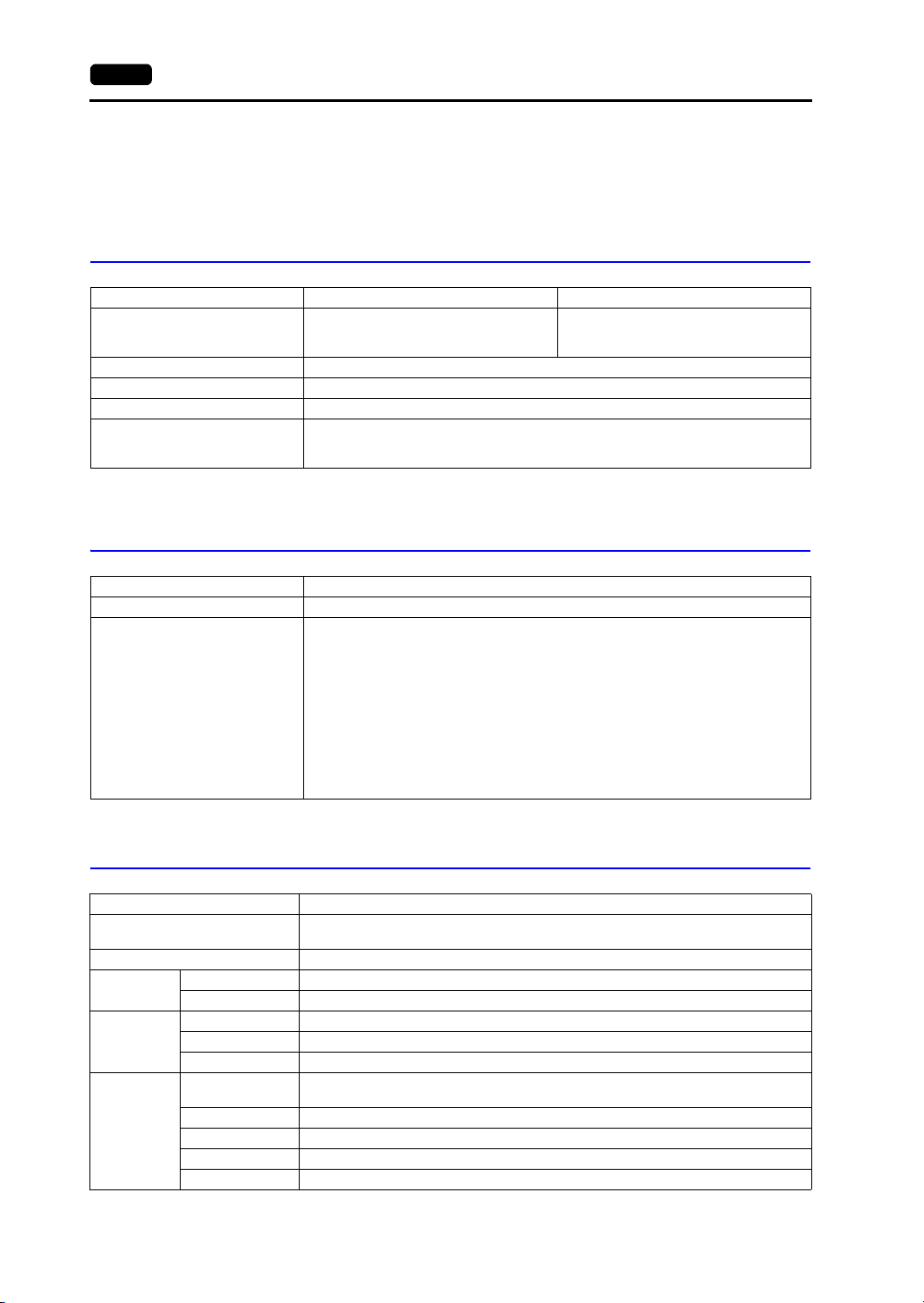

Advanced Model

A high-definition/resolution and high-performance model standardly equipped with a wide

high-resolution LCD, two wired LAN connectors, and connectors for communication interface units.

Capacitive touch panel types are also available.

Unit specifications

Model

V9101iWRLD

V9100iWRLD

V9101iWLD Capacitive type

V9100iWLD

V9071iWRLD

V9071iWLD Capacitive type

External I/F

Model

V9101iWRLD

V9100iWRLD

V9101iWLD

V9100iWLD

V9071iWRLD

V9071iWLD

Display Device Resolution Touch Switch

10.1-inch

Widescreen

7.0-inch

Widescreen

Communication

I/F Unit

Unit Specifications

Capacitive type

Analog resistive

1024 600

dots

800 480

dots

Optional

Units

film type

Analog resistive

film type

Capacitive type

Audio Output Wireless LAN

Power Supply

Type

DC power

supply

Standards

CE/KC/

UL/cUL

Additional

Wired LAN

Standard Model

A high-performance model equipped with connectors for communication interface units, connectors for

optional units, and an audio output connector as standard.

Unit specifications

V9120iS

V9120iSD

V9120iSLD

V9120iSRD UL/cUL

V9100iS

V9100iSD

V9100iSLD

V9100iSRD UL/cUL

V9080iSD

V9080iSLD

V9080iSRD UL/cUL

Model

Unit Specifications

Display Device Resolution Touch Switch

12.1-inch

10.4-inch

8.4-inch

800 600

dots

Analog resistive

film type

Power Supply

Type

AC power

supply

DC power

supply

AC power

supply

DC power

supply

Standards

KC

CE/KC/

UL/cUL

KC

CE/KC/

UL/cUL

CE/KC/

UL/cUL

Page 17

2. Models and Peripheral Equipment 1-5

Lite Model

External I/F

Model

V9120iS

V9120iSD

V9120iSLD

V9120iSRD

V9100iS

V9100iSD

V9100iSLD

V9100iSRD

V9080iSD

V9080iSLD

V9080iSRD

Communication

I/F Unit

Optional

Units

Audio Output Wireless LAN

Additional

Wired LAN

A basic model that does not include the connectors for optional units or the audio output connector.

Unit specifications

Model

V9100iC

V9100iCD

V9080iCD 8.4-inch

Display Device Resolution Touch Switch

10.4-inch

Unit Specifications

640 480

dots

Analog resistive

film type

Power Supply

Type

AC power

supply

DC power

supply

Standards

KC

CE/KC/

UL/cUL

1

Product Outline

External I/F

Model

V9100iC

V9100iCD

V9080iCD

Communication

I/F Unit

Optional

Units

Audio Output Wireless LAN

Additional

Wired LAN

Page 18

1-6 2. Models and Peripheral Equipment

FG

CN1

T1

T2

SD

x10

x1

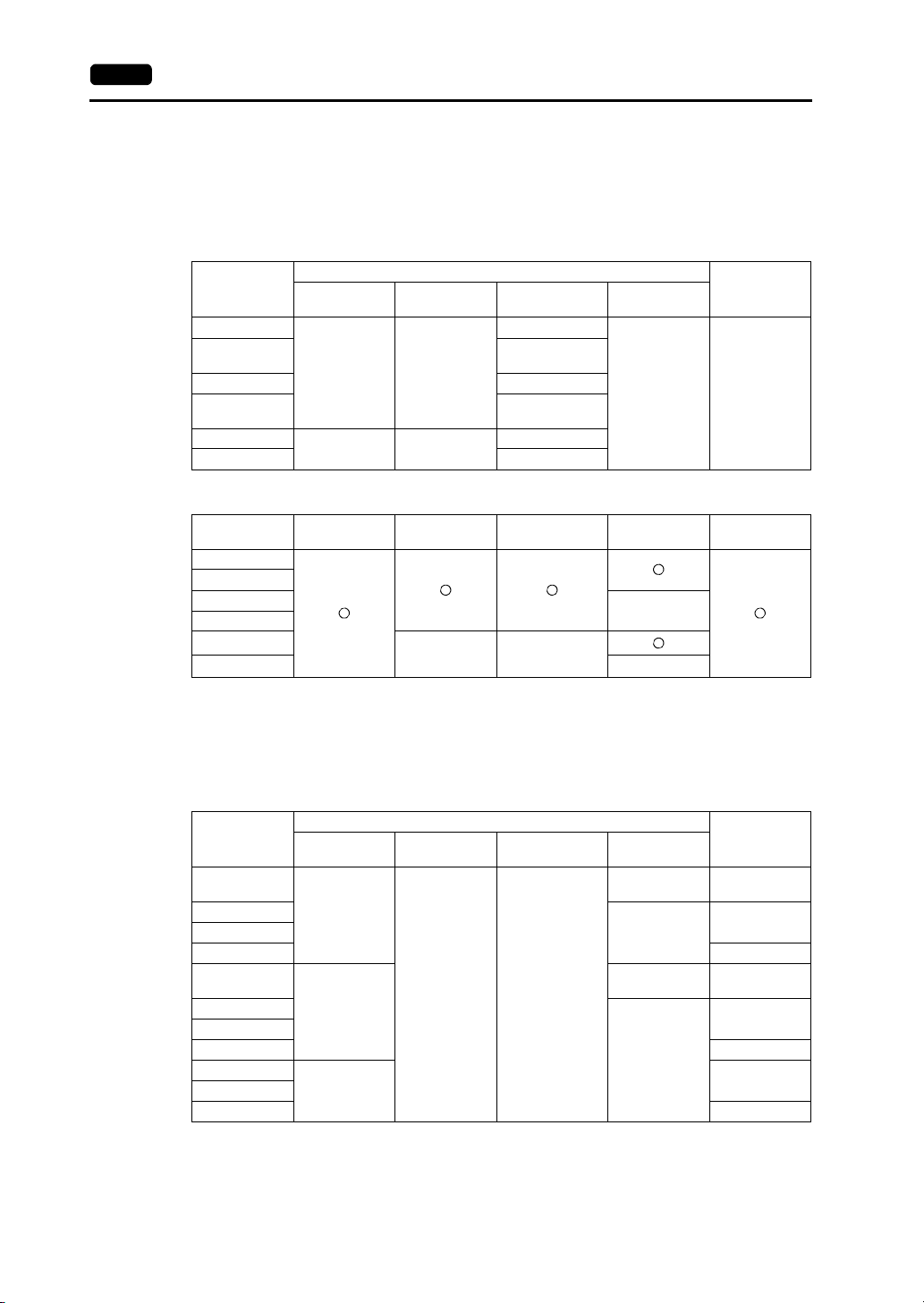

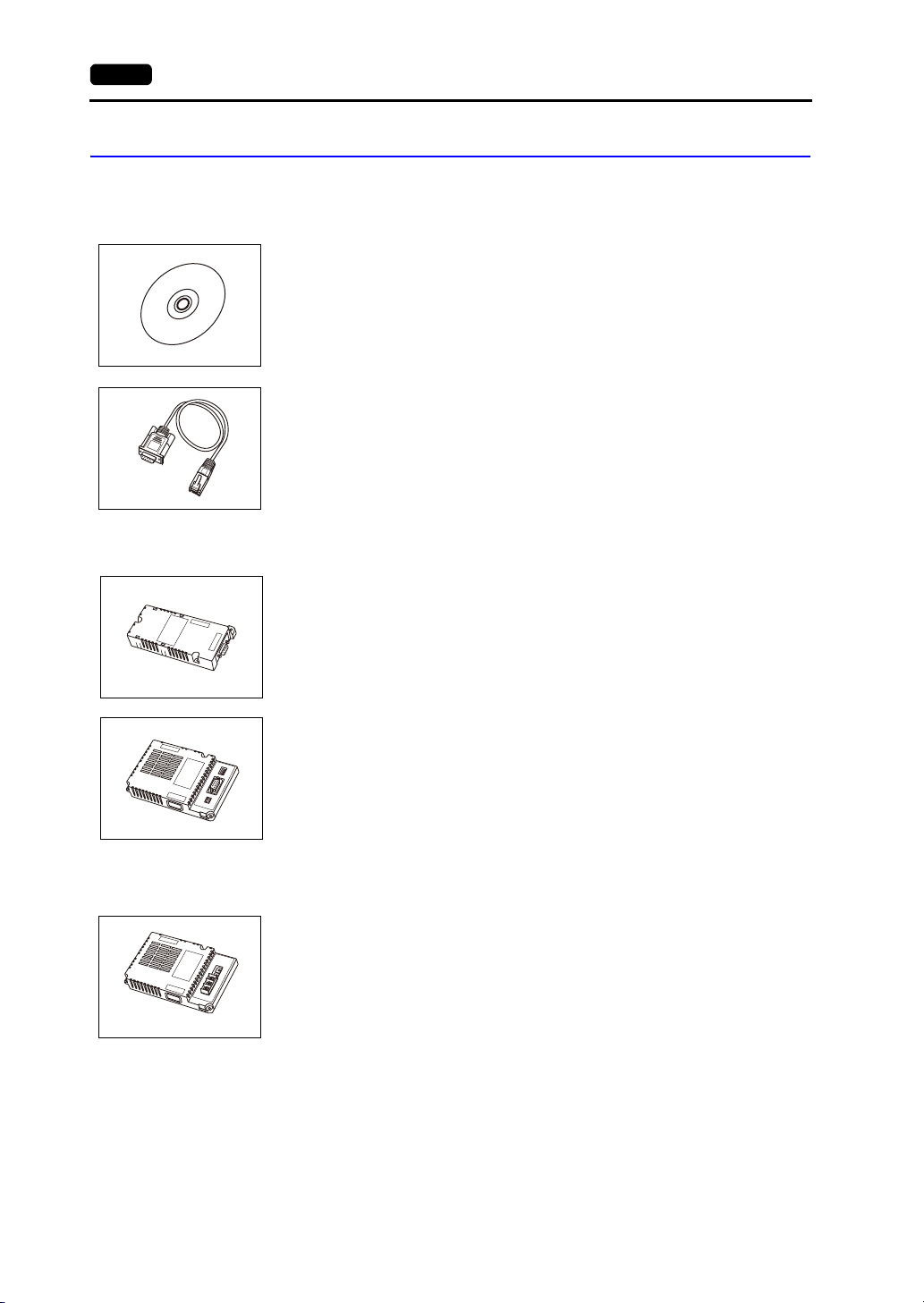

Peripheral Equipment

The following software and equipment are available as options for the V9 series.

Drawing Tool

V-SFT-6 (configuration software)

Application software for editing MONITOUCH screen programs.

Supported OS:

Windows XP, XP 64 Edition, Vista (32-bit, 64-bit), 7 (32-bit, 64-bit), 8 (32-bit, 64-bit) /

8.1 (32-bit, 64-bit)

V-CP (screen program transfer cable) 3 m

A cable used for connecting the V9 series unit to a computer.

Optional Units

GUR-xx

Optional units for the V910xiW and Standard models.

GUR-01 RGB input 1CH

GUR-02 RGB output 1CH

GUR-04 Video input 1CH

DUR-00

Optional unit for the V9071iW.

Supports D-sub 9-pin connectors.

* This unit cannot be used together with a “CUR-xx” communication interface unit.

Communication Interface Unit

CUR-xx

Communication units used for connecting to networks.

* These units cannot be used together with the optional “DUR-00” unit.

CUR-00 OPCN-1

CUR-01 T-Link

CUR-02 CC-Link (under development)

CUR-03 Ethernet

CUR-04 PROFIBUS-DP (under development)

CUR-06 SX-BUS

CUR-07 DeviceNet (under development)

CUR-08 FL-net

Page 19

2. Models and Peripheral Equipment 1-7

Cables

V6-BCD (barcode reader connection cable) 3 m

A cable used for connecting a barcode reader unit to the V9 series.

V6-MLT (multi-link2 master cable) 3 m

A cable used for multi-link2 connection between a V9 master station and V9 slave station.

V6-TMP (connection cable for controllers)

A cable used for connecting the V9 series unit to a controller.

V6-TMP: 3 m

V6-TMP-5M: 5 m

V6-TMP-10M: 10 m

D9-D25 (D-sub 9-pin-to-25-pin conversion cable) 0.3 m

A conversion cable used for connecting the communication cable for the CN1 (D-sub 25-pin)

of the V6/V7 series to the CN1 (D-sub 9-pin) of the V9 series.

1

Product Outline

Protective Sheets

UA-FR (for USB-A port) 1 m

A cable for USB-A (master) that allows connection from the front of the control cabinet.

V9xxx-GS

A sheet used for protecting the operation panel surface (5 pcs./set).

V912S-GS V9120 series

V910S-GS V9100 series

V910W-GS V9100iW (analog resistive film type touch panel) *

* This sheet cannot be used for the V9101iW (capacitive type touch panel).

V908S-GS V9080 series

V9xxx-GSN10

A sheet used for protecting the operation panel surface (5 pcs./set, anti-glare treatment).

The sheet is colored light gray and the graininess on its surface prevents light reflection.

V912S-GSN10 V9120 series

V910S-GSN10 V9100 series

V910W-GS V9100iW (analog resistive film type touch panel) *

* This sheet cannot be used for the V9101iW (capacitive type touch panel).

V908S-GSN10 V9080 series

Page 20

1-8 2. Models and Peripheral Equipment

+5V

SG

+SD

-SD

+RD

-RD

FG

GD

GPP

V

-

M

D

D

1 2 3

Under development

Other Options

V9-BT (replacement battery)

A replacement lithium battery for the V9120/V9100/V910xiW/V9080 series (CR2450S

manufactured by Sony Energy Devices).

V7-BT (replacement battery)

A replacement lithium battery for the V9071iW series.

TC-D9 (terminal converter)

This converter is used for connection between the V9 series unit and a controller at the

RS-422/485 terminal block via CN1 (D-sub 9-pin).

V-MDD (ACPU/QnACPU/FXCPU dual port interface)

An add-on connector with two ports and specifically designed for the connector on

MITSUBISHI ACPU/QnACPU/FXCPU controllers. It is convenient to use this connector

when directly connecting the V9 series unit to a ACPU/QnACPU/FXCPU controller.

V9-ANT (external dipole antenna for wireless LAN)

An external dipole antenna (3 m) for V9 series units that support wireless LAN.

Card Recorder (under development)

USB-CFREC-2 (USB CF card recorder)

A unit that connects to the USB-A port and enables use of CF cards.

Page 21

3. System Configuration 1-9

KEYPAD

CONTROL

P

R

O

MO

DE

Hz

KW

A

RUN

STOP

PRG

RE

S

ET

FUNC

D

A

T

A

Inverter

Ethernet

USB

LAN/LAN2

V9

“V-SFT-6”

“V-CP”

“V6-BCD”

“V6-TMP”

USB-A

MJ1

CN1

Ethernet

PictBridge

AUDIO

LAN/LAN2WLAN

*1

*1

*4

*2

*3

MJ1/MJ2

SD

USB mini-B

V9

V9

V9 series screen

configuration

software

Screen

creation

Screen program transfer

Printer

Barcode reader

Temperature

controller, inverter

Printer (PictBridge)

Video camera

(video input)

Computer

(RGB input)

PLC/

general purpose computer

Computer (PC)

Display

(RGB output)

Speaker

(audio output)

PLC

Temperature controller, inverter

Barcode reader

Barcode reader

Mouse

Keyboard

USB flash drive

Screen program

transfer

Screen

program

transfer

PLC

Network camera

Serial

Optional unit

Communication

cables

Wireless LAN

Printer

Computer (PC)

Ta bl et

SD card

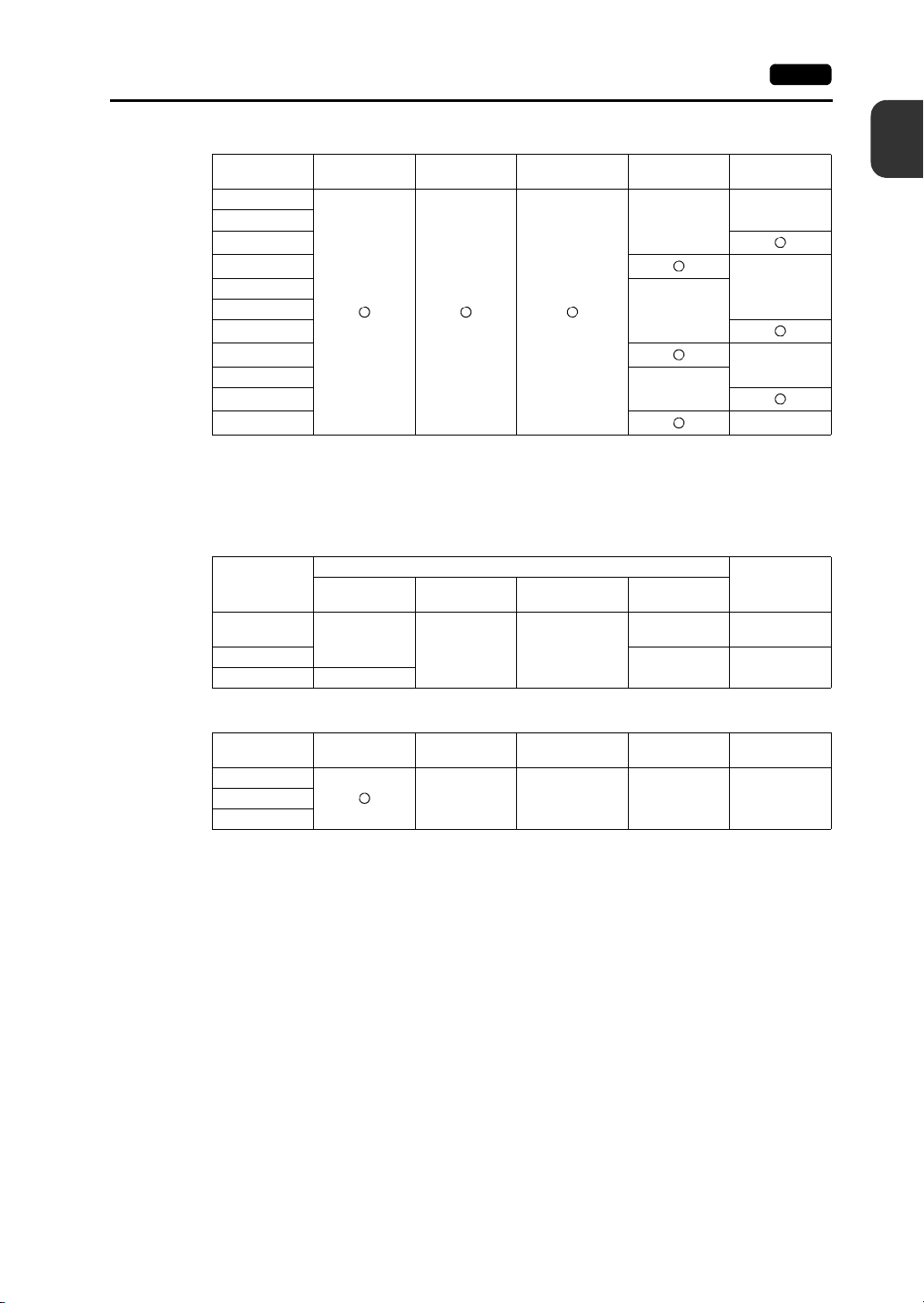

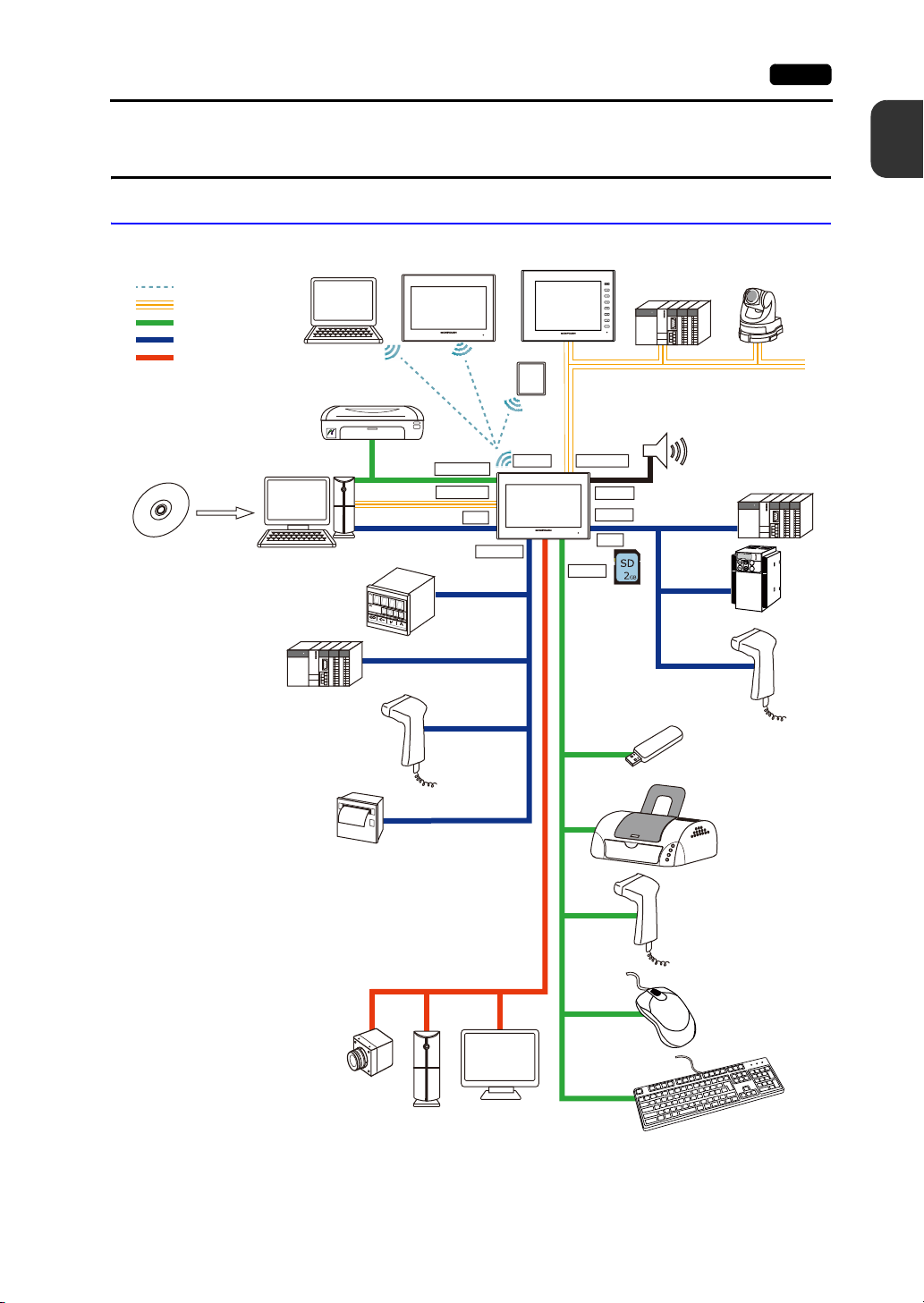

3. System Configuration

Configuration for Advanced Models

The following figure shows the possible system configurations when using the Advanced model.

1

Product Outline

*1 Only for wireless LAN I/F models.

*2 Only for V910xiW.

*3 For the V9071iW, the optional “DUR-00” unit is required.

*4 Only for V910xiW. The optional “GUR-xx” unit is required.

Page 22

1-10 3. System Configuration

Ethernet

USB

KEYPAD

CONTROL

PRO M

O

DE

Hz

KW

A

RUN

STOP

PRG

R

E

S

ET

FUNC

D

A

T

A

Inverter

V9

“V-SFT-6”

“V-CP”

“V6-BCD”

“V6-TMP”

USB-AMJ1/MJ2

MJ1

LAN

CN1

Ethernet

PictBridge

V9

*1

AUDIO

USB mini-B

SD

V9 series screen

configuration

software

Screen

creation

Screen program

transfer

Printer

Barcode reader

Temperature

controller, inverter

Computer (PC)

Video camera

(video input)

Computer

(RGB input)

PLC/

general purpose

computer

Computer (PC)

Display

(RGB output)

Speaker

(audio output)

PLC

Temperature controller, inverter

Barcode reader

Barcode reader

Mouse

Keyboard

USB flash drive

Screen

program

transfer

Screen program transfer

PLC

Network camera

Serial

Optional unit

Communication

cables

Printer (PictBridge)

Printer

SD card

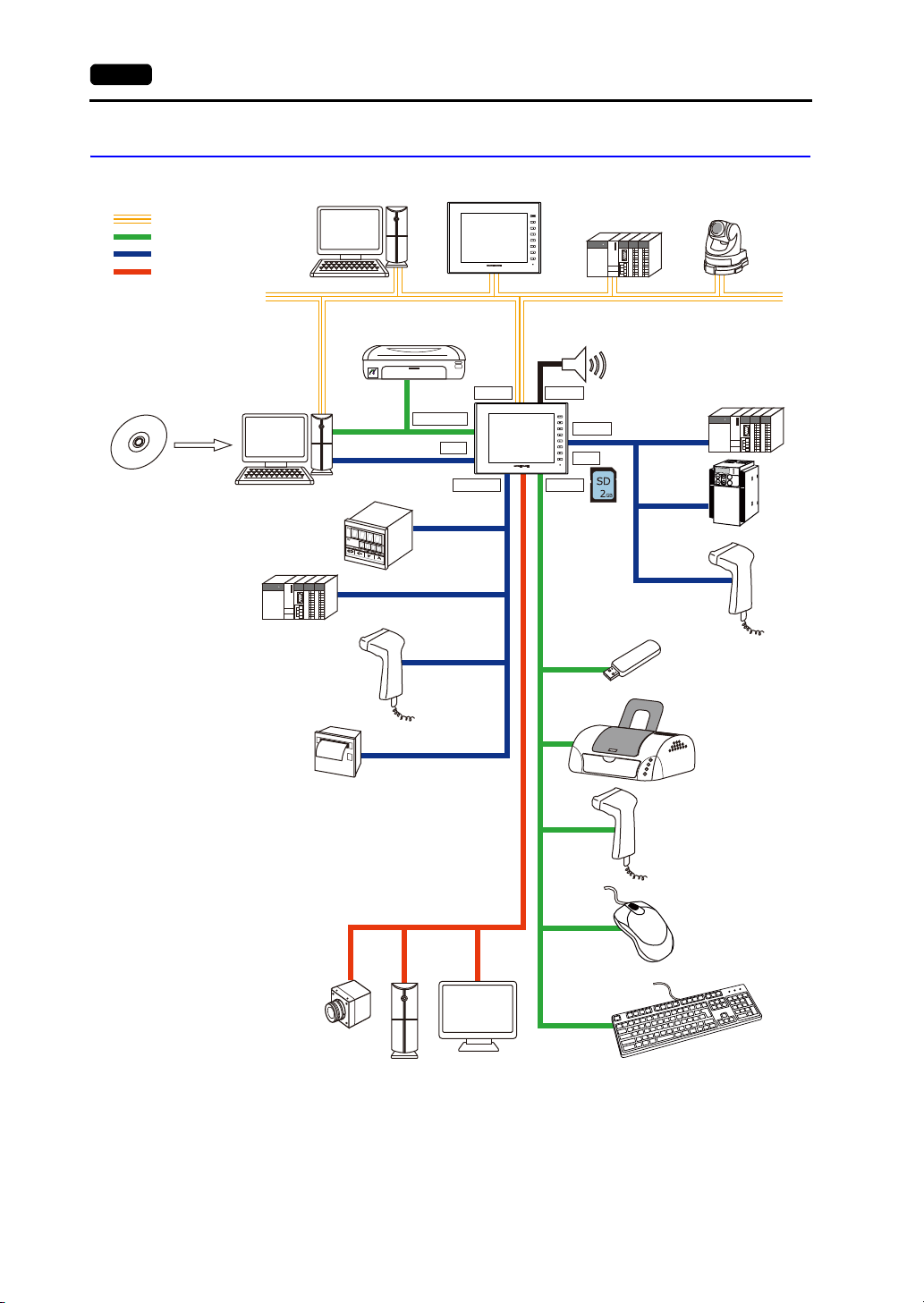

Standard Model Configuration

The following figure shows the possible system configurations when using the Standard model.

*1 The optional “GUR-xx” unit is required.

Page 23

3. System Configuration 1-11

V9 series screen

configuration

software

Screen

creation

Screen program

transfer

Printer

Barcode reader

Temperature

controller, inverter

Computer (PC)

PLC/

general purpose

computer

Computer (PC)

PLC

Temperature controller, inverter

Barcode reader

Barcode reader

Mouse

Keyboard

USB flash drive

Screen

program

transfer

Screen program transfer

PLC

Network camera

Serial

Communication

cables

Printer (PictBridge)

Printer

SD card

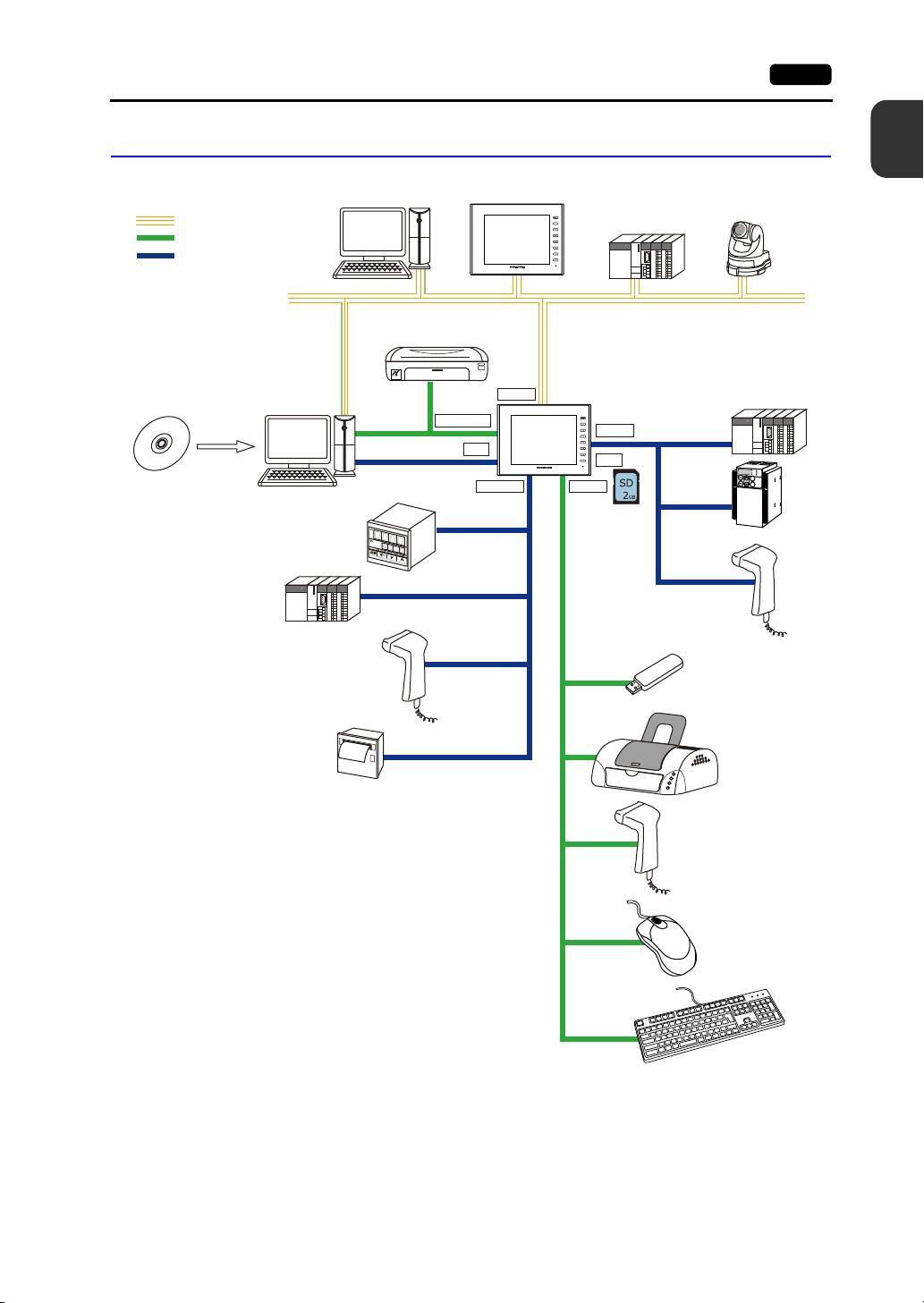

Lite Model Configuration

The following figure shows the possible system configurations when using the Lite model.

Ethernet

USB

“V-SFT-6”

1

Product Outline

V9

Ethernet

PictBridge

LAN

USB mini-B

“V-CP”

MJ1

V9

“V6-TMP”

“V6-BCD”

CN1

SD

USB-AMJ1/MJ2

KEYPAD

Hz

C

ONTROL

A

P

R

O

MOD

E

KW

PRG

R

E

S

E

T

RUN

FUNC

D

A

T

A

STOP

Inverter

Page 24

1-12 3. System Configuration

Please use this page freely.

Page 25

2

1. Advanced Model

2. Standard Model

3. Lite Model

Specifications

Page 26

1. Advanced Model

+0.50+0.50+0.50+0.5

0

1. Advanced Model 2-1

General Specifications

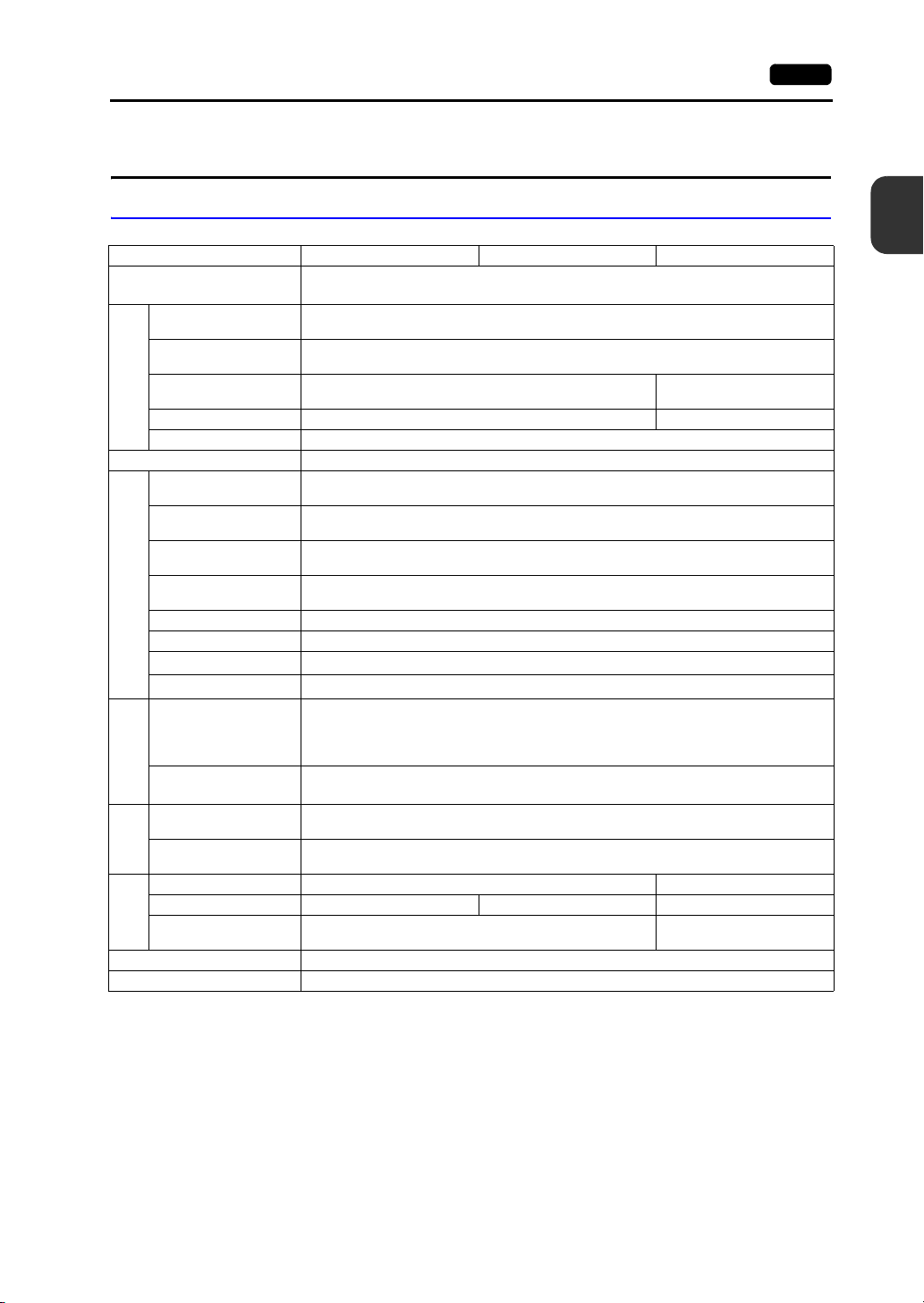

Item V9101iW V9100iW V9071iW

Conformance Standards

Permissible Voltage

Range

Permissible Momentary

Power Failure

Power Consumption

(Max. Rating)

Power Supply

Rush Current 17 A or less, 6 ms 12 A or less, 5 ms

Withstand Voltage DC external terminals to FG: 500 VAC for 1 minute

Insulation Resistance DC external terminals to FG: 500 VDC, 10 M or higher

Operational Ambient

Temperature

Storage Ambient

Temperature

Operational Ambient

Humidity

Storage Ambient

Humidity

Altitude 2000 m or less

Physical Environment

Atmosphere No corrosive gas, no excessive dust, and no conductive dust

Overvoltage Category

Contamination Level

Vibration Resistance

Working

Conditions

Mechanical

Shock Resistance

Noise Resistance

Static Electricity

Working

Electrical

Conditions

Discharge Resistance

Weight Approx. 1.7 kg Approx. 1.0 kg

Dimensions W H D 278.5 198.5 54.4 mm 278.5 198.5 53.2 mm 201.6 147.6 60.3 mm

Panel Cut-out

Mounting

Conditions

Dimensions

Case Color Light gray

Material PC resin

*1 This product complies with the following radio laws:

Japanese Radio Law: Technical Regulations Conformity Certification, Article 2, clause 1-19

FCC Part15 SubPart C

IC RSS210,Gen

R&TTE: EN300328, EN301489-1, EN301489-17, EN62311, EN60950-1

KC

The product will not conform to the above laws if using any antenna other than the built-in antenna of the V9

series unit or the optional V9-ANT for wireless LAN connection.

*2 Use the unit in an environment where the wet-bulb temperature is 39 C or less, otherwise the unit may be

damaged.

*3 This indicates the distribution section to which the unit is intended to be connected to within the path between

the distribution of the public power network and machinery in the facility.

“Category II” applies to devices supplied with power from mains sockets or similar points. The withstand surge

voltage is 2,500 V for devices rated up to 300 V.

Radio laws (Japan: TELEC, USA: FCC, Canada: IC RSS, Europe: R&TTE, South Korea: KC)

*3

*4

Vibration frequency: 5 to 9 Hz, Half-amplitude: 3.5 mm, Vibration frequency: 9 to 150 Hz,

Peak acceleration: 147 m/s

KC, CE (EN61000-6-2, EN61000-6-4), UL508,

24 VDC 10 %

Within 1 ms

27 W or less 22 W or less

0 °C to +50 °C

10 °C to +60 °C

85 % RH or less (without dew condensation)

85 % RH or less (without dew condensation)

Category II

Contamination level 2

JIS B 3502 (IEC61131-2) compliant

Constant acceleration: 9.8 m/s

X, Y, and Z: 3 directions (10 times each)

JIS B 3502 (IEC61131-2) compliant

2

(15 G), X, Y, and Z: 3 directions, 3 times each (18 times in total)

Noise voltage: 1000 Vp-p, Pulse width: 1 s, Rising time: 1 ns

257.0 183.0 mm 187.2 133.4 mm

(Measured using a noise simulator)

Compliant with IEC61000-4-2, contact: 6 kV, air: 8 kV

*2

*2

*2

*2

2

(1 G),

2

*1

Specifications

Page 27

2-2 1. Advanced Model

*4 This is an index that expresses the degree of conductive contamination in the environment where the unit is

used.

“Contamination level 2” indicates the conditions where only non-conductive contamination occurs. However,

due to condensation, temporary conductive contamination may occur.

Installation Specifications

Item Specification

Grounding Less than 100 , FG/SG separated

*1

Protection Structure

Cooling System Natural cooling

Structure Inserted in a mounting panel

Appropriate Mounting Panel Thickness

Panel Front Surface

Rear Case Complies with IP20

*1 Protective structure for the front when the V9 series unit is mounted on a mounting panel.

While the protective structure has passed compliance testing, it is not guaranteed under all environments.

*2 Even when the mounting panel thickness is within the specified range, the panel itself may warp depending on

the material and size of the mounting panel.

Use a panel that can withstand the forces of mounting.

Complies with IP66, with waterproof gasket

1.5 to 4 mm

*2

Display Specifications

Item V9101iW V9100iW V9071iW

Display Device TFT color

Display Size 10.1-inch widescreen 7.0-inch widescreen

Colors

Resolution (W H) 1024 600 dots 800 480 dots

Dot Pitch (W H) 0.2175 0.2088 mm 0.1905 0.1905 mm

Actual Display Dimensions

(W H)

Backlight LED

Backlight Brightness Halftime

Backlight Auto OFF Function Always ON, custom setting

Brightness Adjustment

Touch Panel Operation Surface

POWER Lamp

*1 Only for displaying “picture” images, 3D parts and video images. All other content is displayed using 65,536

colors.

*2 Time until the surface brightness becomes 50 % of the initial value at an ambient temperature of 25 C.

16.77 million colors

222.72 125.28 mm 152.4 91.44 mm

*2

Approx. 50,000 hours Approx. 100,000 hours

System menu: 16 levels

Macro: 128 levels

Touch panel

(Glass)

On: Normal (green)

Flashing: Circuit board or power supply failure

*1

Surface sheet

(PET, 0.188 mm)

Touch panel

(Glass)

Touch Switch Specifications

Item Specification

Type Projected-capacitive type

Surface Treatment Clear

Page 28

1. Advanced Model 2-3

Wireless LAN Specifications (Only for Wireless LAN I/F Models)

Item Specification

Complying Antennas

* For details of other wireless LAN specifications, refer to P 3-20.

Built-in antenna of the V9 series unit

V9-ANT (optional): External dipole antenna for wireless LAN

Interface Specifications

Item Specification

Applicable

standards

Synchronization Asynchronous type

Data Length 7 or 8 bits

*1

D-sub 9-pin (CN1)

Modular Jack, 8-pin

(MJ1, MJ2

Modular Jack, 8-pin

(MJ2

USB Connector

(U-A, U-B)

Ethernet Port

100BASE-TX /

10BASE-T

(LAN, LAN2)

Connector for Wireless LAN Dipole

Antenna (WLAN)

SD Card Interface SD/SDHC card compliant

Communication Interface Unit Connector

(EXT1)

Connector for Optional Unit

(EXT2)

Audio Output Connector (AUDIO)

*3

)

*4

)

*3

Parity None, even, odd

Stop Bit 1 or 2 bits

Baud Rate

Applications PLC, temperature controller, barcode reader connection, etc.

Applicable

standards

Applications

Applicable

standards

Baud Rate

Applications PLC, temperature controller, barcode reader connection, etc.

Applicable

standards

Baud Rate High speed 480 Mbps

USB-A

Applications

Applicable

standards

Baud Rate High speed 480 Mbps

Applications Screen program transfer, PictBridge-compatible printer connection

USB mini-B

Applicable

standards

Baud Rate 100 Mbps, 10 Mbps

Protocol TCP/IP, UDP/IP

Functions Auto-MDIX, Auto-Negotiation

Recommended

*5

Cable

Applications Screen program transfer, PLC connection, etc.

*6

*3

RS-232C, RS-422/485

4800, 9600, 19200, 38400, 57600, 76800, 115k bps

(For PPI/MPI connection with a Siemens PLC: 187.5 kbps

RS-232C, RS-485 (2-wire connection)

Screen program transfer (MJ1), PLC, temperature controller, barcode reader,

printer, multi-link2, V-Link connection, etc.

RS-232C, RS-485 (2-wire connection), RS-422 (4-wire connection)

4800, 9600, 19200, 38400, 57600, 76800, 115k bps

(For PPI/MPI connection with a Siemens PLC: 187.5 kbps

Compliant with USB version 2.0

Printer (EPSON ESC/P-R driver), USB flash drive, USB-CFREC-2 (under

development), keyboard, mouse connection, etc.

Compliant with USB version 2.0

IEEE802.3u compliant (100BASE-TX), IEEE802.3 compliant (10BASE-T)

100 UTP (unshielded twist-pair) cable, category 5, max. 100 m long

Reverse polarity SMA jack

*4

Optional unit “DUR-00”

PROFIBUS-DP, DeviceNet, FL-net connection

* The separate communication interface unit “CUR-xx” (some types currently

under development) is required.

RGB input/output, video input function

* The optional “GUR-xx” unit (under development) is required.

3.5 mm stereo mini jack

, SX-BUS, OPCN-1, T-Link, Ethernet, CC-Link,

*2 *3

*2

)

)

2

Specifications

Page 29

2-4 1. Advanced Model

*1 For the V9071iW, the optional “DUR-00” unit must be attached.

*2 For details, refer to the V9 Series Connection Manual.

*3 Only for V910xiW.

*4 Only for V9071iW.

*5 Both straight and cross cables are usable, irrespective of the presence or absence of a hub.

*6 Only for wireless LAN I/F models.

Clock and Backup Memory Specifications

Item V910xiW V9071iW

Battery

Backup Memory SRAM 800 KB

Backup Retention Period Approx. 5 years (ambient temperature at 25 C)

Battery Voltage Drop Detection Provided (allocated to internal device memory address $s167)

Calendar Accuracy *

* When using the unit at an ambient temperature other than 25 C, clock deviation may increase. Check and

correct the clock periodically.

Coin-type lithium primary cell

(CR2450S manufactured by Sony Energy

Devices)

When powered: Monthly deviation of 210 sec. (ambient temperature at 25 C)

When unpowered: Monthly deviation of 90 sec. (ambient temperature at 25 C, with

battery backup)

Coin-type lithium primary cell

(V7-BT manufactured by Hakko

Electronics)

Screen Configuration Environment

Item Specification

Configuration Method Dedicated configuration software

Name of dedicated configuration software: V-SFT-6

Computer: Pentium IV 2.0 GHz or above recommended

*1

: Windows XP/ XP64 Edition/ Vista(32bit,64bit) / 7 (32bit, 64bit) /

Configuration Tool

*1 Administrator privileges are required for installation.

OS

Memory: 1.0 GB or above (2.0 GB or above recommended)

Hard disk capacity: Free space of approx. 2.0 GB or more

Optical disc drive: DVD-ROM drive

Display: Resolution of 1024 768 or above

Other: Microsoft .NET Framework 4.0 or 4.5

8 (32bit, 64bit) / 8.1 (32bit, 64bit)

Color depth of 16-bit or above

(If a PC does not have .NET Framework 4.0 or 4.5 installed,

Framework 4.0 will be automatically installed on the PC.)

Display Function Specifications

Item Specification

Interface Language

Font Types TrueType fonts, bitmap fonts, Windows fonts

Character

Properties

Graphics

Graphic

Properties

*1

Display Properties Normal, blink, bold, shadow, transparent, italic

Colors 65,536 colors (without blinking) / 32,768 colors (with blinking)

Lines Line, continuous line, box, parallelogram, polygon

Circles Circle, arc, sector, ellipse, elliptical arc

Others Pattern, image, data display (graphics library, data sheets)

Line Types

Tile Patterns 16 types (including 8 user-definable patterns)

Display Properties Normal, blinking

Colors 65,536 colors (without blinking) / 32,768 colors (with blinking)

Color Selection Foreground, background, boundary (line)

*1 For more information, refer to V9 Series Reference Manual 1.

Japanese, English/Western Europe, Chinese (Traditional), Chinese (Simplified), Korean,

6 types (thin, thick, dotted, chain, dashed, two-dot chain)

Line thickness can be selected from 1 to 8 points (excluding thick lines).

Central Europe, Cyrillic, Greek, Turkish, and Baltic

Page 30

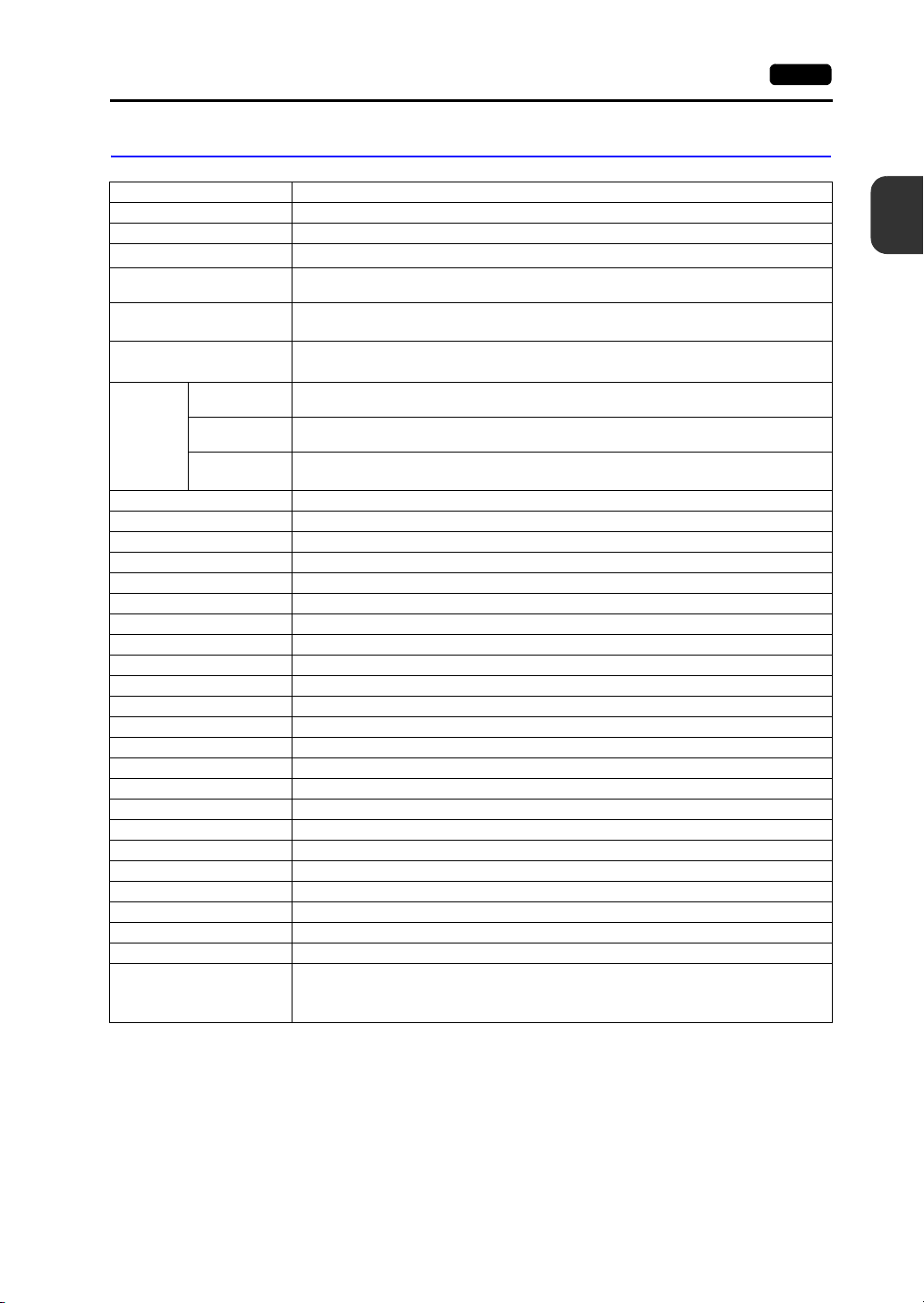

Function Performance Specifications

Item Specification

Screens Max. 4,000

Screen Memory 64 MB of flash memory

Switches

Switch Actions

Lamps

Graphs

Numerical Data

Display

Data

Setting

Messages Max. 32,768 lines

Macro Blocks Max. 1,024

Graphics Library Max. 2,560

Overlap Library Max. 4,000

Screen Library Max. 4,000

Data Blocks Max. 1,024

Patterns Max. 1,024

Data Sheets Max. 1,024

Tags Max. 65,536 lines

Page Blocks Max. 2,048

Direct Blocks Max. 1,024

Screen Blocks Max. 1,024

Comments Max. 32,767

Logging Server Fixed cycle, trigger

Alarm Server Real time, alarm, event

Recipes Max. 256

Scheduler Max. 64

MES Setting Max. 256

Device Memory Map Max. 32 8 (PLC1 to PLC8)

Time Display Provided

Hard Copy Provided

Buzzer Provided, 3 sounds (short beep, long beep, continuous beep)

Auto OFF Function Always ON, custom setting

Self-diagnostic Function

Character

Display

Message

Display

*1 The maximum number of parts that can be placed on one screen is 4,096.

For more information on limitations regarding part placement, refer to the V9 Series Operation Manual.

*2 Layer: 11 layers per screen (base screen and 10 overlap displays)

*3 For more information, refer to the separate V9 Series Troubleshooting/Maintenance Manual.

Max. 4,096 per screen

Set, reset, momentary, alternate, illuminated

It is possible to press two switches on the display at the same time.

Reverse, blinking, exchange of graphics

Max. 4,096 per screen

Pie, bar, panel meter and closed area graph: Max. 4,096 per screen

Statistics and trend graphs: Max. 256 per layer

Max. 4,096 per screen

Max. 4,096 per screen

Max. 4,096 per screen

Maximum number of characters per line: 127 one-byte characters

Touch switch test function

Confirmation function that uses the status bar

Network diagnostic functions (network test, duplicate IP address test)

*1

(including slider switches and scroll bars)

*1

*1

*1

*1

*3

*3

1. Advanced Model 2-5

2

Specifications

*1

*2

*3

Page 31

2-6 1. Advanced Model

+

-

256.0

182.0

278.5

198.5

47.2

7.2

257.0

183.0

54.4

+0.5

-0

+0.5

-0

Side view

Panel cut-out dimensions

Rear view

Bottom view

(Unit: mm)

Front view

V9101iW External Dimensions and Panel Cut-out Dimensions

Page 32

1. Advanced Model 2-7

+

-

256.0

182.0

278.5

198.5

47.2

6.0

257.0

183.0

53.2

+0.5

-0

+0.5

-0

Side view

Panel cut-out dimensions

Rear view

Bottom view

(Unit: mm)

Front view

V9100iW External Dimensions and Panel Cut-out Dimensions

2

Specifications

Page 33

2-8 1. Advanced Model

Side view

Panel cut-out dimensions

Rear view

Bottom view

(Unit: mm)

Front view

V9071iW External Dimensions and Panel Cut-out Dimensions

201.6

147.6

132.4

60.3

186.2

53.1

7.2

-0

+0.5

133.4

187.2

+0.5

-0

Page 34

1. Advanced Model 2-9

Side view

Panel cut-out dimensions

Rear view

Bottom view

(Unit: mm)

Front view

V9071iW with DUR-00 External Dimensions and Panel Cut-out Dimensions

201.6

2

Specifications

85.3

147.6

132.4

60.3

186.2

85.3

53.1

7.2

+0.5

-0

133.4

187.2

+0.5

-0

Page 35

2-10 2. Standard Model

+0.50+0.50+0.50+0.5

0

+0.50+0.5

0

2. Standard Model

General Specifications

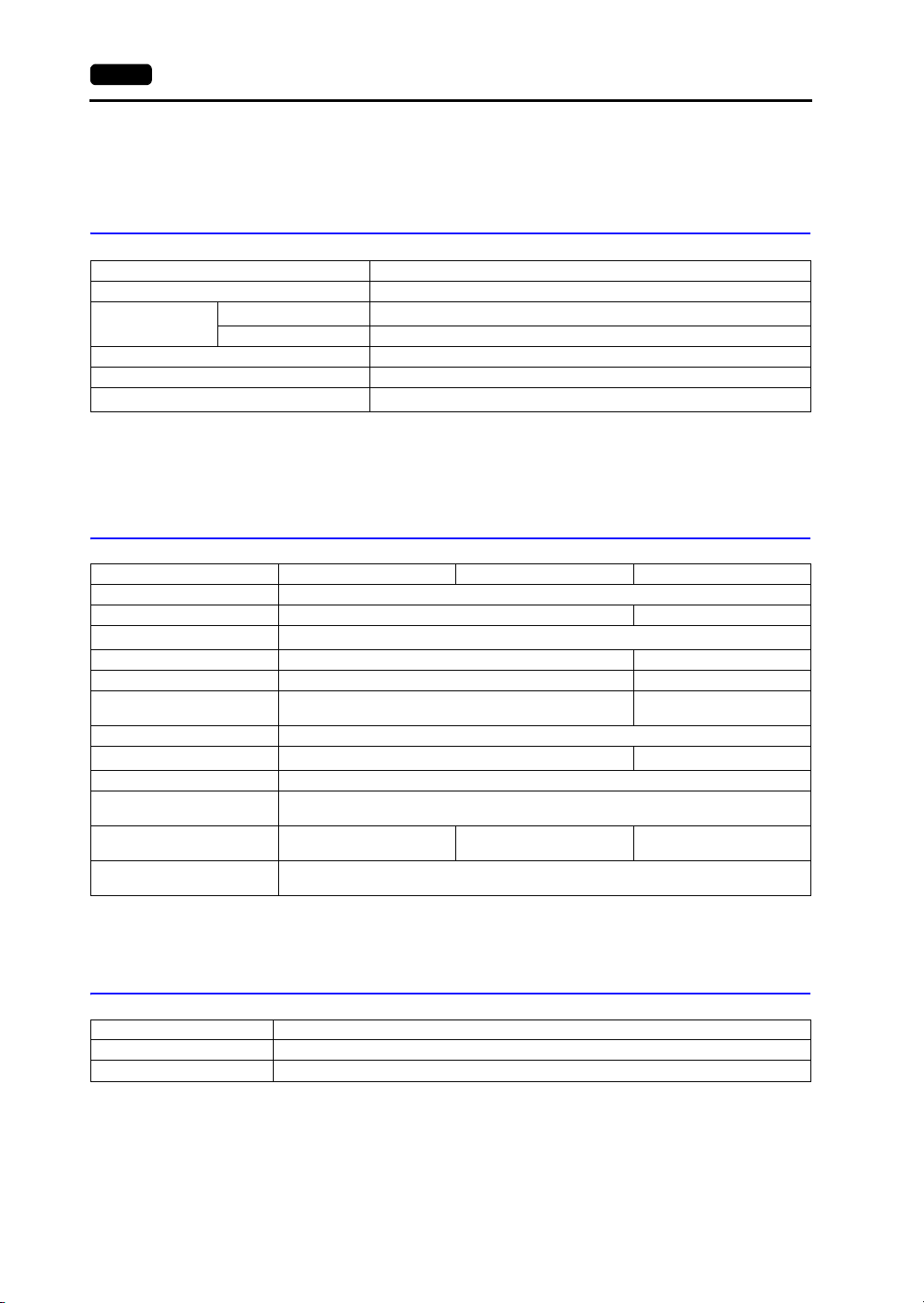

Item V9120iS V9120iSD V9100iS V9100iSD V9080iSD

*1

KC

, CE

Standards KC

Permissible Voltage

Range

Permissible Momentary

Power Failure

Power Consumption

(Max. Rating)

Power Supply

Rush Current

Withstand Voltage

Insulation Resistance

Operational Ambient

Temperature

Storage Ambient

Temperature

Operational Ambient

Humidity

Storage Ambient

Humidity

(EN61000-6-2,

EN61000-6-4)

Radio laws

(Japan: TELEC)

100 to 240 VAC

15 % to +10 %

(47 to 63 Hz)

Within 20 ms

(100 VAC or

higher)

24 VDC 10 %

Within 1 ms

70 VA or less 28 W or less 70 VA or less 28 W or less

30 A or less, 3

ms

18 A or less, 3 ms

AC external terminals to FG: 1,500 VAC for 1 minute,

DC external terminals to FG: 500 VAC for 1 minute

AC external terminals to FG: 500 VDC at 10 M or more,

DC external terminals to FG: 500 VDC at 10 M or more

85 % RH or less (without dew condensation)

85 % RH or less (without dew condensation)

UL508,

*1

,

*2

KC

100 to 240 VAC

15 % to +10 %

(47 to 63 Hz)

Within 20 ms

(100 VAC or

higher)

30 A or less, 3

ms

0 C to +50 C

10 C to +60 C

CE (EN61000-6-2, EN61000-6-4)

Radio laws (Japan: TELEC)

*3

*3

Altitude 2000 m or less

Physical Environment

Atmosphere No corrosive gas, no excessive dust, and no conductive dust

Overvoltage Category

Contamination Level

Vibration Resistance

Working

Conditions

Mechanical

Shock Resistance

Noise Resistance

Static Electricity

Working

Electrical

Conditions

Discharge Resistance

*4

*5

Vibration frequency: 5 to 9 Hz Half-amplitude: 3.5 mm, Vibration frequency: 9 to 150 Hz

JIS B 3502 (IEC61131-2) compliant

Constant acceleration: 9.8 m/s

JIS B 3502 (IEC61131-2) compliant

X, Y, and Z: 3 directions, 3 times each (18 times in total)

Noise voltage: 1500 Vp-p, Pulse width: 1 s, Rising time: 1 ns

Peak acceleration: 147 m/s

(Measured using a noise simulator)

Compliant with IEC61000-4-2, contact: 6 kV, air: 8 kV

Category II

Contamination level 2

2

(1 G), X, Y, and Z: 3 directions (10 times each)

2

(15 G),

Weight Approx. 2.5 kg Approx. 2.0 kg Approx. 1.3 kg

Dimensions

W H D

Panel Cut-out

Mounting

Conditions

Dimensions

327.8 261.0 54.9 mm 303.8 231.0 54.0 mm

313.0 246.2 mm 289.0 216.2 mm

Case Color Light gray

Material PC resin

KC

UL508,

24 VDC 10 %

Within 1 ms

17 A or less, 6 ms

*3

*3

*1

,

235.0 180.0

48.9 mm

220.5

165.5 mm

*1

,

*2

Page 36

*1 Excluding models that support wireless LAN (V9120iSRD, V9100iSRD, V9080iSRD)

*2 Only models that support wireless LAN (V9120iSRD, V9100iSRD, V9080iSRD) are compliant with:

Japanese Radio Law: Technical Regulations Conformity Certification, Article 2, clause 1-19

The product will not conform to the above laws if using any antenna other than the built-in antenna of the V9

series unit or the optional V9-ANT for wireless LAN connection.

*3 Use the unit in an environment where the wet-bulb temperature is 39 C or less, otherwise the unit may be

damaged.

*4 This indicates the distribution section to which the unit is intended to be connected to within the path between

the distribution of the public power network and machinery in the facility.

“Category II” applies to devices supplied with power from mains sockets or similar points. The withstand surge

voltage is 2,500 V for devices rated up to 300 V.

*5 This is an index that expresses the degree of conductive contamination in the environment where the unit is

used.

“Contamination level 2” indicates the condition where only non-conductive contamination occurs. However, due

to condensation, temporary conductive contamination may occur.

Installation Specifications

Item Specification

Grounding Less than 100 , FG/SG separated

*1

Protection Structure

Cooling System Natural cooling

Structure Inserted in a mounting panel

Appropriate Mounting Panel Thickness

Panel Front Surface

Rear Case Equivalent to IP20

*1 Protective structure for the front when the V9 series unit is mounted on a mounting panel.

While the protective structure has passed compliance testing, it is not guaranteed under all environments.

*2 Even when the mounting panel thickness is within the specified range, the panel itself may warp depending on

the material and size of the mounting panel.

Use a panel that can withstand the forces of mounting.

Equivalent to IP66, with waterproof gasket

1.5 to 4 mm

*2

2. Standard Model 2-11

2

Specifications

Display Specifications

Item V9120iS V9100iS V9080iS

Display Device TFT color

Display Size 12.1-inch 10.4-inch 8.4-inch

Colors

Resolution (W H) 800 600 dots

Dot Pitch (W H) 0.3075 0.3075 mm 0.264 0.264 mm 0.213 0.213 mm

Actual Display Dimensions

(W H)

Backlight LED

Backlight Brightness

*2

Halftime

Backlight Auto OFF Function Always ON, custom setting

Brightness Adjustment

Touch Panel Operation

Surface

POWER Lamp

*1 Only for displaying “picture” images, 3D parts and video images. All other content is displayed using 65,536

colors.

*2 Time until the surface brightness becomes 50 % of the initial value at an ambient temperature of 25 C.

16.77 million colors

246.0 184.5 mm 211.2 158.4 mm 170.4 127.8 mm

Approx. 70,000 hours

System menu: 16 levels

Macro: 128 levels

Surface sheet (PC, 0.3 mm) Surface sheet (PET, 0.188 mm)

On: Normal (green)

Flashing: Backlight, circuit board or power supply failure

*1

Page 37

2-12 2. Standard Model

Touch Switch Specifications

Item Specification

Type Analog resistance film type

Switch Resolution 1024 1024

Mechanical Life One million activations or more

Surface Treatment Anti-glare treatment, 6 %

Wireless LAN Specifications (Only for Wireless LAN I/F Models)

Item Specification

Complying Antennas

* For details of other wireless LAN specifications, refer to P 3-20.

Built-in antenna of the V9 series unit

V9-ANT (optional): External dipole antenna for wireless LAN

Function Switch Specifications

Item Specification

Number of Switches 8

Type Membrane switch

Mechanical Life One million activations or more

Interface Specifications

Item Specification

Applicable

Standards

Synchronization Asynchronous type

Data Length 7 or 8 bits

D-sub 9-pin (CN1)

Modular Jack, 8-pin

(MJ1, MJ2)

USB Connector

(U-A / U-B)

Parity None, even, odd

Stop Bit 1 or 2 bits

Baud Rate

Applications PLC, temperature controller, barcode reader connection, etc.

Applicable

Standards

Applications

Applicable

Standards

Baud Rate High speed 480 Mbps

USB-A

Applications

Applicable

Standards

Baud Rate High speed 480 Mbps

Applications Screen program transfer, PictBridge-compatible printer connection

USB mini-B

RS-232C, RS-422/485

4800, 9600, 19200, 38400, 57600, 76800, 115 kbps

(For PPI/MPI connection with a Siemens PLC: 187.5 kbps

RS-232C, RS-485 (2-wire connection)

Screen program transfer (MJ1), PLC, temperature controller, barcode reader,

printer, multi-link2, V-Link connection, etc.

Compliant with USB version 2.0

Printer (EPSON ESC/P-R driver), USB flash drive, USB-CFREC-2 (under

development), keyboard, mouse connection, etc.

Compliant with USB version 2.0

*1

)

Page 38

Item Specification

Applicable

Standards

Ethernet Port

100BASE-TX /

10BASE-T

(LAN / LAN2

Connector for Wireless LAN Dipole

Antenna (WLAN)

SD Card Interface SD/SDHC card support

Communication Interface Unit Connector

(EXT1)

Connector for Optional Unit (EXT2)

Audio Output Connector (AUDIO) 3.5 mm stereo mini jack

*2

Baud Rate 10 Mbps, 100 Mbps

Protocol TCP/IP, UDP/IP

Functions Auto-MDIX, Auto-Negotiation

)

Recommended

*3

Cable

Applications Screen program transfer, PLC connection, etc.

*4

*1 For details, refer to the V9 Series Connection Manual.

*2 Only for additional wired LAN I/F models.

*3 Both straight and cross cables are usable, irrespective of the presence or absence of a hub.

*4 Only for wireless LAN I/F models.

IEEE802.3u compliant (100BASE-TX), IEEE802.3 compliant (10BASE-T)

100 UTP (unshielded twist-pair) cable, category 5, max. 100 m long

Reverse polarity SMA jack

SX-BUS, OPCN-1, T-Link, Ethernet, CC-Link, PROFIBUS-DP, DeviceNet,

FL-net connection

* The separate communication interface unit “CUR-xx” (some types currently

under development) is required.

RGB input/output, video input/output function

* The optional “GUR-xx” unit is required.

2. Standard Model 2-13

2

Specifications

Clock and Backup Memory Specifications

Item Specification

Battery Coin-type lithium primary cell (CR2450S manufactured by Sony Energy Devices)

Backup Memory SRAM, 800 KB

Backup Retention Period Approx. 5 years (ambient temperature at 25 C)

Battery Voltage Drop Detection Provided (allocated the internal device memory address $s167)

Calendar Accuracy

* When using the unit at an ambient temperature other than 25 C, clock deviation may increase. Check and

*

correct the clock periodically.

When powered: Monthly deviation of 210 sec. (ambient temperature at 25 C)

When unpowered: Monthly deviation of 90 sec. (ambient temperature at 25 C, with

battery backup)

Screen Configuration Environment

Item Specification

Configuration Method Dedicated configuration software

Name of dedicated configuration software: V-SFT-6

Computer: Pentium IV 2.0 GHz or above recommended

*1

: Windows XP/ XP64 Edition/ Vista (32 bit, 64 bit) / 7 (32 bit,

Configuration Tool

*1 Administrator privileges are required for installation.

OS

Memory: 1.0 GB or above (2.0 GB or above recommended)

Hard disk capacity: Free space of approx. 2.0 GB or more

Optical disc drive: DVD-ROM drive

Display: Resolution of 1024 768 or above

Other: Microsoft. NET Framework 4.0 or 4.5

64 bit) / 8 (32 bit, 64 bit) / 8.1 (32 bit, 64 bit)

Color depth of 16-bit or more

(If a PC does not have .NET Framework 4.0 or 4.5 installed,

Framework 4.0 will be automatically installed on the PC.)

Page 39

2-14 2. Standard Model

Display Function Specifications

Item Specification

Interface Language

Font Types TrueType fonts, bitmap fonts, Window fonts

Character

Properties

Graphics

Graphic

Properties

*1

Display Properties Normal, blink, bold, shadow, transparent, italic

Colors 65,536 colors (without blinking) / 32,768 colors (with blinking)

Lines Line, continuous line, box, parallelogram, polygon

Circles Circle, arc, sector, ellipse, elliptical arc

Others Pattern, image, data display (graphics library, data sheets)

Line Types

Tile Patterns 16 types (including 8 user-definable patterns)

Display Properties Normal, blinking

Colors 65,536 colors (without blinking) / 32,768 colors (with blinking)

Color Selection Foreground, background, boundary (line)

*1 For more information, refer to the V9 Series Reference Manual 1.

Japanese, English/Western Europe, Chinese (Traditional), Chinese (Simplified), Korean,

6 types (thin, thick, dotted, chain, dashed, two-dot chain)

Line thickness can be selected from 1 to 8 points (excluding thick lines).

Central Europe, Cyrillic, Greek, Turkish, and Baltic

Page 40

Function Performance Specifications

Item Specification

Screens Max. 4,000

Screen Memory 64 MB of flash memory

Switches

Switch Actions

Lamps

Graphs

Numerical Data

Display

Data

Setting

Messages Max. 32,768 lines

Macro Blocks Max. 1,024

Graphics Library Max. 2,560

Overlap Library Max. 4,000

Screen Library Max. 4,000

Data Blocks Max. 1,024

Patterns Max. 1,024

Data Sheets Max. 1,024

Tags Max. 65,536 lines

Page Blocks Max. 2,048

Direct Blocks Max. 1,024

Screen Blocks Max. 1,024

Comments Max. 32,767

Logging Server Fixed cycle, trigger

Alarm Server Real time, alarm, event

Recipes Max. 256

Scheduler Max. 64

MES Setting Max. 256

Device Memory Map Max. 32 8 (PLC1 to PLC8)

Time Display Provided

Hard Copy Provided

Buzzer Provided, 3 sounds (short beep, long beep, continuous beep)

Auto OFF Function Always ON, custom setting

Self-diagnostic Function

Character

Display

Message

Display

*1 The maximum number of parts that can be placed on one screen is 4,096.

For more information on limitations regarding part placement, refer to the V9 Series Operation Manual.

*2 Layer: 11 layers per screen (base + 10 overlap displays including global overlap)

*3 For more information, refer to the separate V9 Series Troubleshooting/Maintenance Manual.

Max. 4,096 per screen

Set, reset, momentary, alternate, illuminated

It is possible to press a function switch and a switch on the display at the same time.

Reverse, blinking, exchange of graphics

Max. 4,096 per screen

Pie, bar, panel meter and closed area graph: Max. 4,096 per screen

Statistics and trend graphs: Max. 256 per layer

Max. 4,096 per screen

Max. 4,096 per screen

Max. 4,096 per screen

Maximum number of characters per line: 100 one-byte characters

Touch switch test function

Confirmation function that uses the status bar

Network diagnostic functions (network test, duplicate IP address test)

*1

(including slider switches and scroll bars)

*1

*1

*1

*3

*3

2. Standard Model 2-15

2

Specifications

*1

*2

*3

Page 41

2-16 2. Standard Model

312.0

245.2

327.8

261.0

47.9

7.0

313.0

246.2

54.9

+0.5

-0

+0.5

-0

Side view

Panel cut-out dimensions

Rear view

Bottom view

(Unit: mm)

Front view