Frymaster BIGL30 Owner’s Manual

FRYMASTER BIGL30 SERIES MANUAL LOV™

This equipment chapter is to be

installed in the Fryer Section of the

Equipment Manual.

MANUFACTURED

BY

OPERATOR’S MANUAL

GAS FRYER

Do Not Store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

FOR YOUR SAFETY

8700 Line Avenue

SHREVEPORT, LOUISIANA 71106

PHONE: 1-318-865-1711

TOLL FREE: 1-800-551-8633

1-800-24 FRYER

FAX: 1-318-219-7135

TABLE OF CONTENTS

WARRANTY STATEMENT ................................................................................................... Page i

INTRODUCTION ................................................................................................................... Page 1-1

INSTALLATION INSTRUCTIONS ....................................................................................... Page 2-1

OPERATING INSTRUCTIONS ............................................................................................. Page 3-1

OPERATING THE BUILT-IN FILTRATION SYSTEM ........................................................... Page 4-1

PREVENTIVE MAINTENANCE ............................................................................................ Page 5-1

OPERATOR TROUBLESHOOTING ..................................................................................... Page 6-1

Frymaster L.L.C., 8700 Line Avenue, Shreveport, LA 71106

PHONE 318-865-1711 FAX 318-219-7135

PRINTED IN THE UNITED STATES SERVICE HOTLINE 1-800-24-FRYER 07/2016

www.frymaster.com Email: service@frymaster.com *8196966*

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS MANITOWOC EQUIPMENT OTHER

THAN AN UNMODIFIED NEW OR RECYCLED PART PURCHASED DIRECTLY FROM FRYMASTER DEAN, OR ANY OF

ITS AUTHORIZED SERVICERS, AND/OR THE PART BEING USED IS MODIFIED FROM ITS ORIGINAL

CONFIGURATION, THIS WARRANTY WILL BE VOID. FURTHER, FRYMASTER DEAN AND ITS AFFILIATES WILL NOT

BE LIABLE FOR ANY CLAIMS, DAMAGES OR EXPENSES INCURRED BY THE CUSTOMER WHICH ARISE DIRECTLY

OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE INSTALLATION OF ANY MODIFIED PART AND/OR PART

RECEIVED FROM AN UNAUTHORIZED SERVICER.

NOTICE

This appliance is intended for professional use only and is to be operated by qualified personnel only. A Frymaster

DEAN Factory Authorized Servicer (FAS) or other qualified professional should perform installation, maintenance,

and repairs. Installation, maintenance, or repairs by unqualified personnel may void the manufacturer’s warranty.

See Chapter 1 of this manual for definitions of qualified personnel.

NOTICE

This equipment must be installed in accordance with the appropriate national and local codes of the country and/or

region in which the appliance is installed. See NATIONAL CODE REQUIREMENTS in Chapter 2 of this manual for

specifics.

NOTICE TO U.S. CUSTOMERS

This equipment is to be installed in compliance with the basic plumbing code of the Building Officials and Code

Administrators International, Inc. (BOCA) and the Food Service Sanitation Manual of the U.S. Food and Drug

Administration.

NOTICE

Drawings and photos used in this manual are intended to illustrate operational, cleaning and technical procedures

and may not conform to onsite management operational procedures.

NOTICE TO OWNERS OF UNITS EQUIPPED WITH COMPUTERS

U.S.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions: 1) This

device may not cause harmful interference, and 2) This device must accept any interference received, including

interference that may cause undesired operation. While this device is a verified Class A device, it has been

shown to meet the Class B limits.

CANADA

This digital apparatus does not exceed the Class A or B limits for radio noise emissions as set out by the ICES-

003 standard of the Canadian Department of Communications.

DANGER

Improper installation, adjustment, maintenance or service, and unauthorized alterations or modifications can

cause property damage, injury, or death. Read the installation, operating, and service instructions thoroughly

before installing or servicing this equipment. Only qualified service personnel may convert this appliance to use

a gas other than that for which it was originally configured.

DANGER

No structural material on the fryer should be altered or removed to accommodate placement of the fryer under a

hood. Questions? Call the Frymaster Dean Service Hotline at 1-800-551-8633.

WARNING

After installation of a gas fryer and after any maintenance to the gas system of a gas fryer-manifold, valve, burners,

etc. – check for gas leaks at all connections. Apply a thick soapy solution to all connections and ensure there are no

bubbles. There should be no smell of gas.

NOTICE

The Commonwealth of Massachusetts requires any and all gas products to be installed by a licensed plumber or

pipe fitter.

DANGER

Adequate means must be provided to limit the movement of this appliance without depending upon the gas line

connection. All fryers equipped with casters must be stabilized by installing restraining chains. If a flexible gas line

is used, an additional restraining cable must be connected at all times when the fryer is in use.

CAUTION

No warranty is provided for any Frymaster fryer used in a mobile or marine installation o r concession. Warranty

protection is only offered for fryers installed in accordance with the procedures described in this manual.

Mobile, marine or concession conditions of this fryer should be avoided to ensure optimum performance.

DANGER

The front ledge of the fryer is not a step! Do not stand on the fryer. Serious injury can result from slips or

contact with the hot oil.

DANGER

Do not store or use gasoline or other flammable liquids or vapors in the vicinity of this or any other appliance.

DANGER

Do not spray aerosols in the vicinity of this appliance while it is in operation.

DANGER

Instructions to be followed in the event the operator smells gas or oth erwise detects a gas leak must b e posted

in a prominent location. This information can be obtained from the local gas company or gas supplier.

DANGER

This product contains chemicals known to the state of California to cause cancer and/or birth defects or other

reproductive harm.

Operation, installation, and servicing of this product could expose you to airborne particles of glasswool or

ceramic fibers, crystalline silica, and/or carbon monoxide. Inhalation of airborne particles of glasswool or

ceramic fibers is known to the State of California to cause cancer. Inhalation of carbon monoxide is known to

the State of California to cause birth defects or other reproductive harm.

DANGER

The crumb tray in fryers equipped with a filter system must be emptied into a fireproof container at the end of

frying operations each day. Some food particles can spontaneously combust if left soaking in certain shortening

material.

WARNING

Do not bang fry baskets or other utensils on the fryer’s joiner strip. Th e strip is p resen t to seal the joint between

the fry vessels. Banging fry baskets on the strip to dislodge shortening will distort the strip, adversely affecting

its fit. It is designed for a tight fit and should only be removed for cleaning.

WARNING

To ensure the safe and efficient operation of the fryer and hood, the electrical plug for the 120-volt line, which

powers the hood, must be fully engaged and locked in its pin and sleeve socket.

NOTICE

The instructions in this manual for using a bulk oil system for filling and discarding oil are for an RTI system.

These instructions may not be applicable to other bulk oil systems.

WARNING

This appliance is not intended for use by children under the age of 16 or persons with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision

concerning use of the appliance by a person responsible for their safety. Do not allow children to play with this

appliance.

WARNING

If the electrical power supply cord is damaged, it must be replaced by a Frymaster Factory Authorized Servicer

or a similarly qualified person in order to avoid a hazard.

MANUAL LOV™ GAS WARRANTY STATEMENT

Frymaster, L.L.C. makes the following limited warranties to the original purchaser only for this

equipment and replacement parts:

A. WARRANTY PROVISIONS - FRYERS

1. Frymaster L.L.C. warrants all components against defects in material and workmanship for a

period of two years.

2. All parts, with the exception of the frypot, O-rings and fuses, are warranted for two years after

installation date of fryer.

3. If any parts, except fuses and filter O-rings, become defective during the first year after

installation date, Frymaster will also pay straight-time labor costs up to two hours to replace the

part, plus up to 100 miles/160 km of travel (50 miles/80 km each way).

B. WARRANTY PROVISIONS - FRYPOTS

1. Frymaster warrants the frypot assembly for fifteen (15) years. First ten (10) years parts and

labor. Years eleven (11) through fifteen (15) frypot only. Components attached to the frypot,

such as the high-limit, probe, gaskets, seals, ignitors and related fasteners, are also covered by the

fifteen year warranty if replacement is necessitated by the frypot replacement. Components that

are not part of the frypot assembly, such as the blower, gas valve, micro switches, doors and

cabinetry are not covered by the frypot warranty. Leaks due to abuse or from threaded fittings

such as probes, sensors, high-limits, drain valves or return piping are not included. If the frypot is

found to be defective, Frymaster will replace the frypot, allowing up to the maximum time per

the Frymaster time allowance chart hours of straight-time labor plus up to 100 miles/160 km of

travel (50 miles/80 km each way) to change the frypot.

2. This warranty is limited to fryers operating on natural or propane (LP) gas. Fryers that operate

on manufactured gas (also known as town gas or high-hydrogen gas) have a lifetime frypot

warranty, parts only.

C. WARRANTY PROVISIONS – COMBUSTION CHAMBERS

1. Frymaster L.L.C. warrants the combustion chambers against defective material or workmanship

for a period of ten years from the original installation date, parts and labor.

2. The combustion chamber consists of the infrared burners and the structural components to mount

the burners. This warranty does not cover ancillary components, including the igniter, blower,

high-limit thermostat, and temperature probe.

3. This warranty is limited to fryers operating on natural or propane (LP) gas.

i

E. PARTS RETURN

All defective in-warranty parts must be returned to a Frymaster Factory Authorized Servicer within

60 days for credit. After 60 days, no credit will be allowed.

F. WARRANTY EXCLUSIONS

This warranty does not cover equipment that has been damaged due to misuse, abuse, alteration, or

accident such as:

• improper or unauthorized repair (including any frypot which is welded in the field);

• failure to follow proper installation instructions and/or scheduled maintenance procedures as

prescribed in your MRC cards. Proof of scheduled maintenance is required to maintain the warranty;

• improper maintenance;

• damage in shipment;

• abnormal use;

• removal, alteration, or obliteration of either the rating plate or the date code on the heating elements;

• operating the frypot without shortening or other liquid in the frypot;

• no fryer will be warranted under the ten-year program for which a proper start-up form has not been

received.

This warranty also does not cover:

• transportation or travel over 100 miles/160 km (50 miles/80 km each way), or travel over two hours;

• overtime or holiday charges;

• consequential damages (the cost of repairing or replacing other property which is damaged), loss of

time, profits, use or any other incidental damages of any kind.

There are no implied warranties of merchantability or fitness for any particular use or purpose.

This warranty is applicable at the time of this printing and is subject to change.

ii

BIGL30 MANUAL LOV™ SERIES GAS FRYER

CHAPTER 1: INTRODUCTION

NOTE: The Frymaster BIGL30 fryer requires a start-up, demonstration and training be-

fore normal restaurant operations can begin.

1.1 General

Read the instructions in this manual thoroughly before attempting to operate this equipment. This manual covers

all configurations of models and BIGL30 Manual LOV™ fryers. Models designated BIGL30 are equipped with

FootPrint Pro built-in filtration systems. The fryers in this model family have most parts in common, and when

discussed as a group, will be referred to as “Manual LOV™ fryers.

Although similar in appearance to the BIPH55 McDonald’s fryers, the BIGL30 Manual LOV™ fryers feature a

low oil volume frypot. The Euro-Look design incorporates a rounded topcap and a large round drain which ensures

that fries and other debris will be washed into the filter pan. The BIGL30 Manual LOV™ fryers are controlled

with an M3000 Manual LOV™ controller. Fryers in this series come in full- or split-vat arrangements, and can be

purchased in batteries of up to five vats.

Manual LOV™ high-efficiency gas fryers employ a unique infrared burner system that uses up to 43% less energy

to cook the same volume as conventional open-burner fryers.

Manual LOV™ gas fryers are of an open-frypot design with no tubes, which makes cleaning the stainless frypot

quick and easy.

Heating is supplied by a pair of infrared burner assemblies mounted on each side of the frypot. A dedicated

blower mounted on the front of the frypot supplies combustion air for the burners. Manual LOV™ Gas fryers can

be configured for natural gas or propane (LP), as required by the customer.

Each frypot is equipped with a temperature probe for precise temperature control.

All fryers in this series require an external source of AC electrical power. Units can be configured for voltages

ranging from 100 VAC to 240 VAC.

BIGL30 Manual LOV™ fryers are shipped completely assembled. All fryers are shipped with a package of

standard accessories. Each fryer is adjusted, tested, and inspected at the factory before crating for shipment.

This appliance is only for professional use and shall be used by qualified personnel only, as defined in

Section 1.6.

1.2 Safety Information

Before attempting to operate your unit, read the instructions in this manual thoroughly. Throughout this manual,

you will find notations enclosed in double-bordered boxes similar to the ones that follow.

CAUTION

CAUTION boxes contain information about actions or conditions that may cause or result

in a malfunction of your system.

WARNING

WARNING boxes contain information about actions or conditions that may cause or result

in damage to your system, and which may cause your system to malfunction.

1-1

DANGER

DANGER boxes contain information about actions or conditions that may cause or result

in injury to personnel, and which may cause damage to your system and/or cause your

system to malfunction.

Your fryer is equipped with automatic safety features:

1. High-temperature detection shuts off gas to the burner assembly should the controlling thermostat fail.

2. A safety circuit on units with filter systems prevents burner ignition with the drain valve open.

1.3 Controller Information

FCC COMPLIANCE

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part

15 of the FCC rules. While this device is a verified Class A device, it has been shown to meet the Class B limits.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses and can radiate radio frequency energy and,

if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of the equipment in a residential area is likely to cause harmful interference in which case the user will

be required to correct the interference at his own expense.

The user is cautioned that any changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to operate the equipment.

If necessary, the user should consult the dealer or an experienced radio and television technician for additional

suggestions.

The user may find the following booklet prepared by the Federal Communications Commission helpful: "How to

Identify and Resolve Radio-TV Interference Problems". This booklet is available from the U.S. Government Printing Office, Washington, DC 20402, Stock No. 004-000-00345-4.

1.4 European Community (CE) Specific Information

The European Community (CE) has established certain specific standards regarding equipment of this type.

Whenever a conflict exists between CE and non-CE standards, the information or instructions concerned are

identified by means of shadowed boxes.

1.5 Installation, Operating, and Service Personnel

Operating information for Frymaster equipment has been prepared for use by qualified and/or authorized personnel

only, as defined in Section 1.6. All installation and service on Frymaster equipment must be performed by

qualified, certified, licensed, and/or authorized installation or service personnel, as defined in Section 1.6.

1-2

1.6 Definitions

QUALIFIED AND/OR AUTHORIZED OPERATING PERSONNEL

Qualified/authorized operating personnel are those who have carefully read the information in this manual and

have familiarized themselves with the equipment functions, or who have had previous experience with the

operation of the equipment covered in this manual.

QUALIFIED INSTALLATION PERSONNEL

Qualified installation personnel are individuals, firms, corporations, and/or companies which, either in person or

through a representative, are engaged in and are responsible for the installation of gas-fired appliances. Qualified

personnel must be experienced in such work, be familiar with all gas precautions involved, and have complied

with all requirements of applicable national and local codes.

QUALIFIED SERVICE PERSONNEL

Qualified service personnel are those who are familiar with Frymaster equipment and who have been authorized by

Frymaster, L.L.C. to perform service on the equipment. All authorized service personnel are required to be

equipped with a complete set of service and parts manuals, and to stock a minimum amount of parts for Frymaster

equipment. A list of Frymaster Factory Authorized Servicers (FAS’s) is located on the Frymaster website at

www.frymaster.com

equipment.

. Failure to use qualified service personnel will void the Frymaster warranty on your

1.7 Shipping Damage Claim Procedure

Your Frymaster equipment was carefully inspected and packed before leaving the factory. The transportation

company assumes full responsibility for safe delivery upon its acceptance of the equipment for transport.

What to do if your equipment arrives damaged:

1. File a claim for damages immediately, regardless of the extent of damages.

2. Inspect for and record all visible loss or damage, and ensure that this information is noted on the freight bill

or express receipt and is signed by the person making the delivery.

3. Concealed loss or damage that was unnoticed until the equipment was unpacked should be recorded and

reported to the freight company or carrier immediately upon discovery. A concealed damage claim must be

submitted within 15 days of the date of delivery. Ensure that the shipping container is retained for inspection.

Frymaster

DOES NOT ASSUME RESPONSIBILITY FOR DAMAGE OR LOSS

INCURRED IN TRANSIT.

1.8 Parts Ordering and Service Information

For non-routine maintenance or repairs, or for service information, contact your local Frymaster Authorized Servicer (FAS). In order to assist you quickly, the Frymaster Authorized Servicer (FAS) or Service Department

representative requires certain information about your equipment. Most of this information is printed on a data

plate affixed to the inside of the fryer door. Part numbers are found in the Service and Parts Manual. Parts orders

may be placed directly with your local FAS or distributor. A list of Frymaster Factory Authorized Servicers

(FAS’s) is located on the Frymaster website at www.frymaster.com

the Frymaster Service Department at 1-800-551-8633 or 1-318-865-1711.

. If you do not have access to this list, contact

1-3

When ordering parts, the following information is required:

Model Number:

Serial Number:

Type of Gas or Voltage:

Item Part Number:

Quantity Needed:

Service information may be obtained by contacting your local FAS/Distributor. Service may also be obtained by

calling the Frymaster Service Department at 1-800-551-8633 or 1-318-865-1711 or by email at

service@frymaster.com

. When requesting service, please have the following information ready:

Model Number:

Serial Number:

Type of Gas:

In addition to the model number, serial number, and type of gas, please be prepared to describe the nature of the

problem and have ready any other information that you think may be helpful in solving your problem.

RETAIN AND STORE THIS MANUAL IN A SAFE PLACE FOR FUTURE USE.

1-4

BIGL30 MANUAL LOV™ SERIES GAS FRYER

CHAPTER 2: INSTALLATION INSTRUCTIONS

2.1 General Installation Requirements

Qualified, licensed, and/or authorized installation or service personnel, as defined in Section

1.7 of this manual, should perform all installation and service on Frymaster equipment.

Conversion of this appliance from one type of gas to another should only be performed by

qualified, licensed, and/or authorized installation or service personnel as defined in Section 1.7

of this manual.

Failure to use qualified, licensed, and/or authorized installation or service personnel (as defined in Section 1.7 of this manual) to install, convert to another gas type or otherwise service

this equipment will void the Frymaster warranty and may result in damage to the equipment

or injury to personnel.

Where conflicts exist between instructions and information in this manual and local or national codes or regulations, installation and operation shall comply with the codes or regulations in

force in the country in which the equipment is installed.

DANGER

Building codes prohibit a fryer with its open tank of hot oil being installed beside an

open flame of any type, including those of broilers and ranges.

Upon arrival, inspect the fryer carefully for visible or concealed damage. (See Shipping Damage

Claim Procedure in Chapter 1.)

2.1.1 Clearance and Ventilation

The fryer(s) must be installed with a 6” (150 mm) clearance at both sides and back when installed

adjacent to combustible construction; no clearance is required when installed adjacent to

noncombustible construction. A minimum of 24” (600 mm) clearance should be provided at the

front of the fryer.

WARNING

Do not block the area around the base or under the fryers.

DANGER

No structural material on the fryer should be altered or removed to accommodate

placement of the fryer under a hood. Questions? Call the Frymaster Dean Service

Hotline at 1-800-551-8633.

2-1

One of the most important considerations of efficient fryer operation is ventilation. Make sure the

fryer is installed so that products of combustion are removed efficiently, and that the kitchen

ventilation system does not produce drafts that interfere with burner operation.

The fryer flue opening must not be placed close to the intake of the exhaust fan, and the fryer must

never have its flue extended in a “chimney” fashion. An extended flue will change the combustion

characteristics of the fryer, causing longer recovery time. It also frequently causes delayed ignition.

To provide the airflow necessary for good combustion and burner operation, the areas surrounding

the fryer front, sides, and rear must be kept clear and unobstructed.

DANGER

This appliance must be installed with sufficient ventilation to prevent the occurrence

of unacceptable concentrations of substances harmful to the health of personnel in

the room in which it is installed.

Fryers must be installed in an area with an adequate air supply and adequate ventilation. Adequate

distances must be maintained from the flue outlet of the fryer to the lower edge of the ventilation

filter bank. Filters should be installed at an angle of 45º. Place a drip tray beneath the lowest edge

of the filter. For U.S. installation, NFPA standard No. 96 states, “A minimum distance of 18 in.

(450 mm) should be maintained between the flue outlet and the lower edge of the grease filter.”

Frymaster recommends that the minimum distance be 24 in. (600 mm) from the flue outlet to the

bottom edge of the filter when the appliance consumes more than 120,000 BTU per hour.

For installations in the United States, information on construction and installation of ventilating

hoods can be found in the NFPA standard cited above. A copy of the standard may be obtained

from the National Fire Protection Association, Battery March Park, Quincy, MA 02269.

2.1.2 National Code Requirements

The type of gas for which the fryer is equipped is stamped on the data plate attached to the inside of

the fryer door. Connect a fryer stamped “NAT” only to natural gas, those stamped “PRO” only to

propane gas, and those stamped “MFG” only to manufactured gas.

Installation shall be made with a gas connector that complies with national and local codes, and,

where applicable, CE codes. Quick-disconnect devices, if used, shall likewise comply with national,

local, and, if applicable, CE codes. In the absence of local codes, installation must conform to the

national Fuel Gas Code, ANSI Z223.1/NFPA 54 or the Natural Gas and Propane Installation code,

CSA B149.1, as applicable including:

1. The appliance and its individual shutoff valve must be disconnected form the gas supply piping

system during any pressure testing of the system at test pressures in excess of ½ psi (3.5 kPa).

2. The appliance must be isolated from the gas supply piping system by closing its individual

manual shutoff valve during any pressure testing of the gas supply piping system at test

pressures equal to or less than ½ psi (3.5 kPa).

2-2

2.1.3 Electrical Grounding Requirements

All electrically operated appliances must be grounded in accordance with all applicable national and

local codes, and, where applicable, CE codes. In the absence of local codes, the appliance must be

grounded in accordance with National Electrical Code, ANSI/NFPA 70, or the Canadian Electrical

Code, CSA C22.2, as applicable. All units (cord connected or permanently connected) should be

connected to a grounded power supply system. A wiring diagram is located on the inside of the

fryer door. Refer to the rating plate on the inside of the fryer door for proper voltages.

DANGER

This appliance is equipped with a special (grounding) plug for your protection

against electrical shock, and must be plugged directly into a properly grounded receptacle. Do not cut, remove, or otherwise bypass the grounding prong on this

plug!

DANGER

This appliance requires electrical power for operation. Place the gas control valve in

the OFF position in case of a prolonged power outage. Do not attempt to operate

this appliance during a power outage.

2.1.4 Australian Requirements

To be installed in accordance with AS 5601, local authority, gas, electricity, and any other relevant

statutory regulations.

If casters are fitted, the installation must comply with AS5601 and AS1869 requirements.

2.2 Caster/Leg Installation

Depending upon the specific configuration ordered, your fryer may have been shipped without

installed casters or legs. DO NOT INSTALL THIS APPLIANCE WITHOUT CASTERS OR

LEGS. If the appliance requires the installation of casters or legs, install them in accordance

with the instructions included in your accessory package.

On an appliance with casters; the installation shall be made with a connector that complies with the

Standard for Moveable Gas Appliances, ANSI Z21.69 • CSA 6.16, and a quick disconnect device

that complies with the Standard for Quick-Disconnect Devices for Use With Gas Fuel, ANSI Z21.41

• CSA 6.9.

2.3 Pre-Connection Preparations

DANGER

DO NOT connect this appliance to the gas supply before completing each step in

this section.

After the fryer has been positioned under the exhaust hood, ensure the following has been

accomplished:

2-3

(1)

1. Adequate means must be provided to limit the movement of fryers without depending upon the

gas line connections. If a flexible gas hose is used, a restraining cable must be connected at all

times when the fryer is in use. The restraining cable and installation instructions are packed with

the flexible hose in the accessories box that was shipped with your unit.

DANGER

Do not attach an apron drainboard to a single fryer. The fryer may become unstable,

tip over, and cause injury. The appliance area must be kept free and clear of

combustible material at all times.

2. Level fryers equipped with legs by screwing out the legs approximately 1 inch then adjusting

them so that the fryer is level and at the proper height in the exhaust hood. Frymaster

recommends that the minimum distance from the flue outlet to the bottom edge of the hood be 24

in. (600 mm) when the appliance consumes more than 120,000 BTU per hour. NOTE: There

are no built-in leveling devices on fryers equipped with casters. The floor where the fryer is to

be installed must be level.

3. Test the fryer electrical system:

a. Plug the fryer electrical cord(s) into a grounded electrical receptacle.

b. Place the computer switch in the ON position. Verify that the display indicates MLT-

CYCL.

c. Place the computer power switch in the OFF position. Verify that the display indicates

OFF.

4. Refer to the data plate on the inside of the fryer door to determine if the fryer burner is configured

for the proper type of gas before connecting the fryer quick-disconnect device or piping from the

gas supply line.

5. Verify the minimum and maximum gas supply pressures for the type of gas to be used in

accordance with the accompanying tables.

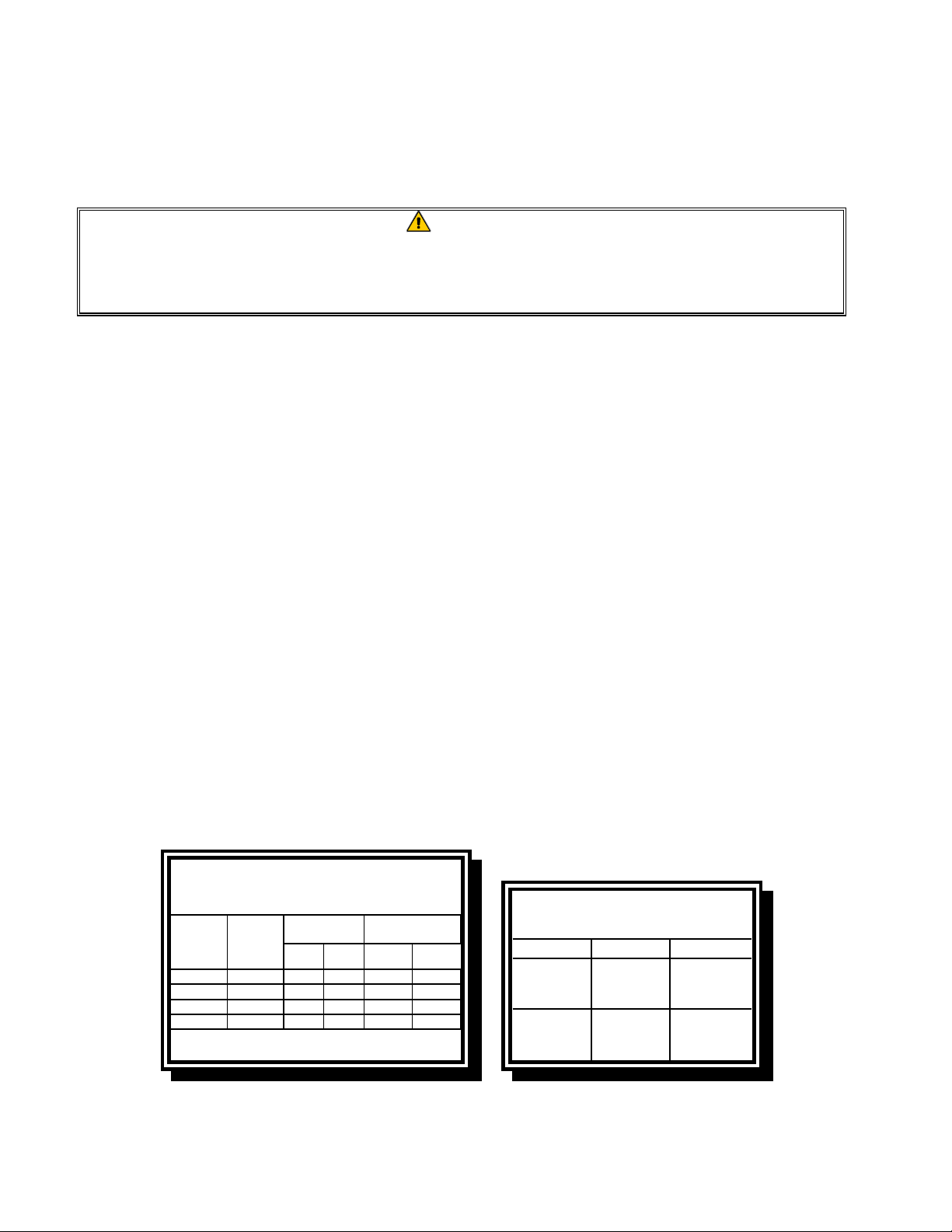

CE Standard

for Incoming Gas Pressures

for Fryers Manufactured After April 1999

Pressure

Gas

G2 0 2 0 2 x 3 . 18 2 x 3 . 18 7 mbar 8 mb ar

G25 20 or 25 2 x 3.18 2 x 3.18 10 mbar 11. 2 mbar

G3 0 28/30 or 50 2 x 1.95 2 x 1 .95 17 mbar 17 mbar

G31 37 or 50 2 x 1.95 2 x 1.95 20. 6 mbar 20.6 mbar

mbar = 10,2 mm H2O

(mbar)

Orific e Diameter

Single

(1)

Vat

Dual

Vat

Regulator Pressur e

Single

Vat

Dual

Vat

Non-CE Standard

for Incoming Gas Pressures

Gas Minimum Maximum

Natural

LP

6" W.C.

1.49 kPa

14.93 mbar

11" W.C.

2.74 kPa

27.37 mbar

14" W.C.

3.48 kPa

34.84 mbar

14" W.C.

3.48 kPa

34.84 mbar

6. For fryers equipped with a FootPrint Pro system or basket lifts, plug the electrical cord(s) into a

power receptacle behind the fryer.

2-4

Loading...

Loading...