Page 1

– 1 –

Thank you for your purchasing "Fuji Digital Temperature Controller."Please check that the product is exactly the

one you ordered and use it according to the following instructions. (Please refer to a separate operation manual

for details.) Dealers are cordially requested to ensure the delivery of this Instruction Manual to hands of the endusers.

NOTICE The contents of this document may be changed in the future without prior notice.

We paid the utmost care for the accuracy of the contents. However, we are not liable for direct and

indirect damages resulting from incorrect descriptions, omission of information, and use of information in this document.

Read before using................................................ 3

Index ................................................................ 7

1. Installation/mounting ...................................... 8

2. Wiring............................................................. 9

3. Usage............................................................. 10

4. Display and operation .................................... 11

5. Setting methods of temperature and

paramenters............................................ 12

1st block parameter........................................ 12

2nd block parameter ...................................... 13

3rd block parameter ....................................... 14

6. Function ......................................................... 15

6-1 ON/OFF control ...................................... 15

6-2 Auto-tuning (A T)...................................... 16

6-3 Self-tuning............................................... 17

6-4 Alarm function [option] ............................ 19

6-5 Ramp/soak function [option] ................... 21

6-6 Communication function [option]............. 22

6-7 Digital input (DI function) [option]............ 23

6-8 Other functions ....................................... 24

7. Setting of input type and control algorithm..... 25

8. Error indications ............................................. 27

[Table1] Input type code ....................................... 28

[Table2] Control output action code...................... 28

[Table3] Input range (Standard range) ................. 29

[Table4] Alarm action type code........................... 30

PXR Model Code Configuration ........................... 31

Specification......................................................... 32

CONENTS

Instruction Manual

Micro-controller X

Model: PXR4

INP-TN1PXRa-E

Fuji Electric Co., Ltd.

Head Office

11-2, Osaki 1-chome, Shinagawa-ku, Tokyo, 141-0032 Japan

http://www.fujielectric.co.jp

Fuji Electric Instruments Co., Ltd.

Sales Div. International Sales Dept.

No.1, Fuji-machi, Hino-city, Tokyo, 191-8502 Japan

Phone : +81-42-585-6201,6202

Fax : +81-42-585-6187,6189

http://www.fic-net.co.jp

Page 2

– 2 –

The related documents

For details, refer to the following documents.

Before using the controller, check if the type and specifications are as ordered. (A Table of Model code configuration is given in Page 4).

Check that all of the following accessories are included in the package box.

Check of specifications and accessories

· Temperature controller 1 unit

· Instruction manual 1 copy

· Mounting bracket 1 pce.

· I/V unit (250Ω resistor) 1 pce. (4-20mA DC input type only)

· Terminal cover 1 pce. (optional item seperately ordered.)

Contents Name

Operation method

MICRO-CONTROLLER X (Model : PXR)

OPERATION MANUAL

Communication functions

COMMUNICATION FUNCTIONS (MODBUS)

INSTRUCTION MANUAL

Specifications

Catalogue

Name

ECNO : 406

INP-TN512642-E

ECNO : 1136

Page 3

– 3 –

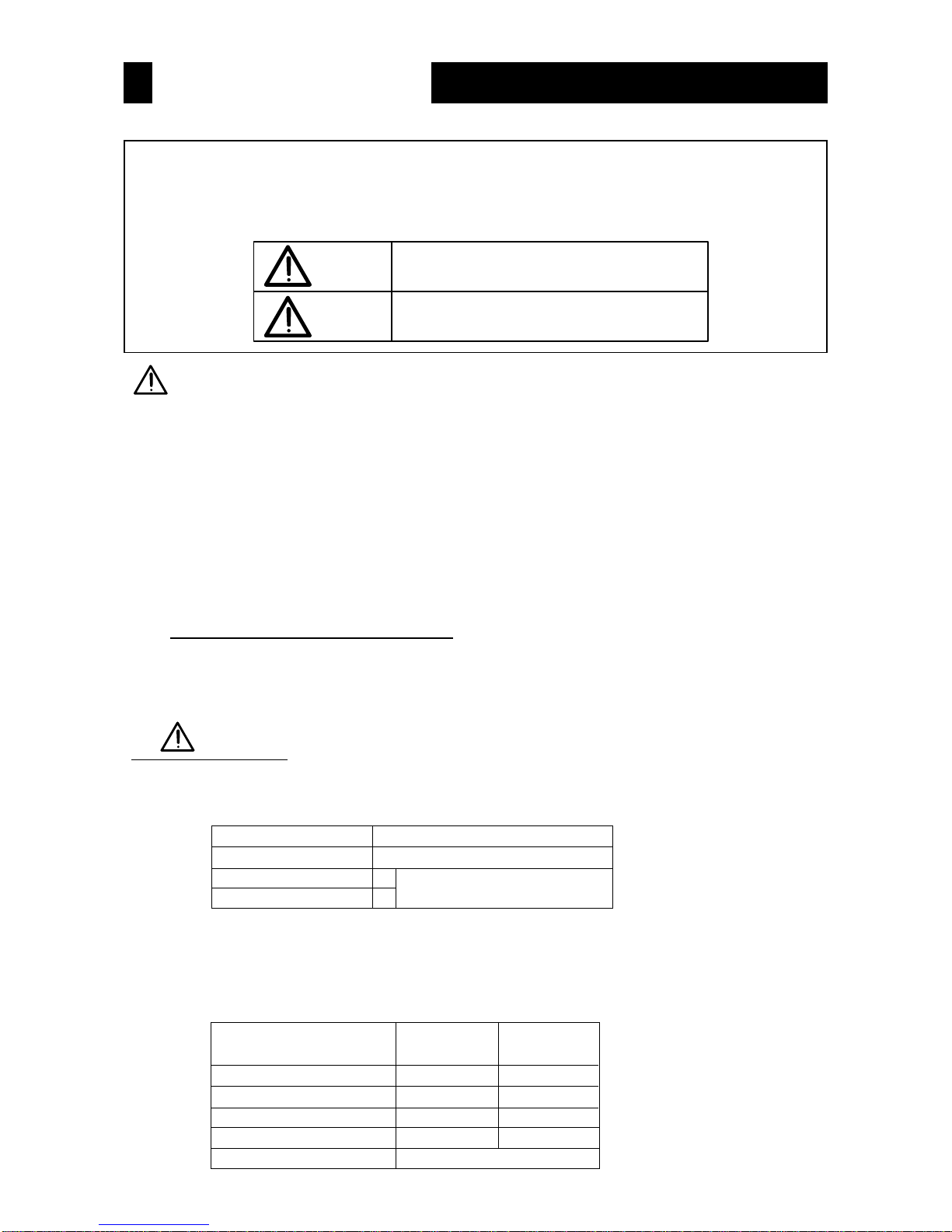

1. Warning

1.1 Installation and wiring

• This controller designed to be installed at the following conditions.

• The controller must be installed such that with the exception of the connection to the mains, creepage

and clearance distances shown in the table below are maintained between the temperature probe

and any other assemblies which use or generate a voltage shown in the table below.

Failure to maintain these minimum distances would invalidate the EN 61010 safety approval.

Operating temperature -10 to +50 [°C ]

Conforming to IEC1010-1

Installation category II

Pollution degree 2

Operating humidity 90%RH or less (Non condensation)

Up to 50Vrms or Vdc

Voltage used or generated

by any assemblies

Clearance

(mm)

Creepage

(mm)

0.2

Up to 150Vrms or Vdc 0.5

Up to 300Vrms or Vdc 1.5

Above 300Vrms or Vdc Contact with our sales office.

Up to 100Vrms or Vdc 0.2

1.2

1.6

3.0

1.4

Before using this product, the user is requested to read the following precautions carefully to ensure

the safety . Safety precautions must be taken by every user to prevent accidents.

The safety requirements are classified into "warning" and "caution" according to the following

interpretations :

Warning

Suggesting that the user's mishandling can

result in personal death or serious injury.

Caution

Suggesting that the user's mishandling can result

in personal injury or damage to the property.

WARNING Over-temperature Pr otection

Any control system should be designed with prior consideration that any part of the system has potential to

fail.

In case of temperature controlling, a continuance of heating on should be regarded as the most dangerous

state.

The followings are the most probable causes of inducing continuance of heating on:

1) The failure of the controller with heating output constantly on

2) The disengagement of the temperature sensor out from the system

3) The short circuit in the thermocouple wiring

4) V alve or switch contact point outside the system is locked to keep heating on

In any application in which it is apprehended that physical injury or destruction of equipment might occur,

please install an independent safeguard equipment to prevent over-temperature which shut down the heating

circuit, and for additional safety, we recommend this equipment to have its own temperature sensor.

The alarm output signal of the controller is not designed to work as protective measures when the controller

is in failure condition.

Safety PrecautionsRead before using

Page 4

– 4 –

• If the voltage shown above exceeds 60Vdc (i.e. hazardous voltage), the basic insulation is required

between all terminals of this controller and the ground, and supplementary insulation is required for

the alarm output.

Isolation class of this controller is as shown below. Be sure to check that the isola-tion class of the

controller satisfies your requirements before installan.

• If there is a danger of a serious accident resulting from a failure or a defect in this unit, provide the unit

with an appropriate external protective circuit to prevent an accident.

• The unit is normally supplied without a power switch and fuses.

Make wiring so that the fuse is placed between the main power supply switch and this controller. (Main

power supply: 2 pole breaker, fuse rating: 250V, 1A)

• When wiring the power supply terminal, use vinyl insulated 600 volt cable or equivalent.

• To avoid the damage and failure of controller, supply the power voltage fitting to the rating.

• T o avoid an electric shock and controller failure, do not turn ON the power before all wiring is completed.

• Be sure to check that the distance is kept to avoid electric shock or firing before turning the power ON.

• Keep away from terminals while the circuit is energized in order to avoid an electric shock and a

malfunction.

• Never attempt to disassemble, fabricate, modify, or repair this unit because tampering with the unit

may result in a malfunction, electric shock, or a fire.

1.2 Maintenance precautions

• Be sure to turn off the power before this controller is installed or removed in order to avoid an electric

shock, malfunction, and fault.

• Regular maintenance is recommended a longer service life of this controller. Some parts of this

controller have a limited life span, or they will be deteriorated with the lapse of time.

• One-year warranty is guaranteed for this unit including accessories, provided that the controller is

properly used.

Mains (Power source) Measured value input, CT input

Control output1 (relay output) Internal circuit

Control output2 (relay output) Control output1 (SSR drive output / Current output)

Alarm outout (AL1)

Alarm outout (AL2) Communication (RS-485) circuit

Heater burnout alarm output (HB) Digital input (DI).

: Basic insulation,

: Non-insulation,

: Functional insulation

Page 5

– 5 –

2. Warning

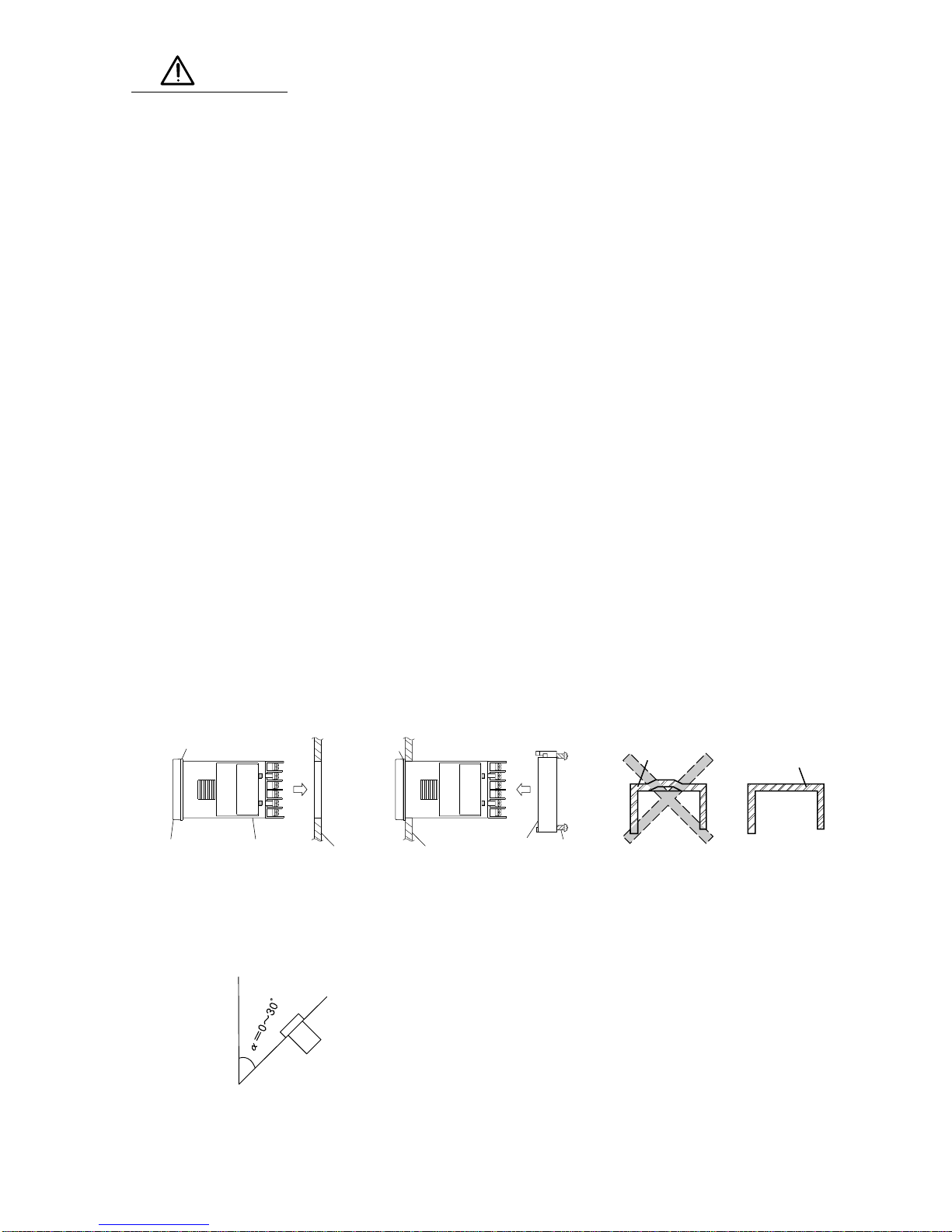

2.1 Cautions on installation

Avoid the following places for installation.

• a place where the ambient temperature may reach beyond the range of from 0 to 50∞C while in

operation.

• a place where the ambient humidity may reach beyond the range of from 45 to 85% RH while in

operation.

• a place where a change in the ambient temperature is so rapid as to cause

condensation.

• a place where corrosive gases (sulfide gas and ammonia gas, in particular) or combustible gases are

emitted.

• a place where the unit is subject directly to vibration or shock.

• a place exposed to water oil, chemicals,steam and vapor.

(if immersed with water, take the inspection by sales office to avoid an electrical leakage and firing )

• a place where the unit is exposed to dust, salt air, or air containing iron particles.

• a place where the unit is subject to intereference with static electricity, magnetism, and noise.

• a place where the unit is exposed to direct sunlight.

• a place where the heat may be accumulated due to the radiation of heat.

2.2 Caution on installation on panel

• Insert the mounting bracket (accessory) from the rear side until the main unit is securely fit into the

panel. If there should be a play , tighten two screws lightly until the play is eliminated. (Do not tighten

the screws excessively because the mounting bracket can be removed from the stopper by the force.)

• The front side of this controller conforms to NEMA 4X(equivalent with IP66). To ensure the

waterproofness between the instrument and the panel, use packings that are provided as accessories

in the following manner: (The improper fitting of packings will ruin the waterproofness.)

q As shown in Figure 1, fit a packing to the case of the unit and then insert it in the panel.

w Tighten screws on the fixing frame or fixtures so that no gaps are given between the front of

controller and packing and between panels. Check that there are no deviation and deformation of

packing as shown in Fig.3.

No. 000001T

PXR4TAA1-1YM00-D

MFD 2000-04

No. 000001T

PXR4TAA1-1YM00-D

MFD 2000-04

Figure 1 Figure 2

Unit Unit

Front

Case

Panel

PackingPacking

Panel

Mounting

bracket

Screw

Figure 3

Packing

Packing

Case

Case

(Bad) (Good)

Standard : Vertical mounting, flush on the panel. (The controller is horizontal.)

When mounting the controller on tilted surface, the maximum tilt angle is 30° (degree) from virtical.

(Caution)

• Don’t block the openings around the controller, or radiation effect will be reduced.

• Don’t block the ventilation openings at the top of the terminal block.

Page 6

– 6 –

2.3 Precautions in wiring connection

• For the thermocouple sensor type, use thermocouple compensation wires for wiring.

For the RTD type, use a wiring material with a small lead wire resistance and no resistance differentials

among three wires.

• Keep input lines away from power line and load line to avoid the influence from noise induced.

• For the input and output signal lines, be sure to use shielded wires and keep them away from each

other.

• If a noise level is excessive in the power supply , the additional installation of an insulating transformer

and the use of a noise filter are recommended. (example: ZMB22R5-1 1 Noise Filter manufactured by

TDK)

Make sure that the noise filter is installed to a place such as a panel that is properly grounded. The

wiring between the noise filter output terminal and the instrument power supply terminal should be

made as short as possible. None of fuses or switches should be installed to the wiring on the noise

filter output side because the filter effect will be degraded by such a installation.

• A better anti-noise effect can be expected by using stranded power supply cable for the instrument.

(The shorter the stranding pitch is, the better the anti-noise effect can be expected.)

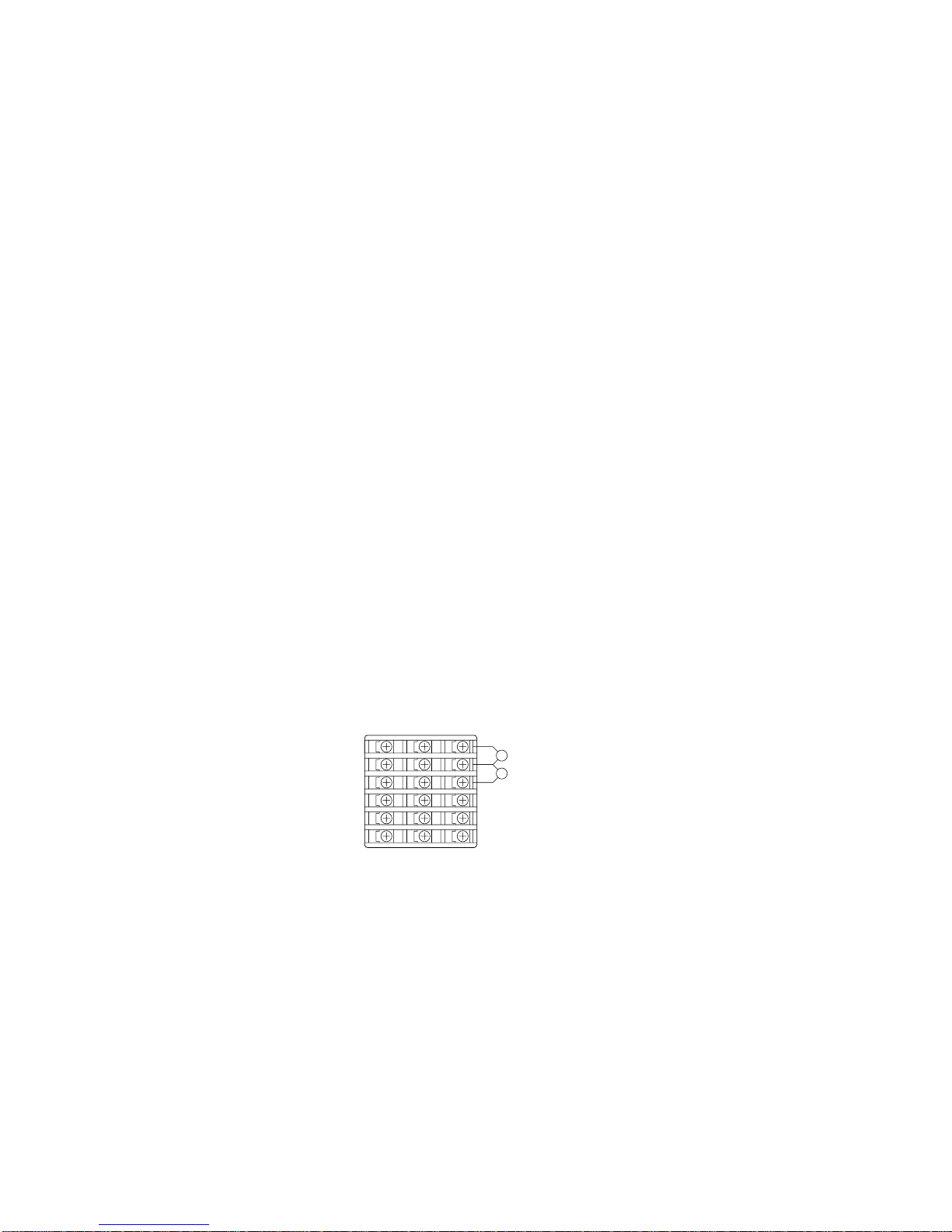

• For the unit with an alarm against a failure (burn-out) in the heater, use the same power line for

connection of the power supplies for the heater and the controller.

• A setup time is required for the contact output when the power is turned on. If the contact output is

used as a signal for an external interlock circuit, use a delay relay at the same time.

• Use the auxiliary relay since the life is shortened if full capacity load is connected to the output relay .

SSR/SSC drive output type is preferred if the output operations occur frequently.

[Proportional interval] relay output: 30 seconds or more, SSR/SSC: one second or more]

• If inductive load such as magnetic switches connected as a relay output load, it is recommended to

use Z-Trap manufactured by Fuji Electric to protect a contact from switching serge and keep a longer

life.

Model : ENC241D-05A (power supply voltage: 100 V)

ENC471D-05A (power supply voltage: 200 V)

Where to install : Connect it between contacts of the relay control

output.

Example)

• The SSR/SSC-driven output, an output of 4 to 20 mA DC, are not electrically insulate from internal

circuits.

Use a non-grounded sensor for resistance bulb or thermocouple.

2.4 Requirement for key operation/operation in abnormalities

• Prior to the operation, be sure to check alarm functions, since a failure in the proper setting will result

in a failure in the proper output of an alarm in case of an abnormality.

• A display of UUUU or LLLL will appear in case of a break in the input. Be sure to turn off the power

when a sensor is replaced.

2.5 Others

• Do not use organic solvents such as alcohol and benzine to wipe this controller. Use a neutral detergent

for wiping the controller.

1 7

13

2 8

14

3 9

15

4

10 16

5

11 17

6

12 18

Z-Trap connection

Page 7

– 7 –

<Reference items>

<Description>

Error indication

8

Power on

Wiring

2

Usages

3

Display and operation

4

Setting method of temperature and parameters

5

Functions

6

Setting of input type and control method.

7

Operation

Installation/mounting

1

Confirming type specification

• Confirming that the delivered

controller is equal to the ordered

one.

• Outline dimensions

• Panel cutout dimensions

• Mounting method on the panel

• Set value change method

• Basic operation method

• List of parameters

• List of input/output/alarm codes

• Setting of input type and ranges

• Selecting of control method

• Terminal connection diagram

*Note

(Note) *To start the operation, wait for about 30 minutes after the power-on for

warm up.

Index.

Page 8

– 8 –

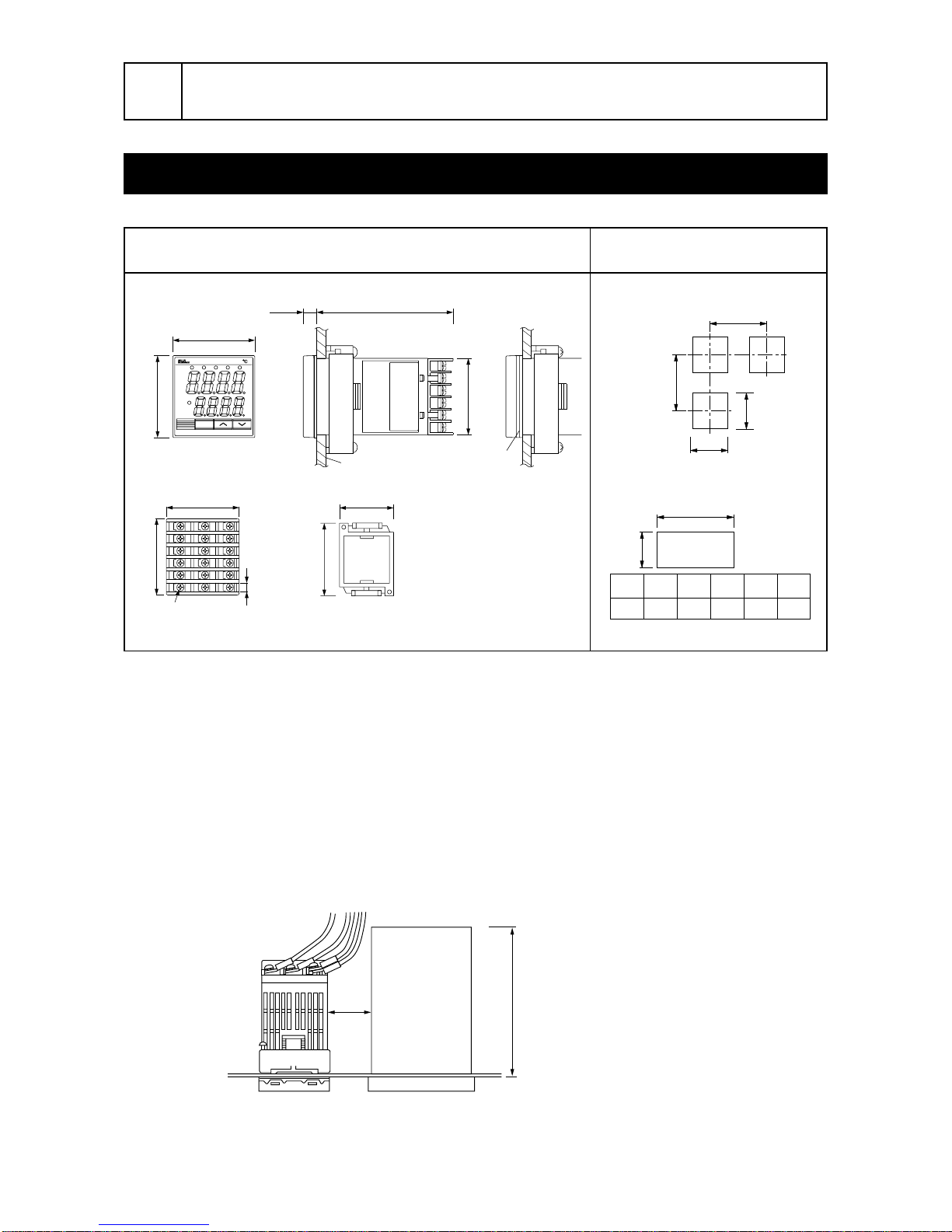

1 Installation/mounting

Outline and Panel Cutout Dimensions (Standard type/ Waterproof type)

Note 1

Caution on side by side installation

• With the power supply of 200 V AC or more, a maximum ambient temperature is 45˚C.

(It is recommended to use a fan for cooling.)

Cautions on wiring

• Wiring should be started from the left side terminal (No. 1 to No. 6).

• Use crimped terminals matched to the screw size. Tightening torque should be 0.8 Nm (Since the

case is made of plastic, do not tighten excessively).

• Do not connect anything to terminals not used.

No. 000001T

PXR4TAA1-1YM00-D

MFD 2000-04

AL2AL1C1 C2 AL3

SEL

PXR-4

SV

PV

48

44.8

44.8

79.88

48

Mounting bracket

Panel

Panel thickness 1 to 8mm

Packing

48

44.8

57

6.2

Terminal screw M3×6

13

16

17

18

14

15

7

8

10

11

12

9

1

2

4

5

6

3

63 or more

73 or more

+0.5

a -0

Number

of units

23456

a 93 141 189 237 285

45

+0.5

0

45

+0.5

0

45

+0.5

0

For side by side installation

Note) See the Note1.

Outline dimensions

Panel cutout dimensions

(Unit : mm)

When there is another instrument (larger than 70mm) or a wall on the right side of this controller, be sure

to install the controller keeping a space of more than 30mm.

30 min.

70 or more

Page 9

– 9 –

2 Wiring

Terminal Connection Diagram (100 to 240 Vac)

· Common

Relay output

Thermocouple Resistance valve Current/Voltage

Current output

uq!3

iw!4

oe!5

!0r

q

w

e

r

!6

!1t!7

!2y

t

y

!8

· Alarm output1 (AL1)

· Alarm output2 (AL2)

· Heater break

alarm output (AL3)

AC100-240V

Digtal input

CT input

CT input Digtal input

50/60Hz

(+)

(-)

SSR/SSC drive output

Control output1

Alarm output

!3

!4

Note1 : Check the power supply voltage before installation.

Note2 : Connect the I/V unit (250Ω resistor) (accesory) between the terminal !7 and !8 in case of

currert input.

u

i

u

i

o

!0

o

!0

!1

!2

u

i

u

i

o

!0

o

!0

o

!0

!1

!2

!1

!2

Communicaton (RS485)

Power supply

+

-

!77

!8

Signal input

A

B

B

!6

!77

!8

Control output 2

!3

!4

+

-

Relay output

Control output 2

!1

!2

Relay output

!77

!8

(Note2)

!3

!4

!5

(

Note1

)

Page 10

– 10 –

3 Usage (Read before using)

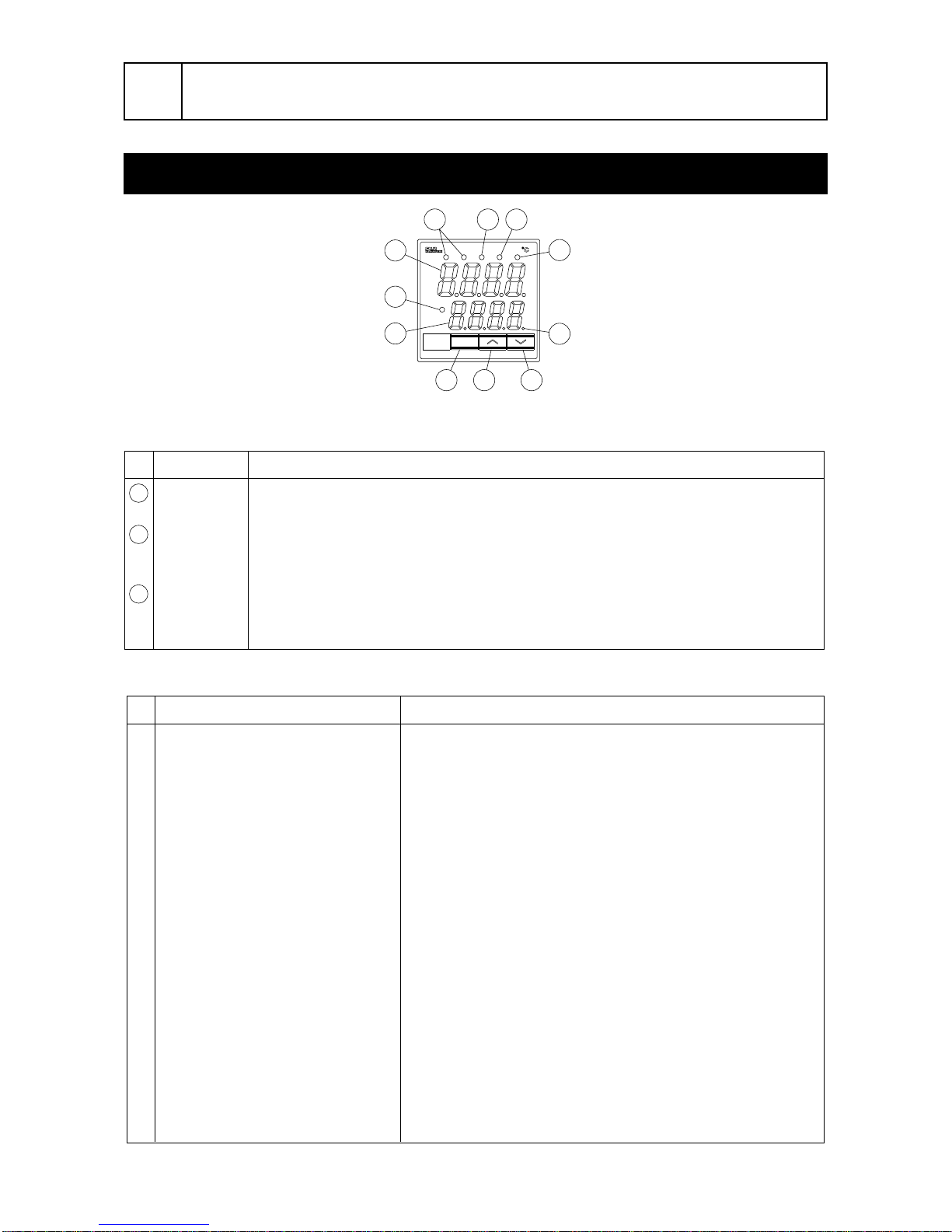

Name of Functional Parts and Functions

AL2AL1C1 C2 AL3

SEL

PXR-4

SV

PV

1

2

3

S1 S2 S3

4

8

765

Model : PXR4

Name Function

Select key The key shifting to the 1st, the 2nd or the 3rd block parameter, switching the display

between parameter and the data at the 1st, the 2nd and the 3rd block.

Setting keys

S1

Down key · The numerical value is decreased by pressing the key once. The numerical value

keeps on decreasing by pressing the key continuously.

· For searching parameters within the 1st, tne 2nd and the 3rd block.

S3

Up key · The numerical value is increased by pressing the key once. The numerical value

keeps on increasing by pressing the key continuously.

· For searching parameters within the 1st, the 2nd and the 3rd block.

S2

Name Function

Process value (PV)/parameter

name display

1) Displays a process value (PV).

2) Displays the parameter symbols at parameter setting mode.

3) Displays various error indications

(refer to the 8, Error indications).

Display/Indication

q

Set value (SV)/parameter setting

display

1) Displays a set value (SV).

2) Display the parameter settings at parameter setting mode.

3) Flickers at Standby mode.

4) Displays the set value (SV ) and “SV-1” alternately when

the SV switching function is used.

e

Set value (SV) indication lamp The lamp is lit while a set value (SV) is displayed.

w

Auto-tuning/self-tuning indicator The lamp flickers while the PID auto-tuning or the self-tuning

is being performed.

r

Control output indication lamp C1 : The lamp is lit while the control output 1 is ON.

C2 : The lamp is lit while the control output 2 is ON.

t

Alarm output 1 (AL1)

indication lamp (Note 1)

The lamp is lit when the alarm output 1 is activated. It flickers

during ON delay operation.

y

Alarm output 2 (AL2)

indication lamp (Note 1)

The lamp is lit when the alarm output 2 is activated. It flickers

during ON delay operation.

u

Heater break alarm output (AL3)

indication lamp (Note 1)

The lamp is lit while the heater break alarm output is ON.

Note 1) Control output 2 and alarm function are optional.

i

Page 11

– 11 –

4 Display and operation

AL2AL1C1 C2 AL3

SEL

PXR-4

SV

PV

AL2AL1C1 C2 AL3

SEL

PXR-4

SV

PV

· To perform standby operation, set "STby" as ON in the

1st block parameter.

· Standby mode:

(Output) Control outputs (1 and 2) and alarm outputs (all) are not provided. However,

depending on setting of "P-n1", control action, control outputs are provided at the

abnormal input.

No alarm output is provided at standby mode, even in (Fault-condition).

Standby mode

Operation mode

Parameter setting mode

Switching by the key

SEL

1

Change of set value (SV)

2

Shift to the 1st, 2nd and 3rd block parameter

To shift to the other blocks, press the key.

When the SV lamp is lit, the set value (SV) is displayed at the lower line.

The set value (SV) can be changed.

After the data setting, the data are registered

automatically in 3 seconds.

Depending on the pressing time of key,

you can select the block to shift.

SEL

SEL

SEL

pressing time Shifting block

About 1 sec pressing 1st block

About 3 sec pressing 2st block

About 5 sec pressing 3st block

Caution

Caution

Caution

Caution

(Control) Control is not performed.

(Display) SV display flickers.

(Setting) SV and parameter settings are able to perform.

Be careful since the equipment does not provide output of the alarm of

the main unit abnormality during the standby operation.

The SV display does not flicker while the 1st, 2nd and

3rd block parameters are displayed.

Switching by 1st block

STby settings

AL2AL1C1 C2 AL3

SEL

PXR-4

SV

PV

AL2AL1C1 C2 AL3

SEL

PXR-4

SV

PV

SEL

SEL

SEL

SEL

SEL

SEL

AL2AL1C1 C2 AL3

SEL

PXR-4

SV

PV

1

Press the

once.

Press the for 2 sec.

Parameter selection

Parameter setting procedure

Select a parameter you want to

set by pressing the or

key.

3

3

1 2

To shift to Operation/Standby

mode, press the key for 2 sec.

2-1

Press the key to allow the

parameter to change.

(Under the changing condition,

the parameter set value flickers).

2-2

Pressing the or key, to

change the parameter set value.

2-3

After the parameter has been

changed, press the key

for registration.

Parameter settings

Shift to operating condition

Parameter search.

1

Registers

parameter set

value, returning

to the parameter shift mode .

Operation mode

Press the . Press the .

Parameter change.

Increases parameter set value

Decreases parameter set value

By repeating the same procedure, the parameters

can be displayed according to the parameter list

shown in 5, Setting methods of temperature and

parameters.

Page 12

– 12 –

5 Setting methods of temperature and paramenters

Standby

AL2AL1C1 C2 AL3

SEL

PXR-4

SV

PV

Control output status

Alarm status

PV value

indication

SV value

indication

When the set value (SV) is displayed at the lower line, the SV lamp is lit.

AL2AL1C1 C2 AL3

SEL

PXR-4

SV

PV

Operation/Standby mode

SV value

indication

flickers.

SEL SEL

Operation

Parameter

display symbol

Parameter

Standby settings

Description of contents

Default

setting

Remarks

STbY

ProG

LACH

AT

TM-2

AL1

A1-L

A2-L

A2-H

LoC

TM-1 Timer 1 display

Timer 2 display

Alarm 1 low limit

set value

Alarm 1 set value

(appears only with alarm action type 16 to 31).

Setting range: Note 1

Alarm 1 high limit

set value

(appears only with alarm action type 1 to 10).

Setting range: Note 1

Alarm 2 set value

10

10

A1-H

AL2

10

10

0

Switches RUN or Standby of the control.

ON: Control standby (output: OFF, alarm: OFF)

OFF: Control RUN

OFF: stop, rUn: Start, HLd: status hold

0: Stop, 1: Standard AT start, 2: Low PV type AT start

OFF

Alarm latch cancel Releases alarm latch.

1: Alarm latch release

0

Ramp/soak control

OFF

Auto-tuning

Time displays remining time at the timer mode.

(appears only with alarm action type 1 to 10).

Setting range: Note 1

(appears only with alarm action type 16 to 31).

Setting range: Note 1

(appears only with alarm action type 16 to 31).

Setting range: Note 1

Alarm 2 high limit

set value

(appears only with alarm action type 16 to 31).

Setting range: Note 1

Alarm 2 low limit

set value

Setting of key lock status. Key lock

10

0

10

10 Table 3

(Page 4)

Table 3

(Page 4)

Table 3

(Page 4)

Table 3

(Page 4)

Table 3

(Page 4)

Table 3

(Page 4)

10

All parameters

Front key

0

1

2

3

4

5

Comm-

unication

SV

Front key Comm-

unication

Note 1) Setting range :0 to 100%FS (in case of absolute value alarm)

100 to 100%FS (in case of deviation alarm)

Note 2) Never set "TC" / "TC2" = 0

· Some parameters may not be displayed on the screen, depending upon the types.

1st block parameter

: Setting enable, : Setting disable

Press for about 1 sec. Press for about 2 sec.

Page 13

– 13 –

Standby

AL2AL1C1 C2 AL3

SEL

PXR-4

SV

PV

Control output status

Alarm status

PV value

indication

SV value

indication

When the set value (SV) is displayed at the lower line, the SV lamp is lit.

AL2AL1C1 C2 AL3

SEL

PXR-4

SV

PV

Operation/Standby mode

SV value

indication

flickers.

SEL SEL

Operation

Parameter

Proportional band

Description of contents

Default

setting

Remarks

P

I

D

TC

TC2

CooL

db

P-SU

P-dP

ALM1

ALM2

HYS

Hysteresis for ON/OFF contorol

Cycle time (control output 2)

Deadband/overlap

Proportional band

coefficient on cooling side

Input type code

Lower limit of input range

As ordered

As ordered

P-n2

P-SL

As ordered

As ordered

0/5

0/9

5.0

Derivative action time

60.0

Integral time (reset)

240

Cycle time (control output 1)

Setting types of alarm action (Setting range: 0 to 34)

Setting of decimal point

position

PVOF

0

PV offset

Type of alarm 1

Upper limit of input range

Type of alarm 2

1

30/2 Note 2

30

1.0

0.0

PTn

1

Selects the ramp/soak execute type.

1: Executes 1st to 4th segment.

2. Executes 5th to 8th segment.

3. Executes 1st to 8th segment.

Ramp/soak execute type

SV-1

to

SV-8

0%FS

Sets the target SV for each ramp segment.

(Setting range: 0 to 100%FS)

Ramp target SV-1 to SV-8

TM1r

to

TM8r

0.00

Sets the time for each ramp segment.

(Setting range: 0 to 99 hours and 59 minutes)

1st ramp segment time to

8th ramp segment time

TM1S

to

TM8S

0.00

Sets the time for each soak segment.

(Setting range: 0 to 99 hours and 59 minutes)

1st soak segment time to

8th soak segmentl time

STAT

-

Ramp/soak status

Shift the display of process value (PV).

(Setting range: -10 to 10%FS)

Displays the current Ramp/Soak status.

No setting can be made.

Setting range: 0.0 to 999.9%

ON/OFF control when "P" = 0

Setting range: 0 to 3200 sec.

No integral action when "I" = 0

Setting range: 0.0 to 999.9 sec.

No derivative action when "d" = 0

Sets cycle time of control output 1.

(Setting range: 1 to 150 sec)

Setting range: 0 to 50% FS

Sets cycle time of control output 2.

(Setting range: 1 to 150 sec)

Sets the proportional band coefficient on the cooling side.

(Setting range : 0.0 to 100.0)

ON/OFF control when "Cool" = 0

Shifts the output value on the cooling side.

(Setting range: -50.0 to 50.0%)

Lower limit of input range

(Setting range: -1999 to 9999)

Upper limit of input range

(Setting range: -1999 to 9999)

Type of input Table 1

(Page 4)

Table 2

(Page 4)

Table 2

Table 2

(Page 4)

Table 3

(Page 4)

Table 3

(Page 4)

Select a decimal point position of display.

(Setting range: 0 to 2)

. .

"1"

0 : No decimal point

"2"

CTrL

PID

Type of control algorithm.

(Setting range: PID, FUZZY, SELF)

Control algorithm

P-dF

Time constant of input filter

5.0

Time constant (Setting range: 0.0 to 900.0 sec.)

2nd block parameter

Parameter

display symbol

Note 2

Table 2

(Page 4)

Press for about 3 sec. Press for about 2 sec.

Page 14

– 14 –

Standby

AL2AL1C1 C2 AL3

SEL

PXR-4

SV

PV

Control output status

Alarm status

PV value

indication

SV value

indication

When the set value (SV) is displayed at the lower line, the SV lamp is lit.

AL2AL1C1 C2 AL3

SEL

PXR-4

SV

PV

Operation/Standby mode

SV value

indication

flickers.

SEL SEL

Operation

Parameter

Control action

Description of contents

Default

setting

Remarks

P-n1

A1hY

A2hY

dLY2

A1oP

A2oP

dLY1 ON delay time of

alarm 1

ON delay time of

alarm 2

Additional function

of alarm 2

Additional function

of alarm 1

Lower limit of SV

(Setting range: 0 to 100%FS)

Lower limit of SV

Upper limit of SV

(Setting range: 0 to 100%FS)

Upper limit of SV

0%FS

100%FS

SV-L

SV-H

0 Table 4

(Page 4)

6-7

(Page 3)

6-6

(Page 3)

Hysteresis for

alarm 1

Sets ON-OFF hysteresis for alarm output.

(Setting range: 0 to 50%FS)

1

Hysteresis for

alarm 2

ON delay time setting for alarm output

(Setting range: 0 to 9999 sec)

Additional function of alarm output

(Setting range: 000 to 111)

Alarm latch (1:use, 0:not use)

Alarm of error status (1:use 0:not use)

De-energized (1:use 0:not use), Note 3.

0

1

0

000

000

dl-1

CT

-

CT (Current Transformer) input valueCT input value

0(OFF)

Selects digital input 1 (DI1) function

(Setting range: 0 to 12)

DI1

function

STno

1

Communication station No. (Setting range: 0 to 255)Station No.

CoM

0

Parity setting

Parity setting. Baud rate is fixed at 9600 bps.

(Setting range: 0 to 2)

PYP

34

Code for PYP input

type

Input type code used when communicating with PYP.

See the OPERATION MANUAL

(Initial value: K: 0 to 400 C)

dSP1

to

dSP13

Parameter mask Specifying parameter mask

Selects the control action.

Hb

0.0

Sets current value to detect the heater disconnection

(Setting range: 1.0 to 50.0A, 0: OFF)

HB alarm set value

Parameter

display symbol

3rd block parameter

Note 3) De-energized: Contact opens when the alarm "ON".

Press for about 5 sec. Press for about 2 sec.

Page 15

– 15 –

6 Functions

• At ON/OFF control mode,output signal is as shown below.

Set parameter “P” = 0 for selecting the ON/OFF control mode.

Set the hysteresis to avoid chattering.

(Default setting: Hys = 1)

• Parameter setting and operation example

Example 1 : Reverse operation

Parameter

P

P-n1

HYS

Relationship of

PV and SV

PV > SV

PV < SV

Output

OFF

ON

Setting value

0.0

0 (or 1)

Any value

PV

when PV

increases

PV

when PV

decreases

HYS

SV

PV

when PV

increases

PV

when PV

decreases

HYS

SV

ON

ON

ON

ON

Example 2 : Direct operation

Parameter

P

P-n1

HYS

Setting value

0.0

2 (or 3)

Any value

6-1 ON/OFF control

Page 16

– 16 –

Setting code (AT)

012

When auto-tuning

is cancelled or not

performed.

Standard type

(auto-tuning at SV)

Low PV type (autotuning at 10%FS

below SV.)

Start of AT

End of AT

PV

PID control

Start of AT

End of AT

PV

PID control

SV-10%FS

Set value (SV)

Set value (SV)

q Standard type (AT=1)

(a) The P.I.D. parameter calculated by auto-tuning remains even if the power is turned off. If the power is

turned off before the auto-tuning is completed, you must restart the auto-tuning.

(b) The PV may be changed greatly depending on the process, because the con trol output is ON/OFF action

(two position operation) in the auto-tuning. So, do not use the auto-turning if the process does not allow a

significant variation of PV.

In addition, the auto-tuning should not be used in any process such as pressure control and flow control,

where a quick-response is required.

(c) If the auto-tuning isn’t completed in four hours, the auto-tuning is suspected to fail. In this case, check the

wiring and parameters such as the control action,

input type, etc.

(d) Carry out the auto-tuning again, if there is any change in SV, input range (P-SL, P-SV or P-dP) or process

condition. Perform the auto-tuning if fuzzy control is selected as the control algorithm.

(e) When resetting the AT parameter , set the parameter to “0” once, then reset it.

6-2 Auto-tuning (AT)

Autotuning is the automatic calculation and entering of the control parameters (P,I and D) into memory. Prior

to the auto-tuning, complete the setting of input range

(P-SL,P-SU, P-dP), a set value (SV), alarm setting (AL1, AL2), and cycle time (TC).

Set the parameter AT as either “1” or “2” by using or key, and press the

SEL

key to start the auto-turning.

Then the point indicator at the lower right starts blinking. At the completion of Auto-tuning, the point indicator

stops blinking, then parameter AT is automatically set to 0.

How to start the auto-tuning

w Low PV type (AT=2) :

Overshoot decreased

at tuning.

Page 17

– 17 –

1) At power on, changing a set value or the external disturbance, tuning is made automatically so that the PID

parameters are re-optimized.

It is useful where modification of PID parameters is required repeatably due to frequent change in process

condition.

If high controllability is important, select the PID or fuzzy control algorithm and use auto-tuning.

2) Setting for self-tuning

q Turn on the power and set the SV.

w Select SELF at “CTrL” (control algorithm) parameter.

e Turn off the power once.

r Turn on the power of the whole system. The controller should be turned on at the same time with the

other equipments or even later. Otherwise, the selftuning might not be performed successfully.

t Self-tuning starts. Then the point indicator at the lower right corner starts blinking until the PID parameters

are re-optimized.

Note) Whenever it is necessary to re-try the self-tuning, please set “CTrL” = PID

once, and then start the above setting procedure from the beginning.

2nd block parameter

· Set "CTrL" (control algorithm) as SELF.

PID PID control

FUZY Fuzzy control

SELF Self-tuning control

PV

SV

PV

SV

6-3 Self-tuning

3) Self-tuning indication

The point indicator at the lower right corner starts blinking until the PID parameters are re-optimized.

SV

PV

C1 C2 AL1 AL2

Page 18

– 18 –

4) Self-tuning is executed by any of the following conditions.

q During temperature rise at power ON.

w During temperature rise at SV changing if necessary.

e When control is out of stable condition and is judged as being out of stable condition continuously.

5) Self-tuning is not executed under the following conditions:

q During standby mode

w During ON/OFF control

e During auto-tuning

r During ramp/soak operation

t During input error

y With dual output (“P-n1” ≥ 4)

u When P, I, D or Ar is manually set

Under the following coditions, self-tuning is canceled.

q When SV is changed.

w When Self-Tuning can not be completed in about 9 hours after the start.

6) Cautions

· Turn on the power of the whole system. The controller should be turned on at the same time with the

other equipments or even later. Otherwise, the self tuning might not be performed successfully.

· Don’t change the SV while the self-tuning is executing.

· Once PID parameters are optimized, the self-tuning is not excuted at the next power on unless SV is

changed.

· After the execution of self-tuning, if the controlability is not your expected level, please select PID or

FUZZY at “CTrL” parameter, and then, start the auto-tuning.

Page 19

– 19 –

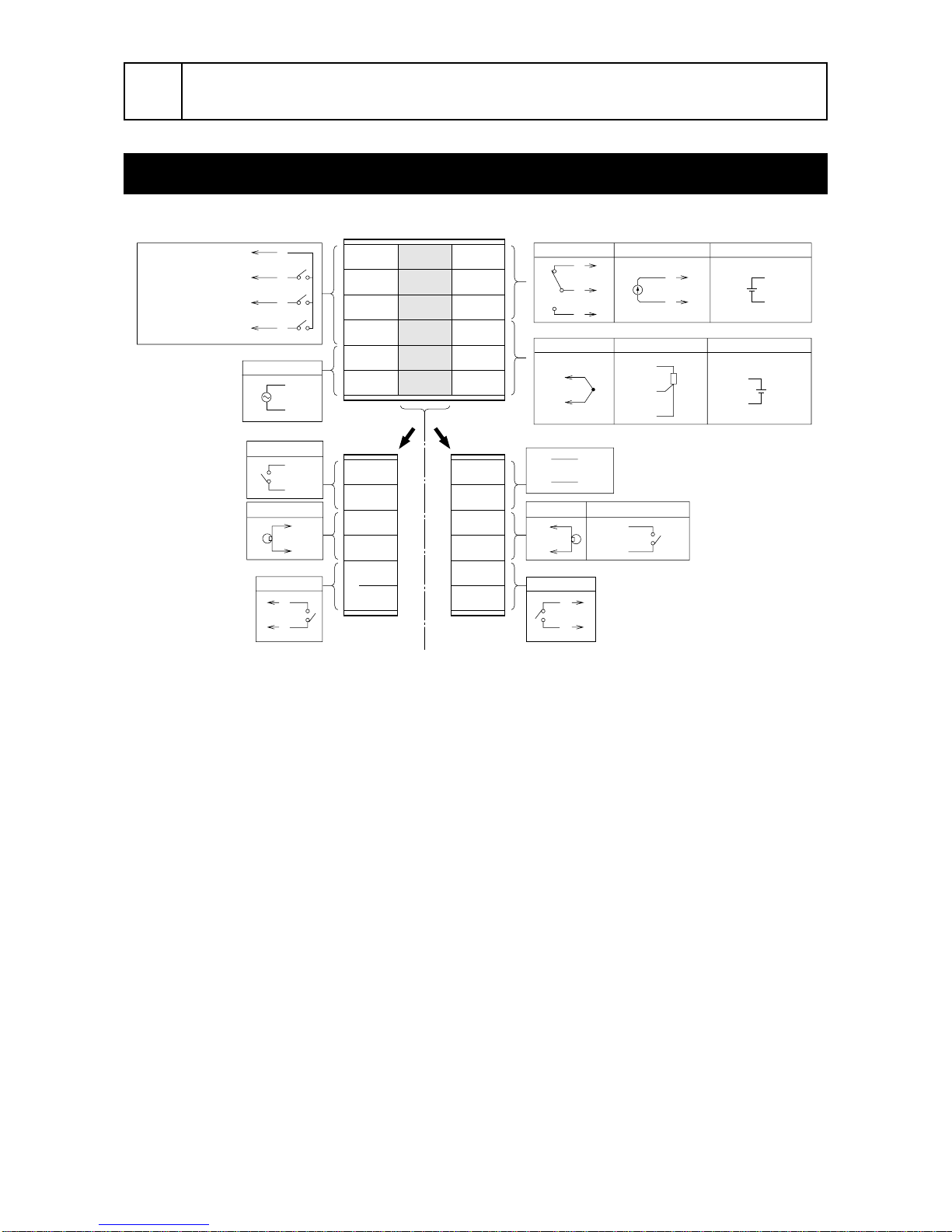

1) Kinds of alarm

• Absolute value alarm, deviation alarm, combination alarm, and zone alarm are available.

(For details, see Table 4, Alarm action type codes on page 4.)

ON delay function

ON delay setting time

ON

Alarm

OFF

ON

OFF

ON

OFF

Without ON delay function

With ON delay function

Relay output

ON

OFF

ON

OFF

ON

OFF

Without

De-energizing

function

With

De-energing

function

No.

Function

Description Parameters to set

q Hysteresis Set the hysterisis to avoid chattering. Alarm 1 :

Alarm 2 :

Alarm 1 :

Alarm 2 :

w ON delay

The alarm is turned on with delay of a certain seconds

as previously set after PV goes in the alarm band.

r Error status

alarm

Alarm is turned on when error indications are

displayed.

t De-energizing Alarm output can be de-energized.

e Alarm latch Keeps the alarm ON status once an alarm is

turend ON. To cancel the alarm latch, please take

one of the following procedure.

i) Turn ON the controller again.

ii) Turn the alarm latch settings to OFF once.

iii) Use alarm lacth cancel parameter.

iv) Cancel by Digtal input (DI1).

v) Cancel by communication function.

Alarm 1 :

Alarm 2 :

Alarm 1 :

Alarm 2 :

Alarm 1 :

Alarm 2 :

6-4 Alarm function [option]

2) Alarm function

Energizing/de-energizing function

Page 20

– 20 –

No. Cautions

Cautions on alarms

Combination of alarm functions

Please see the table as shown below.

O: Possible combination

X: Impossible combination

Note 1) The alarm is not turned on the first time the measured value is in the

alarm band. Instead it turns on only when the measured value goes out

of the band and enters it again.

Items/Classification

1 Note that the ON delay function is effective for alarm in error status.

Alarm in error

status

Alarm at error

indication

2 Even during "Err" display, alarms in error status work.

3

Even when “LLLL” or “UUUU” is displayed, an alarm function works normally.

5 With the HB alarm, ON delay function, de-energizing function and latch

function cannot be used.

HB alarm

Alarm action type

code

4 Alarm action type codes in No.12 to 15 are also included in No.24 to 27.

It is, therefore, recommended to use No.24 to 27. In addition, please note

when selecting No.12 to 15, setting in ALM2, dLY2, and A2hy are effective.

6

The minimum alarm set value is –199.9.

Alarm set value

Note that all of alarm outputs are not provided at the standby condition.

Alarm at standby

mode.

Error status alarm is not provided at the standby mode.

The HOLD function is effective e v en if the PV v alue is in the h ysteresis area

when the power is turned ON.

7 As the alarm action type changed, the alarm set value may also be

changed accordingly.

8

9

10

Alarm in error status

ON delay

De-energizing

Alarm latch

Without HOLD/Timer

O

O

O

O

With HOLD

O

O

Note 1

O

With Timer

X

O

X

X

Page 21

– 21 –

1. Function

Changes the set value (SV) as the time elapses according to a predetermined program pattern, as shown

below.

Either 4 ramp/soak x 2 patterns or 8 ramp/soak x 1 pattern can be programmed. The first ramp starts from

the process value (PV) just before the programming is executed.

2. Setting

· Select the program pattern (PTn) and set the rUn at

“ProG” parameter.

· Ramp/soak pattern can not be changed while ramp/soak program is running.

Note:

· The ramp/soak program is canceled if the controller becomes to standby mode.

Then, if the controller becames to opration mode, the program doesn’t run again.

SV-1

SV-2

SV-3

SV-4

SV-5

SV-6

SV-7

SV-8

Time

TM1rPVTM1s TM4rTM4s TM5rTM5s TM8rTM8s

1st 4 ramp/soak 2nd 4 ramp/soak

8 steps

PTn

1

2

3

Pattern

1

2

1 + 2

Ramp/Soak

4

4

8

and/orand/or

6-5 Ramp/soak function [option]

Page 22

– 22 –

1) Function

· Data can be written/read through the MODBUS® protocol.

2) Before using this function, please set related parameters as shown below.

3rd block parameter

Set the station No. at "STno"

(station No. setting paramter).

[Sample: station No. = 18]

Set the parity at "COM".

[Sample: Odd parity]

CoM

0

1

2

Odd

Even

No parity

PV

SV

PV

SV

Please do not change "PYP"

unless used with PYP,

Color T ouch-Oper ation Unit.

PV

SV

6-6 Communication function [option]

3) Caution

· Station No. can be set in the range of 0 to 255. (No communication is allowed with 0).

· After changing the setting of parity at “COM”, please power off and re-start the controller.

· Baud rate is fixed to 9600 bps.

Page 23

– 23 –

1) Function

· With Digital input, the follwing functions are available.

q SV switching

w Control mode; RUN/STANDBY selection

e Ramp/soak RUN/RESET selection

r Auto-tuning start/stop

t Alarm latch cancel

y Timer start/reset

2) To use DI function;

· Select the function refering to the

Table shown below.

3) Table of DI function

3rd block parameter

PV

SV

DI function code

(0 to 12)

DI

function

code

Function Description

1 Set value (SV) switcing Switching between local SV and " " (remote SV)

5 All alarm latch cancel

When this function is not used, DI is not effective.

6 Alarm 1 latch cancel

2

Control mode, RUN/STANDBY

At standby mode, control is not provided and SV flickers.

3 Auto-tuning (standard)

start

Start/Stop can be switched at the time of DI raising up or

dropping down.

7 Alarm 2 latch cancel

9

ALM1 timer

ON/OFF delay timer operation is available. The remaining

time of the timer can be checked with timer-1 and -2

display parameters (first block).

10

ALM2 timer

12 Ramp/soak RUN/RESET RUN/RESET of ramp/soak can be performed at the time

of DI raising up or dropping down.

4 Auto-tuning (low PV)

start

6-7 Digital input (DI function) [option]

Page 24

– 24 –

Work

Time

Don't work

Integral action

Don't work

Ar

Ar

SV

PV

6-8 Other functions

Mask/Unmask bAL and Ar

1 To unmask

q Display the "dSP3" in the third block parameter and then subtract 128 from current value.

w Display the "dSP4" in the third block parameter and then subtract 1 from current value.

2 To mask

q Display the "dSP3" in the third block parameter and then add 128 to current value.

w Display the "dSP4" in the third block parameter and then add 1 to current value.

The parameters “bAL” and “Ar” are masked at defauit setting.

If necessary to appear these parameters, please refer to the following procedure.

1) Function

•“bAL” and “Ar” are functions to suppress overshoot.

(Usually it is not necessary to change the setting.)

2) If they aren't optimum value, sometime you don't get the good control. Usually it is not necessary to set

them.

3) "Ar"(Anti-reset wind-up) is automatically set by "Auto tuning".

1 bAL

MV is calculated by adding the offset (bAL) to MV’ ,the result of PID calculation, from PV and SV.

2 Ar

The integral range is SV±Ar.

Integral action don't work when PV is out of

the range.

bAL increase

bAL decrease

bAL

50%

100%

0%

Set value (SV)

Proportional band

Control output (MV)

MV' (PV)

PV

SV

PID

bAL

MV'

MV

+

+

Operation value

Page 25

– 25 –

7 Setting of input type and control algorithm

Setting of

the input type

* Skip this procedure

if the input type is

specified when

you order.

1

q Please check if the input type set at “P-n2” is same as

what you use.

Choose the sensor type you use from Table 1 shown below, and set

the code at “P-n2”.

(Example) For T thermo-couple, set “P-n2”=7.

(Note) Please refer to the following table for the modification of the

input type.

Standard range to each sensor is shown in Table 2. Select the

temperature range suitable for the equipments you use, set lower/

upper limit values to “P-SL” / “P-SU” respectively.

(Example) For temperature range 0 to 800 [°C] : Set “P-SL” and

“P-SU” to 0 and 800 respectively.

(Note) If the span of setting ranges is smaller than the one of

minimum standard range, the accuracy (% full scale) is

influenced.

(Note) No standard range is given in case of 1 to 5VDC (4 to 20mA

DC) input. Please set the range within the following limitation.

• Maximum span : 9999 • Lower limit : -1999

• Upper limit : 9999

w Is setting of input temperature range suitable for the

sensor you use?

TC Can be modified by changing “P-n2”.RTD

(within Group I)*

TC/RTD

(Group I)*

Modification not possible

TC : Thermocouple RTD : Resistance bulb

1 to 5Vdc

4 to 20mAdc

(Group II)*

(*Please refer to table 1)

Note:

Please set “P-n2”: Input sensor type and “P-SL/P-SU/P-dP”: input range setting prior to any other parameter

settings. When “P-n2” and/or “P-SL/P-SU/P-dP” is changed, some other parameters may also be in fluenced.

Please check all parameters before starting control.

Page 26

– 26 –

Setting of

the algorithm

2

* Read if the control

doesn't work as you

expect.

q Select the type of control output action.

w Control algorithm (ON/OFF, PID or fuzzy)

Setting

Set “P” =0.0.

Refer to “6-1 ON/OFF control”

Select PID at “CTrL”.

Execute auto-tuning so that optimum

P.I.D can be calculated automatically.

(PID parameters can be set

spontaneously).

*Refer to “6-2 Auto-tuning”.

Select FUZy at “CTrL”.

Then execute the auto-tuning so that

FUZZY control starts.

Select SELF at “CTrL”.

Refer to “6-3 Self-tuning”.

Heating

Cooling

Reverse

Direct

Control

output action

As PV increases,

MV decreases.

As PV decreases,

MV increases.

As PV increases,

MV also

increases.

As PV decreases,

MV also

decreases.

Setting procedure

Set parameter

“P-n1” = 0 or 1.

(Refer to Table 2)

Set parameter

“P-n1” = 2 or 3.

(Refer to Table 2)

Type of control

ON/OFF control

PID control

Fuzzy control

PID control with

self-tuning.

Description

Output is either ON (100%) or OFF

(0%).

(Suitable when frequent output

switching is inconvenient.)

The output signal changes within

the range at 0 to 100% according

to PID calculation which determine

the proportional of ON to OFF in

each TC (cycle time).

Fuzzy operation is added to PID

providing

control with less overshoot.

At power on, changing a set value or

the external disturbance, tuning is

made automatically so that the PID

parameters are re-optimized. It is

useful where modification of PID

parameters is required repeatably due

to frequent change in process

condition.

Description

Page 27

– 27 –

This controller has a display function to indicate several types of error code shown below.

If any of the error codes is displayed, please eliminate the cause of error immediately.

After the cause is eliminated, turn off the power once, and then re-start the controller.

Error code

(SV indication flickers)

Possible cause Control output

Group

q Thermocouple burnt out.

w RTD (A) leg burnt out.

e PV value exceeds P-SU by 5% FS.

q The RTD leg (B or C) burnt out.

w The RTD leg (between A and B or

A and C ) short.

e PV value is below P-SL by 5%FS.

r 1 to 5 VDC or 4 to 20mADC wiring

open or short.

q PV value < -1999.

Note) In case of RTD input, "LLLL" is not

displayed even if the temperature

becomes below -150 ˚C.

Incorrect range setting (P-SL/P-SU).

Fault in the controll.

q when the burn-out control output

is set as the lower limit (standard):

OFF or 4 mA or less

w when the burn-out control output is

set as the upper limit: ON or 20 mA

or larger

Control is continued until the value

reaches -5% FS or less, after which

burn-out condition will occur.

OFF or 4mA or less

Undefined (Stop using this controller

immediately.)

Contact with Fuji Electric Co.,Ltd. or

the nearest repesentatives.

I

II

8 Error indications

Page 28

– 28 –

Input typeGroup

I

· Pt100 (IEC)

RTD

· J

· K

· R

· B

· S

· T

· E

· N

· PL-II

1

2

3

4

5

6

7

8

12

13

Thermocouple

Code

Input type

Group

II 1 to 5VDC,

4 to 20mA DC

16

Code

Can be modified by

changing "P-n2"

Modification

not possible

· In case of 4 to 20mA DC input, mount a 250Ω

resistor enclosed in the package box.

TC RTD

(within Group I)*

TC/RTD

1 to 5 VDC

4 to 20 mA DC

(Group I)* (Group II)*

(*) Outputs when Error Indication Group I.

Please refer to 8 (Error indications).

This is effective even in Standby mode.

Lower limit:OFF or 4mA or less

Upper limit:ON or 20mA or more

[Caution for dual output] (option)

(1) Parameter “I” and “D” can not be set

separately.

(2) In case “P”=0 (ON/OFF control) for heating

side, cooling side becomes ON/OFF

control automatically .

(3) In case “Cool” =0.0, cooling side becomes

ON/OFF control. And hysteresis is fixed at

0.5%FS.

Table 2

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Single

(Control output 1)

Dual

Control output

1 and 2.

Heating/Cooling

Output 1

Reverse action

Direct action

Reverse action

Direct action

Reverse action

Direct action

Output 2

---

Direct action

Reverse action

Output 1

Lower limit

Upper limit

Lower limit

Upper limit

Lower limit

Upper limit

Lower limit

Upper limit

Lower limit

Upper limit

Lower limit

Upper limit

Lower limit

Upper limit

Lower limit

Upper limit

Lower limit

Upper limit

Lower limit

Upper limit

Output 2

---

Lower limit

Upper limit

Lower limit

Upper limit

Lower limit

Upper limit

Lower limit

Upper limit

Control output action

Output at Burn-out*

Code

Output

Parameter :

Control output action code

Table 1

Input type code

Parameter :

Page 29

– 29 –

RTD (IEC)

Thermocouple

Pt100Ω

Pt100Ω

Pt100Ω

Pt100Ω

Pt100Ω

Pt100Ω

Pt100Ω

Pt100Ω

J

J

K

K

K

0 to 150

0 to 300

0 to 500

0 to 600

-50 to 100

-100 to 200

-150 to 600

-150 to 850

0 to 400

0 to 800

0 to 400

0 to 800

0 to 1200

Range

(°C)

Input signal type Input signal type

32 to 302

32 to 572

32 to 932

32 to 1112

-58 to 212

-148 to 392

-238 to 1112

-238 to 1562

32 to 752

32 to 1472

32 to 752

32 to 1472

32 to 2192

Range

(°F)

Range

(°F)

Thermocouple

R

B

S

T

T

E

E

N

PL-II

0 to 1600

0 to 1800

0 to 1600

-199 to 200

-150 to 400

0 to 800

-199 to 800

0 to 1300

0 to 1300

Range

(°C)

32 to 2912

32 to 3272

32 to 2912

-328 to 392

-238 to 752

32 to 1472

-328 to 1472

32 to 2372

32 to 2372

-1999 to 9999

(Scaling is possible)

• Maximum span : 9999

• Lower limit : -1999

• Upper limit : 9999

1 to 5VDCDC voltage

Note 1) Except for the following, the input accuracy is ±0.5% FS ±1 digit ±1°C

(Input accuracy does not be guaranteed for the ranges of measurement

other than in the table above.)

R thermocouple 0 to 400

°

C

B thermocouple 0 to 500

°

C

Note 2) In case a measuring range of -150 to 600

°

C or -150 to 850°C is used for

resistance bulb input, temperatures below -150

°

C does not be indicated

correctly. Therefore, “LLLL” does not appear despite a continuous fall

below -150

°

C.

Note 3) If the resistance bulb or thermocouple is used at a temperature below

the lowest value in the measurement range, the input accuracy cannot

be guaranteed.

Note 4) Addition of decimal point is impossible if the input range or span is larger

than 999.9 at the RTD/thermocouple input.

in these ranges, this controller may

display an incorrect process value

due to the characteristic of the sensor.

:

Input range (Standard range)

Parameter :

, ,

Table 3

Page 30

– 30 –

Note) · When alarm action type code is changed, alarm set value may also become different from previous

settings.

Please check these parameters, turn off the power once, and then re-start the controller, before s

tarting control.

· When selecting No.12 to 15, setting in ALM2, dLY2, and A2hy are effective, and output to the AL2

relay.

ALM1 ALM2 Alarm type Action diagram Alarm type Action diagram

0 0 No alarm PV

11

High alarm

High alarm

(with hold)

Low alarm

(with hold)

Absolute

value

alarm

PV

AL1

AL2

AL1

AL2

55

High alarm

High alarm

(with hold)

Low alarm

(with hold)

Deviation

alarm

PV

SV

22

Low alarm

PV

AL1

AL2

AL1

AL2

PV

AL1

AL2

33

44

PV

66

High/Low

alarm

High/Low

alarm

(with hold)

High/Low

absolute alarm

High/Low

absolute alarm

High/Low

absolute alarm

High/Low

absolute alarm

(with hold)

High/Low

absolute alarm

(with hold)

High/Low

deviation alarm

High/Low

deviation alarm

High/Low

deviation alarm

High/Low

deviation alarm

(with hold)

High/Low

deviation alarm

(with hold)

High absolute

/Low deviation

alarm

High absolute

/Low deviation

alarm (with hold)

High absolute

/Low deviation

alarm

High absolute

/Low deviation

alarm

High absolute

/Low deviation

alarm (with hold)

High deviation

/Low absolute

alarm

High deviation

/Low absolute

alarm (with hold)

High deviation

/Low absolute

alarm

High deviation

/Low absolute

alarm

High deviation

/Low absolute

alarm (with hold)

High/Low

deviation alarm

(ALM1/2 independent

action)

Low alarm

PV

SV

AL1

AL2

77

PV

AL1

AL2

SV

AL1

AL2

11 11

Zone

alarm

Zone

alarm

PV

SV

AL1

AL2

PV

SV

AL1

AL2

99

PV

SV

AL1

AL2

10 10

PV

AL1

AL2

SV

AL1

AL2

AL1

AL2

-12

PV

AL2 AL1

-14

PV

SV AL1

AL2

AL1

-15

PV

SVAL2

-13

PV

SV

AL2 AL1

88

· Alarm code with dual set value· Standard alarm code

ALM1 ALM2

16 16

17 17

High

/Low

limit

alarm

21 21

18 18

19 19

20 20

22 22

23 23

27 27

25 25

26 26

28 28

30 30

31 31

29 29

PV

A1-L

A2-L

A1-H

A2-H

PV

SV

A1-H

A2-H

A1-L

A2-L

PV

SV

A1-H

A2-H

A1-L

A2-L

PV

SV

A1-L

A2-L

A1-H

A2-H

PV

A1-L

A2-L

A1-H

A2-H

PV

SV

A1-H

A2-H

A1-L

A2-L

PV

SV

A1-H

A2-H

A1-L

A2-L

PV

SV

A1-L

A2-L

A1-H

A2-H

PV

SV

A1-L

A2-L

PV

A1-H

A2-H

A1-H

A2-H

PV

SV

A1-H

A2-H

A1-L

A2-L

SV

A1-L

A2-L

PV

A1-L

A2-L

A1-H

A2-H

PV

SV

A1-L

A2-L

PV

A1-H

A2-H

A1-H

A2-H

PV

SV

A1-H

A2-H

A1-L

A2-L

SV

A1-L

A2-L

PV

A1-L

A2-L

A1-H

A2-H

24 24

· Timer code

ALM1 ALM2

Alarm type Action diagram

32 32

ON delay timer

33 33

OFF delay timer

Timer

34 34

ON/OFF

delay timer

DI

OUT

dLY1

dLY2

DI

OUT

DI

OUT

dLY1

dLY2

dLY1

dLY2

dLY1

dLY2

Table 4

Parameter :

Alarm action type code

,

Page 31

– 31 –

PXR Model Code Configuration

PXR

4 5 6 7 8 9 10 11 12 13 14

4

4

1

0

M

S

V

F

Note 3

Note 1) In case of 7th digit code "A", the codes "3", "7", "F" and "G" in 9th digit are not available.

Note 2) In case of 9th digit code "3", "7", "F" or "G", the code "A" in 7th digit is not available.

In case of 9th digit code "2", "3", "6" or "7", the code "E" in 6th digit is not available,

and the code "V00" in 11th to 13th digit is not available.

Note 3) In case of 11th to 13th code "V00", the code "2", "3", "6" and "7" in 9th digit is not

available.

Note 2

Note 1

N

Y

V

T

R

N

S

B

A

A

C

E

Y

A

1

0

1

2

3

4

5

6

7

F

G

0

0

0

0

0

0

0

0

<Size of front H X W>

48

X 48mm Screw terminal type

<Input signal>

Thermocouple °C

Thermocouple °F

RTD Pt100 3-wire type °C

RTD Pt100 3-wire type °F

4 to 20mA DC

1 to 5VDC

<Control output 1>

Relay contact output

SSR / SSC drive output

DC4 to 20mA output

<Control output 2>

None

Relay contact output

<Revision code>

<Optional specification 1>

None

One alarm

Heater break alarm

One alarm + heater break alarm

8 ramps / soaks

One alarm + 8 ramps / soaks

Heater break alarm + 8 ramps / soaks

One alarm + Heater break alarm + 8 ramps / soaks

Two alarms

Two alarms + 8 ramps / soaks

<Instruction manual> <Power supply voltage>

None 100 to 240VAC

Japanese 100 to 240VAC

English 100 to 240VAC

<Optional specification 2>

None

RS485 transmission

Dgital input 1 point

RS485 transmission + Digital input 1 point

<Non-standard specification>

Non-standard parameter setting

4

5

6

7

9

8

10

11

12

13

14

Digit Specification

Page 32

– 32 –

Specification

Power voltage: 100 (- 15%) to 240V AC (+10%), 50/60Hz

Power consumption: 15V AC or less/240V AC

Relay contact output: Control output 1: SPDT contact, 220VAC /

30VDC 3A (resistive load)

Control output 2: SPST contact, 220VAC /

30VDC 3A (resistive load)

SSR/SSC driving output: ON: 24V DC (17 to 25V DC)

(voltage pulse output) OFF: 0.5V DC or less

Maximum current ; 20mA or less

Resistive load 850W or more

4-20mA DC output: Allowable load resistor 600W or less

Alarm output (up to 2 outputs): Relay contact (SPST contact) 220V AC /

30V DC 1A (resistive load)

Heater disconnection alarm output: Relay contact (SPST contact) 220V AC /

30V DC 1A (resistive load)

Communication function : RS-485 Modbus interface

Transmission system ; Half-dueplex bit serial

start-stop synchronization

Transmission rate ; 9600bps

Transmission protocol ; In conformity to Modbus RTU

Transmission distance ;Up to 500m (total length)

Connectable units ; Up to 31units

Digital input : Number of input;1 input

Input contact capacity ; 5V, 2mA DC

Ambient temperature: -10 to 50°C

-10 to 45°C (when side by side mounting)

Operating ambient humidity: 90%RH or less (no condensation)

Preservation temperature: -20 to 60°C

Modbus RTU : A trademark of Modicon Corp.,USA

Loading...

Loading...