Page 1

Электростанция сварочная

Welding power station

WHS 190 DC

WHS 210 DC

Operator's Manual

Инструкция по эксплуатации

www.fubag.ru

Page 2

Omperator's anual

WARNING! BEFORE USING THE MACHINE READ THE INSTRUCTION MANUAL

CAREFULLY!

Our generators are designed to give safe anddependable service if operated

according to instructions.

Read and understand the anual before operating the generator . Failure to

do so could resultin personal injury orequipment damage.

1. General safety

www.fubag.ru

FUBAG

FUBAGm

WARNING!

WARNING!

WARNING!

WARNING!

Exhaust gas contains poisonouscarbon monoxide.

Never run the generator in an enclosed area. Be sure to provide adequate

ventilation. When installed inventilated protection are tobe observed.

The muffler becomes very hot during operation and remains hot for a while

after stopping the engine.

Be careful not to touch the muffler while it is hot. Let the engine cool before

storing the generator indoors. The engine exhaust system will be heated

during operation andremainhot immediately after stoppingthe engine.

To prevent scalding, pay attention to the warning marks attached to the

generator.

Gasoline is extremely flammable and explosive under certain conditions.

Refuel in a wellventilated area with theengine stopped.

Keep away from cigarette, smoke and sparks when refueling the generator.

Always refuel in awell-ventilated location.

Wipe up spilled gasolineat once.

Connections for standby power to a building's electrical system must be

made bya qualifiedelectrician andmust complywith allapplicable lawsand

electrical codes. Improper connections can allow electrical current from the

generator to back feed into the utility lines. Such back feed may electrocute

utility company workers or others who contact the lines during a power

outage, and when utility power is restored, the generator may explode, burn

or cause fires inthe building's electrical system.

- 1 -

Page 3

Omperator's anual

www.fubag.ru

-

WARNING!

-5

Place the generator atleast m away from buildingsor other equipment duringoperation.

-

Operate the generator ona level surface. Ifthe generator is tiled,fuel spillage may result.

-

Know how to stop the generator quickly and understand operation of all the controls.Never permit

anyone to operate thegenerator without proper instructions.

-

Keep children and petsaway from the generatorwhen it is inoperation.

-

Keep away from rotatingparts while the generatoris running.

-

The generator is a potential source of electrical shocks when misused; do not operate with wet

hands.

-

Do not operate thegenerator in rain orsnow and do notlet it get wet.

- The power generator isa mains replacement that generates electrical powerfor supply to a mobile

distribution system.

- The power generator must be operated outdoors within the prescribed voltage, output and rated

speed limits (seetype plate).

- The powergenerator must notbe connected to other electrical supply systems or electric generation

systems (e.g. otherpower generators).

- The powergenerator may notbe used inenvironments where thereis a riskof explosion.

- The powergenerator may notbe used inenvironments where thereis a riskof fire.

- The power generator must be operated in accordance with the conditions set out in the technical

documentation.

- All improper use of the power generator including all uses not described in these instructions will

constitute unauthorized incorrectusage for which the manufacturer is not legally liable.

- Operation inenvironments where there is a risk of explosion and fire.

- Operation inenclosed areas and under direct exposure to rain or snowfall.

- Operation without the requisite safety precautions and connected to existing supply network

systems.

- Spraying withhigh-pressure cleaners or fire extinguishing equipment.

- Non-compliance withregular servicing requirements.

- Failure tocarry out measurements and checks for early detection of defects.

- Know and apply the Prevention of Injury regulations and the safety instructions for the power

generator.

- Understand andbe able to practically implement the technical documentation.

- The operatormust know thefunctions of, andbe able touse, the componentsof the powergenerator.

- The operatormust wear theappropriate personal safetyequipment.

- The labellingon the electricalgenerator must becomplete and maintainedin a readablecondition.

- Constructive changesmay not be carried out on the electrical generator.

- The ratedspeed of themotor has beenset during manufactureand may notbe changed.

- The operatingsafety and correctfunctioning must bechecked before andafter each use.

- No naked flames, lights or spark-emitting appliances may be used within the hazard area of the

power generator.

- Smoking withinthe hazard area of the power generator is strictly forbidden.

- During operation,the power generator must be protected from dirt and foreign matter.

- The powergenerator may onlybe transported whencold.

- The powergenerator may onlybe lifted usingthe carry handlesintended for thispurpose.

- The electricalsafety must bechecked before eachoperational use.

- The appliancemay not becovered. The airintake may notbe blocked orobstructed.

- When starting,the load may not be connected.

- Only certifiedand approved cables may be used for the wired network.

- The powerdrawn may notexceed the maximumrated power.

Always make a pre-operation inspection before you start the engine. You

may prevent an accidentor equipment damage.

- 2 -

Page 4

Omperator's anual

www.fubag.ru

- The power generatormay not be operatedwithout the sound absorber.

- The power generatormay not be operatedwithout the air filteror with the airfiltercover open.

- The generator's tankmay not be refilledduring operating.

- The tank maynot be refilled whenthe power generator ishot.

- The power generatormay not be cleanedand serviced when inoperation; when hot.

-Always remove spark plugconnector prior to commencingservicing and repair work.

- The power generatormust be shut downwhen not required forperiods longer than 30days.

- The power generatormust be stored ina dry enclosed room.

Safety perationwelding o

- No

work of power station in a mode "welding" and "generator" is forbidden. Before carrying out

of welding works disconnect all consumers from sockets.

-

It is highly recommended always to follow the safety rules. Wear protective clothes and special

means to avoid injuriesto eyes and skins.

-

Use the welding mask or special protective glasses while working with the welding machine.

Only by viewing through the filter lens on the welding mask your eyes are secured by your

operation.

-

Prevent the sparks and spatter from harming your body.

-

Under no circumstance allow any part of your body to touch the welder's output bipolarity (torch

and work piece).

-

Fumes and gases produced when welding are hazardous to health. Make sure to work in

places where there are exhaust or ventilation facilities to keep fumes or emissions away from the

breathing zone.

-

Please remember to keep arc rays away from the other nearby people when welding. This is

only due to the interference from arc rays.

-

There will be high temperature when welding work piece, so please don't directly touch on it

-

No welding for the container loaded inflammable or explosive materials.

-

Welders possible have electromagnetism and frequency interference, so keep away people

with heart pace or the articles which can be interfered by electromagnetism and frequency.

-

Taking welder power for pipe unfreezing device will be prohibited.

-

Check is needed from time to time to make sure the welding cable is in good condition if the

welding machine is in frequent use. Check at least once each month if the welder is in regular

use. It is necessary to check when the welder is in mobile use.

-

Electrode must be taken down from holder when no welding.

- 3 -

Page 5

Omperator's anual

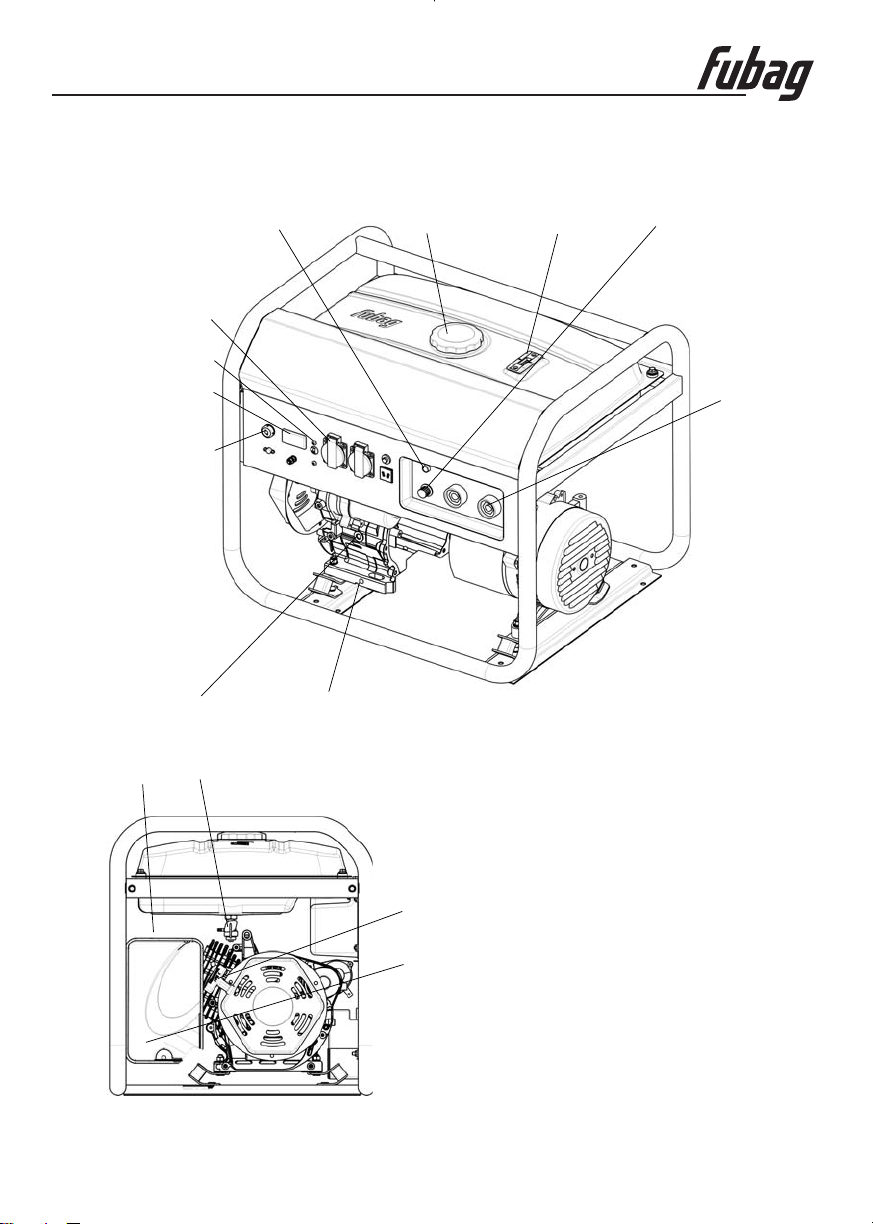

2. Description

www.fubag.ru

13

11

12

8

5

6

7

4

3

2

9

1

10

1.

Starting key

2.

Digital display

3. C

ircuit breaker

4. S

ocket 220V

5. F

uel tank cap

6. F

uel gauge

7. C

urrent regulation knob

8.

14

15

Indicator lamp

9. W

elder teminals

1. O

0 il drain plug

1. O

1 il filler cap

1. F

2 uel valve

1. C

3 hoke lever

1. R

4 ecoil starter

1. A

5 ir cleaner

--4

Page 6

Omperator's anual

www.fubag.ru

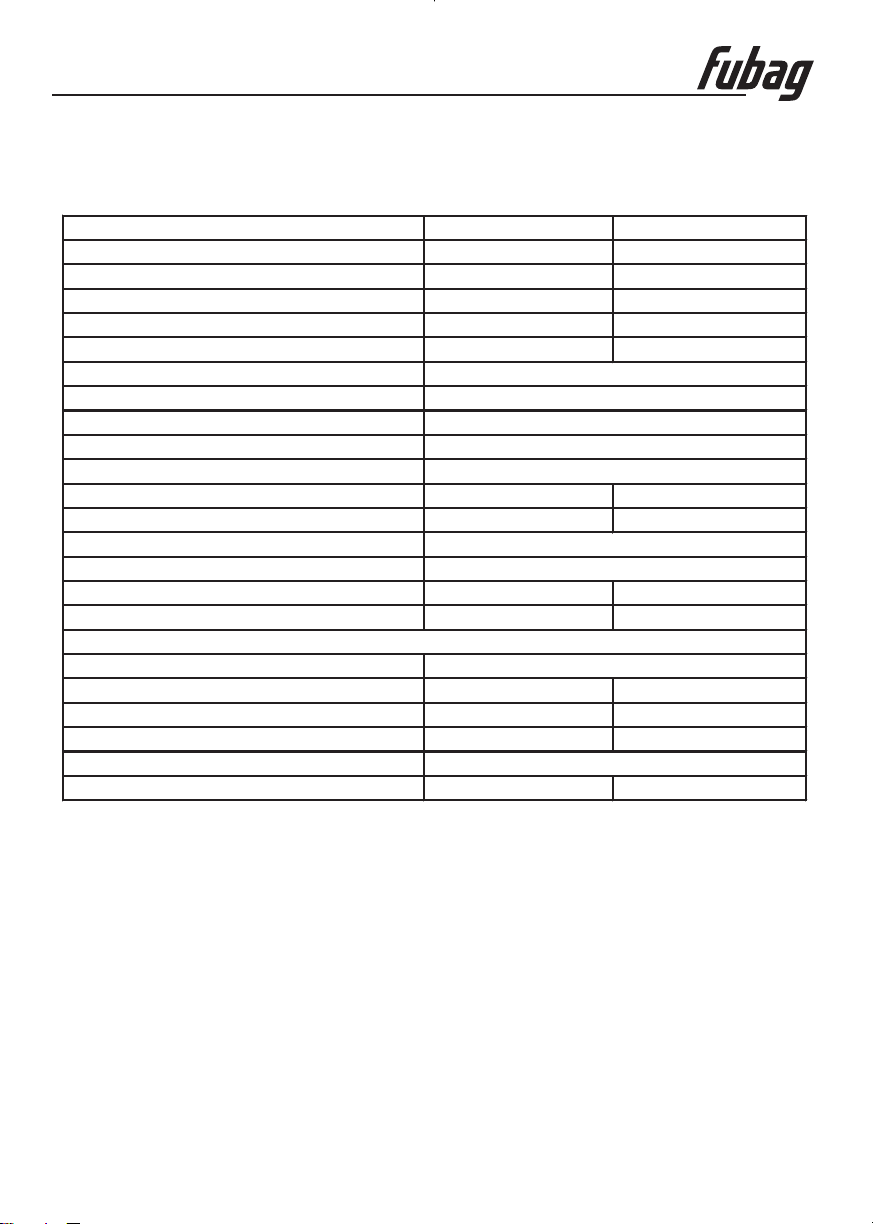

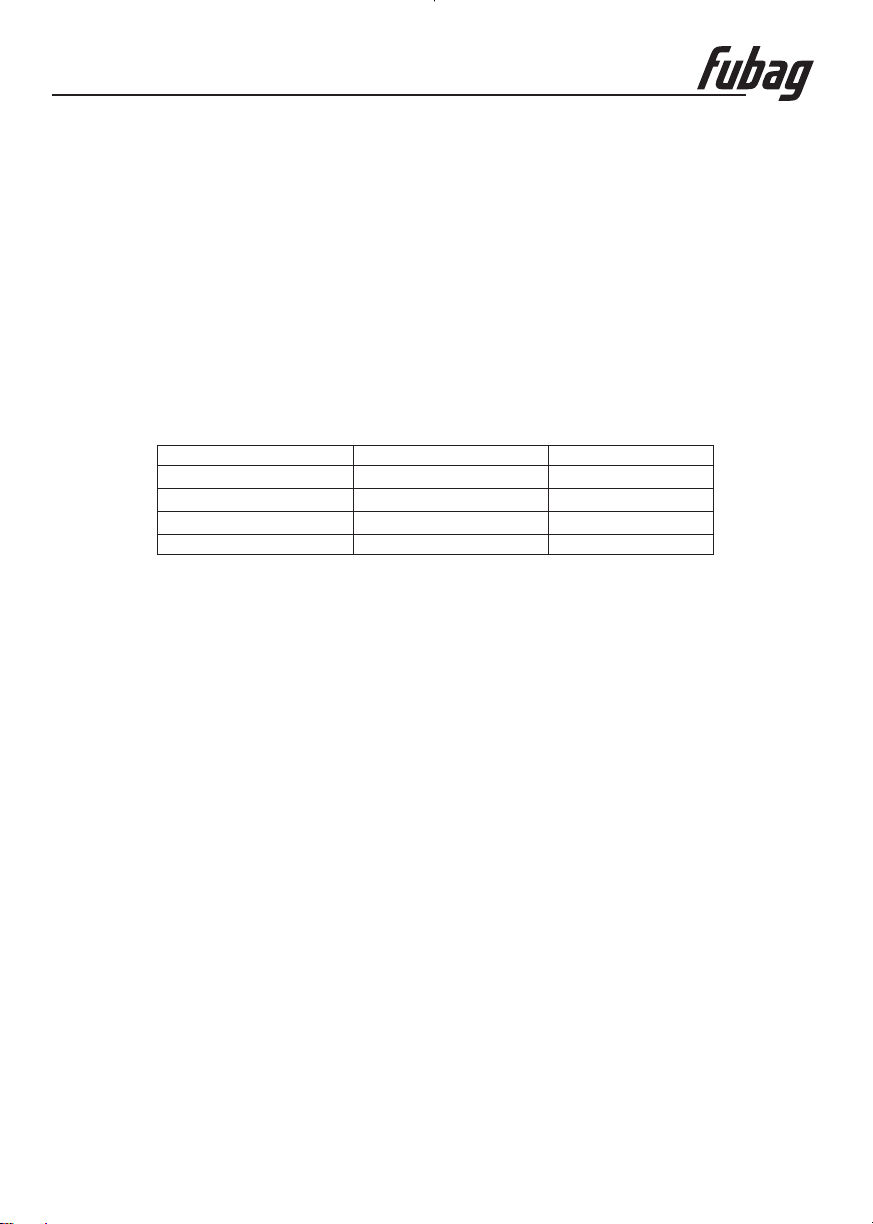

3. Specifications

Specifications\Model WHS 190 DC WHS 210 DC

Rated voltage, V 230 230

Rated frequency, Hz 50 50

Max. output, kWA 4,5 5

Rated output, kW 4 4,5

Rated current, А 18,2 20,5

Cos phi

IP

Motor type

HONDA GX390

Power, kW/hp

Fuel

automotive unleaded gasoline

Tank capacity, l 25 25

Oil tank capacity, l 1,1 1,1

Oil type

Starting system

electric/recoil starter

Weight (without fuel), kg 89 92

Dimension, mm 729x537x592 729x537x592

Welding specifications

Welding current type

Welding current, А 50-190 60-210

Rated no-load voltage, V 65 65

Welding current of duty cycle 60%, A 120 140

Мin. electrode diameter, mm

Маx. electrode diameter, mm 4 5

The manufacturer reserves himself the right to make the manual's content or

function change without anypreliminarynotificationof the users.

1

IP23

9,6/13

SAE 10W30

DC

1,6

power generator

4. Putting the Power Generator into Operation

Operating conditions

Power stations provide steady work at ambient temperature from -15°C to +40°C, (gasoline and oil

type should be pickedup according to theseconditions). Relative humidity <60%.

Generating set performance is reduced by approximately 4% for every additional 10°C and/or

approximately 1% for everyadditional 100m in altitude.

--5

Page 7

Omperator's anual

www.fubag.ru

Positioning the generating set for operation

Place the generating set on a flat, horizontal surface which is firm enough to prevent the set sinking

down (under no circumstancesshould the set tiltany direction by morethan 10°).

Earthing the generating set

To earth the generating set, use a 10 mm copper wire attached to the generating set earth

2

connection and to an earthing rod of galvanised steel set in the ground to a depth of 1 metre. This

also dissipates the staticelectricity that builds upin the electrical machines.

Checking the oil level

- Remove the dipstick/plug on the exhaust side

Oil

filler

plug

by unscrewing it, andwipe the dipstick.

- Insert the dipstick into the filler neck without

screwing it in. A second plug, without a

dipstick, is available if necessary on the

other side of theengine.

- Check the level and top up if necessary. If it is

necessary:

- Using a funnel, fill the engine oil sump right up

Drain

plug

to the top ofthe filler opening.

- Screw the plugfully back onto thefiller tube.

- Check that thereare no leaks.

- Wipe off excessoil with a cleancloth.

5W

10W

Single grade

20W

#20

#30

#40

Multigrade

Ambient

temperature

-20 -10 0 10 20

-4

14 32 50 68 86

10W-30

10W-40

40

C

30

104

F

Checking the fuel level

Check the fuel leveland top up ifnecessary:

See indicator

- the fuel tank .

- Fill the tankusing a funnel, takingcare not to spillpetrol.

- Screw the capback on to thefuel tank.

Only use clean fuel without any water. Do not overfill the tank (there should not be any fuel in the

filler neck). When you havefilled up, ensure thatthe tank cap isclosed correctly.

Take care not tospill any fuel whenfilling the tank.

Before starting up the generating set, and if any fuel has been spilt, make sure that it has dried and

that the vapours havecleared away.

--6

Page 8

Omperator's anual

5. Using the generator set

www.fubag.ru

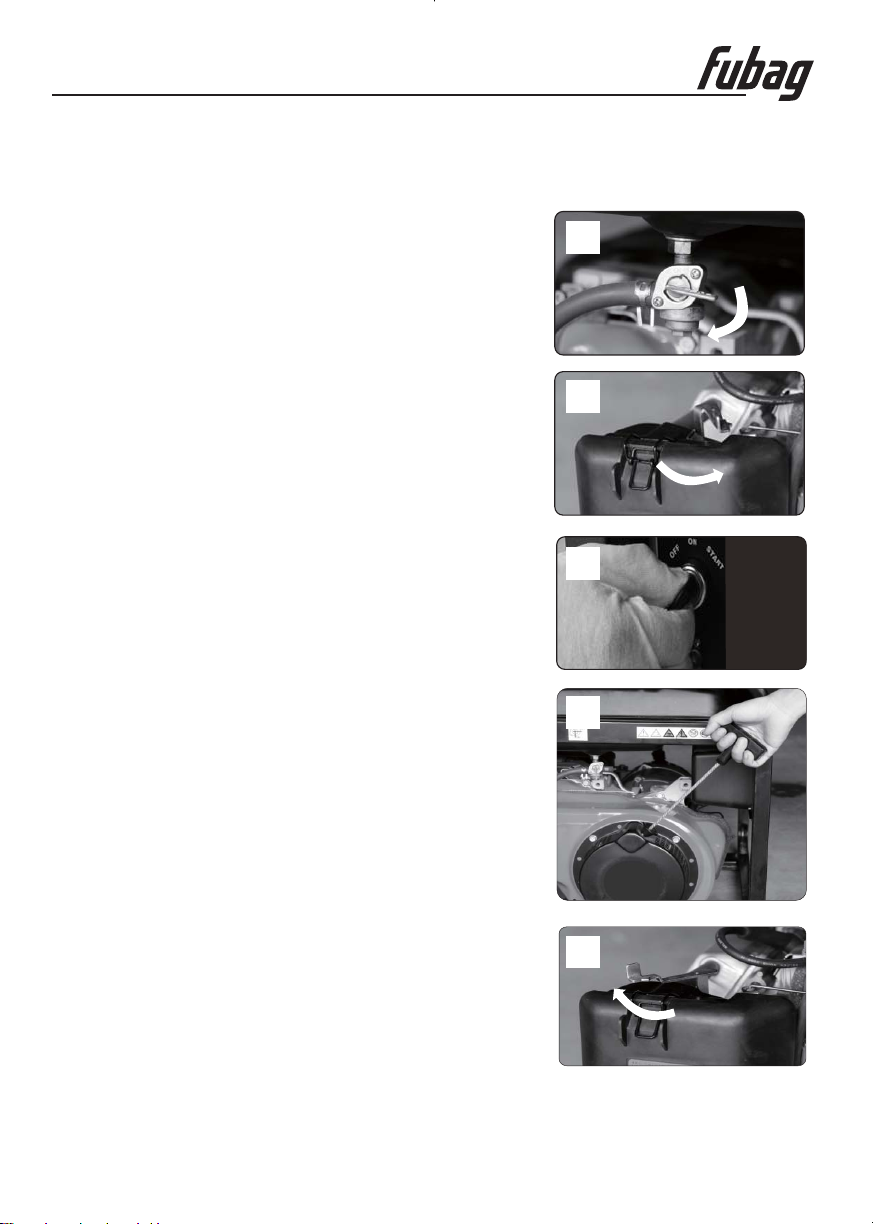

Starting

1. Open the fueltap by turning leverto the right.

2. Move the chokeknob to the closedposition.

Do not use the choke when the engine is warm or when

Note:

the atmospheric temperature ishigh.

3. Move the engineswitch to ON.

4. Pull the starter handle slowly until resistance is felt. Return

the handle to its original position and pull swiftly. Do not fully

pull out the rope. After starting, allow the starter return to its

original position whilestillholding the handle.

5. When the enginehas started, gradually openthe choke.

If the engine has not started, repeat the procedure until the

engine starts while graduallyopening the choke

Warmup the engine withoutload for a fewminutes.

.

1

OPEN

2

CLOSE

3

4

- 7 -

5

OPEN

Page 9

Omperator's anual

www.fubag.ru

U

sing electric power

1. Check the voltmeterdisplay for proper voltage.

2. Check the amperage of the socket, and be sure not to take a current exceed the exceed the

specified amperage. Be sure that the total wattage of all appliances does not exceed the rated

output of the machine.

3. Turn off the switch(es) ofthe electrical appliance(s) beforeconnecting to the machine.

4. Insert the plug(s)of the electrical appliance(s)into the receptacle.

Welding instructions

No work of power station in a mode "welding" and "generator" is forbidden. Before carrying out of

welding works disconnect all consumers from sockets.

1. Check the weldingcable, connect the weldingcables to the welder’s DC terminals

Start the engine, runat no load towarm up fully

2. .

Set the current adjustknob to the propercurrent level.

3.

Plate thickness Electrode diameter Settings current

2.0~3.0 mm

3.0~4.0 mm

4.0~6.0 mm

7.0+mm 5.0 mm 140-210 A

2.0 mm 50-80 A

3.2 mm 70-120 A

4.0 mm 110-170 A

Switching off

1 . Take the plugs out of the sockets and allow the engine to run without any charge for 1 to 2

minutes.

2. Place the engineswitch on "OFF" andthe set will stop.

3. Close the fueltap.

.

O

il sensor

The oil sensor detects thefall in oil in the crankcase and automaticallystops the engine when theoil

level falls down below the safety limit. If the engine does not start by usual starting procedures,

check the oil level.

High altitude operation

At high altitude, the standard carburetor air-fuel mixture will be excessively rich. Performance will

decrease, and fuel consumption will increase. High altitude performance can be improved by

installing a smaller diameter main fuel jet in the carburetor and readjusting the pilot screws. lf you

always operate the generator at altitudes higher than1000 m abovesea level, have your authorized

dealer perform these carburetormodifications.

Even with suitablecarburetor jetting, enginehorsepower will decrease approximately 3.5% for each

300 m increase in altitude. The affect of altitude on the horsepower will be greater than this if no

carburetor modification ismade.

Operation of the generator at an altitudelower than the carburetor isjetted for may result in reduced

performance,overheating,and serious enginedamage

caused by an excessivelylean air/fuel mixture.

- 8 -

Page 10

Omperator's anual

www.fubag.ru

Preparation and maintenance in winter time

Maintenance in wintertime is consideredto be the period when the temperatureof the ambientair is

fixed below +5 С. The low temperature of the ambient air hampers the engine start, negatively

О

influences the operationof all its systems.Toprepare the generatorand provide its furtherno-failure

operation it is necessaryto make the followingsteps:

- Use up allthe old fuel completely, discharge the remainingone.

- Clean the filterof the fuel valve.

- Check the airfilter.Changeit if necessary.

- Substitute the engineoil for the oilcorresponding to the season.

- Fill the fuel tank with the fuel to avoid ingress of water and its further freezing in the fuel

tank and the carburetor.

The generator is to be kept in a place at the temperature from +5 С and above in winter time. If the

О

engine stops formore than 15 minutesduring the operation atnegative temperatures it isnecessary

to place the set into a warm place to prevent the condensate freezing in the breather pipe and the

throttle before its start. It may cause the pressure boost in the crankcase housing and the gaskets

break down. The monitoring of the set operation is to be carried out oftener than under usual

operating conditions astheyare considered to berough.

6. Maintenance

-

The maintenance interval frequency and the operations to be carried out are outlined in the

maintenance programme.

-

However, it should be added that it is the environment in which the generating set is operating

which determines this programme. Accordingly, if the set is used in extreme conditions, shorter

intervals between maintenance procedures should be adopted.

These maintenance schedules apply only to generating sets running on fuel and oil, that

conform to the specifications given in this booklet.

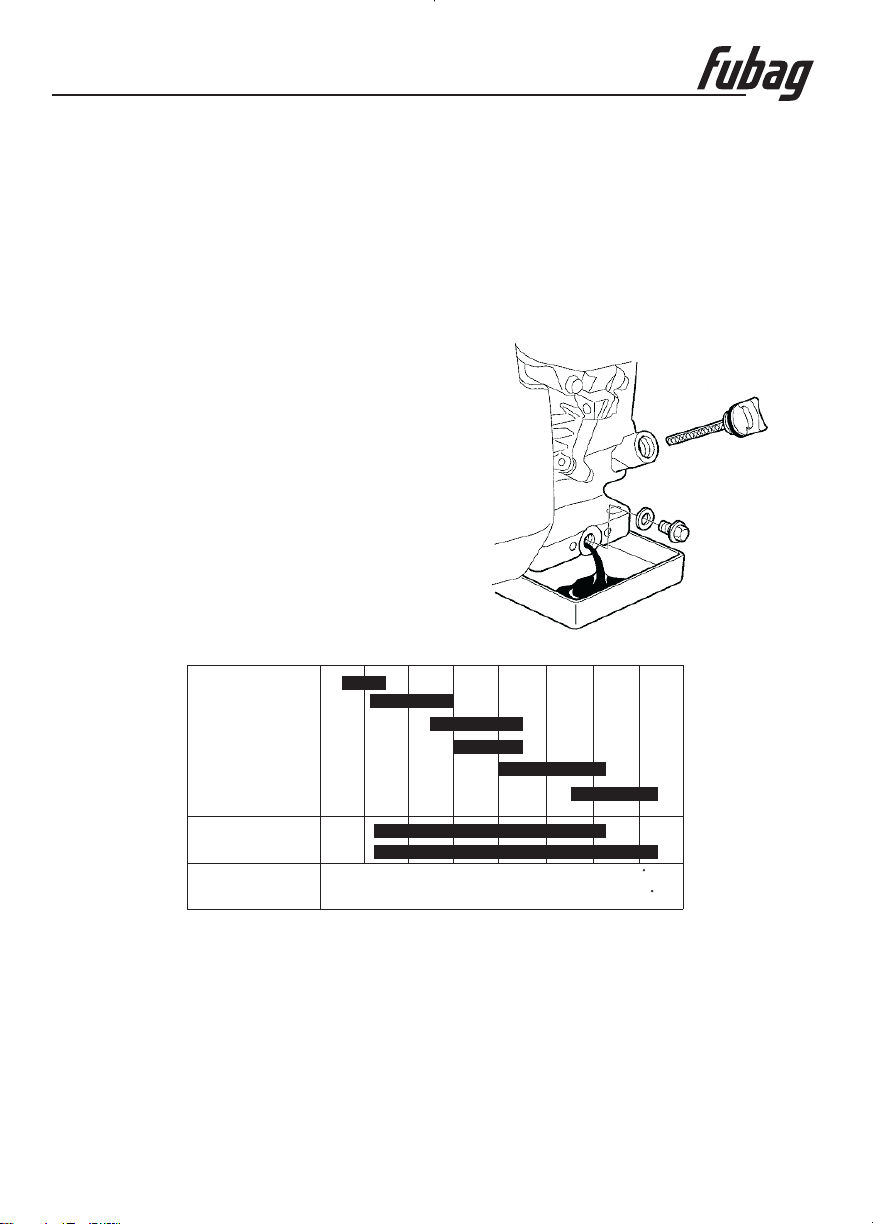

? Check the air cleaner

Daily

50 hours

(Weekly)

100 hours

300 hours or

every year

3 years

? Check oil level and refill to the upper level before starting the

engine.

? Check all the points indicated in " Putting the Generator into

Operation".

? Clean and wash air-cleaner element.

? More often if used in dirty or dusty environments.

? Change engine oil.(The initial oil change must be conducted

after the 25 hours operation.)

? Check spark plug, and clean and adjust if necessary.

? Check and clean the fuel shut-off valve.

? Replace spark plug.

? Replace air-cleaner element.

? Decarbonize cylinder head, valves and piston.

? Check and replace carbon brushes.

? Inspect control panel components.

? Check rotor and stator.

? Replace engine mount rubber.

? Overhaul engine.

? Change fuel lines.

- 9 -

Page 11

Omperator's anual

www.fubag.ru

Renewing the motor oil

Initial oil change should performed after first 25 hours of use Thereafter change oil every 50 hours

Before changing oil check for a suitable way to dispose of the old oil Do not pour it down into

sewage drains onto garden soilor into open streams

,.

,.

Drain the oil whenthe engine is stillwarm, to ensure thatdrainage is rapid andcomplete.

1. Place an appropriate container under the drain plug, remove the dipstick/filler plug and the drain

plug.

2. On completion, screwin and tighten thedrain plug.

3. Fill the engineoil sump with therecommended oil, then checkthe level.

4. Reposition the dipstick/fillerplug and tighten.

5.After filling, check thatthere are no oilleaks.

6. Wipe off anytrace of oil witha clean cloth.

Cleaning the air filter

Remove the air filtercover,then remove the latter

1. .

Remove the assembly consisting element, and separate

2.

them. Check carefully that the element are not torn or

pierced. Replace themifthey are damaged

Wash the oam element in a solution of household

3.

f

.

cleaning product and warm water, then rinse thoroughly, or

wash it in non-flammable solventor solvent witha high flash

point. Leave the element to dry fully. Soak the element in

clean engine oil and remove the excess oil. The engine will

smoke when it is started for the first time if too much oil

remains in the foam

Carry out refitting following the reverse procedure to that

4.

.

used for removal.

..

UP

ELEMENT

COVER

GRID

Checking the spark plug

1 . Remove the spark plug cap and use a spark plug

spanner to remove thespark plug.

2. Visually inspect the spark plug and discard it if the

electrodes are worn or if the insulation is split or chipped.If it

is to be re-used,clean the spark plugwith a wire brush.

3. Measure the electrode gap with a feeler gauge. The

electrode gap should be from 0,7 to 0,8 mm. Check that the

spark plug washer is in good condition and screw the spark

plug in by hand,in order to avoiddamaging the threads.

4. After fitting the spark plug, tighten it with a spark plug

spanner to secure thewasher.

when fitting a new spark plug, tighten it by 1/2 turn

Note:

after it isin place, in order to press thewasher tightly. For the

installation of an old spark plug, tighten it by a 1/8–1/4 turn

after it is inplace, in order topress the washer tightly.

.

- 10 -

0,7-0,8mm

Page 12

Omperator's anual

www.fubag.ru

Clianing fuel strainer

Dirt and water inthe fuel are removedby the fuel strainer.

1. Remove the strainercup and throw awaywater and dirt.

2. Clean the screensand strainer cup withgasoline.

3. Tightly fasten the cup to main body, making sure to avoid

fuel leak.

7. Preparation for storage

Certain operations must be carried out on generating sets

which are to remain unused for a long period of time,in order

to keep them in good condition. Check that the storage area

is not dusty or humid. Clean the exteriorof the generating set

and apply a rustproofingproduct.

- Drain fuel from fuel tank carefully. Gasoline left in the fuel

tank will eventually deteriorate making engine-starting

difficult.

Loosen the drainscrew on thebottom of thecarburetor float

chamber,and drain the fuelcompletely.

Change engine oil.

-

Check for loose boltsand screws, tighten themif necessary.

-

Clean generator thoroughly with oiled cloth. Spray with

preservative if available.

- Pull starter handle until resistance is felt, leaving handle in

that position.

Store generator in awell ventilated, low humidityarea.

-

DRAIN

FUEL

SCREEN 1

BODY

SCREEN 2

GASKET

CUP

- 11 -

Page 13

Omperator's anual

www.fubag.ru

8. TroubleShooting

When welder engine fails to start after several attempts, or if no electricity is available at the output

socket, check the following chart. If your welder still fails to start or have no electricity, contact your

nearest welder dealer forfurther information or correctiveprocedures.

When Engine Fails to Start:

Check if choke lever is in its

proper position

Check if fuel cock is open.

Check fuel level.

Check to make sure generator is not

connected to an appliance.

Check spark plug for loose spark

plug cap.

Check spark plug for contamination.

When No Electricity Is Generated at Receptacle:

Check to make sure no-fuse breaker

is in the ON Position.

Check DC terminals for loose

connections.

Check the appliance or equipment

have any defects .

Set the choke lever to

"CLOSE" position.

If closed, open fuel cock.

If empty, refill fuel tank making

sure not to overfill

If connected, turn off the

power switch on the connected

appliance and unplug.

If loose, push spark plug cap

back into place.

Remove spark plug and clean

electrodes.

After making sure that the total

wattage of the electrical appliance is

within permissible limits and there are

no defects in the appliance, turn the

circuit breaker to the"ON"position. If

breaker, continue to actuate, consult

your nearest servicing dealer.

Secure connections if necessary.

Replace or repair it.

- 12 -

Page 14

Omperator's anual

9 iring diagram.W

www.fubag.ru

10. Warranty

Warranty refer to defects of materials and components and do not refer to components subject to

natural wear and maintenancework.

Only machines cleanedfrom dust and dirtin original factory packingfully completed, providedwith

instruction manual, warranty card with fixed sales date with a shop stamp factory serial number

and originals of sales and ware receipt issued by salesman are subjects of warranty. Within the

warranty period the service center eliminate free of charge all detected production defects. The

manufacturer disclaims warranty and legal responsibilities if nonobservance of the instruction

manual by user, unqualified disassembling repair ormaintenance ofthe machine as well does not

bear responsibility forcausedinjury to persons ordamages.

- 13 -

Page 15

Инструкция по эксплуатации

www.fubag.ru

ВНИМАНИЕ! ПЕРЕД ИСПОЛЬЗОВАНИЕМ ЭЛЕКТРОСТАНЦИИ ВНИМАТЕЛЬНО

ОЗНАКОМЬТЕСЬ С ДАННОЙ ИНСТРУКЦИЕЙ.

К использованию и обслуживанию электростанции допускается только

квалифицированный и специально обученный персонал, ознакомленный с данной

инструкцией.

В этой инструкции содержится описание, правила безопасности и вся необходимая

информация для правильной эксплуатации электростанции FUBAG. Сохраняйте данную

инструкцию и обращайтесь к ней при возникновении вопросов по безопасной эксплуатации,

обслуживанию, хранению и транспортировкеэлектростанцииFUBAG.

1. Правила безопасности

ВНИМАНИЕ!

ВНИМАНИЕ!

ВНИМАНИЕ!

ВНИМАНИЕ!

Выхлопы содержат вредный угарный газ. Никогда не эксплуатируйте

электростанцию в закрытом помещении. Перед включением

убедитесь, что обеспечена хорошая вентиляция. При установке в

хорошо проветриваемых зонах обращайте внимание на обеспечение

безопасности.

При работе электростанции глушитель становится очень горячим и

остывает некоторое время после ее выключения. Будьте внимательны

и не дотрагивайтесь до глушителя, пока он горячий. Дайте двигателю

остыть до того, какпоставить его на хранение впомещение.

Выхлопная система двигателя будет нагреваться при работе и

останетсягорячейнекотороевремя после выключения двигателя.

Для предотвращения ожогов обращайте внимание на

предупредительные наклейки наэлектростанции.

Бензин является легко воспламеняемым ивзрывоопаснымвеществом.

Осуществляйте заправку электростанции топливом только в хорошо

проветриваемых зонах при выключенном и остывшем двигателе.

Поблизости не должно быть курящих, источника искр и дыма. Всегда

заправляйте электростанцию в хорошо проветриваемом месте.

Пролитый бензин необходимосразу удалить.

Подсоединение электростанции к электросистеме должно

осуществляться только квалифицированным электриком и должно

соответствовать всем электротехническим правилам и нормам.

Неправильное подсоединение ксистеме может стать причинойвыхода

из строя электрогенератора, неисправности электросети и

подключенных к ней электроприборов, а также привести к поражению

электричеством людей.

-4 -1

Page 16

Инструкция по эксплуатации

www.fubag.ru

ВНИМАНИЕ!

- При работе размещайте электростанцию на расстояние не менее 5м от зданий/стен или

другогооборудования.

- Во времяработы электростанция должна стоятьна горизонтальной поверхности.

- Внимательно изучите и запомните параграфы инструкции, касающиеся остановки

электростанции, и органов управления. Не допускайте к работе с электростанцией лиц, не

ознакомившихся с инструкцией.

- Не допускайте к работающей электростанции детей и домашних животных.

- Электростанция является источником электротока и при неправильной эксплуатации может

стать причиной поражения электрическим током. Не осуществляйте эксплуатацию

электростанции мокрыми руками ипри большой влажности.

- Не эксплуатируйте электростанцию в дождьили снег и не допускайте попадания на нее влаги.

- Лицам, работающим с электростанцией, необходимо знать его устройство, функции его

элементов и уметь их использовать.

- Работающие с электростанцией несутответственность за безопасность его эксплуатации.

- Работающие с электростанцией несут ответственность за то, чтобы к нему не допускались

лица, не имеющиесоответствующей квалификации.

- Работающие с электростанцией обязаны использовать защитное снаряжение.

- На корпусе электростанции должны присутствовать и быть легко читаемыми все

обозначения.

- Любые изменения конструкции электростанции запрещаются. Запрещается изменять

частоту вращения двигателя, установленную заводом-производителем.

- Перед каждым запуском и после него следует проверять безопасность и исправность

прибора.

- Электростанцию можно использоватьтолько вне закрытых помещений.

- Вблизи электростанции необходимо остерегаться открытого огня и искр. Курение вблизи

электростанции строго запрещается.

- Электростанцию необходимо защищать от попаданияв нее грязии инородных предметов.

- Электростанцию разрешается транспортировать только вохлаждённом состоянии.

- Электростанцию разрешается перевозить, только если она надёжно зафиксирована и не

можетопрокинуться.

- Перед каждым запуском необходимо проверить электробезопасность.

- Запрещается использовать средства для облегчения запуска.

- Подключать потребители электроэнергии можно только послезапуска и прогревадвигателя.

- Необходимо использовать только качественные иисправные соединительные провода.

- Общая мощность подключаемых потребителей, по активной нагрузке, не должна превышать

номинальной расчетной мощности электростанции. Общая мощность подключаемых

потребителей, по индуктивной нагрузке, не должна превышать 0,5 от номинальной мощности

электростанции.

- Запрещается использовать электростанцию без глушителя, воздушного фильтра или при

открытой крышке воздушного фильтра

- Запрещается производить заправку электростанции во время работы. Запрещается

производить заправку неостывшей электростанции. Используйте при заправке воронку.

- Запрещается производить чистку электростанции во время работы. Запрещается

производить чистку ещёне остывшей электростанции.

- Запрещается обслуживать электростанцию во время работы. Запрещается обслуживать не

остывшую электростанцию.

- Всегда проводите предэксплуатационный осмотр электростанции до

запуска двигателя. Вы можете предотвратить аварию или повреждение

оборудования.

-5 -1

Page 17

Инструкция по эксплуатации

www.fubag.ru

- Обслуживающему персоналу разрешается производить только те работы по обслуживанию

электростанции, которые описаны в данном руководстве. Любые другие работы разрешается

проводить только специалистам сервиснойслужбы.

- Перед началом работ по обслуживанию и ремонту обязательно снимайте колпачок свечи

зажигания.

- Соблюдайте интервалы технического обслуживания, указанные в руководстве.

- Консервируйте электростанцию, если им не пользуются более 30 дней.

- Храните электростанцию в сухом и закрытом помещении.

Меры безопасности при сварочных работах.

- Запрещается одновременная работа электростанции в режиме "сварка" и "генератор".

Перед проведением сварочных работ отсоедините всех потребителей от розеток.

- Всегда надевайте защитную маску во время работы сварочным аппаратом или

используйте очки с защитным затемненным стеклом.

- Старайтесь, чтобы искры и брызги не попали на тело.

- Избегайте контактов с открытыми токоведущими кабелями сварочного аппарата, не

прикасайтесь к электрододержателю/горелке и свариваемой поверхности.

- Дым и газ, которые попадают в воздух при сварке, опасны для здоровья. Перед началом

работ убедитесь, что вытяжка и вентиляция исправно работают.

- Убедитесь, что излучение дуги не попадет на других людей, находящихся поблизости от

места сварки.

- Помните, что при сварке температура обрабатываемой поверхности повышается,

поэтому старайтесь не прикасаться к обрабатываемым деталям во избежание ожогов.

- Никогда не производите сварку емкостей, в которых могут содержаться

легковоспламеняющиеся или взрывоопасные материалы.

- Сварочные аппараты излучают электромагнитные волны и создают помехи для

радиочастот, поэтому следите за тем, чтобы в непосредственной близости от аппарата не

было людей, которые используют стимулятор сердца или другие принадлежности, для

которых электромагнитные волны и радиочастоты создают помехи.

- Запрещено использовать сварочный аппарат для размораживания труб.

- Время от времени следует проверять состояние сварочного кабеля. Если аппарат

используется регулярно, его следует проверять не менее одного раза в месяц.

- Если аппарат не эксплуатируется, электрод следует вынимать из держателя.

-6 -1

Page 18

Инструкция по эксплуатации

2. Описание

www.fubag.ru

13

11

12

8

5

6

7

4

3

2

9

1

10

1. Выключатель двигателя

2. Цифровой вольтметр

3. Защита от перегрузки

4. Розетка 220 В

5. Крышка топливного бака

6. Индикатор уровня топлива

7. Регулятор тока

14

15

8. Индикатор работы

9. Сварочные клеммы

10. Пробка слива масла

11. Крышка маслозаливной

горловины

12. Топливный кран

13. Воздушная заслонка

14. Ручной стартер

15. Воздушный фильтр

-7 -1

Page 19

Инструкция по эксплуатации

www.fubag.ru

3. Технические характеристики

Параметр\Модель WHS 190 DC WHS 210 DC

Номинальное напряжение, В 230 230

Частота, Гц 50 50

Максимальная мощность, кВА 4,5 5

Номинальная мощность, кВт 4 4,5

Номинальный ток, А 18,2 20,5

Коэфициент мощности, cos φ

Класс защиты

Двигатель

HONDA GX390

Мощность двигателя, кВт/л.с

Топливо

Автомобильный бензин А-92

Объем топливного бака, л 25 25

Объем масляного картера, л 1,1 1,1

Тип масла

Тип стартера

Вес (без топлива), кг 89 92

Габаритные размеры, мм 729x537x592 729x537x592

Сварочные характеристики

Род сварочного тока

Постоянный DC

Диапазон регулировки сварочного тока, А 50-190 60-210

Напряжение холостого хода, В 65 65

Сварочный ток при ПВ=60%, A 120 140

Минимальный диаметр электрода, мм

Максиальный диаметр электрода, мм 4 5

Производитель имеет право вносить изменения, как в содержание данной инструкции, так и в

конструкцию электростанции безпредварительногоуведомленияпользователей.

1

IP23

9,6/13

SAE 10W30

ручной

1,6

4. Ввод в эксплуатацию

Условия эксплуатации

Электростанции обеспечивают устойчивую работу при температуре окружающей среды от

° до ° тип бензина и масла должны быть подобраны в соответствии с этими

-15 C +40 C, (

условиями). Относительная влажность: %

Характеристики электростанции снижаются на при увеличении температуры на каждые

° и/или примерно на при увеличении высоты над уровнем моря на каждые

10 C 1% 100

метров.

<60

4%

-8 -1

Page 20

Инструкция по эксплуатации

www.fubag.ru

Место эксплуатации

Выберите чистое, хорошо проветриваемое и защищенное от неблагоприятного

атмосферного воздействия место. Установите электростанцию на ровную горизонтальную

площадку, достаточно прочную, чтобы выдержать вес установки (наклон установки во всех

направлениях не должен превышать 10°).

Заземление генераторной установки

Для заземления электростанции установки используйте медный провод сечением 10 мм ,

который следует соединить с точкой заземления установки и со штырем заземления из

оцинкованной стали, углубленным на 1метрвземлю.

Пробка

Проверка уровня масла

- Отверните пробку маслоналивной

маслоналивной

горловины

горловины.

- Проверьте уровень масла. Уровень

должен находится выше середины

по масломерному щупу.

- Добавьте масло принеобходимости.

- Заверните пробку маслоналивной

горловины.

- Удалите подтеки масла чистой

Пробка

слива

масла

тканью.

5W

10W

Незагущенное

мало

Загущенное

мало

Тем-ра окружающей

среды

-20 -10 0 10 20

-4

20W

#20

#30

10W-30

10W-40

14 32 50 68 86

#40

40

C

30

104

F

2

Проверка уровня топлива

Используя индикатор топлива проверьте его уровень. При необходимости, долейте топливо

в следующем порядке:

- Закройте топливный кран.

- Заполните бак при помощиворонки,стараясь не пролить топливо.

- Заверните пробку топливного бака.

Используйте только чистое топливо без примеси воды. Не переполняйте топливный бак

(внутри заправочной горловины не должно бытьтоплива).

По окончании заправки убедитесь, что пробка заливной горловины топливного бака

правильно закрыта. Если было пролито топливо, то прежде чем включать установку,

убедитесь,что топливо высохло иегопары испарились.

-9 -1

Page 21

Инструкция по эксплуатации

5. Эксплуатация

www.fubag.ru

Запуск

Убедитесьвтом, что электростанция надежно заземлена.

1. Откройте топливный кран.

2. Закройте воздушную заслонку.

Примечание:

запуске горячего двигателя или при повышенной

температуреокружающеговоздуха.

3. Поверните выключатель двигателя в положение ВКЛ.

4. Медленно потяните ручку стартера, пока не

почувствуете некоторое сопротивление, затем медленно

верните ее в исходное положение. Сильно и резко

вытяните ручку стартера, затем медленно верните ее в

исходноеположение.

5. После запуска двигателя медленно верните воздушную

заслонку в положение «OPEN».

Если двигатель не запустится, повторяйте эту операцию

вплоть до запуска двигателя, постепенно открывая

воздушнуюзаслонку.

Прогрейте двигатель без нагрузки в течение нескольких

минут.

не используйте воздушную заслонку при

1

OPEN

2

CLOSE

3

4

- 20 -

5

OPEN

Page 22

Инструкция по эксплуатации

www.fubag.ru

Подключениепотребителей

1. Проверьтеправильность напряжения по вольтметру.

2. Проверьте амперную нагрузку и убедитесь, что ток не превышает требуемое значение.

Убедитесь, что общая потребляемая мощность приборов не превышает номинальную

мощность электростанции.

3. Выключите электроприборы перед подсоединением к электростанции.

4. Подсоедините вилку электроприбора крозеткеи включите его.

Сварочныеработы

Запрещается одновременная работа электростанции в режиме "сварка" и "генератор".

Перед проведением сварочных работ отсоедините всех потребителей от розеток.

1. Проверьте сварочные кабели и подсоедините их к клеммам

выбирайте в соответствии с типом электрода указаннымна упаковке.

Запустите двигатель дайте устройству проработать без нагрузки до полного нагрева.

2. ,

Установите нужный токсварки,используярегулятортока.

3.

Толщина пластины Диаметр электрода Настройки тока

2.0~3.0 мм

3.0~4.0 мм

4.0~6.0 мм

7.0+мм 5.0 мм 140-210 A

2.0 мм 50-80 A

3.2 мм 70-120 A

4.0 мм 110-170 A

Выключение электростанции

1. Остановите и отключите приборы.

2. Дайте двигателю поработатьвхолостую в течение нескольких минут.

3. Установитевыключатель двигателяв положение OFF. Электростанция остановится.

4. Закройте топливный кран.

Полярность подключения

.

Датчик масла

При низком уровне масла в картере двигатель останавливается автоматически. В этом

случае необходимо проверьте уровень маслаи при необходимости долить.

Эксплуатацияв условиях высокогорья

При эксплуатации в условиях высокогорья топливовоздушная смесь в карбюраторе сильно

обогащается. В этом случае выходная мощность сокращается, а объем потребления

топлива возрастает.

Для восстановления производительности двигателя, достаточно установить топливный

жиклер меньшего диаметра и отрегулировать контрольный винт карбюратора. Если

двигатель эксплуатируется на высоте 1000 метров над уровнем моря, следует обратиться к

уполномоченному представителю и приобрести карбюратор соответствующего типа. В

противном случае, придется понизить выходную мощность.

Даже если карбюратор отвечает всем необходимым требованиям, мощность двигателя

будет падать, приблизительно,на 3,5% накаждые 300 метров подъема выше уровняморя.

Если в стандартных условиях эксплуатации используется карбюратор, предназначенный

для эксплуатации в условиях высокогорья, то в результате обеднения воздушно-топливной

смеси выходная мощность двигателя понизится, что может привести к его перегреву и

повреждению.

- 21 -

Page 23

Инструкция по эксплуатации

www.fubag.ru

Эксплуатацияв зимний период

Зимним периодом эксплуатации считается такой период, когда температура окружающего

воздуха устанавливается ниже +5 С. Низкая температура окружающего воздуха затрудняет

О

пуск двигателя,оказываетотрицательное влияние на работу всех его систем. Для подготовки

электростанции безаварийнойего эксплуатации необходимо:

- полностью выработать старое топливо, остатки топлива слить через дренажное отверстие

в нижней части карбюратора.

- произвести очистку фильтра топливного крана.

- проверить свечу зажигания. Если имеются повреждения, либо на керамической наружной

части корпуса естькоричневый налет, необходимо заменить свечу.

- проверить воздушный фильтр, при необходимости заменить его.

- заменить моторное маслона соответствующее сезону.

- в топливный бак залить отстоянный бензин во избежание попадания и дальнейшего

замерзания воды в топливном баке и карбюраторе.

В зимнее время электростанция должна храниться в помещении с температурой выше

О

С

+5 . Если во время работы при отрицательных температурах производится остановка

двигателя более чем на 15 минут, то перед запуском необходимо поместить установку в

теплое место для предотвращения замерзания конденсата в трубке сапуна и в дроссельной

заслонке, так как это может привести к повышению давления в картере и выходу из строя

сальников. Контроль за работой электростанции вэтот период должен осуществляться чаще

обычного, так как условияэксплуатацииявляются тяжелыми.

6. Техническое обслуживание

- Обслуживание аппарата может производиться только квалифицированным персоналом.

- Всегда выключайте электростанцию и снимайте колпачок свечи зажигания.

Проводите следующие работы по обслуживанию регулярно и с соблюдением указанных

интервалов.

? Проверьте воздушный фильтр.

Ежедневно

50 часов

(Еженедельно)

100 часов

300 часов или

развгод

3года

? Перед запуском двигателя проверьте уровень масла и долейте до

верхнего уровня.

? Проверьте все пункты, указанные в главе «Ввод в эксплуатации».

? Почистите и промойте элементы воздушного фильтра.

? Выполняйте процедуру чаще, если устройство используется в

грязном или пыльном помещении.

? Замените моторное масло (Первую замену масла необходимо

выполнить после 25 часов эксплуатации устройства).

? Проверьте свечу зажигания, почистите и отрегулируйте при

необходимости.

? Проверьте и почистите отсечн ый топливный клапан.

? Замените свечу зажигания.

? Замените фильтрующий элемент воздушного фильтра.

? Удалите нагар с головки цил индра, клапанов и поршня.

? Проверьте и замените угольные щетки.

? Осмотрите компоненты панели управления.

? Проверьте ротор и статор.

? Замените резиновые монтажные опоры двигателя.

? Проведите капитальный ремонт двигателя.

? Замените топливные шланги.

- 22 -

Page 24

Инструкция по эксплуатации

www.fubag.ru

Замена моторногомасла

Первую замену масла необходимо выполнить после 25 часов эксплуатации устройства.

Меняйте масло каждые 50 часов. Перед заменой масла обеспечьте наличие

соответствующих средств для слива отработанного масла. Не сливайте отработанное масло

в канализацию, наземлюили в речку.

Для быстрого и полного слива масла выполняйте эту операцию нагорячемдвигателе.

1. Снимите пробку-щупгорловиныдля заправки масла ипробку сливного отверстия, и слейте

масло в подходящую емкость.

2. По окончаниислива заверните и затяните пробку сливногоотверстия.

3. Наполните картер моторным масломрекомендованноготипа и проверьтеуровень масла.

4. Установитена место и затяните пробку-щуп заправочной горловины.

5. Проверьтеотсутствиеутечек масла послезаправки.

6. Удалитевсе следы масла чистой тряпкой.

Очистка воздушного фильтра

1. Отстегните зажим крепления крышки воздушного

фильтра и снимитекрышку.

2. Извлеките фильтрующий элемент и внимательно

проверьте на отсутствие в них дыр и разрывов.

Замените в случае повреждения.

3. Промойте элемент из пеноматериала в теплом

растворе бытового моющего средства и тщательно

прополощите, или промойте в невоспламеняющемся

или трудно воспламеняющемся растворителе.

Тщательно просушите элемент. Пропитайте элемент

чистым моторным маслом и отожмите излишек масла.

Если в элементе останется слишком много масла, при

первом запуске двигатель будет дымить.

4. Произведите сборку в обратном порядке

ВВЕРХ

ФИЛЬТРУЮЩИЙ

ЭЛЕМЕНТ

КРЫШКА

РЕШЕТКА

Проверка свечи зажигания

1. Снимите колпачок со свечи зажигания и при помощи

свечногоключавыверните свечу.

2. Осмотрите свечу зажигания. Свечу зажигания с

изношенными электродами, оплавленным или

отслаивающимся изолятором, следует утилизировать.

Если Вы будете использовать свечу зажигания далее,

очиститеее металлической щеткой.

3. Проверьте зазор между электродами свечи - должен

составлять 0,7-0,8 мм. Проверьте состояние

уплотнительной шайбы свечи зажигания и заверните

свечувручную, чтобы не повредить резьбу.

4. Завернув свечу зажигания вручную, довернитеее при

помощи свечногоключа, чтобы сжать шайбу.

Примечание:

Устанавливая новую свечу, доверните ее

на 1/2 оборота, чтобы сжать шайбу.Устанавливая ранее

использовавшуюся свечу, доверните ее на 1/8 –1/4

оборота,чтобы сжать шайбу.

-3 -2

0,7-0,8мм

Page 25

Инструкция по эксплуатации

www.fubag.ru

Очистка стакана отстойника

Грязь и вода из топлива удаляются с помощью

отстойника.

1. Снимите чашку отстойника иудалите воду и грязь.

2. Почистите сеточки и чашку отстойника бензином.

3. Надежно прикрепите чашку к основному корпусу,

избегаяпоявленияутечек.

7. Консервирование электростанции

Если электростанция не будет эксплуатироваться в

течение длительного времени, ее следует специально

подготовить к хранению. Убедитесь в том, что в зоне

хранения нет избытка пыли или влаги. Очистите

внешние поверхности и нанесите средство против

ржавчины.

- Осторожно слейтетопливо из топливного бака. Бензин,

который остается в топливном баке ухудшится по

качеству, что впоследствии приведет к трудностям

запуска двигателя.

-

Ослабьте сливной винт в нижней части карбюратора и

полностью слейте топливо.

-

Замените моторное масло.

-

Проверьте наличие ослабленных винтов и болтов, и

при необходимостизатяните.

- Тщательно протрите электростанцию промасленной

тканью.

-

Потяните ручку стартера, пока не почувствуете

сопротивление,оставьте ручку вэтомположении.

Храните генератор в хорошо проветриваемом

-

помещении с низким уровнемвлажности.

СЛИВ

ТОПЛИВА

СЕТКА 1

КОРПУС

СЕТКА 2

ПРОКЛАДКА

ЧАШКА

-4 -2

Page 26

Инструкция по эксплуатации

www.fubag.ru

8. Неисправности и их устранение

Если после нескольких попыток электростанция не запускается или на выходной розетке

отсутствует напряжение, тогда выполните процедуры, которые указаны ниже. Если

двигатель все равно не запускается или отсутствует напряжение, тогда обратитесь в

ближайшийофициальный Сервисный Центр дляполучениядополнительнойинформации.

Если двигатель не запускается:

Проверьте, чтобы воздушная

заслонка находилась в правильном

положении.

Проверьте, чтобы топливный кран

был открыт.

Проверьте уровень топлива. Если бак пустой, долейте топливо,

Убедитесь в том, что

электростанция не соединен с

потребителем.

Проверьте, чтобы колпачок свечи

зажигания не был ослаблен.

Проверьте свечу зажигания на

наличие грязи.

Переведите воздушную заслонку в

положение «CLOSE» (ЗАКРЫТЬ).

Откройте кран, если он закрыт.

убедившись, что он не переполнен.

Если потребитель подсоединен,

выключите выключатель питания на

подсоединенном потребителе и выньте

вилку из розетки.

Если колпачок ослаблен, поставьте его

на место.

Снимите свечу зажигания и почистите

электроды.

Если в розетке отсутствует напряжение:

После проверки, что общая мощность

электрического потребителя находится

Проверьте, чтобы выключатель

автоматической защиты не

находится в положении ON (ВКЛ).

Проверьте наличие ослабленных

соединений на клеммах

постоянного тока.

Проверьте, не имеет ли

потребитель или оборудование

какие-либо дефекты.

в допустимых пределах и устройство не

имеет дефектов, переведите

прерыватель цепи в положение «ON»

(ВКЛ). Если прерыватель продолжает

срабатывать, тогда обратитесь в

ближайший Сервисный Центр.

При необходимости затяните

ослабленные соединения.

Замените или отремонтируйте

потребитель или оборудование.

-5 -2

Page 27

Инструкция по эксплуатации

9. Схемаэлектрическая

www.fubag.ru

10. Гарантийные обязательства

Гарантийныйсрок на оборудование указывается в прилагаемомсервисном талоне.

Гарантия относится к дефектам в материалах и узлах и не распространяется на компоненты,

подверженные естественному износу и работы по техническому обслуживанию.

Гарантийному ремонту подлежат только очищенные от пыли и грязи аппараты в заводской

упаковке, полностью укомплектованные, имеющие инструкцию по эксплуатации, гарантийный

талон с указанием даты продажи, при наличии штампа магазина, заводского номера и

оригиналов товарного и кассового чеков, выданных продавцом.

В течение гарантийного срока Сервисный центр устраняет за свой счёт выявленные

производственные дефекты. Производитель снимает свои гарантийные обязательства и

юридическую ответственность при несоблюдении потребителем инструкций по эксплуатации,

самостоятельной разборки, ремонта и технического обслуживания аппарата, а также не несет

никакой ответственностиза причиненные травмыи нанесенный ущерб.

-6 -2

Loading...

Loading...