Page 1

Cascade Filtration Systems

Installation and Operation Manual

Models CF35, CF60 & CF80

Dean, a member of the Commercial Food Equipment Service Association, recommends using

CFESA Certified Technicians.

24-Hour Service Hotline 1-800-551-8633

Price: $6.00

819-5666

07-98

Page 2

Please read all sections of this manual and retain for future reference.

GAS APPLIANCE

CONDUCTOR, GROUNDED CORD OF 16 GAUGE OR GREATER.

Installation, maintenance, and repairs should be performed by your Dean Factory

Authorized Service Agency.

CAUTION

INSTRUCTIONS TO BE FOLLOWED IN CASE THE USER SMELLS GAS ARE TO

BE POSTED IN A PROMINENT LOCATION. THIS INFORMATION SHALL BE

OBTAINED BY CONTACTING THE LOCAL GAS COMPANY OR GAS SUPPLIER.

CAUTION

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS AND LIQUIDS IN THE VICINITYOF THIS OR ANY OTHER

.

WARNING!

SAFE AND SATISFACTORY OPERATION OF YOUR EQUIPMENT

DEPENDS ON ITS PROPER INSTALLATION.

INSTALLATION MUST CONFORM TO LOCAL CODES, OR IN THE ABSENCE OF

LOCAL CODES, WITH THE NATIONAL ELECTRIC CODE, NFPA 70-1984

(OR LATEST EDITIONS).

WARNING!

ELECTRICAL GROUNDING INSTRUCTIONS

This filter is equipped with a three-prong, grounded plug for your protection against

shock hazard and should be plugged directly into a properly grounded, three-hole

receptacle. Do not cut off, remove or otherwise bypass the grounding prong on this plug.

IF IT IS NECESSARY TO USE AN EXTENSION CORD, IT MUST BE A THREE-

CAUTION

HOT FLUID – DO NOT FILL BEYOND MAXIMUM FILL LINE

LOCATED ON THE OIL CONTAINER.

Page 3

CASCADE FILTRATION SYSTEMS

INSTALLATION AND OPERATION MANUAL

TABLE OF CONTENTS

PAGE

1. PARTS ORDERING AND SERVICE INFORMATION 2

2. IMPORTANT INFORMATION 3

3. INSTALLATION 4

4. DAILY OPERATION 6

5. CLEANING AND MAINTENANCE 11

6. TROUBLESHOOTING GUIDE 12

1. PARTS ORDERING AND SERVICE INFORMATION

1.1 ORDERING PARTS:

Customers may order parts directly from their

local Authorized Parts Distributor. For this

address and phone number, contact your

Maintenance & Repair Center or call the

factory. The factory address and phone

number are on the cover of this manual.

To speed up your order, the following

information is required:

Model Number

Type

Serial Number

With/Without Heater

Optional Equipment

Item Part Number

Quantity Needed

1.2 SERVICE INFORMATION:

Call the “800” number on the cover of this

manual for the location of your nearest

Maintenance & Repair Center or contact the

factory direct. Always give the model and

serial numbers of your filter and fryer.

To assist you more efficiently, the following

information will be needed:

Model Number

Type

Serial Number

With/Without Heater

Optional Equipment

Nature of Problem

Any other information which may be helpful in

solving your service problem

2

Page 4

2. IMPORTANT INFORMATION

2.1 GENERAL: The Micro-Flo CF-35,

CF-60, and CF-80 Cascade Oil Filters are

units with an oil capacity of 50 pounds,

60 pounds, and 110 pounds (respectively)

that fit inside the Dean Industries’

Decathlon D35G, D60G, and D80G

fryers. The Cascade Filters can be used

as portable units also.

The used oil drains by gravity from the

fryer into the filter pan and then it is

pumped back to the fryer vessel.

Filtering is accomplished through two

sheets of replaceable filter paper assisted

by a micro pre-coat filter powder.

CAUTION

The on-site supervisor is responsible for

ensuring that operators are made aware of the

inherent dangers of operating a hot oil filter

system, particularly aspects of oil filtration,

draining, and cleaning of the filter.

special parts or information, this data is

essential for proper identification.

2.5 PRE-INSTALLATION:

a. GENERAL: These filters, when

used in combination with a fryer,

require no additional space. When

used as a portable filter, it will require

an area of floor space approximately

1-1/2' x 2-1/2' (3.75 sq ft).

b. STANDARDS: Installation must be

in accordance with all applicable state

and local codes.

c. ELECTRICAL CONNECTIONS:

The filter may or may not be equipped

with a pan heater. Only one

connection is required to a

115V/60HZ 15-amp electrical supply

receptacle on the fryer. When used as

a portable filter, the 2-1/2' flexible 163 SJT power cord is to be connected

to a suitable extension cord.

2.2 OPERATING CONTROLS: An

“ON/OFF” switch is mounted on the

pump motor housing. If equipped with an

optional pan heater, a three (3) position

switch (HEAT/OFF/PUMP) is mounted

on the pump motor housing in lieu of the

“ON/OFF” switch.

2.3 SAFETY FEATURES: A 7-amp

circuit breaker switches the power OFF if

an overload occurs.

NOTE: IF CIRCUIT BREAKER IS

TRIGGERED, THE RESET BUTTON

NEEDS TO BE DEPRESSED TO

ACIVATE THE CIRCUIT AFTER

NATURE OF FAILURE HAS BEEN

DETECTED AND FIXED.

2.4 RATING PLATE: Information on

this plate includes the model and serial

numbers, as well as electrical

requirements. When communicating with

the factory about a unit or requesting

2.6 UNPACKING THE FILTER:

Check that the container is upright.

Unpack the filter carefully and remove all

accessories from the carton. Do not

discard or misplace these, as they will be

needed.

Loose parts include starter kit, the filter

hose and wand for portable operation and

accessories that may have been ordered.

These are packaged inside the filter tank.

The tank top is strapped to the shipping

frame.

After unpacking, immediately check the

equipment for visible signs of shipping

damage. If such damage has occurred,

contact the carrier and file the appropriate

freight claims. Do not contact the

factory, as the responsibility of shipping

damage is between the carrier and the

dealer or end-user.

3

Page 5

3. INSTALLATION:

3.1 GENERAL: On initial installation and

before each use, remove all loose parts from

the filter, wash the filter pan and all

accessories in hot, soapy water and dry

thoroughly.

3.2 ASSEMBLYING THE FILTER:

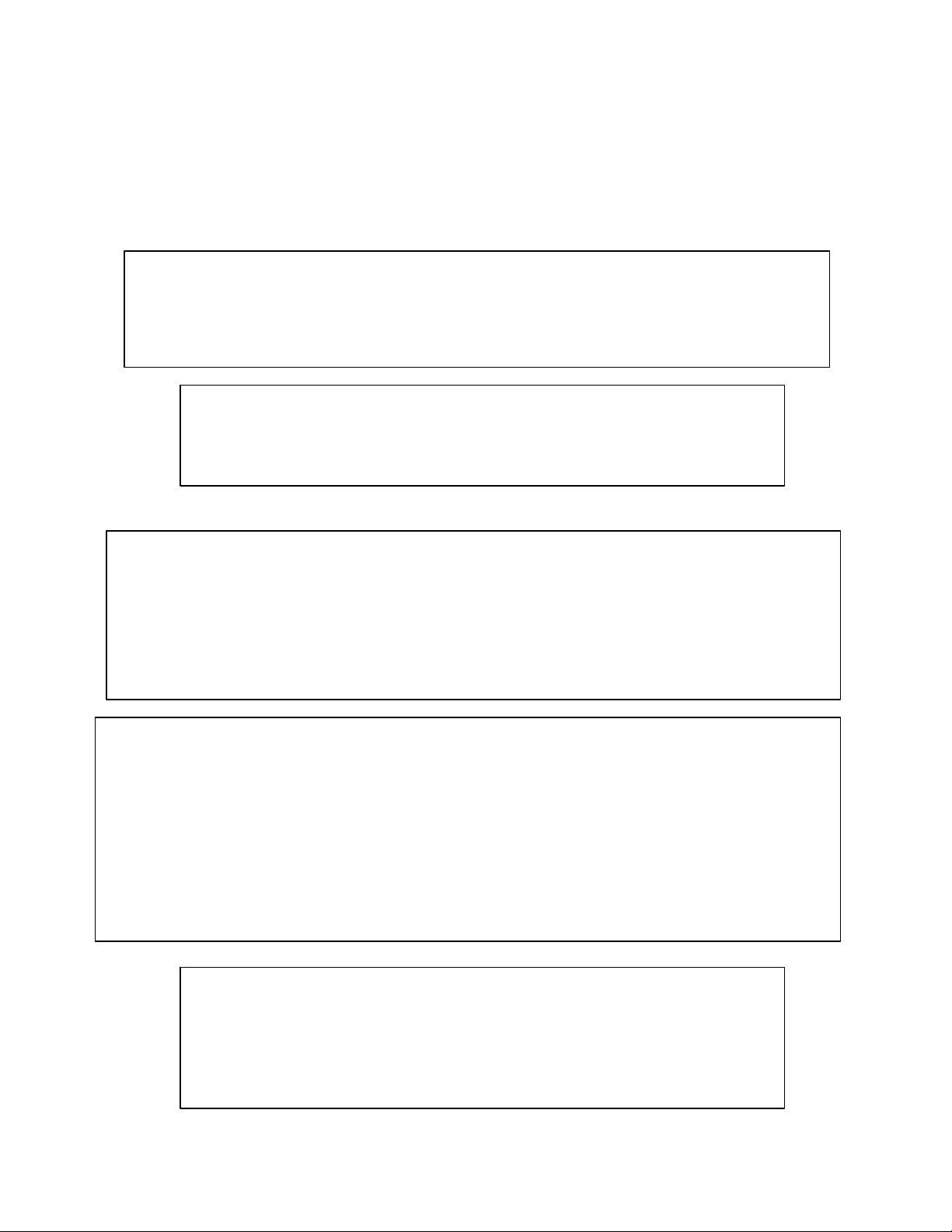

a. Figure 3-1 shows the proper assembly of

these parts:

1. Filter Pan Assembly

2. Protective Screen/Support Grid

3. Filter Paper (2 sheets)

4. Hold-Down Ring

5. Crumb Catcher Screen

6. Filter Pan Cover

Exploded View of a Cascade Filter.

Filter Hose

Nozzle

Holster

Cover

d. Position the hold-down ring on top of the

filter paper and latch the hold-down ring

and filter paper securely against the filter

pan bottom. When positioning the holddown ring, do it evenly around the filter

pan and paper to create a good seal

around the support grid which prevents

any air from getting into the system.

e. Prepare two quarts of precoat/slurry per

precoat manufacturer’s instructions. Pour

the precoat/slurry on the filter paper.

Make sure the filter paper is completely

covered with precoat.

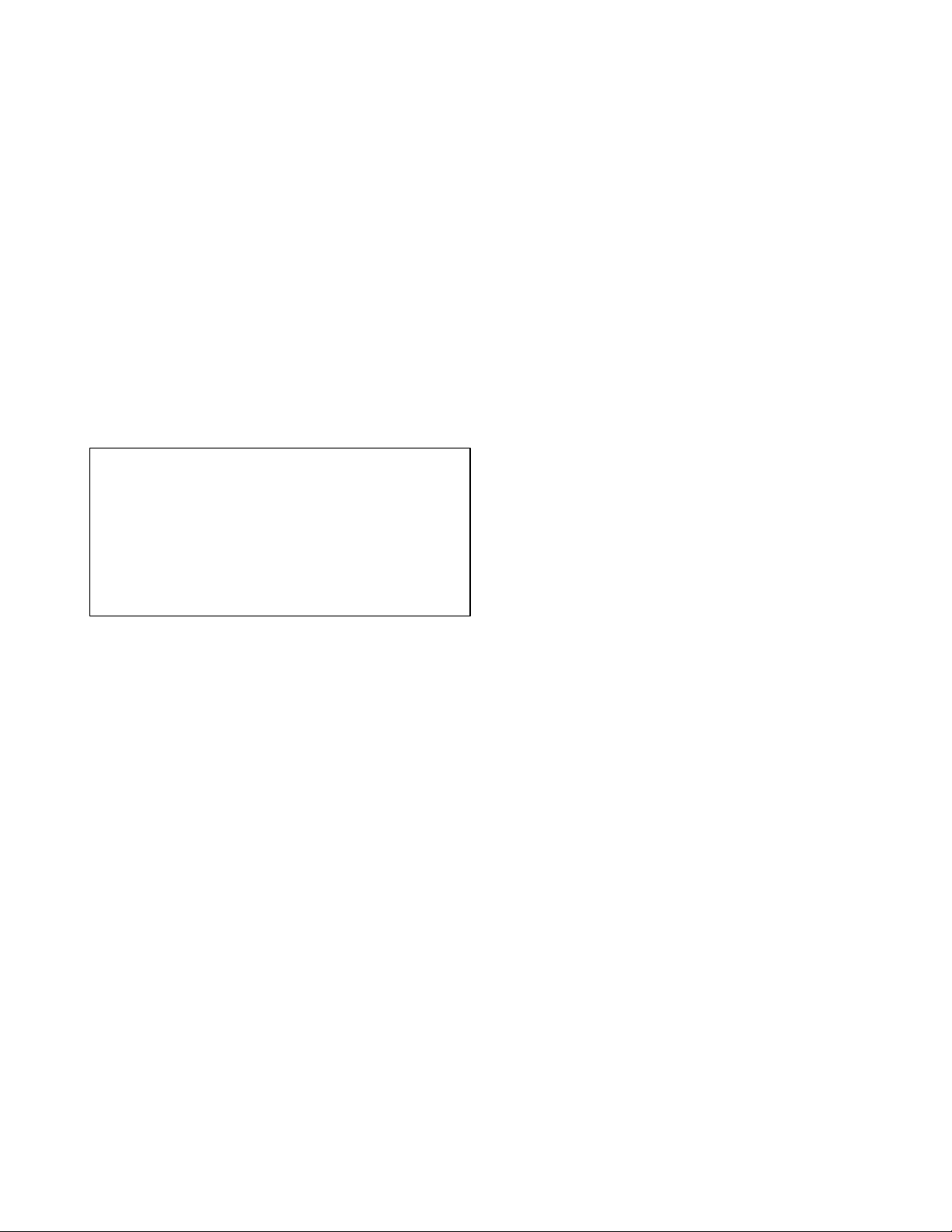

f. Place the crumb catcher screen in the

filter pan. Allow the crumb catcher to

rest on the top edges of the hold-down

ring.

Installing crumb catcher screen.

Crumb

Catcher

Filter Paper (2)

Support

Grid/Screen

Filter Pan

Assembly

Figure 3-1

b. First place the support grid in the bottom

of filter pan. The small box or brackets

under the screen should fit into the space

provided in the bottom of filter pan. Your

Cascade Filter may be equipped also with

a second, smaller support grid screen that

must be placed in the filter pan trough

before the larger support grid/protective

screen is installed.

c. Put two filter paper sheets on top of the

support grid. Be sure the paper covers the

whole filter pan bottom.

Hold-

Down Ring

Figure 3-2

g. Place filter pan cover onto the filter pan

assembly.

h. Roll the filter into position, either inside

the fryer for built-in operations, or

position the filter underneath the fryer

drain valve for portable operations.

i. Prior to connecting the oil return lines,

ensure the filter switch is “OFF” and the

power cord is disconnected from the

power source.

j. Connect the oil return line connector to

the fryer’s oil return line quick disconnect

coupling. Plug the power cord into the

power source.

4

Page 6

3.3 INSTALLING THE FILTER IN

Figure 3-5

THE FRYER:

3.4 INSTALLING THE FILTER

(PORTABLE OPTION):

a. Slide the filter inside the fryer cabinet.

Filter installed inside fryer cabinet.

Figure 3-3

b. Connect the filter’s oil return line (male

quick disconnect) into the quick

disconnect (female) in the fryer’s return

line.

c. Slide filter latching device into the fryer to

lock in-position.

a. Make sure the filter switch is in the “OFF”

position before connecting the power cord

to the power supply.

b. Connect the six foot (6') flexible

hose/nozzle assembly into the filter

discharge line (female into male quick

disconnect). Place the hose in holster and

then connect the flexible power cord to the

power supply.

Insert drain

extension here.

Insert flexible

hose nozzle here.

Latching Device

Figure 3-4

d. Connect the flexible power cord to the

power supply provided in the fryer. The

power supply receptacle is found in the

front, upper left corner of the fryer cabinet

near the front door hinge.

Figure 3-6

c. Roll the filter unit to the fryer to be

filtered.

d. Attach drain valve extension (if needed) to

the fryer’s drain valve. This prevents hot

oil from splattering out of the filter pan.

e. Move the filter unit into position by

aligning the filter pan lid drain port with

the fryer’s drain valve extension.

5

Page 7

4. DAILY OPERATIONS:

Figure 4-1

4.1 GENERAL:

The Cascade Filter is designed to operate as

either a built-in filter unit or as a portable

filter unit. Operations always start by

ensuring the unit is properly plugged in,

then rolling the filter to the fryer to be

filtered. The filter will work directly under

the fryer’s drain valve.

CAUTION

ALWAYS USE INSULATED GLOVES

DURING THE WHOLE FILTERING

PROCESS.

DO NOT ALLOW WATER TO PASS

THROUGH THE PUMP, OTHERWISE

THE WARRANTY WILL BE VOID.

DRY FILTER UNIT AND ACCESSORIES

THOROUGHLY AFTER CLEANING,

RESIDUAL WATER WILL CAUSE

SPLATTERING OF HOT OIL AND MAY

CAUSE SEVERE BURNS.

4.2 FILTERING TOOLS:

These tools are not required, but are

recommended to make the filtering task

easier.

a. One-gallon aluminum pitcher or

bucket: Used for mixing pre-coat to

make slurry; also for dumping oil into

fryer to flush out debris.

b. Remove the filter pan cover and crumb

screen.

c. Visually inspect the filter paper. Scrape

debris off the filter paper. If the filter

paper appears scuffed or darkened,

replace the filter paper per instructions

found in Section 4.4 of this manual.

d. Prepare slurry/pre-coat solution per

instructions provided by the pre-coat

manufacturer. Pour the mixture onto

the filter paper in the filter tank. Make

sure the top filter paper sheet is

completely covered.

e. Now re-install the crumb catcher.

Allow the crumb catcher to rest on top

of the hold-down ring.

f. Place filter pan cover on top of the filter

pan and slide the Cascade Filter into the

fryer. Next turn the main power switch

on the fryer to the “OFF” position.

Then connect the filter return line

connector into the quick disconnect in

the fryer return line. Plug the filter

power cord connector into the

receptacle provided on the fryer.

4.4 CHANGING FILTER PAPER:

The filter paper should be discarded when

it becomes dark or scuffed in appearance.

Follow this procedure:

Removing the Filter Pan Cover.

b. Whip: Used for mixing slurry.

c. Measuring Cup: Used to measure

sixteen (16) ounces by volume of precoat.

d. Gloves: Used to expedite filtering and

prevent burns from splashing oil.

4.3 FILTER PREPARATION:

a. Pull the filter unit from underneath the

fryer.

a. Remove filter cover and crumb catcher

screen. See figure 4-1.

6

Page 8

b. Open the locking clips of the hold-

Hold-down ring locking clips.

Installing hold-down ring.

Figure 4-3

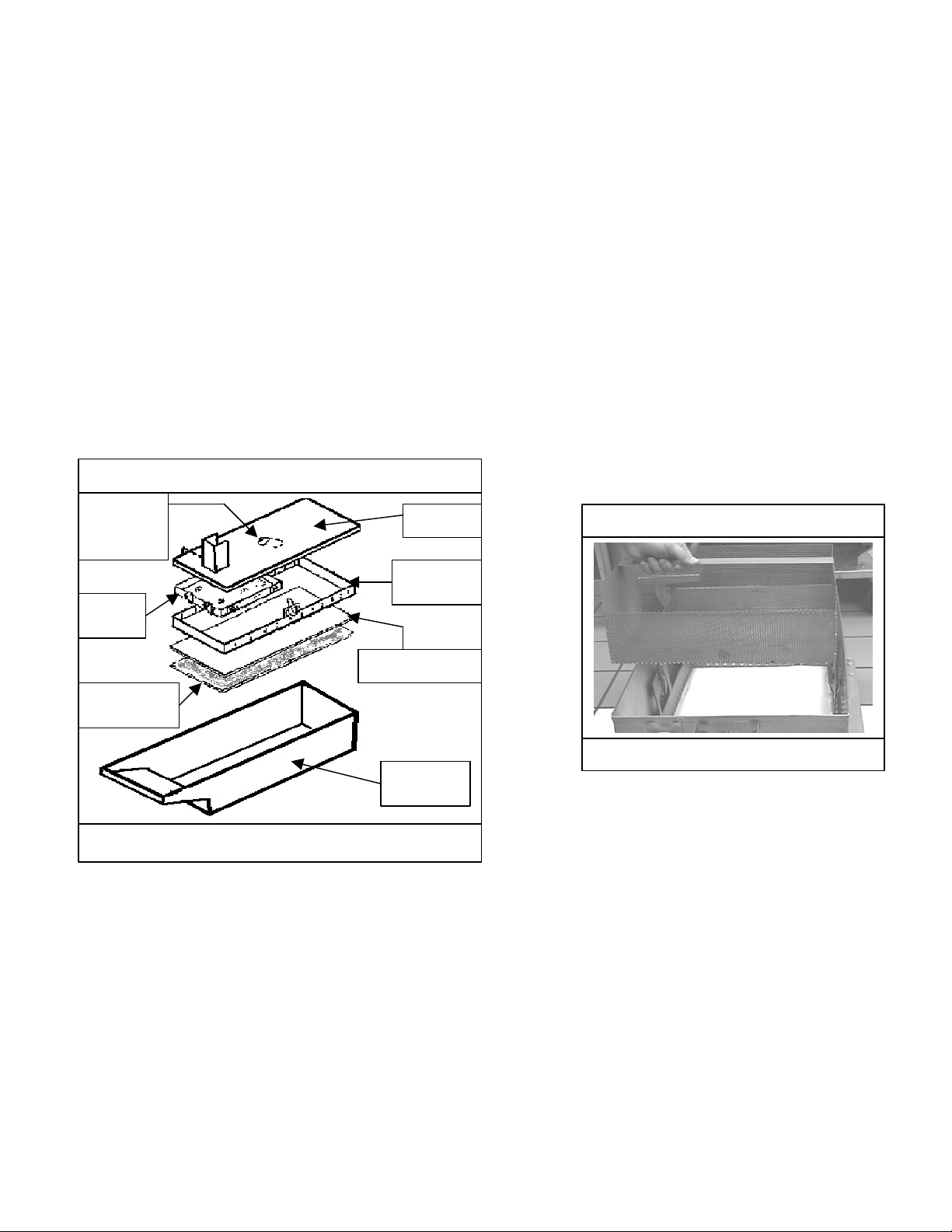

Built-in Filter Operations (Cut-away)

Pump

Fryer Vessel

Filter Paper (2)

Oil

Drain

Cascade

Heating

down ring and lift the ring out of the

filter tank.

Figure 4-2

c. Roll both ends of the used (top) sheet

of paper into the center, making sure

no sediment falls out and discard.

d. Remove and check the protection

screen for cleanliness and scrub if

necessary.

e. Check the filter pan for cleanliness and

scrub if necessary; check the drain

ports at the bottom rear of the filter

pan also.

f. Replace the bottom protection screen

and place a new sheet of filter paper on

top.

Valve w/

Extension

Filter

Figure 4-4

4.5 BUILT-IN OPERATIONS:

Figure 4-4 shows the flow of oil during

built-in operations. When filtering, follow

these steps:

a. Unlock the latching device on the filter

and disconnect filter from fryer. See

Sections 4.3 and 4.4 to prepare the

filter paper. Once filter paper is

prepared, re-install the filter unit.

Tubes

Return

Line

g. Replace the hold-down ring and

secure.

h. Replace crumb catcher and cover.

CAUTION

MAKE SURE QUICK DISCONNECTS ARE

PROPERLY CONNECTED OR SERIOUS

INJURY MAY OCCUR. SLIDE LATCHING

DEVICE INTO LOCK POSITION, THEN

TURN SWITCH ON FILTER TO “ON”

POSITION OR PUMP POSITION IF

PROVIDED WITH A HEATER.

b. When using solid shortening, before

filtering, turn the filter switch to the

heater position for a few minutes in

7

Page 9

order to melt the solid shortening in

SPRAY HOT OIL.

Figure 4-5

Fryer Vessel

Filter

Pump

Drain

Extension

Quick

Portable Filtration System

the pump lines.

c. Turn the power switch on the fryer to

the “OFF” position.

Fryer Power SwitchFilter Power Switch

WARNING!

DO NOT LEAVE A FILTER

MACHINE UNATTENDED DURING

OPERATION. THE ACTION OF THE

OIL MOVING THROUGH THE LINES

COULD CAUSE A FLEXIBLE

RETURN HOSE TO POP LOOSE AND

g. Push on the drain valve handle to close

it. It takes approximately 5 to 7

minutes for the filter to pump all the

oil back into the fryer.

h. Turn filter switch on the fryer to the

“OFF” position after all the oil has

been pumped back into the fryer.

Allow the pump to run for 10 – 15

seconds after air bubbles appear in the

fryer vessel before shutting off to clear

shortening/oil from the return lines.

WARNING!

THE OIL TEMPERATURE OF THE

FRYER TO BE FILTERED SHOULD BE

AROUND 350°F (175°C). AT ALL TIMES

HOLD THE FLEXIBLE HOSE NOZZLE

IN THE FRYING VESSEL OR SECURED

IN THE FILTER PAN PRIOR TO

OPERATING ANY SWITCHES OR

VALVES. FAILURE TO DO THIS CAN

RESULT IN SEVERE BURNS.

NOTE: AFTER FILTERING IT MAY BE

NECESSARY TO SCRAPE OFF ALL OF THE

DEBRIS ACCUMULATED ON TOP OF THE

FILTER PAPER AND DISCARD.

d. Open the fryer door and be sure that

the filter is in the proper position

under the fryer drain valve.

e. To open the drain valve, pull the

handle out and allow all the oil in the

fryer to drain into the filter pan.

CAUTION

DO NOT DRAIN MORE THAN ONE

FRYER INTO THE FILTER PAN TO

AVOID SERIOUS SPILLING OF HOT

OIL ONTO THE FLOOR.

f. Turn filter switch “ON” to begin

pumping clean oil into the fryer; allow

the oil to flow for a few seconds to

wash out sediment on the bottom of

the cooking vessel before closing the

drain valve.

Oil

Return

Hose

Disconnect

Valve

with

Arrows show

direction of oil

flow.

Figure 4-6

8

Page 10

CAUTION

WARRANTY.

OPERATING THE BURNERS

WITHOUT OIL IN THE FRYER

VESSEL WILL CAUSE DAMAGE TO

THE FRYER AND VOID THE

4.6 PORTABLE FILTER

OPERATION:

Figure 4-6 shows the oil flow during

portable filter operations. Follow these

instructions for portable operations:

Turn the pump on and return the

remaining oil to the fryer.

h. When there is no more oil coming out

of the hose nozzle, allow the pump to

run an additional 10-15 seconds before

turning the pump off. This will allow

the pump to clear the oil return lines

and the hose assembly of remaining oil

or shortening.

i. Disconnect the hose nozzle assembly

and hang up the assembly to allow it to

dry.

a. Prepare a precoat/slurry per the pre-coat

manufacturer’s instructions.

b. Turn “OFF” fryer to be filtered. Pour

the mixture onto the filter pad.

c. Remove filter lid cover and position the

filter pan under the fryer drain valve,

then install drain extender. Attach

return hose.

d. Open the drain valve and drain fryer oil

into the filter. If there is an abundance

of sediment in the fryer, put a strainer

under the drain valve to remove these

particles before they get into the filter

pan. This will conserve filter paper and

shorten filtering time.

e. Hold return hose in the fryer vessel,

then turn the filter pump on. Wash all

remaining sediment from the fryer into

the filter with the hot oil return hose.

f. Shut the drain valve and return the oil

to fryer.

g. When pumping oil back into the last

fryer, turn the filter off and direct the

hose nozzle back into the filter when

about one inch of oil remains in the

filter pan. Turn the filter back on and

use this hot oil to flush sediment from

bottom corners and side walls of the

filter pan. Once finished flushing the

filter pan, turn the filter off and direct

the hose nozzle back into the fryer.

j. Remove the filter pan cover and scrape

any solid matter from the filter paper.

k. Wipe the filter pan dry with dry

toweling.

l. Replace cover onto the filter pan and

store filter unit.

4.7 OPERATING PROBLEMS:

Plugged lines and plugged filter paper

account for over ninety percent of

malfunctions. The troubleshooting

flowcharts found in Chapter 6 can provide

a step-by-step guide to correct these and

other common malfunctions.

a. PLUGGED LINES:

1. If you are using solid shortening

and the filter is operated

improperly, the motor may shut off

before the hot oil is completely

pumped back into the fryer and

solidification of the oil in the lines

could occur as the oil cools. The

illustrations in Figures 4-4 and 4-6

show the path of oil in a filter

circuit for the portable and built-in

operational modes.

2. Oil drains from the fryer vessel into

the filter pan, then it is drawn

through the filter paper, exits the

pan through the ports on the filter

pan bottom, then flows through a

rigid tube to the filter pump. From

9

Page 11

the pump, oil returns to the fryer

through the flexible oil return hose

or the internally-plumbed oil return

line in the fryer.

3. A solid shortening plug can exist

anywhere in this path; locate the

plug using the procedures found in

Chapter 6, Troubleshooting Guide.

4. To guard against plugged lines when

using solid shortening, follow these

guidelines:

a. If your filter is equipped with a

pan heater, use it every time you

filter.

b. Also, at the end of the filtering

cycle, let the filter flow bubbles

into the fryer through the

flexible hose for about ten

seconds. If it is blowing

bubbles, air is moving through

the lines and they cannot be

plugged.

c. When filtering is completed,

always disconnect the flexible

line and hang it up to drain.

b. PLUGGED PAPER: Improper use of

the filter pre-coat powder will cause a

slow oil flow return rate. The filter

paper should at least be scraped (if not

discarded) after filtering a particularly

dirty fryer. First indication of paper

plugging is a surging, jerking movement

of the hose. To correct, check the

instructions for the right use of powders

and scrape the filter paper more

frequently. Also review procedures

found in Chapter 6, Troubleshooting

Guide.

10

Page 12

5. CLEANING & MAINTENACE

5.1 GENERAL:

Cleaning operations fall into three general

categories:

a. The continuing habit of clean-up every

time the filter unit is used;

b. The daily clean-up at the close of each

business day;

c. And, a more thorough weekly cleaning.

5.2 EACH FILTER USE:

Every time your Cascade Filter System is

used:

a. Wash down the sides of the filter pan with

hot oil.

b. Scrape and possibly change the top sheet

of filter paper. Always scrape sediment

and debris from the paper when the

system is warm; this prolongs the life of

the paper.

c. Wipe up any oil which may have splashed

or spilled.

d. Wipe all exterior surfaces of the filter unit.

5.3 DAILY-CLOSE OF BUSINESS:

One of the last orders of business at the close

of a working day should be to filter the oil in

all fryers. When the last fryer is finished,

follow these steps:

c. Remove the filter pan cover, the crumb

catcher (if equipped) and hold-down ring

assembly; then take out the paper and

protection screen.

d. Wash all of removed items with soapy

water.

e. Clean the filter pan with a dry towel.

f. Be sure that all items have been dried

thoroughly before reassembling.

5.4 WEEKLY:

Follow the same procedure as for “DAILY”,

with these additional steps:

a. Check the connections of the inlet lines.

Tighten if the inlet lines become loose or

start to leak oil.

b. Wash the filter pan with hot, soapy water

and a brush. Dry and reassemble with

new filter paper.

c. Clean thoroughly under, around, and

behind the fryers and filtering area.

d. Avoid getting water inside the

motor/pump housing when washing the

filter pan.

WARNING!

a. If used as a portable filter, run the filter

pump for an additional 10 – 15 seconds

after air bubbles come out of the filter

hose nozzle before shutting “OFF”.

Keep the filter hose pointed down into

the last fryer’s fryer vessel until done.

This should clear the hose line of any

remaining oil or shortening.

b. Remove the filter unit from the fryer.

Scrape the top piece of filter paper.

Replace filter paper if it is scuffed or

dark.

DO NOT RUN WATER THROUGH THE

FILTERING SYSTEM AS PART OF THE

CLEANING PROCESS. THE FILTER

PUMP IS NOT DESIGNED TO HANDLE

WATER. THIS WILL VOID THE

WARRANTY FOR THAT SYSTEM,

HASTEN PUMP FAILURE AND CAUSE

ACCIDENTS IF WATER MIXES WITH

HOT OIL.

11

Page 13

6. TROUBLESHOOTING GUIDE

CIRCUIT WILL BE EXPOSED.

These troubleshooting procedures help locate the most

encountered problems and will give possible

solutions/corrective action to be taken.

To use these flowcharts, start at the top of the

diagram. Follow each step in sequence.

DANGER!

USE EXTREME CARE DURING

ELECTRICAL CIRCUIT TESTS. LIVE

Filter Pump Fails to Pump Oil?

Filter Pump

fails to pump oil.

Does

your filter have a

heater?

No

If the answer to a question is “yes”, proceed

downward to the next step.

If the answer is “no”, follow the arrow to the right

and follow the next step. Arrows direct the

troubleshooter through the sequence.

WARNING

INSPECTION, TESTING, AND REPAIR

OF GAS OR ELECTRICAL EQUIPMENT

SHOULD BE PERFORMED BY

QUALIFIED PERSONNEL.

Yes

Turn heater "ON"

and run heater

for 15 minutes.

Then insert flexible oil

return hose into the

filter pan holster. Turn

pump motor "ON".

Does oil

flow?

Yes

No

Submerge hose into hot water

(over 120 degrees F). Keep both

ends out of the water. If water

gets into the hose, the water will

cause severe splattering when

hose is reconnected to the filter.

Once shortening has

softened, reconnect

the flexible oil return

hose to the filter.

No

Disconnect flexible oil

return hose. Make sure it

is cool before handling.

Try blowing air through it.

Can you

blow air through

it?

Yes

Conduct normal

filter operations.

Insert flexible oil return

hose into the filter pan

holster. Turn pump

motor "ON".

Yes No

Does oil

flow?

12

Blockage is between

the bottom of the filter

pan and the flex hose

valve. Go to page 14.

Page 14

Rate of oil

return to the fryer

is slowing.

Rate of Oil Return to Fryer Slows?

Is this the

first fryer to be filtered

during this filtering

session?

Yes

Check the filter

paper in the filter

pan.

Is the filter

paper properly secured

by the hold down

ring?

Yes

Paper may be

plugged by improper

use of precoat/slurry.

Change the filter paper.

Throw away the old top

sheet and use the old

bottom sheet as the new top

sheet.

Check the filter sump.

No

No

Sediment collects

around the suction pipe

in the filter bottom.

Paper may not be

secured by the hold down

ring. Air is being allowed

to get into the system.

Remove the filter

pan cover.

Unlatch hold-down ring and

remove the filter paper and

filter paper support grid.

Clean support grid

and set aside

temporarily.

Wipe sediments

out of the bottom

of the filter pan.

Inspect drain ports at the

bottom rear of the filter pan

and remove any sediment

or visible blockages.

Take a new sheet and

place it in the bottom

of the pan. Place the

new top sheet over it.

Secure the filter

papers by latching

the hold down ring.

Pour slurry over new filter

papers.

13

Reassemble the filter

pan assembly. Turn

the pump motor "ON".

Has

the oil return rate

improved?

Yes

Conduct normal

filter operations.

Blockage may be

No

between the filter pan

bottom and the flex

hose valve.

Go to flowchart titled

"Blockage between

Filter Pan and Flex Hose

Valve" on page 14.

Page 15

Blockage between Filter Pan and Flex Hose Valve?

Blockage has been

determined to be between

the filter pan bottom and

the flex hose valve.

Check wall circuit

breaker.

If wall circuit breaker has

tripped, turn heater "OFF".

Reset wall circuit breaker.

Verify power cord is

connected to the outlet.

No

heater "ON". Does

the suction line feel

The heater is working

Does your

filter have a

heater?

Yes

Turn the

warm?

Yes

properly.

No

Turn the heater "OFF".

Disconnect oil line from the

filter pan to the pump at the

pump end.

Put finger over the inlet

connection to the pump.

Turn heater "ON".

If the suction line fails to

warm, the heater is faulty.

Contact your local

Factory Authorized

Service Center!

14

Check filter circuit breaker.

Push the circuit breaker

reset button.

Pump motor is clogged or

faulty.

Contact your local

Factory Authorized

Service Center.

Turn the pump "ON".

No

No

Pump is clear of any

Does the pump

motor run?

Yes

Do you feel

suction?

Yes

blockages.

Page 16

Dean, 8700 Line Avenue, Shreveport, Louisiana 71135

TEL 1-318-865-1711 FAX (Parts) 1-318-219-7140 (Tech Support) 1-318-219-7135

PRINTED IN THE UNITED STATES

SERVICE HOTLINE

1-800-551-8633

Price: $6.00

819-5666 07-98

Loading...

Loading...