Page 1

– 1 –

Thank you for purchasing the Fuji Digital temperature Controller.

Once you have confirmed that this is the product you ordered, please use it in accordance with the following instructions.

For detailed information on operating this equipment, please refer to the separate operations manual.

In addition, please keep this instruction manual within easy reach of the actual person using this equipment.

CAUTION

The contents of this manual are subject to change without notice.

This manual is complied with possible care for the purpose of accuracy, however, Fuji Electric

Systems shall not be held liable for any damages, including indirect damage,

caused by typographical errors, absence of information or use of information in this manual.

Please Read First (Safety Warnings)

Please read this section thoroughly before using and observe the mentioned safety warnings

fully. Safety warnings are categorized as “Warning” or “Caution”.

1

Warning

1-1

Limitations in Use

This product was developed, designed and manufactured on the premise that it would be used

for general machinery.

In particular, if this product is to be used for applications that require the utmost safety as

described below, please take into consideration of the safety of the entire system and the

machine by adopting such means as a fail-safe design, a redundancy design as well as the

conducting of periodical inspections.

•

Safety devices for the purpose of protecting the human body

•

Direct control of transportation equipment

•

Airplanes

•

Space equipment

•

Atomic equipment, etc

Please do not use this product for applications which directly involve human lives.

1-2

Installation and Wiring

●

This equipment is intended to be used under the following conditions.

●

Between the temperature sensor and the location where the voltage reaches or generates

the values described below, secure clearance space and creepage distance as shown in

the table below.

If such space cannot be secured, the EN61010 safety compliance may become invalid.

●

For the above, if voltage exceeds 50Vdc (called danger voltage), grounding and basic insulation

for all terminals of the equipment, and auxiliary insulation for digital outputs 1 to 3 is required,

Note that the insulation class for this equipment is as follows. Before installing, Please confirm

that the insulation class for equipment meets usage requirements.

Basic insulation (1500VAC)

Functional insulation (500VAC)

No insulation

•

In cases where damage or problems with this equipment may lead to serious accidents,

install appropriate external protective circuits.

•

As this equipment does not have a power switch or fuses, install them separately as necessary. Fuse should be wired between main power switch and this equipment. (Main

power switch: Bipolar breaker, fuse rating: 250V 1A)

•

For power supply wiring, use wire equal to 600V vinyl insulated wire or above.

•

To prevent damage and failure of the equipment, provide the rated power voltage.

•

T o pre v ent shock and equipment failure, do not turn the power ON until all wiring is complete.

•

Before turning on power, confirm that clearance space has been secured to prevent shock

or fire.

•

Do not touch the terminal while the machine is on. Doing so risks shock or equipment errors.

•

Never disassemble, convert, modify or repair this equipment. Doing so risks abnormal

operation, shock or fire.

•

Output relay is the part has a limited life. When output relay contact comes to the end of

its life, it might remain on-state, or off-state. For safety, use a protective circuit outside.

1-3

Maintenance

•

When installing or removing the equipment, turn the power OFF. Otherwise, shock, operational errors or failures may be caused.

•

Periodic maintenance is recommended for continuous and safe use of this equipment.

•

Some parts installed on this equipment have a limited life and/or may deteriorate with age.

•

The warranty period for this unit (including accessories) is one year, if the product is used

properly.

2

Caution

2-1

Cautions when Installing

Please avoid installing in the following locations.

•

Locations in which the ambient temperature falls outside the range of –10 to 50°C when

equipment is in use. (If the power supply is 200V AC, the recommended maximum ambient temperature is 45°C.)

•

Locations in which the ambient humidity falls outside the range of 45 to 90% RH when

equipment is in use.

•

Locations with rapid temperature changes, leading to dew condensation

•

Locations with corrosive gases (especially sulfide gas, ammonia, etc.) or flammable gases.

•

Locations with vibration or shock directly.

•

Locations in contact with water, oil, chemicals, steam or hot water.

(If the equipment gets wet, there is a risk of electric shock or fire, so have it inspected by

Fuji distributor.)

•

Locations with high concentrations of atmospheric dust, salt or iron particles.

•

Locations with large inductive interference, resulting in static electricity, magnetic fields or noise

•

Locations in direct sunlight.

•

Locations that build up heat from radiant heat sources, etc.

Warning Mishandling may lead to death or serious injury.

Caution Mishandling may cause injury to the user or property damage.

Fuji Electric Co., Ltd.

International Sales Div

Sales Group

Gate City Ohsaki, East Tower 11-2, Osaki 1-chome,

Shinagawa-ku, Tokyo 141-0032, Japan

http://www.fujielectric.com

Phone: 81-3-5435-7280, 7281 Fax: 81-3-5435-7425

http://www.fujielectric.com/products/instruments/

INP-TN1PXG5/9e-E

Confirming Specifications and Accessories

Before using the product, confirm that it matches

the type ordered.

(For model code, please refer to page 19.)

Confirm that all of the following accessories are

included.

Temperature Controller 1 unit

Instruction Manual 1 copy

Mounting Fixture 2 pcs

I/V Unit (250Ω Resistor) 1 pc

Waterproof packing 1 pc

Unit nameplate 1 pc

Option

Name Order No.

Terminal cover ZZPPXR1-B230

PC loader

communication cable

ZZPPXH1*TK4H4563

Related Information

Refer to the following reference materials for

details about the items described in this manual.

The latest materials can also be downloaded at

the following URL: http://www.fic-net.jp/eng

Document

Reference

No.

Catalog

ECNO:1125

Micro Controller (Model: PXG)

Operation Manual

ECNO:1411

Micro Controller (Model: PXG)

Communication Functions

Manual (MODBUS)

INPTN514450-E

Ambient temperature -10 °C to 50 °C

Ambient humidity 90% RH or below (with no condensation)

Installation category

II

by IEC 1010-1

Pollution level 2

Voltage used or generated

by any assemblies

Clearance Space (mm) Creepage Space (mm)

Up to 50 Vrms or Vdc 0.2 1.2

Up to 100 Vrms or Vdc 0.2 1.4

Up to 150 Vrms or Vdc 0.5 1.6

Up to 300 Vrms or Vdc 1.5 3.0

Above 300 Vrms or Vdc Please consult our distributor

Power

Internal circuit

Measurement input

Control output 1 (Relay contact)

or

Motorized valve OPEN output

Valve opening feedback input

Auxiliary analog input (remote SV)

Heater current detector input

Control output 1 (SSR drive, current, voltage)

Control output 2 (Relay contact)

or

Motorized valve CLOSE output

Control output 2 (SSR drive, current, voltage)

or Auxiliary analog output (Re-transmission output)

or Transmitter power supply

Digital input 1 to 5Digital output 1 (Relay contact) Digital output 1 to 3

(Relay contact)

Digital output 4, 5

Digital output 2 (Relay contact) (Transistor output)

Communication (RS-485)

When the ninth digit in the

model code is J

When the ninth digit in the

model code is not J

(Do1,2 are independent common) (Do1 to 3 shared common)

Instruction Manual

Micro Controller X

Model: PXG5/9

hazardous

voltage

Page 2

– 2 –

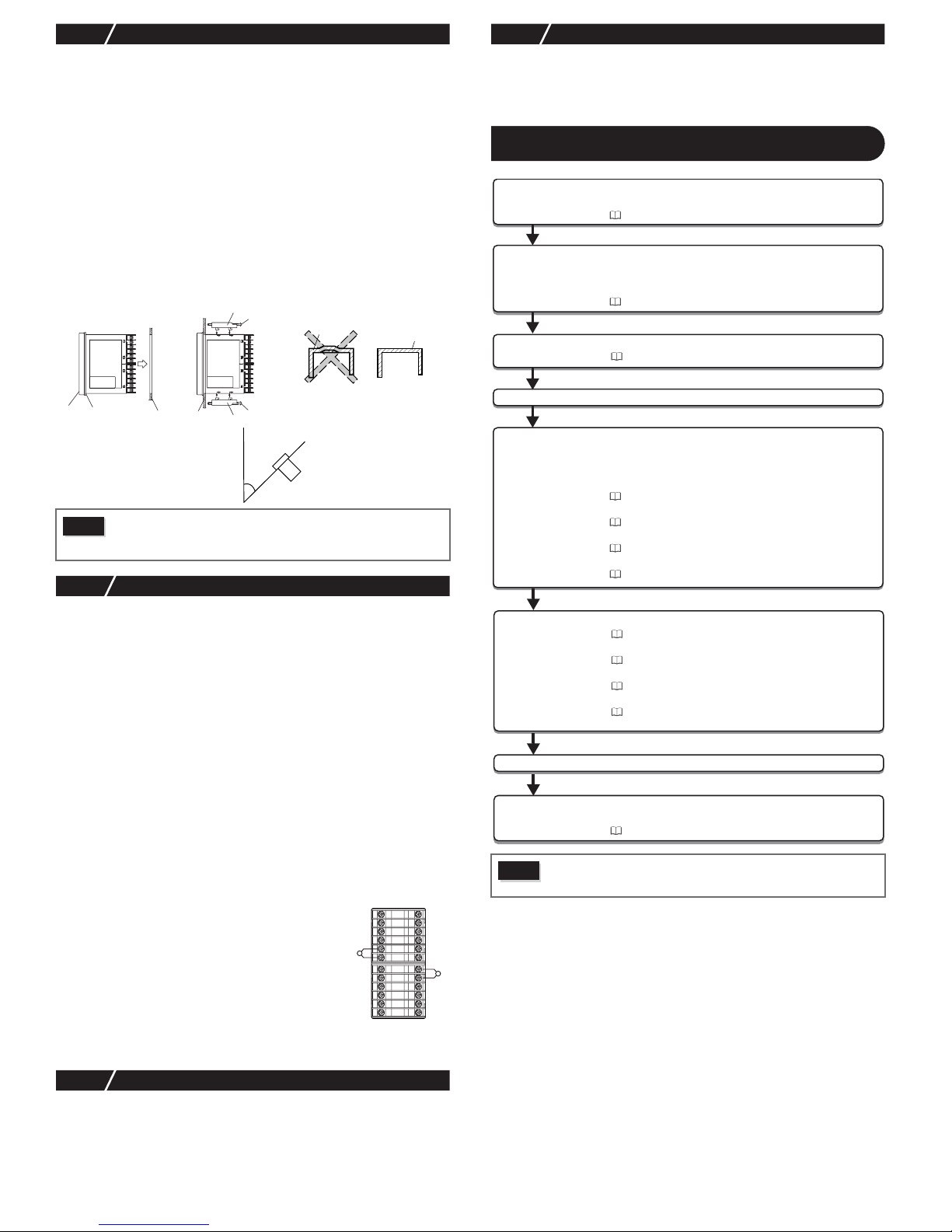

2-2

Cautions when Attaching to the Panels

•

Please attach the PXG5/PXG9 with the included fixtures (2 pieces) to the top and bottom,

and tighten with a screwdriver.

•

The clamp torque is approximately 0.15 N/m (1.5 kg/cm)

It is designed such that overtightening will cause left/right cracking to the central area of

the Fixtures and hence reduce the torque.

Cracking to the central area will not cause any problems in terms of usability of the equipment.

(However, do exercise caution in not applying too much torque because the casing is

made of plastic.)

•

The front of this equipment is waterproof in compliance with NEMA-4X standards (IP66equivalent).

To effect waterproof, the included packing is shall be attached between the controller and

the panel according to the guidelines below. (Incorrect attachment may cause the equipment to lose its waterproof capabilities.)

(1) As shown in Fig. 1, insert to the panel after attaching the packing to the equipment

case.

(2) As shown in Fig. 2, tighten the fixture screws so that no gaps can remain between the

equipment face, the packing and the panels. Once finished, confirm that there are no

changes in shape such as displaced or improperly-fitted packing, etc. as shown in

Fig. 3.

•

If the panel does not have enough strength, gaps may develop between the packing and

the panel to lose waterproofing capabilities.

2-3

Cautions for Wiring

•

For thermocouple input, use the designated compensation lead; for resistance bulb input,

use wires with small lead wire resistance and without any resistance difference among the

three wires.

•

To avoid noise conductor effects, input signal wires should be separated from electric

power lines or load lines.

•

Input signal wire and output signal wire should be separated each other. And both should be shield

wire.

•

If there is a lot of noise from the power source, adding an insulation transducer and using a

noise filter is recommended.

(Example: ZMB22R5-11, noise filter Maker: TDK)

Always attach a noise filter to a panel that is grounded securely, and keep the wiring

between the noise filter output side and the measuring equipment power terminal wiring

to a minimum length.

Please do not attach fuses and switches, etc. to the noise filter output wiring, otherwise the

filter’s effectiveness will be decreased.

•

Twisting the power wires is effective when connecting the wires. (The shorter the pitch of

the twist, the more effective the connection is against noise.)

•

If there is a function of heater current detection, heater wires and power wires should be

connected with same power line.

•

Operation preparation time is required for the contact output when power is turned on. If

using it as a signal to an external interlock circuit, please couple it with a delayed relay.

•

Concerning the output relay, connecting the maximum rated load will shorten the product’s life; so please attach an auxiliary relay. If the output operation frequency is high,

selecting a SSR/SSC drive output type is recommended.

[Proportionate cycles] Relay output: 30 seconds or more, SSR/SSC drive output: 1

second or more

•

When inductive loads such as magnetic opening/closing equipment, etc. as relay output equipment are connected, use of

“Z-trap,” manufactured by Fuji Electric Device Technology Co.,

Ltd., is recommended in order to protect the contacts against

opening/closing surges and to ensure long-term use.

Model names : ENC241D-07A

(For 100V power voltage)

ENC471D-07A

(For 200V power voltage)

Attachment position : Please connect between the relay

control output contacts.

(Refer to Fig. 4.)

2-4

Key Operation Caution/Error Operation

•

The alarm function does not work properly when an error takes place unless the settings

are made correctly. Always verify its setting before operation.

•

If the input wiring breaks, the display will read “

UUUU

”. When replacing the sensor, always

turn the power OFF.

2-5

Others

•

Please do not wipe the equipment with organic solvents such as alcohol or benzene, etc.

If wiping is necessary, use a neutral cleaning agent.

•

Do not use mobile phones near this equipment (within 50 cm). Otherwise a malfunction

may result.

•

Trouble may occur if the equipment is used near a radio, TV, or wireless device.

For Proper Usage

Caution

•

In order to aid heat dissipation, do not block the sides of the equipment.

•

Do not block the air vents on the upper part of the terminal.

•

For the PXG9, please attach the fixtures to the attachment holes in the

center of the main unit.

Fig. 3

Packing

Packing

Case

Case

(Bad)

(Good)

Unit

Fig. 1 Fig. 2

Front

Panel

Screw

Screw

Panel

Packing

Mounting fixture

Mounting fixture

α = 0 to 30°

Standard: vertical attachment

(horizontal position attachment)

If attached at an angle, the maximum

gradient is a 30° downslope.

12

11

10

9

8

7

36

35

34

33

32

31

6

5

4

3

2

1

25

26

27

28

29

30

Fig.4 Attachment posi-

tion of Z-Trap

(Example)

Caution

Wait 30 minutes for the controller to stabilized thermally. Operations such as

measurements should be taken after the equipment has been on for 30 minutes or more.

Confirmation of model code

Please confirm that the model delivered matches your order.

"12 Model Specifications" (page 19)

2

Wiring Connection

Terminal connections diagram

"4 Wiring" (page 4)

3 Display and Operations

4 Parameter List

5 Functions of the Temperature Controller

Changing set value

Basic Operation Methods

Parameter List

Input/Output/Control

"5 Display and Operations" (page 5)

"5 Display and Operations" (page 5)

"6 Parameter List" (page 6)

"7 Functions" (page 10)

Turn Power On

6 Advanced Usage Setting of input sensor and input range

Selecting control method

Controlling through auto-tuning

Automatic setting parameters

"8-1 Input Setting" (page 17)

"8-3 Control Setting" (page 18)

"7-6 Auto-tuning" (page 11)

"7-3 Fuzzy PID Control", "7-4 Self-tuning Control" (page 10)

7 Error Indications

Display during equipment error

"9 Error Indications" (page 18)

Operation

1 Installation and Mounting

External dimensions

• Panel cut dimensions

• Mounting the panel

"3 Installation and Mounting" (page 3)

Page 3

– 3 –

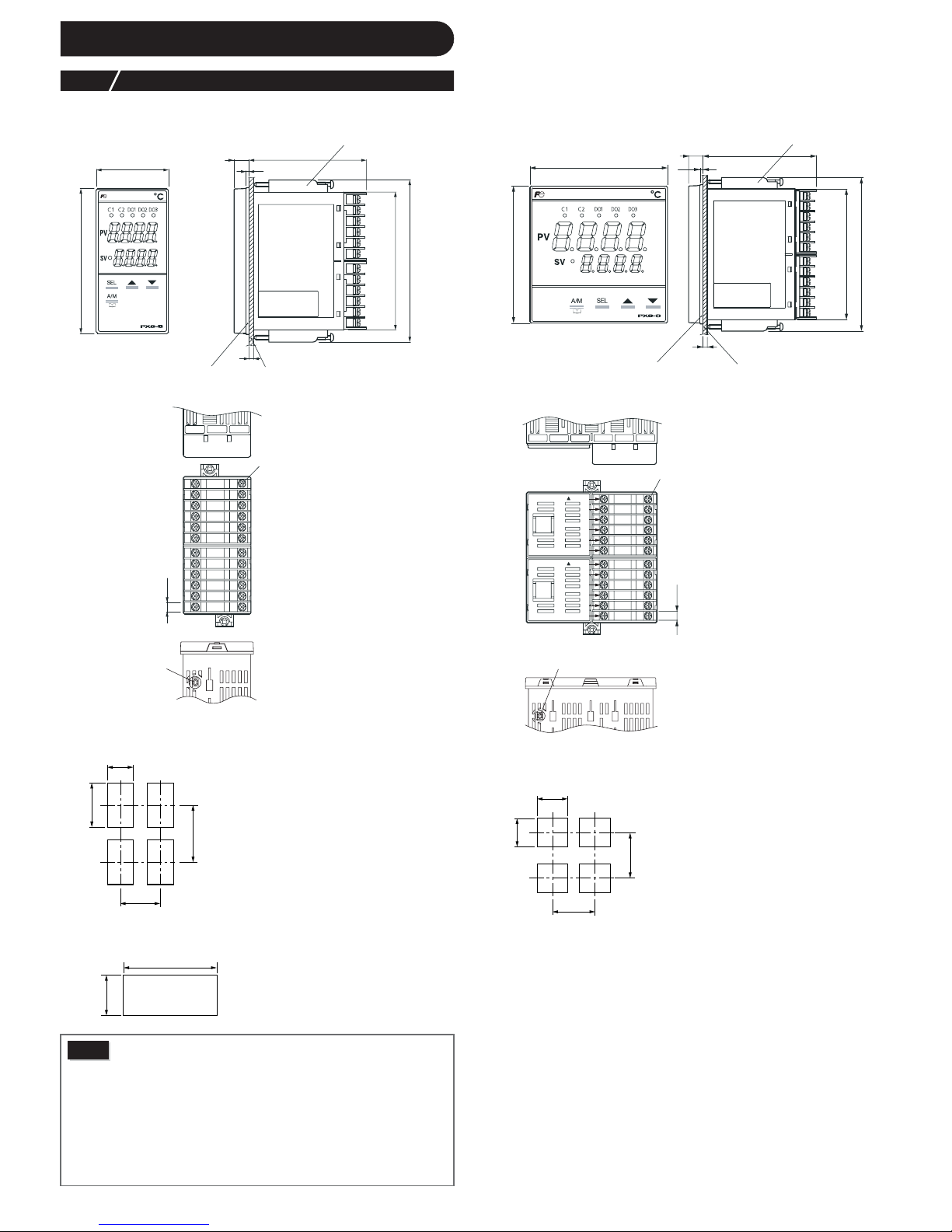

3

Installation and Mounting

3-1

External/Panel Cut Dimensions

Caution

Panel cut dimensions should also meet the above dimensions after the panel

is coated.

Cautions when Close Fit Mounting:

•

When the power supply is AC 200V, keep the maximum ambient temperature

at 45°C. For vertical close-fit mounting, use a power source of AC 100V. (In

both cases, a fan is recommended as a measure against radiation.)

•

When there is an instrument larger than 70 mm or a wall to the right of

the controller, move it as least 30 mm away.

Cautions when wiring:

•

Start by wiring from the left-hand terminals (terminals 1 to 12).

•

Use a screw that is the right size on terminals and tighten them with a

torque of about 0.8 N/m.

•

Do not attach anything to unused terminals. (Do not use relay terminals.)

PC loader interface

PXG9

TOP

TOP

13-2437-48 61-7249-60

1-12

25-36

waterproof packing

panel

terminal screw M3

96

96

79.510

2

91.5

115.5 MAX

t

6.2

31

32

33

34

35

36

7

8

9

1

2

3

4

5

6

10

11

12

mounting fixture

(fastening torque 0.15 N•m)

25

26

27

28

29

30

Panel thickness

1 to 8 mm

PC loader interface

25-36

1-12

13-24

Waterproof packing

panel

terminal

screw M3

48

96

Mounting fixture

(fastening torque 0.15 N•m)

PXG5

7810

2

91.5

115.5 MAX

t

Panel thickness

1 to 8 mm

6.2

12

11

10

36

35

34

33

32

31

9

8

7

6

5

4

3

2

1

25

26

27

28

29

30

Installing multiple controllers

Installing multiple controllers horizontally

(In this installing, the waterproof of PXG is lost.)

50 MIN.

45

92

+0.6

0

116 MIN.

+0.8

0

(48 × n–3)

+0.8

0

+0.8

0

92

Installing multiple controllers

92

+0.8

0

92

+0.8

0

116 MIN.

100 MIN.

Page 4

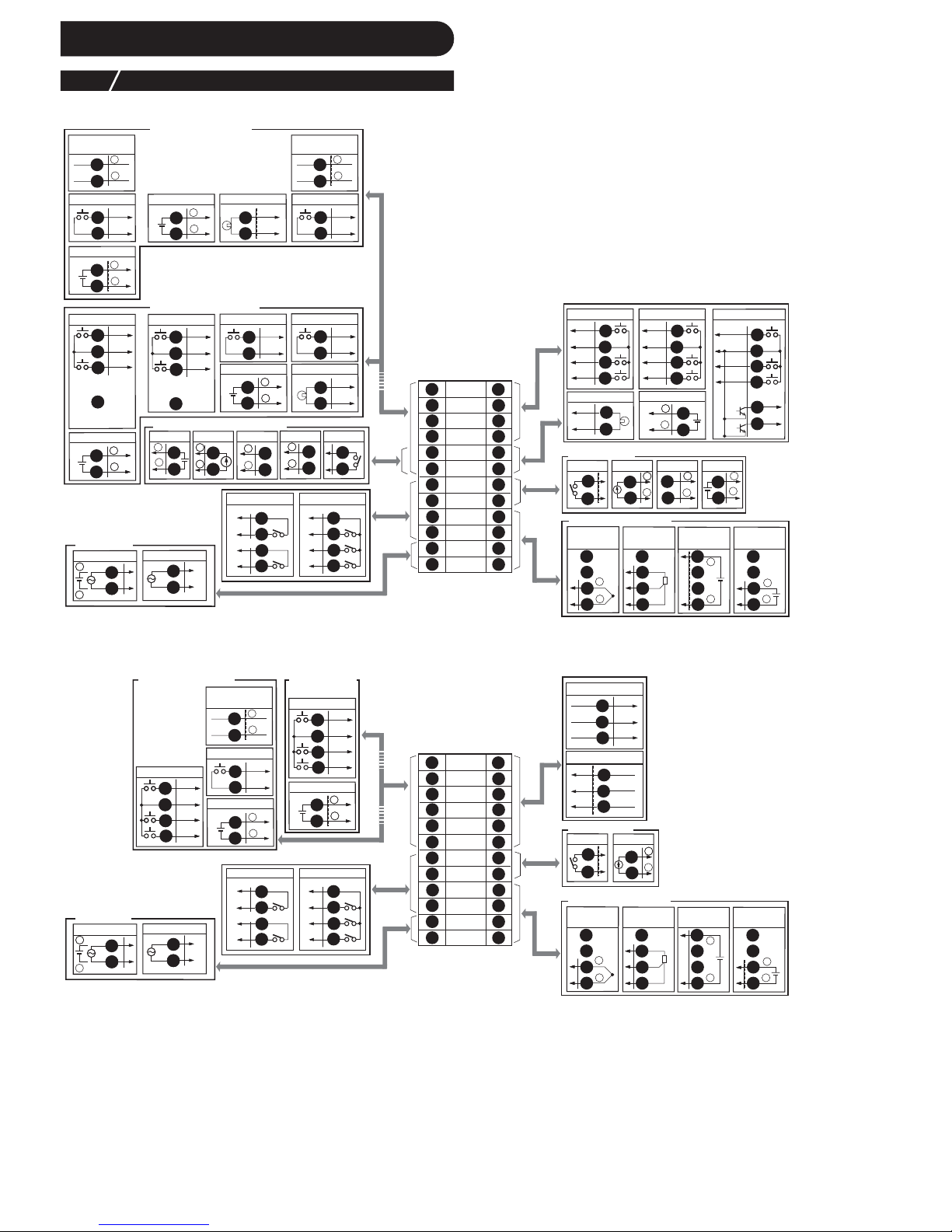

– 4 –

4

Wiring

4-1

Terminal Connection Diagram (100 to 240V AC, 24V AC/DC)

●

Standard T ype

●

Motorized Valv e Type

Note 1: Check the power supply voltage before making the connections.

Note 2: When inputting current, connect the additional I/V unit (250

Ω

resistor) between the terminals number 33 and 36.

Note 3: Transmitter power output is an option only for PXG9.

1

2

3

4

5

6

7

8

9

10

11

12

25

26

27

28

29

30

31

32

33

34

35

36

1

2

DI–COM

DI1

1

2

3

4

CT1 input

Digital input

1

2

DI–COM

DI1

Digital input

RSV1 input

Digital input

343

4

–

++

No communication function

Relay output

5

6

Current output

SSR drive

XPS output

125

6

++

–

125

6

–

++

Voltage output

Digital input

Control output 2/Re–transmission

1

2

DI–COM

DI1

3

4

DI2

1

2

3

4

DI2

RSV1 input

5

6

–

++

7

8

9

10

DO1

DO–COM

DO2

DO3

7

8

9

10

DO1

DO1–COM

DO2

DO2–COM

11

4

12

–

++

50/60Hz

11

4

12

DIgital output

Digital output

AC100 to 240V

AD/DC 24V

1

2

DI–COM

DI1

3

4

DI2

No

connection

No

connection

1

2

3

4

DI2

Relay output

31

32

Current output

31

32

–

++

SSR drive

125

6

++

–

3

4

–

+

32

31

Voltage output

Control output 1

33

34

35

36

+

–

Thermocouple

input

33

34

35

36

A

B

B

Resistance

bulb input

33

34

35

36

+

–

Current/voltage

input

Voltage (mV)

input

33

34

35

36

+

–

Measurement value input

29

30

–

++

29

30

RSV2 input

CT2 input

25

26

27

28

DIO–COM

DI3

DI5

DI4

Digital input

25

26

27

28

DIO–COM

DI3

DI5

DI4

Digital input

25

26

27

28

29

30

DIO–COM

DI3

DI5

DI4

DO4

DO5

Digital input/output

5

6

–

+

Power supply

(Note 3)

(Note 1)

(Note 2)

50/60Hz

–

++

31

32

–

+

DI–COM

DI1

3

4

3

4

3

4

–

+

5

6

1

2

–

+

DI–COM

DI1

3

4

1

2

–

+

RS485

communicator

RS485

communicator

Communication function

included

Digital input Digital inputRSV1 input

RSV1 input

CT input

1

2

3

4

5

6

7

8

9

10

11

12

25

26

27

28

29

30

31

32

33

34

35

36

Digital input

RS485

communicator

RSV1 input

5

6

+

DI–COM

DI1

3

4

1

2

+

7

8

9

10

DO1

DO–COM

DO2

DO3

7

8

9

10

DO1

DO1–COM

DO2

DO2–COM

11

4

12

++

50/60Hz

11

4

12

Digital output Digital output

AC100 to 240V

AD/DC 24V

AUX DO

31

32

Control output 1

33

34

35

36

+

Thermocouple

input

33

34

35

36

A

B

B

Resistance

bulb input

33

34

35

36

+

Current/voltage

input

Voltage (mV)

input

33

34

35

36

+

Measurement value input

Power supply

(Note 1)

(Note 2)

50/60Hz

Communication function

included

Digital input

1

2

DI–COM

DI1

3

DI2

3

4

DI1

5

6

DI3

1

2

DI–COM

DI1

3

DI2

1

2

3

4

DI3

Digital input

RSV1 input

5

6

–

–

–

–

–

––

++

No communication

function

28

29

30

I +

I 0

I –

25

26

27

PFB input

CLOSE

COM

OPEN

Valve control output

–

++

31

32

XPS output

(Note 3)

Page 5

– 5 –

5

Display and Operations

5-1

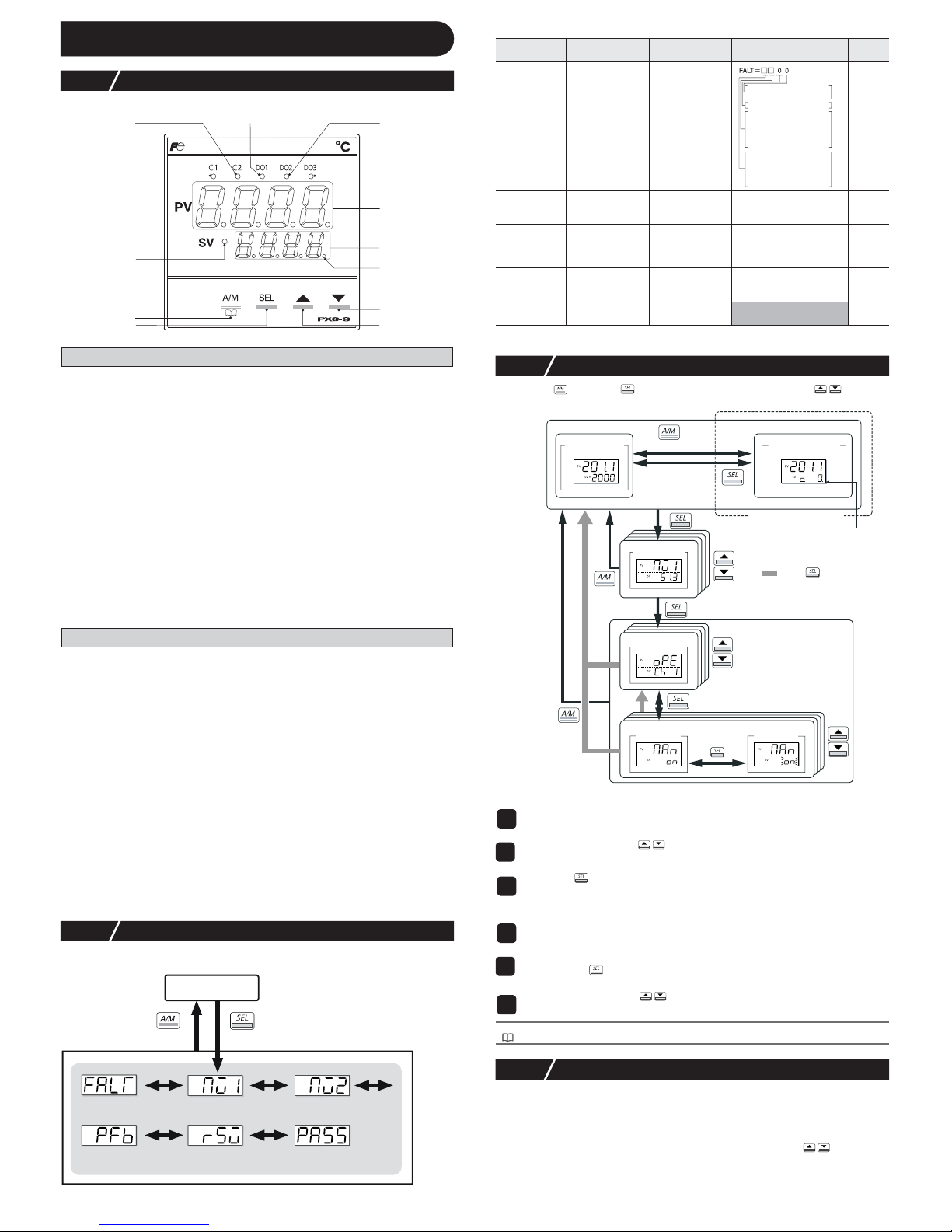

Part names and functions

Operation Parts

USER Key

Pressing this key in monitoring mode display or setup mode display returns you to the PV/SV display.

Pressing this key on the PV/SV display allows you to set the function for "

UkEY

" under the system menu

("

SYS Ch 7

"). (The factory set function for this key is switching between auto and manual.)

SEL Key

Switches the PV/SV display to the monitoring mode display or setup mode display.

Switches to setup mode when parameter display , and this k e y functions as the select ke y when changing

parameters.

Holding this key down in channel display or parameter display returns you to the PV/SV display.

Pressing this key at PV/SV display in manual mode, manual output value is shown

in the lower display.

▲ Key

Pressing once will increase the setting value by one. Holding down the button will continue to

increase the value.

It changes SV on the PV/SV display.

It is also used to move between items in channel screen display and parameter screen display.

▼ Key

Pressing once will decrease the setting value by one. Holding down the button will continue to

decrease the value. It changes SV on the PV/SV display.

It is also used to move between items in channel screen display and parameter screen display.

Display

C1/C2 Lamp

Displays the condition of the control output. Lights ON at 100% output and goes out at 0% output. For values between 0% and 100%, the output is indicated by the length of time the lamp

flickers.When acting as a valve control, the C1 lamp will light with OPEN output, and the C2

lamp will flickers with CLOSE output.

DO1/2/3 Lamp

Lights ON when there is digital output is on state (DO1, DO2, DO3). The lamp flickers when

delay behavior is on.

PV Display

Displays the measurement value (PV). Displays the name of the parameter when setting

parameters.

SV Display

Displays the setting value (SV). Also can display the output value during manual mode. Displays the parameter setting value when setting parameters. Displays "

rEM" during remote SV

operation, and "

SoFT" and set value alternately during soft start.

SV Lamp

Lights when displaying the setting value (SV). Goes out when displaying the manual output

value.

The lamp flickers while performing ramp soak or lamp SV operations.

MAN/AT/SELF Lamp

Normally lights up during manual mode and blinks during auto-tuning or self-tuning.

5-2 Monitor Display and Status Display

In monitor mode, the PV display shows item names, while the SV display shows the

input/output values.

For more details on “

PASS” (PASS), see “5-6 Key Lock and Password” (page 6).

For more details on (Note) in the Remarks column, see “6 Parameter List” (page 6).

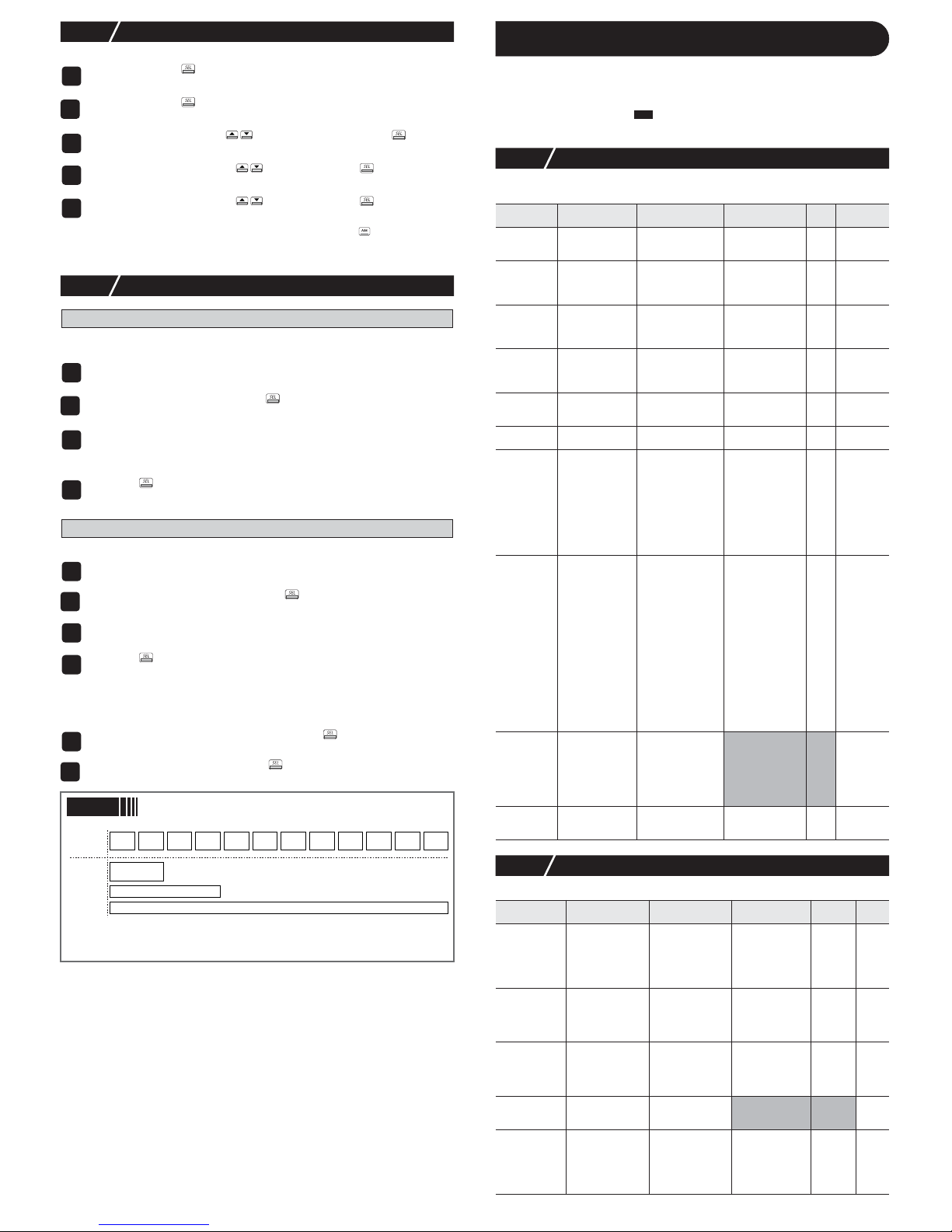

5-3 Basic Operations

Pressing the key or the key switches between modes. Pressing in monitor

mode or setup mode allows you to choose menu items.

● Changing SV (set values)

● Changing MV (control output values)

5-4 Operations

For the following modes, the PV display will show the PV input value.

● Operation Mode

SV display shows the SV setting value.

● Manual Mode

An LED light decimal point lights ON in the lowest digit place in the SV display. An “o”

appears in the highest decimal place during MV display. Pressing the keys sets the

MV (%).

DO1 Lamp

DO2 Lamp

DO3 Lamp

PV Display

SV Display

▼ Key

▲ Key

C2 Lamp

C1 Lamp

SV Lamp

USER Key

SEL Key

MAN/AT/SELF

Lamp

PFB input value

display (%)

RSV terminal

input value display

Password entry

hold down

MV1 (%)Error source

display

MV2 (%)

monitor mode

operation mode

Parameter

display symbol

Parameter name Function Setting range

Remarks

"

FALT

"

(FALT)

Error source

display

Displays the

source of an error

"

Mv1

" (Mv1) MV1 Displa ys the output

value of the control

output (OUT1)

-3.0 to 103.0%

"

Mv2

" (Mv2) MV2 Displays the output

value of the control

output (OUT2)

(during dual control)

-3.0 to 103.0% (Note4)

"

PFb

" (PFb) Displays the PFB

input value

Displays the input

value of the

position feedback

-3.0 to 103.0% (Note8)

"

rSv

" (rSv) RSV input value

display

Displays the input

value of the RSV

-5 to 105% FS (initial value) (Note1)

1

Change the display to PV/SV display (shown when you turn on the power and

the SV lamp is lit).

2

Change the SV with the keys.

3

Press the key to save the values.

(The value will be automatically saved after 3 seconds even if a key is not pressed.)

1

Switch to manual mode.

2

Change the display to PV/MV display (MAN/AT/SELF lamp is lit).

(Pressing the key in manual mode toggles between PV/SV display and PV/MV

display.)

3

Change the MV with the keys.

(Changes are reflected to the MV as it is changed.)

Refer to

See “7-9 Manual Output” (page 12) for more about changing to manual mode.

fixed at 0

8bit : PV input underflow

9bit : PV input overflow

10bit: underrange

11bit: overrange

12bit: RSV underrange

13bit: RSV overrange

14bit: range setting error

15bit: EEPROM error

0bit: PFB input underflow

1bit: PFB input overflow

initial display

(PV/SV display)

observation

value display

channel menu

parameter

menu

parameter

setting

manual output

(PV/MV display)

hold down

(change

mode)

operation mode

monitor mode

manual mode

setup mode

hold down

hold down

hold down

only during manual mode

manual lamp ON

(change

display only)

channel display

: Press several times

parameter display

Page 6

– 6 –

5-5

Setting Parameters

The following explains how to set the parameters.

●

No matter where you are in monitor or setup mode, pressing the key returns you to

operation mode. When setting the parameters in manual mode, pressing the key holds

manual mode and returns you to operation mode.

5-6

Key Lock and Password

Setting Key Lock

When key lock is activated, parameters cannot be changed but can displayed. Use the following steps to set key lock.

Saving and entering a password

Use the following steps to save a password.

●

The authority of the passwords grows from "

PAS1

" to "

PAS2

" to "

PAS3

". The higher the author-

ity, the greater number of channels for display and settings.

Use the following steps to enter a password.

6

Parameter List

The following explains each channel parameter.

The list also shows the operational range of set values for parameters that are limited.

•

When the PV input lower limit (Pvb), PV input upper limit (PvF), or decimal place position

(Pvd) is changed, reconfigure all the initial parameter setting values.

•

When the parameter that has

on its Remarks column is changed, turn off the power

once, and then re-start the controller.

6-1

Operation (Ch1)

The following is a menu to oper ate the controller. Switchover between auto and manual control

output, switchover between RUN and standby, and other such functions.

6-2

PID (Ch2)

Sets parameters for controls such as PID.

1

Press and hold the key in operation mode, or manual mode.

This switches you to the monitor mode Mv1.

2

Press and hold the key in monitor mode

This switches you to the channel menu of setup mode.

3

Choose the channel with the keys, then press and hold the key.

This switches you to the parameter menu.

4

Choose the parameter with the keys, then press the key.

The set value flickers.

5

Choose the parameter with the keys, then press the key.

The set value is fixed.

1

Display the operation menu ("oPE Ch 1").

2

Display key lock ("LoC") and press the key.

3

Set the value.

0 : No lock (all parameters can be changed. Initial value.)

1 : All lock (no parameters can be changed.)

2 : All lock without SV (only the SV can be changed.)

4

Press the key to set the value.

1

Display the password menu ("PAS Ch11").

2

Display password 1 ("PAS1") and press the key.

3

Set the password.

You can enter the hexadecimal value 0000 through FFFF.

4

Press the key to set the value.

"

PAS2" and "PAS3" can be saved in the same way.

1

In monitoring mode, display ("PASS") and press the key.

2

Enter a saved password and press the key.

You will be able to operate the equipment depending on the authority of your password.

Point

Each parameter channel and the authority of passwords 1 to 3

Note: When “

FEFE” (FEFE) is entered as “PASS” (PASS), all of the channels “OPE ch” to

“DSP ch” can be displayed and set. This “super password” function is useful when

you forget the set passwords.

oPE ch

PAS1 permissions

<"PASS" = "PAS1">

PAS2 permissions <"PASS" = "PAS2">

PAS3 permissions <"PASS" = "PAS3">

Pid ch PLT ch PrG ch Mon ch SET ch SyS ch ALM ch CoM ch PFb ch PAS ch dSP ch

Password

level

Parameter

display symbol

Parameter name Function Setting range

Initial

value

Remarks

"

man" (MAn) Switchover

between auto and

manual mode

Switchover between

auto and manual

modes

oFF (auto) / on

(manual)

oFF

"

STbY" (STby) Switchover

between RUN

and standby

Switchover the

operation mode

between RUN and

standby

oFF (RUN) / on

(standby)

oFF

"

rEm" (rEM) Switchover

between local

and remote SV

operation

Switchover between

local and remote SV

operation

LoCL (local) / rEM

(remote)

LoCL

(Note1)

"PrG" (PrG) Ramp soak

control command

Changes ramp soak

run states

oFF (stop)

rUn (run)

hLd (hold)

oFF

Displays End

(when ending)

or GS (during

guaranty soak).

"At" (AT) Auto-tuning run

command

Runs auto-tuning. oFF (stop/finish)

on (normal type)

Lo (low PV type)

oFF

"

LA[h"

(LACh)

DO output latch

release command

Cancels the DO

latch state

oFF / rST

(latch resets)

oFF (Note2)

"

Svn" (Svn) Currently

selected SV No.

Choose the SV No.

used for control

Sv0

Sv1

Sv2

Sv3

Sv4

Sv5

Sv6

Sv7

di (chooses SV

according to di)

Sv0

(Note20)

"PLn1" (PLn1) Currently

selected PID No.

Choose the PID

group No. used for

control

Pid 0 (PID ch)

P

id

1

(PID group No. 1)

P

id

2

(PID group No. 2)

P

id

3

(PID group No. 3)

P

id

4

(PID group No. 4)

P

id

5

(PID group No. 5)

P

id

6

(PID group No. 6)

P

id

7

(PID group No. 7)

di (chooses PID

group according to di)

Pid0

"

AL1

" (AL1)

"

AL1L

" (AL1L)

"

AL1h

" (AL1h)

"

AL5

" (AL5)

"

AL5L

" (AL5L)

"

AL5h

" (AL5h)

AL1 set value

AL1L set value

AL1h set value

AL5 set value

AL5L set value

AL5h set value

Set the alarm value.

0 to 100% FS

(absolute value

alarm)

-100 to 100% FS

(deviation alarm)

10°C

(Note3)

"

LoC

" (LoC) Key lock Sets the key lock to

prevent wrong

operation

0 (no lock)

1 (all lock)

2

(All but SV locked)

0

Parameter

display symbol

Parameter name Function Setting range

Initial

value

Remarks

" P

" (P) Proportional band Sets the

proportional band

of the PID

parameter. Setting

"0.0" will turn it to

an ON/OFF control.

0.0 to 999.9% 5.0%

"

i

" (i) Integration time

Sets the integration

time of the PID

parameter. Setting

"0" will turn off

integration.

0 to 3200 sec 240 sec

"

d

" (d) Differential time

Sets the differential

time of the PID

parameter. Setting

"0.0" will turn off

derivation.

0.0 to 999.9 sec 60.0 sec

"

hyS

" (hyS) ON/OFF control

hysteresis

Sets the hysteresis

width for the ON/

OFF control.

0 to 50% FS 1°C

"

[oL

" (CoL) Cooling

proportional band

coefficient

Sets the cooling

proportional band

coefficient. Setting

"0.0" will turn the

cooling into an ON/

OFF control.

0.0 to 100.0 1.0

(Note4)

RST

…

…

Page 7

– 7 –

6-3

PID Palette (Ch3)

Saves the palette values of PV and PID. Up to seven sets can be saved.

6-4

Ramp soak (Ch4)

Create a pattern of temperatures using ramp soak combinations. You can create a temperature

pattern with up to 16 steps.

"

db" (db) Dead band Shifts the cooling

proportional band

from the set value

-50 to 50% 0%

(Note4)

"bAL" (bAL) Output

convergence value

Offset value which

is added to the MV

output value

-100 to 100% 0/50

(single/

dual)

"

Ar" (Ar) Anti-reset

windup

Sets the range of

integration control

0 to 100% FS 100%FS

"

rEv" (rEv) Sets normal/

reverse operations

Sets the control

action

rv-- (heat (reverse)

/cool (none))

no-- (heat (normal)

/cool (none))

rvno (heat (reverse)

/cool (normal))

norv (heat (normal)

/cool (reverse))

rvrv (heat (reverse)

/cool (reverse))

nono (heat (normal)

/cool (normal))

rv--/rvno

(single/

dual)

"

SvL" (SvL) SV limit

(lower limit)

Sets the lower limit

of SV

0 to 100% FS 0% FS

(Note5)

"Svh" (Svh) SV limit

(upper limit)

Sets the upper

limit of SV

0 to 100% FS 100% FS

(Note5)

"t[1" (TC1) OUT1 proportion

cycle

Sets the proportion

cycle of the control

output (OUT1)

(contacts, SSR drive)

1 to 150 sec 30:

Contact

2: SSR

drive

(Note7)

"t[2" (TC2) OUT2 proportion

cycle

Sets the proportion

cycle of the control

output (OUT2)

(contacts, SSR drive)

1 to 150 sec 30:

Contact

2: SSR

drive

(Note4)

"Plc1" (PLC1)

OUT1 lower limit

Sets the lower limit

of the control output

(OUT1)

-3.0 to 103.0% -3.0%

"

Ph[1" (PhC1)

OUT1 upper limit

Sets the upper limit

of the control output

(OUT1)

-3.0 to 103.0% 103.0%

"

PL[2" (PLC2)

OUT2 lower limit

Sets the lower limit

of the control output

(OUT2)

-3.0 to 103.0% -3.0%

(Note4)

"Ph[2" (PhC2)

OUT2 upper limit

Sets the upper limit

of the control output

(OUT2)

-3.0 to 103.0% 103.0%

(Note4)

"P[UT" (PCUT) Selects the type of

output limiter

Sets the type of

output limiter

0 to 15 0

Parameter

display symbol

Parameter name Function Setting range

Initial

value.

Remarks

"Sv1" (Sv1) SV 1 Sets the SV set

value

SV limit (lower)

(SVL) to

SV limit (upper)

(SVH) %FS

0%FS

(Note5)

"P1" (P1) Proportional band 1 Sets the

proportional band

0.0 to 999.9% 5.0%

"

i1" (i1) Integration time 1 Sets the

integration time

0 to 3200 sec 240 sec

"

d1" (d1) Differential time 1 Sets the

differential time.

0.0 to 999.9 sec

60.0 sec

"hyS1" (hyS1) ON/OFF control

hysteresis 1

Sets the hysteresis

when using the

ON/OFF control.

0 to 50% FS 1 °C

"

[oL1" (CoL1) Cooling proportional

band 1

Sets the cooling

proportional band

0.0 to 100.0 1.0

(Note4)

"db1" (db1) Dead band 1 Sets the dead

band

-50.0 to 50.0% 0%

(Note4)

"bAL1" (bAL1)

Output convergence

value 1

Offset value which

is added to the

control output

-100.0 to 100.0% 0/50

(single/

dual)

"

Ar1" (Ar1) Anti-reset windup 1 Sets the anti-reset

windup

0 to 100% FS

100%FS

"rEv1" (rEv1) Sets normal/

reverse 1

Sets the control

action

rv-- (heat (reverse)/

cool (none))

no-- (heat (normal)/

cool (none))

rvno (heat (reverse)/

cool (normal))

norv (heat (normal)/

cool (reverse))

rvrv (heat (reverse)/

cool (reverse))

nono (heat (normal)/

cool (normal))

rv--/rvno

(single/

dual)

(Note6)

"Sv7" (Sv7) SV 7 Sets the SV set

value

SV limit (lower)

(SVL) to

SV limit (upper)

(SVH) %FS

0%FS

(Note5)

"P7" (P7)

Proportional band 7

Sets the

proportional band

0.0 to 999.9% 5.0%

"

i7" (i7) Integration time 7 Sets the

integration time

0 to 3200 sec 240 sec

"

d7" (d7) Differential time 7 Sets the

differential time.

0.0 to 999.9 sec

60.0 sec

"hyS7" (hyS7) ON/OFF control

hysteresis 7

Sets the hysteresis

when using the

ON/OFF control.

0 to 50% FS 1 °C

"

[oL7" (CoL7)

Cooling proportional

band 7

Sets the cooling

proportional band

0.0 to 100.0 1.0

(Note4)

Parameter

display symbol

Parameter name Function Setting range

Initial

value

Remarks

RST

RST

…

…

…

…

…

…

"db7" (db7) Dead band 7 Sets the dead

band

-50.0 to 50.0% 0%

(Note4)

"bAL7" (bAL7)

Output convergence

value 7

Offset value which

is added to the

control output

-100.0 to 100.0% 0/50

(single/

dual)

"

Ar7" (Ar7)

Anti-reset windup 7

Sets the anti-reset

windup

0 to 100% FS

100% FS

"rEv7" (rEv7) Sets normal/reverse 7Sets the control

action

rv-- (heat (reverse)

/cool (none))

no--(heat (normal)

/cool (none))

rvno (heat (reverse)

/cool (normal))

norv (heat (normal)

/cool (reverse))

rvrv (heat (reverse)

/cool (reverse))

nono (heat (normal)

/cool (normal))

rv--/rvno

(single/

dual)

(Note6)

"SvMX" (SvMX) Sets the Max SV

selection number

Choosing SV with

the user key sets it

to the maximum

possible number.

Sv0

Sv1

Sv2

Sv3

Sv4

Sv5

Sv6

Sv7

di

Sv7

"

PL1m" (PL1M) Set the Max PID

selection number

Choosing PID with

the user key sets it

to the maximum

possible number.

Pid0

Pid1

Pid2

Pid3

Pid4

Pid5

Pid6

Pid7

di

P

id

7

Parameter

display symbol

Parameter name Function Setting range

Initial

value

Remarks

"

Ptn

" (PTn) Ramp soak

operation pattern

(Step No.)

Sets which

steps to use in

the ramp soak

operation

pattern

0 (uses steps 1 to 4)

1 (uses steps 5 to 8)

2 (uses steps 1 to 8)

3 (uses steps 9 to 12)

4 (uses steps 13 to 16)

5 (uses steps 9 to 16)

6 (uses steps 1 to 16)

di (according to di)

6

(Note 21)

"

TiMU

" (TiMU) Ramp soak time

units

Sets the units

of the ramp

soak time

hh.MM (hour:min)

MM.SS (min:sec)

hh.MM

"

Sv-1

"

(Sv-1)

Ramp soak 1 seg/

SV

Sets the SV

0 to 100% FS 0%FS

"

tm1r

" (TM1r) Ramp soak 1 seg

ramp time

Sets the ramp

time

00.00 to 99.59 (hour:min/

min:sec)

00:00

(hour:min)

"

tm1S

" (TM1S) Ramp soak 1 seg

soak time

Sets the soak

time

00.00 to 99.59 (hour:min/

min:sec)

00:00

(hour:min)

"

Sv16

"

(Sv16)

Ramp soak 16 seg/

SV

Sets the SV

0 to 100% FS 0%FS

"

t16r"

(T16r")

Ramp soak 16

seg ramp time

Sets the ramp

time

00.00 to 99.59 (hour:min/

min:sec)

00:00

(hour:min)

"t16S" (T16S) Ramp soak 16

seg soak time

Sets the soak

time

00.00 to 99.59 (hour:min/

min:sec)

00:00

(hour:min)

"mod" (Mod)

Ramp soak mode

Sets the

program

operation

method

0 to 15 0

"

Gsok" (Gsok) Guaranty soak

ON/OFF

Sets the

guaranty soak

ON or OFF

oFF (guaranty soak off)

on (guaranty soak on)

oFF

"

GS-L"(GS-L) Guaranty soak

band (lower)

Sets the lower

limit of guaranty

soak

0 to 50% FS 5°C

"

GS-h"(GS-h) Guaranty soak

band (upper)

Sets the upper

limit of guaranty

soak

0 to 50% FS 5°C

"PvST"( PvST) PV start Sets whether or

not to start

ramp soak with

PV.

oFF (PV start OFF)

on (PV start ON)

oFF

" ConT "(ConT) Restore mode Sets how to

restart when

the controller is

restored after a

power loss.

rES (Reset)

Con (Continue)

ini (Restart)

rES

(Note 20)

"

PTnM

" (PTnM) Sets the Max

pattern selection

Choosing

pattern with the

user key sets it

to the

maximum

possible

number.

0 to 6,di 6

" PMin "(PMin) Sets the Min

pattern selection

Choosing

pattern with the

user key sets it

to the minimum

possible

number.

0 to 6, di 0

Parameter

display symbol

Parameter name Function Setting range

Initial

value.

Remarks

RST

…

…

…

…

…

…

RST

Page 8

– 8 –

6-5

Monitor (Ch5)

You can check the ramp soak progress, control output, heater current, remaining time, and

other status functions.

6-6

Setup (Ch6)

Sets up the input range, output range, and other items for the equipment.

6-7

System (Ch7)

Assigns the functions of the DI/DO, LED lamp, and other controls.

Parameter

display symbol

Parameter name Function Setting range

Remarks

"

StAt

" (STAT) Ramp soak

progress

Displays the

progress of the

ramp soak

oFF (ramp soak stopped)

1-rP (ramp in step 1)

1-Sk (soak in step 1)

16rP (ramp in step 16)

16Sk (soak in step 16)

End (ramp soak finished)

"

Mv1

" (Mv1) MV1 Displa ys the output

value of the control

output (OUT1)

-3.0 to 103.0%

"

Mv2

" (Mv2) MV2 Displays the output

value of the control

output

(OUT2)(during dual

control)

-3.0 to 103.0% (Note4)

"

PFb

" (PFb) Displays the PFB

input value

Displays the input

value of the

position feedback

-3.0 to 103.0% (Note8)

"

rSv

" (rSv) RSV input value

display

Displays the input

value of the RSV

-5 to 105% FS (Note1)

"

[t1

"

(CT1)

Heater current 1

Displays the current

through the CT

0, 0.4 to 50.0A

(Note10)

(Note13)

"

LC1

" (LC1)

Leak current value

1

Displays the leak

current value of CT.

0, 0.4 to 50.0A

(Note 10)

(Note 13)

"

tm1

"

(TM1)

Remaining time on

timer 1

Displays the remaining

time on timer 1

0 to 9999 sec/ 0 to 9999min (Note3)

"

tm5

"

(TM5)

Remaining time on

timer 5

Displays the remaining

time on timer 5

0 to 9999 sec/ 0 to 9999min

"

FALT

"

(FALT)

Error source

display

Displays the

source of an error

" PLno "( PLno) Current palette No. Displays the PID

palette No.

currently selected.

0 to 7

" PTno "( PTno) Current pattern

No.

Displays the

pattern No. of the

ramp soak

currently selected.

0 to 6

Parameter

display symbol

Parameter name Function Setting range

Initial

value

Remarks

"

PvT

" (PvT) PV input type Sets the type

of input sensor

0 (no function)

1 (PT 100

Ω

)

2 (J)

3 (K)

4 (R)

5 (B)

6 (S)

7 (T)

8 (E)

9 (no function)

10(no function)

11 (no function)

12 (N)

13 (PL-

2

)

14 (no function)

15 (0 to 5V / 0 to 20mA)

16 (1 to 5V / 4 to 20mA)

17 (0 to 10V)

18 (2 to 10V)

19 (0 to 100mV)

3 (K)

"

Pvb

" (Pvb) PV input lower

limit

Sets the lower

limit of PV input

-1999 to 9999 0

°

C

"

PvF

" (PvF) PVinput upper

limit

Sets the upper

limit of PV input

-1999 to 9999 400

°

C

"

Pvd

" (Pvd) Decimal point

position

Sets the number

of decimal point

positions for the

PV/SV

0 (No digit after decimal point)

1 (1 digit after decimal point)

2 (2 digit after decimal point)

0

"

PvoF

" (PvoF) PV input shift

Sets the amount

of shift for PV

input

-10 to 10% FS

0%FS

"

tF

" (TF) PV input filter

Sets the time

constant for the

PV input filter

0.0 to 120.0 sec 5.0 sec

"

rEm0

" (rEM0) RSV Zero

adjustment

Adjusts the zero

RSV input

-50 to 50% FS

0%FS (Note1)

"

rEmS

" (rEMS) RSV Span

adjustment

Adjusts the

span RSV input

-50 to 50% FS

0%FS (Note1)

"

rEmr

" (rEMr) RSV input

range

Sets the range

for RSV input

0-5 (0 to 5V)

1-5 (1 to 5V)

1-5

(Note1)

"

rtF

" (rTF) RSV input

filter

Sets the time

constant for the

RSV input filter

0.0 to 120.0 sec 0.0 sec

(Note1)

…

…

…

…

…

fixed at 0

8bit : PV input underflow

9bit : PV input overflow

10bit: underrange

11bit: overrange

12bit: RSV underrange

13bit: RSV overrange

14bit: range setting error

15bit: EEPROM error

0bit: PFB input underflow

1bit: PFB input overflow

RST

RST

RST

RST

"

[1r

" (C1r) OUT1 range Sets the range

of the control

output (OUT1)

0-5 (0 to 5V)

1-5 (1 to 5V)

0-10 (0 to 10V)

2-10 (2 to 10V)

0-20 (0 to 20mA)

4-20 (4 to 20mA)

0-10

(voltage

) 4-20

(current)

(Note9)

(Note14)

"

[2r

" (C2r) OUT2 range

Sets the range

of the control

output (OUT2)

(Also sets for the

re-transmission

output)

0-5 (0 to 5V)

1-5 (1 to 5V)

0-10 (0 to 10V)

2-10 (2 to 10V)

0-20 (0 to 20mA)

4-20 (4 to 20mA)

0-10

(voltage

)

4-20

(current)

(Note12)

(Note14)

(Note18)

"

FLo1

" (FLo1) Output 1 set

value during

FALT

Sets the output

value for the

control output

(OUT1) during

FALT

-3.0 to 103.0% -3.0%

"

Flo2

" (FLo2) Output 2 set

value during

FALT

Sets the output

value for the

control output

(OUT2) during

FALT

-3.0 to 103.0%

-3.0% (Note4)

"

SFo1

" (SFo1) Soft Start

output 1 set

value

Sets the output

value for the

control output

(OUT1) during

soft start

-3.0 to 103.0%

103.0%

"

SFtm

" (SFTM) Soft Start set

time

Sets the time from

startup to the finish

of soft start

00:00 to 99:59 (hour:min) 0.00

(hour:

min)

Be

sure to

set

0.00

during

dual

control.

"

Sbo1

" (Sbo1) OUT1 output

set value

during standby

Sets the output

value for the

control output

(OUT1) during

standby

-3.0 to 103.0% -3.0%

"

Sbo2

"

(

Sbo2)

OUT2 output

set value

during standby

Sets the output

value for the

control output

(OUT2) during

standby

-3.0 to 103.0% -3.0% (Note4)

"

Sbmd

" (SbMd) Standby mode

setting

Sets the alarm

output, retransmission

output, and

PV/SV display

during standby

0

(Note15)

"

Aot

" (AoT) Types of AO

output

Displays the

types of retransmission

output

PV

SV

MV

DV

Pv

(Note12)

"

AoL

" (AoL) AO lower limit

scaling

Sets the lower

limit of AO

-100 to 100% 0%

(Note12)

"

Aoh

" (Aoh) AO upper limit

scaling

Sets the upper

limit of AO

-100 to 100% 100%

(Note12)

Parameter

display symbol

Parameter

name

Function Setting range

Initial

value

Remarks

"

UkEy

" (UkEy) Assigns the

USER key

Sets the

function of the

[USER] key

0 (no function)

1 (Switchover between STBY ON/OFF)

2 (Switch

over

between Auto/Manual)

3 (Switchover between Local/Remote)

4 (no function)

5 (Starts AT (standard))

6 (Starts AT (low PV))

7 (Ramp SV on/off)

8 (Ramp SV HOLD)

9 (Ramp soak OFF)

10 (Ramp soak RUN/HOLD)

11 (no function)

12 (Latch release (all))

13 (Latch release (DO1))

14 (Latch release (DO2))

15 (Latch release (DO3))

16 (Latch release (DO4))

17 (Latch release (DO5))

18 (Start timer (DO1))

19 (Start timer (DO2))

20 (Start timer (DO3))

21 (Start timer (DO4))

22 (Start timer (DO5))

23 (SV No. + 1 (send))

24 (PID No. + 1 (send))

25 (no function)

26 (Ra

mp soak

pattern No.

+ 1 (send))

27 (SV No. + 1,

PID No. + 1 (send))

2

Parameter

display symbol

Parameter name

Function

Setting range

Initial

value

Remarks

ALM

display/

output

Ao

outpu

t

PV/SV

displa

y

0 OFF ON ON

1ON ON ON

2 OFF OFF ON

3ON OFF ON

4 OFF ON OFF

5ON ON OFF

6 OFF OFF OFF

7ON OFF OFF

RST

RST

Page 9

– 9 –

6-8

Alarm (Ch8)

Sets the detect conditions for each type of alarm.

6-9

Communication (Ch9)

Sets the communication conditions towards the host computer.

6-10

PFB (Ch10)

Changes settings to use valve control.

"

di1

" (di1) DI-1 function

selection

Sets the

function of

DI-1

0 (No function)

1 (Switchover between STBY ON/OFF)

2 (Switch

over

between Auto/Manual)

3 (Switchover between Local/Remote)

4 (No function)

5 (No function)

6 (Start AT (standard))

7 (Start AT (low PV))

8 (No function)

9 (No function)

10 (Ramp SV ON/OFF)

11 (Ramp SV HOLD)

12 (Ramp soak OFF)

13 (Ramp soak RUN/HOLD)

14 (No function)

15 (Latch release (all))

16 (Latch release (DO1))

17 (Latch release (DO2))

18 (Latch release (DO3))

19 (Latch release (DO4))

20 (Latch release (DO5))

21 (Start timer (DO1))

22 (Start timer (DO2))

23 (Start timer (DO3))

24 (Start timer (DO4))

25 (Start timer (DO5))

26 (SV No. + 1)

27 (SV No. + 2)

28 (SV No. + 4)

29 (PID No. + 1)

30 (PID No. + 2)

31 (PID No. + 4)

32 (No function)

33 (No function)

34 (No function)

35 (SV No.+1, PID No.+1)

36 (SV No.+2, PID No.+2)

37 (SV No.+4, PID No.+4)

38 (Pattern No.+1)

39 (Pattern No.+2)

40 (Pattern No.+4)

41 (Soft start)

42 (Ramp soak RUN)

43 (Ramp soak HOLD)

44

(Ramp soak RUN at DO1 startup)

45 (Ramp soak RUN at DO2 startup)

46

(Ramp soak RUN at DO3 startup)

47

(Ramp soak RUN at DO4 startup)

48 (Ramp soak RUN at DO5 startup)

0

(Note11)

"

di5" (di5) DI-5 function

selection

Sets the

function of

DI-5

0 to 48 0

"

do1t" (do1T) Sets the DO1

output event

type

Sets the

function of

DO1

0 to 102 0

"

doP1" (doP1) Sets DO1

option function

Assigns the

four types of

option

functions in

bit units

0000 to 1111 0000

(Note3)

"do5t" (do5T) Sets the DO5

output event

type

Sets the

function of

DO5

0 to 102 0

"

doP5" (doP5) Sets DO5

option function

Assigns the

four types of

option

functions in

bit units

0000 to 1111 0000

"

rmP" (rMP) ramp SV

ON/OFF

Sets the

ramp SV

ON/OFF

oFF (ramp SV OFF)

on (ramp SV ON)

on

"

rmPL" (rMPL) Ramp SV-

Decline

Sets the slope

for a falling SV

during ramp

SV operations

0 to 100% FS 0°C

"rmPh" (rMPH) Ramp SV-

Incline

Sets the slope

for a rising SV

during ramp

SV operations

0 to 100% FS 0°C

"rmPU" (rMPU) Ramp SV-

slope units of

time

Sets the unit

of time for the

slope during

ramp SV

operations

hoUr (slope temperature/hour)

Min (slope temperature/min)

hoUr

"Svt" (SvT) Ramp SV - SV

display mode

selection

Displays the

SV during

ramp

operations or

the SV goal

value on the

SV display

rMP (SV during ramp)

TrG (target SV)

rMP

"

[trL" (CTrL) Control

methods

Allows you to

select the

control

method.

Pid (PID control)

FUZY (Fuzzy PID control)

SELF (Self-tuning control)

Pid2 (PID2 control)

Pid

Sections

5-1 to

5-8

(Note19)

Parameter

display symbol

Parameter

name

Function Setting range

Initial

value

Remarks

RST

…

…

…

…

…

bit0 : output latch function

bit1 : error alarm function

bit2 : non-excitation output

alarm function

bit3 : hold reset function

□□□□

RST

…

…

…

…

…

□□□□

bit0 : output latch function

bit1 : error alarm function

bit2 : non-excitation

output alarm function

bit3 : hold reset function

RST

"PrCS" (PrCS) Control target Allows you to

select the

control target.

SRV1 (Servo control 1)

SRV2 (Servo control 2)

PFB (Position feedback

control)

PFb/

Srv1

(with

PFB/

without

PFB)

(Note16)

"Stmd" (STMd) Start mode Sets the

operation

mode when

starting up

Auto (auto mode startup)

Man (manual mode startup)

Rem

(remote mode startup)

STby

(standby make startup)

AUTo

Parameter

display symbol

Parameter name Function Setting range

Initial

value

Remarks

"A1hY" (A1hy) ALM1 hysteresis Sets the hysteresis

for alarm output 1

ON/OFF

0 to 50% FS 1°C

(Note3)

"dLY1" (dLY1) ALM1 delay Sets the delay

before detecting

alarm output 1

0 to 9999 [sec/min] 0(sec/

min)

"

dL1U" (dL1U) ALM1 delay time

units

Sets the delay time

units for alarm

output 1

sec (second)

Min (minute)

sec

"

A5hY" (A5hy) ALM5 hysteresis Sets the hysteresis

for alarm output 3

ON/OFF

0 to 50% FS 1°C

"

dLY5" (dLY5) ALM5 delay Sets the delay

detecting for alarm

output 3

0 to 9999 [sec/min]

0(sec/

min)

"

dL5U" (dL5U) ALM5 delay time

units

Sets the delay time

units for alarm

output 3

sec (second)

Min (minute)

sec

"

hb1" (hb1) HB alarm set value

for CT

Sets the heater

burnout alarm

detection value for

CT

0.0 to 50.0A 0.0A

(Note10)

(Note13)

"hb1h" (hb1h) HB alarm

hysteresis for CT

Sets the heater

burnout alarm ON/

OFF hysteresis for

CT

0.0 to 50.0A 0,5A

(Note10)

(Note13)

"hS1" Load short-circuit

alarm setting value

for CT

Sets the heater

load short-circuit

alarm setting value

for CT.

0.0 to 50.0A 0.0A

(Note10)

(Note13)

"hS1h" Load short-circuit

alarm hysteresis

for CT

Sets the heater

load short-circuit

alarm ON/OFF

hysteresis for CT.

0.0 to 50.0A 0.5A

(Note10)

(Note13)

"lbTm" (LbTM) Loop break

detection time

Sets the time

before detecting a

broken loop

0 to 9999 sec 0 sec

"

LbAb" (LbAb) Loop break

detection range

(°C)

Sets the

temperature range

before detecting a

broken loop

0 to 100% FS 10°C

Parameter

display symbol

Parameter name

Function Setting range

Initial

value

Remarks

"Stno" (Stno) ST No. setting Sets the station

number.

0 to 255 (0:

unresponsive

communication)

1

(Note17)

"CoM" (CoM) baud rate/parity

setting

Sets the baud

rate and parity

check

96od (9600 bps/odd)

96Ev (9600 bps/even)

96no (9600 bps/none)

19od (19200 bps/odd)

19Ev (19200 bps/even)

19no (19200 bps/none)

96od

(Note17)

"S[[" (SCC) Communication

permissions

Sets whether or

not overwriting is

possible from the

master side (PC,

etc.)

r (read only permission)

rW (read and overwrite

permission)

rW

(Note17)

Parameter

display symbol

Parameter name Function Setting range

Initial

value

Remarks

"PGAP" (PGAP)

PFB dead band Sets the PFB dead

band

0.0 to 100.0% 5%

(Note16)

"trvL" (TrvL) Valve stroke time Sets the full stroke

time for the valve

5 to 180 sec 30 sec

(Note16)

"[AL" (CAL) PFB input

adjustment

command

Adjusts the zero/

span for PFB input

0 (none/forcibly termination)

1 (zero adjustment)

2 (span adjustment)

3 (automatic adjustment)

-

(Note8)

Parameter

display symbol

Parameter

name

Function Setting range

Initial

value

Remarks

RST

…

…

…

…

…

RST

Page 10

– 10 –

6-11

Password Setup (Ch11)

Sets the password. Passwords can be set at three levels.

6-12

Display (Ch12)

Sets the parameter mask function Optional parameters can be set not to display.

For details on the parameter mask function, refer to the "Operation Manual".

Note 1: Displayed when the seventh digit of the model code is H, K, F, 2 or E, or the eleventh

digit is D.

Note 2: Displayed when the ninth digit of the model code is not 0, or the

eleventh digit is C.

Note 3: Display changes according to the DO number and the selected alarm type.

Note 4: Displayed when the fifth digit of the model code is not V or S and the sixth digit is A,

C, E or P.

Note 5: “

SvL” and “Svh” must be set so that SvL < Svh.

When the setting values of “

SvL” and “Svh” are changed, check SV setting value 1

(“

Sv1 Ch3”) through SV setting value 7 (“Sv7 Ch3”).

Note 6: Set the same value as the one for the Normal/Reverse setting (“

rEv Ch2”).

Note 7: Displayed when the fifth digit of the model code is A or C.

Note 8: Displayed when the fifth digit of the model code is V.

Note 9: Displayed when the fifth digit of the model code is E or P.

Note 10: Displayed when the seventh digit of the model code is G or J, or when the eleventh

digit is A.

Note 11: The number of parameters to be displayed varies depending on the number of DIs

that PXG has.

For more details on “41: DI soft start”, refer to the “Operation Manual”.

Note 12: Displayed when the sixth digit of the model code is R or S.

Note 13: The parameter uses this even if the terminal uses CT2 input.

Note 14: Select the proper setup range for the output type.

Note 15: Do not set 4 to 7.

Note 16: Displayed when the fifth digit of the model code is V or S.

Note 17: Displayed when the seventh digit of the model code is M, V, K, J, F or U.

Note 18: Displayed when the sixth digit of the model code is E or P.

Note 19: When the fifth digit of the model code is S or V, be sure to select PID control. Options

other than PID control cannot be used.

Note 20: When changing the SV with the front key, do not change the “

Svn” parameter via

communication.Otherwise, the changed SV may not be stored correctly.

Note 21: Do not change this parameter during the ramp soak operation.

Be sure to set “

PrG” = “oFF” before changing the parameter.

7 Functions

This controller has five types of temperature control functions and three types of valve control

functions. Select according to type and use.

● Temperature Control Functions

● Valve Control Functions

7-1 ON/OFF (2-position) Control

Acts as an ON/OFF control when the PID parameter is set to "P" = 0.0 ("Pid Ch 2").

ON/OFF control switches the control output to ON (100%) or OFF (0%) according to the size relationship of PV and SV.The output hysteresis can be set under the parameter "

hYS

" ("

Pid Ch 2

").

Reverse Operation (heat control)

Method used to control the electrical heating furnace."Set the hYS" to an appropriate value

according to the control target.

Normal Operation (cooling control)

Method used to control the cooling machine.

7-2 PID Controls

PID controls run as long as the parameter is set to "P" ≠ 0.0 ("Pid Ch 2") and "CTrL" = PID ("SYS

CH 7

"). The PID controls calculate PID based on the set values for parameters "P", "i", "d", and

"

Ar", and output the calculated result (-3% to 103%).

Each parameter can be set either by manually tuning the values or by running auto-tuning (AT)

to automatically set the values.

Setting PID Control

7-3 Fuzzy PID Control

Related to normal PID controls, fuzzy PID control acts with small overshoot.

You will need to run auto-tuning to set the PID parameter when using fuzzy control.

Setting fuzzy PID control

Display Parameter name Function Setting range

Initial

value

Remarks

"PAS1" (PAS1) Password1 setup Sets password 1. 0000 to FFFF 0000

"PAS2" (PAS2) Password2 setup Sets password 2. 0000 to FFFF 0000

"PAS3" (PAS3) Password3 setup Sets password 3. 0000 to FFFF 0000

Display Parameter name Function Setting range

Initial

value

Remarks

"dP01" (dP01) Parameter mask of

each parameter

Sets the

parameters to be

displayed/not

displayed.

0000 to FFFF

Value

different

depending

on the

model

code

"dP30" (dP30) Parameter mask of

each parameter

Sets the

parameters to be

displayed/not

displayed.

0000 to FFFF

Value

different

depending

on the

model

code

Caution

The ramp soak function ( page 12), remote SV function ( page 15), and

SV selection function ( page 16) cannot be combined.

ON/OFF (2-position)

control

Turns the control output ON/OFF according to the size

relationship of PV and SV Can build a control system

out of simple elements such as SSR. Suitable when

accuracy is not requested.

7-1

(page 10)

PID Controls PID calculation and controls proceed according to the

previously set PID parameters.

PID parameters can be set manually or through autotuning (AT).

It is the most basic control in this equipment.

7-2

(page 10)

Fuzzy PID Control PID control with function that reduces the amount of

overshoot during control. It is effective when you want

to suppress overshoot when SV is changed, even if you

may take a long time to reach the target value.

7-3

(page 10)

Self-tuning Control Automatically calculating PID control according to the

control target or SV change. It is effective when the

control conditions change frequently.

7-4

(page 11)

PID2 Control In case which the power supply of the control target

goes ON → OFF → ON, this PID2 control can suppress

the amount of overshoot during control target turns OFF

→ ON.

7-5

(page 11)

…

…

…

…

…

…

Servo Control 1

(Servo 1)

Regulates the valve position according to [OPEN] and

[CLOSE] of the contact output.

7-7

(page 11)

Servo Control 2

(Servo 2)

Regulates the valve position according to [OPEN] and

[CLOSE] of the contact output.It can also display the

valve ís degree of openness according to the position

position signal from the valve. However, it cannot be

used to calculate the control output.

7-7

(page 11)

Position Feedback

(PFB Control)

Controls the valve according to a calculation performed

on the opening signal.Regulates the valve position

according to [OPEN] and [CLOSE] of the contact

output.

It can be used when there is an opening signal coming

from the valve.

7-8

(page 12)

Parameter Set Value

"P" 0.0

"rEv rv-"hYS" arbitary (factory

setting: 1 °C)

Parameter Set Value

"P" 0.0

"rEv no-"hYS" arbitary (factory

setting: 1 °C)

Point

During ON/OFF control, the I and D settings do not affect control.

The manual operation during ON/OFF control will become MV=100%

when the key is pressed, and MV=0% when the key is pressed.

If the hysteresis width is narrow, and PV and SV are nearly equal, the

output may frequently switch ON and OFF. Note that it may affect the

operation life of the contact output.

Refer to

For more details on auto-tuning, see "7-6 Auto-tuning" (page 11)

1

Display the system menu ("SYS Ch 7").

2

Display the control parameter ("CTrL") and choose PID controls ("Pid").

3

Press the key to set the value.

1

Display the system menu ("SYS [h 7").

2

Display the controller parameter ("[trL") and choose fuzzy ("FUZY").

3

Press the key to set the value.

Refer to

For more details on auto-tuning, see "7-6 Auto-tuning" (page 11)

PV

ON

OFF

control output

t

SV

process value

PV<SV

PV>SV

HYS

PV<SV

PV>SV

PV

ON

OFF

control output

t

SV

process value

HYS

Page 11

– 11 –

7-4 Self-tuning Control

Self-tuning Control is a control which automatically calculate the value of PID, under the condition that the control target or set value (SV) changes.

Self-tuning is especially effective for situations when a high level of control is not needed, but

auto-tuning cannot be run due to frequent changes in the control target conditions.

Conditions where self-tuning can be used

Self-tuning is used in the following situations:

• When temperature rises when the power is turned on

• When temperature rises when SV changes (or when the controller decides it is necessary)

• When the controller decides it is necessary because the controls have become unstable

Conditions where self-tuning cannot be used

Self-tuning cannot be used in the following situations:

• During control standby

• During ON/OFF (2-position) control

• During auto-tuning

• During ramp soak progress

• When there is error input

• When set for dual output

• When any of the P, I, D, Ar parameters are set to manual

• During manual mode

• During soft start progress

Conditions to halt self-tuning

Halt self-tuning in the following situations:

• When there is a change in SV (This includes the case where SV changes because of the

ramp soak function, remote SV function, or ramp SV.)

• When self-tuning has not finished after running for nine or more hours

Setting self-tuning

7-5 PID2 Control

In case which the power supply of the control target goes ON → OFF → ON, this PID2 control

can suppress the amount of overshoot.

This control introduces an algorithm to prevent the calculated PID result from becoming a miscalculation, even when the control loop is open.

You will need to run auto-tuning to set the Pid parameter when using Pid2 control.

● Features of PID2 Control

Setting PID2 control

7-6 Auto-tuning

Run auto-tuning to set the PID parameter automatically.

● Normal type ● Low PV type

Running auto-tuning

7-7 Valve Control (Servo Control 1 / Serve Control 2)

Valve controls adjust and control the valve position according to [OPEN] and [CLOSE] of the

contact signal.

Turn on the contact outputs in man ual mode, so that pressing the key means "OPEN", and

pressing the key means "CLOSE"

Servo control 1 and servo control 2 have the following differences.

• Servo Control 1: No valve position display

• Servo Control 2: Has valve position display

Neither control can be used to control the valve position itself.

Setting Servo Control 1 or Servo Control 2

Point

When a high level of control is required, choose PID control, fuzzy PID

control, or PID2 control.

1

Turn on power of the controller and set the SV.

2

Display the system menu ("SYS [h 7").

3

Display the controller parameter ("[trL") and choose self-tuning ("SELF").

4

Press the key to set the value.

5

Turn off power of the controller.

6

Turn on power of the control target equipment and the controller. Turn on

power of the control equipment first.

Self-tuning will begin.

Point

• The equipment will not tune correctly if power of the controller is

turned on first.

• To reset self-tuning, set the control method to PID ("PiD") once

before changing back to self-tuning.

1

Display the system menu ("SYS Ch 7").

2

Display the control parameter ("CTrL") and choose PID2 ("Pid2").

3

Press the key to set the value.

dead time

t

process value

tuning

SV

lag time

suppress overshoot

ON

OFF

control equipment power

t

SV

process value

control loop

close

close

open

PV

"At" set value Behavior Function