Page 1

Мотопомпа для грязной воды

Trash water pump

PG 950 T

Operator's Manual

Инструкция по эксплуатации

www.fubag.ru

Page 2

Omperator's anual

WARNING! BEFORE USING THE MACHINE READ THE INSTRUCTION MANUAL

CAREFULLY!

Our are designed to give safe anddependable service if operated

pump

according to instructions.

Read and understand the anual before operating the . Failure to do so

could result in personal injury or equipmentdamage.

1. General safety

FUBAG

m pump

www.fubag.ru

FUBAG

WARNING!

WARNING!

WARNING!

WARNING!

Exhaust gas contains poisonous carbon monoxide.

Never run the in an enclosed area. Be sure to provide adequate

ventilation. When installed in ventilated protection aretobe observed.

The muffler becomes very hot during operation and remains hot for a while

after stopping the engine.

Be careful not to touch the muffler while it is hot. Let the engine cool before

storing the indoors. The engine exhaust system will be heated during

operation and remain hot immediately after stopping the engine.

To prevent scalding, pay attention to the warning marks attached to the

.

pump

Gasoline is extremely flammable and explosive under certain conditions.

Refuel in a well ventilated area with the engine stopped.

Keep away from cigarette, smoke and sparks when refueling the .

Always refuel in a well-ventilated location.

Wipe up spilled gasoline at once.

Caution: The motorpump is supplied without oil.

Before starting upthe motor pump, always checkthe oil level.

pump

pump

pump

--1

Page 3

Omperator's anual

www.fubag.ru

WARNING!

-

Always make a pre-operation inspection before you start the engine. You may prevent an accident

or equipment damage.

- pump

Know how to stop the quickly and understand operation of all the controls. Never permit

anyone to operate the withoutproper instructions.

- pump

Keep children and pets away from the when it isin operation.

- Failure to carry out measurements and checks for early detection of defects.

- The rated speed of the motor has beenset during manufacture and may not be changed.

- No naked flames, lights or spark-emitting appliances may be used within the hazard area of the

pump

.

- Smoking within the hazard area of the is strictly forbidden.

pump

- The may only be transported when cold.

pump

- The may only be lifted using thecarry handlesintended for this purpose.

- The appliance may not be covered. The air intake may not be blockedor obstructed.

- All other servicing and repair work may only be carried out by personnel who are qualified and

licensed for this purpose.

- Always removespark plug connector prior to commencing servicing andrepair work.

- The service intervals set out in these instructionsmust be observed.

pump

- The must be shut down when notrequired forperiods longer than 30 days.

pump

- The must be stored in a dryenclosed room.

pump

pump

- 2 -

Page 4

Omperator's anual

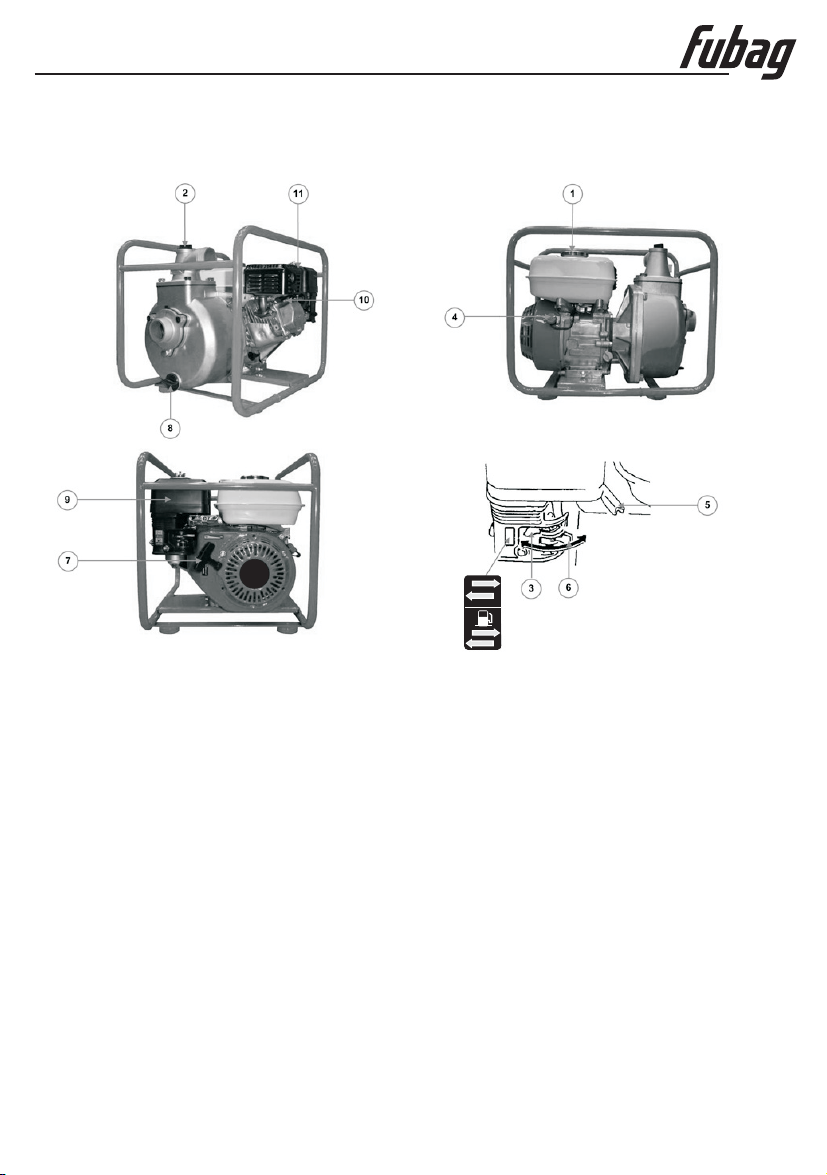

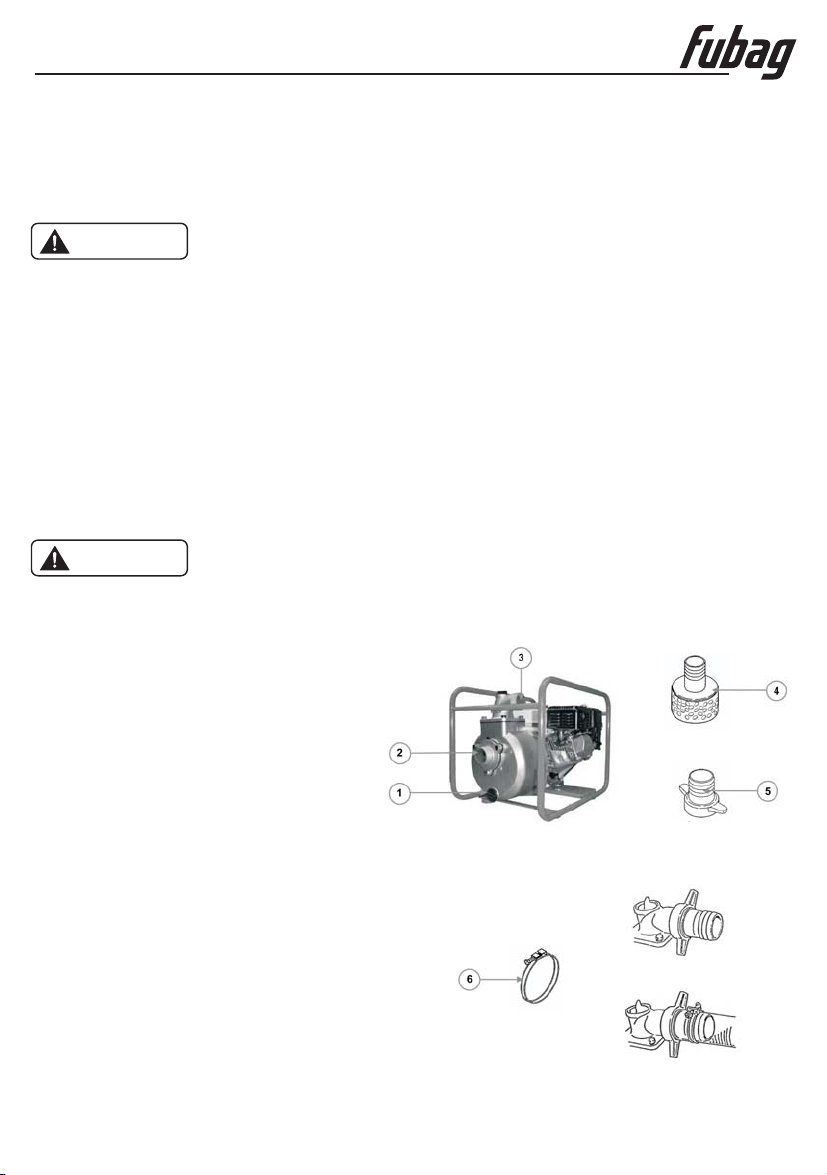

2. Description

www.fubag.ru

START

CHOKE

ON

OFF

1.

Fuel tank plug

2.

Pump filler cap

3.

Choke

4.

Motor contactor

5.

Throttle lever

6.

Fuel tap

7.

Recoil starter

8.

Pump drain plug

9.

Air filter

10.

Spark plug

11.

Exhaust silencer

- 3 -

Page 5

Omperator's anual

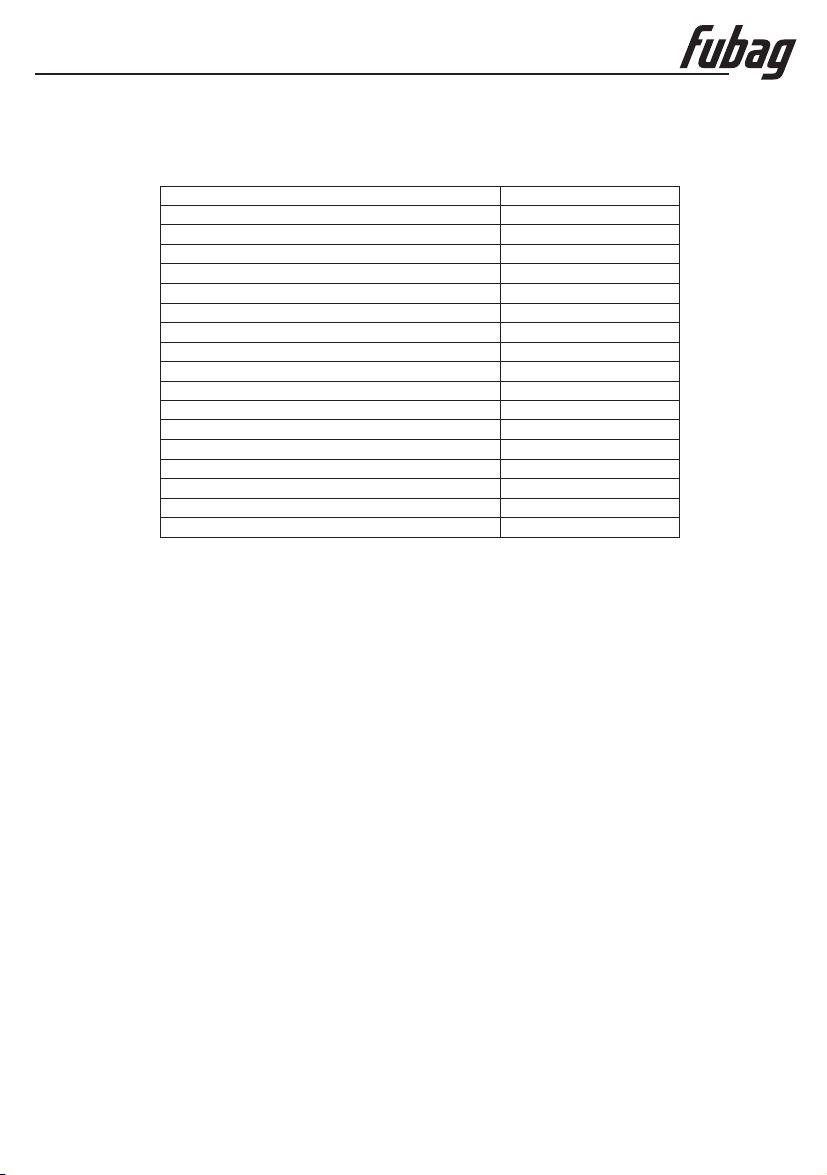

3. Specifications

Particle size of the liquid pumped, mm 30

www.fubag.ru

МODEL PG 950 T

Engine type F170

Suction diameter, mm 80

Discharge diameter, mm 80

Max. flow rate, L/min 1300

Max. elevation head, m 26

Max. suction head, m 8

Type of liquid Trash water

Fuel tank capacity, L 3,6

Recommended fuel Unleaded petrol

Recommended oil SAE 10W30

Liquid temperature,ОC 0 ~ +60

Ambient temperature,ОC -40 ~ +40

Relative humidity (at 40ОС), % 50

Relative humidity (at 20ОС), % 90

Dimensions L х W х H, mm 562 455 4 72

Weight, kg 43

The manufacturer reserves himself the right to make the manual's content or function

change without anypreliminary notification ofthe users.

pump

4. Preparation before use

Positioning for operation

Place the motor pump on a sufficiently strong, flat and horizontal surface so that the electric pump

cannot sink in (the inclination must not exceed 10° in any direction).

Select a clean location, ventilatedand protected from inclement weather, and providean oil and fuel

supply close to the place of motor pump usage, while still maintaining a safe distance.

Select a location which will not impede the movement of people or vehicles.

Make sure that the motor pump remains stable and immobile while in operation. Don't forget that the

suction hose tends to pull the motor pump towards the water source during pumping.

Place the motor pump as close as possible to the liquid being drawn-in. The shorter the vertical

distance between the motor pump and the liquid surface, the more rapid the priming and the greater

the volume of liquid pumped.

Submerge the strainer completely within the liquid, taking care that it is not blocked.

- 4 -

Page 6

Omperator's anual

www.fubag.ru

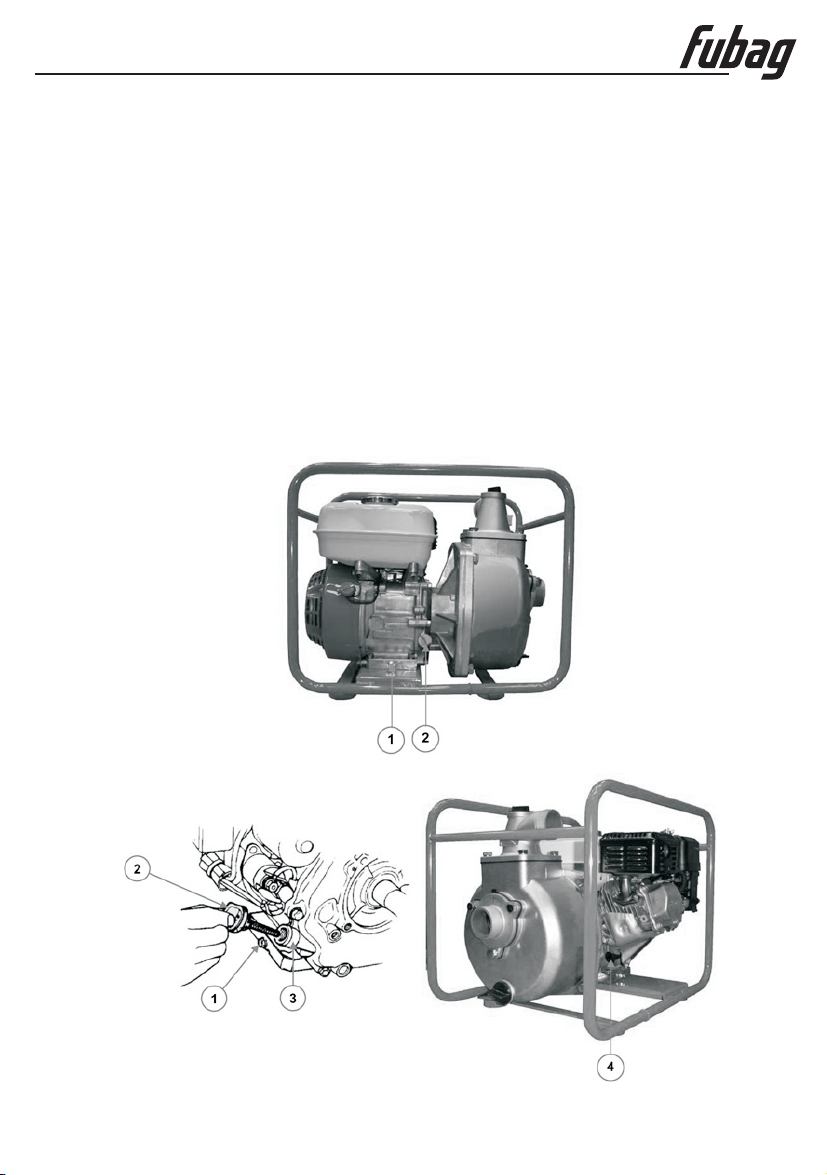

Oil level

1.

Remove the filler plug-dipstick (no. 2) by unscrewing it, and wipe the dipstick.

2.

Insert the dipstick into the filler neck (no. 3) without screwing it. N.B.: A second black plug (no. 4)

without a dipstick, is available if necessary on the other side of the engine.

3.

Visually check thelevel and top up if necessary.

4.

Tighten the filler plug-dipstick (no. 2) completely onto the filler neck (no. 3).

5.

Check that there are no leaks.

6.

Wipe off excessoil with a clean cloth.

- 5 -

Page 7

Omperator's anual

Fuel level

Only use clean fuel without any water. Do not overfill the tank (there should

WARNING!

Visually check thefuel level. Topup if necessary:

Close the fuel tap.

1.

Remove the fuel tank plug.

2.

Fill the fuel tank with a funnel, taking care not to spill any fuel.

3.

Tighten the plug on the tank.

4.

Open the fuel tap.

5.

Assembly of pipings

WARNING!

1. Pass the pipe fixing clamps (no. 6)

around the suction & discharge hoses.

Mount the hose couplings (no. 5) on the

2.

suction (no. 2) & discharge of the pump

(no. 3).

Fix the suction & discharge hoses on

3.

their respective couplings using the pipe

fixing clamps.

Place one of the pipe fixing clamps

4.

around the other end of the suction hose.

Attach the strainer (no. 4) at the end of

5.

the suction hose.

Fix the strainer with a pipe fixing clamp.

6.

not be any fuel in the filler neck).

After filling, always check that the plug is fitted properly on the tank. If fuel has

been spilled, make sure that it has dried and that the fumes are dissipated

before starting the motor pump set.

Never use the motor pump without the appropriate strainer (risk of pump

deterioration).

Always ensure that the sealing joints of the couplings are firmly in place (risk

of poor suction of the liquid).

www.fubag.ru

- 6 -

Page 8

Omperator's anual

5. Usage of the motor pump

Starting-up

www.fubag.ru

WARNING!

Fully immerse the strainer in the liquid to be drawn-in. If there is a risk of blockage, place the

1.

strainer on a rock bed.

Unscrew the pump filler plug.

2.

Top up thepump housing with water.

3.

Screw the pump filler plug back on.

4.

Move the choke knob into position .

5.

N.B: Do not use the starter when the engine is hot or when the atmospheric temperature is high.

Set the engine switch to “ ” and activate the gas lever.

6.

Slowly pull the recoil starter handle once until encountering resistance, allow it to return back

7.

gently.

Pull the recoil starter firmly & strongly until the engine starts.

8.

Gently set the choke knob to and wait for an engine temperature increase before releasing the

9.

gas lever.

If the engine does not start, repeat the operation until the engine starts-up. If the pump does not

discharge, stop the motor pump and check the suction circuit.

Operation

WARNING!

Always top up the pump housing before starting the engine.

Presence of liquid is necessary to prime & lubricate a pump (risk of

deterioration).

I

During the operation, don'tallow anyforeign bodies to block thesuction or the

discharge.

Don't block the discharge pipe: don't allow any vehicle to park on the pipe.

Never close a valve abruptly: water-hammer action can seriously damagethe

pump.

When the speed of the motor pump has stabilised (around 3 min), move the gas lever into position

for the desired speed.

The motor pump discharges the liquid not only according to the speed but also the elevation height

for suction & discharge, and the quality of liquid to be drawn-in.

- 7 -

Page 9

Omperator's anual

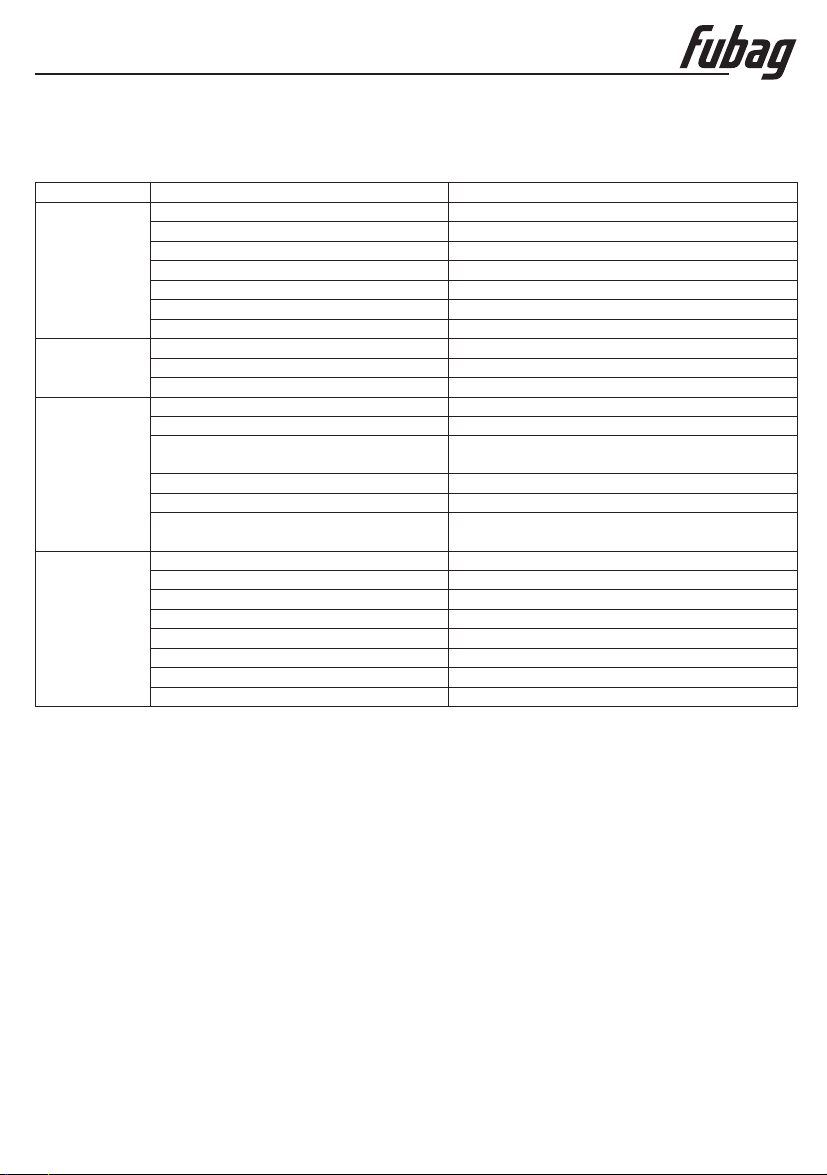

Component

Operations to be

carried out at

whichever

deadline is

reached first

Each time it is

used

First month

or after the

first 20 hours

3monthsor

Every 50

hours

6monthsor

Every 100

hours

12 months or

Every 300

hours

Check the level

·

Engine oil

Change

··

Check

·

Air filter

Clean

·

Motor pump Clean

·

Strainer and

Sediment bowl

Clean

·

Spark plug Check / Clean

·

Valves * Check/adjust*

·*

Fuel tank* Clean*

·*

Fuel line*

Check (replace if

necessary)

Every 2 years*

* Operation(s) must only be carried out by one of our agents.

www.fubag.ru

Switching off

1.

Restore the gas lever to its original position.

2.

Set the engine switch to the “ ” position. The motor pump stops.

3.

Drain the motor pump then rinse it if its use is over for the day.

O

Rinsing

Once the motor pump is shutdown and cold:

1.

Empty the suction & discharge hoses, allow the liquid to drain out.

2.

Unscrew the drain plug from the pump in order to drain-out the pump housing.

3.

Screw the pump drain plug back on once drainage is complete.

4.

Remove the pump filler plug and fill the pump housing with clean water.

5.

Slowly pull the recoil starter handle several times till encountering resistance, allow it to return

back gently.

6.

Unscrew the pump drain plug and drain the pump housing.

7.

Screw the pump fill & drain plugs back on.

8.

Clean the strainer.

Safety features

If there is no oil in the engine sump or if the oil pressure is low, the oil safety mechanism

automatically stops the engine to prevent any damage. If this occurs, check the engine oil level and

top it up if necessary before looking for any other cause of the problem.

6. Maintenance

This section describes how to service the .

pump

Servicing and repair work not described in this section must be carried out by the manufacturer’s

personnel.

The following servicing work must be carried out in accordance with the corresponding periods.

- 8 -

Page 10

Omperator's anual

www.fubag.ru

Checking bolts, nutsand screws

To prevent faultsor breakdowns, carefully check all the nuts, bolts and screws on a daily basis.

Inspect the motor pump assembly before & after every start-up and usage.

1.

Tighten any loose nuts or bolts.

2.

Warning: the cylinder head bolts must be tightened by a specialist. Refer to the agent for your

region.

Renewing the engineoil

Follow the environment protection instructions and drain the oil in a suitable container.

With the engine still hot, place a suitable container under the oil drain screw, then remove the oil

1.

filler gauge plug and the oil drain screw.

N.B.: If necessary, a second black filler plug, but without a gauge, is available on the other side of the

engine.

After complete draining, screw the oil drain screw back on.

2.

Top up withrecommended oil then check the level.

3.

Refit and tighten the oil filler gauge plug.

4.

After filling, check that there are no oil leaks.

5.

Wipe away any traces of oil with a clean cloth.

6.

Cleaning the sedimentbow

1.

Close the fuel tap.

2.

Place a suitable container and a funnel underneath the

carburettors.

3.

Unscrew the fuel drain plug (no. 1) to drain the fuel.

4.

After draining, refit the fuel drain plug.

5.

Remove the sediment bowl (no. 3) and the seal (no. 2).

6.

Clean the sediment bowl (no. 3) with non-flammable

solvent or solvent with a high flash point. Dry it completely.

7.

Refit the seal ( no. 2) and the sediment bowl (no. 3).

8.

Open the fuel tap and check that there are no leaks.

- 9 -

Page 11

Omperator's anual

Cleaning the airfilter

1.

Remove wing nut and cover from the air filter (no. 1 & 2).

2.

Remove the filter elements (no. 4 & 5) and clean them:

no.

Paper element

a)

Gently tap the element several times on a hard

surface to remove any excess dirt.

OR: Pass compressed air through the filter, from the

inside out. Never try to remove dirt using a brush.

b)

Replace the paper element if it is too dirty.

Foam element

a)

Wash the element in a solution of household

cleaner and warm water and rinse thoroughly.

OR: wash with non-flammable solvent or solvent

with a high flash point. Allow the element to dry

completely.

b)

Soak the element in clean engine oil and remove

the excess oil.

Note: If there is too much oil remaining in the foam,

the engine will emit smoke when it is first started.

3.

Check carefully that the two elements are not torn or

pierced. Replace them if they are damaged.

4.

Carry out refitting following the reverse procedure for

removal.

( 4):

no

( . 5):

www.fubag.ru

Checking the sparkplug

1.

Remove the cap (fig. F - no. 1) from the spark plug, then remove the spark plug (fig. F - no. 2)

using a spark plug spanner.

2.

Check the condition of the spark plug:

If the electrodes are worn or if the insulation is split or flaking:

3.

Replace the spark plug.

4.

Fit a new spark plug in position and tighten it by hand to avoid damaging the threads.

5.

Use a spark plug spanner to tighten the spark plug by 1/2 turn after it is seated to compress the

washer.

Otherwise:

3.

Clean the spark plug with a metal brush.

4.

With a feeler gauge, check the electrode gap "X": it must be between 0.7 and 0.8 mm inclusive.

- 10 -

Page 12

Omperator's anual

www.fubag.ru

5.

Check the condition of the washer.

6.

Fit the spark plug in position and tighten it by hand to avoid damaging the threads.

7.

Use a spark plug spanner to tighten it by 1/8-1/4 turn after it is seated to compress the washer.

7. and Preparation for storageCleaning

1.

Remove all dust and particles around the exhaust silencer.

2.

Clean the motor pump, especially the air inlets & outlets of the engine, with a cloth and a brush.

3.

Check the general condition of the motor pump and if change any defective parts.

If the pump is not used for a long period of time, it must be stored in accordance with the following

guidelines.

1.

Unscrew the pump drain plug and empty the pump housing.

2.

Clean the inside of the pump housing cover with a water jet.

3.

Screw the pump drain plug back on.

4.

Drain the fuel through the filler neck of the fuel tank.

5.

Withdraw the spark plug, pour a maximum of 15ml of oil into the cylinder then refit the spark plug.

6.

Slowly pull the recoil starter handle several times until encountering resistance, allow it to return

back gently, so thatthe oil is distributed throughout inside the cylinder.

7.

Clean the outside of the motor pump, apply an anti-rust product over the damaged areas.

8.

Cover the motor pump with a drop cloth to protect it from dust and store it in a clean and dry

location.

- 11 -

Page 13

Omperator's anual

FAULT POSSIBE CAUSE REMEDY

Air filter clogged up. Clean the air filter.

Fuel tap closed. Open the fuel tap.

Fuel level too low

Fill up with fuel.

Fuel filter clogged up. Clean the fuel filter.

Oil level too low. Check the oil level and top up if necessary.

Fuel supply blocked or leaking Have it checked, repaired or replaced.*

Engine not

starting

Spark plug defective. Check the spark plugand replace if necessary.

Blocked ventilation inlets Clean the air inlet and outlet guards

Fuel level too low

Fill up with fuel.

Engine

shutdown

Oil level too low. Check the oil level and top up if necessary.

Level of liquid being pumped is too low. Immerse the strainer completely.

Water level in the pump casing too low. Add water in the pump casing.

Pump drain plug not screwed on

properly.

Tighten the pump drain plug.

Air coming in through the suction side. Check the pipe suction side.

Engine not running properly. Have it checked, repaired or replaced.*

Priming

failure

Air coming in through the mechanical

joint.

Have it checked, repaired or replaced.*

Pipe too long or bent. Shorten or stretch the pipe.

Suction side is too high up. Lower the height of operation.

Air coming in through the suction side. Check the pipe suction side.

Liquid leaking in the pipes. Repair the leak.

Wheel clogged up Have it checked, repaired or replaced.*

Wheel worn Have it checked, repaired or replaced.*

Mechanical joint broken. Have it checked, repaired or replaced.*

Low flow

Engine power loss. Have it checked, repaired or replaced.*

* Operation(s) to be entrusted to one of our agents.

8. Trouble Shooting

www.fubag.ru

9. Warranty

Warranty refer to defects of materials and components and do not refer to components subject to

natural wear and maintenance work.

Only machines cleaned from dust and dirt in original factory packing fully completed, provided with

instruction manual, warranty card with fixed sales date with a shop stamp factory serial number and

originals of sales and ware receipt issued by salesmanare subjects of warranty. Within thewarranty

period the service center eliminate free of charge all detected production defects. The manufacturer

disclaims warranty and legal responsibilities if nonobservance of the instruction manual by user,

unqualified disassembling repair or maintenance of the machine as well does not bear responsibility

for caused injury to persons or damages.

- 12 -

Page 14

Инструкция по эксплуатации

www.fubag.ru

ВНИМАНИЕ! ПЕРЕД ИСПОЛЬЗОВАНИЕМ МОТОПОМПЫ ВНИМАТЕЛЬНО

ОЗНАКОМЬТЕСЬ С ДАННОЙИНСТРУКЦИЕЙ.

К использованию и обслуживанию мотопомпы допускается только

квалифицированный и специально обученный персонал, ознакомленный с данной

инструкцией.

В этой инструкции содержится описание, правила безопасности и вся необходимая

информация для правильной эксплуатации мотопомпы FUBAG. Сохраняйте данную

инструкцию и обращайтесь к ней при возникновении вопросов по безопасной эксплуатации,

обслуживанию, хранению итранспортировке помпы FUBAG.

1. Правила безопасности

ВНИМАНИЕ!

ВНИМАНИЕ!

ВНИМАНИЕ!

ВНИМАНИЕ!

Выхлопы содержат вредный угарный газ. Никогда не

эксплуатируйтепомпу в закрытом помещении. Перед включением

убедитесь, что обеспечена хорошая вентиляция. При установке в

хорошо проветриваемых зонах обращайте внимание на обеспечение

безопасности.

При работе помпы глушитель становится очень горячим и остывает

некоторое время после ее выключения. Будьте внимательны и не

дотрагивайтесь до глушителя, пока он горячий. Дайте двигателю

остыть до того, как поставить его на хранениев помещение.

Выхлопная система двигателя будет нагреваться при работе и

останетсягорячей некоторое время после выключения двигателя.

Для предотвращения ожогов обращайте внимание на

предупредительные наклейки.

Бензин является легко воспламеняемым и взрывчатым веществом.

Осуществляйте заправку помпы топливом только в хорошо

проветриваемых зонах при выключенном и остывшем двигателе.

Поблизости не должно быть курящих, источника искр и дыма. Всегда

заправляйте помпу в хорошо проветриваемом месте. Пролитый бензин

необходимосразу удалить.

Внимание: помпа поставляется без масла.

Перед каждым включением помпы проверьтеуровень масла.

-3 -1

Page 15

Инструкция по эксплуатации

www.fubag.ru

ВНИМАНИЕ!

- Всегда проводите предэксплуатационный осмотр до запуска двигателя. Вы можете

предотвратитьаварию или повреждение оборудования.

- Внимательно изучите и запомните параграфы инструкции. Не допускайте к работе с

мотопомпой лиц, не ознакомившихся с инструкцией.

- Не допускайте к работающей помпе детей и домашних животных.

- На корпусе мотопомпы должны присутствовать и быть легко читаемыми все обозначения.

- Любые изменения конструкции запрещаются. Запрещается изменять частоту вращения

двигателя, установленную заводом-производителем.

- Перед каждым запуском и после него следует проверять безопасность и исправность

прибора.

- Вблизи помпы необходимо остерегаться открытого огня и искр. Курение вблизи строго

запрещается.

- Помпу разрешается транспортировать только вохлаждённом состоянии.

- Помпу разрешается перевозить, только если она надёжно зафиксирована и не может

опрокинуться.

- Запрещается использовать средства для облегчения запуска.

- Запрещается производить заправку во время работы. Запрещается производить заправку не

остывшей мотопомпы. Используйте при заправке воронку.

- Запрещается обслуживать мотопомпу во время работы. Запрещается обслуживать не

остывшую помпу.

- Обслуживающему персоналу разрешается производить только те работы по обслуживанию,

которые описаны в данном руководстве. Любые другие работы разрешается проводить только

специалистам сервисной службы.

- Перед началом работ по обслуживанию и ремонту обязательно снимайте колпачок свечи

зажигания.

- Соблюдайте интервалы технического обслуживания.

- Консервируйте помпу, если им не пользуются более 30 дней.

- Храните помпу в сухом и закрытом помещении.

-4 -1

Page 16

Инструкция по эксплуатации

2. Описание

ЗАСЛОНКА

ВЫКЛ

www.fubag.ru

ПУСК

ВКЛ

1. Крышка топливного бака

2. Крышка заливочного отверстия насоса

3. Рычаг воздушной заслонки

4. Включатель двигателя

5. Газовый рычаг

6. Топливный кран

7. Пусковой шнур

8. Крышка слива насоса

9. Воздушный фильтр

10. Свеча зажигания

11. Глушитель

-5 -1

Page 17

Инструкция по эксплуатации

3. Техническиехарактеристики

МОДЕЛЬ PG 950 T

Диаметр всасывающего отверстия, мм 80

Диаметр нагнетательного отверстия, мм 80

Максимальный расход жидкости, л/мин 1300

Максимальная высота напора, м 26

Максимальная высота всасывания, м 8

Гранулометрический состав

перекачиваемой жидкости, мм

Емкость топливного бака, л 3,6

Тем-ра перекачиваемой жидкости,ОC 0 ~ +60

Тем-ра окружающей среды,ОC -40 ~ +40

Относительная влажность (при 40ОС), % 50

Относительная влажность (при 20ОС), % 90

Габаритные размеры Д х Ш х В, мм 562 455 4 72

Производитель имеет право вносить изменения, как в содержание данной инструкции, так и в

конструкцию мотопомпы без предварительногоуведомленияпользователей.

Двигатель F170

Тип жидкости Грязная вода

Рекомендованное топливо

Рекомендованное масло SAE 10W30

Вес, кг 43

www.fubag.ru

30

Неэтилированный

бензин марки А-92

4. Подготовкак работе

Установка

Установите помпу на ровной горизонтальной поверхности, достаточно прочной, чтобы

помпа не вдавливалась в землю (наклон не должен превышать 10 градусов в любом

направлении).

Выберите место, где помпа не будетмешать проходу людей илиавтомобилей.

Удостоверьтесь, что помпа стоит устойчиво и не сможет сместиться во время работы. Не

забывайте, что шланг всасывания тянет насос к источнику воды во время работы.

Также следует расположить насос по возможности ближе источнику воды. Чем меньше

вертикальное расстояние между насосом и поверхностью воды, тем эффективнее будет

работа насоса ибольше объем выкаченной жидкости.

Полностью погрузите фильтрв жидкость, стараясьуменьшить риск засорения.

-6 -1

Page 18

Инструкция по эксплуатации

www.fubag.ru

Уровеньмасла

1. Отвинтите иизвлеките пробку-щуп заправочного отверстия ( поз. 2) ивытрите щуп.

2. Вставьте щуп в заправочную горловину (поз. 3) не заворачивая его. Примечание: В случае

необходимостиимеется вторая пробка (поз. 4)без щупа сдругой стороны двигателя.

3. Визуально проверьте уровеньмасла и при необходимости долейте его.

4. До упора завинтите пробку-щуп заправочного отверстия (поз. 2)в горловину (поз. 3).

5. Убедитесь в отсутствии протечкимасла.

6. Удалите следы масла чистой ветошью.

-7 -1

Page 19

Инструкция по эксплуатации

www.fubag.ru

Уровеньтоплива

Используйте только чистое топливо без примеси воды.

Не переполняйте топливный бак (внутри заправочной горловины не

ВНИМАНИЕ!

Визуально проверьте уровень топлива. При необходимости долейте необходимое

количество топлива:

1. Закройте топливныйкран.

2. Отвинтите крышке топливного бака.

3. Залейте топливо в бак через воронку, стараясь не пролить.

4. Заверните крышкугорловины топливного бака.

5. Откройте топливныйкран.

Монтаж трубопроводов

ВНИМАНИЕ!

должно быть топлива).

После заливки топливаубедитесь, что пробкабака хорошо закрыта.

Если топливо пролилось, прежде чем включать насосную установку,

убедитесь, что оно высохло и что парыулетучились.

Никогда не используйте насос без фильтра на всасывающей трубе

(опасность повреждения насоса).

Всегда проверяйте, что герметичные соединения шланга в порядке

(опасность плохоговсасывания жидкости).

1. Закрепите зажимные хомуты (поз. 6)

на шлангах всасывания и нагнетания.

2. Закрепите муфтовые соединения

для шланга (поз. 5) на трубе

всасывания (поз. 2) и на трубе

нагнетания насоса (поз. 3).

3. Закрепите шланги всасывания и

нагнетания с соответствующими

муфтами при помощи зажимных

хомутов.

4. Закрепите один из зажимных

хомутов на другом конце шланга

всасывания.

5. Установите фильтр (поз. 4) на конце

шланга всасывания.

6. Закрепите фильтр при помощи

зажимного хомута.

- 18 -

Page 20

Инструкция по эксплуатации

5. Эксплуатация

Запуск

www.fubag.ru

ВНИМАНИЕ!

1. Полностью погрузите всасывающий фильтр в жидкость для всасывания. Поместите

фильтр на каменное основание во избежание закупоривания.

2. Выкрутите крышкузаливки насоса.

3. Заполните корпус насоса водой.

4. Закрутите крышкузаливки насоса.

5. Переведите рычаг воздушной заслонки в положение

Примечание: Не закрывайте воздушную заслонку полностью при нагретом двигателе или

при повышенной температуре окружающей среды.

6. Установите включатель двигателяв положение «I» («ВКЛ»),переключите ручку газа.

7. Медленно дерните за ручку пускового шнура до упора и дождитесь пока он снова не

свернется.

8. Затем сильно и тяните шнур стартера без рывков до тех пор, пока двигатель не

запуститься.

9. Медленно переключитерычаг воздушной заслонки в положение и дождитесь разогрева

двигателя перед отпусканием ручки газа.

Если двигатель не запустился, повторяйте эти действия, пока не произойдет запуск. Если

подача воды не началась, остановите насос и проверьте систему всасывания.

Работапомпы

ВНИМАНИЕ!

Перед запуском двигателявсегда заливайте в насос воду.

Наличие жидкости необходимо для начального заполнения насоса и его

смазки.

Не допускайте попадания инородных предметов в систему всасывания

и нагнетания воды во время работы насоса.

Не допускайте закупоривания нагнетательной трубы: не допускайте

наезда автомобиля на трубу.

Никогда не закрывайте водяной вентиль резко: мощный удар может

привести к серьезным повреждениям насоса.

Когда скорость работы помпы стабилизируется (примерно через 3 мин), поверните газовый

рычаг в положение,соответствующее желаемой скорости.

Насос подает жидкость согласно установленной скорости, а также в зависимости от высоты

всасывания и подачи воды и качества подаваемой жидкости.

- 19 -

Page 21

Инструкция по эксплуатации

Элемент Операции

При каждом

использовании

Первый

месяц или по

окончании

первых 20

часов

3 месяцев

или

после 50

часов

6 месяцев

или

после

100 часов

12 месяцев

или

после 300

часов

Проверьте

уровень

·

Моторное масло

Замените

··

Проверьте

·

Воздушный фильтр

Очистите

·

Приводной насос Очи стит е

·

Сетку и

Стакан отстойника

Очистите

·

Свеча зажигания

Проверьте и

очистите

·

Клапаны *

Проверьте -

отрегулируйте*

·*

Топливный бак * Очистите*

·*

Топливопровод*

Проверьте (при

необходимости

замените)

Через каждые два года*

* Операцию или операции должен выполнять специалист, прошедший специальную подготовку.

www.fubag.ru

Выключение

1. Вернуть газовый рычаг в начальное положение.

2. Установить включатель двигателя в положение «O». Помпадолжна остановиться.

3. Опорожнить помпуи промыть водой,если она небудетиспользоваться в течении дня.

Промывка

После остановки иохлаждения насоса нужно промытьего водой:

1. Спустите воду со шлангов всасывания и нагнетания.

2. Отвинтите пробку слива воды для опорожнения корпуса насоса.

3. После полного слива воды завинтите пробку обратно.

4. Отвинтите пробку заливки и заполните корпуснасоса чистой водой.

5. Медленно дергайте за ручку пускового шнура до упора и дождитесь пока он снова

свернется.

6. Отвинтите пробку слива и опорожните корпуснасоса.

7. Завинтите пробкизаливки и сливанасоса.

8. Почистите фильтрвсасывающей трубы.

Защитные устройства

При отсутствии масла в картере двигателя или при слишком низком давлении масла,

система контроля масла автоматически останавливает двигатель во избежание любых

повреждений.

В таком случае, следует проверить уровень масла в картере двигателя и довести его до

нормы, в случае необходимости, прежде чем приступать к поиску иной причины

неисправности.

6. Техническое обслуживание

- Обслуживание аппарата может производиться только квалифицированным персоналом.

- Всегда выключайте помпу и снимайте колпачок свечи зажигания.

Проводите следующие работы по обслуживанию регулярно и с соблюдением указанных

интервалов.

-0 -2

Page 22

Инструкция по эксплуатации

www.fubag.ru

Проверка винтовых соединений

Для предотвращения несчастного случая или поломки необходим ежедневный тщательный

контроль всех резьбовых соединений.

1. Осматривайте мотопомпу перед каждым запуском и после каждого использования.

2. Подтягивайте резьбовые соединения, затяжка которых ослабла.

Примечание: затяжка болтов головки блока цилиндров должна выполняться

специалистом.

Замена моторного масла

Выполняйте требования по защите окружающей среды и сливайте масло в подходящую

емкость.

1. Пока двигатель не остыл,поместите подходящую емкость под винт для слива масла, затем

извлеките пробку-щуп отверстия для заливки маслаи винт для сливамасла.

Примечание: В случае необходимости вторая пробка отверстия длязаливки масла имеетсяс

обратной стороны двигателя.

2. После того как масло слито, завинтите на местовинт для сливамасла.

3. Залейте необходимое количество рекомендованного масла и проверьте уровень.

4. Установите на место и завинтите пробку-щуп отверстия для заливки масла.

5. Проверьте отсутствие утечек масла после заправки.

6. Вытрите следы масла чистой ветошью.

Очистка стакана отстойника

1. Закройте топливныйкран.

2. Установите под карбюратор подходящую емкость и

воронку.

3. Отверните крышку(поз. 1) и слейте топливо.

4. После окончания слива заверните крышку

отверстия для слива топлива.

5. Снимите стакан отстойника (поз. 3) и прокладку

(поз. 2).

6. Промойте стакан отстойника (поз. 3)

невоспламеняющимся или трудно воспламеняю

щимся растворителем. Тщательно просушите его.

7. Установите прокладку (поз. 2) и стакан отстойника (

поз. 3).

8. Откройте топливный кран и убедитесь в

отсутствии утечек.

-

Очистка воздушного фильтра

1. Отверните барашковую гайку и снимите крышку

воздушногофильтра (поз. 1 и 2).

2. Извлеките фильтрующие элементы (поз. 4 и 5) и

очистите их:

-1 -2

Page 23

Инструкция по эксплуатации

www.fubag.ru

Элемент из бумаги

Несколько раз слегка постучите элементом по

a)

твердой поверхности, чтобы удалить

избыточные загрязнения.

ИЛИ: Направьте струю сжатого воздуха через

фильтр изнутри. Никогда не пытайтесь удалить

загрязнения при помощищетки.

Если бумажный элемент слишком сильно

b)

загрязнен, замените его.

Элемент из пеноматериала

Промойте элемент бытовым моющим

a)

средством и горячей водой, затем тщательно

промойте чистой водой.

ИЛИ: Промойте элемент невоспламеняющимся

или трудно воспламеняющимся растворителем.

Тщательно просушите элемент.

Пропитайте элемент чистым моторным

b)

маслом и отожмите излишек масла.

Примечание: Если в элементе из

пеноматериала останется слишком много

масла, при первом запуске двигатель будет

дымить.

Внимательно проверьте оба элемента на отсутствие

3.

в них дыр и разрывов. Замените поврежденные

элементы.

Установите детали в обратном порядке.

4.

(поз. 4):

(поз. 5):

Проверка свечи зажигания

1. Снимите колпачок (поз. 1) со свечи зажигания и при помощи свечного ключа выверните

свечу зажигания (поз. 2).

2. Проверьте состояние свечи зажигания:

Если свеча зажигания с изношенными электродами, оплавленным или отслаивающимся

изолятором:

3. Замените свечу.

4. Установите на место новую свечу зажигания и заверните ее от руки, чтобы не повредить

резьбу.

5. Доверните свечу с помощьюсвечногоключа на 1/2оборота, чтобы сжать шайбу.

Если свеча зажигания не изношена:

3. Очистите свечу металлической щеткой.

4. С помощью щупа поверьте зазор «X» между электродами: он должен составлять 0,7 - 0,8

мм.

-2 -2

Page 24

Инструкция по эксплуатации

www.fubag.ru

5. Проверьте состояние шайбы.

6. Установите на место свечу зажигания и заверните ееот руки, чтобы не повредить резьбу.

7. Доверните свечу с помощьюсвечногоключа на 1/8- 1/4 оборота,чтобы сжать шайбу.

7. Очистка и хранение

1. Удалите пыль и загрязнения вокруг глушителя системы выпуска отработавших газов.

2. Очистите насос ветошью и щеткой, в частности входные и выходныевоздушные отверстия

двигателя.

3. Проверьте общее состояние насоса и замените неисправныедетали.

В случае длительного неиспользования следует произвести следующие указания по

хранению.

1. Отвинтите пробку слива воды и опорожните корпус насоса.

2. Промойте внутренниестенки корпуса насоса струей воды.

3. Зажмите крышку слива воды.

4. Слейте топливо через воронку заливкитопливного бака.

5. Извлеките свечу зажигания, залейте не больше 15 мл масла в цилиндр и установите свечу

обратно.

6. Медленно дергайте за ручку пускового шнура до упора и дождитесь пока он снова

свернется,таким образом, чтобы масло равномерно распределилось в цилиндре.

7. Очистите внешнюю поверхность насоса и нанесите антикоррозийное средство на

пораженные части.

8. Накройте насос защитным чехлом для предотвращения попадания пыли и поместите его в

чистое сухое место.

-3 -2

Page 25

Инструкция по эксплуатации

НЕИСПРАВНОСТЬ ПРИЧИНА УСТРАНЕНИЕ

Засорен воздушный фильтр. Почистите воздушный фильтр.

Закрыт топливный кран. Откройте топливный кран.

Недостаточный уровень топлива. Залейте необходимое количество топлива.

Засорен топливный фильтр. Почистите топливный фильтр.

Недостаточный уровень масла.

Проверьте уровень масла и при необходимости

долейте.

Засорен или протекает топливопровод. Проверьте и отремонтируйте или замените.*

Двигатель не

запускается

Повреждена свеча зажигания.

Проверьте свечу зажигания и замените в случае

необходимости.

Засорены вентиляционные отверстия.

Почистите защитные кожухи всасывающих и

нагнетательных отверстий.

Недостаточный уровень топлива. Залейте необходимое количество топлива.

Остановка

двигателя

Недостаточный уровень масла.

Проверьте уровень масла и при необходимости

долейте.

Недостаточный уровень жидкости для всасывания. Полностью погрузите фильтр в жидкость.

Недостаточный уровень воды в корпусе насоса . Долейте воду в корпус насоса.

Не закрыта пробка слива насоса. Завинтите пробку слива насоса.

Попадание воздуха в систему всасывания. Проверьте всасывающую трубу.

Плохое вращение двигателя. Проверьте и отремонтируйте или замените.*

Отказ включения

Попаданиевоздухавмеханическиесоединения. Проверьте и отремонтируйте или замените.*

Шланг слишком длинный или плохо развернут. Укоротите или заново разверните шланг.

Слишком большая высота всасывания. Уменьшите рабочую высоту.

Попадание воздуха в систему всасывания. Проверьте всасывающую трубу.

Протекание воды в трубах. Устраните течь.

Засорение ротора. Проверьте и отремонтируйте или замените.*

Износ ротора. Проверьте и отремонтируйте или замените.*

Разрыв механических соединений. Проверьте и отремонтируйте или замените.*

Малая мощнос ть

Падение мощности двигателя. Проверьте и отремонтируйте или замените.*

* Работы выполняются специалистами сервисной службы.

8. Неисправности и их устранение

www.fubag.ru

9. Гарантийные обязательства

Гарантийный срок наоборудование указывается в прилагаемом сервисном талоне.

Гарантия относится к дефектам в материалах и узлах и не распространяется на компоненты,

подверженные естественному износу и работы по техническому обслуживанию.

Гарантийному ремонту подлежат только очищенные от пыли и грязи аппараты в заводской

упаковке, полностью укомплектованные, имеющие инструкцию по эксплуатации, гарантийный

талон с указанием даты продажи, при наличии штампа магазина, заводского номера и

оригиналов товарного и кассового чеков, выданных продавцом.

В течение гарантийного срока Сервисный центр устраняет за свой счёт выявленные

производственные дефекты. Производитель снимает свои гарантийные обязательства и

юридическую ответственность при несоблюдении потребителем инструкций по эксплуатации,

самостоятельной разборки, ремонта и технического обслуживания аппарата, а также не несет

никакой ответственности за причиненные травмы и нанесенный ущерб.

-4 -2

Loading...

Loading...