/ Battery Charging Systems / Welding Technology / Solar Electronics

Implementation Guide

Gateway Modbus UDP extended

Operating Instructions

Roboter Interface

EN

42,0410,1536 010-05022013

Dear Reader

Introduction

Thank you for choosing Fronius - and congratulations on your new, technically highgrade Fronius product! This instruction manual will help you get to know your new

machine. Read the manual carefully and you will soon be familiar with all the many

great features of your new Fronius product. This really is the best way to get the most

out of all the advantages that your machine has to offer.

Please also take special note of the safety rules - and observe them! In this way, you

will help to ensure more safety at your product location. And of course, if you treat your

product carefully, this definitely helps to prolong its enduring quality and reliability - things

which are both essential prerequisites for getting outstanding results.

EN

ud_fr_st_et_00493 01/2012

Table of Contents

Ethernet......................................................................................................................................................... 2

Hardware.................................................................................................................................................. 2

Protocol .................................................................................................................................................... 2

Modbus ......................................................................................................................................................... 3

Protocol description.................................................................................................................................. 3

Data encoding .......................................................................................................................................... 3

Application Data Unit (ADU) ..................................................................................................................... 4

Modbus Functions ......................................................................................................................................... 5

03 (0x03) Read Holding Registers ........................................................................................................... 5

06 (0x06) Write Single Registers ............................................................................................................. 6

16 (0x10) Write Multiple Registers ........................................................................................................... 7

23 (0x17) Read/Write Multiple registers ................................................................................................... 8

100 (0x64) Configure Streaming Data ...................................................................................................... 9

101 (0x65) Action Streaming Data ......................................................................................................... 10

102 (0x66) Streaming Data ..................................................................................................................... 11

Exception codes .......................................................................................................................................... 13

Code 0x01 - Illegal Function .................................................................................................................. 13

Code 0x02 - Illegal Data Address .......................................................................................................... 13

Code 0x03 - Illegal Data Value ............................................................................................................... 13

Code 0x04 - Slave Device Failure .......................................................................................................... 13

Code 0x06 - Slave Device Busy ............................................................................................................ 13

Timeout Lifecycle ........................................................................................................................................ 14

General .................................................................................................................................................. 14

Client ...................................................................................................................................................... 14

Server .................................................................................................................................................... 14

Modbus UDP - Process image for MIG/MAG standard synergic, MIG/MAG pulse synergic and CMT ....... 15

Process data from controller to power source (0xF000 - 0xF0FF)......................................................... 15

Process data from power source to controller (0xF100 - 0xF1FF)......................................................... 16

Modbus UDP - Process image for TIG........................................................................................................ 18

Process data from controller to power source (0xF000 - 0xF0FF)......................................................... 18

Process data from power source to controller (0xF100 – 0xF1FF) ........................................................ 19

Modbus UDP - Process image for CC/CV .................................................................................................. 21

Process data from controller to power source (0xF000 – 0xF0FF) ....................................................... 21

Process data from power source to controller (0xF100 – 0xF1FF) ........................................................ 22

Modbus UDP - Process image for MIG/MAG standard manual .................................................................. 23

Process data from controller to power source (0xF000 – 0xF0FF) ....................................................... 23

Process data from power source to controller (0xF100 – 0xF1FF) ........................................................ 24

Special data ................................................................................................................................................. 26

Generic .................................................................................................................................................. 26

MIG/MAG ............................................................................................................................................... 28

Manually ................................................................................................................................................. 29

CC/CV-mode .......................................................................................................................................... 29

Stick (Rod electrode welding / MMA) ..................................................................................................... 29

TIG ......................................................................................................................................................... 30

Real Values ............................................................................................................................................ 31

Limits ...................................................................................................................................................... 31

Special process: MIG/MAG manual standard ........................................................................................32

Special process: MIG/MAG manual pulse.............................................................................................. 32

Pilot Plasma ........................................................................................................................................... 33

TAG Table ................................................................................................................................................... 34

1

Ethernet

Hardware

Protocol

- Data transfer rate 10 Mbaud

- Ethernet connector RJ45 / IP67 VarioSub (Phoenix Contact)

- Standard Ethernet cable (Twisted Pair, shielded)

Modbus UDP (Modbus Application Protocol Specification V1.1)

One Modbus transaction is defined.

Adjustable UDP-Port (Factory setting is Port 502)

Public defined Modbus function 03 (0x03) Read Holding Registers

Public defined Modbus function 06 (0x06) Write Single Register

Public defined Modbus function 16 (0x10) Write Multiple Register

Public defined Modbus function 23 (0x17) Read/Write Multiple Register

User defined Modbus function 100 (0x64) Configure Streaming Data

User defined Modbus function 101 (0x65) Action Streaming Data

User defined Modbus function 102 (0x66) Streaming Data

Process data exchange between controller and power source:

- Function 23 (0x17) - Read/Write Multiple Register (0xF100-0xF0110 / 0xF0000xF00E)

- Function 03 (0x03) – Read Holding Register (0xF100-0xF110)

- Function 06 (0x06) – Write Single Register (0xF000-0xF00E)

- Function 16 (0x10) – Write Multiple Register (0xF000-0xF00E)

Special Data, which not defined in the process image:

- Function 03 (0x03) - Read Holding Register (0xE000-0xE0C5). It is limited to read

one register.

- Function 06 (0x06) – Write Single Register (0xE000-0xE0C5)

- Function 16 (0x10) – Write Multiple Register (0xE000-0xE0C5)

2

Modbus

Protocol description

The MODBUS application data unit is built by the client that initiates a MODBUS transaction. The function indicates to the server what kind of action to perform. The MODBUS

application protocol establishes the format of a request initiated by a client.

The function code field of a MODBUS data unit is coded in one byte. Valid codes are in

the range of 1 ... 255 decimal (128 – 255 reserved for exception responses). When a

message is sent from a Client to a Server device the function code field tells the server

what kind of action to perform.

Sub-function codes are added to some function codes to define multiple actions.

The data field of messages sent from a client to server devices contains additional

information that the server uses to take the action defined by the function code. This can

include items like discrete and register addresses, the quantity of items to be handled,

and the count of actual data bytes in the field.

The data field may be nonexistent (of zero length) in certain kinds request, in this case

the server does not require any additional information. The function code alone specifies

the action.

If no error occurs related to the MODBUS function requested in a properly received

MODBUS ADU the data field of a response from a server to a client contains the data

requested. If an error related to the MODBUS function requested occurs, the field

contains an exception code that the server application can use to determine the next

action to be taken.

For example a client can read the ON / OFF states of a group of discrete outputs or

inputs or it can read/write the data contents of a group of registers.

When the server responds to the client, it uses the function code field to indicate either a

normal (error-free) response or that some kind of error occurred (called an exception

response). For a normal response, the server simply echoes the original function code.

Data encoding MODBUS uses a ‘big-Endian’ representation for addresses and data items. This means

that when a numerical quantity larger than a single byte is transmitted, the most significant byte is sent first.

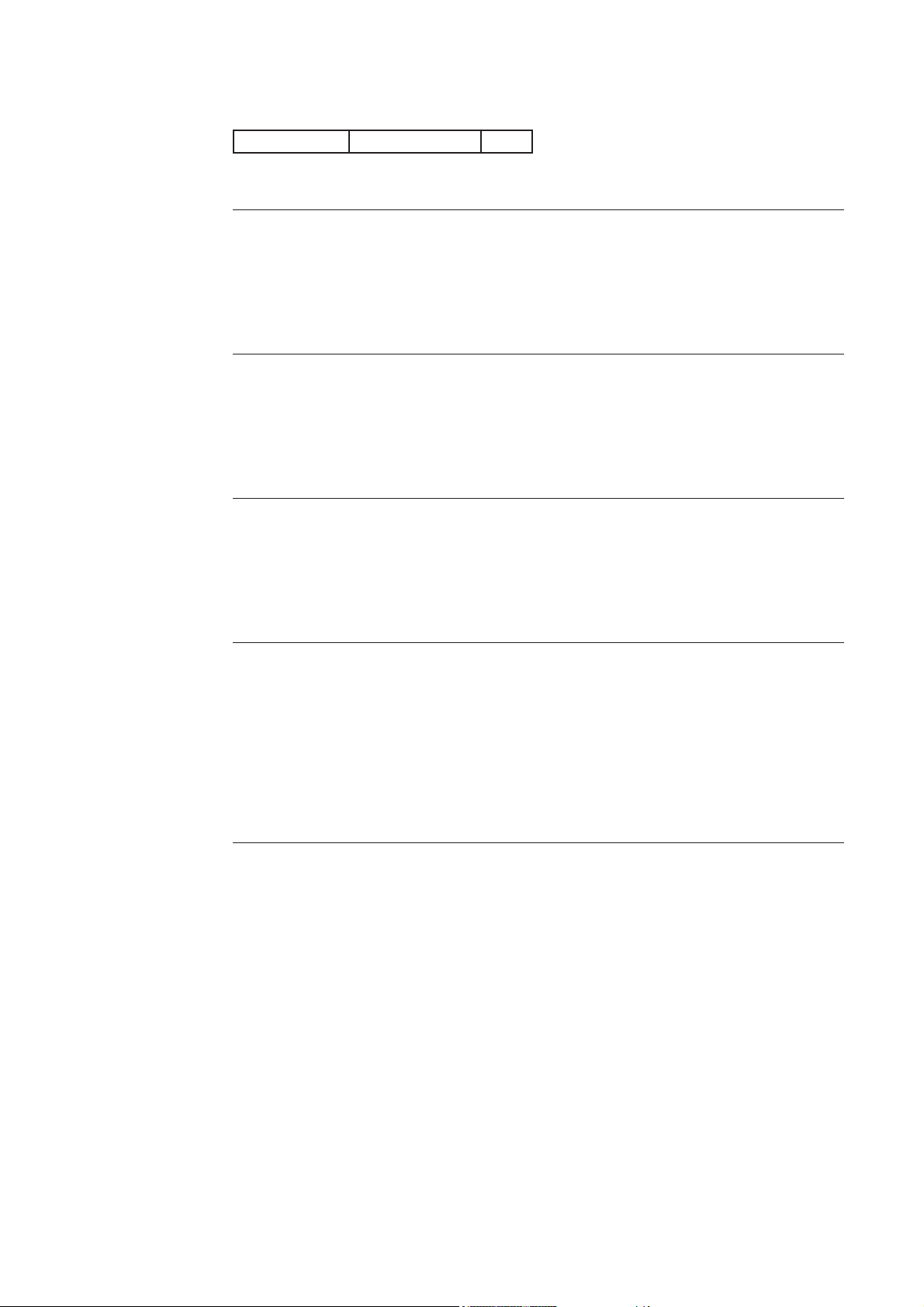

Register size Value

16 Bit 0x1234 the first byte sent is 0x12 then 0x34

3

Application Data

Unit (ADU)

This section describes the encapsulation of a MODBUS request or response when it is

carried on a MODBUS UDP network.

MPAP Header Function code Data

MPAP Header description:

Transactions Identifier

It is used for transaction pairing, the MODBUS server copies in the response the transaction identifier of the request.

Length: 2 Byte

Description: Identification of a MODBUS Request / Response transaction

Client: Initialized by the client

Server: Recopied by the server from the received request

Protocol Identifier

It is used for intra-system multiplexing. The MODBUS protocol is identified by the value

0.

Length: 2 Byte

Description: 0 = Modbus protocol

Client: Initialized by the client

Server: Recopied by the server from the received request

Length

The length field is a byte count of the following field, including the Unit Identifier, Function

code and the data field.

Length: 2 Byte

Description: Number of following bytes

Client: Initialized by the client

Server: -

Unit Identifier

This field is used for intra-system routing purpose. It is typically used to communicate to

a MODBUS or MODBUS+ serial line slave through a gateway between an Ethernet

network and a MODBUS serial line. This field is set by the MODBUS Client in the request and must be returned with the same value in the response by the server.

Length: 1Byte

Description: Identification of a remote slave connected on a serial line or on other

buses

Client: Initialized by the client

Server: Recopied by the server from the received request

Important! All MODBUS/UDP ADU are sent via UDP on registered port 502.

4

Modbus Functions

03 (0x03) Read

Holding Registers

This function code is used to read the contents of a contiguous block of holding registers

in a remote device. In the Special Data area this contiguous block is limited from 1-4

registers. The request PDU specifies the starting register address and the number of

registers. In the PDU registers are addressed starting at zero. Therefore registers

numbered 1-16 are addressed as 0-15.

The register data in the response message are packed as two bytes per register, with

the binary contents right justified within each byte. For each register, the first byte contains the high order bits and the second contains the low order bits.

Request

Function code 1 Byte 0x03

Starting Address 2 Bytes 0x0000 to 0xFFFF

Quantity of Registers 2 Bytes 1 to 125 (0x7D)

Response

Function code 1 Byte 0x03

Byte count 1 Byte 2 x N*

Register value N* x 2 Bytes -

N* = Quantity of Register

Error

Error code 1 Byte 0x83

Exception code 1 Byte 01 or 02 or 03 or 04

Example

Here is an example of a request to read registers 0xE011 (Gas preflow).

Request

Field Name (Hex)

Transaction Identifier Hi 00

Transaction Identifier Lo 01

Protocol Identifier Hi 00

Protocol Identifier Lo 00

Length Hi 00

Length Lo 06

Unit Identifier 00

Function code 03

Starting Address Hi E0

Starting Address Lo 11

No. of Registers Hi 00

No. of Registers Lo 01

Response

Field Name (Hex)

Transaction Identifier Hi 00

Transaction Identifier Lo 01

Protocol Identifier Hi 00

Protocol Identifier Lo 00

Length Hi 00

Length Lo 05

Unit Identifier 00

Function code 03

Byte Count 02

Register value Hi (108) 08

Register value Lo (108) 98

The contents of register 0xE011 (Gas preflow) are shown as the two byte values of 08

98 hex, or 2200 decimal.

5

06 (0x06) Write

Single Registers

This function code is used to write a single holding register in a remote device.

The request PDU specifies the address of the register to be written. Registers are

addressed starting at zero. Therefore register numbered 1 is addressed as 0.

The normal response is an echo of the request, returned after the register contents have

been written.

Request

Function code 1 Byte 0x06

Register Address 2 Bytes 0x0000 to 0xFFFF

Register Value 2 Bytes 0x0000 or 0xFFFF

Response

Function code 1 Byte 0x06

Register Address 2 Bytes 0x0000 to 0xFFFF

Register Value 2 Bytes 0x0000 or 0xFFFF

Error

Error code 1 Byte 0x86

Exception code 1 Byte 01 or 02 or 03 or 04

Example

Here is an example of a request to write register 0xE011 (Gas preflow) with the value

0x898 (decimal 2200):

Request

Field Name (Hex)

Transaction Identifier Hi 00

Transaction Identifier Lo 01

Protocol Identifier Hi 00

Protocol Identifier Lo 00

Length Hi 00

Length Lo 06

Unit Identifier 00

Function code 06

Register Address Hi E0

Register Address Lo 11

Register Value Hi 08

Register Value Lo 98

Response

Field Name (Hex)

Transaction Identifier Hi 00

Transaction Identifier Lo 01

Protocol Identifier Hi 00

Protocol Identifier Lo 00

Length Hi 00

Length Lo 06

Unit Identifier 00

Function code 06

Register Address Hi E0

Register Address Lo 11

Register Value Hi 08

Register Value Lo 98

6

16 (0x10) Write

Multiple Registers

This function code is used to write a block of contiguous registers (1 to 20 registers) in a

remote device. The requested written values are specified in the request data field. Data

is packed as two bytes per register. The normal response returns the function code,

starting address and quantity of registers written.

Request

Function code 1 Byte 0x10

Starting Address 2 Bytes 0x0000 to 0xFFFF

Quantity of Registers 2 Bytes 0x0001 or 0x0078

Byte Count 1 Byte 2 x N*

Register Values N* x 2 Bytes Value

N* = Quantity to Write

Response

Function code 1 Byte 0x10

Starting Address 2 Bytes 0x0000 to 0xFFFF

Quantity of Registers 2 Bytes 1 to 123 (0x7B)

Error

Error code 1 Byte 0x90

Exception code 1 Byte 01 or 02 or 03 or 04

Example

Here is an example of a request to write two registers (0xF00B – 0xF00C)

Request

Field Name (Hex)

Transaction Identifier Hi 00

Transaction Identifier Lo 01

Protocol Identifier Hi 00

Protocol Identifier Lo 00

Length Hi 00

Length Lo ??

Unit Identifier 00

Function code 10

Starting Address Hi F0

Starting Address Lo 0B

Quantity of Registers Hi 00

Quantity of Registers Lo 02

Response

Field Name (Hex)

Transaction Identifier Hi 00

Transaction Identifier Lo 01

Protocol Identifier Hi 00

Protocol Identifier Lo 00

Length Hi 00

Length Lo 06

Unit Identifier 00

Function code 10

Starting Address Hi F0

Starting Address Lo 0B

Quantity of Registers Hi 00

Quantity of Registers Lo 02

Byte Count 04

Register Value Hi 7F

Register Value Lo FF

Register Value Hi 7F

Register Value Lo FF

7

23 (0x17) Read/

Write Multiple

registers

This function code performs a combination of one read operation and one write operation in a single MODBUS transaction. The write operation is performed before the read.

Holding registers are addressed starting at zero. Therefore holding registers 1-16 are

addressed in the PDU as 0-15.

The request PDU specifies the starting address and number of holding registers to be

read as well as the starting address, number of holding registers, and the data to be

written. The byte count specifies the number of bytes to follow in the write data field.

The normal response contains the data from the group of registers that were read. The

byte count field specifies the quantity of bytes to follow in the read data field.

Request

Function code 1 Byte 0x17

Read Starting Address 2 Bytes 0x0000 to 0xFFFF

Quantity to Read 2 Bytes 0x0001 to approx.0x0076

Write Starting Address 2 Bytes 0x0000 to 0xFFFF

Quantity to Write 2 Bytes 0x0001 to approx. 0X0076

Write Byte Count 1 Byte 2 x N*

Write Registers Value N* x 2 Bytes

N* = Quantity to Write

Response

Function code 1 Byte 0x17

Byte Count 1 Byte 2 x N'*

Read Registers value N'* x 2 Bytes

N* = Quantity to Read

Error

Error code 1 Byte 0x97

Exception code 1 Byte 01 or 02 or 03 or 04

Example

Here is an example of a request to read six registers and to write three registers:

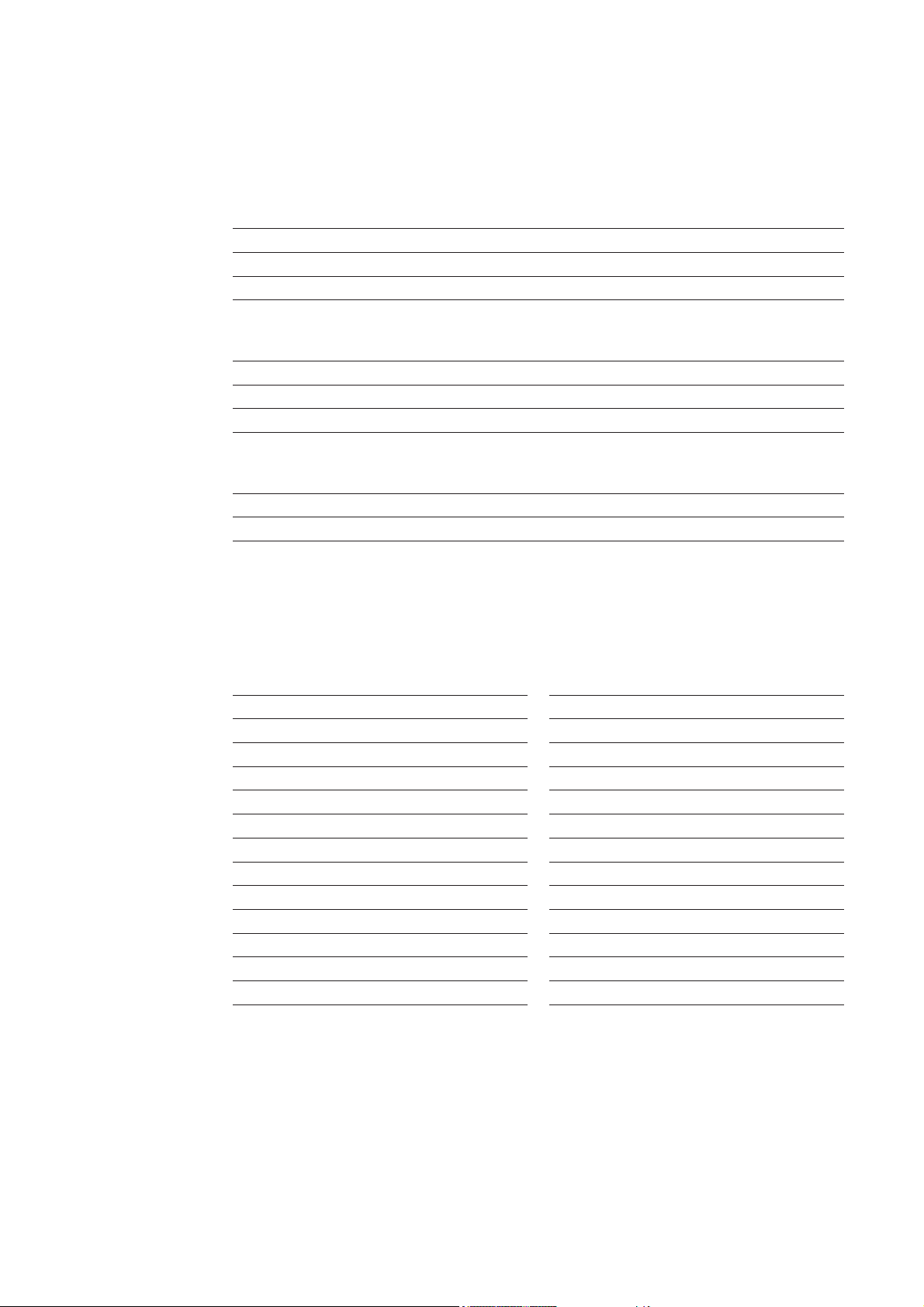

Request

Field Name (Hex)

Transaction Identifier Hi 00

Transaction Identifier Lo 01

Protocol Identifier Hi 00

Protocol Identifier Lo 00

Length Hi 00

Length Lo 11

Unit Identifier 00

Function code 17

Read Starting Address Hi F1

Read Starting Address Lo 00

Quantity to Read Hi 00

Field Name (Hex)

Write Starting Address Hi F0

Write Starting address Lo 00

Quantity to Write Hi 00

Quantity to Write Lo 03

Write Byte Count 06

Write Registers Value Hi 01

Write Registers Value Lo FA

Write Registers Value Hi 02

Write Registers Value Lo FB

Write Registers Value Hi 03

Write Registers Value Lo FC

Quantity to Read Lo 06

8

Write Multiple

registers

(continued)

Response23 (0x17) Read/

Field Name (Hex)

Transaction Identifier Hi 00

Transaction Identifier Lo 01

Protocol Identifier Hi 00

Protocol Identifier Lo 00

Length Hi 00

Length Lo 0F

Unit Identifier 00

Function code 17

Byte Count 0C

Read Registers value Hi 00

Read Registers value Lo FE

Field Name (Hex)

Read Registers value Hi 0A

Read Registers value Lo CD

Read Registers value Hi 00

Read Registers value Lo 01

Read Registers value Hi 00

Read Registers value Lo 03

Read Registers value Hi 00

Read Registers value Lo 0D

Read Registers value Hi 00

Read Registers value Lo FF

100 (0x64) Configure Streaming

Data

This function code is used to configure the data in the streaming frame. This frame will

be sent without a request from the client (or master).

The request PDU specifies the IP-address and the port number of the client, the streaming frequency and the addresses of the register. The port number 15000 and 15001

are reserved for Fronius Applications.

The normal response is an echo of the request.

Request

Function code 1 Byte 0x64

IP Address Hi Word 2 Bytes 0x0000 to 0xFFFF

IP Address Lo Word 2 Bytes 0x0000 to 0xFFFF

Port number 2 Byte 0x0000 to 0xFFFF

Frequency 2 Byte 0x0000 to 0xFFFF

Number of register 1 Byte 0x00 to 0xFF

Register Address N* x 2 Bytes

N* = Quantity of Register

Response

Function code 1 Byte 0x64

IP Address Hi Word 2 Bytes 0x0000 to 0xFFFF

IP Address Lo Word 2 Bytes 0x0000 to 0xFFFF

Port number 2 Byte 0x0000 to 0xFFFF

Frequency 2 Byte 0x0000 to 0xFFFF

Number of register 1 Byte 0x00 to 0xFF

Register Address N* x 2 Bytes

N* = Quantity of Register

Error

Error code 1 Byte 0xE5

Exception code 1 Byte 01 or 02 or 03 or 04

9

100 (0x64) Configure Streaming

Data

(continued)

Example

Here is an example of a request to configure the streaming data.

IP-Address: 192.168.0.2

Port number: 500

Frequency: 20 Hz

Address 1: 0xE070

Address 2: 0xE071

Address 3: 0xE068

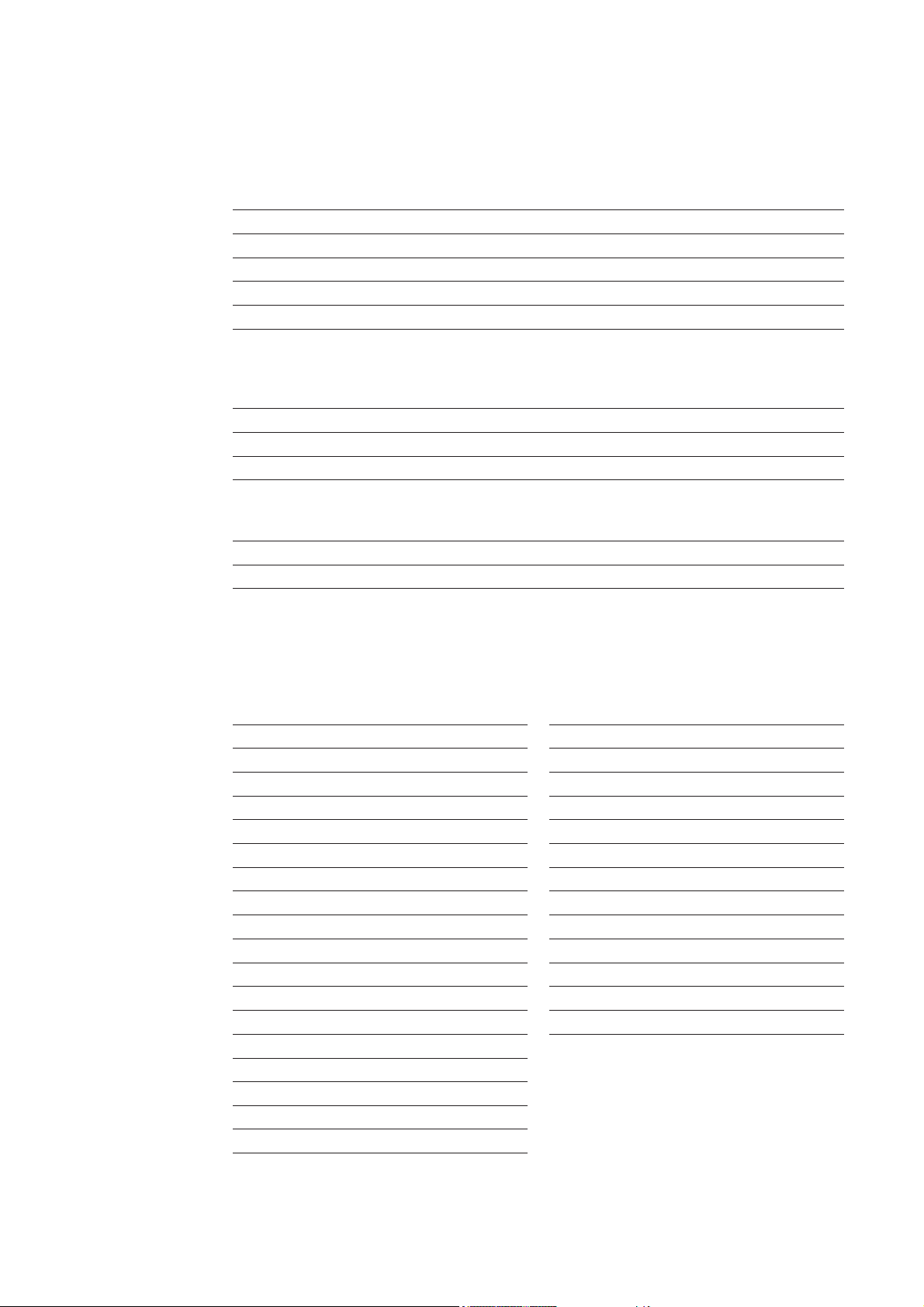

Request

Field Name (Hex)

Transaction Identifier Hi 00

Transaction Identifier Lo 01

Protocol Identifier Hi 00

Protocol Identifier Lo 00

Length Hi 00

Length Lo 0F

Unit Identifier 00

Function code 64

IP Address Hi Word Hi C0

IP Address Hi Word Lo A8

IP Address Lo Word Hi 00

IP Address Lo Word Lo 02

Port number Hi 01

Port number Lo E4

Frequency Hi 00

Frequency Lo 14

Number of register 03

Registers Value Hi E0

Registers Value Lo 70

Registers Value Hi E0

Registers Value Lo 71

Registers Value Hi E0

Registers Value Lo 68

Response

Field Name (Hex)

Transaction Identifier Hi 00

Transaction Identifier Lo 01

Protocol Identifier Hi 00

Protocol Identifier Lo 00

Length Hi 00

Length Lo 0F

Unit Identifier 00

Function code 64

IP Address Hi Word Hi C0

IP Address Hi Word Lo A8

IP Address Lo Word Hi 00

IP Address Lo Word Lo 02

Port number Hi 01

Port number Lo E4

Frequency Hi 00

Frequency Lo 14

Number of register 03

Registers Value Hi E0

Registers Value Lo 70

Registers Value Hi E0

Registers Value Lo 71

Registers Value Hi E0

Registers Value Lo 68

101 (0x65) Action

Streaming Data

This function code is used to start and stop the streaming frame without a request from

the client (or master).

The request PDU specifies the start (0x01) or stop (0x00) of the streaming frame.

The normal response is an echo of the request.

Request

Function code 1 Byte 0x65

Action 1 Bytes Bit 0…0 (Stop streaming)

Bit 0…1 (Start streaming)

10

101 (0x65) Action

Streaming Data

(continued)

Response

Function code 1 Byte 0x65

Action 1 Bytes Bit 0…0 (Stop streaming)

Bit 0…1 (Start streaming)

Error

Error code 1 Byte 0xE5

Exception code 1 Byte 01 or 04 or 10

Example

Here is an example of a request to start the streaming data.

102 (0x66) Streaming Data

Request

Field Name (Hex)

Transaction Identifier Hi 00

Transaction Identifier Lo 01

Protocol Identifier Hi 00

Protocol Identifier Lo 00

Length Hi 00

Length Lo 03

Unit Identifier 00

Function code 65

Action streaming data 01

Response

Field Name (Hex)

Transaction Identifier Hi 00

Transaction Identifier Lo 01

Protocol Identifier Hi 00

Protocol Identifier Lo 00

Length Hi 00

Length Lo 03

Unit Identifier 00

Function code 65

Action streaming data 01

This function will be send from the server without a request from the client.

The Transaction Identifier will be incremented every cycle by the server. The Protocol

Identifier is the Protocol Identifier from the function 100 (0x64) Configure Streaming

Data.

The Unit Identifier is the Unit Identifier from the function 100 (0x64) Configure Streaming

Data.

Response

Function code 1 Byte 0x66

Frequency 2 Byte 0x0000 to 0xFFFF

Timestamp in ms 2 Byte 0x0000 to 0xFFFF

Number of registers 1 Byte 0x00 to 0xFF

Register address 1 2 Byte 0x0000 to 0xFFFF

Register value 1 2 Byte 0x0000 to 0xFFFF

Register address n 2 Byte 0x0000 to 0xFFFF

Register value n 2 Byte 0x0000 to 0xFFFF

11

102 (0x66) Streaming Data

(continued)

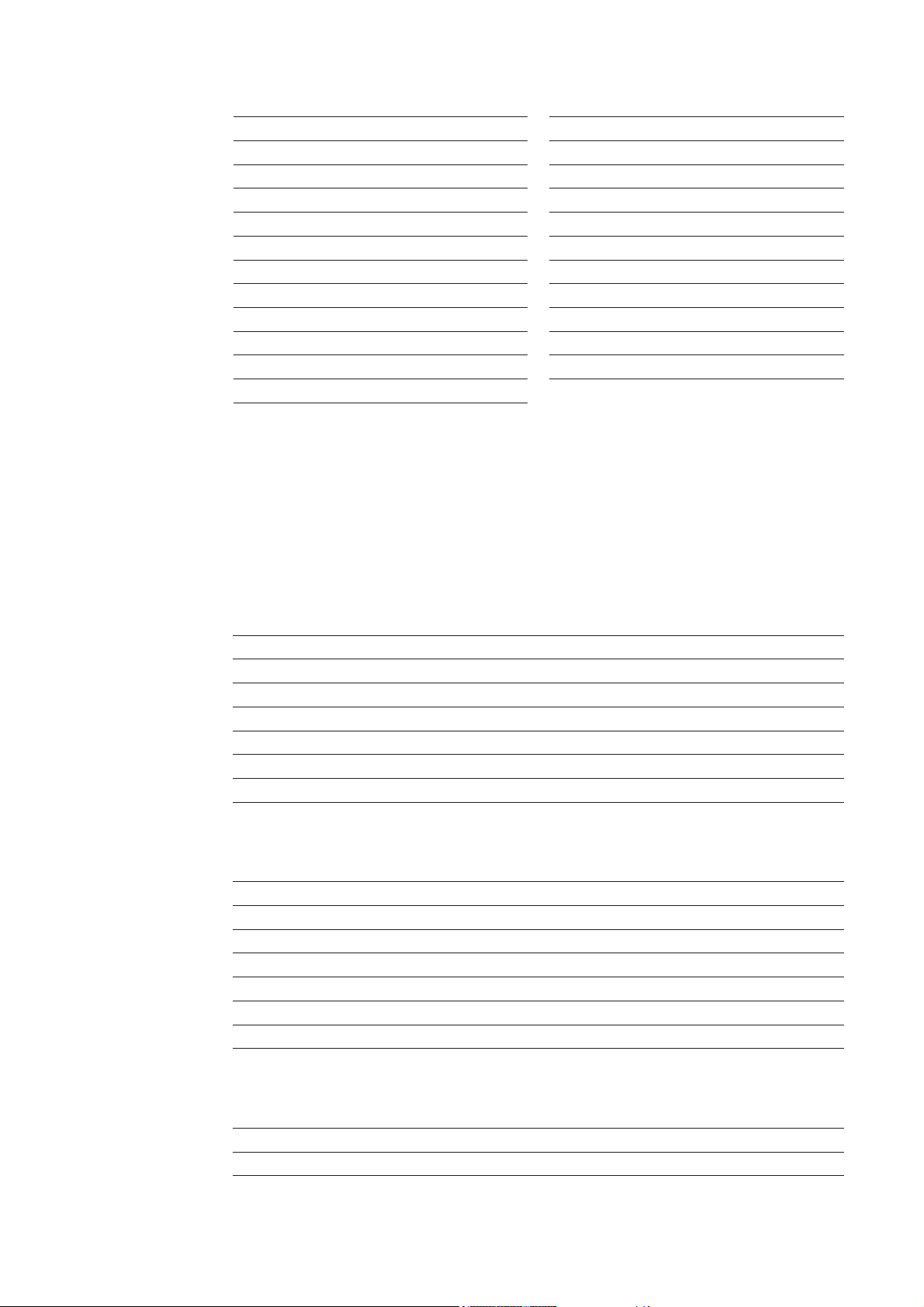

Example

Here is an example of a response of the streaming data.

Frequency: 20 Hz

Timestamp: 1613 ms

Nr. of register: 0x03

Address 1: 0xE070

Address 2: 0xE071

Address 3: 0xE068

Response

Field Name (Hex)

Transaction Identifier Hi 00

Transaction Identifier Lo 01

Protocol Identifier Hi 00

Protocol Identifier Lo 01

Length Hi 00

Length Lo 13

Unit Identifier 00

Function code 66

Frequency Hi 00

Frequency Lo 14

Timestamp Hi 06

Timestamp Lo 4D

Number of register 03

Field Name (Hex)

Register address 1 Hi E0

Register address 1 Lo 70

Register value 1 Hi 01

Register value 1 Lo FF

Register address 2 Hi E0

Register address 2 Lo 71

Register value 2 Hi 02

Register value 2 Lo FF

Register address 3 Hi E0

Register address 3 Lo 68

Register value 3 Hi 03

Register value 3 Lo FF

12

Exception codes

Code 0x01 Illegal Function

Code 0x02 Illegal Data

Address

Code 0x03 Illegal Data V alue

The function code received in the query is not an allowable action for the server (or

slave). This may be because the function code is only applicable to newer devices, and

was not implemented in the unit selected. It could also indicate that the server (or slave)

is in the wrong state to process a request of this type, for example because it is unconfigured and is being asked to return register values.

The data address received in the query is not an allowable address for the server (or

slave). More specifically, the

combination of reference number and transfer length is invalid. For a controller with 100

registers, a request with offset 96 and length 4 would succeed, a request with offset 96

and length 5 will generate exception 02.

A value contained in the query data field is not an allowable value for server (or slave).

This indicates a fault in the

structure of the remainder of a complex request, such as that the implied length is

incorrect. It specifically does NOT mean that a data item submitted for storage in a

register has a value outside the expectation of the application program, since the

MODBUS protocol is unaware of the significance of any particular value of any particular

register.

Code 0x04 Slave Device

Failure

Code 0x06 Slave Device

Busy

An unrecoverable error occurred while the server was attempting to perform the requested action.

What is the reason for this error:

- License Gateway Level 1 (4,061,115) not installed in the power source

- Modbus protocol not activated (UniveralBusSteuerung -> Config)

- Wrong Firewall IP address Modbus

The server (or slave) is engaged in processing a long-duration command. The client (or

master) should retransmit the message later when the server (or slave) is free.

13

Timeout Lifecycle

General

Client

Server

Modbus UDP is a connectionless transport protocol. It provides no control mechanism

when exchanging data between client and server. This results in a higher processing

speed than, for example, TCP. Therefore the connection must be controlled by the client

and the server.

In the process image 0xF000 (Bit 0-7) Control Flag Group 1 contents the signal Timeout

Lifecycle.

If the value is zero, there is no control of the communication active.

A value between 1-255 means a timeout from 10ms - 2550ms.

Every request of a Modbus function 23 (0x17) reset the lifecycle timer in the server.

After a overrun of this lifecycle timer the power source stops immediately.

If the lifecycle time run over, in the process image 0xF100 Bit 1 Status Flag Group 1 the

signal Modbus Timeout will be set.

After a restart of the Modbus communication this flag is set as long, till the signal Source

Error Reset will be set.

14

Modbus UDP - Process image for MIG/MAG standard

synergic, MIG/MAG pulse synergic and CMT

Process data

from controller to

power source

(0xF000 - 0xF0FF)

Address Description Unit Type Factor R / W

0xF000 Control Flag Group 1

Bit 0 - 7 Timeout Lifecycle ms Byte 10 r/w

Bit 8 - 15 Reserved - - - -

0xF001 Control Flag Group 2

Bit 0 Welding start - Boolean - r/w

Bit 1 Robot ready - Boolean - r/w

Bit 2 Source error reset - Boolean - r/w

Bit 3 Gas test - Boolean - r/w

Bit 4 Wire inching - Boolean - r/w

Bit 5 Wire retract - Boolean - r/w

Bit 6 Torch blow out - Boolean - r/w

Bit 7 Welding simulation - Boolean - r/w

Bit 8 Touch sensing - Boolean - r/w

Bit 9 Master selectioin Twin - Boolean - r/w

Bit 10 SFI disable - Boolean - r/w

Bit 11 SynchroPuls disable - Boolean - r/w

Bit 12 Pulse/Dynamik correction disable - Boolean - r/w

Bit 13 Burn back correction disable - Boolean - r/w

Bit 14 Power full range - Boolean - r/w

Bit 15 Reserved - Boolean - -

0xF002 Control Flag Group 3

Bit 0 - 15 Reserved - Boolean - -

0xF003 Control Flag Group 4

Bit 0 - 15 Reserved - Boolean - -

0xF004 Control Flag Group 5

Bit 0 - 15 Reserved - Boolean - -

0xF005 Control Flag Group 6

Bit 0 - 15 Reserved - Boolean - -

0xF006 Control Flag Group 7

Bit 0 - 15 Reserved - Boolean - -

0xF007 Control Flag Group 8

Bit 0 - 15 Reserved - Boolean - -

0xF008 Operating mode

0 MIG/MAG standard synergic welding - - - r/w

1 MIG/MAG pulse synergic welding - - - r/w

2 Job mode - - - r/w

3 Parameter selection internal - - - r/w

4 MIG/MAG standard manual welding - - - r/w

5 CC/CV - - - r/w

6 TIG welding - - - r/w

7 CMT - - - r/w

8 Special process: manual standard - - - r/w

9 Special process: manual pulse - - - r/w

0xF009 Job number - Byte - r/w

0xF00A Program number - Byte - r/w

0xF00B Power % - Word r/w

0xF00C Arc length correction % Word r/w

0xF00D Pulse/Dynamik correction % Byte r/w

0xF00E Burn back correction ms Byte r/w

15

Process data

from controller to

power source

(0xF000 - 0xF0FF)

(continued)

Address Description Unit Type Factor R / W

0xF00F Reserved - - - -

0xF010 External wirefeeder

Wirefeed speed actual value m/min Word - r/w

0xF011 External wirefeeder

Main error - Byte - r/w

0xF012 External wirefeeder

Sub error - Byte - r/w

0xF013 External wirefeeder

Bit 0 External wirefeeder enable - Boolean - r/w

Bit 1 - 15 Reserved - - - -

Process data from

power source to

controller (0xF100

- 0xF1FF)

Address Description Unit Type Factor R / W

0xF100 Status Flag Group 1

Bit 0 Modbus timeout ms Boolean - r

Bit 2 - 15 Reserved - Boolean - -

0xF101 Status Flag Group 2

Bit 0 Communication ready - Boolean - r

Bit 1 Power source ready - Boolean - r

Bit 2 Arc stable - Boolean - r

Bit 3 Process active - Boolean - r

Bit 4 Main current signal - Boolean - r

Bit 5 Torch collision protection - Boolean - r

Bit 6 Wire stick control - Boolean - r

Bit 7 Wire available - Boolean - r

Bit 8 Shortcircuit timeout - Boolean - r

Bit 9 Power out of range - Boolean - r

Bit 10 Robot access - Boolean - r

Bit 11 Data documentation ready - Boolean - r

Bit 12 Limit signal - Boolean - r

Bit 13-15 Reserved - Boolean - r

0xF102 Status Flag Group 3

Bit 0 - 15 Reserved - - - -

0xF103 Status Flag Group 4

Bit 0 - 15 Reserved - - - -

0xF104 Status Flag Group 5

Bit 0 - 15 Reserved - - - -

0xF105 Status Flag Group 6

Bit 0 - 15 Reserved - - - -

0xF106 Status Flag Group 7

Bit 0 - 15 Reserved - - - -

0xF107 Device SubError - Byte - r

0xF108 Main error number - Word - r

0xF109 Reserved - - - -

0xF10A Welding voltage actual value V Word - r

0xF10B Welding current actual value A Word - r

0xF10C Motor current actual value A Word - r

0xF10D Reserved - - - -

0xF10E Reserved - - - -

16

Process data from

power source to

controller (0xF100

- 0xF1FF)

(continued)

Address Description Unit Type Factor R / W

0xF10F Reserved - - - -

0xF110 Wire speed actual value m/min Word - -

0xF111 External wirefeeder

Wirefeed speed command value m/min Word - r

0xF112 External wirefeeder

Wirefeed speed ramp value 15m/min/s Word r

17

Modbus UDP - Process image for TIG

Process data

from controller to

power source

(0xF000 - 0xF0FF)

Address Description Unit Type Factor R / W

0xF000 Control Flag Group 1

Bit 0 - 7 Timeout Lifecycle ms Byte 10 Bit 8 - 15 Reserved - - - -

0xF001 Control Flag Group 2

Bit 0 Welding start - Boolean - Bit 1 Robot ready - Boolean - Bit 2 Source error reset - Boolean - Bit 3 Gas test - Boolean - Bit 4 Wire inching - Boolean - Bit 5 Wire retract - Boolean - Bit 6 Cold wire disable - Boolean - Bit 7 Welding simulation - Boolean - Bit 8 Touch sensing - Boolean - Bit 9 Reserved - - - Bit 10 Reserved - - - Bit 11 Reserved - - - Bit 12 Base current disable - Boolean - Bit 13 Duty cycle disable - Boolean - Bit 14-15 Reserved - - - -

0xF002 Control Flag Group 3

Bit 0 - 15 Reserved - Boolean - -

0xF003 Control Flag Group 4

Bit 0 - 15 Reserved - Boolean - -

0xF004 Control Flag Group 5

Bit 0 - 15 Reserved - Boolean - -

0xF005 Control Flag Group 6

Bit 0 - 15 Reserved - Boolean - -

0xF006 Control Flag Group 7

Bit 0 - 15 Reserved - Boolean - -

0xF007 Control Flag Group 8

Bit 0 - 15 Reserved - Boolean - -

0xF008 Operating mode

0 MIG/MAG standard synergic welding - - - r/w

1 MIG/MAG pulse synergic welding - - - r/w

2 Job mode - - - r/w

3 Parameter selection internal - - - r/w

4 MIG/MAG standard manual welding - - - r/w

5 CC/CV - - - r/w

6 TIG welding - - - r/w

7 CMT - - - r/w

8 Special process: manual standard - - - r/w

9 Special process: manual pulse - - - r/w

0xF009 Job number - Byte - r/w

0xF00A Bit 0 DC / AC - Boolean - -

Bit 1 DC- / DC+ - Boolean - Bit 2 Cap shaping - Boolean - Bit 3 Pulse disable - Boolean - Bit 4 Pulse range Bit 0 - Boolean - Bit 5 Pulse range Bit 1 - Boolean - Bit 6 Pulse range Bit 2 - Boolean - Bit 7 Reserved - - - -

0xF00B Main current A Word - -

18

Process data

from controller to

power source

(0xF000 - 0xF0FF)

(continued)

Address Description Unit Type Factor R / W

0xF00C External parameter - Word - -

0xF00D Base current % Byte - -

0xF00E Duty cycle % Byte - -

0xF00F Wire speed cold wire m/min 10 Bit - -

0xF010 External wirefeeder

Wirefeed speed actual value m/min Word - -

0xF011 External wirefeeder

Main error - Byte - -

0xF012 External wirefeeder

Sub error - Byte - -

0xF013 External wirefeeder

Bit 0 External wirefeeder enable - Boolean - Bit 1-15 Reserved - - - -

Pulse range selection Bit 6 Bit 5 Bit 4

Set pulse range on power source 0 0 0

Pulse setting range deactivated 0 0 1

0,2 - 2 Hz 0 1 0

2 - 20 Hz 0 1 1

20 - 200 Hz 1 0 0

200 - 2000 Hz 1 0 1

Process data

from power

source to controller (0xF100 –

0xF1FF)

Address Description Unit Type Factor R / W

0xF100 Status Flag Group 1

Bit 0 Modbus timeout ms Boolean - Bit 2-15 Reserved - Boolean - -

0xF101 Status Flag Group 2

Bit 0 Communication ready - Boolean - Bit 1 Power source ready - Boolean - Bit 2 Arc stable - Boolean - Bit 3 Process active - Boolean - Bit 4 Main current signal - Boolean - Bit 5 Torch collision protection - Boolean - Bit 6 Reserved - - - Bit 7 Wire available (cold wire) - Boolean - Bit 8 Reserved - - - Bit 9 Reserved - - - Bit 10 Reserved - - - Bit 11 Reserved - - - Bit 12 Reserved - - - Bit 13 High frequency active - Boolean - Bit 14 Pulse high - Boolean - Bit 15 Reserved - - - -

0xF102 Status Flag Group 3

Bit 0 - 15 Reserved - Boolean - -

0xF103 Status Flag Group 4

Bit 0 - 15 Reserved - - - -

0xF104 Status Flag Group 5

Bit 0 - 15 Reserved - - - -

0xF105 Status Flag Group 6

Bit 0 - 15 Reserved - - - -

19

Process data

from power

source to controller (0xF100 –

0xF1FF)

(continued)

Address Description Unit Type Factor R / W

0xF106 Status Flag Group 7

Bit 0 - 15 Reserved - - - -

0xF107 Device SubError - Byte - r

0xF108 Main error number - Word - -

0xF109 Reserved - - - -

0xF10A Welding voltage V Word - -

0xF10B Welding current A Word - -

0xF10C Motor current (cold wire) A Word - -

0xF10D Reserved

0xF10E Arc length actual value (AVC) V Byte - -

0xF10F Reserved - - - -

0xF110 Wire speed (cold wire) m/min Word - -

0xF111 External wirefeeder

Wirefeed speed command value m/min Word - -

0xF112 External wirefeeder

Wirefeed speed ramp value 15m/min/s Word - -

20

Modbus UDP - Process image for CC/CV

Process data

from controller to

power source

(0xF000 –

0xF0FF)

Address Description Unit Type Factor R / W

0xF000 Control Flag Group 1

Bit 0 - 7 Timeout Lifecycle ms Byte 10 Bit 8 - 15 Reserved - - - -

0xF001 Control Flag Group 2

Bit 0 Welding start - Boolean - Bit 1 Robot ready - Boolean - Bit 2 Source error reset - Boolean - Bit 3 Gas test - Boolean - Bit 4 Wire inching - Boolean - Bit 5 Wire retract - Boolean - Bit 6 Torch blow out - Boolean - Bit 7 Welding simulation - Boolean - Bit 8 Touch sensing - Boolean - Bit 9 Master selectioin Twin - Boolean - Bit 10-15 Reserved - - - -

0xF002 Control Flag Group 3

Bit 0 - 15 Reserved - Boolean - -

0xF003 Control Flag Group 4

Bit 0 - 15 Reserved - Boolean - -

0xF004 Control Flag Group 5

Bit 0 - 15 Reserved - Boolean - -

0xF005 Control Flag Group 6

Bit 0 - 15 Reserved - Boolean - -

0xF006 Control Flag Group 7

Bit 0 - 15 Reserved - Boolean - -

0xF007 Control Flag Group 8

Bit 0 - 15 Reserved - Boolean - -

0xF008 Operating mode

0 MIG/MAG standard synergic welding - - - r/w

1 MIG/MAG pulse synergic welding - - - r/w

2 Job mode - - - r/w

3 Parameter selection internal - - - r/w

4 MIG/MAG standard manual welding - - - r/w

5 CC/CV - - - r/w

6 TIG welding - - - r/w

7 CMT - - - r/w

8 Special process: manual standard - - - r/w

9 Special process: manual pulse - - - r/w

0xF009 Job number - Byte - -

0xF00A Reserved - - - -

0xF00B Welding current A Word - -

0xF00C Wire feed speed m/min Word - -

0xF00D Welding voltage V Byte - -

0xF00E Reserved - - - -

0xF00F Reserved - - - -

0xF010 External wirefeeder

Wirefeed speed actual value m/min Word - -

0xF011 External wirefeeder

Main error - Byte - -

21

Process data

from controller to

power source

(0xF000 –

0xF0FF)

(continued)

Address Description Unit Type Factor R / W

0xF012 External wirefeeder

Sub error - Byte - -

0xF013 External wirefeeder

Bit 0 External wirefeeder enable - Boolean - Bit 1-15 Reserved

Process data

from power

source to controller (0xF100 –

0xF1FF)

Address Description Unit Type Factor R / W

0xF100 Status Flag Group 1

Bit 0 Modbus timeout ms Boolean - Bit 2 - 15 Reserved - Boolean - -

0xF101 Status Flag Group 2

Bit 0 Communication ready - Boolean - Bit 1 Power source ready - Boolean - Bit 2 Arc stable - Boolean - Bit 3 Process active - Boolean - Bit 4 Main current signal - Boolean - Bit 5 Torch collision protection - Boolean - Bit 6 Wire stick control - Boolean - Bit 7 Wire available - Boolean - Bit 8 Shortcircuit timeout - Boolean - Bit 9 Power out of range - Boolean - Bit 10 Robot access - Boolean - Bit 11 Data documentation ready - Boolean - Bit 12 Limit signal - Boolean - Bit 13-15 Reserved - - - -

0xF102 Status Flag Group 3

Bit 0 - 15 Reserved - Boolean - -

0xF103 Status Flag Group 4

Bit 0 - 15 Reserved - - - -

0xF104 Status Flag Group 5

Bit 0 - 15 Reserved - - - -

0xF105 Status Flag Group 6

Bit 0 - 15 Reserved - - - -

0xF106 Status Flag Group 7

Bit 0 - 15 Reserved - - - -

0xF107 Device SubError - Byte - r

0xF108 Main error number Word

0xF109 Reserved - - - -

0xF10A Welding voltage V Word

0xF10B Welding current A Word

0xF10C Motor current A Word

0xF10D Reserved - - - -

0xF10E Reserved - - - -

0xF10F Reserved - - - -

0xF110 Wire speed m/min Word - -

0xF111 External wirefeeder

Wirefeed speed command value m/min Word - -

0xF112 External wirefeeder

Wirefeed speed ramp value 15m/min/s Word - -

22

Modbus UDP - Process image for MIG/MAG standard

manual

Process data

from controller to

power source

(0xF000 –

0xF0FF)

Address Description Unit Type Factor R / W

0xF000 Control Flag Group 1

Bit 0-7 Timeout Lifecycle ms Byte 10 Bit 8-15 Reserved - - - -

0xF001 Control Flag Group 2

Bit 0 Welding start - Boolean - Bit 1 Robot ready - Boolean - Bit 2 Source error reset - Boolean - Bit 3 Gas test - Boolean - Bit 4 Wire inching - Boolean - Bit 5 Wire retract - Boolean - Bit 6 Torch blow out - Boolean - Bit 7 Welding simulation - Boolean - Bit 8 Touch sensing - Boolean - Bit 9 Master selection Twin - Boolean - Bit 10 Reserved - - - Bit 11 Reserved - - - Bit 12 Dynamik correction disable - Boolean - Bit 13 Burn back correction disable - Boolean - Bit 14 Power full range - Boolean - Bit 15 Reserved - - - -

0xF002 Control Flag Group 3

Bit 0 - 15 Reserved - Boolean - -

0xF003 Control Flag Group 4

Bit 0 - 15 Reserved - Boolean - -

0xF004 Control Flag Group 5

Bit 0 - 15 Reserved - Boolean - -

0xF005 Control Flag Group 6

Bit 0 - 15 Reserved - Boolean - -

0xF006 Control Flag Group 7

Bit 0 - 15 Reserved - Boolean - -

0xF007 Control Flag Group 8

Bit 0 - 15 Reserved - Boolean - -

0xF008 Operating mode

0 MIG/MAG standard synergic welding - - - r/w

1 MIG/MAG pulse synergic welding - - - r/w

2 Job mode - - - r/w

3 Parameter selection internal - - - r/w

4 MIG/MAG standard manual welding - - - r/w

5 CC/CV - - - r/w

6 TIG welding - - - r/w

7 CMT - - - r/w

8 Special process: manual standard - - - r/w

9 Special process: manual pulse - - - r/w

0xF009 Reserved - - - -

0xF00A Program number - Byte - -

0xF00B Wire speed m/min Word - -

0xF00C Welding voltage V Word - -

0xF00D Dynamik correction % Byte - -

0xF00E Burn back correction ms Byte - -

23

Process data

from controller to

power source

(0xF000 –

0xF0FF)

(continued)

Address Description Unit Type Factor R / W

0xF00F Reserved - - - -

0xF010 External wirefeeder

Wirefeed speed actual value m/min Word - -

0xF011 External wirefeeder

Main error - Byte - -

0xF012 External wirefeeder

Sub error - Byte - -

0xF013 External wirefeeder

Bit 0 External wirefeeder enable - Boolean - Bit 1-15 Reserved - - - -

Process data

from power

source to controller (0xF100 –

0xF1FF)

Address Description Unit Type Factor R / W

0xF100 Status Flag Group 1

Bit 0 Modbus timeout ms Boolean - Bit 2-15 Reserved - Boolean - -

0xF101 Status Flag Group 2

Bit 0 Communication ready - Boolean - Bit 1 Power source ready - Boolean - Bit 2 Arc stable - Boolean - Bit 3 Process active - Boolean - Bit 4 Main current signal - Boolean - Bit 5 Torch collision protection - Boolean - Bit 6 Wire stick control - Boolean - Bit 7 Wire available - Boolean - Bit 8 Shortcircuit timeout - Boolean - Bit 9 Power out of range - Boolean - Bit 10 Robot access - Boolean - Bit 11 Data documentation ready - Boolean - Bit 12 Limit signal - Boolean - Bit 13-15 Reserved - - - -

0xF102 Status Flag Group 3

Bit 0 - 15 Reserved - Boolean - -

0xF103 Status Flag Group 4

Bit 0 - 15 Reserved - - - -

0xF104 Status Flag Group 5

Bit 0 - 15 Reserved - - - -

0xF105 Status Flag Group 6

Bit 0 - 15 Reserved - - - -

0xF106 Status Flag Group 7

Bit 0 - 15 Reserved - - - -

0xF107 Device SubError - Byte - r

0xF108 Main error number - Word - -

0xF109 Reserved - - - -

0xF10A Welding voltage V Word - -

0xF10B Welding current A Word - -

0xF10C Motor current A Word - -

0xF10D Reserved - - - -

0xF10E Reserved - - - -

0xF10F Reserved - - - -

0xF110 Wire speed m/min Word - -

24

Process data

from power

source to controller (0xF100 –

0xF1FF)

(continued)

Address Description Unit Type Factor R / W

0xF111 External wirefeeder

Wirefeed speed command value m/min Word - -

0xF112 External wirefeeder

Wirefeed speed ramp value 15m/min/s Word - -

25

Special data

Generic

Address Description Read Write Unit Type Factor

E000 Main error TRUE FALSE - Word 1

E001 Sub error TRUE FALSE - Word 1

E002 Status Flag TRUE FALSE - Word 1

0 main current - - - - 1 cooler - - - - 2 fan 1 - - - - 3 gas 1 - - - - 4 cooler sensor - - - - 5 process run - - - - 6 process act - - - - 7 wf started - - - - 8 weld start - - - - 9 inching - - - - 10 gas test - - - - 11 keylock - - - - 12 UST-fan - - - - 13 current flow - - - - 14 started up - - - - 15 hold - - - - -

E003 Status Flag TRUE FALSE - Word 1

0 DC+ enable - - - - 1 Needle OVL - - - - 2 is 3 phase machine - - - - 3 is Magic Wave - - - - 4 is TIG - - - - -

E004 reserved TRUE FALSE - Word 1

E005 Job number TRUE TRUE - Word 1

E007 Push pull unit [PPU] TRUE TRUE - Word 1

E008 Operating mode TRUE TRUE - Word 1

0 MIG/MAG standard synergic - - - - -

welding

1 MIG/MAG pulse synergic - - - - -

welding

2 Stick * - - - - 3 TIG welding - - - - 4 Job mode - - - - 5 MIG/MAG standard manual - - - - -

welding

6 CC / CV - - - - 7 CMT / special process - - - 8 Unused - - - - 9 Special process: manual - - - - -

standard

10 Special process: manual - - - - -

pulse

255 Invalid - - - - -

E009 Cooler-flow TRUE FALSE l/min Word 0,001

E00A Cooler filter time [C-t] TRUE TRUE s Word 1

E078 Powermaster setting [P-C] TRUE TRUE - Boolean 1

E0A2 Key lock TRUE TRUE - Word 1

0 unlocked - - - - 1 locked - - - - -

26

Generic

(continued)

Address Description Read Write Unit Type Factor

E0AC Hourmeter currentflow lowward TRUE FALSE Min Word 0,1

E0AD Hourmeter currentflow highward TRUE FALSE Min Word 0,1

E0AE Hourmeter total lowward TRUE FALSE Min Word 0,1

E0AF Hourmeter total highward TRUE FALSE Min Word 0,1

E0B0 Write 0x78E3 for factory- FALSE TRUE - Integer 1

command-unlock

E0B1 Write 0x56AA for factory- FALSE TRUE - Integer 1

command; unlock and command

have to be set at the same time

E0B2 Result of factory-command TRUE FALSE - Integer 1

0 Factory command never - - - - -

started

1OK - - - - 2 unlock was written, but no - - - - -

command

3 unlock OK, but command - - - - -

not

4 unlock was wrong - - - - -

E0B3 Write 0x65F7 for RL-adjust- FALSE TRUE - Integer 1

command-unlock

E0B4 Write 0x3FEA for RL-adjust- FALSE TRUE - Integer 1

command; unlock and command

have to be set at the same time

E0B5 Result of RL-adjust-command TRUE FALSE - Integer 1

0 RL-adjust command never - - - - -

started

1OK - - - - 2 unlock was written, but no - - - - -

command

3 unlock OK, but command - - - - -

not

4 unlock was wrong - - - - 5 test is running - - - - 6 command cannot be started - - - - -

E0B6 RL-adjust error TRUE FALSE - Integer 1

E0B7 Write 0x7BC3 for PPU-adjust- FALSE TRUE - Integer 1

command-unlock

E0B8 Write for PPU-adjust-command; FALSE TRUE - Integer 1

unlock and command have to be

in the same message

Bit [7...0] Testnumber

Valid are: 0 = Test1, 1 = Test2

Bit8

0 = Stop Test, 1 = Start Test

E0B9 Result of PPU-adjust-command TRUE FALSE - Integer 1

0 PPU-adjust command - - - - -

never started

1OK - - - - 2 unlock was written, but no - - - - -

command

3 unlock OK, but command - - - - -

not

4 unlock was wrong - - - - 5 test is running - - - - 6 command cannot be - - - - -

started

27

Generic

(continued)

Address Description Read Write Unit Type Factor

E0BA PPU-adjust error TRUE FALSE - Integer 1

E0BB Logical PPU-min TRUE FALSE - Word 1

(PPU-min = PPU-max = 255

means no PPU adjustment

possible !)

E0BC Logical PPU-max TRUE FALSE - Word 1

(PPU-min = PPU-max = 255

means no PPU adjustment

possible !)

E0BD Logical PPU, can be adjusted in TRUE TRUE - Word 1

the range logical-PPU-min to

logical-PPU-max

E0BE This is the real PPU-number, TRUE FALSE - Word 1

generated out of the logical

PPU-number

E0C4 Error-Quit FALSE TRUE - Boolean 1

E0C5 Enable / Disable synergic TRUE TRUE - Boolean 1

calculation; disable this, before

you start to transmit a manual

data; enable it, after the

transmission. This ensure

synchron calculation

E0C6 Device suberror TRUE FALSE - Word 1

E0C8 Inch mode TRUE TRUE - Boolean 1

E0C9 R-result of RL-adjustment TRUE FALSE mOhm Word 0,1

E0CA L-result of RL-adjustment TRUE FALSE μH Word 0,01

E0CB Clear Hold TRUE TRUE - Boolean 1

E0CD Frontpanel Type TRUE FALSE - Word 1

0 None - - - - 1 Normal - - - - 2 CMT-Version - - - - 3 US-Version - - - - 4 RCU 5000i - - - - 255 Other - - - - -

MIG/MAG

Address Description Read Write Unit Type Factor

E00B Wirespeed TRUE TRUE m/min Integer 0,01

E00C Arc length correction TRUE TRUE % Integer 0,1

E00D Dynamic/Pulse correction TRUE TRUE - Integer 0,01

E00E Burnback correction [bbc] TRUE TRUE - Integer 0,1

E00F Gas command value TRUE TRUE l Integer 0,01

E010 Gas factor TRUE TRUE - Integer 0,1

E011 Gas preflow [Gpr] TRUE TRUE s Word 0,001

E012 Gas postflow [Gpo] TRUE TRUE s Word 0,001

E013 Inching speed [Fdi] TRUE TRUE m/min Word 0,01

E014 Softstart [Fdc] TRUE TRUE m/min Integer 0,01

E015 Power offset [dFd] TRUE TRUE m/min Integer 0,01

E016 SynchroPuls [F] TRUE TRUE Hz Word 0,1

E017 Cooling unit cut-out [C-C] TRUE TRUE - Word 1

E018 Wire stick [Stc] TRUE TRUE - Boolean 1

28

MIG/MAG

(continued)

Address Description Read Write Unit Type Factor

E019 Ignition timeout [Ito] TRUE TRUE s Word 1

E01A Arc break watchdog [Arc] TRUE TRUE s Word 0,01

E01B 4 TT option [S4t] TRUE TRUE - Word 1

E01C Jobmaster special mode [Gun] TRUE TRUE - Word 1

E01D Start current [I-S] TRUE TRUE % Word 0,1

E01E Start time [t-S] TRUE TRUE s Word 0,1

E01F Slope [SL] TRUE TRUE s Word 0,001

E020 End current [I-E] TRUE TRUE % Word 0,1

E021 End time [t-E] TRUE TRUE s Word 0,1

E022 Spot time [SPt] TRUE TRUE s Word 0,001

E023 Characteristic reference (high) TRUE TRUE - Word 1

E024 Characteristic reference (low) TRUE TRUE - Word 1

E025 Gun mode TRUE TRUE Word 1

0 2-step - - - - 1 4-step - - - - 2 special-4-step - - - - 3 spotwelding - - - - -

E026 Welding-circuit resistance MIG TRUE TRUE mOhm Word 0,1

E027 Voltage guide value MIG/MAG TRUE FALSE V Integer 0,01

E028 Current guide value MIG/MAG TRUE FALSE A Integer 0,1

E029 Sheet thickness parameter TRUE FALSE mm Word 0,01

E0C0 Welding-circuit MIG inductance TRUE FALSE μH Word 0,01

E0C7 Arc length correction 2 TRUE TRUE % Integer 0,1

Manually

CC/CV-mode

Stick

(Rod electrode

welding / MMA)

Address Description Read Write Unit Type Factor

E02A Wirespeed TRUE TRUE m/min Integer 0,01

E02B Voltage parameter manually TRUE TRUE V Integer 0,01

E02C Dynamic parameter manually TRUE TRUE - Word 0,01

Address Description Read Write Unit Type Factor

E02D CC/CV-vD TRUE TRUE

m/min

Integer 0,01

E02E CC/CV-I TRUE TRUE A Integer 0,1

E02F CC/CV-U TRUE TRUE V Integer 0,01

E030 Inching speed [Fdi] TRUE TRUE m/min Word 0,01

E031 Gas command value [GAS] TRUE TRUE l Integer 0,01

E032 Gas factor [Cor] TRUE TRUE - Word 0,1

Address Description Read Write Unit Type Factor

E033 Current parameter stick TRUE TRUE A Integer 0,1

E034 Dynamic parameter stick TRUE TRUE - Integer 0,1

E035 Electrode line [Eln] TRUE TRUE - Word 0,01

E036 Hot current time [Hti] TRUE TRUE - Word 0,001

E037 Hot start current [HCU] TRUE TRUE % Word 0,1

29

Stick

(Rod electrode

welding / MMA)

(continued)

Address Description Read Write Unit Type Factor

E038 Antistick [Ast] TRUE TRUE - Boolean 1

E039 Voltage cut off [Uco] TRUE TRUE V Integer 0,01

E03A Balance [bAL] TRUE TRUE - Integer 0,1

E03B AC mode stick TRUE TRUE Word 1

0AC - - - - 1 DC-minus - - - - 2 DC-plus - - - - 255 invalid - - - - -

E03C AC frequency [ACF] TRUE TRUE Hz Word 0,1

E0C1 Welding-circuit resistance stick TRUE TRUE mOhm Word 0,1

E0C3 Welding-circuit inductance stick TRUE FALSE μH Word 0,01

TIG

Address Description Read Write Unit Type Factor

E03D Current parameter TIG TRUE TRUE A Integer 0,1

E03E Start current [I-S] TRUE TRUE % Word 1

E03F Upslope time [UPS] TRUE TRUE s Word 0,01

E040 Reduced current [I-2] TRUE TRUE % Word 1

E041 Downslope time [dSL] TRUE TRUE s Word 0,01

E042 End current [I-E] TRUE TRUE % Word 1

E043 Start time [t-S] TRUE TRUE s Word 0,01

E044 End time [t-E] TRUE TRUE s Word 0,01

E045 AC mode TIG TRUE TRUE - Word 1

0AC - - - - 1 DC-minus - - - - 2 DC-plus - - - - 255 invalid - - - - -

E046 AC frequency [ACF] TRUE TRUE Hz Word 0,1

E047 Balance [bAL] TRUE TRUE - Integer 0,1

E048 Positive waveform [pos] TRUE TRUE - Word 1

E049 Negative wave form [nEG] TRUE TRUE - Word 1

E04A Pulse frequency [F-P] TRUE TRUE Hz Word 0,01

E04B Pulse frequency [F-P] TRUE TRUE Hz Word 1

E04C Dutycycle [dcY] TRUE TRUE - Word 1

E04D Background current [I-G] TRUE TRUE % Word 1

E04E Gas preflow [GPr] TRUE TRUE s Word 0,1

E04F Gas postflow high [G-H] TRUE TRUE s Word 0,1

E050 Gas postflow low [G-L] TRUE TRUE s Word 0,1

E051 Gas command value [GAS] TRUE TRUE l Integer 0,01

E052 Gas factor [Cor] TRUE TRUE - Integer 0,1

E053 Tacking time [tAC] TRUE TRUE s Word 0,1

E054 Needle diameter [Eld] TRUE TRUE mm Word 0,1

E055 Guntrigger mode TRUE TRUE - Word 1

0 2-step - - - - - 1 4-step - - - - - -

E056 Spot time [SPt] TRUE TRUE s Word 0,01

E057 Standard-TIG cooling unit cut-out TRUE TRUE - Word 1

[C-C]

E058 Calotte TRUE TRUE - Boolean 1

30

TIG

(continued)

Address Description Read Write Unit Type Factor

E059 Comfort Stop Senesitivity [CSS] TRUE TRUE V Integer 0,01

E05A Ignition timeout [Ito] TRUE TRUE s Word 0,1

E05B Arc break watchdog [Arc] TRUE TRUE s Word 0,1

E05C Special 4-step [SFS] TRUE TRUE - Word 1

E05D External parameter [E-P] TRUE TRUE - Word 1

E05E Phase [PHA] TRUE TRUE - Word 1

only available on 3-phase

powersources!

E05F Reverse polarity ignition [rPi] TRUE TRUE - Boolean 1

E060 HF-time TRUE TRUE ms Word 1

E061 Welding-circuit TIG resistance TRUE TRUE mOhm Word 0,1

E062 Feeder 1 [Fd.1] TRUE TRUE m/min Integer 0,01

E063 Feeder 2 [Fd.2] TRUE TRUE % Word 1

E064 Inching speed [Fdi] TRUE TRUE m/min Word 0,01

E065 Feeder-delay 1 [dt1] TRUE TRUE s Word 0,1

E066 Feeder-delay 2 [dt2] TRUE TRUE s Word 0,1

E067 Feeder back [Fdb] TRUE TRUE mm Word 1

E09F Pre-HF-time TRUE TRUE s Word 0,1

E0A0 Spezial-2-step TRUE TRUE - Word 1

E0AB Gas purge TRUE TRUE - Word 1

E0C2 Welding-circuit TIG inductance TRUE FALSE μH Word 0,01

E0CC IOFFSET [Io] TRUE TRUE A Integer 1

Real Values

Limits

Address Description Read Write Unit Type Factor

E068 Actual welding time TRUE FALSE s Word 0,1

E069 Pulse-synchron sliding window TRUE FALSE A Integer 0,1

for TIG-current

E06A Pulse-synchron sliding window TRUE FALSE V Integer 0,01

for TIG-voltage

E06B Current at end of pulse TRUE FALSE A Integer 0,1

E06C Voltage at end of pulse TRUE FALSE V Integer 0,01

E06D Current at end of ground-phase TRUE FALSE A Integer 0,1

E06E Voltage at end of ground-phase TRUE FALSE V Integer 0,01

E06F Real value arc length TRUE FALSE V Integer 0,01

E070 Real value voltage TRUE FALSE V Integer 0,01

E071 Real value current TRUE FALSE A Integer 0,1

E079 Current mean value of neg. wave TRUE FALSE A Integer 0,1

E07A Voltage mean value of neg. wave TRUE FALSE V Integer 0,01

E0BF Real value gas TRUE FALSE ml Integer 1

Address Description Read Write Unit Type Factor

E072 Min. feeder-value TRUE FALSE m/min Integer 0,01

E073 Max. feeder-value TRUE FALSE m/min Integer 0,01

E074 Min. voltage command value TRUE FALSE V Integer 0,01

31

Limits

(continued)

Address Description Read Write Unit Type Factor

E075 Max. voltage command value TRUE FALSE V Integer 0,01

E076 Min. current command value TRUE FALSE A Integer 0,1

E077 Max. current command value TRUE FALSE A Integer 0,1

E0A9 Min. Eld value TRUE FALSE mm Word 0,1

E0AA Max. Eld-value TRUE FALSE mm Word 0,1

Special process:

MIG/MAG manual

standard

Special process:

MIG/MAG manual

pulse

Address Description Read Write Unit Type Factor

E07B Feeder creep speed TRUE TRUE m/min Integer 0,01

E07C Ignition current TRUE TRUE A Integer 0,1

E07D Ignition current time TRUE TRUE ms Word 0,01

E07E Wirefeed speed TRUE TRUE m/min Integer 0,01

E07F Background current TRUE TRUE A Integer 0,1

E080 Voltage command value TRUE TRUE V Integer 0,01

E081 Characteristic slope TRUE TRUE μOhm Word 1

E082 Special dynamic TRUE TRUE - Word 1

E083 Current decrease TRUE TRUE - Word 1

E084 Current rise TRUE TRUE - Word 1

E085 Burn back time TRUE TRUE s Word 0,01

E086 Burn back pulse time TRUE TRUE ms Word 0,01

E087 Burn back pulsing current TRUE TRUE A Integer 0,1

Address Description Read Write Unit Type Factor

E088 Feeder creep speed TRUE TRUE m/min Integer 0,01

E089 Ignition current TRUE TRUE A Integer 0,1

E08A Ignition current time TRUE TRUE ms Word 0,01

E08B Base current TRUE TRUE A Integer 0,1

E08C Current rise TRUE TRUE A/ms Word 0,1

E08D Current rise tau TRUE TRUE ms Word 0,01

E08E Pulsing current TRUE TRUE A Integer 0,1

E08F Pulsing current time TRUE TRUE ms Word 0,01

E090 Current decrease TRUE TRUE A/ms Word 0,1

E091 Current drop tau TRUE TRUE ms Word 0,01

E092 Droplet detachment current TRUE TRUE A Integer 0,1

E093 Droplet detachment time TRUE TRUE ms Word 0,01

E094 Pulsing frequency TRUE TRUE Hz Word 0,1

E095 Wirefeed speed TRUE TRUE m/min Integer 0,01

E096 Voltage command value TRUE TRUE V Integer 0,01

E097 Fact I_b_control_pi TRUE TRUE % Word 0,01

E098 Fact I_p1_control_pi TRUE TRUE % Word 0,01

E099 Fact f_control_p TRUE TRUE % Word 0,01

E09A Fact I_b_correction TRUE TRUE % Word 0,01

E09B Fact I_p1_correction TRUE TRUE % Word 0,01

E09C Fact f_correction TRUE TRUE % Word 0,01

32

Special process:

MIG/MAG manual

pulse

(continued)

Address Description Read Write Unit Type Factor

E09D Current rise sc TRUE TRUE A/ms Word 0,1

E09E Burn back time TRUE TRUE s Word 0,01

E0A1 Regulator output TRUE FALSE - Integer 1

Pilot Plasma

Address Description Read Write Unit Type Factor

E0A3 Gas preflow [GPr] TRUE TRUE s Word 0,001

E0A4 Gas postflow [GPo] TRUE TRUE s Word 0,001

E0A5 Gas command value [GAS] TRUE TRUE l Integer 0,01

E0A6 Gas factor [Cor] TRUE TRUE - Word 0,1

E0A7 Pre-/Post Gas command value TRUE TRUE l Integer 0,01

[GPA]

E0A8 Pilot current TRUE TRUE A Integer 0,1

33

TAG Table

Adress Description Read Write Group Unit Type Factor

E000 Main error True False Generic Word 1

E001 Sub error True False Generic Word 1

E002 Status Flag True False Generic Word 1

Bit 0 maincurrent

Bit 1 cooler

Bit 2 fan1

Bit 3 gas1

Bit 4 coolersensor

Bit 5 processrun

Bit 6 processact

Bit 7 wf started

Bit 8 weldstart

Bit 9 inching

Bit 10 gastest

Bit 11 keylock

Bit 12 UST-fan

Bit 13 currentflow

Bit 14 started up

Bit 15 hold

E003 Status Flag True False Generic Word 1

Bit 0 1=DC+ enable

Bit 1 1=Needle OVL

Bit 2 1=3 phase machine

Bit 3 1=Magic Wave

Bit 4 1=TIG

Bit 5 1=I-RV-display

Bit 6 1=U-RV-display

Bit 7 1=Fd-RV-display

Bit 8 1=enable jobchange

Bit 9 1=par.-select.-int.

Bit 10 1=Touchsensing active

E004 Reserved True False Generic Word 1

E005 Jobnumber True True Generic Word 1

E007 Push pull unit [PPU] True True Generic Word 1

E008 Opterating mode True True Generic Word 1

0 MIG Standard

1 MIG Pulse

2 Stick

3 TIG

4 Job mode

5 Manual mode

6 CC/CV

7 CMT special mode

8 Unused

9 Manual standard

10 Manual puls

255 Invalid

E009 Coolerflow True False Generic l/min Word 0,001

E00A Cooler filtertime [C-t] True True Generic s Word 1

E078 Powermaster-setting [P-C] True True Generic Boolean 1

34

Adress Description Read Write Group Unit Type Factor

E0A2 Key lock True True Generic Word 1

0 unlocked

1 locked

E0AC Hourmeter currentflow low-word True False Generic Min Word 0,1

E0AD Hourmeter currentflow high-word True False Generic Min Word 0,1

E0AE Hourmeter total low-word True False Generic Min Word 0,1

E0AF Hourmeter total high-word True False Generic Min Word 0,1

E0B0 Write 0x78E3 for factory- False True Generic Integer 1

comand-unlock

E0B1 Write 0x56AA for factory- False True Generic Integer 1

comand, unlock and command

have to set at the same

message

E0B2 Result of factory-command True False Generic Integer 1

0 Factory-command never

started

1OK

2 unlock was written,

but no command

3 unlock OK, but command

not

4 unlock was wrong

E0B3 Write 0x65F7 for RL-adjust- False True Generic Integer 1

command-unlock

E0B4 Write 0x3FEA for RL-adjust- False True Generic Integer 1

command, unlock and command

have to set at the same message

E0B5 Result of RL-adjustment- True False Generic Integer 1

command

0 RL-adjustment-command

never started

1OK

2 unlock was written,

but no command

3 unlock OK, but command

not

4 unlock was wrong

5 test is running

6 command cannot be

started

E0B6 RL-adjust error True False Generic Integer 1

E0B7 Write 0x7BC3 for PPU-adjust- False True Generic Integer 1

command-unlock

E0B8 Write for PPU-adjust- False True Generic Integer 1

command, unlock and command

have to be in the same message

Bit[7....0] Testnumber

Valid are 0 = Test1

1 = Test2

Bit8 0 = Stop Test

1 = Start Test

35

Adress Description Read Write Group Unit Type Factor

E0B9 Result of PPU-adjust- True False Generic Integer 1

command

0 PPU-adjustment-

command never started

1OK

2 unlock was written,

but no command

3 unlock OK, but command

not

4 unlock was wrong

5 test is running

6 command cannot be

started

E0BA PPU-adjust error True False Generic Integer 1

E0BB Logical PPU-min (PPU-min = True False Generic Word 1

PPU-max==255 means no PPU

adjustment possible!)

E0BC Logical PPU-max (PPU-min = True False Generic Word 1

PPU-max==255 means no PPU

adjustment possible!)

E0BD Logical PPU, can be adjusted True True Generic Word 1

in the range of logical-PPU-min

to logical-PPU-max

E0BE This is the real PPU-number, True False Generic Word 1

generated out of the logical-PPUnumber

E0C4 Error-Quit False Ture Generic Boolean 1

E0C5 Enable / Disable synergic True True Generic Boolean 1

calculation - disable this before

you start to transmit a manual

data, enable it after the

transmission.

This ensures synchron calculation

E0C6 Device suberror True False Generic Word 1

E0C8 Inch mode True True Generic Boolean 1

E0C9 R-result of RL-adjustment True False Generic mOhm Word 0,1

E0CA L-result of RL-adjustment True False Generic μH Word 0,01

E0CB Clear Hold True True Generic Boolean 1

E0CD Frontpanel Type True False Generic Word 1

0 None

1 Normal

2 CMT-Version

3 US-Version

4 RCU5000i

255 Other

E0CE Jobnumber for jobcorrection True True Generic Word 1

E0CF Jobcorrection for TIG True True Generic A Integer 0,1

main current

E0D0 Jobcorrection-min for TIG True False Generic A Integer 0,1

main current

E0D1 Jobcorrection-max for TIG True False Generic A Integer 0,1

main current

36

Adress Description Read Write Group Unit Type Factor

E0D5 Programmcode=process<<DM<< True True Generic Word 1

Mat

Process 0=Puls

1=Standard

2=CMT

Mat 0=SG2...

15=SP2

DM 0=0,8 mm

4=SP

E0D6 Reference-number-high for True False Generic Word 1

position defined in Tag E0D5

E0D7 Reference-number-high for True False Generic Word 1

position defined in Tag E0D5

E0D8 low=data [0], high=data [1] True False Generic Word 1

E0D9 low=data [2], high=data [3] True False Generic Word 1

E0DA low=data [4], high=data [5] True False Generic Word 1

E0DB low=data [6], high=data [7] True False Generic Word 1

E0DC virtual pointer to matlist True True Generic Word 1

beginning with 0.

E0DD size of matlist True False Generic Word 1

E0DE 0=matlist is not ready, True False Generic Boolean 1

!0=matlist is ready

E00B Wirespeed True True MigMag m/min Integer 0,01

E00C Arc length correction True True MigMag % Integer 0,1

E00D Dynamik/Puls correction True True MigMag Integer 0,01

E00E Burnback correction [bbc] True True MigMag Integer 0,1

E00F Gas commandvalue True True MigMag l Integer 0,01

E010 Gasfactor True True MigMag Integer 0,1

E011 Gas preflow [Gpr] True True MigMag s Word 0,001

E012 Gas postflow [Gpo] True True MigMag s Word 0,001

E013 Inching speed [Fdi] True True MigMag m/min Word 0,01

E014 Softstart [Fdc] True True MigMag m/min Integer 0,01

E015 Power offset [dFd] True True MigMag m/min Integer 0,01

E016 Synchropuls [F] True True MigMag Hz Word 0,1

E017 Cooling unit cut-out [C-C] True True MigMag Word 1

E018 Wire stick [Stc] True True MigMag Boolean 1

E019 Ignition timeout [Ito] True True MigMag s Word 1

E01A Arc break watchdog [Arc] True True MigMag s Word 0,01

E01B 4 TT option [S4t] True True MigMag Word 1

E01C Jobmaster special mode [Gun] True True MigMag Word 1

E01D Start current [I-S] True True MigMag % Word 0,1

E01E Start time [t-S] True True MigMag s Word 0,1

E01F Slope [SL] True True MigMag s Word 0,001

E020 End current [I-E] True True MigMag % Word 0,1

E021 End time [t-E] True True MigMag s Word 0,1

E022 Spot time [SPt] True True MigMag s Word 0,001

E023 Characteristic reference (high) True True MigMag Word 1

E024 Characteristic reference (low) True True MigMag Word 1

37

Adress Description Read Write Group Unit Type Factor

E025 Gun mode True True MigMag Word 1

0 2-step

1 4-step

2 special-4-step

3 spotwelding

E026 Welding-circuit resistance MIG True True MigMag mOhm Word 0,1

E027 Voltage guide value MIG/MAG True False MigMag V Integer 0,01

E028 Current guide value MIG/MAG True False MigMag A Integer 0,1

E029 Sheet thickness parameter True False MigMag mm Word 0,01

E0C0 Welding-circuit inductance MIG True False MigMag μH Word 0,01

E0C7 Arc length correction 2 (Al2) True True MigMag % Integer 0,1

E0E0 ALS True True MigMag Word 1

E0E1 ALt, 0=OFF, steps in 0,05s-units True True MigMag s Word 0,05

E02A Wirespeed True True Manually m/min Integer 0,01

E02B Voltageparameter manually True True Manually V Integer 0,01

E02C Dynamicparameter manually True True Manually Word 0,01

E02D CC/CV-vD True True CC_CV_mode m/min Integer 0,01

E02E CC/CV-I True True CC_CV_mode A Integer 0,1

E02F CC/CV-U True True CC_CV_mode V Integer 0,01

E030 Inching speed [Fdi] True True CC_CV_mode m/min Word 0,01

E031 Gas commandvalue [GAS] True True CC_CV_mode l Integer 0,01

E032 Gasfactor [Cor] True True CC_CV_mode Word 0,1

E033 Currentparameter stick True True Stick A Integer 0,1

E034 Dynamicparameter stick True True Stick Integer 0,1

E035 Electrode line [Eln] True True Stick Word 0,01

E036 Hot current time [Hti] True True Stick Word 0,001

E037 Hot start current [HCU] True True Stick % Word 0,1

E038 Antistick [Ast] True True Stick Boolean 1

E039 Cutoff voltage [Uco] True True Stick V Integer 0,01

E03A Balance [bAL] True True Stick Integer 0,1

E03B AC mode Stick True True Stick Word 1

0AC

1 DC-minus

2 DC-plus

255 invalid

E03C AC frequency [ACF] True True Stick Hz Word 0,1

E0C1 Welding-circuit resistance Stick True True Stick mOhm Word 0,1

E0C3 Welding-circuit inductance Stick True False Stick μH Word 0,01

E03D Currentparameter TIG True True TIG A Integer 0,1

E03E Start current [l-S] True True TIG % Word 1

ATTENTION: this will write both

values - for AC and DC

simultanously

E03F Upslope time [UPS] True True TIG s Word 0,01

ATTENTION: this will write both

values - for 2-step and 4-step

simultanously

38

Adress Description Read Write Group Unit Type Factor

E040 Reduced current [l-2] True True TIG % Word 1

E041 Downslope time [dSL] True True TIG s Word 0,01

ATTENTION: this will write both

values - for 2-step and 4-step

simultanously

E042 End current [I-E] True True TIG % Word 1

E043 Start time [t-S] True True TIG s Word 0,01

E044 End time [t-E] True True TIG s Word 0,01

E045 AC mode TIG True True TIG Word 1

0AC

1 DC-minus

2 DC-plus

255 invalid

E046 AC frequency [ACF] True True TIG Hz Word 0,1

E047 Balance [bAL] True True TIG Integer 0,1

E048 Positive waveform [pos] True True TIG Word 1

E049 Negative waveform [nEG] True True TIG Word 1

E04A Pulse frequency [F-P] True True TIG Hz Word 0,01

E04B Pulse frequency [F-P] True True TIG Hz Word 1

E04C Dutycycle [dcY] True True TIG Word 1

E04D Background current [I-G] True True TIG % Word 1

E04E Gas preflow [GPr] True True TIG s Word 0,1

E04F Gas postflow high [G-H] True True TIG s Word 0,1

E050 Gas postflow low [G-L] True True TIG s Word 0,1

E051 Gas commandvalue [GAS] True True TIG l Integer 0,01

E052 Gasfactor [Cor] True True TIG Integer 0,1

E053 Tacking time [tAC] True True TIG s Word 0,1

E054 Needle diameter [Eld] True True TIG mm Word 0,1

E055 Guntrigger mode True True TIG Word 1

0 2-step

1 4-step

E056 Spot time [SPt] True True TIG s Word 0,01

E057 Standard-TIG Cooling unit True True TIG Word 1

cut-out [C-C]

E058 Calotte True True TIG Boolean 1

E059 Comfort Stop Senesitivity [CSS] True True TIG V Integer 0,01

E05A Ignition timeout [Ito] True True TIG s Word 0,1

E05B Arc break watchdog [Arc] True True TIG s Word 0,1

E05C Special 4-step [SFS] True True TIG Word 1

E05D External parameter [E-P] True True TIG Word 1

E05E Phase [PHA] True True TIG Word 1

only available on 3-phase

powersources!

E05F Reverse polarity ignition [rPi] True True TIG Boolean 1

E060 HF-time True True TIG ms Word 1

E061 Welding-circuit resistance TIG True True TIG mOhm Word 0,1

E062 Feeder 1 [Fd.1] True True TIG m/min Integer 0,01

E063 Feeder 2 [Fd.2] True True TIG % Word 1

39

Adress Description Read Write Group Unit Type Factor

E064 Inching speed [Fdi] True True TIG m/min Word 0,01

E065 Feeder-delay 1 [dt1] True True TIG s Word 0,1

E066 Feeder-delay 2 [dt2] True True TIG s Word 0,1

E067 Feeder back [Fdb] True True TIG mm Word 1

E09F Pre-HF-time True True TIG s Word 0,1

E0A0 Spezial-2-step True True TIG Word 1

E0AB Gas purge True True TIG Word 1

E0C2 Welding-circuit inductance TIG True False TIG μH Word 0,01

E0CC Ioffset [Io] True True TIG A Integer 1

E0D2 Start current [l-S] True True TIG % Word 1

ATTENTION: there are two

different values for AC and DC,

so change ACMODE before

changing this value

E0D3 Upslope time [UPD] True True TIG s Word 0,01

ATTENTION: there are two

different values for 2-step and

4-step, so change GUNMODE