Page 1

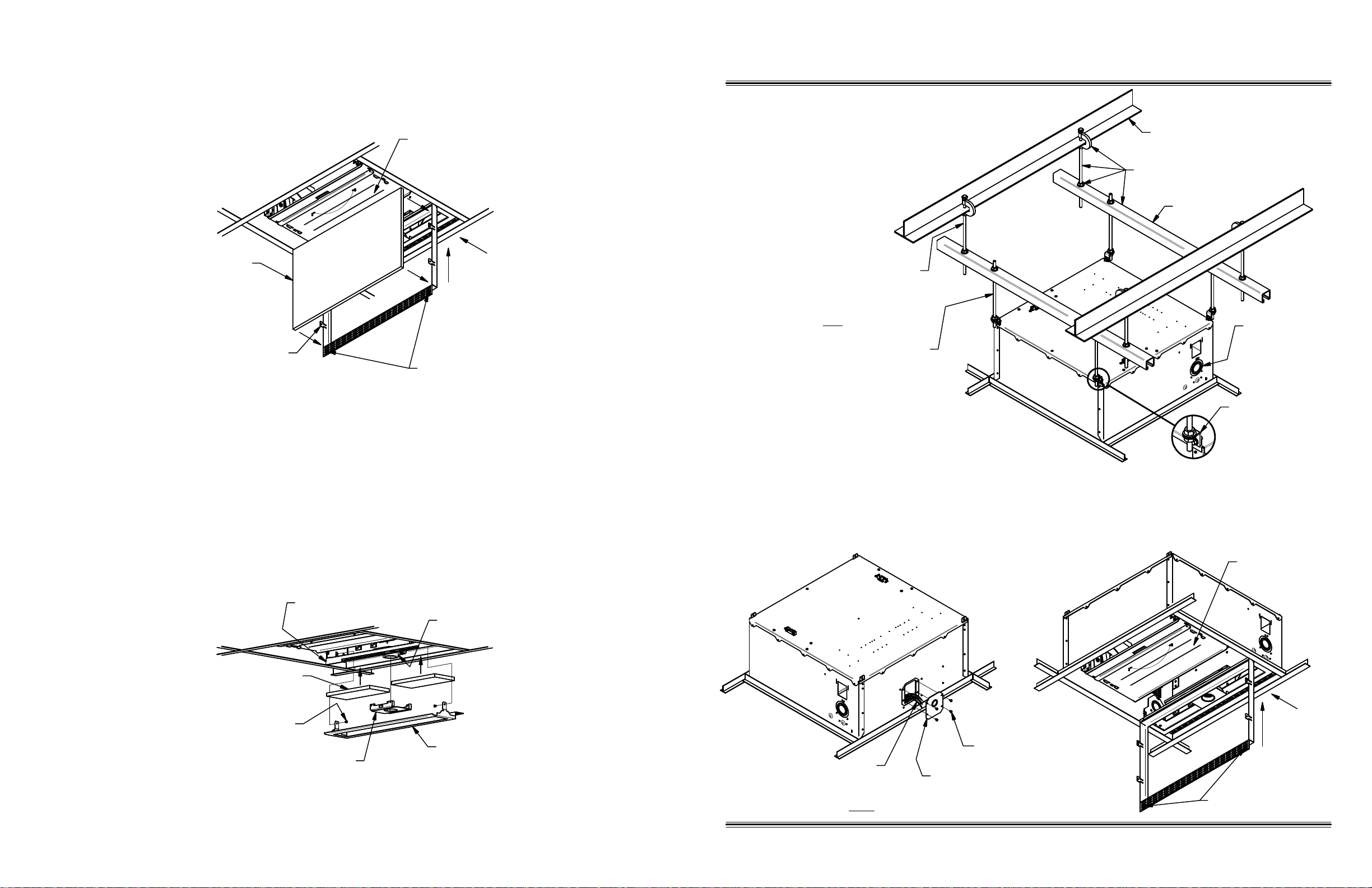

CEILING TILE INSTRUCTIONS

10.

INSTALL 14-3/8" x 22-3/4" DROP CEILING MATERIAL (SUPPLIED

BY CUSTOMER) INTO DOOR. BEND CAPTURE TABS OVER

CEILING PANEL TO HOLD IN PLACE.

14-3/8" x 22-3/4"

DROP CEILING

PANEL MATERIAL

(SUPPLIED BY

CUSTOMER)

(4) CAPTURE

11.

REMOVE CEILING BOX DOOR (SEE STEP 9), REMOVE

(2) #8-32 SCREWS AND ADJUSTMENT BAR COVER. SUPPORT

ADJUSTMENT BAR COVER WHILE REMOVING SCREWS.

POLE MOUNT FLANGE COVER IS NOT FASTENED AND JUST

SLIPS OUT. INSTALL (2) 4" WIDE (SEE NOTE) DROP CEILING

PANELS MATERIAL (SUPPLIED BY CUSTOMER) INTO POLE

ADJUSTMENT BAR. CUT LENGTH AS NEEDED BASED ON

POLE MOUNT POSITION.

TAB

NOTE: 4" x 9" PANEL SIZE IS ONLY VALID WHEN POLE MOUNT

FLANGE IS CENTERED ON THE POLE ADJUSTMENT

BAR (DEFAULT FACTORY INSTALLED LOCATION). IF

POLE MOUNT IS RELOCATED PANELS WILL NEED TO

BE CUT-TO-FIT.

DROP-DOWN

RACK-MOUNT

CARRIAGE

a

LOOSEN SCREWS

TO OPEN DOOR

DOOR IS REMOVABLE.

(a) PUSH DOOR UP

b

TOWARDS CEILING AND

(b) PUSH TOWARDS

DROP-DOWN

RACK-MOUNT CARRIAGE

- REVERSE PROCEDURE

TO INSTALL.

DISCONNECT SAFETY

CABLE TO COMPLETELY

REMOVE DOOR.

CB-224P/SP INSTALLATION INSTRUCTIONS

FSR

1.

INSTALL CB-224P/SP TO A STRUCTURAL CEILING ABLE TO

SUPPORT FIVE TIMES THE NOTED GROSS WEIGHT. USE

APPROPRIATE MOUNTING METHODS BASED ON LOCAL

BUILDING CODES. INSTALL SAFETY CABLE AS REQUIRED BY

LOCAL BUILDING CODES. ROUTE CONDUITS TO BOX AS

REQUIRED.

NOTE: MAXIMUM GROSS WEIGHT - 125 LBS

NOTE: THREADED ROD IS THE

RECOMMENDED CEILING BOX

MOUNTING SUSPENSION

(SHOWN), TO MINIMIZE

FIXTURE TILTING DUE

TO THE WEIGHT OF ANY

SUSPENDED EQUIPMENT.

14 GA. STEEL TIE WIRE MAY BE USED

(SUPPLIED BY CUSTOMER OR USE FSR KIT)

AT 70,000 PSI TENSILE STRENGTH OR

BETTER AS REQUIRED BY BUILDING CODES.

2.

NOTE: WIRES SUPPORT CEILING

BOX, AND ARE NOT

THREADED ROD OR CABLE TO

BE PLUMB WITH CEILING AND FLOOR

AVAILABLE KITS (SOLD SEPARATELY):

CB-MNT1 - CABLE INSTALLATION KIT

CB-THRD - THREADED ROD INSTALLATION KIT

TO INSTALL AC MAIN POWER INTO THE UNIT, REMOVE

THE AC ACCESS PLATE BY REMOVING (4) #8-32

SCREWS, AS SHOWN. WIRING MUST BE PERFORMED

BY A QUALIFIED ELECTRICIAN ONLY. WIRING MUST BE

DONE IN ACCORDANCE WITH ALL NEC AND OTHER

APPLICABLE CODES. RE-INSTALL AC ACCESS PLATE

AFTER AC WIRING IS COMPLETE.

244 Bergen Boulevard, Woodland Park, NJ 07424, Phone: 973.785.4347 - Fax: 973.785.4207

SAFETY CABLES

STRUCTURAL

MEMBER

ALL MOUNTING HARDWARE

SUPPLIED BY CUSTOMER

STRUCTURAL

CHANNEL

ROUTE CONDUIT

(SUPPLIED BY

CUSTOMER) TO

KNOCKOUTS

AS REQUIRED

3.

IF POLE MOUNT FLANGE IS TO BE LEFT AT FACTORY

POSITION, PROCEED TO STEP 7. IF FLANGE IS TO BE

RE-POSITIONED, OR IF INSTALLING FAN KIT, REMOVE

CEILING BOX DOOR. LOOSEN SCREWS TO OPEN DOOR.

(a) PUSH DOOR UP TOWARDS CEILING AND (b) PUSH

TOWARDS DROP-DOWN RACK-MOUNT CARRIAGE REVERSE PROCEDURE TO INSTALL. DISCONNECT

SAFETY CABLE TO COMPLETELY REMOVE DOOR.

BRACKET - FSR'S

THREADED ROD

INSTALLATION KIT

(HARDWARE SUPPLIED

BY CUSTOMER)

DROP-DOWN

RACK-MOUNT

CARRIAGE

4" WIDE DROP CEILING PANEL

MATERIAL - SEE STEP 10 NOTE

(SUPPLIED BY CUSTOMER)

(2) #8-32 x 1/4"-LONG

PAN HEAD SCREW

POLE MOUNT FLANGE COVER

POLE ADJUSTMENT BAR

POLE MOUNT FLANGE

(SHOWN CENTERED)

ADJUSTMENT

BAR COVER

FSR Inc.

244 Bergen Boulevard, Woodland Park, NJ 07424

Phone: 973.785.4347 - Fax: 973.785.4207

Web: www.fsrinc.com - E-mail: sales@fsrinc.com

b

a

(4) #8-32 x 1/4"- LONG

AC POWER INPUT

WIRING MUST BE

PERFORMED BY

A QUALIFIED

ELECTRICIAN ONLY

43973 LIT1365A

AC ACCESS

PLATE

PAN HEAD SCREW

LOOSEN SCREWS

TO OPEN DOOR

Page 2

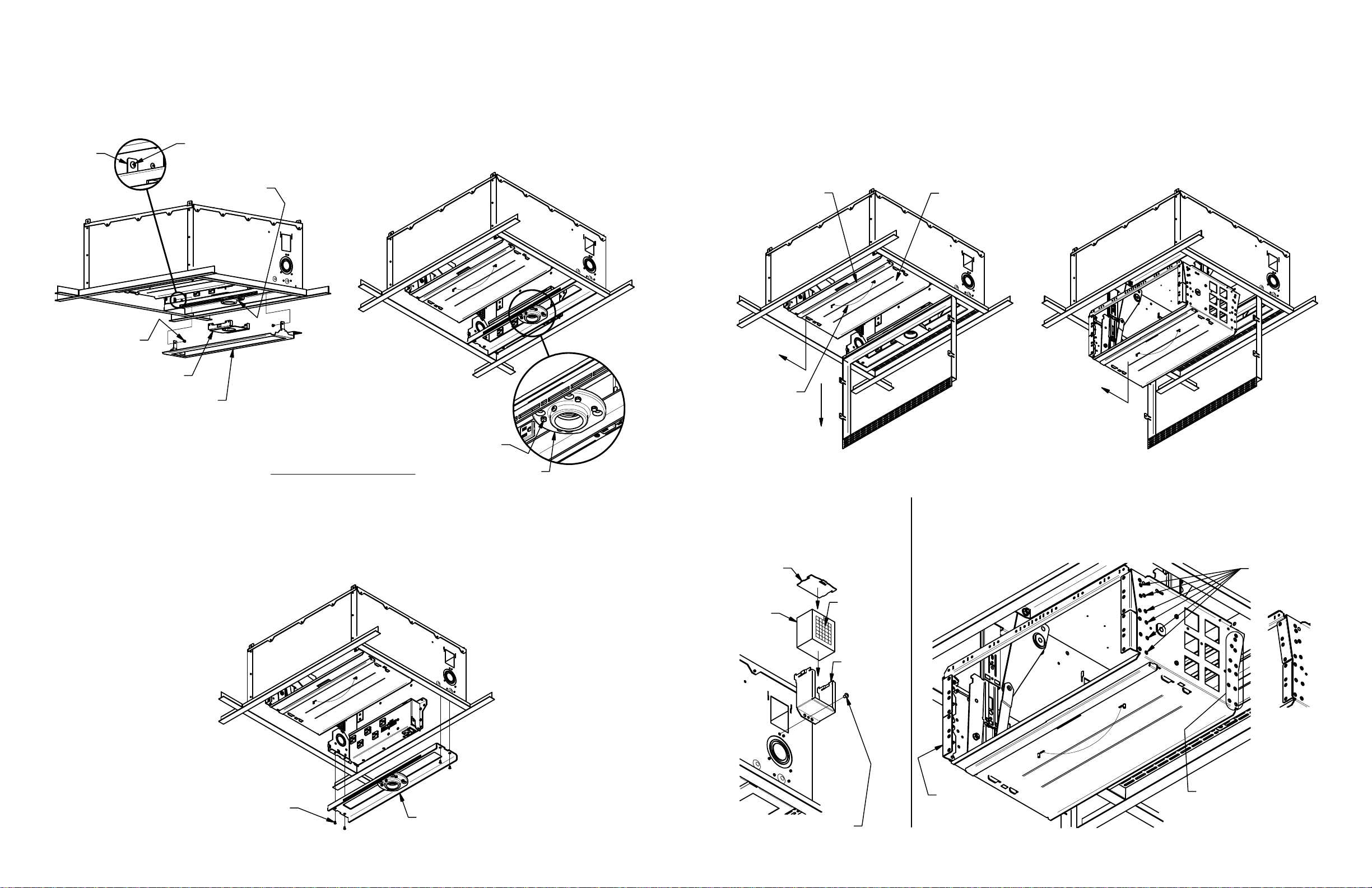

4.

REMOVE (2) #8-32 SCREWS AS SHOWN, AND REMOVE

ADJUSTMENT BAR COVER. SUPPORT ADJUSTMENT

BAR COVER WHILE REMOVING SCREWS. POLE

MOUNT FLANGE COVER IS NOT FASTENED AND JUST

SLIPS OUT.

PART OF

POLE MOUNT

FLANGE

COVER

SCREWS LOCATED IN

INTERIOR OF CEILING BOX

FLANGE

5.

DETERMINE LOCATION OF POLE MOUNT FLANGE.

LOOSEN (4) #10-32 HEX SCREWS AND SLIDE POLE

MOUNT FLANGE TO NEW POSITION AND TIGHTEN HEX

SCREWS. IF INSTALLING FAN KIT PROCEED TO STEP

6. RE-INSTALL POLE MOUNT FLANGE COVER,

ADJUSTMENT BAR COVER AND CEILING BOX DOOR

BACK INTO CEILING BOX BY REVERSING THEIR

REMOVAL STEPS. PROCEED TO STEP 7.

NOTE: MAXIMUM PROJECTOR LOAD INCLUDING

MOUNTED ACCESSORIES - 50LBS

MOUNTING ELECTRONICS INSTRUCTIONS

7.

PULL DOWN DROP-DOWN RACK-MOUNT CARRIAGE TO MOUNT

ELECTRONICS. (a) PUSH LOCK ARM AWAY FROM POLE MOUNT

AND (b) AND PULL DOWN ON CHAIN. ONCE THE DROP-DOWN

CARRIAGE IS PULLED FULLY DOWN (c) AGAIN PUSH THE LOCK

ARM AWAY FROM POLE MOUNT TO LOCK CARRIAGE IN THE

'DOWN' POSITION. REVERSE PROCEDURE TO RETRACT

CARRIAGE BACK INTO CEILING BOX.

NOTE: MAXIMUM LOAD INSIDE CARRIAGE - 25 LBS

LOCK ARM

DROP-DOWN

RACK-MOUNT

CARRIAGE

(2) #8-32 x 1/4"-LONG

PAN HEAD SCREW

POLE MOUNT FLANGE COVER

ADJUSTMENT BAR COVER

NOTE: THE CENTER OF MASS

OF SUSPENDED EQUIP MENT MUST BE WITHIN

A 2.5" RADIUS OF THE

CENTER LINE OF THE

POLE MOUNT FLANGE

OF THE CEILING BOX.

(4) #10-32 x 3/4"-LONG

HEX SCREW

INSTALLING OPTIONAL FAN KIT:

6.

REMOVE (4) #8-32 SCREWS AS SHOWN, AND EXTRACT POLE

ADJUSTMENT BAR. INSTALL FAN KIT PER INSTRUCTIONS. RE-INSTALL

POLE ADJUSTMENT BAR, POLE MOUNT FLANGE COVER, ADJUSTMENT

BAR COVER AND CEILING BOX DOOR BACK INTO CEILING BOX BY

REVERSING THEIR REMOVAL STEPS. PROCEED TO STEP 7.

CAUTION: ONCE THE LAST SCREW IS REMOVED FROM THE POLE

ADJUSTMENT BAR, IT CAN FALL OUT. HOLD POLE

ADJUSTMENT BAR IN PLACE WHILE REMOVING SCREWS.

POLE MOUNT FLANGE

a

PULL CHAIN

8.

INSTALL WIRE BUNDLE INLET, WIRE

INLET FOAM, AND WIRE INLET COVER

TO SIDES OF BOX. REMOVE THE FOAM

BLOCKS NECESSARY FOR THE WIRE

BUNDLE EXITING THE BOX. PULL

WIRES TO CEILING BOX THRU WIRE

INLET OR CONDUIT AS REQUIRED.

(2) WIRE

INLET

COVER

(2) WIRE

INLET

FOAM

b

REMOVABLE

FOAM BLOCKS

9.

INSTALL 1RU TO 4RU x 19" EIA RACK-SIZED ELECTRONICS.

MAKE ELECTRICAL CONNECTIONS AS REQUIRED. RACK

MOUNT BRACKETS CAN BE RE-POSITIONED TO ALTERNATE

HOLES, OR ADDITIONAL BRACKETS MAY BE PURCHASED

(CB-224RKRL).

NOTE: MAXIMUM LOAD INSIDE CARRIAGE - 25 LBS

c

ALTERNATE

RACK MOUNT

BRACKET HOLES

(4) #8-32 x 3/8"-LONG

FLAT HEAD SCREW

POLE ADJUSTMENT BAR

(2) #8-32 x 1/4-LONG

PAN HEAD SCREW

(2) WIRE

BUNDLE

INLET

(4) RACK

MOUNT

BRACKET

INCLUDED

VIEW SHOWING

ALTERNATE

BRACKET

HOLES USED

ALTERNATE/ADDITIONAL

RACK MOUNT BRACKET

HOLES ON OPPOSITE

SIDE OF CARRIAGE

Loading...

Loading...