Page 1

Two Great Frying Brands,

Proudly Made in America,

Oer the Most Fryer Choices

in the World

Page 2

Table of Contents

Introduction ......................................................................................................... 3

Filter Quick® with Fully-Automatic Filtration Fryers ...................... 5

OCF30® Fryers ..................................................................................................... 6

1814 High-Production Gas Fryers .......................................................... 7

1814 High-Production Electric Fryers .................................................. 8

High-Eciency Gas Fryers (H55) ............................................................. 9

High-Eciency Gas Fryers (HD) ............................................................ 10

High-Eciency Low Flue Temp Gas Fryers (LHD65) ................ 11

High-Eciency Value Gas Fryer (ESG35T) ...................................... 12

Master Jet Series Performance Gas Fryers (MJ)........................... 13

Standard Gas Fryers (GF) ........................................................................... 14

Countertop Gas Fryers (J1C) ................................................................... 14

Ultra High-Eciency E4 (RETC) Electric Fryers ............................ 15

High-Eciency E4 (RE) Electric Fryers ............................................... 16

High-Production E4 (HPRE) Electric Fryers ..................................... 17

Other Products ................................................................................................ 17

Fryer Controllers ............................................................................................. 18

Oil Station Management Equipment ................................................ 19

Frymaster Accessories ................................................................................ 22

Frymaster Product Specications ....................................................... 23

Decathlon Performance Gas Fryers (D) ............................................ 25

Super Marathon Standard Gas Fryers (SM) .................................... 26

Super Runner Value Gas Fryers (SR) .................................................... 27

Super Runner Value Electric Fryers (SR) ........................................... 27

Dean Oil Station Management ............................................................. 28

Dean Accessories ........................................................................................... 30

Dean Specications ..................................................................................... 31

2

Page 3

Two Great Frying Brands Proudly Made in America, Oer the

Most Fryer Choices in the World

80-years Strong and Continuing

80-plus years of industry leadership has set Frymaster apart among other fryer manufacturers and

made Frymaster and Dean fryers the brands preferred by experts. Frymaster has a proud tradition

of manufacturing technologically superior and reliable commercial fryers reecting Frymaster’s

commitment to:

• Continuous innovation.

• The delivery of high quality products that reduce operating costs.

• Setting industry standards for cooking quality, energy eciency, safety, and reliability.

Advanced Heat Exchange Technology

Whether it’s burners for open pot fryers (heat exchange occurs outside of the frypot) or tube type

fryers (heat exchange occurs inside the frypot), Frymaster and Dean gas fryers are designed to

meet a broader range of frying needs than any other manufacturer. The high-eciency infrared

burners, incorporated into our Frymaster branded FilterQuick®, OCF30 and H55 gas fryers and the

high eciency tube burner system incorporated into our Frymaster branded 1814, HD, LHD and

ESG35T gas fryers exceed ENERGY STAR® guidelines for eciency and qualify for energy savings

rebates as high as $1,200/ frypot in some areas. Frymaster’s electric fryers have proprietary selfstanding, at-bar, low watt density, long-life elements that deliver outstanding energy eciency.

These fryers also exceed ENERGY STAR guidelines and qualify for energy saving rebates. Frymaster

makes more ENERGY STAR certied models than any other fryer manufacturer.

Oil Station Management

Frymaster is an oil station management pioneer, as the rst company that introduced built-in

ltration, and continues its legacy as an industry-leading advocate of oil-conserving technology.

Frymaster leads the way with the world’s rst fryer to have fully-automatic ltration (AF) and

an optional integrated Oil Quality Sensor. Fingertip operation of the AF makes routine ltration

eortless. The contaminants created by high-heat frying take a toll on oil life and food quality

unless a daily system of ltering and cleaning is in place. The oil quality sensor monitors the

health of the oil and advises the crew when to discard the oil, eliminating the discard dilemma

most operations face today. This keeps food quality and customer satisfaction at an all-time high.

Frymaster’s complete line of Frymaster and Dean ltration equipment, both built-in and portable,

is designed to make ltration quick, convenient and reliable for the operator. Nothing maintains

food and oil quality better than routine oil ltration and fryer cleaning, and no fryer manufacturer

supports making these tasks easy better than Frymaster.

3

Page 4

CookingControl

When you need the reliability of consistent cooking, programmable controllers provide the

perfect solution. They automatically adjust cooking times to ensure foods are cooked to the

same quality standard regardless of load size. Programmable buttons make it easy to assign

menu items for push button selection; and the LED displays clearly identify the products cooking parameters such as time and temperature. Some controllers even guide oil management

functions and record important cooking and oil management information.

Manitowoc KitchenCare®

Performance for a Lifetime

Manitowoc KitchenCare helps protect, service and maintain your Manitowoc Foodservice quipment throughout the

life cycle of your business. Designed with your needs in mind and structured around three areas of support: StarCare, a

team of quick response factory trained service network providers for your service needs; ExtraCare for troubleshooting

and technical support including our 24/7 1-800 number; and LifeCare for planned maintenance of your equipment.

When it comes to your kitchen, put your trust in Manitowoc KitchenCare.

4

Page 5

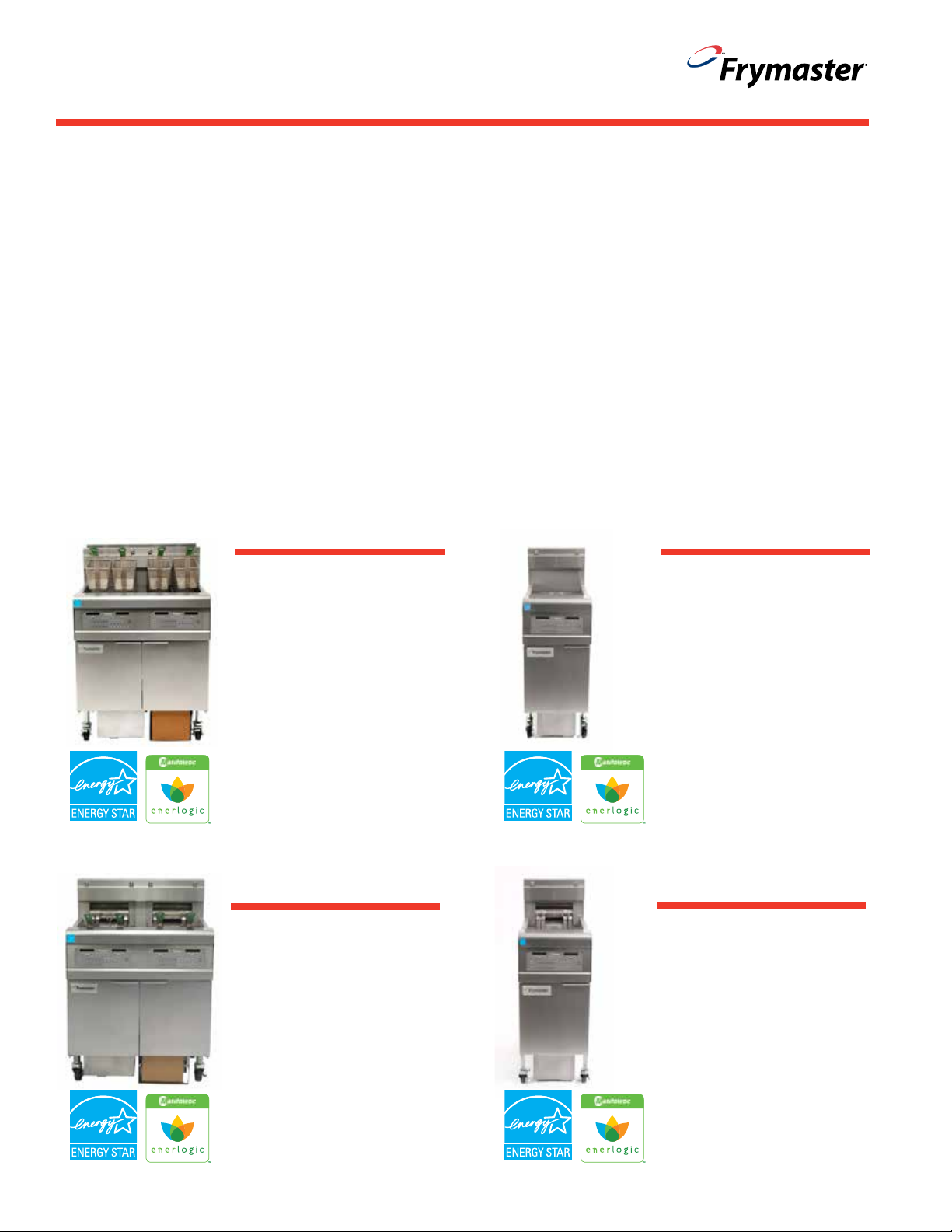

Filter Quick

®

Fully-Automatic Filtration (AF) and

Optional Integrated Oil Quality Sensor Fryers

40% Less Oil, 10% Less Energy, Outstanding Results

FilterQuick oers an exclusive combination of world-leading, oil-conserving technologies -- fully-automatic ltration (AF),

automatic top-o (ATO) and an optional integrated oil quality sensor in one amazing fryer. FilterQuick’s closed cabinet AF

puts caring for the oil at your ngertips and operation where it is easiest to use, right on the front of the fryer. Additional

SMART4U® technology includes the Oil Attendant®, a feature that automatically replenishes oil from an in-cabinet oil supply,

keeping oil fresher longer. It also includes the FilterQuick controller that monitors and helps control food and oil quality,

oil life, and equipment performance. And nally, the innovative new optional Oil Quality Sensor rounds out the exclusive

combinations. The oil quality sensor measures oil contaminants and advises when the oil needs to be discarded, eliminating

the age old “when-to-change-the-oil” dilemma.

• Outstanding Performance

- 30-lb. open frypot design requires 40% less oil and ensures quick

and easy cleaning. Matches production capacity of 50-lb fryers.

• Fingertip, Closed Cabinet, Fully-Automatic Filtration (AF)

- Puts automatic ltration at your ngertips.

- Safety technology ensures only one frypot can drain at a time.

- Pump is protected from dead heading.

• Automatic Top-O (ATO)

- Senses the oil level and adds oil as needed from an in-cabinet oil

supply.

• Optional Integrated Oil Quality Sensor

- Monitors the health of the oil by measuring the oil’s total polar

materials (TPMs) and advises when oil needs to be discarded.

- High-quality oil ensures high food quality and optimal product

healthfulness, two must-haves for protability.

NEW!

• Intelligent Controls

- The full-featured SMART4U FilterQuick controller manages both

cooking and fryer operations.

• State-of-the-Art Combustion

- Both gas and electric models exceed ENERGY STAR® guidelines

and qualify for energy-saving rebates.

• Minimal Oil Handling

- The Oil Attendant® automatic top-o feature (ATO) and fully-

automatic ltration keep the oil fresh with minimal intervention.

The bulk oil option further reduces exposure to hot oil.

• Safety First

- Safer frying, ltering, cleaning and oil handling are all built-i

n.

FQG30U

• Automatic Filtration

• Auto top-o

• 75,000 Btu/hr. (18,892 kcal/hr.)

(21.9 kw/hr.), full frypot;

37,500 Btu/hr. (9,446 kcal/hr.

(10.9 kw/hr.), split frypot

• 13” x 14” x 3-3/4” (33 x 35.6 x 9.5

cm), full frypot frying area; 6” x 14”

x 3-1/2” (15.2 x 35.6 x 8.9 cm) split

frypot frying area

• 30-lb (15-liter) oil capacity,

full frypot; 17-lb. (8.5-liter) oil

capacity, split frypot

• Cooks 67-lbs. (30 kg) of French

fries/hr.

• Optional oil quality sensor

FQE30U

• Automatic Filtration

• Auto top-o

• 14 kw/hr., full frypot; 7 kw/hr., split

frypot or 17 kw/hr., full frypot;

8.5 kw/hr., split frypot

• 13” x 14” x 3-3/4” (33 x 35.6 x 9.5

cm), full frypot frying area; 6” x 14”

x 3-3/4” (15.2 x 35.6 x 9.5 cm) split

frypot frying area

• 30-lb. (15-liter) oil capacity, full

frypot; 16-lb. (8-liter) oil capacity,

split frypot

• Cooks 71-lbs. (32 kg) of French

fries/hr., full 14 kw frypot;

78-lbs. (35 kg) French fries/hr.,

full 17kw frypot

• Optional oil quality sensor

5

Page 6

OCF30® Fryers

40% Less Oil, 10% Less Energy, Outstanding Results

Frymaster’s OCF30 open-pot, oil-conserving fryers oer the next generation of cost savings and green

benets to the industry. Green benets range from reduction of oil use to less energy consumption

while minimizing oil handling and maintaining food quality.

• Outstanding Performance

- Frymaster 30-lb. OCF fryers match the production capacity of

50-lb. fryers.

• 40% Less Oil

- The 30-lb frypot positively impacts operating budgets and

the environment.

• 10% Less Energy

- The reduced oil volume requires less energy.

• State-of-the-Art Combustion

- Fuels eciency. Infrared heat transfer on gas models exceeds

ENERGY STAR® guidelines and qualies gas fryers for energysaving rebates. Electric models have durable, self-standing,

swing-up, at-bar elements to deliver energy eciency that

exceeds ENERGY STAR® guidelines and protects against oil

migration.

Auto Top-O

OCF30-ATOG

• 75,000 Btu/hr. (18,892 kcal/hr.)

(21.9 kw/hr.), full frypot;

37,500 Btu/hr. (9,446 kcal/hr. )

(10.9 kw/hr.), split frypot

• 13” x 14” x 3-3/4” (33 x 35.6 x 9.5

cm), full frypot frying area; 6” x 14”

x 3-1/2” (15.2 x 35.6 x 8.9 cm) split

frypot frying area

• 30-lb (15-liter) oil capacity,

full frypot; 17-lb. (8.5-liter) oil

capacity, split frypot

• Cooks 67-lbs. (30 kg) of French

fries/hr.

• Built-in ltration with rear oil ush

• Minimal Oil Handling

- The Oil Attendant® automatic top-o option, and FootPrint

PRO® in-cabinet ltration keep the oil fresh with minimal

intervention. Bulk oil option further reduces handling.

• Intelligent Control

- The full-featured SMART4U® 3000 controller manages both

cooking and fryer operations.

• Robust Product Line

- Oerings include 2-4 frypot (full and split) batteries and

models to handle all shortening types (liquid, semi-solid and

solid).

• Safety First

- Safer frying, cleaning and oil handling are all built in.

Manual Top-Off

OCF30-G (single

fryer only)

• 75,000 Btu/hr. (18,892 kcal/hr.)

(21.9 kw/hr.), full frypot;

37,500 Btu/hr. (9,446 kcal/hr.)

(10.9 kw/hr.), split frypot

• 13” x 14” x 3-3/4” (33 x 35.6 x 9.5

cm), full frypot frying area; 6” x 14”

x 3-1/2” (15.2 x 35.6 x 8.9 cm) split

frypot frying area

• 30-lb (15-liter) oil capacity,

full frypot; 17-lb. (8.5-liter) oil

capacity, split frypot

• Cooks 67-lbs. (30 kg) of French

fries/hr.

• Built-in ltration with rear oil ush

Manual Top-Off

Auto Top-O

OCF30-ATOE

• 14 kw/hr., full frypot; 7 kw/hr., split

frypot or 17 kw/hr., full frypot;

8.5 kw/hr., split frypot

• 13” x 14” x 3-3/4” (33 x 35.6 x 9.5

cm), full frypot frying area; 6” x 14”

x 3-3/4” (15.2 x 35.6 x 9.5 cm) split

frypot frying area

• 30-lb. (15-liter) oil capacity, full

frypot; 16-lb. (8-liters) oil capacity,

split frypot

• Cooks 71-lbs. (32 kg) of French

fries/hr., full 14 kw frypot;

78-lbs. (35 kg) French fries/hr.,

full 17kw frypot

• Built-in ltration with rear oil ush

6

OCF30-E (single

fryer only)

• 14 kw/hr., full frypot; 7 kw/hr., split

frypot or 17 kw/hr., full frypot;

8.5 kw/hr., split frypot

• 13” x 14” x 3-3/4” (33 x 35.6 x 9.5

cm), full frypot frying area; 6” x 14”

x 3-3/4” (15.2 x 35.6 x 9.5 cm) split

frypot frying area

• 30-lb. (15-liter) oil capacity, full

frypot; 16-lb. (8-liters) oil capacity,

split frypot

• Cooks 71-lbs. (32 kg) of French

fries/hr., full 14 kw frypot;

78-lbs. (35 kg) French fries/hr.,

full 17kw frypot

• Built-in ltration with rear oil ush

Page 7

1814 High-Production Gas Fryers

Conserve Oil, Energy and Space

Coming from a supplier with over 80 years of commercial frying leadership, the Frymaster 1814 gas,

high-production, tube fryers have been eld tested and are proven to deliver exible, high-production

performance that conserves your resources. The 1814 fryers oer a trio of savings; conserving oil, energy

and space.

11814

• Use 11-15% less hood and oor space than standard

fryer systems.

• Use upwards of 50% less energy than standard 3-fryer

systems. Exceed ENERGY STAR® guidelines, qualifying

for energy savings rebates.

• Use less oil reducing operating costs and environmental

impact - 16 - 20% less than 3 standard 50-lb. fryers (126

lbs. of oil vs. 150 lbs.); 12-14% less than 4 standard 50-lb.

fryers (176 lbs. of oil vs. 200 lbs.).

• Deliver exible, high-production cooking with one or

two 18” x 14” cooking area(s) that can cook three

baskets of food in each frypot at the same time.

• SMART4U® Lane controller has programmable cook

buttons and features that make it easy to produce

consistent, great-tasting food. Analog, Digital, CM3.5

and SMART4U® 3000 controller options are also

available.

• Save on equipment costs:

- Two fryers do the work of three 50-lb. fryers.

- Three fryers do the work of four 50-lb. fryers.

• Support oil station management in batteries with

built-in ltration.

• Optimize heat transfer with 6” high vs. 4” high tubes,

which provide a 36” larger surface for oil contact.

• 18” x 14” x 3-3/4” (45.7 x 35.6 x 9.5 cm)

frying area per frypot

• 119,000 Btu/hr. (29,975 kcal/hr.)

(34.9 kw/hr.) per frypot

• 63-lb. (31-liter) oil capacity per frypot

• Three twin baskets per frypot

• Cooks 100 lbs. (45 kg) of French fries/hr.

per frypot

• Optional ltration

11814 shown with optional casters

21814GF/31814GF/

41814GF

Has standard Features of

the 11814 Plus:

• Built-in ltration, putting ltration

where it’s most convenient to use, right

in the fryer battery

• 8 GPM pump

• Additional twin baskets

• Adjustable casters

• Front and bulk oil disposal options

1814G models with SMART4U®

controllers meet ENERGY STAR®

guidelines and are part of the

Manitowoc Enerlogic™ program

• Handle high-sediment foods with ease. Sloping bottom

ensures fast drainage and easy cleaning.

Filtration for 11814, 21814, 31814, 41814

and 1814/HD50/11814

• Space-saving lter which ts inside fryer cabinet

• 8 GPM pump

• Steel gear pump with powerful 1/3 H.P. motor

• Large capacity lter pan removes easily for cleaning

• Sloped drain pan leaves minimal oil in the pan after ltering

• Large 3” (8.0 cm) round drain line allows oil to drain freely

• 1-1/4” (3.175 cm) drain valve

• Drain safety switch

• Stainless steel crumb catcher

• Filter starter kit

• Front and bulk oil disposal options

11814/HD50G/11814

Has standard Features of

the 21814 Plus:

• An HD50G frypot, with a 50-lb.

(25-liter) oil capacity

• 100,000 Btu/hr. per frypot

(25,189 kcal/hr.) (29.3 kw/hr.),

a 14” x 14” x 3-3/4” (35.6 x 35.6

x 9.5 cm) frying area

• Two additional twin baskets

• Cooks 100 lbs. (44 kg) of French

fries/hr. per 1814 frypot and 72 lbs.

(33 kg) of French fries per

HD50 frypot

11814/HD50G/11814 shown with built in ltration

1814G models with SMART4U®

controllers meet ENERGY STAR®

guidelines and are part of the

Manitowoc Enerlogic™ program

1814G models with SMART4U®

controllers meet ENERGY STAR®

guidelines and are part of the

Manitowoc Enerlogic™ program

7

Page 8

1814 High-Production Electric Fryers

Conserve Oil, Energy and Space

Coming from a supplier with over 80 years of commercial frying leadership, the Frymaster 1814 electric,

high-production fryers have been eld tested and are ready to deliver exible, high-production

performance that conserves your resources. The 1814 fryers oer a trio of savings; conserving oil, energy

and space.

• Use 10-15% less hood and oor space than standard

fryer systems.

• Use less oil, reducing operating costs and

environmental impact:

– 20% less than 3 standard 50-lb. fryers (120 lbs. of oil

vs. 150 lbs.)

– 15% less than 4 standard 50-lb. fryers (170 lbs. of oil

vs. 200 lbs.)

• Use upwards of 30% less energy than comparable

3-fryer systems. Exceed ENERGY STAR® guidelines,

qualifying for energy-saving rebates.

• Deliver exible, high-production cooking with one

or two 18” x 14” cooking area(s) that can cook three

baskets of food at the same time.

• SMART4U® Lane controller has programmable cook

buttons and features that make it easy to produce

consistent, great-tasting food. Analog, Digital, CM3.5

and SMART4U 3000 controller options are also

available.

• Save on equipment costs:

– Two 1814E fryers do the work of three 50-lb. fryers

– Three fryers (two 1814E and one RE17) do the work of

four 50-lb. fryers

• Support oil station management in batteries with

built-in ltration, making it easy to preserve oil life and

ensure consistent, great-tasting food.

Filtration for 11814E, 21814E, 31814E,

41814E and11814E/RE17/11814E

• Space-saving lter which ts inside fryer cabinet

• 8 GPM pump

• Steel gear pump with powerful 1/3 H.P. motor

• Large capacity lter pan removes easily for cleaning

• Sloped drain pan leaves minimal oil in the pan

after ltering

• Large 3” (8.0 cm) round drain line allows oil

to drain freely

• 1-1/4” (3.175 cm) drain valve

• Drain safety switch

• Stainless steel crumb catcher

• Filter starter kit

• Front and bulk oil disposal options

11814E

• 18” x 14” x 4-1/4” (45.7 x 35.6 x 10.8

cm) frying area

• 17 kw input

• 60-lb. (30-liter) oil capacity

• Three twin baskets

• Cooks 90 lbs. (41 kg) of French fries/hr.

• Optional ltration

21814E/31814E/

41814E

Has standard Features of the

11814E Plus:

• Built-in ltration, putting ltration

where it’s most convenient to use,

right in the fryer battery

• 8 GPM pump

• Additional twin baskets

• Adjustable casters

• Front and bulk oil disposal options

11814E/RE17/11814E

Has standard Features of the

21814E Plus:

• An RE17 frypot that meets ENERGY

STAR® guidelines with a 50-lb. (25-liter)

oil capacity.

• 17 kw/hr. input, a 14” x 14” x 3-1/2” (35.6

x 35.6 x 8.9 cm) frying area

• Two additional twin baskets

• Cooks 90 lbs. (41 kg) of French fries per

1814 frypot and 70 lbs. of French fries

per RE17 frypot

1814E models with SMART4U®

controllers meet ENERGY STAR®

guidelines and are part of the

Manitowoc Enerlogic™ program

1814E models with SMART4U®

controllers meet ENERGY STAR®

guidelines and are part of the

Manitowoc Enerlogic™ program

21814E shown with built in

lteration

1814E models with SMART4U®

controllers meet ENERGY STAR®

guidelines and are part of the

Manitowoc Enerlogic™ program

8

Page 9

High-Eciency Gas Fryers (H55)

Set the Standard for High-Eciency, Open-Pot Frying

Frymaster’s H55 gas fryer is a premium open-pot fryer that combines state-of-the-art technology with

decades of frying experience and customer satisfaction to set the standard for high-eciency frying. H55

fryers are the industry’s rst green fryers meeting ENERGY STAR® guidelines long before any guidelines

were established. H55 fryers are the foundation of Frymaster’s ever-evolving conserving fryer technology.

• Combine state-of-the-art combustion technology with

decades of frying experience to set a work standard for

high-eciency frying.

• Are the industry’s rst green fryers, exceeding ENERGY

STAR® guidelines long before any guidelines were

established. H55 fryers are the foundation of Frymaster’s

ever-evolving conserving fryer technology.

• Have a renowned infrared burner and blower system

that delivers an ultra-rened air-gas mixture so the fryer

operates well in any gas application.

– High altitudes

– Sub-optimal air circulation environments

– When gas heating quality is diminished

• Ensure consistent, great-tasting food. RTD, center-

mounted temperature probe and digital controller deliver

precise heat responses, safeguarding oil life and producing

a uniformly-cooked product. Controller and basket lift

options provide additional cooking control. The CM3.5

and SMART4U® 3000 controller options oer cooking

compensation.

• Oer easy-to-operate, quick, convenient and reliable

ltration options that maintain food quality, extending

the useful cooking life of oil and saving money. Built-in

ltration supports a regular program of ltration proven

to dramatically extend oil life, saving thousands of dollars

annually on oil costs.

• Qualify for energy-saving rebates.

• Oer standard features that add convenience and ease

of use.

– Open frypot is easy to clean

– Electronic ignition (no pilot to light), melt cycle mode

and boil-out temperature control.

• Protect purchases with an unmatched 7-Year Warranty that

covers the entire combustion chamber (frypot, infrared

burners, and combustion components).

• Have been tested by time and are trusted by

operator’s worldwide.

H55

• 80,000 Btu/hr. (20,151 kcal/

hr.) (23.4 kw/hr.)

• 14” x 15” x 4-1/2” (35.6 x 38.1

x 11.4 cm) frying area

• 50-lb. (25-liter) oil capacity

• Cooks 68 lbs. (31 kg) of

French fries/hr.

PH155 shown with optional CM3.5

controller and casters

H55-2

• Split frypot for frying

versatility and avor integrity

• 40,000 Btu/hr. (10,076 kcal/

hr.) (11.7 kw/hr.) each split

frypot

• 6-1/2” x 15” x 4-3/4” (16.5 x

38.1 x 12.1 cm) frying area

each split frypot

• 25-lb. (12-liter) oil capacity

each split frypot

PH155-2 shown with optional CM3.5

controller and casters

9

Page 10

High-Eciency Gas Fryers (HD)

Tube Fryers Good Enough to be Frymaster

Maximize your prots and make the most of your energy dollars with innovative design changes that

have improved the eciency of the HD Fryers over 40%. The MVPs of high-eciency, tube-type

frying, the HD gas fryers have low idle costs, oer low gas consumption per pound of food cooked, and

extend oil life.

• Improved gas ow and heat transfer designs improve eciency more than

40% over previous models.

• 6” vs 4” diameter tubes provide 36% more surface area for heat transfer

from the input energy to the oil. This minimizes the heat stress on the oil,

preserving oil life.

• Exclusive Thermo-Tube design and proprietary baes eciently transfer

the fryer’s energy input into the oil. Less heat goes unused up the vent and

into the kitchen - this saves energy dollars and keeps the kitchen cooler.

• Instant and controlled response to changes in cooking loads lowers gas

consumption per pound of food cooked and reduces idle costs.

• High-production cooking capacity and fast recovery meet high-volume

peak demands, while realizing energy savings.

• The Thermatron temperature control system ensures pinpoint oil

temperature accuracy (within plus or minus one degree) and allows the

fryer’s heat exchange system to respond instantly to changes in load

conditions.

• Robust, RTD, 1º compensating temperature probe.

• Wide cold zone and forward sloping bottom help collect and remove

sediment from the frypot to safeguard oil quality and make routine frypot

cleaning easy.

HD50/HD60

High-Eciency Decathlon Series Fryers

HD50

· 100,000 Btu/hr. (25,189 kcal/hr.)

(29.3 kw/hr.)

· 14” x 14” x 3-3/4 “ (35 x 35 x 9.5 cm)

frying area

· 50-lb. (25-liter) oil capacity

· Cooks 72 lbs. (33kg) of French fries/hr.

HD60

· 125,000 Btu/hr. (31,486 kcal/hr.) (36.6 kw/hr.)

· 18” x 18” x 3-3/4” (46 x 46 x 9.5 cm)

frying area

· 80-lb. (40-liter) oil capacity

· Cooks 107 lbs. (49kg) of French fries/hr.

Model HD150G shown with optional casters

10

Page 11

High-Eciency Low Flue Temp Gas Fryers (LHD65)

Low Flue Temperature Fryers, High on Production

Keep the kitchen cool and production capacity high. Frymaster’s new large vat LHD65 fryers have ue

temps less than 550°F and an ENERGY STAR® eciency rating of 57%. These fryers make quick work of

frying heavy loads of bone-in chicken, sh, wings, and much more.

• Have ue temperatures less than 550°F with proprietary

Thermo-Tube design and controlled ow diusers. This

high performance fryer provides maximum production,

transferring energy into the oil, with less going unused

up the ue.

• Can handle heavy loads of fresh breaded bone-in

chicken and other products with a 100-lb. oil capacity

and an 18” x 18” x 5-3/4” cooking area.

• Exceed ENERGY STAR® guidelines with an ASTM rating of

57%, qualifying for energy saving rebates.

• Are available as a single fryer without built-in ltration

or in batteries of 2-6 fryers with built-in ltration.

• Built-in lter models have an 8 GPM pump.

• Have a large cold zone that traps crumbs and sediment

away from the oil and a forward sloping bottom for fast,

thorough draining.

• Come standard with a SMART4U® 3000 controller

that has a segmented cooking feature. This allows

programming a cook with up to 5 dierent set

temperatures and times as designed for cooking

bone-in chicken.

LHD65

Low Flue Temperature,

High-Eciency Decathlon Series Fryers

LHD265

• 105,000 Btu/hr. (26,448 kcal/hr.) (30.8 kw/hr.) per frypot

• 18” x 18” x 5-3/4” (46 x 46 x 14.6 cm) frying area per

frypot

• 100-lb. (50 liter) oil capacity per frypot

• Cooks 128 pieces of 8-piece cut bone-in chicken/hr. per

frypot

Model FPLHD265 shown with 3000 controller

11

Page 12

High-Eciency Value Gas Fryer (ESG35T)

High-eciency, value frying at its best. Designed for all-purpose value frying usage.

Frymaster has a whole new category of fryers, “High-Eciency, Value” The new ESG35T is a value fryer

that exceeds ENERGY STAR guidelines and qualies for energy-saving rebates, which helps to reduce the

cost of ownership.

ESG35T

• 70,000 Btu/hr. (17,632 kcal/hr.) (20.5

kw/hr.)

• 14” x 13-3/4” x 4-1/5” (35 x 34.9 x

10.7 cm) frying area

• 35-lb. (17-liter) oil capacity

• Cooks 58 lbs. (25 kg) of

French fries/hr.

• Exceeds ENERGY STAR® guidelines

• Tube-type frypot design

• 6” heating tubes have proprietary baes and painted

interiors that deliver super heat transfer, reducing heat loss

by 27%

• Insulated frypot allows for a low idle rate of 6,143 Btu/hr.,

futher enhancing the energy savings

• The 35-lb. fryer has the same cooking capacity as a 45-lb.

fryer, saving 10-lbs. of oil every time the frypot is lled.

• Wide cold zone keeps crumbs and sediment away from the

cooking area, keeping oil fresh longer.

• Frypot bottom slopes to the front so that the oil, sediment

and crumbs can be easily ushed out of the frypot

• Durable temperature probe ensures prompt recovery

• Has a millivolt controller, no electrical hook-up required

• A Piezo ignitor option allows simple push button ignition.

12

Page 13

Master Jet Performance Gas Fryers (MJ)

World-Recognized Masters of Open-Pot Frying

These Frymaster gas fryers are unsurpassed in their versatility, proven world-wide performance, and

low maintenance needs. Whether it’s a single fryer, a fryer with built-in lter, or a battery of fryers with a

ltration system, Master Jet fryers achieve a long and dependable life through simplicity of design.

MJ35

• 110,000 Btu/hr. (27,708 kcal/hr.)

(32.2 kw/hr.)

• 12” x 15” x 4-1/4” (30.5 x 38.1 x 10.8

cm) frying area

• 40-lb. (20-liter) oil capacity

• Cooks 57 lbs. (26 kg) of

French fries/hr.

PMJ135 shown with legs

MJ45, MJ45-2

• 122,000 Btu/hr. (30,730 kcal/hr.)

(35.8 kw/hr.), full frypot;

63,500 Btu/hr. (15,995 kcal/hr.)

(18.6 kw/hr.), split frypot

• 14” x 15” x 5” (35.6 x 38.1 x 12.7 cm),

full frypot frying area; 7” x 15” x

4-3/4” (17.8 x 38.1 x 12.1 cm), split

frypot frying area

• 50-lb. (25-liter) oil capacity, full

frypot; 25-lb. (12-liter) oil capacity,

split frypot

• Cooks 69 lbs. (31 kg) of French

fries/hr., full frypot

• Split frypot model for frying

versatility and avor integrity

PMJ45E shown with optional CM3.5 controller

and casters

MJCF

• Oer an open-pot gas line-up unmatched in the industry.

Model oerings provide 40, 50 and 80-lb. oil capacity options

with and without electrical hook-up. Respective fry areas

are 12” x 15” x 4-1/4”, 14” x 15” x 5” and 18” x 19” x 4-1/2”.

Respective Btu/hr. inputs are 110,000, 122,000 and 150,000.

• Have models that can handle the breadth of menu items

from French fries to breaded sh to bone-in chicken.

• Are named for their signature Master Jet burner technology

that has earned a legendary reputation for durability and

reliability. MJ burners require no burner cleaning or air

shutter adjustment.

• Are easy to clean. Open-pot design allows safe access to every

inch of the frypot.

• Are simple to operate. Just set the desired frying

temperature and start cooking. A Piezo ignitor option allows

simple push button ignition.

• Oer options to meet a variety of operation and food quality

control needs:

– Built-in ltration, electronic ignition, basket lifts (MJ45

only) multiple frypot batteries and controller options

including CM3.5 and SMART4U 3000 compensating

controllers

• Automatically shut o the fryer if temperature exceeds the

high-limit.

• Collect and aid sediment removal with a deep collection

zone and large 1-1/4” IPS ball-type drain valve.

• Specically designed for chicken

and/or sh

• 150,000 Btu/hr. (37,783 kcal/hr.)

(44.0 kw/hr.)

• 18” x 19” x 4-1/2” (45.7 x 48.3 x

11.4 cm) frying area

• 80-lb. (40-liter) oil capacity

• Cooks 80 lbs. (36 kg) chicken/hr.;

100 lbs. (45 kg) sh/hr.

MJ1CFE shown with optional analog controller

and casters

13

Page 14

Standard Gas Fryers (GF)

Deliver Outstanding Open-Pot Frying Performance

These all-purpose fryers feature outstanding Frymaster reliability and durability. GF fryers are designed

for versatile frying production. Model oerings provide 40- and 50-lb. oil capacity options.

• Are designed for versatile frying production.

• Are easy to clean. Open-pot design allows safe access to every inch of the frypot.

• Are simple to operate. Just set the desired frying temperature and start cooking. A Piezo ignitor option allows simple push

button ignition.

• Automatically shut o the fryer if temperature exceeds the high-limit.

• Require no electrical hookup.

• Have a durable heat transfer system that can be counted on for years of reliable performance.

• Have durable accessories that support frying operation including the Piezo ignitor, frypot covers, full size baskets, basket

support screen and casters.

• Collect and aid sediment removal with a deep collection zone and large 1-1/4” IPS ball-type drain valve.

• GF Fryers oer all the benets of open-pot frying at an entry level price.

GF14

• 100,000 Btu/hr. (25,189 kcal/hr.) (29.3

kw/hr.)

• 12” x 15” x 4” (30.5 x 38.1 x 10.2 cm)

frying area

• 40-lb. (20-liter) oil capacity

• Cooks 57 lbs. (26 kg) of French fries/hr.

GF14 shown with optional casters

Countertop Gas Fryers (J1C)

Designed for Operations with Lower-Volume Requirements or Space Limitations

• Open-pot design is easy to clean, allows safe access to every

inch of the frypot.

• Master Jet burner’s durable heat transfer system can be

counted on for years of reliable performance.

• Reliable, centerline fast-action temperature probe.

• Millivolt controller is standard and requires no electrical

connection.

J1C Countertop Fryer

• 45,000 Btu/hr. (11,335 kcal/hr.)

(26.4 kw/hr.)

• 11” x 12” x 3-1/4” (27.9 x 30.5 x 8.3 cm)

frying area

• 20-lb. (10-liter) oil capacity

GF40

• 122,000 Btu/hr. (30,730 kcal/hr.)

(35.8 kw/hr.)

• 14” x 15” x 5” (35.6 x 38.1 x 12.7 cm)

frying area

• 50-lb. (25-liter) oil capacity

• Cooks 69 lbs. (31 kg) of French fries/hr.

GF40 shown with optional casters

• Deep cold zone with forward-sloping bottom and 1-1/4”

IPS full-port, ball-type drain valve collect and aid sediment

removal.

• Piezo ignitor (push button) option.

14

• Cooks 30-lbs. (14 kg) of French fries/hr.

Page 15

Ultra High-Eciency E4 (RETC)

Electric Fryers

Designed for Industry-Leading Energy Eciency

Responding to operators’ needs for foodservice equipment with maximum energy eciency and greater

reliability, Frymaster oers this ultra-ecient electric fryer. These fryers have patented Triac controls, a

fully insulated frypot, and Frymaster’s proprietary self-standing, swing-up elements, allowing full access

to the open frypot. The advanced controls modulate the energy input during start-up, saving energy.

They also have no moving parts to wear out making them extremely reliable and durable.

• Eciency exceeds ENERGY STAR® guidelines with an

industry leading ASTM rating of 86.6% and an idle rate

of 772 watts qualifying these fryers for energy-saving

rebates.

• Robust, center-mounted, RTD, 1° compensating

temperature probe anticipates rate of temperature

change. It ensures precise temperature control, which

maximizes oil life and produces uniformly-cooked

products.

• Triac controls “pulse” the amount of energy required

to the electric elements in much smaller increments

than traditional on/o electrical contactors or gas

controls. The result: greater reliability and more

precise temperature control.

• Insulated frypot reduces standby energy consumption

by an additional 10%.

• Enhanced diagnostics assist in troubleshooting key

components to prevent equipment downtime.

• Proprietary, self-standing swing-up, at-bar, low-watt

density long life heating elements allow for ecient

and uniform transfer of heat and easy cleaning.

• CM3.5 controller ensures pinpoint accuracy of oil

temperature and adjusts cooking time for consistent,

high-quality production.

RE14TC, RE14-2TC

• 14 kw/hr. full frypot, 7 kw/hr. split frypot

• 14” x 15-1/2” x 3-3/4” (35.6 x 39.4 x 9.5 cm)

full frypot frying area; 6-3/4” x 15-1/2” x

3-3/4” (17.1 x 39.4 x 9.5 cm) split frypot

frying area

• 50-lb. (25-liter) oil capacity full frypot;

25-lb. (12-liter) oil capacity split frypot

• Cooks 70 lbs. (32 kg) of French fries/hr.,

full 14 kw frypot

RE14TC shown with optional casters

RE17TC, RE17-2TC

• 17 kw/hr. full frypot, 8.5 kw/hr. split frypot

• 14” x 15-1/2” x 3-3/4” (35.6 x 39.4 x 9.5 cm)

full frypot frying area; 6-3/4” x 15-1/2” x

3-3/4” (17.1 x 39.4 x 9.5 cm) split frypot

frying area

• 50-lb. (25-liter) oil capacity full frypot;

25-lb. (12-liter) oil capacity split frypot

• Cooks 74 lbs. (34 kg) of French fries/hr.,

full 17 kw frypot

RE17TC shown with optional casters

• Deep cold zone with forward-sloping bottom and

1-1/4” IPS, full-port, ball-type drain valve collect and

aid sediment removal.

• Melt cycle and boil-out mode are standard.

• Built-in ltration options available. Rear oil ush

standard with lter systems.

RE22TC, RE22-2TC

• 22 kw/hr. full frypot, 11 kw/hr. split frypot

• 14” x 15-1/2” x 3-3/4” (35.6 x 39.4 x 9.5 cm)

full frypot frying area; 6-3/4” x 15-1/2” x

3-3/4” (17.1 x 39.4 x 9.5 cm) split frypot

frying area

• 50-lb. (25-liter) oil capacity full frypot;

25-lb. (12-liter) oil capacity split frypot

• Cooks 77 lbs. (35 kg) of French fries/hr.,

full 22 kw frypot

RE22TC shown with optional casters

15

Page 16

High-Eciency E4 (RE) Electric Fryers

Put Every kw to Work at Maximum Eciency

Frymaster electric fryers lead the industry in energy eciency. With ASTM ratings greater than 83%,

the E4 Series fryers won the Electric FoodService Council’s President’s Choice Award for outstanding

contribution to the advancement of electric foodservice equipment. Precise temperature control

protects product quality, permits rapid response to loads and maximizes oil life.

RE14, RE14-2

• 14 kw/hr. full frypot, 7 kw/hr. split frypot

• 14” x 15-1/2” x 3-1/2” (35.6 x 39.4 x 8.9 cm)

full frypot frying area; 6-3/4” x 15-1/2” x

3-1/2” (17.1 x 39.4 x 8.9 cm) split frypot

frying area

• 50-lb. (25-liter) oil capacity full frypot;

25-lb. (12-liter) oil capacity split frypot

• Cooks 68 lbs. (30 kg) of French fries/hr. full

14 kw frypot

RE14 shown with optional CM3.5 controller and casters

RE17, RE17-2

• 17 kw/hr. full frypot, 8.5 kw/hr. split frypot

• 14” x 15-1/2” x 3-1/2” (35.6 x 39.4 x 8.9 cm)

full frypot frying area; 6-3/4” x 15-1/2” x

3-1/2” (17.1 x 39.4 x 8.9 cm) split frypot

frying area

• 50-lb. (25-liter) oil capacity full frypot;

25-lb. (12-liter) oil capacity split frypot

• Cooks 70 lbs. (32 kg) of French fries/hr.

full 17 kw frypot

RE17 shown with optional CM3.5 controller and casters

• Deliver award-winning performance.

• Help keep the kitchen cool. With more energy going into the

oil, there is less heat going into the ambient air which keeps

workers comfortable and reduces demand on HVAC.

• Have industry leading energy eciency with ASTM ratings

greater than 83%. RE fryers exceed ENERGY STAR® guidelines

and qualify for energy-saving rebates.

• Analog controller standard. CM3.5, SMART4U 3000 and

Digital controller options.

• Can signicantly extend oil life, saving thousands of dollars

annually on oil costs with built-in ltration options that make

it easy to preserve oil life and ensure great tasting food.

• Support a broad range of frying needs with 14 kw, 17 kw and

22 kw models, controller options that add features all the

way to cook compensation and basket lift options.

• Protect and conserve with safe, self-standing, swing-up,

at-bar heating elements that allow a highly ecient and

uniform transfer of heat into the oil. A sealed rotation

housing protects against oil migration.

• Produce consistent, high quality food time after time. RTD,

temperature probe and analog controller deliver precise heat

response, safeguarding oil life and producing a uniformlycooked product.

RE22, RE22-2

• 22 kw/hr. full frypot, 11 kw/hr. split frypot

• 14” x 15-1/2” x 3-1/2” (35.6 x 39.4 x 8.9 cm)

full frypot frying area; 6-3/4” x 15-1/2” x

3-1/2” (17.1 x 39.4 x 8.9 cm) split frypot

frying area

• 50-lb. (25-liter) oil capacity full frypot;

25-lb. (12-liter) oil capacity split frypot

• Cooks 76 lbs. (34 kg) of French fries/hr.

full 22 kw frypot

RE22 shown with optional CM3.5 controller and casters

16

• Are easy to clean. Open frypot design and sturdy self-stand-

ing elements allow safe access to every inch of the frypot.

• RE Fryers deliver a lifetime of performance.

Page 17

High-Production E4 (HPRE) Electric Fryers

Designed to Meet High-Production, High Sediment Frying Needs

When your foodservice operation runs into those tough jobs that require high production, Frymaster’s

brawny HPRE fryer is there for you! Its 80-lb. oil capacity makes short work of heavy loads and handles

the demands of a varied menu with ease. And the high-eciency, electric heat transfer system is easy

on the oil so you can consistently produce great-tasting foods that bring customers back through your

doors for more. . . time after time.

• Designed specically for high-production frying of a varied

menu including bone-in chicken and other fresh-breaded

products.

• Open-pot design is easy to clean. Allows safe access to every

inch of the frypot.

• Industry-leading energy eciency.

• Digital controller standard. CM3.5, and SMART4U 3000

controller options.

• Robust, center-mounted RTD 1° compensating temperature

probe anticipates rate of temperature change. It ensures precise temperature control, which maximizes oil life and produc-

es uniformly cooked products.

• Proprietary, self-standing, swing-up, at-bar, low-watt density,

long-life heating elements allow for ecient and uniform transfer of heat and easy cleanup.

• Large cold zone with forward-sloping bottom and 1-1/4” IPS,

full-port, ball-type drain valve collect and aid sediment removal.

• Melt cycle and boil-out mode standard.

• Built-in ltration options available. Rear oil ush is standard

with lter systems.

E4 SERIES RE80 (HPRE

• 17kw/hr. or 21kw/hr. input models

• 18” x 18” x 5” (45.7 x 45.7 x 12.7 cm)

frying area

• 80-lb. (40-liter) oil capacity

• Cooks 84 lbs. (42 kg) of French fries/hr.

per 17 kw frypot

RE80 shown with optional CM3.5 controller, ltration,

basket lifts, and casters

)

Other Products

Sandwich Holding Station (SHS)

Specically Designed Heated Holding Unit that Optimizes

the Hot Holding of Wrapped Foods

• Open-top, no lamps or bulbs needed

• Controlled heat, prevents cooking and drying

• Stainless steel construction

• Simple to operate pass-through design

• Available in 18” and 22” depths

Cleaning Disposal Caddy

Specically Designed For Transport and Disposal of Fryer

Water-based cleaning Solutions (hot or cold)

• 50-lb. (25-liter) frypot capacity

• Latching lid for safe transport

• Fold-down handle for safe and easy storage

• Durable stainless steel pan

• 2” low-prole casters

• 1/2” drain pipe and shut-o valve

NEW!

17

Page 18

Fryer Controllers

Ensure Product Consistency

Frymaster oers many dierent types of controllers. If you have a high volume operation and want to ensure all employees

will fry consistently to the same quality specications, then the more advanced controls that oer compensation or “stretch”

cooking would be the controllers of choice.

ITEM DESCRIPTION COOKING PERFORMANCE MODEL OPTIONS PICTURE

SMART4U FILTERQUICK

CONTROLLER*

3000

CONTROLLER*

LANE

CONTROLLER

CM3.5

CONTROLLER*

Operates Fingertip semi-automated ltration. Oers push button cooking for 20 products. Times the cook operation and signals audibly when

cooking is complete. Can display Fahrenheit or Celsius temperature

values and stores the current time and temperature settings when the

unit is turned o. Features temperature check, boil-out, melt cycle and

lighted digital display. Controller operates the ATO-Automatic Top O

Oil Attendant. Controller can monitor oil management functions such as

cook counts, prompt when it is time to lter, and guide workers through

step-by-step oil management functions such as ltration, oil dispose

and boil out. Also can be programmed for segmented cooking, used to

Operates standard built-in ltration. Oers push button cooking for 20

products. Times the cook operation and signals audibly when cooking

is complete. Can display Fahrenheit or Celsius temperature values

and stores the current time and temperature settings when the unit

is turned o. Features temperature check, boil-out, melt cycle and

lighted digital display. Controller operates the ATO-Automatic Top O

Oil Attendant. Controller can monitor oil management functions such as

cook counts, prompt when it is time to lter, and guide workers through

step-by-step oil management functions such as ltration, oil dispose

and boil out. Also can be programmed for segmented cooking, used to

Times the cook operation and signals audibly when cooking is complete.

Automatically selects Fahrenheit/Celsius temperature values and stores

the current time and temperature settings when the unit is turned

o. The 3-lane controller has 10 programmable product buttons, a

40-product library feature, temperature check, boil-out, melt cycle, hold

timers, cook compensation and lighted digital display. Control operates

as a lane controller with the ability to select not only the product, but

also where it will cook, lane 1, 2 or 3. A 2-lane version is available for

the HD50 gas and RE electric fryers in the 1814 battery.

Smooth, touch-pad surface; multi-product programmable controller

automatically stretches cook time to provide consistent food quality

regardless of the product load. LEDs display cooking time countdown

(with audible alarm) and provide precise frypot temperature checks. The

unit also features controlled boil-out at a steady 195°F (80°C), recovery

“test time”, programmable “shake” and “hold” times and more. Available

cook bone-in chicken

cook bone-in chicken.

for full or split-pot fryers.

Compensation or “stretch” cooking ensures

the exact heat load will be utilized for

each cook. The result is more consistent

and higher quality food products.

Compensation or “stretch” cooking ensures

the exact heat load will be utilized for

each cook. The result is more consistent

and higher quality food products.

Compensation or “stretch” cooking ensures

the exact heat load will be utilized for

each cook. The result is more consistent

and higher quality food products.

Compensation or “stretch” cooking ensures

the exact heat load will be utilized for

each cook. The result is more consistent

and higher quality food products.

FQ30U

OCF30, 1814, LHD65, H55, H55-2,

MJCFE, RE14, RE14-2, RE17, RE17-2,

RE22, RE22-2, HD50G, HD60G

1814

OCF30, 1814, LHD65, H55, H55-

2,MJ35E, MJ45E, MJ45E-2, MJCFE,

RE14, RE14-2, RE17, RE17-2, RE22,

RE22-2, RE80, HD50G, HD60G,

D50G, D60G, D80G

ELECTRONIC TIMER

CONTROLLER**

DIGITAL

CONTROLLER

ANALOG

CONTROLLER

THERMATRON

CONTROLLER

* Basket lifts only available with CM3.5, 3000 and FilterQuick controllers.

**Can substitute Electronic Timer Controller for CM3.5 for no additional cost.

Times the cook operation and signals audibly when cooking is complete.

Automatically selects Fahrenheit/Celsius temperature values and stores

the current time and temperature settings when the unit is turned o.

The electronic timer controller also operates full or split-pot models

with basket lifts. Features temperature check, boil-out, melt c ycle and

Smooth, touch-pad control panel is attractive and easy to operate.

Features constant temperature display, melt cycle, lighted digital

Standard controller for many Frymaster high eciency gas and electric

fryers. Simple to operate with on/o switch, temperature set dial and

Standard controller for many Dean fryers. Simple to operate with on/o

switch, temperature set dial and melt cycle and boil-out options.

display and Fahrenheit/Celsius values.

melt cycle option. Works with electronic ignition.

18

lighted digital display.

1814, H55, H55-2, MJ35E, MJ45E,

MJ45E-2, MJCFE, RE14, RE14-2,

RE17, RE17-2, RE22, RE22-2, RE80,

HD50G, HD60G, D50G, D60G, D80G

1814, LHD65, H55, H55-2, MJ35E,

MJ45E, MJ45-2, MJCFE, RE14,

RE14-2, RE17, RE17-2, RE22,

RE22-2, RE80, HD50G, HD60G,

D50G, D60G, D80G

1814, MJ35E, MJ45E, MJ45E-2,

MJCFE, RE14, RE14-2, RE17, RE17-2,

RE22, RE22-2

HD50G, HD60G, D50G, D60G, D80G,

1824, 2424

Page 19

Oil Station Management Equipment

Designed to Support Good Oil Station Management and Maximize Oil Life

Nothing maintains food quality and maximizes oil life better than routine ltration. The by-products created from high-heat

frying take a toll on oil life unless a daily system of ltration and cleaning removes them. Frymaster’s complete line of ltration

equipment, both built-in and portable, is designed to make ltration quick, convenient, reliable and safe. A convenient, easy

ltering process encourages frequent ltering – a critical part of maximizing oil life, especially with trans-fat free oils.

Built-In Filtration

Frymaster’s renowned, built-in ltration puts ltration where it’s most convenient to use — right within the fryer -- eliminating the need for

additional oor and storage space.

The ltering process is fast and easy, encouraging frequent ltering -- a critical part of maximizing oil life, especially with trans-fat free oils. It

is also sequential, so one fryer may be ltered while the others are still in use. It is engineered with features that allow added convenience,

easier serviceability and allows for using three dierent lter mediums with one pan.

This ltration is enhanced with a gravity draining system that allows residual oil to drain into the lter pan so that drain lines are always

open. The lter, housed beneath two Frymaster fryers or one fryer and a spreader, is capable of ltering up to six fryers, individually, without

having to be moved from fryer to fryer, saving valuable labor. One fty-pound fryer can be ltered in about four minutes, while other fryers

in the battery keep on cooking. Single ltration is also available for OCF30, H55 and RE full and split frypot models.

The lter has a powerful pump to maximize ltering eciency and minimize clogging. Large sump with secure hold-down ring ensures

proper vacuum and oil return. The stainless steel lter pan slides out easily over oor mats and uneven oor tiles.

Fully-Automatic Filtration -- FilterQuick Models Only

• Push-button start makes caring for the oil and optimizing food quality simple.

• 30-lb open frypot design requires 40% less oil and ensures quick and easy cleaning. Saves

money, time and labor.

• Independent frypot construction allows convenient frypot repairs in the eld, if needed.

• State-of-the-art combustion fuels eciency. Infrared heat transfer qualies fryers for energysaving rebates.

• SMART4U® FilterQuick Controller has operation management features that monitor and help

control food and oil quality, oil life, and equipment performance. Has 20 programmable cook

buttons and auto adjusts cook time to load size.

• FilterQuick’s closed cabinet, Automatic Filtration uses push-button start to make caring for the

oil and optimizing food quality simple

• Innovative safety features oer proprietary advantages over other fryers -- prevent simultaneous

vat ltrations.

Filtration for 2 or More Fryers -- Non-FilterQuick Models

• Space-saving lter which ts inside a fryer cabinet housing two full

or qualifying split frypots in two left most cabinets of the battery

• Filter pan is lightweight for easy removal

• Sloped drain pan leaves minimal oil in the pan after ltering

• Large 3” (8.0 cm) round drain allows oil to drain freely

• Filter cycle is complete from start to nish in less than 5 minutes, while other frypots in the system are in use

• Filters all fryers in one battery

• Six or more fryers/cabinets ship in two cartons

• 1-1/4” (3.2 cm) full-port drain valve standard on full frypots

• 1” (2.5 cm) full-port drain valve standard on split frypots

• Drain safety switch

• 1/3 H.P. lter motor

• Stainless steel crumb catcher

• Filter starter kit

• Single LHD65 and RETC models require a spreader cabinet combo to get built-in ltration. Single MJCF requires a lter cabinet to get built-in

ltration

19

Page 20

Oil Station Management Equipment

Designed to Make Daily Filtration Easy, Quick and Ecient

Filtration for Single Fryers

• Space-saving lter which ts inside a fryer cabinet housing one frypot

• Filter pan is lightweight and easy to remove for cleaning

• Sloped drain pan leaves minimal oil in the pan after ltering

• Filter cycle is complete from start to nish in under 5 minutes

• Drain safety switch

• 1-1/4” (3.2 cm) drain valve standard on full frypots

• 1” (2.5 cm) drain valve standard on split frypots

• 1/3 H.P. lter motor

• Stainless steel crumb catcher

• Filter starter kit

• Available for single models: 1814, HD50, HD60, H55, H55-2, RE14, RE14-2,

RE17, RE17-2, RE22, RE22-2

FPRE14 shown with optional CM3.5 controller

Filtration System Under a Frypot and Spreader

• Space-saving lter which ts inside a fryer cabinet housing a frypot and a spreader cabinet in the two left most cabinets of

the battery

• Large capacity lter pan design is lightweight for easy removal

• Sloped drain pan leaves minimal residue oil behind after ltering

• Large 3” round drain line creates 13% more capacity for oil to drain freely

• Single RETC models require a spreader cabinet combo to get built-in ltration

• Available for models : 1814 gas, HD50G, HD60G, H55, H55-2, RE14, RE14-2, RE14TC, RE14-2TC, RE17, RE17-2, RE17TC,

RE17-2TC, RE22, RE22-2, RE22TC, RE22-2TC, 1814E

Filtration for HPRE Fryers

• 80-lb. (40 liter) oil capacity

• Space-saving lter which ts inside fryer cabinet

– Filtration available for single frypot fryers (FP conguration), multiple frypot fryers (FP conguration) and fryers that

include a spreader cabinet (FM conguration).

• Steel gear pump with powerful 1/3 H.P. motor

• Large capacity lter pan removes easily for cleaning

• Sloped drain pan leaves minimal oil in the pan after ltering

• Drain safety switch

• Stainless steel crumb catcher

• Filter starter kit

• Maximum 3 frypots and spreader or 4 frypots

Filtration for 1814 Fryers

See pages 6 and 7

20

Page 21

Oil Station Management Equipment

Designed to Make Daily Filtration Easy, Quick and Ecient

Filtration for MJCFE Fryers

• 80-lb. (40 liter) oil capacity

• Space-saving lter has its own cabinet.

• Large capacity lter pan is lightweight and easy to

remove for cleaning

• Sloped drain pan leaves minimal oil in the pan

after ltering

• Large 3” (8.0 cm) round drain valve

• Drain safety switch

• Power Shower® oil return allows ltered oil to wash

down crumbs from the frypot walls

• Filters 60 to 80 lbs. (30 to 40 liter) of oil in under ve

minutes, while other frypots in the system are in use

• 1/3 H.P. lter motor

• Stainless steel crumb catcher

• Filter Starter Kit

• Five or more fryers/cabinets ship in two cartons

Portable Filtration

Designed to Make Daily Filtration Easy, Quick and Ecient

Frymaster ltration units are designed to support routine oil ltration which preserves oil life and maintains consistent fried food quality. Crumbs, sediment, and by-products created by high-heat frying take a

toll on oil life unless a daily system of ltration and frypot cleaning is in place.

• Simple to use

• Easy to clean

• Powerful steel gear pump with 1/3 H.P. motor lters 50-lbs.

(25-liters) of oil in 5 minutes

• 5 ft. (152 cm) hose returns ltered oil with ease amply reaching

the frypot to wash crumbs from the walls and the bottom of

the frypot

• Durable stainless steel pan and pump housing is made to stand

up to heavy use and make the lter easy to clean

• The included Filter Starter Kit contains all needed lter supplies

so ltration can begin as soon as the lter arrives

• Suction line heated for solid shortening

• Cover with fold-down handle

• PF50 portable lters t under the drain of all Frymaster

50-lb. fryers

PF50S/PF50R

• 50-lb. (25-liter) oil capacity

• Model PF50R features reversible pump

Model PF50R features reversible pump.

PF95LP

• Large capacity, 80-lb. (40 liter) oil

capacity

• Low prole – ts under most fryers

Model PF95LP shown with reversible pump.

Shortening Disposal Units (SDU)

• Available in 50- and 100-lb. (25 and 50-liter) oil

capacity models

• 9-5/8” drain height with cover open – ts under all

Frymaster fryers and most other fryers

• Heavy-duty manual pump empties 50 lbs. of oil in

less than 60 seconds

• One-way check valve for easy priming of pump

• Large 6” high-strength wheels

Model SDU50 and SDU100 shown.

21

Page 22

Accessories

Baskets & Trays

Baskets

Sediment Tray - Gas

Shelves, Scoops, & Casters

Splash Shield Crumb Scoop Casters

Food Warmers

Fish Plate

Rod-Style Heat Lamp

Food Warmer & Cafeteria Pan

Frypot Accessories

Frypot Cover

22

Top Connecting Strip

Rod-Style Heat Lamp

Food Warmer & Scoop Pan

L-shaped Fryer Brush

Flue Deector

Page 23

Product Specications

Model

Number

11814

11814/

HD50G/11814

FQG30U Series

FQG30 Split

Series

FPGL130 Series

FPGL130 Split

Series

FPGL230ATO

Series

FPGL230ATO

Series Splits

ESG35T

Description

Oil-Conserving Gas Fryer

(without lter)

Oil-Conserving Gas Fryer

(with lter)

FilterQuick® with Fully-

Automatic Filtration and

Optional Oil Quality Sensor

Oil-conserving Gas Fryers

OCF30 Oil-Conserving Gas

Fryer (Full Frypot)

OCF30 Oil-Conserving Gas

OCF30 Oil-Conserving Gas

Fryer (Full Frypot) with ATO

OCF30 Oil-Conserving Gas

Fryer (Split Frypot) with ATO

Gas Value High Eciency

Fryer

Fryer (Split Frypot)

Energy

Requirements

119,000 Btu/hr.

(29,975 kcal) (34.9 kw)

11814

119,000 Btu/hr.

(29,975 kcal) (34.9 kw)

HD50G

100,000 Btu/hr. (25,189

kcal) (29.3 kw)

75,000 Btu/hr.

(18,892 kcal) (21.97 kw)

37,500 Btu/hr. (9,446 kcal)

(10.98 kw)

per split

75,000 Btu/hr.

(18,892 kcal) (21.97 kw)

37,500 Btu/hr. (9,446 kcal)

(10.98 kw)

per split

75,000 Btu/hr.

(18,892 kcal) (21.97 kw)

37,500 Btu/hr. (9,446 kcal)

(10.98 kw)

per split

70,000 Btu/hr.

(17,632 kcal) (20.5 kw)

Oil

Capacity

63 lb.

(31 liters)

63 lb.

(31 liters)

per 1814

frypot &

50 lb.

(25 liters)

30 lb.

(15 liters)

17 lb.

(8.5 liters)

30 lb.

(15 liters)

17 lb.

(8.5 liters)

30 lb.

(15 liters)

17 lb.

(8.5 liters)

35 lb.

(17 liters)

Cooking

Area

Inches (cm)

W x D X H

18 x 14 x 3-3/4 (45.7 x

35.6 x 9.5)

18 x 14 x 3-3/4

(45.7 x 35.6 x 9.5)

per 1814 frypot &

14 x 14 x 3-1/2

(35.6 x 35.6 x 8.9)

13 x 14 x 3-3/4

(33 x 36 x 9.5)

6 x 14 x 3-1/2

(15 x 36 x 8.9

13 x 14 x 3-3/4

(33 x 36 x 9.5)

6 x 14 x 3-1/2

(15 x 36 x 8.9)

13 x 14 x 3-3/4

(33 x 36 x 9.5)

6 x 14 x 3-1/2

(15 x 36 x 8.9)

14 x 13-3/4 x 4-1/5

(35 x 34.9 x 10.7)

Width

Inches

(cm)

20

(50.8)

55-5/8

(141.3)

31-1/4

(79.4

15-5/8

(39.7)

31-1/4

(79.4)

15-1/2

(39.4)

Depth

Inches

33-1/8

33-1/8

29-7/8

29-5/8

29-5/8

Height

Inches

(cm)

47-3/4

(84.1)

(121.3)

47-3/4

(84.1)

(121.3)

46-1/2

(76)

45-5/8

(75.3)

(115.8)

45-5/8

(75.3)

(115.8)

29-1/8

(74)44(111.8)

(cm)

(118)

Production

Per Hr.

(Full Frypot)

100 lbs. Fries/hr.

100 lbs. Fries/hr.

per 11814

frypot

72 lbs. Fries/hr. per

HD50G frypot

67 lbs. Fries/hr.

67 lbs. Fries/hr.

67 lbs. Fries/hr.

58 lbs. Fries/hr.

Cubic Feet

Approx.

Shipping Wt.

40

255 lbs. (116 kg)

88

907 lbs. (411 kg)

52

544 lbs. (247 kg)

21

265 lbs. (120 kg)

52

544 lbs. (247 kg)

22

165 lbs. (75 kg)

HD150 Gas High Eciency Fryer

HD160 Gas High Eciency Fryer

LHD65

PH155

PH155-2

PMJ145

PMJ145-2

PMJ135 Gas Fryer

MJ1CF Gas Fryer

GF40 Gas Fryer

GF14 Gas Fryer

J1C Gas Countertop Fryer

Gas, Low Flue Temperature

High Eciency Gas Fryer

High Eciency Gas Fryer

Gas Fryer (Full Frypot)

Gas Fryer (Split Frypot)

Fryer

(Full Frypot)

(Split Frypot)

100,000 Btu/hr.

(25,189 kcal) (29.3 kw)

125,000 Btu/hr.

(31,486 kcal) (36.6 kw)

105,000 Btu/hr

(26,448 kcal) (30.8 kw)

80,000 Btu/hr.

(20,151 kcal) (23.4 kw)

40,000 Btu/hr. (10,075

kcal) (11.7 kw)

per split

122,000 Btu/hr.

(30,730 kcal) (35.8 kw)

63,500 Btu/hr.

(15,995 kcal) (18.6 kw)

per split

110,000 Btu/hr.

(27,700 kcal) (32.2 kw)

150,000 Btu/hr.

(37,783 kcal) (44 kw)

122,000 Btu/hr.

(30,730 kcal) (35.8 kw)

100,000 Btu/hr.

(25,189 kcal) (29.3 kw)

45,000 Btu/hr.

(11,335 kcal/hr.) (26.4 kw)

50 lbs.

(25 liters)

80 lbs.

(40 liters)

100-lb.

(50 liters)

50 lb.

(25 liters)

25 lb.

(12 liters)

50 lb.

(25 liters)

25 lb.

(12 liters)

40 lb.

(20 liters)

80 lb.

(40 liters)

50 lb.

(25 liters)

40 lb.

(20 liters)

20 lb.

(10 liters)

14 x 14 x 3-1/2

(35 x 35 x 9.5)

18 x 18 x 3-3/4

(46 x 46 x 9.5)

18 x 18 x 5-3/4

(46 x 46 x 14.6)

14 x 15 x 4-1/2

(35.6 x 38.1 x 11.4)

6-1/2 x 15 x 4-3/4

(16.5 x 38.1 x 12.1)

14 x 15 x 5

(35.6 x 38.1 x 12.7)

7 x 15 x 4-3/4

(17.8 x 38.1x 12.1)

12 x 15 x 4-1/4

(30.5 x 38.1 x 10.8)

18 x 19 x 4-1/2

(45.7 x 48.3 x 11.4)

14 x 15 x 5

(35.6 x 38.1 x 12.7)

12 x 15 x 4

(30.5 x 38.1 x 10.2)

11 x 12 x 3-1/4

(27.9 x 30.5 x 8.3)

15-1/2

15-5/8

15-5/8

15-5/8

20-7/8

15-5/8

15-5/8

(39.4)

20

(50.8)

20

(50.8)

(39.7)

(39.7)

(39.7)

(52.9)

(39.7)

(39.7)

14

(35.6)

31-1/4

(79.4)

36-3/4

(93.4)

36-1/2

(92.7)43(109.2)

29-5/8

(75.3)

31-1/2

(80.1)

31-1/2

(80.1)

39-7/8

(101.3)

30-7/8

(78.3)

30-7/8

(78.3)

24-7/8

(63.2)

45

(114.3)

45

(114.3)

45-5/8

(115.8)

46

(116.8)

41

(104.1)

46-1/8

(117.2)

46-1/8

(117.1)

41-1/8

(104.4)

23-1/2

(59.8)

72 lbs. Fries/hr.

107 lbs. Fries/hr.

128 pcs. bone-in

chicken/hr.

68 lbs. Fries/hr.

69 lbs. Fries/hr.

57 lbs. Fries/hr.

80 lbs. chicken/hr.

100 lbs. sh/hr.

69 lbs. Fries/hr.

57 lbs. Fries/hr.

30 lbs. Fries/hr.

22

180 lbs. (82 kg)

40

255 lbs. (116 kg)

72.9

260 lbs. (118 kg)

21

202 lbs. (92 kg)

21

202 lbs. (92 kg)

20

177 lbs. (80 kg)

32

297 lbs. (135 kg)

21

176 lbs. (80 kg)

21

152 lbs. (69 kg)

19

121 lbs. (55 kg)

Frymaster, whose policy is one of constant improvement, reserves the right to amend specications without prior notice.

23

Page 24

Product Specications - Continued

Model

Number

11814E

11814E/RE17/11814E

FQE30U Series

FQE30U Series Splits

FPEL114 Series

FPEL114 Series Splits

FPEL214 ATO Series

FPEL214 ATO Series

Splits

RE14TC/17TC/22TC

RE14-2TC/17-2TC/

22-2TC

RE14/17/22

RE14-2/17-2/22-2

RE180 Electric Fryer

PF95LP Low Prole Portable Filter

PF50S &

PF50R

PSDU50 Shortening Disposal Unit N/A

PSDU100 Shortening Disposal Unit N/A

SHS 18 Sandwich Holding Station

SHS 22 Sandwich Holding Station

Description

Electric Oil-Conserving Fryer

(without lter)

Electric Oil-Conserving Fryer

(with lter)

FilterQuick® with Fully-

Automatic Filtration and

Optional Oil Quality Sensor

Oil-conserving Electric Fryers

OCF30 Oil-Conserving

Electric Fryer (Full Frypot)

OCF30 Oil Conserving

Electric Fryer (Split Frypot)

OCF30 Oil-Conserving

Electric Fryer (Full Frypot)

with ATO

OCF30 Oil Conserving

Electric Fryer (Split Frypot)

with ATO

Electric Fryer (Full Frypot)

Electric Fryer (Split Frypot)

Electric Fryer (Full Frypot)

Electric Fryer (Split Frypot)

Portable Filter 120V/60 Hz. 9 Amp

Energy

Requirements

17 kw

17 kw

per frypot

14 kw

14/17 kw

7/8.5 kw per split

14/17 kw

7/8.5 kw per split

14/17/22 kw

7/8.5/11 kw per split

14/17/22 kw

7/8.5/11 kw per split

17 kw

21 kw

120V/60 Hz

1 PH -6.2A

208V 12A

2.5 kw

208V 12A

2.5 kw

Oil

Capacity

60 lb.

(30 liters)

60 lb.

(30 liters)

per 1814

frypot &

50 lb.

(25 liters)

30 lb.

(15 liters)

16 lb.

(8 liters)

30 lb.

(15 liters)

16 lb.

(8 liters)

30 lb.

(15 liters)

16 lb.

(8 liters)

50 lb.

(25 liters)

25 lb

(12 liters)

50 lb.

(25 liters)

25 lb.

(12 liters)

80 lb.

(40 liters)

80 lb.

(40 liters)

50 lb.

(25 liters)

50 lb.

(25 liters)

100 lb.

(50 liters)

N/A N/A

N/A N/A

Cooking Area

18 x 14 x 4-1/4

(45.7 x 35.6 x 10.8)20(50.8)

18 x 14 x 4-1/4

(45.7 x 35.6 x 10.8)

14 x 14 x 3-1/2

(35.6 x 35.6 x 8.9)

13 x 14 x 3-3/4

(33 x 36 x 9.5)

6 x 14 x 3-3/4

(15 x 36 x 9.5)

13 x 14 x 3-3/4

(33 x 36 x 9.5)

6 x 14 x 3-3/4

(15 x 36 x 9.5)

13 x 14 x 3-3/4

(33 x 36 x 9.5)

6 x 14 x 3-3/4

(15 x 36 x 9.5)

14 x 15-1/2 x 3-3/4

(35.6 x 39.4 x 9.5)

6-3/4 x 15-1/2 x 3-3/4

(17.1 x 39.4 x 9.5)

14 x 15-1/2 x 3-1/2

(35.6 x 39.4 x 8.9)

6-3/4 x 15-1/2 x 3-1/2

(17.1 x 39.4 x 8.9)

(45.7 x 45.7 x 12.7)

Inches (cm)

W x D X H

per frypot

18 x 18 x 5

N/A

N/A

N/A

N/A

Width

Inches

(cm)

56-1/4

(142.8)

31-1/4

(79.4)

15-5/8

(39.7)

31-1/4

(79.4)

15-5/8

(39.7)

15-5/8

(39.7)

20

(50.8)

18-1/4

(46.4)

13-1/4

(33.7)

15-3/8

(39)

21

(53.3)

24”

(61.0)

24”

(61.0)

Depth

Inches

30-7/8

30-7/8

30-7/8

30-7/8

30-7/8

39-5/8

(100.6)

33-1/2

37-1/2

18-1/2”

Height

Inches

(cm)

(78.4)

(78.4)

(78.6)

(78.6)

(78.6)

(78.6)

(78.6)

(85.2)

(76.2)

(81.1)

(95.3)50(127)

(47)

(55.9)

31

31

30

32

22”

(cm)

45-3/8

(114.9)

45-3/8

(114.9)

45-3/8

(115.2)

45-3/8

(115.2)

45-3/8

(115.2)

45-3/8

(115.2)

45-3/8

(115.2)

44-3/4

(113.7)

9-3/8

(23.9)

13-1/4

(33.7)

(122.1)

7-3/4”

(19.6)

7-3/4”

(19.6)

83 lbs. Fries/hr.

83 lbs. Fries/hr.

per 11814E frypot

70 lbs. Fries/hr.

per RE17 frypot

71 lbs. Fries/hr.

71 lbs. Fries/hr.

78 lbs. Fries/hr.

71 lbs. Fries/hr.

78 lbs. Fries/hr.

48

Production

Per Hr.

(Full Frypot)

14 kw

14 kw

17 kw

14 kw

17 kw

70/74/77 lbs.

(32/34/35 kg)

Fries/hr.

68/70/76 lbs.

(30/31/34 kg)

Fries/hr.

84 lbs. Fries/hr.

N/A

N/A

N/A

N/A

N/A

N/A

Cubic Feet

Approx.

Shipping Wt.

255 lbs. (116 kg)

907 lbs. (411 kg)

544 lbs. (247 kg)

255 lbs. (116 kg)

535 lbs. (200 kg)

190 lbs. (86 kg)

190 lbs. (86 kg)

285 lbs. (129 kg)

140 lbs. (67 kg)

120 lbs. (54 kg)

62 lbs. (28 kg)

80 lbs (36 kg)

55 lbs. (25 kg)

65 lbs. (30 kg)

40

89

52

21

52.5

21

21

28

18

8

10

10

4.66

5.06

24

Frymaster, whose policy is one of constant improvement, reserves the right to amend specications without prior notice.

Page 25

Decathlon Performance Gas Fryers (D)

Designed for high-volume frying and controlled performance.

Satisfy customers with consistently great-tasting foods. Thermo-Tube design and Thermatron

temperature control system ensure ecient heat transfer and precise temperature control.

• High-production cooking capacity and fast recovery meet high-volume frying needs.

• A larger heat-transfer area reduces the heat per square inch needed to attain

and maintain desired cooking temperatures, which reduces the oil’s heat load

and therefore the breakdown of the oil.

• Stainless-steel baes and reliable, built-to-last, burners keep maintenance

to a minimum.

• Precise temperature control during heat–up and recovery protects oil

from excessive high-heat damage.

• Robust, RTD, 1º compensating temperature probe.

• The wide cold zone traps sediment away from the cooking area,

safeguarding oil quality and the quality of the food.

• Easy clean-up features that allow quick oil and sediment draining

are a forward sloped bottom, 1-1/4” to 1-1/2” full-port drain

valve, and a 3” drain line. A built-in ltration option supports

routine frypot cleaning and oil ltration, key practices

that maximize oil life and maintain food quality.

• Multiple customization options allow you to combine two

or more units into a single battery. Add an optional built-in

ltration system, or specify a CM 3.5 controller or basket lifts

to further ensure premium product consistency.

D50G/D60G/D80G

D50G

• 120,000 Btu/hr. (30,600 kcal/hr.) (35.2 kw/hr.)

• 14” x 14” x 3-1/4” (35 x 35 x 8.3 cm) frying area

• 50-lb. (25-liter) oil capacity

• Cooks 63 lbs. (27kg) of French fries/hr.

D60G

• 150,000 Btu/hr. (37,783 kcal/hr.) (44kw/hr.)

• 18” x 18” x 3-3/4” (46 x 46 x 9.5 cm) frying area

• 75-lb. (37-liter) oil capacity

• Cooks 92 lbs. (42kg) of French fries/hr.

D80G

• 165,000 Btu/hr. (41,562 kcal/hr.) (48.3 kw/hr.)

• 20” x 20” x 3-3/4” (51 x 51 x 9.5 cm) frying area

• 100-lb. (50-liter) oil capacity

• Cooks 105 lbs. (48kg) of French fries/hr.

Model D160G shown with optional CM 3.5 controller, basket lifts, and casters

25

Page 26

Super Marathon Standard Gas Fryers (SM)

Designed for versatile frying production and solid performance.

These all-purpose fryers feature outstanding Dean reliability and durability. Whether it’s a single fryer,

a fryer with a built-in lter, or a battery of fryers with a ltration system, Super Marathon fryers achieve

long and dependable life through simplicity of design.

• Millivolt pilot system – requires no electrical hookup.

• Durable temperature probe eciently senses

temperature changes and activates burner response.

• Oil capacity options accommodate a wide range of

frying needs – everything from French fries, breaded

products, and specialty foods to bone-in chicken.

• Wide cold zone and forward sloping bottom help

collect and remove sediment from the frypot to

safeguard oil quality and support routine frypot

cleaning.

• Proven Thermo-Tube heat transfer system ensures

outstanding reliability and durability.

SM40G/SM50G

SM140G

• 105,000 Btu/hr. (26,481 kcal/hr.) (30.8 kw/hr.)

• 14” x 14” x 3-1/4” (35 x 35 x 8.3 cm) frying area

• 43-lb. (21-liter) oil capacity

• Cooks 57 lbs. (26kg) of French fries/hr.

SM150G

• 120,000 Btu/hr. (30,600 kcal/hr.) (35.2 kw/hr.)

• 14” x 14” x 3-1/2 “ (35 x 35 x 8.9 cm) frying

area

• 50-lb. (25-liter) oil capacity

• Cooks 60 lbs. (27kg) of French fries/hr.

Model SM150G shown with optional casters

SCFSM250G

SCFSM250G

• 120,000 Btu/hr. (30,600 kcal/hr.)

(35.2 kw/hr.) per frypot

• 14” x 14” x 3-1/2 “ (35 x 35 x 8.9 cm)

frying area per frypot