Page 1

www.fubag.ru

Page 2

Omperator's anual

www.fubag.ru

www.fubag.ru

WARNING! BEFORE USING THE WELDING MACHINE READ THE INSTRUCTION

MANUAL CAREFULLY! FOR QUALIFIED AND SPECIALLY TRAINED PERSONS

ONLY AFTER PROPER READING OF THIS MANUAL IS ALLOWED TO USE AND TO

MAINTAINTHIS WELDING MACHINE.

The detailed description, safety rules and all required information necessary for proper operation

and maintenance of FUBAG welding machine are provided below. Keep this instruction manual by

machine and refer to it by any doubts concerning safety operation, maintenance storage and

handling ofFUBAG welding machine.

1. Safety perationo

It is highly recommended always to follow the safety rules. Wear protective clothes and

special means to avoid injuries to eyes and skins.

Use the welding mask or special protective glasses while working with the welding

machine. Only by viewing through the filter lens on the welding mask your eyes are

secured by your operation.

Prevent the sparks and spatter from harming your body.

-

Under no circumstance allow any part of your body to touch the welder's output bipolarity

(torch and work piece).

Do not operate under water or more humid place.

-

Fumes and gases produced when welding are hazardous to health. Make sure to work in

places where there are exhaust or ventilation facilities to keep fumes or emissions away

from the breathing zone.

Please remember to keep arc rays away from the other nearby people when welding. This

is only due to the interference from arc rays.

There will be high temperature when welding work piece, so please don't directly touch on it

-

No touching on the output connection or any other electrification parts while welding.

-

No touching on the electrification parts after turning on the power. Cut off the power supply

after operation or before leaving the welding site.

No welding in the dangerous site where easily get an electrical shock.

-

No welding for the container loaded inflammable or explosive materials.

-

Safe measures should be adoptted while operating in high place to avoid accident.

-

No entering the welding site for persons not concerned.

-

Welders possible have electromagnetism and frequency interference, so keep away people

with heart pace or the articles which can be interfered by electromagnetism and frequency.

WARNING. The welder voltage is always higher, so the safety precaution should be taken

before repair to avoid accidental shock. Switch off the power supply before each type of

maintenance work. The untrained people are not allowed to make maintenance of the

machine.

-1-

Page 3

Omperator's anual

www.fubag.ru

www.fubag.ru

-

Check the connection of input and output cables and the earth (ground) connection, etc...

-

Maintenance should be conducted by the trained personnel.

-

The newly installed machine or the welder not in use for some time needs to be checked by

multimeter have the right insulation resistance between each winding and the case, which

can not be less than 1Mohm.

When the welder is used outdoors, it should be kept from rain or long exposure to the sun.

Check is needed from time to time to make sure the welding cable is in good condition if the

-

welding machine is in frequent use. Check at least once each month if the welder is in

regular use. It is necessary to check when the welder is in mobile use.

If the welder is not in use either for a long time or temporarily, it should be kept dry and have

-

good ventilation to free it from moisture, erodible or toxic gas. The tolerable temperature

ranges are from -25 to +55 , and the relative humidity can not be more than 90% (25 ).

Dust removal is needed every year. Check the machine's fasteners, moving-iron, current

-

regulation screws, etc to make sure there are no loose connection problems.

The dust, acid and erodible dirt in the air at the job site can not exceed the amount required

-

by the norm (excluding the emission from the welder).

The welder must be installed in the place where it can not be exposed to sun and rain. Also it

-

must be stored in less humid place with the temperature range at -10 40°C.

There should be 50 cm space about for the welding machine to have good ventilation.

Make sure that there is no metal-like foreign body to enter the welding machine.

Electrode must be taken down from holder when no welding.

No violent vibration in the welder's surrounding area.

Make sure that there is no interference with the surrounding area at the installation site.

-

°C °C

Safety Check:

Each item listed below must be carefully checked before operation:

Make sure that there is no short circuit connection with welder's both outputs.

Make sure that there is always sound output and input wire connection instead of exposing it

outside.

Regular check needs to be conducted by the qualified personnel after the welding machine has

been installed over a long period or re-operation, which involves as follows:

Check the welding cable to see if it can continue to be used before it is worn out.

-

Replace thewelder's input cable as soon as it is found to be broken or damaged.

-

Make sure whether there is enough power supply to make the welding machine work properly.

Any power source required to access the welding machine must be installed with some

protective equipments.

Please do not hesitate to contact us for technical assistance whenever you come across the

problems youcan not work out or you may deem difficult to fix.

--2

Page 4

Omperator's anual

www.fubag.ru

www.fubag.ru

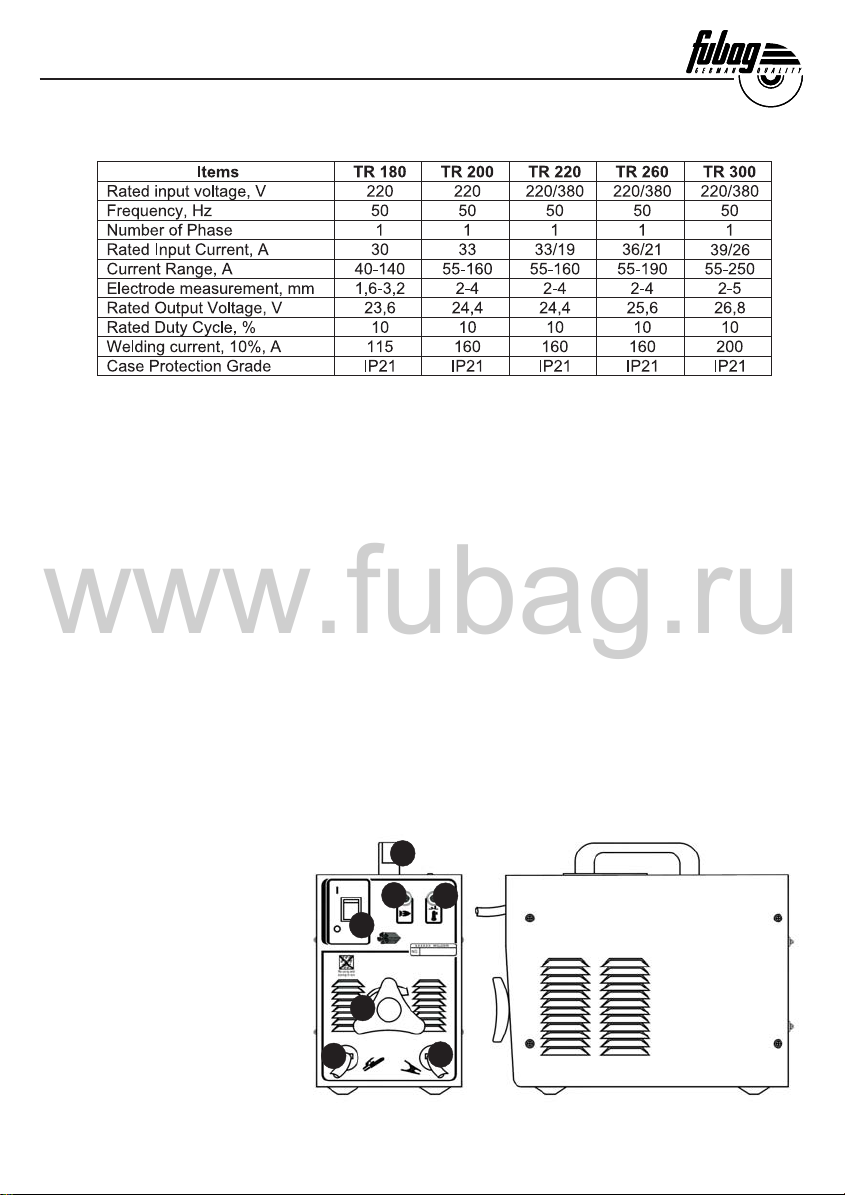

2. Technical pecificationss

The manufacturer reserves himself the right to make the manual's content or welder's function

change without any preliminary notification of the users.

The environment temperature range: When welding: -10 +40°C.

During transportor in storage: -25 +55°C.

Relative humidity:by 40°C 50%,by 20°C 90%.

---

The dust, acid and erodible materials in the air can not exceed the amount required by the norm

-

(apart from the emissions from the welder). No violent vibration at the operation area.

Altitude no more than 1,000 m.

-

The voltage oscillogram should display actual sine wave. The oscillation of the supplied voltage

-

should notexceed ±10% of the rated value.

3. Product escriptiond

FUBAG series portable arc welder is an arc welding power source (MMA) manually operated with

regulation of welding current. This type of welding machine is a sliding iron-core type arc welding

transformer. It has many advantageous features: compact structure, reasonable design, portable,

low noise, excellent performance and convenient maintenance.

The machine is armed with automatic temperature control and wind-cooling device for ensuring

long term efficient and safe work. It adopts sliding iron-core controllable current design with 220V or

380V, 50Hz or 60Hz AC power. The quality is steady and reliable with good performance for thick

and thin plate welding.

Switch

1.

Handle

2.

Regulator of a current

3.

E

4. lectrode holder

W

5. ork piece

Indicator of power supplies

6.

Indicator of temperature

7.

protection

4

2

6

7

1

3

5

--3

Page 5

Omperator's anual

www.fubag.ru

www.fubag.ru

REMARKS: Accessories for the welding machine are provided as per contract or according to the

user's demand. No guarantee has been made yet to get the welding accessories repaired at any

time because of its breakable attribute.

Complete et pecification:

50 /60

IA)

2

ss

1~

aw

Ground

Descending

Manual weldingwith coated electrode

Power source & AC single phase

Single phaseare welder transformer

1~

Rated open circuit voltage

AC, Rated frequency 50Hz or 60Hz

Max. and Min. of welding current and relevant current tolerance 10%

Symbol and measurement for standard electrode

- portable rc elder

hm

- andhold ask

s

- lag removing brush

o m and p c

- perator's anual roduct ertificate

wc

- arranty ard

Illustration of signs

1~

U(0V)

Hz Hz

±10%(

(мм)

()

(

IA)

2

Ts)

W

Ts)

R

U(

1

IA)

1Eff

IA)

1Max

Rated welding current

Timeof continuous uninterrupted welding

(

(

Rest time for cooling

V)

Power source voltage and frequency rated data

(

Rated currentdata

(

Symbol, ated data and max. current data

Needed fusedata

A

r

--4

Page 6

Omperator's anual

www.fubag.ru

www.fubag.ru

IP21S

Case protection class.

IP is the code of International Protection. Figure 2 means preventing user's finger from

the dangerous parts; preventing the solid material with the diameter no less than 12 5

mm into the box. Figure 1 means preventing water dropping vertically which is

harmless. Letter S means water proof test is conducting while the movable parts is

standstill.

nsulation gradeI

H

,

4. Installation

Before any maintenance or cable connection ensure that the welding machine is out of power

supply.

Choose the proper place for operation. Ensure in sufficient ventilation and in hindrance absence for

fresh air input and output. Ensure that no dust providing vapors, moisture, etc comes not in

ventilation.

The welder needs larger input current when operating. If power net cannot provide sufficient power

source, it will negatively influence the welding quality as well the power of other electrical

appliances. Ifyou have any problem relevant to this, you should consult with electrical specialist.

Connection between elder and ower ourcewps

Please always make sure before connecting that the voltage must be in conformity with the voltage

given on the welder's indication plate.

The plug of input power cable must be adapted to socket. Before making any electrical

connection checkfor the main voltage ratings to correspond to available voltageand main

frequency;

The socket used must be equipped with fuses or an automatic switch of adequate capacity

corresponding tothe information given on the data plate of the machine.

Connection between elder and lectrode older& ork iecewehwp

One end of welder' output cable is connected with welder as shown on the

panel, the other end is connected with work piece and electrode holder

(2)

.

If the end of welder' output cable is quick connector (option), it must be

touched by clockwise, if loose, the quick connector and welding cable will

be ruined.

(1)

1

2

--5

Page 7

Omperator's anual

www.fubag.ru

5. Welding perationo

www.fubag.ru

ATTENTION

satisfactorily and can prolong welder's operating life. When using the welder, please

make sure there is a good connection of input, output and earth (ground) before

connecting thepower source.

- After the welder's power is connected, the current regulation switch

needs to shift to the required position until the needed welding

current is obtained before operation.

- Before conducting welding work, make sure that the rust, paint,

varnish are thoroughly cleaned up of the work piece.

- Only when the electrode burns up to 2 3 cm away from the electrode

holder does it become necessary to replace it with a new one in

order to proceed with welding.

ATTENTION: Electrode burns at high temperature. Please do not use hand to replace it.

The replaced electrode end should be placed in a metal container.

Do not use the electrode holder to clamp the electrode coating.

- Rotate the hand-wheel clockwise to increase the current. Rotate the hand-wheel in anticlockwise, to decrease the current.

NOTE

: In case the value of current reaches its minimal and maximal value, turn the handle smoothly

to avoid damage of the regulator.

ATTENTION!

thoroughly checkthe quality of welded part joint.After that continue welding if necessary.

NOTE

:

-

Only until the slag cools off and becomeshardened can the removal work starts.

-

To avoid the slag injuring people, never point at the nearby people when you remove slag.

Before operation it is required to read carefully the instruction manual on the packing of electrodes

for right choose of the current and polarity.

Remember that for the same electrodes the higher current is used for welding on the floor and at the

same time the lower current for welding vertical or overhead.

Mechanical characteristics of the welded joint as well the current intensity are defined by electrodes

diameter and quality, arc length, operation speed and position of the electrode concerning the work

piece as well by correct storage of electrodes to be protected from humidity.

After using each welding rod, remove slag with a special hammer and brush,

: To properly operate the welder can assure the welder to work

ADJUSTMENT

WELDING CURRENT

-

MIN

MAX

Attention!

While welding, duty cycle should be less than rated data, otherwise over-load will accelerate the

component ageing, short the welder life and burn out the welder. Additionally, there is over-heat

protection relay inside the welder, when temperature surpass one data, the relay will work and cut

off the power. While relay is working, the light on the panel will lighting.

relay is working, the light on the panel will lighting. Afterthe over-heat protection has been activated

and till the repeated switched on of the welder it is necessary to find out and exclude the reasons led

to over-heating of the welder.

After welding parameter choosing it is required to choose the duty cycle of the machine.

and cut off the power. While

--6

Page 8

Omperator's anual

www.fubag.ru

www.fubag.ru

6. Maintenance

Warning! Never remove the cover or operate with the welding machine without unplug the main

power supply before. Moreover consider that some time after switch off the machine and some

components remainunder voltage and can cause the electrical shocks.

- Check the interior of the machine according to its use and dustiness of place. When

removing dust from transformer, reactance and rectifier always use dry compressed air at

a pressure of not more than max 10 bar.

- At the same time verify that electric connections are tight and check wiring for insulation failure.

When control operation is over, replace covers and check for screws to be tight.

- Never weld while machine is open!

7. Transport& torage

When the welder is in storage and transportation, please try to keep it from being exposed to the

rain. When loading, attach ATTENTION to the welder packing. It is recommended to free it from

moisture, erodible gas and dust in storage where it must be kept dry and have good ventilation. The

tolerable temperatureranges from -25 to +55 , and the relative humidity can notbe more than 90%

°C

(25 ).

After the package has been opened, it is suggested to repack the product as per requirement for

future storage and transport.

s

°C

8. Warranty

The manufacturer warranties the normal working of the machine within 12 months from the date of

its sale through retail network as well its repair and components replacement untimely broken

through manufacturer's fault providing observance of all requirement by installation, operation and

periodic maintenance.

Warranty refer to defects of materials and components and do not refer to components subject to

natural wear and maintenance work.

Only machines cleaned from dust and dirt in original factory packing fully completed, provided with

instruction manual, warranty card with fixed sales date with a shop stamp factory serial number and

originals of sales and ware receipt issued by salesman are subjects of warranty. Within the warranty

period the service center eliminate free of charge all detected production defects.The manufacturer

disclaims warranty and legal responsibilities if nonobservance of the instruction manual by user,

unqualified disassembling repair or maintenance of the machine as well does not bear responsibility

for caused injury to persons or damages.

--7

Page 9

Omperator's anual

www.fubag.ru

9s. Trouble hooting

www.fubag.ru

--8

Page 10

Инструкция по эксплуатации

www.fubag.ru

www.fubag.ru

ВНИМАНИЕ! ПЕРЕД ИСПОЛЬЗОВАНИЕМ СВАРОЧНОГО АППАРАТА

ВНИМАТЕЛЬНООЗНАКОМЬТЕСЬ С ДАННОЙ ИНСТРУКЦИЕЙ.

К использованию и обслуживанию сварочного аппарата допускается только

квалифицированный и специально обученный персонал, ознакомленный с данной

инструкцией.

В этой инструкции содержится описание, правила безопасности и вся необходимая

информация для правильной эксплуатации сварочного аппарата FUBAG. Сохраняйте

данную инструкцию и обращайтесь к ней при возникновении вопросов по безопасной

эксплуатации,обслуживанию, хранению и транспортировке сварочногоаппарата FUBAG.

1. Правила безопасности

- Всегда соблюдайте правила безопасности. Носите защитную одежду и специальные

средства защиты, чтобы избежать повреждения глаз и кожных покровов.

- Всегда надевайте защитную маску во время работы сварочным аппаратом или

используйте очки с защитным затемненным стеклом.

- Старайтесь, чтобы искры и брызги не попали на тело.

- Избегайте контактов с открытыми токоведущими кабелями сварочного аппарата, не

прикасайтесь к электрододержателю/горелке и свариваемой поверхности.

- Не работайте под водой или в месте с повышенной влажностью.

- Дым и газ, которые попадают в воздух при сварке, опасны для здоровья. Перед

началом работ убедитесь, что вытяжка и вентиляция исправно работают.

- Убедитесь, что излучение дуги не попадет на других людей, находящихся поблизости

от места сварки.

- Помните, что при сварке температура обрабатываемой поверхности повышается,

поэтому старайтесь не прикасаться к обрабатываемым деталям во избежание ожогов.

- Не прикасайтесь к месту подключения питания или к другим частям сварочного

аппарата, которые находятся под током. Отключайте питание сразу после окончания

работы или перед тем, как оставить место работы.

- Никогда не работайте там, где существует опасность получения электрошока.

- Никогда не производите сварку емкостей, в которых могут содержаться

легковоспламеняющиеся или взрывоопасные материалы.

- При высотных работах во избежание несчастного случая соблюдайте правила техники

безопасности работы на высоте.

- Следите за тем, чтобы на рабочей площадке не было посторонних людей.

- Сварочные аппараты излучают электромагнитные волны и создают помехи для

радиочастот, поэтому следите за тем, чтобы в непосредственной близости от

аппарата не было людей, которые используют стимулятор сердца или другие

принадлежности, для которых электромагнитные волны и радиочастоты создают

помехи.

ВНИМАНИЕ. Сварочный аппарат находится поднапряжением, поэтому прежде, чем

приступить к его обслуживанию, следует обесточить его во избежание электрошока.

Перед проведением любых работ всегда необходимо отключать источник питания. К

работамсо сварочным аппаратом допускаютсятолько специалисты.

--9

Page 11

Инструкция по эксплуатации

www.fubag.ru

www.fubag.ru

- Проверьте подключение входных и выходных кабелей, заземление и т.д.

- Техническое обслуживание должны выполнять только квалифицированные

специалисты.

- Если ваш сварочный аппарат был только что установлен или к работе приступает

новый оператор, следует проверить сопротивление изоляции между обмотками и

кожухом должно быть не менее 1 МОм.

- Когда сварочный аппарат используется при работах вне помещений, его следует

беречь от дождя и предохранять от длительного воздействия солнечных лучей.

- Время от времени следует проверять состояние сварочного кабеля. Если аппарат

используется регулярно, его следует проверять не менее одного раза в месяц.

Состояние сварочного кабеля также следует проверять, если сварочный аппарат

используется как переносной.

- Если сварочный аппарат не используется

продолжительное время, его следует хранить в сухом, хорошо проветриваемом

помещении, не допуская попадания на него влаги, коррозионно-опасных или

токсичных газов. Допустимая температура хранения от -25 до +55 и относительная

влажность не более 90%.

- Раз в год следует очищать сварочный аппарат от пыли. Проверьте, не ослаблены ли

детали крепления аппарата, электромагнитную систему, ручки настройки тока и т.д.

- Наличие в воздухе пыли, а также едких и коррозионных веществ не должно

превышать допустимых норм.

- Сварочный аппарат должен быть установлен в таком месте, где на него не будет

попадать дождь и солнечные лучи.

- Необходимо обеспечить доступ воздуха к сварочному аппарату, для этого вокруг него

должно быть свободное пространство не менее 50 см.

- Убедитесь, что на месте работы сварочного аппарата нет металлических или

инородных предметов во избежание их попадания в аппарат.

- Если аппарат не эксплуатируется, электрод следует вынимать из держателя.

- Не устанавливайте сварочный аппарат на вибрирующую поверхность.

- Убедитесь, что в месте установки сварочного аппарата отсутствуют посторонние

помехи.

временно не используется или

°C

Перед началом работы следует тщательно проверить:

- чтобы не было короткого замыкания между кабелями сварочного аппарата;

- прочность соединения разъемов и кабелей.

Квалифицированный персонал должен регулярно проводить проверку сварочного аппарата

в том случае, если он используется после длительного хранения или ремонта. Эти проверки

включаютследующие процедуры:

- проверку сварочного кабеля. Кабель должен быть заменен прежде, чем будет

полностью изношен. Входной кабель должен быть заменен в случае повреждения;

- проверку мощности источника питания. Любой источник питания, использующийся

для сварочного аппарата, должен быть оснащен защитными системами.

Если вы столкнулись с проблемами, с которыми не можете справиться, обращайтесь в

Сервисный центр.

-1 -0

Page 12

Инструкция по эксплуатации

www.fubag.ru

www.fubag.ru

2. Технические характеристики

Производительимеет право вносить изменения как в содержание данной инструкции, так и в конструкцию

сварочногоаппаратабез предварительногоуведомления пользователей.

- Температура окружающей среды: при работе: -10 +40°C. При транспортировке или

хранении: -25 +55°C.

- Относительнаявлажность: при температуре 40°C - не более 50%. При температуре20°C не более 90%.

- Наличие в воздухе пыли, а также едких и коррозионных веществ не должно превышать

допустимой нормы.

- Высотанад уровнем моря не более 1000 м.

- Колебания напряжения электропитания не должны превышать ±10% предельно

допустимогозначения.

3. Описание

Переносной сварочный аппарат FUBAG с регулировкой сварочного тока предназначен для

ручной дуговой сварки (MMA). Сварочный аппарат FUBAG отличается компактными

размерами и малым весом, низким уровнем шума, простотой эксплуатации и удобством

обслуживания.

Сварочный аппарат снабжен устройством автоматического контроля температуры и

воздушного охлаждения, что обеспечивает продолжительную, эффективную и безопасную

работу.

1. Выключатель (переключатель )

электропитания

2. Ручка

3. Регулятор тока

4. Кабель электрододержателя

5. Кабель массы

6. Индикаторпитания

7. Индикатортермозащиты

4

2

6

7

1

3

5

-1 -1

Page 13

Инструкция по эксплуатации

www.fubag.ru

www.fubag.ru

Работает от напряжения 220 или 380В частотой 50 Гц. Он имеет устойчивые характеристики

как при сварочныхработах с тонколистовым металлом,так и при работе с металломбольшой

толщины.

В комплект поставкивходят:

- сварочный аппарат

- сварочная маска

- щетка для удаленияшлака

- инструкция по эксплуатациии сертификат изделия

- гарантийный талон

ПРИМЕЧАНИЕ: Вспомогательные приспособления поставляются по запросу.

Гарантийныеобязательства на вспомогательныеприспособления не распространяются.

Расшифровка пиктограмм и предупредительных знаков

Заземление

Наклон

Ручная сварка покрытым электродом

1~

1~

U(0V)

50 /60

Hz Hz

IA)

±10%(

2

(мм)

(

IA)

2

Ts)

W

Ts)

R

U(

1

IA)

1Eff

IA)

1Max

Источникпитания и питание от однофазнойсети переменного тока

Однофазныйаппарат для дуговой сварки

1~

Номинальное напряжение разомкнутой цепи

Переменный ток, номинальная частота50 или 60 Гц

Макс. или мин. сварочный ток и соответствующий допуск по току 10%

Обозначениедиаметра для стандартного электрода

Номинальный сварочный ток

Время беспрерывной работы поднагрузкой в секундах

(

(

Время остывания в секундах

V)

Напряжение источника питания и номинальная частота

(

Ток холостого ходатрансформатора

(

Максимальное значениепотребляемоготока

Параметрыплавких предохранителей

A

()

-1 -2

Page 14

Инструкция по эксплуатации

www.fubag.ru

www.fubag.ru

IP21S

H

Класс защиты. IP - это код международной защиты. Цифра 2 обозначает, что

пользователь не должен прикасаться руками к опасным частям аппарата; не

вставлять посторонние предметы диаметром менее 12,5 мм. Цифра 1

обозначает, что следует предотвращать попадание капель воды, падающих

вертикально вниз, - это очень опасно. Буква S обозначает проведениетеста на

водостойкость в тот момент, когда движущиеся детали находятся в спокойном

состоянии.

Класс изоляции

4. Установка

- Перед проведением любых работ убедитесь,что аппарат отключен от сети питания.

- Выберите удобное для работы место. Убедитесь в достаточной вентиляции и отсутствии

препятствий для поступления и выхода свежего воздуха. Убедитесь, что в вентиляцию

не попадет пыль, котораяможет служить проводником паров, влаги и прочего.

При работе сварочного аппарата требуется большой ток на входе. Если мощность сети

недостаточна, это отрицательно скажется как на качестве работы, так и на самом сварочном

аппарате.Если у вас возникла подобнаяпроблема, вам следуетобратиться кспециалисту.

Подключениек электроснабжению

Перед подключением сварочного аппарата к источнику питания убедитесь, что напряжение в

сетисоответствует напряжению, указанному на заводскойтабличке сварочного аппарата.

Вилка силового кабеля должна соответствовать розетке. Электросеть, к которой

производится подключение, должна быть оснащена предохранителями или автоматическим

выключателем, рассчитанными на ток и напряжение в соответствиис техническими данными

на фирменной табличке сварочного аппарата.

Присоединение сварочных кабелей

Один конец кабеля на выходе должен быть присоединен к

сварочному аппарату, как это показано на панели, а другой (1) к

обрабатываемому изделию и держателю электрода (2). Если на

аппарате установлена быстроразъемная клемма (опция), то разъем

кабеля следует поворачивать по часовой стрелке для того, чтобы

зафиксировать его; если он не будет достаточно затянут, то можно

повредить сварочный кабельи разъем.

-1 -3

1

2

Page 15

Инструкция по эксплуатации

www.fubag.ru

5. Сварочные работы

www.fubag.ru

ВНИМАНИЕ

продлит срок его эксплуатации. Перед включением питания следует убедиться в

правильности подсоединения кабелей на входе - выходе и кабеля заземления.

- После подключения сварочного аппарата к источнику питания и

до начала работы следует установить ручку настройки тока в

нужное для работы положение.

- Перед началом сварки убедитесь, что обрабатываемое

изделиетщательноочищено от ржавчины,краски или лака.

- Когда до держателя остается 2-3 см, электрод следует

заменить.

ВНИМАНИЕ

него голой рукой. Снятый электрод следует поместить в металлический

контейнер.

Следуетвставлятьэлектрод в держатель свободным отпокрытия концом.

- Для увеличения величины сварочного тока нужно повернуть ручку по часовой стрелке,

а для уменьшения - против часовой стрелки.

ПРИМЕЧАНИЕ:

минимальному значению, поворачивайте ручку плавно, чтобы не повредить регулятор.

ВНИМАНИЕ!

помощью специального молотка и щетки, затем внимательно проверить качество

соединения свариваемых деталей,после чего продолжить работу.

ПРИМЕЧАНИЕ: Шлак можно удалятьтолько после того, как он остынет и затвердеет.

Чтобы во время удаления шлака не поранить людей, находящихся рядом с местом

работы, направляйте ударымолотком всторону от них.

Перед работой необходимо внимательно изучить инструкции на упаковке электродов для

правильного выбора тока и полярности.

Помните, что для одних и тех же электродов большие значения тока сварки используютсяпри

сварке на полу, в то время как меньшие значения для сварки в вертикальном положении или

над головой.

Механические характеристики сварного соединения, а также интенсивность тока,

определяются: диаметром и качеством электрода, длиной дуги, скоростью работы и

положением электрода относительно свариваемой поверхности, а также правильным

хранением электродов, которые должны быть защищеныот влаги.

Внимание!

продолжительность включения сварочного аппарата. Продолжительность включения

сварочного аппарата не должна превышать предельно допустимого значения, в противном

случае вследствие перегрузки произойдет преждевременный износ компонентов аппарата,

что, в свою очередь, сократит его срок службы и/или может привести к выходу его из строя.

Кроме этого, датчик защиты от перегрева, который находится внутри сварочного аппарата,

сработает при превышении температуры и отключит питание. Когда реле сработает,

загорится индикатор. После срабатывания защиты от перегрева и до повторного включения

аппарата в работу необходимо выяснить и устранить причины, приведшие к перегреву

сварочногоаппарата.

После выбора параметров сварочных работ следует обязательно определить

: Проведение проверки перед началом работы сварочного аппарата

РЕГУЛИРОВКА

СВАРОЧНОГО ТОКА

MIN

: Электрод оплавляется при высокой температуре. Не беритесь за

Когда величина тока приближается к максимальному или

После использования каждого электрода необходимо удалить шлак с

MAX

-1 -4

Page 16

Инструкция по эксплуатации

www.fubag.ru

www.fubag.ru

6. Техническое обслуживание

ПРЕДУПРЕЖДЕНИЕ! НИКОГДА НЕ СНИМАЙТЕ КОЖУХ И НЕ ПРОИЗВОДИТЕ КАКИЕ-

ЛИБО РАБОТЫ ПО ОБСЛУЖИВАНИЮ СВАРОЧНОГО АППАРАТА, ПРЕДВАРИТЕЛЬНО НЕ

ВЫКЛЮЧИВ ЕГО И НЕ ОТСОЕДИНИВ ОТ ЭЛЕКТРОСНАБЖЕНИЯ. КРОМЕ ТОГО,

НЕОБХОДИМО УЧИТЫВАТЬ, ЧТО НЕКОТОРОЕ ВРЕМЯ ПОСЛЕ ОТКЛЮЧЕНИЯ

ОПРЕДЕЛЕННЫЕ ЧАСТИ УСТАНОВКИ МОГУТ ОСТАВАТЬСЯ ПОД НАПРЯЖЕНИЕМ И

СТАТЬ ПРИЧИНОЙ ПОРАЖЕНИЯ ЭЛЕКТРИЧЕСКИМ ТОКОМ.

- Необходимо регулярно осматривать сварочный аппарат на предмет чистоты, в

особенности при работах в пыльных помещениях. При удалении пыли с

трансформатора необходимо использовать сухой сжатый воздух давлением не более

10 бар.

- Необходимо регулярно проверять все кабели на предмет их целостностии исправности

изоляционногопокрытия.

- После технического обслуживания все детали конструкции должны быть установлены

на свои места, а все винты и гайки хорошо закручены.

- Ни в коем случае не начинайте сварку, если установка еще не полностью собрана.

7. Хранение и транспортировка

Во время транспортировки и хранения сварочного аппарата старайтесь беречь его от

попадания влаги.

При погрузке следуйте указаниям «ATTENTION» на упаковке. Рекомендуется хранить

сварочный аппарат в сухом, хорошо проветриваемом помещении и не подвергать его

воздействию повышенной влажности, коррозионно-опасных газов и пыли. Допустимый

диапазон температур для хранения от - 25 до +55 , и относительная влажность не более

90%.

После вскрытия упаковки рекомендуется снова упаковать сварочный аппарат, если

предполагается перевозить его к месту работы или на хранение.

O

C

8. Гарантийные обязательства

Производитель гарантирует нормальную работу аппарата в течение 12 месяцев со дня его

продажи через розничную сеть, а также ремонт или замену деталей, преждевременно

вышедших из строя по вине предприятия-изготовителя, при условии соблюдения

требований по монтажу, эксплуатациии периодическому техническому обслуживанию.

Гарантияотносится к дефектам в материалах и узлах и не распространяется на компоненты,

подверженныеестественному износу и работы по техническому обслуживанию.

Гарантийному ремонту подлежат только очищенные от пыли и грязи аппараты в заводской

упаковке, полностью укомплектованные, имеющие инструкцию по эксплуатации,

гарантийный талон с указанием даты продажи, при наличии штампа магазина, заводского

номера и оригиналов товарного и кассового чеков, выданных продавцом.

В течение гарантийного срока Сервисный центр устраняет за свой счёт выявленные

производственные дефекты. Производитель снимает свои гарантийные обязательства и

юридическую ответственность при несоблюдении потребителем инструкций по

эксплуатации, самостоятельной разборки, ремонта и технического обслуживания аппарата,

а также не несетникакой ответственностиза причиненные травмы и нанесенный ущерб.

-1 -5

Page 17

Инструкция по эксплуатации

www.fubag.ru

9. Неисправности и их устранение

.

-

-

-

www.fubag.ru

-1 -6

Loading...

Loading...