Page 1

/ Battery Charging Systems / Welding Technology / Solar Electronics

FRONIUS IG

15 / 20 / 30 / 40 / 60 / 60 HV

Operating Instructions

Grid-connected inverters for

EN

photovoltaic systems

42,0410,0828 008-31032015

Page 2

Page 3

Dear Reader

Introduction

Thank you for choosing Fronius - and congratulations on your new, technically highgrade Fronius product! This instruction manual will help you get to know your new

machine. Read the manual carefully and you will soon be familiar with all the many

great features of your new Fronius product. This really is the best way to get the most

out of all the advantages that your machine has to offer.

Please also take special note of the safety rules - and observe them! In this way, you

will help to ensure more safety at your product location. And of course, if you treat your

product carefully, this definitely helps to prolong its enduring quality and reliability - things

which are both essential prerequisites for getting outstanding results.

EN

ud_fr_st_et_00493 01/2012

Page 4

Page 5

Safety rules

DANGER!

WARNING!

CAUTION!

NOTE!

“DANGER!” indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury. This signal word must be

limited to the most extreme situations. This signal word is not used for

hazards relating to property damage unless there is also a risk of personal

injury appropriate to this level.

“WARNING!” indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury. This signal word is not used

for hazards relating to property damage unless there is also a risk of personal injury appropriate to this level.

“CAUTION!” indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. It may also be used to draw

attention to unsafe practices that may cause damage to property.

“NOTE!” indicates a situation which implies a risk of impaired results and

damage to the equipment.

EN

Important!

General Remarks

“Important!” indicates practical hints and other particularly useful informati-

on. It is not a signal word for a harmful or dangerous situation.

Whenever you see any of the symbols shown above, pay close attention to

the contents of the manual!

This equipment has been manufactured in accordance with the state of the

art and general safety-engineering principles. Nevertheless, incorrect operation or misuse may still endanger

- the life and well-being of the operator or of third parties,

- the equipment and other tangible assets belonging to the owner/operator,

- working efficiently with the equipment.

All persons involved in any way with starting up, servicing and maintaining

the equipment must

- be suitably qualified

- have good knowledge of dealing with electrical installations and

- read this instruction manual thoroughly and follow the instructions to the

letter.

The instruction manual must be kept at the machine location at all times. In

addition to the instruction manual, it is important to comply with both the

generally applicable and local accident prevention and environmental protection regulations.

All the safety instructions and warning signs on the machine itself:

- must be kept in a legible condition

- must not be damaged, must not be removed

- must not be covered, pasted or painted over

I

ud_fr_se_sv_00923 022009

Page 6

General Remarks

(continued)

For information about where the safety instructions and warning signs are

located on the machine, please refer to the section of your machine’s instruction manual headed “General Remarks”.

Any malfunctions which might impair machine safety must be remedied

immediately before the machine is switched on.

Your safety is at stake!

Utilisation for

Intended Purpose

Only

Ambient

Conditions

The machine may only be used for jobs as defined by the “intended purpose”.

Utilisation for any other purpose, or in any other manner, shall be deemed "not

in accordance with the intended purpose". The manufacturer shall not be

liable for any damage resulting from such improper use.

Utilisation in accordance with the “intended purpose” also comprises

- thorough reading of and compliance with all the instructions, safety instructions and warnings given in this manual

- performing all stipulated inspection and servicing work

- installation in accordance with the instruction manual

Where appropriate, the following guidelines should also be applied:

- regulations of the power supply company for input to the grid

- information provided by the manufacturer of the solar modules

Operation or storage of the machine outside the stipulated range is deemed

“not in accordance with the intended use”. The manufacturer shall not be

liable for any damage resulting therefrom.

Please refer to the technical data in your instruction manual for accurate

information about the permissible ambient conditions.

Qualified Staff The servicing information provided in this instruction manual is only intended

for qualified staff. An electric shock can be fatal. Please do not carry out any

activities other than those referred to in the documentation. This also applies

even if you are suitably qualified.

All cables and other leads must be firmly attached, undamaged, properly

insulated and adequately dimensioned. Have loose connections, scorched,

damaged or under-dimensioned cables and wires repaired immediately by

an authorised specialist company.

Maintenance and repair may only be carried out by an authorised specialist

company.

There is no guarantee in the case of parts sourced from other suppliers that

these parts have been designed and manufactured to cope with the stresses

and safety requirements that will be placed on them. Use only original spare

parts (this also applies to standard parts).

Do not carry out any alterations, installations or modifications to the machine

without first getting the manufacturer’s permission.

Replace immediately any components that are not in perfect condition.

ud_fr_se_sv_00923 022009

II

Page 7

Safety Precautions at the Machine Location

Ensure when installing machines with cooling-air vents that the cooling air can flow freely

through the air vents without obstruction. Only operate the machine with the degree of

protection specified on the rating plate.

Information on

noise emission

values

EMC device

classifications

The inverter generates a maximum sound power level of <80 dB(A) (ref. 1pW)

when operating under full load in accordance with IEC 62109-1.

The device is cooled as quietly as possible with the aid of an electronic temperature control system, and depends on the amount of converted power, the

ambient temperature, the level of soiling of the device, etc.

It is not possible to provide a workplace-related emission value for this device

because the actual sound pressure level is heavily influenced by the installation situation, the power quality, the surrounding walls and the properties of the

room in general.

Devices with emission class A:

- are only designed for use in an industrial setting

- can cause conducted and emitted interference in other areas.

Devices with emission class B:

- satisfy the emissions criteria for residential and industrial areas. This

also applies to residential areas in which power is supplied from the

public low-voltage grid.

EMC device classification as per the rating plate or technical specifications

EN

EMC measures In certain cases, even though a device complies with the standard limit

values for emissions, it may affect the application area for which it was

designed (e.g. when there is sensitive equipment at the same location, or if

the site where the device is installed is close to either radio or television

receivers).

If this is the case, then the operator is obliged to take appropriate action to

rectify the situation.

Mains connection

High-performance devices (> 16 A) can affect the voltage quality on the mains

network because they can feed powerful current into the main supply.

This may affect a number of types of device in terms of:

- connection restrictions

- criteria with regard to maximum permissible mains impedance

- criteria with regard to minimum short-circuit power requirement

*)

at the interface with the public mains network

*)

*)

see Technical Data

In this case, the plant operator or the person using the device should check

whether or not the device is allowed to be connected, where appropriate

through discussion with the power supply company.

III

ud_fr_se_sv_00923 022009

Page 8

Electrical Installations

Electrical installations may only be executed in accordance with the relevant

national and regional standards and specifications.

ESD Protective

Measures

Safety Precautions in Normal

Operation

Safety markings

Danger of damage to electronic components due to electrostatic discharge.

Take appropriate protective measures when replacing and installing the

components.

Only operate the machine if all its protective features are fully functional. If

any of the protective features are not fully functional, there is a danger to:

- the life and well-being of the operator or other persons

- the equipment and other tangible assets belonging to the owner/operator

- working efficiently with the equipment.

Have any safety features that are not fully functional repaired by an authorised specialist company before switching the machine on again.

Never bypass or disable safety features.

Equipment with the CE mark fulfils the basic requirements of the Guideline

Governing Low-Voltage and Electromagnetic Compatibility. (More detailed

information about this may be found in the Annex or in the section of your

documentation headed “Technical Data”.)

Disposal

Data security

Copyright

Do not dispose of this device with normal domestic waste!

To comply with the European Directive 2002/96/EC on Waste Electrical and

Electronic Equipment and its implementation as national law, electrical

equipment that has reached the end of its life must be collected separately

and returned to an approved recycling facility Any device that you no longer

require must be returned to our agent, or find out about the approved collection and recycling facilities in your area.

Ignoring this European Directive may have potentially adverse affects on the

environment and your health!

The user is responsible for backing up data relating to changes made to

factory settings. The manufacturer will not accept liability if personal settings

are deleted.

Copyright to this instruction manual remains the property of the

manufacturer.

The text and illustrations are all technically correct at the time of going to

print. The right to make modifications is reserved. The contents of the

instruction manual shall not provide the basis for any claims whatever on the

part of the purchaser. We should be most grateful for your comments if you

have any suggestions for improvement, or can point out to us any mistakes

which you may have found in the manual.

ud_fr_se_sv_00923 022009

IV

Page 9

Table of Contents

Safety of persons ................................................................................................................... 4

Safety............................................................................................................................ 4

Housing unit .................................................................................................................. 4

Galvanic insulation ........................................................................................................ 4

Monitoring the electrical mains network ........................................................................ 4

Photovoltaic generator .................................................................................................. 5

Mains connection .......................................................................................................... 5

DC plugs ....................................................................................................................... 5

AC plugs ....................................................................................................................... 5

The Safety Concept ............................................................................................................... 6

Standards and Regulations........................................................................................... 6

Conformity Declaration ................................................................................................. 6

General Introduction............................................................................................................... 7

How a photovoltaic system works ..................................................................................... 7

General information ...................................................................................................... 7

Your roof is your power generator ................................................................................. 7

Electricity is converted under the roof ........................................................................... 8

ENEN

The FRONIUS IG Unit in the Photovoltaic System ........................................................... 9

General information ...................................................................................................... 9

Transforming DC into AC electricity .............................................................................. 9

Fully automatic operation management ........................................................................ 9

Voltage transformation and galvanic insulation ............................................................. 9

Monitoring the mains network ..................................................................................... 10

Display function and data communication .................................................................. 10

Your advantage ............................................................................................................ 11

Product description .............................................................................................................. 12

The FRONIUS IG Unit..................................................................................................... 12

How it functions........................................................................................................... 12

Startup phase.............................................................................................................. 12

Overview for FRONIUS IG (for indoor housing) ......................................................... 14

Overview for FRONIUS IG Outdoors .......................................................................... 15

LED for operating status ............................................................................................. 16

Operating scheme ................................................................................................................18

The Display .....................................................................................................................18

General information .................................................................................................... 18

Functions of the keys .................................................................................................. 18

Symbols ...................................................................................................................... 18

Navigating in the Display ................................................................................................. 19

Display illumination ..................................................................................................... 19

Menu level................................................................................................................... 20

Select display mode .................................................................................................... 20

Scrolling between display functions ............................................................................ 21

1

Page 10

Display Modes................................................................................................................. 21

Scheme of display modes ........................................................................................... 21

Scheme of display readings ........................................................................................ 22

Display mode „Now“ .................................................................................................... 23

Display mode „Day / Year / Total“ ................................................................................ 26

The Setup Menu.............................................................................................................. 29

List of menu items....................................................................................................... 29

Display mode „Setup“ ................................................................................................. 30

Enter the setup menu ................................................................................................. 30

Scroll among menu items ........................................................................................... 30

Setting the menu items ............................................................................................... 31

Additional information........................................................................................................... 41

Upgrading the system ................................................................................................. 41

Forced ventilation........................................................................................................ 42

Installation manual ............................................................................................................. 43

Open the housing ................................................................................................................. 44

FRONIUS IG (installation of the indoor housing) ........................................................ 44

FRONIUS IG Outdoors ............................................................................................... 45

Installation ............................................................................................................................ 46

Choosing the location general .................................................................................... 46

Choosing the location - indoor housing....................................................................... 46

Choosing the location - outdoor housing..................................................................... 47

Fixing the wall mounting frame for indoor housing...................................................... 48

Fixing the wall mounting frame for FRONIUS IG Outdoors ....................................... 49

Connection ........................................................................................................................... 52

Connection to the Solar Modules and to the Public Mains .............................................. 52

Solar modules ............................................................................................................. 52

Mains network monitoring ........................................................................................... 52

Schemes with more than one inverter ........................................................................ 52

AC-side overcurrent protection ................................................................................... 53

Connection alternatives .............................................................................................. 53

1. Terminal block ......................................................................................................... 53

2. DC plug ................................................................................................................... 54

3. AC plug connection and DC plug ............................................................................ 55

4. FRONIUS IG Outdoors ........................................................................................... 57

Start up Operation ................................................................................................................ 59

Configuring your Inverter ................................................................................................. 59

Factory pre-set configuration ...................................................................................... 59

Your personal configuration ........................................................................................ 59

LocalNet ............................................................................................................................... 60

System upgrading /slot-in board system ..................................................................... 60

Data recorder .............................................................................................................. 60

COM Card ................................................................................................................... 60

Insert slot-in boards, FRONIUS IG (Installation for indoor housing) ........................... 61

2

Page 11

Configuration............................................................................................................... 62

Example ...................................................................................................................... 62

Status diagnosis and repair .................................................................................................. 64

Service-Codes Displayed ................................................................................................ 64

Service display ............................................................................................................ 64

General service codes ................................................................................................ 64

Complete failure .......................................................................................................... 65

FRONIUS IG with several power stage sets ............................................................... 65

Class 1 ........................................................................................................................ 66

Class 2 ........................................................................................................................ 67

Class 3 ........................................................................................................................ 68

Class 4 ........................................................................................................................ 69

Class 5 ........................................................................................................................ 71

Customer service ........................................................................................................ 72

Annex ................................................................................................................................... 73

Technical Data................................................................................................................. 73

Fronius IG 15 / 20 / 30 ................................................................................................ 73

Fronius IG 40 / 60 / 60 HV .......................................................................................... 74

Our product complies with the following standards and regulations ........................... 75

ENEN

Warranty and Liability ....................................................................................................... 76

Fronius manufacturer's warranty ................................................................................... 76

Maintenance and disposal of obsolete equipment ............................................................ 76

Maintenance ................................................................................................................ 76

Recycling ..................................................................................................................... 76

EC-Declaration of conformity ................................................................................................ 77

3

Page 12

Safety of persons

Safety

Housing unit

Galvanic insulation

Warning! Incorrect operation and work performed incorrectly can

cause serious injury & damage! Only qualified staff are authorized to

put your FRONIUS IG unit into operation and only within the scope

of the respective technical regulations. Do not start operation or

carry out maintenance works before you have read the chapter

„Safety Conditions“!

Only qualified installers are authorized to open the connection area.

Opening the connection area is only permitted when it is not under voltage.

The separately insulation encased power stage shall only be opened

when not under voltage and only by Fronius-trained service staff.

The design and function of the FRONIUS IG unit offer a maximum of safety,

both during installation as well as in operation. A complete galvanic insulation between DC and AC side guarantees maximum safety.

Monitoring the

electrical

mains network

The FRONIUS IG takes over the tasks of galvanic insulation and network

monitoring. The passive and active measures for the protection of persons and equipment are understood by this.

Whenever conditions in the electric mains network are inconsistent with

standard conditions (for example mains switch-off, interruption), your

FRONIUS IG unit will immediately stop operating and interrupt the supply

of power into the mains.

Your FRONIUS IG unit can monitor the situation in the mains in several

ways, by

- monitoring voltage

- monitoring cycle frequency

- ENS (optional)

The ENS option is compulsory in only a few countries, and only for them

the FRONIUS IG unit is available with this option. In any case however

will the monitoring and safety systems integrated in the FRONIUS IG unit

be available as standard equipment.

4

Page 13

Monitoring the

electric mains

network

(continued)

The permanent ENS mains monitoring scheme is an additional link in its

safety chain. One of the signs by which ENS identifies abnormal situations in the mains is a sudden increase of the impedance in the mains

network.

Photovoltaic

generator

Both the permanent mains monitoring by your FRONIUS IG unit directly

as well as ENS make sure that in case of a mains blackout (due to being

switched off by the utility company or due to a defect in the transmission

line) it stops feeding power into the mains.

This scheme definitely prevents dangerous voltages at the AC lines and

constitutes an essential contribution towards avoiding hazards for the

maintenance staff.

Before connecting the solar modules, you must check whether the voltage

parameters laid down in the manufacturer’s data correspond with reality.

When checking the voltage reading, please take into account that solar

modules supply a higher no-load voltage when temperatures are low and

insolation remains unchanged.

At an outside temperature of -10 degrees centigrade the no-load voltage

of the solar modules must in no case exceed 500 V - or 530 V for the IG

60 HV. The data sheet of the solar module will tell you the temperature

factors applicable for ascertaining the theoretical no-load voltage at -10

degrees centigrade.

ENEN

Mains connection

DC plugs

AC plugs

In case the solar modules exceed a no-load voltage of 500 V - or 530 V

for the IG 60 HV - the FRONIUS IG unit will be completely damaged and

all warranty rights will cease to exist.

Only a licenced electricity installer is authorized to carry out the connection works to the public mains network.

Note! If DC plugs are provided, they must never be disconnected

from the sockets of the solar modules as long as the FRONIUS IG

unit is feeding power into the mains. Before disconnecting the DC

plug you must always disconnect in the fuse for the house distribution.

Note! Disconnect AC plug connections only when the equipment

is not under voltage, after having disconnected the fuse for the inhouse distribution panel.

5

Page 14

The Safety Concept

Standards and

Regulations

Your FRONIUS IG unit complies with all applicable standards and regulations.

They comprise in particular:

- Guideline 89/336/EEC electromagnetic compatibility

- Guideline 93/68/EEC CE-marking

- European standards EN 50 081-1, EN 50 082-2, EN 61 000-3-2

- „Guideline for parallel operation of self-owned photovoltaic generating

systems with the low voltage mains network of the utility supply company“, issued by the Association of German Electric Utility Supply Companies (VDEW)

- „Technical Guidelines for parallel operation of self-owned photovoltaic

generating systems with the low voltage mains network of the utility

supply company“, issued by the Association of Electric Utility Supply

Companies of Austria

- „Safety requirements for photovoltaic energy generation plants“

(ÖNORM/ÖVE E2750), to the extent that these regulations are applicable for the inverter.

Conformity

Declaration

The respective conformity declarations you will find in the appendix to

these operating instructions.

6

Page 15

General Introduction

How a photovoltaic system works

ENEN

General information

Your roof is

your power

generator

The energy from worldwide insolation amounts to a total of about

1,540,000,000,000,000,000 kWh/year (1,540 Peta kWh/year). This is

15.000 times as much as the electricity consumption worldwide. We

congratulate you on your decision to actively use world’s biggest energy

pool. By the way, it was a scientist in the field of of physics, AlexandreEdmond Bequerel, who first discovered the photo-voltaic effect in 1839.

The name photo-voltaic comes from the driving force behind this technology, which is the ray of light. The ray of light consists of unimaginably tiny

particles, the photons.

Let us simply start our explanation with a straight silicon solar cell. Remembering our physics class in school, we know that there are four electrons in the outside electron shell of a silicon atom arranged around its

atomic nucleus, they are the so-called peripheral valency electrons. The

sunlight’s photons enter the solar cells and concentrate energy in the

valency electrons. The electron eventually separates from the silicon atom

and leaves behind it an atom with a positive charge.

So that the free electrons will flow in one direction and thus generate

electricity, the poles on the front and back side of the cell must be different from each other.

The silicon atoms of the front must be packed with a slight quantity of

phosphor atoms which contain an additional valency electron. On the

back of the cell, atoms of boron having only three valency electrons are

added to the silicon atoms.

The result is an imbalance which makes the electrons flow, and this is

how electric power is generated.

Many such solar cells united together and packed behind glass form one

of your solar modules.

7

Page 16

Your roof is

your power

generator

(continued)

+

Power output and voltage are

increased by combining a number

of solar cells. If solar modules are

connected in series like on a string,

mod. 1

tension

module 1

both the output potential as well as

the voltage will increase.

string

mod. 2

tension

module 2

total string tension

Electricity is

converted

under the roof

mod. n

tension

module 3

-

+

In a parallel connection of several

such strings the potential output

and the modular electric power will

string 1

string 2

string 3

increase, while the voltage will

remain unchanged. The total of all

mod. 1 mod. 2 mod. n

total string tension =

tension module 1, 2, ... n

solar modules connected parallel

and in series is called solar generator.

-

The direct current generated in the solar modules can be fed into the

public mains network or put to home use after having been transformed in

an inverter.

This is the basic purpose of your FRONIUS IG unit.

8

Page 17

The FRONIUS IG Unit in the Photovoltaic System

General information

Transforming

DC into AC

electricity

Fully automatic operation

management

Your FRONIUS IG unit is the latest generation of solar inverters. It is the

highly complex link between solar modules and the public electricity

mains network.

As such it is in charge of a number of highly qualified tasks.

The FRONIUS IG unit transforms the direct current generated by the solar

modules into alternating current. This alternating current is fed into your

home system or into the public mains synchronically with the voltage

which is used there. The FRONIUS IG has been designed exclusively for

use in mains connected photovoltaic schemes. It cannot generate electric

power independent from the public mains network.

The operation of the FRONIUS IG unit is fully automatic. Starting with

sunrise, as soon as the solar modules generate enough power, the automatic control unit starts monitoring voltage and frequency. As soon as

there is a sufficient level of insolation, your solar inverter starts supplying

and feeding power. A few Watts of solar power output are sufficient to

achieve this, depending on which version the unit is!

ENEN

Voltage transformation and

galvanic insulation

The operation of the FRONIUS IG unit ensures that at any time the maximum possible power output is drawn from the solar modules.

This function is called MPPT (Maximum Power Point Tracking). It operates with extremely high precision. As dusk starts there is no more sufficient energy available to feed power into the mains, the FRONIUS IG unit

shuts the mains connection completely and stops operating. All settings

and data recorded are of course saved.

The FRONIUS IG has been designed for use with solar modules of a wide

range of input voltages. This allows the use of the greatest variety of

types of solar modules. Important notice: the parameters indicated for

maximum DC voltage (total voltage of the solar cells connected) must at

no time be exceeded!

By its design and operation, the FRONIUS IG offers a maximum of safety

during installation as well as in operation.

9

Page 18

Voltage transformation and

galvanic insulation

(continued)

The FRONIUS IG is equipped with an HF-transformer (HF = high frequency) which assures a galvanic insulation between the DC side and the

mains. In addition, the HF principle results in a drastic reduction of the

transformer’s size, which means that it requires less space and has considerably less weight. In spite of its full galvanic insulation, the FRONIUS IG

unit achieves a high degree of efficiency, due to its innovative circuit

schemes.

Monitoring the

mains network

The FRONIUS IG unit is in charge of monitoring the mains network. This

responsibility comprises all measures necessary for the protection of

persons and machines in case of a power blackout.

The FRONIUS IG unit is programmed to stop operation immediately and

stop supplying power whenever conditions in the mains network deviate

from standard (for example when power is switched off or in case of any

other kind of interruption).

There are several ways how the FRONIUS IG unit can identify a mainscutoff, it can do so for example by monitoring:

- voltage

- frequency

- resistance (only FRONIUS IG with ENS)

For this purpose it is important that the specific monitoring procedures

applicable for the respective countries are carried out directly by the FRONIUS IG unit without the use of additional electronic monitoring devices.

This will result in a substantial reduction of the installation work and cost.

Display function and data

communication

The complex technical systems of innovative solar inverters make it necessary to design the display which is the interface with the user very

carefully. It is an unwavering design aiming at ease of operation and

permanent availability of the system’s data.

The FRONIUS IG unit is equipped with a basic recording function for

monitoring minimum and maximum data on a daily and a cumulative

basis directly from the display. There is also an option to allow the reading

of the following weather data on the display:

- two different temperature readings (for example temperature at the

solar modules as well as the outside temperature in the shade)

- insolation

In additition to the functions installed in the FRONIUS IG unit, a wide

choice of elements offered for data communication allows for many possibilities of recording and visualising data. The respective components

required to upgrade the system are easy to install using the FRONIUS IG

DatCom operating instructions. The installation of system upgrades, such

as DatCom components, allows for possible remote system monitoring

10

Page 19

Display function and data

communication

(continued)

via modem, text messages to mobile phones in the event of faults, data

visualisation and data comparison on the PC.

ENEN

Your advantage

With each additional task, as described above and controlled directly by

the inverter, installation becomes easier and less costly because no additional peripheral equipment will be required. Based on our experience and

the use of the most innovative technologies, the FRONIUS IG unit is able

to manage all these tasks simultaneously.

In addition, the FRONIUS IG unit complies with a whole number of requirements established for the safety of people and other household appliances, as well for its own safety.

Some of these requirements are:

- ability to monitor the mains network

- the quality of the electricity supplied

- detection of outside disturbance and interference (for example mobile

telephones).

Annexed you will find the respective certificates.

11

Page 20

Product description

The FRONIUS IG Unit

How it functions

The FRONIUS IG unit is designed for fully automatic operation. Basically

no personal control is necessary for feeding the power it generates into

the mains network.

The FRONIUS IG unit starts operating automatically as soon as the solar

modules produce sufficient power output after sunrise. From this point

onwards, you will also receive system information from the FRONIUS AG

graphic display.

During its operation the FRONIUS IG unit maintains the voltage of the

solar modules at any time within the range of optimal power withdrawal.

- the optimal voltage for any particular status of operation of the solar

modules is called MPP voltage (MPP = maximum power point)

- exactly maintaining the MPP voltage guarantees an optimal level of the

efficiency factor of your solar modules at any time (MPP-tracking).

As soon as dusk begins there is no more sufficient energy available to

feed into the mains network, the FRONIUS IG unit fully shuts off the

mains connection.

- during the night the FRONIUS IG unit does not draw any energy from

the public mains

- the data and parameters set remain available

- it is also possible to shut the unit off manually

Startup phase

After having switched on automatically, the FRONIUS IG unit goes through a self-test, and after that through a test of the public mains network.

This test takes between only few seconds up to several minutes, depending on the regulations in your country. During startup the LED illumination is yellow.

(1) Segment test

- all display elements light up for about one second

(2) TEST

- self test of important components of the FRONIUS IG unit

- The FRONIUS IG unit goes through a master check list for a period

of only a few seconds

- the display says „TEST“ and indicates the respective component

which is being tested (for example „LED“)

12

Page 21

Startup phase

(continued)

(3) Synchronisation with mains

- The screen displays „SYNC

“

AC

- „WAITPS“ is displayed: The

FRONIUS IG is waiting for all

power supplies in the network

- „SYNCAC“ is displayed subsequently.

to be on stand-by. This procedure takes place dependent

on the DC-voltage.

(4) Startup test

- Before the FRONIUS IG unit starts supplying power into the mains,

the conditions of the mains network are tested in detail in accordance with the regulations of your country.

- the screen displays „STARTUP“

ENEN

Depending on the regulations of each country, the startup test can take

between just a few seconds up to several minutes. The time elapsed is

indicated by a bar shrinking from top down.

Whenever two scale divisions stop flashing and disappear, 1/10 of the total duration of the test is over

(5) Synchronisation ENS (option)

- if the FRONIUS IG unit is equipped with the ENS option, every

detail of the ENS will be tested and synchronized

- the screen displays „SYNC

ENS

“

Depending on the operating status of the ENS, test and synchronization

may take up to several seconds.

(6) Operation of feeding power supply into the mains network

- After termination of the tests, the FRONIUS IG unit starts feeding

power into the mains network.

- The LED lights up green, and the FRONIUS IG unit starts operating

13

Page 22

Overview for

FRONIUS IG

(for indoor

housing)

(1) storage area for operation and installation manual

(2) ventilation grill

(3) LED for operation status

(4) display

(5) keyboard

(6) slot -in board area

(7) various versions of connection plate

(8) connection area - to be opened only by licensed electricity installers

(9) power stage, separately insulation encased - to be opened only by

Fronius trained service staff

(1)

(9)

(8)

(7)

(2)

(3)

(4)

(5)

(6)

14

Page 23

Overview for

FRONIUS IG

Outdoors

(1)

(2)

(8)

(1) (6)

(7)

ENEN

(2)

(1)

(3)

(4)

(5)

(1) tightening screws for housing

(2) cooling bonnets

(3) LED for operation status

(4) display outside

(5) keyboard outside

(6) covering for AC connection and slot-in board area

(7) connection rail Multicontact

(8) cover slide to protect the buttons and the display from the sun’s rays.

Note! We recommend that the cover slide is pushed in front of the

display in cases of direct sunshine.

15

Page 24

LED for operating status

LED

Depending on the operating status, the LED assumes different colours

(1) LED lights up green:

- a green light starts as soon as the FRONIUS IG unit has completed

the startup phase, it stays green as long as the operation of feeding

power into the network continues

- it indicates faultless operation of the photovoltaic equipment

(2) LED flashes green:

- as long as the photovoltaic equipment is operating without fault

- and an additional message is displayed on the screen

Note! A message appears for example if there is an insulation

fault, which however does not affect the function of the FRONIUS

IG. However for safety reasons we recommend that the insulation

fault is remedied as soon as possible.

Depending on the country setup, the inverter can also disconnect

from the public grid when there is an insulation error and stop

feeding energy into the grid.

The FRONIUS IG with display shows a status message. A message is

displayed in the FRONIUS IG.access software for the FRONIUS IG without display.

If a message (e.g. „502“, Section „Status diagnosis and remedy) is shown,

rectify the relevant status and acknowledge this by pressing the „Enter“

button.

(3) LED lights up orange:

- The FRONUS IG unit will enter the automatic startup-phase, as soon

as after sunrise the photovoltaic modules yield sufficient power output

16

Page 25

LED for operating status

(continued)

(4) LED flashes orange:

- when a warning is being displayed on the screen

- or the FRONIUS IG unit has been set to standby operation in the

setup menu = manual shutoff of power supply operation

- after the next day sunrise, power supply operation will be resu-

med automatically

- during the time while the orange LED keeps flashing, the power

supply operation can be resumed manually at any time (see

chapter „Setup Menu“)

(5) LED lights up red:

- general status: the respective service code is displayed on the

screen

Inverter does not feed energy into the public grid.

A list of all service codes, the corresponding status informations, their

status causes and repair measures can be found in the chapter „Status Diagnosis and Repair“ of the installation and service manual.

(6) LED remains dark:

- there is no connection to the solar modules

- no power output from module due to darkness

ENEN

17

Page 26

Operating scheme

The Display

General information

Functions of

the keys

The FRONIUS IG unit is pre-configured to be ready for operation, therefore it is not necessary to make any adjustments in order to be able to get it

to operate fully automatic and feed power into the mains.

The display is powered by the solar module and is therefore available

throughout the day.

Important! The display of the FRONIUS IG is not a calibrated measuring

device. A slight deviation by a few percent is inherent in the system.

Therefore, a calibrated meter is required for accurate settlement of data

with the electricity supply company.

Key (A) and (B):

- for scrolling

key (C):

- for switching to the menu level

(„Menu“) or exit from the setup

menu („Esc“) key „Enter“ (D):

- for confirming a choice

(C) (D)(B)(A)

Symbols

(2)

(5)

(1) (3)

(1) symbols for keys (A) through (D)

(2) symbols for the display modes „Now“ through „Setup“

18

(12)

(11)

(10)

(9)

(7)

(8)

(6)

(4)

Page 27

Symbols

(continued)

(3) area for data display ... for displaying the data value measured

(4) area for unit display ... for displaying the measuring unit applicable

(5) segment bar ... indicates at any time the power output fed into the

mains at a given time - independent from the display mode chosen.

The screen displays % of the maximum possible power supply out

put of your solar inverter

(6) ... appears with data readings which are directly related to the

public mains network

(7) ... appears with data readings which are directly related to

the solar modules

(8) ... appears with data readings which are related directly to the

FRONIUS IG unit

(9) ... appears with data readings which are related to environment

conditions, like insolation and temperature (optional)

ENEN

(10) ...appears with data readings which are transmitted by the con-

sumption sensor (optional)

(11) Max ... the data reading indicates the maximum within the period of

observation (depending on the display mode chosen)

(12) Min ... the data reading indicates the minimum within the period of

observation (depending on the mode of display chosen)

Important! The Min. and Max. values do not correspond to the absolute

extreme values, as the measuring data value capture takes place at two

second intervals

Navigating in the Display

Display illumination

Press any key to activate the display lighting. If no key is pressed during

30 seconds, the display lighting stops. At the same time the setup menu

offers a choice between permanently lit or permanently dark display.

19

Page 28

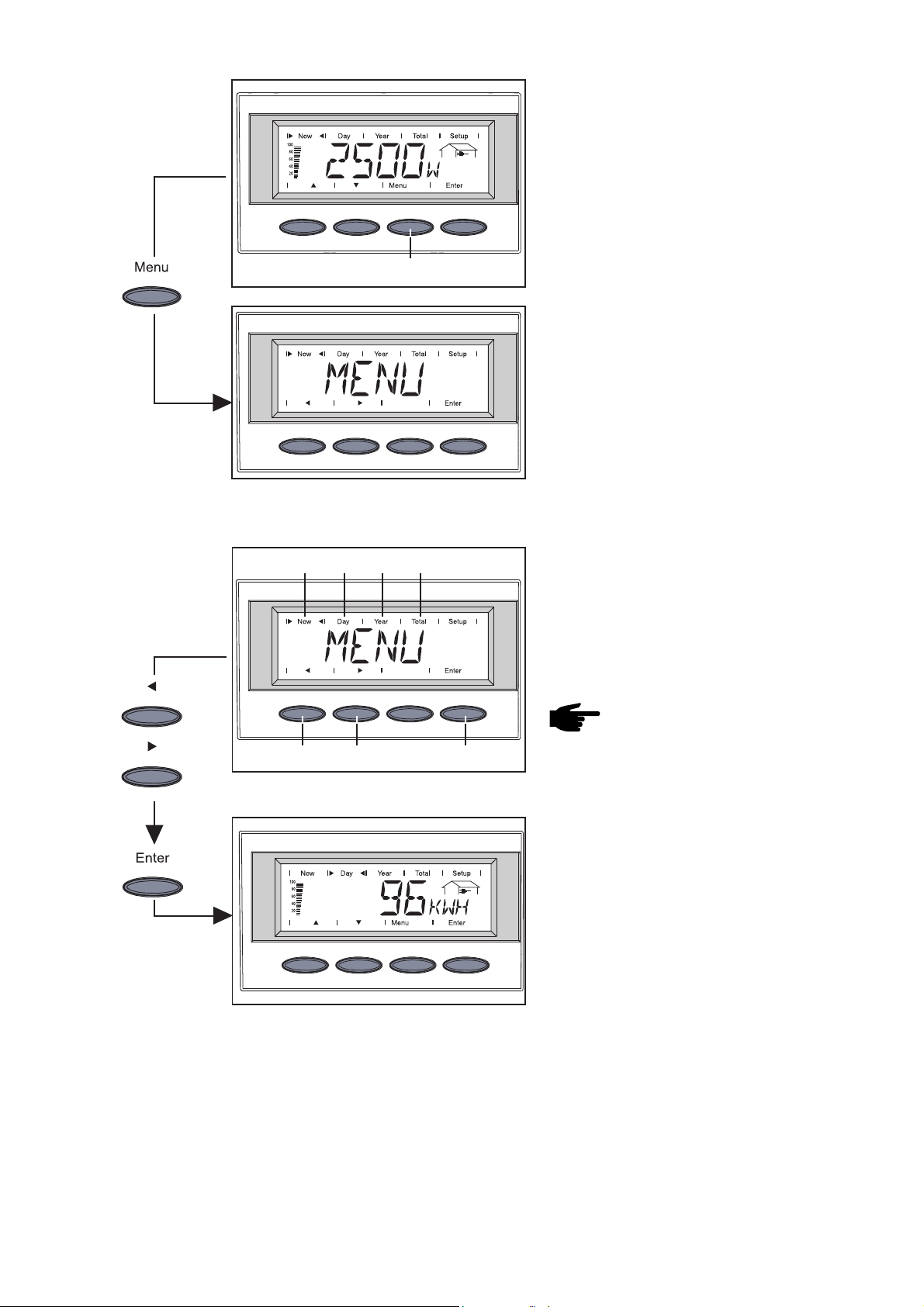

Menu level

From the menu level you enter the

display mode or the setup menu.

Move into the menu surface by

pressing key (C)

(C)

(C)

- the screen displays „Menu“

- the display is operating in the

menu level

Select display

mode

(A)

(B)

(D)

(1) (2) (3) (4)

(A) (B) (D)

- move into the menu level

- select the desired display mode

(1) to (4) by pressing keys (A) or

(B)

- enter the display mode selected:

press key „Enter“ (D)

Note! for the menu item

„Year“ a real time clock is

required. The menu item

„Year“ is only supported

when the option data recorder is connected. This

system upgrade is equipped

with a real time clock.

20

Page 29

Scrolling

between display functions

- select the desired display mode (see above)

- scroll between the display functions available with keys (A) or (B)

Display Modes

ENEN

(A) (B) (A) (B)

(A) (B)

Scheme of

display modes

The following display modes are available:

display mode „Now“ ...shows present data

display mode „Day“ ... shows data for supply into the mains for the

current day

display mode „Year“ ...shows data for supply into the mains in current

calendar year - only in combination with data recorder option

display mode „Total“ ... shows data for supply into the mains since your

FRONIUS IG unit has been first operating

21

Page 30

Scheme of

display readings

The following scheme contains a brief list of the display readings available.

Display readings without footnote are shown when the setting „standard“

is chosen (factory setting).

* optional - if the required option card is not available, the message

„N.A.“ (nicht angeschlossen = not connected) is displayed.

Mode „Now“ Mode „Day“ / „Year“ / „Total“

output supplied

(W)

voltage

(V)

electricity supplied

(A)

mains frequency

(Hz)

* mains impedance

(Ohm)

module voltage

(V)

module power

(A)

* module temperature

(°C;alternatively also °F)

insulation resistance

(MOhm)

energy supplied

(kWh / MWh)

yield

(set applicable currency)

CO2-reduction

(kg / t)

power output supplied (maxim.)

(W)

mains voltage (maximum)

(V)

mains voltage (minimum)

(V)

module voltage (maximum)

(V)

* energy as read by consumption

meter

(kWh / MWh)

* module temperature (maximum)

(°C; alternat. also °F)

* output reading of consumption

meter

(W)

* ambient temperature

(°C; alternnatively also in °F)

* insolation

(W/m²)

* time

(HH:MM)

* module temperature (minimum)

(°C; alternat. also °F)

* ambient temperature(maximum)

(°C; alternat. also °F)

* ambient temperature( minimum)

(°C; alternat. also °F)

* insolation (maximum)

(W/m²)

operating hours of FRONIUS IG

unit

(HH:MM)

22

Page 31

Display mode

„Now“

Displays present readings

- select display mode „Now“ (chapter „The Display“)

- the first display function of the display mode „Now“ appears

* optional - in case the card for the required option is not available, the

message „N.A.“ is displayed

power supplied .. power

supplied to mains at this moment (Watt)

- for the next item press key (B)

(A) (B)

- to scroll back press key (A)

mains voltage

(Volt)

ENEN

power supplied ...power

supplied to mains at the particular moment (Ampere)

mains frequency

(cycles)

* mains impedance ... resi-

stance of mains - parameter for

safe power supply to mains

(Ohm; optional ENS)

The resistance of the local low voltage mains up to the next transformer

station is metered.

Whenever the local low voltage mains network is switched off for repair

works, the mains impedance will increase substantially, in this case the

FRONIUS IG unit will interrupt power supply for safety reasons.

23

Page 32

Display mode

„Now“

(continued)

module voltage... voltage in

the solar modules at the moment of data display

The voltage indicated during power supply into mains is equal to the socalled MPP voltage (MPP = maximum power point). The FRONIUS IG

unit keeps the module voltage always within the maximum possible power

output withdrawal from the solar modules. This always guarantees an

optimum efficiency performance of your photovoltaic generator..

module power ... power supplied by solar modules at the

moment of data display (Ampere)

The FRONIUS IG unit keeps the module voltage always within the range

of the maximum possible power withdrawal from the solar modules. This

results in the optimum for the module electricity.

* module temperature ... tem-

perature at solar modules

(degrees centigrade; can also

be set for degrees Fahrenheit;

temperature sensor No.1;

sensor card optional)

isolation resistance of photovoltaic generator (MOhm)

Isolation resistance is the resistance between the positive pole or the

minus pole of the photovoltaic generator and the grounding potential.

Whenever an isolation resistance higher than 500 kOhm is shown, the

photovoltaic generator is sufficiently insulated.

Warning! An isolation resistance < 500 kOhm can be caused by an

insufficiently insulated DC cable or by defective solar modules. In

case of an insufficient isolation resistance you must in any case

contact your Fronius service partner.

Important! Only an isolation resistance of less than 500 kOhm indicates

that there is an error. Whenever a higher insulation reistance is shown it is

not to be interpreted as an error.

Whenever there is an isolation resistance of less than 10 MOhm, the

display differentiates between the negative potential and the earthing

(minus sign „-“) and the positive potential and the earthing (plus sign „+“)

24

Page 33

Display mode

„Now“

(continued)

Display example for negative potential (sign „-“)

Short circuit between DC- line and

earth

Display example for positive potential (sign „+“)

Short circuit between DC+ line and

earth

* power output drawn from

mains supply... present con-

sumption (Watt; sensor card

optional)

* ambient temperature (°C;°C;

can also be set for °F in setup

menu; temperature sensor

Nr.2; sensor card optional)

* insolation ... insolation power

output impact per square meter

(Watt/m²; sensor card option)

ENEN

* time of the day (data recorder

is optional)

25

Page 34

Display mode

„Day / Year /

Total“

Display mode „Day“ ... shows readings for mains supply feed-in of current

day - only in combination with bus-master option

Important! For the FRONIUS IG unit, the day begins with the moment it

switches on. In case the DC supply line is disconnected, the following

parameters will be re-set after repeating the start-up:

- power supplied (kWH)

- yield (currency can be selected)

-CO

-reduction (kg)

2

- maximum power supplied (Watt)

- maximum mains voltage(Volt)

- minimum mains voltage (Volt)

- energy drawn from mains supply (kWh)

- operating hours for FRONIUS IG unit

The information given above does not apply for the data recorder option.

If the data recorder option is available the display values listed always

apply for the whole of the mains supply feed day.

Display mode „Year“ ...shows readings of power supply for the current

calendar year (only in conjunction with data recorder)

Display mode „Total“ ...shows readings of power supply since original start

of operation of the FRONIUS IG unit.

- select display mode „Day“ / „Year“ / „Total“ (chapter „The Display“)

- the first display function of the display mode selected will appear

* optional - in case the required sensor card is not available, the mes-

sage „N.A.“ is displayed.

26

Page 35

Display mode

„Day / Year /

Total“

(continued)

Energy supplied ... energy

supplied during period monitored (kWh / MWh)

(A) (B)

Due to different monitoring systems there can be deviations in comparison with readings of other metering instruments. For invoicing of the

energy supplied only the readings of the calibrated meter supplied by the

electric utility company are relevant.

- press key (B) for next item

- to scroll back press key (A)

Yield ... money earned during

period monitored (set currency

in setup menu)

Important! As was the case for the energy supplied, also here readings

may differ from those of other instruments.

Chapter „Setup Menu“ tells how to set currency and rate applicable for

invoicing. The factory setting is 0,48 Euro/kWh.

ENEN

CO2-reduction ... CO2 emissi-

on saved during monitored

period (kg/t)

Indication of CO2 emission (in kg/t) which would be released during generation of same amount of electricity in a thermal power station. Set for

0,59 kg/kWh in the factory (source of information: DGS - German Society

for Solar Energy).

Maximum power input ..

highest power input into main

during observation period (W)

Maximum mains voltage ...

highest reading of mains voltage (V) during observation

period

27

Page 36

Display mode

„Day / Year /

Total“

(continued)

Note! Fit the temperature

probe on the rear side of

the solar module.

Minimum mains voltage...

lowest reading of mains voltage (V) during observation

period

Maximum module voltage...

highest reading of module

voltage (V) during observation

period

* Energy consumption meter

reading

energy consumed during observation period (kWh / MWh;

applicable for consumption

sensor)

* maximum temperature at

module... highest temperature

reading at solar modules during observation period (°C;

can also be set for°F in setup

menu; temperature sensor No.

1; applicable for sensor card)

* minimum temperature at

module...lowest temperature

reading at solar modules during observation period (°C;

can also be set for°F in setup

menu; temperature sensor No.

1; applicable for sensor card)

* maximum ambient tempera-

ture ... highest temperature

reading during observation

period (°C; can also be set for

°F in setup menu; temperature

sensor No. 2; applicable for

sensor card)

* minimum ambient tempera-

ture...lowest temperature

reading at solar modules during observation period (°C;

can also be set for °F in setup

menu;temperature sensor No2;

applicable for sensor card)

28

Page 37

Display mode

„Day / Year /

Total“

(continued)

* maximum insolation... high-

est insolation during observation period (W/m²; sensor card

optional)

Duration of operation is shown in hours and minutes upto 999 h and 59

min (display: „999:59“). From then on only full hours are displayed.

Although the FRONIUS IG unit is not operating during the night, all data

required for the sensor card option are monitored and saved around the

clock.

The Setup Menu

List of menu

items

The following brief scheme shows the menu items provided for readjusting preset parameters of the FRONIUS IG unit

operating hours ... duration of

operation of FRONIUS IG unit

(HH:MM)

ENEN

Standby

Contrast

LightMode

Cash

IG-NR

DatCom

Time

Extended

State_PS

Enter

0 ... 7

AUTO ON

currency

01 ... 99 (100. FRONIUS IG = 00)

OKCom

Date

Iso_Warn

Status display - power stage sets

Error

Time

OFF

rate / kWh

SIGCD_TEST

ON OFF

Version

MainCtrl

29

PS01

ENS

Page 38

Display mode

„Setup“

The setup menu allows easy readjustment of the preset parameters of the

FRONIUS IG unit in order to adapt to your needs and requirements in the

best possible way.

Enter the

setup menu

(A)

(B)

(D)

(1) (2) (3) (4) (5)

(A) (B) (D)

- move to to the menu level (chapter „Navigating in the Display“)

- select mode „Setup (5)“ with keys

(A) or (B)

- enter the mode „Setup“ (5) :

press key „Enter“ (D)

- „Standby“, the first item on the

menu, is displayed

Scroll among

menu items

(A) (B) (A) (B)

(A) (B)

- select the desired display mode (see above)

- scroll with keys (A) or (B) among the menu items available

30

Page 39

Setting the

menu items

- „Standby“ ...activate/deactivate

the standby operation by pressing the „Enter“ key

(D)

The menu item „Standby“ allows manual activation of the standby operation of the FRONIUS IG unit.

During standby operation the electronic system of the power stage is

switched off. No power is fed into the mains. There is an orange flash on

the LED. The following message is flashed intermittently on the screen::

„STANDBY“ „ENTER“

- The orange flashing LED stops with dusk arriving.

- After the subsequent sunrise, the power supply operation into the mains

is resumed automatically (after termination of the startup phase the

LED is illuminated green)

- mains supply operation can be resumed at any time whenever the LED

is flashing orange (deactivate „standby“)

ENEN

- LED with green light: activate „standby“ =manual shutoff of operation

supplying power into mains system:

- press key „Enter“ (D)

- LED with orange flash: deactivate „standby“ = resuming operation

supplying power into mains system

- press key „Enter“ (D)

31

Page 40

(C) (D)

(D)

- select from settings „0“ to

„7“ - press key (A) or (B):

- „Contrast“ ... set contrast on

LCD display

- enter „Contrast“: press key „Enter“ (D)

As contrast depends on temperature, it may be necessary to adjust

the menu item „Contrast“ when

ambient conditions change.

Settings for minimum possible

contrast (0) upto maximum possible contrast (7):

(A)

(B)

(C) (D)

...

(C) (D)

(C)

- accept: press key „Enter (D)“

- maintain previous setting: press

key „Esc“ (C)

- „Menu Mode“ ... cannot be

selected

32

Page 41

(C) (D)

- To switch between settings

(D)

Auto 1., On 2. and Off 3.

- press keys (A) or (B):

(C) (D)

(A)

(B)

- „Light Mode“ ... pre-setting of

display illumination

- to enter „Light Mode“: press key

„Enter“ (D)

ENEN

1.The display illumination will stop

30 seconds after the last time a

key has been pressed

- accept: press key „Enter“ (D)

- maintain previous setting: press

key „Esc“ (C)

2.The display will remain permanently illuminated for the duration

of the operation of power supply

into the mains

(A)

(C) (D)

- accept: press key „Enter“ (D)

- maintain previous setting: press

key „Esc“ (C)

(B)

3.The display illumination will be

permanently off:

- accept: press key „Enter“ (D)

- maintain previous setting: press

(C) (D)

key „Esc“ (C)

Important! These instructions are only applicable for the display background illumination. It is not necessary to deactivate the display itself

because its energy consumption is less than one mW (1/1000 W).

- „Cash“ ... setting of currency

and rate for invoicing the energy

supplied

- enter „Cash“ by pressing key

(C) (D)

„Enter“ (D)

(D)

1

33

2

Page 42

1

(D)

... ...

(D)

(A)

(B)

(B) (D)(A)

...

(C)

1. Enter currency (factory pre-set

2

for EUR)

- first digit starts flashing

- select a character for the first

(D)(C)

digit by pressing key (A) or (B)

- confirm by pressing key

„Enter“(D)

- next digit starts flashing

- follow same procedure as described above for subsequent digits

- accept the currency selected by

pressing key „Enter“ (D)

- to maintain previous setting,

press key „Esc“ (C)

2.Enter rate per kWh according

currency selected (preset rate:

0,48 EUR/kWh)

(D)

(D)

(A)

(B) (D)

(C)

...

(B) (D)(A)

(B)(A)

Note! numbers between

000,1 and 99,99 may be

selected

(C)

(C)

(D)

- first digit starts flashing

- select a figure for the first digit by

pressing key (A) or (B)

- confirm by pressing key „Enter“

(D)

- next digit starts flashing

- for subsequent digits, follow

same procedure as described

above for first digit

- decimal point starts flashing

- move the decimal point to the

position desired by pressing keys

(A) or (B)

- accept the rate set by pressing

key „Enter“ (D)

- to maintain previous setting,

press key „Esc“ (C)

34

Page 43

(D)

(D)

(A)

(B)

(C) (D)

- „IG-NR“ ...Setting the number

(=address) of the FRONIUS IG

unit in a setup comprising more

than one photovoltaic inverter

linked with each other

(D)(C)

ENEN

- enter „IG-NR“ by pressing the

key „Enter“ (D)

enter address (01 ... 99)

(factory setting: 01)

- first digit starts flashing

- select a figure for the first digit by

pressing key (A) or (B)

- confirm with key „Enter“ (D)

- subsequent digit starts flashing

- for second digit follow procedure

as described above for first digit

(B) (D)(A)

- accept the IG-No. selected: press key „Enter“ (D)

- maintain previous setting: press key „Esc“ (C)

Note! Allocate an own address to each FRONIUS IG when connecting several FRONIUS IG into a data communication network

using data recorders.

It is important to give each FRONIUS IG an own address, so that the data

recorder can differentiate between the individual static inverters. If two

FRONIUS IG are in the system with the same address, they cannot communicate with the data recorder. Set another address on the FRONIUS IG

showing the status-message 504.

35

Page 44

(D)

(C) (D)

(B)(A) (B)(A)

If a successful data link has been

(B)

set up then „OK

“ is displayed.

COM

- Press key (B) to call up the Signal Card test

(D)

- Start the Signal Card test by

pressing the „Enter“ key (D)

(D)

„Error“ is displayed if DatCom is

not installed or the data link is

not functioning correctly.

(C)

Signal Card not installed

(C)

Signal Card active

- The Signal Card‘s acoustic signal sounds for confirmation.

Important! Check the signal lines if the signal fails to sound.

36

Page 45

Important! The menu item „Year“ is

only supported when the option

data recorder is connected.

(D)

(D)

(D)

(C) (D)

(B)(A)

(B) (D)(A)

(C)

(D)(C)

- „Time“ ... setting of date and

time

- enter „Time“ by pressing key

„Enter“ (D)

1.Enter date (e.g.: 03.10.2003)

- first digit starts flashing

- select a character for the first

digit by pressing key (A) or (B)

- confirm by pressing key „Enter“

(D)

- next digit starts flashing

- follow the same procedure as

described above for subsequent

digits

- accept the date selected by

pressing key „Enter“ (D)

- to maintain previous setting,

press key „Esc“ (C)

ENEN

(D)

2.Enter time (e.g.: 15:47)

- first digit starts flashing

- select a figure for the first digit by

pressing key (A) or (B)

(B)(A)

(D)(C)

- confirm by pressing key „Enter“

(D)

- next digit starts flashing

- for subsequent digits, follow

same procedure as described

above for first digit

- accept the time set by pressing

key „Enter“ (D)

(B) (D)(A)

(C)

- to maintain previous setting,

press key „Esc“ (C)

37

Page 46

- „Extended“ ... Isolation warning

activation and deactivation

- Press „Enter“ (D)

(D)

(D)

(A)

(B)

(D)

- Isolation warning menu display

- Press „Enter“ (D)

(D) (C)

- Use button (A) or (B) to selected

the „Off“ or „On“ setting

- Press „Enter“ (D) to apply the

setting

When the setting is „Off,“ the „State

502“ Isolation warning is deactivated.

„Off“ is recommended for solar

modules with a high ohm grounded

DC+ and DC- connection.

(D)

2x

(C)

38

Page 47

- „STATE_PS“ ... Status display of

power stage sets

- Press „Enter“ key (D)

Alternately

(D)

(D)

(C)

(D)

(D)

(C)

ENEN

- In this case for example the first

power stage set (PS00) is on

„Standby“

- „Standby“ means no electricity is

being fed into the public mains

- Press „Enter“ key (D)

- Display of the most recently

stored service code (e.g. „State

406“)

Important! The most recently

stored service code and the display

„State Load“ appear alternately.

- Press „Esc“ key (C)

Alternately

(B)

(D)

(B)

(D)

- The display for the first power

stage set (PS00) re-appears

- Change over to the second power stage set by pressing key (B)

- In this case for example the

second power stage set (PS01)

is on „Run“

- „Run“ means intact delivery of

electricity to the public mains

- Press „Enter“ key (D)

- Display of the most recently

stored service code (e.g. „State---

-“)

Important! The most recently

stored service code and the display

„State Load“ appear alternately.

2x

(C)

- Escape: Press „Esc“ key (C)

twice

Important! Status displays 306 (Power Low) and 307 (DC-Low) appear

naturally every morning and evening due to low solar irradiation. These

status messages are not the result of a fault.

39

Page 48

- To switch between displays

(D)

MAIN

1., PS01 2. and ENS

CTRL

3. - press key (A) or (B)

(C) (D)

(A)

display

version number

- „Version“ displays version num-

ber and serial number of the IG

control unit and the power stage

- enter „Version“by pressing key

„Enter“(D)

1. For displaying version number of

the IG control unit : press key

„Enter“ (D)

- exit by pressing key „Esc“ (C)

- to switch into display of serial

number for the IG control unit:

press keys“ (A) or (B)“

- exit with key „Esc (C)“

(B)

(A)

(B)

(A)

(B)(A)

display

serial number

(C) (D)

display

version number

(B)

display

serial number

(C)

(C)

2

2.To display version number of

power stage, press key „Enter

(D)“ - exit with key „Esc (C)“

- to switch into display of serial

number of the power stage,

press keys „(A) or (B)“ - exit with

key „Esc (C)“

3.To display type number of ENS:

press key „Enter“ (D)

- exit with key „Esc“ (C)

- to switch into display of version

number for ENS:

press keys (A) or (B)

- exit with key „Esc“ (C)

(A)

(C) (D)

display

type number

(B)

display

version number

(C)

Note! in case the FRONIUS

IG unit is not equipped with

the ENS option, type number and version number

cannot be displayed.

- after the „Enter“ key (D) has

been pressed, the message

„N.A.“ is displayed on the screen

- exit by pressing key „Esc (C)“

40

Page 49

Additional information

Upgrading the

system

The FRONIUS IG unit is prepared for a whole series of system upgrades,

such as:

- for communicating between FRONIUS IG and outside system extensions, for example with other FRONIUS IG units

- Data logger (for recording and managing data from your photovoltaic

system by PC) including datalogger and modem connection

- Various large displays (FRONIUS IG Public Display)

- Actuators / Relays / Alarm (FRONIUS IG Signal Card)

- Sensors (Thermo sensors / Irradiance / Metering)

The system upgrades are offered in slot-in boards, similar to those on

your personal computer.

ENEN

For increased flexibility, all upgradings are also available in a version with

external housing

For an unlimited individual use of system upgradings, Fronius has developed the LocalNet. LocalNet is a data network which allows linking

more than one FRONIUS IG units with the system upgrade elements.

LocalNet is a bus system. One single cable is sufficient to allow communication between one or several FRONIUS IG units with all system upgrade

elements. This reduces the cable requirement to a minimum.

41

Page 50

Upgrading the

system

(continued)

Please take further details from the chapter „LocalNet“ of the installation

and service manual.

Forced ventilation

The FRONIUS IG unit is equipped with a temperature and rotation controlled air circulator which provides for the following features:

- smaller heat sinks - more compact housing

- components are better cooled - efficiency increases / longer life