Page 1

OPERATOR'S MANUAL

Hydraulic

DEBRIS BLOWER

BL2130

OM 0401-A

02/11

Page 2

Page 3

TABLE OF CONTENT

SPÉCIFICATIONS ........................................................................................................................................... 3

INTRODUCTION – TO THE PURCHASER .................................................................................................... 4

SAFETY ...................................................................................................................................................... 5-11

Before Operation .................................................................................................................................. 5

Notice .................................................................................................................................................. 6

Debris Blower ....................................................................................................................................... 6

Before Operation...................................................................................................................... 6

Debris Blower Operation ......................................................................................................... 7

The Tractor ........................................................................................................................................... 8

General Information ................................................................................................................. 8

Operating the Tractor ............................................................................................................... 8

During Operation...................................................................................................................... 9

Maintenance ....................................................................................................................................... 10

Transportation .................................................................................................................................... 11

Storage ............................................................................................................................................... 11

DECALS .......................................................................................................................................................... 12

ASSEMBLY ...................................................................................................................................... 13-18

Tractor Preparation .............................................................................................................................. 13

Debris Blower Assembly ...................................................................................................................... 13

Debris Blower removing front wooden crate ...................................................................... 14

Installation of the Debris Blower ......................................................................................... 14

Installation of the Hydraulic Hoses ..................................................................................... 15

Installation of the Cooling Unit – 5RDF0036 ................................................................. 16-17

Removing Debris Blower from Tractor ............................................................................... 18

OM 0401-A

1

Page 4

TABLE OF CONTENT

OPERATION ............................................................................................................................................ 19-21

Optimum Performances ....................................................................................................................... 19

General Preparation ............................................................................................................................. 19

Operating Controls ............................................................................................................................... 20

Debris Blower Commands .................................................................................................. 20

Debris Blower Utilization .................................................................................................... . 20

Nozzle air ejection Orientation ............................................................................................ 20

Adjustments .................................................................................................................. ....................... 21

Belt Tension Adjustment .................................................................................................... 21

MAINTENANCE ........................................................................................................................................ 22-26

Maintenance ......................................................................................................................................... 22

Storage ................................................................................................................................ 22

Hydraulic Oil ........................................................................................................................ 22

Lubrication ........................................................................................................................... 23

Periodic Checks .................................................................................................................. 23

Belt Replacement ................................................................................................................ 24

Impeller Removing and Reinstallation ................................................................................ 25

Troubleshooting ................................................................................................................................... 26

PARTS ...................................................................................................................................................... 27-36

Introduction ............................................................................................................................................... 27

Manual Holder ........................................................................................................................................... 27

Debris Blower –Belt Drive System ...................................................................................................... 28-29

Debris Blower – Housing .......................................................................................................................... 30

Debris Blower – Impeller Housing ............................................................................................................ 31

Debris Blower – Hitch and Wheels ........................................................................................................... 32

Hydraulic Components .......................................................................................................... ................... 33

Hydraulic Motor - 5RD3910088 ........................................................................................................... 34-35

Cooling Unit – 5RDF0036 (Option) .............................................................................................. ............ 36

TORQUE SPECIFICATION TABLE .................................................................................................... .... 37-39

OM 0401-A

2

Page 5

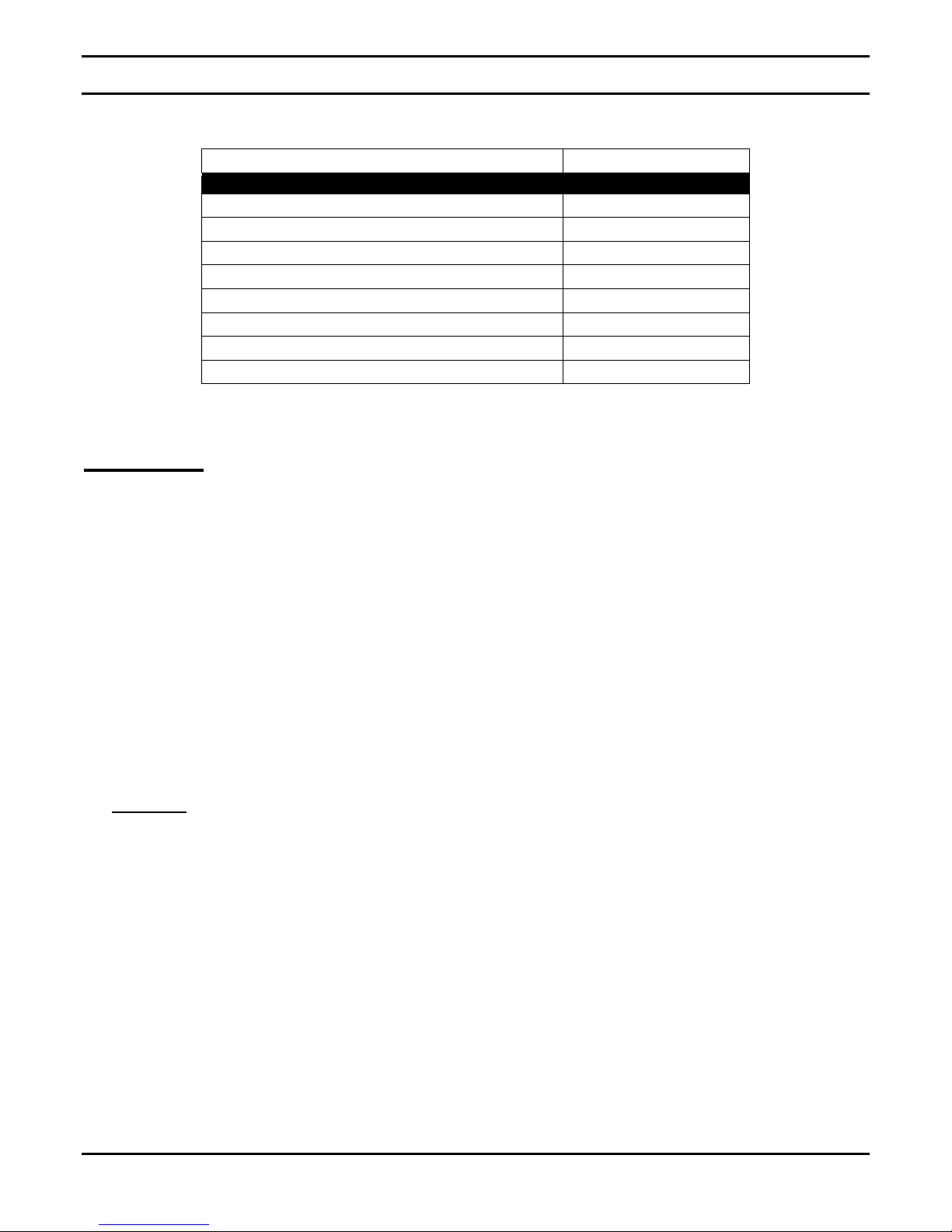

SPECIFICATION

Features and Specifications

Recommended Flow 12 to 23 gpm

Recommended Pressure 2000 @ 3000 psi

Air flow 6061 cfm @ 20 gpm

Impeller dimension 29 3/4" x 10" – 12 blades

Impeller speed 1560 rpm to 20 gpm

Air velocity 141 m/h – 227 km/h

Outlet area 70.4 sq.in – 454.2 sq.cm

Drive Belt 4-5VX560 "power ban d"

BL2130

Impeller Drive 125 cc/rev hydraulic motor

Check Valve Impeller motor

Main Hydraulic Hoses 3/4"

Approx. Set-up Time 2 to 3 hours ( including hydraulic pump)

Directional control Manual – left or right

Ground clearance 3 1/ 8"

Height adjustment Determined by tractor

Caster wheel 3 wheels – 12" dia. X 3" pn eumatic

Impeller housing

Dimension 46 1/2" length x 48 1/2" height x 49 1/4" width

Weight 655 lbs

Rear & front panel: 10ga

Housing edge : 12ga

OM 0401-A

3

Page 6

TO THE PURCHASER

INTRODUCTION

All products are designed to give safe, dependable

service if they are operated and maintained

according to instructions.

Read and understand this manual before

operation.

This manual has been prepared to assist the

owner and operators in the safe operation and

suitable maintenance of the implements. The

information was applicable to products at the time

of manufacture and does not include modifications

made afterwards.

Read and understand this operator's manual

before attempting to put an implement into

service. Familiarize yourself with the operating

instructions and all the safety recommendations

contained in this manual and those labeled on the

implements and on the tractor. Follow the safety

recommendations and make sure that those with

whom you work follow them.

The Dealer is responsible for wa rran t y re gistra ti on of t he uni t y ou h ave pu rchas ed . T o assis t yo ur deal er i n

handling your needs, please record here after the mo del numb er and seri al number o f your imple ment and

tractor. It is also advisable to supply them to your insurance company. It will be helpful in the event that an

implement or tractor is lost or stolen.

Illustrations

The illustrations may not necessarily reproduce

the full detail and the exact sha pe of the parts or

depict the actual models, but are intended for

reference only.

Direction Reference

Right Hand and Left Hand are determined by

those seen by the conductor standing behi nd the

equipment.

TRACTOR DEBRIS BLOWER

MODEL :

SERIAL NUMBER :

DATE OF PURCHASE :

OM 0401-A

4

Page 7

SAFETY

SAFETY FIRST

This symbol, the industry's "Safety Alert Symbol", is used th roughout this manual and on labels

on the machine itself to warn of the possibility of personal injury. Read these instructions

carefully. It is essential that you read the instructions and safety regulations before yo u attempt

to assemble or use this unit.

DANGER : Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING : Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION : Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

IMPORTANT : Indicates that equipment or property damage could result if instructions

are not followed.

NOTE : Gives helpful information.

All products are designed to give saf e, dependable service if they are operated and maintained according

to instructions. Read and understand this man ual before operation

be certain anyone operating this product reads this manual, and all other applicable manuals , to become

familiar with this equipment and all safety precautions. Failure to do s o could result in serious personal

injury or equipment damage. If you have any questions, consult your dealer.

. It is the owner's responsibility to

BEFORE OPERATION

Children and Bystanders

Tragic accidents can occur if the operator is not

alert to the presence of children. Children are

generally attracted to machines and the work

being done. Never assume children will remain

where you last saw them.

1. Keep children out of the operating area and

under the watchful eye of another

responsible adult.

2. Be alert and turn machine off if children enter

the work area.

3. Before and when backing, look behind and

look for small children.

4. Never carry children while operating the

machine. They may fall off and be seriously

injured or interfere with safe operation of the

machine.

5. Never allow children to play on the machine

or attachment even when turned off.

6. Never allow children to operate the machine

even under adult supervision.

7. Use extra care when approaching blind

corners, shrubs, trees, or other obstructions

that might hide children from sight.

OM 0401-A

5

Page 8

SAFETY - continued

NOTICE

A safe operator is the best insuranc e against accidents. All operators, no matter how experienced t hey

may be, should read this Operator's Manual and all other related manuals before attempting to opera te

an implement. Please read the following section and pay particular attention to all safety recommendations contained in this manual and those labeled on the implements and on the tractor.

DEBRIS BLOWER

Before Operation

1. Read and understand this operator's

manual and tractor operator's manual.

Know how to operate all controls and how

to stop the unit and disengage the controls

quickly.

2. Never wear loose, torn, or bulky clothing

around the tractor and implement. It may

catch on moving parts or controls, leading

to the risk of accident.

3. Clear the area of people, animals and large

debris before beginning operation

4. Disengage clutch and shift into neutral

before starting the engine.

5. Do not operate equipment in wintertime

without wearing adequate winter garments.

6. Never attempt to make any adjustments

while engine is running. Read this manual

carefully to acquaint yourself with the

equipment as well as the tractor operator's

manual. Working with unfamiliar equipment

can lead to accidents. Be thoroughly

familiar with the controls and proper use of

the equipment. Know how to stop the unit

and disengage the controls quickly.

9. Replace all missing, illegible, or damaged

safety and warning decals. See list of

decals in the operator's manual.

10. Do not modify or alter this equipment or

any of its components or any equipment

function without first consulting your dealer.

11. Keep safety decals clean of dirt and grime.

12. Make sure the tractor is counterweighted

as recommended by your dealer. Weights

provide the necessary balance to prevent

tip-over or loss of traction or steering

7. Keep all shields in place and properly

tighten all mounting hardware.

8. Periodically, inspect all moving parts for

wear and replace with authorized service

parts if an excessive amount of wear is

present.

OM 0401-A

6

Page 9

SAFETY - continued

Debris Blower Operation

1. Before leaving the tractor/debris blower

unattended, take all possible precautions.

Park the tractor/debris blower on level

ground, set the parking brake, disengage

debris blower drive, lower the debris blower

to the ground, place all levers including

auxiliary control levers in neutral, shut off the

engine and remove the ignition key.

2. Prior to operation, clear work area of all

objects that can be picked up and thrown.

Mark all curbs, pipes, etc. that cannot be

moved.

3. Be sure the debris blower drive is in OFF

position before starting engine.

4. Exercise extreme caution when operating on

or crossing a gravel drive, walks, or roads.

Stay alert for hidden hazards or traffic.

5. Do not carry passengers.

6. Keep clear of all rotating parts. Do not put

hands or feet under, or into debris blower

with engine running. Be especially

observant of the debris blower areas of

discharge, intake or all other mechanical

motions.

7. Park the tractor/debris blower on level

ground, set the parking brake, disengage

the debris blower drive, lower the debris

blower to the ground, place all control levers

in neutral, shut off the engine, remove the

ignition key and allow the rotating parts to

stop BEFORE making any repairs,

adjustments or inspections.

8. If the debris blower starts to vibrate

abnormally, disengage the pulley, stop the

engine immediately and check for cause.

Excessive vibration is generally a sign of

trouble.

9. Do not ru n the engine indoors except when

starting engine and transporting attachment

in or out of building. Carbon monoxide gas

is colorless, odorless and deadly.

10. Do not attempt to operate on ste ep slopes. If

operating on slopes is necessary, exercise

extreme caution when changing direction.

11. Never operate debris blower without guards,

and other safety protective de vices in place.

All tractor and debris blower shields and

covers must be correctly installed at all times.

When necessary to remove these, th ey must

be reinstalled immediately.

12. Never operate debris blower near glass

enclosures, automobiles, window wells,

embankments, etc., without proper

adjustment of the angling deflector.

13. Never operate machine at high transport

speeds on a slippery surface.

14. Use extra caution when backing up.

15. Disengage power to debris blower when

transporting or when n ot in use.

16. Never operate the debris blower without good

visibility and lighting.

17. Prolonged exposure to loud noise c an cause

impairment or loss of hearing. Wear a

suitable hearing protective device such as

earmuffs or earplugs to protect against

objectionable or uncomfortable noises.

18. Never allow anyone near the work area.

19. Never allow anyone to operate the debris

blower until they have read the manual

completely and are thoroughly familiar with

basic tractor and debris blower operation.

20. Always make sure all debris blower

components are properly installed and

securely fastened BEFORE operation.

21. Keep away from discharge. This debris

blower has the capacity to throw deb ris at far

distances.

22. Never direct discharge towards people or

animals. Thrown debris can cause serious

injury.

OM 0401-A

7

Page 10

THE TRACTOR

General Information

SAFETY - continued

1. Read the operator's manual carefully before

using tractor. Lack of operating knowledge

can lead to accidents.

Operating the Tractor

1. Never run the tractor engine in a closed

building without adequate ventilation, as

the exhaust fumes are very dangerous.

2. Never allow an open flame near the fuel

tank or battery.

3. Make sure the shield is installed when

using a PTO-driven equipment and always

replace the shield if damaged.

4. Always bring the tractor to a complete stop,

shut off the engine, lower the implement to

the ground and remove the ignition key

before leaving the tractor.

5. Never park the tractor on a steep slope.

6. Do not attempt to operate on steep slopes.

2. Do not allow anyone but the operator to ride

on the tractor. There is no safe place for

extra riders

14. A minimum 20% of tractor and equipment

weight must be on the tractor front wheels

when attachments are in transport position.

Without this weight, tractor could tip over,

causing personal injury or death. The

weight may be attained with a loader, front

wheel weights, ballast in tires or front

tractor weights. Weigh the tractor and

equipment. Do not estimate.

15. Always make sure all debris blower

components are properly installed and

securely fastened BEFORE operation.

7. Use of tire chains for better traction and

stability is recommended.

8. Always drive the tractor at speeds

compatible with safety, especially when

operating over rough ground, crossing

ditches, or when turning.

9. Handle fuel with care, as it is highly

flammable.

10. Use approved fuel container.

11. Never add fuel to a running engine or a hot

engine.

12. Fill fuel tank outdoors with extreme care.

Never fill fuel tank indoors. Replace fuel

cap securely and wipe up spilled fuel.

13. Never allow anyone to operate the debris

blower until they are thoroughly familiar

with basic tractor and debris blower

operation.

OM 0401-A

8

Page 11

SAFETY - continued

During Operation

1. Do not allow passengers on the

tractor/equipment at any time. There is no

safe place for passengers on this

equipment. The operator MUST sit in the

tractor seat.

2. Eye and hearing protection is

recommended when operating the

equipment.

3. Operate only during daylight hours, or when

the area is well lit with bright artificial light.

4. Park the tractor/ equipment on level ground,

place the transmission in neutral, set the

parking brake, disengage the PTO, lower

the equipment to the ground, place all

control levers in neutral, shut off the engine

and remove the ignition key BEFORE

leaving the operator’s seat.

5. Inspect the equipment after striking any

foreign object to assure that all equipment

parts are secure and not damaged.

6. Be especially observant of the operating

area and terrain. Watch for holes, rocks, or

other hidden hazards. ALWAYS inspect the

area prior to operating equipment.

7. DO NOT operate equipment near the edge

of drop-offs or banks.

Roll-Over Protective Structure "ROPS"

(If Equipped)

1. DO NOT weld, drill or alter the ROPS.

Damaged ROPS must not be straightened

or used. If damage does occur, consult your

dealer.

2. If the ROPS is lowered or removed from the

tractor for any reason, it must be erected

and/or refitted immediately. Original bolts or

equivalent replacements must be used and

tightened to the correct torque. The

manufacturer does not recommend usage

of tractor with ROPS removed.

4. If a fold-down ROPS is used, the ROPS

can be folded down for storage, but it must

be pinned in the upright position prior to

operation.

5. Seat belt usage: With ROPS installed on

the tractor it is imperative that the seat belt

be installed, used and correctly adjusted, at

all times. DO NOT use a seat belt if

operating without ROPS.

Additional Safety Equipment

A fire extinguisher and first aid kit should be

kept readily accessible.

8. DO NOT operate equipment on steep

slopes as overturn may result.

9. Operate up and down (not across)

intermediate slopes. Avoid sudden starts

and stops.

10. Drive tractor backwards up steeper slopes

with equipment off. Then operate as you

travel down the slope.

11. Slow down before you change directions on

any slope.

12. Make sure the tractor is counterweighted as

recommended by your dealer. Weights

provide the necessary balance to improve

stability, traction and steering.

13. Never stand alongside of the equipment

while the engine is running.

OM 0401-A

9

Page 12

MAINTENANCE

SAFETY - continued

ALWAYS USE GENUINE PARTS WHEN

REPLACEMENT PARTS ARE REQUIRED

1. Keep the tractor and equipment properly

maintained.

2. Park the tractor/ equipment on level ground,

place the transmission in neutral, set the

parking brake, disengage the PTO, lower

the equipment to the ground, place all

control levers in neutral, shut off the engine

and remove the ignition key and allow the

rotating parts to stop BEFORE making any

equipment adjustments.

3. To avoid injury, do not adjust, unblock the

driving system, or service the equipment

with the tractor engine running. Make sure

rotating components have completely

stopped before leaving the operator’s seat.

4. Keep the tractor/ equipment clean. Snow ,

dirt or ice build-up can lead to malfunction

or personal injury from thawing and

refreezing in garage.

5. Always wear eye protection when cleaning

or servicing the equipment.

6. DO NOT service the tractor while the

engine is running or hot, or if the unit is in

motion. Always lower equipment to the

ground. If necessary to service equipment

in raised position, securely support with

stands or suitable blocking before working

underneath. Do not rely on hydraulically

supported devices for your safety. They can

settle suddenly, leak down, or be

accidentally lowered.

7. Do not attempt to service machine, clear

obstructions or unclog the equipment's

driving system with the engine running.

Always shut off engine and allow all motion

to cease.

8. The manufacturer will not accept

responsibility for fitment of unapproved

parts and/or accessories and any damages

as a result of their use.

9. Make sure all shields and guards are

securely in place following all service,

cleaning, or repair work.

10. Do not modify or alter this equipment or

any of its components or operating

functions. If you have questions

concerning modifications, consult with

your dealer.

11. Do not operate a equipment that is

defective or has missing parts. Make sure

that all recommended maintenance

procedures are completed before

operating the equipment.

12. Check all controls regularly and adjust

where necessary. Make sure that the

brakes are evenly adjusted.

13. Periodically check all nuts and bolts for

tightness, especially wheel hub and rim

nuts.

14. To avoid serious personal injury:

Escaping hydraulic/diesel fluid under

pressure can penetrate the skin causing

serious injury. Do not use your hands to

check for leaks. Use a piece of cardboard

or paper to search for leaks.

15. Stop engine and relieve pressure before

connecting or disconnecting hydraulic

hoses. Tighten all connections before

starting engine or pressurizing hoses.

OM 0401-A

10

Page 13

SAFETY - continued

TRANSPORTATION

1. If the tractor/ debris blower is to be driven on

public roads, it must be equipped with an

SMV (Slow Moving Vehicle) sign. Check

local traffic codes that may apply to unit

usage on public roads and highways in your

area.

2. Be alert for all ot her traffic when driving the

tractor/ debris blower on public roads or

highways.

STOR AGE

1. Before storing the debris blower, certain

precautions should be taken to protect it

from deterioration.

2. Clean the debris blower thoroughly.

3. Make all the necessary repairs.

4. Replace all Safety Signs that are

damaged, lost, or otherwise become

illegible. If a part to be replaced has a sign

on it, obtain a new safety sign from your

dealer and install it in the same place as on

the removed part.

5. Repaint all parts from which paint has worn

or peeled.

6. Lubricate the debris blower as instructed

under "Lubrication" section.

7. When the debris blower is dry, oil all

moving parts. Apply oil liberally to all

surfaces to protect against rust.

8. Store in a dry place.

OM 0401-A

11

Page 14

5RD2500785

DECALS

Replace immediately if damaged

5RD2500790

5RD2500791

5RD2500786

5RD2500827

5RD2500624

5RD664391

5RD664391

5RD2500828

BL2130

5RD2500819

5RD664391

OM 0401-A

5RD2500624

5RD2500616

5RD2500830

12

Page 15

ASSEMBLY

TRACTOR PREPARATION

See Dealer for Tractor Preparation information.

DEBRIS BLOWER ASSEMBLY

Use the present manual and lay out all parts for assembly. Separate bolts and nuts into various sizes. After

assembly, torque all the bolts according to the Torque Specification Table at the end of the manual.

Debris Blower removing front wooden crate (Fig. 1)

1. Remove the six 3/8"NC x 3/4" carriage bolt

and six 3/8"NC serrated flange nut to

remove the belt protector (item 1).

2. Keep the hardware for further use. Remove

the four screws (item 4) and 1/4" flat

washers (item 5) that maintain the Debris

Blower to the crate.

3. Reinstall the belt protector (item 1) with the

six 3/8"NC x 3/4" carriage bolt and six

3/8"NC serrated flange nut removed

previously.

4. Remove the three round wire lock pins

(item 6) from the wheel support pins and

attach them in the holes provided on the

side of the Debris Blower (item A).

5. You may use the two lifting holes (item 7) to

move the Debris Blower more easily.

OM 0401-A

Figure 1

13

Page 16

ASSEMBLY

Debris Blower Installation (Figures 2-3)

1. For installation on a Tractor equipped with a

HP2134-HP2120

Keep the ø3/4"NPT quick couplers already

installed on hoses.

2. For installation on a Tractor equipped with a

HP2025

Figure 2: Install the ø1/2"NPT quick couplers

attached to the hoses with a plastic film.

A- Remove the ø3/4" NPT female quick coupler

B- Remove the ø3/4" NPT male quick coupler

C- The ø3/4"NPT male and female quick

3. Figure 3: Install the two

universal hitch hooks (item 1) to

the two front load brackets

(item 2). Insert the two universal

hitch pins (item 3) in the front

load bracket holes (item 4) and

secure with two linchpins

provided with the front load

brackets (item 5).

Hydraulic Unit:

(item 3). With thread sealant, install the

ø1/2" NPT female quick coupler (item 1).

(item 4). With thread sealant, install the

ø1/2" NPT male quick coupler (item 2).

couplers won't be needed any further.

Hydraulic Unit:

Figure 2

Figure 3

OM 0401-A

14

Page 17

ASSEMBLY

Installation of the Hydraulic Hoses (Figures 4-5)

1. Figure 4: Insert the hydraulic hoses (items 1-

2) through the hose support of the universal

hitch (item 3) then through the front support

of the loader (item 4). Make sure the hose

protector (item 5) is under the bar of the

universal hitch hose support (item 3). Place

the other hose protector (item 7) above the

front loader tube (item 6).

7

6

2. Figure 5: Connect the male coupler of the

debris blower hose (item 1) to female coupler

of the hydraulic pump hose (item 2). Conn ect

the female coupler of the debris bl ower hose

(item 3) to male coupler of the hydraulic

pump hose (item 4).

Figure 4

4

3

2

1

Figure 5

5

2

1

4

3

OM 0401-A

15

Page 18

ASSEMBLY

Installation of the Cooling Unit 5RDF0036 (Figures 6a to 6g)

For Debris blower working in warm region, use the 5RDF0036 oil cooler. If you own a HP2120 power

unit, use the 5RDF0037 cooling unit upgrade.

IMPORTANT:

NOTE

hydraulic oil from overheating. When the hydraulic block is not power supplied, the oil is in recirculation

mode meaning that the equipment will not function. To power the block, refer to the Hydraulic Pump

Manual.

1. Figure 6a: Unscrew the 1 1/16" JIC elbow

2. Figure 6b: Unscrew the straight 1-1/16"JIC

3. Figure 6c: Install the oil cooler support (item 1)

4. Figure 6d: Install the support plates (item 1)

: The new HP2025 and HP2134 pumps are equipped with a safety system to prevent the

(item 1) from the in-tank filter. Remove the

3/4"NC x 2" lg bolt (item 2) and the stover nut

(item 3). Remove the stover nut (item 4) from

the 3/4"NC x 4 1/2" lg bolt but do not remove the

bolt.

adapter (item 1) and rotate the hose of 90° up to

bring up the 90° 1-1/16"JIC elbow adapter

(item 2). Tighten the straight 1-1/16"JIC adapter,

to rotate the hose, at 65-75 ft-lb (93-101 N-M).

with a 3/4" NC x 2" lg bolt (item 2) and the 3/4"

stover nut (item 3) removed previously. Reinstall

the 3/4" NC stover nut (item 4) previously

removed on the 3/4" NC x 4 1/2" bolt.

with six 5/16" NC x 1" bolts (item 2), eight 5/16"

flat washers (item 3) and six 5/16" NC nylon

insert nuts (item 4) making sure to place a flat

washer between the support plates and the "U"

section of the frame.

To not damage the oil cooler, it is essential to disconnect the fan of the oil cooler

when the temperature is under 0°C.

Figure 6a

Figure 6b

Figure 6d

OM 0401-A

Figure 6c

16

Page 19

ASSEMBLY

5. Figure 6e: Install the rubber bushings (items 1-

2) on the support then attach the oil cooler

(item 3) with four 5/16" NC x 2 1/4" bolts

(item 4), 5/16" flat washers (item 5), the flat

washers supplied with the rubber bushings

(item 6) and 5/16" NC nylon insert nuts

(item 7).

Figure 6e

IMPORTANT

pass valve (item 8) faces the rear as illustrated.

6. Figure 6f: Install the 1 5/8" ORB – 1 1/16" JIC

elbows (item 1) on the oil cooler's inlet and

outlet in the positions illustrated. Connect the

straight end of the outlet hose (item 2) to the oil

cooler elbow and the bent end to the filter.

Connect the inlet hose (item 3) previously

disconnected from the filter to the other elbow

making sure it passes outside the support plate

(item 4).

7. Figure 6g: Connect the oil cooler fan harness

(item 1) to the available connector on the

hydraulic pump's wiring harness (item 2).

Figure 6g

: Position the oil cooler so the by-

1

Figure 6f

OM 0401-A

2

17

Page 20

ASSEMBLY

Removing Debris Blower from Tractor (Figures 7 to 10)

1. Set parking brake and turn engine off.

2. Figure 7: Direct the wheel supports

(item 2) along the housing suppo rt tube

(as illustrated) and lock in position with

three round wire lock pins (item 1), that

are attached to the debris blower

housing (item A).

3. Figure 8: Disconnect the male coupler

(item 1) of the debris blower hos e from

the female coupler (item 2) of the

hydraulic pump hose. Disconnect the

female coupler (item 3) of the debris

blower hose from the male coupler

(item 4) of the hydraulic pump hose.

Install the dust caps (item 5) on each

coupler (items 1-2-3-4).

Figure 7

Figure 8

2

1

4. Figure 9:

(items 1-2) from the front support of the

loader (item 3). Roll up the hoses

around the universal hitch so they don't

drag on the ground.

5. Figure 10:

(item 5). Disengage the two universal

hitch pins (item 3) from the holes of the

front loader (item 4).

6. Figure 10:

hitch hooks (item 1) from the loader

brackets (item 2). Back away slowly.

IMPORTANT

debris blower, retorque all bol ts a fter the

first 10 hours of operatio n.

Figure 10

Remove the hydraulic hoses

Remove the two linchpins

Disengage the two universal

: To avoid damages to the

4

3

5

Figure 9

1

3

OM 0401-A

2

18

Page 21

OPERATION

OPTIMUM PERFORMANCES

IMPORTANT: The hydraulic motors of the rotary broom must have a breaking in period. If it is

not respected, the warranty could be voided. The breaking in period must follow these steps:

1- 15-30 minutes of operation at half engine speed (tractor RPM around 1250).

2- Check for unusual noises coming from the motors. If everything sounds normal, the

load and engine speed can be increased.

The new HP2025 and HP2134 pumps are equipped with a safety system to prevent the

hydraulic oil from overheating. When the hydraulic block is not power supplied, the oil is in

recirculation mode meaning that the equipment will not function. To power the block, the

ignition key must be in the "ON" or "START" position. If the system remains in the

recirculation mode, refer to the "Troubleshooting" section at page 26.

GENERAL PREPARATION

1. Read the operator’s manual carefully

before using the tractor and debris

blower. Be thoroughly familiar with the

controls and proper use of the

equipment. Know how to stop the unit

and disengage the controls quickly.

2. Make sure the impeller operates freely.

3. Check the shear bolt on the PTO, for

proper tightness.

4. Wear adequate winter outer garments

while operating equipment.

WARNING: To avoid serious injuries or

death:

• Do not allow bystanders near working area.

• Do not allow anyone to ride on debris blower.

• Before cleaning, adjusting or repairing the

debris blower: bring the tractor to a complete

stop, wait for all movement to stop, apply

parking brake, lower the implement to the

ground, shut off the engine and remove the

ignition key.

• Never put any part of your body under the

debris blower while making adjustments.

WARNING: To avoid serious injuries:

• Always operate the debris blower from the

operator's seat only. Never allow anyone to

ride on the machine.

• Operate the debris blower at a speed that

matches the working conditions. Be extremely

careful when working on banks or uneven

terrain.

• Always wear protective eyewear when

operating the debris blower.

OM 0401-A

19

Page 22

OPERATING CONTROLS

OPERATION

Debris Blower Commands

1. Use the PTO button to start and stop the

impeller. Start the engine and put the

throttle lever at low engine speed.

Engage the PTO lever and maintain

engaged. Make sure the debris blower is

turning in the right direction. If not, switch

the quick couplers. To stop the rotation,

disengage the PTO button.

2. Never engage or disengage the debris

blower at high engine speed or the

hydraulic motor(s) could get damaged.

3. Raise and lower the debris blower using

the hydraulic lift lever located on the

tractor. Pulling the lever backward raises

the debris blower, pushing the lever

forward lowers the debris blower.

4. Control impeller speed with the RPM that

controls the debris ejection power.

Debris Blower Utilization

1. A debris blower purpose to displace rather light

debris to a variable distance according to the

impeller speed. For heavy debris, it is

recommended using some other equipmen t type

such as a rotary broom. For an optimum

performance, lower the debris blower as the 3

wheels touch the ground. Make sure th e loader

control lever is in floating position to allow the

equipment to follow the ground variation and so

more debris to be blown.

WARNING: To avoid equipment

damage

debris blower.

2. For light debris, use a higher vehicle ground

speed. For heavier debris, use a reduced vehicle

ground speed. For small area, lowe r the tractor

motor speed to eject debris on a short dis tance.

For wider area, use higher speed.

: never raise the tractor front with the

Nozzle air ejection Orientation

Equipment air ejection can be don e to the right or

the left. To change direction, move the orientation

arms on the debris blower. See decal on equipment

to check arm positions for right orientation.

WARNING: To avoid serious injuries:

never move the orientation arm when th e debris

blower is running.

OM 0401-A

20

Page 23

OPERATION

ADJUSTMENTS

Belt Tension Adjustment (Figure 11)

1. Remove the belt protector (item 5) by removing

the six 3/8"NC x 3/4" carriage bolts and six

serrated flange nuts (item s 6-7) .

2. Loosen the eight 1/2"NC nylon insert locknut

(item 1).

3. Tighten eyebolt nuts (item 2). With a belt

tension gauge check for a 35lbs tension and a

3/16" displacement in the center in all belt axis

(item 3).

4. Reali gn the driving pulley asse mbly (item 4) by

pressing the support against the bolted gui des.

Tighten loosely the eight 1/2"NC nylon insert

locknuts (item 2) loosen previously. With a long

ruler that may cover the distance between

pulleys, check the pulleys alignment, If

alignment is good, tighten the eight 1/2"NC

nylon insert locknuts (item 2). If not, follow next

step.

5. If the belts are not well aligned, loosen the

guide nuts and the eyebolt nuts. Align the two

pulleys, slightly tighten the eigh t 1/2"NC nylon

insert locknuts (item 2). Press the guides

against the driving pulley assembly (item 4)

and tighten guide nuts. Redo step 2. Check the

pulleys alignment and if the driving pulley

assembly is well pressed on guides. If so,

tighten firmly the eight 1/2"NC nylon insert

locknuts. If not, repeat procedure.

6. Reins tall the belt protec tor (item 5) with the si x

3/8"NC x 3/4" carriage bolts and six serrated

flange nuts (items 6-7).

Figure 11

OM 0401-A

21

Page 24

MAINTENANCE

MAINTENANCE

ALWAYS USE GENUINE PARTS WHEN

REPLACEMENT PARTS ARE REQUIRED

Storage

1. Check hardware at regular intervals to

ensure it is always tightened properly.

2. Never park the tractor inside a building

where an open flame or sparks are present.

Allow the engine to cool down before storing

in any enclosure.

WARNING: Provide adequate blocking

before working under the debris blower when

in raised position.

Hydraulic Oil

Check oil level before each use. Refer to the

operation's manual of the HP2120, HP2025 and

HP2134 hydraulic pumps.

IMPORTANT

pump, it is recommended to use the

5RDF0037 update kit.

: If you own a HP2120 hydraulic

ATTENTION: Escaping

hydraulic/diesel fluid under pressure can

penetrate the skin causing severe injuries.

• Do not use your hands to

check for leaks. Use a

piece of cardboard or paper

to search for leaks.

• Shut engine off and relieve pressure

before connecting or disconnecting lines.

• Tighten all connections before starting

engine or pressurizing lines.

• If any fluid is injected into the skin, obtain

medical attention immediately or

gangrene may result.

1. Hydraulic line

2. Cardboard

3. Magnifying glass

OM 0401-A

22

Page 25

MAINTENANCE

LUBRICATION

Use oil or a grease gun and lubricate as follows:

DESCRIPTION TIME INTERVAL LUBRICATION REQUIRED

And Wheels

Bearing

24 hours of operation

Grease each bearing of the impeller shaft, the

wheel support pins and the wheels.

PERIODIC CHECKS

DESCRIPTION TIME INTERVAL REQUIRED CHECKS

Belt Each lubrication Check for damages

Hoses Each lubrication Check for leaks

Hydraulic motor Each lubrication Check for leaks

Housing, hitches, impeller

wheel supports

Hardware 24 hours of use Check a n d t ig h t e n i f n e e d e d

Tires Each utilization Check pressure

OM 0401-A

100 hours of use Repair if needed

23

Page 26

MAINTENANCE

Belt Replacement (figures 12a-12b)

1. Figure 12a: Remove the belt guard (item 1) and

the six 3/8"NC x 3/4" carriage bolts (item 2) and

six 3/8"NC serrated flange nuts (item 3).

2. Figure 12a: Remove the 1/2"NC x 2 1/2" bolt

hex (item 4) and the 1/2" lockwasher (item 5),

the 1/2" flat washer (item 6), the spacer (item 7)

and the 1/2" nylon insert locknut (item 8).

3. Figure 12a: Remove the 3/8" x 5" eyebolt

(item 9), the flat washer (item 10) and the nylon

insert locknut (item 11).

4. Figure 12a: Perform the 2 and 3 steps for the

second eyebolt.

5. Figure 12a: Remove the eight 1/2"NC nylon

insert locknuts (item 12), the eight 1/2"

lockwashers (item 13), the eight 1/2" (9/16" int.)

flat washers (item 14) and the eight 1/2"NC x 1

3/4" carriage bolts (item 15).

6. Figure 12b: With a hoist, raise the drive pulley

assembly (item 2) with a two hook chain (item 1)

to well balance the weight. (This assembly

weights approximately 75 pounds).

7. Put the drive pulley assembly to the ground.

8. Remove the belt by the new one and install it

on the small upper pulley.

9. Raise the drive pulley assembly with the hoist

and reinstall the eight 1/2"NC x 1 3/4"

carriage bolts with the flat washers,

lockwashers and nylon insert locknuts. Do

not tighten.

10. Reinstall the two 3/8" x 5" eyebolts with the

1/2"NC x 2 1/2" hex bolts, the 1/2"

lockwashers, the 1/2" flat washers, the

spacers and the 1/2" nylon insert locknuts.

11. Go to «BELT TENSION ADJUSTMENT »

section.

OM 0401-A

Figure 12b

Figure 12a

24

Page 27

MAINTENANCE

Impeller Removing and Reinstallation (figures 13a-13b)

TO REMOVE THE IMPELLER:

1. Figure 13a: If the debris blower is in

storage, remove the round wire lockpin

(item 1). Then remove the 1/4" cotter pin

(item 2), the flat washer (item 3) and the

wheel assembly (item 4). Place the arm

on a small wood block as a temporary

support.

2. Figure 13a: Attach the housing (item 7)

to a hoist with the hook provided on the

housing (item 5). Remove the twelve 3/8"

NC serrated flange nuts (item 6) and

move the housing to the front to take it

out from the impeller.

3. Figure 13b: Remove the 1/2"NC x 1" hex

bolt, the lockwasher and the flat washer

(items 2, 3 and 4) in front of the impeller

(item 1).

4. Figure 13b: Remove the 1/2"NC x 3 1/2"

hex bolt (item 5) and the 1/2"NC nylon

insert locknut (item 6).

5. Figure 13b: The impeller is provided with

an ejection device, so just screw a

3/4"NC x +/- 2 1/2" hex bolt (item 7) that

pushes against the shaft end and ejects

the impeller (item 1).

T

O REINSTALL THE IMPELLER:

1. Figure 13b: Remove the 3/4" x +/- 2 1/2" hex bolt

(item7).

2. Figure 13b: Apply grease on the shaft to

facilitate the reinstallation. Make sure to align the

hole in the impeller with the hole on the shaft,

where the 1/2"NC x 3 1/2" hex bolt was installed

(item 5). A light punch on the impeller should be

enough to insert it on the shaft.

3. Figure 13b: Attach with the 1/2"NC x 1" hex bolt,

the lockwasher and the flat washer (items 2, 3

and 4) in front of the impeller.

4. Figure 13b: Then attach the impeller with the

1/2"NC x 3 1/2" hex bolt (item 5) and the 1/2"NC

nylon insert locknut (item 6).

5. Figure 13a: Reinstall the front housing and the

wheels (follow the preceding procedure in

reverse).

Figure 13b

OM 0401-A

Figure 13a

25

Page 28

TROUBLESHOOTING

MAINTENANCE

Optimum Performance

IMPORTANT: The optimum performances of

the debris blower are only achieved after 10 to

15 minutes of debris blower operation. It is

therefore important to ensure that the hydraulic

oil reaches a temperature of over 40ºC (104ºF)

before judging the debris blower performances.

The following chart serves as a guide in case

of a malfunction. If the problem is not solved

after taking the appropriate corrective

measure, contact your dealer.

PROBLEM CORRECTIVE MEASURE

• Check if an object is blocking the impeller

• Check that the PTO is engaged

• Check for oil leaks

1. The Impeller does

not turn

• Check if the pump is in recirculation mode

• Check hydraulic pump oil level and add some if needed

• Check that the input and output hoses are connected

• Check that the input and output hoses are in the right position, if not

reverse their position

• Check if the belt is broken or damaged.

2. The Impeller is

turning in reverse

3. The debris are not

thrown very far

• Check that the hoses are connected correctly to the hydraulic manifold and

reverse their position if necessary

• The engine is not at full RPM

• Check hydraulic pump oil level and add some if needed

• Check hydraulic pump hydraulic pressure, adjust if too low

• Check hydraulic pump hydraulic flow

• Reduce the ground speed (Refer to Operation section)

• Check the hoses for leaks, replace if needed

• Check hydraulic pump, replace if needed

• Check the impeller motor; replace if needed

WARNING: Several corrective measures

present a certain risk, which may cause serious

injuries or death.

Only a qualified person, familiar with the risks

associated with hydraulics, electricity and machinery

should perform the repairs. Review the safety

precautions at the beginning of this manual.

WARNING: Hot engine parts and hydraulic oil

can cause serious burns. Always let the engine

cool before proceeding with repairs or

maintenance.

CAUTION: The oil temperature must never go

above 65ºC (149ºF) to avoid damages to the

hydraulic components.

4. The hydraulic motor

of the Impeller leaks

oil from the shaft

OM 0401-A

• Check that the maximum hydraulic pressure is below the allowable level

• Check that the maximum return pressure is below the allowable level

• Replace the motor seals

• Replace the motor

26

Page 29

PARTS

I

NTRODUCTION

All parts are illustrated in "exploded views" which show the individual parts in their normal relationship to

each other. Reference numbers are used in the illustrations . These numbers correspond to those in the

"Reference Number" (REF) column, and are followed by the description and quantity required.

Right Hand and Left Hand are determin ed by th ose see n by the oper ator sta nding behind the equ ipment.

The manufacturer reserves the rights to change , modify, or eliminate from time to time, for technical or

other reasons, certain or all data, specifications, or the product or products themselves, without any liability

or obligation.

The parts listed here are available through your local dealer.

MANUAL HOLDER

EF. DESCRIPTION QTY PART #

R

1 Manual holder 1 5RD4200030

2 Bolt hex. 5/16" NC x 1" lg gr. 5, PTD 2 5RD0100019

3 Nylon insert locknut 5/16" NC, PTD 2 5RD1000005

OM 0401-A

27

Page 30

PARTS

DEBRIS BLOWER –BELT DRIVE SYSTEM

OM 0401-A

28

Page 31

PARTS

DEBRIS BLOWER – BELT DRIVE

REF. DESCRIPTION QTY PART #

1 CCW impeller 1 5RD669549

2 Rear bearing support 1 5RD669606

3 Hydraulic Motor (incl. Check Valve) 1 5RD3910088

4 Tension guide 2 5RD669576

5 Spacer ring - Upper shaft 1 5RD669571

6 Bushing - Tensioner 2 5RD669572

7 Key 5/16" x 5/16" x 1 3/4" 1 5RD661166

8 Driven shaft 1 3/8" 1 5RD669559

9 Bushing 3/4" lg 1 5RD669608

10 Bearing 1 3/8" with setscrew 2 5RD4300019

11 Eye bolt 3/8" NC x 5" (Hex. nut 3/8" NC included) 2 5RD661426

12 Pulley 14" diam., "4V", TYPE "5V" 1 5RD4800020

13 Hub Type E-1 3/8" dia. 1 5RD4800021

Including: H ex bolt 1/2"NC x 2 3/4" Gr.5 "full threa d"

Lockwasher ø1/2" PTD

Set screw 3/8"NC x 3/8"

14 Pulley 5.2" diam., "4V", TYPE "5V" 1 5RD4800022

15 Hub Type SD-1 3/8" dia. 1 5RD4800023

Including: H ex bolt 1/ 4"NC x 2" Gr.5 "full th read"

Lock washer ø1/4" PTD

Set screw 1/4"NC x 1/4"

16 Belt "Power Band" 4-R5VX560 1 5RD4800024

17 Bolt hex. 1/2"NC x 1 3/4" Gr.5 PTD 5 5RD0100071

18 Carriage bolt 1/2"NC x 1 3/4" Gr.5 PTD 8 5RD0300025

19 Nylon insert locknut 1/2"NC, PTD 19 5RD1000011

20 Lockwasher 1/2", PTD 16 5RD1200006

21 Flat washer 1/2" (9/16" int.), PTD 16 5RD1400006

22 Bolt hex. 1/2"NC x 3 1/2" Gr.5 PTD 1 5RD0100079

23 Key 1/4" x 1/8" x 5/16" x 1 1/8" 1 5RD669609

24 Carriage bolt 3/8"NC x 1 1/4" Gr.5 PTD 4 5RD0300009

25 Lockwasher 3/8", PTD 4 5RD1200004

26 Nylon insert locknut 3/8"NC, PTD 6 5RD1000006

27 Flat washer 3/8" (7/16" int.), PTD 6 5RD1400004

28 Allen Socket Head Cap Screw 1/2NC x 2 1/2" Gr.5 PTD, cylinder.head 4 5RD0800021

29 Bolt hex. 1/2"NC x 2 1/2" Gr.5 PTD 2 5RD0100076

30 Lockwasher 5/8", PTD 1 5RD1200007

31 Bolt hex. 1/2"NC x 1" Gr.5 PTD 1 5RD0100068

32 Bolt hex. 5/8"NF x 1 1/2" Gr.5 PTD 1 5RD0100240

3 3 1 -

3 3 1 -

OM 0401-A

29

Page 32

PARTS

DEBRIS BLOWER – HOUSING

R

EF. DESCRIPTION QTY PART #

1 Housing 1 5RD669547

2 Belt shield 1 5RD669556

3 Lateral bracket 1 5RD669573

4 Carriage bolt ø3/8"NC x 3/4" Gr.5 PTD 6 5RD0300007

5 Carriage bolt ø1/2"NC x 1 3/4" Gr.5 PTD 10 5RD0300025

6 Serrated flange nut ø3/8"NC PTD 6 5RD0900035

7 Nylon insert locknut 1/2"NC, PTD 10 5RD10000 11

8 Lockwasher 1/2", PTD 10 5RD1200006

9 Flat washer 1/2" (9/16" int. ), PT D 6 5RD1400006

OM 0401-A

30

Page 33

PARTS

DEBRIS BLOWER – IMPELLER HOUSING

R

EF. DESCRIPTION QTY PART #

1 Impeller housing 1 5RD669548

2 Intake cover 1 5RD669550

3 Orientation deflector 1 5RD669553

4 Angling arm 1 5RD669554

5 Cotter pin 3/16" x 1 1/4" 1 5RD1500012

6 Bolt serrated flange 3/8"NC x 3/4" Gr.5 PTD 3 5RD0200066

7 Bolt hex. 1/4"NC x 1" Gr.5 PTD 2 5RD0100004

8 Flat washer 1/4" (5/16" int. ), PT D 4 5RD1400002

9 Nylon insert locknut 1/4"NC, PTD 2 5RD1000003

10 Serrated flange nut ø3/8"NC PTD 12 5RD0900035

OM 0401-A

31

Page 34

PARTS

DEBRIS BLOWER – HITCH AND WHEELS

R

EF. DESCRIPTION QTY PART #

1 Universal rear Support 1 5RD669579

2 Wheels support 3 5RD669555

3 Welded Universal Hitch 1 5RD669148

4 Spacer 1.015" ID x 1" lg. 6 5RD661119

5 Wheel bushing 3 5RD669560

6 Wheel and rim 3 5RD660658

7 Upper Hitch 1 5RD669583

8 Bolt hex. 3/4"NC x 3 3/4" Gr.5 PTD 2 5RD0100123

9 Lockwasher 3/4", PTD 2 5RD1200008

10 Nut hex 3/4"NC, PTD 2 5RD0900008

11 Bolt hex. 5/8"NC x 4 1/2" Gr.5 PTD 1 5RD0100104

12 Round Wire Lock Pin 1/4" x 1 3/4" 3 5RD1900006

13 Lockwasher 5/8", PTD 1 5RD1200007

14 Cotter pin 1/4" x 2" 3 5RD1500022

15 Flat washer 1 1/8" (1 1/4" int.) , PTD 3 5RD1400014

16 Bolt hex. 5/8"NC x 7" Gr.5 PTD 3 5RD0100109

17 Nylon insert locknut 5/8"NC, PTD 4 5RD1000012

18 Flat washer 5/8" (11/16" int.), PTD 4 5RD1400008

19 Grease fitting 1/4NF 3 5RD654106

20 Bolt hex. 1/2"NC x 1 1/2" Gr.5 PTD 2 5RD0100070

21 Flat washer 1/2" (9/16" int.), PT D 2 5RD1400006

22 Nylon insert locknut 1/2"NC, PTD 2 5RD1000011

OM 0401-A

32

Page 35

PARTS

HYDRAULIC COMPONENTS

R

EF. DESCRIPTION QTY

Hydraulic Motor 127 c.c. without relief valve, 1 1/4"shaft with check valve

1

and inner drain

2

- Chech Valve (incl. in 5RD3910088)

3

Plastic Guard for hoses, black

4

Elbow 45°-1 1/16" JIC m. X 7/8" ORB m.

5

Quick Coupler 3/4NPT, female

6

Dust Plug 3/4"

7

Quick Coupler 3/4NPT, male

8

Dust Cap 3/4"

9

Adapter 1/2NPT m. rig. X 3/4NPT fem. rig.

10

Quick Coupler 1/2NPT fem.

11

Dust Plug for coupler

12

Male Quick Coupler 1/2NPT Fem

13

Dust Cap for coupler

14

Hose 3/4" X 95" - 1-1/16 "JIC swiv. fem. short bend X 1-1/16"JIC swiv.fem.

P

ART #

1 5RD3910088

1 5RD3910089

2 5RD669154

2 5RD2600166

1 5RD661294

1 5RD2600196

1 5RD661293

1 5RD2600197

2 5RD2600217

1 5RD662702

1 5RD2600133

1 5RD2600092

1 5RD664898

2 5RD3700161

OM 0401-A

33

Page 36

PARTS

HYDRAULIC MOTOR - 5RD3910088

OM 0401-A

34

Page 37

PARTS

HYDRAULIC MOTOR - 5RD3910088

EF. DESCRIPTION QTY PART #

R

Seal Kit (Includes #1 to 11) 5RD3900042

1 Dust seal 1 ----2 Retaining ring 1 ----3 Backup shim 1 ----4 High pressure seal 1 ----5 Backup shim 1 ----6 Teflon backup seal 1 ----7 Shaft seal 1 ----8 Body seal 5 ----9 Collector seal 1 -----

10 O-Ring seal 1 ----11 Teflon backup seal 1 ----12 Seal carrier 1 5RD3900132

13 Thrust washer 3 5RD3900044

14 Thrust bearing 2 5RD3900045

15 Housing bearing 2 5RD3900046

16 Housing Kit, (includes #13-14-15-29) 1 5RD3900047

17 Wear plate 1 5RD3900133

18 Drive link 1 5RD3900049

19 Rotor 1 5RD3900053

20 Collector 1 5RD3900056

21 Commutator assembly 1 5RD3900057

22 End cover piston 1 5RD3900059

23 Piston spring 1 5RD3900060

24 End cover (includes #10-11-22-23) 1 5RD3900063

25 Serial number plate 1 --26 Bolt set kit (4) 1 5RD3900065

27 Shaft 1 1/4" 1 5RD3900068

28 Key 1 5RD3900069

29 Bearing spacer 1 5RD3900071

OM 0401-A

35

Page 38

PARTS

COOLING UNIT – 5RDF0036 (OPTION)

REF. DESCRIPTION QTY PART #

1 Oil cooler with relief valve and 12V fan 1 5RD669585

2 - Bolts and seal kit (incl.in 5RD669585) 1 5RD3900475

3 - Hydraulic plug kit (incl.in 5RD669585) 1 5RD3900476

4 - Relief valve 25 PSI kit (incl.in 5RD669585) 1 5RD3900477

5 - Fan 12V ass. (incl.in 5RD669585) 1 5RD669620

6 Cooler support 1 5RD669510

7 Cooler support plate 2 5RD669540

8 Hose 3/4" x 30 1/2" lg 1 5RD3700158

9

Elbow 90° 1 5/8"ORB M x 1 1/16"JIC M

10 Shock absorber for vibration 4 5RD4200043

11 Bolt hex. 3/4"NC x 2 1/4" gr5, PTD 1 5RD0100118

12 Bolt hex. 5/16"NC x 2 1/4" gr5, PTD 4 5RD0100025

13 Bolt hex. 5/16"NC x 1" gr5, PTD 6 5RD0100019

14 Flat washer 5/16" (3/8" int.), PTD 16 5RD1400003

15 Nylon insert locknut 5/16"NC, PTD 10 5RD1000005

2 5RD2600218

OM 0401-A

36

Page 39

TORQUE SPECIFICATION TABLE

GENERAL SPECIFICATION TABLE

Use the following torques when special torques are not given

NOTE: These values apply to fasteners as rec eived from supplier, dry, or when lubricated with normal engine oil. They do not apply if

special graphited or moly sidulphide greases or other extreme pressure lubricants are used. This applies to both UNF and UNC threads.

BOLT HEAD IDENTIFICATION

MARKS AS PER GRADE

NOTE: MANUFACTURING

MARKS WILL VARY.

Torque Torque Torque

BOLT SIZES Pounds-Foot Newtons-Meter Pounds-Foot Newtons-Meter Pounds-Foot Newtons-Meter

Inches Millimeters MIN. MAX. MIN. MAX. MIN. MAX. MIN. MAX. MIN. MAX. MIN. MAX.

1/4 6.35 5 6 6.8 8.13 9 11.0 12.2 14.9 12 15 16.3 30.3

5/16 7.94 10 12 13.6 16.3 17 20.5 23.1 27.8 24 29 32.5 39.3

3/8 9.53 20 23 27.1 31.2 35 42.0 47.5 57.0 45 54 61.0 73.2

7/16 11.11 25 30 40.7 47.4 54 64.0 73.2 86.8 70 84 94.9 113.9

1/2 12.70 45 52 61.0 70.5 80 96.0 108.5 130.2 110 132 149.2 179.0

9/16 14.29 65 75 88.1 101.6 110 132.0 149.2 179.0 160 192 217.0 260.4

5/8 15.88 95 105 128.7 142.3 150 180 203.4 244.1 220 264 298.3 358.0

3/4 19.05 150 185 203.3 250.7 270 324 366.1 439.3 380 456 515.3 618.3

7/8 22.23 160 200 216.8 271.0 400 480 542.4 650.9 600 720 813.6 976.3

1 25.40 250 300 338.8 406.5 580 696 786.5 943.8 900 1080 1220.4 1464.5

1 1/8 25.58 - - - - 800 880 1084.8 1193.3 1280 1440 1735.7 1952.6

1 1/4 31.75 - - - - 1120 1240 1518.7 1681.4 1820 2000 2467.9 2712.0

1 3/8 34.93 - - - - 1460 1680 1979.8 2278.1 2380 2720 3227.3 3688.3

1 1/2 38.10 - - - - 1940 2200 2630.6 2983.2 3160 3560 4285.0 4827.4

Coarse thread Fine Thread

Pitch

(mm)

1.0

1.25

1.5

1.75

2.0

2.0

2.0

2.5

Pounds-Foot Newtons-Meter

MIN. MAX. MIN. MAX. MIN. MAX. MIN. MAX.

3.6

5.8

7.2

7.2

17

20

20

34

38

28

51

57

49

81

96

67

116

129

88

150

175

108

186

213

Size of

screw

M6

M8

M10

M12

M14

M16

M18

M20

Grade No.

4T

7T

8T

4T

7T

8T

4T

7T

8T

4T

7T

8T

4T

7T

8T

4T

7T

8T

4T

7T

8T

4T

7T

8T

METRIC BOLT TORQUE SPECIFICATIONS

Pitch

(mm)

5.8

9.4

10

14

22

26

25

40

46

34

59

66

56

93

109

77

130

145

100

168

194

130

205

249

4.9

7.9

9.8

9.8

23

27.1

27.1

46.1

51.5

37.9

69.1

77.2

66.4

109.8

130.1

90.8

157.2

174.8

119.2

203.3

237.1

146.3

252

288.6

7.9

12.7

13.6

19.0

29.8

35.2

33.9

54.2

62.3

46.1

79.9

89.4

75.9

126

147.7

104.3

176.2

196.5

136

227.6

262.9

176.2

277.8

337.4

-

1.0

1.25

1.25

1.5

1.5

1.5

1.5

107

120

140

100

177

202

132

206

246

Pounds-Foot Newtons-Meter

-

-

-

12

19

22

20

35

40

31

56

62

52

90

69

-

-

-

17

27

31

29

47

52

41

68

75

64

106

124

83

138

158

117

199

231

150

242

289

-

-

-

16.3

25.7

29.8

27.1

47.4

54.2

42

75.9

84

70.5

122

145

93.5

162.6

189.7

136

239.8

273.7

178.9

279.1

333.3

-

-

-

23.0

36.6

42

39.3

63.7

70.5

55.6

92.1

101.6

86.7

143.6

168

112.5

187

214.1

158.5

269.6

313

203.3

327.9

391.6

OM 0401-A

37

Page 40

TORQUE SPECIFICATION TABLE

TORQUE SPECIFICATION TABLE FOR HYDRAULIC FITTINGS

Use the following torques when a specific torque is not given. Note: These values apply to

fittings when dry. These values do not apply if lubricants are used..

SIZE OF FITTINGS TORQUE

SIZE ( JIC ) - INCHES foot-pounds Newton-meters

03 - 3/8"- 24 8-9 12-13

04 - 7/16"- 20 13-15 18-20

05 - 1/2"- 20 14-15 19-21

06 - 9/16"- 18 23-24 32-33

08 - 3/4"- 16 40-43 55-57

10 - 7/8"- 14 43-48 59-64

12 - 1 1/16"- 12 68-75 93-101

14 - 1 3/16"- 12 83-90 113-122

16 - 1 5/16"- 12 112-123 152-166

20 - 1 5/8"- 12 146-161 198-218

24 - 1 7/8"- 12 154-170 209-230

32 - 2 1/2"- 12 218-240 296-325

SIZE ( ORB ) - INCHES foot-pounds Newton-meters

03 - 3/8"- 24 8-10 11-13

04 - 7/16"- 20 14-16 20-22

05 - 1/2"- 20 18-20 24-27

06 - 9/16"- 18 24-26 33-35

08 - 3/4"- 16 50-60 68-78

10 - 7/8"- 14 72-80 98-110

12 - 1 1/16"- 12 125-135 170-183

14 - 1 3/16"- 12 160-180 215-245

16 - 1 5/16"- 12 200-220 270-300

20 - 1 5/8"- 12 210-280 285-380

24 - 1 7/8"- 12 270-360 370-490

OM 0401-A

38

Page 41

ASSEMBLY

TORQUE SPECIFICATION TABLE

SIZE ( NPT ) - INCHES Torque FFT

1/8"- 27 2.0 - 3.0

1/4"- 18 2.0 - 3.0

3/8"- 18 2.0 - 3.0

1/2"- 14 2.0 - 3.0

3/4"- 16 2.0 - 3.0

1"- 11 1/2" 1.5 - 2.5

1 1/4"- 11 1/2" 1.5 - 2.5

1 1/2"- 11 1/2" 1.5 - 2.5

The method used to assemble fittings with

NPT threads is in two stages. First tighten

firmly by hand then tighten one again

according to the number of turns listed on

the above table. The following method is

recommended to minimize the risks of leaks

and/or damages to the parts.

Inspect threads and tapping to make sure they

are clean.

Apply a sealant/lubricant product to the NPT

threads (Teflon covered threads are

preferable to other lubricating products). If

PTFE tape (Teflon) is used, make 1,5 or 2

turns clockwise.

Attention

distortion or cracks in the orifice.

Tighten the fitting by hand.

: More than 2 turns can cause

Screw the fitting the number of turns listed on

the above table making sure that in the case

of a shape fitting the end is aligned to the

desired position. Never unscrew a fitting

to obtain the proper alignment.

If the leak persists after having followed the

preceding instructions, check that the

threads are not damaged and the number of

seated threads.

If the threads are very damaged, replace the

fitting. If the tapping is damaged, retap if

possible or replace the part.

Usually, the number of threads seated is

between 3, 5 and 6. If the range is different it

would indicate that the fitting was tightened too

much or not enough or that the tightening was

not within thread tolerances. If the fitting is not

tight enough, tighten but never more than one

turn. If it's too tight, control the threading and

tapping and replace the section that has

threads that are not within tolerances.

OM 0401-A

39

Page 42

Page 43

Page 44

PART NO.

5RDBL2130A

All Rights Reserved

Loading...

Loading...