Fuelab 41402 User Manual

Model Number 41402-c (-sp)

Electronic Fuel Pump

Operating and Installation Instructions

This Product is Patent Pending. Application available upon request

CAUTION!

This product is to be installed only by persons knowledgeable in the repair and modification of vehicle fuel systems

and general vehicle systems modification. Only a qualified technician or mechanic who is aware of applicable

safety procedures should perform the installation of this product.

This fuel pump utilizes an electronic DC motor system that is not typical of conventional fuel pumps, and therefore

GASOLINE AND OTHER FUELS ARE FLAMMABLE AND CAN BE EXPLOSIVE!

Perform the installation in a well ventilated location only to minimize the build up of fuel vapors. NO open flames,

smoking or other sources of ignition are to be present during installation, to prevent fire or explosion that can cause

serious injury or death. Grinding, cutting, and drilling must be performed with care to prevent ignition. Draining and

removal of all fuel and ventilation of vapors in vehicle and fuel system is recommended when performing such

procedures. Proper eye and personal protection is required at all times during installation.

The Vehicle’s fuel system may be under pressure! Do not loosen any fuel connections until relieving all fuel system

pressure. Consult an applicable service manual for instructions to relieve fuel system pressure safely.

This product is intended for racing, off-road, or marine use only. This fuel system component may not be legal for

sale or use on emission controlled motor vehicles; consult local, state and national laws.

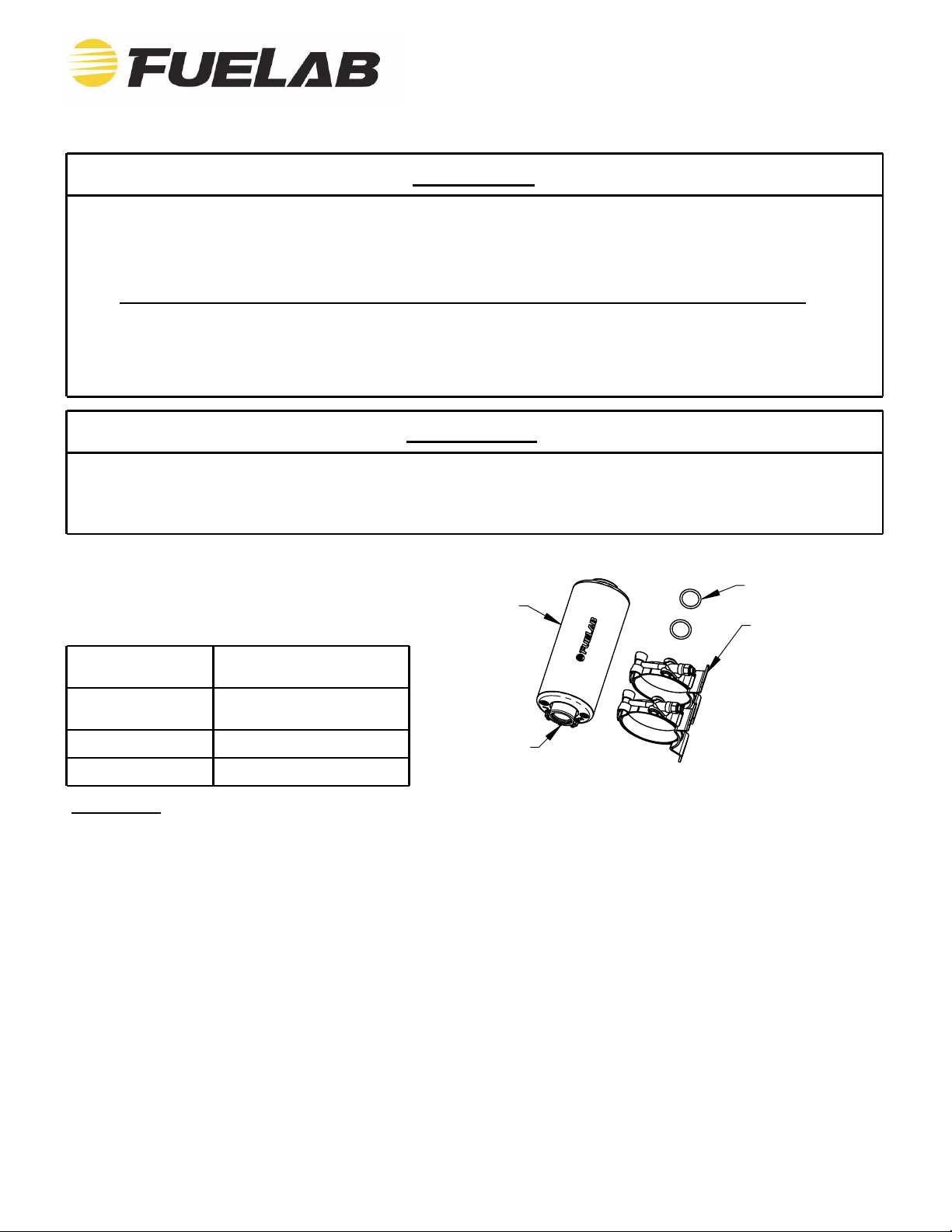

Product Contents:

Check the diagram and list of components (right)

to ensure that no components are missing from

box. Contact your Fuelab distributor immediately

for replacement.

41402-c (-sp) Features and Performance Ratings:

Inlet and Outlet

Port Sizes

Rated Flow Rate

Maximum Pressure

Operating Voltage

extra precautions must be adhered to as contained in instructions herein.

WARNING!

Electronic

Fuel Pump

-10AN Military Port

140 GPH @ 45 PSI, 13.5V

(530 LPH @ 3 Bar)

100 PSI (6.8 Bar)

8-18 Volts

(3X) 8-32 Nuts

with Washers

(2X) -910 O-rings

(2X) T-Bolt Style

Mounting Brackets

with Rubber

Cushions

WARNING!

Power Supply Voltage must be constant as specified in above specification. Only install fuel

pump on vehicles using 12 Volt (6 cell lead acid battery) with a normal operating alternator charging

system or vehicles using 16 Volt (8 cell lead acid battery). Pulse-Width Modulation or other means of

reducing input power voltage may result in erratic or non-operational condition. Electronic Power

Supplies have not shown to be a problem with normal operation, however testing has not been

performed on all systems. Consult these instructions on using pulse width modulated frequencies for

means of fuel pump speed control.

Before Installation, Plan Entire Fuel System:

A complete design plan of entire fuel system must be created for the specific application. These instructions are a

guide to help design this plan with respects to integrating this model of fuel pump only. Consult other sources of

information and manufacturers’ instructions for the various components of the fuel system. These instructions are

limited to general topics of fuel pump installation and may not include specific information pertaining to your specific

application. These instructions are written assuming the use of Multi-Point Electronic Fuel Injection using a

standard return (bypass) style fuel pressure regulator. This fuel pump may be integrated in some returnless EFI or

general carbureted systems. Visit our company website for specific details pertaining to example fuel systems and

other solution ideas. Additional information including advanced troubleshooting, any special alerts and FAQ’s

pertaining to this and other products is also available. A good design plan for the fuel system must contain

consideration for: Pressure and flow rate through various components, quality of components, operating

environment (temperature, vibration, shock, general exposure to elements) and local area laws. Begin installation

of fuel pump only after a complete plan is established to help avoid fuel system component failure, costly rework,

and excessive installation time.

110020271-1, Rev C Page 1 of 6

Plumbing Planning Notes:

Fuel Pump may be mounted inside a fuel tank or cell, inlet screen strainer is still required. Adequate structural

mounting and support is the responsibility of the fabricator and installer. Mount the fuel pump as low as possible

without it being vulnerable to road hazards or debris. Minimize the length of the fuel line feeding fuel pump. Do not

use “cross drilled” style 90° elbow fittings, check valves or other restrictions (other than high flow fuel filter strainer

or shut-off valve) before or upstream of fuel pump. Minimize plumbing restrictions between fuel tank and fuel pump

and regulator for peak performance, use -10AN (5/8”) to -12AN (3/4”) line as required per flow rate requirements of

the vehicle’s engine and fuel pump speed setting. Typically -6AN (3/8”) to -10AN (5/8”) line is required for the rest

of the fuel system, after or upstream of fuel pump. Use of a strainer filter upstream of fuel pump is required to

protect fuel pump from damage. All fuel line used must handle high pressure. The use of fuel line such as stainless

steel braided line and “AN” style fitting connections is recommended. The fuel ports (one

-10AN Outlet Port

) use “AN” or “military” style fittings. This plumbing standard is commonly used with racing and

-10AN Inlet Port

and one

high performance applications. See step 4 on page 5 for additional information on this port standard. A fuel filter

with a 60 micron or lower particle rating is required to be used upstream of regulator and downstream from fuel

pump to protect it and the fuel injectors from foreign object damage. Reference the Schematic Diagram below for

filter locations. Fuel tank must have a modification of an additional sump, or use aftermarket fuel cell as indicated.

Use of a “pick-up” tube system is not recommended. Use of a liquid filled gauge exposed to engine compartment

heat is not recommended as the liquid inside the gauge may exert measurement errors, all mechanical gauges and

pressure transducers have amounts of error due to temperature fluctuation, be aware of inaccurate pressure

readings.

DO NOT

plumb gauge port to any gauge mounted inside the vehicle or in passenger compartment. A

line burst can spill fuel inside passenger compartment and on occupants, possibly causing serious injury or death.

An electronic gauge or pressure transducer system is recommended for readings in a passenger compartment.

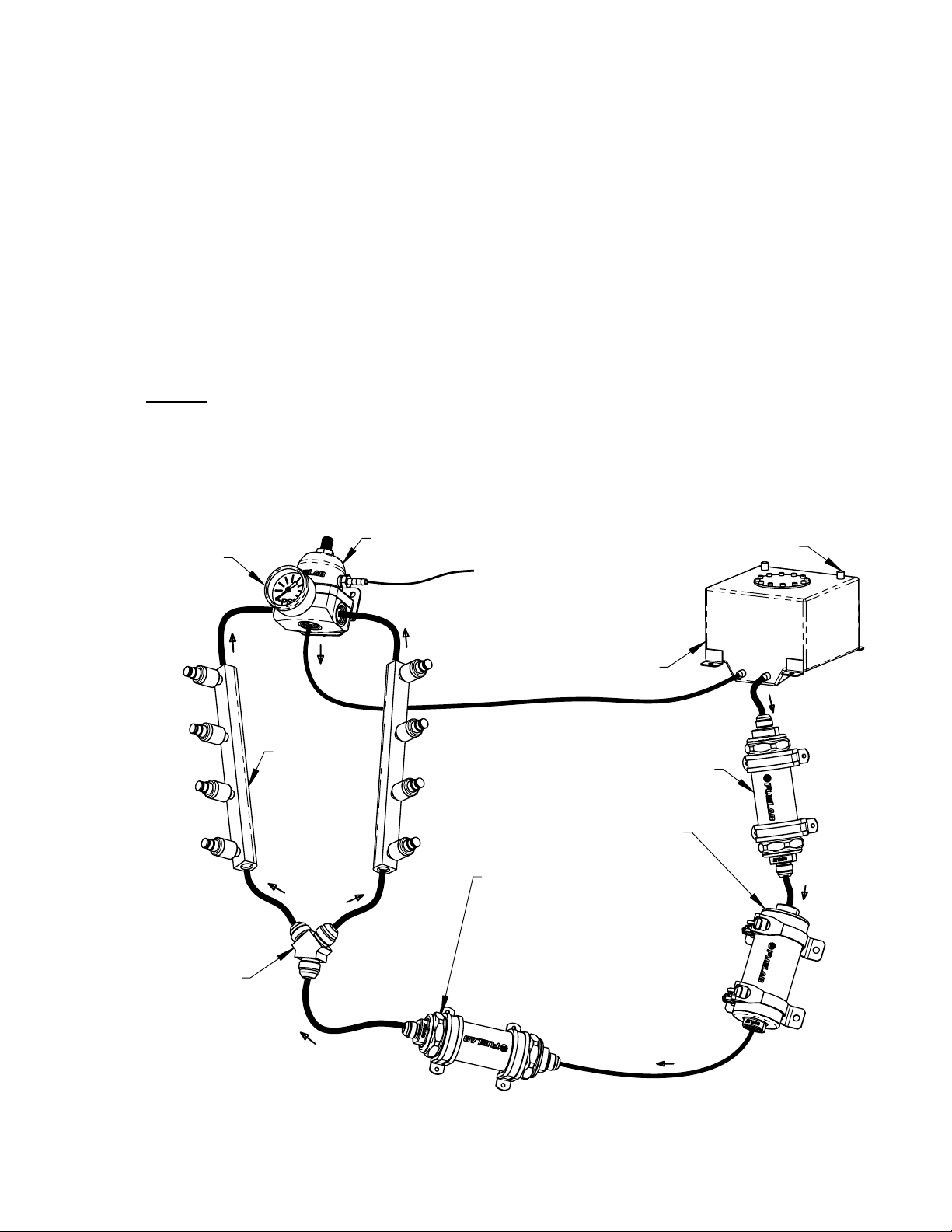

Typical EFI V-8 Fuel System Plumbing Schematic Diagram:

Fuel Gauge Shown in

Gauge Port, Liquid Fille d

Gauge may have Error Due

to Temperature Variations.

Y-Block or "T" Fitting,

to Split Flow into Two

Fuel Rail System

(2X) Fuel Rails

with Injectors

EFI Regulator

Follow Fuel Cell Manufacturer's

Recommendations for Proper

To Engine Intake Manifold (Air)

Vented Fuel Cell or Fuel Tank.

Tank must be Plumbed According

to Maximum Pump Flow Rate.

Line Size Required t o feed Straining

Fuel Straining Filter Required, Typical Micron

-8AN or 1/2" Miniumum

Fuel Filter and Fuel Pump.

Rating: 75-150, Fuelab 828xx Series,

75 Micron Filter Recommended.

41402-c (-sp) Fuel Pump

Fuel Filter with 60 Micron or

Lower Particle Rating is Required.

Fuelab Filter with 6, 10 or 40

Micron Rating is Recommended.

Check Valve Required for Reduced

Vehicle Emissions and Improved

Engine Starting. Fuelab 858xx Series

Filter has Ch eck Valve Assembly

Built in.

Cell Vent Plumbing

Special Note: Use in carbureted systems require a bypass return or relief valve.

Do not "Dead Head" Fuel Pump.

110020271-1, Rev C Page 2 of 6

Loading...

Loading...