Page 1

Super Runner Series Electric Fryers

Service & Parts Manual

Super Runner Electric Series

SR114E

NON-CE &

Dean, a member of the Commercial Food Equipment Service Association, recommends using

CFESA Certified Technicians.

24-Hour Service Hotline 1-800-551-8633

*8196109*

10/2015

Page 2

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS ENODIS

EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED PART PURCHASED

DIRECTLY FROM FRYMASTER DEAN, OR ANY OF ITS AUTHORIZED SERVICE CENTERS,

AND/OR THE PART BEING USED IS MODIFIED FROM ITS ORIGINAL CONFIGURATION, THIS

WARRANTY WILL BE VOID. FURTHER, FRYMASTER DEAN AND ITS AFFILIATES WILL NOT BE

LIABLE FOR ANY CLAIMS, DAMAGES OR EXPENSES INCURRED BY THE CUST OMER WHICH

ARISE DIRECTLY OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE INSTALLATION OF

ANY MODIFIED PART AND/OR PART RECEIVED FROM AN UNAUTHORIZED SERVICE CENTER.

DANGER

Copper wire suitable for at least 167°F (75°C) must be used for power connections.

DANGER

The electrical power supply for this appliance must be the same as indicated on the

rating and serial number plate located on the inside of the fryer door.

DANGER

This appliance must be connected to the voltage and phase as specified on the rating

and serial number plate located on the inside of the fryer door.

DANGER

All wiring connections for this appliance must be made in accordance with the wiring

diagrams furnished with the equipment. Wiring diagrams are located on the inside of

the fryer door.

DANGER

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

WARNING

Do not attach accessories to this fryer unless fryer is secured from tipping. Personal

injury may result.

WARNING

Frymaster Dean fryers equipped with legs are for permanent installations. Fryers fitted

with legs must be lifted during movement to avoid damage and possible bodily injury.

For a moveable or portable installation, Frymaster optional equipment casters must be

used.

Questions? Call 1-800-551-8633

WARNING

Do not use water jets to clean this equipment.

DANGER

All wiring connections for this appliance must be made in accordance with the wiring

diagrams furnished with the equipment. Wiring diagrams are located on the inside of

the fryer door.

WARNING

This equipment is intended for indoor use only. Do not install or operate this

equipment in outdoor areas.

ii

Page 3

Super Runner Series Electric Fryers

TABLE OF CONTENTS

Page

CAUTIONARY STATEMENTS ii

ELECTRICAL POWER SPECIFICATIONS iv

CHAPTER 1 – SERVICE PROCEDURES 1-1

1.1 General 1-1

1.2 Calibrating the Temperature Control Knob 1-1

1.3 Accessing the Control Box Electronics 1-2

1.4 Replacing a Temperature Control Board 1-2

1.5 Replacing a Transformer, Contactor or Relay 1-2

1.6 Replacing a Power Switch or Indicator Lamp 1-3

1.7 Replacing a Temperature Probe or High-Limit Thermostat 1-3

1.8 Replacing a Heating Element 1-4

1.9 Replacing a Frypot 1-4

1.10 Probe Resistance Chart 1-5

1.11 Troubleshooting Guides 1-5

1.12 Wiring Diagrams 1-7

CHAPTER 2 – PARTS LIST 2-1

2.1 Accessories 2-1

2.2 Cabinetry 2-2

2.3 Control Box 2-5

2.4 Electronics Components, Elements and Cable 2-6

iii

Page 4

A

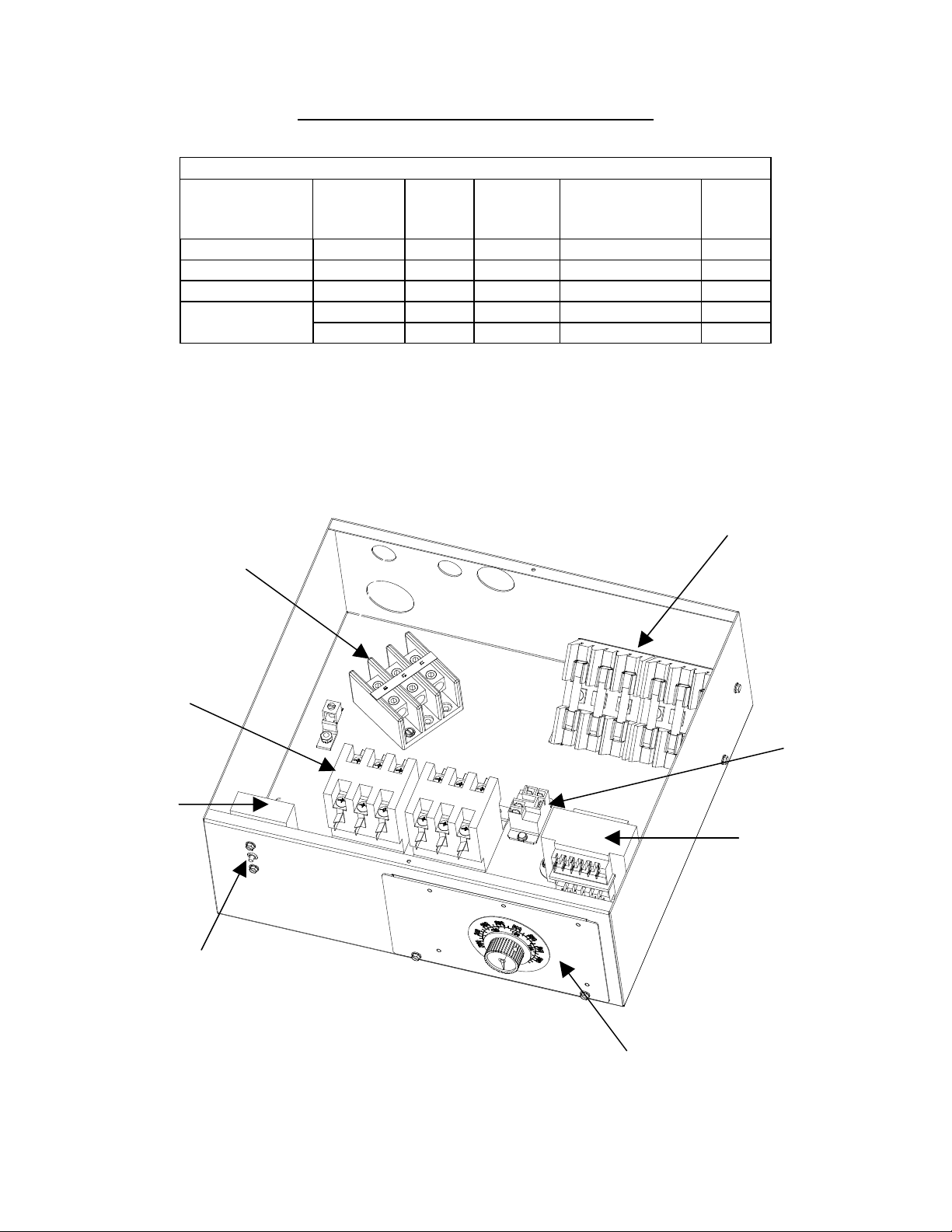

ELECTRICAL POWER SPECIFICATIONS

Use copper wire ONLY, suitable for at least 170F (75C)

MODEL VOLTAGE PHASE

14 kW 208 Single 3 3 (5.83) 68

14 kW 208 3 3 6 (4.11) 39

14 kW 240 Single 3 4 (5.19) 59

14 kW 240 3 3 8 (3.26) 34

14kW 230/400 3 4 6 (4.11) 21

WIRE

SERVICE

MINIMUM WIRE

SIZE

WG mm

AMPS

(per

leg)

Interior View of the Control Box

Contactors

High-Limit

Terminal

Block

Fuse Block

Relay

Transformer

High-Limit Reset

Switch

Single Phase Control Box Shown

Note: The three phase control box

differs from the single phase by

eliminating the fuse block and terminal

block.

iv

Controller

Assembly

Page 5

SUPER RUNNER SERIES ELECTRIC FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.1 General

Before performing any maintenance on your Dean Super Runner Electric fryer, you must disconnect

the electrical power supply.

When electrical wires are disconnected, it is recommended that they be marked in such a way as to

facilitate re-assembly.

DANGER

Hot oil will cause severe burns. Never attempt to move this appliance when filled with hot

oil, or to transfer hot oil from one container to another.

DANGER

This equipment should be unplugged when servicing, except when electrical circuit tests are

required. Use extreme care when performing such tests.

Disconnect all power cords before servicing.

Inspection, testing and repair of electrical components should be performed by an

authorized service agent only.

1.2 Temperature Control Knob Calibration

If the temperature controller knob requires adjustment, do the following:

1. Set the temperature controller dial to the desired oil temperature and wait for the temperature to

stabilize.

2. When the oil temperature reaches operating temperature, let the heating elements cycle at least

four times (indicated by the HEAT light going out and coming back on).

3. Insert a thermometer or pyrometer probe near the temperature-sensing probe approximately three

inches deep into the oil. When the heating elements cycle on for the fourth time, the temperature

should read within 5F ( 3C) of the temperature control knob setting.

4. Loosen the knob setscrew and rotate the knob to the correct temperature setting on the faceplate.

5. Check the temperature again with a high-quality immersion thermometer to confirm that the

setting is correct.

6. Re-tighten the knob setscrew at the calibrated position.

1-1

Page 6

1.3 Accessing the Control Box Electronics

(Transformer, Contactor and Relay)

1. Unplug the power cord.

2. Open front door of cabinet and remove the two screws from the top of the control box cover to

remove the cover.

1.4 Replacing a Temperature Control Board

1. Unplug the power cord. Perform Procedure 1.3, Steps 1-2, Accessing the Control Box

Electronics.

2. Remove the 2 screws from the bottom of the controller faceplate.

3. Remove the setscrew from the controller knob.

4. Unplug the connector from the controller board.

5. Remove the nuts from each stud on the control board and slide the board from the studs. Ensure

that standoffs remain in place on studs, prior to installing new board. Install the new board by

reversing the previous procedures.

6. Perform Procedure 1.2 to recalibrate the temperature control knob.

1.5 Replacing a Transformer, Contactor or Relay

1. Unplug the power cord. Perform Procedure 1.3, Steps 1-2, Accessing the Control Box

Electronics.

2. Remove all wiring from the terminals of the transformer, contactor or relay to be replaced,

ensuring that each wire is marked for reattachment.

3. Remove the screws that secure the transformer, contactor or relay to the control box.

4. Install the new transformer, contactor or relay by reversing the preceding procedures. Make sure

you reconnect the wiring to the proper terminals.

1-2

Page 7

1.6 Replacing a Power Switch or Indicator Lamp

1. Unplug the power cord.

2. Remove the two screws on the bottom of the faceplate. Pull out and lift up slowly. Note that

when lowering the faceplate, the door will lower and swing out to be set aside.

3. Mark wires for reattachment as you disconnect them.

4. Remove the old switch or lamp.

5. Install new switch or lamp and reassemble in reverse order.

1.7 Replacing a Temperature Probe or High-Limit Thermostat

1. Unplug the power cord.

2. Drain the cooking oil from the frypot and leave the drain open.

3. Remove the two screws from the top control box cover.

4. Remove the screws from the back fryer cover.

5. If replacing the temperature probe, disconnect the wire plug containing the probe wiring.

6. Using an open end wrench, loosen the temperature probe or high-limit probe. Pull the probe

through the hole and remove the probe.

7. If replacing the high-limit thermostat, remove the two screws that attach the high-limit reset

switch to the control box. Remove the two wires attached to the high-limit reset switch. Pull the

probe through the bushing in the rear of the control box. Attach new high-limit reset switch to

the control box and reattach wires. Thread through the bushing in the rear of the control box.

8. Thread the new probe through the proper hole in the rear of the frypot. Ensure that the probe is

aligned with the holes on the bracket attached to the element.

9. Apply Loctite PST567 sealant to replacement threads.

10. Screw the replacement probe into the frypot and tighten 170-180 inch-pounds torque. DO NOT

OVERTIGHTEN.

11. Reattach the connector and reassemble in reverse order.

1-3

Page 8

1.8 Replacing a Heating Element

1. Perform Procedure 1.7, Replace Temperature Probe, Steps 1-4.

2. Mark wires of the elements before disconnecting from the contactor to facilitate easy

reassembly. Pull the wires through the conduit.

3. Remove element using an open-end wrench or other suitable tool to loosen the compression

fitting.

4. Gently remove the element by sliding out into the frypot and lifting up as you remove it.

5. Insert new element and reassemble in reverse order. Ensure that the element wires are correctly

attached to the contactor.

1.9 Replacing a Frypot

1. Perform Procedure 1.3, Accessing the Control Box Electronics, Steps 1-2.

2. Perform Procedure 1.7, Replacing a Temperature Probe, Steps 1-7.

3. Perform Procedure 1.8, Replacing a Heating Element, Steps 1-4.

4. Remove the screws holding the fluecap to the side panels.

5. Remove the screws attaching the faceplate bracket and heatshield to the front of the frypot

6. Remove the screws securing the frypot to the front frame of the fryer.

7. Carefully lift the frypot from the cabinet.

8. Remove the drain valve from the old frypot and install on the new frypot.

9. Apply Loctite Sealant PST 567 to the high-limit threads, temperature probe threads and element

threads. Install high-limit, temperature probe and elements into the new frypot.

10. Follow the preceding steps in reverse to install the new frypot into the fryer.

1-4

Page 9

1.10 Probe Resistance Chart

b

Use the chart below when testing temperature probes and probe circuits for proper operation.

Probe Resistance Chart

F OHMS C F OHMS C F OHMS C F OHMS C F OHMS C

60 1059 16 130 1204 54 200 1350 93 270 1493 132 340 1634 171

65 1070 18 135 1216 57 205 1361 96 275 1503 135 345 1644 174

70 1080 21 140 1226 60 210 1371 99 280 1514 138 350 1654 177

75 1091 24 145 1237 63 215 1381 102 285 1524 141 355 1664 179

80 1101 27 150 1247 66 220 1391 104 290 1534 143 360 1674 182

85 1112 29 155 1258 68 225 1402 107 295 1544 146 365 1684 185

90 1122 32 160 1268 71 230 1412 110 300 1554 149 370 1694 188

95 1133 35 165 1278 74 235 1422 113 305 1564 152 375 1704 191

100 1143 38 170 1289 77 240 1432 116 310 1574 154 380 1714 193

105 1154 41 175 1299 79 245 1442 118 315 1584 157 385 1724 196

110 1164 43 180 1309 82 250 1453 121 320 1594 160 390 1734 199

115 1174 46 185 1320 85 255 1463 124 325 1604 163 395 1744 202

120 1185 49 190 1330 88 260 1473 127 330 1614 166 400 1754 204

125 1195 52 195 1340 91 265 1483 129 335 1624 168 405 1764 207

1.11 Troubleshooting

1.11.1 Control and Heating Problems

Problem Probable Causes Corrective Action

A. Power cord is not plugged in or circuit

breaker is tripped.

B. Controller has failed.

Controller won't

activate.

C. Power supply component or

temperature control board has failed.

Fryer heat cycles on

and off during warm

up cycle.

Fryer does not heat.

A. Fryer in melt cycle.

B. Controller has failed.

A. Plug power cord in and verify that

the circuit breaker is not tripped.

B. If available, substitute a controller

known to be working for the

suspect controller. If the substitute

controller functions correctly, order

a new controller from a FASC.

C. If any of the components in the

power supply system (including the

transformer and temperature control

oard) fail, power will not be

supplied to the controller and it will

not function.

A. This is normal behavior while the

fryer temperature is below 180ºF

(82ºC).

B. If available, substitute a controller

known to be working for the

suspect controller. If the substitute

controller functions correctly, order

a new controller from a FASC.

(continued on following page)

1-5

Page 10

Problem Probable Causes Corrective Action

Fryer does not heat.

Fryer heats until high-

limit trips with heat

indicator ON.

Fryer heats until high-

limit trips with heat

indicator OFF.

Fryer stops heating

with heat indicator

ON.

C. One or more other components have

failed.

Temperature probe or controller has

failed.

Contactor, controller or element has

failed

The high-limit thermostat or contactor

has failed.

C. If the circuitry in the fryer control

system cannot determine the frypot

temperature, the system will not

allow the element to be energized

or will de-energize the element if it

is already energized. If the

contactor, element, or associated

wiring fails, the element will not

energize.

If available, substitute a controller

known to be working for the suspect

controller. If the substitute controller

functions correctly, order a new

controller from FASC. If substitution

of the controller does not resolve the

problem, the most likely cause is a

failed temperature probe.

If available, substitute a controller

known to be working for the suspect

controller. If the substitute controller

functions correctly, order a new

controller from FASC. If the

substitution of the controller does not

resolve the problem, the most likely

cause is a contactor that has failed in

the closed position or a bad element.

The fact that the heat indicator is ON

indicates that the controller is

functioning properly and is calling for

heat. The high-limit thermostat

functions as a normally closed switch.

If the thermostat fails, the "switch"

opens and power to the elements is

shut off. If the contactor fails to close,

no power is supplied to the elements.

1-6

Page 11

1.12.1 Wiring Diagram SR114E Single Phase

1-7

Page 12

1.12.2 Wiring Diagram SR114E 3 Phase

1-8

Page 13

1.12.3 Wiring Diagram SR114E WYE

1-9

Page 14

SUPER RUNNER SERIES ELECTRIC FRYERS

2.1 Accessories

CHAPTER 2: PARTS LIST

1

5

Item Part Number Description

1 803-0197 Fryer Friend 27” (Cleanout Rod)

2 803-0209 Brush, Frypot Cleaning

3 809-0171 Thumbscrew, ¼-20 X 1⅜-inch Basket Hanger

4 810-2793 Hanger, Basket

5 803-0019 Basket, Twin

6 803-0132 Basket Support Rack, Full Vat

7 826-0900 Kit, Chain Restraint for Casters

8 826-1095 Kit, Anchor Strap for Legs

2

6

3

4

7 8

2-1

Page 15

2.2 Cabinetry

2.2.1 Back, Base, Casters, Sides, Fluecap, Top Cap and Frypot

11

12

14

15

10

13

4

1

3

8

6

7

9

5

2

16

17

18

2-2

Page 16

Item

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

*

*

*

17

*

*

*

18

*

*

*

* Not Illustrated

Part Number Description

106-3528 Cabinet Assembly, Economy Electric SR114E

106-4419 Assembly, Heat Shield

200-5998 Channel, Base

200-8378 Brace, Cabinet Front

201-5802 Side, Cabinet Left

202-5802 Side, Cabinet Right

809-0117 Screw, 10-32 x 3/8 SLTD TR HD SS

809-0256 Nut, KEPS 10-32 HX ZP

809-0412 Screw, #10 – ½ HX HD

200-5810 Back, Cabinet

210-8401 Panel, Front

210-5803 Fluecap

106-4423 Frypot Assembly

810-1338 Valve, 1” Universal Ball

810-1567 Handle, Drain Valve Red w/ Lock Pin

812-1227 Nipple, Drain 1”

810-0356 Caster, 5” Wheel w/o Brake

826-2003 Mounting Hardware SR114E Casters

809-0428 Screw, ¼-20x ½ Hex Head ZP

809-0071 Nut, ¼-20 HX ZP

809-0191 Washer, Lock ¼ Spring ZP

810-0357 Caster, 5” Wheel w/ Brake

826-2003 Mounting Hardware SR114E Casters

809-0428 Screw, ¼-20x ½ Hex Head ZP

809-0071 Nut, ¼-20 HX ZP

809-0191 Washer, Lock ¼ Spring ZP

826-1903 Leg Accessory Pack, Includes 810-2053 and hardware below

810-2053 Leg, Black Adjustable w/Mount Plate

809-0131 Screw, ¼-20x ¾ Hex Head ZP

809-0071 Nut, ¼-20 Hex ZP

809-0191 Washer, Lock ¼ Spring ZP

2-3

Page 17

2.2.2 Door Assembly and Component Parts

6

9

10

11

2

7

4

3

1

8

Item Part Number Description

106-3586 Door Assembly

1 106-4067 Pin Assembly, Door

809-0216 Pin, Hinge Cover & Door

810-0658 Retaining Ring (Unplated)

2 210-9491 Panel, Door

3 210-9544 Bracket, Door Hinge

4 809-0083 Rivet, Pop Al 1/8” Dia

5 809-0193 Washer, Flat ¼” Nylon

6 809-0266 Screw, #10-½” Phil TR Head ZP

7 810-0066 Catch, Magnetic Door

8 810-0275 Spring, Door Hinge

9 810-1422 Handle, Door

10 816-0529 Bumper, Rubber Self Adhesive

11 816-0630 Cap, Vinyl 172 x .500

5

2-4

Page 18

2.3 Control Boxes

6

11

2

2

4

10

3

15

13

7

5

9

1716

8

1

5

14

12

9

1716

3-Phase Control Box Single Phase Control Box

Item Part Number Description

106-3747 Control Box Assembly, Single Phase

106-3583 Control Box Assembly, 3 Phase

1 106-3748 Controller Assembly

802-2198 Label, Thermatron Dial

810-0387 Control Knob

2 200-8240 Box, Control

3 200-8369 Mount, Fuse Economy

4 807-0065 Block, Terminal Field

5 807-0070 Terminal Ground Lug

6 807-0501 Fuse Block, Buss #2968 3-Pole

7 807-1683 Relay, 12 VDC

8 807-5129 Transformer, V&T Dual Voltage, 208/222/230/240V

9 807-3559 High-Limit, 435°F w/ Manual Reset

* 807-3560 High-Limit, 410°F (210°C) w/Manual Reset (CE)

10 807-4017 Fuse, 50 AMP 480VAC, 300VDC

11 809-0112 Screw, 8-32 x 1 ¼ TR SL HD SS

12 809-0117 Screw, 10-32 x 3/8 SLTD TR HD SS

13 809-0247 Nut, 8-32 HEX KEPS ZP

14 809-0256 Nut, KEPS 10-32 HX ZP

15 809-0359 Screw, #8 x ¼ HX HD Washer Slotted HD ZP

16 809-0361 Screw, Drill #8 x ½ HX HD ZP

17 810-1202 Contactor, 3 Pole 600V 40 AMP

* 200-8241 Cover, Control Box

* Not Illustrated

7

8

1

2-5

Page 19

2.4 Electronic Components, Elements and Cable

3

1

2

4

10

5

9

7

Item Part Number Description

1 807-4036 Switch

* 807-1525 Light, White 24V Front Panel Indicator

2 807-3559 High-Limit, 435T w/ Manual Reset

3 813-0617 Probe Fitting, 3/16” CC x ¼” NPT Compression

4 Elements

807-4031 Element, 208V / 14KW

807-4331 Element, 220V / 14KW

807-4072 Element, 240V / 14KW

807-4340 Element, 230V/ 14KW

5 210-8392 Clamp, Element

6 210-8393 Bracket, Mount Hi-Limit

7 210-8390 Mount, Element Support

* 809-0518 Screw, 8-32 x 3x8” Slotted Head

8 910-5022 Bracket, Element Probe

9 807-4110 Cable, 3 Phase 4 Wire 208-240V

10 826-2222

Probe, Temperature includes compression fitting

* Not Illustrated

6

8

2-6

Page 20

Dean, 8700 Line Avenue, PO Box 51000, Shreveport, Louisiana 71135-1000

Shipping Address: 8700 Line Avenue, Shreveport, Louisiana 71106

TEL 1-318-865-1711 FAX (Parts) 1-318-219-7140 FAX (Tech Support) 1-318-219-7135

PRINTED IN THE UNITED STATES

SERVICE HOTLINE

1-800-551-8633

819-6109

10/2015

Loading...

Loading...