Fuelab 52502 User Manual

Model Number 52502

Fuel Pressure Regula tor

Operating and Installation Instructions

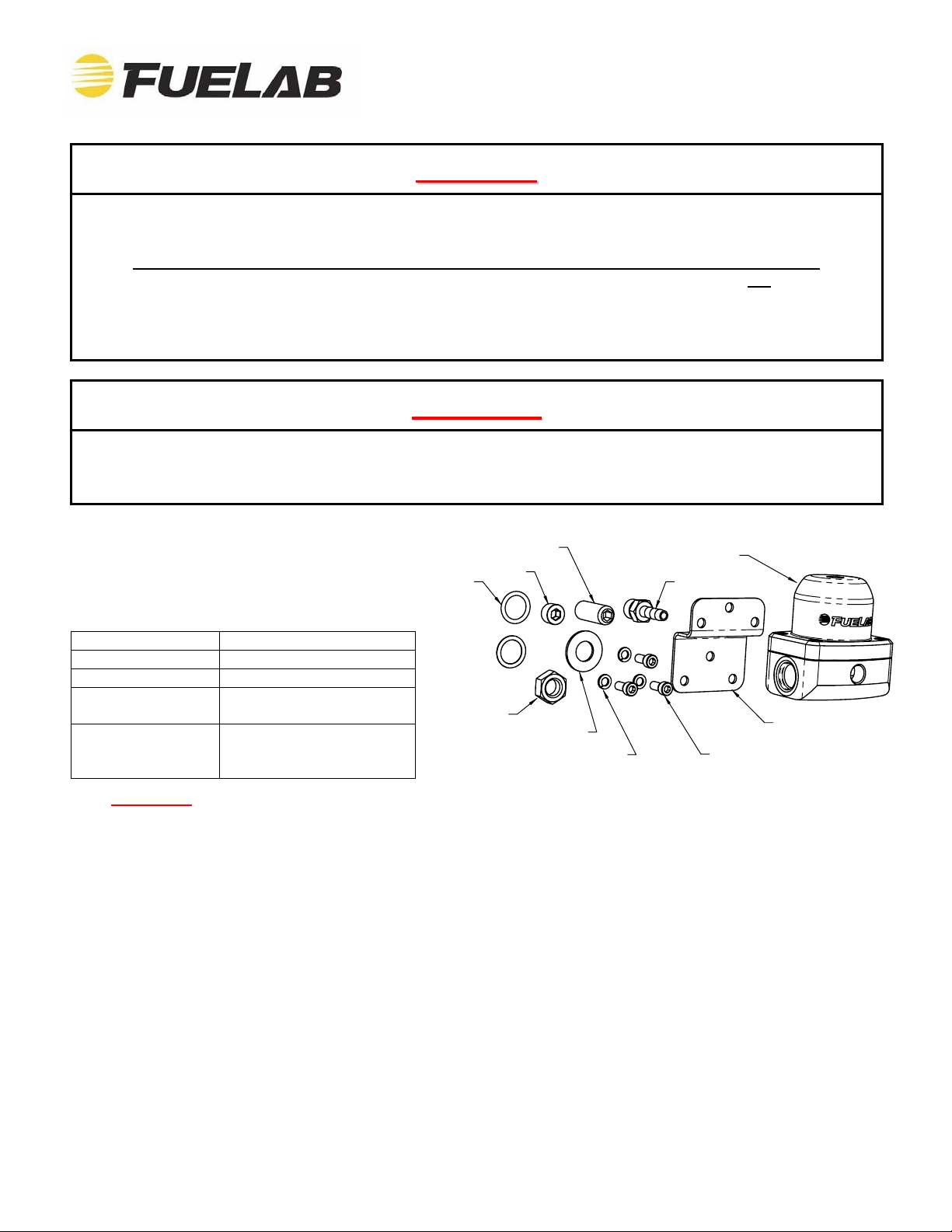

Plug

Flat Washer

Regulator

Barbed Fitting

Bracket

(3X) Bracket Screws

CCAAUUTTIIOONN!!

This product is to be installed only by persons knowledgeable in the repair and modification of vehicle fuel systems

and general vehicle systems modification. Only a qualified technician or mechanic who is aware of applicable

safety procedures should perform the installation of this product.

GASOLINE AND OTHER FUELS ARE FLAMMABLE AND CAN BE EXPLOSIVE!

Perform the installation in a well vent il ated loc ati on onl y to minim i ze the build up o f fuel vapor s. NO open flames,

smoking or other sources of ignition are to be present during installation, to prevent fire or explosion that can cause

serious injury or death. Grinding, cutting, and drilling must be performed with care to prevent ignition. Draining and

removal of all fuel and ventilation of vapors in vehicle and fuel system is recommended when performing such

procedures. Proper eye and personal protection is required at all times during installation.

WWAARRNNIINNGG!!

The Vehicle’s fuel system may be under pressure! Do not loosen any fuel connections until relieving all fuel system

pressure. Consult an applicable service manual for instructions to relieve fuel system pressure safely.

This product is intended for racing, off-road, or marine use only. This fuel system component is capable of altering

engine tuning and therefore not legal for sale or use on emission controlled motor vehicles.

Product Contents:

Check the diagram and list of components

(right) to ensure that no components are

missing from box. Contact your Fuelab

distributor immediately for replacement.

52502 Features and Performance Ratings:

Inlet Port Size -6AN Military Port

Seat Size Large

Regulation Slope 0.75 PSI/GPM

Maximum Flow

Capacity

Pressure

Adjustment Range

2.5 GPM at 5 PSID

(570 LPH at 0.35 Bar)

Pressure Range “C”

4-12 PSID

(0.28-0.82 Bar)

(2X) -906 O-ring

Adjustment Screw

Jam Nut

(3X) Bracket Lock Washers

WARNING! Exceeding maximum flow capacity may result in an over-pressure operating condition.

Before Installation, Plan Entire Fuel System:

These instructions are limited to general topics of regulator component installation and may not include specific

information pertaining to your application. These instructions are written assuming the use of an electric fuel pump

capable of at least 15 PSIG outlet pressure and limited to the specified

regulator has an internal spring that can be changed for other pressure ranges, including “L” range, for 1.5-3.5

PSID, “T” range for 10-25 PSID, if required by the specific application. Higher, fuel injection pressure ranges are

recommended for a different model of regulator (unless for very high flow EFI applications). Visit our company

website for specific details pertaining to example fuel systems and other solution ideas. Additional information

including advanced troubleshooting, any special alerts and FAQ’s pertaining to this and other products is also

available.

General Regulator Performance Notes:

The notation “PSIG” means pressure in Pounds per Square Inch (PSI) relative to the prevailing atmospheric

condition or outside air. This is referred to as Gauge Pressure. The notation “PSID” means pressure in PSI relative

to another pressure source or called the Differential Pressure (relative to

pressure ratings). This regulator acts as a relief valve to control pressure (returning fuel back to fuel cell). Only

“blow-through” boosted applications for carbureted systems should have a line plumbed to the pressure reference

port. The amount of pressure difference to expect with application of full throttle compared to idle (for naturally

aspirated engines) is a function of how much flow the engine is using (reference

calculations).

Maximum Flow Capacity

Pressure Reference Port

Regulation Slope

105020203-1, No Rev Page 1 of 4

(above). This

in case of

, above for

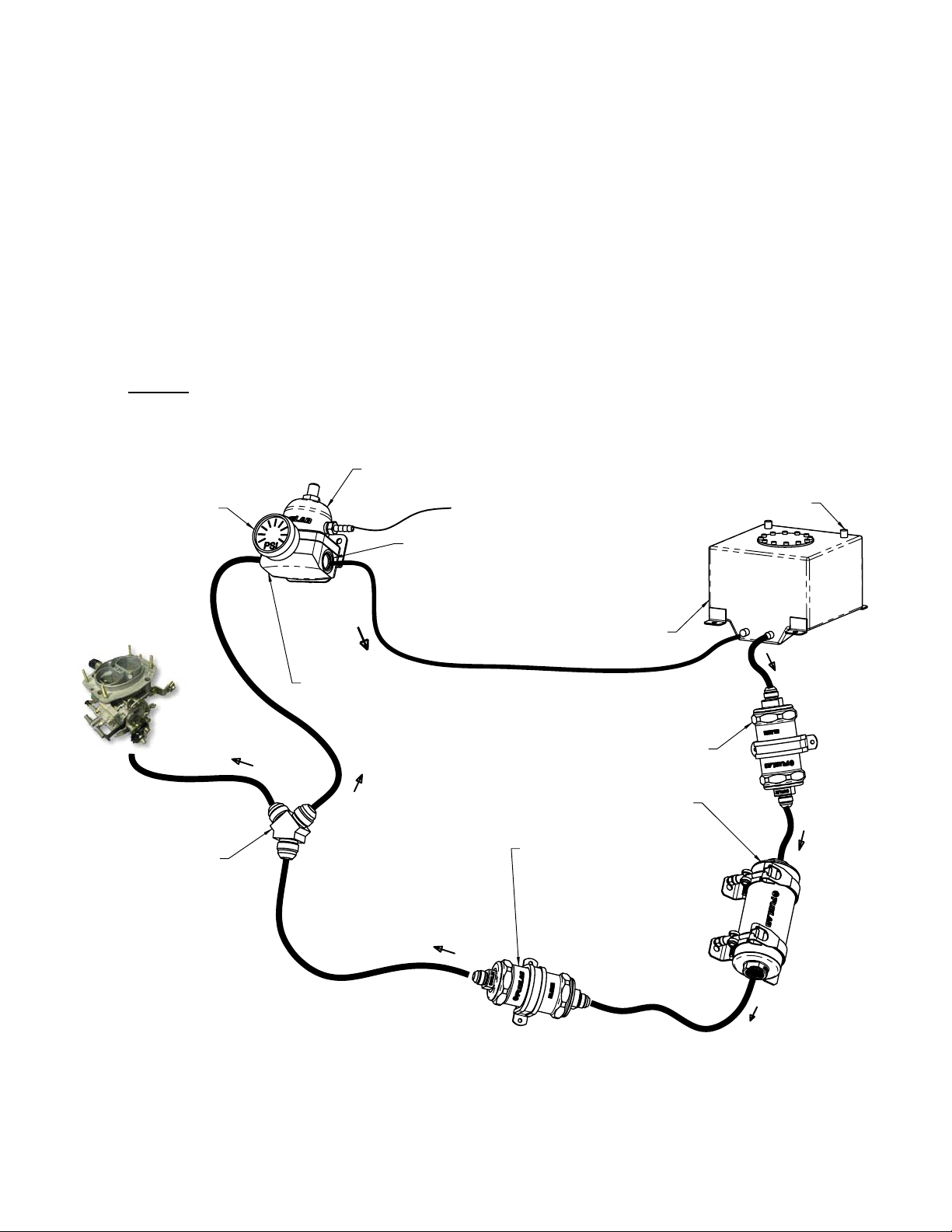

Plumbing Planning Notes:

”

Minimize plumbing restrictions between carburetor(s) and regulator for peak performance. Use –6AN (3/8”) to

–10AN (5/8”) line as required per flow rate requirements of the vehicle’s engine and fuel pump. See company website for nitrous oxide use and alternate plumbing schematics. Plumb the return line back to the fuel tank. Use of a

–8AN (1/2”) return line is typically recommended for this model of regulator. See diagram on next page as well as

diagram below, to identify the ports used on the regulator. Pressure is relieved from the regulator out to the rest of

the fuel system, by returning unused fuel back to the fuel cell. Use a “T” or “Y” Block fitting to allow fuel to be feed

into carburetor prior to plumbing to fuel pressure regulator (see diagram below). Plumb the Pressure Reference

Port using the barbed fitting for “blow-through” carbureted applications only, “blow-through” means that a turbo or

supercharger is used to pressurize the carburetor(s). When this occurs, fuel pressure must be compensated by the

change in float bowl pressure. If motor is naturally aspirated (Normal carbureted application, with float bowl vented

to atmosphere) allow this port to vent to atmosphere, do not plug or plumb to any pressure source. The fuel line

used must handle high pressure. The use of fuel line such as stainless steel braided line and “AN” style fitting

connections is recommended. The fuel ports (one

–6AN Inlet Port

and one

–6AN Return Port

) use “AN” or “military

style fittings. This plumbing standard is commonly used with racing and high performance applications. See step 6

on next page for additional information on this port standard. A fuel filter with a 40 micron or lower particle rating is

required to be used upstream of regulator and downstream from fuel pump to protect it and the carburetor from

foreign object damage. Reference the Schematic Diagram below for filter locations. Use of a liquid filled gauge

exposed to engine compartment heat is not recommended as the liquid inside the gauge may exert measurement

errors.

DO NOT

plumb gauge port to any gauge mounted inside the vehicle or in passenger compartment. A line

burst can spill fuel inside passenger compartment and on occupants, possibly causing serious injury or death. An

electric gauge or pressure transducer system is recommended for readings in a passenger compartment.

Typical Carbureted Fuel System Schematic Diagram:

Fuel Gauge Shown in

Gauge Port, Liquid Fille d

Gauge may have Error Due

to Temperature Variations.

52502 Regulator

Return Port on Right Side

Follow Fuel Cell Manufacturer's

To Induction Tube (for BlowThrough Applications Only!

Otherwise Do Not Plumb or Plug)

Vented Fuel Cell or Fuel Tank.

Tank must be Plumbed According

to Maximum Pump Flow Rate.

Specifications and Recommendations.

Consult Pump Manufacturer's

Recommendations for Proper

Cell Vent Plumbing

Use Y-Block, Fuel Log

or T-Fitting to Split

Flow to Carburetor

Inlet Port on Left Side

Fuel Straining Filter Required, Typical

75 Micron Filter Recommended. Straining

Consult Pump Manufacturer's Specifications.

Micron Rating: 75-150, Fuelab

Filter may be Installed in Fuel Pump,

Fuelab Prodigy Series

Fuel Pump Recommended.

Fuel Filter with 60 Micron or

Lower Particle Rating is Required.

Fuelab Filter with 6, 10 or 40

Micron Rating is Recommended.

Fuel Pump

Installation Steps:

1. Disconnect the ground terminal from battery and allow the vehicle’s engine and exhaust system to cool.

Relieve fuel system per applicable service manual. Follow all Warnings and Cautions written on previous page

of these instructions.

2. Modify, remove or replace other fuel system components as required per established build plan (reference

notes on previous page and above).

105020203-1, No Rev Page 2 of 4

Loading...

Loading...