Page 1

TS

Training Manual

series

Page 2

Record of Revisions

Reference numbers are shown at the bottom left corner on the back cover of each manual.

Creation Date Reference No. Revised Contents

April, 2013 1203NE0 First edition

Page 3

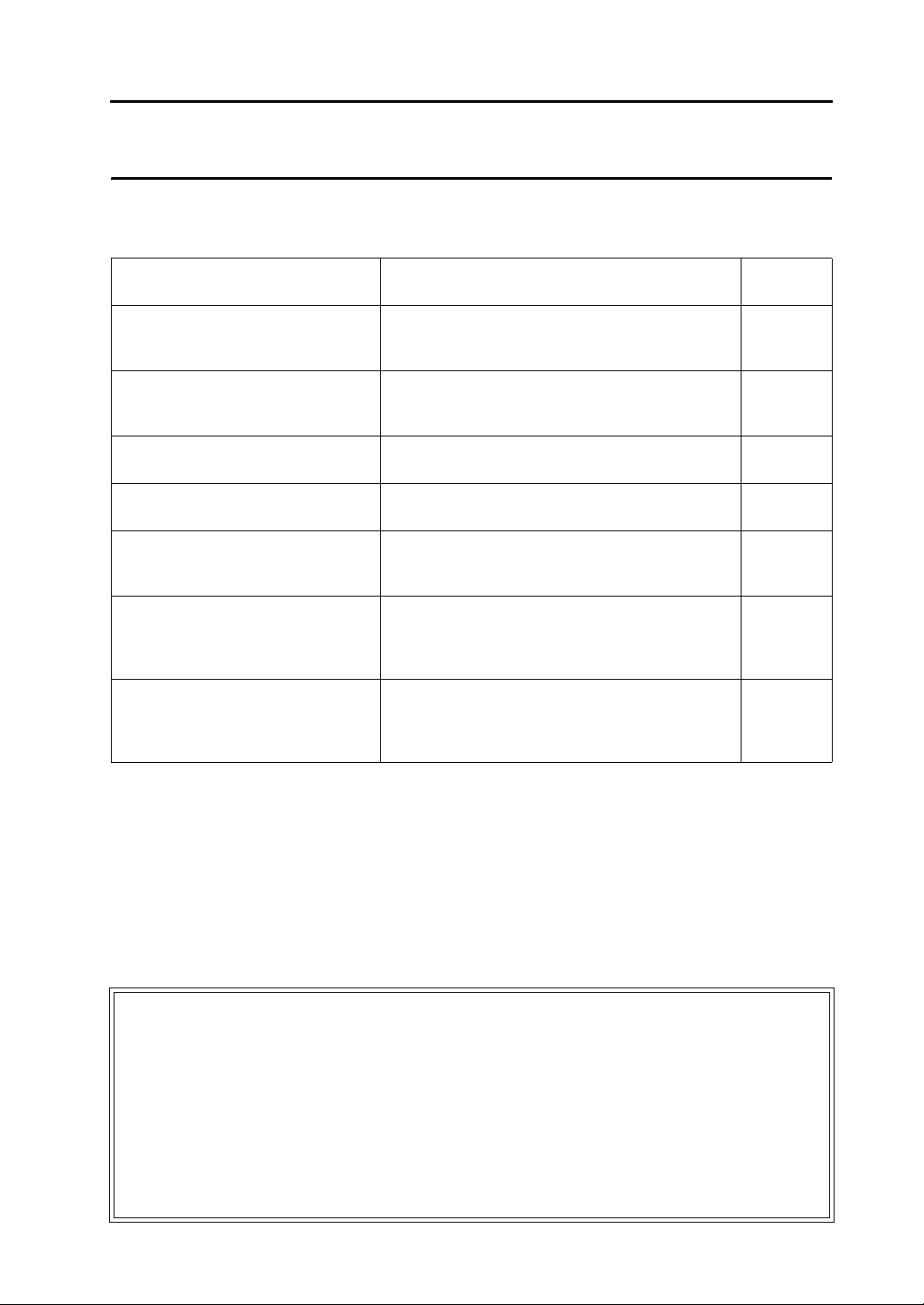

Preface

Thank you for purchasing the Techno Shot Series monitor (hereafter referred to as “TS Series”).

Thoroughly read and understand the contents of this manual to ensure correct usage of the TS Series unit.

The following manuals relate to the TS Series unit. Reference these manuals as required.

Manual Name Description Reference

TS Series Training Manual (this manual) This manual provides detailed explanations of the

TS Series Connection Manual This manual provides detailed explanations of the

TS Series Hardware Specifications This manual explains the hardware specifications and

V8 Series Reference Manual This manual explains the functions and operating

V8 Series Reference: Additional

Functions

V Series Macro Reference This reference provides an overview of the macros

V8 Series Operation Manual This manual provides detailed explanations of

screen creation process with examples using V-SFT

version 5.

connections between the TS Series unit and each type

of controller as well as communication settings.

operating methods of the TS Series unit.

methods of the V8 Series.

This manual explains the V8 Series functions and

operating methods added to V-SFT version 5.1.0.0 and

later.

available in V-SFT version 5 as well as detailed

explanations of macro editor operations and macro

commands.

information related to operating V-SFT version 5, such

as software composition, editing procedures, and

limitations.

1203NE

2203NE

2022NE

1055NE

1060NE

1056NE

1058NE

No.

For more information on each type of controller (PLC, temperature control, etc.), refer to the manufacturer’s

instruction manual for the corresponding controller.

Notes:

1. No part of this manual may be reproduced without prior permission.

2. The contents of this manual may change without prior notice.

3. Windows and Excel are registered trademarks of Microsoft Corporation in the United States and other

countries.

4. All other company names or product names are trademarks or registered trademarks of their

respective holders.

5. While the utmost care has been taken in the production of this manual, please contact your local

distributor regarding any doubts on the accuracy of explanations.

Page 4

Notes on Safety

In this manual, you will find various notes categorized under the following levels with the signal words “DANGER,”

and “CAUTION.”

DANGER

CAUTION

Note that there is a possibility that items listed with may have serious ramifications.

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury and could cause property damage.

CAUTION

DANGER

• Never use the input and output signals of the TS Series unit for operations that may threaten human life,

cause damage to the system, or as emergency switches. Please design the system so that it can withstand

touch switch malfunctions. Touch switch malfunctions may result in machine accidents or damage.

• Turn off the power supply when you set up the unit, connect new cables, or perform maintenance or

inspections. Failure to do so could cause electric shock or damage to the unit.

• Never touch any terminals while the power is on. Otherwise, electric shock may occur.

• The liquid crystal in the LCD panel is a hazardous substance. If the LCD panel is damaged, avoid ingesting

any leaking liquid crystal. If any liquid crystal spills onto your skin or clothing, use soap to wash it off

thoroughly.

• Never disassemble, recharge, deform by pressure, short-circuit, or reverse the polarity of lithium batteries,

and never dispose of lithium batteries in fire. Failure to follow these conditions may lead to explosion or

ignition.

• Never use lithium batteries that are deformed, leaking, or exhibit any other abnormalities. Failure to follow

these conditions may lead to explosion or ignition.

Page 5

CAUTION

• Check the appearance of the TS Series unit after unpacking. Do not use the unit if any damage or

deformation is found. Using the unit in such a state may lead to fire, damage, or malfunction.

• Please consult your local distributor before using this product in facilities or systems related to nuclear

energy, aerospace, medical, traffic equipment, or mobile installations.

• Operate (and store) the TS Series unit under the environmental conditions indicated in the general

specifications of this manual and related manuals. Failure to do so could cause fire, malfunction, physical

damage or deterioration.

• Understand the following environmental limits for use and storage of TS Series units. Failure to follow these

conditions may result in fire or damage to the unit.

- Avoid locations where there is a possibility that water, corrosive gas, flammable gas, solvents, grinding

fluids, or cutting oil may come into contact with the unit.

- Avoid high temperature, high humidity, and outside weather conditions, such as wind, rain, or direct

sunlight.

- Avoid locations where excessive dust, salt, or metallic particles are present.

- Avoid installing the unit in a location where vibrations or physical shocks may be transmitted.

• Equipment must be correctly mounted so that the main terminal of the TS Series unit cannot be touched

inadvertently. Failure to do so may result in electric shock or accidents.

• Periodically check that the terminal screws on the power supply terminal block and mounting nuts are firmly

tightened. Using the unit with loose screws may result in fire or malfunction.

• Tighten the terminal screws on the TS Series power supply terminal block to an equal torque of 0.5 to

0.6 N•m (5 to 6 kgf•cm). Failure to tighten these screws properly may result in fire, malfunction, or damage

to the system.

• Tighten the mounting nuts on the TS Series unit to equal torque within the specified range. Note that

excessive tightening may distort the panel surface. Failure to tighten these nuts properly may cause the TS

Series unit to fall, malfunction, or short-circuit.

• The TS Series features a glass screen. Do not drop or impart physical shocks to the unit. Such handling will

damage the unit.

• Connect the cables correctly to the terminals of the TS Series unit in accordance with the specified voltage

and wattage. Failure to supply the correct voltage or wattage, or improper cable connection may cause fire,

malfunction, or damage to the unit.

• Always ground the TS Series unit. Ground the FG terminal of the TS Series unit with an independent D

class grounding (ground resistance of 100 Ω or less). Failure to do so may result in electric shock or fire.

• Prevent any conductive particles from entering into the TS Series unit. Failure to do so may lead to fire,

damage, or malfunction.

• Do not attempt to repair the TS Series unit at your site. Contact Hakko Electronics Co., Ltd. or the

designated contractor for repairs.

• Do not attempt to repair, disassemble, or modify the TS Series unit. Hakko Electronics Co., Ltd. is not

responsible for any damages resulting from repairs, disassembly, or modification of TS Series units

performed by unauthorized personnel.

• Do not use sharp-pointed tools to press touch switches. Doing so may damage the screen.

• Only personnel who possess the required knowledge and technical skills are authorized to set up the unit,

connect the cables, and perform maintenance and inspections.

• Lithium batteries contain combustible material such as lithium and organic solvents. Mishandling may cause

heat, explosion, or ignition resulting in fire or injury. Read the related manuals carefully and handle lithium

batteries correctly as instructed.

• Do not press two or more positions on the screen at the same time. If two or more positions are pressed at

the same time, the switch located between the pressed positions will be activated.

• Take sufficient safety precautions during operations such as changing settings during running, forced output,

start, and stop. Operating errors may cause unexpected machine motions, resulting in machine accidents or

damage.

• In facilities where TS Series unit failure could lead to accidents that threaten human life or result in other

serious damage, make sure that such facilities are equipped with adequate safeguards.

• TS Series units must be disposed of as industrial waste.

• Before touching the TS Series unit, discharge any static electricity from your body by touching grounded

metal. Excessive static electricity may cause malfunction or damage to the unit.

Page 6

[General Notes]

• Never bundle control cables and communication cables with high-voltage and large-current carrying cables

such as power supply cables. Keep these cables at least 200 mm away from high-voltage and large-current

carrying cables. Otherwise, malfunction may occur due to noise.

• When using the TS Series unit in an environment where a source of high-frequency noise is present, it is

recommended that the FG shielded cable (communication cable) be grounded at both ends. However, the

cable may be grounded only at one end if necessary due to unstable communication conditions or for other

reasons.

• Plug connectors and sockets of the TS Series unit in the correct orientation. Otherwise, malfunction or

damage may occur.

• Do not use thinners for cleaning because it may discolor the surface of the TS Series unit. Use a commercially

available alcohol-based cleaner instead.

• If a “data receive error” occurs when the TS Series unit and the counterpart unit (PLC, temperature controller,

etc.) are started at the same time, read the instruction manual for the counterpart unit and handle the error

accordingly.

• Avoid discharging static electricity on the mounting panel of the TS Series unit. Static charge can cause

malfunctions due to noise.

• Avoid prolonged display of any fixed pattern. An afterimage may remain due to the characteristics of the liquid

crystal display. If a prolonged display of a fixed pattern is expected, use the backlight’s auto OFF function.

[Notes on the LCD Screen]

Note that the following conditions may occur under normal circumstances.

• The response time, brightness, and colors of the TS Series unit may be affected by the ambient temperature.

• Tiny spots (dark or luminescent) may appear on the display due to liquid crystal characteristics.

• Each unit varies slightly with respect to brightness and colors.

Page 7

Contents

Preface

Notes on Safety

1. Creating New Files .......................................................................................................... 1-1

2. Creating Switches and Lamps......................................................................................... 2-1

3. Creating Overlaps ........................................................................................................... 3-1

4. Entry Screens.................................................................................................................. 4-1

5. Alarm Screens.................................................................................................................5-1

6. Trend Screen (Trend Sampling)...................................................................................... 6-1

7. Screen Data Transfer ...................................................................................................... 7-1

Page 8

1. Creating New Files

1. Creating New Files

This chapter explains how to create new files and the initial screen displayed when the unit first

starts up after turning on the power.

Contents

Screen Example.................................................................................................................. page 1-1

Screen Creation .................................................................................................................. page 1-2

1. Creating a New File .................................................................................................. page 1-2

2. Changing the Background Color .............................................................................. page 1-5

3. Drawing Graphics ..................................................................................................... page 1-7

4. Moving and Aligning Parts...................................................................................... page 1-13

5. Saving Files ............................................................................................................ page 1-16

Unit Operation................................................................................................................... page 1-17

Error Display............................................................................................................... page 1-17

Screen Example

The drawing tools are used to draw graphics, place text, and paste image files (JPEG, bitmap).

1

Contents

1-1

Page 9

1. Creating New Files

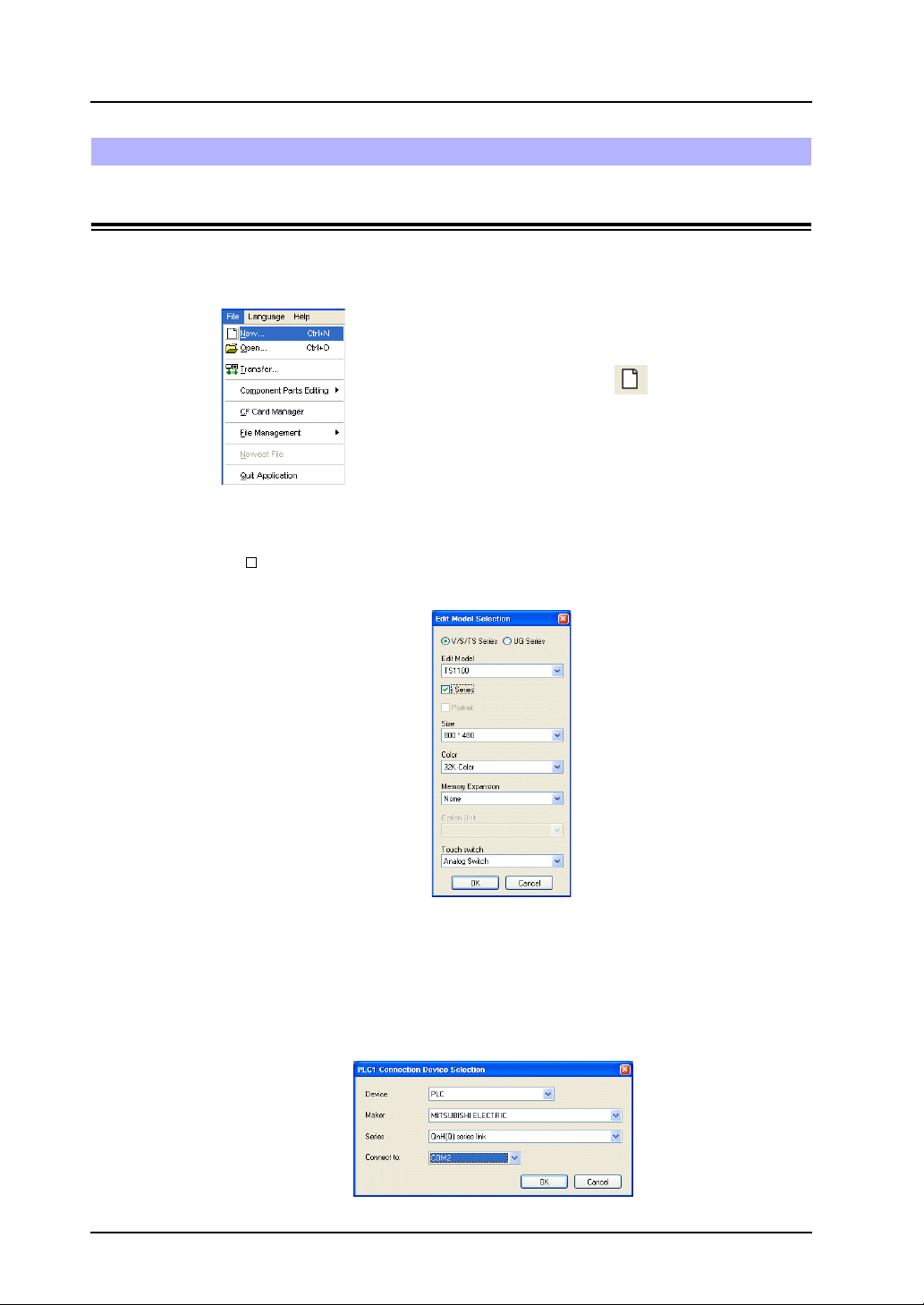

1. Creating a New File

1. Start V-SFT-5.

2. Click [File] → [New] or click the [New File] icon.

3. Configure the following settings in the [Edit Model Selection] dialog box and click [OK].

Create the example screen in this manual with the following settings.

Edit Model : TS1100

i Series : Selected

Color : 32K-Color

Screen Creation

New file icon

or

1-2

4. Configure the PLC type and TS connection port in the [PLC1 Connection Device Selection]

dialog box and click [OK].

Create the example screen in this manual with the following settings.

Device connected : PLC

Maker : MITSUBISHI ELECTRIC

Series : QnH (Q) series link

Connect to : COM2

Page 10

1. Creating New Files

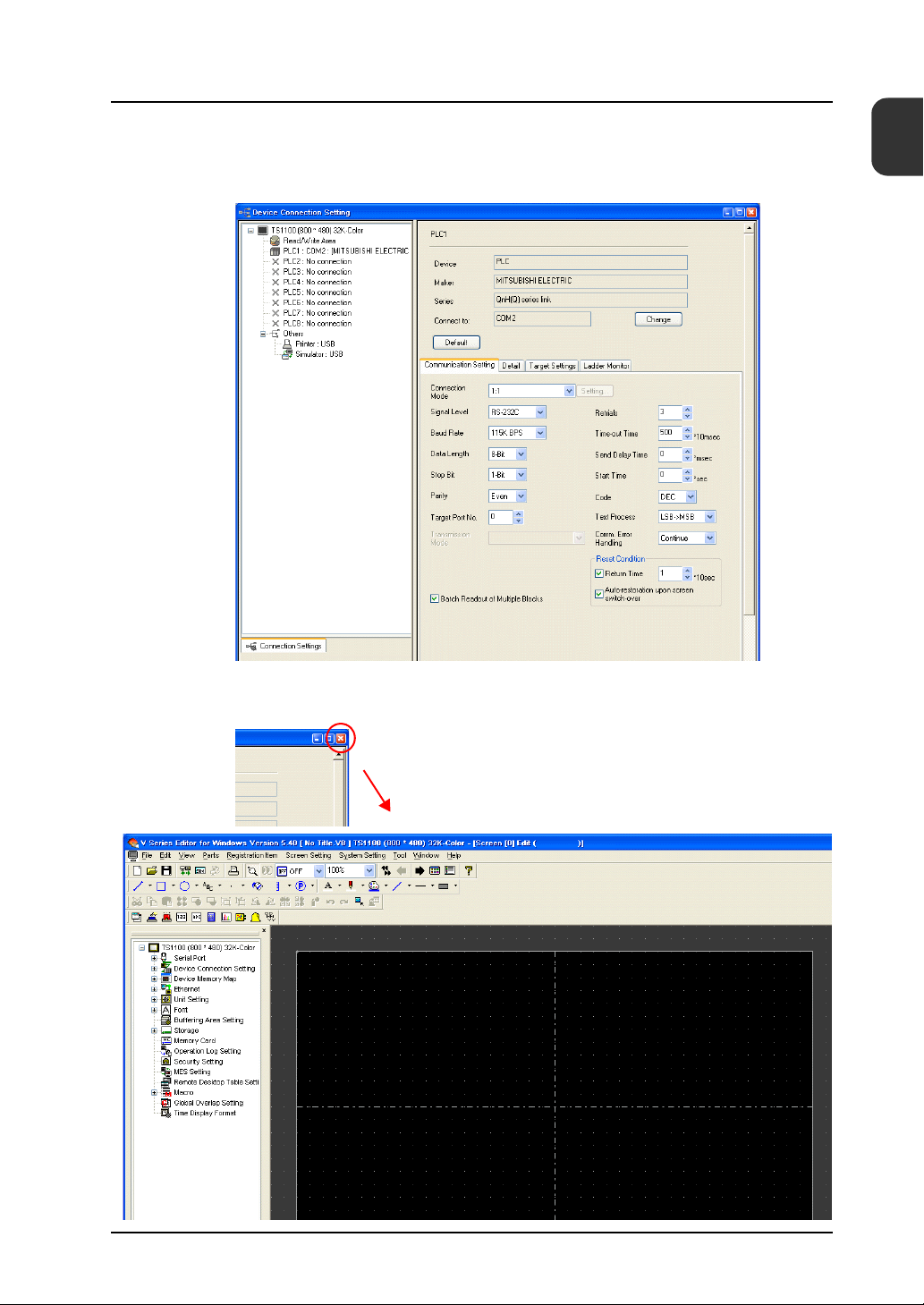

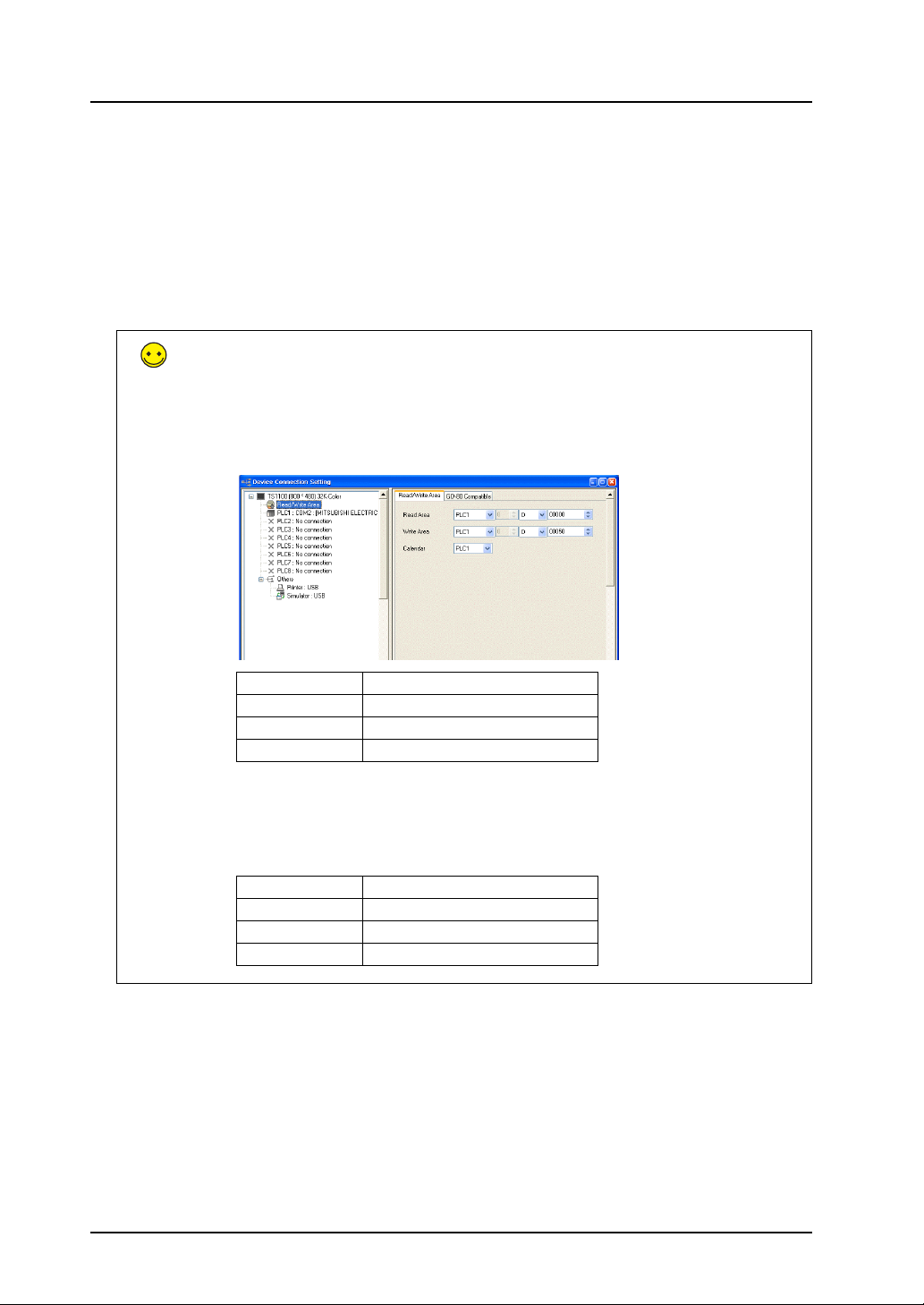

5. Configure the communication parameters in the [Device Connection Setting] window. For

more information on settings in the [Device Connection Setting] window, refer to the “TS

Series Connection Manual.”

1

Screen Creation

6. Click the [Close] button to close the [Device Connection Setting] window.

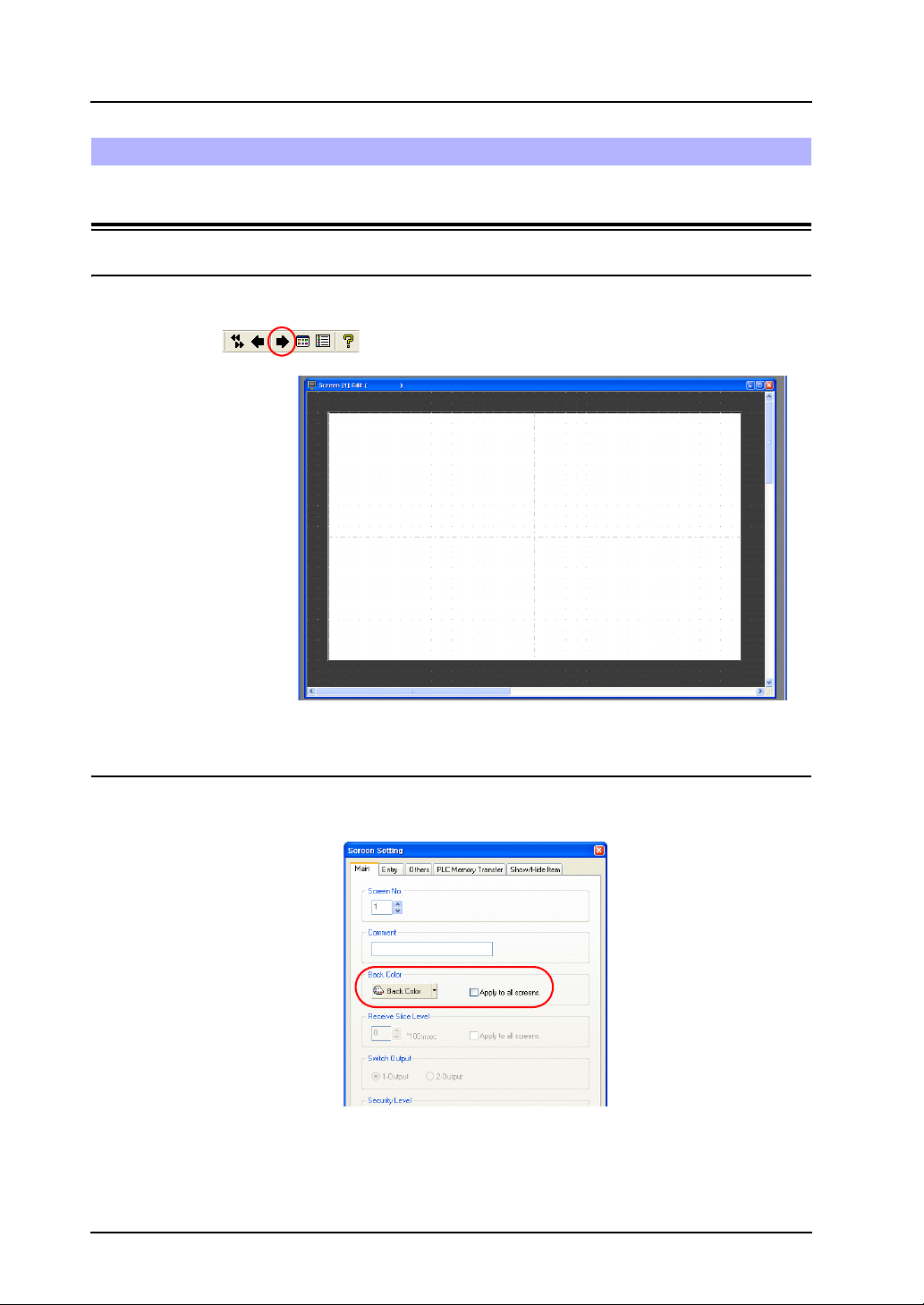

The [Screen [0] Edit] window is displayed.

Close

1-3

Page 11

1. Creating New Files

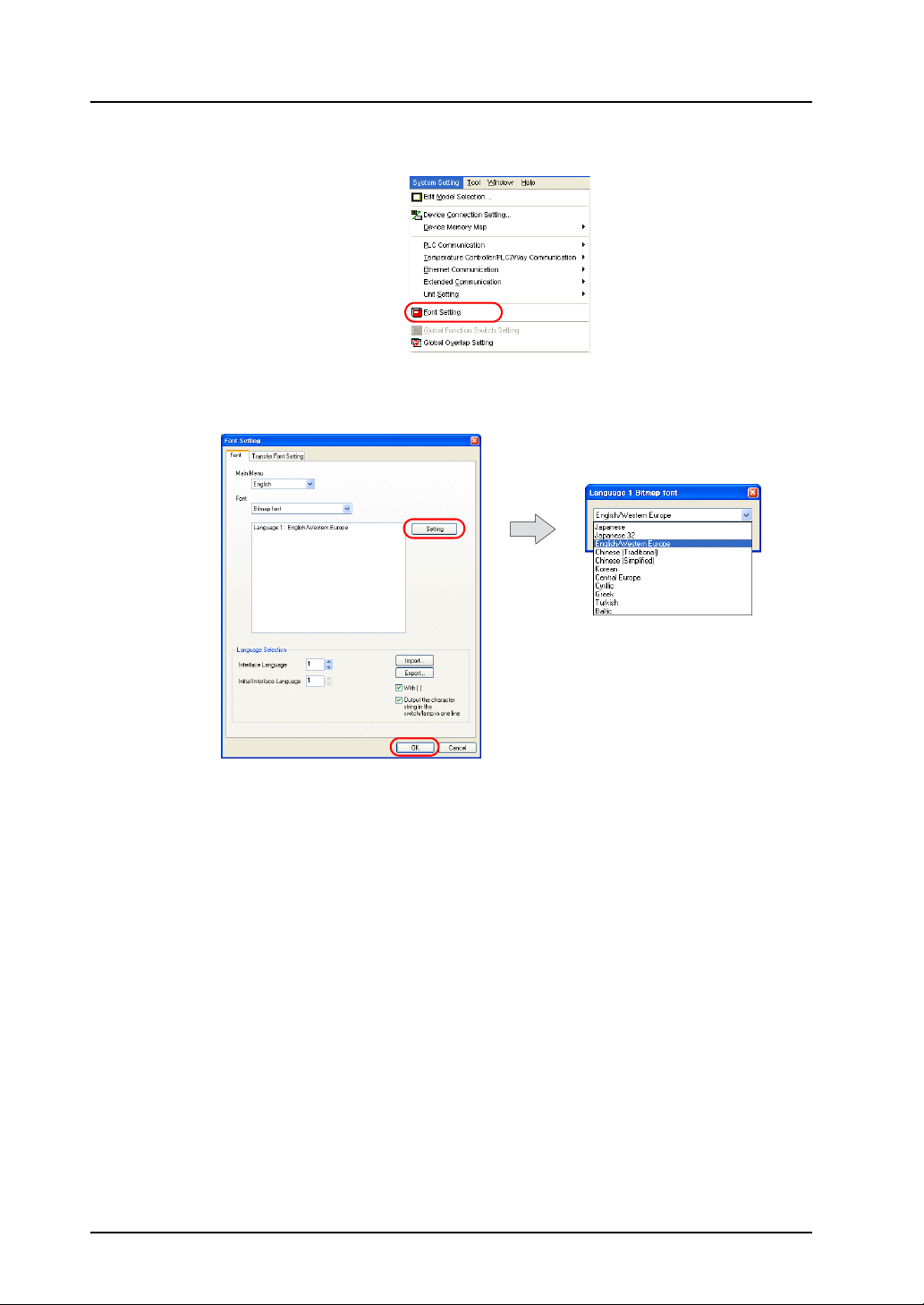

7. Click [System Setting] → [Font Setting]. The [Font Setting] dialog box is displayed.

8. Set the font using the [Setting] button. Click the [OK] button to close the dialog box.

For more information on settings in the [Font Setting] dialog box, refer to the “V8 Series

Reference Manual.”

1-4

Page 12

1. Creating New Files

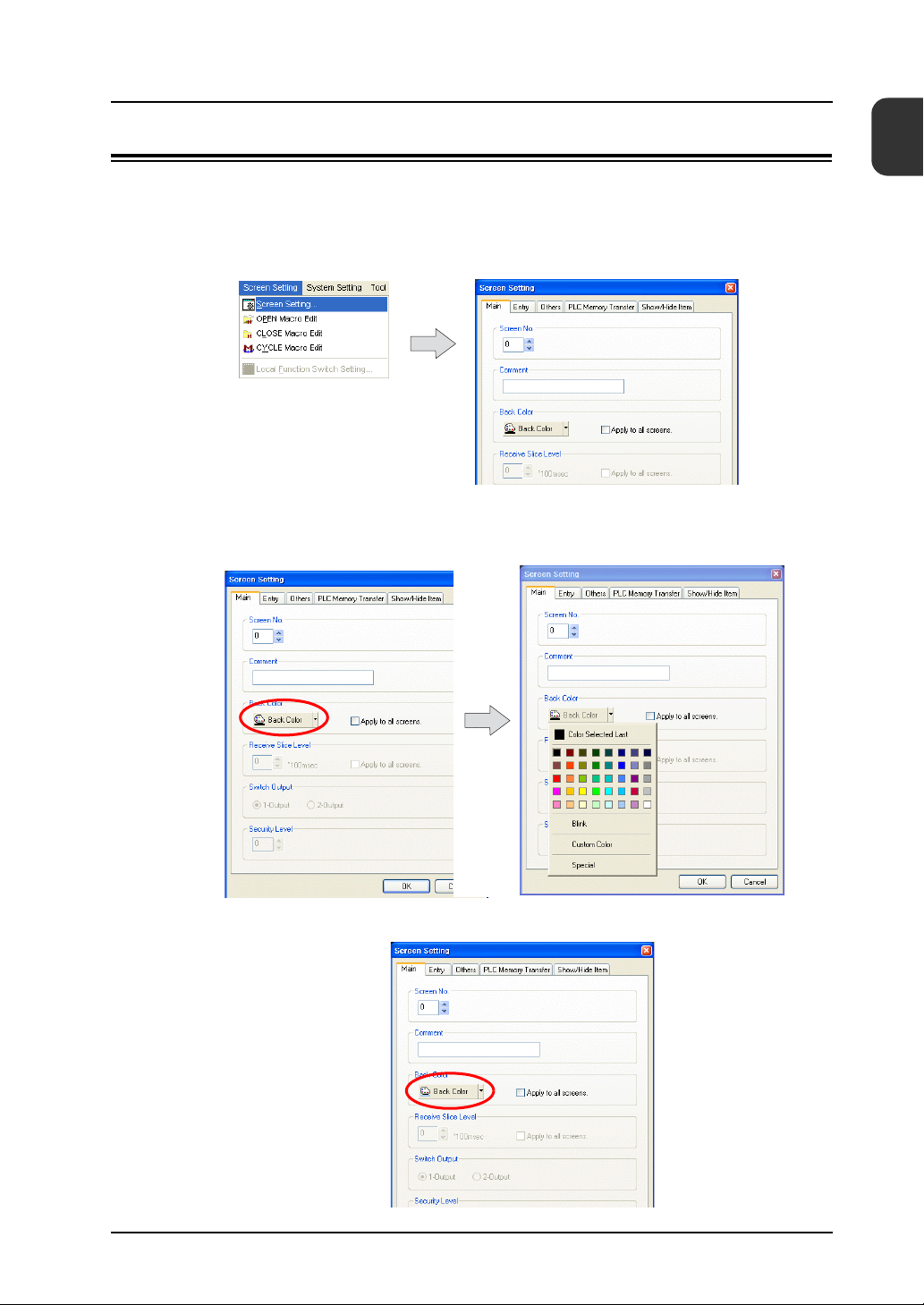

2. Changing the Background Color

This section explains how to change the background color.

1. Click [Screen Setting] → [Screen Setting].

The [Screen Setting] dialog box is displayed.

2. Click the [Back Color] button on the [Main] tab. A drop-down list for color selection is

displayed.

Select the desired background color.

1

Screen Creation

3. The selected color is displayed on the icon and the background changes to this color.

1-5

Page 13

1. Creating New Files

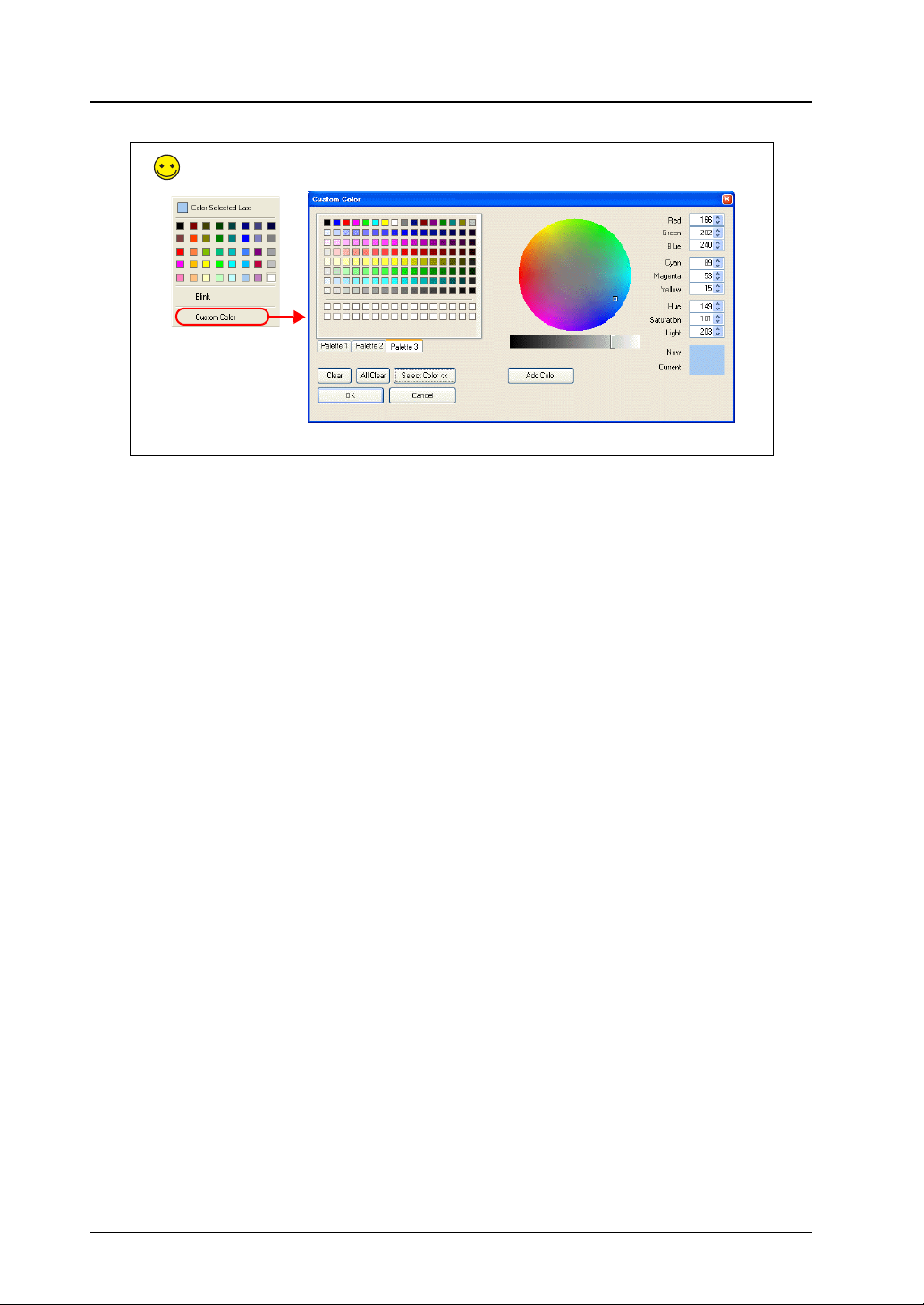

Click [Custom Color] to select a color that is not shown on the drop-down list. The [Custom Color]

dialog box is displayed.

Select the desired background color.

1-6

Page 14

1. Creating New Files

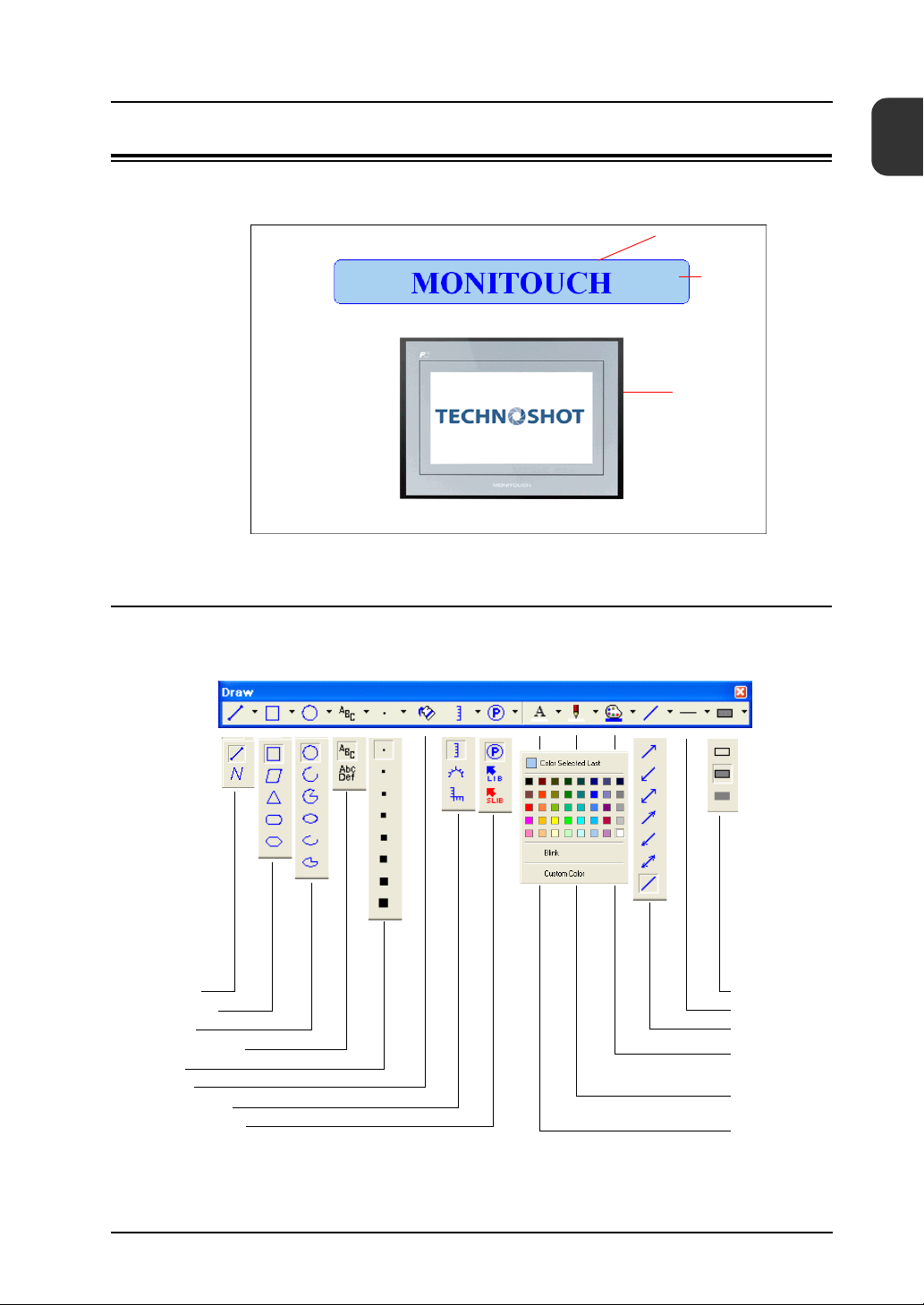

3. Drawing Graphics

This section explains how to use the drawing tools to create text and draw graphics.

3.1 Draw Toolbar

The icons on the [Draw] toolbar are shown below. Click the → symbol on the right of each icon to

change the properties of each icon’s function.

1

Screen Creation

Te xt

Rectangle

Bitmap image

Straight

Line

Rectangle

Circle

Text/Multi Text

Dot

Paint

Graph Scale

Pattern/Library

Frame Type

Line Type

Arrow Type

Paint Color/

Background

Line

Color/Frame

Color

Character Color

1-7

Page 15

1. Creating New Files

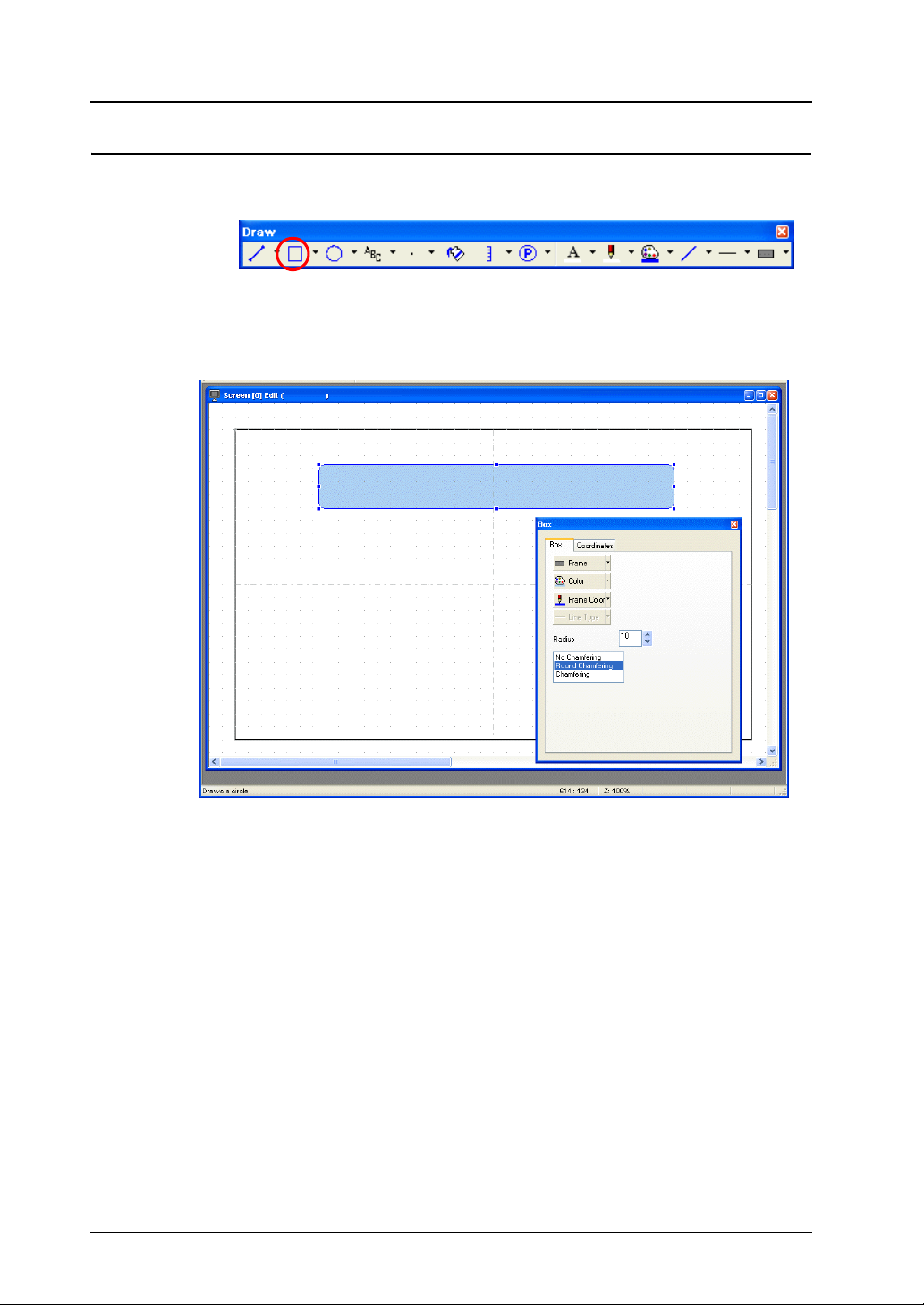

3.2 Creating a Rectangle

1. Click the [Rectangle] icon on the [Draw] toolbar. The [Rectangle] icon becomes depressed

and the mouse cursor changes to a cross-shaped cursor.

2. Drag from the start point to the end point on screen using the mouse. This draws a rectangle.

3. Set the color and frame type in the item dialog box.

1-8

Page 16

1. Creating New Files

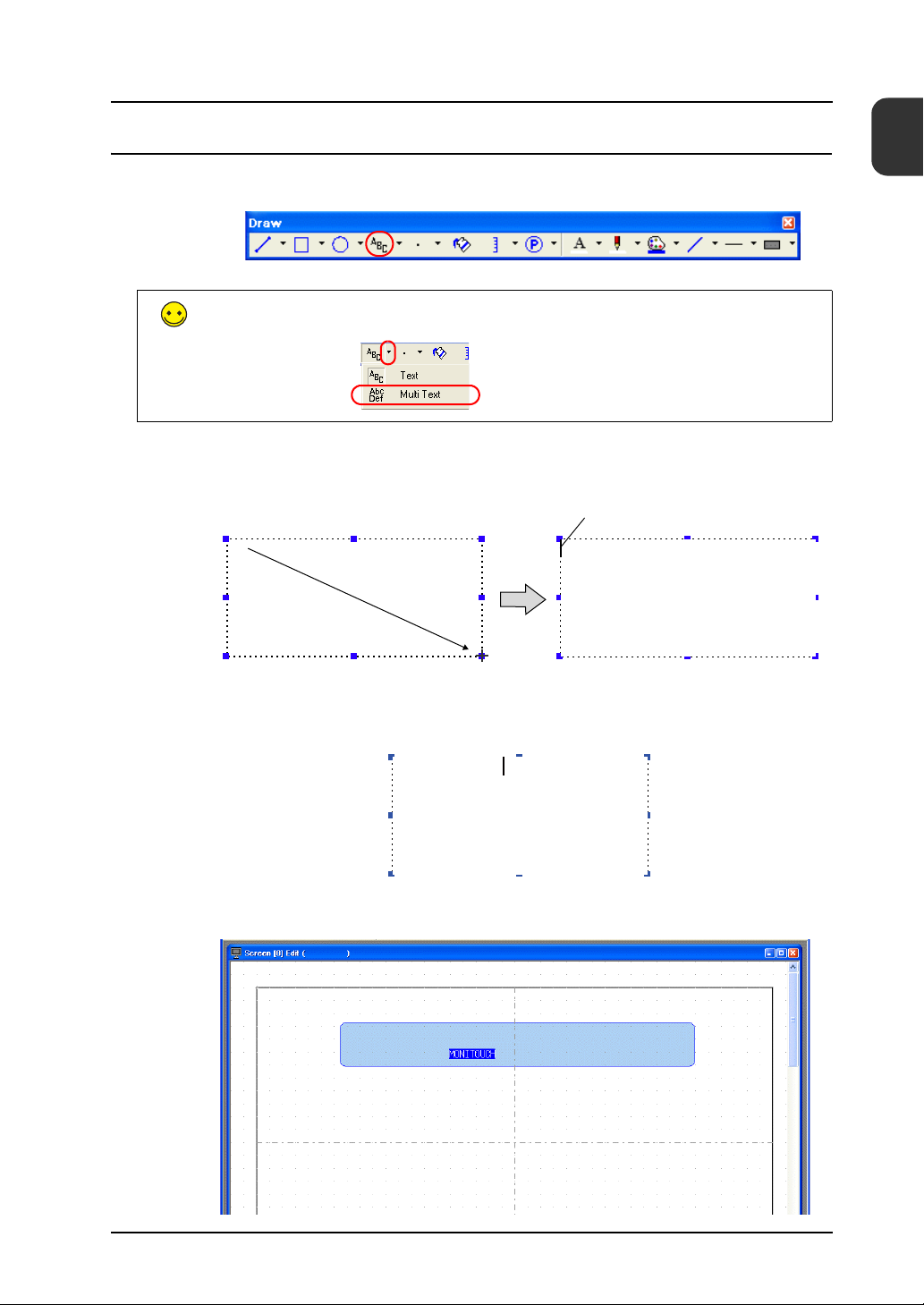

3.3 Creating Text

1. Click the [Text] icon on the [Draw] toolbar.

The [Text] icon becomes depressed.

Use [Multi Text] to enter more than two lines of text.

2. Drag from the start point to the end point on screen using the mouse.

The specified area and a blinking cursor are displayed on screen.

1

Screen Creation

Blinking cursor

Drag

3. Enter text.

MONITOUCH

4. Click a location on the screen other than the text.

1-9

Page 17

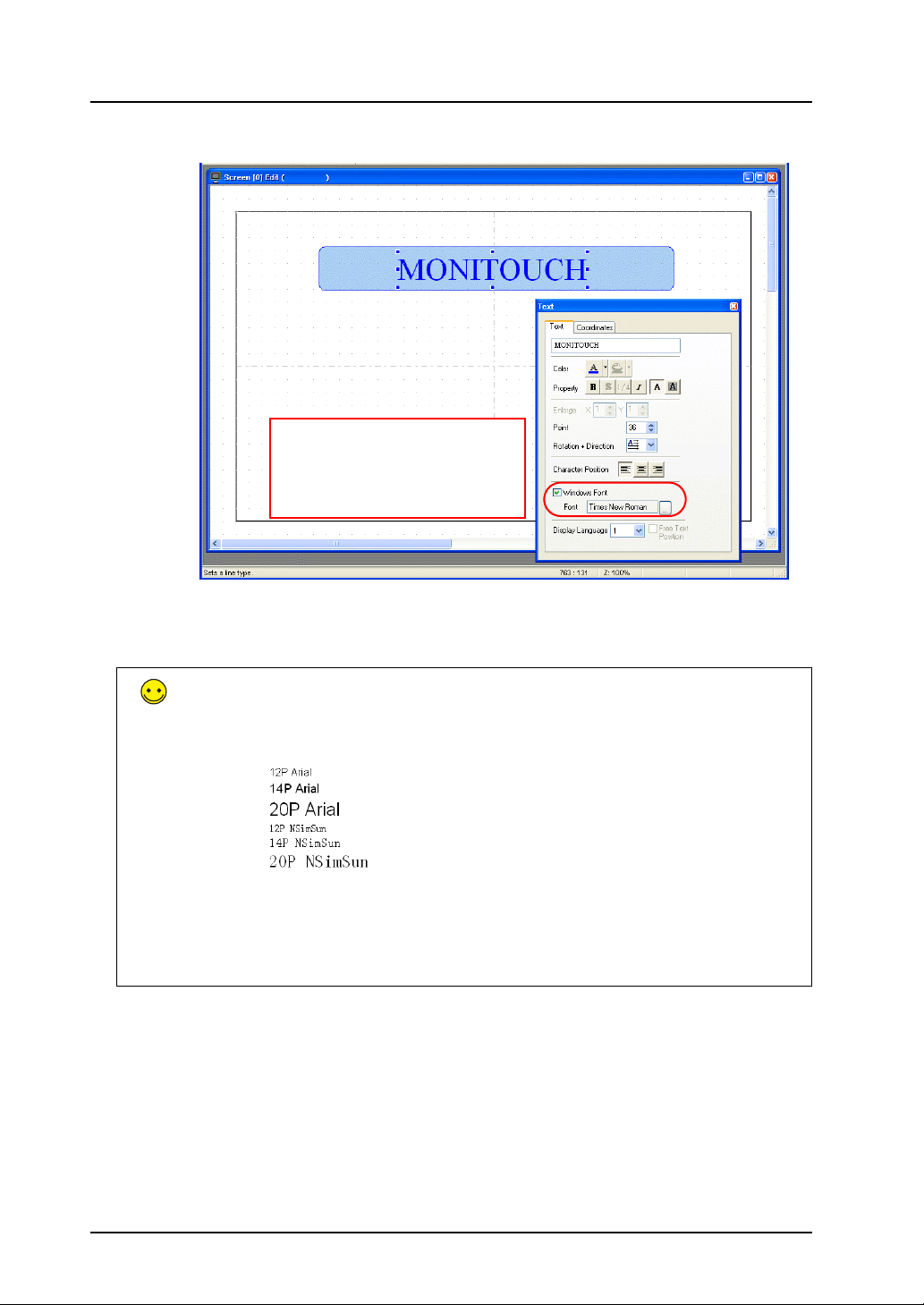

1. Creating New Files

5. Click the text to display its item dialog box. Change the text color and text size properties.

Windows fonts on the computer can

also be set in addition to the standard

bitmap fonts.

Windows fonts on the computer can

also be set.

Windows Fonts

The use of Windows fonts enables text size settings from 6 to 999 points and results in

smoother display.

However, note that a common font should be used when editing on multiple computers

because the types of Windows fonts can vary between computers.

A warning message is displayed if attempting to use a Windows font that is not present on

the computer. In this case, editing cannot be performed unless the missing font is

substituted with another Windows font or the missing font is installed.

1-10

Page 18

1. Creating New Files

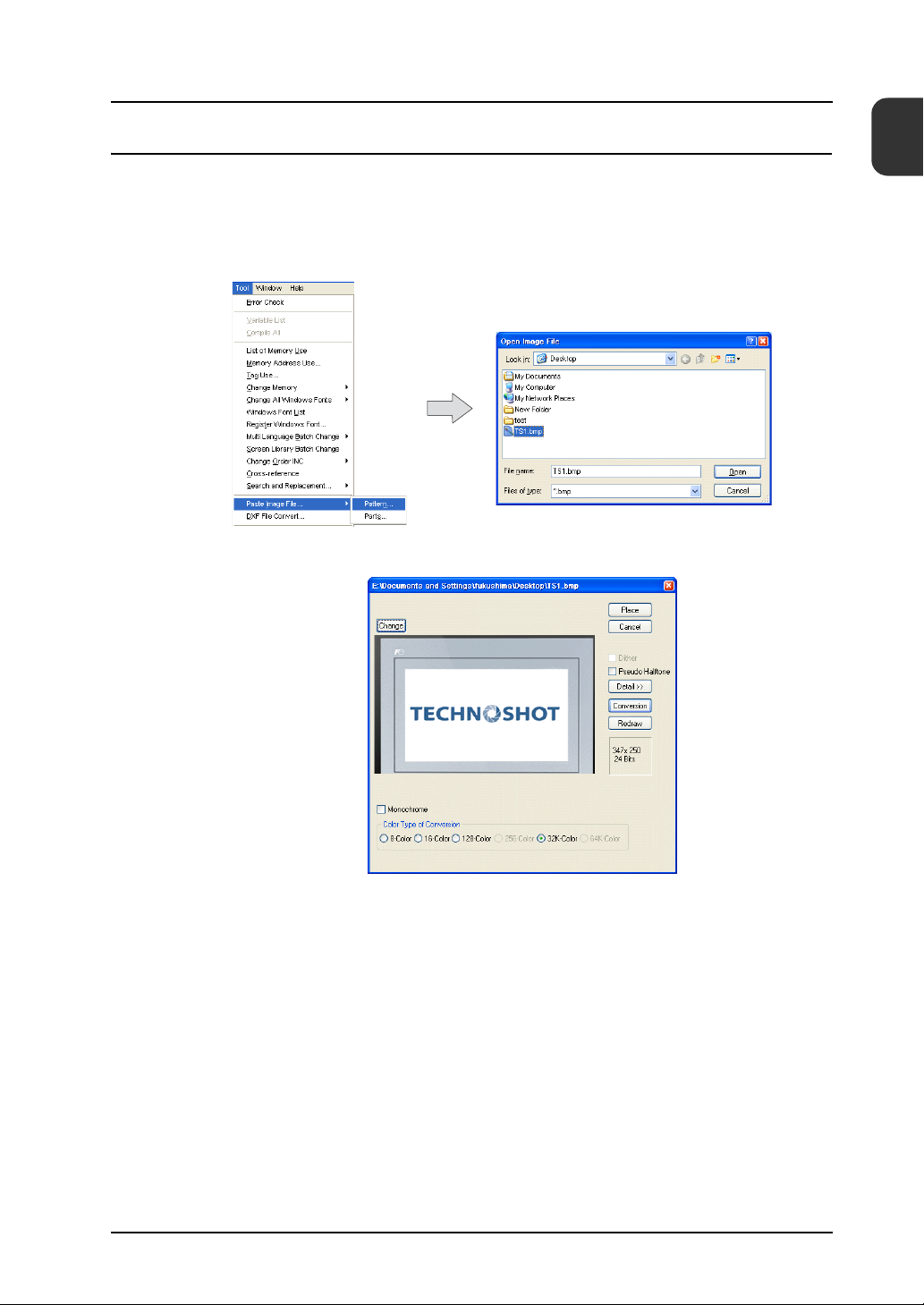

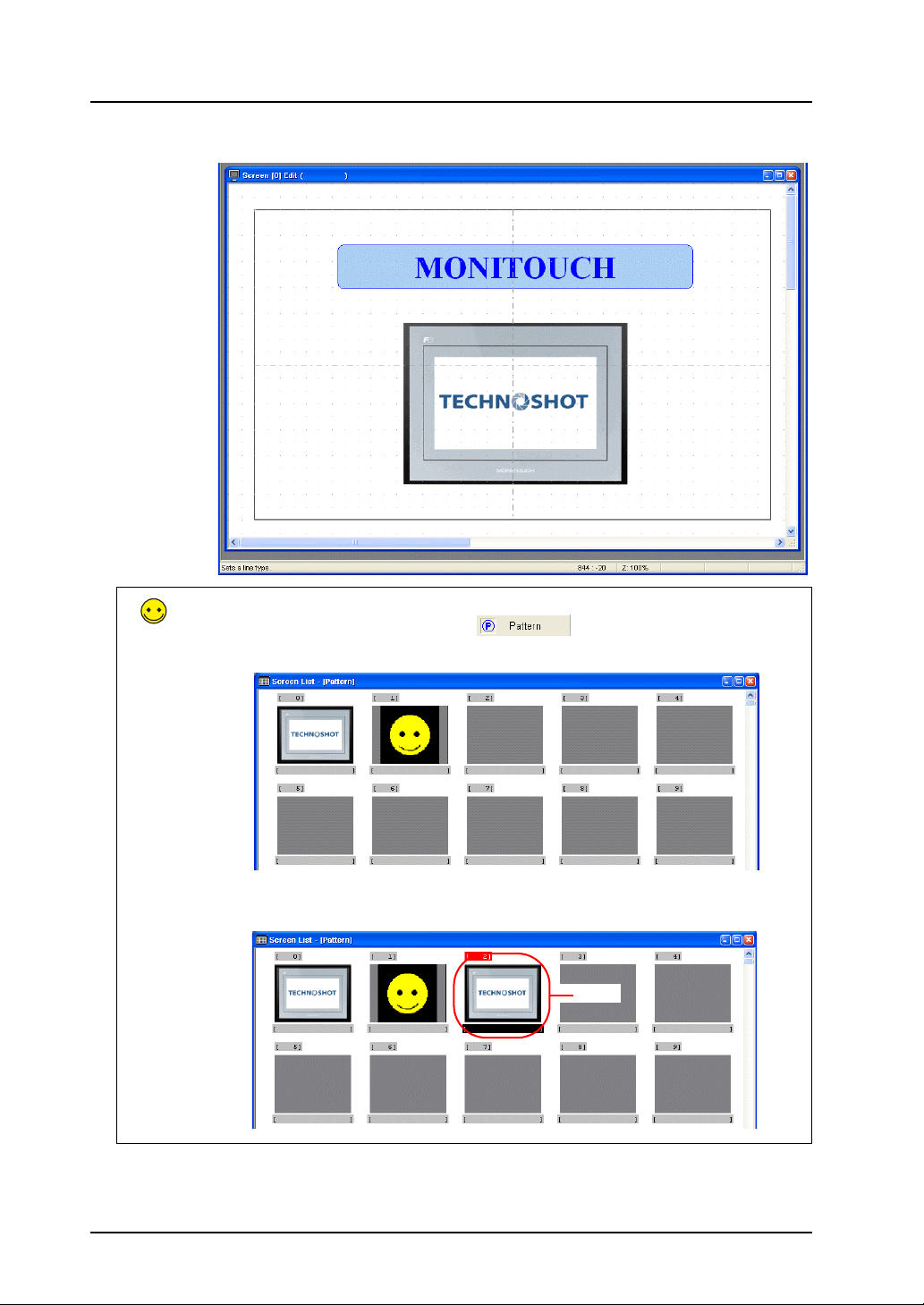

3.4 Pasting JPEG/Bitmap Files

This section explains how to load JPEG or bitmap files of company logos or machine image data

onto the screen as pattern data.

1. Click [Tool] → [Paste Image File] → [Pattern].

The [Open Image File] dialog box is displayed.

2. Select the file to load and click [Open]. The loaded image is displayed.

1

Screen Creation

1-11

Page 19

1. Creating New Files

3. Click the [Place] button to place the image on the screen.

The loaded image is registered to [Registration Item] → [Pattern]. The image can be used on

other screens by clicking the [Pattern] icon ( ) on the [Draw] toolbar and selecting

the image for placement.

Loading the same image multiple times results in multiple registrations and increases the screen

data size. Delete any unnecessary patterns.

Delete

1-12

Page 20

1. Creating New Files

4. Moving and Aligning Parts

This section explains how to move parts, change item size, and align multiple parts.

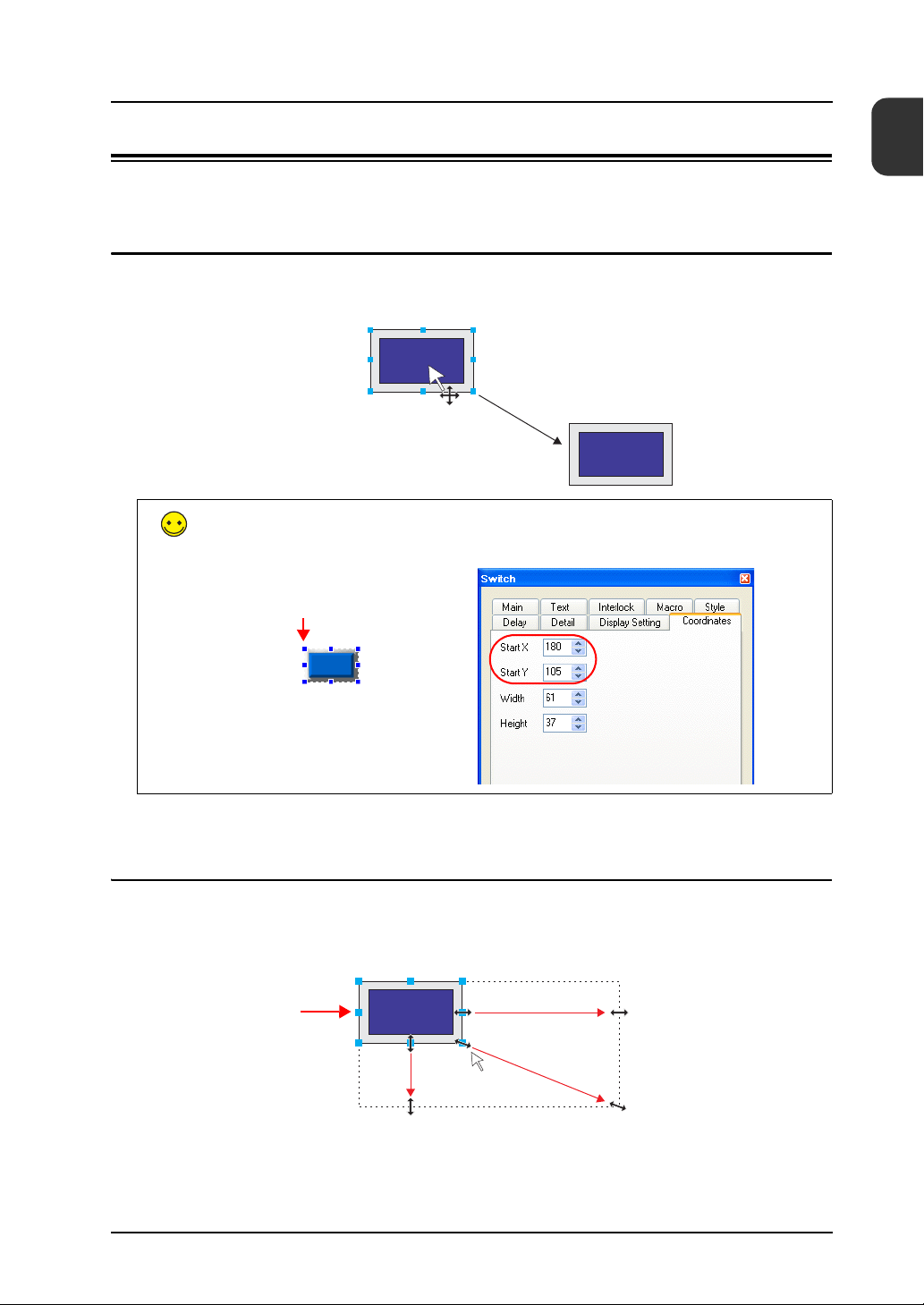

4.1 Moving Parts

1. Click on the part. Handles are displayed around the part.

2. With the mouse cursor displaying a cross-shaped mark, drag the part to another position.

The part position can also be set using [Start X] and [Start Y] on the [Coordinates] tab in the item

dialog box.

Start point

1

Screen Creation

Move

4.2 Enlarging and Reducing Part Size

1. Click on the part. Handles are displayed around the part.

2. Place the mouse cursor over a handle. The mouse cursor changes to a ↔ mark.

3. Drag the handle with the mouse cursor displayed as ↔.

Handle

Mouse cursor changes to

↔ when nearing a handle

Enlarge vertically

Enlarge horizontally

Enlarge horizontally and vertically

1-13

Page 21

1. Creating New Files

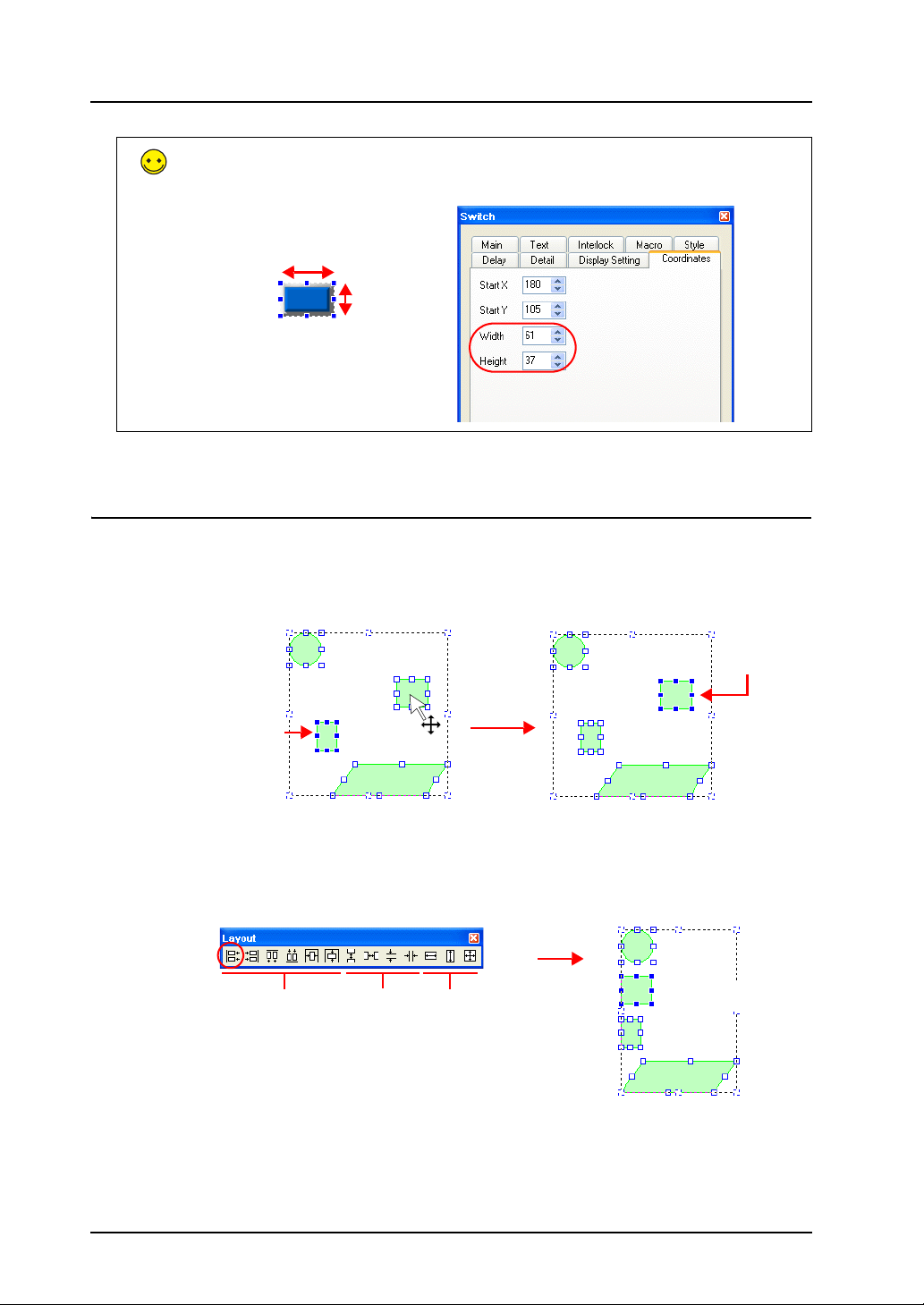

The part size can also be set using [Width] and [Height] on the [Coordinates] tab in the item

dialog box.

Width

Height

4.3 Aligning Parts and Matching Size

This section explains how to align the positions and match the sizes of multiple parts at once.

1. Select the parts for alignment. Handles are displayed around the parts.

2. Hold down the [Ctrl] key and click the reference part. The handle color of this part changes

and the part is specified as the reference part.

Reference partClick

Reference part

3. Use the [Layout] icons or the [Edit] menu → [Arrangement (Equal)] submenu or [Put All in

Same Size] submenu to align the positions or match the sizes of parts.

Example: Left justification

Align parts to the left of

Placement Arrange/

equalize

Match

size

the reference part.

1-14

Page 22

1. Creating New Files

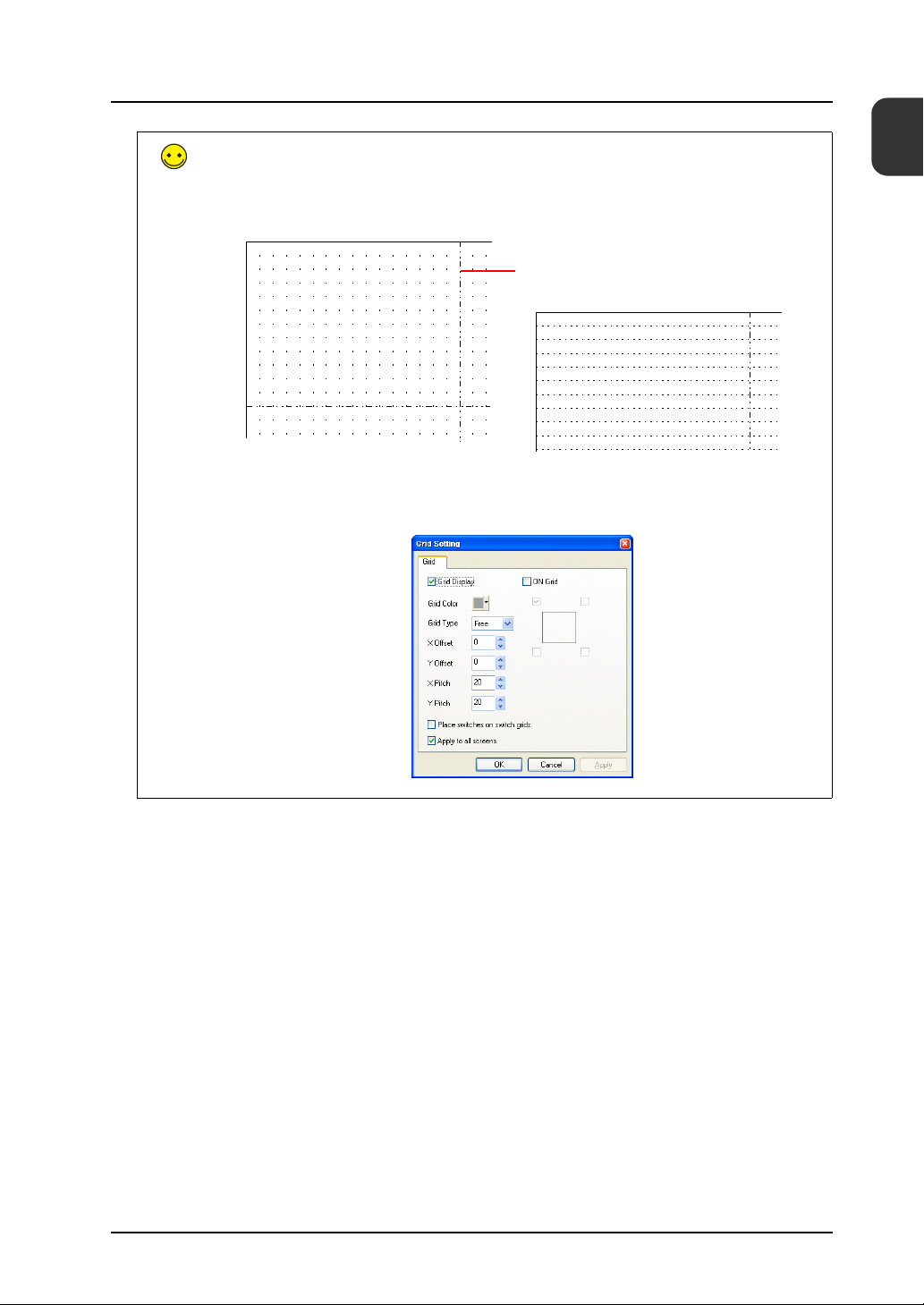

Grid Settings/Center Line Display

Use [Center Line Display] and [Grid Display] to display center lines and grid lines of reference on

screen to assist with item placement. These lines are only displayed in the V-SFT software and

not on the unit.

Center line

Display the center lines by clicking [View] → [Customize] → [Center Line Display].

Display grid line settings by clicking [View] → [Grid] → [Grid Display] and configure grid lines by

clicking [View] → [Grid] → [Grid Setting].

1

Screen Creation

1-15

Page 23

1. Creating New Files

5. Saving Files

5.1 Saving as a New File

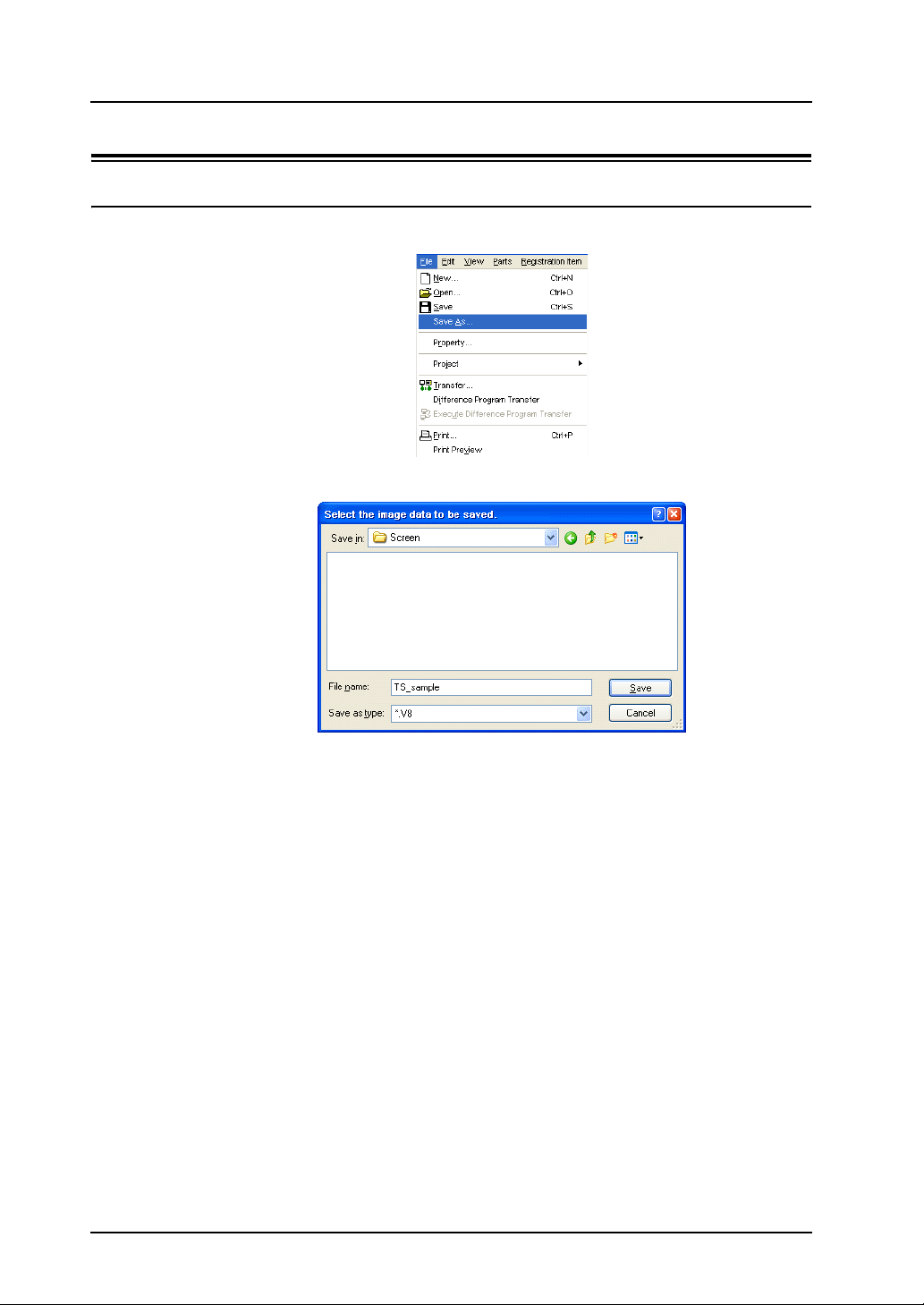

1. Click [File] → [Save As]. The [Select the image data to be saved.] dialog box is displayed.

2. Enter the desired filename and click [Save].

1-16

File creation is complete. Screen data may now be transferred to the unit.

Page 24

1. Creating New Files

Unit Operation

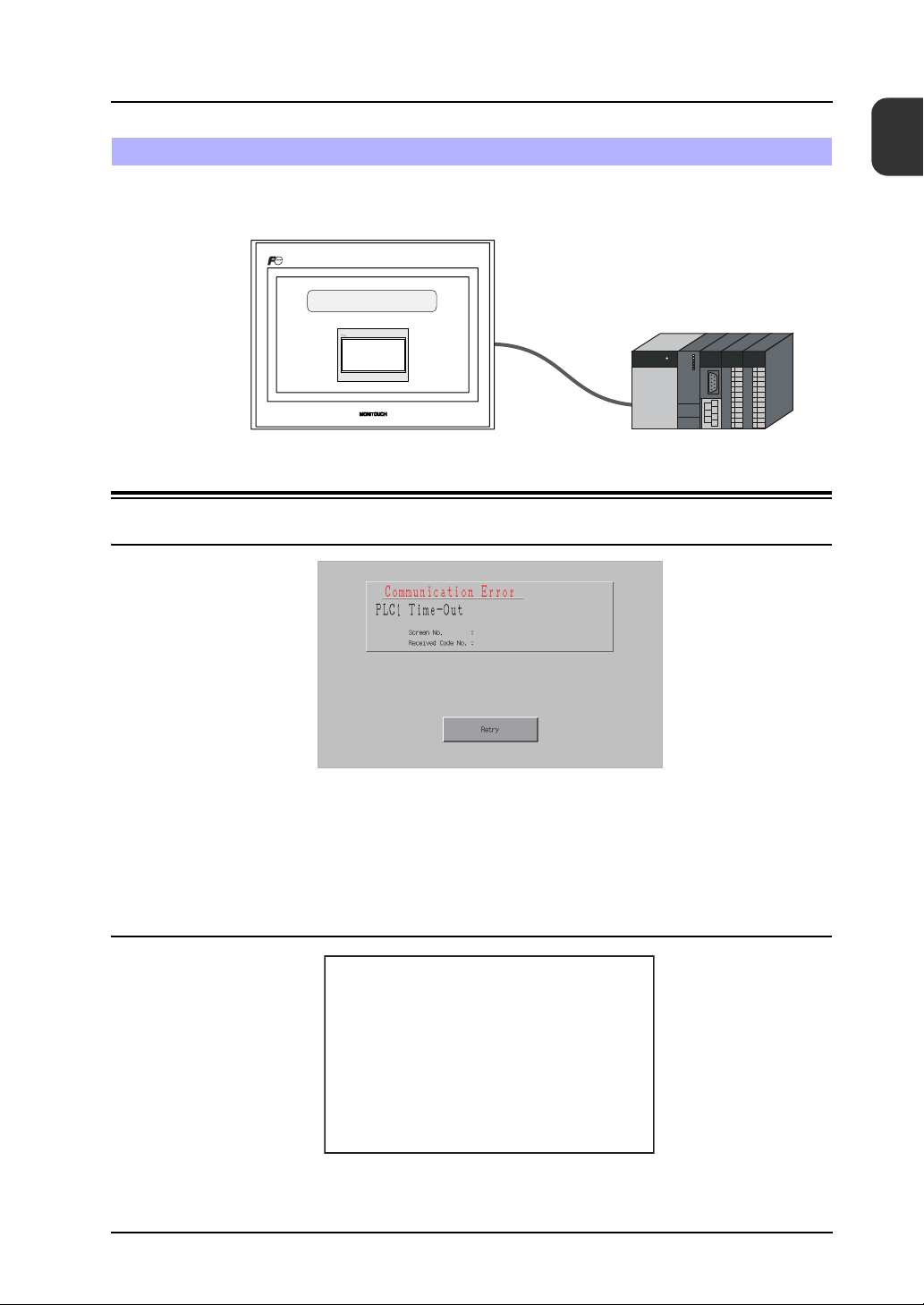

Screen data is displayed when the TS Series unit and PLC are connected correctly. Check that

the unit operates properly.

MONITOUCH

TECHNOSHOT

1. Error Display

1.1 Communication Error - Timeout

1

Unit Operation

Communication is not being performed correctly due to any of the following reasons.

• The model select for screen data in the [Device Connection Setting] window differs from the

actual connected model.

• The communication parameters of the TS Series unit and the PLC do not match.

• The communication cable is not connected correctly or disconnected.

1.2 Screen No. Error

Check the value of the screen number command specified in the read area (n + 2).

Data Loading...

Screen No. Error

1-17

Page 25

1. Creating New Files

The TS Series unit displays screens by looking at the memory value of the screen number

command when communication starts. The “Screen No. Error” message is displayed if this value

is set to a screen number that does not exist.

For the screen data in this manual, the [Read Area] value is “D0000” so the screen number

command memory is “D0002”. For data where screen numbers 0 to 5 have been created:

Read Area

The [Read Area] and [Write Area] settings can be accessed by clicking [System Setting] →

[Device Connection Setting].

The read area is the memory address where the PLC issues display or operation commands to

the TS Series unit. Three words of consecutive memory addresses are secured for this

purpose.

D0002 = 0 to 5 → Display correctly

D0002 = 6 to 9999 → Screen No. Error

Read Area Description Setting Example

n Subcommand D0

n + 1 Screen status command D1

n + 2 Screen number command D2

Write Area

This memory address is for outputting the screen status from the TS Series unit to the PLC.

Three words of consecutive memory addresses are secured for this purpose.

Write Area Description Setting Example

n Subcommand state D50

n + 1 Screen status D51

n + 2 Displayed screen number D52

1-18

Page 26

2. Creating Switches and Lamps

2. Creating Switches and Lamps

This chapter explains how to create screens that contain switches and lamps.

Contents

Screen Example.................................................................................................................. page 2-1

Screen Creation .................................................................................................................. page 2-2

1. Editing Screens ...................................................................................................... page 2-13

2. Procedure for Changing Parts ................................................................................ page 2-13

Confirming Unit Operation ................................................................................................ page 2-19

1. Memory Addresses................................................................................................. page 2-19

2. Unit Operation ........................................................................................................ page 2-19

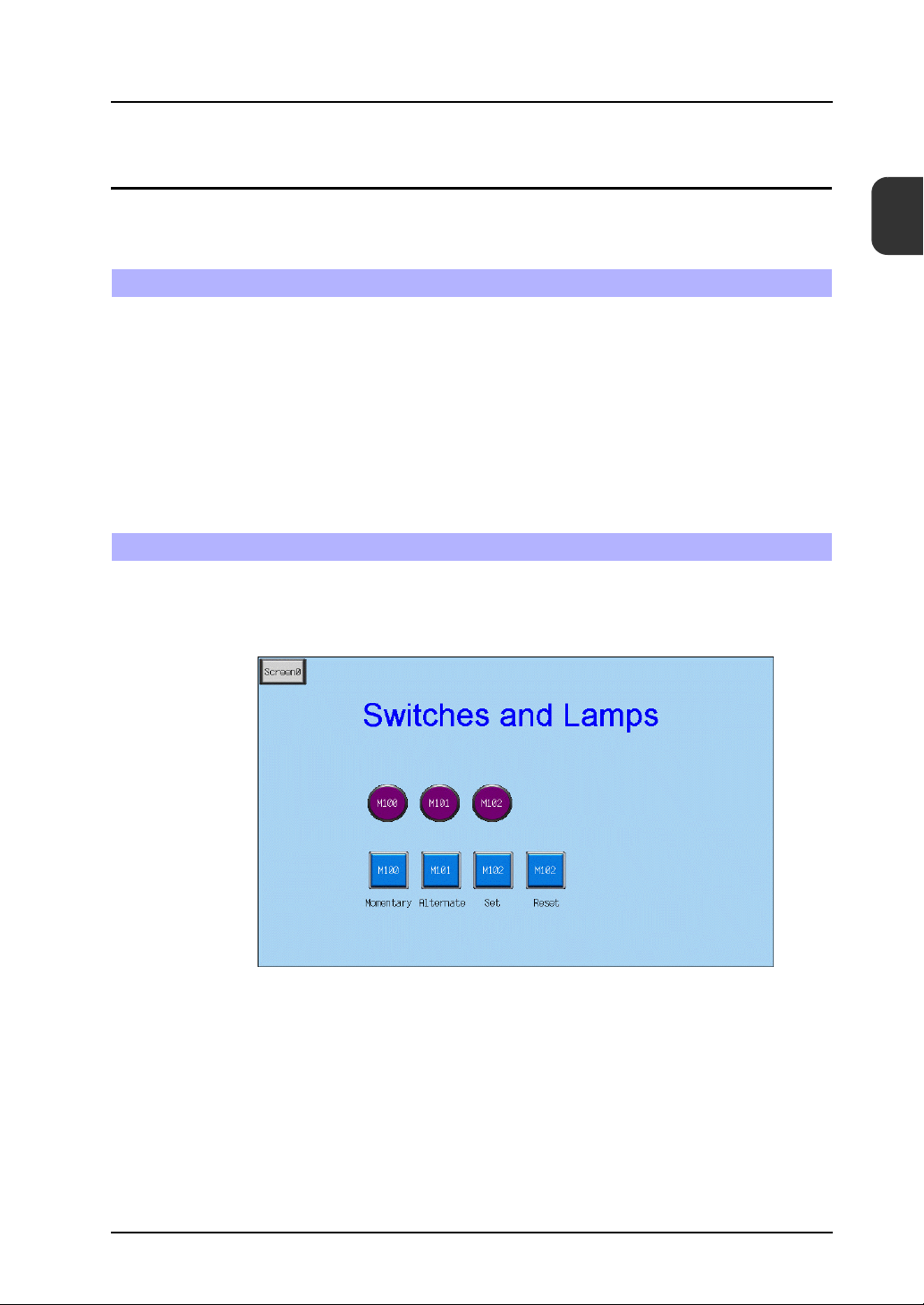

Screen Example

Create the following example screen that uses switch output to turn lamps on and off and switches

to another screen using a switch.

2

Contents

2-1

Page 27

2. Creating Switches and Lamps

1. Editing Screens

1.1 Creating a New Screen

3. Click the [Next Screen] icon to display the [Screen [1] Edit] window.

Screen Creation

1.2 Changing the Background Color

Change the background color of the screen by clicking [Screen Setting] → [Screen Setting].

For more information, refer to “Changing the Background Color” on page 1-5.

2-2

Page 28

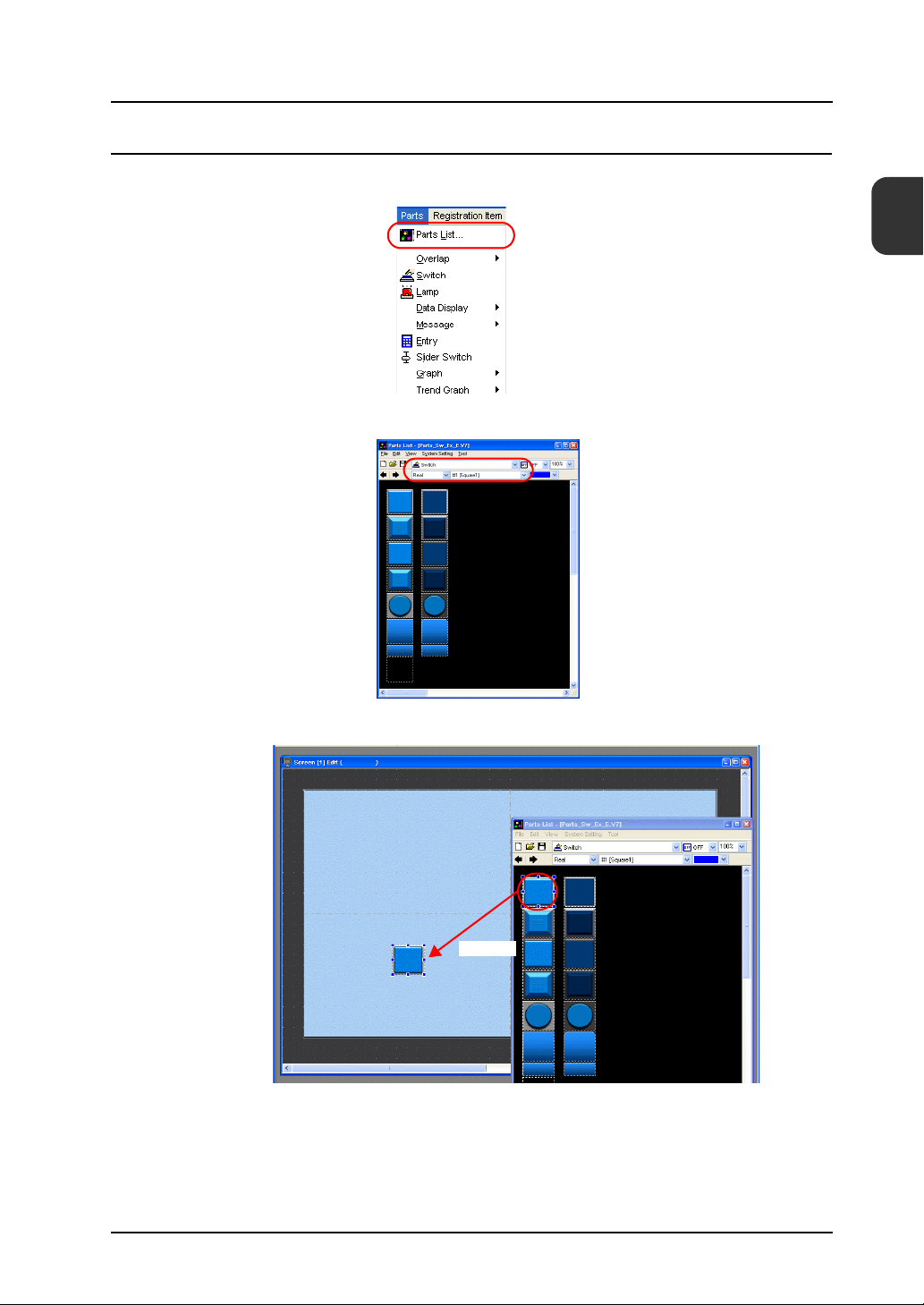

1.3 Placing Switches

1. Click [Parts] → [Parts List]. The [Parts List] window is displayed.

2. Select [Switch], [Real], and [#1 [Square1]].

2. Creating Switches and Lamps

2

Screen Creation

3. Select a switch and drag it onto the screen. This places the switch on the screen.

Drag

2-3

Page 29

2. Creating Switches and Lamps

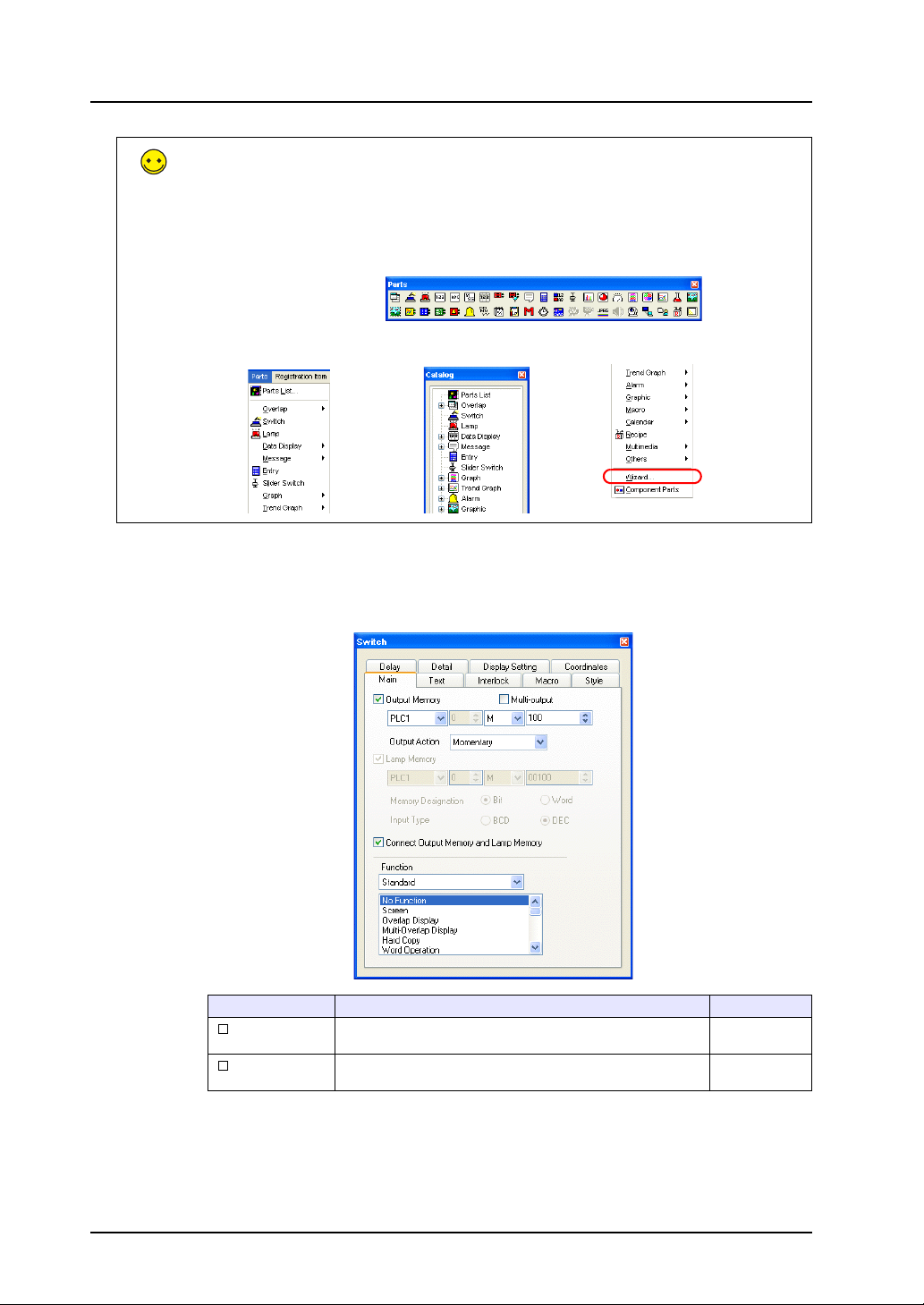

In addition to the [Parts List], the following four methods are available for placing parts.

1. Placement from the parts icons

2. Placement from the [Parts] menu

3. Placement from the [Catalog] dialog box

4. Placement using the wizard

1. Parts icons

2. [Parts] menu

3. [Catalog] dialog box

4. Wizard ([Parts] menu)

5. Configure each setting in the switch’s item dialog box.

•[Main] tab

Set the bit memory address for output and select a setting for [Function].

2-4

Item Details Setting Value

Output Memory

Multi-output

Set the bit memory address to output when the switch is pressed. Selected

Select this checkbox to perform a single output action with

respect to multiple memory addresses.

M100

Deselected

Page 30

2. Creating Switches and Lamps

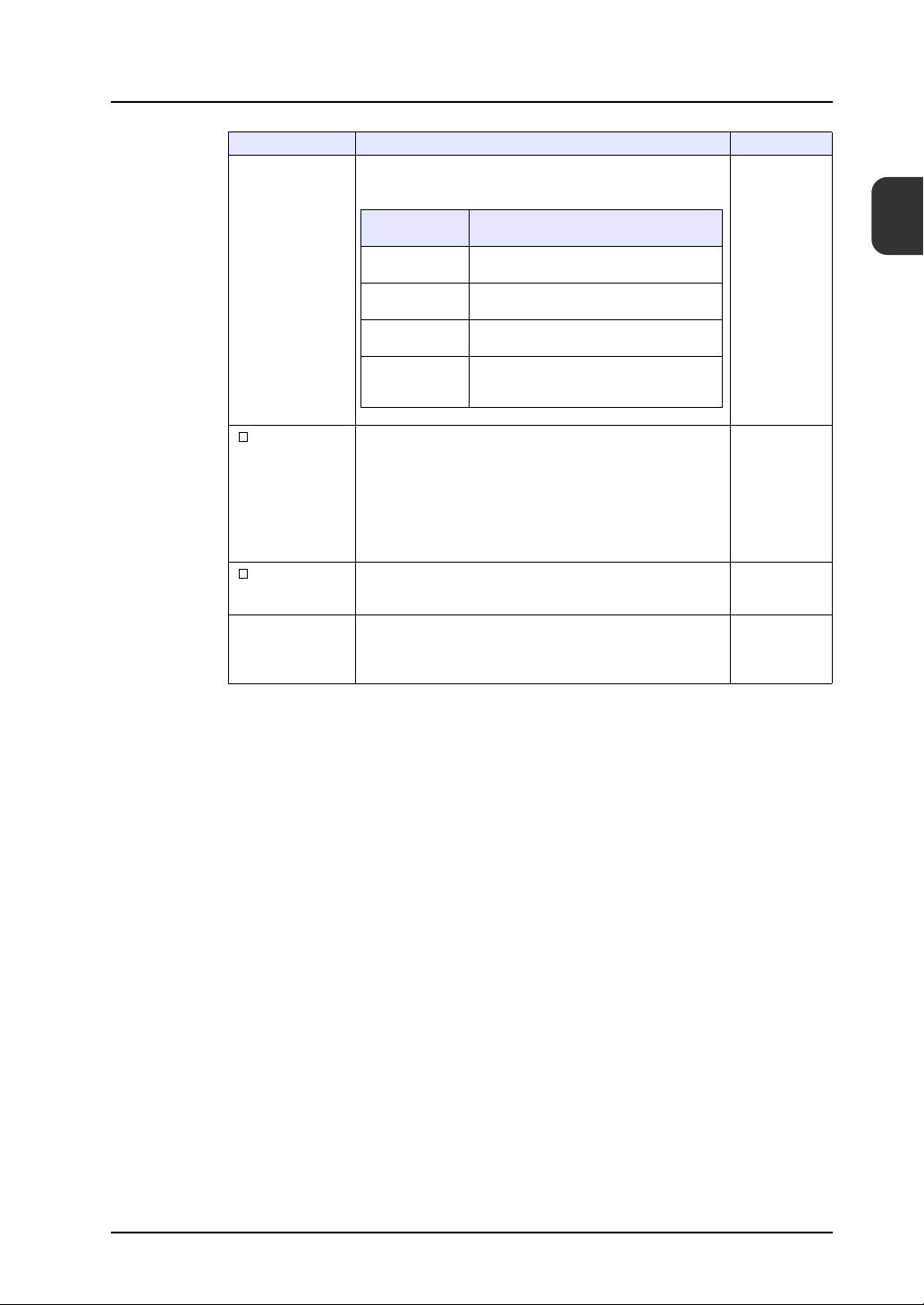

Item Details Setting Value

Output Action Set the write operation to perform with respect to the output

memory address.

Momentary

Switch

Operation

Set The specified bit memory address is set to

Reset The specified bit memory address is reset

Momentary

Momentary W

Alternate The specified bit memory address is

Lamp Memory

Connect Output

Memory and Lamp

Memory

Function Set the function of the switch, or in order words, how the switch

*1 For more information on functions, refer to the “V8 Series Reference Manual.”

Change the display of the switch area.

Deselected:

Pressing the switch turns on the lamp in the switch. Releasing

your finger from the switch turns the lamp off.

Selected:

Set the memory address for the lamp display using [Memory

Designation] and [Input Type].

Select this checkbox to use the same memory address for output

memory and lamp memory.

should work when it is pressed. Functions that are frequently

used include “Screen”, “Overlap Display”, and “Multi-Overlap

*1

Display”.

“ON”.

to “OFF”.

The specified bit memory address is set to

“ON” while the switch is depressed.

alternately set (ON) and reset (OFF) each

time the switch is pressed.

Output Processing

2

Screen Creation

-

Selected

No Function

2-5

Page 31

2. Creating Switches and Lamps

•Text

Set the text displayed on the switch.

If the switch displays

different text in the ON and

OFF states, register the

text to display in each state

on the [ON] and [OFF]

tabs.

Item Details Setting Value

OFF, ON to P128

Pattern No.

Color

Property

Enlarge

Point

Rotation + Direction

Windows Font

Register the text to be displayed on the switch. M100

Set the text color, properties, and text size. -

• Changes to the settings on the [Interlock], [Macro], [Style], [Delay], [Detail], and [Display

Setting] tabs are not covered in this section.

2-6

Page 32

1.4 Creating Multiple Copies of Switches

This section explains how to copy a switch multiple times.

1. Select a switch. Handles are displayed around the switch.

2. Click [Edit] → [Multi Copy] or click the [Multi-copy] icon. The [Multi Copy] dialog box is

displayed.

2. Creating Switches and Lamps

2

Screen Creation

or

3. Set the options as shown below and click [OK]. This copies the switch multiple times.

2-7

Page 33

2. Creating Switches and Lamps

4. Click [View] → [Customize] → [Memory Display]. Memory addresses are displayed at the

lower left on each switch.

5. Change the switch text and output action to the following.

[Main] tab

Output Action: Alternate

[Text] tab

OFF: M101

This completes the switch creation process.

[Main] tab

Output Action: Set

[Text] tab

OFF: M102

[Main] tab

Output Memory:

M102

Output Action: Reset

[Text] tab

OFF: M102

2-8

Page 34

1.5 Placing Lamps

1. Click [Parts] → [Parts List]. The [Parts List] window is displayed.

2. Select [Lamp], [Real], and [#0 [Circle1]].

3. Select a lamp and drag it onto the screen. This places the lamp on the screen.

2. Creating Switches and Lamps

2

Screen Creation

Drag

4. Configure each setting in the lamp’s item dialog box.

•[Main] tab

Set the memory address for the lamp.

Item Details Setting Value

Lamp Memory The display of the lamp area can be changed.

Function Set the lamp’s function.

Set the memory address for the lamp display using [Memory

Designation] and [Input Type].

Normally select [No Function].

M100

No Function

2-9

Page 35

2. Creating Switches and Lamps

• [Text] tab

Set the text displayed on the lamp.

If the lamp displays different text in

the ON and OFF states, register the

text to display in each state on the

[ON] and [OFF] tabs.

Item Details Setting Value

OFF, ON to P128

Pattern No.

Color

Property

Enlarge

Point

Rotation + Direction

Windows Font

Register the text to be displayed on the lamp. M100

Set the text color, properties, and text size. -

• Changes to the settings on the [Style], [Detail], and [Display Setting] tabs are not covered in

this section.

2-10

Page 36

1.6 Creating Multiple Copies of Lamps

Create multiple copies of lamps using the same procedure for multiple copies of switches.

2. Creating Switches and Lamps

1. Select the lamp. Handles are displayed around the lamp.

2. Click [Edit] → [Multi Copy] or click the [Multi-copy] icon. The [Multi Copy] dialog box is

displayed.

or

2

Screen Creation

3. Set the options as shown below and click [OK]. This copies the lamp multiple times.

2-11

Page 37

2. Creating Switches and Lamps

4. Change the text displayed on each lamp.

This completes the lamp creation process.

[Text] tab

M101

[Text] tab

M102

2-12

Page 38

2. Procedure for Changing Parts

Perform the following procedure to change the design or color of parts placed on the screen.

2.1 Changing Parts

2. Creating Switches and Lamps

2

1. Select the part for changing to display its item dialog box.

2. Click [Style] → [Change Part]. The [Change Part] window is displayed.

Screen Creation

2-13

Page 39

2. Creating Switches and Lamps

3. Select the part using [Change Part Color] and [Part Type Change].

Item Details

Maintain Size

Pattern Change The pattern image of OFF, ON, and patterns up to P128 can be checked.

Change Part Color Change the color.

Part Type Change Change the part type.

Deselected:

Change to the default size.

Selected:

Maintain the size prior to changing.

Real/Sign/3D

Circle/Square/Plant/Icon etc.

4. Select the part properties for changing and click [Select] to change the lamp on the screen.

2-14

Page 40

2.2 Changing the Color of Parts

1. Select the part for changing to display its item dialog box.

2. Select the pattern (OFF/ON/P3 or higher) whose color is to be changed on the [Style] tab and

click [Customize].

2. Creating Switches and Lamps

2

Screen Creation

3. Select an image and color in the [Change the image] window.

2-15

Page 41

2. Creating Switches and Lamps

Different color settings for OFF and ON can be configured by changing the color in the [Change

the image] window.

Before change

After change

OFF ON

2-16

Page 42

2.3 Placing Text

This section explains how to place the screen title and other text elements.

♦ Creating Text

1. Click the [Text] icon on the [Draw] toolbar. A cross-shaped cursor is displayed.

2. Creating Switches and Lamps

2

Te xt

Screen Creation

Te xt

2. Click on the screen. A text frame is displayed.

3. Enter text.

4. Click a location on the screen other than the text.

5. Click the text to display its item dialog box. Change the text color and text size properties.

2-17

Page 43

2. Creating Switches and Lamps

2.4 Creating a Switch for Changing to Another Screen

This section explains how to place a switch that changes between screen 0 and screen 1 when

pressed.

1. Place a switch.

2. Set [Function] to “Screen” in the switch’s item dialog box and set [Screen No.] to the number of

the destination screen.

Screen 1

Switch

Function: Screen 0

Screen 0

Switch

Function: Screen 1

3. Adjust the switch color and position.

This completes the screen creation process. The next section covers confirming screen operation

on the TS Series unit.

2-18

Page 44

1. Memory Addresses

The memory addresses used in this example are listed below.

2. Creating Switches and Lamps

Confirming Unit Operation

2

Memory

Address

M100 Switch output memory (momentary), lamp memory

M101 Switch output memory (alternate), lamp memory

M102 Switch output memory (set/reset), lamp memory

2. Unit Operation

This section explains how to confirm screen operation after transferring screen data to the unit.

2.1 Switching Screens

1. Screen 0 is displayed initially.

(Refer to the next page if a different screen or “Screen No. Error” is displayed.)

Memory Contents

Confirming Unit Operation

2. Press [Screen1] at the upper right of the screen. The screen changes to display screen 1.

2-19

Page 45

2. Creating Switches and Lamps

Changing Screens Using PLC Commands (External Commands)

The [Read Area] and [Write Area] settings, accessed by clicking [System Setting] → [Device

Connection Setting], are used for this purpose. “D0002” is used for the screen number

command memory in this manual.

Setting “D0002” to the screen number will allow the display to change. Note that the screen

number of the currently displayed screen is stored using “D0052” in the [Write Area].

PLC

Screen0

D0002

D0052

D0002

D0052

0

0

PLC

Screen1

1

1

2-20

The screen number to display when the unit is powered on is also determined by “D0002”.

The “Screen No. Error” message is displayed if a screen number that does not exist is set.

For more information on the [Read Area] and [Write Area], refer to page 1-17.

Page 46

2.2 Switch Output and Lamp Display

♦ Momentary Switch

The output memory address is set to “ON” while the switch is depressed.

1. Press the M100 (momentary) switch. The M100 lamp turns on.

2. Releasing your finger from the switch turns the M100 lamp off.

2. Creating Switches and Lamps

2

Confirming Unit Operation

2-21

Page 47

2. Creating Switches and Lamps

♦ Alternate Switch

The specified bit memory address is alternately set (ON) and reset (OFF) each time the switch is

pressed.

1. Press the M101 (alternate) switch. The M101 lamp turns on.

2. The M101 lamp stays on even after releasing your finger from the switch.

2-22

3. Press the M101 (alternate) switch again. The M101 lamp turns off.

The ON/OFF state of the lamp changes each time the switch is pressed.

Page 48

♦ Set/Reset Switch

The specified bit is set to “ON” or “OFF”.

2. Creating Switches and Lamps

1. Press the M102 (set) switch. The M102 lamp turns on.

2. The M102 lamp stays on even after releasing your finger from the switch.

2

Confirming Unit Operation

3. Press the M102 (reset) switch. The M102 lamp turns off.

2-23

Page 49

2. Creating Switches and Lamps

2-24

Please use this page freely.

Page 50

3. Creating Overlaps

Windows can be temporarily overlaid on the displayed screen when necessary. These types of

windows are referred to as “overlaps”.

A maximum of four overlaps can be displayed at once on the screen.

3. Creating Overlaps

Screen 1 Screen 1

113 5

120

1564

554

1653

10.23

9.89

7.23

11.02

12.03

849

988

489

156

484

5548

6615

4485

9981

116 5

7 8 9

UP

120

4 5 6

DW

1564

1 2 3

CL

Do you wish to save?

554

0 . +/-

CR

1653

10.23

11.02

12.03

9.89

7.23

849

5548

Error Occurred

6615

988

4485

489

156

9981

484

116 5

113 5

Overlaps that are frequently used include normal overlaps, which can only be displayed on the

screen on which they are created, and multi-overlaps registered to the overlap library that can be

used across several screens.

• Normal Overlap

Screen 1 Screen 2

113 5

120

AAA

1564

554

1653

10.23

11.02

12.03

9.89

7.23

BBB

849

988

489

156

484

5548

6615

CCC

4485

9981

116 5

4407

4508

4356

4640

4412

10.23

9.89

7.23

11.02

5.89

CCC

849

988

489

156

780

126

129

189

172

168

• Multi-overlap

Overlap library

7 8 9

4 5 6

1 2 3

0 . +/-

UP

DW

CL

CR

Do you wish to save?

Menu

Error

3

Screen 1 Screen 2 Screen 3

113 5

10.23

849

120

1564

554

1653

988

489

156

484

5548

6615

4485

9981

116 5

Menu Menu Menu

9.89

7.23

11.02

12.03

4407

4508

4356

4640

4412

10.23

9.89

7.23

11.02

5.89

849

988

489

156

780

126

129

189

172

168

540

561

587

510

532

9.81

9.89

7.23

11.02

6.92

115 4

114 1

1205

119 5

117 9

105.6

100.6

99.8

115.2

92.5

3-1

Page 51

3. Creating Overlaps

Screen Example.................................................................................................................. page 3-2

Screen Creation .................................................................................................................. page 3-3

Confirming Unit Operation ................................................................................................ page 3-14

Add a multi-overlap to screen 1, which was created with switches and lamps.

Contents

1. Editing the Overlap Library ....................................................................................... page 3-3

2. Editing Screens ........................................................................................................ page 3-8

1. Unit Operation ........................................................................................................ page 3-14

Screen Example

3-2

Page 52

1. Editing the Overlap Library

This section explains how to create overlaps.

3. Creating Overlaps

Screen Creation

Almost all items including switches, lamps, and alarms can be placed on overlaps.

1.1 Placing Overlaps

1. Click [Registration Item] → [Overlap Library]. The [Overlap Library] dialog box is displayed.

2. Select a registration number and click the [OK] button. The [Overlap Library Edit] window is

displayed.

3

Screen Creation

3. Click [Parts] → [Overlap] → [Normal Overlap] to place an overlap.

3-3

Page 53

3. Creating Overlaps

4. Configure settings in the item dialog box.

•[Main] tab

Item Description

System Button

Select this checkbox to add a switch function (move/dismiss) to

the upper left corner of the overlap area.

For more information on the operation of this switch, refer to

“1.2 Overlap System Button Function” (page 3-15).

•[Style] tab

Item Description

Color

Frame, Area

Change Part Change the part used for the overlap. -

Set the area color. -

Setting

Val ue

Selected

Setting

Val ue

3-4

• [Detail] tab

Settings on this tab do not require configuration.

• [Coordinates] tab

Set the placement position and size of the overlap.

Page 54

3. Creating Overlaps

The size of the overlap can also be changed by selecting the overlap and dragging the displayed

handles.

3

1.2 Placing Text

This section explains how to place text on the overlap.

1. Click the [Text] icon ( ). A cross-shaped cursor is displayed.

2. Click on the overlap. A text frame is displayed.

3. Enter text.

4. Click a location on the screen other than the text.

5. Click the text to display its item dialog box. Change the text color and text size properties.

Drag

Screen Creation

3-5

Page 55

3. Creating Overlaps

1.3 Placing Switches

This section explains how to create a switch for hiding the overlap.

1. Click [Parts] [Parts List]. The [Parts List] window is displayed.

2. Select [Switch], [Real], and [#18 [Icon10]].

3. Select a switch and drag it onto the overlap. This places the switch on the overlap.

Drag

3-6

Page 56

4. Set the [Function] option in the switch’s item dialog box.

Function: Standard, Overlap Display

Overlap ID: 0

Action: OFF

Match the overlap ID to the ID of the screen’s overlap

icon.

(For more information on the overlap icon, refer to page

3-12.)

3. Creating Overlaps

3

Screen Creation

Edit items on the overlap by clicking [Overlap Editing] → [No. 0] on the right-click menu.

This allows multiple items to be selected by dragging with the mouse.

The completes the overlap editing process.

3-7

Page 57

3. Creating Overlaps

2. Editing Screens

This section explains how to register a multi-overlap icon and a switch for displaying a

multi-overlap.

2.1 Placing the Switch

Multi-overlap

icon

Switch

1. Display the [Screen [1] Edit] window.

2. Click [Parts] [Parts List]. The [Parts List] window is displayed.

3-8

Page 58

3. Creating Overlaps

3. Select [Switch], [Real], and [#1 [Square1]].

4. Select the switch and drag it onto the screen. This places the switch on the screen.

3

Screen Creation

Drag

In addition to the [Parts List], the following four methods are available for placing parts.

1. Placement from the parts icons

2. Placement from the [Parts] menu

3. Placement from the [Catalog] dialog box

4. Placement using the wizard

1. Parts icons

2. [Parts] menu

3. [Catalog] dialog box

4. Wizard ([Parts] menu)

3-9

Page 59

3. Creating Overlaps

5. Set the [Function] option in the switch’s item dialog box.

•[Main] tab

Item Details Setting Value

Output Memory

Lamp Memory

Function Select the function of the switch, or in order words, how the

Overlap ID Set the overlap ID.

Overlap Library No. Set the overlap library number.

Display Position

*1 The settings for normal overlap display are:

[Main] tab

Function: Overlap Display

Action: ON

Set the bit memory address to output when the switch is pressed. Deselected

Change the display of the switch area.

Deselected:

Pressing the switch turns on the lamp in the switch. Releasing

your finger from the switch turns the lamp off.

Selected:

Set the memory address for the lamp display using [Memory

Designation] and [Input Type].

switch should work when it is pressed. Functions that are

frequently used include “Screen”, “Overlap Display”, and

“Multi-Overlap Display”.

Setting value: 0 to 2

Setting value: 0 to 9999

Set the [X Coordinate] and [Y Coordinate] values for the display

position of the overlap.

Specify with Mouse: Specify the coordinates by clicking with the

*2

mouse.

*1

Deselected

Multi-Overlap

Display

0

0

Selected

X120

Y125

3-10

Page 60

3. Creating Overlaps

*2 Mouse specification method

Click the [Specify with Mouse] button. A cross-shaped cursor and a rectangle the size of the overlap are

displayed.

OVLP

Click

Click on a position where the rectangle does not protrude outside the screen. The mark that shows

the display position of the multi-overlap moves to the clicked position.

• [Text] tab

Register the text displayed on the switch.

3

Screen Creation

This completes the switch creation process.

3-11

Page 61

3. Creating Overlaps

2.2 Registering an Overlap Icon

1. Click [Parts] → [Overlap] → [Multi-Overlap].

2. Click on the screen to place the multi-overlap icon.

3. Configure settings in the item dialog box.

•[Main] tab

Item Details Setting Value

Overlap ID A maximum of three overlaps can be displayed at once.

Designate

Internal, External

Set the area of IDs 0 to 2 in which to display the overlap

registered in the overlap library.

Setting value: 0 to 2

Internal

Display the overlap using the switch function.

External

Specify the overlap library number in a memory address and

show or hide the overlap according to the bit in the read area

or command memory.

0

Internal

3-12

Page 62

3. Creating Overlaps

Item Details Setting Value

Info Output Memory Stores the currently displayed overlap library number.

Overlap Library No. This option is valid when [Designate] is set to “External”.

Coordinate

Designation

This memory address stores “-1” when the overlap display is

hidden.

This memory address specifies the overlap library number.

This option is valid when [Designate] is set to “External”.

Select this checkbox to set the display position of the overlap (X

and Y coordinates).

-

-

-

• [Detail] tab

Settings on this tab do not require changing.

This completes the screen creation process. The next section covers confirming screen operation

on the TS Series unit.

3

Screen Creation

3-13

Page 63

3. Creating Overlaps

Confirming Unit Operation

1. Unit Operation

This section explains how to confirm screen operation after transferring screen data to the unit.

1.1 Showing and Hiding Multi-overlaps

1. Display screen 1.

2. Press the [OVLP] switch. The overlap is shown.

3. Press the [CLOSE] switch. The overlap is hidden.

3-14

Page 64

1.2 Overlap System Button Function

A system button function can be added to overlaps.

This function can perform the following two operations.

• Overlap movement

• Overlap dismissal

Movement and dismissal of overlaps is only available when the [System Button] checkbox is

selected in the overlap settings.

1. Press the [OVLP] switch to display the multi-overlap.

3. Creating Overlaps

3

Confirming Unit Operation

2. Press the upper left corner of the overlap. The periphery of the overlap starts flashing.

Periphery of the

overlap flashes

3-15

Page 65

3. Creating Overlaps

3. While the periphery of the overlap is flashing, press the position to move the overlap.

The overlap moves to the specified position.

Press the position to move the

overlap with your finger

3-16

4. Double-tap the upper left corner of the overlap to dismiss it.

Page 66

4. Entry Screens

This chapter explains how to create a keypad entry screen. As keypads are usually not

permanently displayed on screens, here we will create a screen that displays a keypad only when

entry is required.

• Normal: Keypad OFF

• Entry: Keypad displayed

4. Entry Screens

4

Contents

Tap the numerical data

display to display the keypad.

Press the [Enter] key to hide

the keypad.

Contents

Screen Example.................................................................................................................. page 4-2

Screen Creation .................................................................................................................. page 4-3

1. Editing Screens ........................................................................................................ page 4-3

2. Overlap Library ....................................................................................................... page 4-14

Confirming Unit Operation ................................................................................................ page 4-19

1. Memory Addresses................................................................................................. page 4-19

2. Unit Operation ........................................................................................................ page 4-19

4-1

Page 67

4. Entry Screens

Screen Example

In this section, create a screen for entering values into parts “D100” through “D115”.

D100

D101

D102

D103

Keypad display

PLC

0 Dec

0 Dec

0 Dec

0 Dec

4-2

Entry

D100

D101

D102

D103

PLC

33 Dec

0 Dec

0 Dec

0 Dec

Page 68

1. Editing Screens

Screen editing involves registration of numerical data and character displays targeted for writing as

well as multi-overlaps.

4. Entry Screens

Screen Creation

Multi-overlap

Numerical

data display

1.1 Placing Numerical Data Displays and Registering Keypads

1. Click [Parts] → [Parts List]. The [Parts List] window is displayed.

2. Select [Entry], [Real #0 NUM.Display].

Character

display

4

Screen Creation

4-3

Page 69

4. Entry Screens

3. Select a numerical data display part and drag it onto the screen. This places the numerical

data display on the screen.

Drag

4. Configure each setting in the numerical data display’s item dialog box.

•[Main] tab

Set the memory address for writing and select a setting for [Function].

Item Details Setting Value

Memory Set the memory address for writing. D100

Offset Value

Designation

Memory

Data Length Set the data length of the memory address for writing.

Select this checkbox to specify an offset.

Not used in this section. For more information, refer to the “V8

Series Reference Manual.”

Setting value: 1-Word/2-Word

Deselected

1-Word

4-4

Page 70

4. Entry Screens

Item Details Setting Value

Digits Set the number of digits used by the memory address for writing.

Decimal Point Select whether to include a decimal point.

Display Type Set the format of numbers to be displayed on the screen. DEC

Input Type Set the format for reading values from memory. DEC

Zero Suppress

Function Set the numerical data display function. Entry Target

Order INC Set the order in which the cursor moves when multiple entry

With Entry Key

Overlap ID Set the overlap ID to be used for showing the entry keys.

Overlap Library No.

Register button

Display Position

X Coordinate

Y Coordinate

Specify with

Mouse button

*1 Registration method

Setting [Overlap Library No.] to “1” and clicking the [Register] button displays the [Change Part] window.

Select the design and color and then click the [Select] button.

Setting value: 1 to 32

Setting value:

0: No decimal point

1 to 10: Insert decimal point (at corresponding 1st to 10th

decimal place)

Select this checkbox to enable zero suppression. Selected

Selected (Flush Right)

12

Space

targets are placed on the screen.

Function: Entry Target (enabled when selected)

Select this checkbox to add the entry key call function.

Setting value: 0 to 2

Set the overlap library number for registering the entry keys.

*1

Select the desired keypad by pressing the [Register] button and

register the keypad to the overlap library.

If the keypad is already registered to the overlap library, simply

specify the overlap library number.

Setting value: 0 to 9999

Set the [X Coordinate] and [Y Coordinate] values for the display

position of the overlap.

[Specify with Mouse] button: Specify the coordinates by clicking

with the mouse.

*2

Deselected

00012

(with sign +-)

Flush Right

Selected

Selected

X Coordinate:

240

Y Coordinate:

145

5

0

4

Screen Creation

0

0

1

A keypad is registered to the specified overlap library number. For more information on the registered

details, refer to page 4-14.

If the specified overlap library number is already registered, the following confirmation message is

displayed.

Select [Yes] to overwrite the overlap library number or select [No] to register the keypad to another overlap

library number.

4-5

Page 71

4. Entry Screens

*2 Mouse specification method

Click the [Specify with Mouse] button. A cross-shaped cursor and a rectangle the size of the overlap are

displayed.

Click

OVLP

Click on a position where the rectangle does not protrude outside the screen. The mark that shows

the display position of the multi-overlap moves to the clicked position.

•[Style] tab

Set text properties of the entry target.

Use the [Change Part] button to change parts.

• Operation/Alarm

Set the alarm options.

Item Details Setting Value

Alarm Select this checkbox to use the alarm function. Selected

Min. Set the minimum and maximum entry values.

Max. 5000

Word Operation Not used in this section.

Scaling

Values outside this range cannot be entered.

For more information, refer to Chapter 5 in the “V8 Series

Reference Manual.”

−5000

Red

Blue

Deselected

4-6

• Changes to the settings on the [Detail], [Comment], and [Display Setting] tabs are not covered

in this section.

Page 72

1.2 Creating Multiple Copies of Numerical Data Displays

1. Select the numerical data display on the screen. Handles are shown around the numerical

data display.

4. Entry Screens

4

Screen Creation

2. Click [Edit] → [Multi Copy] or click the [Multi-copy] icon. The [Multi Copy] dialog box is

displayed.

or

3. Set the options as shown below and click [OK]. This copies the numerical data display.

X

(100)

Y

(5)

Copy direction

4-7

Page 73

4. Entry Screens

4. Select [View] → [Customize] → [Memory Display].

Memory addresses are displayed at the lower left on each numerical data display. The

memory addresses are set from “D100” to “D109”.

4-8

5. Change the settings of each numerical data display. In this section, change the settings to the

following.

[Main] tab

Decimal Point: 1

[Main] tab

Digits: 4

Display Type: HEX

Zero Suppress: Deselected

Display Position

X Coordinate: 400

Y Coordinate: 145

[Operation/Alarm] tab

Alarm: Deselected

Page 74

4. Entry Screens

Configuring Multiple Items at Once in the Item Dialog

The settings of multiple items can be configured at once by selecting multiple instances of the

same item.

1. Select all of the numerical data display items for configuration.

The [Num. Display (Multiple Selection)] item dialog box is displayed.

2. Change [Decimal Point] to “1”. All the selected numerical data displays are updated with

this change.

4

Screen Creation

Note that blank settings denote

setting values that differ for each

item.

Take care when changing these

settings.

This completes the numerical data display and entry key registration process.

4-9

Page 75

4. Entry Screens

1.3 Placing Character Displays and Registering Character Keys

1. Click [Parts] → [Parts List]. The [Parts List] window is displayed.

2. Select [Entry], [Real #1 CHRA.Display].

3. Select a character display part and drag it onto the screen. This places the character display

on the screen.

Drag

4-10

Page 76

4. Configure each setting in the character display’s item dialog box.

•[Main] tab

Set the memory address for writing and select a setting for [Function].

4. Entry Screens

4

Screen Creation

Item Details Setting Value

Memory Set the memory address for writing. D110

Offset Value

Designation

Memory

No. of Bytes Set the number of bytes for the character array.

Character Position Select either flush-left or flush-right for the character display. Flush Left

Text Process Set the order of the 1st byte and 2nd byte in 1 word.

Function Set the character display function. Entry Target

Order INC Set the order in which the cursor moves when multiple entry

With Entry Key

Overlap ID Set the overlap ID to be used for showing the character entry

Overlap Library No.

Register button

Select this checkbox to specify an offset.

Not used in this section. For more information, refer to the “V8

Series Reference Manual.”

Setting value: 1 to 127

Flush Left → ABC

Flush Right → ABC

[LSB → MSB]

[MSB → LSB]

targets are placed on the screen.

Function: Entry Target (enabled when selected)

Select this checkbox to add the entry key call function.

keys.

Setting value: 0 to 2

Set the overlap library number for registering the character entry

*1

keys. Select the desired keyboard by pressing the [Register]

button and register the keyboard to the overlap library.

If the keyboard is already registered to the overlap library, simply

specify the overlap library number.

Setting value: 0 to 9999

15 0

MSB LSB

2nd byte 1st byte

15 0

LSB MSB

1st byte 2nd byte

Deselected

12

LSB→MSB

0

Selected

0

2

4-11

Page 77

4. Entry Screens

Item Details Setting Value

Display Position

X Coordinate

Y Coordinate

Specify with

Mouse button

*1 Registration method

Setting [Overlap Library No.] to “2” and clicking the [Register] button displays the [Change Part] window.

Select [Real #4 [Character TS]] and click the [Select] button.

Set the [X Coordinate] and [Y Coordinate] values for the display

position of the overlap.

[Specify with Mouse] button: Specify the coordinates by clicking

with the mouse.

*2

Selected

X Coordinate:

Y Coordinate:

100

182

The character keys are registered to the specified overlap library number. For more information on the

registered details, refer to page 4-14.

If the specified overlap library number is already registered, the following confirmation message is

displayed.

Select [Yes] to overwrite the overlap library number or select [No] to register the character keys to another

overlap library number.

*2 Mouse specification methodRefer to

page 4-6.

This completes the character display and entry key registration process.

4-12

Page 78

1.4 Placing Text

This section explains how to place the screen title and text that indicates memory address

numbers.

1. Click the [Text] icon ( ). A cross-shaped cursor is displayed.

2. Click on the screen. A text frame is displayed.

3. Enter text.

4. Click a location on the screen other than the text.

5. Click the text to display its item dialog box. Change the text color and text size properties.

4. Entry Screens

4

Screen Creation

Te xt

1. [Text] icon

The completes the screen editing process.

4-13

Page 79

4. Entry Screens

2. Overlap Library

The following items are registered to the overlap library contain the entry keys registered using the

[Register] button. These can be used without changing any settings.

If size adjustment or color changes are required, change these settings in the [Overlap Library

Edit] window.

• Overlap library number 1 (keypad)

Entry icon

Overlap

• Overlap library number 2 (character keys)

Entry icon

Overlap

2.1 Editing the Overlap Library

Max. value display

Min. value display

Entry display

Keypad

Entry display

Character entry keys

4-14

1. Click [Registration Item] → [Overlap Library]. The [Overlap Library] dialog box is displayed.

Page 80

2. Specify number “1” for the overlap library to which the entry key is registered.

The [Overlap Library Edit] dialog box is displayed.

4. Entry Screens

4

♦ Overlap Settings

1. Click the overlap to display its item dialog box. Properties such as area color and size can be

changed in this dialog box.

•[Main] tab

Item Description

System Button

•[Style] tab

Select this checkbox to add a switch function (move/dismiss) to

the upper left corner of the overlap area.

For more information on the operation of this switch, refer to

page 3-14 in “Showing and Hiding Multi-overlaps.”

Deselected

Screen Creation

Setting

Val ue

Item Description

Color

Area

Change Part Change the part used for the overlap. -

Set the area color. -

Setting

Val ue

4-15

Page 81

4. Entry Screens

♦ Settings of Items Placed on the Overlap

• [Detail] tab

Settings on this tab do not require changing.

• [Coordinates] tab

Set the placement position and size of the overlap. Settings on this tab do not require

changing.

The size of the overlap can also be changed by selecting the overlap and dragging the displayed

handles.

Drag

Edit items on the overlap by clicking [Overlap Editing] → [No. 0] on the right-click menu.

2.2 Entry Icon

An entry icon for configuring keypad settings is displayed at the upper left of the keypad placed on

the screen. If this entry icon is not displayed or settings are incorrect, the keypad will not function

correctly.

In this section, use the keypad without changing any settings.

For more information on the entry icon, refer to Chapter 7 in the “V8 Series Reference Manual.”

4-16

Entry icon

Page 82

2.3 Entry Display Part/Max. Value Display Part/Min. Value Display Part

The entry display part function temporarily displays values entered using the entry keys.

The max. value display part and min. value display part functions display the range of values that

can be entered using the entry keys.

The maximum and minimum values set for [Alarm] when [Function] is set to “Entry Target” are

displayed automatically.

This section only explains the essential settings for each function.

♦ Overlap Library No. 1

1. Click on the overlap. The numerical data display’s item dialog box is displayed.

2. Configure the numerical data display settings.

•[Main] tab

4. Entry Screens

4

Screen Creation

Item Description Setting Value

Digits For entry display parts on the TS Series unit, the system

Decimal Point 1

Display Type DEC

Zero Suppress Selected

Function Set the function to use. Entry Display

automatically refers to the properties set for the entry

target. Configure these settings for the purpose of

layout. Set the part by referring to the greatest value or

the longest display among the entry targets.

(with sign +-)

Flush Right

Max. Value

Display Part

Min. Value

Display Part

•[Style] tab

Set text properties of the entry target.

Use the [Change Part] button to change parts.

• [Detail] tab

Item Description

ID Set the ID. Always set the same ID as that shown on the entry icon. 0

• [Coordinates] tab

Adjust the placement position.

5

Part

Setting

Val ue

4-17

Page 83

4. Entry Screens

♦ Overlap Library No. 2

1. Click on the overlap. The character display’s item dialog box is displayed.

2. Configure the character display settings.

•[Main] tab

Item Description

No. of Bytes For entry display parts on the TS Series unit, the system

Character Position Select either flush-left or flush-right for the character display. Flush

Function Set the function to use. Entry

automatically refers to the properties set for the entry target.

Configure these settings for the purpose of layout. Set the part

by referring to the greatest value or the longest display among

the entry targets.

Flush Left → ABC

Flush Right → ABC

Setting

Val ue

12

Right

Display

Part

•[Style] tab

Set text properties of the entry target.

Use the [Change Part] button to change parts.

• [Detail] tab

Item Description

ID Set the ID. Always set the same ID as that shown on the entry

icon.

Setting

Val ue

0

• [Coordinates] tab

Adjust the placement position.

The completes the overlap library editing process. The next section covers screen operation after

transferring screen data to the TS Series unit.

4-18

Page 84

1. Memory Addresses

The memory addresses used in this example are listed below.

4. Entry Screens

Confirming Unit Operation

Memory

Address

D100 to 109 Numerical data display (Entry Target)

D110 to 115 Character display (Entry Target)

$u16330 * Entry mode (Command Memory)

$u16340 * Entry mode (Info Output Memory)/Multi-overlap (Info Output Memory)

* Change to a different memory address to control the entry mode and use information

output memory.

2. Unit Operation

2.1 Entering Values

1. Press the numerical data display for “D100”. This displays the keypad overlap and highlights

the value for “D100”.

Memory Contents

4

Confirming Unit Operation

The maximum and

minimum values are also

!

p

i

l

B

displayed because an

alarm is configured for the

“D100” entry target.

The entry display part

displays the current value

for “D100”.

If an alarm is configured for the entry target, [Max.] and [Min.] are displayed on the overlap. The

[Enter] key cannot be pressed if the entered value is outside the displayed range.

4-19

Page 85

4. Entry Screens

2. Press “3” twice on the keypad. “33” is displayed on the entry display part.

Entry display part displays

“33”

3. Press the [Enter] key. The keypad overlap disappears and the value of “D100” displays “33”.

Checking the “D100” address on the PLC should show that “33” is written.

PLC

Writing operations for other data are performed in the same manner.

Entering negative values, such as “-200”:

Press “2” “0” “0” “+/-” and then [Enter] on the keypad.

D100

D101

D102

D103

33 Dec

0 Dec

0 Dec

0 Dec

4-20

Page 86

2.2 Entering Text

1. Press the character display for “D110”. This displays the character overlap and highlights the

value for “D110”.

2. Press “D” “A” “T” “E” using the character entry keys. “DATE” is displayed on the entry display

part.

4. Entry Screens

4

Confirming Unit Operation

3. Press the [Enter] key. The character entry overlap disappears and “DATE” is displayed.

Checking the “D110” and “D111” addresses on the PLC should show that “4144Hex” and

“4554Hex” are written.

PLC

D110

4144 Hex

D111

4554 Hex

D112

D113

0 Hex

0 Hex

4-21

Page 87

4. Entry Screens

4-22

Please use this page freely.

Page 88

5. Alarm Screens

• Alarm tracking (historical)

Depending on the ON/OFF state of the relevant bit, the corresponding error message and time

information (occurrence/reset) are displayed on a single line. This information is stored in the

buffering area as alarm history.

5. Alarm Screens

TS

PLC

Menu

Alarm Tracking

Occurrence/Reset Time

16:15:43 16:21:12

#2 Roller error

#1 Sensor error

16:15:51 16:21:54

#1 Roller error

16:15:52 16:21:55

#2 Sensor error

17:05:02 18:08:01

#3 Sensor error

17:06:31 18:08:01

#5 Roller error

19:21:30 21:09:44

#4 Sensor error

19:22:45 21:10:22

DWUP

-+

DELRET RESET

Configure the following settings for [Alarm Tracking] that stores the alarm history.

- Store the alarm history → Buffering area

- Display the stored alarm history → Alarm tracking parts

- Register error messages → Message editing

Buffering Area

This area is used to store sampling data. Select either the internal memory (DRAM/SRAM) of

the TS Series unit or the external storage device for the storage target.

#2 Roller error occurred

16:15:43

#1 Sensor error occurred

16:15:51

#1 Roller error occurred

16:15:52

#2 Roller error reset

16:21:12

#1 Sensor error reset

16:21:54

#1 Roller error reset

16:21:55

#2 Sensor error occurred

17:05:02

#3 Sensor error occurred

17:06:31

#2 Sensor error reset

18:08:01

#3 Sensor error reset

18:08:01

#5 Roller error occurred

19:21:30

#4 Sensor error occurred

19:22:45

#5 Roller error reset

21:09:44

#4 Sensor error reset

21:10:22

Buffering area

D200-00

D200-01

D200-02

D200-03

D200-04

D200-05

D200-06

Changes to data in the PLC memory are

monitored and stored.

5

• Real time alarm display

History information from alarm tracking can be used to just display the currently occurring

error.

5-1

Page 89

5. Alarm Screens

Contents

Screen Example................................................................................................................. page 5-2

Screen Creation (1)............................................................................................................ page 5-3

1. Placing Parts............................................................................................................. page 5-3

2. Alarm Tracking Parts ................................................................................................ page 5-4

3. Alarm Tracking Settings............................................................................................ page 5-5

4. Buffering Area Settings............................................................................................. page 5-8

5. Editing Messages ................................................................................................... page 5-12

6. SRAM/Clock Settings ............................................................................................. page 5-15

7. Placing Text ............................................................................................................ page 5-16

8. Checking the Display Area Size ............................................................................. page 5-17

Screen Creation (2).......................................................................................................... page 5-21

1. Placing Parts........................................................................................................... page 5-21

2. Real Time Alarm Display Parts............................................................................... page 5-22

3. Real Time Alarm Display Settings .......................................................................... page 5-22

4. Placing Text ............................................................................................................ page 5-24

5. Creating a Switch for Changing to Another Screen................................................ page 5-25

Confirming Unit Operation ............................................................................................... page 5-26

1. Memory Addresses and Registered Messages ...................................................... page 5-26

2. Unit Operation ........................................................................................................ page 5-28

Screen Example

Create the following screens in this section.

Alarm Tracking

Single line display of

bit ON and OFF times

Real Time Alarm Display

Message display of the

currently occurring

error (bit ON)

ON

OFF

5-2

Page 90

1. Placing Parts