Fubag TS-MIG 190, TS-MIG 150, TS-MIG 170, TS-MIG 180 User Manual [ru]

Omperator's anual

www.fubag.ru

WARNING! BEFORE USING THE WELDING MACHINE READ THE INSTRUCTION

MANUAL CAREFULLY! FOR QUALIFIED AND SPECIALLY TRAINED PERSONS

ONLY AFTER PROPER READING OF THIS MANUAL IS ALLOWED TO USE AND TO

MAINTAINTHIS WELDING MACHINE.

The detailed description, safety rules and all required information necessary for proper operation

and maintenance of FUBAG welding machine are provided below. Keep this instruction manual by

machine and refer to it by any doubts concerning safety operation, maintenance storage and

handling of FUBAG weldingmachine.

1. Safety perationo

It is highly recommended always to follow the safety rules. Wear protective clothes and

special means to avoid injuries to eyes and skins.

Use the welding mask or special protective glasses while working with the welding

machine. Only by viewing through the filter lens on the welding mask your eyes are

secured by your operation.

Prevent the sparks and spatter from harming your body.

-

Under no circumstance allow any part of your body to touch the welder's output bipolarity

(torch and work piece).

Do not operate under water or more humid place.

-

Fumes and gases produced when welding are hazardous to health. Make sure to work in

places where there are exhaust or ventilation facilities to keep fumes or emissions away

from the breathing zone.

Please remember to keep arc rays away from the other nearby people when welding. This

is only due to the interference from arc rays.

There will be high temperature when welding work piece, so please don't directly touch on it

-

No touching on the output connection or any other electrification parts while welding.

-

No touching on the electrification parts after turning on the power. Cut off the power supply

after operation or before leaving the welding site.

No welding in the dangerous site where easily get an electrical shock.

-

No welding for the container loaded inflammable or explosive materials.

-

Safe measures should be adoptted while operating in high place to avoid accident.

-

No entering the welding site for persons not concerned.

-

Welders possible have electromagnetism and frequency interference, so keep away people

with heart pace or the articles which can be interfered by electromagnetism and frequency.

WARNING. The welder voltage is always higher, so the safety precaution should be taken

before repair to avoid accidental shock. Switch off the power supply before each type of

maintenance work. The untrained people are not allowed to make maintenance of the

machine.

- 1 -

Omperator's anual

www.fubag.ru

Check the connection of input and output cables and the earth (ground) connection, etc.

Maintenance should be conducted by the trained personnel.

The newly installed machine or the welder not in use for some time needs to be checked by

-

multimeter have the right insulation resistance between each winding and the case.

When the welder is used outdoors, it should be kept from rain or long exposure to the sun.

Check is needed from time to time to make sure the welding cable is in good condition if the

-

welding machine is in frequent use. Check at least once each month if the welder is in

regular use. It is necessary to check when the welder is in mobile use.

If the welder is not in use either for a long time or temporarily, it should be kept dry and have

-

good ventilation to free it from moisture, erodible or toxic gas.

- The welder must be installed in the place where it can not be exposed to sun and rain. Also it

must be stored in less humid place with the temperature range at -10 +40 .

Dust removal is needed every year. Check the machine's fasteners, moving-iron, current

-

regulation screws, etc to make sure there are no loose connection problems.

The dust, acid and erodible dirt in the air at the job site can not exceed the amount required

-

by the norm (excluding the emission from the welder).

The welder must be installed in the place where it can not be exposed to sun and rain. Also it

-

must be stored in less humid place with the temperature.

There should be 50 cm space about for the welding machine to have good ventilation.

Make sure that there is no metal-like foreign body to enter the welding machine.

Electrode must be taken down from holder when no welding.

No violent vibration in the welder's surrounding area.

Make sure that there is no interference with the surrounding area at the installation site.

The welder should be installed on the horizontal surface and if it over 15°, there should be

-

added some anti-dump set.

Take measures to prevent wind while operating in the strong wind since the welder is gas

-

shielded. The wind speed is limited below 1 0 m/s, or the wind shield device must be loaded.

,

O

C

Safety Check:

Each item listed below mustbe carefully checked beforeoperation:

Make sure that there isno short circuit connection withwelder's both outputs.

Make sure that there is always sound output and input wire connection instead of exposing it

outside.

Regular check needs to be conducted by the qualified personnel after the welding machine has

been installed over a longperiod or re-operation, whichinvolves as follows:

Check the welding cable tosee if it cancontinue to be usedbefore it is wornout.

-

Replace the welder's inputcable as soon asit is found tobe broken or damaged.

-

Make sure whether there is enough power supply to make the welding machine work properly.

Any power source required to access the welding machine must be installed with some

protective equipments.

Please do not hesitate to contact us for technical assistance whenever you come across the

problems you can notwork out or youmay deem difficult to fix.

--2

Omperator's anual

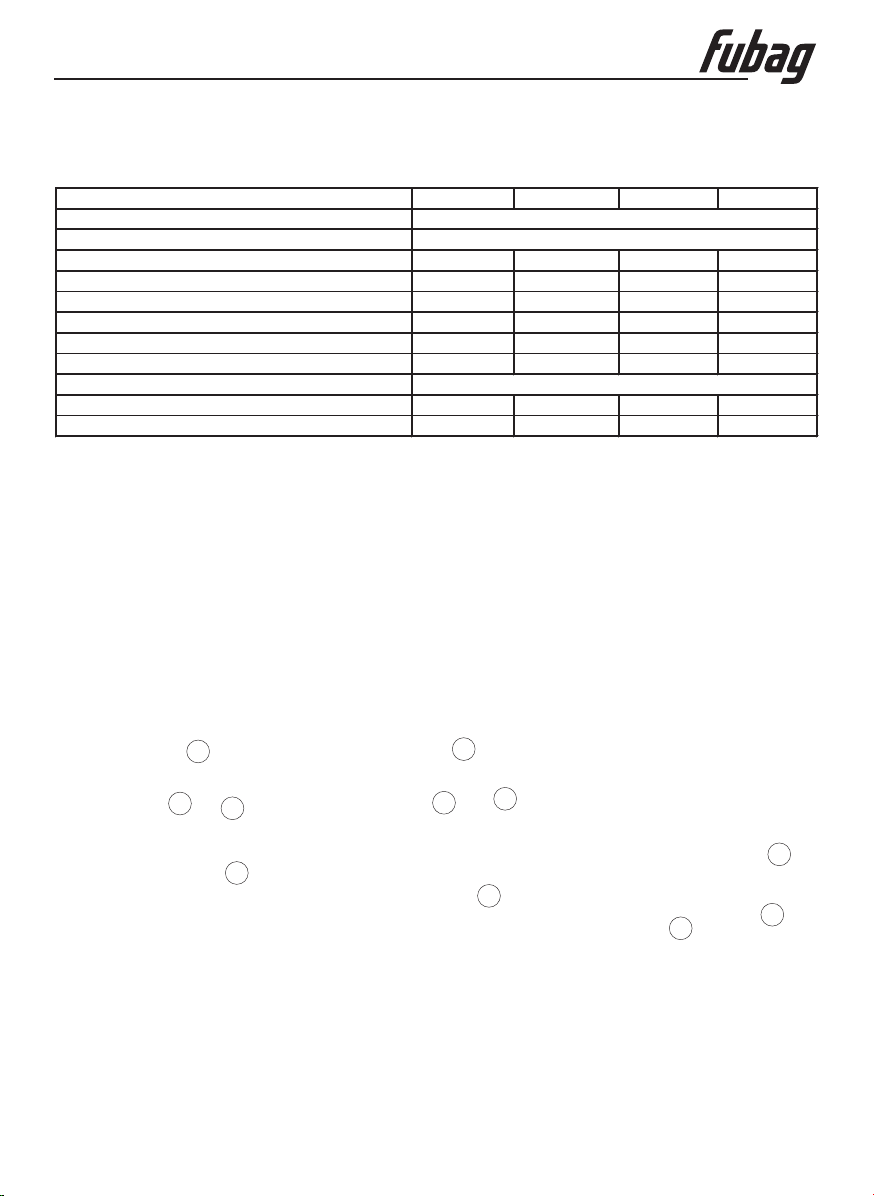

2. Technical Specification

www.fubag.ru

Моdel

Input power V

Frequency Hz

Rated input current А 19 20

Rated input capacitance kVA 4,2 4,4

No-load voltage V 32 30

Welding current А 30~105 30~115 30~145 30~170

Rated duty cycle % 20 15

Enclosure protection IP 21S 21S 21S 21S

Cooling type

Dimension L W H cm 44х23,8х36 44х23,8х36 44х23,8х36 57х33,6х44,5

Weight kg 23 23,5

The manufacturer reserves himself the right to make the manual's content or welder's function

change without any preliminary notification of the users.

TS-MIG 150 TS-MIG 170 TS-MIG 180 TS-MIG 190

220

50

26 36,6

5,7 8

35 34

15 15

Fan cooled

27 27,5

3. Description

The wire feed portable MIG/MAG welder adopts box structure: The front panel installs the power

switch, adjustment knobs, overheating indicator, MIG torch, work lead and power cord. If open the

case , you can see the wire feeding system on the left part of machine. The main transformer and

control PCB etc. are installedon the right partof machines.

5

5

1

2

4

1. Power

2. Сurrent

3.

Сurrent Adjusted Knob

ON/OFF

Adjusted switch

--3

1

3

4

4. Wire Speed Adjusted Knob

5. Overload light

6. Voltage Adjusted Knob

5

4

6

Omperator's anual

www.fubag.ru

If welding with large current for a long time and exceed the duty cycle, the overload lamp will be on

(orange), the machine will stop working until looking to the stated temperature. When the overload

lamp light you must stopwelding and wait about15 minutes, you cancontinue.

4. Environment

Environment to Which the Product Is Subject:

- The surroundingtemperature range: when welding: -10 + 40 С;

During transport or instorage: -25 +55 С

- Relative humidity: when at40 С: ≤50%, 20 С: ≤ 90%

ОО

О

when at

О

- The dust, acid and erodible materials in the air can not exceed the amount required by the norm

(apart from the emissions fromthe welding process). Noviolent vibration at thejob site.

- Keep from raining whenit is used outdoor.

-Altitude no more than1,000m.

Requirement for Main Supply:

- The oscillationof the supplied voltage should not exceed ±10% of the rated value.

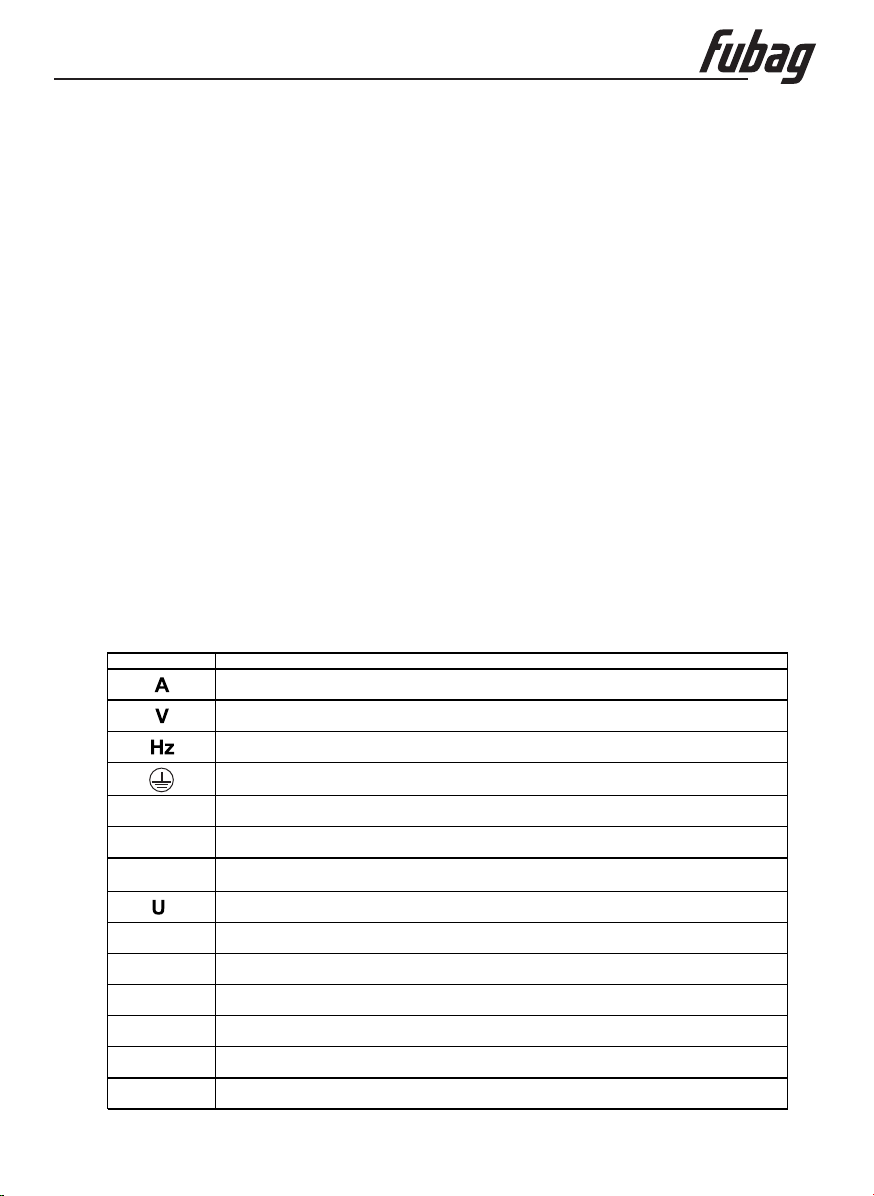

5. Sign & Pictures Illustration

SIGN

H

IP21

0

X

I

I

U

U

Current

Power

Frequency

Ground

Insulation grade

Protection class

Power source

Rated pen ircuit oltageoc v

Duty cycle

1

2

1

2

Rated nput urrentic

Rated elding urrentwc

Welder’s tructures

Rated nput oltageiv

Rated oadl voltage

NAME

--4

Omperator's anual

www.fubag.ru

6. Installation

WARNING! The welder must be well grounded before using. No disassembling of earth cable if

welding is not end, otherwise, it will do harm to human body. When several welders or some other

electrical appliances are using a common grounding device, they must be parallel connection,

series connection is forbidden. The welder's ground cable sectional area should not be less than

that of input power cable.

-

The welder must be loaded in the placewhere are less dust, no chemical, erodible,inflammable or

explosive gas and likeitems around the weldingsite.

-

The welder should be installed in the place where it can not be exposed to sun and rain. Also it

must be stored in lesshumid place with the temperaturerange: -10~40

-

There should be at least50 cm space forthe welding machine.

-

Apparatus to exclude wind andsmoke should be equippedif the inside aerationis not sound.

℃.

7 wire. Installation

-

Open the left side board,you can see the wirefeeding system.

-

Install the wire spool tothe wire spool axle, andthen fix.

-

Open the wire feed compaction equipment, let the terminal of wire through the wire guide tube,

drive roller and import the wire guide tube of welding torch, and close the impaction equipment,

adjust the compaction nut ofdrive roller.

3

2

1 - Wire spool axle

2 - Compaction equipment

3 - Compaction nut

1

- 5 -

Loading...

Loading...