Page 1

Page 2

Omperator's anual

www.fubag.ru

WARNING! BEFORE USING THE WELDING MACHINE READ THE INSTRUCTION

MANUAL CAREFULLY! FOR QUALIFIED AND SPECIALLY TRAINED PERSONS

ONLY AFTER PROPER READING OF THIS MANUAL IS ALLOWED TO USE AND TO

MAINTAIN THIS MACHINE.

The detailed description, safety rules and all required information necessary for proper operation

and maintenance of FUBAG machine are provided below. Keep this instruction manual by machine

and refer to it by any doubts concerning safety operation, maintenance storage and handling of

FUBAG machine.

1. Safety perationo

-

It is highly recommended always to follow the safety rules. Wear protective clothes and

special means to avoid injuries to eyes and skins.

-

Prevent the sparks and spatter from harming your body.

-

Do not operate under water or more humid place.

-

Make sure to work in places where there are exhaust or ventilation facilities to keep fumes

or emissions away from the breathing zone.

-

No touching on the electrification parts after turning on the power. Cut off the power supply

after operation or before leaving the welding site.

-

Safe measures should be adoptted while operating in high place to avoid accident.

-

No entering the welding site for persons not concerned.

WARNING. The voltage is always higher, so the safety precaution should be taken before

repair to avoid accidental shock. Switch off the power supply before each type of

maintenance work. The untrained people are not allowed to make maintenance of the

machine.

- 1 -

Page 3

Omperator's anual

www.fubag.ru

-

Maintenance should be conducted by the trained personnel.

- plasma

When the is used outdoors, it should be kept from rain or long exposure to the sun.

-

Check is needed from time to time to make sure the cable is in good condition if the

machine is in frequent use. Check at least once each month if the is in regular use. It

is necessary to check when the is in mobile use.

-

Dust removal is needed every year. Check the machine's fasteners, moving-iron, current

regulation screws, etc to make sure there are no loose connection problems.

-

The dust, acid and erodible dirt in the air at the job site can not exceed the amount required

by the norm.

-

The welder must be installed in the place where it can not be exposed to sun and rain. Also it

must be stored in less humid place with the temperature.

-

Make sure that there is no metal-like foreign body to enter the machine.

-

No violent vibration in the welder's surrounding area.

-

Make sure that there is no interference with the surrounding area at the installation site.

Safety Check:

Each item listedbelow must be carefully checked before operation:

-

Make sure that there is no shortcircuit connection with welder's both outputs.

-

Make sure that there is always sound output and input wire connection instead of exposing it

outside.

Regular check needs to be conducted by the qualified personnel after the machine has been

installed over a long period or re-operation,which involves as follows:

-

Check the cable to see if itcan continue to be used before itis worn out.

-

Replace the input cable as soon asit is found to be broken ordamaged.

-

Make sure whether there is enough power supply to make the welding machine work properly.

Any power source required to access the machine must be installed with some protective

equipments.

plasma

plasma

Please do not hesitate to contact us for technical assistance whenever you come across the

problems you can not work out oryou may deem difficult to fix.

--2

Page 4

Omperator's anual

MODEL PLASMA 20 AIR PLASMA 30 LV

Rated voltage/frequency, V/Hz

220/50

85-265/50

Max. input power, kW

3,5

3,68

Max. input current, А

16

16

Current, А

5-20

5-30

Current of duty cycle %, А

20 at 34

30 at 32

Max. cutting thickness steel, mm

6

10

Max. cutting thickness aluminium, mm

4

8

Capacity, l/min

40

115

Pressure, bar

3

2,5-6

IP

IP23

Dimension, mm

480х220х360

410х185х290

Weight, kg

18,5

12

Ambient temperature, °С

-10…+40

Relative humidity, %

at 20°С up to 90%; at 40°С up to 50%

Acessories

2 electrodes, 2 tips

diffuser, 2 electrodes, 2 tips, air

connector

www.fubag.ru

2. Technical pecificationss

The manufacturer reserves himself the right to make the manual's content or function change

without any preliminarynotification of theusers.

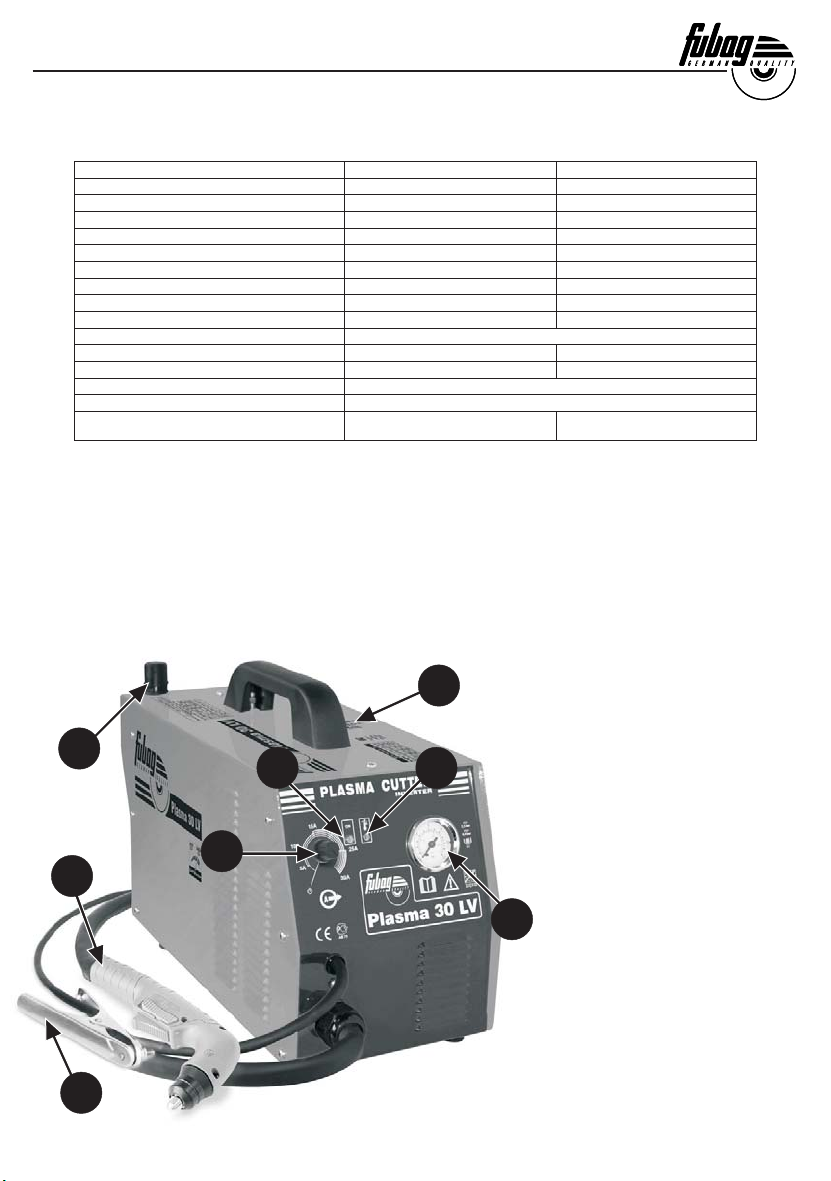

3. еDescription

Fubag

Plasma are inverter plasma cutters, portable, single phase, ventilated. They enable to cut in

direct current (DC) steel, stainless steel, aluminium, copper. They work with a single phase input

220V (Plasma 30 LV- )

spread between 85V to 265V .

5

1

6

7

2

8

3

- 3 -

1. Current setting

2. Power indicator

3. Thermal protection indicator

4. Manometer

(only

Plasma 30 LV)

5. Pressure regulato

Plasma 30 LV)

6. Torch

arth clamp

7. E

Compressor with filter

8.

(only Plasma 0 )

4

2 AIR

r (only

Page 5

Omperator's anual

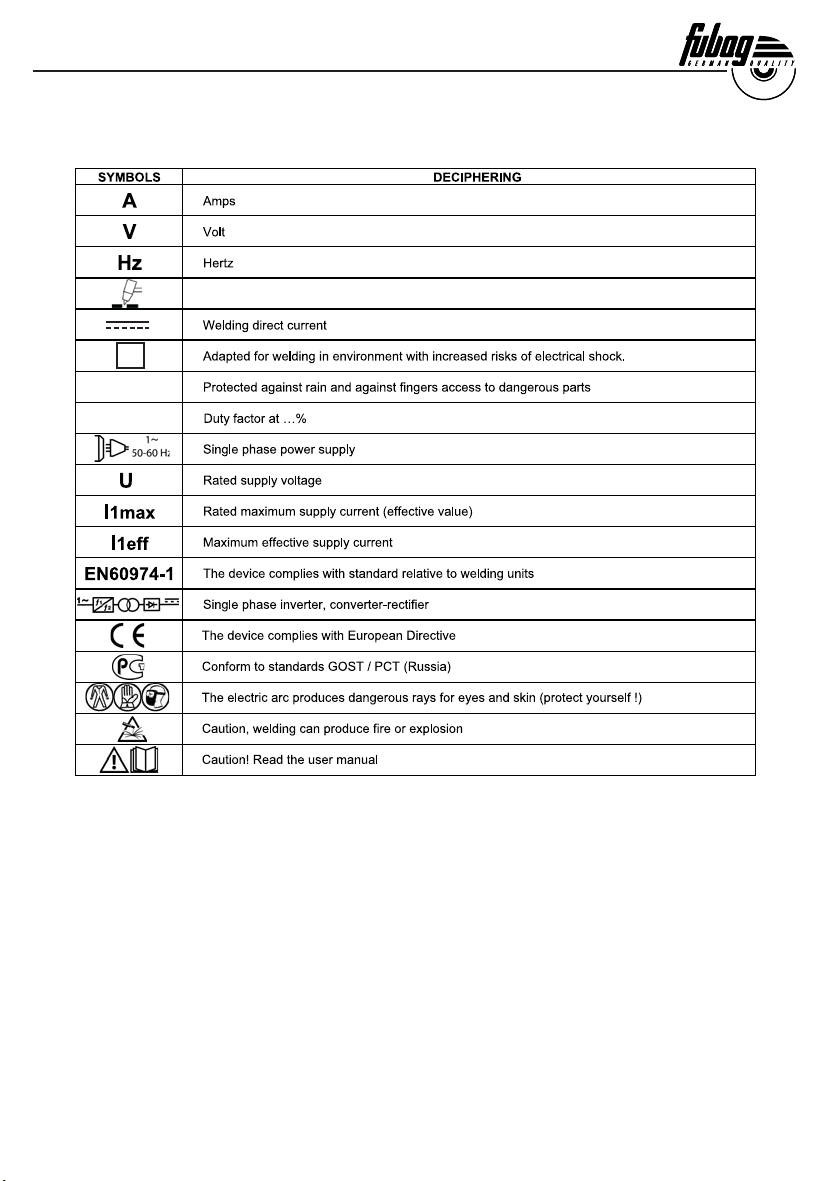

4. Illustration of signs

Plasma cutting machine

S

IP23

X: 45%; 60%; 100%

0

www.fubag.ru

5 ower supply.P

-

This machine has to be on a power supply 220V. The absorbed effective current is shown on the

machine, for maximal using conditions. Check that the main supply and its protections (fuse and/or

circuit breaker) are compatible with the requiredcurrent in use.

-

To start the equipment, turn on the potentiometer to the desired current position (put the

potentiometer on "O" for standby mode).

-

The machines are protected against over voltages and pass automatically in standby mode if the

supply voltage . To point out this defect, the yellow indicator for thermal protection blinks

twice then lights off. Normal operation will resume after thirty seconds when the voltage has

returned to its nominal range.

top limit

- 4 -

Page 6

Omperator's anual

www.fubag.ru

6 Cutting.

- Plasma 30 LV connect the unit to the electricity

network and to the air distribution. Adjust the

pressure regulator have 2.5 to 6 bar on the

manometer.

electricity network only.

- From 10 A* and to optimize the cutting

performances, use the «air flow tester»

Plasma 30 LV)

Press the torch trigger (the arc is appearing).

Release, the electrical arc stops but the air

continues to flow for about 15 seconds.

During this time, put your «air flow tester» at

the end of your torch, then adjust your air flow

(115 l/min) by placing the ball in between the

mini/maxi zone.

* For a cutting < 10A, directly adjust to 3 bars.

nb:

--Switch on the unit.

Adjust the current according to the type of metal

and the thickness to cut.

Plasma 20 AIR connect to the

(only

. Process:

Plasma

20 AIR

Plasma

30 LV

(mm)

Speed

Current (A)

Thickness

(m/min)

0,6 5 4,1 5 4,1

1 12 2,5 12 2,5

1,5 15 1,2 15 1,2

2,5 18 0,65 18 0,65

3 20 0,35 20 0,35

Steel

4 20 0,26 20 0,26

6 20 0,15 25 0,20

8 - - 30A 0,16

10 - - 30 0,09

0,6 8 2,5 8 2,5

1 12 1,2 12 1,2

1,6 15 0,65 15 0,65

2,5 20 0,25 20 0,25

4 20 0,15 25 0,21

6 - - 30 0,23

Aluminium

8 - - 30 0,09

Current (A)

Speed

(m/min)

- Connect the earth clamp on astripped zone of the piece to cut.

- The plasma cutting machine is equipped with pilot arc system. This system allows starting

the arc without touching the piece to cut. You have 2 ways to cut your piece:

Press on the trigger pilot arc formation cutting by contact with the piece

??

Contact with the piece press on the trigger immediate cutting

??

- During the cutting, make sure to maintain the contact between the nozzle and the piece to

cut.

7 aintenance.M

-

Refer all servicing to qualified personnel.

-

Disconnect the generator and wait until the ventilator stopped before working on the unit.

Inside the device, voltages and current are dangerous.

- Regularly blow the machine with the pressed air through the ventilation inlets

- 5 -

.

Page 7

Omperator's anual

ANOMALIES CAUSES REMEDIES

The machine delivers no power.

The green working indicator is

on. The thermal protection

indicator is continuously on.

The thermal protection

of the welding unit is on.

Wait until the end of the cooling phase.

The machine delivers no power.

The green working indicator is

on. The thermal protection

ondicator blinks 2 times then

lights off.

The input voltage is

outside the limits.

Check your electrical network or your

electric generator then switch off and

on your machine.

Torch defect. Check your torch assembly.

The machine delivers no power.

The green working indicator is

on. The thermal protection

indicator blinks quickly.

Air supply too weak.

Increase the air pressure, then switch

off and on your machine.

By pressing the trigger, the air

flows but the pilot arc is not

working.

Consumables shabby.

Check and change the consumables,

then switch off and on your machine.

The electrical arc switches off

after about 3 seconds.

Earth problem.

Check the earth clamp is well

connected to a clean area (not painted

and not fat) of the part to cut.

After having switched off the

plasma (position «O»), the

ventilator and the compressed

air continues to run.

Torch Cooling phase

Normal behaviour of the machine, wait

for the end of the cooling phase (+/-15

sec).

8. Troubleshooting

www.fubag.ru

9. Transport& torage

When the is in storage and transportation, please try to keep it from being exposed to the

rain. When loading, attach ATTENTION to the packing. It is recommended to free it from

moisture, erodible gas and dust in storage where it must be kept dry and have good ventilation. The

tolerable temperature, and the relative humidity.

plasma

After the package has been opened, it is suggested to repack the product as per requirement for

future storage and transport.

10. Warranty

Warranty refer to defects of materials and components and do not refer to components subject to

natural wear and maintenance work.

Only machines cleaned from dust and dirt in original factory packing fully completed, provided with

instruction manual, warranty card with fixed sales date with a shop stamp factory serial number and

originals of sales and ware receipt issued by salesman are subjects of warranty. Within the warranty

period the service center eliminate freeof charge all detected production defects.The manufacturer

disclaims warranty and legal responsibilities if nonobservance of the instruction manual by user,

unqualified disassembling repair or maintenance of themachine as well doesnot bear responsibility

for caused injury to persons or damages.

s

plasma

- 6 -

Page 8

Инструкция по эксплуатации

www.fubag.ru

ВНИМАНИЕ! ПЕРЕД ИСПОЛЬЗОВАНИЕМ ПЛАЗМОРЕЗА ВНИМАТЕЛЬНО

ОЗНАКОМЬТЕСЬ С ДАННОЙИНСТРУКЦИЕЙ.

К использованию и обслуживанию аппарата допускается только

квалифицированный и специально обученный персонал, ознакомленный с данной

инструкцией.

В этой инструкции содержится описание, правила безопасности и вся необходимая

информация для правильной эксплуатации плазмореза FUBAG. Сохраняйте данную

инструкцию и обращайтесь к ней при возникновении вопросов по безопасной эксплуатации,

обслуживанию, хранению итранспортировке.

1. Правила безопасности

- Всегда соблюдайте правила безопасности. Носите защитную одежду и специальные

средства защиты, чтобы избежать повреждения глаз и кожных покровов.

- Старайтесь, чтобы искры и брызги не попали на тело.

- Не работайте под водой или в месте с повышенной влажностью.

- Перед началом работ убедитесь, что вытяжка и вентиляция исправно работают.

- Отключайте питание сразу после окончания работы или перед тем, как оставить

место работы.

- Никогда не работайте там, где существует опасность получения электрошока.

- При высотных работах во избежание несчастного случая соблюдайте правила техники

безопасности работы на высоте.

- Следите за тем, чтобы на рабочей площадке не было посторонних людей.

- Плазморез излучает электромагнитные волны и создают помехи для радиочастот,

поэтому следите за тем, чтобы в непосредственной близости от аппарата не было

людей, которые используют стимулятор сердца или другие принадлежности, для

которых электромагнитные волны и радиочастоты создают помехи.

ВНИМАНИЕ. Аппарат находится под напряжением, поэтому прежде, чем

приступить к его обслуживанию, следует обесточить его во избежание электрошока.

Перед проведением любых работ всегда необходимо отключать источник питания. К

работам с аппаратом допускаются только специалисты.

--7

Page 9

Инструкция по эксплуатации

www.fubag.ru

- Техническое обслуживание должны выполнять только квалифицированные

специалисты.

- Когда плазморез используется при работах вне помещений, его следует беречь от

дождя и предохранять от длительного воздействия солнечных лучей.

- Время от времени следует проверять состояние всех кабелей. Если аппарат

используется регулярно, его следует проверять не менее одного раза в месяц.

- Если аппарат не используется продолжительное

время, его следует хранить в сухом, хорошо проветриваемом помещении, не

допуская попадания на него влаги, коррозионно-опасных или токсичных газов.

- Регулярно следует очищать аппарат от пыли. Проверьте, не ослаблены ли детали

крепления аппарата, электромагнитную систему, ручки настройки тока и т.д.

- Наличие в воздухе пыли, а также едких и коррозионных веществ не должно

превышать допустимых норм.

- Аппарат должен быть установлен в таком месте, где на него не будет попадать дождь

и солнечные лучи.

- Необходимо обеспечить доступ воздуха к аппарату.

- Убедитесь, что на месте работы аппарата нет металлических или инородных

предметов во избежание их попадания в аппарат.

- Не устанавливайте аппарат на вибрирующую поверхность.

- Убедитесь, что в месте установки отсутствуют посторонние помехи.

Перед началом работы следует тщательно проверить:

- прочность соединения разъемов и кабелей.

Квалифицированный персонал должен регулярно проводить проверку аппарата в том

случае, если он используется после длительного хранения или ремонта. Эти проверки

включают следующие процедуры:

- проверку всех кабелей. Кабель должен быть заменен прежде, чем будет полностью

изношен. Входной кабель должен быть заменен в случае повреждения;

- проверку мощности источника питания. Любой источник питания, должен быть

оснащен защитными системами.

временно не используется или

Если вы столкнулись с проблемами, с которыми не можете справиться, обращайтесь в

Сервисный центр.

--8

Page 10

Инструкция по эксплуатации

МОДЕЛЬ PLASM A 20 AIR PLASM A 30 LV

Напряжение/частота питания, В/Гц

220/50

85-265/50

Max. потребляемая мощность, кВт

3,5

3,68

Max. потребляемый ток, А

16

16

Рабочий ток, А

5-20

5-30

Рабочий ток при цикле %, А

20 при 34

30 при 32

Max. толщина резки стали, мм

6

10

Max. толщина резки алюминия, мм

4

8

Воздушный поток, л/мин

40

115

Давление, бар

3

2,5-6

Класс защиты

IP23

Габариты, мм

480х220х360

410х185х290

Вес, кг

18,5

12

Тем-ра окружающей среды, °С

-10…+40

Относительна влажность, %

при 20°С до 90%; при 40°С до 50%

Комплектация

2 электрода, 2 сопла

диффузор, 2 электрода, 2

сопла, воздушный коннектор

2. Технические характеристики

Производитель имеет право вносить изменения как в содержание данной инструкции, так и в

конструкцию аппарата без предварительногоуведомления пользователей.

3. Описание

www.fubag.ru

Fubag

Plasma является аппаратом плазменной резки переносным инверторным. Он

позволяет резать сталь, нержавейку, алюминий, медь при постоянном токе (DC). Аппарат

работаетот однофазной электрической сети В ( от 85В до265В .

220 Plasma 30 LV - )

8

1. Регулятор тока

2. Индикатор включения

3. Индикатор термозащиты

5

2

3

4. Манометр только у

Plasma 30 LV)

5. Регулятор давления

только у

( Plasma 30 LV)

(

6. Горелка

Зажим массы

1

6

7

--9

7.

Встроенный компрессор

8.

с фильтром (только у

Plasma 20 AIR)

4

Page 11

Инструкция по эксплуатации

www.fubag.ru

4. Расшифровка пиктограмм и предупредительных знаков

Аппарат плазменной резки

Работа на постоянном токе

S

IP23

X: 45%; 60%; 100%

0

5. Электропитание

- Данный аппарат питается от розетки 220В. Количество потребляемой энергии при

интенсивном использование, указано на аппарате. Проверьте совместимость

электрического питания и систем защиты (предохранитель и/или авт. выключатель) с

электрическим током, необходимым для работы аппарата.

- Запуск в работу осуществляется поворотом потенциометра на желаемую величину тока

(режим ожидания – возврат потенциометра в позицию 0).

- Защита аппарата срабатывает и останавливает аппарат, если напряжение питания

превышает пороговое. При этом желтый индикатор мигает 2 раза и затем гаснет. Аппарат

переходит на нормальное функционирование через 30 сек после того как напряжение

питания вернулось к номинальному значению.

- 1 -0

Page 12

Инструкция по эксплуатации

www.fubag.ru

6. Резка

-

Подключить к электрической

сетииккомпрессору. Настроить регулятор

давления таким образом, чтобы манометр

показывал от 2,5 до 6 бар

только к электрической сети.

- Начиная от 10 A в целях улучшения качества

резки, используйте «тестер расхода воздуха»

только для . Для этого:

( Plasma 30 LV)

Нажмите на гашетку вашей горелки

(появится дуга).

Отпустите. Электрическая дуга исчезнет, но

воздух будет продолждать поступать в течение

примерно 15 секунд.

В течение этого промeжутка установите

«тестер расхода воздуха» на кончик горелки,

затем настройте подачу воздуха (115 л/мн) так

чтобы указатель находиля в зоне min/maxi.

* для резки при менее чем 10A,

Примечание:

настраивать на 3 бара.

Включить аппарат

-

Настроить силу тока в зависимости от типа и

толщины металла, предназначенного для резки

Plasma 30 LV

. Plasma 20 AIR

*

Толщина (мм)

Plasma

20 AIR

Ток ( A)

(м/мин)

Скорость

Plasma

30 LV

Ток ( A)

0,6 5 4,1 5 4,1

1 12 2,5 12 2,5

1,5 15 1,2 15 1,2

2,5 18 0,65 18 0,65

3 20 0,35 20 0,35

Сталь

4 20 0,26 20 0,26

6 20 0,15 25 0,20

8 - - 30A 0,16

10 - - 30 0,09

0,6 8 2,5 8 2,5

1 12 1,2 12 1,2

1,6 15 0,65 15 0,65

2,5 20 0,25 20 0,25

4 20 0,15 25 0,21

Алюминий

6 - - 30 0,23

8 - - 30 0,09

(м/мин)

Скорость

- Установить зажим массына зачищенной части детали, предназначеннойдля резки.

- Аппарат оснащён системой управления дуги, которая обеспечивает розжиг, не

касаясь детали, которую надо разрезать. Таким образом, резка может осуществляться

двумя способами:

Нажатие на гашетку образование управляемой дуги резка при

? ?

соприкосновении с деталью

Соприкосновение с деталью нажатие на гашетку последующая резка

??

- Во время резки следует убедиться, что сопло касается разрезаемой детали.

7. Техническое обслуживание

- Обслуживание аппарата должно производиться только квалифицированным персоналом.

Всегда сначала отключите аппарат от сети, затем дождитесь остановки вентилятора. Токи и

напряжения внутри аппарата значительны и представляют опасность.

-Регулярнопродувайте аппарат сжатым воздухом через вентиляционные отверстия.

- Необходимо регулярно проверять состояниеэлектрического шнура. Если он повреждён, то

должен быть заменёнв Сервисе иликвалифицированным специалистом.

- 1 -1

Page 13

Инструкция по эксплуатации

НЕИСПРАВНОСТЬ ПРИЧИНА УСТРАНЕНИЕ

Аппарат не выдает мощности.

Зеленый индикатор функци-

онирования горит. Индикатор

термозащиты постоянно горит.

Сработала

термозащита

аппарата.

Подождите пока аппарат

охладится.

Аппарат не выдает мощности.

Горит зеленый индикатор

функционирования. Индикатор

термозащиты мигает 2 раза, и

затем гаснет.

Напряжение сети

превышает ниже 85

или выше 265 В.

Проверьте состояние электросети

или электрогенератора, затем

выключите и снова включите ваш

аппарат.

Дефект горелки.

Проверьте, правильно ли собрана и

подключена горелка, затем

выключите и снова включите ваш

аппарат.

Аппарат не выдает мощности.

Горит зеленый индикатор

функционирования. Индикатор

термозащиты быстро мигает.

Слишком слабая

подача воздуха.

Увеличьте давление воздуха, затем

выключите и снова включите ваш

аппарат

При нажатии на гашетку идет

подача воздуха, но дуга не

появляется.

Износ частей горелки. Обратитесь в Сервисный центр.

Электрическая дуга исчезает

приблизительно после 3

секунд.

Плохой контакт с

массой.

Проверьте зажим массы. Он должен

быть подключен к чистой (не жирной

и не покрашенной) части

разрезаемой детали.

После выключения аппарата

(позиция «O») вентилятор и

сжатый воздух продолжают

работать.

Цикл охлаждения

горелки.

Нормальное поведение аппарата.

Подождите окончания цикла

охлаждения (+/-15 сек)

8. Неисправности и их устранение

Напряжение сети

вышло за

предельные значения.

www.fubag.ru

910. Хранение и транспортировка

Во время транспортировки и хранения аппарата старайтесь беречь его от попадания влаги.

Рекомендуется хранить аппарат в сухом, хорошо проветриваемом помещении и не подвергать

его воздействию повышенной влажности, коррозионно-опасных газов и пыли. После вскрытия

упаковки рекомендуется снова упаковать аппарат, если предполагается перевозить его к месту

работы или на хранение.

. Гарантийные обязательства

Гарантийный срок наоборудование указывается в прилагаемом сервисном талоне

Гарантия относится к дефектам в материалах и узлах и не распространяется на компоненты,

подверженные естественному износу и работы по техническому обслуживанию.

Гарантийному ремонту подлежат только очищенные от пыли и грязи аппараты в заводской

упаковке, полностью укомплектованные, имеющие инструкцию по эксплуатации, гарантийный

талон с указанием даты продажи, при наличии штампа магазина, заводского номера и

оригиналов товарного и кассовогочеков, выданныхпродавцом.

В течение гарантийного срока Сервисный центр устраняет за свой счёт выявленные

производственные дефекты. Производитель снимает свои гарантийные обязательства и

юридическую ответственность при несоблюдении потребителем инструкций по эксплуатации,

самостоятельной разборки, ремонта и технического обслуживания аппарата, а также не несет

никакой ответственности за причиненныетравмы и нанесенный ущерб.

- 1 -2

.

Page 14

Loading...

Loading...