Page 1

Setup Manual

Page 2

Record of Revisions

Reference numbers are shown at the bottom left corner on the back cover of each manual.

Printing Date Reference No. Revised Contents

December, 2014 1067NE0 First edition

Page 3

Preface

Thank you for selecting the MONITOUCH V9 series.

For correct setup of the V9 series, you are requested to read through this manual to understand more about the product.

For details on other operating procedures for the V9 series, refer to the following related manuals.

Manual Name Contents

V9 Series

Reference Manual [1]

V9 Series

Reference Manual [2]

V9 Series

Setup Manual

V9 Series

Troubleshooting/Maintenance

Manual

V9 Series Training Manual

Beginner’s Guide

V9 Series Training Manual Practical

Guide

V9 Series

Macro Reference

V9 Series

Operation Manual

V9 Series

Connection Manual [1]

V9 Series

Connection Manual [2]

V9 Series

Connection Manual [3]

V9 Series Hardware Specifications Explains hardware specifications and precautions when handling the V9 series. 2023NE

Explains the functions and operation of the V9 series. 1065NE

Explains the installation procedure of V-SFT version 6, the creation process of

simple screen programs as well as how to transfer a created screen program using

V-SFT version 6.

Provides an error list and explains the operating procedures for the V9 series. 1068NE

Explains the screen creation process for the V9 series using V-SFT version 6 with

examples.

Provides an overview of macros of V-SFT version 6 and explains macro editor

operations and macro command descriptions in detail.

Explains the configuration of V-SFT version 6, the editing process of each part and

limitations regarding operation in detail.

Explains the connection and communication parameters for the V9 series and

controllers in detail.

Included Makers

ALLEN BRADLEY, Automationdirect, Azbil, Baumuller, BECKHOFF, CHINO,

CIMON, DELTA, DELTA TAU DATA SYSTEMS, EATON Cutler-Hammer,

EMERSON, FANUC, FATEK AUTOMATION, FUFENG, Fuji Electric, Gammaflux,

GE Fanuc, Hitachi, Hitachi Industrial Equipment Systems

Explains the connection and communication parameters for the V9 series and

controllers in detail.

Included Makers

IAI, IDEC, JTEKT, KEYENCE, KOGANEI, KOYO ELECTRONICS, LS,

MITSUBISHI ELECTRIC, MODICON, MOELLER, M-SYSTEM, OMRON,

Oriental Motor, Panasonic, RKC, RS Automation

Explains the connection and communication parameters for the V9 series and

controllers in detail.

Included Makers

SAIA, SAMSUNG, SanRex, SANMEI, SHARP, SHIMADEN, SHINKO TECHNOS,

Siemens, SINFONIA TECHNOLOGY, TECO, Telemecanique, TOHO, TOSHIBA,

TOSHIBA MACHINE, TURCK, UNIPULSE, UNITRONICS, VIGOR, WAGO, XINJE,

YAMAHA, Yaskawa Electric, Yokogawa Electric, MODBUS, Barcode Reader,

Slave Communication Function, Universal Serial Communication

Reference

No.

1066NE

1067NE

1069NE

1070NE

1071NE

1072NE

2210NE

2211NE

2212NE

For details on devices including PLCs, inverters, and temperature controllers, refer to the manual for each device.

Notes:

1. This manual may not, in whole or in part, be printed or reproduced without the prior written consent of Hakko Electronics

Co., Ltd.

2. The information in this manual is subject to change without prior notice.

3. Windows and Excel are registered trademarks of Microsoft Corporation in the United States and other countries.

4. All other company names or product names are trademarks or registered trademarks of their respective holders.

5. This manual is intended to give accurate information about MONITOUCH hardware. If you have any questions, please

contact your local distributor.

Page 4

Notes on Safe Usage of MONITOUCH

DANGER

CAUTION

CAUTION

DANGER

CAUTION

In this manual, you will find various notes categorized under the following levels with the signal words “DANGER” and “CAUTION”.

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury and could

cause property damage.

Note that there is a possibility that items listed with may have serious ramifications.

• Never use the output signal of the V9 series for operations that may threaten human life or damage the system, such as signals

used in case of emergency. Please design the system so that it can cope with a touch switch malfunction. A touch switch

malfunction may result in machine accidents or damage.

• Turn off the power supply when you set up the unit, connect new cables, or perform maintenance or inspections. Otherwise,

electrical shock or damage may occur.

• Never touch any terminals while the power is on. Other wise, electrical shock may occur.

• You must cover the terminals on the unit before turning the power on and operating the unit. Otherwise, electrical shock may occur.

• The liquid crystal in the LCD panel is a hazardous substance. If the LCD panel is damaged, do not ingest the leaked liquid crystal. If

leaked liquid crystal makes contact with skin or clothing, wash it away with soap and water.

• Never disassemble, recharge, deform by pressure, short-circuit, reverse the polarity of the lithium battery, nor dispose of the lithium

battery in fire. Failure to follow these conditions will lead to explosion or ignition.

• Never use a lithium battery that is deformed, leaking, or shows any other signs of abnormality. Failure to follow these conditions will

lead to explosion or ignition.

• Switches on the screen are operable even when the screen has become dark due to a faulty backlight or when the backlight has

reached the end of its service life. If the screen is dark and hard to see, do not touch the screen. Otherwise, a malfunction may occur

resulting in machine accidents or damage.

• Check the appearance of the unit when it is unpacked. Do not use the unit if any damage or deformation is found. Failure to do so

may lead to fire, damage, or malfunction.

• For use in a facility or as part of a system related to nuclear energy, aerospace, medical, traffic equipment, or mobile installations,

please consult your local distributor.

• Operate (or store) the V9 series under the conditions indicated in this manual and related manuals. Failure to do so could cause fire,

malfunction, physical damage, or deterioration.

• Observe the following environmental restrictions on use and storage of the unit. Otherwise, fire or damage to the unit may result.

- Avoid locations where there is a possibility that water, corrosive gas, flammable gas, solvents, grinding fluids, or cutting oil can

come into contact with the unit.

- Avoid high temperatures, high humidity, and outside weather conditions, such as wind, rain, or direct sunlight.

- Avoid locations where excessive dust, salt, and metallic particles are present.

- Avoid installing the unit in a location where vibrations or physical shocks may be transmitted.

• Equipment must be correctly mounted so that the main terminal of the V9 series will not be touched inadvertently. Otherwise, an

accident or electric shock may occur.

• Tighten the mounting screw on the fixtures of the V9 series to an equal torque of 0.6 N·m.

Excessive tightening may distort the panel surface. Loose mounting screws may cause the unit to fall down, malfunction, or

short-circuit.

• Check periodically that terminal screws on the power supply terminal block and fixtures are firmly tightened. Loosened screws or

nuts may result in fire or malfunction.

• Tighten the terminal screws on the power supply terminal block of the V9 series to an equal torque of 7.1 to 8.8 inch-lbf (0.8 to

1.0 N·m). Improper tightening of screws may result in fire, malfunction, or other serious trouble.

• The V9 series has a glass screen. Do not drop the unit or impart physical shocks to the unit. Otherwise, the screen may be damaged.

• Correctly connect cables to the terminals of the V9 series in accordance with the specif ied voltage and wattage. Overvoltage,

overwattage, or incorrect cable connection could cause f ire, malfunction, or damage to the unit.

• Always ground the V9 series. The FG terminal must be used exclusively for the V9 series with the level of grounding resistance less

than 100 . Otherwise, electric shock or a fire may occur.

• Prevent any conductive particles from entering the V9 series. Failure to do so may lead to fire, damage, or malfunction.

• After wiring is finished, remove the paper used as a dust cover before starting operation of the V9 series. Operation with the dust

cover attached may result in accidents, fire, malfunction, or other trouble.

Page 5

• Do not attempt to repair the V9 series yourself. Contact Hakko Electronics or the designated contractor for repairs.

CAUTION

• Do not repair, disassemble, or modify the V9 series. Hakko Electronics Co., Ltd. is not responsible for any damages resulting from

repair, disassembly, or modification of the unit that was performed by an unauthorized person.

• Do not use sharp-pointed tools to press touch switches. Doing so may damage the display unit.

• Only experts are authorized to set up the unit, connect cables, and perform maintenance and inspection.

• Lithium batteries contain combustible material such as lithium and organic solvents. Mishandling may cause heat, explosion, or

ignition resulting in fire or injury. Read the related manuals carefully and correctly handle the lithium battery as instructed.

• Do not press two or more positions on the screen at the same time. If two or more positions are pressed at the same time, the

switch located between the pressed positions may be activated.

• Take safety precautions during operations such as changing settings when the unit is running, forced output, and starting and

stopping the unit. Any misoperations may cause unexpected machine movement, resulting in machine accidents or damage.

• In facilities where the failure of the V9 series could lead to accidents that threaten human life or other serious damage, be sure that

such facilities are equipped with adequate safeguards.

• When disposing of the V9 series, it must be treated as industrial waste.

• Before touching the V9 series, discharge static electricity from your body by touching grounded metal. Excessive static electricity

may cause malfunction or trouble.

• Insert an SD card into the unit in the same orientation as pictured on the unit. Failure to do so may damage the SD card or the slot

on the unit.

• The SD card access LED flashes red when the SD card is being accessed. Never remove the SD card or turn off power to the unit

while the LED is flashing. Doing so may destroy the data on the SD card. Check that the LED has turned off before removing the SD

card or turning off the power to the unit.

[General Notes]

• Never bundle control cables or input/output cables with high-voltage and large-current carrying cables such as power supply cables.

Keep control cables and input/output cables at least 200 mm away from high-voltage and large-current carrying cables. Otherwise,

malfunction may occur due to noise.

• When using the V9 series in an environment where a source of high-frequency noise is present, it is recommended that the FG

shielded cable (communication cable) be grounded at each end. However, when communication is unstable, select between

grounding one or both ends, as permitted by the usage environment.

• Be sure to plug connectors and sockets of the V9 series in the correct orientation. Failure to do so may lead to damage or malfunction.

• If a LAN cable is inserted into the MJ1 or MJ2 connector, the device on the other end may be damaged. Check the connector names

on the unit and insert cables into the correct connectors.

• Do not use thinners for cleaning because it may discolor the V9 series surface. Use commercially available alcohol.

• If a data receive error occurs when the V9 series unit and a counterpart unit (PLC, temperature controller, etc.) are started at the same

time, read the manual of the counterpart unit to correctly resolve the error.

• Avoid discharging static electricity on the mounting panel of the V9 series. Static charge can damage the unit and cause malfunctions.

Discharging static electricity on the mounting panel may cause malfunction to occur due to noise.

• Avoid prolonged display of any fixed pattern. Due to the characteristic of liquid crystal displays, an afterimage may occur. If prolonged

display of a fixed pattern is expected, use the backlight’s auto OFF function.

• The V9 series is identif ied as a class-A product in industrial environments. In the case of use in a domestic environment, the unit is

likely to cause electromagnetic interference. Preventive measures should thereby be taken appropriately.

[Notes on the LCD]

Note that the following conditions may occur under normal circumstances.

• The response time, brightness, and colors of the V9 series may be affected by the ambient temperature.

• Tiny spots (dark or luminescent) may appear on the display due to the characteristics of liquid crystal.

• There are variations in brightness and color between units.

Page 6

Contents

1Introduction

1.1 About V-SFT Version 6 ............................................................................................................................................... 1-1

1.1.1 Operating Environment .................................................................................................................................................................... 1-1

1.1.2 Installation Procedure .......................................................................................................................................................................1-2

1.1.3 Configuration of Installation Folder ............................................................................................................................................ 1-6

1.1.4 Uninstallation ....................................................................................................................................................................................... 1-6

2Starting

2.1 Creating a New Screen Program ............................................................................................................................ 2-1

2.2 Layout of V-SFT Ver. 6 ................................................................................................................................................ 2-4

3 Screen Configuration

3.1 Screen Example ............................................................................................................................................................. 3-1

3.2 Registering Screen Comments and Changing the Background Color..................................................... 3-2

3.3 Creating Text .................................................................................................................................................................. 3-3

3.4 Creating Switches ......................................................................................................................................................... 3-4

3.5 Creating Lamps.............................................................................................................................................................. 3-6

3.6 Entry Settings ................................................................................................................................................................. 3-8

3.6.1 Numerical Display .............................................................................................................................................................................. 3-8

3.6.2 Character Display ................................................................................................................................................................................3-9

4 Transferring (via USB)

4.1 Overview .......................................................................................................................................................................... 4-1

4.2 Installing the USB Driver ............................................................................................................................................ 4-2

4.3 Transfer Procedure (Downloading from PC to V9 Series Unit) ................................................................... 4-4

4.4 Connecting to a PLC .................................................................................................................................................... 4-5

Page 7

1Introduction

1.1 About V-SFT Version 6

1.1 About V-SFT Version 6

1.1.1 Operating Environment

Make sure that your system meets the following system requirements before starting V-SFT version 6.

Computer PC/AT compatible computer for W indows

OS* Windows XP / XP64 Edition / Vista (32-bit, 64-bit) / 7 (32-bit, 64-bit) / 8 (32-bit, 64-bit) / 8.1 (32-bit, 64-bit)

CPU Pentium III processor with 800 MHz or above (Pentium IV 2.0 GHz or higher recommended)

Memory 1 GB or more (2 GB recommended)

Hard disk Free disk space before installation: 1.8 GB or more

CD-ROM drive 24 or higher recommended

Display resolution 1024 768 dots (XGA) or higher

Display colors High color (16-bit) or higher

Others Microsoft .NET Framework 4.0 or 4.5

* Administrator privileges are required for installation.

Software Copyrights

• The software as well as its copyright and any other copyrights and rights related to the software are property of Hakko

Electronics Co., Ltd.

• The software may not be used or copied, whether in whole or in part, without permission of Hakko Electronics Co., Ltd.

• The specifications and components of the software are subject to change without prior notification.

• Hakko Electronics Co., Ltd. bears no responsibility for any results of using the software.

• You must purchase one set of software per computer in principle.

• Windows is a registered trademark of Microsoft Corporation in the United States.

• All other product names are trademarks or registered trademarks of their respective holders.

(If a PC does not have .NET Framework 4.0 or 4.5 installed, Framework 4.0 will be automatically installed on the

PC.)

1

2

3

4

5

Notes on Usage

• The software may not be correctly installed if resident programs and applications such as an antivirus program are

running. Be sure to close all applications before installing the software.

• The face of the CD-ROM is the side with the product name printed on it. The blank side is the data side.

• If the CD-ROM is scratched with a sharp object, it may be read incorrectly. Touching the data side and leaving fingerprints

may lead to a malfunction because the computer reads data from the data side. Handle both sides of the CD-ROM with

care.

• When placing the CD-ROM in the CD-ROM drive, pay attention to the orientation of the disc and place the disc in the

drive as instructed in the instruction manual of your computer.

• If free memory space becomes insufficient while the configuration software is running, Windows may forcefully terminate

the software.

In order to prevent losing data from a forced termination, save the screen program regularly.

6

7

8

9

1-1

10

Page 8

1 Introduction

Computer

Disc 1

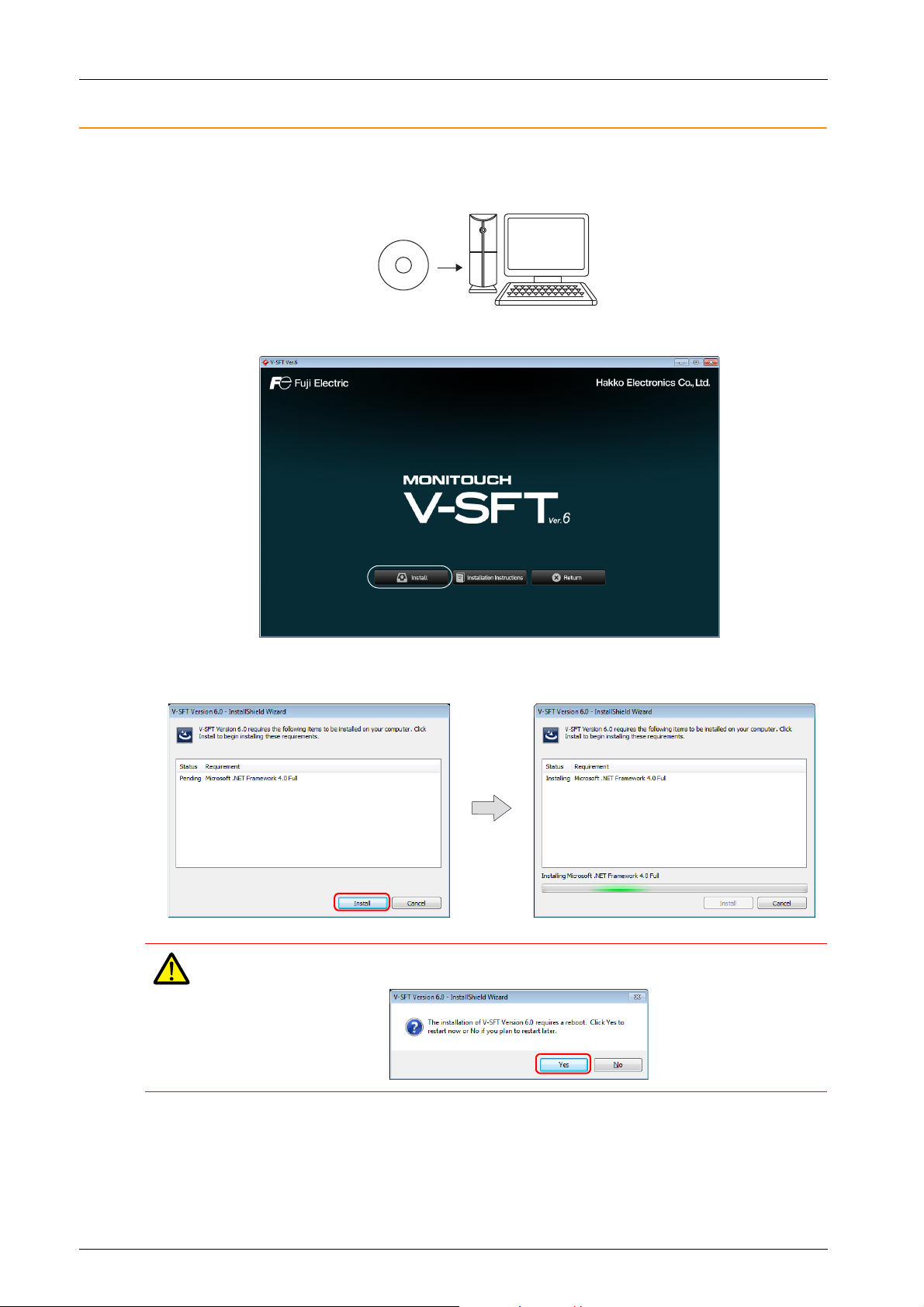

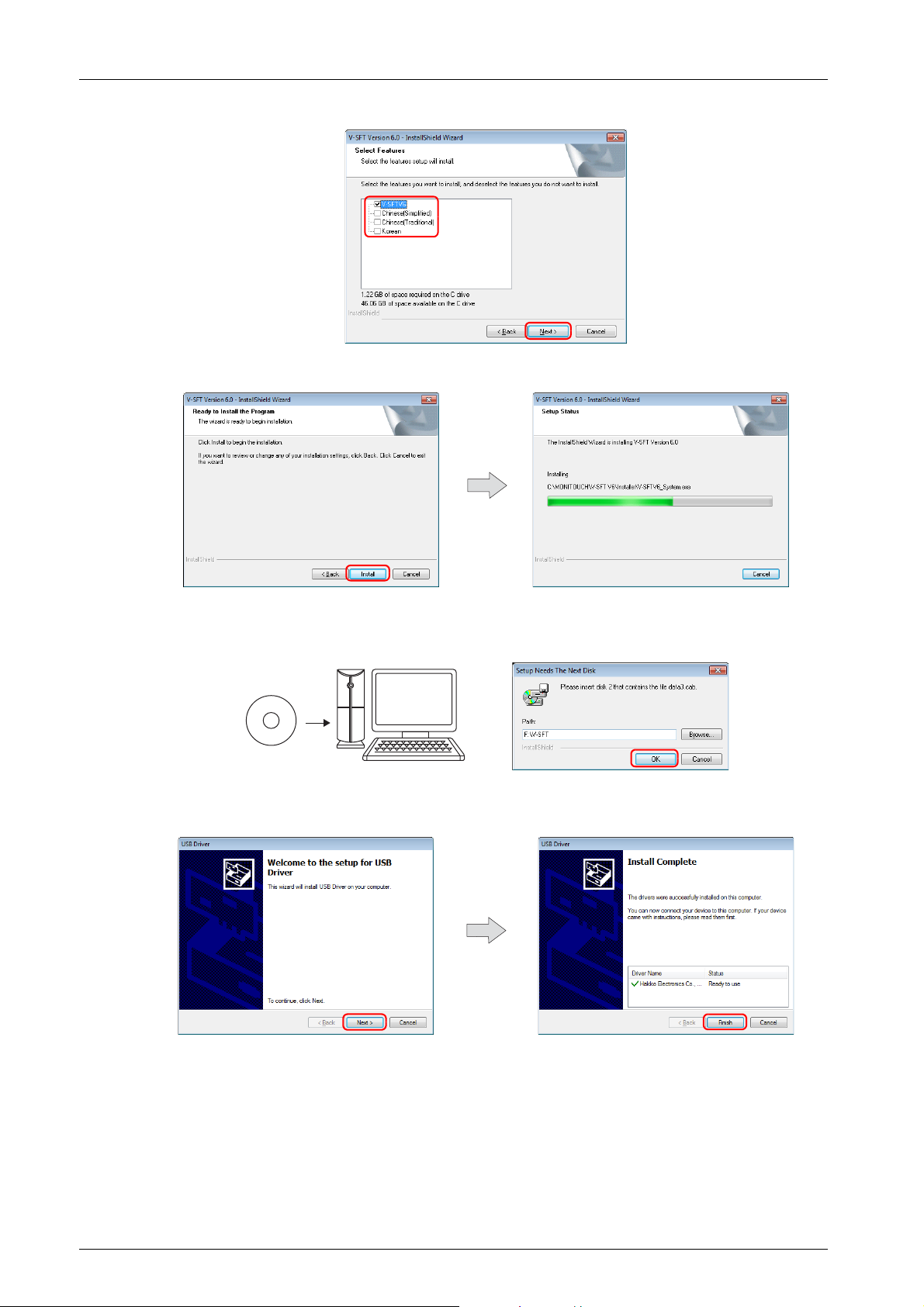

1.1.2 Installation Procedure

Example: Windows 7

1. Startup Windows and place the “V-SFT Ver. 6 Disc 1” CD-ROM in the CD-ROM drive.

2. The following installation window is automatically displayed. Click [Install].

3. When Microsoft .NET Framework 4.0 or 4.5 is not installed on the computer, the following dialog box is displayed.

Click [Install]. Installation of .NET Framework 4.0 automatically starts.

After installation of .NET Framework 4.0, a message prompting you to reboot the computer may be displayed.

If displayed, be sure to reboot the computer.

1-2

Page 9

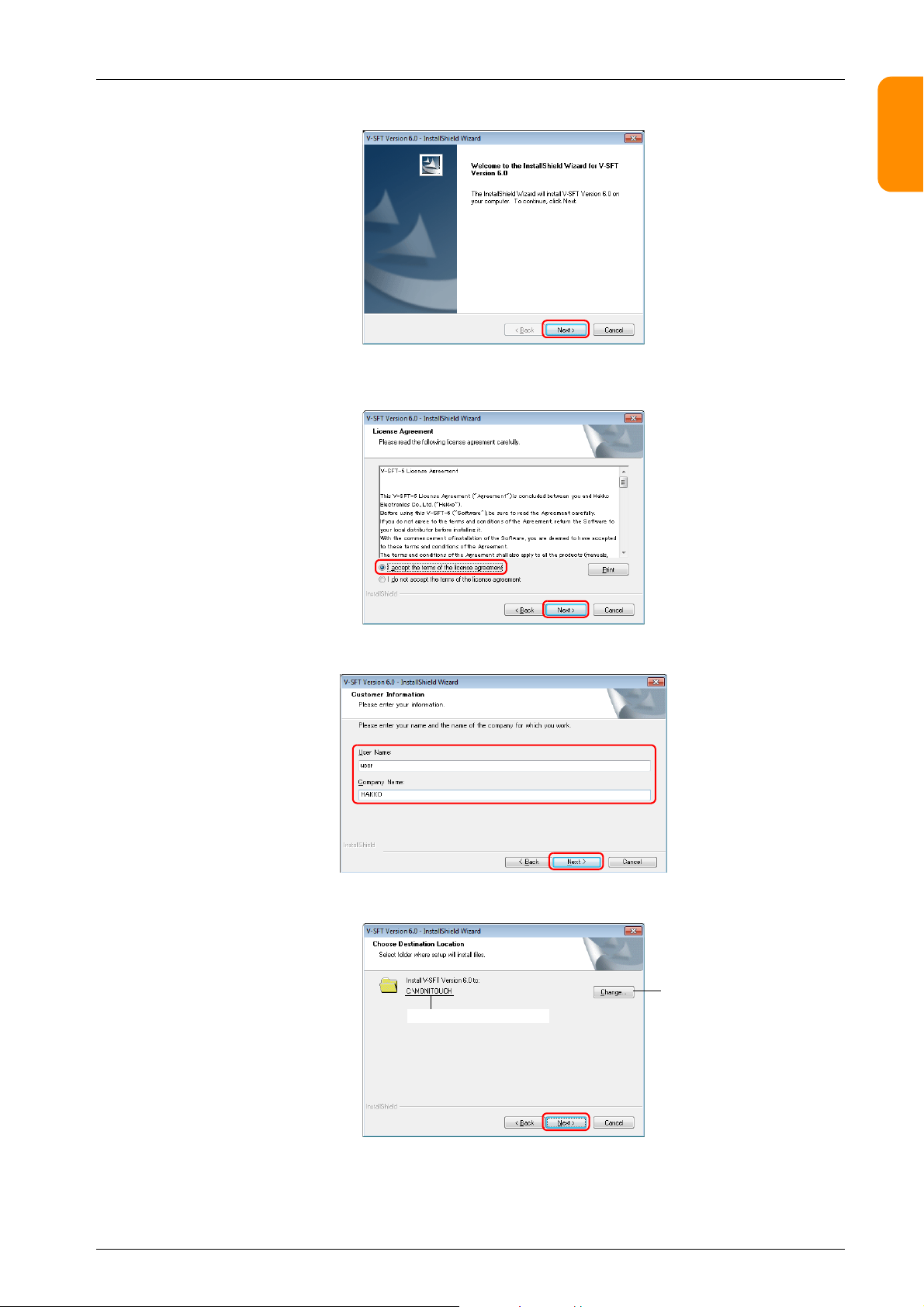

4. The following dialog box is displayed. Click [Next].

Installation location (default)

Click to change the

installation location

1.1 About V-SFT Version 6

1

2

5. The [License Agreement] dialog box is displayed.

Read the contents carefully, select [I accept the terms of the license agreement], and then click [Next].

6. The [Customer Information] dialog box is displayed. Enter your [User Name] and [Company Name], and then click [Next].

3

4

5

6

7. The [Choose Destination Location] dialog box is displayed. Click [Next].

7

8

9

10

1-3

Page 10

1 Introduction

Computer

Disc 2

8. The following dialog box is displayed. Select a display language(s) to use on the V-SFT editor, and then click [Next].

9. The following dialog box is displayed. Click [Install]. Installation automatically starts.

10. The [Setup Needs The Next Disk] dialog box is displayed. Insert the “V-SFT Ver. 6 Disc 2” CD-ROM in the CD-ROM drive

and then click [OK]. Installation will resume.

11. When installation of V-SFT version 6 is complete, the [Welcome to the setup for USB Driver] dialog box is displayed.

Click [Next] to install the USB driver.

1-4

Page 11

1.1 About V-SFT Version 6

Selected:

The “README” file is

displayed.

Selected:

V-SFT Version 6 is started up.

12. After all installation processes are complete, the [Install Complete] dialog box is displayed. Click [Finish].

1

2

This completes the installation procedure.

3

4

5

6

7

8

9

10

1-5

Page 12

1 Introduction

USB driver, system programs, etc.

User files such as image f iles

“Vsft60.exe” application software etc.

1.1.3 Configuration of Installation Folder

The default installation location is as follows:

C:\MONITOUCH

“Common”, “User”, and “V-SFT V6” subfolders are created inside the “MONITOUCH” folder.

The “Vsft60.exe” application software is located in the “V-SFT V6” folder.

1.1.4 Uninstallation

The procedure for uninstalling V-SFT version 6 differs depending on your operating system.

For Windows Vista, 7, 8 or 8.1

Display the list of installed programs from [Control Panel] [Programs] [Programs and Features]. Select “V-SFT Version

6.0” from the list and click [Uninstall].

For Windows XP or XP 64 Edition

Display the list of installed programs from [Control Panel] [Add or Remove Programs]. Select “V-SFT Version 6.0” from the

list and click [Remove].

1-6

Page 13

2Starting

• Double-click the shortcut on the Desktop.

Start menu

• Click “V-SFTV6” in the Start menu.

• Double-click “Vsft60.exe” located in the installation folder.

Example: C:\MONITOUCH\V-SFT V6\VSft60.exe

[New]

Click to open an existing screen program file.

2.1 Creating a New Screen Program

2.1 Creating a New Screen Program

The procedures for starting the V-SFT and creating a new screen program are described.

1. Start V-SFT version 6 by any of the following methods.

1

2

3

4

2. The startup menu is displayed. Click [New].

5

6

7

8

When opening an existing screen program file, either click on [Open] in the Startup menu, or double-click on

the relevant screen program file.

9

10

2-1

Page 14

2 Starting

Port on V9

series unit

[PLC Properties] window

[Hardware

Setting]

window

Close

Device memory for switching the screen

using an external command

The first screen that is displayed

when entering RUN mode

3. Select the model for editing and device to connect and click [Finish].

4. The hardware settings and PLC properties are displayed. Configure the communication settings in the [PLC Properties]

window and then close the window. (Example: MITSUBISHI ELECTRIC QnU series CPU for PLC1)

5. Click [Control Area] in the [Hardware Setting] window and conf igure the following settings.

2-2

Page 15

2.1 Creating a New Screen Program

Screen configuration area

6. Click the [Close] button to close the [Hardware Setting] window. The [Screen [0] Edit] tab window is displayed.

1

2

7. Click [System Setting] [Multi-language setting].

8. The [Font Setting] window is displayed. Press the [Setting] button and set the font. Then click [OK] to close the window.

3

4

5

6

This completes the settings required to create a new screen program.

7

8

9

10

2-3

Page 16

2 Starting

Quick access toolbar

Catalog

Project

Function item

view window

Item list

Editing window

Application button

Status bar

Item settings window

Ribbon menu

2.2 Layout of V-SFT Ver. 6

The layout of the V-SFT editor is shown below.

2-4

Page 17

3 Screen Configuration

Numerical data entry

Device memory address

D100

page 3-8

Lamps

Device memory

addresses M0, M1

page 3-6

Switches

Device memory

addresses M0, M1

page 3-4

Numerical

data display

Character

display

Character entry

Device memory

addresses D101 to D104

page 3-8

Te xt

•M0: Momentary

•M1: Alternate

Release

Press

Press

Release

Press

The lamp turns on

while the switch is

pressed.

The lamp turns

on/off each time the

switch is pressed.

On

Off

On

Off

On

Keypad

Press

3.1 Screen Example

This section describes methods for configuring screen components.

For the procedure on creating a new screen program, refer to “2.1 Creating a New Screen

Program”.

3.1 Screen Example

Create the following example screen that uses switch output to turn lamps on and off and includes data entry parts.

•Screen No. 0

1

2

3

4

- Switch output (switch/lamp)

- Data entry: Keypad/keyboard display (numerical data display, character display)

5

6

7

8

9

10

3-1

Page 18

3 Screen Configuration

Comment

Background color

Enter a comment.

3.2 Registering Screen Comments and Changing the Background Color

Add a comment to the screen and change the background color.

1. Click [Screen Setting] [Screen Setting].

2. Add a comment and change the background color on the [Main] tab window.

3. Click [OK].

This completes the settings.

Comments can also be entered from the screen list.

Click [Home] [Screen List].

3-2

Page 19

3.3 Creating Text

Te xt

Select [Multi Text]

when entering two or

more lines.

Cursor

Start point

End point

Drag

MONITOUCH

Enter text.

Set the color and background

color of the text.

Set the text size.

3.3 Creating Text

Create the following part.

1. Click [Home] [Text] [Text]. The mouse cursor changes to a crosshair.

2. Drag from the start point to the end point on screen using the mouse. The specified area and a blinking cursor are

displayed on screen.

1

2

3

4

3. Enter text.

4. Click a location on the screen other than the text to accept the text entry.

5. Click the text to display its settings window. Change the text color and text size properties.

This completes the text creation process.

5

6

7

8

9

10

3-3

Page 20

3 Screen Configuration

Switches

Output

Switches

3.4 Creating Switches

Create the following parts.

1. Click [Home] [Switch] and place a switch on the screen.

2. Double-click on the switch to display its settings window. Configure each setting.

• [Char. Prop.]

Set the text to display on the switch.

•[Output Device]

Set the bit device memory for output and the operation to perform.

3. Click [Finish] to exit settings.

3-4

Page 21

4. Copy the created switch and configure the following settings.

Handle

Drag

3.4 Creating Switches

Copy method

•[Edit] [Copy]/[Paste]

• Right-click menu [Copy]/[Paste]

• [Char. Prop.]

•[Output Device]

1

2

3

4

5. Click [Finish] to exit settings.

A placed part can be enlarged or reduced. Click on the placed part to display its handles, and drag a handle with the mouse.

5

6

7

8

9

10

3-5

Page 22

3 Screen Configuration

Lamps

Input

OFF: Red

ON: Green

3.5 Creating Lamps

Create the following parts.

1. Click [Home] [Lamp] and place a lamp on the screen.

2. Double-click on the lamp to display its settings window. Configure each setting.

•[Style]

Set the ON/OFF colors of the lamp and the lamp device memory.

• [Char. Prop.]

Set the text to display on the lamp.

3-6

3. Click [Finish] to exit settings.

Page 23

4. Copy the created lamp and configure the following settings.

OFF: Red

ON: Green

3.5 Creating Lamps

Copy method

•[Edit] [Copy]/[Paste]

• Right-click menu [Copy]/[Paste]

•[Style]

• [Char. Prop.]

1

2

3

4

5. Click [Finish] to exit settings.

5

6

7

8

9

10

3-7

Page 24

3 Screen Configuration

Numerical data display

Character display

Entry from

keypad

Reading

(Display)

3.6 Entry Settings

Create the following parts.

3.6.1 Numerical Display

1. Click [Home] [Data Display] [Num. Display] and place a numerical display part on the screen.

2. Double-click on the numerical data display part to display its settings window. Configure each setting.

•[Contents]

•[Function]

3-8

3. Click [Finish] to exit settings.

Page 25

3.6.2 Character Display

3.6 Entry Settings

1. Click [Home] [Data Display] [Char. Display] and place a character display part on the screen.

2. Double-click on the character display part to display its settings window. Configure each setting.

•[Contents]

1

2

3

4

•[Function]

5

6

7

8

3. Click [Finish] to exit settings.

This completes the screen creation process.

Transfer the screen program to the V9 series unit and check the screen operation.

9

10

3-9

Page 26

3 Screen Configuration

3-10

Page 27

4 Transferring (via USB)

USB-A

USB-miniB

Computer

V9

Commercially available cable

Computer

V9

Commercially available

straight * or cross cable

* The V9 series suppor ts

Auto-MDIX.

D-sub 9pin

MJ1

Computer

V9

Hakko Electronics

“V-CP” cable

* If the computer is not equipped

with a serial port (D-sub 9-pin),

use a commercially available

USB-to-serial converter.

SD

USB

Memory

V9

SD card or USB flash drive

4.1 Overview

4.1 Overview

This section describes the procedure for transferring a screen program using a USB cable.

Screen programs can also be transferred by the following methods.

For details, refer to the V9 Series Operation Manual.

• Transfer via Ethernet

• Serial transfer

Ethernet

1

2

3

4

• Transfer via storage device

5

6

7

8

9

10

4-1

Page 28

4 Transferring

Computer

V9

With power on

The installation

wizard starts up.

Click to start installation.

4.2 Installing the USB Driver

A USB driver must be installed on the computer in advance to perform transfer using a USB cable.

Connect the V9 series unit (with power on) to the computer using a USB cable.

USB-miniB

For Windows Vista, 7, 8 or 8.1

The USB driver is automatically installed.

For Windows XP

Install the USB driver by the following procedure.

USB-A

4-2

Page 29

Confirming Successful Installation of the USB Driver

• Windows Vista, 7, 8, 8.1 • Windows XP

4.2 Installing the USB Driver

When the driver has been installed successfully, “Operation Panel - Operation Panel USB Driver” is displayed in the [Device

Manager] window.

This item will disappear when the USB connection is disconnected.

If [Other Device] or a mark other than shown above is displayed even while connected via USB, the USB driver is not

recognized. If this happens, uninstall the USB driver and reinstall it.

When USB Driver Installation Fails

If installation of the USB driver has failed, reinstall it.

1

2

3

4

5

Install by double-clicking “USBDriverInstaller.exe” in the “C:\MONITOUCH\Common\Driver” folder.

6

7

8

9

4-3

10

Page 30

4 Transferring

USB-A

USB-miniB

Computer

V9

Commercially available cable

Tra ns fe r

Screen program

Unselected

Computer (V-SFT) V9 series unit (Local mode) *

System menu

4.3 Transfer Procedure (Downloading from PC to V9 Series Unit)

This section explains how to transfer a screen program from the computer to the V9 series unit.

1. Click [Transfer] [Download] to display the [Transfer] window.

2. Configure the following settings.

Simulator

If a PLC is not available during debugging, use the simulator to check screen operation with only the V9 series unit.

The simulator runs on the computer and acts as a PLC. For details, refer to the V9 Series Training Manual Beginner's Guide.

3. Click [PC ].

A screen program is transferred and written to the V9 series unit. The following screens are displayed respectively during

transfer.

* If the V9 series unit does not automatically switch to Local mode and transfer does not start, manually switch to Local mode and execute

the transfer.

To switch to Local mode, press the [SYSTEM] switch and press [Local] on the system menu displayed at the top of the screen.

4-4

- When the [Local] switch is not displayed (with [Mode Switch Prohibited] selected):

Display the system menu and hold down the [F1] switch and the [F7] switch (max. 30 seconds).

- When the system menu is not displayed (with [System Switch Prohibited] selected):

Hold down the [SYSTEM] switch and the [F7] switch (max. 30 seconds).

Page 31

4.4 Connecting to a PLC

V9

Communication cable

PLC

Checking connection with PLC

(A splash screen can be set by

preference. *)

* For details, refer to V9 Series

Reference Manual 2.

The created screen program is

displayed.

The V9 series unit will switch to RUN mode once

the cause of the error is resolved.

* For details on errors, refer to the V9 Series

Troubleshooting/Maintenance Manual.

4.4 Connecting to a PLC

Connect the V9 series unit with a PLC and switch to RUN mode.

1. Use a communication cable to connect the V9 series unit with a PLC.

For details of wiring, refer to the V9 Series Connection Manual.

2. If communication is established, the created screen program (in RUN mode) is displayed.

If the Local mode screen or a communication error screen is displayed, press the switch indicated below to switch to RUN

mode.

1

2

3

4

5

6

7

8

This completes the necessary settings.

9

10

4-5

Page 32

4 Transferring

4-6

Loading...

Loading...