Page 1

PREP EQUIPMENT

Frymaster

Universal Holding Cabinet-High Density

Models UHC-HD

Frymaster Universal Holding Cabinet-High Density (UHC-HD) Models UHC-HD PR 50

PR 50

Daily maintenance tasks

PR 50 Clean UHC

Annual maintenance tasks

PR 50 Clean air exhaust

fans and driver

board

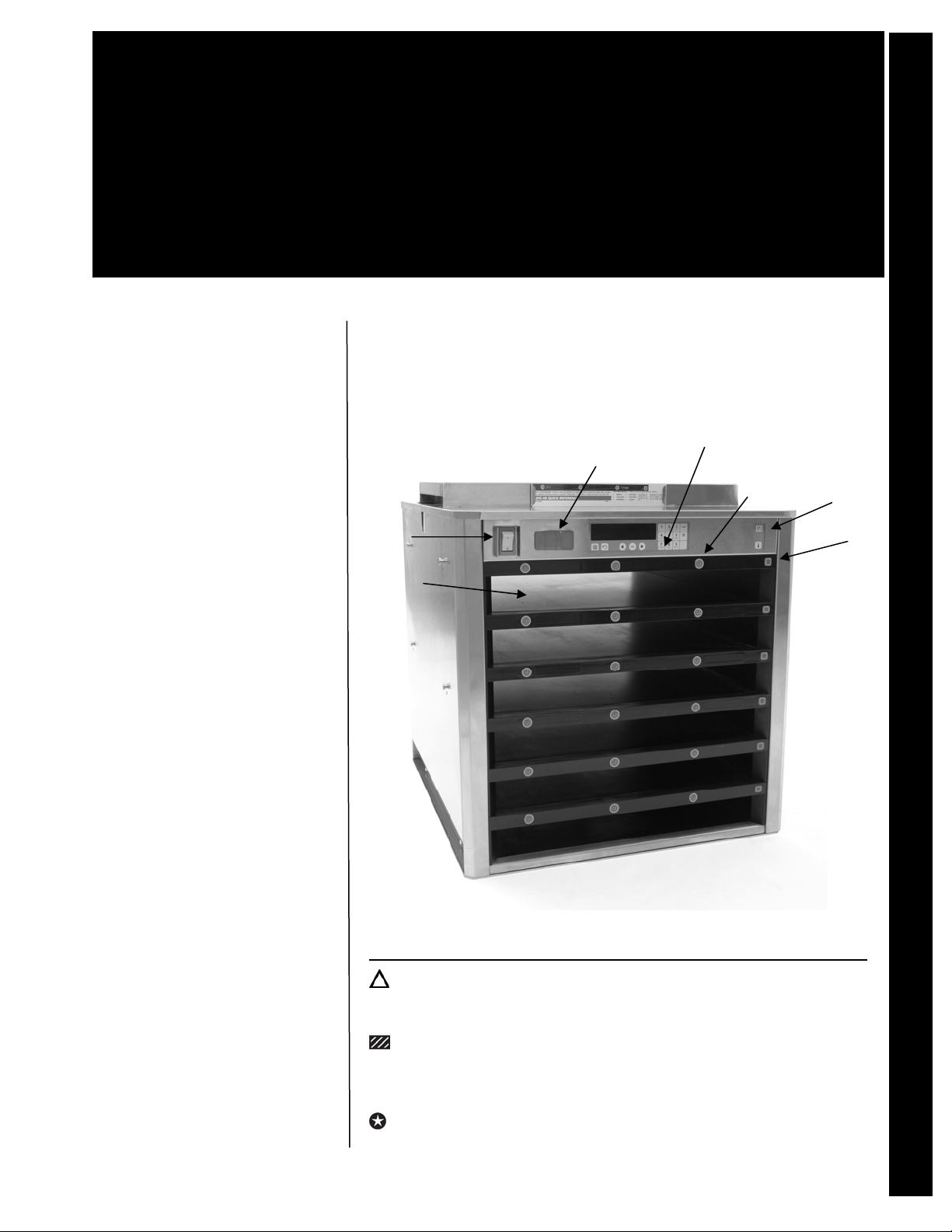

Model UHC-HD, 6-row

A. Power switch. B. Row. C. USB Port. D. Master Controller. E. Item Timer Button.

F. Time/Temperature Button. G. Row Mode Button.

D

C

E

F

A

B

G

Hazards

These icons alert you to a possible risk of personal injury.

Equipment alerts

Look for this icon to find information about how to avoid damaging the

equipment while doing a procedure.

Tips

Look for this icon to find helpful tips about how to do a procedure.

©McDonald’s Corporation · Planned Maintenance Manual · Revised April 2010

Page 2

Clean UHC Daily PR 50

Why

To maintain effectiveness of the heater plate and to reduce the risk of cross contamination

Frymaster Universal Holding Cabinet (UHC) Model UHCHD

Time required

Time of day

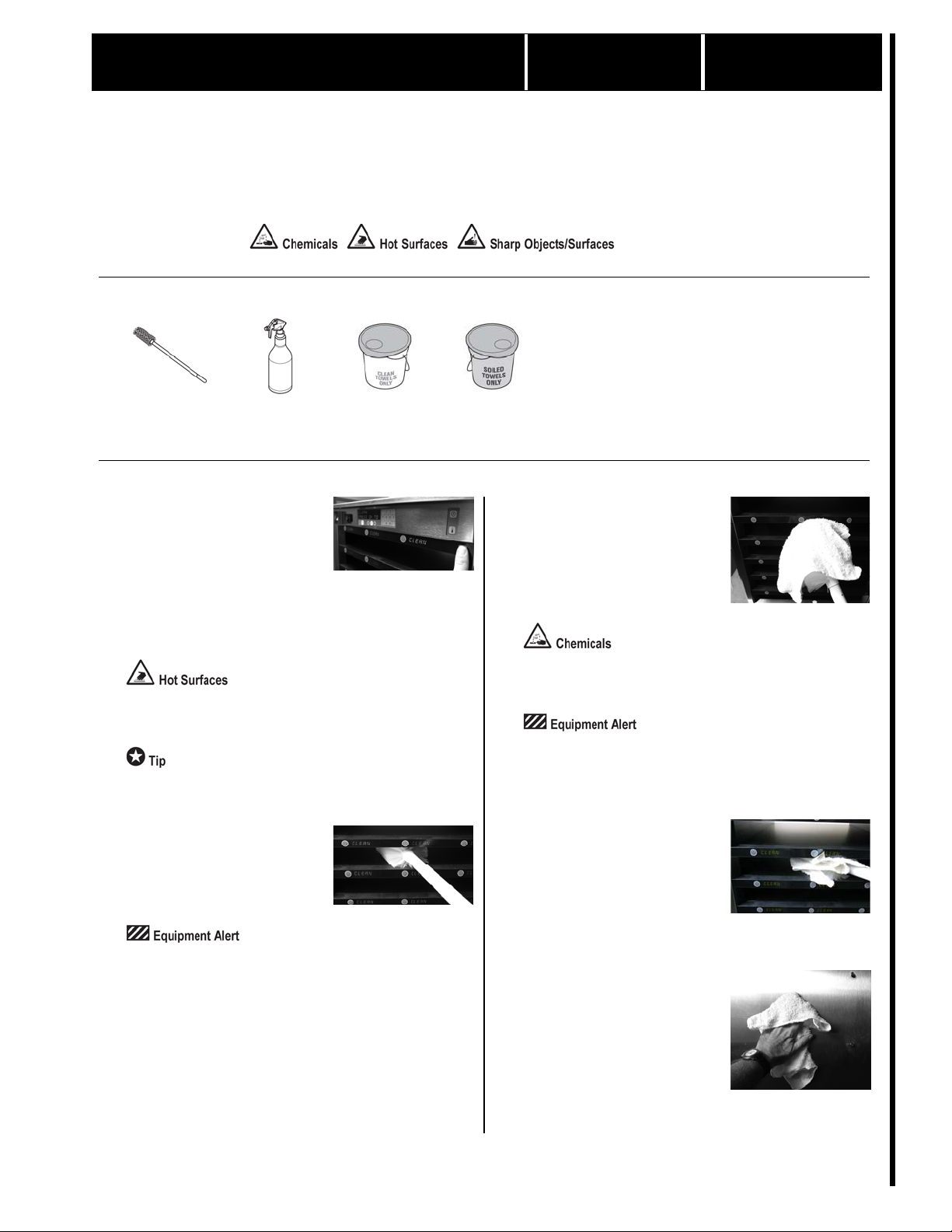

Hazard icons

Tools and supplies

Brush, UHC

Procedure

Prepare UHC for cleaning and

1

allow to cool.

Set the UHC to “CLEAN

MODE” and remove all UHC

trays and wire racks. The display alternates between

CLEAN and Not Safe Yet.

Allow UHC to cool.

Do not attempt to clean a hot

UHC.

30 minutes to prepare 15 minutes to complete

After close For 24-hour restaurants: during low-volume times

McD All Purpose

Super Concentrate

(APSC) solution

Take the UHC trays and racks

to the back sink to clean.

Bucket, clean and

sanitized towels

.

Bucket, soiled towels

3

Clean UHC slots.

Wrap the UHC brush with a

clean, sanitized towel soaked

in McD APSC. Use the

wrapped brush to clean the

top and bottom of each slot.

Sanitizer solution,

McD APSC

Do not use other cleaning

products. They can damage

the controls.

Wipe slots with clean,

Remove loose debris.

2

Use the UHC brush to push

loose crumbs and debris out

the opposite side of the UHC.

Do not use no-scratch pads,

scrapers, or other brushes.

They can damage the surface.

4

sanitized towel.

Wipe each slot with a fresh

clean, sanitized towel

wrapped around the UHC

brush.

Clean outside of UHC.

5

Wipe down the outside of the

entire UHC with a clean, sanitized towel saturated with

McD APSC.

Daily PR 50

©McDonald’s Corporation · Planned Maintenance Manual · Revised July 2007 Page 1 of 1

Page 3

Clean air exhaust fan and driver board Annual PR50

Why

To maintain proper cooling of electronic components

Frymaster Universal Holding Cabinet (UHC) Models UHC-HD

Time required

Time of day

Hazard icons

Tools and supplies

Tools supplied by

technician

Procedure

2 minutes to prepare 30 minutes to complete

After close For 24-hour restaurants: during low-volume periods

QUALIFIED TECHNICIANS ONLY

Perform all UHC daily maintenance procedures.

1

Set the UHC to “CLEAN MODE” and remove all

UHC trays and wire racks. Allow the UHC to cool until

CLEAN is displayed. Perform all daily maintenance

procedures.

Do not attempt to clean a hot UHC.

Unplug UHC power cord.

2

Remove the UHC power cord plug from the wall outlet.

Failure to unplug the power at the wall outlet could

result in serious injury or death. The power switch on

the UHC does not disconnect all incoming power to the

cabinet.

5

6

Access exhaust fan.

Remove the 8 screws in the top panel. Use a

socket wrench or nut driver. Place screws in a small

container to avoid misplacing or loss. Remove the top

panel.

If removing the cabinet from its fixed position for disassembling and cleaning, the UHC requires at least 2

people.

Clean air exhaust fan blades.

Wipe the blades of each air exhaust fan with a clean,

sanitized towel sprayed with McD APSC solution. Do

not allow the moist towel to touch any electrical connections.

Sanitizer solution, McD APSC

5

/16-in

QUALIFIED TECHNICIANS ONLY

Replace top and side panels.

Remove side panels.

3

Remove the 2 screws in each side panel with a Phillips

screwdriver. Set the screws aside. Remove the side

panels from the UHC.

Brush dust from circuit boards.

4

Use a dust free anti-static brush to gently brush any

dust from the circuit boards on the left side of the

UHC.

819‐6712

©McDonald’s Corporation · Planned Maintenance Manual · Revised July 2007 Page 1 of 1

7

Replace the top panel. Insert and tighten the 8 screws.

Replace the side panels. Insert and tighten the 2 screws

per side.

Annual PR 50

Loading...

Loading...