OPERATOR'S MANUAL

BOX BLADES

BB3272

BB3284

BB3296

BB32_5TL15288_07/10

TO THE DEALER:

Assembly and proper installation of this product is the responsibility of the Frontier dealer. Read manual instructions and safety rules. Make sure all items on the Dealer’s Pre-Delivery and Delivery Check

Lists in the Owner’s/Operator’s Manual are completed before releasing equipment to the owner.

The dealer must complete the Warranty Registration located on the Frontier website.

TO THE OWNER:

Read this manual before operating your Frontier equipment. The information presented will prepare

you to do a better and safer job. Keep this manual handy for ready reference. Require all operators to

read this manual carefully and become acquainted with all the adjustment and operating procedures

before attempting to operate. Replacement manuals can be obtained from your selling dealer.

The equipment you have purchased has been carefully engineered and manufactured to provide

dependable and satisfactory use. Like all mechanical products, it will require cleaning and upkeep.

Lubricate the unit as specified. Observe all safety information in this manual and safety decals on the

equipment.

For service, your authorized Frontier dealer has trained mechanics, genuine Frontier service parts, and

the necessary tools and equipment to handle all your needs.

Use only genuine Frontier service parts. Substitute parts will void the warranty and may not meet standards required for safe and satisfactory operation. Record the model number and serial number of your

equipment in the spaces provided:

Model:____________________________________ Date of Purchase:_________________

Serial Number: (see Safety Decal section for location)_______________________________

Provide this information to your dealer to obtain correct repair parts.

Throughout this manual, the term IMPORTANT is used to indicate that failure to observe can cause

damage to equipment. The terms CAUTION,WARNING and DANGER are used in conjunction with the

Safety-Alert Symbol, (a triangle with an exclamation mark), to indicate the degree of hazard for items

of personal safety.

This Safety-Alert Symbol indicates a hazard and means ATTENTION!

BECOME ALERT! YOUR SAFETY IS INVOLVED!

DANGER

WARNING

CAUTION

Indicates an imminently hazardous situation that, if not avoided, will result in

death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, could result in

death or serious injury, and includes hazards that are exposed when guards

are removed.

Indicates a potentially hazardous situation that, if not avoided, may result in

minor or moderate injury.

IMPORTANT

Indicates that failure to observe can cause damage to equipment.

NOTE

Indicates helpful information.

Introduction ii

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

SPECIFICATIONS / GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SAFETY DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

DEALER INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 10

OWNER SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 12

PARTS CATALOG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 - 14

BOLT SIZE AND BOLT TORQUE CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table of Contents

SPECIFICATIONS

BB3272 BB3284 BB3296

3-Point Hitch Category I and II Quick Hitch

(iMatch Compatible)

Working Width 72" 84" 96"

Tractor HP (MAX) 80 HP 80 HP 80 HP

Shipping Weight 856 lbs. 970 lbs. 1086 lbs.

Approximate Operating

Weight

Beam Type Tubular Scarier Beam Tubular Scarier Beam Tubular Scarier Beam

Scarier Shanks Notched Four Position Notched Four Position Notched Four Position

Points Heat Treated Points Heat Treated Points Heat Treated Points

Capacity 21 cu. ft. 24.50 cu. ft. 28 cu. ft.

Cutting Edges (2) 1/2” x 6’ Reversable (2) 1/2” x 6’ Reversable (2) 1/2” x 6’ Reversable

Beam Size 4” x 4” x 3/8” 4” x 4” x 3/8” 4” x 4” x 3/8”

End Plate Thickness 1/2” 1/2” 1/2”

Height 20” 20” 20”

Depth 26 1/2” 26 1/2” 26 1/2”

Tailgate Floating Floating Floating

Assembly Time 15 min. 15 min. 15 min.

Moldboard Thickness 1/4” 1/4” 1/4”

816 lbs. 911 lbs. 1036 lbs.

Category I and II Quick Hitch

(iMatch Compatible)

Category I and II Quick Hitch

(iMatch Compatible)

GENERAL INFORMATION

The purpose of this manual is to assist you

in operating and maintaining your Box

Blade. Read it carefully. It furnishes information and instructions that will help you

achieve years of dependable performance.

These instructions have been compiled

from field experience and engineering data.

Some information may be general in nature,

due to unknown and varying operating

conditions. However, through experience

and these instructions, you should be able

to develop procedures suitable to your particular situation.

1 Specifications

The illustrations and data used in this

manual were current at the time of printing. However, due to possible inline production changes, your machine may vary

slightly in detail. We reserve the right to

redesign and change the machines as

may be necessary without notification.

Throughout this manual, references are

made to right and left direction. These are

determined by standing behind the tractor

facing the direction of forward travel.

SAFETY & INSTRUCTIONAL DECALS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN SERIOUS INJURY OR DEATH

Replace Decals Immediately If Damaged!

5TL15286B

5TL15286C

5TL15286A

Safety Decals 2

BB3296 ONLY

SAFETY REFLECTOR DECALS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN SERIOUS INJURY OR DEATH

Replace Decals Immediately If Damaged!

9” YELLOW REFLECTORS

5TL15200

3 Safety Decals

9” RED REFLECTORS

5TL15199

Check that all reflector decals are installed

and in good condition. Replace if decals are

worn or damaged.

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Safety is a primary concern in the design and

manufacture of our products. Unfortunately, our

efforts to provide safe equipment can be wiped

out by an operator’s single careless act.

In addition to the design and configuration of

equipment, hazard control and accident prevention are dependent upon the awareness, concern, judgement, and proper training of personnel involved in the operation, transport, maintenance and storage of equipment.

It has been said “The best safety device is an

informed, careful operator.”We ask you to be

that kind of operator.

TRAINING

• Safety instructions are important! Read all

attachment and power unit manuals; follow all

safety rules and safety decal information.

(Replacement manuals are available from selling dealer.) Failure to follow instructions or

safety rules can result in serious injury or

death.

• If you do not understand any part of this manual and need assistance, see your dealer.

• Operators must be instructed in and be capable of the safe operation of the equipment, its

attachments, and all controls. Do not allow anyone to operate this equipment without proper

instructions.

rough-soled work shoes and protective equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

• Make sure attachment is properly secured,

adjusted, and in good operating condition.

• Power unit must be equipped with ROPS or

ROPS cab and seat belt. Keep seat belt

securely fastened. Falling off power unit can

result in death from being run over or crushed.

Keep foldable ROPS system in “locked up”

position at all times.

• A minimum 20% of tractor and equipment

weight must be on the tractor front wheels

when attachments are in transport position.

Without this weight, tractor could tip over, causing personal injury or death. The weight may be

attained with a loader, front wheel weights, ballast in tires or front tractor weights. Weigh the

tractor and equipment. Do not estimate.

TRANSPORTATION

• Always comply with all state and local laws

governing highway safety and lighting and

marking requirements.

• Never allow riders on power unit or attachment.

• Do not operate or transport on steep slopes.

• Never allow children or untrained persons to

operate equipment.

• Train all new personnel and review instruction’s

frequently with existing workers. A person who

has not read and understood all operating and

safety instructions is not qualified to operate the

machine. An untrained operator exposes himself

and bystanders to possible serious injury or

death.

PREPARATION

• Always wear relatively tight and belted clothing to

avoid getting caught in moving parts.Wear sturdy,

• Use extreme care and reduce ground speed

on slopes and rough terrain.

• Do not operate or transport equipment while

under the influence of alcohol or drugs. Consult

your doctor about operating this machine while

taking prescription medications.

OPERATION

• Never go underneath equipment (lowered to

the ground or raised) unless it is properly

blocked and secured. Never place any part of

the body underneath equipment or between

Safety Rules continued on next page.

Safety Rules 4

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Safety Rules continued from previous page.

OPERATION (cont’d)

moveable parts even when the engine has

been turned off. Hydraulic system leak down,

hydraulic system failures, mechanical failures,

or movement of control levers can cause

equipment to drop or rotate unexpectedly and

cause severe injury or death.

• Always comply with all state and local laws

governing highway safety and lighting and

marking requirements.

• Operate only in daylight or good artificial

light.

• Keep bystanders away from equipment.

• Keep hands, feet, hair, and clothing away

from equipment while engine is running. Stay

clear of all moving parts.

• Power unit must be equipped with ROPS or

ROPS cab and seat belt. Keep seat belt

securely fastened. Falling off power unit can

result in death from being run over or crushed.

Keep foldable ROPS system in “locked up”

position at all times.

• Never allow riders on power unit or attachment.

• Always sit in power unit seat when operating

controls or starting engine. Securely fasten

seat belt, place transmission in neutral, engage

brake, and ensure all other controls are disengaged before starting power unit engine.

• Look down and to the rear and make sure

area is clear before operating in reverse.

• Use extreme care when working close to fences,

ditches, other obstructions, or on hillsides.

• Do not operate or transport on steep slopes.

• Do not stop, start, or change directions sud-

denly on slopes. Always operate down slopes;

never across the face.

• Use extreme care and reduce ground speed

on slopes and rough terrain.

• Keep alert and watch the front as well as the

rear when operating.

• When making adjustments, be careful to keep

hands and feet clear of sliding parts and possible pinch points.

• Stop power unit and equipment immediately

upon striking an obstruction. Turn off engine,

remove key, inspect, and repair any damage

before resuming operation.

• Before leaving operator’s seat, lower lift arms

and put attachment on the ground. Engage

brake, stop engine, remove key, and remove

seat belt.

MAINTENANCE

• Always wear relatively tight and belted clothing to avoid getting caught in moving parts.

Wear sturdy, rough-soled work shoes and protective equipment for eyes, hair, hands, hearing, and head; and respirator or filter mask

where appropriate.

• Never go underneath equipment (lowered to

the ground or raised) unless it is properly

blocked and secured. Never place any part of

the body underneath equipment or between

moveable parts even when the engine has

been turned off. Hydraulic system leak down,

hydraulic system failures, mechanical failures,

or movement of control levers can cause equipment to drop or rotate unexpectedly and cause

severe injury or death.

• When performing maintenance or repairs

make sure the equipment is in the lowered

position and both the mainframe and gangs are

properly blocked and secured to prevent rolling.

Safety Rules continued on next page.

5 Safety Rules

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Safety Rules continued from previous page.

MAINTENANCE(cont’d)

Failure to do so can cause serious injury or

death.

• Make sure attachment is properly secured,

adjusted, and in good operating condition.

• Before leaving operator’s seat, lower lift arms

and put attachment on the ground. Engage

brake, stop engine, remove key, and remove

seat belt.

• Never perform service or maintenance with

engine running.

• Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

• Tighten all bolts, nuts, and screws to torque

chart specifications. Check that all cotter pins

are installed securely to ensure equipment is in

a safe condition before putting unit into service.

STORAGE

• Block equipment securely for storage.

• Keep children and bystanders away from stor-

age area.

Safety Rules 6

DEALER INSTRUCTIONS

Pre-Assembly

Attaching Scarifier Shanks in the Box

Blade

Remove scarifier shanks and shank keys from

carton inside box scraper.

Block up machine by placing two 4” x 4” blocks

under each side frame of the box blade.

Insert the scarifier shank in the shank hole from

the bottom up.

Note: The scarifier shank has four notches for

adjustments. The bottom notch is for transport.

The top three notches are for ground penetration to be determined by the user.

After inserting scarifier shank, place shank key

on the back side of shank. This will prevent the

shank from working loose.

Dealer Checklist

(Dealer’s Responsibility)

Inspect the equipment thoroughly after assembly to be certain it is set up properly before

delivering it to the customer. The following

check list is a reminder of points to inspect.

Check off each item if it is found satisfactory or

after proper adjustment is made.

____ Show customer the safe, proper procedures to be used when mounting, dismounting,

and storing equipment.

____ For mounted units, add wheel weights,

ballast in front tires, and/or front tractor weight

to enhance front end stability. A minimum 20%

of tractor and equipment gross weight must be

on front tractor wheels. When adding weight to

attain 20% of tractor and equipment weight on

front tractor wheels, you must not exceed the

ROPS weight certification. Weigh the tractor

and equipment. Do not estimate!

____ Show customer how to make adjustments.

____ Present Owner’s/Operator’s Manual and

request that customer and all operators read it

before operating equipment. Point out the

manual safety rules, explain their meanings

and emphasize the increased safety hazards

that exist when safety rules are not followed.

____ Point out the safety decals. Explain their

meaning and the need to keep them in place

and in good condition. Emphasize the increased

safety hazards when instructions are not followed.

____ Check that all safety decals are installed

and in good condition. Replace if damaged.

____ Check all bolts to be sure they are tight.

____ Check that all cotter pins and safety pins

are properly installed. prior to delivery to customer.

____ Explain to customer the potential crushing

hazards of going underneath raised equipment.

Instruct customer that service work does not

require going underneath unit and never to do

so.

____ Complete the Warranty Registration

located on the Frontier website.

7 Dealer Instructions

Operation

Safety is a primary concern in the design and

manufacture of our products. Unfortunately, our

efforts to provide safe equipment can be wiped

out by an operator’s single careless act.

In addition to the design and configuration of

equipment, hazard control and accident prevention are dependent upon the awareness, concern, judgement, and proper training of personnel involved in the operation, transport, maintenance and storage of equipment.

It has been said “The best safety device is an

informed, careful operator.”We ask you to be

that kind of operator.

The operator is responsible for the safe operation

of this equipment. The operator must be properly

trained. Operators should be familiar with the

equipment, the tractor, and all safety practices

before starting operation. Read the safety rules

and safety decals on pages 2-6.

Owner should check and tighten all hardware after

the first hour of operation. The break in stage of

your new box blade can cause minimal loosening

of hardware. Please see Bolt Torque Chart (page

16) for proper torque information.

• NEVER GO UNDERNEATH EQUIPMENT.

Never place any part of the body underneath

equipment or between moveable parts even

when the engine has been turned off. Hydraulic

system leak down, hydraulic system failures,

mechanical failures, or movement of control

levers can cause equipment to drop or rotate

unexpectedly and cause severe injury or death.

• Service work does not require going underneath.

• Read Manual for service instructions or have

service performed by a qualified dealer.

• Stop tractor and implement immediately upon

striking an obstruction. Turn off engine, remove

key, inspect, and repair any damage before

resuming operation.

• Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and

head.

Owner/Operator Pre-Operation

Checklist

(Owner’s/Operator’s Responsibility)

WARNING

• Power unit must be equipped with ROPS or

ROPS cab and seat belt. Keep seat belt

securely fastened. Falling off power unit can

result in death from being run over or crushed.

Keep foldable ROPS systems in “locked up”

position at all times.

• Never allow children or untrained persons to

operate equipment.

• Keep bystanders away from equipment.

____ Review and follow all safety rules and

safety decal instructions on page 2 through

page 6.

____ Check that equipment is properly and

securely attached to tractor.

____ Check that all safety decals are installed

and in good condition. Replace if damaged.

____ Check that all hardware is properly

installed and secured.

____ Do not allow riders.

____ Make sure tractor ROPS or ROPS CAB

and seat belt are in good condition. Keep seat

belt securely fastened during operation.

Operation 8

Connecting Box Blade to the Tractor

The box blade is compatible with tractors

equipped with Category 1 or Category 2, 3-point

hitch systems that use side-swing type lower lift

arms. The box blades will also fit tractors

equipped with a Category 1 and 2 Quick Hitch

system.

NOTE: When attaching box blade to any hitch

other than a standard Category 1 hitch, bushings must be purchased separately.

Category 1 Standard (Figure 1)

1. Attach the tractor’s lower lift arms to the box

blade through the lower, inner set of holes.

Figure 2. Category 1 Quick Hitch Set-up

Category 1 Quick Hitch (Figure 2)

2. Use the hitch pin supplied with your box

blade and re-install the lynch pins.

3. Attach the tractor’s top link to the box blade’s

mast using the heavy-duty top link pin and

lynch pin supplied with the top link.

Figure 1. Category 1 and 2 Hitch Set-up

1. Connect the tractor’s Quick Hitch to the box

blade through the upper, inner set of holes.

2. Slide lower sleeve (sold seperatly) over the

mounting pin supplied with box blade. Re-install

lynch pins.

3. Slide upper sleeve over the heavy-duty top

link pin supplied with top link. Reinstall retaining

pin.

Category 2 Standard (Figure 1)

1. Use Category 1 Standard instructions except

use lower, outer set of holes.

9 Operation

Figure 3. Category 2 Quick Hitch Set-up

Category 2 Quick Hitch (Figure 3)

1. Connect the tractor’s Quick Hitch to the box

blade through the upper, outer set of holes.

2. Slide upper sleeve over the heavy-duty top

link pin supplied with top link. Reinstall retaining

pin.

Operation(cont.)

ADJUSTING TOP LINK

The box blade is leveled by adjusting the

length of the tractor’s top link.

• Shortening the top link will deepen the scarifier tooth penetration.

• Lengthening the top link will provide better

scraping and leveling action.

• Experience will allow the operator to determine the best setting for the application being

done.

SCARIFYING

1. Place the scarifier shanks in position with

the points facing toward the tractor.

2. Lock into position with the shank key provided. The lower shank position provides the

greatest ground penetration.

3. Lower the box blade and drive the tractor

ahead to begin the scarifying operation.

4. Adjust the depth of the scarifier by tilting

the unit with the tractor top link. Shortening

the top link will provide deeper and more

aggressive operation.

3. To change the level of the box blade, shorten

or lengthen the tractor lift arm tilt link to provide

the correct slope.

4. Spread material by gradually raising the box

blade as the tractor moves forward. Top link

adjustment for loose or previously scarified

material will differ from adjustment for hard or

compacted material.

BACKFILLING

1. Raise or remove scarifier shanks.

2. Lower the box blade to the ground and back

up into the fill material.

3. Shorten the top link to raise the cutting blade

and control how much the box blade digs in.

LEVELING

1. Raise or remove scarifier shanks.

2. Shorten the top link so the cutting edge

clears the ground.

3. Drive forward with the box blade in this position and loose material will be leveled.

SCRAPING

1. Raise or remove the scarifier shanks.

Lower the box blade and drive forward to

move material.

2. Adjust the depth of the box blade by tilting

the unit with the tractor top link. Shortening

the top link when scraping will transfer more

weight on the front of the box blade and will

raise the cutting blade to provide a more shallow cut.

NOTE: When the top link is adjusted properly,

the bowl of the box blade should fill easily and

material can be pulled to a desired location.

WARNING

STORAGE

• Block equipment securely for storage (see

Blocking Up Box Blade, page 11).

• Keep children and bystanders away from

storage area.

Operation 10

Owner Service

The information in this section is written for operators who possess basic mechanical skills. If you

need help, your dealer has trained service technicians available. For your protection, read and

follow the safety information in this manual.

WARNING

• NEVER GO UNDERNEATH EQUIPMENT.

Never place any part of the body underneath

equipment or between moveable parts even

when the engine has been turned off. Hydraulic

system leak down, hydraulic system failures,

mechanical failures, or movement of control

levers can cause equipment to drop or rotate

unexpectedly and cause severe injury or death.

• Service work does not require going underneath.

• Read Manual for service instructions or have

service performed by a qualified dealer.

BLOCKING UP BOX BLADE

WARNING

NOTE: To service the box blade when attached

to the tractor, it must be blocked up off the

ground.

1. Place two 4" x 4" blocks under each side frame

of the box blade as shown in Figure 4.

2. Lower the box blade to rest securely on the

blocks.

3. Do not block the machine any higher than

needed for removing the shanks or cutting edge.

Storage

When storing your box blade make sure the unit

is placed on level ground and that the box blade

is properly chocked by bracing with 4” x 4” blocks

on the front and rear side of each end of the box

blade.

WARNING

• Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

• Before dismounting power unit or performing

any service or maintenance, follow these steps:

disengage power to equipment, lower the 3 point

hitch and all raised components to the ground,

CAUTION

operate valve levers to release any hydraulic

pressure, set parking brake, stop engine, remove

key, and unfasten seat belt.

• Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and

head.

4” x 4” blocks securing gang for storage

Figure 4

11 Owner Service

REMOVING SCARIFIER SHANKS

1

2

REPLACING SCARIFIER TOOTH

Scarifier shanks have four operating positions in

the box blade. They may be removed if scarifying

action is not needed.

1. Block up machine by placing two 4" x 4" (10

x 10 cm) blocks under each side-frame of the box

blade (see Page 11, Figure 4).

2. Lower the box blade to rest securely on the

blocks.

NOTE: Do not block the machine any higher than

necessary to remove the shanks or cutting

edge.

3. Remove shank key for disengagement of

shank.

4. Disengage shank retaining notch from box

blade frame.

5. Remove shank from bottom of tube (see

Figure 5).

1. Remove scarifier shank from the scarifier bar.

2. To replace the tooth from the scarifier shank

you will need a hand grinder to remove the weld

that bonds the tooth to the shank. A new tooth

can be rewelded to the shank. Or you can order

a complete replacement scarifier shank from your

dealer.

3. Reinstall the shank in the scarifier bar.

1. SHANK

2. TOOTH

Retaining

Notch

Shank

Figure 5. Scarier Shanks Adjustment

Shank Key

REPLACING CUTTING EDGE

To service the box blade when attached to the

tractor, it must be blocked up off the ground.

1. Place two 4" x 4" (10 x 10 cm) blocks under

each side-frame of the box blade (see Figure 4).

2. Lower the box blade to rest securely on the

blocks.

NOTE: Do not block the machine any higher than

necessary to remove the shanks or cutting

edge.

3. Refer to parts drawing, page 13. Remove the

hex nuts (15) and plow bolts (13) from box blade.

Turn cutting edge over and use new edge, or

replace it if both edges have been used.

4. Attach cutting edge to box blade and secure

with plow bolts and hex nuts previously

removed.

Owner Service 12

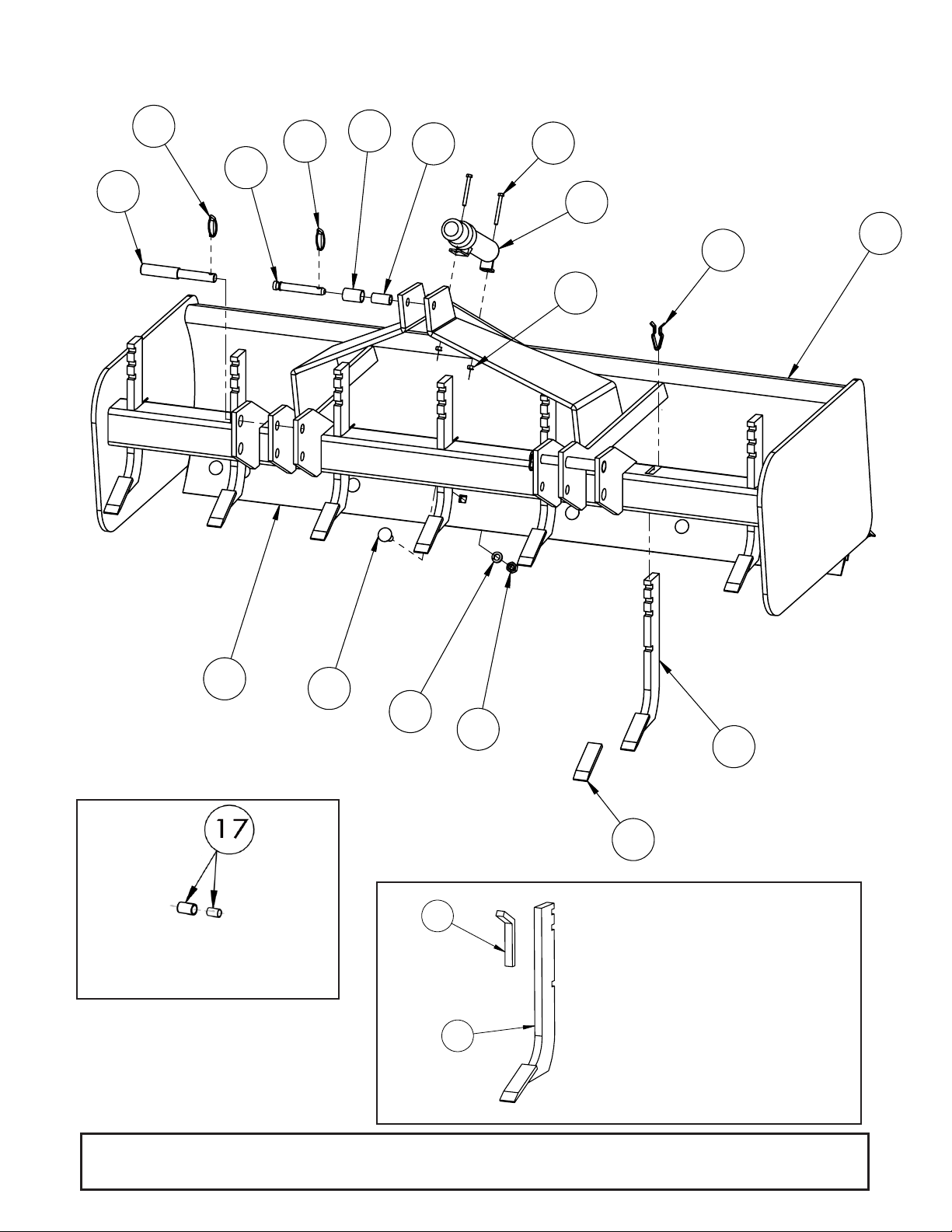

3

6

5

11

13

12

10

8

16

15

1

14

7

2

4

3

9

NYLON INSERT LOCK NUT, 5/16"

2

P-BOLT 5/8" X 1 3/4" GR. 5

16

T-24

LOCK WASHER, 5/8"

16

T-22

HEX NUT, 5/8"

16

Figure 1

8A

7A

PART NUMBER

DESCRIPTION

QTY.

14834

SCARIFIER SHANK

1

10697

SCARIFIER POINT

1

15281 1

Set of Lower Hitch

Bushings for iMatch

(Sold Separately)

Part # 5TL14834 & # 5TL15281

Used on units prior to

Serial #XFBB32X000153

13 Parts Catalog

Parts List (cont’d)

Ref.# Part # Description Qty.

1 5TL15259

5TL15260

5TL15261

2 5TL13257 CAT. 1 & 2 HITCH PIN 2

3 5TLVP252 LYNCH PIN 3

4 5TL15206 CAT. 1 TOP LINK PIN, 3 7/8" USABLE LENGTH 1

5 5TL15209 CAT. 1 BUSHING, 1 15/16" 1

6 5TL15210 CAT. 2 BUSHING, 1 15/16" 1

7 5TL15413 SHANK RETAINER CLIP *MS

7A 5TL15281 SHANK KEY *MS

8 5TL14835F SCARIFIER SHANK WITH WELD ON POINT *MS

8A 5TL14834 SCARIFIER SHANK WITH WELD ON POINT *MS

9 5TL10697 SCARIFIER POINT ONLY *MS

10 5TL10704

5TL10705

5TL10706

11 5TL15189 ASSEMBLY MANUAL TUBE AND CAP 1

12 5TL15287 HEX BOLT, 5/16" X 3" GR. 2 2

13 5TL15198 NYLON INSERT LOCK NUT, 5/16" 2

14 5TL10699 PLOW BOLT, 5/8" X 1 3/4" *MS

15 5TLT24 5/8" LOCKWASHER *MS

16 5TLT22 5/8" HEX NUT *MS

17 5TL15638 SET OF LOWER HITCH BUSHINGS FOR IMATCH N/A

5TL15288 BB32 ASSEMBLY MANUAL (NOT SHOWN) 1

5TL15282 MODEL BB3272 DECAL (NOT SHOWN) 1

5TL15283 MODEL BB3284 DECAL (NOT SHOWN) 1

5TL15284 MODEL BB3296 DECAL (NOT SHOWN) 1

5TL15285 3 1/3" FRONTIER LOGO DECAL (NOT SHOWN) 2

5TL15286 SAFETY DECAL SHEET (incl. 4 decals)(NOT SHOWN) 1

5TL15199 9” RED REFLECTOR (NOT SHOWN) 2

5TL15200 9” YELLOW REFLECTOR (NOT SHOWN) 2

MAIN BOX WELDMENT MODEL BB3272

MAIN BOX WELDMENT MODEL BB3284

MAIN BOX WELDMENT MODEL BB3296

CUTTING EDGE, 72" MODEL BB3272

CUTTING EDGE, 84" MODEL BB3284

CUTTING EDGE, 96" MODEL BB3284

1

1

1

2

2

2

* M/S - Model Specific Parts Catalog 14

Bolt Size Chart

SAE Torque Chart

15 Bolt Size and Bolt Torque Chart

Notes

Notes 16

PART NO.

5TL15288

© 2010 Monroe Tufline Manufacturing, Inc. All Rights Reserved

Loading...

Loading...