Page 1

V8 Series

SYSTEM

F 1

F 2

F 3

F 4

F 5

F 6

F 7

Page 2

Record of Revisions

Reference numbers are shown at the bottom left corner on the back cover of each manual.

Printing Date Reference No. Revised Contents

December, 2007 2016NE0 First edition

May, 2008 2016NE1 Second edition

• V810C/V808C added

• USB keyboard/mouse etc. added

August, 2009 2016NE2 Third edition

• V812/V810/V808 (Hardware version

• Error message during card transfer modified

“j” or later) added

Page 3

Page 4

Preface

Thank you for selecting the V8 series.

For correct set-up of the V8 series, you are requested to read through this manual to understand more about the

product.

The manuals shown below are related manuals for the V8 series. Refer to them as necessary.

Manual Name Contents Reference No.

V8 Series Reference Manual The functions and instructions of the V8

series are explained.

V8 Series Reference Additional Functions Additional specifications for the Reference

Manual are explained.

V Series Macro Reference An overview of macros as well as macro

editor operations and macro command

descriptions are explained in detail.

V8 Series Introductory Manual The basic operating procedure of V-SFT

version 5 is explained in detail.

V8 Series Connection Manual The connection and communication

parameters for the V8 series and controllers

are explained in detail.

V Series DLL Function Specifications An overview and contents of DLL files used

for Ethernet (HKEtn20.DLL) and CF card

(VCFAcs.DLL) are explained in detail.

For further details about controllers (PLCs, temperature controllers, etc.), refer to the manual issued by each

controller manufacturer.

1055NE

1060NE

1056NE

1057NE

2201NE

1059NE

Notes:

1. This manual may not, in whole or in part, be printed or reproduced without the prior written consent of

Hakko Electronics Co., Ltd.

2. The information in this manual is subject to change without prior notice.

3. Windows and Excel are registered trademarks of Microsoft Corporation in the United States and other

countries.

4. All other company names or product names are trademarks or registered trademarks of their

respective holders.

5. If the specifications of the software do not correspond with the contents of this manual, the software

specifications have priority.

Page 5

Page 6

Notes on Safe Usage of MONITOUCH

In this manual, you will find various notes categorized under the following levels with the signal words “DANGER,”

and “CAUTION.”

DANGER

CAUTION

Note that there is a possibility that the item listed with may have serious ramifications.

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury and could cause property damage.

CAUTION

DANGER

• Never use the output signal of MONITOUCH for operations that may threaten human life or damage the

system, such as signals used in case of emergency. Please design the system so that it can cope with the

malfunctions of a touch switch. A malfunction of a touch switch will result in machine accident or damage.

• Turn off the power supply when you set up the unit, connect new cables or perform maintenance or

inspections. Otherwise, electrical shock or damage may occur.

• Never touch any terminals while the power is on. Otherwise, electric shock may occur.

• You must put a cover on the terminals on the unit when you turn the power on and operate the unit.

Otherwise, electric shock may occur.

• The liquid crystal in the LCD panel is a hazardous substance. If the LCD panel is damaged, do not ingest

the leaked liquid crystal. If the liquid crystal spills on skin or clothing, use soap and wash off thoroughly.

• Never disassemble, recharge, deform by pressure, short-circuit, reverse the polarity of the lithium battery,

nor dispose of the lithium battery in fire. Failure to follow these conditions will lead to explosion or ignition.

• Never use a lithium battery that is deformed, leaks, or shows any other signs of abnormality. Failure to

follow these conditions will lead to explosion or ignition.

• The power lamp flashes when the backlight is at the end of life or is faulty. However, the switches on the

screen are operable at this time. Do not touch the screen when the screen becomes dark and the power

lamp flashes. Otherwise, a malfunction may occur and result in machine accident or damage.

Page 7

CAUTION

• Check the appearance of the unit when it is unpacked. Do not use the unit if any damage or deformation is

found. Failure to do so may lead to fire, damage or malfunction.

• For use in a facility or for a system related to nuclear energy, aerospace, medical, traffic equipment, or

mobile installations, please consult your local distributor.

• Operate (or store) MONITOUCH under the conditions indicated in this manual and related manuals. Failure

to do so could cause fire, malfunction, physical damage or deterioration.

• Understand the following environmental limits for use and storage of MONITOUCH. Otherwise, fire or

damage to the unit may result.

- Avoid locations where there is a possibility that water, corrosive gas, flammable gas, solvents, grinding

fluids or cutting oil can come into contact with the unit.

- Avoid high temperature, high humidity, and outside weather conditions, such as wind, rain or direct

sunlight.

- Avoid locations where excessive dust, salt, and metallic particles are present.

- Avoid installing the unit in a location where vibration or physical shock may be transmitted.

• Equipment must be correctly mounted so that the main terminal of MONITOUCH will not be touched

inadvertently. Otherwise, an accident or electric shock may occur.

• Tighten the fixtures of MONITOUCH with a torque in the specified range. Excessive tightening may distort

the panel surface. Loose tightening may cause MONITOUCH to come off, malfunction or be short-circuited.

• Check periodically that terminal screws on the power supply terminal block and fixtures are firmly tightened.

Loosened screws may result in fire or malfunction.

• Tighten terminal screws on the power supply terminal block equally to a torque of 0.8 N•m for MONITOUCH.

Improper tightening of screws may result in fire, malfunction, or trouble.

• MONITOUCH has a glass screen. Do not drop or give physical shock to the unit. Otherwise, the screen

may be damaged.

• Connect the cables correctly to the terminals of MONITOUCH in accordance with the specified voltage and

wattage. Over-voltage, over-wattage, or incorrect cable connection could cause fire, malfunction or damage

to the unit.

• Be sure to establish a ground of MONITOUCH. The FG terminal must be used exclusively for the unit with

the level of grounding resistance less than 100 Ω. Otherwise, electric shock or a fire may occur.

• Prevent any conductive particles from entering into MONITOUCH. Failure to do so may lead to fire,

damage, or malfunction.

• After wiring is finished, remove the paper used as a dust cover before starting to operate MONITOUCH.

Operation with the cover attached may result in accident, fire, malfunction, or trouble.

• Do not attempt to repair MONITOUCH at your site. Ask Hakko Electronics or the designated contractor for

repair.

• Do not repair, disassemble or modify MONITOUCH. Hakko Electronics Co., Ltd. is not responsible for any

damages resulting from repair, disassembly or modification of MONITOUCH that was performed by an

unauthorized person.

• Do not use a sharp-pointed tool when pressing a touch switch. Doing so may damage the screen. Doing so

may damage the screen.

• Only experts are authorized to set up the unit, connect the cables or perform maintenance and inspection.

• Lithium batteries contain combustible material such as lithium or organic solvent. Mishandling may cause

heat, explosion or ignition resulting in fire or injury. Read related manuals carefully and handle the lithium

battery correctly as instructed.

• When using a MONITOUCH that has analog switch resolution with resistance film, do not press two or more

points on the screen at the same time. If two or more positions are pressed at the same time, the switch

located between the pressed positions activates.

• Take safety precautions during such operations as setting change during running, forced output, start, and

stop. Any misoperation may cause unexpected machine motions, resulting in machine accident or damage.

• In facilities where a failure of MONITOUCH could lead to accident threatening human life or other serious

damage, be sure that the facilities are equipped with adequate safeguards.

• At the time of disposal, MONITOUCH must be treated as industrial waste.

• Before touching MONITOUCH, discharge static electricity from your body by touching grounded metal.

Excessive static electricity may cause malfunction or trouble.

• Insert the CF card into the V8 unit in the correct orientation. Failure to do so may damage the CF card or the

socket at the unit.

• The LED lamp on the CF card interface cover illuminates in red when the power is supplied to the CF card.

Never remove the CF card or turn off the power of MONITOUCH while the LED lamp is lit. Doing so may

destroy the data on the CF card. Check that the LED lamp has gone off before removing the CF card or

turning off the power of MONITOUCH.

Page 8

[General Notes]

• Never bundle control cables nor input/output cables with high-voltage and large-current carrying cables such

as power supply cables. Keep these cables at least 200 mm away from the high-voltage and large-current

carrying cables. Otherwise, malfunction may occur due to noise.

• When using MONITOUCH in an environment where a source of high-frequency noise is present, it is

recommended that the FG shielded cable (communication cable) be grounded at its ends. However, the cable

may be grounded only at one end if this is necessary due to unstable communication conditions or for any

other reason.

• Plug connectors or sockets of MONITOUCH in the correct orientation. Failure to do so may lead to damage or

malfunction.

• If a LAN cable is inserted into the MJ1 or MJ2 connector on MONITOUCH, the counterpart device may be

damaged. Check the indication on the unit and insert a cable into the correct position.

• Do not use thinners for cleaning because they may discolor MONITOUCH surface. Use alcohol or benzine

commercially available.

• If a data receive error occurs when MONITOUCH and the counterpart (PLC, temperature controller, etc.) are

started at the same time, read the manual for the counterpart unit and remove the error correctly.

• Avoid discharging static electricity on the mounting panel of MONITOUCH. Static charges can damage the

unit and cause malfunctions. Otherwise, malfunction may occur due to noise.

• Avoid prolonged display of any fixed pattern. Due to the characteristics of the liquid crystal display, an

afterimage may occur. If a prolonged display of a fixed pattern is expected, use the auto OFF function of the

backlight.

[Notes on LCD]

Note that the following conditions may occur under normal circumstances.

• The response time, brightness and colors of MONITOUCH may be affected by the ambient temperature.

• Tiny spots (dark or luminescent) may appear on the display due to the liquid crystal characteristics.

• There are variations in brightness and colors on each unit.

• Cold cathode tubes are incorporated into the LCD display for backlights. Optical properties (brightness,

irregular colors, etc.) may change in a low-temperature environment or over time of operation.

Page 9

Page 10

Preface

Notes on Safe Usage of MONITOUCH

Chapter 1 Product Outline

1. Features......................................................................................................... 1-1

2. Models and Peripheral Equipment ................................................................. 1-2

MONITOUCH Models ................................................................................................ 1-2

Peripheral Equipment ................................................................................................ 1-4

3. System Composition ......................................................................................1-7

System Composition of V8i/V8iC Series.................................................................... 1-7

System Composition of V8/V8C Series...................................................................... 1-8

Chapter 2 Specifications

1. Specifications.................................................................................................2-1

General Specifications............................................................................................... 2-1

Installation Specifications........................................................................................... 2-4

Display Specifications................................................................................................ 2-4

Touch Switch Specifications ...................................................................................... 2-4

Function Switch Specifications................................................................................... 2-4

Interface Specifications.............................................................................................. 2-5

Clock and Backup Memory Specifications................................................................. 2-5

Drawing Environment................................................................................................. 2-6

Display Function Specifications ................................................................................. 2-6

Function Performance Specifications......................................................................... 2-7

2. Dimensions and Panel Cut-out.......................................................................2-8

External Dimensions and Panel Cut-out Dimensions for V812S / V812iS................. 2-8

External Dimensions and Panel Cut-out Dimensions for V810S / V810iS / V810T /

V810iT........................................................................................................................ 2-9

External Dimensions and Panel Cut-out Dimensions for V810C / V810iC .............. 2-10

External Dimensions and Panel Cut-out Dimensions for V808S / V808iS............... 2-11

External Dimensions and Panel Cut-out Dimensions for V808C / V808iC .............. 2-12

3. Names and Functions of Components.........................................................2-13

Contents

4. Serial Connector (CN1)............................................................... ... .............. 2-16

Connector for a Controller........................................................................................ 2-16

5. Modular Jack (MJ1 / MJ2)............................................................................ 2-17

Modular Jack 1 (MJ1) / 2 (MJ2) ............................................................................... 2-17

6. USB Connector ............................................................................................ 2-20

USB-A (Master Port)................................................................................................ 2-20

USB-B (Slave Port).................................................................................................. 2-24

Securing USB Cable................................................................................................ 2-29

Page 11

7. LAN Connector (LAN)...................................................................................2-32

LAN Connector......................................................................................................... 2-32

Wiring....................................................................................................................... 2-33

8. CF Card ........................................................................................................2-34

CF Card Connector.................................................................................................. 2-34

Notes on Handling the CF Card............................................................................... 2-35

Chapter 3 Installation

1. Mounting Procedure........................................................................................3-1

Mounting Procedure................................................................................................... 3-1

Mounting Angle.......................................................................................................... 3-2

2. Power Supply Cable Connection....................................................................3-3

Power Supply Cable Connection ............................................................................... 3-3

Notes on Usage of 100 - 240 VAC Specifications...................................................... 3-4

Grounding .................................................................................................................. 3-4

Chapter 4 Instructions

1. Coin-type Lithium Battery (V7-BT)..................................................................4-1

Battery Usage ............................................................................................................ 4-1

Battery Mounting Procedure ...................................................................................... 4-1

Battery Voltage Drop Detection.................................................................... .............. 4-2

Battery Replacement.................................................................................................. 4-3

2. DIP Switches.................................. .................................... .............................4-5

DIP Switch (DIPSW) Setting...................................................................................... 4-5

3. Function Switches...........................................................................................4-7

Types ......................................................................................................................... 4-7

Function of Switches.................................................................................................. 4-7

Chapter 5 MONITOUCH Operations

1. Before Operation.............................................................................................5-1

Procedure before Operation....................................................................................... 5-1

Transferring Screen Data to MONITOUCH for the First Time ...................................5-2

2. Main Menu Screen..........................................................................................5-3

Displaying the Main Menu Screen ............................................................................. 5-3

Main Menu Screen..................................................................................................... 5-3

[Main Menu] Switch.................................................................................................... 5-4

Main Menu Screen Composition................................................................................ 5-4

1. RUN.................................................................................................................... 5-5

2. Language Selection............................................................................................ 5-5

3. Communication Parameter................................................................................. 5-6

4. Ethernet.............................................................................................................. 5-7

4-1. IP Address Setting of the V8 Series......................................................... 5-8

5. SRAM/Clock..................................................................................................... 5-11

5-1. Date and Time Adjustment..................................................................... 5-12

5-2. Formatting SRAM................................................................................... 5-12

Page 12

5-3. Japanese FEP Function Learning/User Phrase Area............................ 5-13

6. Extension Program Information........................................................................ 5-14

7. Card Transfer................................................................................................... 5-15

7-1. Folder Configuration in the CF Card...................................................... 5-17

7-2. Transferring Screen Data....................................................................... 5-18

7-3. Saving Backup Copies of SRAM............................................................ 5-24

7-4. Transferring Ethernet Table (Under Development)................................ 5-26

7-5. Deleting Data on the CF Card................................................................ 5-27

7-6. Transferring Data to the Card Recorder................................................. 5-28

7-7. Message Dialog Displayed during Data Transfer (between V8 and Card) ....

5-30

8. RGB Adjustment............................................................................................... 5-31

8-1. Adjusting the Display Position of the RGB Screen................................. 5-32

9. I/O Test............................................................................................................. 5-34

9-1. Self-loop Test......................................................................................... 5-35

9-2. USB Test................................................................................................ 5-40

9-3. Printer Test............................................................................................. 5-40

9-4. [SYSTEM] Switch & Function Switch Test............................................. 5-41

9-5. Touch Switch Test.................................................................................. 5-42

9-6. Keyboard Selection................................................................................ 5-44

10. Extended Function Setting ............................................................................... 5-45

10-1. Setting Baud Rate between V8 Series and Modem............................... 5-46

10-2. Setting V-Link Local Port Number.......................................................... 5-47

10-3. Local Port Number Setting for Modbus Slave Communication.............. 5-47

Chapter 6 Error Handling

1. Error Messages.............................................................................................. 6-1

1. Communication Error ......................................................................................... 6-1

1-1. Error Messages for Network Communication .......................................... 6-2

2. Data Loading.............................................................. ..................... ................... 6-6

3. Warning.............................................................................................................. 6-6

4. SYSTEM ERROR............................................................................................... 6-7

5. Touch Switch Is Active ....................................................................................... 6-7

2. Troubleshooting..............................................................................................6-8

In the Event of an Error.............................................................................................. 6-8

Probable Symptoms................................................................................................... 6-8

Chapter 7 Inspection and Maintenance

1. Inspection and Maintenance ............................................................. .. ... ........ 7-1

Daily Inspection.......................................................................................................... 7-1

Periodical Inspection.................................................................................................. 7-1

Page 13

2. Warranty Policy...............................................................................................7-2

Inquiries about Failure................................................................................................ 7-2

Warranty Period......................................................................................................... 7-2

Free-of-charge Repair................................................................................................ 7-2

Chargeable Repair..................................................................................................... 7-2

Inquiry Form....................................................... ..................... ..................... .............. 7-3

Page 14

1

1. Features

2. Models and Peripheral Equipment

3. System Composition

Product Outline

Page 15

Page 16

1. Features 1-1

1. Features

The V8 series inherits and heightens the features of the V7 series as described below.

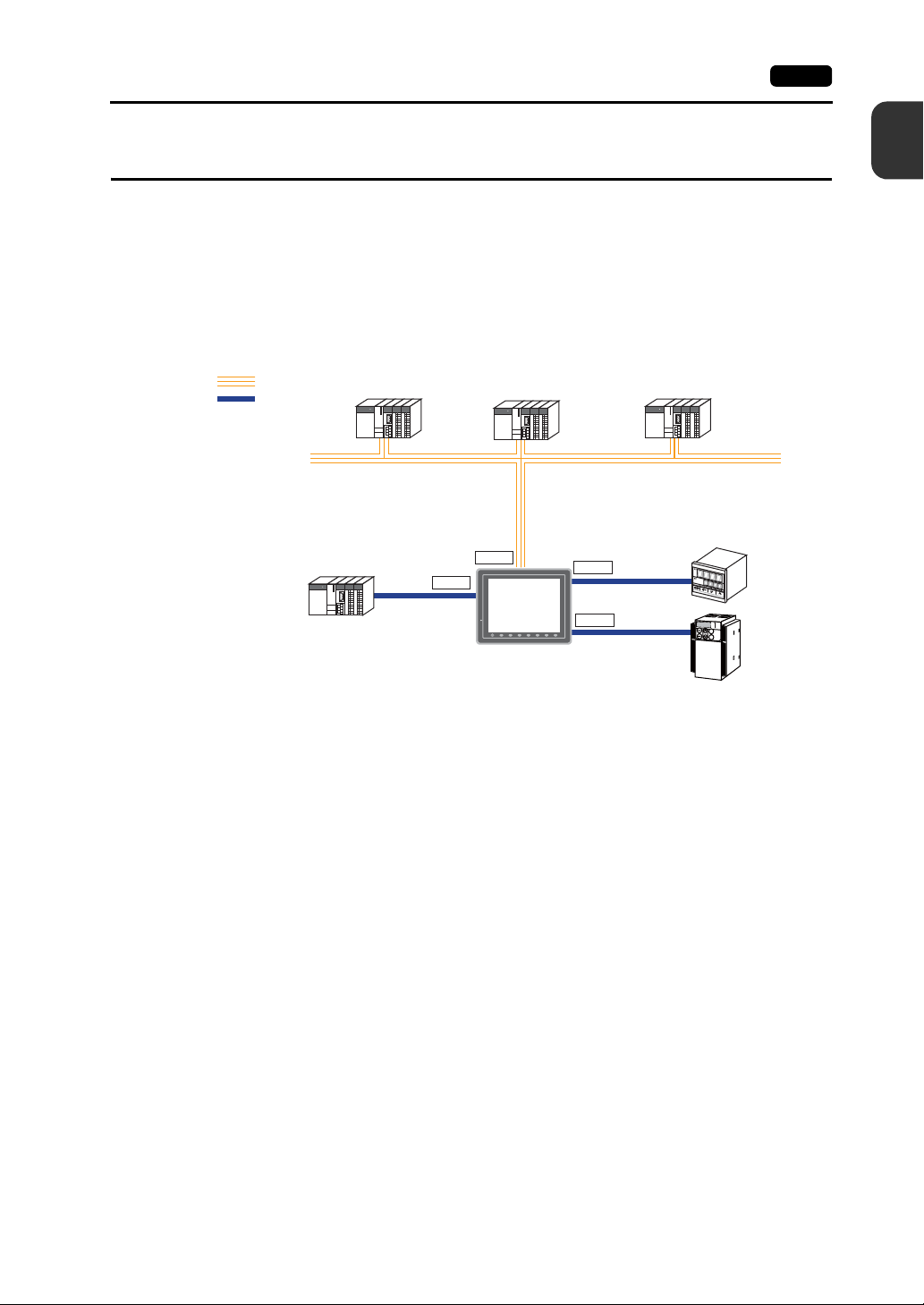

1. 8-way communication

A maximum of eight controllers, such as PLCs or peripheral equipment, of different models and

manufacturers can be connected to one V8 series via mixed network of Ethernet (max. 8

protocols) and serial communications (max. 3 protocols).

The V8 series can communicate with eight types of devices at one time and can exchange data

among connected devices.

Connection example: serial 3 ports + Ethernet

Ethernet

Serial

Manufacturer

A

CN1

LAN

1

Product Outline

A maximum of 5 types

of devices can be

connected.

Manufacturer

B

MJ1

V8

MJ2

SYSTEM

F 7F 6F 5F 4F 3F 2F 1

Manufacturer

C

K

E

Y

P

A

D

Hz

C

O

N

T

R

O

L

A

P

R

O

M

O

D

E

KW

PRG

R

E

S

E

T

R

U

N

FUNC

D

A

T

A

S

T

O

P

Inv

er

te

r

Ethernet

2. 65536-color display

A high-definition display of 65,536 colors (without blinks, 32,768 colors with blinks) is possible.

Photographs (JPEG) or illustrations (bitmap) are displayed close to the real image. An operator

can view operating conditions easily because of the increased viewability.

3. 16770k-color display & 30-frame display per second for video (V812iS/V810iS/V810iT/V808iS

only)

Video image is displayed in 16770k-color and with 30 frames per second.

Even if takt time is short, the video image can be displayed in real time.

* For V808iS: 260k-color

4. Stroke font

Unlike standard bitmap fonts, the font size can be adjusted as desired regardless of the display

resolution. Quality expression is possible.

5. Process for screen data creation is reduced with use of “component parts”.

A “component part” is a part which consists of multiple components having different functions or

different macro programs.

Screen data with advanced functions can be created easily and rapidly.

6. CF-card 2 drives provided

CF cards can be used at the same time in both built-in CF interface and USB-CFREC.

Data can be transmitted between two CF cards. You can use CF cards for various purposes as

required.

7. PictBridge-compatible printer available

A PictBridge-compatible printer can be connected.

Simple printing using a USB cable is possible.

Page 17

1-2 2. Models and Peripheral Equipment

2. Models and Peripheral Equipment

MONITOUCH Models

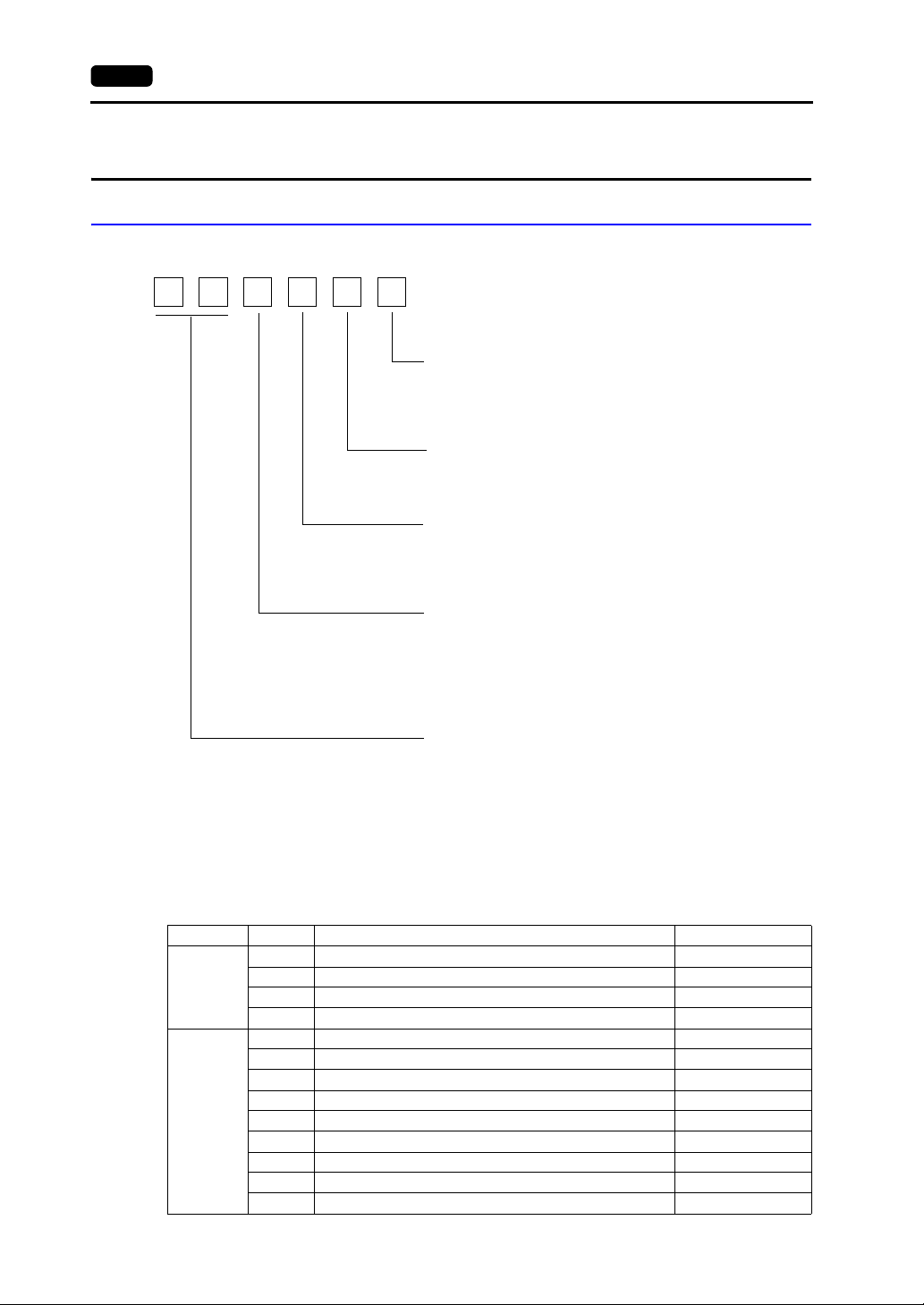

The model name consists of the following information.

V8

Power supply specification

None: 100 - 240 VAC specification

D: 24 VDC specification

(CE/UL/cUL approved)

Touch switch specification

None: Analog

M: Matrix

Device specification

S: TFT color LCD (SVGA)

T: TFT color LCD (VGA)

C: TFT color LCD (VGA)

Functional specification

i: High-performance type

(With built-in LAN port and optional unit port

None: Standard type

(Without built-in LAN port nor

optional unit port)

Screen size

12: 12.1-inch

10: 10.4-inch

08: 8.4-inch

* V810iC/ V808iC: without optional unit port

The following models are available.

Analog resistance film type

Series Model Specifications Remarks

V812S TFT color, 800 × 600 dots, standard, AC power supply

V812 series

12-inch

V810 series

10-inch

V812SD TFT color, 800 × 600 dots, standard, DC power supply CE/UL/cUL approved

V812iS TFT color, 800 × 60 0 dot s, h igh-performan ce, AC power supply

V812iSD TFT color, 800 × 600 dots, high-perf ormance, DC power supply CE/UL/cUL approved

V810S TFT color, 800 × 600 dots, standard, AC power supply

V810SD TFT color, 800 × 600 dots, standard, DC power supply CE/UL/cUL approved

V810iS TFT color, 800 × 60 0 dot s, h igh-performan ce, AC power supply

V810iSD TFT color, 800 × 600 dots, high-performance, DC power supply CE/UL/cUL approved

V810T TFT color, 640 × 480 dots, standard, AC power supply

V810TD TFT color, 640 × 480 dots, standard, DC power supply CE/UL/cUL approved

V810iT TFT color, 640 × 480 dots, high-perf ormance, AC power supply

V810iTD TFT color, 640 × 480 dots, high-performance, DC power supply CE/UL/cUL approved

V810C TFT color, 640 × 480 dots, standard, AC power supply

*

)

Page 18

2. Models and Peripheral Equipment 1-3

Series Model Specifications Remarks

V810 series

10-inch

V808 series

8-inch

V810CD TFT color, 640 × 480 dots, standard, DC power supply CE/UL/cUL approved

V810iC TFT color, 640 × 480 dots, high-p erforman ce, AC power supply

V810iCD TFT color, 640 × 480 dots, high-performance, DC power supply CE/UL/cUL approved

V808SD TFT color, 800 × 600 dots, standard, DC power supply

V808iSD TFT color, 800 × 600 dots, high-performance, DC power supply

V808CD TFT color, 640 × 480 dots, standard, DC power supply

V808iCD TFT color, 640 × 480 dots, high-performance, DC power supply

CE/UL/cUL approved

Matrix resistance film type

Series Model Specifications Remarks

V812SM TFT color, 800 × 600 dots, standard, AC power supply

V812 series

12-inch

V810 series

10-inch

V812SMD TFT color, 800 × 600 dots, standard, DC power supply CE/UL/cUL approved

V812iSM

V812iSMD

V810TM TFT color, 640 × 480 dots, standard, AC power supply

V810TMD TFT color, 640 × 480 dots, standard, DC power supply CE/UL/cUL approved

V810iTM

V810iTMD

V810CM TFT color, 640 × 480 dots, standard, AC power supply

V810CMD TFT color, 640 × 480 dots, standard, DC power supply CE/UL/cUL approved

V810iCM

V810iCMD

TFT color, 800 × 600 dots, high-performance, AC power

supply

TFT color, 800 × 600 dots, high-performance, DC power

supply

TFT color, 640 × 480 dots, high-performance, AC power

supply

TFT color, 640 × 480 dots, high-performance, DC power

supply

TFT color, 640 × 480 dots, high-performance, AC power

supply

TFT color, 640 × 480 dots, high-performance, DC power

supply

CE/UL/cUL approved

CE/UL/cUL approved

CE/UL/cUL approved

1

Product Outline

Page 19

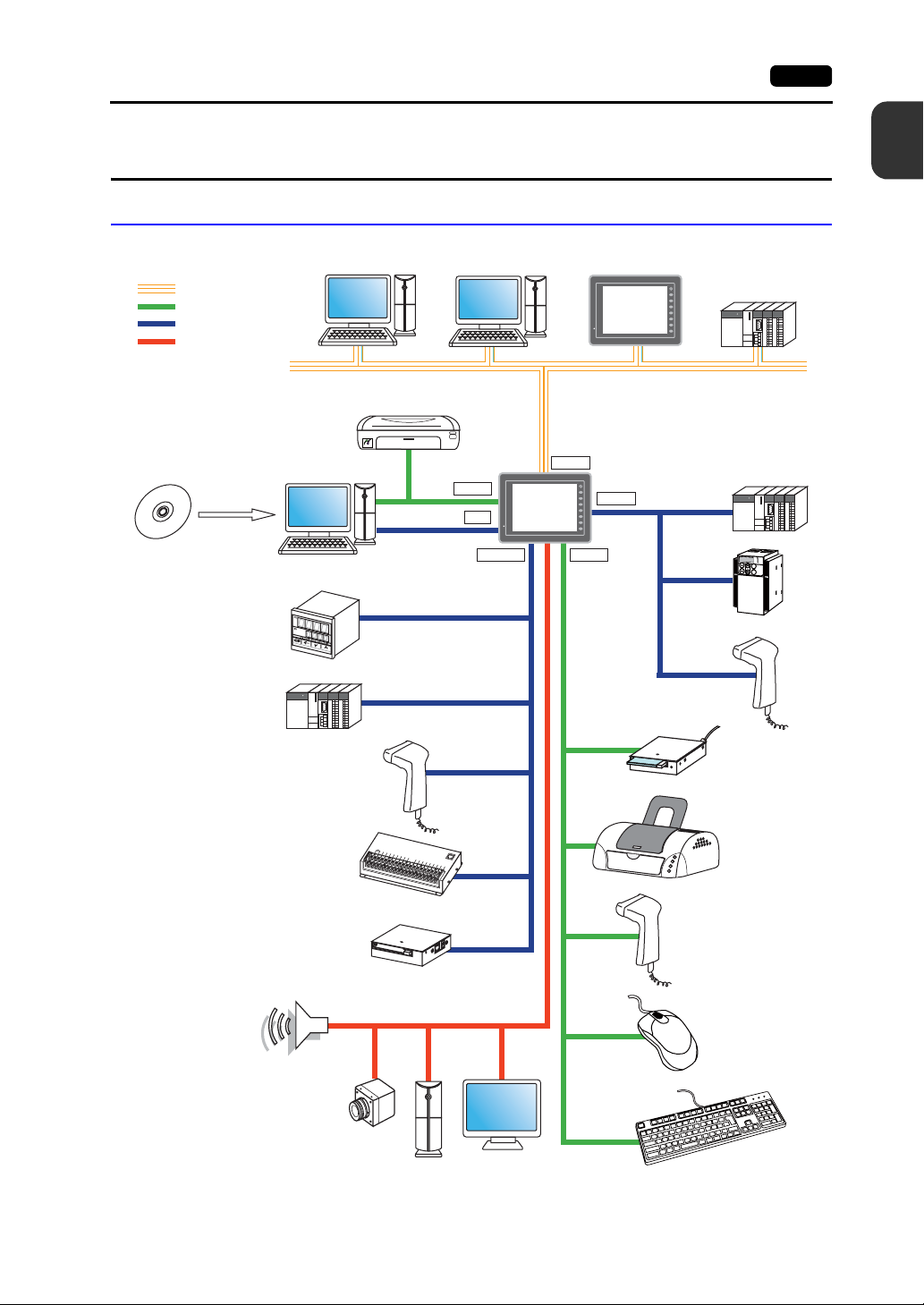

1-4 2. Models and Peripheral Equipment

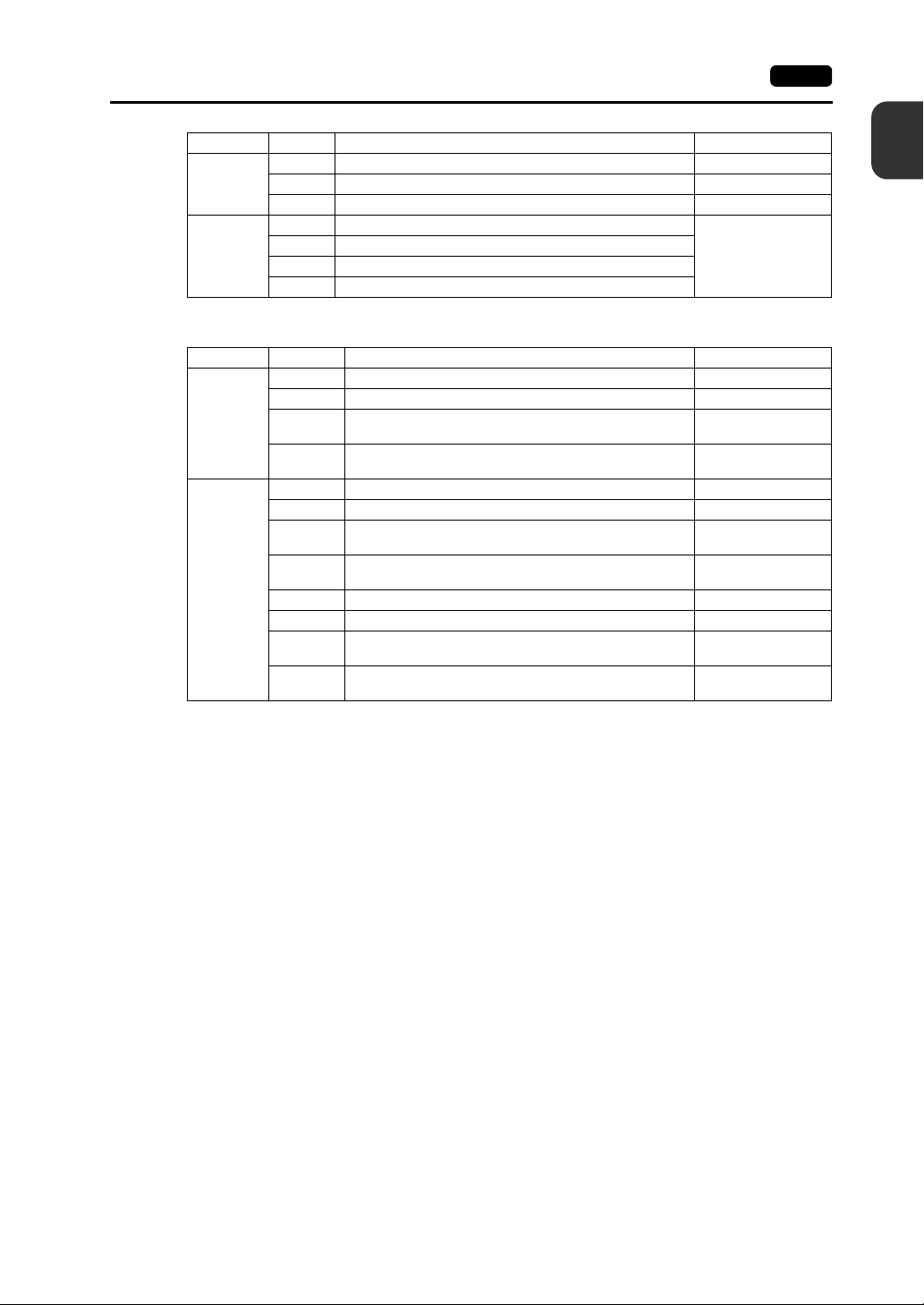

Peripheral Equipment

The following devices are available as options for the V8 series.

Drawing Tool

V-SFT-5 (configuration software: English version)

Application software for editing screen data for MONITOUCH.

(Windows98SE/NT4.0/Me/2000/XP/XP 64 Edition/Vista 32-bit compatible)

V-CP (screen data transfer cable) 3 m

Used for connection between the V8 series and a computer, or a computer and the card

recorder (CREC).

Optional Unit

GU-xx

Optional unit for the V812iS/ V810iS/ V810iT/ V808iS

GU-00 → Video input (4 channels) + sound output (1 channel)

GU-01 → RGB input (1 channel) + sound output (1 channel)

GU-02 → RGB output (1 channel) + sound output (1 channel)

GU-03 → Sound output (1 channel)

GU-10 → Video input (2 channels) + RGB input (1 channel)

GU-11 → RGB input (2 channels)

Communication Interface Unit

CU-xx

Communication unit used for each network

CU-00 → OPCN-1

x1

x10

SD

T2

T1

CU-01 → T-LINK

CU-02 → CC-LINK

CU-03-3 → Ethernet

CU-04 → PROFIBUS-DP

CU-06 → SX BUS

CU-07 → DeviceNet (I/F driver under development)

CU-08 → FL-NET

Cable

V6-BCD (barcode reader connection cable) 3 m

Used for connection between the V8 series and a barcode reader.

V6-MLT (multi-link 2 master cable) 3 m

Used for multi-link 2 connection between the V8 master station and the V8 slave sta tion.

Page 20

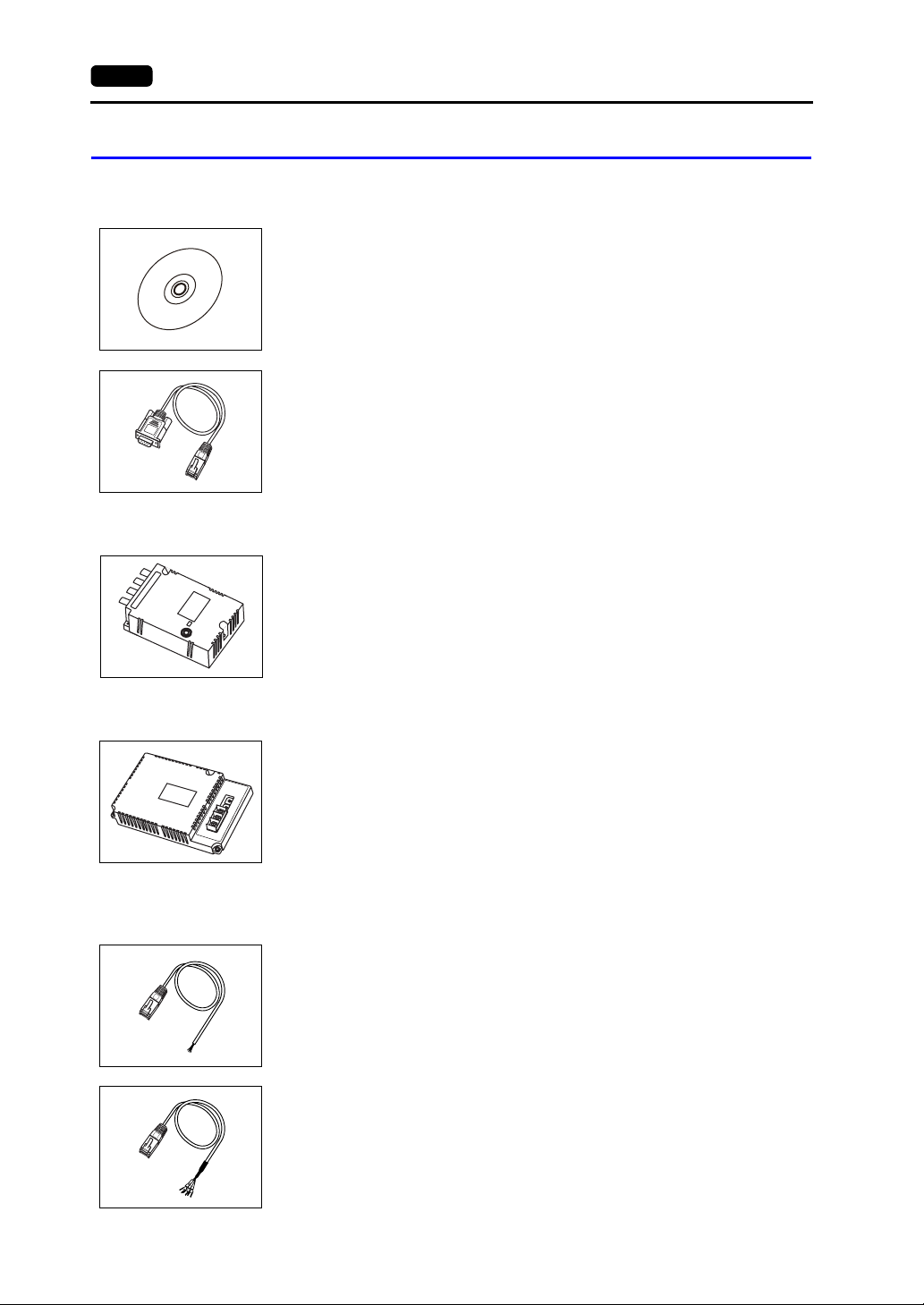

2. Models and Peripheral Equipment 1-5

V6-TMP (connection cable for controllers)

Used for connection between the V8 series and a controller.

V6-TMP: 3 m

V6-TMP-5M: 5 m

V6-TMP-10M: 10 m

D9-D25 (D-sub9 to D-sub25 conversion cable) 0.1 m

Conversion cable for use of the communication cable used at CN1 (D-sub 25 pin) of the

V6/V7 series at CN1 (D-sub 9 pin) of the V8 series

UA-FR (for USB-A port) 1 m

Cable for USB-A (master), with which connection from the front of the control cabinet is

possible.

UB-FR (for USB-B port) 1 m

Cable for USB-B (slave), with which connection from the front of the control cabinet is

possible.

1

Product Outline

Protective Sheet

Other Options

V8xx-GS

Used for protecting the operation panel surface (5 pcs./set).

V812-GS → V812 series

V810-GS → V810 series

V808-GS → V808 series

V8xx-GSN10

Used for protecting the operation panel surface (5 pcs./set, anti-glare treated).

The sheet is colored in light gray and has graininess on its surface to avoid light reflection.

V812-GSN10 → V812 series

V810-GSN10 → V810 series

V808-GSN10 → V808 series

V7-BT (replacement battery)

Replacement lithium battery for the V8 series, V7 series and V606e.

Page 21

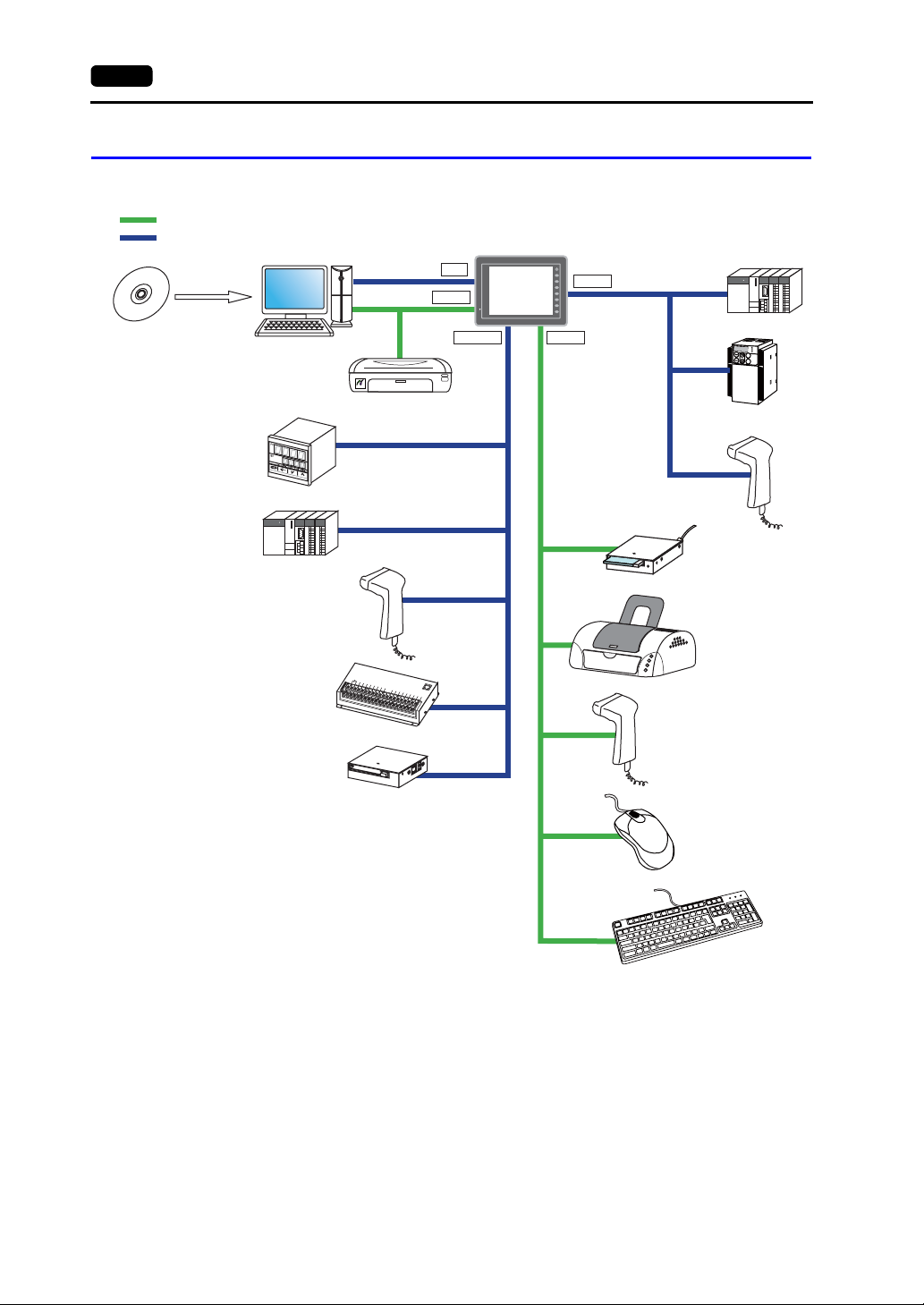

1-6 2. Models and Peripheral Equipment

V8xxx-FL (replacement backlight for TFT)

Replacement backlight for the V8 series.

V812-FL → V812 series

V810-FL → V810S/V810T/V810C series

V808S-FL → V808S series

V808C-FL → V808C series

TC-D9 (terminal converter)

Used for connection between the V8 series and a controller at the RS-422/485 terminal

+5V

SG

+SD

-SD

+RD

-RD

FG

block via CN1 (D-sub 9-pin).

V-MDD (ACPU/QnACPU/FXCPU dual port interface)

Add-on connector with two ports, specifically desi gned for the connector on the

V

-

M

GPP

D

1 2 3

D

GD

MITSUBISHI’s ACPU/QnACPU/FXCPU programmer. Operability can be improved when

directly connecting the V8 series to the ACPU/QnACPU/FXCPU programmer.

V-I/O (serial extension I/O)

DC24V

IN1 IN3

FG

IN5

IN0 IN2

IN7 IN9

IN4

IN11

IN6

IN13 IN15

IN8

IN10

IN12

IN14

COM+

OUT0

OUT1 OUT3 OUT5 OUT7

OUT2 OUT4

MJ1

OUT8 OUT10

OUT6 COM1

OUT12 OUT14

OUT9

COM2

OUT11

OUT13

OUT15

Used as an external I/O unit. It has 16 inputs and 16 outputs.

Card Recorder

USB-CFREC (USB CF card recorder)

Unit that connects to the USB-A port of the V8 series and makes a CF card available.

CREC (card recorder)

Used for creating a backup copy of screen data or works as an external memory storage

system for memory manager and data logging functions by connecting to the MJ port.

REC-MCARD (memory card compliant with JEIDA ver. 4.0)

Used with the card recorder (CREC) when making a backup copy of screen data or saving

data on an external medium for memory manager and data logging functions.

SRAM 256 K, 512 K, 1 M, 2 M, 4 Mbytes

FLASH ROM 4 Mbytes

Page 22

3. System Composition 1-7

3. System Composition

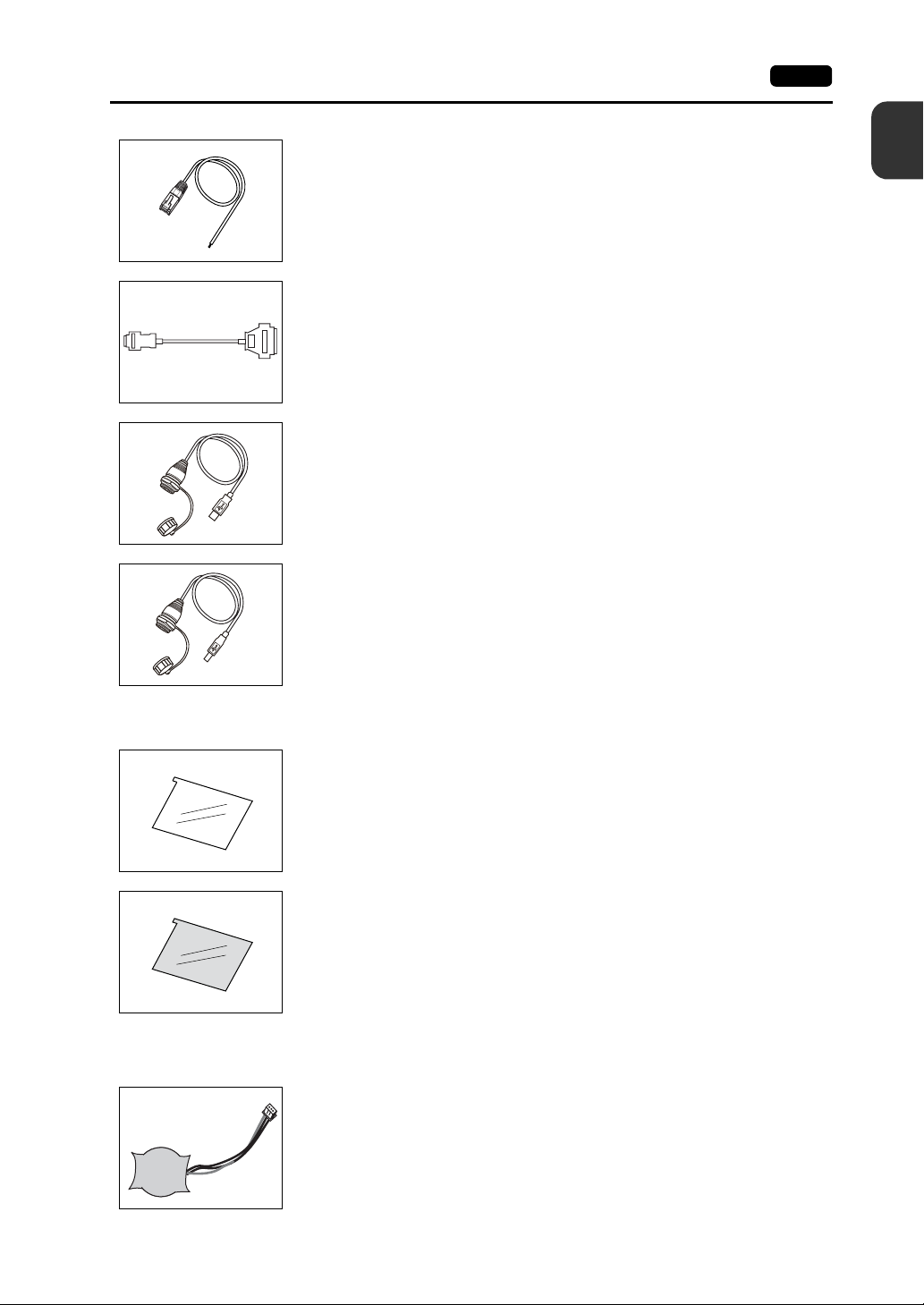

System Composition of V8i/V8iC Series

The following illustration shows possible system configurations using the V8i/V8iC series.

Ethernet

USB

Serial

Optional unit

V series

configuration

software

"V-SFT-5"

Temperature

controller, inverter

Computer (PC)

Printer (PictBridge)

PictBridge

Creating screens

Computer (PC)

Computer (PC)

"V-CP"

Transferring

screen data

"V6-TMP"

USB-B

MJ1

V8i

LAN

1

Product Outline

SYSTEM

F 1

F 2

F 3

F 4

V8i

F 5

F 6

F 7

Ethernet

PLC/general-purpose

SYSTEM

F 1

F 2

F 3

F 4

F 5

F 6

F 7

CN1

Communication

cables

USB-AMJ1/MJ2

computer

K

E

Y

P

A

D

Hz

C

O

N

T

R

O

L

A

P

RO

M

O

D

E

KW

PRG

R

E

S

E

T

R

U

N

FUNC

D

A

T

A

S

T

O

P

Inve

rte

r

Temperature controller,

inverter

PLC

"V6-BCD"

Barcode reader

Serial extension I/O unit

"V-I/O"

N

5

I

N

0

I

N

7

I

N

2

IN

4

I

N

6

I

N

8

M

J

I

N

9

I

N

1

1

I

N

1

1

I

N

1

3

I

N

1

5

0

I

N

1

O

2

U

T1

I

N

O

1

U

4

T

3

C

O

O

M

U

+

T

5

O

U

O

T

U

0

T7

O

U

O

T2

U

T

8

O

U

O

T4

U

T

1

0

O

O

U

U

T

6

T1

2

C

O

O

M

U

1

T

14

O

U

C

T

O

9

M

2

O

U

T

1

1

O

U

T

13

O

U

T

1

5

D

C

2

4

V

I

N

1

F

G

I

N

3

I

Card recorder

"CREC"

Speaker

(Sound output)

Video camera

(Video input)

Computer (RGB input)

Display (RGB output)

*1 For the V8i series only. The option unit (GU-xx) is required.

Barcode reader

USB CF card recorder

"USB-CFREC"

Printer

Barcode reader

*1

Mouse

Keyboard

Page 23

1-8 3. System Composition

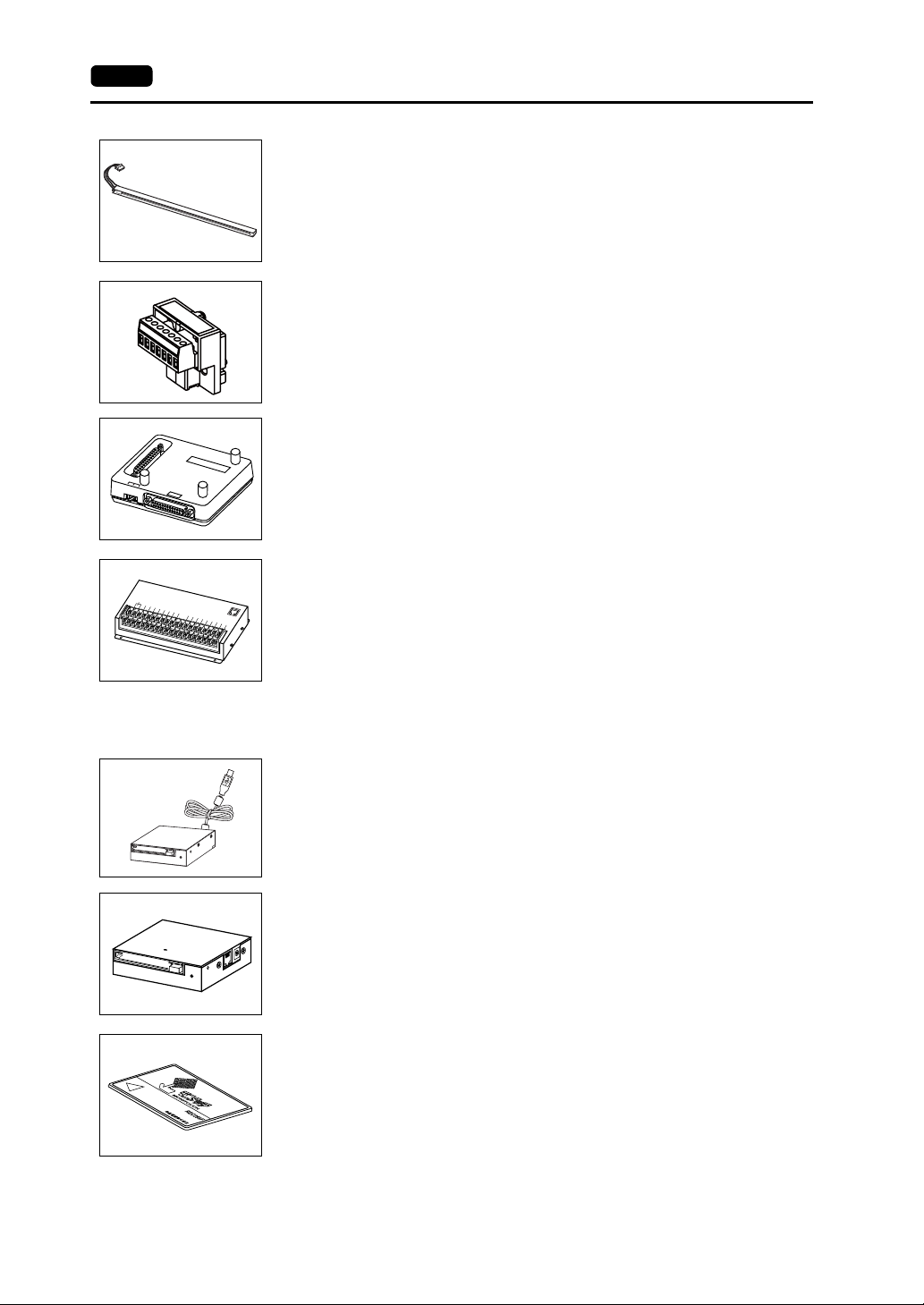

System Composition of V8/V8C Series

The following illustration shows possible system configurations using the V8/V8C series.

USB

"V-SFT-5"

V series

configuration

software

Serial

Creating screens

Temperature

controller, inverter

PLC

Barcode reader

Transferring screen data

"V-CP"

USB-B

PictBridge

Printer (PictBridge)

"V6-TMP"

"V6-BCD"

MJ1

V812S

V8

V810S/T/C

V808S/C

SYSTEM

F 1

F 2

F 3

F 4

F 5

F 6

F 7

USB-AMJ1/MJ2

CN1

Communication

cables

PLC/general-purpose

computer

Temperature

controller, inverter

K

E

Y

P

A

D

Hz

C

O

N

T

R

O

L

A

P

R

O

M

O

D

E

KW

PRG

R

E

S

E

T

R

U

N

FUNC

D

A

T

A

S

T

O

P

In

ve

r

te

r

Barcode reader

USB CF card recorder

"USB-CFREC"

Serial extension I/O unit

"V-I/O"

Card recorder

"CREC"

Printer

D

C

2

4

V

I

N

1

F

G

I

N

3

I

N

5

I

N

0

I

N

7

IN

2

IN

4

I

N

6

I

N

8

M

I

N

9

I

N

1

0

J1

IN

1

1

IN

1

3

IN

1

5

IN

1

O

2

U

T

1

I

N

O

1

U

4

T

3

C

O

O

M

U

+

T

5

O

U

O

T0

U

T

7

O

U

O

T

U

2

T

8

O

U

O

T4

U

T

1

0

O

O

U

U

T

6

T

1

2

C

O

O

M

U

1

T1

4

O

U

C

T

O

9

M

2

O

U

T

1

1

O

U

T

1

3

O

U

T

15

Barcode reader

Mouse

Keyboard

Page 24

2

1. Specifications

2. Dimensions and Panel Cut-out

3. Names and Functions of Components

4. Serial Connector (CN1)

5. Modular Jack (MJ1 / MJ2)

6. USB Connector

7. LAN Connector (LAN)

8. CF Card

Specifications

Page 25

Page 26

1. Specifications

1. Specifications 2-1

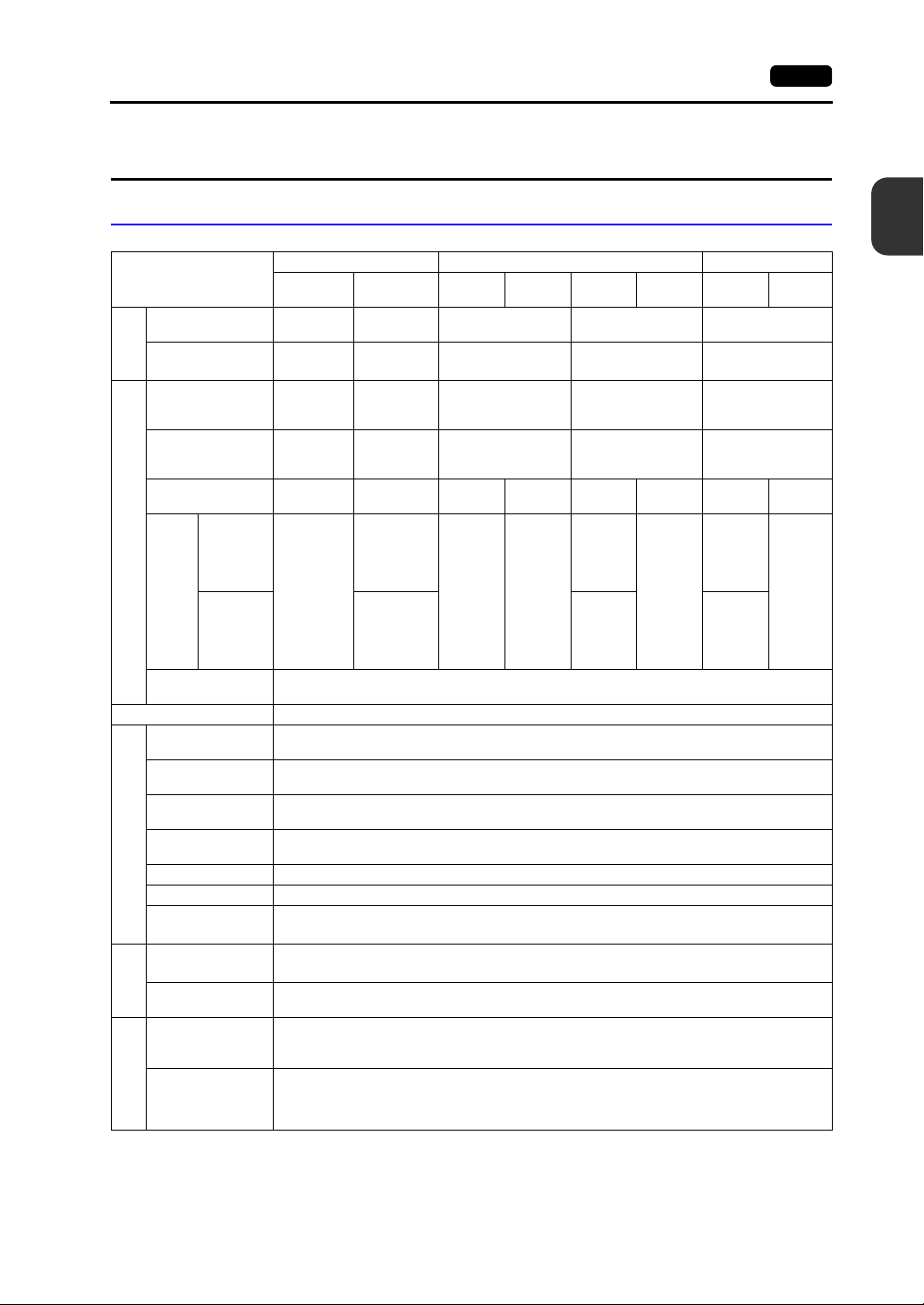

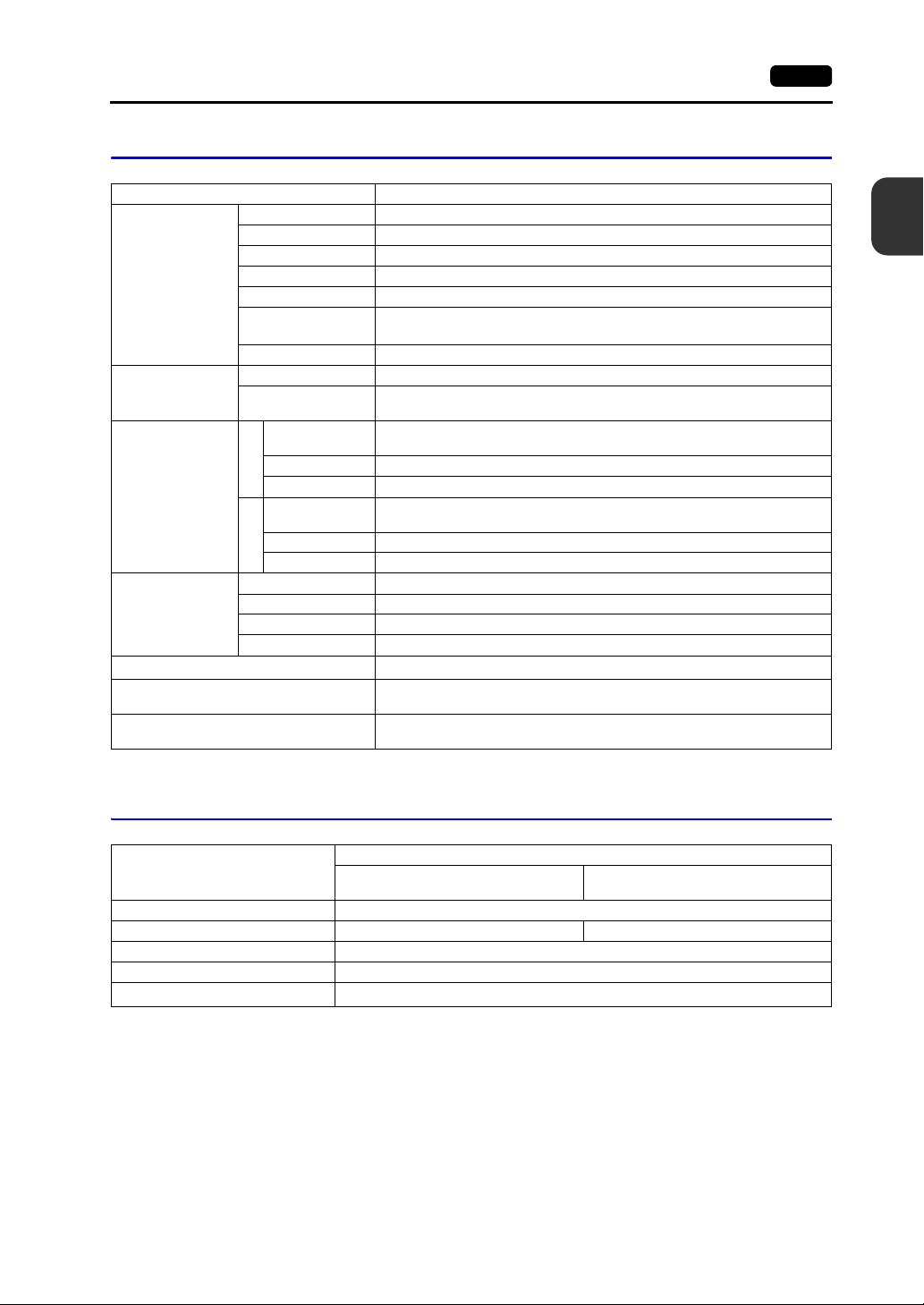

General Specifications

Item

CE Marking -

UL/cUL -

Standards

Permissible Range

of Voltage

Permissible

Momentary Power

Failure

Power Consumption

(Maximum Rating)

to “i”

“a”

Power Supply

Rush

Current

“j” or later

Withstand Voltage

Insulation Resistance 500 VDC, 10 MΩ or above

Surrounding Air

Temperature

Storage Surrounding

Air Temperature

Surrounding Air

Humidity

Storage Surrounding

Air Humidity

Altitude 2000 m or less

Physical Environment

Atmosphere No corrosive gas, no excessive dust, and no conductive dust

Contamination

*6

Level

Vibration Resistance

Working

Shock Resistance

Mechanical

Noise Resistance

100 - 240

VAC ± 10 %

(47 to 63 Hz)

Within 20 ms

70 VA or

less

For 100

*3

VAC:

20 A, 10 ms

or less

For 200

VAC:

*3

40 A, 10 ms

or less

AC external terminals to FG: 1500 VAC, 1 minute

DC external terminals to FG: 500 VAC, 1 minute

0 °C to +50 °C

−10 °C to +60 °C

85 % RH or less (without dew condensation, max. wet-bulb temperature: 39 °C or less)

85 % RH or less (without dew condensation, max. wet-bulb temperature: 39 °C or less)

Contamination level: 2

Vibration frequency: 10 to 150 Hz, acceleration: 9.8 m/s

X, Y, Z: 3 directions for one hour

Pulse shape: sine half wave, peak acceleration: 147 m/s

Noise voltage: 1500 Vp-p, pulse width: 1 μs, rising time: 1 ns

(Measured by using a noise simulator.)

V812 V810 V808

V812xS V812xSD

EN61000-6-2

EN61000-6-4

UL508

*1

UL1604

24 VDC ±

*2

10 %

For 24 VDC:

Within 1 ms

30 W or less

For 24 VDC:

20 A, 2 ms or

less

For 24 VDC:

30 A, 1 ms or

less

*4

V810xS

V810xT

100 - 240 VAC

± 10 %

(47 to 63 Hz)

Within 20 ms

70 VA or

less

For 100

VAC:

20 A,

10 ms or

less

For 200

VAC:

40 A,

10 ms or

less

V810xC

-

-

60 VA or

less

For 100

VAC:

16 A,

6 ms or

less

For 200

VAC:

32 A,

7 ms or

less

V810xSD

V810xTD

EN61000-6-2

EN61000-6-4

UL508

UL1604

24 VDC ± 10 %

For 24 VDC:

Within 1 ms

25 W or

less

For 24

VDC:

20 A,

2 ms or

less

For 24

VDC:

30 A,

1 ms or

less

2

2

V810xCD V808xSD V808xCD

EN61000-6-2

EN61000-6-4

*2

UL508

*1

UL1604

24 VDC ± 10 %

For 24 VDC:

Within 1 ms

23 W or

less

For 24

VDC:

20 A,

2 ms or

less

For 24

VDC:

30 A,

1 ms or

less

20 W or

less

For 24

VDC:

20 A,

1 ms or

less

*5

*5

*1

20 W or

less

For 24

VDC:

20 A,

1 ms or

less

(1.0 G), half-amplitude: 0.075 mm,

(15 G), X, Y, Z: 3 directions six times each

2

Specifications

*2

Static Electricity

Condition

Discharge

Resistance

Electrical Working

Compliant with IEC61000-4-2, contact: 6 kV, air: 8 kV

Page 27

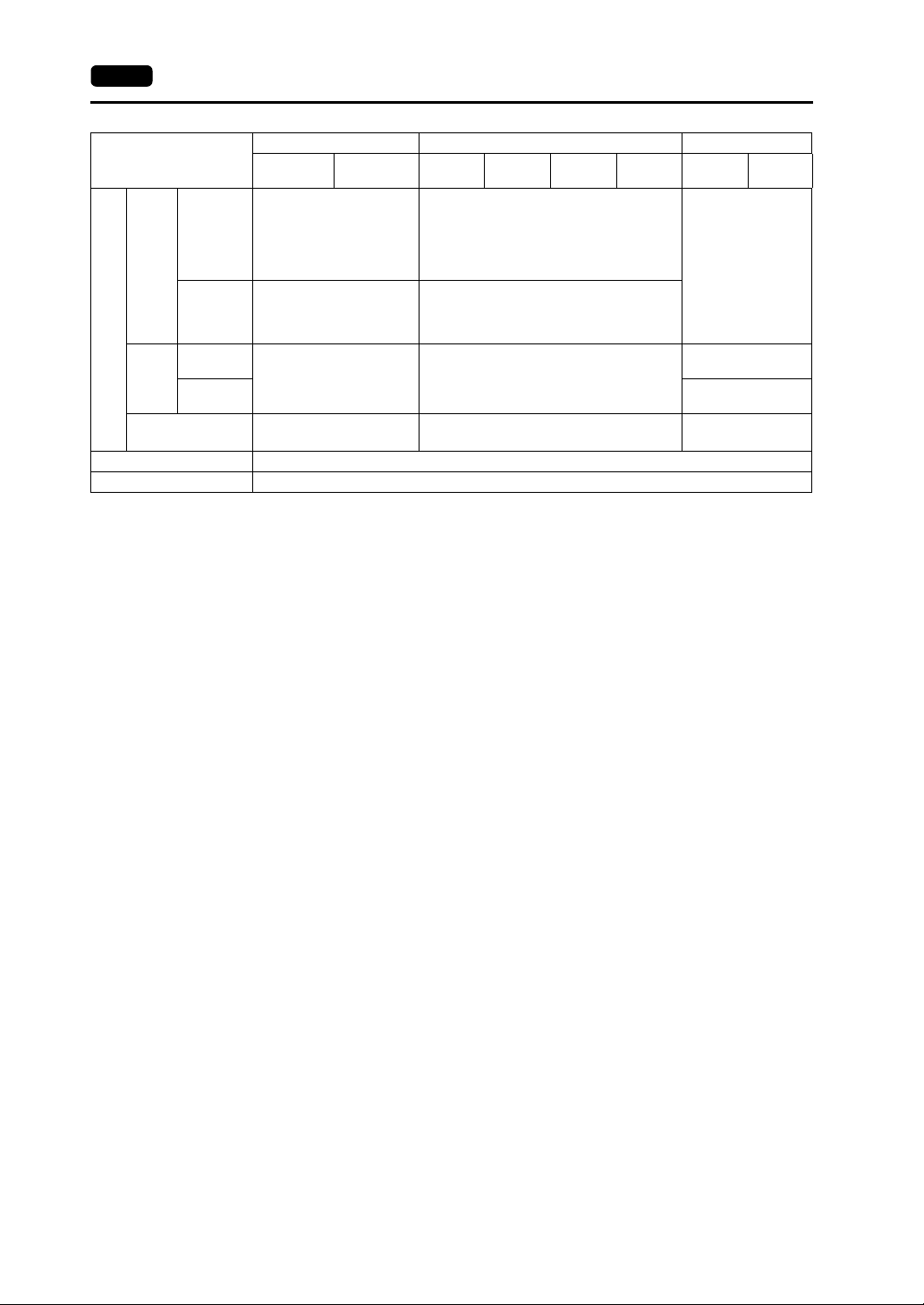

2-2 1. Specifications

Item

“a” to “i”

V812xS V812xSD

*3

Approx. 2.9 kg

Weight

Analog resistance film type

Approx. 2.4 kg

*3

Mounting

Conditions

Dimensions

W × H

× D

Panel Cut-out

Dimensions

“j” or later

“a” to “i”

“j” or later

Matrix resistance film type

Approx. 2.8 kg

*3

326.4 × 259.6 × 69.0 mm 303.8 × 231.0 × 69.0 mm

*3

+0.5

313.0 × 246.2 mm 289.0 × 216.2 mm

−0

Case Color Gray

Material PC/ABS resin

*1 The hardware version “a” to “i” is only approved. For more information on the hardware version, refer to

page 7-3.

*2 Use the Class 2 power supply for the 24-VDC power unit.

*3 This is the hardware version for the V8 unit. For more information on the hardware version, refer to page 7-3.

*4 Sorrounding air temperature is 0 °C to + 45 °C when applying for UL listing using V810 series, hardware

version “j” or later.

*5 Use MONITOUCH in the environment whose wet-bulb temperature is 39 °C or less. Otherwise, MONIT O UCH

may be damaged.

*6 This is an index that expresses the degree of conductive contamination in the environment where

MONITOUCH is used.

“Contamination level 2” indicates the condition where only non-conductive contamination occurs. However,

due to condensation, temporary conductive contamination may occur.

V812 V810 V808

V810xS

V810xT

Analog resistance film type

Matrix resistance film type

V810xC

V810xS/ V810xT: Approx. 2.5 kg

V810xC: Approx. 2.2 kg

V810xT: Approx. 2.5 kg

V810xC: Approx. 2.6 kg

V810xSD

V810xTD

V810xCD V808xSD V808xCD

Approx. 1.5 kg

V810xS/ V810xT: Approx. 2.1 kg

233.0 × 178.0 × 65.8

mm

233.0 × 178.0 × 65.6

mm

+0.5

220.5 × 165.5

+0.5

−0

+0.5

−0

+0.5

−0

mm

−0

+0.5

−0

About UL/cUL Approval

The V8 series (DC power supply type) is UL/cUL-approved.

(File No.: E313548 (UL508), File No.: E315977 (UL1604))

The V8 series conforms to the following four standards.

• UL 508 : Industrial Control Equipment

• UL1604 : Electrical Equipment for Use in Class I, Division 2 Hazardous Locations

• CSA-C22.2 : No. 142-M1987 Process Control Equipment

• CSA-C22.2 No. 213-M1987 : Non-Incendive Electrical Equipment for Use in Class I, Division 2

Hazardous Locations

UL1604/CSA-C22.2 No. 213 Compliance and Handling Cautions

• Power, input and output wiring must be in accordance with Class I, Division 2 wiring methods -

Article 501 - 10(B) of the National Electrical Code, NFPA 70.

• This product is certified for use in Class I, Division 2, Groups A, B, C or D hazardous location or

non-hazardous locations.

• WARNING: Explosion Hazard: Substitution of components may impair compliance to Class I,

Division 2.

• WARNING: Explosion Hazard: Do not disconnect the device while the circuit is alive unless area is

known to be non-hazardous. Perform system set-up or diagnostics of the CF card port, USB-A

and USB-B port only in a non-hazardous location.

• WARNING: Explosion Hazard: For use in a hazardous location, turn off the power before replacing

or wiring modules.

• Do not replace a battery in a hazardous location.

• In the case of use in a hazardous location, be sure to check that the externally connected unit and

each interface have been secured with screws or have been locked. In a hazardous location, it is

impossible to insert or remove a cable from the applicable port. Be sure to check that the location

is non-hazardous before inserting or removing it.

Page 28

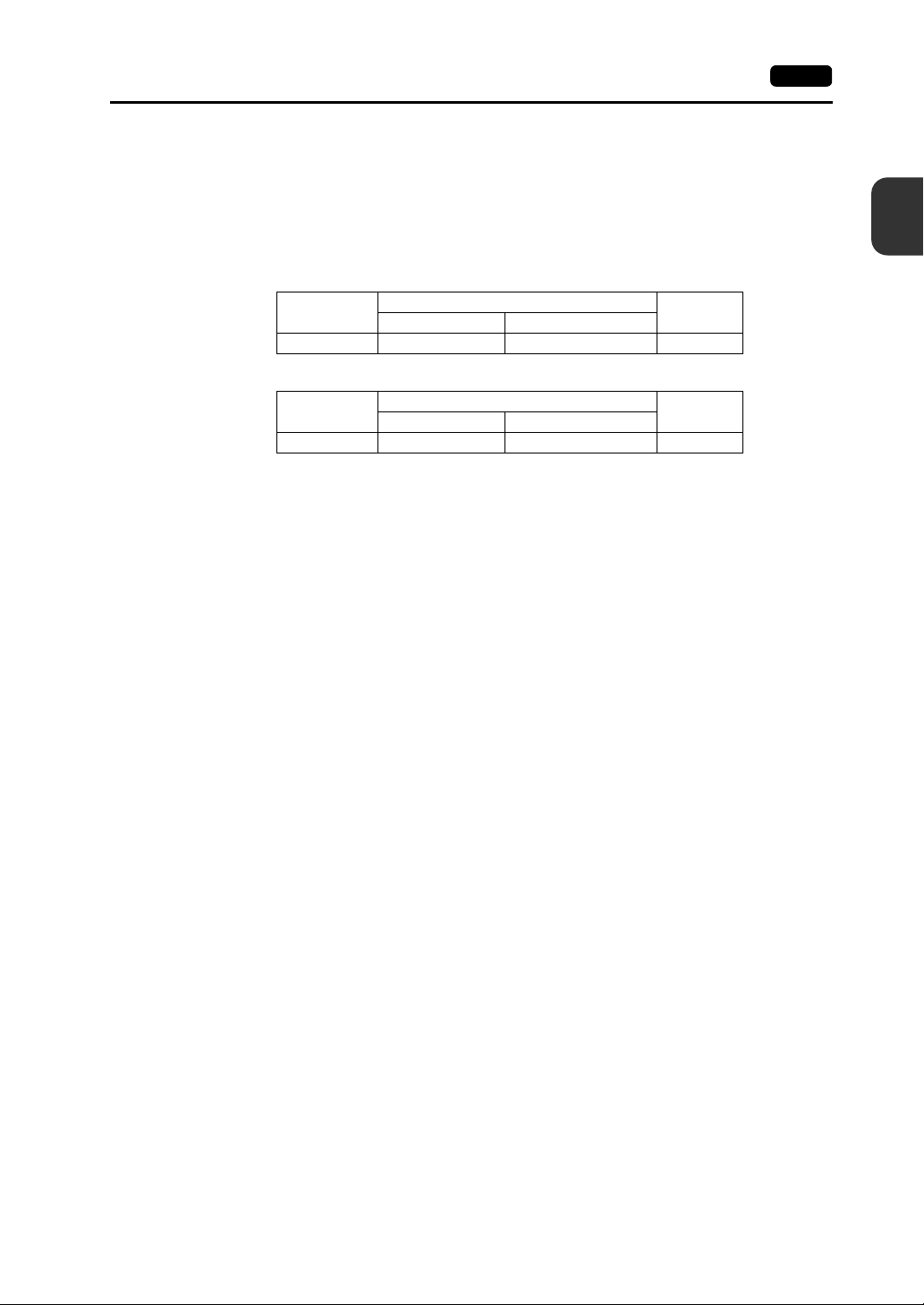

UL Listing Application for a System Equipped with the V8 Series

CE Marking

1. Specifications 2-3

• The back panel of the V8 series is not approved as an enclosure. For UL listing application, build

the V8 series in the system, and configure an enclosure so that the entire system will be

UL-approved.

• Use the V8 series indoors only.

• For use on a flat surface of a type 1 enclosure

• In the case of the V812/V810 series, use a UL-approved crimp-style terminal for wiring of the

power supply cable.

Model

V812/V810 M3.5 0.8 N•m AWG16 - 18

• In the case of the V808 series, use naked wires for wiring of the power supply cable.

Model

V808 M3.5 0.8 N•m AWG14 - 16

• Use the Class 2 power supply for the 24-VDC power unit.

• The V8 series (DC power supply type) complies with the following EMC Directives:

EN61000-6-2, EN61000-6-4

• The V8 series is identified as a class-A product in an industrial environment. In the case of usage

in a domestic environment, the V8 series is likely to cause electromagnetic interference.

Appropriate preventive measures should be taken.

Screw Size Tightening Torque

Screw Size Tightening Torque

Terminal Screw

Terminal Screw

Power Cable

Power Cable

2

Specifications

Page 29

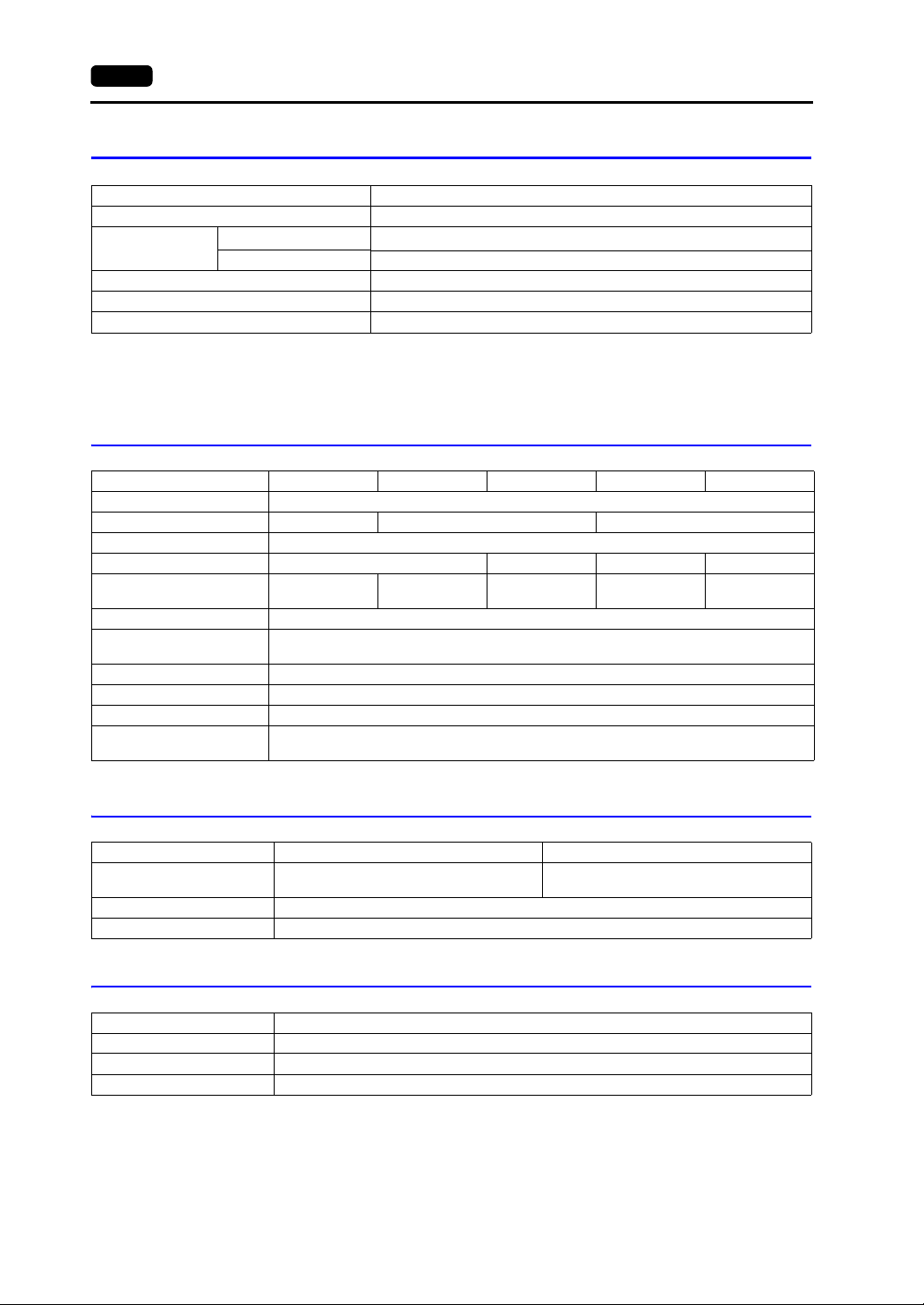

2-4 1. Specifications

Installation Specifications

Item Specifications

Grounding Less than 100Ω, FG/SG separated

Protection Structure

Cooling System Cooling naturally

Structure Inserted in a mounting panel

Appropriate Mounting Panel Thickness 1.5 to 5 mm

Front Panel

Rear Case Compliant with IP20

*1 Protection structure for the front when the V8 seri es is mounted on the mounting panel

*2 It is recommended to use the mounting panel who se th ickness ( steel , st a inless) is 3 .0 mm or mor e t o keep th e

unit compliant with IP65. The strength differs depending on the material of the mount ing panel. Check the

environment where the V8 series is used.

*1

Compliant with IP65 (when using waterproof gasket)

*2

Display Specifications

Item V812xS V810xS V810xT/ V810xC V808xS V808xC

Display Device TFT color

Display Size 12.1-inch 10.4-inch 8.4-inch

Colors 65,536 colors (without blinks) / 32,768 colors (with blinks)

Display Resolution (W × H) 800 × 600 dots 640 × 480 dots 800 × 600 dots 640 × 480 dots

Dot Pitch (W × H)

Backlight Cold cathode tube

Backlight Life

(average life of backlight only)

Backlight Auto OFF Function Always ON, random setting

Brightness Adjustment Function switch: 3 levels / Macro: 128 levels

Surface Sheet Material Polycarbonate, 0.3 mm thick

POWER Lamp

0.3075 × 0.3075 mm0.264 × 0.264

Approx. 50,000 hours (at the normal temperature of 25°C)

ON: Normal (green)

Blink: Backlight error

mm

0.33 × 0.33 mm

0.213 × 0.213 mm0.267 x 0.267

mm

Touch Switch Specifications

Item Analog Resistance Film Type Matrix Resistance Film Type

Number of Switches 1024 × 1024

Mechanical Life One million activations or more

Surface Treatment Hard-coated, anti-glare treat ment 5%

Function Switch Specifications

Item Specifications

Number of Function Switches 8 pcs.

Method Matrix resistance film type

Mechanical Life One million activations or more

12-inch: 50 × 30

10-inch: 40 × 24

Page 30

Interface Specifications

Item Specifications

Applicable Standards RS-232C, RS-422/485

Synchronization Asynchronous type

Data Length 7- or 8-bit

D-sub 9-pin (CN1)

Modular Jack 8-pin

(MJ1/MJ2)

USB Connector

(USB-A/B)

Ethernet Port

100BASE-TX/10BA

SE-T

(LAN)

CF Card Interface

Extensional Communication Port (CN5)

Optional Unit Port (CN7)

Parity None, odd, even

Stop Bit 1- or 2-bit

Baud Rate

Applications PLC, temperature controller, barcode reader, etc.

Applicable Standards RS-232C, RS-485 (2-wire connection)

Applications

Applicable

Standards

Baud Rate Low speed: 1.5 Mbps, full speed: 12 Mbps

USB-A

Applications Printer (EPSON STYLUS PHOTO series), USB-CFREC, keyboard, mouse, etc.

Applicable

Standards

Baud Rate Low speed: 1.5 Mbps, full speed: 12 Mbps

USB-B

Applications Screen data transfer, PictBridge-compatible printer

Applicable Standards Compliant with IEEE802.3u (100BASE-TX), IEEE802.3 (10BASE-T)

Baud Rate 10 Mbps, 100 Mbps

Recommended Cable 100Ω UTP (unshielded twist-pair cable), category 5, max. 100 m long

Applications PLC connection, etc.

* For details, refer to the V8 Series Connection Manual.

1. Specifications 2-5

4800, 9600, 19200, 38400, 57600, 76800, 115k bps

(187500 bps for MPI connection

Screen data transfer (MJ1), PLC, temperature contro ller, CREC, barcode

reader, V-I/O, Multi-link 2, V-Link, etc.

Compliant with USB version 1.1

Compliant with USB version 1.1

Compliant with CompactFlash

SX Bus, T-Link, Ethernet, CC-Link, PROFIBUS-DP, DeviceNet, etc.

(The communication interface unit “CU-xx” is necessary.)

RGB input/output, video, sound

(The optional unit “GU-xx” is necessary.)

TM

*

)

2

Specifications

Clock and Backup Memory Specifications

Item

Battery Specification Coin-type lithium primary cell

Backup Memory SRAM 512 kbytes SRAM 128 kbytes

Backup Period 5 years (ambient temperature at 25°C)

Battery Voltage Dr op Detection Provided (internal memory of $s167 allocated)

Calendar Accuracy

* Time loss is approximately 90 seconds a month in an ambient temperature of 25°C in the non-energized state

(backup with battery). Depending on the ambient temperature, the calendar may lose 356 seconds or advance

189 seconds in a month at the maximum. Correct the clock periodically.

V812xS/ V810xS/ V810xT/ V810iC/

V808xS/ V808iC

Monthly deviation ±90 sec (ambient temperature at 25°C)

Specifications

*

V810C/ V808C

Page 31

2-6 1. Specifications

Drawing Environment

Item Specifications

Drawing Method Exclusive configuration software

Name of exclusive configuration software: V-SFT-5

Personal computer: Pentium III 800 MHz or above

Drawing Tool

OS: Windows98SE/NT4.0/Me/2000/XP/XP64 Edition/

Capacity of hard disk required: Free space of approx. 850 Mbytes or more

Memory: 512 Mbytes or more

Display: Resolution 1024 × 800 or above

Display Function Specifications

Item Specifications

Interface Language

1/4-size, 1-byte ANK code Latin 1 ASCII code ASCII code ASCII code

Characters

Font

Character

Size

Number of

Displayable

Characters

Character

Properties

Graphics

Graphic

Properties

2-byte 16-dot JIS #1, 2 levels −

2-byte 32-dot JIS #1 level −−−−

*1 In addition, the following fonts are available.

*2 Applicable when Gothic font, Windows font or stroke font is used.

*

1/4-size 8 × 8 dots

1-byte 8 × 16 dots

2-byte 16 × 16 dots or 32 × 32 dots

Enlargement

Factor

Display

Resolution

1/4-size 100 characters × 75 lines 80 characters × 60 lines

1-byte 100 characters × 37 lines 80 characters × 30 lines

2-byte 50 characters × 37 lines 40 characters × 30 lines

Display

properties

Colors 65,536 colors (without blinks) / 32,768 colors (with blinks)

Lines Line, continuous line, box, parallelogram, polygon

Circles Circle, arc, sector, ellipse, elliptical arc

Others Tile patterns

Line types 6 (thin, thick, dot, chain, broken, two-dot chain)

Tile patterns 16 (incl. user-definable 8 patterns)

Display

properties

Colors 65,536 colors (without blinks) 32,768 colors (with blinks)

Color selection Foreground, background, boundary (line)

Gothic, English/Western Europe HK Gothic, English/Western Europe HK Times, Central Europe, Cyrillic,

Greek, Turkish

For more information, refer to the V8 Series Reference Manual.

Japanese

Normal, reverse, blink, bold, shadow, transparent

Normal, reverse, blink

English/Western

Europe

*2

Point

: 8, 9, 10, 11, 12, 14, 16, 18, 20, 22, 24, 26, 28, 36, 48, 72

800 × 600 640 × 480

(Pentium IV 2.0 GHz or above recommended)

Vista 32-bit

Screen color: 16 bits or more

Chinese

(Traditional)

Chinese

(traditional)

Windows font

Stroke font

X: 1 to 8 times, Y: 1 to 8 times

Chinese

(Simplified)

Chinese

(simplified)

Korean

Hangul

(without Kanji)

Page 32

Function Performance Specifications

1. Specifications 2-7

Item

Screens Max. 1024

Screen Memory (Flash memory)

Switch 1024 per screen

Switch Actions

Lamp

Graph

Numerical Data

Display

Data

Setting

Sampling

Graphic Library Max. 2560

Overlap Library Max. 1024

Data Blocks Max. 1024

Messages Max. 32768 lines

Patterns Max. 1024

Macro Blocks Max. 1024

Page Blocks Max. 1024

Direct Blocks Max. 1024

Screen Blocks Max. 1024

Data Sheets Max. 1024

Screen Library Max. 1024

Comments Max. 32767

Device Memory Map Max. 32 × 8 (PLC1 to PLC8)

Time Display Provided

Hard Copy Provided

Buzzer Provided, 2 sounds (short beep, long beep)

Auto OFF Function Always ON, random setting

Self-diagnostic Function

Character

Display

Message Display

*1 The number of setting memory locations is limited to 1024 per screen.

*2 Layer: 4 per screen (base + 3 overlap displays)

V812xS/ V810xS/ V810xT/ V810iC/ V808xS/

Approx. 12.5 Mbytes

(varies depending on the font)

Set, reset, momentary, alternate, to light

(Possible to press a function switch and a switch on the display at the same time)

Reverse, blink, exchange of graphics

1024 per screen

Pie, bar, panel meter and closed area graph:No limitation

Statistics and trend graphs: Max. 256 per layer

No limitation

No limitation

Display Resolution: 800 × 600: Max. 100 characters (1-byte)

No limitation

Sampling display of buffer data

(Constant sampling, bit synchronization, alarm logging, time order alarming, alarm function)

Switch self-test function

Communication parameter set t in g ch eck function

Communication check funct i on

V808iC

640 × 480: Max. 80 characters (1-byte)

Specifications

V810C/ V808C

Approx. 4.5 Mbytes

(varies depending on the font)

*2

2

Specifications

Page 33

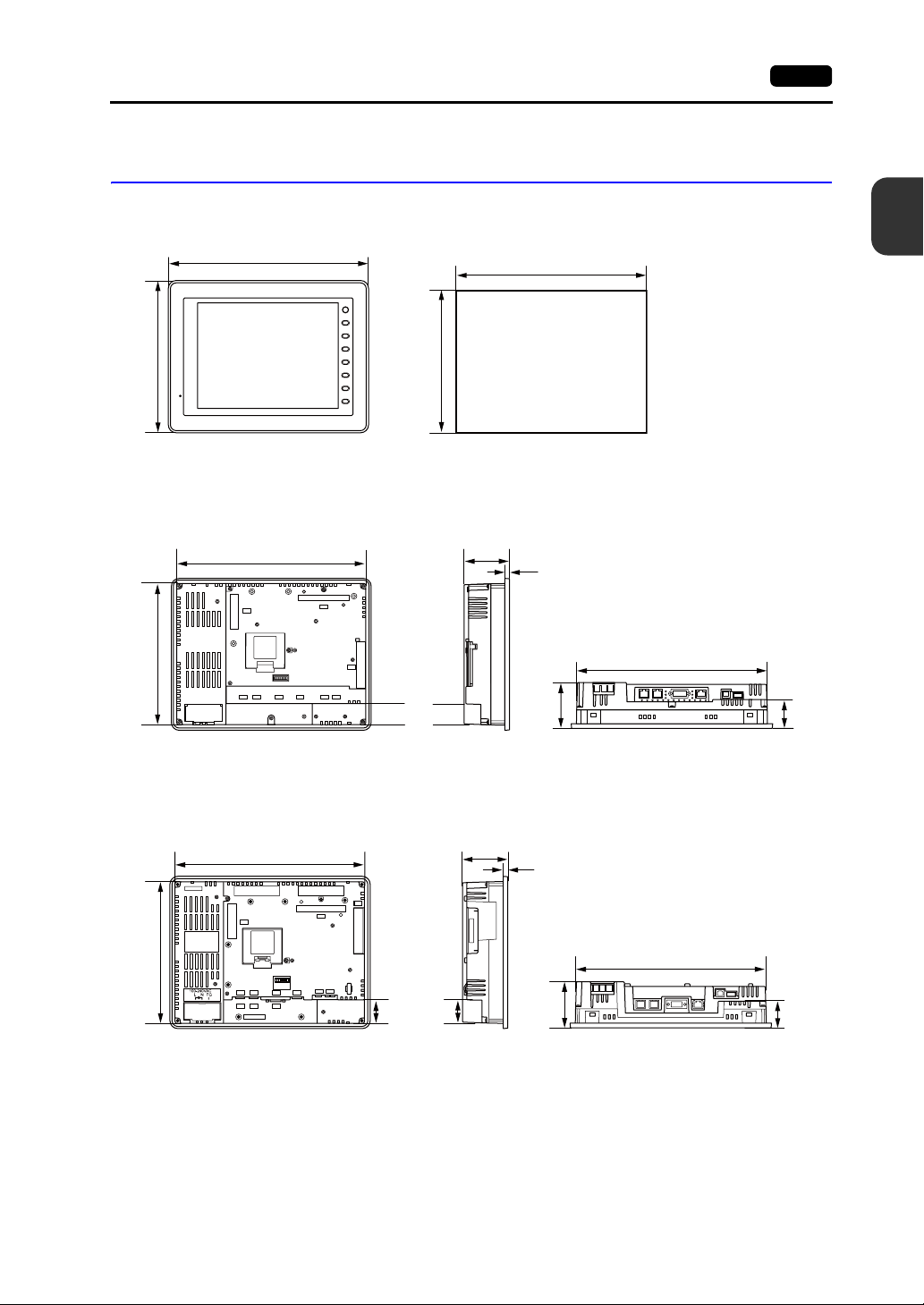

2-8 2. Dimensions and Panel Cut-out

2. Dimensions and Panel Cut-out

External Dimensions and Panel Cut-out Dimensions for V812S / V812iS

• Front View

326.4

• Panel Cut-out Dimensions

+0.5

313.0

-0

-0

+0.5

259.6

246.2

F 2

F 1

SYSTEM

F 7F 6F 5F 4F 3

Hardware version : a to i

• Rear View • Side View • Bottom View

245.2

312.0

CN5

CN7

CF

U-B U-A

CN1MJ2MJ1

LAN

58.1

69.0

7.0

69.0

(Unit: mm)

312.0

43.5

Hardware version : j or later

• Rear View • Side View • Bottom View

312.0

CN5

CF

CN7

69.0

7.0

245.2

U-B U-A

CN1

MJ1

MJ1

LAN

MJ2

MJ2

CN1

61.23

69.0

* For more information on the hardware version, refer to page 7-3.

312.0

40.0

Page 34

2. Dimensions and Panel Cut-out 2-9

External Dimensions and Panel Cut-out Dimensions for V810S / V810iS / V810T / V810iT

• Front View

231.0

303.8

SYSTEM

F1

F2

F3

F4

F5

F6

F7

• Panel Cut-out Dimensions

+0.5

289.0

-0

-0

+0.5

216.2

Hardware version : a to i

• Rear View • Side View • Bottom View

69.0

7.0

69.0

215.2

CN5

MJ1

288.0

MJ2

CN7

CF

LAN

CN1

U-AU-B

31.47

288.0

(Unit: mm)

43.5

2

Specifications

Hardware version : j or later

• Rear View • Side View • Bottom View

69.0

7.0

CN5

288.0

CF

CN7

215.2

U-B

CN1MJ1 MJ2

CN1MJ1 MJ2

U-A

LAN

34.43

69.0

* For more information on the hardware version, refer to page 7-3.

288.0

40.0

Page 35

2-10 2. Dimensions and Panel Cut-out

External Dimensions and Panel Cut-out Dimensions for V810C / V810iC

• Front View

231.0

• Rear View

215.2

CN5

303.8

288.0

CN1MJ1 MJ2

(Unit: mm)

SYSTEM

F1

F2

F3

F4

F5

F6

F7

• Side View

69.0

7.0

CF

U-B

U-A

LAN

35.2

• Bottom View

69.0

288.0

46.3

• Panel Cut-out Dimensions

289.0

-0

+0.5

216.2

+0.5

-0

Page 36

2. Dimensions and Panel Cut-out 2-11

External Dimensions and Panel Cut-out Dimensions for V808S / V808iS

• Front View

178.0

233.0

SYSTEM

F1

F2

F3

F4

F5

F6

F7

• Panel Cut-out Dimensions

+0.5

220.5

-0

-0

+0.5

165.5

Hardware version : a to i

• Rear View • Side View • Bottom View

220.0

65.8

6.9

CF

CN7

CN5

165.0

24VDC

FG

LAN

U-B

CN1

U-A

MJ2

MJ1

24.3

65.8

(Unit: mm)

2

Specifications

220.0

44.6

Hardware version : j or later

• Rear View • Side View • Bottom View

220.0

CF

CN7

CN5

65.6

6.9

165.0

24VDC

FG

CN1

LAN

U-B

U-A

MJ2

FG

MJ1

24.3

65.6

* For more information on the hardware version, refer to page 7-3.

44.5

Page 37

2-12 2. Dimensions and Panel Cut-out

External Dimensions and Panel Cut-out Dimensions for V808C / V808iC

• Front View

178.0

165.0

(Unit: mm)

233.0

SYSTEM

F1

F2

F3

F4

F5

F6

F7

• Side View• Rear View

65.8

220.0

CF

CN5

24VDC

FG

CN1

U-A

U-B

LAN

MJ1

MJ2

61.8

6.9

12.8

• Bottom View

65.8

220.0

44.6

• Panel Cut-out Dimensions

+0.5

220.5

-0

-0

+0.5

165.5

Page 38

3. Names and Functions of Components 2-13

3. Names and Functions of Components

V812S / V812iS

1

2

F 2

F 1

SYSTEM

F 7F 6F 5F 4F 3

3

V810S / V810iS / V810T / V810iT

1

SYSTEM

F 1

F 2

F 3

3

F 4

F 5

2

F 6

F 7

46 5

8

CN5

MJ1

MJ2

CN7

CF

U-B U-A

CN1

LAN

16

1514131211109

17

678

45

CN5

MJ2

MJ1

CN7

CF

LAN

CN1

U-AU-B

2

Specifications

7

V810C / V810iC

2

16

11 12 13

9

10

14 15

17

1

SYSTEM

F1

F2

F3

3

F4

F5

F6

F7

678

4

CN5

CF

U-B

CN1MJ1 MJ2

U-A

LAN

16

10

11 12 13

9

14 15

17

Page 39

2-14 3. Names and Functions of Components

V808S / V808iS

2

V808C / V808iC

2

1

456

CF

CN7

CN5

3

24VDC

FG

9

LAN

U-B

CN1

12

MJ2

MJ1

13

14 15

10

11

7

16

U-A

8

17

1

SYSTEM

F1

F2

F3

3

F4

F5

F6

F7

4 6

CF

CN5

7

16

24VDC

FG

CN1

9

12

U-B

LAN

MJ1

13

14 15

8

U-A

MJ2

10

11

17

1. Display

This is the display unit.

2. Power lamp (POWER)

Illuminates in green when the V8 series is powered on, and is operating normally. Flashes when

an error occurs to the backlight (burned-out backlight, etc.).

3. Function keys

Used for RUN/STOP selection, brightness adjustment and backlight ON/OFF (setting on the

V-SFT-5 editor required). These switches can be used as user-defined switches in the RUN

mode.

4. Communication interface unit connector (CN5)

This is the connector where the communication unit (“CU-xx”, optional) for OPCN-1, T-LINK,

CC-Link, Ethernet, PROFIBUS-DP, SX Bus or DeviceNet is mounted.

5. Optional unit connector (CN7) V812iS/V810iS/V810iT/V808iS only

Used for mounting the optional unit “GU-xx” for video input, sound output, RGB input or RGB

output.

6. Battery holder

Contains a backup battery for SRAM and clock.

When the battery voltage drops, replace the battery with a new one (V7-BT).

7. CF card connector (CF)

This is the connector where the CF card is inserted. Access to the CF card is enabled when the

cover is closed.

Page 40

3. Names and Functions of Components 2-15

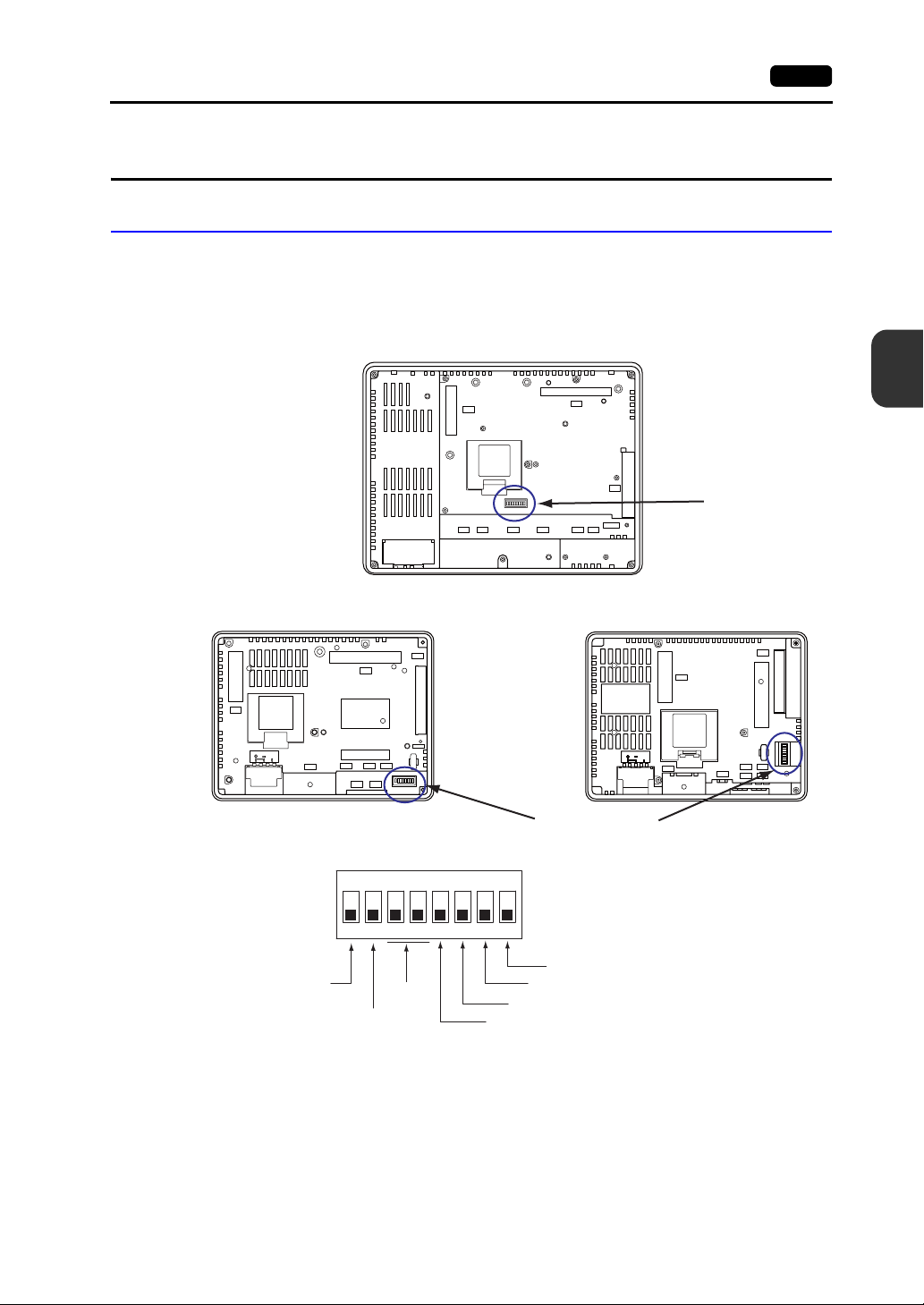

8. DIP switch

8-bit DIP switch used for setting terminating resistance of the CN1 signal line and the MJ1/MJ2

RS-485 signal line.

9. Power supply terminal block

Supplies the power to the V8 series (100 to 240 VAC, 24 VDC).

10. Modular jack 1 (MJ1)

Used for screen data transfer and connection with PLCs or other peripheral devices.

11. Modular jack 2 (MJ2)

Used for connection with PLCs or other peripheral devices.

12. PLC communication connector (CN1)

Used for connection with a controller (PLC, temperature controller, inverter, etc.).

13. 100BASE-TX/10BASE-T connector (LAN) V8i/V8iC series only

Used for Ethernet connection.

14. USB-B (slave port)

Used for screen data transfer or connection with a PictBridge-compatible printer.

15. USB-A (master port)

Used for connection with a printer, a USB CF card recorder

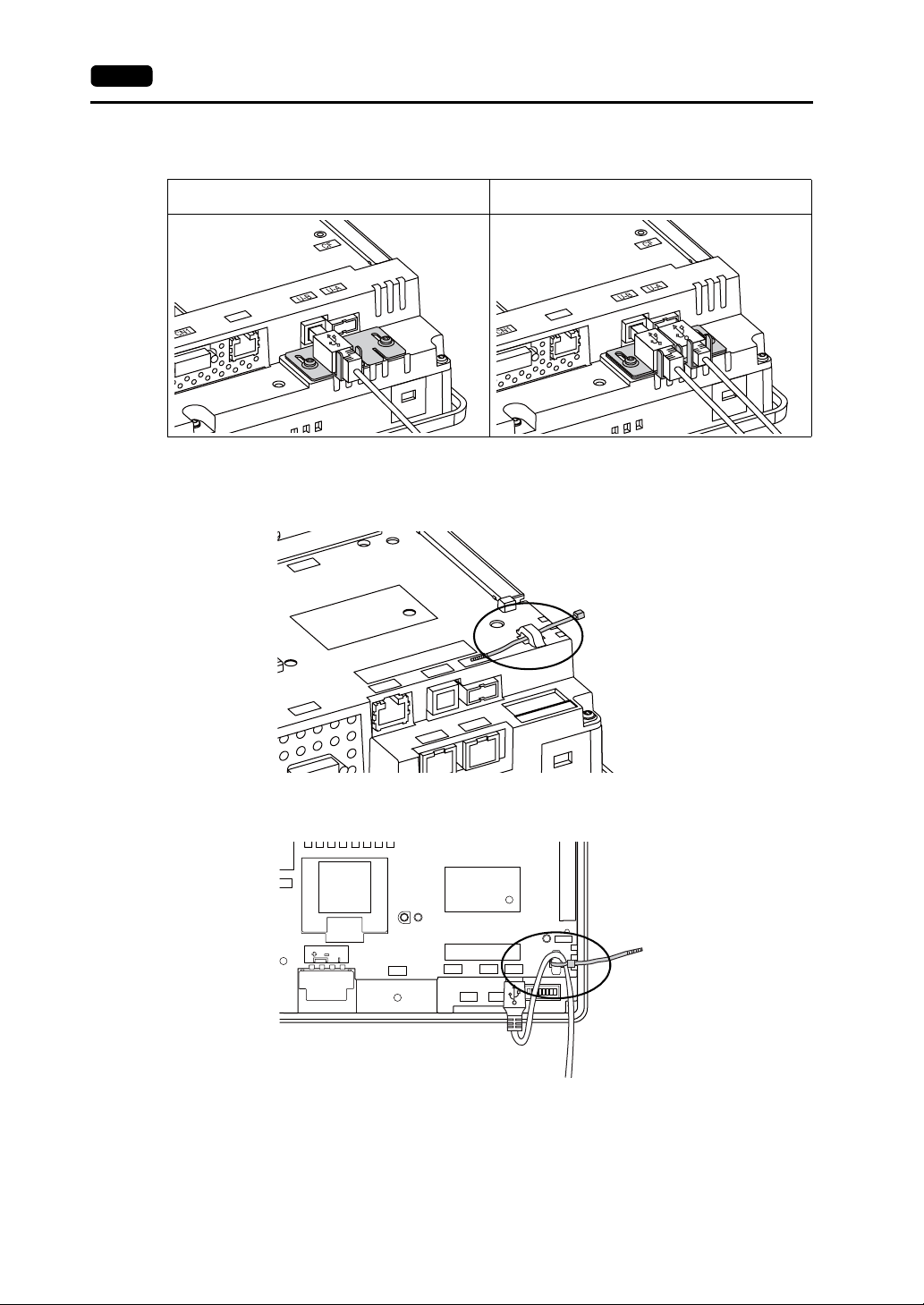

16. USB cable clamp mounting hole

For V810/V812, this hole is used for attaching a USB cable clamp.

For V808, this hole is used for attaching a USB cable tie.

17. Mounting holes

Used for inserting fixtures when securing the V8 series to the mounting panel.

“USB-CFREC”, keyboard, mouse etc.

2

Specifications

Page 41

2-16 4. Serial Connector (CN1)

4. Serial Connector (CN1)

Connector for a Controller

Communication (RS-232C, RS-422/485) with a controller is enabled via the serial connector (CN1).

• For V812/V810 • For V808

Bottom View

The serial connector pins correspond to signals as given below.

CN1 (D-sub 9-pin, fem ale)

Bottom View

5

9

*1

Pin No.

1 NC Not used +RD Receive data (+)

2 RD Receive data -RD Receive data (−)

3 SD Send data -SD Send data (−)

4 NC Not used +SD Send data (+)

5 SG Signal ground SG Signal ground

6 NC Not used +RTS Request to send (+)

7 RTS Request to send -RTS Request to send (−)

8 CTS Clear to send NC Not used

9 NC Not used +5V

*1 The signal level can be changed between RS-232C and RS-422/485 on the configuration software.

When RS-232C is selected, set the DIP switches 5 and 7 to the OFF position.

(For more information on the DIP switch, refer to “Chapter 4”.)

*2 When RS-422/485 is selected, +5V is output from pin No. 9.

+5V is used as the power supply for the external terminating resistance for RS-4 22/485 communication. It

cannot be used as an external power supply.

Signal Contents Signal Contents

RS-232C

1

6

RS-422 / RS-485

*1

Use prohibited

Recommended Connector

The following connector is recommended for a self-made cable.

Recommended

connector

DDK’s 17JE-23090-02(D8C)-CG

D-sub 9-pin / male / inch screw thread (#4-40UNC) type

/ with hood / lead- and cadmium-free

*2

PLC/Temperature Controller Connection

The V8 series can communicate with PLC or temperature controller.

For more information about the connectable device models and the setting on V-SFT-5, refer to the “V8

Series Connection Manual”.

Barcode Reader Connection

The V8 series can receive the barcode data from the connected barcode reader. For more information

about the connectable device models and the setting on V-SFT-5, refer to the “V8 Series Connection

Manual”.

Page 42

5. Modular Jack (MJ1 / MJ2)

5. Modular Jack (MJ1 / MJ2) 2-17

Modular Jack 1 (MJ1) / 2 (MJ2)

A screen data transfer cable (MJ1 only), temperature controller, barcode reader, CREC, or V-I/O can

be connected to the modular jack (MJ1 or MJ2).

• For V812/V810 • For V808

Bottom View Bottom View

Pins of MJ1 and MJ2 correspond to signals as given below.

MJ1/2 Pin No. Signal Contents

8 76 5 43 21

*1 Allowable current for the external power supply +5V at MJ1/MJ2/USB-A of the V8 series

- For MJ1 and MJ2, the maximum allowable current is 150 mA in total.

- When connecting an optional unit or communication unit, be careful not to exceed the total allowable

current for USB-A, MJ1 and MJ2.

Type Optional Unit

V812xS / V810xS

V810xT / V808xS

V812iS / V810iS

V810iT / V808iS

V810xC / V808xC -

1 +SD/RD RS-485 + data

2 −SD/RD RS-485 − data

3+5V

4+5V

5SG

6SG

7 RD RS-232C receive data

8 SD RS-232C send data

None

GU-00 - GU-03

GU-10 / GU-11

Externally supplied +5 V

Signal ground

Communication Unit

(CU-xx)

None

None

Provided 550 mA

None 650 mA

Provided 250 mA

None 500 mA

Provided 150 mA

(MJ1 + MJ2 + USB-A)

2

Specifications

*1

Allowable Current

650 mAProvided

Combined Use of MJ1 and MJ2 Functions

Multi-link 2 and ladder transfer function cannot be used at the same time.

Page 43

2-18 5. Modular Jack (MJ1 / MJ2)

PLC/Temperature Controller Connection

The V8 series can communicate with PLC or temperature controller.

For more information about the connectable device models and the setting on V-SFT-5, refer to the “V8

Series Connection Manual”.

Transferring Screen Data

When transferring screen data, use Hakko Electronics' data transfer cable (V-CP: 3 m) to connect MJ1

of the V8 series to a personal computer.

* Screen data can be transferred via Ethernet or using a CF card in addition to serial transfer.

Connection Example

V8

SYSTEM

* When [MJ1] is selected for [No Connection] on the V-SFT editor, it is possible to transfer data in

the RUN mode because the RUN/STOP mode (on the Main Menu screen) can be automatically

selected. Also, the RUN/STOP mode is automatically selected when the difference program

transfer and the simulator are used.

When an option other than [No Connection] is selected for [MJ1], select the STOP mode (on the

Main Menu screen) and transfer screen data. Simulation or Difference Program Transfer is not

available.

V-SFT-5 Setting

Select [File] → [Transf er] → [Communication Setting], and select “Serial Port” for [Communication

Port] in the [Communication Setting] window.

F 7F 6F 5F 4F 3F 2F 1

Barcode Reader Connection

The V8 series can connect to the barcode reader at the MJ1/2 of the V8 series with Hakko Electronics'

optional cable (V6-BCD: 3 m), and receive the barcode data from it. For more information about the

connectable device models and the setting on V-SFT-5, refer to the “V8 Series Connection Manual”.

MJ1

V-CP

D-sub 9-pin

PC

Page 44

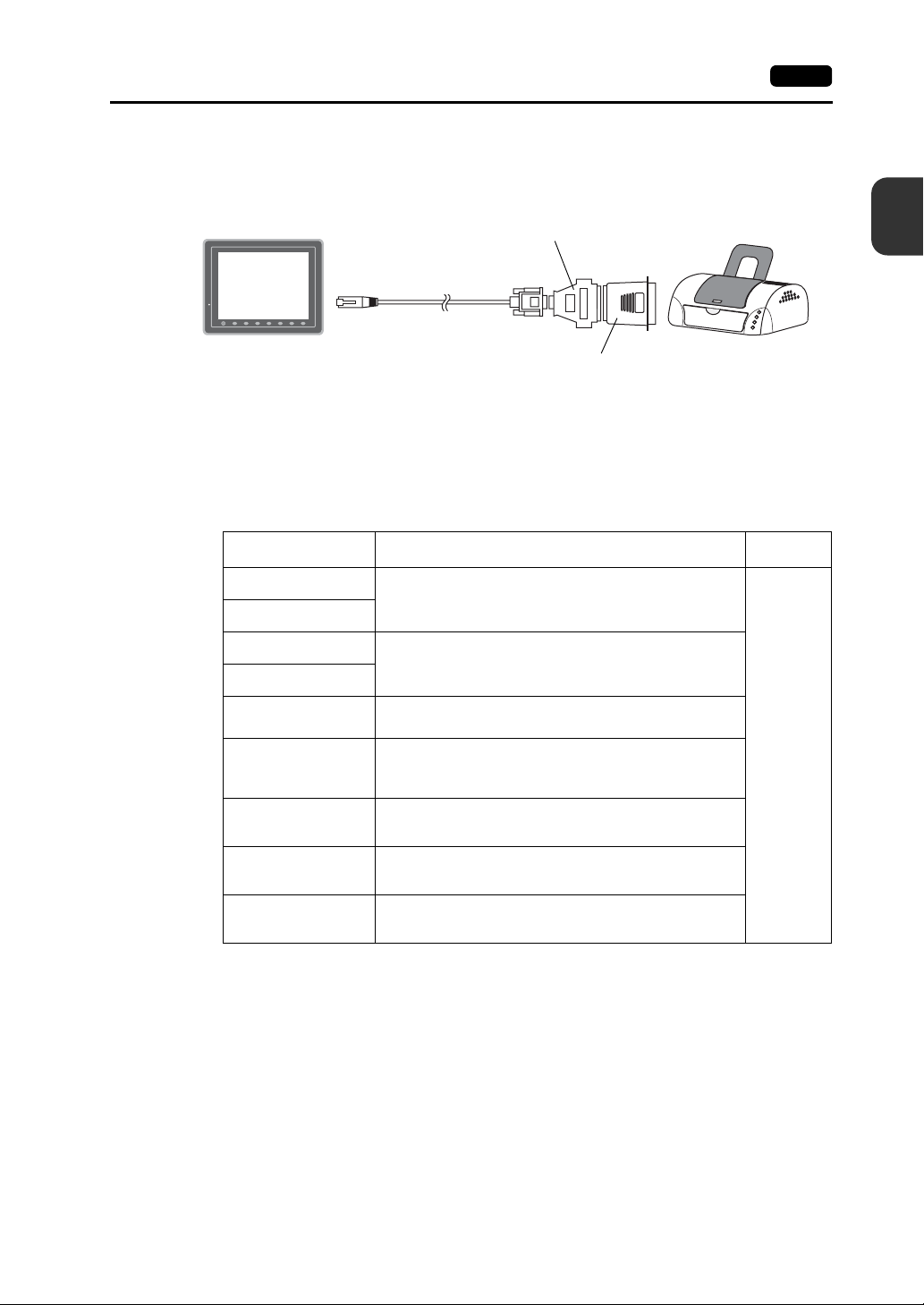

Printer Connection (Serial Printer)

The printer for the serial interface is connected with the MJ1/2 port of the V8 series, and it is possible

to print.

5. Modular Jack (MJ1 / MJ2) 2-19

D-sub 25-pin ←→ 9-pin converter

Parallel port

V8

SYSTEM

*1 Refer to the specification sheet of the printer to be used for the connecting cable for serial interface. For

information on MJ1/MJ2 signals, refer to page 2-17.

*2 To connect to a printer equipped with a p arallel i nterfa ce, u se a commercially available p ara llel-se rial converter.

When the serial connector of the converter is a D-sub 9-pin male connector, use Hakko Electronics’ V-CP

connection cable.

MJ1/2

F 7F 6F 5F 4F 3F 2F 1

V-CP

Parallel ←→ serial converter

Printer

Compatible Printer Models

Editor Setting

*

PR201 Monochrome

PR201 Color

ESC-P Monochrome

ESC-P Color

CBM292 / 293

MR - 400

EPSON STYLUS

PHOTO

EPSON STYLUS

C86 Series

EPSON STYLUS

C65 Series

PC-PR201 series models with which printing from

MS-DOS is possible

ESC/P24-J84, ESC/P-J84, ESC/P Super models with

which printing from MS-DOS is possible

Citizen CBM Line Thermal Printer

(Hard copy is not possible)

Sato barcode printer MR-400 Series

(Hard copy, data sheet print, and sample print are not

possible.)

EPSON Color Inkjet Printer STYLUS PHOTO

(Hard copy print in 32k colors is possible.)

EPSON Color Inkjet Printer STYLUS C86

(Hard copy print in 32k colors is possible.)