Page 1

BIGLA30 Series

LOV™ Gas Fryer

Parts Manual

This manual is updated as new information and models are released. Visit our website for the latest manual.

This equipment chapter is to be installed in the Fryer Section of the

FOR YOUR SAFETY

Do Not Store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

*8197259*

Part Number: FRY_P_8197259 10/2016

Equipment Manual

.

Page 2

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS MANITOWOC FOOD

SERVICE EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED PART PURCHASED

DIRECTLY FROM FRYMASTER DEAN, OR ANY OF ITS AUTHORIZED SERVICE CENTERS, AND/OR THE

PART BEING USED IS MODIFIED FROM ITS ORIGINAL CONFIGURATION, THIS WARRANTY WILL BE

VOID. FURTHER, FRYMASTER DEAN AND ITS AFFILIATES WILL NOT BE LIABLE FOR ANY CLAIMS,

DAMAGES OR EXPENSES INCURRED BY THE CUSTOMER WHICH ARISE DIRECTLY OR INDIRECTLY, IN

WHOLE OR IN PART, DUE TO THE INSTALLATION OF ANY MODIFIED PART AND/OR PART RECEIVED

FROM AN UNAUTHORIZED SERVICE CENTER.

NOTICE

This appliance is intended for professional use only and is to be operated by qualified personnel only. A

Frymaster DEAN Authorized Service Agency (ASA) or other qualified professional should perform

installation, maintenance, and repairs. Installation, maintenance, or repairs by unqualified personnel may

void the manufacturer’s warranty.

NOTICE

This equipment must be installed in accordance with the appropriate national and local codes of the

country and/or region in which the appliance is installed. Refer to the operators manual.

NOTICE TO U.S. CUSTOMERS

This equipment is to be installed in compliance with the basic plumbing code of the Building Officials and

Code Administrators International, Inc. (BOCA) and the Food Service Sanitation Manual of the U.S. Food

and Drug Administration.

NOTICE

Drawings and photos used in this manual are intended to illustrate operational, cleaning and technical

procedures and may not conform to onsite management operational procedures.

NOTICE TO OWNERS OF UNITS EQUIPPED WITH COMPUTERS

U.S.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions:

1) This device may not cause harmful interference, and 2) This device must accept any interference

received, including interference that may cause undesired operation. While this device is a verified Class

A device, it has been shown to meet the Class B limits.

CANADA

This digital apparatus does not exceed the Class A or B limits for radio noise emissions as set out by the

ICES-003 standard of the Canadian Department of Communications.

Cet appareil numerique n’emet pas de bruits radioelectriques depassany les limites de classe A et B

prescrites dans la norme NMB-003 edictee par le Ministre des Communcations du Canada.

WARNING

To ensure the safe and efficient operation of the fryer and hood, the electrical plug for the 120-volt line,

which powers the hood, must be fully engaged and locked in its pin and sleeve socket.

DANGER

No structural material on the fryer should be altered or removed to accommodate placement of the fryer

under a hood. Questions? Call the Frymaster Dean Service Hotline at 1-800-551-8633.

NOTICE

The instructions in this manual for using a bulk oil system for filling and discarding oil are for an RTI

system. These instructions may not be applicable to other bulk oil systems.

Page 3

WARNING

After installation of a gas fryer and after any maintenance to the gas system of a gas fryer-manifold, valve,

burners, etc. – check for gas leaks at all connections. Apply a thick soapy solution to all connections and

ensure there are no bubbles. There should be no smell of gas.

DANGER

Improper installation, adjustment, maintenance or service, and unauthorized alterations or modifications

can cause property damage, injury, or death. Read the installation, operating, and service instructions

thoroughly before installing or servicing this equipment. Only qualified service personnel may convert

this appliance to use a gas other than that for which it was originally configured.

DANGER

Adequate means must be provided to limit the movement of this appliance without depending upon the

gas line connection. Single fryers equipped with legs must be stabilized by installing anchor straps. All

fryers equipped with casters must be stabilized by installing restraining chains. If a flexible gas line is

used, an additional restraining cable must be connected at all times when the fryer is in use.

DANGER

The front ledge of the fryer is not a step! Do not stand on the fryer. Serious injury can result from slips

or contact with the hot oil.

DANGER

Do not store or use gasoline or other flammable liquids or vapors in the vicinity of this or any other

appliance.

DANGER

Instructions to be followed in the event the operator smells gas or otherwise detects a gas leak must be

posted in a prominent location. This information can be obtained from the local gas company or gas

supplier.

DANGER

This product contains chemicals known to the state of California to cause cancer and/or birth defects or

other reproductive harm.

Operation, installation, and servicing of this product could expose you to airborne particles of glasswool

or ceramic fibers, crystalline silica, and/or carbon monoxide. Inhalation of airborne particles of glasswool

or ceramic fibers is known to the State of California to cause cancer. Inhalation of carbon monoxide is

known to the State of California to cause birth defects or other reproductive harm.

DANGER

The crumb tray in fryers equipped with a filter system must be emptied into a fireproof container at the

end of frying operations each day. Some food particles can spontaneously combust if left soaking in

certain shortening material.

WARNING

Do not bang fry baskets or other utensils on the fryer’s joiner strip. The strip is present to seal the joint

between the fry vessels. Banging fry baskets on the strip to dislodge shortening will distort the strip,

adversely affecting its fit. It is designed for a tight fit and should only be removed for cleaning.

Page 4

BIGLA30 SERIES LOV™ GAS FRYERS

PARTS MANUAL

TABLE OF CONTENTS

CHAPTER 1: Parts List

1.1 Accessories .................................................................................................................................................................................. 1-1

1.2 Doors, Sides, Flue Caps, Cap-N-Splash, Top Caps and Casters .................................................................................. 1-2

1.3 Drain Valves and Associated Parts ...................................................................................................................................... 1-3

1.3.1 Linear Actuator Drain Valves ........................................................................................................................... 1-3

1.3.2 Rotary Actuator Drain Valve ............................................................................................................................. 1-3

1.4 Drain Tube Sections and Associated Parts ....................................................................................................................... 1-4

1.5 Electronics and Electrical Components ............................................................................................................................. 1-5

1.5.1 High-Limit Thermostat and Temperature Probe ...................................................................................... 1-5

1.5.2 Component Boxes ............................................................................................................................................... 1-5

1.5.3 Transformer Boxes .............................................................................................................................................. 1-7

1.5.4 Computers and Associated Components ................................................................................................... 1-8

1.6 Wiring ............................................................................................................................................................................................ 1-9

1.6.1 Main Wiring Harnesses ...................................................................................................................................... 1-9

1.6.2 Miscellaneous Wiring ...................................................................................................................................... 1-10

1.6.3 M3000, MIB, AIF and ATO Wiring Harnesses ........................................................................................... 1-10

1.7 Frypots and Associated Components ............................................................................................................................. 1-11

1.7.1 Full-Vat Frypot Components ........................................................................................................................ 1-11

1.7.2 Dual-Vat Frypot Components ...................................................................................................................... 1-13

1.7.3 Frypot Assemblies and Associated Parts .................................................................................................. 1-15

1.7.3.1 Frypots with Linear Actuators ........................................................................................................ 1-15

1.7.3.2 Frypots with Rotary Actuators ........................................................................................................ 1-16

1.8 Oil Return Manifolds ............................................................................................................................................................. 1-17

1.9 Return Valves and Associated Components ................................................................................................................. 1-17

1.10 Gas Supply and Combustion System Components ................................................................................................... 1-18

1.11 Gas Valves and Associated Components ....................................................................................................................... 1-20

1.12 Filtration System Components ......................................................................................................................................... 1-22

1.13 Auto Intermittent Filtration Components ..................................................................................................................... 1-23

1.13.1 LOV Indicator Light and MIB Assembly .................................................................................................... 1-23

1.13.2 AIF (Automatic Intermittent Filtration) Linear Actuator Board Assembly ..................................... 1-24

1.14 ATO (Automatic Top-Off) Components .......................................................................................................................... 1-24

1.14.1 JIB Cradle, JIB Cap and Pick-Up Assembly and ATO(Automatic Top-Off) Board ......................... 1-24

1.14.2 ATO Pump Assembly ....................................................................................................................................... 1-25

1.14.3 ATO Pump Assembly Larger Lines .............................................................................................................. 1-26

1.14.4 Shortening Melting Unit ................................................................................................................................ 1-27

1.15 RTI System Components ....................................................................................................

1.15.1 RTI Dispose Waste Valve and Test Box ...................................................................................................... 1-28

1.15.2 RTI Manifold and Accessories prior to Oct 2010 .................................................................................... 1-28

1.15.3 RTI Manifold and Accessories after Oct 2010 .......................................................................................... 1-30

1.16 Oil Quality Sensor (OQS) and Associated Parts ............................................................................................................ 1-32

................................................. 1-28

i

Page 5

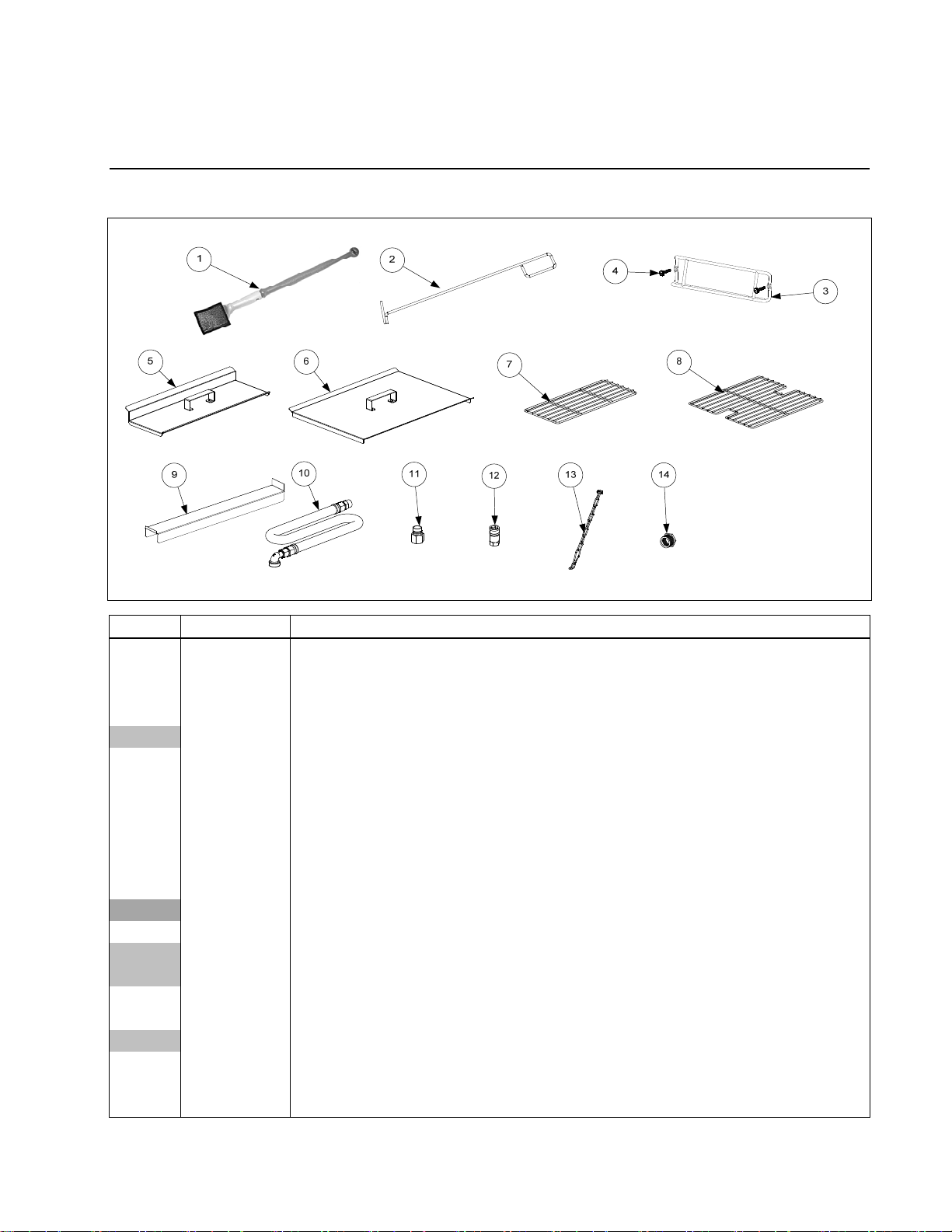

1.1 Accessories

BIGLA30 SERIES LOV™ GAS FRYERS

CHAPTER 1: PARTS LIST

ITEM PART # COMPONENT

1 8030430 Brush, Frypot Ecolab

2 8030388 Fryers Friend LOV™

3 8102793 Hanger, Basket

4 8090171

8090402 Thumbscrew, ¼ -20 X ½-inch Cap-N-Splash Hood

5 1068931 Cover, Frypot, Dual Vat

6 1068930 Cover, Frypot, Full Vat

* 8260993SP Handle Kit, Frypot Cover (includes handle and screws)

7 8030372 Basket Support Rack, Dual Vat

8 8030375 Basket Support Rack, Full Vat

* 8030136 Basket Support Screen, Full Vat (screen w/handle used in place of Item 8)

9 2302975

1086156SP

10 8100478 Gas Line, 1-Inch Dormont Flexible

8061698SP 36-Inch (for gas line only (w/o Items 11 and 12), use 8100088)

8061699 48-Inch (for gas line only (w/o Items 11 and 12), use 8100085)

11 8100074 Quick-Disconnect Fitting, 1-Inch Male

12 8100073 Quick-Disconnect Fitting, 1-Inch Female

8103745 Quick Disconnect Fittings, ¾-inch set (includes male and female connectors)

13 8260900 Kit, Chain Restraint

14 8261045 Bushing, Flexible Gas Line (8130032)

* 8261157 Kit, Fuse and Fuse Puller (2 Fuses)

* Not illustrated.

Thumbscrew, ¼-20 X 1⅜-inch Universal Hood (use 8090921 for Spacer)

Connecting Strip, Frypot prior to 07/2014

Connecting Strip, Frypot after 06/2014

1-1

Page 6

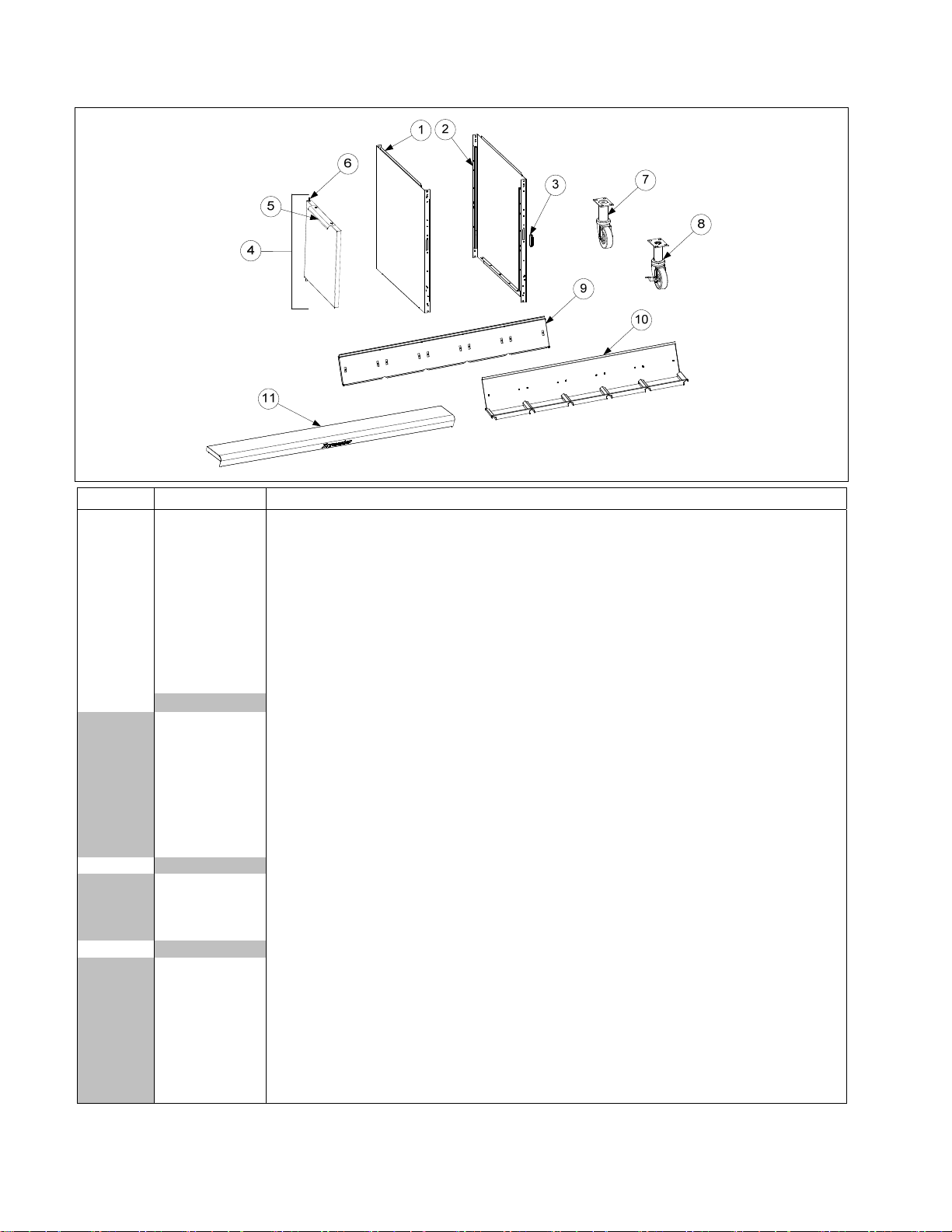

1.2 Doors, Sides, Flue Caps, Cap-N-Splash, Top Caps and Casters

ITEM PART # COMPONENT

1 2317908 Side, Standard Cabinet Left SS (use 2210323 for Enameled Steel)

2 2327908 Side, Standard Cabinet Right SS (use 2220323 for Enameled Steel)

3 8101105 Magnet, Door (vertical) (use 8102346 for horizontal over filter pan)

4 1064397 Door, Left or Right (move handle to bottom for right) (use 1080915 for Door w/ Manual Holder)

5 2304960 Handle, Eurolook Door

6 1064067SP Pin Assembly, Door

* 8100275 Spring, Door Pin

* 8090970 Retaining Ring

* 2307192 Hinge, Door Lower

7 8100327 Caster without Brake

8 8100944 Caster with Brake

9

8237656

8238926

8237657

8238927

8237658

8238928

8238064

8238930

Flue Cap-Stainless Steel (Use Aluminized steel with Cap-N-Splash)

Two Station (8236666 for Alz Steel)(Use 2302635 for Hood Strip) prior to 07/2014

Two Station(8239031 for Alz Steel)(Use 2302635 for Hood Strip) after 06/2014

Three Station (8236681 for Alz Steel) (Use 2302405 for Hood Strip) prior to 07/2014

Three Station (8239032 for Alz Steel)(Use 2302405 for Hood Strip) after 06/2014

Four Station (8236680 for Alz Steel) (Use 2302636 for Hood Strip) prior to 07/2014

Four Station (8239033 for Alz Steel)(Use 2302636 for Hood Strip) after 06/2014

Five Station (8238100 for Alz Steel) (Use 2302637 for Hood Strip) prior to 07/2014

Five Station(8239034 for Alz Steel)(Use 2302637 for Hood Strip) after 06/2014

10 Cap-N-Splash Assemblies

8237659 Two Station Fryer

8237660 Three Station Fryer

8237661 Four Station Fryer

8238101 Five Station Fryer

11 Top Cap (Cap for 5-staion fryer shown)

1081522

1086158SP

1081523

1086159SP

1081524

1086160SP

1083030

1086161

Two Station Fryer prior to 07/2014

Two Station Fryer after 06/2014

Three Station Fryer prior to 07/2014

Three Station Fryer after 06/2014

Four Station Fryer prior to 07/2014

Four Station Fryer after 06/2014

Five Station Fryer prior to 07/2014

Five Station Fryer after 06/2014

* Not illustrated.

1-2

Page 7

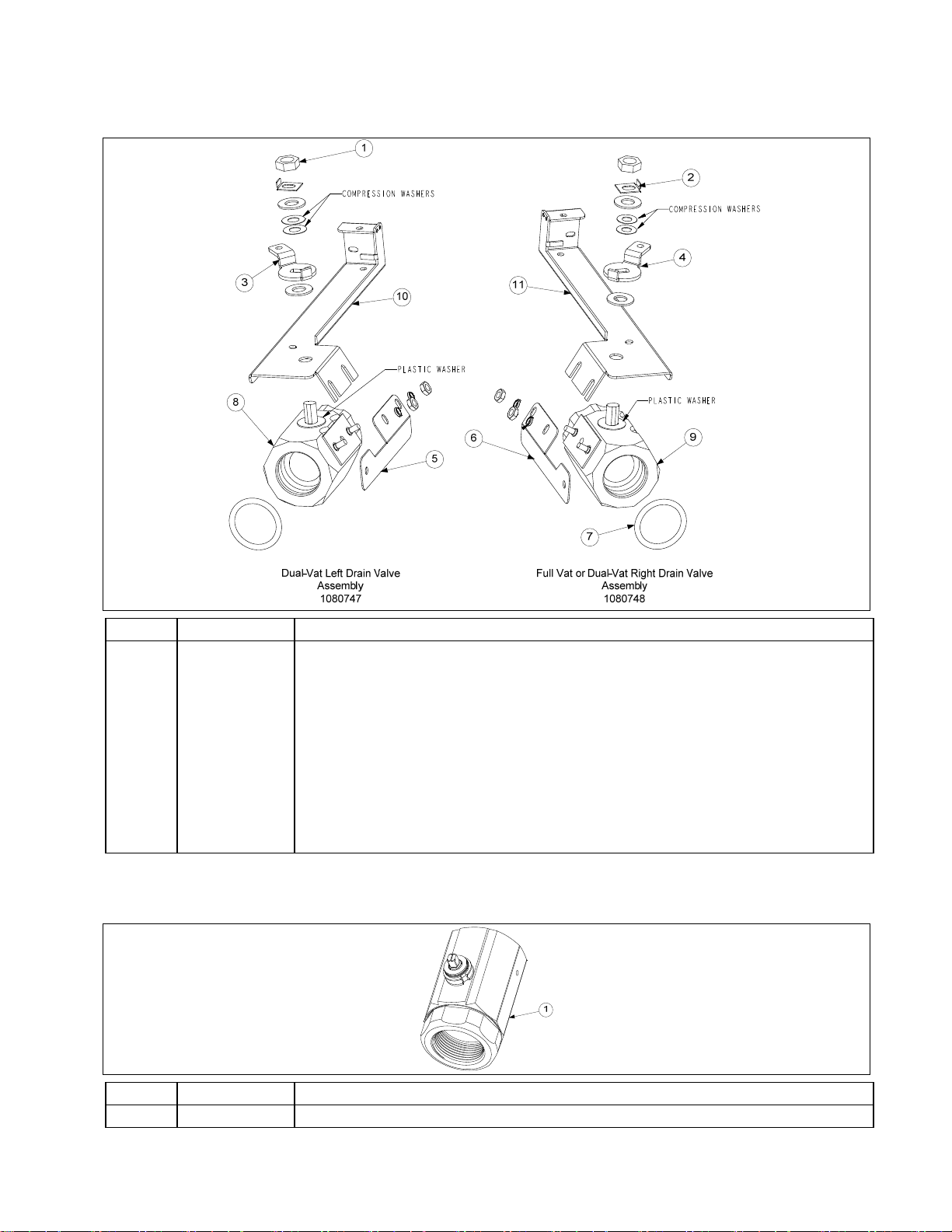

1.3 Drain Valves and Associated Parts

1.3.1 Linear Actuator Drain Valves

ITEM PART # COMPONENT

1 8090540 Nut, ½-13 2-Way Hex Lock

2 9002936 Retainer, Nut Drain Valve

3 2316294 Handle, Drain Valve DV Left

4 2326294 Handle, Drain Valve FV or DV Right

5 2216306 Bracket, Drain Valve Lt.

6 2226306 Bracket, Drain Valve Rt.

7 8160544 O-Ring, Round Drain Seal

8 8237230

9 8237231

Valve, 1¼-inch Drain Lt. (02/2010-04/2012)

Valve, 1¼-inch Drain Rt. (02/2010-04/2012)

10 8242146 Mount, Stud Drain Actuator Gas Lt.

11 8242147 Mount, Stud Drain Actuator Gas Rt.

1.3.2 Rotary Actuator Drain Valves

ITEM PART # COMPONENT

1 8103755

Valve, 1¼-inch NPT Rotary Actuator

(05/2012 – Present)

1-3

Page 8

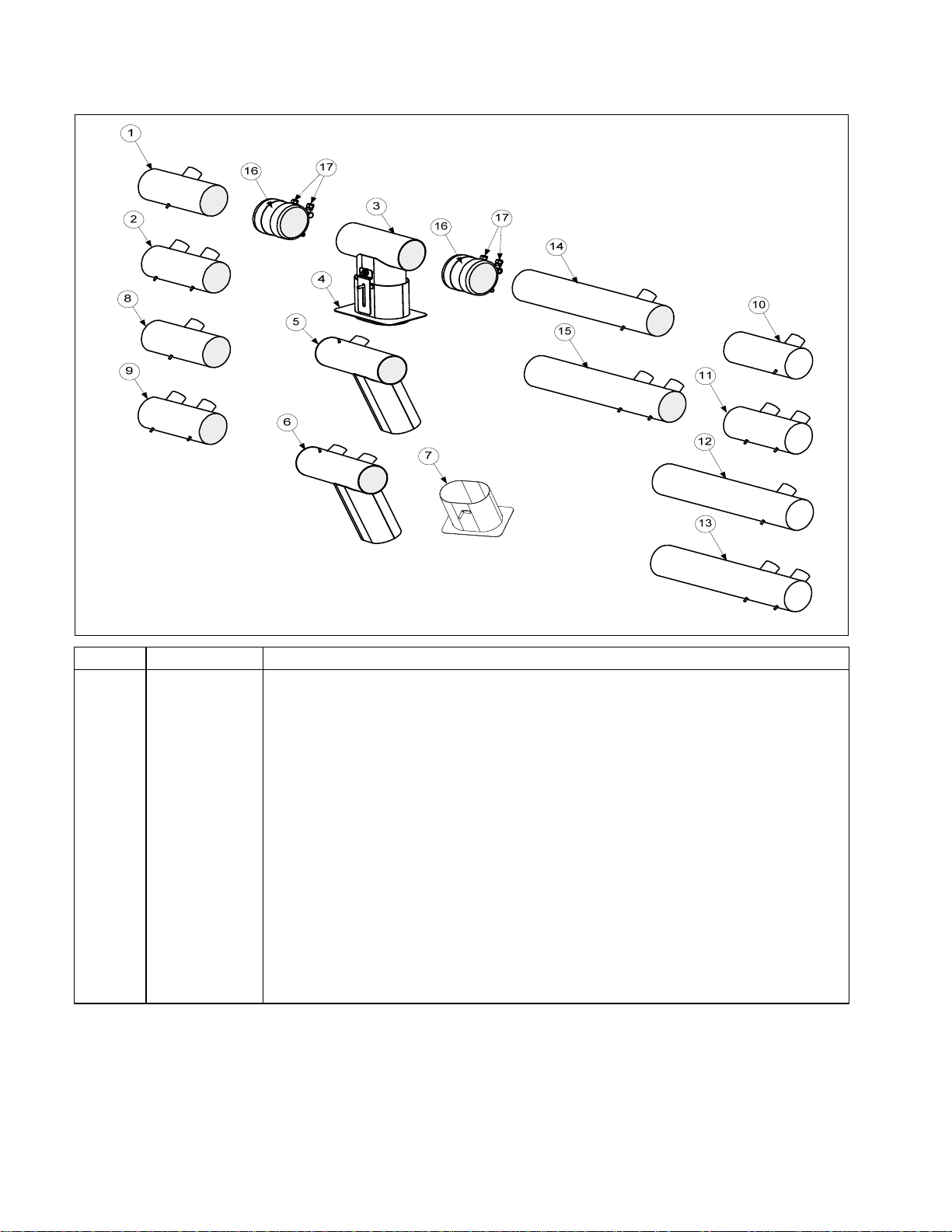

1.4 Drain Tube Sections and Associated Parts

See Section 1.3 for Drain Valves

ITEM PART # COMPONENT

1 8237323 Drain Tube, Full-Vat Left Closed/Right End Open

2 8237325 Drain Tube, Dual-Vat Left Closed/Right End Open

3 1080887SP Drain Tube, Dump

4 8237468 Shroud, Filter Pan Lid (attaches to item # 3)

5 1081118SP Drain Tube, Full-Vat 2 Bat. Dump Left Closed/Right End Open

6 1081120 Drain Tube, Dual-Vat 2 Bat. Dump Left Closed/Right End Open

7 8237480 Shroud, Filter Pan Lid 2 Bat. (attaches to item # 5 and 6)

8 8237322 Drain Tube, Full-Vat Left and Right Open

9 8237324 Drain Tube, Dual-Vat Left and Right Open

10 8237330 Drain Tube, Full-Vat 2 Bat. Left Open/Right End Closed

11 8237331 Drain Tube, Dual-Vat 2 Bat. Left Open/Right End Closed

12 8237329 Drain Tube, Full-Vat Left Open/Right End Closed

13 8237326 Drain Tube, Dual-Vat Left Open/Right End Closed

14 8237328 Drain Tube, Full-Vat Left and Right Open

15 8237327 Drain Tube, Dual-Vat Left and Right Open

16 8160772 Sleeve

17 8090969 Clamp

* 8160630 Vinyl Cap

* Not illustrated.

1-4

Page 9

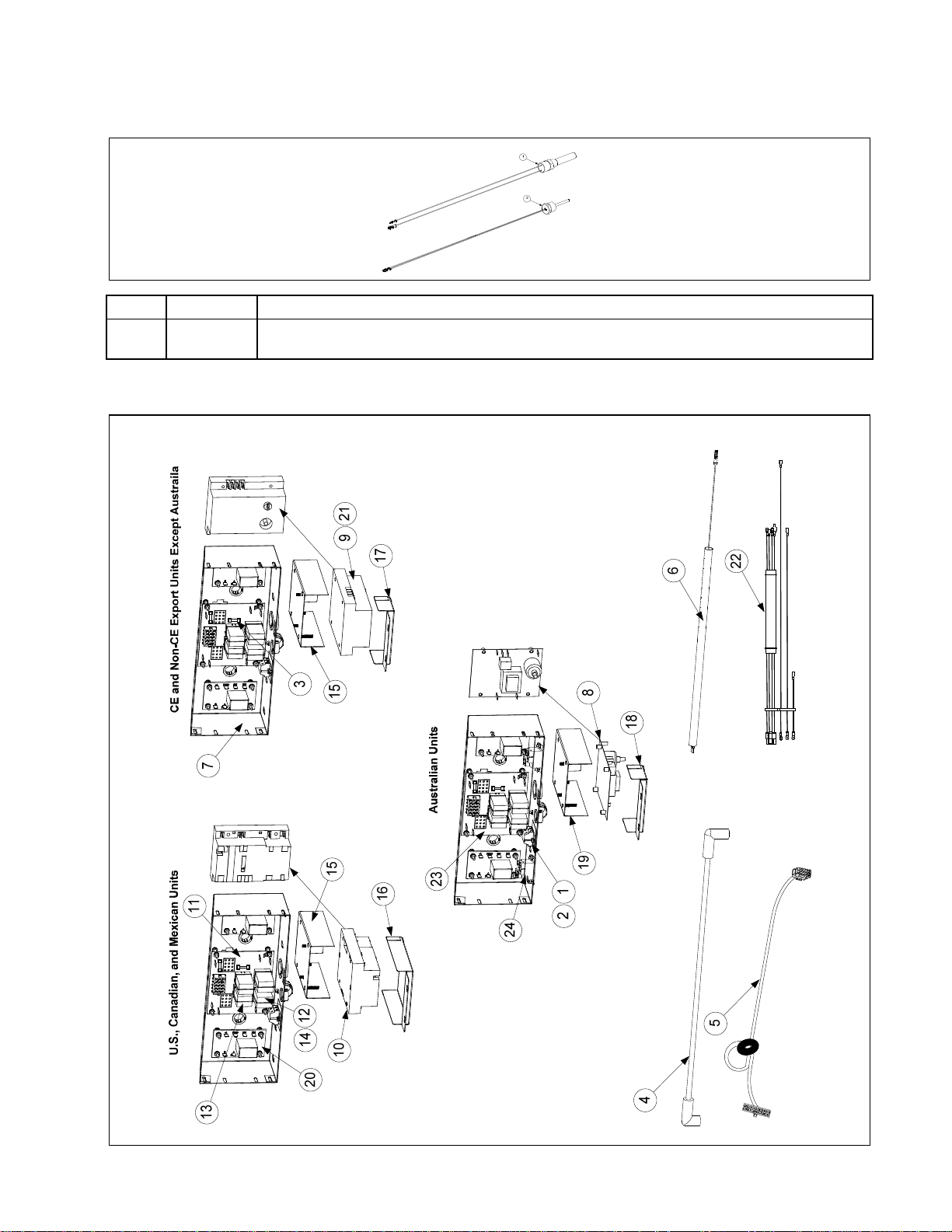

1.5 Electronics and Electrical Components

1.5.1 High-Limit Thermostat and Temperature Probe

ITEM PART # COMPONENT

√ 1 8261177

√ 2 8262900

√ Recommended parts.

Thermostat Assembly, HE FM High-Limit 425F/218C

Temperature Probe, LOV™

1.5.2 Component Boxes

1-5

Page 10

1.5.2 Component Boxes cont.

ITEM PART # COMPONENT

1 8101164 Block, One-Piece Screwless Terminal

2 8160217 Insulation, Terminal Block Paper

3 8073843 Fuse 3A 250V Domestic

√

8073293

4 8075008 Cable, 21-inch Ignition – For 8073366/8073365 Modules

√

* 8075009 Cable, Ignition 19” (CE)

* 8075266 Cable, Ignition, Australian units

* 8073484 Connector, Rajah

5 8074199 Cable, 20-pin Computer to 15-pin Interface Board - SMT

6 8066085SP Wire Assembly, Ignitor

7 2206102 Box, One-Piece Component

8 8072971 Ignition Module, (Australia)

√

9 8071006 Ignition Module, CE Honeywell

√

10 8075691~ Ignition Module Capable Controls Single-Spark Full-Vat and Dual-Vat CE/Non-CE

√

8073366† Ignition Module, Honeywell Dual-Spark Full-Vat (Domestic and Non-CE export unit

√

8073365† Ignition Module, Honeywell Single-Spark Dual-Vat (Domestic and Non-CE export

√

11 8262264 Interface Board Kit SMT

√

8074330 Speaker Adapter Harness SMT

8074343 Wire Harness, SMT Interface Board to Ignition Module

12 8070833

√

13 8070834

√

14 8102243 Spring, Relay Retaining

15 1081094 Plate, Ignition Module

16 8242090 Cover, Ignition Module

17 8242091 Cover, Ignition Module CE

18 2207085 Cover, Ignition Module Australia

19 1081544 Plate, Ignition Module Australia

20 8074812

8074934

21 1060531SP Fuse Assembly, Inline (not used on all models)

* 8072659 Switch, Momentary (Control Power Reset, only used in far left component box)

* 8074403 Speaker SMT

22 1081260SP Wire Assembly, Ignition Module Domestic and Non-CE export, except Australia.

1082353 Wire Assembly, Ignition Module CE

23 8064973 Interface Board – Australia Only

24 8071683 Relay, 12VDC Reset Switch

* Not illustrated.

√ Recommended parts.

~ For Full-vat or Dual-vat units, use two 8075691 Single Spark Ignition Modules (see NOTE 1).

† For Full-vat units, use one 8073366 Honeywell Dual Spark Ignition Module (see NOTE 3).

† For Dual-vat units, use two 8073365 Honeywell Single Spark Ignition Modules (see NOTE 3).

NOTE 1: Fryers using 8075691 Single-Spark Capable Controls modules use two modules for both Full-Vat and DualVat Fryers. Also, in full-vat units, only two latch relays (Item 12) are used, located in the sockets on the right side of

the interface board. These relays are located in the bottom sockets of the interface board and control the heating

circuit.

NOTE 2: The relays in the top sockets control the oil level sensors.

NOTE 3: Domestic U.S. and Non-CE Export except Australia units use two different modules depending upon the

configuration of the frypot. Full-Vat units use one 8073366 Dual-Spark Ignition Module while Dual-Vat units use two

8073365 Single-Spark Ignition Modules. Also, in full-vat units, only two latch relays (Item 12) are used, located in the

sockets on the right side of the interface board. These relays are located in the bottom sockets of the interface board

and control the heating circuit.

Fuse 5A 125V International Only

except Australia)

unit except Australia)

Relay, DPDT 5A 12VDC Latch (See NOTE 1.)

Relay, SPDT 15A 12VDC Oil Level Sensor (See NOTE 2.)

Relay, 7-second Time Delay 120V (U.S., Canadian and Mexico units)

Relay, 7-second Time Delay 220V, 230V, 240V and 250V units (International units)

1-6

Page 11

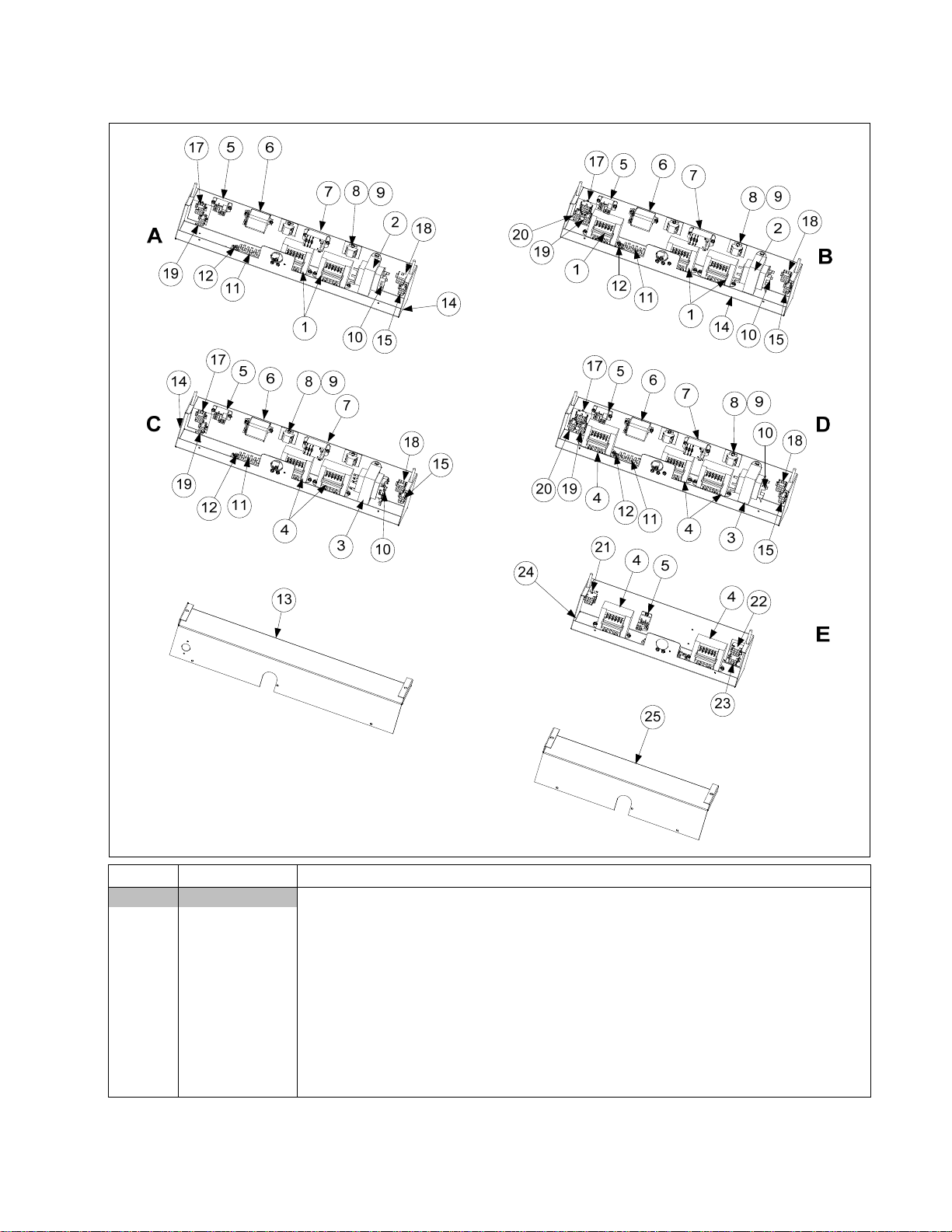

1.5.3 Transformer Boxes

ITEM PART # COMPONENT

Box Assembly, Transformer

A 1068135SP GL230 and 430 (430 has added cordset 1080871)

B 1068122SP GL330

C 1069734 GL230 and 430 CE Export (430 has added cordset 1080871) (1069750 430 CE Ex-

port with 1080871)

D 1069710SP GL330 CE Export

E 1081423 GL 430 CE Export

1 8072176 Transformer, 100-120V V/F Dual Voltage

√

2 8072181 Transformer, 100-120V/24V 62VA Filter and MIB

√

3 8072180 Transformer, 100-120VV/24V 50VA Filter and MIB

√

4 8071999 Transformer, V&F Dual Voltage 208/222/230/240V

√ Recommended parts.

1-7

Page 12

1.5.3 Transformer Boxes cont.

ITEM PART # COMPONENT

5 8071683 Relay, Hood 12V DC

√

6 8074346 Relay, DPDT 20A 120VAC (Control Reset Button) (used for control power reset in

√

domestic units)

8074770 Relay, DPDT 20A 240V (used for control power reset in international units)

√

7 8074482 Relay, Filter 30A 24VDC DPDT

√

8 8160217 Insulation, Terminal Block Paper

9 8101164 Block, One-Piece Screwless Terminal

10 8071597 Fuse, 3amp Slo-Blow

√

11 8071973 Terminal, Post

12 8070070 Terminal, Ground Lug

13 2203191 Cover, Large Transformer Box

14 8236324 Box, Large Transformer/Filter

15 1068133SP Cable Assembly, Transformer Box Line GL230, 330, 430, 230 and 330 CE Export

and 430 CE Export

16 1068168 Cable Assembly, Transformer Box Line GL230 CE Export

17 1068170 Cable Assembly, Transformer Box Filter Pump GL230, 330, 230 and 330 CE Export

18 1080994SP Cable Assembly, Transformer Box #1 GL230,330, 230 and 330 CE Export

19 1080995SP Cable Assembly, Transformer Box #2 GL230, 330, 230 and 330 CE Export

20 1080996SP Cable Assembly, Transformer Box #3 GL330 and 330 CE Export

21 8068706 Plug Assembly, LT #252

22 8068707 Plug Assembly, RT #252

23 1066996 Harness Assembly, Cord set Female McD

24 8237400 Box, Transformer/Filter GL30 4-Battery

25 2206514 Cover, GL30 4-Battery Transformer Box

* WIR 0100 Wire Assembly, GL 430 McD Double (used in Item E)

* WIR 0623 Wire Assembly, GL230/430 Hood Relay (used in Item A, B, C and D)

* WIR 0798 Wire Assembly, GL330 Transformer/Filter Box (used in Item B, C and D)

* WIR 0799 Wire Assembly, GL230/430 Transformer/Filter Box (used in Item A)

* Not illustrated

√ Recommended parts.

1.5.4 Computers and Associated Components

NOTE: See Page 1-5 for Interface Board to Computer Wiring Harness.

ITEM PART # COMPONENT

Computer, McDonald’s M3000 Gas Fryer SMT

√ 1081284SP

√ 1081282

√ 1082969

√ 1081290

Non-CE M3000 (For use in US, Canada, Mexico and other non-CE countries)

CE M3000 (For use in European CE countries)

M3000 (For use in Russia only)

M3000 (Australia Only)

* 8074403 M3000 Speaker SMT

* Not illustrated.

√ Recommended parts.

1-8

Page 13

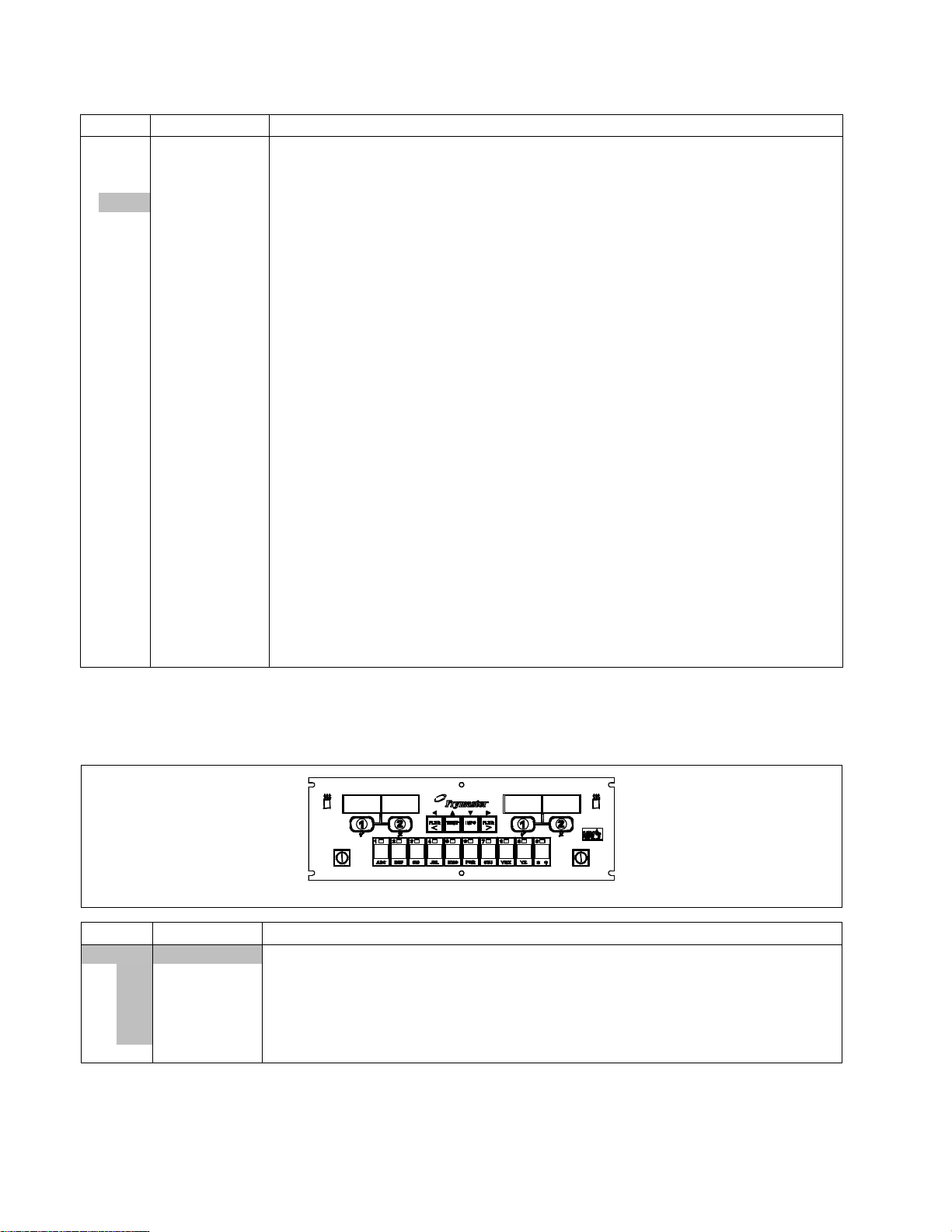

1.6 Wiring

1.6.1 Main Wiring Harnesses

2-PIN FEMALE

CONNECTOR

12-PIN MALE

CONNECTOR

12-PIN MALE

CONNECTOR

2-PIN FEMALE

CONNECTOR

807-1978

9-PIN MALE

CONNECTOR

12-PIN MALE

CONNECTOR

807-4014

12-PIN MALE

CONNECTOR

ITEM PART # COMPONENT

8071978 Main Wiring Harness Vat 1 (Far left controller) (9-pin)

8074014 Main Wiring Harness Vat 2, 3, 4 and 5 (6-pin)

1-9

6-PIN MALE

CONNECTOR

Page 14

1.6.2 Miscellaneous Wiring

ITEM PART # COMPONENT

1 8074316 Power Cord, 120V w/Grounding Plug 5 wire (w/Ring Terminals, no Clamp)

2 8074317 Power Cord, CE

8075225 Power Cord, 3-Wire 15A, 250V (Korea)

3 8069678SP Plug Assembly, CE Gas Valve

1.6.3 M3000, MIB, AIF and ATO Wiring Harnesses (Refer to wiring diagram on page 1-60 in the

BIGLA30 LOV Service Manual.)

ITEM PART # COMPONENT

* 8074546 Computer Communication (used from Computer to Computer)

* 8074547 AIF Communication/Power (used from AIF to AIF and AIF to ATO)

* 8074850 Communication/Power (used from MIB to AIF)

* 8074562

* 8074655 FV/DV Harness RTD Extension 20” (used from RTD to ATO Board)

* 8074845 FV/DV Harness RTD Extension 28” (used from RTD to ATO Board)

* 8262569 FV/DV ATO/RTD Probe Kit

* 8074621 FV/DV Harness RTD Short (used from RTD to ATO Board)

* 8074771 ATO Power (used from Transformer to ATO Board)

* 8074555 ATO Yellow LED (used from ATO Board to Yellow LED)

* 8074573

* 8074552

* 1068977SP Long Top-off Power (used between Transformer Box to ATO Box) Domestic

* 1081589SP Long Top-off Power (used between Transformer Box to ATO Box) CE and Export

* 1069544 ATO Power to Secondary ATO box (4 and 5 battery only)

* 8074671

√ * 8074660PK SMT Pin Service Repair Kit

√ * 2302345 SMT Pin Extractor

* Not illustrated.

√ Recommended parts.

See page 1-27, 1-32, 1-39 and 1-50 in the BIGLA30 Service Manual for Pin Positions.

MIB Power/Blue LED/Pan Sw (used from Transformer and Fltr Rly to MIB to Blue

LED and Pan Sw)

Computer Locator Wire (used from Computer to Interface Board) See wiring dia-

gram 805-1725 for locator pin positions.

Communications Terminator (used on Computer pin J6 and ATO board pin J10 to

terminate network)

Harness, LOV™ RTI-MIB connector

1-10

Page 15

1.7 Frypots and Associated Components

1.7.1 Full-Vat Frypot Components

NOTE: All insulation and

gaskets can be ordered in

a single kit, P/N 826-2595.

Kit 826-2592 contains the

insulation and gaskets re-

quired when replacing

burners.

1-11

Page 16

1.7.1 Full-Vat Frypot Components cont.

ITEM PART # COMPONENT

1080858SP

1081752SP

8262595 Insulation Kit, Complete Full-Vat

8262592 Insulation Kit, Burner Full-Vat

1 1080925SP Flue Assembly, Full-Vat

2 2206470 Back, Lower Full-Vat Combustion Chamber

3 2206529 Retainer, Full-Vat Upper Insulation

4 2206664 Retainer, Outer Frypot

5 2306960 Plate, FV Collector Mounting

6 2202851 Brace, FV Rear Insulation

7 2202920 Brace, Foam Deck Insulation

√ 8 8103435 Burner, Universal Replacement LOV™

9 8120356 Insulation, Burner Sight Glass

10 8160900 Insulation, Burner

11 8120706 Insulation, Upper Burner Rail

12 8121029 Insulation, Combustion Chamber Side

13 8140048SP Glass, Burner Sight

14 8160837 Insulation, FV Rear Lower

15 8160731 Insulation, FV LH/RH Front Seal

16 8160976

17 8160733 Insulation, FV Front Upper

18 8160978

19 8160746 Insulation, Foam Deck

20 8237283

8238932

21 8238193 Retainer, FV LH Upper Burner

22 8238194 Retainer, FV RH Upper Burner

23 8238577 Retainer, FV Front Insulation

24 8238575 Retainer, FV Outer Front

25 8242164 Front Upper Seal Weldment, FV LH

26 8242165 Front Upper Seal Weldment, FV RH

27 9001031 Retainer, Burner Sight Glass

28 9300818 Bracket, Flue to Pot

29 9004253 Strip, Fluecap Retainer

30 9001049 Retainer, Plenum Gasket

31 8160057 Gasket, Plenum

32 8238574

* 8160059 Gasket, Ignitor

* 9102474 Pot-to-Pot Gap Clip

* Not illustrated.

√ Recommended parts.

Frypot Assembly Full-Vat LOV™ HE (NAT/PRO) prior to 07/2014

Frypot Assembly Full-Vat LOV™ HE (NAT/PRO) after 06/2014

Insulation, FV Lower Inner Front (may require 8238577 for serial #’s after 1209)

Insulation, FV Outer Front (may require 8238575 for serial #’s after 1209)

Frypot, FV LOV™ 30 439 SS prior to 07/2014

Frypot, FV LOV™ 30 439 SS ) after 06/2014

Plenum, Full-Vat LOV™ (use 8238590 for CE and Export Non-CE units)

1-12

Page 17

1.7.2 Dual-Vat Frypot Components

NOTE: All insulation and

gaskets can be ordered

in a single kit, P/N 826-

2596. Kit 826-2593 contains the

insulation and gaskets

required when replacing

burners.

1-13

Page 18

1.7.2 Dual-Vat Frypot Components cont.

ITEM PART # COMPONENT

* 1080860SP

* 1081753SP

* 8262596 Insulation Kit, Complete Dual-Vat

* 8262593 Insulation Kit, Burner Dual-Vat

1 1080926SP Flue Assembly, Dual-Vat

2 1067960 Plate Assembly, Dual-Vat Collector

3 2206530 Retainer, Dual-Vat Upper Insulation

4 2206665 Retainer, Dual-Vat Outer Frypot

5 2206180 Back, Dual-Vat Lower Combustion Chamber

6 2202920 Brace, Foam Deck Insulation

7 2202972 Brace, Dual-Vat Rear Insulation

√ 8 8103435 Burner, Universal Replacement

9 8120356 Insulation, Burner Sight Glass

10 8160900 Insulation, Burner

11 8120706 Insulation, Upper Burner Rail

12 8121029 Insulation, Combustion Chamber Side

13 8140048SP Glass, Burner Sight

14 8160838 Insulation, Dual-Vat Rear Lower

15 8160741 Insulation, Dual-Vat LH/RH Front Seal

16 8160977

17 8160743 Insulation, Dual-Vat Front Upper

18 8160979

19 8160746 Insulation, Foam Deck

20 8120688 Insulation, Flue Collection

21 8238196 Retainer, Dual-Vat RH Upper Burner

22 8238195 Retainer, Dual-Vat LH Upper Burner

23 8238578 Retainer, Dual-Vat Front Insulation

24 8238576 Retainer, Dual-Vat Outer Front

25 8241796 Riser W/A Dual-Vat Pot

26 8242166 Dual-Vat LH Upper W/A Seal

27 8242167 Dual-Vat RH Upper W/A Seal

28 9001031 Retainer, Sight Glass

29 9300818 Bracket, Flue to Pot

30 9004253 Strip, Fluecap Retainer

31 9001049 Retainer, Plenum Gasket

32 8160057 Gasket, Plenum

* 8160059 Gasket, Ignitor

33 8238573

34 8237288

8238942

* 9102474 Pot-to-Pot Gap Clip

* Not illustrated.

√ Recommended parts.

Frypot Assembly Dual-Vat w/RF HE (NAT/PRO) prior to 07/2014

Frypot Assembly Dual-Vat w/RF HE (NAT/PRO) after 06/2014

Insulation, Dual-Vat Lower Inner Front (may require 8238578 for serial #’s after

1209)

Insulation, Dual-Vat Outer Front (may require 8238576 for serial #’s after 1209)

Plenum, Dual-Vat LOV™ (use 8238589 for CE units and Export Non-CE units)

Frypot, Dual-Vat LOV™ 30 439 SS prior to 07/2014

Frypot, Dual-Vat LOV™ 30 439 SS after 06/2014

1-14

Page 19

1.7.3 Frypot Assemblies and Associated Parts

1.7.3.1 Frypots with Linear Actuators (02/2010-04/2012)

See Page 1-21 for

Return Valve

Full Vat Dual Vat

Assemblies.

ITEM PART # COMPONENT

1 1080858SP Frypot Assembly, Full-Vat LOV™ Natural/Propane

2 1080860SP Frypot Assembly, Dual-Vat LOV™ Natural/Propane

√ 3 8262587 Actuator, Linear AIF 24VDC Kit (includes 8101776)

√ 4 8091012 Pin, Clevis, ¼ x 1¼

√ 5 8091036 Pin, Clevis, ¼ x 2

√ 6 8101776 Cotter Pin, Toaster Ring

7

8

9

10

11

12

13

√ 14 8262706 Probe, RTD AIF/ATO Kit

√ 15 8074817 Probe, Temperature Cooking

√ 16 8074815 Sensor Assy, Oil 120V

√ 17

18 2206472 Bracket, Rear AIF Mounting

19 2203183 Brace, DV AIF Support

20 2206666 Bracket, Actuator Support

21 2205299 Bracket, Front AIF Mounting

√ Recommended parts.

1080748SP

1080747SP

1080750SP

1080749SP

8130165

8101668

8101055

8074947

8074935

8074942

8261177

Valve, Drain Assy. LOV™ AIF FV or DV Right viewed front of frypot. (02/10-04/12)

Valve, Drain Assy LOV™ AIF DV Left as viewed front of frypot. (02/10-04/12)

Valve, Return Assy LOV™ AIF FV or DV Right viewed from front of frypot. (02/10-

04/12)

Valve, Return Assy LOV™ AIF DV Left as viewed from front of frypot. (02/10-04/12)

Elbow, Street ½” x ½” NPT 90 BM

Adaptor, Male ⅝” OD x ½”

Flexline, ⅝” OD x 11.50” Long

Sensor Assy, Oil 220V International

Sensor Assy, Oil 230V International

Sensor Assy, Oil 240V and 250V International

Thermostat Assembly, HE High-Limit 425F/218C Standard

See Page 1-3

for Drain Valve

Assemblies.

1-15

Page 20

1.7.3.2 Frypots with Rotary Actuators (05/2012-Present)

Full Vat Dual Vat

ITEM PART # COMPONENT

1 1081752SP Frypot Assembly, Full-Vat LOV™ Natural/Propane

2 1081753SP Frypot Assembly, Dual-Vat LOV™ Natural/Propane

√ 3

√

4

√

5

√

6

7

8

9

√ 10 8262706 Probe, RTD AIF/ATO Kit

√ 11 8263196 Probe, Temperature Kit

√ 12 8074815 Sensor Assy, Oil 120V

√ 13

√ Recommended parts.

8074961

8074962

8104353

8103754

8130165

8101668

8101055

8074947

8074935

8074942

8261177

Actuator, Rotary 24VDC (#1) Blue (05/2012-Present)

Actuator, Rotary 24VDC (#2) Black (05/2012-Present)

Valve, 1¼ Drain Rotary Actuator LOV™ (05/2012-Present)

Valve, ½ NPT Return Rotary Actuator LOV™ (05/2012-Present)

Elbow, Street ½” x ½” NPT 90 BM

Adaptor, Male ⅝” OD x ½”

Flexline, ⅝” OD x 11.50” Long

Sensor Assy, Oil 220V International

Sensor Assy, Oil 230V International

Sensor Assy, Oil 240V and 250V International

Thermostat Assembly, HE High-Limit 425F/218C Standard

1-16

Page 21

1.8 Oil Return Manifolds

ITEM PART # COMPONENT

1 8103275 Manifold, Two-Station Fryer

2 8103245 Manifold, Three-Station Fryer

3 8103368 Manifold, Four-Station Fryer

* 8130907 Cap, 15/16-inch Valve

* Not illustrated

1.9 Return Valves and Associated Parts

1.9.1 Return Valves and Associated Parts (Linear Actuators) (02/2010-04/2012)

Dual-Vat

Left Return Valve

Assy.

1080749SP

ITEM PART # COMPONENT

1 2316295 Handle, Return Valve Gas LOV™ DV Left

2 2326295 Handle, Return Valve Gas LOV™ FV or DV Right

3 2306011 Brace, Gas Return Actuator Bracket

4 8102201

Valve, ½-inch Ball

(02/2010-04/2012)

5 8237273 Mount, Gas Return Actuator LH

6 8237274 Mount, Gas Return Actuator RH

7 9002935 Retainer, Nut Oil Return Valve

1.9.2 Return Valve (Rotary Actuators) (05/2012-Present)

Full-Vat or DualVat Right ReturnValve Assy.

1080750SP

Full-Vat or Dual-

1

Vat Return Valve

ITEM PART # COMPONENT

1 8103754

Valve, ½-inch NPT Rotary Actuator (05/2012-Present)

1-17

Page 22

1.10 Gas Supply and Combustion System Components

See pages 1-13 through 1-15

for burners and burner insulation part numbers.

1-18

See Page 1-20 – 1-21 for details of gas

valves and related components.

Page 23

1.10 Gas Supply and Combustion System Components cont.

ITEM PART # COMPONENT

√ 1 Ignitor

8263054 Natural Gas (G20, G25) (includes gasket 8160981, which may be ordered sepa-

rately)

8262994 Propane (G30, G31) (includes gasket 8160981, which may be ordered separately)

√ 2 Blower Assembly, Combustion Air (includes harness and Item 3)

1087153SP 115V 50/60 Hz (Right)

1087155 220V 60 Hz (Right)

1062998SP 208-240V 50/60 Hz (Right) Non-CE International

1082360SP 230V 50Hz CE FV Australia

1082361SP 230V 50Hz (Right) CE DV Australia

1063001SP 230V 50/60 Hz CE (Right) CE (Wide Body)

3 8160554 Cover, Blower Motor (component of most blowers listed above)

* 8068806SP Harness Assembly, Blower Motor (component of all blowers listed above)

4 Orifice, Burner

8103977 1.88mm 75% Butane/25% Butane (Standard Elevation)

** 8103865 1.95mm Propane/Butane (G30, G31) Australia Only

** 8103860 2.05 mm Propane/Butane (G30, G31) (0-4999 Ft, 0-1524 M)

** 8103863 2.10 mm Propane/Butane (G30, G31) (5000-6999 Ft, 1525-2133 M)

** 8103867 2.84mm Natural Gas (G20, G25) Australia Only DV

** 8103866 2.92mm Natural Gas (G20, G25) Australia Only FV

** 8103864 3.18 mm Natural Gas (G20, G25) (0-4999 Ft, 0-1524 M) CE, Non-CE

** 8103861 3.26 mm Natural Gas (G20, G25) (0-4999 Ft, 0-1524 M)

** 8103862 3.40 mm Natural Gas (G20, G25) (5000-6999 Ft, 1525-2133 M)

** 8262965 Conversion Kit, Natural Gas FV (G20, G25) to Propane/Butane(G30,G31) Non-CE

** 8262966 Conversion Kit, Natural Gas DV (G20, G25) to Propane/Butane(G30,G31) Non-CE

** 8262967 Conversion Kit, Propane/Butane FV(G30, G31) to Natural Gas (G20,G25) Non-CE

** 8262968 Conversion Kit, Propane/Butane DV(G30, G31) to Natural Gas (G20,G25) Non-CE

** 8262969 Conversion Kit, Nat Gas FV (G20, G25) to Prop/Butane(G30,G31) Aust Non-CE

** 8262970 Conversion Kit, Nat Gas DV (G20, G25) to Prop/Butane(G30,G31) Aust Non-CE

** 8262971 Conversion Kit, Prop/But FV(G30, G31) to Natural Gas (G20,G25) Aust Non-CE

** 8262972 Conversion Kit, Prop/But DV(G30, G31) to Natural Gas (G20,G25) Aust Non-CE

** 8262975 Conversion Kit, Nat Gas (G20, G25) to Prop/Butane(G30,G31) CE

** 8262976 Conversion Kit, Prop/But (G30, G31) to Natural Gas (G20,G25) CE

√ 5 1081455SP Switch, Air Pressure Assembly DV (8122141 switch alone)

√ 1083346 Switch, Air Pressure Assembly FV (8122226 switch alone)

* Not illustrated.

√ Recommended parts.

8121138 1.85 mm Propane/Butane (G30, G31) (0-4999 Ft, 0-1524 M) (CE)

8121137 1.95mm Propane/Butane (G30, G31) Australia Only

8100416 2.05 mm Propane/Butane (G30, G31) (0-4999 Ft, 0-1524 M)

8100386 2.10 mm Propane/Butane (G30, G31) (5000-6999 Ft, 1525-2133 M)

8121135 2.15 mm Propane/Butane (G30, G31) (7000-10,999 Ft, 2134-3352 M)

8103840 2.84mm Natural Gas (G20, G25) Australia Only DV

8103839 2.92mm Natural Gas (G20, G25) Australia Only FV

8103740 3.18 mm Natural Gas (G20, G25) (0-4999 Ft, 0-1524 M) CE

8103269 3.26 mm Natural Gas (G20, G25) (0-4999 Ft, 0-1524 M)

8100403 3.40 mm Natural Gas (G20, G25) (5000-6999 Ft, 1525-2133 M)

8120909 3.45 mm Natural Gas (G20, G25) (7000-8999 Ft, 2134-2743 M)

8121133 3.50 mm Natural Gas (G20, G25) (9000-10,999 Ft, 2744-3352 M)

**For fryers manufactured OCT 2010 and after. NPT Threads

For fryers manufactured prior to OCT 2010

1-19

Page 24

1.11 Gas Valves and Associated Components

1-20

Page 25

1.11 Gas Valves and Associated Components cont.

ITEM PART # COMPONENT

√ 1 Valve, Non-CE Gas

8261122 Natural Gas (G20, G25)

8261120 Kit Natural Gas w/ flexlines and hardware

8261123 Propane Gas (G30, G31)

8261121 Kit, Propane Gas w/ flexlines and hardware

√ 2 8101715 Valve, CE Gas (G20, G25, G30, G31)

3 8101041 Accessory Kit (contains parts to adapt Item 2 to specific fryer configuration)

4 8100691

Tube, ⅛-inch Vent

5 8100494 Ferrule (Nut), Orifice

6 8101355

7 8101354

8101353

8 8110800

* 8103807

9 8130301

10 8130302

Gas Line, ⅜-inch OD X 15-inch SS Flexible

Gas Line, ⅜-inch OD X 12-inch SS Flexible

Gas Line, ⅜-inch OD X 9-inch SS Flexible (Used on some split pots)

Tube, ⅛-inch OD X 12.5-inch Enrichment (cut and form to fit)

Tube, ⅛-inch OD X 6.5-inch Enrichment (Used after Oct 2010)

Tee, ¼-inch Male NPT to ⅜-inch Tube

Elbow, ¼-inch Male NPT to ⅜-inch Tube 90° (used on DV valve)

11 8130304 Bushing, ½-inch NPT to ¼-inch NPT Flush Reducing

12 8130405

13 8130378

14 8130340

15 8130154

16 8101176

17 8130377

18 8130354

19 8130016

20 8101006

Nipple, ⅛-inch NPT X 2-inch

Fitting, ⅛-inch NPT Cross

Adapter, ⅛-inch NPT to ⅛-inch Tube

Plug, ⅛-inch NPT Hex Head Pipe

Tap, ⅛-inch NPT Pressure

Tee, ⅛-inch NPT Female

Elbow, ⅛-inch NPT X ⅛-inch Tube Compression

Nipple, ⅛-inch NPT X Close

Bushing, ¼-inch NPT to ⅛-inch NPT Reducing

21 8130495 Tee, ¼-inch Male NPT to Female NPT

22 8101025

Connector, ¼-inch Male NPT to ⅜-inch Tube

23 8101026 Tee, ¼-inch Male NPT to Female NPT Street

24 8130700 Nipple, ¼-inch NPT x 3-inch

25 8103147 Bushing, ¾-inch OD x ½ -inch ID NPT Flush

26 8103807 Tube, FPGL Gas Enrichment

27 8130449 Tee, ¼ -inch NPT Brass

√ Recommended parts.

1-21

Page 26

1.12 Filtration System Components

Pump plumbing may differ somewhat from

illustration depending on configuration and

date of manufacture.

ITEM PART # COMPONENT

1 8237602 Lid, Multi-Vat Fryers, Standard Size Filter Pan

8237502 Lid, Two-Vat Fryer, Half Size Filter Pan

2 8103276 Crumb Tray, Standard Size Filter Pan 3, 4 and 5 Vat

8103288 Crumb Tray, Two-Vat Fryer, Half Size Filter Pan

3 8103268

8103289

4 2002240 SanaGrid Filter Screen, Standard Size Filter Pan

2202901 SanaGrid Filter Screen, Two-Vat Fryer, Half Size Filter Pan

5 1081209SP Pan, One-Piece Filter LOV™ Standard Size (Use 1069148 for French Pan)

1068211SP Pan, Two-Vat Fryer, LOV™ Half Size

√ * 8261392 O-Ring (Pkg. of 5; used with Item 5)

* 8130568

6 8233879 Suction Tube Standard LOV™

8236458 Suction Tube Two Vat LOV™

7 8103007 Magnet, Pull Ring

* Not illustrated. √ Recommended parts

Hold-Down Ring 16.56” x 22.32”, Standard Size Pan (3, 4, and 5 Vat Fryers)

Hold-Down Ring 11.20” x 19.10”, Half Size Filter Pan (2-Vat Fryer)

Plug, ⅛-inch Socket Head Pipe (used with Item 5; two required)

1-22

Page 27

1.12 Filtration System Components cont.

ITEM PART # COMPONENT

8 1082218SP Assembly, Filter Pan Switch 3, 4 and 5 Battery

1080839SP Assembly, Filter Pan Switch 2 Battery

√ * 1065876SP Sensor, Magnet

9 2203879 Rail, Filter Pan Retaining Standard

2314821 Rail, Filter Pan Retaining Two Vat Left (use 2324822 for Right)

9a 2304820 Rail, RH LH Lower Two Vat

10 2207911 Support, Left Filter Pan

2207909 Support, Left Filter Pan Two Vat LOV™

11 2207912 Support, Right Filter Pan

2207910 Support, Right Filter Pan Two Vat LOV™

√ 12 Motor and Gasket Kit

8261785 100V 50/60 Hz

8261712 115V 50/60 Hz

8261756 208V 50/60 Hz

8261270 220-240V 50/60 Hz

8261755 250V 50/60 Hz

√ 13 8263191 Pump and Gasket Kit, 4 GPM

8160093 Gasket, Pump/Motor

* 8091062 Cap Screw, 5/16-inch-18 4.00” NC Hex (Connects pump to motor use 8090194 washers)

14 8130165 Elbow, ST ½-inch x ½-inch NPT 90° BM

15 8101668

Adapter, ⅝-inch to ½-inch NPT Male

16 8101067 Flexline, 8.5-inch Oil Return

17 8101057 Flexline, 13-inch Oil Return

18 8130342 Elbow, Street 45° x ½-inch NPT

19 8130002 Nipple, ½-inch x Close NPT BM

20 8100667 Check Valve ½-inch NPT

21 2206190 Brace, Pump Motor

* 8071105 Heater Strip Assembly, 100-120V 25W 18”

* 8071098 Heater Strip Assembly, 208-250V 25W 18”

* Not illustrated. √ Recommended parts.

1.13 Auto Intermittent Filtration Components

1.13.1 LOV™ Indicator Light and MIB (Manual Interface Board) Assembly

1068231SP LOV™ Panel Assembly

ITEM PART # COMPONENT

1 1068106SP Light, Blue 24VDC LED Flush

2 1068105SP Light, Yellow 24VDC LED Flush

3 2206554 Cover, MIB

√ 4 1082158SP Assembly, MIB Computer w/ Metalwork ( use 8074481 for overlay)

5 1069999 Assembly Back, Box MIB

6 8091021 Screw, 10x 3/8 Torx Pan

√ Recommended parts.

1-23

Page 28

1.13.2 AIF (Automatic Intermittent Filtration) Linear Actuator Board Assembly and ATO

(Auto Top-Off) Components

1081306 AIF Actuator Board Assembly

ITEM PART # COMPONENT

√ 1081306 AIF Assembly

1 8241991 Cover, Linear Actuator Board

2 8160814 Gasket, Linear Actuator Board

3 8160815 Gasket, Computer Board

4 1081304 Board, AIF Linear Actuator

5 8160820 Seal, Linear Actuator Board

6 1080097 Box, Linear Actuator Stud

√ Recommended parts.

1.14 ATO (Auto Top-Off) Components

1.14.1 JIB Cradle, JIB Cap/ Pick-Up Assembly and ATO Board Assemblies

1080506SP

120V Assy

ITEM PART # COMPONENT

1 2208363 Cradle, JIB Gas LOV™

2 1082005SP Cap, JIB Assembly (use 1082002SP for BIB [Europe])(use 1087215SP Middle East)

3 1082001SP Cap, JIB (use 8239175 for BIB [Europe]) (use 8122390 Metal Cap Middle East)

4 8072469 Bushing, Heyco (use 8104716 Middle East)

5 8103823 Hose, JIB

6 8237738 Tip Assy (use 8238742 for BIB [Europe] and Middle East)

7 1080653 Box, Assembly Auto Top Off Board ( used 2205679 for ATO Box Cover)

√ 8 1081279 PCB Board, Automatic Top Off

√ 9 8072181 Transformer, 100-120V/24V 62VA

√ 10 8070855 Transformer, 120V 50/60-12V 20VA

√ 11 8072180 Transformer, 208-240V/24V 50VA

√ 12 8072191 Transformer, 208/230/240 -12V 30VA

13 8071321 Holder, Fuse AGC Panel Mount ¼”

√ * 8071597 Fuse, 3A Slow-Blow

√ 14 8070012 Relay, 18AMP 1/3 HP 24V Coil (Top off pump)

* Not illustrated. √ Recommended parts.

NOTE: Top off boxes for vats 4 and 5 have either item 9 or item 11, both have item 8.

1080507SP

208-240V

Assy

1-24

Page 29

1.14.2 ATO Pump Assembly

International Units

JIB hose connects here.

JIB hose connects here.

Domestic Units

Item 2

connects

to a check

valve before going

into the oil

return

manifold.

ITEM PART # COMPONENT

√ 1 1080639 Pump, Shurflo 24VAC

2 8103263 Flexline, ½” OD x 36-inch (Out to oil check valve and to return manifold)

8103375 Flexline, ½” OD x 17-inch (Out to oil check valve and to return manifold) Two battery

only)

* 8100667 Check valve, ½ NPT 1 PSI

3 8101069

Flexline, ⅝” OD x 29.5-inch 2-Battery(In from RTI fresh oil solenoid) Domestic units

only

8103669

Flexline, ⅝” OD x 45-inch 3, 4 and 5-Battery(In from RTI fresh oil solenoid) Domestic

units only

4 8103666 Fitting, Shurflow Pump

5 8160782 O-Ring, Viton #111

6 8130940

Elbow, ¼” NPT x ⅜ Flare

7 8103770 Fitting, ¼” NPT Male Barb

8 8160710 Fitting, Elbow ¼” NPT x ½” Barb

9 8111139 Hose, Silicone Braided 5”

10 8237380 Bracket W/A, RTI Gas JIB Connection

11 8130304 Bushing, ½” x ¼” BM Flush

12 8237167 Bracket W/A, GL 30 JIB Connection

13 1082234 Stud Assy, 2 Battery Topoff Tray

1082238 Stud Assy, 3, 4, and 5 Battery Topoff Tray

14 8101668

Adaptor, Male ⅝” OD x ½”

15 1069206SP Assembly, JIB Reset Button Bracket

√ 16 8074678 Switch, Momentary JIB Reset

* Not illustrated.

√ Recommended parts.

1-25

Page 30

1.14.3 ATO Pump Assembly Service Kit (Larger Top Off Lines)

m

Item 2 connects to a check valve

before going into the oil return

anifold.

TO TOPOFF MANIFOLD

1

3

4

2

TO FILL POT

FROM BULK

IN FROM FRESH

OIL COUPLING

(FROM RTI)

18

17

18

14

12

16

20

TO/FROM JIB

19

8

14

21

5

15

14

11

9

7

10

6

INSTALL

O-RINGS

HERE

11

13

12

ITEM PART # COMPONENT

1083392SP Pump, Assy GL230 RTI ATO (use 1083447 for GL330 RTO ATO)

√ 1 1080639 Pump, Shurflo 24VAC

2 8103263 Flexline, ½” OD x 36-inch (Out to oil check valve and to return manifold)

8103375 Flexline, ½” OD x 17-inch (Out to oil check valve and to return manifold) Two battery

* 8100667 Check valve, ½ NPT 1 PSI

3 8101055

4 8101369

Flexline, ⅝” OD x 11.50-inch (Inlet to Top Off Pump) Domestic units only

Flexline, ⅝” OD x 17.50-inch

5 1066830SP Solenoid

6 8130940

Elbow, ¼” NPT x ⅜ Flare

7 1083403 Fitting, Shurflow Connect

8 8130530 Tee, Reducing ½” x ¼” x ½” (JIB hose connects here)

9 1082054SP Fitting Assy, Shurflow Connect

10 8160782 O-Ring, Viton #111

11 8130062 Elbow, ½” BM 90°

12 8130165 Elbow, Street ½” x ½” NPT 90° BM

13 8130304 Bushing, BM Flush

14 8101668

Adaptor, Male ⅝” OD x ½”

15 8130838 Nipple, ¼” NPT BM Close

16 8130003 Tee, ½” x ½” x ½” BM

17 8103583 Check Valve ½” NPT 4 PSI

18 8103738 Adapter, Check Valve Close NPT

19 8101669

Adapter, Female ⅞” OD x ½”

20 8130022 Nipple, ½” x Close NPT BM

21 8130537 Nipple, ¼” x 2.00” NPT

* Not illustrated.

√ Recommended parts.

1-26

Page 31

1.14.4 Shortening Melting Unit

14

10

9

8

2

12

9

6

15

7

1

4

5

3

16

11

ITEM PART # COMPONENT

1083406SP Assembly, Heated Shortening

1 1082983 Box Assembly, Heated Shortening

2 1083001 Assembly, Heated Shortening Lid

3 8103957 Pan, Heated Shortening

4 1083372SP Cover, Shortening Box Front

5 8100180 Handle

√ 6 8261392 O-Ring (Pkg. of 5)

7 8130568

8 8238079 Bracket W/A, Shortening Suction 3 battery

8238147 Bracket W/A, Shortening Suction 4 battery

9 8101669

10 8101055

11 8071321 Holder, Fuse

√ * 8071555 Fuse 5 Amp

12 8130908 Adapter, ½” NPT 90°

13 8103820 Fitting, Quick Connect Shurflo Pump

14 8160782 O-Ring, Viton #111

15 8075268 Strips, Hot Box Heater with controller

16 8074036 Switch

* 8071098 Heater Strip Assembly, 240V, 25W 18”

* 8071419 Heater Strip Assembly, 240V, 45W 36”

* 8071473 Heater Strip Assembly, 240V, 70W 56”

17 8103578 Fitting, LOV Shurflo Pump

* 8160782 O-Ring, Viton #111

18 8130940

19 8103375 Flexline, ½” OD x 17-inch (Out to oil return manifold)

20 1080639 Pump, Shurflo 24VAC

* Not illustrated. √ Recommended parts.

Plug, ⅛-inch Socket Head Pipe

Adaptor, Female ⅞” OD x ½”

Flexline, ⅝” OD x 11.5-inch

Elbow, ¼” NPT x ⅜ Flare

1-27

Page 32

1.15 RTI System Components

1.15.1 RTI Dispose Waste Valve and Test Box

ITEM PART # COMPONENT

1081433 Valve, RTI Dispose Waste

1 1081437 Bracket, RTI Waste Valve

2 2205899 Handle, RTI Waste Valve

3 8074936 Microswitch, Gold Sealed

4 8100278 Valve, ½” Ball

5 9002935 Retainer, Nut Return Valve

6 9012348 Cover, DV Safety Switch

7 9022348 Cover, DV Safety Switch

8 8160220 Insulation, RF Switch

9 1080716SP Box, LOV™ RTI Test

1.15.2 RTI Manifold and Accessories Prior to Oct. 2010

3

15

9

19

7

OUT TO

DISPOSE OIL

COUPLING

(TO RTI)

18

8

IN FROM

FRESH OIL

COUPLING

(FROM RTI)

TO TOP OFF

PUMP INTAKE

AND TO FILL

RTI JIB

1114

17

14

13

14

17

10

6

5

TO OIL

RETURN

MANIFOLD

3

4

21

WASTE OIL

TO RTI

DISPOSE

TANK

22

FRESH OIL

FROM RTI

TANK

2

1

13

16

12

20

25

24

23

26

1-28

Page 33

1.15.2 RTI Manifold and Accessories prior to Oct 2010 cont.

ITEM PART # COMPONENT

√ 1 1066830SP Solenoid Assembly

2 1081433 Valve, RTI Waste Assembly (see page 1-29 for parts)

3 8101668

Adaptor, Male ⅝” OD x ½”

4 8074760 Harness, RTI – MIB connection

5 8101669

6 8101680

8101055

7 8101055

8 8103669

8101069

9 8101057

Adaptor, Female ⅝” OD x ½”

Flexline, ⅝” OD x 6.50-inches long (used on 3, 4 and 5 battery units)

Flexline, ⅝” OD x 29-inches long (used on 2 battery units)

Flexline, ⅝” OD x 11.50-inches long

Flexline, ⅝” OD x 45-inches long (used on 3, 4 and 5 battery units)

Flexline, ⅝” OD x 29-inches long (used on 2 battery units)

Flexline, ⅝” OD x 13-inches long

10 8130251 Nipple, ½” x 4.50-inches NPT BM (used on 3, 4 and 5 battery units)

11 8103583 Valve, Check ½” NPT 4 PSI RTI Manifold

12 8130087 Nipple, ½” x 1.50-inches NPT BM

13 8130003 Tee, ½” x ½” x ½” BM

14 8103738 Adaptor, Check Valve Close Nipple

15 8130304 Bushing, ½” x ¼”

16 8130571 Nipple, ¼” x 1.50-inches NPT BM

17 8130062 Elbow, ½” BM 90°

18 8130838 Nipple, ¼” NPT

19 8130555 Reducer, Bell Fitting, ½” to ¼” NPT BM

20 8130298 Nipple, ½” x 2-inches NPT BM

21 8237205 Bracket W/A, Gas LOV™ RTI

1080686SP Handle and Lock Assy, Gas LOV™ RTI

22 8090657 Clip, Clevis Right Rod End

23 2205656 Brace, RTI Handle

24 2205657 Cover, RTI Handle

25 8237208 Handle, Gas LOV™ RTI Waste Pull

26 8103587 Lock, RTI Waste Handle (includes keys)

√ Recommended parts.

1-29

Page 34

1.15.3 RTI Manifold and Accessories after Oct. 2010

1-30

Page 35

1.15.3 RTI Manifold and Accessories after Oct 2010 cont.

ITEM PART # COMPONENT

√ 1 1066830SP Solenoid Assembly

2 1081433 Valve, RTI Waste Assembly (see page 1-29 for parts)

3 8101669

4 8074760 Harness, RTI – MIB connection

5 8101669

6 8101067

8101057

7 8101055

8 8101369

9 8130022 Nipple, ½ ” x Close NPT BM

10 8130251 Nipple, ½” x 4.50-inches NPT BM (used on 3, 4 and 5 battery units)

11 8103583 Valve, Check ½” NPT 4 PSI RTI Manifold

12 8130958 Tee, ¼” NPT BM

13 8130003 Tee, ½” x ½” x ½” BM

14 8103738 Adaptor, Check Valve Close Nipple

15 8130304 Bushing, ½” x ¼”

16 8103160 Adaptor, ½ ” NPT x 15/16”

17 8130062 Elbow, ½” BM 90°

18 8130838 Nipple, ¼” NPT

19 8160708 Fitting, ¼” NPT Male Barb

20 8130298 Nipple, ½” x 2-inches NPT BM

21 8237863 Bracket W/A, Gas LOV™ RTI Dispose

1080686SP Handle and Lock Assy, Gas LOV™ RTI

22 8090657 Clip, Clevis Right Rod End

23 2205656 Brace, RTI Handle

24 2205657 Cover, RTI Handle

25 8237208 Handle, Gas LOV™ RTI Waste Pull

26 8103587 Lock, RTI Waste Handle (includes keys)

27 8130265 Nipple, ½ ” x 2.50-inches NPT BM

28 8130336 Plug, ½ ” NPT SQ HD SS

29 8237838 Bracket W/A, Gas LOV™ RTI Fresh Oil

30 8100667 Valve, Check ½” NPT 1 PSI RTI Manifold

31 8103270

32 8130165 Elbow, ST ½ ” NPT 90° BM

33 8130093 Nipple, ½” x 4-inches NPT BM

34 1082192 Stud Assy, GL Solenoid Bracket

√ Recommended parts.

Adaptor, Male ⅝” OD x ½”

Adaptor, Female ⅝” OD x ½”

Flexline, ⅝” OD x 8.50-inches long (used on 3, 4 and 5 battery units)

Flexline, ⅝” OD x 13-inches long (used on 2 battery units)

Flexline, ⅝” OD x 11.50-inches long

Flexline, ⅝” OD x 17.50-inches long

Fitting, ⅜” Flare x ¼” NPT

1-31

Page 36

1.16 Oil Quality Sensor (OQS) and Associated Parts

3, 4, 5 - Battery Gas

2- Battery Gas

2- Battery Gas

3, 4, 5 - Battery Gas

1-32

Page 37

1.16 Oil Quality Sensor (OQS) and Associated Parts cont.

ITEM PART # COMPONENT

8263194 Kit, OQS LOV Gas 2-Battery (Kit to add to existing LOV Gas Fryers w/out OQS)

8263193 Kit, OQS LOV Gas 3, 4 and 5 Battery (Kit to add to existing LOV Gas Fryers w/out

OQS)

1 8263292 Sensor, LOV OQS Replacement (Kit for LOV Fryers with OQS)

2 8101055

Flexline, ⅝” OD x 11.5-inch

3 2400931 Clamp, Bracket EBRO Sensor

4 2400930 Bracket, Vertical EBRO Sensor

5 2400929 Bracket, Horizontal EBRO Sensor

6 8238335 Screen, Suction Line Filter

7 8238903 Body W/A, Pre-Filter Final EBRO BIGL230

8 8104167 Lanyard, In-Line Filter

9 8101369

10 8101067

11 8101668

Flexline, ⅝” OD x 17.50-inch

Flexline, ⅝” OD x 8.50-inch

Adapter, ⅝” to ½” NPT Male

12 2401086 Wrench, Pre-Filter Cap

13 8238901 Body, W/A Pre-Filter EBRO Sensor

14 8101400

Flexline, ⅝” OD x 21-inch

15 2400924 Strap, Bracket EBRO Sensor

16 1086101 Bracket Assy, EBRO Sensor 3, 4 & 5 Battery

17 2401035 Support, EBRO Sensor Bracket

* 8238990 Wrench, 1-1/16” (27mm)

* 8238991 Wrench, 1-1/16” (27mm) crows foot

1-33

Page 38

THIS PAGE INTENTIONALLY LEFT BLANK

Page 39

8700LINEAVENUE,SHREVEPORT,LA71106‐6800

FRYMASTER

WWW.FRYMASTER.COM

EMAIL:FRYSERVICE@MTWFS.COM

318‐865‐1711

800‐551‐8633

844‐724‐CARE(2273)

*8197259*

Every new piece of Manitowoc Foodservice equipment comes with KitchenCare™ and you choose the level of service that meets

your operational needs from one restaurant to multiple locations.

– Warranty & lifetime service, certified OEM parts, global parts inventory, performance audited

StarCare

– CareCode, 24/7 Support, online/mobile product information

ExtraCare

– Install & equipment orientation, planned maintenance, KitchenConnect™, MenuConnect

LifeCare

Talk with KitchenCare™

To learn how Manitowoc Foodservice and its leading brands can equip you, visit our global web site at

www.manitowocfoodservice.com, then discover the regional or local resources available to you.

©2016 Manitowoc Foodservice except where explicitly stated otherwise. All rights reserved. Continuing product improvement may necessitate change of specifications without notice.

Part Number FRY_P_8197259 10/2016

- 1-844-724-CARE - www.mtwkitchencare.com

Loading...

Loading...