Page 1

series

USER'S MANUAL

General Purpose Communication Module

Type: NP1L-RS1 (RS-232C: 1CH, RS-485: 1CH)

NP1L-RS2 (RS-232C: 1CH)

NP1L-RS3 (RS-232C: 2CH)

NP1L-RS4 (RS-485: 1CH)

NP1L-RS5 (RS-485: 2CH)

FEH225d

Page 2

Preface

This User’s Manual explains the system configuration of SPH general purpose communication module, the specifications

and operation of the modules.

Read this manual carefully to ensure correct operation. When using modules or peripheral devices, be sure to read the

corresponding user’s manuals listed below.

<Relative manuals for the SX-Programmer Expert (D300win)>

eltiT .oNlaunaM stnetnoC

,noitcurtsnIlaunaMs'resU

seiresXS-XERCIM

s'resU,erawdraHlaunaM

HPSseiresXS-XERCIM

,>ecnerefeR<niw003DlaunaMs'resU

seiresXS-XERCIM

,>ecnerefeR<niw003DlaunaMs'resU

seiresXS-XERCIM

resU,BFdednetxEdradnatSlaunaMs'

seiresXS-XERCIM

002HEF ehtfosnoitinifedmetsysdnaegaugnal,yromemehtsnialpxE

.seiresXS-XERCIM

102HEFdnasnoitacificepseht,noitarugifnocmetsysehtsnialpxE

.seiresXS-XERCIMehtniseludomfosnoitarepo

452HEFehtfolladna2Vniw003DfonocidnaunemehtsnialpxE

.2Vniw003Dfosnoitarepo

752HEFehtfolladna3Vniw003DfonocidnaunemehtsnialpxE

.3Vniw003Dfosnoitarepo

552HEFfonoitacificepsehtsnialpxEBFdednetxEdradnatSehtfo

.niw003Dottnemhcatta

<Relative manuals for the SX-Programmer Standard (Standard Loader)>

eltiT .oNlaunaM stnetnoC

,noitcurtsnIlaunaMs'resU

seiresXS-XERCIM

s'resU,erawdraHlaunaM

HPSseiresXS-XERCIM

launaMs'resU

,>ecnerefeR<dradnatSremmargorP-XS

seiresXS-XERCIM

*This manual is structured to be applicable to both D300win and Standard Loader.

*In addition to the above manuals, the following Fuji Electric FA Components & Systems Co., Ltd. site offers various

manuals and technical documents associated with MICREX-SX.

885HEF ehtfosnoitinifedmetsysdnaegaugnal,yromemehtsnialpxE

.seiresXS-XERCIM

102HEFdnasnoitacificepseht,noitarugifnocmetsysehtsnialpxE

.seiresXS-XERCIMehtniseludomfosnoitarepo

095HEF dradnatSremmargorP-XSehtfonocidnaunemehtsnialpxE

URL http://www.fujielectric.co.jp/fcs/eng/index.html

.dradnatSremmargorP-XSehtfosnoitarepoehtfolladna

Notes

1.

This manual may not be reproduced in whole or part in any form without prior written approval by the

manufacturer.

2. The contents of this manual (including specifications) are subject to change without prior notice.

3. If you find any ambiguous or incorrect descriptions in this manual, please write them down (along with the manual

No.shown on the cover) and contact FUJI.

Page 3

Be sure to read the “Safety Precautions” thoroughly before using the module.

Here, the safety precaution items are classified into “Warning” and “Caution.”

Safety Precautions

Warning

Caution

Even some items indicated by “Caution” may also result in a serious accident.

Both safety instruction categories provide important information. Be sure to strictly observe these instructions.

: Incorrect handling of the device may result in death or serious injury.

: Incorrect handling of the device may result in minor injury or physical damage.

Warning

Never touch any part of charged circuits as terminals and exposed metal portion while the power is turned ON.

It may result in an electric shock to theoperator.

Turn OFF the power before mounting, dismounting, wiring, maintaining or checking, otherwise, electric shock, erratic

operation or troubles might occur.

Place the emergency stop circuit, interlock circuit or the like for safety outside the PLC.

A failure of PLC might break or cause problems to the machine.

Do not connect in reverse polarity, charge (except rechargeable ones), disassemble, heat, throw in fire or short-circuit

the batteries, otherwise, they might burst or take fire.

If batteries have any deformation, spilled fluids, or other abnormality, do not use them. The use of such batteries might

cause explosion or firing.

Do not open the FG terminal with the LG-FG short circuited.

(It must be grounded, otherwise it might cause electric shock.)

Page 4

Safety Precautions

Caution

Do not use one found damaged or deformed when unpacked, otherwise, failure or erratic operation might be caused.

Do not shock the product by dropping or tipping it over, otherwise, it might be damaged or troubled.

Follow the directions of the operating instructions when mounting the product.

If mounting is improper, the product might drop or develop problems or erratic operations.

Use the rated voltage and current mentioned in the operating instructions and manual. Use beyond the rated values

might cause fire, erratic operation or failure.

Operate (keep) in the environment specified in the operating instructions and manual. High temperature, high humidity,

condensation, dust, corrosive gases, oil, organic solvents, excessive vibration or shock might cause electric shock, fire,

erratic operation or failure.

Select a wire size to suit the applied voltage and carrying current. Tighten the wire terminals to the specified torque.

Inappropriate wiring or tightening might cause fire, malfunction, failure, or might cause the product to drop from its

mounting.

Contaminants, wiring chips, iron powder or other foreign matter must not enter the device when installing it, otherwise,

erratic operation or failure might occur.

Remove the dust-cover seals of modules after wiring, fire, accidents, failue or fault might occur.

Connect the ground terminal to the ground, otherwise, an erratic operation might occur.

Periodically make sure the terminal screws and mounting screws are securely tightened.

Operation at a loosened status might cause fire or erratic operation.

Put the furnished connector covers on unused connectors, otherwise, failure or erratic operation might occur.

Install the furnished terminal cover on the terminal block, otherwise, electric shock or fire might occur.

Sufficiently make sure of safety before program change, forced output, starting, stopping or anything else during a run.

The wrong operation might break or cause machine problems.

Engage the loader connector in a correct orientation, otherwise, an erratic operation might occur.

Before touching the PLC, discharge any static electricity that may have been collected on your body.

To discharge it, touch a grounded metallic object. Static electricity might cause erratic operation or failure of the module.

Be sure to install the electrical wiring correctly and securely, observing the operating instructions and manual. Wrong or

loose wiring might cause fire, accidents, or failure.

When disengaging the plug from the outlet, do not pull the cord, otherwiase, break of cable might cause fire or failure.

Do not attempt to change system configurations (such as installing or removing I/O modules) while the power is ON,

otherwise, failure or erratic operation might occur.

Do not attemp to repair the module by yourself contact your Fuji Electric agent. When replacing the batteries, correctly

and securely connect the battery connectors, otherwise, fire, accidents or failure might occure.

To clean the module, turn power off and wipe the module with a cloth moistened with warm water. Do not use thinner or

other organic solvents, as the module surface might become deformed or discolored.

Do not remodel or disassemble the product, otherwise, a failure might occur.

Follow the regulations of industrial wastes when the device is to be discarded.

The modules covered in these operating instructions have not been designed or manufactured for use in equipment or

systems which, in the event of failure, can lead to loss of human life.

If you intend to use the modules covered in these operating instructions for special applications, such as for nuclear

energy control, aerospace, medical, or transportation, please consult your Fuji Electric agent.

Be sure to provide protective measures when using the module covered in these operating instructions in equipment

which, in the event of failure, may lead to loss of human life or other grave results.

External power supply (such as 24V DC power supply) which is connected to DC I/O should be strongly isolated from

AC power supply.

Page 5

nodetnirP .oNlaunaM* stnetnocnoisiveR

8991.peS522HEFnoitidetsriF

2002.naJa522HEF .snoitacificepsBFdednetxefosegnahcotgnidroccadegnahcstnetnoC

4002.raMb522HEF

5002.naJc522HEF

6002.luJd522HEF

Revisions

.revocehtnonwohssi.oNlaunaM*

• larudecorp-nonehtfotrapafonoisulcniotgnidroccadegnahcstnetnoC

.BFlarudecorp-nonehtfoyticapacehtfonoitcuderdnaerawmrifehtniBF

• .noitcnufredaolmedomehtfonoitiddaotgnidroccadegnahcstnetnoC

• dnadeteled2xidneppAniBFdednetxedradnatsehtfosnoitpircseD

eludoMnoitacinummoCesopruPlareneGrofsBFdednetxEdradnatS"nidetnirper

".)552HEF(

• .deweiversaw"dohtemgniriW2-6"fotnetnocehT

• .detcerrocsaw7-2-3hpargarapninoitpircsedgnorW

• "redaolgnimmargorP"dna"redaolmedoM"rofsnoitacificepsnoitacinummoC

.2-3-2hpargarapotdeddaerewsedom

• deddasaw3SR-L1PN

• .detcerrocsaw1-4-3hpargarapninoitpircsedgnorW

• .deddasaw2etoN1-3-4hpargaraP

• .detcerrocsaw2-2-6hpargarapninoitpircsedgnorW

• .deteledh10,h00edocepytyromeM1-3-2xidneppA

• )4xidneppA(deddasaw5SR-L1PN

Page 6

Contents

Preface

Safety Precautions

Revisions

Contents

Page

Section 1 General ..........................................................................................1-1

1-1 General ............................................................................................................................................ 1-1

1-2 Selections and Programs for the Communication ..................................................................... 1-2

1-3 General Purpose Communication Package for Factory Automation Machine ........................ 1-3

1-4 Product Versions and Supported Functions ............................................................................... 1-4

1-4-1 Supported functions .............................................................................................................................. 1-4

1-4-2 Available standard extended FB ........................................................................................................... 1-4

Section 2 Specifications ...............................................................................2-1

2-1 General Specifications .................................................................................................................. 2-1

2-2 Communication Specifications..................................................................................................... 2-2

2-3 Names and Functions .................................................................................................................... 2-3

2-3-1 Names ................................................................................................................................................... 2-3

2-3-2 Functions ............................................................................................................................................... 2-4

2-4 Dimensions ..................................................................................................................................... 2-7

Section 3 System Configuration ..................................................................3-1

3-1 Mounting Restrictions ................................................................................................................... 3-1

3-1-1 Mounting position ................................................................................................................................. 3-1

3-1-2 Number of mountable modules ............................................................................................................ 3-1

3-2 System Configurations .................................................................................................................. 3-2

3-2-1 1:1 Connection using RS-232C port ..................................................................................................... 3-2

3-2-2 1:N Connection using RS-485 port (N = max. 31 modules) ................................................................. 3-3

3-2-3 Connecting independently to RS-232C and RS-485 ports ................................................................... 3-4

3-2-4 Connection using RS-232C and RS-485 ports (2) ............................................................................... 3-5

3-2-5 Connecting a personal computer loader to the RS-232C port and RS-485 port ................................. 3-7

3-2-6 Loader network configuration using RS-485 ........................................................................................ 3-7

3-2-7 Loader network configuration using modems (1) ................................................................................. 3-8

3-3 Loader Connecting Cable .............................................................................................................. 3-9

3-3-1 When connecting to RS-232C port ....................................................................................................... 3-9

3-3-2 When connecting to RS-485 port .......................................................................................................... 3-9

3-4 Self-diagnosis ............................................................................................................................... 3-10

3-4-1 Self-diagnosis mode 1 ........................................................................................................................ 3-10

3-4-2 Self-diagnosis mode 2 ........................................................................................................................ 3-11

Section 4 Software Interface ........................................................................4-1

4-1 General ............................................................................................................................................ 4-1

4-2 Specifications for Non-procedural FB ......................................................................................... 4-3

4-2-1 Communication specification ................................................................................................................ 4-3

4-2-2 FB format ............................................................................................................................................... 4-4

4-2-3 FB terminals .......................................................................................................................................... 4-5

Page 7

Contents

Page

4-3 Initialization ..................................................................................................................................... 4-7

4-3-1 Initialization parameters ........................................................................................................................ 4-7

4-3-2 Initialization procedure ........................................................................................................................ 4-10

4-3-3 OPEN status list .................................................................................................................................. 4-10

4-4 Data Sending ................................................................................................................................ 4-11

4-4-1 Data sending procedure ...................................................................................................................... 4-11

4-4-2 Send status list .................................................................................................................................... 4-12

4-5 Data Receiving .............................................................................................................................. 4-13

4-5-1 Data receiving procedure .................................................................................................................... 4-13

4-5-2 Receiving status list ............................................................................................................................ 4-14

4-6 RAS Information ........................................................................................................................... 4-15

Section 5 Programming ................................................................................5-1

5-1 Communication Program .............................................................................................................. 5-1

5-2 Installation Procedure of Standard Extended FB ....................................................................... 5-2

5-3 Registration in Library ................................................................................................................... 5-5

5-4 Pasting Non-procedural FB ........................................................................................................... 5-6

5-5 Communication Parameters Setting ............................................................................................ 5-7

5-6 Writing the Send Data .................................................................................................................... 5-8

5-7 Connecting Variables and Commands to FB Terminals ............................................................. 5-9

5-7-1 Connecting variable to “PARA” terminal ................................................................................................ 5-9

5-7-2 Operation for starting FB ....................................................................................................................... 5-9

5-7-3 Operation for sending data.................................................................................................................. 5-10

5-7-4 Data receiving operation ..................................................................................................................... 5-10

Section 6 Wiring.............................................................................................6-1

6-1 Precautions ..................................................................................................................................... 6-1

6-2 Wiring Method ................................................................................................................................. 6-2

6-2-1 When RS-485 is used (2-wire) .............................................................................................................. 6-2

6-2-2 When RS-485 is used (4-wire system) ................................................................................................. 6-2

6-2-3 When RS-232C is used ......................................................................................................................... 6-3

Section 7 RAS ................................................................................................7-1

7-1 RAS Information of General Purpose Communication Module ................................................ 7-1

Appendix 1 JIS Code............................................................................. App.1-1

JIS 7-bit Codes ........................................................................................................................... App.1-1

JIS 8-bit Codes ........................................................................................................................... App.1-1

Appendix 2 Data Access by Command ...............................................App.2-1

Appendix 2-1 Command Overview ............................................................................................. App.2-1

Appendix 2-2 Send Data Format of Commands ........................................................................ App.2-2

Appendix 2-3 Loader Command Details .................................................................................... App.2-4

Appendix 2-3-1 Read data ....................................................................................................................... App.2-4

Appendix 2-3-2 Write data ....................................................................................................................... App.2-6

Appendix 2-3-3 Batch Start of CPUs .......................................................................................................App.2-7

Appendix 2-3-4 Batch Initialization Start of CPUs .................................................................................. App.2-7

Appendix 2-3-5 Batch Stop of CPUs ....................................................................................................... App.2-7

Appendix 2-3-6 Batch Reset of CPUs .....................................................................................................App.2-8

Page 8

Contents

Page

Appendix 2-3-7 Individual Start of CPU .................................................................................................. App.2-8

Appendix 2-3-8 Individual Initialization Start of CPU .............................................................................. App.2-8

Appendix 2-3-9 Individual Stop of CPU ................................................................................................... App.2-9

Appendix 2-3-10 Individual Reset of CPU ............................................................................................... App.2-9

Appendix 3 Additional Explanation for NP1L-RS3 .............................App.3-1

Appendix 3-1 Applicable Version for NP1L-RS3........................................................................ App.3-1

Appendix 3-2 General Specifications ......................................................................................... App.3-1

Appendix 3-3 Names and Functions .......................................................................................... App.3-1

Appendix 3-3-1 Names ............................................................................................................................ App.3-1

Appendix 3-3-2 Functions ........................................................................................................................ App.3-2

Appendix 3-4 Self-diagnosis ....................................................................................................... App.3-3

Appendix 3-4-1 Self-diagnosis mode 1 .................................................................................................. App.3-3

Appendix 3-4-2 Self-diagnosis mode 2 ................................................................................................... App.3-3

Appendix 3-5 Initialization Parameters ...................................................................................... App.3-3

Appendix 3-6 Detailed RAS ......................................................................................................... App.3-4

Appendix 4 Additional Explanation for NP1L-RS5 .............................App.4-1

Appendix 4-1 Applicable Version for NP1L-RS5........................................................................ App.4-1

Appendix 4-2 General Specifications ......................................................................................... App.4-1

Appendix 4-3 Names and Functions .......................................................................................... App.4-1

Appendix 4-3-1 Names ............................................................................................................................ App.4-1

Appendix 4-3-2 Functions ........................................................................................................................ App.4-2

Appendix 4-4 Self-diagnosis ....................................................................................................... App.4-4

Appendix 4-4-1 Self-diagnosis mode 1 .................................................................................................. App.4-4

Appendix 4-4-2 Self-diagnosis mode 2 ................................................................................................... App.4-4

Appendix 4-5 Initialization Parameters ...................................................................................... App.4-4

Appendix 4-6 Loader Network Functions .................................................................................. App.4-4

Appendix 4-7 Detailed RAS ......................................................................................................... App.4-5

Page 9

Section 1 General

Page

1-1 General......................................................................................................................... 1-1

1-2 Selections and Programs for the Communication................................................... 1-2

1-3 General Purpose Communication Package for Factory Automation Machine...... 1-3

1-4 Product Versions and Supported Functions ............................................................ 1-4

1-4-1 Supported functions .............................................................................................................. 1-4

1-4-2 Available standard extended FB ........................................................................................... 1-4

Page 10

General

Section 1 General

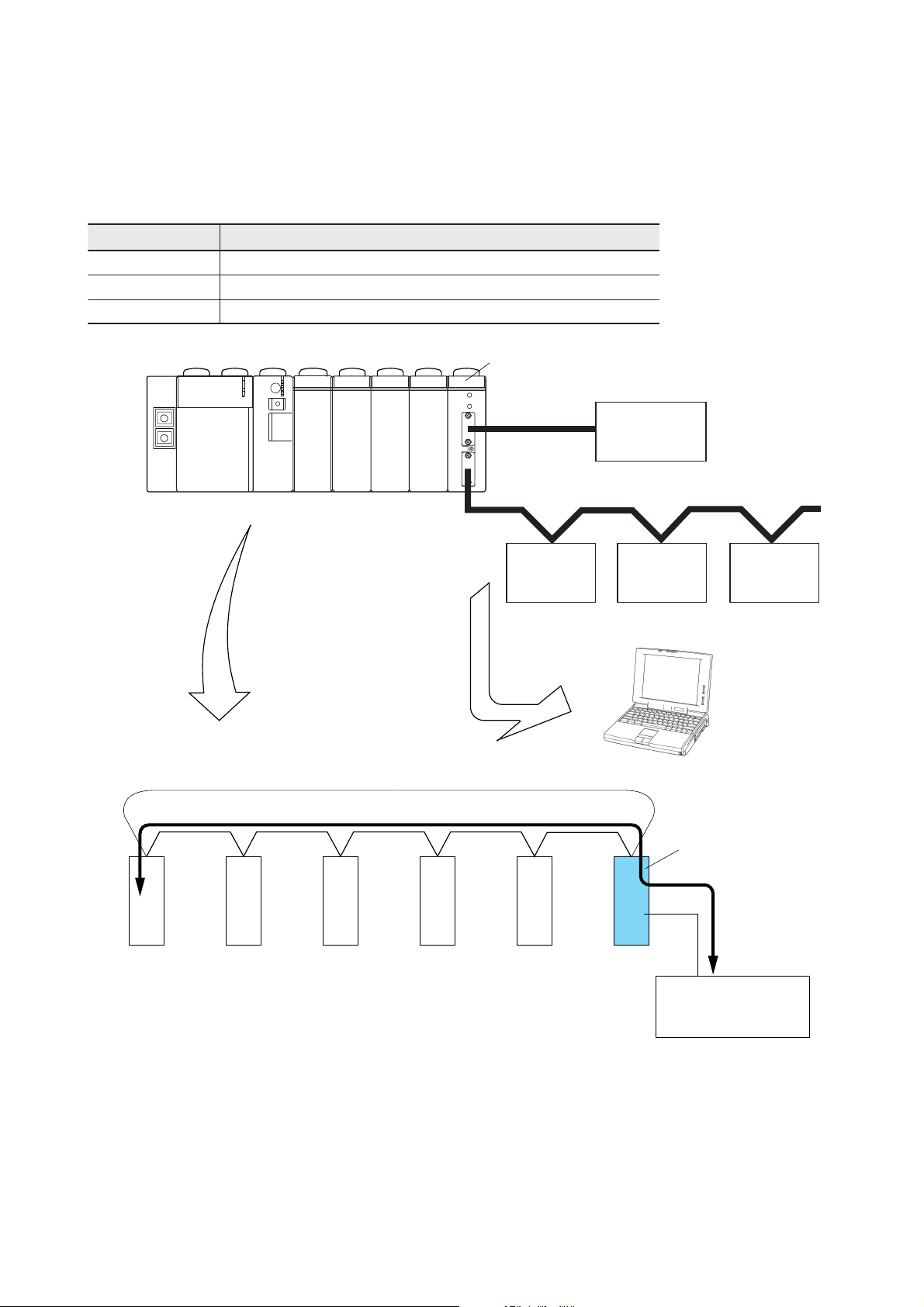

1-1 General

NP1L-RS1/2/4 are communication modules which enable data communication between a CPU module and external

devices, and which are connected to the base board (on the SX bus) of MICREX-SX series. (NP1L-RS1/2/4 are

sometimes abbreviated as RS1/2/4.)

The port type and the number of ports are as follows:

epyT stropfo.oN

1SR-L1PNlennahc1:584-SR,lennahc1:C232-SR

2SR-L1PNlennahc1:C232-SR

4SR-L1PNlennahc1:584-SR

RS1

RS-232C

Power

supply

(1:1)

CPU I/O I/O I/O I/O

RS-485

(1:n) n = Max. 31

External

device

As an external device,

it is possible to connect

a loader software

package for in a

personal computer.

<Overview of SX bus connection>

Total length of SX bus: Max. 25m

I/O I/O I/O I/O

CPU

Data transmission between CPU and an

external device is performed via the SX bus.

External

device

Loader software package for a personal computer

External

device

External

device

General purpose

communication module

External device

1-1

Page 11

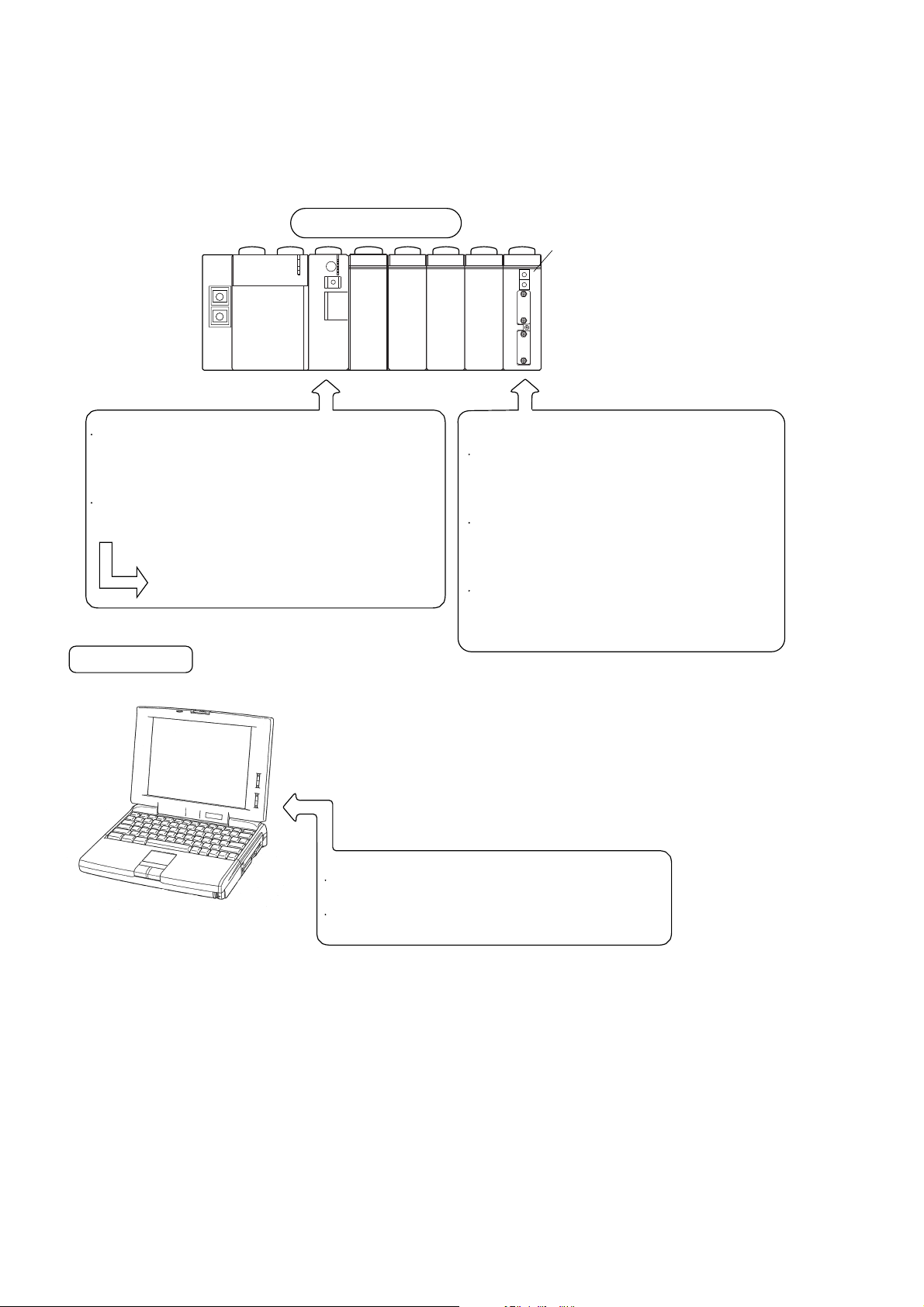

1-2 Selections and Programs for the Communication

The following preparations are necessary for RS1/2/4 to communicate between a CPU module of MICREX-SX series and

external devices.

MICREX-SX series

RS1/2/4

Power

supply

<CPU modules side>

Initializing parameters for a RS-232C port and a

RS-485 port.

(Transmission speed, data length, parity bit, stop

bits etc.,)

Application software for the communication.

FA packages are optionally provided

for each external device.

External device

CPU I/O I/O I/O I/O

<RS1/2/4 side>

Selection switch of the module is used.

RS-485 station No. selection switch (0 to F)

If RS-485 port is not used, the selection is not

necessary.

Mode selection switch

Device selection of RS-232C port and RS-485

port, Data conversion

RS-485 terminating resistor ON/OFF switch

ON/OFF of terminating resistor is selected.

If RS-485 port is not used, this switch is ignored.

<External device side>

Transmission speed, data length, parity bit, stop bits etc.

Application software for the communication.

1-2

Page 12

1-3 General Purpose Communication Package

for Factory Automation Machine

Nonsequenced FB is provided for NP1L-RS1/2/4 to communicate with external serial devices. (Included in D300win.)

General purpose communication package for Factory Automation machine (NP4N-COMF) is provided to communicate

with specified external serial devices.

NP4N-COMF includes following function blocks.

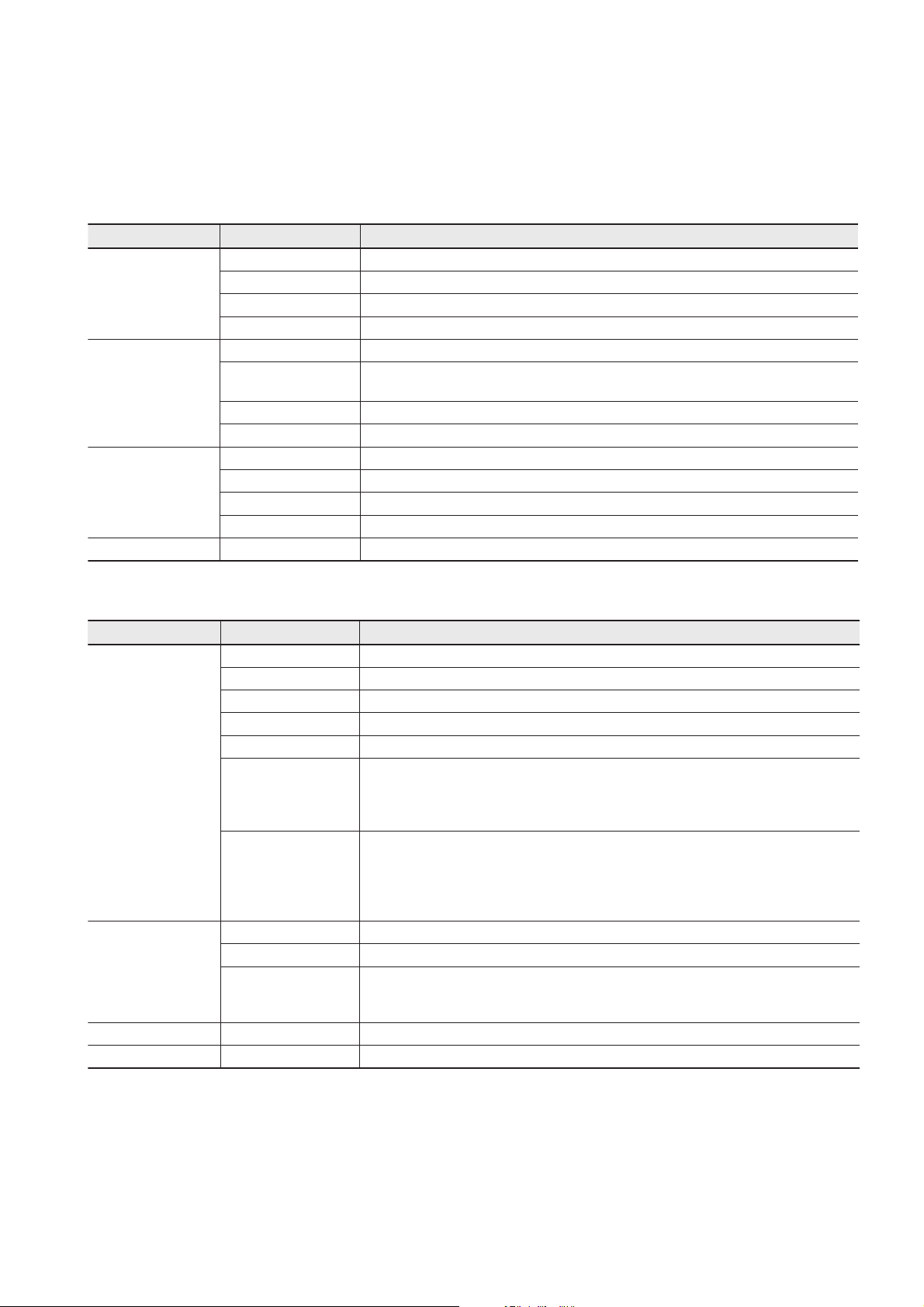

erudecorP emanBF eciveD

XERkrC_ seiresRS-XERAF,D-XER,F-XER.DTL,.OCUOYGOKAKIR

erutarepmeT

rellortnoc

metsysDI

redaeredocraB

SCESSCES_C_ )ylnoI-SCESrof(metsysgnirutcafunamrotcudnocimeserudecorpSCES

XAmoC_ seiresJX5E,XA5ErellortnocerutarepmetlatigiD.noitaroproCNORMO

KCmoC_ seiresKC5ErellortnocerutarepmetlatigiD.noitaroproCNORMO

CDSmyC_ seiresG04/A04CDSrellortnocerutarepmetcinortigiD.noitaroproCekatamaY

6VmoC_seires006V.noitaroproCNORMO

SDhsC_

MAWmyC_ seires021MAWmetsysDIhsiugnitsidedoC.noitaroproCekatamaY

PFziC_ seiresA1PFmetsysreirracataD.NOITAROPROCIMUZICEDI

DCTktC_ seiresVR0023-SMLT,0058/0028DCT.dtL,.oCNEKOHT

CCBdnC_ 007LB,005LB,seires0062CCB.DTL,.OCYRTSUDNICIRTCELENOPPIN

LBykC_seires081LB.NOITAROPROCECNEYEK

SDziC_ seiresSDredaeredocraB.DTL,.OCCIGOLATADIMUZI

seiresSDmetsys

etalpDIevaworciM.NOITAROPROCMETSYSGNIRUTCAFUNAMPRAHS

Note: General purpose communication FB in the table below is included in D300win.

epyT emanBF weivrevOBF

eerf_C_)1etoN(sdrow215:evieceRsdrow215:dneSBFlarudecorp-noN

252rfC_)1etoN(sdrow252:evieceRsdrow252:dneSBFlarudecorp-noN

821rfC_)1etoN(sdrow821:evieceRsdrow821:dneSBFlarudecorp-noN

46rfC_)1etoN(sdrow46:evieceRsdrow46:dneSBFlarudecorp-noN

23rfC_)1etoN(sdrow23:evieceRsdrow23:dneSBFlarudecorp-noN

BFlarudecorp-noN

retrevnIIJUFroF

retaehIJUFroFXYPdfC_)2etoN(seiresHYPdnaseiresXYPretaehIJUFroF

edocrabIJUFroFKPdfC_)2etoN(seires2KPredaeredocrabIJUFroF

rprfC_)1etoN(

2prfC_)2etoN(

NRFdfC_)2etoN(seiresCINERFretrevnIIJUFroF

RVFdfC_)2etoN()SUB-IGF(seires11C-RVFretrevnIIJUFroF

rprvfC_)2etoN(

.eludomehthtiwgnissecorp

.eludomehthtiwgnissecorp

sdrow215:evieceRsdrow215:dneS

sdrow215:evieceRsdrow215:dneS

locotorpnoitacinummocotnitliubhcihwBFerudecorp-noN

noitacinummocehtfotrapagnimrofrepybdecudersiyticapacmargorpehT

locotorpnoitacinummocotnitliubhcihwBFerudecorp-noN

noitacinummocehtfotrapagnimrofrepybdecudersiyticapacmargorpehT

ebnacgnissecorpnoitacinummoc,noitiddanI.eludomehthtiwgnissecorp

.stropegassemsubXSowtgnisuybdeeps-hgihebam

)SUB-IGF(seires11C-RVFretrevnIIJUFroF

noitacinummocehtfotrapagnimrofrepybdecudersiyticapacmargorpehT

Note 1: Refer to Section 4 in this manual.

Note 2: For _Cfrp2, _CfdFRN, _CfdFVR, _Cfvrpr, _CfdPYX, and _CfdPK, refer to “MICREX-SX USER'S MANUAL

STANDARD EXTENDED FB (FEH255).”

1-3

Page 13

1-4 Product Versions and Supported Functions

For the general purpose communication module, supported functions and available FBs depend on the product version.

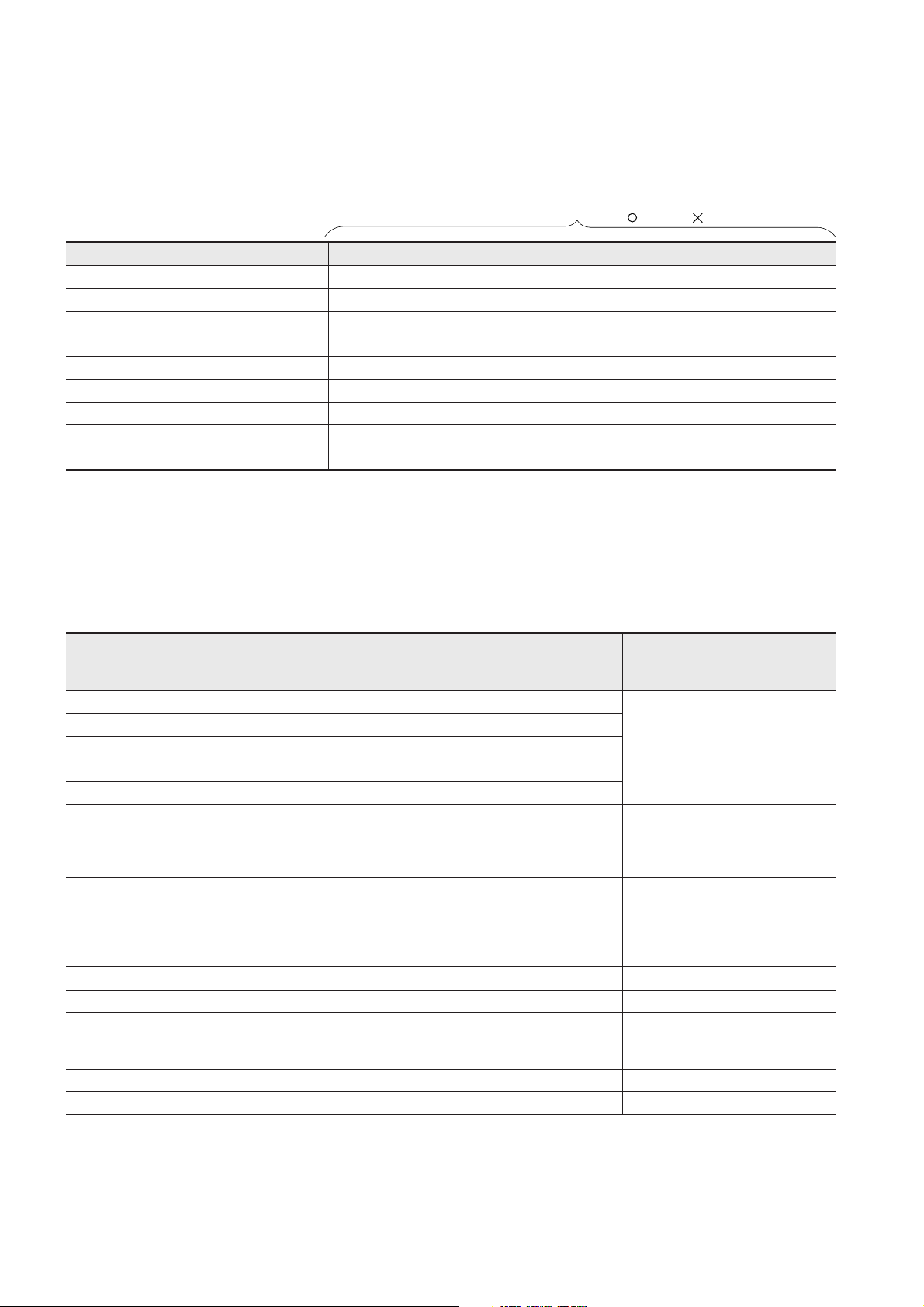

1-4-1 Supported functions

Note 2: : supported : Not supported

noisrevdnatamroF 1noitcnufredaoldesab-medoM 2noitcnufredaoldesab-medoM

1301.V1SR-L1PNnahtreilraExx

1301.V2SR-L1PNnahtreilraExx

1301.V4SR-L1PNnahtreilraE1etoN— 1etoN—

retalro1301.V1SR-L1PNox

retalro1301.V2SR-L1PNox

retalro1301.V4SR-L1PN1etoN— 1etoN—

retalro5352.V1SR-L1PNoo

retalro5352.V2SR-L1PNoo

retalro5352.V4SR-L1PN1etoN— 1etoN—

Note 1: The modem-based loader functions are functions which realize remote operation and programming by connecting

a modem to the RS-232C port and using the public circuit. These functions cannot be used with the NP1L-RS4

which is provided only with the RS-485 port.

Note 2: With modem-based function 1, the transmission rate between this module and a commercial modem is fixed to

19200 bps. With modem-based function 2, the transmission rate can be selected from 9600, 19200, and 38400

bps.

1-4-2 Available standard extended FB

emaNBF weivrevOBF

eerf_C_sdrow215:evieceRsdrow215:dneSBFlarudecorp-noN

252rfC_sdrow252:evieceRsdrow252:dneSBFlarudecorp-noN

821rfC_sdrow821:evieceRsdrow821:dneSBFlarudecorp-noN snoisrevllA

46rfC_sdrow46:evieceRsdrow46:dneSBFlarudecorp-noN

23rfC_sdrow23:evieceRsdrow23:dneSBFlarudecorp-noN

locotorpnoitacinummocotnitliubhcihwBFerudecorp-noN

rprfC_

.eludomehthtiwgnissecorp

2PRfC_

NRFdfC_seiresCINERFretrevnIIJUFroF 1etoNsnoisrevllA

RVFdfC_)SUB-IGF(seires11C-RVFretrevnIIJUFroF 1etoNsnoisrevllA

rprvfC_

.eludomehthtiwgnissecorp

XYPdfC_seiresHYPdnaseiresXYPretaehIJUFroF 1etoNsnoisrevllA

KPdfC_seires2KPredaeredocrabIJUFroF 2etoNsnoisrevllA

sdrow215:evieceRsdrow215:dneS

noitacinummocehtfotrapagnimrofrepybdecudersiyticapacmargorpehT

locotorpnoitacinummocotnitliubhcihwBFerudecorp-noN

sdrow215:evieceRsdrow215:dneS

noitacinummocehtfotrapagnimrofrepybdecudersiyticapacmargorpehT

ebnacgnissecorpnoitacinummoc,noitiddanI.eludomehthtiwgnissecorp

.stropegassemsubXSowtgnisuybdeeps-hgihebam

)SUB-IGF(seires11C-RVFretrevnIIJUFroF

noitacinummocehtfotrapagnimrofrepybdecudersiyticapacmargorpehT

eludom

retalro5352.V

retalro6352.V

noitacinummocesoprup

1etoNretalro6352.V

larenegfonoisrevelbacilppA

Note 1: This FB uses the RS-485 port. Cannot be used with the NP1L-RS2 which is provided only with the RS-232C port.

Note 2: This FB uses the RS-232C port. Cannot be used with the NP1L-RS4 which is provided only with the RS-485 port.

1-4

Page 14

Section 2 Specifications

Page

2-1 General Specifications ............................................................................................... 2-1

2-2 Communication Specifications ................................................................................. 2-2

2-3 Names and Functions................................................................................................. 2-3

2-3-1 Names ................................................................................................................................... 2-3

(1) NP1L-RS1 ............................................................................................................................................... 2-3

(2) NP1L-RS2 ............................................................................................................................................... 2-3

(3) NP1L-RS4 ............................................................................................................................................... 2-4

2-3-2 Functions .............................................................................................................................. 2-4

2-4 Dimensions.................................................................................................................. 2-7

Page 15

General specifications

metI noitacificepS

erutarepmet

egarotS

lacisyhP

latnemnorivne

snoitidnoc

lacinahceM

ecivres

snoitidnoc

lacirtcelE

ecivres

snoitidnoc

noitcurtsnoCepytdetnuom-lenaP

gnilooCgniloocriA

dohtemnoitalosIrelpuocotohP

htgnertscirtceleiD )dnuorgdnasniprotcennocO/Ineewteb(etunim1CAV544

ecnatsisernoitalusnIM01 Ω )dnuorgdnasniprotcennocO/Ineewteb(reggemCDV005htiweromro

ssaM

snoisnemiD4-2nidebircseD

erutarepmet

noitarbiV s/m6.91:noitareleccatnatsnoC,mm51.0:edutilpmaflaH

kcohSs/m741:kaepnoitareleccA

citatsortcelE

egrahcsid

dleifcite

noitpmusnoctnerruclanretnI

tneibmagnitarepO

ytidimuhevitaleRnoitasnednoconHR%59ot02

eergednoitulloP2

ytinumminoisorroC .stnevloscinagrohtiwdeniatstoN.sesagevisorrocmorfeerF

edutitlagnitarepO )eromroaPk07:noitidnoctropsnarT(levelaesevobasselrom0002

ytinummiesioN

-ngamortceleoidaR

55ot0 ° C

07+ot52- ° C

)rotalumis

:egrahcsidlaireA ± Vk8

Section 2 Specifications

2-1 General Specifications

2

2

1htdiweslup,sn1emitesir,)enilnoissimsnartotgnipmalc:Vk1(Vk5.1 µ esion(s

:egrahcsidtcatnoC ± Vk6

)zHM0001otzHM08(m/V01

sselroAm011,CDV42:1SR-L1PN

sselroAm09,CDV42:2SR-L1PN

sselroAm08,CDV42:4SR-L1PN

g071.xorppA:1SR-L1PN

g061.xorppA:2SR-L1PN

g061.xorppA:4SR-L1PN

2-1

Page 16

2-2 Communication Specifications

metI noitacificepS

C232-SR584-SR

epyT

External interface

troP

dohtem

seludom

tolsdeipuccO

1SR-L1PN

2SR-L1PN

—lennahc1

4SR-L1PN

dohtemnoitacinummoC

noitazinorhcnyS

deepsnoissimsnarT

ecnatsidnoissimsnarT

elbatcennocfo.oN

dohtemnoitcennoC

locotorpnoissimsnarT

DELnoitacidnisutatS

lennahc1lennahc1

lennahc1—

sselrom51 )sselrospbk2.91:deepsnoissimsnart(sselromk1

)ecivedlanretxeenO(1:1).xaM(13:1

)elamef(rotcennocnip-9,bus-D)elam(rotcennocnip-9,bus-D

tols1

neerG—gnidneslangiS:DXT

Communication specifications

4SR-L1PN,2SR-L1PN,1SR-L1PN

)1etoN(noitacinummocxelpud-flah

noissimsnartsuonorhcnyspots-tratS

)2etoN(spb00675/00483/00291/0069/0084/0042/0021

)3etoN()slennahc2folatotnisselrospb00675.xam,1SRrof(

.eludomUPCehtni)BF(margorpnoitacilppaehtnosdnepeD

)niw003DnidedulcnI(BFlarudecorp-noN

neerG—gninnuryllamroN:LNO

deR—eludomnoitacinummocesopruplareneG:RRE

deR—rorrenoitacinummoC:MLA

neerG—gniviecerlangiS:DXR

neerG—sisongaid-fleS:2ST,1ST

deR—rorrenoitacinummoC:MLA

neerG—gniviecerlangiS:DXR

neerG—gnidneslangiS:DXT

Note 1: The use of the non-procedural FB allows this mode to be used like the full-duplex mode on applications.

Note 2: Transmission rates 300, 600, 76800, and 115200 bps can be used in the following combinations:

esopruplarenegfonoisreV

eludomnoitacinummoc

retalro5352.V )locotorpni-tliubhtiwBFlarudecorp-noN(rprfC_

retalro6352.V

Note 3: This limitation is applied to RS1 before version V2535.

BFdednetxedradnatS

)noisrevegassem-2,locotorpni-tliubhtiwBFlarudecorp-noN(2prfC_

)locotorpni-tliubhtiwBFerudecorpretrevnI(rprvfC_

2-2

Page 17

Names and functions

2-3-1 Names

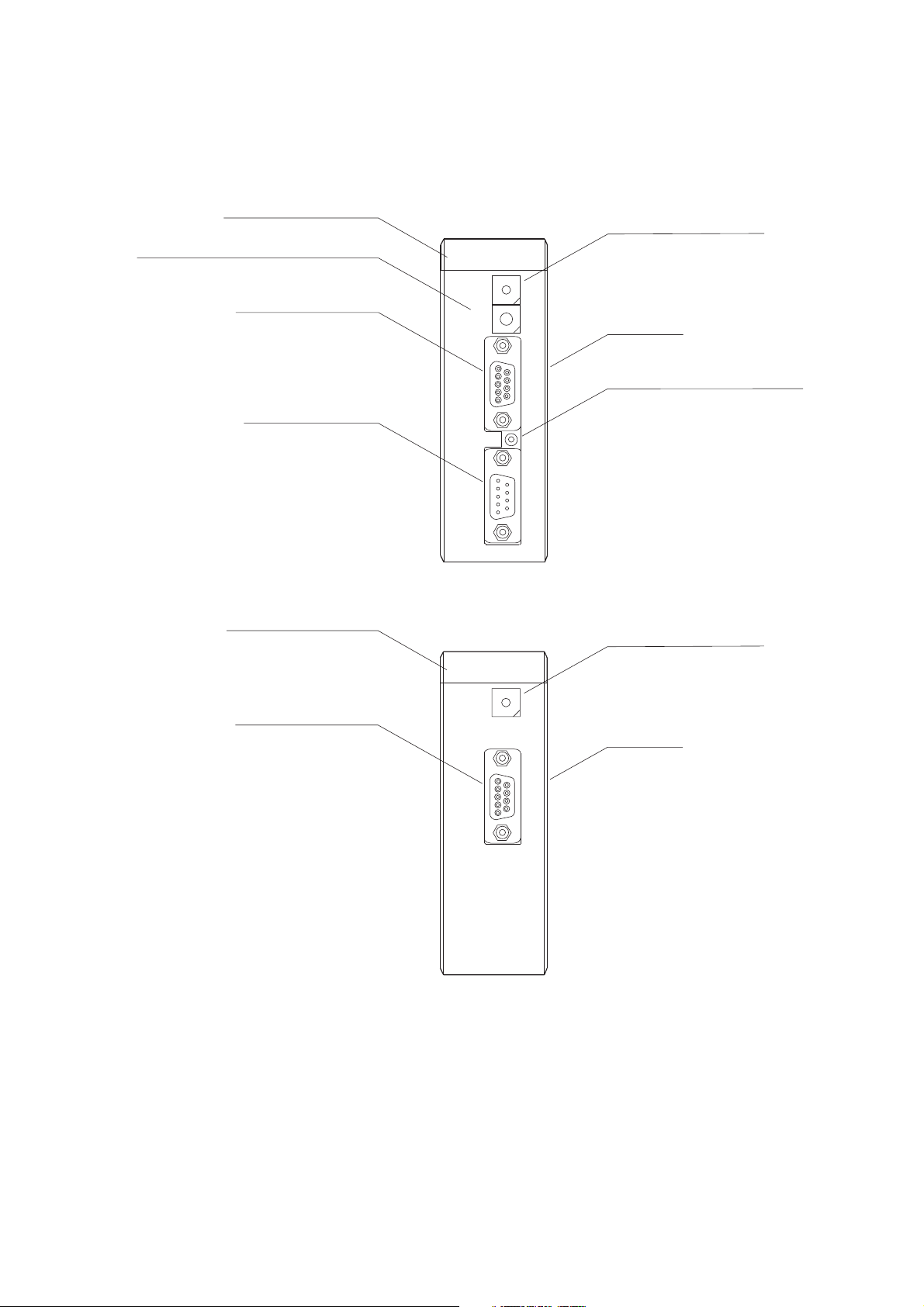

(1) NP1L-RS1

1) Status indication LED

3) RS-485 station No. selection switch

4) RS-232C port

(D-sub, 9-pin, female)

6) RS-485 port

(D-sub, 9-pin, male)

ONL

ERR

RS232C

RS485

TERM.

RS485

No.

(0-F)

RS232 TS1

ALM RXD TXD

RS485

7

6

5

MODE

4

B

A

9

8

7

6

1-2-3

2-3 Names and Functions

2) Mode selection switch

TS2

8

9

0

1

2

3

c

D

E

F

0

1

2

3

5

4

Nameplate

5) RS-485 terminating resistor

ON-OFF switch

(2) NP1L-RS2

1) Status indication LED

4) RS-232C port

(D-sub, 9-pin, female)

RS485

ONL

ERR

RS232C

RS232 TS1

ALM RXD TXD

7

6

5

MODE

4

2) Mode selection switch

TS2

8

9

0

1

2

3

Nameplate

2-3

Page 18

2-3 Names and Functions

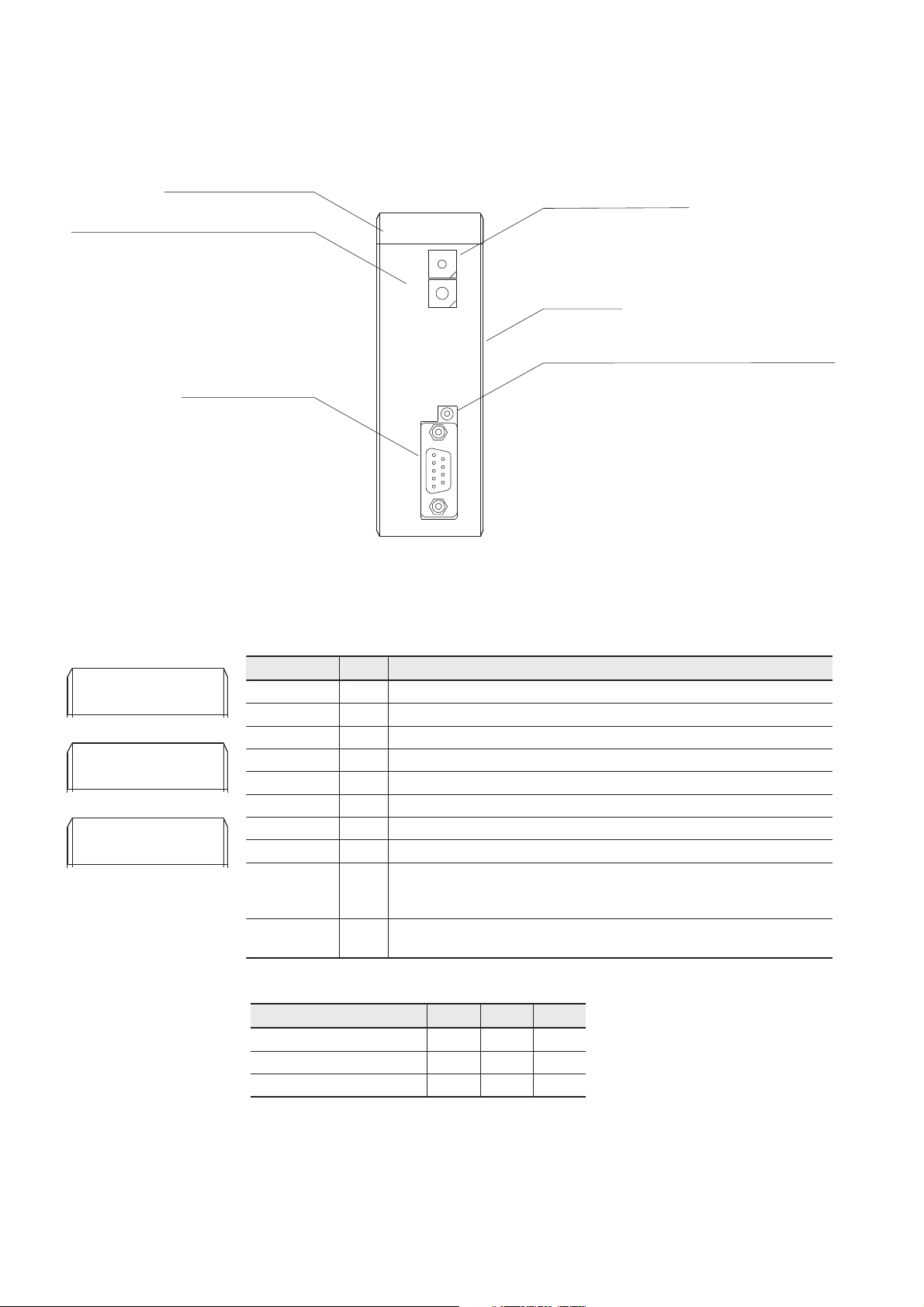

(3) NP1L-RS4

1) Status indication LED

3) RS-485 station No. selection switch

6) RS-485 port

(D-sub, 9-pin, male)

ONL

ALM RXD TXD

ERR

MODE

RS485

No.

(0-F)

RS485

TERM.

RS485

1-2-3

RS485

Names and functions

2) Mode selection switch

TS1

TS2

8

7

9

6

0

5

1

4

2

3

c

D

B

E

A

F

9

0

8

1

7

2

6

3

5

4

Nameplate

5) RS-485 terminating resistor ON-OFF switch

2-3-2 Functions

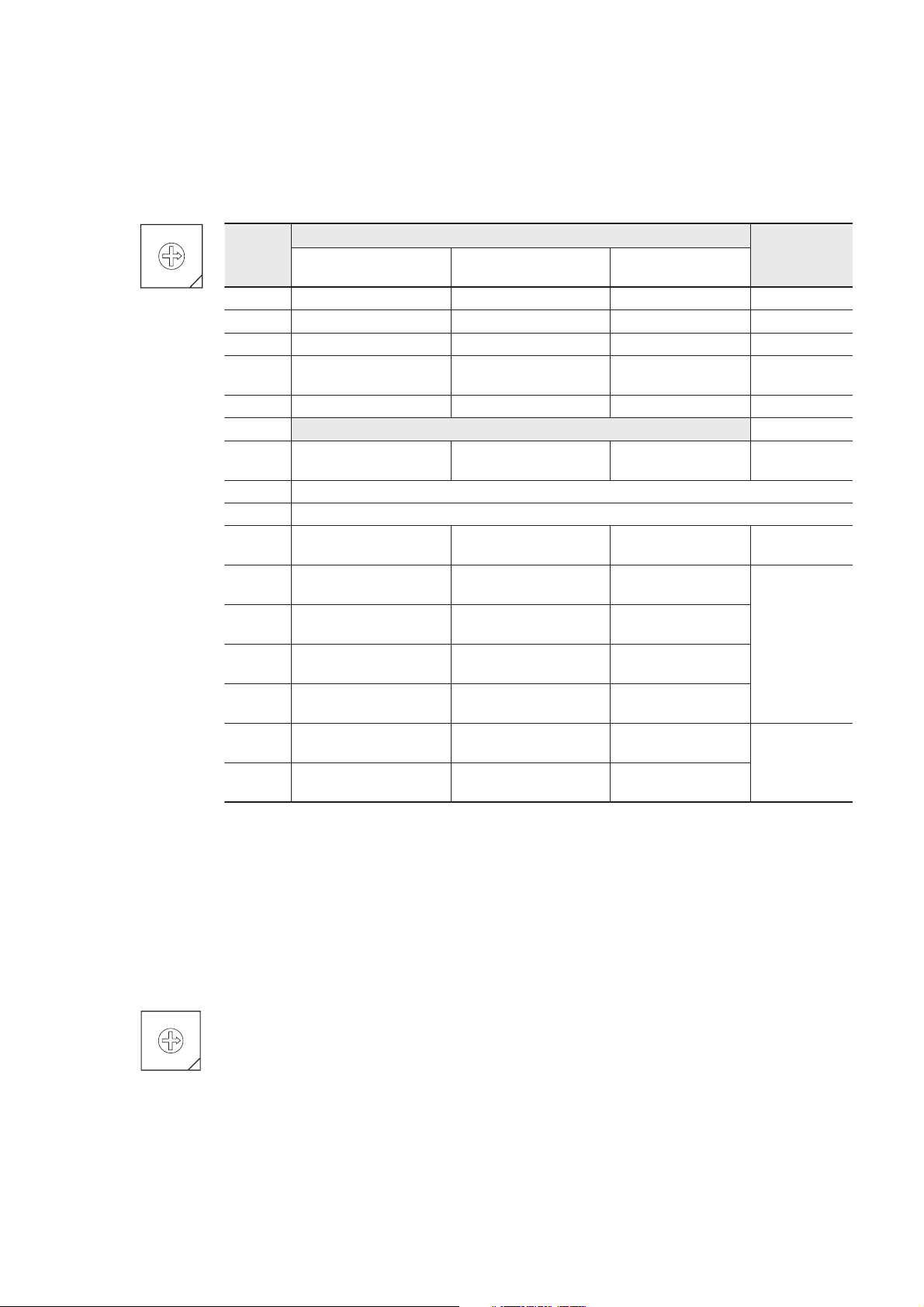

1) Status indication LED

This LED indicates the running status of NP1L-RS1/2/4.

NP1L-RS1

ONL

ALM RXD TXD

ERR

NP1L-RS2

ONL

ALM RXD TXD

ERR

NP1L-RS4

ONL

ALM RXD TXD

ERR

RS232 TS1

RS485

RS232 TS1

RS485

TS2

TS2

TS1

TS2

lobmyS roloC noitpircseD

LNOneerG .subXSehthtiwetacinummocotydaersieludomehtnehwnosnruT

RREdeR.lamronbasieludomehtnehwnosnruT

MLAC232SRdeR.lamronbasiC232-SRaivatadnoitacinummocehtnehwnosnruT

DXRC232SRneerG.atadgniviecersitropC232-SRehtnehwnosnruT

DXTC232SRneerG.tropC232-SRehtmorftnesgniebsiatadnehwnosnruT

MLA584SRdeR.lamronbasi584-SRaivatadnoitacinummocehtnehwnosnruT

DXR584SRneerG.atadgniviecersitrop584-SRehtnehwnosnruT

DXT584SRneerG.trop584-SRehtmorftnesgniebsiatadnehwnosnruT

1STneerG

2STneerG

eludomfotluaflataFFFONO —

eludomfotluaflatafnoNNONO —

rorreataDNOFFONO

.7edomsisongaid-flesnidetcetedsirorreMARlanretninehwsknilB

sisongaid-flesnilamronbasitsetkcabgninrutC232-SRnehwsknilB

)rorrekcab-gninrutSTC-TSR(.8edom

sisongaid-flesnilamronbasitsetkcabgninrutC232-SRnehwsknilB

)rorrekcab-gninrutRSD-RTD(.8edom

sutatseludomybsutatsDELfoelpmaxE*

LNO RRE MLA

2-4

Page 19

Functions

2-3 Names and Functions

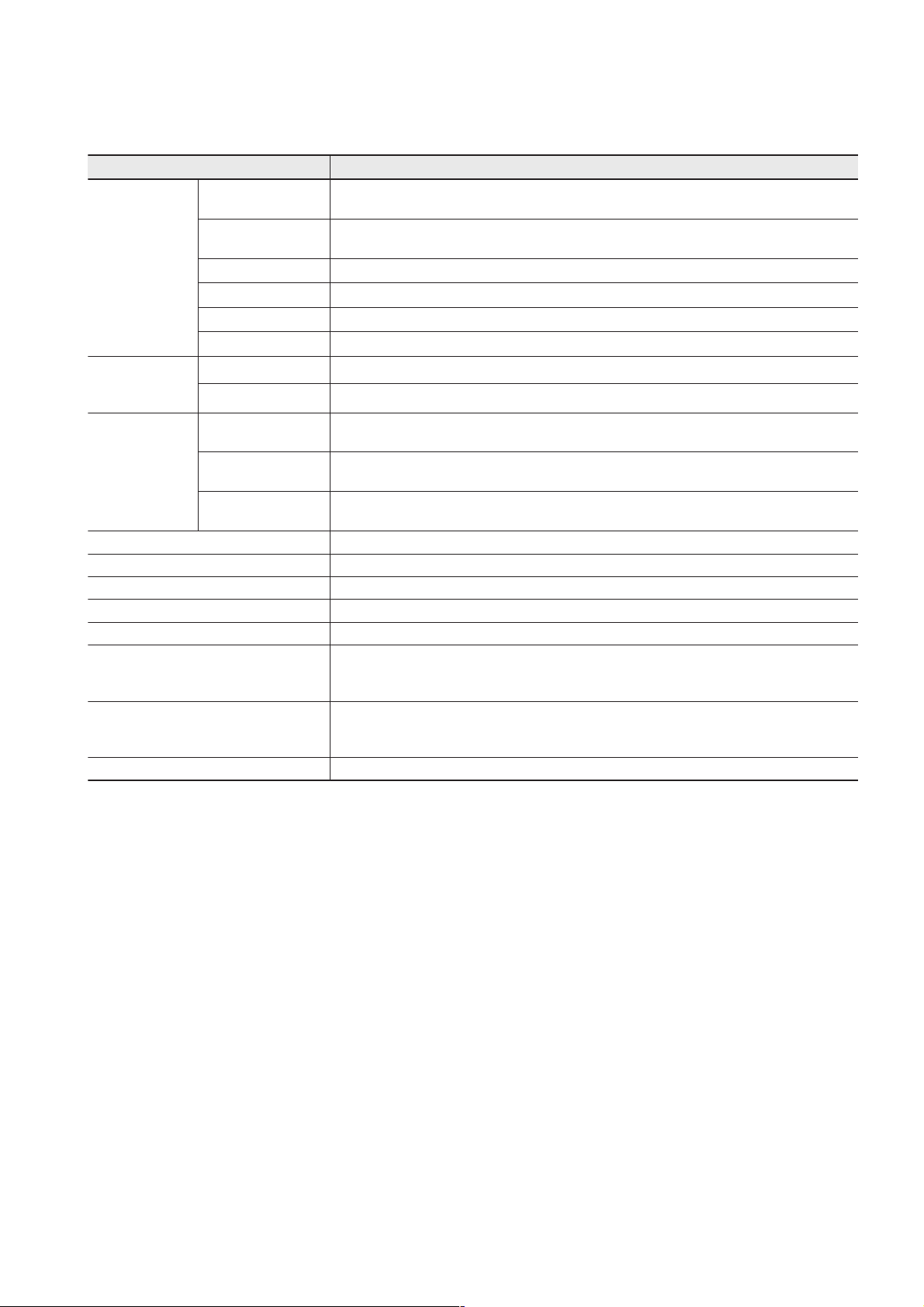

2) Mode selection switch

This switch is used to select a connectable device, the signal conversion and the self-diagnosis for the RS-232C port and

the RS-485 port.

C

MODE

D

B

E

A

F

9

8

7

6

3

5

4

Switch

0

1

2

No.

Mode

RS-232C port RS-485 port

RS-232C <=> RS-485

Signal conversion

Remarks

0 General purpose device General purpose device Not available

1 Programming loader General purpose device Not available

2 General purpose device Programming loader Not available

3 Programming loader Programming loader Not available

Applies to

V2535 or later.

4 General purpose device General purpose device Available

5

Not used

6

Modem-loder

19200 bps

General purpose device Not available

Applies to

V1031 or later.

7 Self-diagnosis mode 1 (diagnoses internal memory and LED)

8 Self-diagnosis mode 2 (diagnoses RS-232C, RS-485 turning back)

Modem-loder

9

19200 bps

Modem-loder

A

9600 bps

Modem-loder

B

9600 bps

Modem-loder

C

38400 bps

Modem-loder

D

38400 bps

Modem-loder

E

76800 bps

(Note 5)FModem-loder

115200 bps

Programming loader Not available

General purpose device Not available

Programming loader Not available

General purpose device Not available

Programming loader Not available

General purpose device Not available

Modem-loder

115200 bps

—

Applies to

V1031 or later.

Applies to

V2535 or later.

Applies to

V2536 or later.

Note 1: For details of the function mode, refer to “3-2 System configuration.”

Note 2: For the self-diagnosis, refer to “3-4 Self-diagnosis.”

Note 3: “Programming loader” is the mode for connecting to D300win. Communication specifications are fixed to” 38400

bps” for transmission speed, “8 bits” for data length, “1 bit” for stop bits, and “even” for parity.

Note 4: “Modem-loader" is the mode that is basically used to connect to D300win loader via a modem. In general, for

modems, “none” is specified for parity. Therefore, in this mode, communication specifications become “8 bits” for

data length, “1 bit” for stop bits, and “none” for parity.

Note 5: Either channel is selected and used.

3) RS-485 station No. selection switch

This switch used to select a RS-485 station number of NP1L-RS1 or NP1L-RS4. Selecting range is 0 to F.

C

D

B

E

A

RS485

No.

(0-F)

F

9

0

8

1

7

2

6

3

5

4

2-5

Page 20

2-3 Names and Functions

Functions

4) RS-232C port

This port is D-sub, 9-pin connector (female). This connector is connected to D-sub, 9-pin connector (male).

niP

.oN

1

5

6

9

1DC==<tcetedreirraC

2DR==<atadevieceR

3DS>==ataddneS

4RE>==ydaerlanimretataD

emanlangiS ecivedlanretxeot2/1SRnoitceridlangiS noitpircseD

5GS )nruternommoc(dnuorglangiS

6RD==<ydaertesataD

M2.6

Screw

7SR>==dnesottseuqeR

8SC==<dnesotraelC

9IR==<noitacidnillaC

5) RS-485 terminating resistor ON/OFF switch

This switch used to select the ON/OFF of the RS-485 terminating resistor. There are three positions for this switch.

noitisophctiwS sutatS

tfeL.elbaliavasirotsisergnitanimreT,epyteriw-2

retneC.elbaliavatonsirotsisergnitanimreT

thgiR.elbaliavasirotsisergnitanimreT,epyteriw-4

6) RS-485 port

This port is D-sub, 9-pin connector (male). This connector is connected to D-sub, 9-pin connector (female).

niP

.oN

emanlangiS ecivedlanretxEot4/1SRnoitceridlangiS noitpircseD

1BDS>==)-(enillangisataddneS

5

9

2ADS>==)+(enillangisataddneS

3)BDS(>==))-(enillangisataddneS(

1

6

4)ADS(>==))+(enillangisataddneS(

5GS )nruternommoc(dnuorglangiS

6GFdnuorgemarF

7

M2.6

Screw

8BDR==<)-(BenillangisatadevieceR

9ADR==<)+(AenillangisatadevieceR

Note: For wiring, refer to “6-2 Wiring.”

2-6

Page 21

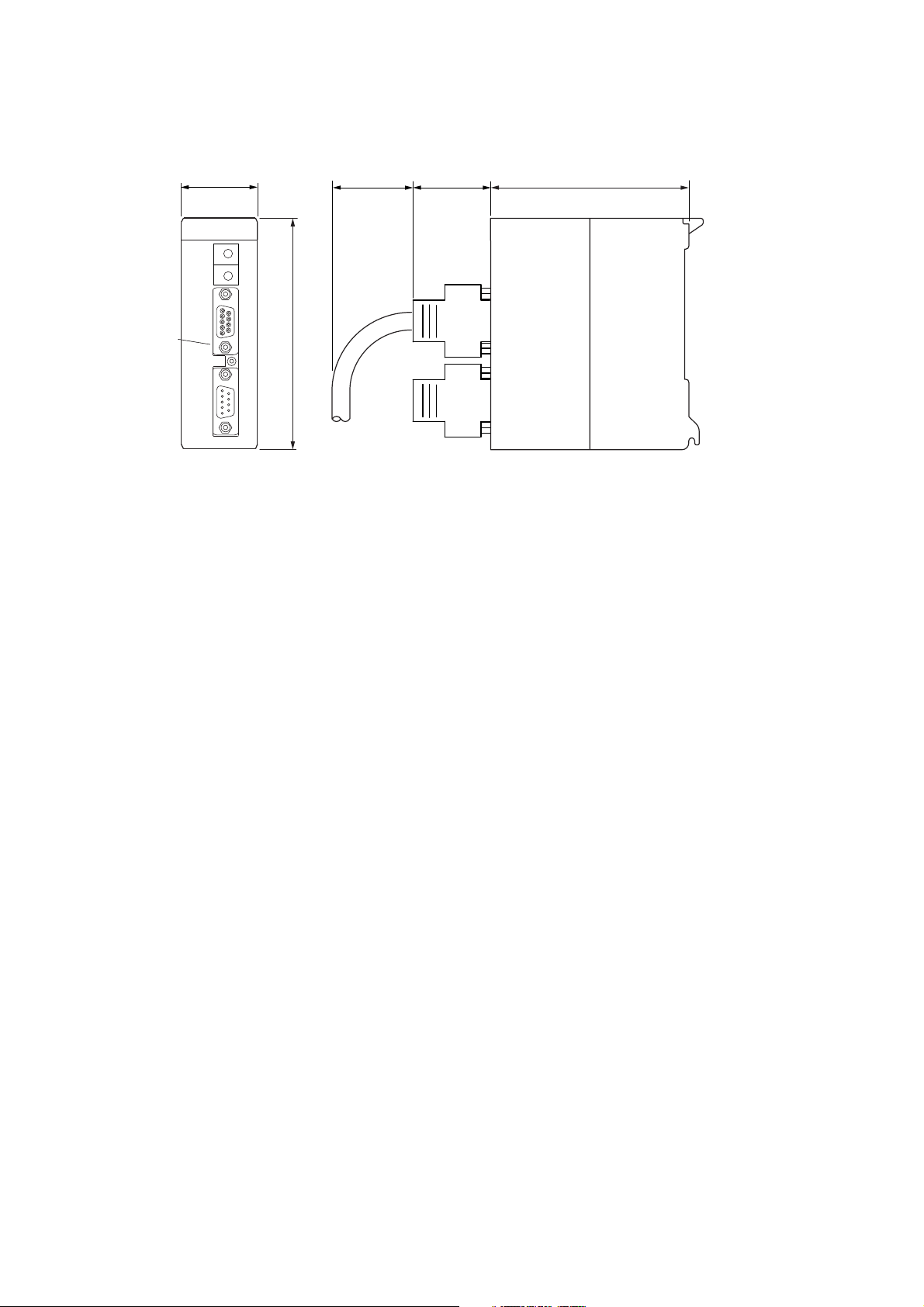

Dimensions

Dimensions are same for NP1L-RS1,NP1L-RS2 and NP1L-RS4.

35

(90)

(37)

2-4 Dimensions

90

(Note)

105

Note: Front formation depends on each type.

2-7

Page 22

Section 3 System Configuration

Page

3-1 Mounting Restrictions ................................................................................................ 3-1

3-1-1 Mounting position .................................................................................................................. 3-1

3-1-2 Number of mountable modules ............................................................................................. 3-1

3-2 System Configurations............................................................................................... 3-2

3-2-1 1:1 Connection using RS-232C port ..................................................................................... 3-2

3-2-2 1:N Connection using RS-485 port (N = max. 31 modules) .................................................. 3-3

3-2-3 Connecting independently to RS-232C and RS-485 ports ................................................... 3-4

3-2-4 Connection using RS-232C and RS-485 ports (2) ................................................................ 3-5

3-2-5 Connecting a personal computer loader to the RS-232C port and RS-485 port .................. 3-7

3-2-6 Loader network configuration using RS-485 ......................................................................... 3-7

3-2-7 Loader network configuration using modems (1) .................................................................. 3-8

3-3 Loader Connecting Cable .......................................................................................... 3-9

3-3-1 When connecting to RS-232C port ....................................................................................... 3-9

3-3-2 When connecting to RS-485 port .......................................................................................... 3-9

3-4 Self-diagnosis ........................................................................................................... 3-10

3-4-1 Self-diagnosis mode 1 ........................................................................................................ 3-10

3-4-2 Self-diagnosis mode 2 ........................................................................................................ 3-11

(1) RS to CS signal check .......................................................................................................................... 3-11

(2) ER to DR signal check .......................................................................................................................... 3-11

(3) RS-232C/RS-485 data check................................................................................................................ 3-11

(4) Preservation of the result of the check.................................................................................................. 3-11

Page 23

Mounting restrictions

Section 3 System Configuration

3-1 Mounting Restrictions

3-1-1 Mounting position

NP1L-RS1/2/4 is a general purpose communication module which is connected to the SX bus of MICREX-SX series. The

mounting position on the base board is restricted as follows:

They can be mounted in any slot except those for the power supply module (the two slots from the left on the base board).

<Base board other than 6-slots base board>

<6-slots base board>

Mountable slots

Note: The general purpose communication modules cannot be mounted on T-link or OPCN-1 slave station base boards.

Power

supply

T-link master module

CPU

Mountable slots

T-link interface module

I/O I/O I/O I/O

Power

supply

3-1-2 Number of mountable modules

A maximum of 16 modules per configuration can be connected. However, when other communication related modules are

used in the same configuration, the maximum number of 16 is the total of these and NP1L-RS1/2/4 modules.

P-link module (NP1L-PL1)

PE-link module (NP1L-PE1)

FL-net (OPCN-2) module (NP1L-FL1)

General purpose communication module (NP1L-RS1/2/4)

PC card interface module (NP1F-PC2)

Memory card interface module (NP1F-MM1)

Maximum of 16 modules per configuration.

3-1

Page 24

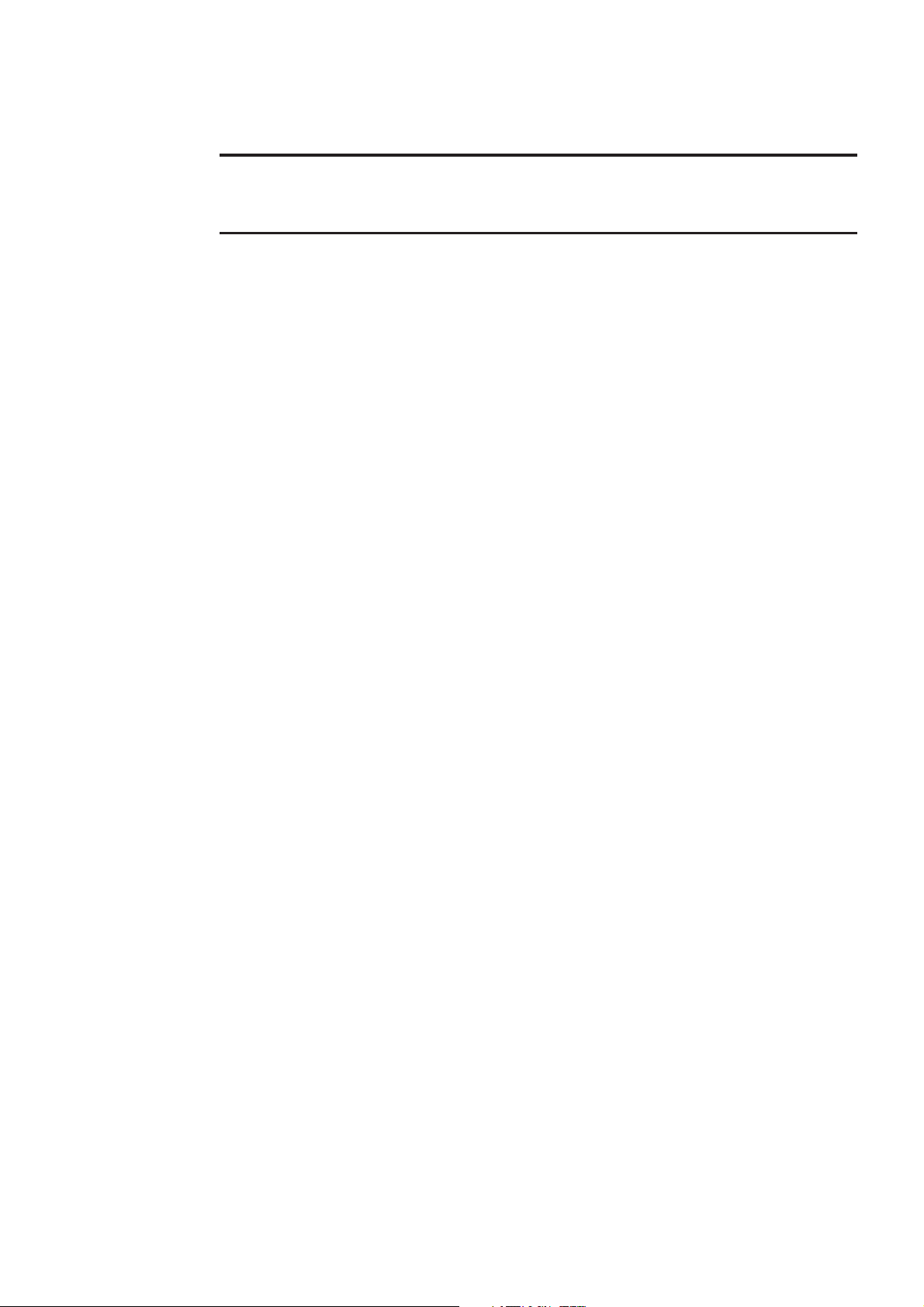

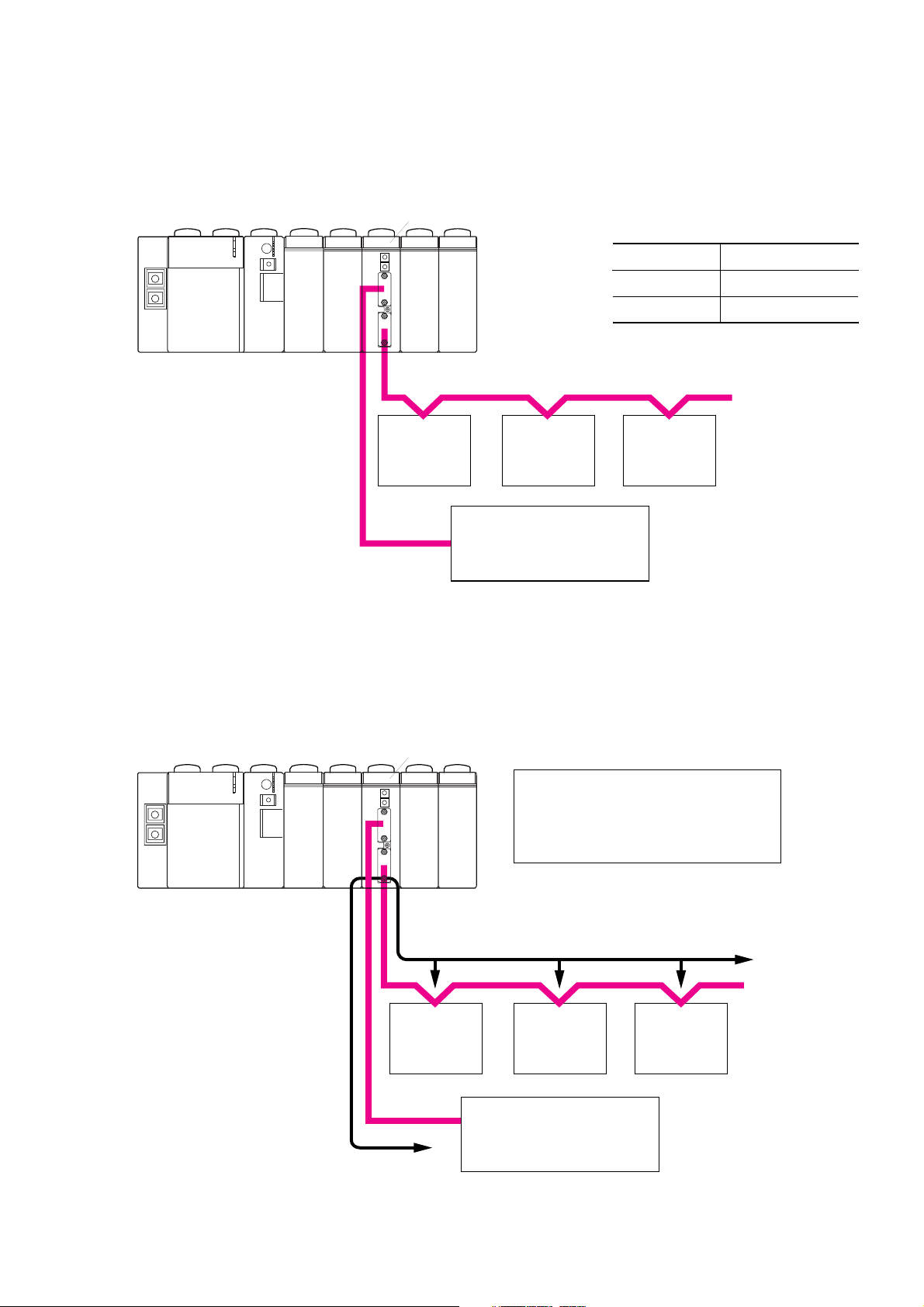

3-2 System Configurations

3-2-1 1:1 Connection using RS-232C port

This configuration connects to an external device having an RS-232C interface via the RS-232C port.

The mode selection switch is set to “0” (zero).

RS1 or RS4

<Mode selection switch: “0”>

RS-232C port

1: 1 connection

General purpose device

Power

supply

CPU

RS-485 port

Signal conversion

General purpose device

None

RS-232C

External device

* With RS1, a D300win personal computer loader can be connected to an RS-485 port which is not used.

In this case, the mode selection switch needs to be set to “2.”

RS1

<Mode selection switch: “2”>

General purpose device

Loader

None

Power

supply

CPU

RS-485

RS-232C port

RS-485 port

Signal conversion

RS-232C

External device

For the connection, refer to “3-3-2 When

connecting to RS-485 port.”

3-2

Page 25

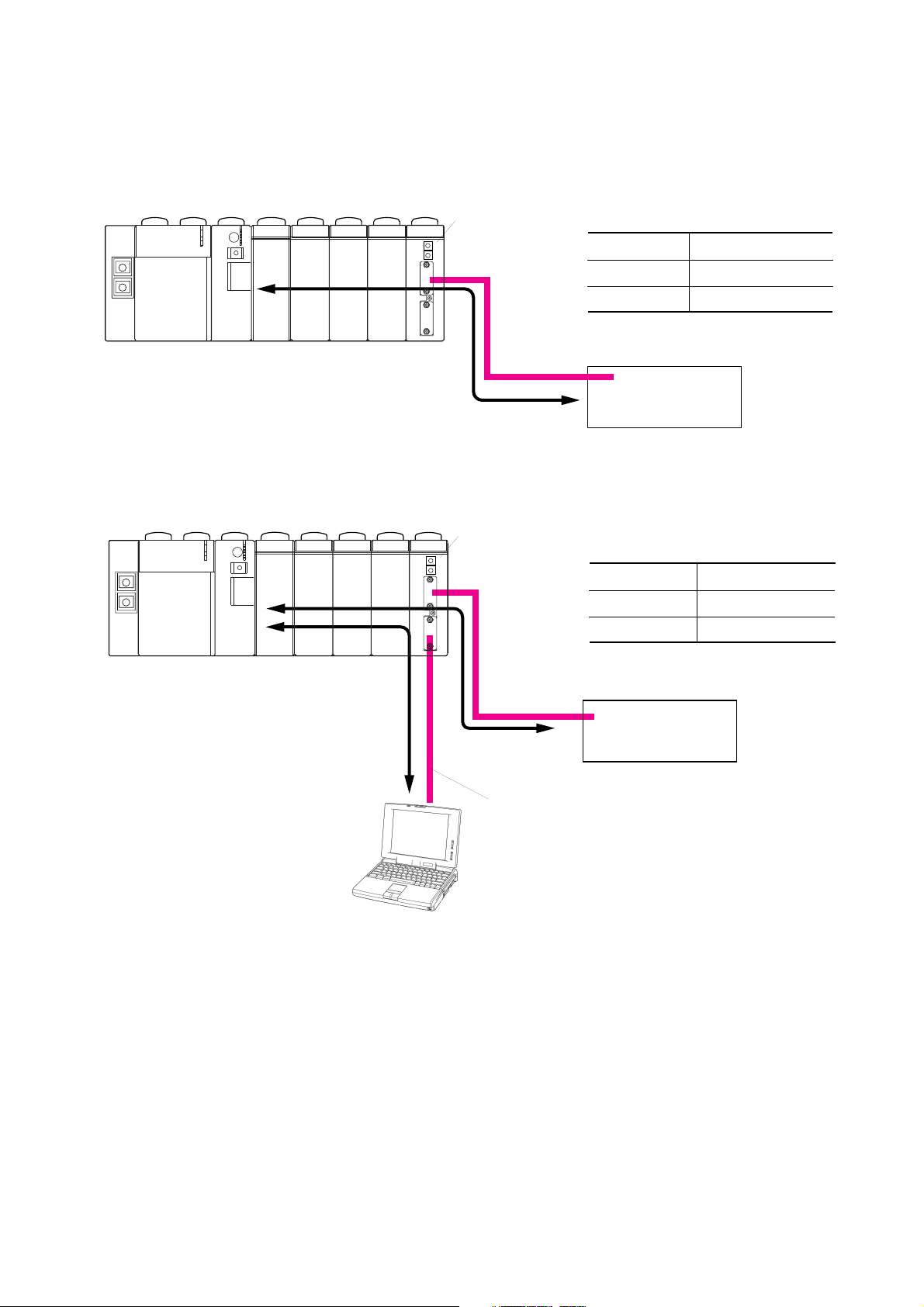

1: N connection

3-2 System Configurations

3-2-2 1:N Connection using RS-485 port (N = max. 31 modules)

This configuration connects to external devices having an RS-485 interface via the RS-485 port. The mode selection

switch is set to “0.” A maximum of 31 external devices can be connected. However, when all external devices are RS1 or

RS4, the maximum number is limited to 15 because only 0 to F are available for addressing.

RS1 or RS4

<Mode selection switch: “0”>

Power

supply

CPU

RS-232C port

RS-485 port

Signal conversion

RS-485

General purpose device

General purpose device

None

External device External device External device

ABC

Note: External devices A , B and C must be the same in type as well

as communication protocol. For example, this connection is not

available when A and B are temperature controllers and C is a

bar code reader.

* With NP1L-RS1, a D300win personal computer loader can be connected to an RS-232C port which is not in use.

In this case, the mode selection switch needs to be set to “1.”

RS1

<Mode selection switch: “1”>

Loader

General purpose device

None

Power

supply

CPU

RS-232C

RS-232C port

RS-485 port

Signal conversion

RS-485

External device External device External device

ABC

For the connection, refer to “3-3-1 When

connecting to RS-232C port.”

3-3

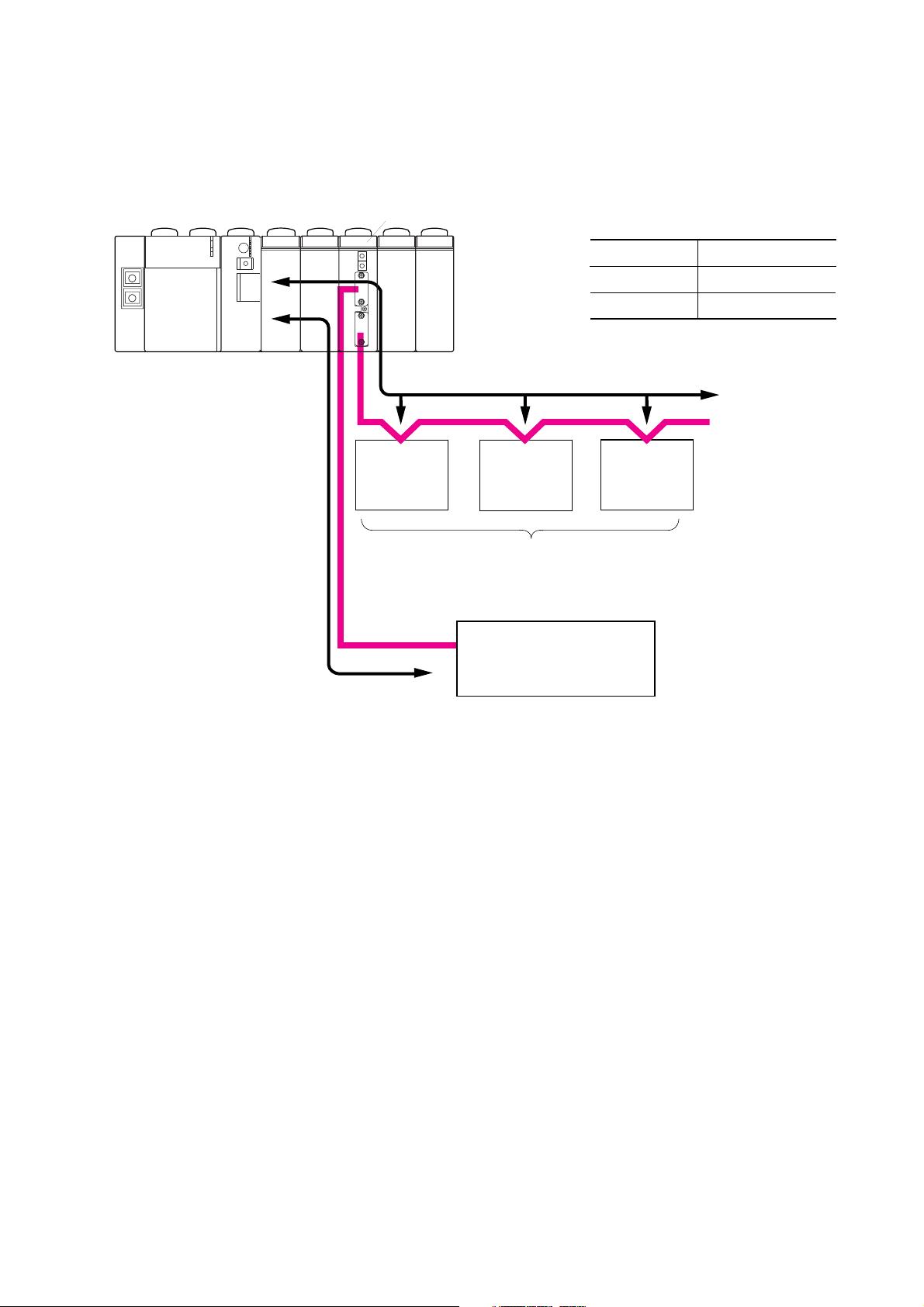

Page 26

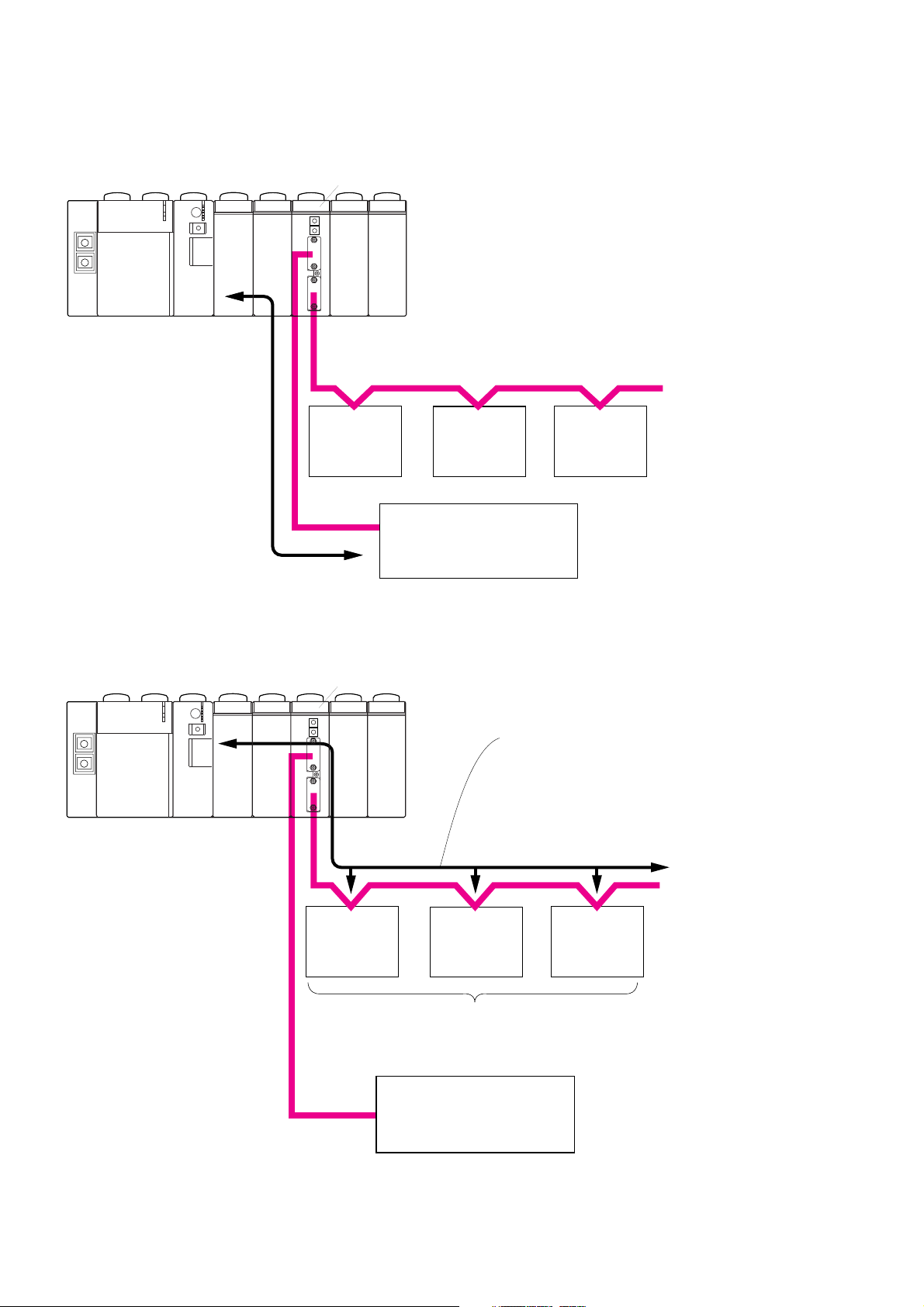

3-2 System Configurations

1: 1 / 1: N connection

3-2-3 Connecting independently to RS-232C and RS-485 ports

This configuration connects to external devices using the RS-232C port and RS-485 port. In this case, communication

through these ports is performed independently.

Power

supply

RS1

CPU

RS-485

<Mode selection switch: “0”>

RS-232C port

RS-485 port

Signal conversion

General purpose device

General purpose device

None

External device

ABC

Note: External devices A , B and C must be the same in type as well

as communication protocol. For example, this connection is not

available when A and B are temperature controllers and C is a

bar code reader.

RS-232C

External device External device

External device

3-4

Page 27

1: 1 / 1: N connection

3-2 System Configurations

3-2-4 Connection using RS-232C and RS-485 ports (2)

This configuration connects to external devices using the RS-232C port and RS-485 port.

RS1

Power

supply

CPU

External device

External device External device

BCD

RS-232C

External device

(personal computer, etc.)

With this configuration, the following communications can be performed :

1) Communication between external device A and external device B, C or D (not via the CPU module)

2) Communication between external device A and CPU module

3) Communication between external device B, C or C and CPU module

<Mode selection switch: “0”>

RS-232C port

RS-485 port

Signal conversion

RS-485

A

General purpose device

General purpose device

Yes

<1) Communication between external device A and external device B, C or D>

This communication is performed directly, namely not via the CPU module.

RS1

Transmission speed is 38400 bps (default) for

both RS-232C and RS-485. Changing

transmission speed is done through the user

Power

supply

CPU

program (expansion FB).

RS-485

External device

External device External device

BCD

RS-232C

External device

(personal computer, etc.)

A

3-5

Page 28

3-2 System Configurations

<2) Communication between external device A and the CPU module>

RS1

1: 1 / 1: N connection

Power

supply

CPU

RS-485

External device

B

External device External device

C

RS-232C

External device A

(personal computer, etc.)

(Note)

<3) Communication between external device B, C or D and the CPU module>

RS1

D

Note: A user program for

controlling external

device A is necessary.

Power

supply

CPU

Note: When the station number designated in the

send data is the same as the setting of the

RS-485 station number setting switch of RS1,

FB in the CPU module receives the data.

RS-485

External device

External device External device

BCD

Note: External devices A, B and C must be the same in type as well as

communication protocol. For example, this connection is not available

when A and B are temperature controllers and C is a bar code reader.

RS-232C

External device A

(personal computer, etc.)

3-6

Page 29

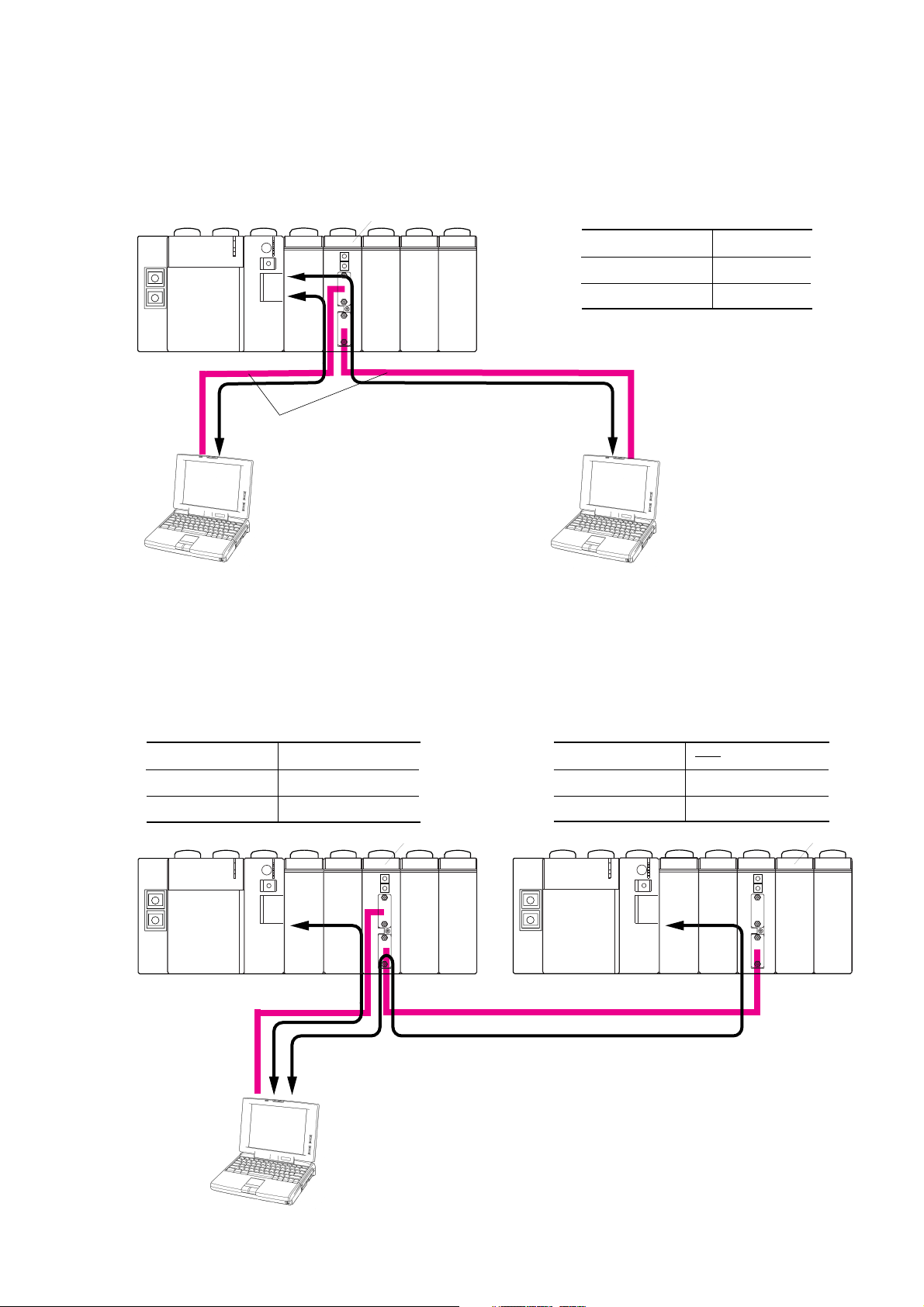

1: 1 / 1: N connection

3-2 System Configurations

3-2-5 Connecting a personal computer loader to the RS-232C port and RS-485 port

This configuration connects a D300win personal computer loader to each of RS-232C and RS-485 ports.

Power

supply

RS1

CPU

RS-232C

<Mode selection switch: “3”>

RS-232C port

RS-485 port

Signal conversion

RS-485

Loader

Loader

None

For the connection, refer to

“3-3 Loader Connecting Cable.”

3-2-6 Loader network configuration using RS-485

This configuration connects a D300win personal computer loader to the RS-232C port of RS1 on System 1.

A D300win can communicate with both CPUs of System 1 and System 2.

<Mode selection switch of System 1: “5”>

RS-232C port

RS-485 port

Signal conversion

Power

supply

Loader

General device/loader

Yes

CPU

RS-232C

<Mode selection switch of System 2: “2”>

RS-232C port

Loader

Normal

RS1

RS1

RS-485 port

Signal conversion

Power

supply

CPU

RS-485

• When connected to the CPU of System 1, designate, from the

programming loader, the CPU which is in the configuration.

• When connected to the CPU of System 2, designate, from the

programming loader, the RS-485 station number of RS1 on System 2.

3-7

Page 30

3-2 System Configurations

Modem connecting

3-2-7 Loader network configuration using modems (1)

This configuration enables remote programming using the public circuit by connecting a modem to the RS-232C port.

RS1 or RS2

When the NP1L-RS1 is used and the mode

Power

supply

CPU

selection switch is set to 6, A, or C,

general purpose devices can be

connected to the RS-485 port.

RS-232C

Straight

cable

External device

*

Modem

Modem

Set with

D300win.

RS-485

External device External device

ABC

Modem setup is made using "WINDOWS Hyper Terminal and

other application software" with the following communication mode:

Stop bit: 1 Data length: 8 bits Parity: None

Baud rate: 9600/19200/38400/76800/115200

(set by the mode selection switch of this module)

Issue AT commands to perform the following:

Restore the setup of the current value area to "Factory Setup."

Do not perform the flow control.

Set the number of rings until automatic receive of the modem to 3.

Do not return the response code.

Write the current modem setup condition to PROFILE(1).

Use the contents of PROFILE(1) as the setup used when the power

is turned ON.

Example: AT&F&K0S0=3Q1&W0&Y0

Note: For details, refer to the instruction manual supplied

with the modem used.

3-8

Page 31

Loader connecting

To connect a D300win personal computer loader to the RS-232C or RS-485 port of the general purpose communication

module, the cable must be connected in the following manner.

3-3 Loader Connecting Cable

3-3-1 When connecting to RS-232C port

Because the RS-232C connector of the general purpose communication module is “female,” attach the male connector

onto the cable connector for the general purpose communication module, as shown in the figure below:

General purpose communication module side Personal computer side

9-pin D-sub connector (male) 9-pin D-sub connector (female.)

CD

RD

SD

ER

SG

DR

RS

CS

RI

1)

2)

3)

4)

5)

6)

7)

8)

9)

1)

2)

3)

4)

5)

6)

7)

8)

9)

CD

RD

SD

ER

SG

DR

RS

CS

RI

3-3-2 When connecting to RS-485 port

Because the RS-485 connector of the general purpose communication module is “male,” attach the female connector onto

the cable connector for the general purpose communication module, as shown in the figure below:

General purpose communication module Personal computer side

9-pin D-sub connector (female) 9-pin D-sub connector (female)

SDB

SDA

(SDB)

(SDA)

SG

FG

RDB

RDA

1)

2)

3)

4)

5)

6)

7)

8)

9)

RS-485/RS-232C converter

RXRX+

TXTX+

1)

2)

3)

4)

5)

6)

7)

8)

9)

CD

RD

SD

ER

SG

DR

RS

CS

RI

For conversion from RS-232C to RS-485

port on personal computer, use a

commercially available converter.

3-9

Page 32

3-4 Self-diagnosis

3-4-1 Self-diagnosis mode 1

Setting the mode selection switch of the module to “7” activates Self-diagnosis Mode “1.”

This mode is used to check the internal memory and the lighting condition of LEDs.

<Diagnosis flow>

Start Set the mode selection switch to “7.”

Check the internal

memory of general

purpose communication

module.

Self-diagnosis

Normal?

Yes

Repeat Self-diagnosis

Mode operations when

there is no change in the

status of the mode

selection switch.

1) Internal memory check

After the completion of LED lighting check, automatically returns to the diagnosis of the internal memory of general

purpose communication module.

If an internal memory error is detected, “TS1” blinks.

2) LED lighting check

Of the external LEDs of the module, the lighting condition of those operated by the general purpose communication

module are checked. When the mode selection switch is set to “7,” “TS1,” “TS2,” “RS-485 ALM” and “RS-232C ALM” LEDs

light up in this order.

<Normal lighting condition of LEDs>

TS1

TS2

Check the lighting

of LEDs.

No

TS1 blinks (0.25s)

Continue to blink if RAM error

is detected, and the check of

LED lighting condition will not

be executed.

RS485 ALM

RS232C ALM

1s

1s 10s

1s

1s

3-10

Page 33

Self-diagnosis

3-4 Self-diagnosis

3-4-2 Self-diagnosis mode 2

This mode is used to check the completeness of communications by looping back sent data and control signals via the

communication port.

(1) RS to CS signal check

In this check, the general purpose communication module turns RS signal ON to check whether CS signal is looped back

and turns ON, and then checks that this signal turns OFF.

When normal, “TS2” lights up; proceeds to step (2).

If abnormal, “TS2” blinks (at 0.5-second intervals) after 5 seconds; proceeds to step (2).

(2) ER to DR signal check

In this check, the general purpose communication module turns ER signal ON to check whether DR signal is looped back

and turns ON, and then checks that this signal turns OFF.

When normal, “TS1” lights up; proceeds to step (3).

If abnormal, “TS1” blinks (at 0.5-second intervals) after 5 seconds; proceeds to step (3).

(3) RS-232C/RS-485 data check

The general purpose communication modules sends 16 bytes of data once and checks the looped back data received.

If both ports are normal, “RS-232C ALM” and “RS-485 ALM” light up; proceeds to step (4).

If RS-485 is abnormal, “RS-232C ALM” lights up after 10 seconds and “RS-485 ALM” blinks (at 0.5-second intervals);

proceeds to step (4).

If RS-232C is abnormal, “RS-232C ALM” blinks (at 0.5-second intervals) after 10 seconds and “RS-485 ALM” lights up (at

0.5-second intervals); proceeds to step (4).

If both ports are abnormal, “RS-232C ALM” and “RS-485 ALM” blinks (at 0.5-second intervals); proceeds to step (4).

(4) Preservation of the result of the check

After 10 seconds of displaying the results from (3) above, the module returns to step (1). Here, if the setting of the mode

selection switch has been changed, Self-diagnosis Mode 2 is ended to enter the designated mode.

Note 1: When an RS-232C dedicated module (NP1L-RS2) is used, “RS-485 ALM” is kept turned off. When an RS-485

dedicated module (NP1L-RS4) is used, “RS-232C ALM,” “TS1” and “TS2” are kept turned off.

Note 2: When judged as “normal,” the next operation is started without any waiting time. Therefore, after all LEDs have

turned off at the start of diagnosis, the corresponding LED lights up instantaneously.

<RS-232C loop-back connector>

Pin No.

CD

RD

SD

ER

SG

DR

RS

CS

1)

2)

3)

4)

5)

6)

7)

8)

9)RI

<RS-485 loop-back connector>

Pin No.

SDB

SDA

(SDB)

(SDA)

SG

FG

RDB

RDA

1)

2)

3)

4)

5)

6)

7)

8)

9)

3-11

Page 34

Section 4 Software Interface

Page

4-1 General......................................................................................................................... 4-1

4-2 Specifications for Non-procedural FB ...................................................................... 4-3

4-2-1 Communication specification ................................................................................................ 4-3

4-2-2 FB format .............................................................................................................................. 4-4

4-2-3 FB terminals .......................................................................................................................... 4-5

4-3 Initialization ................................................................................................................. 4-7

4-3-1 Initialization parameters ........................................................................................................ 4-7

4-3-2 Initialization procedure ........................................................................................................ 4-10

4-3-3 OPEN status list .................................................................................................................. 4-10

4-4 Data Sending ............................................................................................................. 4-11

4-4-1 Data sending procedure ...................................................................................................... 4-11

4-4-2 Send status list .................................................................................................................... 4-12

4-5 Data Receiving .......................................................................................................... 4-13

4-5-1 Data receiving procedure .................................................................................................... 4-13

4-5-2 Receiving status list ............................................................................................................ 4-14

4-6 RAS Information........................................................................................................ 4-15

Page 35

Section 4 Software Interface

4-1 General

The non-procedural FB supplied with the D300wind is used for communication between the NP1L-RS1/2/4 and external

devices. The non-procedural FB performs data communication between the CPU module and external devices based on

the start-stop synchronous transmission protocol.

The following seven types of non-procedural FBs are offered.

emaNBF weivrevOnoitacificepS

eerf_C_sdrow215:evieceR,sdrow215:dneSBFlarudecorp-noN

252rfC_sdrow252:evieceR,sdrow252:dneSBFlarudecorp-noN

821rfC_sdrow821:evieceR,sdrow821:dneSBFlarudecorp-noN

46rfC_sdrow46:evieceR,sdrow46:dneSBFlarudecorp-noN

23rfC_sdrow23:evieceR,sdrow23:dneSBFlarudecorp-noN

rprfC_

2prfC_

.deepsgnissecorpehtesaercniotdesuera

sdrow215:evieceR,sdrow215:dneSBFlarudecorp-noN

.eludomehtnierawmrifehtybdessecorpsignissecorpnoitacinummocfotrapA

sdrow215:evieceR,sdrow215:dneSBFlarudecorp-noN

sdraobegassemowtdnaeludomehtnierawmrifehtybdessecorpsignissecorpnoitacinummocfotrapA

Note 1: _Cfrpr FB can be used with V.2535 or later versions of the NP1L-RS1, JP1L-RS2, and NP1L-RS4. The functions

of the non-procedural FB are shown below.

Note 2: _Cfrp2 FB can be used with V.2536 or later versions of the NP1L-RS1, JP1L-RS2, and NP1L-RS4. For the

specifications of _Cfrp2, refer to “EXTENDED FB FOR COMMUNICATION USER’S MANUAL FH255.”

1) Initialization of communication ports

Initializes RS-232C and RS-485 ports (sets transmission speed, data bit length, parity bits, etc., so as to match the

external device.)

2) Data sending/receiving function

Sends the data from an application program in the CPU of MICREX-SX series via RS1 to an external device, or outputs

the data received via the general purpose communication module to an application program.

3) Monitoring of transmission condition

Monitors the condition of data transmission and, if abnormal, outputs error information.

<Function diagram of Non-procedural FB>

CPU module RS1/2/4

Application program

Non-procedural

FB

1)

External device

2) 3)

4-1

Page 36

4-1 General

<FB operating conditions>

System configuration:

One FB is necessary for each external device which is connected by RS-232C or RS-485 to one general purpose

communication module. However, when RS-232C/RS-485 signal conversion is enabled (the mode selection switch is set

to 4) for the general purpose communication module, each FB is used by two channels.

Processor

Non-procedural

FB

for RS-232C

Non-procedural

FB

for RS-485

Processor

Non-procedural

FB

for both channels

General purpose

communication

module

(normal mode)

General purpose

communication

module

(conversion mode)

External device

connected to

RS-232C

External device

connected to

RS-485

External device

connected to

RS-232C

External device

connected to

RS-485

* When used in RS-232C/RS-485 conversion mode, channel number for the parameter (PARA [1]) is 1 (= RS-485).

Memory capacity:

emaNBF

eerf_C_6562sdrow204sdrow6563sdrow0sdrow28

252rfC_7572sdrow474sdrow4712sdrow0sdrow28

821rfC_7572sdrow474sdrow6881sdrow0sdrow28

46rfC_7572sdrow474sdrow8571sdrow0sdrow28

23rfC_7572sdrow474sdrow2761sdrow0sdrow28

rprfC_0911sdrow221sdrow8061sdrow0sdrow28

Note 1: The above memory capacity includes that of non-procedural FB itself as well as of the sub-FB which is called

from non-procedural FB.

Note 2: “Standard memory” or “Retain memory” includes the memory capacity necessary for data transmissin.

yticapacmargorP

)petS(

yromemecnatsnI

BFresurof

yromemdradnatS yromemniateR

metsysrof

4-2

yromemecnatsnI

Page 37

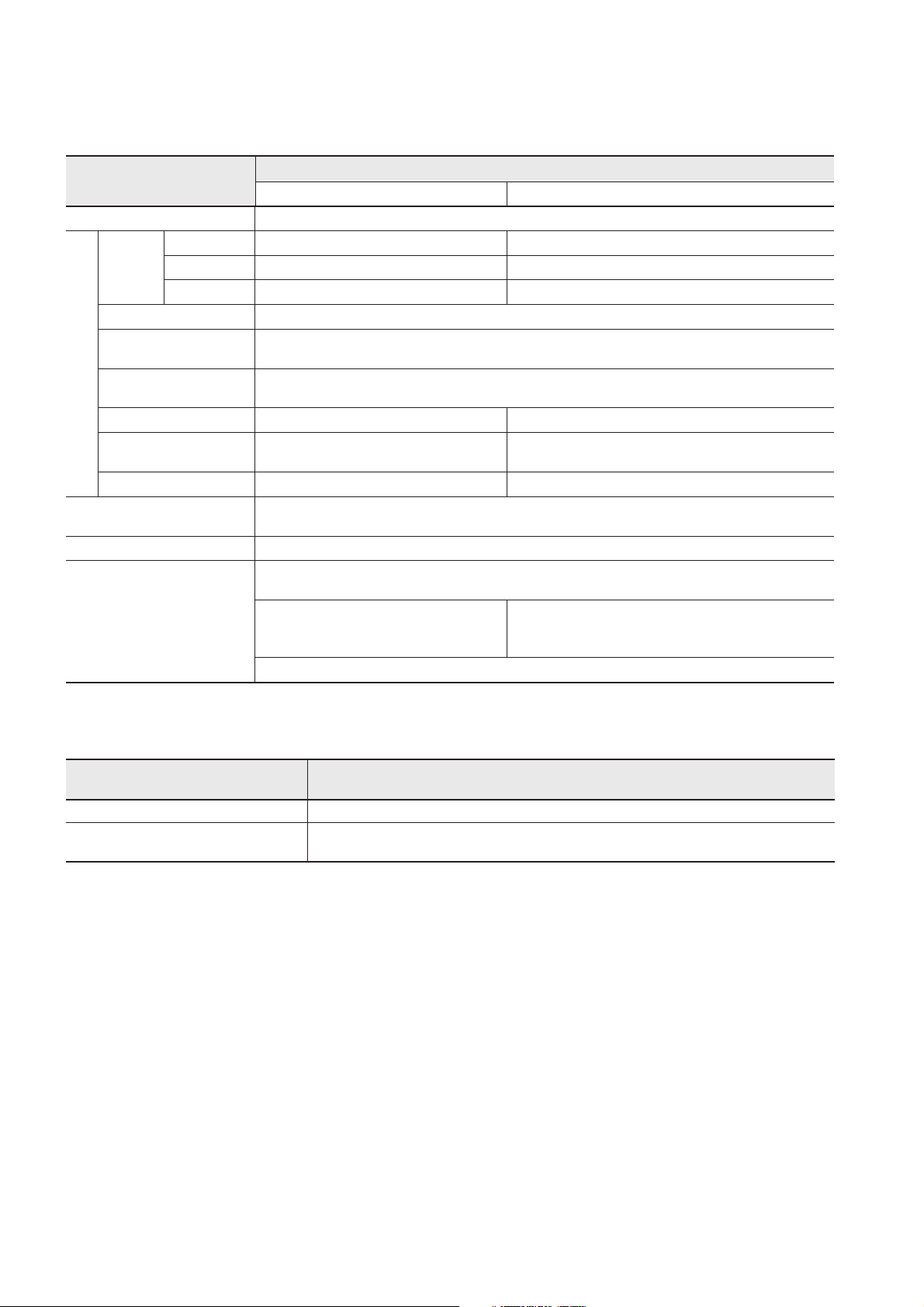

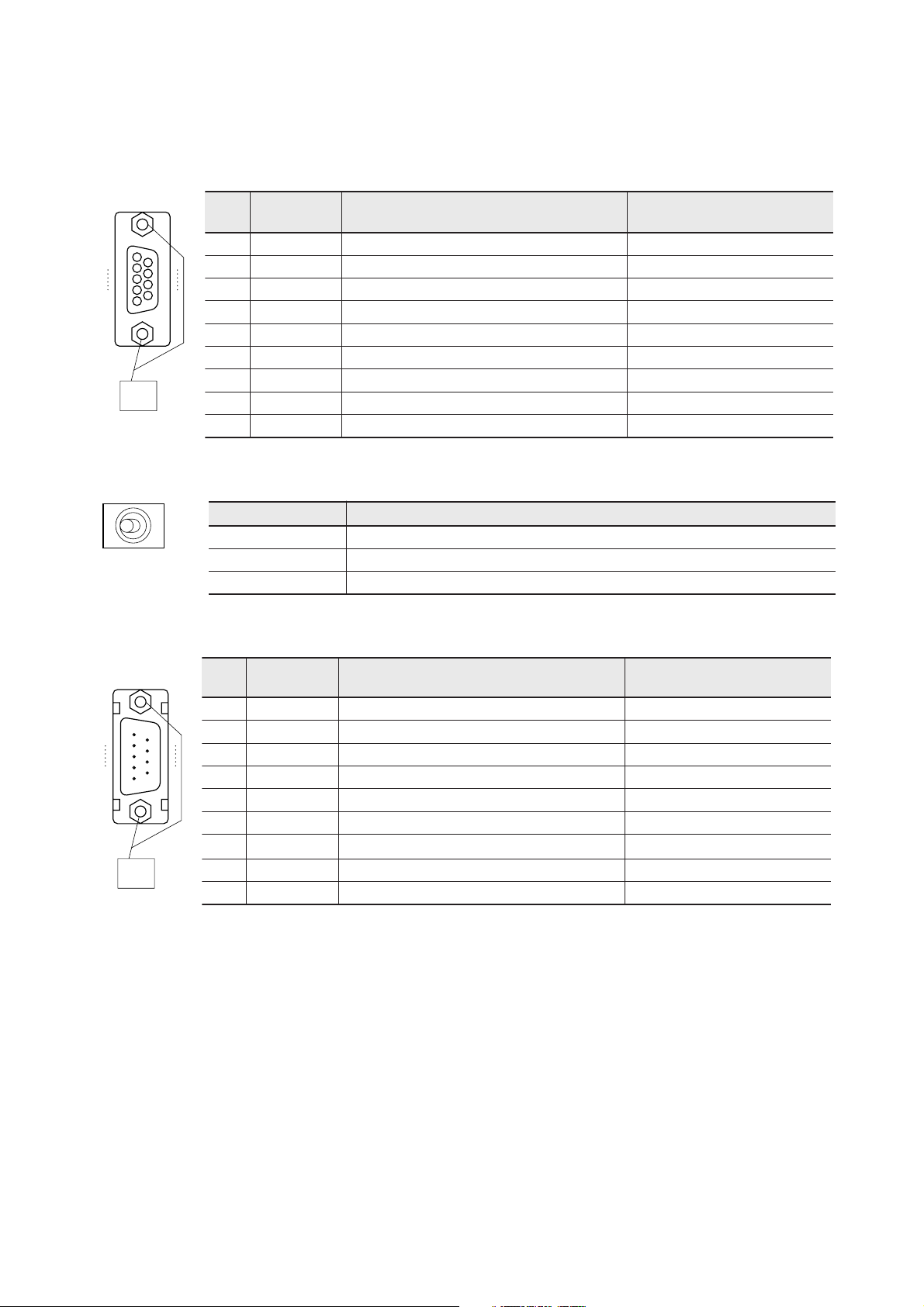

4-2-1 Communication specification

metI noitacificepS

deepsnoissimsnarT

stibataD

tibytiraP

stibpotS

ECD

lortnoclangiS

wolflangiS

lortnoc

lortnocFFOX/NOX

edom584-SR

noisrevnocedoC

noitcetedemarF

ytiraplatnoziroH

)CCB(

edomETD

edomECD

edomETD

edomECD

enoN

htgneldexiF

htgnelelbairaV

enoN

eulavremitnoissimsnarT

4-2 Specifications for Non-procedural FB

)etoN(spb00675/00483/00291/0069/0084/0042/0021

stib8/7morfdetceleS

neve/ddo/enoN

stib2/1morfdetceleS

edomETDmedom/ECD/ETDmorfdetceleS

gniviecernehwNODCnruT:edomETDmedoM

NOsyawla:RE

NOsyawla:RD

lanoitidnocnu:gnidneS;NOsyawla:SRffO

NOsiSCnehw:gnidneS;gnidnesgnirudNO:SRnO

lanoitidnocnu:gnidneS;NOsyawla:SCffO

NOsiREnehw:gnidneS;NOsiSRnehwNO:SCnO

elbatceleS

eriw-2/eriw-4morfdetceleS

noisrevnocCIDCBE/noisrevnocIICSA/enoNmorfdetceleS

).elbairavgnirtsretcarahcotniatadyranibtrevnoC(

.noitcnufnoitcetedemarfelbasiD

setybatadeviecerforebmunehtetangiseD

.sedocdnednatratsetangiseD

enoN

redrorewoL/redroreppU

redroreppU/redrorewoL

sm01x

.noitisopetangiseD.noitangisedegnarnoitaluclaC

CRC/ROE/trevnidnadda/ddamorfdetceleS:alumroF

edocyranib/edocretcarahcmorfdetceleS:edocCCB

Note: Transmission rates 300, 600, 76800, and 115200 bps can be used in the following combinations:

noitacinummocesopruplarenegfonoisreV

eludom

retalro5352.V )locotorpni-tliubhtiwBFlarudecorp-noN(rprfC_

retalro6352.V )noisrevegassem-2,locotorpni-tliubhtiwBFlarudecorp-noN(2prfC_

BFdednetxedradnatS

4-3

Page 38

4-2 Specifications for Non-procedural FB

4-2-2 FB format

Input terminal name Output terminal name

Open

Send request

Send data length

Send data

Receive data

Communication parameter

(BOOL) OPEN

(BOOL) S_REQ

(INT) S_LEN

(_C_SND_TYP11) S_DAT

(_C_RCV_TYP11) R_DAT

(_C_PAR_TYP11) PARA

_C_free

(Note 1)

(BOOL) OK

(WORD) O_STS

(BOOL) S_END

(BOOL) S_ERR

(WORD) S_STS

(BOOL) R_END

(BOOL) R_ERR

(WORD) R_STS

(INT) R_LEN

(INT) STN_NO

Communication ready

Open status

Send end

Send error

Send status

Receive end

Receive error

Receive status

Receive data length

RS-485 station No.

Send data

Receive data

Communication parameter

IN-OUT

terminal

(Note 2)

RAS information

* ( ) indicates data type.

Note 1: All non-procedural FBs have the same pin assignment.

Note 2: Only the FB pins necessary for control are used by connecting variables to them. However, be sure to connect

variables to the IN-OUT pins.

(_C_work_TYPE11) RAS

RAS information

4-4

Page 39

4-2-3 FB terminals

<Terminal list>

emanlanimreT lanimreT

nepO

tseuqerdneS

ataddneS

htgnel

ataddneS

noitacinummoC

retemarap

noitacinummoC

ydaer

sutatsnepOSTS_ODROWTUO.noitazilaitinifotluserehtetacidniotedoclamicedaxehtigid-2

dnedneSDNE_SLOOBTUO.detelpmocsahgnidnesnehwNOsnruT

rorredneSRRE_SLOOBTUO.derruccosahrorrednesafiNOnruT

sutatsdneSSTS_SDROWTUOgnidnesfotluserehtetacidniotedoC

dneevieceRDNE_RLOOBTUO.detelpmocsahgniviecernehwNOsnruT

rorreevieceRRRE_RLOOBTUO.derruccosahrorreeviecerafiNOsnruT

sutatsevieceRSTS_RDROWTUOgniviecerfotluserehtetacidniotedoC

atadevieceR

htgnel

atadevieceR

noitats584-SR

.oN

noitamrofniSAR

4-2 Specifications for Non-procedural FB

epytataD O/I noitpircseD

eman

NEPOLOOBNIlarenegehtot"sretemarapnoitacinummoc"ehtsdneS:NO

QER_SLOOBNI ebotsdeensiht,dednesahgnidnesnehW.ataddnesotstratS

NEL_STNINI.setybforebmunehtybataddnesfohtgnelehtsetangiseD

TAD_SDROWfoyarrA

)etoN(

ARAPTNIfoyarrA

)etoN(

KOLOOBTUOtahtetacidniotyllamrondednesahnoitazilaitininehwNOsnruT

NEL_RTNITUO.htgnelataddeviecerehtstuptuO

TAD_RDROWfoyarrA

)etoN(

ON_NTSTNITUOehtfohctiwsputesrebmunnoitats584-SRehtfonoitidnocehT

SARerutcurtS

)etoN(

TUO_NI.ataddnesserotS

NI.sretemarapnoitazilaitiniehtserotS

TUO_NI.ataddeviecerserotS

TUO_NI.BFsihtfonoitamrofnignitarepO

ezilaitinioteludomnoitacinummocesoprup

,elbissopsemocebnoitacinummocnehW.noitacinummoc

.NOsnrut"ydaernoitacinummoc"

.noitacinummocgnidnerofgnissecorpehtsmrofreP:FFO

.FFOsnrut"ydaernoitacinummoC"

.margorpnoitacilppaehtybFFOdenrut

.atadgniviecer/gnidnesrofydaersimetsyseht

.nipsihtottuptuosieludomnoitacinummocesopruplareneg

".noitamrofnISAR",6-4otrefer,sliatedroF

Note: The data format differs for each non-procedural FB.

<Send data S_DAT(WORD array)>

<Variable declaration example>

S_DAT [0]

VAR

S_DAT:_C_SND_TYP11;

END_VAR

S_DAT [1]

S_DAT [31]

<Data type list>

emaNBF TAD_SfoepytataD

eerf_C_11PYT_DNS_C_