Page 1

CF SERIES GAS FRYERS

Return to Cover

CHAPTER 3: OPERATING INSTRUCTIONS

3.1 Start-Up Procedure

CAUTION

If this is the first time the fryer is being

used after installation, refer to Section

3.2, Boil-Out Procedure.

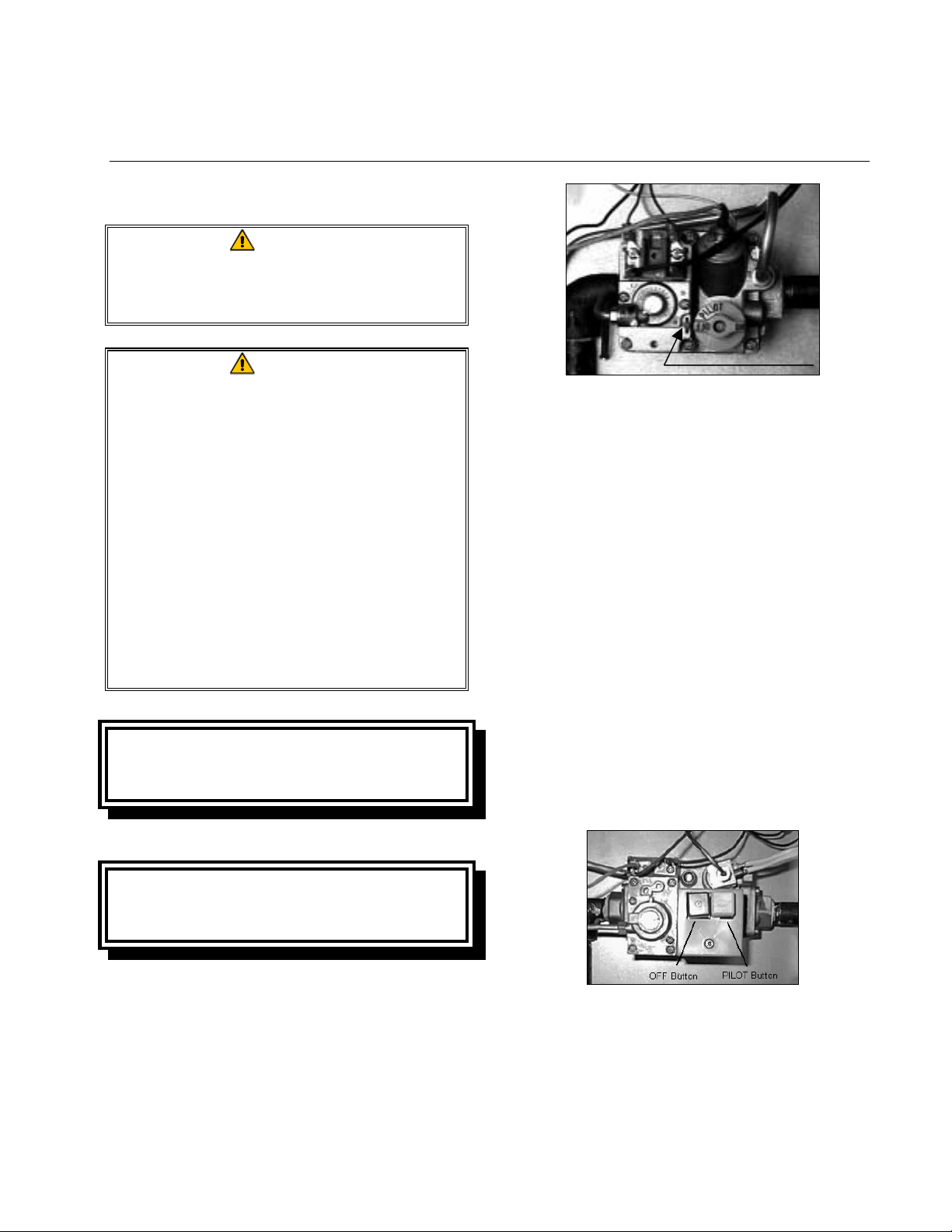

Knob is shown in

OFF position.

CAUTION

The cooking oil/shortening capacity of

the 45 Series fryer is 80 lbs (43 liters)

at 70ºF (21ºC).

Before lighting the fryer, make sure the

fryer is OFF and the frypot drain valve

is closed. Remove the basket support

rack, if installed, and fill the frypot to

the bottom OIL-LEVEL line.

To prevent scorching, if solid

shortening is being used, make sure it

is tightly packed down into the bottom

of the frypot.

Non-CE Standard

Units configured to Non-CE standards are

equipped with Robertshaw valves.

Note index mark.

3. Place a flame near the pilot assembly, push

and hold the knob in, light the pilot, and

continue to depress the knob for at least 60

seconds after the pilot lights. Failure to

hold the knob in long enough will cause

the pilot to go out when the knob is released. If the pilot goes out when the knob

is released, wait at least 5 minutes then repeat this step.

4. Turn the gas valve knob to the ON position.

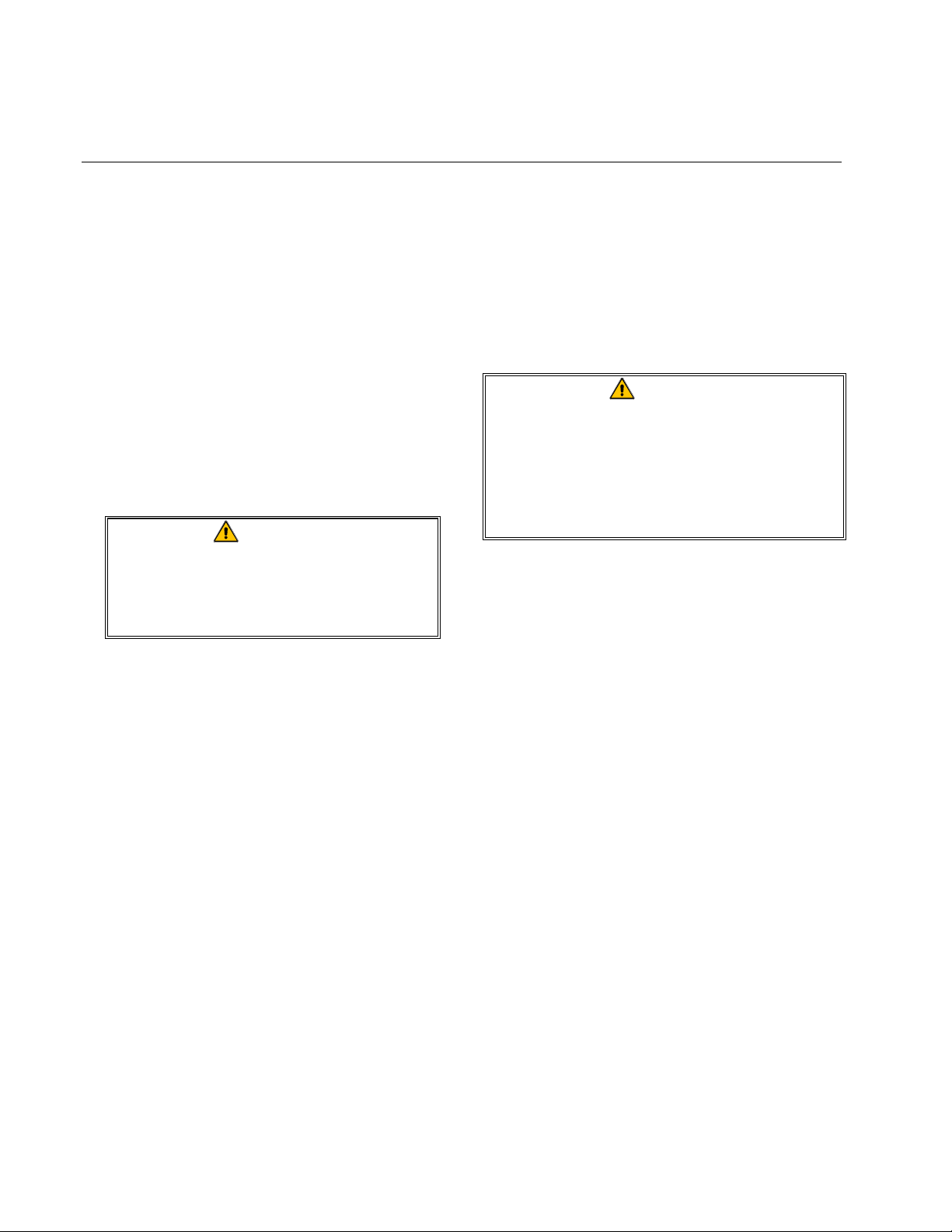

Lighting the Pilot on Honeywell Valves:

1. Ensure power to the unit is OFF.

2. Press the OFF (red) button. Wait 5 minutes.

CE Standard

Units configured to CE standards are

equipped with Honeywell valves.

Lighting the Pilot on Robertshaw Valves:

1. Ensure power to the unit is OFF.

2. Turn the gas valve knob to the OFF position. Wait 5 minutes, then turn the knob

to the PILOT position.

3. Place a flame near the pilot assembly, push

and hold the PILOT (white) button in,

light the pilot, and continue to depress the

button for at least 60 seconds after the

pilot lights. Failure to hold the button in

long enough will cause the pilot to go out

3-1

Page 2

CF SERIES GAS FRYERS

CHAPTER 3: OPERATING INSTRUCTIONS

when the button is released. If the pilot

goes out when the button is released, wait

at least 5 minutes then repeat this step.

Placing the Fryer into Operation.

For units equipped with Thermostat

Controls:

Place the Melt Cycle switch (if equipped)

to the ON position. Set the thermostat

knob to the desired cooking temperature.

The U-shaped burner should “light-off”

and burn with a strong, blue flame.

CAUTION

Thermostat-controlled fryers will

stay in the Melt Cycle mode until

the Melt Cycle switch is placed in

the OFF position.

For units equipped with other than

Thermostat Controls:

Place the computer/controller ON/OFF

switch in the ON position and set the controller to—or program the computer for—

the desired cooking temperature, referred

to as the setpoint. The U-shaped burner

should “light off” and burn with a strong,

blue flame. The unit automatically enters

the Melt Cycle mode if the frypot temperature is below 180ºF (82ºC). (NOTE:

During the melt cycle, the burner will repeatedly fire for a few seconds, then go out

for a longer period.) When the frypot

temperature reaches 180ºF (82ºC), the unit

will automatically switch to the Heating

mode. The burner will remain lit until the

frypot temperature reaches the programmed cooking temperature (setpoint).

3.2 Boiling-Out the Frypot

To ensure that the frypot is free of any contamination resulting from its manufacture,

shipping, and handling during installation, the

frypot must be boiled out before first use.

Frymaster recommends boiling out the frypot

each time the oil or shortening is changed.

DANGER

Never leave the fryer unattended

during the boil-out process. If the boil-

out solution boils over, turn off power

to the fryer immediately and let the

solution cool for a few minutes before

resuming the process.

1. Before lighting the burner, close the fryer

drain valve(s) and fill the frypot to the

bottom OIL-LEVEL line with a mixture of

cold water and Frymaster™ FRYER ‘N’

GRIDDLE cleaner or detergent.

2. For units equipped with thermostat con-

trollers, set the thermostat to 280ºF

(140ºC).

For units equipped with analog or digital

°°°°

controllers, set the setpoint to 200

(93

°°°°

C).

F

For units equipped with Computer Magic

III computers, select the Boil-Out feature

in accordance with the procedure Using

the Boil-Out Feature on page 3-7.

3. Place the fryer into operation in accor-

dance with Section 3.1.

4. Simmer the solution for 1 hour.

5. After the solution simmers for 1 hour, turn

the fryer off, allow the solution to cool,

3-2

Page 3

CF SERIES GAS FRYERS

CHAPTER 3: OPERATING INSTRUCTIONS

then add 2 gallons (7.75 liters) of cold

water and stir. Drain the solution into a

suitable container and clean the frypot

thoroughly.

WARNING

Do not drain boil-out solution into

the built-in filtration system. Doing

so may cause damage to the

filtration pump.

6. Rinse the frypot at least twice by filling the

frypot with clean water and draining. Dry

the frypot thoroughly with a clean, dry

towel.

DANGER

Remove all drops of water from the

frypot before filling with cooking

oil/shortening. Failure to do so may

cause spattering of hot liquid when

the oil/shortening is heated to

cooking temperature.

3.3 Shutting the Fryer Down

For short-term shut down during the work day,

place the fryer power switch in the OFF position and put the frypot covers in place (if the

fryer is so equipped).

When shutting the fryers down at closing time,

place the fryer power switch in the OFF position, place the gas valve in the OFF position,

and put the frypot covers in place (if the fryer

is so equipped).

3.4 Controller Operation and

Programming

Fryers in the 45 Series can be equipped with

any of the following types of controlling devices:

• Computer Magic III

• Thermostat Controller

• Analog Controller

• Digital Controller

Each type is discussed in detail in the following pages.

3-3

Page 4

N

OTE:

Some computers

may have this

earlier style

ON/OFF switch:

ON

OFF

CF SERIES GAS FRYERS

CHAPTER 3: OPERATING INSTRUCTIONS

1 234 5

c y c l c y c l

Frymaster

L1 23445

6 78

1 Left LED Display 5 Right Power Switch

2 Right LED Display 6 Left Product Selection & Coding Keys

3 Temperature Check/Program Lock 7 Right Product Selection & Coding Keys

4 Left Power Switch 8 Program Mode Switch

6

COMPUTER MAGIC

78

9

0R

COMPUTER MAGIC III CONTROLLER

COMPUTER OPERATING INSTRUCTIONS

Turn the computer on by pressing the Power

switch (or ON/OFF switch

ON

OFF

). NOTE:

A decimal between digits 1 and 2 in either

LED Display indicates that the burner is on.

1. One of the following will be displayed:

a. cycl, indicating that the fryer is op-

erating in the melt cycle mode. The

fryer will remain in the melt cycle

mode until it reaches 180ºF (82ºC) or

is canceled manually by pressing the R

key.

CAUTION

Do not cancel the melt cycle mode

until solid shortening is completely

melted!

b. hi, indicating that the frypot tem-

perature is 21ºF (12ºC) higher than the

setpoint.

c. LO, indicating that the frypot tem-

perature is 21ºF (12ºC) lower than the

setpoint.

d. “- - - -”, indicating that the frypot tem-

perature is in the cooking range.

NOTE: For best results, cooking

should not be attempted unless the display indicates “- - - -”.

e. help, indicating a heating problem.

f. hot, indicating the frypot tempera-

ture is in excess of 410ºF (210ºC).

g. prob, indicating that the computer

temperature probe circuit is open.

3-4

Page 5

CF SERIES GAS FRYERS

CHAPTER 3: OPERATING INSTRUCTIONS

2. Press a product switch to initiate a cook

cycle.

a. The display will indicate the previ-

ously programmed cook time and begin countdown.

b. If shake time is programmed, the op-

erator will be notified of the need to

shake the product “X” seconds after

the cook cycle has begun (X = amount

of time programmed). An alarm will

sound, and the display will read SH####,

where “#” will be the switch number.

If no shake time has been programmed,

sh#### will not appear during the cook

cycle. The alarm is self-canceling.

c. At the end of the cooking cycle, an

audible alarm will sound, cooc will

be displayed, and the associated product switch indicator will flash. To

cancel the cook alarm, press the appropriate switch.

d. At this time, the hold time will be dis-

played (if programmed greater than

zero), and the countdown will begin.

When the countdown reaches zero,

hD_

hD_ will be displayed and an alarm

hD_hD_

will sound. The blank will be the

switch number. The hold alarm is canceled by pressing the Programming

switch

. NOTE: If the display is in

use, the hold time countdown will not

be displayed.

3. To check the frypot temperature at any

time, press the Temperature Check switch

once. To check the setpoint, press the

switch twice. If you suspect the temperature probe is defective, check the temperature of the frypot with a thermometer

or pyrometer to verify that the computer

readout is reasonably close to the measured reading.

4. During idle periods when the fryer is on

but not in use, “- - - -” should appear in

both displays. If not, check the actual

temperature and setpoint.

CAUTION

The electronic circuitry in your

computer can be affected adversely by

current fluctuations and electrical

storms. Should it fail to function or

program properly for no apparent

reason, the computer should be reset

by unplugging the computer and

plugging it back in. This could prevent

a service call.

COMPUTER PROGRAMMING INSTRUCTIONS

1. Turn the computer on by pressing the

Power switch (or ON/OFF

ON

OFF

switch).

2. Enter the programming mode by pressing

the Program Mode switch . Code

appears in the left display. If you enter the

programming mode by mistake, press the

switch again to exit the programming

mode. NOTE: If you try to enter the programming mode while the computer is

cooking, the display will flash busy

busy.

busybusy

3. Enter the number 1650 by pressing the

number keys.

4. sp----r (Setpoint) will appear in the left

display. Any previously programmed

temperature setpoint will appear in the

right display. To change the setpoint, enter the desired setpoint temperature using

the number keys. For CE units, the highest

setpoint allowed is 370ºF (188ºC). For

Non-CE units the number is 375ºC

3-5

Page 6

CF SERIES GAS FRYERS

CHAPTER 3: OPERATING INSTRUCTIONS

(191ºC). Press the Program Mode switch

to lock in the new setpoint (or the old

setpoint, if it was not changed). If the unit

is a dual vat fryer, sp-L will appear, allowing the setpoint for the left vat to be

adjusted or confirmed.

5. selp (Select Product) will appear in the

left display. Press the product button to be

programmed (or press

normal operating mode).

6. sens (Sensitivity) appears in the left

display. Any previously programmed sensitivity setting will appear in the right display. To change the sensitivity setting,

enter the new setting and press to lock

it in. If the setting was not changed,

pressing accepts the previous setting.

Sensitivity is a built-in feature that adjusts

cooking time to compensate for the drop in

frypot temperature when a basket of product is placed into it. Different food products will vary in density, basket load size,

and initial temperature. Food products

will also vary in how well cooked a product is required to be. A proper sensitivity

setting for each product will assure a

high-quality product each time. For example: four ounces of fries can be programmed to be cooked to the same quality

as two and one-half pounds. Some experimenting with the range of 0 - 9 (0 being least sensitive and 9 being most sensitive) may be required to obtain the desired

quality to meet your specifications, but

setting 5 is the recommended starting

point.

7. cooc (Cook Time) will now show in the

left display. Any previously programmed

time will appear in the right display.

to return to the

Pressing will accept the current cooking time. To change the cooking time,

enter the new time using the number keys.

Press to lock in the new time.

8. sh____ (Shake Time) appears in the left dis-

play. If your product requires shaking

during the cooking process, set the number

of seconds to cook before shaking using

the number keys.

For example, entering “30” means the

product needs to be shaken after it has

been cooking for 30 seconds. At the end

of 30 seconds, an alarm will sound and the

product switch will flash for 3 seconds. If

your product does not require shaking,

enter “0”. The number entered will appear

in the right display. Press to lock in the

programmed time.

9. hd____ (Hold Time) will appear in the left

display. Set the time the product may be

held before serving, anything from 13 seconds to 60 minutes. If you do not wish to

use the hold time feature, enter 0. Press

to lock in the time.

In the event the same product is being

cooked in more than one basket, any product button can be programmed to use the

hold timer normally used with a different

product button. Example: Program button 3 for 7:00 minutes hold time. Then,

when programming button R for hold time,

press address 4. Both product button 3

and product button R will then use the

same hold time of 7:00 minutes. The button numbers and their assigned address

numbers are:

Button: L 1 2 3 4 5 6 7 8 9 0 R

Address: 1 2 3 4 5 6 7 8 9 10 11 12

3-6

Page 7

CF SERIES GAS FRYERS

CHAPTER 3: OPERATING INSTRUCTIONS

10. selp (Select Product) will again appear

in the left display. If more products are to

be programmed, return to Step 5 and follow all instructions to this point, repeating

for each product.

11. When you complete your programming,

lock in the whole program by pressing the

Temperature Check/Program Lock switch

.

USING THE BOIL-OUT FEATURE

CAUTION

Before using this feature, ensure the

frypot is filled with a mixture of cold

water and

Frymaster

FRYER ‘N’

GRIDDLE cleaner or detergent.

1. To program the fryer for boil-out, press the

Power switch (or ON/OFF

ON

OFF

switch)

followed by the Program Mode switch .

Code will appear in the left display.

no more than 2 minutes and 30 seconds. If the

recovery time is greater, call your FASC.

1. To check recovery time, press the Program

Mode switch . Code will appear in

the left display.

2. Enter the code number 1652 on the

number keypad. The recovery time will

appear in both displays for 5 seconds.

SELECTING FAHRENHEIT– CELSIUS DISPLAY

MODE

1. The computer can display temperatures in

either Fahrenheit or Celsius. To change

from one to the other, press the Program

Mode switch . Code will appear in

the left display.

2. Enter the code number 1658 on the

number keypad. The computer will toggle

the temperature display from Celsius to

Fahrenheit or from Fahrenheit to Celsius.

2. Enter the code number 1653. The right

display will read boil

boil. The temperature is

boilboil

automatically set for 195ºF (91ºC). The

fryer will attain this temperature and remain there until the Power (or ON/OFF

ON

OFF

) switch is pressed, which cancels the

boil-out mode. In high-altitude locations,

the fryer must be monitored constantly for

boil-over conditions. If boil-over occurs,

turn off the fryer immediately, allow it to

cool, then re-enter the boil-out mode to

continue the boil-out process.

FRYER RECOVERY TIME CHECK FEATURE

“Recovery time” is the amount of time it takes

the fryer to increase the temperature from

275

°

F (135°C) to 325°F (163°C). It is a

measure of the fryer’s efficiency. It should be

3. Press the Temperature Check/Program

Lock switch

to display the temperature

in the newly selected mode.

SELECTING FRYPOT TEMPERATURE DISPLAY

MODE

1. To display the actual frypot temperature at

all times, press the Program Mode switch

. Code will appear in the left display.

2. Enter code 165L on both number key-

pads. The computer will display the actual

frypot temperature. NOTE: During the

product cooking process, the cooking time

will not be displayed, but timing is taking

place.

3. To return to setpoint display, repeat Steps

1 and 2.

3-7

Page 8

CF SERIES GAS FRYERS

CHAPTER 3: OPERATING INSTRUCTIONS

Heat

Mode

Light

3

Frymaster

ON/OFF

Switch

2

ON

OFF

C

F

Temperature

THERMOSTAT CONTROLLER

.

THERMOSTAT CONTROLLER

The Thermostat Controller utilizes a frypot

thermostat that is directly connected to a temperature knob mounted on the control panel.

Rotating the knob to the desired cooking temperature (setpoint) directly adjusts the thermostat control to that temperature. Placing the

ON/OFF switch in the ON position supplies power to the fryer’s components and

causes the switch to illuminate. Placing the

Melt Cycle switch in the ON position

causes the fryer burner to repeatedly cycle on

for a few seconds and off for a longer period.

The purpose is to gradually melt solid shortening to prevent scorching, and to prevent

1

Knob

4

Melt Cycle

Switch

creation of “hot spots” on the frypot. The

switch is illuminated when in the ON position.

CAUTION

The fryer remains in the Melt Cycle

mode until the Melt Cycle switch is

placed in the OFF position.

The Heat Mode Indicator illuminates when

the frypot is below setpoint.

The Thermostat Controller requires no programming, but it may require calibration from

time to time. To determine if it requires calibration, refer to Check Thermostat Controller

Thermostat Calibration on page 5-4.

3-8

Page 9

CF SERIES GAS FRYERS

CHAPTER 3: OPERATING INSTRUCTIONS

Power

Light

Frymaster

Power

Switch

ANALOG CONTROLLER

Heat

On

Mode

Light

Temperature

ANALOG CONTROLLER

In units equipped with analog controllers, the

frypot thermostat has been replaced with a

solid-state temperature probe and solid-state

electronics mounted on the control panel, reducing the number of moving parts and eliminating the need to calibrate the thermostat.

The temperature probe is connected to the

control circuitry via an interface board behind

the control panel.

The cooking temperature setpoint is set by rotating the Temperature Knob to the desired

temperature.

When the Power switch is placed in the ON

position, electrical current is supplied to the

Trouble

C

F

Knob

Melt

Cycle

Light

Light

?

SOLID STATE

Melt Cycle

Switch

fryer’s components and the Power On Light

illuminates.

Placing the Melt Cycle switch in the ON

position causes the burner to cycle on for a

few seconds and off for a longer period until

the temperature in the frypot reaches 180ºF

(82ºC). At that time the unit automatically

enters the heat mode, causing the burner to

remain lit until the setpoint is reached. When

in the melt cycle, the Melt Cycle Light

alternately illuminate and go out as the burner

cycles on and off. When the unit enters the

heat mode, the Heat Mode Light

illuminate and remain on until the setpoint is

reached. The Trouble Light indicates probe

circuit or high limit circuit problems.

will

will

3-9

Page 10

CF SERIES GAS FRYERS

CHAPTER 3: OPERATING INSTRUCTIONS

Celcius or

ON/OFF

Switch

Frymaster

Digital

Display

9 . 9 9 9

Fahrenheit

Display Switch

T emperature

or Setpoint

Display Switch

DIGITAL CONTROLLER

DIGITAL CONTROLLER

This controller uses a temperature probe and

solid-state electronics. Pressing the ON/OFF

switch supplies electrical power to the

fryer, and causes the controller software version number to display for 4 seconds in the

Digital Display.

Following the software version number display, the SETPOINT TEMPERATURE

WILL DISPLAY CONSTANTLY. Pressing

the Temperature/Setpoint Display switch will

display the actual frypot temperature.

The fryer will automatically enter the melt

cycle mode and will continue to cycle on for a

few seconds and off for a longer period until

the temperature in the frypot reaches 180ºF

(82ºC). At that time, it will enter the heat

mode. The purpose of the melt cycle is to

gradually melt solid shortening to prevent

Setpoint

Adjustment

Arrows

Melt

Cycle

Switch

Heating

Mode

Indicator

scorching, and to prevent creation of “hot

spots” on the frypot. To cancel the melt cycle,

press the Melt Cycle switch .

The fryer will remain in the heat mode until

the setpoint is reached. The Heat Mode Indicator is a decimal point that appears between

the first two numbers of the digital display to

indicate the unit is heating. When the setpoint

is reached, the decimal will go out; indicating

the fryer is ready for cooking.

To enter or change the setpoint, press an arrow

key to raise or lower the temperature setting.

The display will change at a rate of about 1degree per second for approximately the first

12 degrees, then change to a faster rate if an

arrow is continuously pressed.

The temperature can be displayed in either

Fahrenheit or Celsius. To change from one to

the other, press the C/F switch .

3-10

Loading...

Loading...