Page 1

/ Perfect Charging / Perfect Welding / Solar Energy

HyLOG Fleet

24015F

Operating Instructions

EN

Energy cell

42,0426,0271,EN 003-22112018

Page 2

2

Page 3

Dear reader,

Introduction Thank you for the trust you have placed in our company and congratulations on buying this

high-quality Fronius product. These instructions will help you familiarise yourself with the

product. Reading the instructions carefully will enable you to learn about the many different

features it has to offer. This will allow you to make full use of its advantages.

Please also note the safety rules to ensure greater safety when using the product. Careful

handling of the product will repay you with years of safe and reliable operation. These are

essential prerequisites for excellent results.

EN

3

Page 4

4

Page 5

Contents

Safety rules ................................................................................................................................................ 7

Explanation of safety symbols .............................................................................................................. 7

General ................................................................................................................................................. 7

Proper use ............................................................................................................................................ 8

Safety measures in operation ............................................................................................................... 9

Environmental conditions...................................................................................................................... 9

Safe use................................................................................................................................................ 9

Protecting yourself and others .............................................................................................................. 10

Danger from gases, hazardous materials and suffocation.................................................................... 10

Safety measures in normal operation ................................................................................................... 10

Specific hazards.................................................................................................................................... 11

General information regarding the handling of batteries....................................................................... 11

Danger from batteries ........................................................................................................................... 11

Danger from pressure vessels .............................................................................................................. 11

Warranty and liability............................................................................................................................. 12

Safety inspection................................................................................................................................... 12

Safety symbols...................................................................................................................................... 12

Disposal ................................................................................................................................................ 12

Copyright............................................................................................................................................... 13

General ...................................................................................................................................................... 14

Functionality and device concept.......................................................................................................... 14

Advantages ........................................................................................................................................... 14

Properties.............................................................................................................................................. 15

System configuration ............................................................................................................................ 15

Warning notices on the device.............................................................................................................. 16

Control elements and connections............................................................................................................. 18

Safety.................................................................................................................................................... 18

Controls and connections ..................................................................................................................... 18

Control panel......................................................................................................................................... 20

Before commissioning................................................................................................................................ 23

Safety.................................................................................................................................................... 23

Proper use/intended purpose................................................................................................................ 23

Before using for the first time ................................................................................................................ 24

Connections .......................................................................................................................................... 24

Start-up ...................................................................................................................................................... 26

Safety.................................................................................................................................................... 26

Advance information ............................................................................................................................. 26

Connecting the power interface to the vehicle ...................................................................................... 26

Pin assignment for the vehicle connection............................................................................................ 27

Specification for the vehicle connection................................................................................................ 27

Potential Equalization ........................................................................................................................... 28

Application example for the vehicle connection .................................................................................... 28

Refuelling ................................................................................................................................................... 29

Safety.................................................................................................................................................... 29

General ................................................................................................................................................. 29

General refuelling.................................................................................................................................. 29

Time-optimised refuelling...................................................................................................................... 30

Pressure tolerances .............................................................................................................................. 32

Refuelling process ................................................................................................................................ 32

Operation ................................................................................................................................................... 33

Safety.................................................................................................................................................... 33

Operating conditions ............................................................................................................................. 33

Starting energy delivery ........................................................................................................................ 34

Stopping energy delivery ...................................................................................................................... 34

Troubleshooting ......................................................................................................................................... 35

Safety.................................................................................................................................................... 35

Fault diagnosis...................................................................................................................................... 35

Displayed service codes ....................................................................................................................... 36

Care, maintenance and disposal ............................................................................................................... 38

Safety.................................................................................................................................................... 38

EN

5

Page 6

Minimum maintenance work ................................................................................................................. 39

Once a year / every 1000 operating hours............................................................................................ 39

Annual safety inspection ....................................................................................................................... 39

Maintenance work every 1000 operating hours ....................................................................................40

Service life ............................................................................................................................................ 40

Pressure equipment.............................................................................................................................. 40

Disposal ................................................................................................................................................ 40

Technical data............................................................................................................................................ 41

HyLOG Fleet 24015F............................................................................................................................ 41

6

Page 7

Safety rules

EN

Explanation of

safety symbols

DANGER!

Indicates immediate and real danger.

If it is not avoided, death or serious injury will result.

WARNING!

Indicates a potentially dangerous situation.

Death or serious injury may result if appropriate precautions are not taken.

CAUTION!

Indicates a situation where damage or injury could occur.

If it is not avoided, minor injury and/or damage to property may result.

NOTE!

Indicates a risk of flawed results and possible damage to the equipment.

General

IMPORTANT!

Indicates tips for correct operation and other particularly useful information.

It does not indicate a potentially damaging or dangerous situation.

If you see any of the symbols depicted in the "Safety rules" chapter, special care is required.

The device is manufactured using state-of-the-art technology and according to recognised

safety standards. If used incorrectly or misused, however, it can cause:

- injury or death to the operator or a third party

- damage to the device and other material assets belonging to the operator,

- inefficient operation of the device

According to the extent to which they are operating and using the device, all users (drivers,

service personnel, etc.) must

- be suitably qualified

- be trained

- read and follow these Operating Instructions carefully.

The Operating Instructions must always be at hand wherever the device is being used. In

addition to the Operating Instructions, attention must also be paid to any generally applicable and local regulations regarding accident prevention and environmental protection.

All safety and danger notices on the device:

- must be in a legible state,

- must not be damaged,

- must not be removed,

- must not be covered, pasted or painted over.

7

Page 8

For the location of the safety and danger notices on the device, refer to the section headed

"General remarks" in the Operating Instructions for the device.

The following problems can result in safety issues, and must therefore be resolved before

the device is commissioned:

- dirty or blocked cooling air inlet

- power connector connected incorrectly

This is for your personal safety!

These Operating Instructions are concerned only with the vehicle's energy delivery system

and describe the technical and safety-relevant interfaces on the vehicle relating to energy

delivery.

The overall safety of the system (HyLOG Fleet device, vehicle and its operation in a working area) is the responsibility of the vehicle manufacturer / system integrator. The vehicle

manufacturer / system integrator is the manufacturer of the logistics vehicle that installs the

energy cell in the vehicle and is responsible for the conformity of the system as a whole.

The overall system safety encompasses:

- Weight compensation (driving stability, traction, etc.)

- Information provided to the driver and surrounding area concerning safety-relevant

operating states of the energy cell (warning of hydrogen leak, etc.)

- Analysis of overall system safety and supply of general system user documentation

(energy cell and vehicle) adapted for use of the vehicle with the HyLOG Fleet energy

cell.

Proper use

The device is to be used exclusively for its intended purpose.

Any use above and beyond this purpose is deemed improper. The manufacturer shall not

be held liable for any damage arising from such usage.

Proper use includes:

- ensuring that the device is undamaged and in perfect condition

- carefully reading and obeying all the instructions in these operating instructions, especially the safety rules and all safety and danger notices

- installing the device in accordance with the vehicle manufacturer's operating instructions

- carrying out all the specified inspection and maintenance work *

- observing all instructions of the vehicle manufacturer and the refuelling system manufacturer

- obeying other relevant national safety rules

Inspection and maintenance work form part of the responsibility of the operator. However,

the operator may arrange for the manufacturer of the vehicle or the fuel cell system to perform inspection and maintenance work (e.g. as part of a maintenance agreement).

The device must only be operated in rooms with a volume of more than 10 m³ (353.15 ft³)

and with an air circulation rate of not less than 0.6/h. With a room volume of 10 m³ (353.15

ft³), an air circulation rate of 0.6/h means that 6 m³ (211.89 ft³) of air are renewed per hour.

The device may not be used if any part has been submerged in or flooded with water. Notify

the manufacturer or its representative immediately so that the device can be checked and

any affected parts replaced.

The device must not be used in conditions of frost or (condensing) humidity. Operating the

device in frosty or humid conditions can result in damage. Only use the device in rooms

that are free from frost and condensing air. Detailed information can be found in the "Technical data" chapter.

8

Page 9

Remove the device before washing the vehicle. Never clean the device itself with water,

liquid detergents or steam cleaners.

Safety measures

in operation

Environmental

conditions

Information on cleaning the device can be found in the "Care, maintenance and disposal"

chapter.

When installing devices with openings for cooling air, ensure that the cooling air can enter

and exit unhindered through the air ducts. Only operate the charger in accordance with the

degree of protection shown on the rating plate. Observe the "Operating conditions" chapter

of the device operating instructions.

Operation or storage of the device outside the stipulated environmental conditions will be

deemed to be not in accordance with the intended purpose. The manufacturer shall not be

held liable for any damage arising from such usage.

Additional information on the permitted environmental conditions can be found in the

"Technical data" chapter.

The surrounding air must be clean and free from

- possible ignition sources

- smoke

- naked flames and light

- petrol and other flammable materials in the form of liquids, vapours or electrically conductive dusts, e.g. metallic powder

- corrosive gases or substances

EN

Safe use

Can be used at altitudes of up to 1600 m (5249 ft.)

The operating instructions are primarily intended for system integrators who incorporate

the device as a component into an overall vehicle. The contents are therefore intended for

qualified personnel.

The user must have received verifiable training from a qualified technician authorised by

the manufacturer.

The user must also observe all warning notices of the vehicle supplier and for the hydrogen

refuelling system.

An electric shock can be fatal. Do not perform any actions other than those described in

this documentation. All cables and leads must be secured, undamaged, insulated and adequately dimensioned. Loose connections, scorched, damaged or inadequately dimensioned cables and leads must be immediately repaired by authorised personnel.

Leaks in the hydrogen supply, in combination with an ignition source, pose a risk of fire and

explosion. The hydrogen refuelling system must therefore be set up in compliance with the

applicable standards and guidelines and operated in accordance with the manufacturer's

instructions. The technical data shown on the rating plate applies.

Maintenance and repair work on the device may only be carried out by trained personnel

authorised by the manufacturer.

It is impossible to guarantee that bought-in parts are designed and manufactured to suit

their application, or that they satisfy safety requirements. Use only original replacement

parts (also applies to standard parts).

9

Page 10

Do not carry out any modifications, alterations, etc. to the device without the manufacturer's consent.

Components that are not in perfect condition must be replaced immediately.

Protecting yourself and others

Danger from gases, hazardous

materials and suffocation

Keep unauthorised persons, especially children, away from the device and the vehicle containing the device during operation. If, however, there are people in the vicinity,

- make them aware of all dangers associated with use of the device (possible risk of suffocation due to lack of oxygen in the air, danger from output current, etc.)

- adhere to the permitted operating conditions as specified in the "Operating conditions"

section of the "Operation" chapter

Before leaving the vehicle in which the device is installed, make sure that no injury or damage can occur in your absence.

The fuel is supplied in the form of gaseous hydrogen. Hydrogen is a dangerous substance,

which requires great care when handling. Further information on handling hydrogen can

be found in the safety data sheet of the hydrogen supplier.

Only use the device in well-ventilated areas to prevent the accumulation of explosive gas.

Spaces are not deemed to be at risk of explosion if a concentration of hydrogen of less than

4% by volume can be adequately guaranteed by the use of natural or forced ventilation.

Keep possible ignition sources, fires and naked flames away from the device, also inflammable materials, liquids and gases.

Using the device in spaces with inadequate ventilation can cause suffocation with no visible or otherwise detectable warning. This is because of the oxygen consumption of the device, which can lead to a lack of oxygen in the room if it is inadequately ventilated. The

device must only be operated in rooms with a volume of not less than 10 m³ and with an

air circulation rate of not less than 0.6/h. Example: With a room volume of 10 m³, an air

circulation rate of 0.6/h means that 6 m³ of air are renewed per hour. Other spatial conditions require an exact calculation of the air circulation rate in consultation with the device

manufacturer.

Safety measures

in normal operation

10

Only operate the device if all of its protection devices are fully functional. If the protection

devices are not in full working order, there is a risk of

- injury or death to the operator or a third party

- damage to the device and other material assets belonging to the operator

- inefficient operation of the device

Any safety devices that are not functioning properly must be repaired before switching on

the device.

Never bypass or disable protection devices.

Before switching on the device, ensure that no one is likely to be endangered.

Observe the commissioning and operating requirements as set out in the "Before commissioning" and "Commissioning" chapters.

Page 11

Generally-speaking, the following applies:

- Ensure adequate ventilation of the installation location

- Ensure that the cooling air can flow into and out of the device unhindered

- Refer to the "Care, maintenance and disposal" chapter of the device Operating Instructions

- Regularly check the device and its accessories for obvious damage and proper functioning of safety device(s)

- Never operate the unit if there is any evidence of damage

- Always use the unit in compliance with

- the "Proper use" section of the "Before commissioning" chapter

- the "Operating conditions" section of the "Operation" chapter

EN

Specific hazards

General information regarding the

handling of batteries

Keep hands, hair, clothing and tools away from moving parts, for example fans.

Unauthorised opening or tampering with the device will invalidate the guarantee and poses

the risk of serious damage to people and property.

The unit contains a back-up battery (NiMH-technology) which requires careful handling.

- The back-up battery is maintenance-free

- It must not be tampered with by unauthorised personnel

- If external recharging of the back-up battery is required, this must only be carried out

with a battery charging system approved by the manufacturer (maximum charging current: 35 A, e.g. Acctiva Professional 35A, item number 4,010,335,874. The need to recharge the battery externally represents a fault that can only occur in special situations

(prolonged shutdown, overuse, etc.)

- Do not expose the back-up battery to excessive heat (e.g. do not leave the vehicle

parked in bright sunlight)

- The back-up battery is equipped with a protective circuit. This protects it against:

- Overcharging of the cells (damages the cells)

- Deep discharge of the cells (damages the cells)

- Destruction of cells by short circuit

- Polarity reversal

- Incorrect charging

- Overtemperature

Danger from batteries

Danger from

pressure vessels

The unit contains a back-up battery (NiMH-technology), which requires careful handling.

Batteries contain substances harmful to the eyes and skin. These can only be released in

the event of serious damage (e.g. overheating, accident, etc.).

- Substances escaping from batteries must not come into contact with the eyes, skin or

clothes.

- Do not inhale escaping gases or vapours, and make sure premises are well-ventilated

- Avoid short circuits

- Do not expose the battery to excessive heat or throw it onto an open fire

Further details can be found in the supplementary safety data sheet available from the

manufacturer.

The device is fed with hydrogen from an integrated pressure vessel. Ensure compliance

with the safety rules for pressure vessels.

There is a container of pressurised hydrogen in the device, and it must therefore be treated

with care. Detailed information on proper use can be found in the "Before commissioning"

section.

11

Page 12

Protect the pressure vessel from excessive heat, mechanical impact, naked flames, sparks

and arcs.

Keep pressure vessels away from electrical circuits.

The manufacturer's instructions must be observed as well as applicable national and international regulations for pressure vessels and accessories.

Warranty and liability

Safety inspection

The duration of the guarantee for the device depends on the supply contract. However, the

manufacturer will not accept any liability if the damage was caused by one or more of the

following:

- Use of the charger not in accordance with the intended purpose

- Incorrect operation

- Operating the charger with faulty protection devices

- Non-compliance with the operating instructions

- Unauthorised modifications to the charger

- Catastrophes caused by the activities of third parties and force majeure

A safety inspection must be carried out by a qualified expert

- before using for the first time after installing in the vehicle

- after any changes are made

- after any additional parts are installed, or after any conversions

- after repair, care and maintenance has been carried out

- and at least once every twelve months

The operator is required to carry out a safety inspection of the unit at least once every 12

months and to have the safety elements on the unit function-tested. Applicable national

regulations must be observed.

Maintenance, technical inspections and checks must only be carried out by qualified personnel (service organisations) who have been trained in the safety and maintenance of

these devices. In addition, all repair and maintenance work must be performed exclusively

using original replacement parts. All changes to the device and the use of parts that are

not original replacement parts may only be made with the approval of the manufacturer.

If these conditions are not met, the manufacturer cannot guarantee the safety of the device. Starting up the device without having performed safety-related maintenance work is

done at your own risk.

The manufacturer therefore accepts no liability for damage caused by inadequate maintenance carried out by a third party or by the non-performance of maintenance.

Safety symbols Devices with the CE marking satisfy the essential requirements of the applicable European

directives. Further information can be found in the "Technical data" chapter.

Disposal Do not dispose of this device with normal domestic waste! To comply with the European

Directive on Waste Electrical and Electronic Equipment and its implementation as national

law, electrical equipment that has reached the end of its life must be collected separately

and returned to an approved recycling facility. Any device that you no longer require must

either be returned to your dealer or given to one of the approved collection and recycling

facilities in your area. Ignoring this European Directive may have potentially adverse affects on the environment and your health!

12

Page 13

Copyright Copyright of these operating instructions remains with the manufacturer.

The text and illustrations are all technically correct at the time of printing. We reserve the

right to make changes. The contents of the operating instructions shall not provide the basis for any claims whatsoever on the part of the purchaser. If you have any suggestions for

improvement, or can point out any mistakes that you have found in the instructions, we will

be most grateful for your comments.

EN

13

Page 14

General

Functionality and

device concept

The HyLOG Fleet device allows transport

vehicles for internal logistics to be operated

with hydrogen as the energy source. This

eliminates the long breaks in operation required with normal charging times, as refuelling takes only a few minutes. The result

is higher productivity and lower maintenance costs. Ideally the hydrogen is generated

locally from renewable energy sources. The

only emissions from HyLOG Fleet are small

quantities of pure water.

The key component of HyLOG Fleet is the electrochemical unit in the device - the fuel cell.

This generates electrical energy from hydrogen and from oxygen in the surrounding air.

The fuel cell consists of several individual cells connected in series. A digital control unit

supplies it with hydrogen and air in the correct ratio and maintains the operating temperature.

When used correctly, hydrogen is a safe source of energy. The energy cell has a range of

safety features that comply with applicable standards. The explosion protection requirements are covered by precautionary measures integrated into the device to the extent that

no further explosion protection measures are required at the installation location. Care

must be taken to ensure sufficient circulation of air in the operating environment.

Advantages A great economic advantage of HyLOG Fleet is that long battery charging times are re-

placed by a refuelling process that takes only a few minutes. This results in greater availability and productivity of the in-house transport vehicles, combined with lower

maintenance costs. The hydrogen tank can be refilled virtually any number of times, within

the intended product life cycle of 10 years, whereas batteries always have a limited service

life.

Use of the fuel cell offers a range of other benefits as well:

Water is the only combustion product of the fuel cell, which means that it does not produce

any pollutants. Another advantage of the fuel cell is that it is quiet and requires practically

no maintenance. In contrast to conventional generators, the fuel cell electrochemically converts the chemically-bound energy of the hydrogen directly into electrical power. The hydrogen consumption is therefore very low.

Given the finite nature of energy resources and the need for environment-friendly energy

production, HyLOG Fleet sets new standards for energy efficiency and emission reduction.

The overall logistics system is particularly environment-friendly when renewable energy

sources are used, for example:

- Solar

- Wind

- Water

- Biomass

- Biogas

14

Page 15

The benefits of using HyLOG Fleet as the energy source for internal transport vehicles can

be summed up as follows:

- Long battery charging times of 8 to 10 hours are replaced by a refuelling process that

takes less than 3 minutes

- Lower maintenance costs mean optimum productivity compared with conventional

battery solutions

- Lower operating costs thanks to longer service life of the fuel-cell-based system

- Less space required since there are no battery charging stations

- Absence of poisonous and odorous emissions

- Quiet

- Energy efficiency is roughly 3 times better than that of conventional systems using internal combustion engines

Properties - Fuel cell-based generator

PEM type (polymer electrolyte membrane)

- Simple to operate

- Can easily be integrated into existing vehicle designs

- High standard of safety due to safety functions integrated into the device and explosion protection

- High degree of efficiency

- Quiet, low-maintenance operation

- Interface for data communication

EN

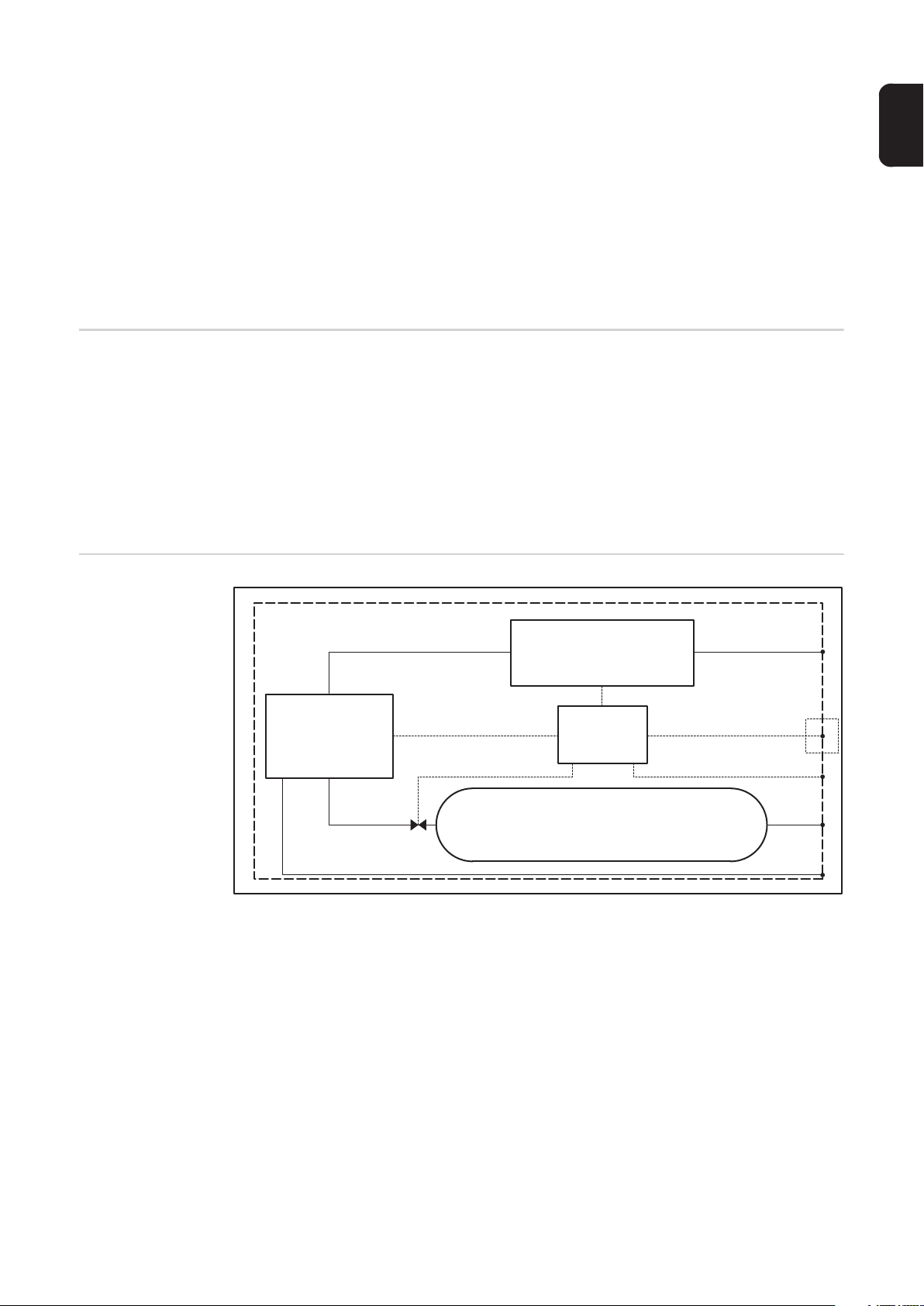

System configuration

NiMH-Battery

Fuel Cell Control Unit

Tank

Power

Control panel

Signal

Refilling

Condensate

15

Page 16

System components

Position Explanation Detailed explanation, specification

Fuel cell Fuel cell Generates electricity via an electrochemical process

from hydrogen and oxygen in the surrounding air ("cold

combustion"). Therefore the fuel cell is extremely efficient.

Battery Battery with nick-

el-metal hydride

technology

Since the fuel cell always works at close to optimum efficiency, it is used primarily to charge the batteries in order to store the energy. If power consumption increases

due to heavy acceleration of the vehicle, this is largely

met by the battery.

On the other hand, when the vehicle is braked, surplus

braking energy is stored in the battery again. The vehicle's drive unit is therefore a highly efficient hybrid system. Once the battery is fully charged, the fuel cell stops.

When the state of charge drops below a certain level, the

fuel cell starts recharging again.

The battery also supplies the energy needed to start the

fuel cell.

Tank A steel vessel for

hydrogen gas

with a capacity of

27 litres (7.13 gallons)

Control

Unit

Control and regulation unit

Contains the energy for operating the vehicle in the form

of hydrogen gas. During the refuelling process, the hydrogen is compressed to a pressure of 350 bar (5074.55

psi.), resulting in high storage density and long operating

intervals between refuelling stops.

Controls the battery charging process and the related

activity of the fuel cell. The optimum state of charge of

the battery is always adapted to the current vehicle operation.

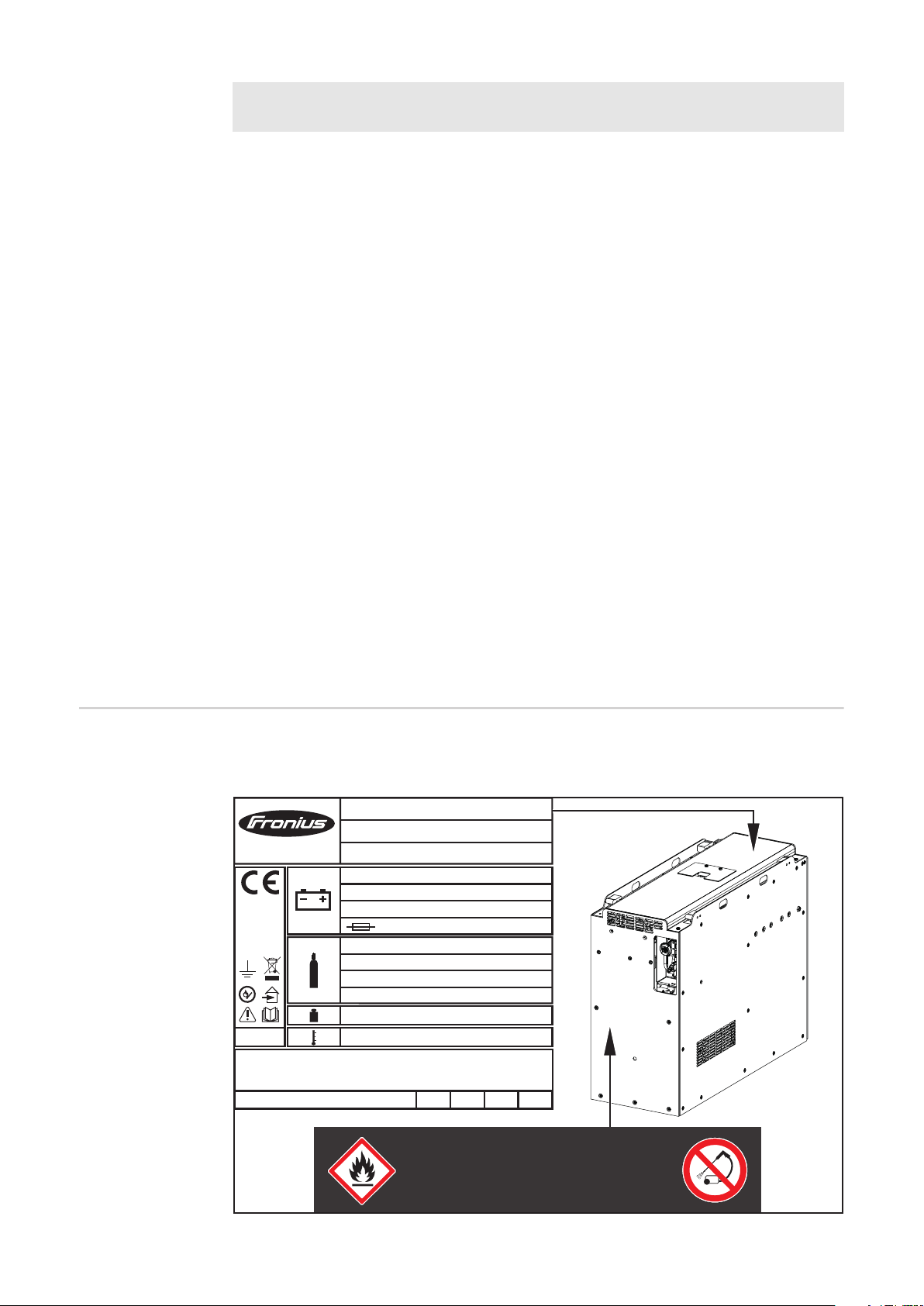

Warning notices

on the device

The device is fitted with a rating plate and safety symbols. The rating plate and safety symbols must not be removed or painted over.

Fronius HyLog Fleet 24015F

Type

Art.No.

www.fronius.com

0036

IP20

WARNING:

OPERATE IN VENTILATED AREAS ONLY - min. Room size 10m³

FOR INDOOR USE ONLY. Do not operate outdoors!

Pressure Vessel production year

Ser.No.

UDC

nom.

I

BATT max.

P

EL. nom.

Fuel type

Pressure nom./max.

Capacity

Receptacle

Weight

Ambient temperature

2015

4,005,101

00000000000

26 V

500 A

1800 W

250 A

Hydrogen SAE J2719

350/438 bar

27 l

SAE J2600 H35

240 kg

+2°C...+40°C (60°C)

2017

2016

2018

CONTAINS HYDROGEN GAS,

HIGHLY FLAMMABLE

DO NOT JET WASH!

16

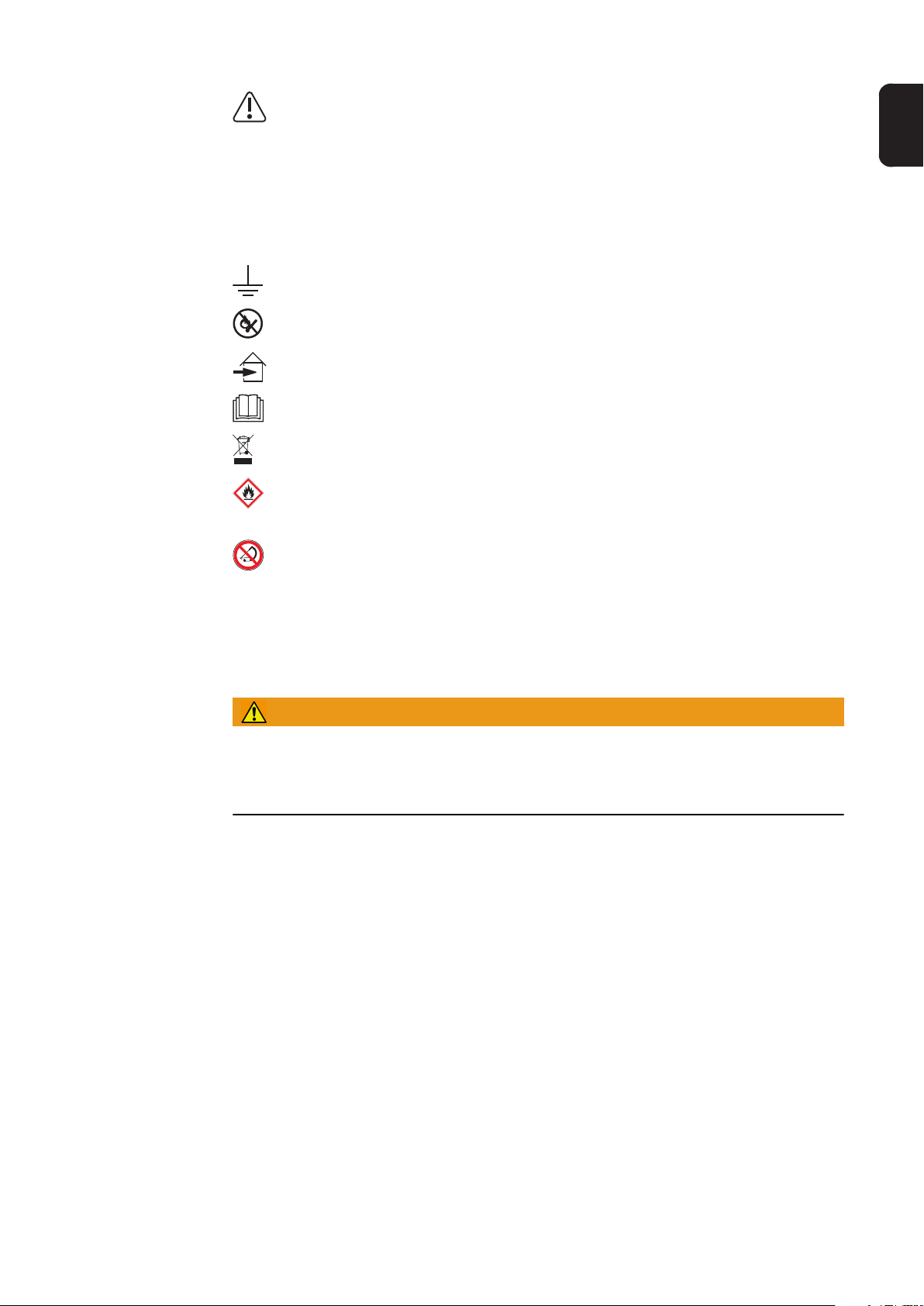

Page 17

Inadequate ventilation increases the risk of fire, explosion and suffocation. Always operate the device

- with protective grilles fitted on the housing openings for the cooling air supply and outlet

- with sufficient ventilation

- in rooms with a volume of more than 10 m³ (353.15 ft³), with an air circulation rate* of at least 0.6/h

- whilst avoiding oxygen depletion of the surrounding air by ensuring adequate room ventilation

Earthing symbol: A permanent potential equalization must be established between the HyLOG Fleet unit and the vehicle chassis.

Possible sources of ignition, such as fire, sparks and naked lights, must be kept

away from the HyLOG Fleet device.

Degree of protection IP20: For indoor use only. Do not expose to rain.

Do not use the functions until you have read all the Operating Instructions.

Do not dispose of used devices with domestic waste. Dispose of them according

to the safety rules.

Fire hazard! Ensure that the pressurised hydrogen container built into the device

is never exposed to high temperatures, mechanical impact, naked flames or

arcs.

There is a container of pressurised gas in the device, and it must therefore be

treated with care. Never use anything other than a damp cloth to clean the device. Ensure that the device is never exposed to damp conditions.

Pressure Vessel Production Year

EN

* Example: With a room volume of 10 m³ (353.15 ft³), an air circulation rate of 0.6/h

means that 6 m³ (211.89 ft³) of air are renewed per hour.

WARNING!

Danger of serious injury and damage.

The battery must never be short-circuited, penetrated, thrown into a fire, crushed, immersed in water, forcibly discharged or exposed to temperatures outside the permissible

range for the device. The battery must never be used if it is in a defective condition.

In the event that electrolyte and gases escape from the battery as a result of improper treatment, you should proceed as follows:

- If anyone breathes in the escaping gases they may experience breathing difficulties:

Immediately provide air from a fan or take the person outside for fresh air, and in more

serious cases summon medical assistance immediately

- If electrolyte comes into contact with skin, irritations may develop:

Wash the affected area of skin thoroughly with soap and water

- If electrolyte comes into contact with eyes, irritations of the eye may develop:

Immediately rinse the eyes thoroughly with water for 15 minutes and then call a doctor

17

Page 18

Control elements and connections

Safety

NOTE!

After firmware updates, you may notice that your device has certain functions that

are not described in these operating instructions.

Certain illustrations may also differ slightly from the actual controls on your device, but

these controls function in exactly the same way. If you have any further questions, please

contact the manufacturer.

WARNING!

Operating the equipment incorrectly can cause serious damage and injury.

Do not use the functions described here until you have thoroughly read and understood the

following documents:

► these operating instructions

► all the operating instructions for the system peripherals (gas supply, battery, etc.), es-

pecially the safety rules

WARNING!

Work carried out incorrectly and electric shocks can have fatal results.

► All covers of the device and the housing in general should only be opened or removed

by trained technicians

► Unauthorised opening or tampering with the device will invalidate the warranty and cre-

ate the risk of serious injury or damage.

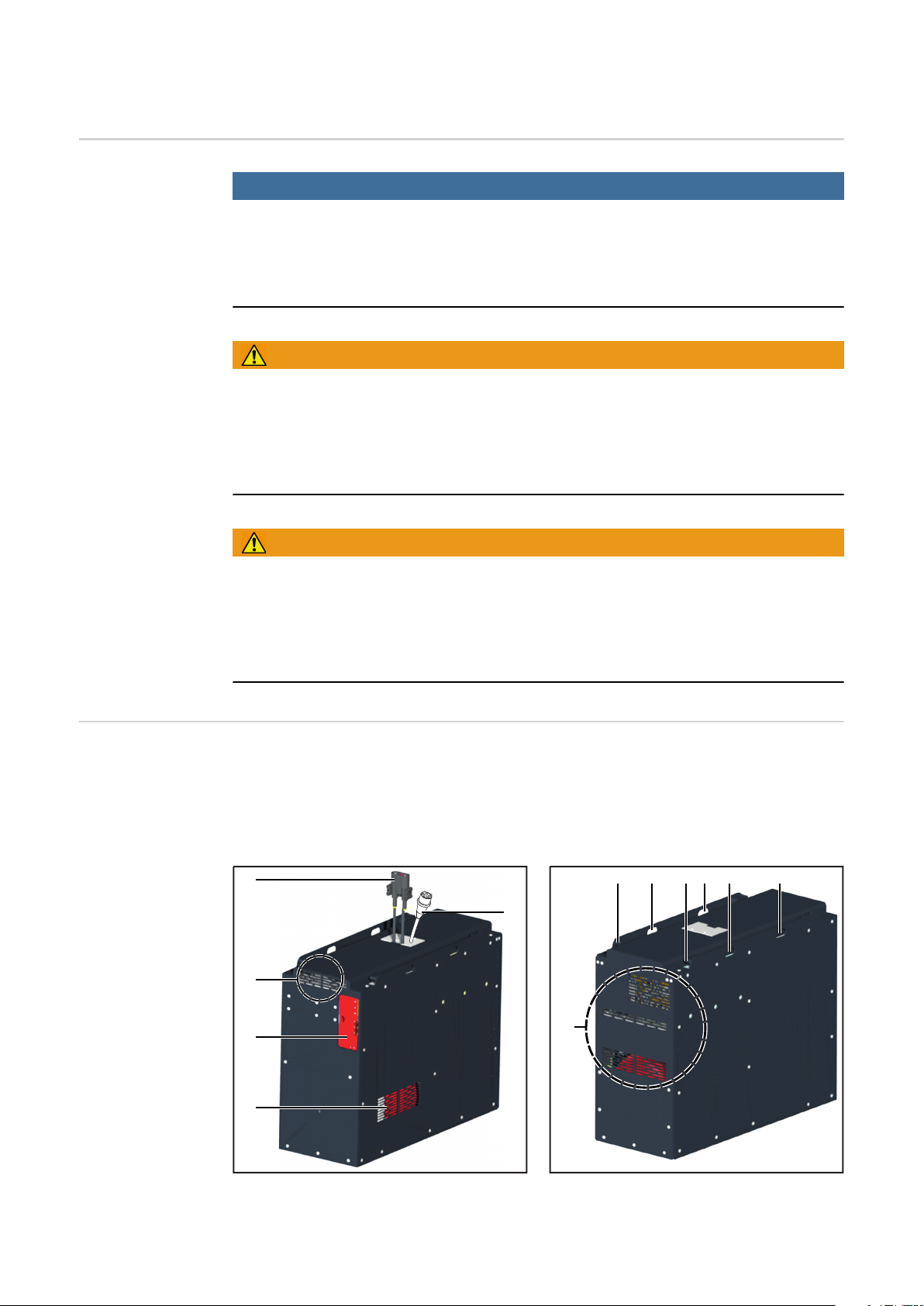

Controls and connections

The device is intended to be installed in vehicles with side-on battery replacement. The device is symmetrically designed in terms of the provided mechanical fixing elements and can

therefore be mounted on the vehicle turned through 180°. This allows you to choose

whether to have the filler connection on the left or right hand side of the vehicle. This issue

should be addressed by the vehicle manufacturer when installing the device in the vehicle.

(8)

(4)

(3)

(2)

(1)

(5)

(6)

(7) (7)(8) (8) (8)

18

Page 19

No. Function

(1) Process air intake

Housing openings for admission of combustion air of the fuel cell process. The volumetric flow is 100 m³/h (3531.5 ft³/h)

WARNING!

If operation of the device is impaired by blocked process air intake openings, there

is a risk of explosion.

Keep all air openings completely clear.

(2) Tank cover, includes:

Tank connection 350 bar (5074.55 psi)

Connection for refilling the compressed hydrogen gas 5.0 (3.0 possible on request), via connection in accordance with ISO 17268 / SAE J2600, connection:

DMB HFR 350 bar (5074.55 psi)

Detailed information can be found in the supplementary document "Refuelling regulations".

Connection socket for condensate drainage

For draining the collection container for reaction water that occurs as condensate.

Detailed information can be found in the supplementary document "Refuelling regulations".

NOTE!

EN

If operation of the device is impaired by a blocked condensate drainage connection,

there is a risk of water leakage.

Keep the condensate drainage connection completely clear.

(3) Cooling air outlet and process exhaust air

Cooling air and exhaust air from the fuel cell process containing steam as a combustion product. The volumetric flow is up to 600 m³/h (21,188.8 ft³/h) at a maximum of 65 °C (149 °F).

WARNING!

If operation of the device is impaired by blocked process air exhaust openings, there

is a risk of explosion.

Keep all air openings completely clear.

(4) Power interface

Connection for the electricity produced. Constant power is up to 1.8 kW at 25.6 V

DC, connection socket: REMA 75012-56

and equipotential bonding

Connection to static equipotential bonding

(5) Connection for the control panel

Connection for the external control panel, which can be mounted on the vehicle

(6) Cooling air intake

Housing openings for admission of cooling air. The volumetric flow is up to 500 m³/

h (17,657.3 ft³/h) at an ambient temperature of up to 40 °C (104 °F)

WARNING!

If operation of the device is impaired by blocked cooling air intake openings, there

is a risk of explosion.

Keep all air openings completely clear.

19

Page 20

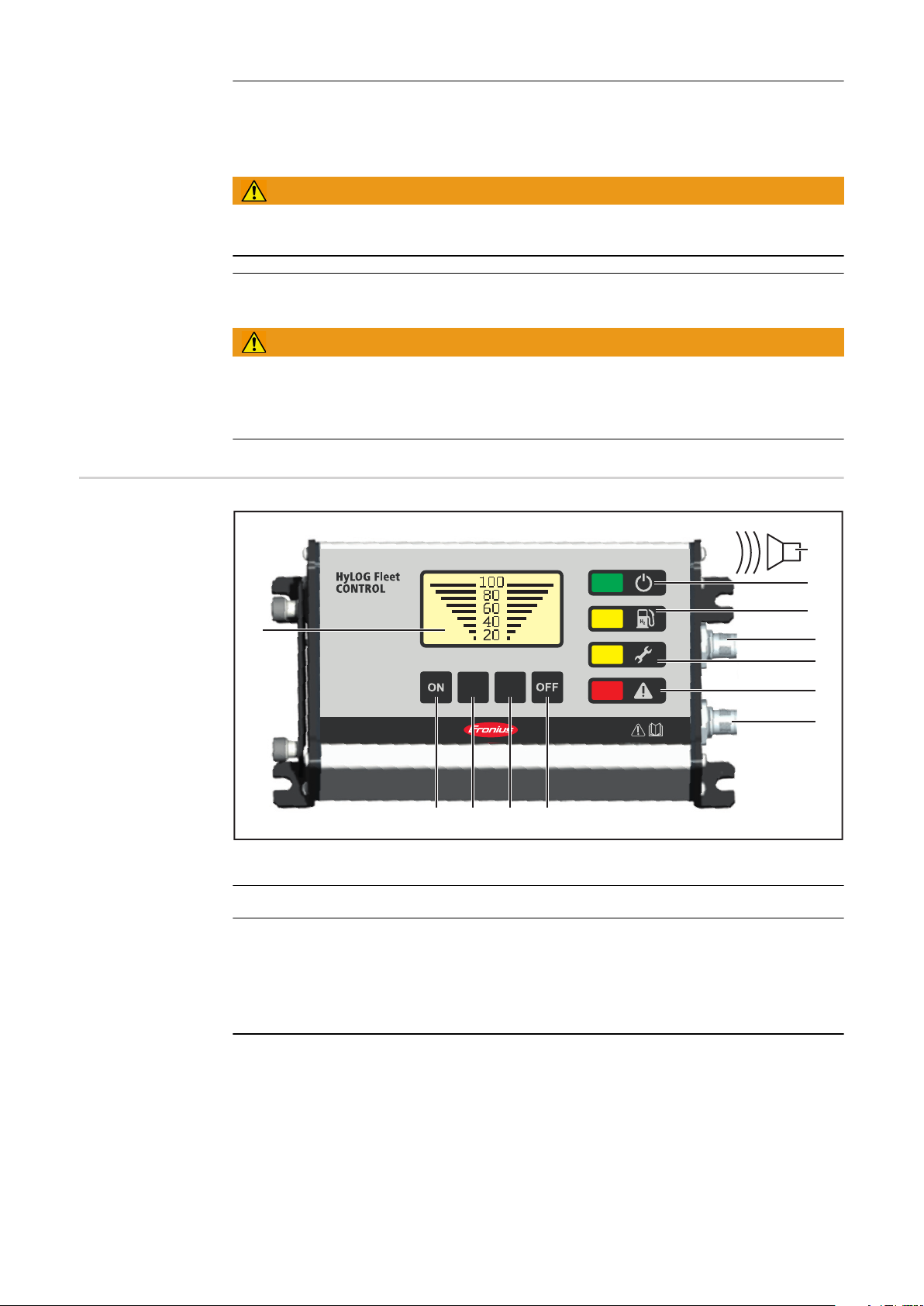

Control panel

(7) Locking of the device on the vehicle

Pins for securing the device in the vehicle

If the device is not successfully locked in place, the vehicle will operate in creep

mode (slow travel speed).

WARNING!

Devices that fall over can cause serious injury and damage.

Always ensure that the pins are properly locked.

(8) Crane holder

For transporting the device with suitable load-carrying equipment

WARNING!

Falling devices can cause serious injury and damage.

When transporting with a crane, only use chains or ropes of the same length.

Mount chains or ropes at all the fixing points of the crane holder.

Route the chains or ropes so that the angle to the vertical is as small as possible.

(1)

No. Function

(1) Display

The "H2 Tank Level" indicator shows how much hydrogen is left, from 0 to 100% of

the available tank capacity.

Call up of information on operating hours and maintenance

Display of specific text messages on indicators (6), (8), (9) and (10)

(12)

(11)

(10)

(9)

(8)

(7)

(6)

(2) (3) (4) (5)

20

(2) "ON" button

Pressing the "ON" button starts energy delivery. The energy is available immediately. Initially it is provided only by the back-up battery, which at the same time supplies the energy needed to start the fuel cell. The "Power ON" indicator (10) lights

up green.

Page 21

(3) "INFO" button 1

The current function of the button is shown on the display.

The "INFO 1" button provides information on the number of hours for which the de-

vice has already been operated, and how many more operating hours can be expected until the next scheduled maintenance.

The display returns to the "H2 Tank Level" indicator either when the "INFO" 2 button is pressed, or automatically after a certain time.

(4) "INFO" 2 button

The current function of the button is shown on the display.

The "INFO" 2 button acknowledges the relevant indicator on the display and caus-

es a return to the "H2 Tank Level" indicator.

When the "H2 Tank Level" indicator is active, the "INFO" 2 button makes it possible

to call up a list of the most-recently saved service messages. The "INFO" 1 button

is used to scroll through the list.

(5) "OFF" button

The "OFF" button initiates shut down of the fuel cell into the safe state. In the safe

state, all the hydrogen valves that can be activated by the fuel cell are closed.

As soon the fuel cell has been shut down, energy delivery stops.

(6) Connection of control panel

For connecting the control panel to the device

EN

(7) "Fault" indicator, red

In addition to the "Fault" indicator a text message can appear, showing the cause

of the fault. Basically any safety relevant fault leads to a shut down of the device

into the safe state. Try a restart as follows:

Press the "OFF" button - as soon as the device has been shut down, the "Power

ON" indicator goes off

After a waiting time of 10 s press the "ON" button

If the "Fault" indicator still lights up after this new start attempt, contact a Froniustrained service technician, for checking the device.

Another cause of the "Fault" indicator lighting up may be a low state of charge within the integrated back-up battery. If this cause of the fault can be unambiguously

identified based on the text message, recharge the back-up battery using a suitable

charger. More information can be found under "Fault diagnosis" in the "Troubleshooting" section.

(8) "Service" indicator, yellow

The "Service" indicator warns that maintenance is due to be carried out soon.

As soon as the "Service" indicator lights up, contact the manufacturer to arrange

for the necessary maintenance work to be carried out.

NOTE!

Delaying necessary maintenance work can result in performance degradation.

As soon as the "Service" indicator lights up, contact the manufacturer to arrange for the

necessary maintenance work to be carried out.

(9) Vehicle connection

For connecting the control panel to the vehicle. For more information on this, see

the "Commissioning" chapter, and the following sections:

Pin assignment for the vehicle connection

Specification for the vehicle connection

Application example for the vehicle connection

21

Page 22

(10) "Refuel" indicator, yellow

The "Refuel" indicator indicates that refuelling will shortly be required. The display

shows a specific message depending on urgency.

Tank contents less than 20%: indicator lights up yellow

Tank contents less than 10%: indicator flashes yellow

If the tank cover is opened by mistake, the indicator also lights up, with a warning

text. If the message is ignored, it will appear again after one minute.

(11) "Power ON" indicator, green

The "Power ON" indicator signals that the device is ready for use. Thanks to the

integrated back-up battery, energy can be called up at any time - the vehicle can

be started up.

As soon as the fuel cell has powered up, it takes over and meets the energy demand according to the operating strategy by interacting accordingly with the backup battery. The hydrogen in the tank together with the ambient air sucked into the

unit is converted into electricity and water as a combustion product. The back-up

battery primarily caters for low loads and peak demand.

The fuel cell operates in its optimal efficiency range and recharges the back-up battery with surplus power. Once the back-up battery is fully charged, the fuel cell can

be automatically and temporarily shut down.

(12) Acoustic signal - only at devices with Fronius Display

As soon as the device’s internal hydrogen sensor trips, an acoustic warning signal

sounds. At the same time, the "Fault" indicator (6) lights up red. This points to a

hydrogen leak in the system.

In addition to the "Fault" indicator a text message can appear, showing the cause

of the fault. Basically any safety relevant fault leads to a shut down of the device

into the safe state. Try a restart as follows:

Press the "OFF" button - as soon as the device has been shut down, the "Power

ON" indicator goes off

After a waiting time of 10 s press the "ON" button

If the "Fault" indicator still lights up after this new start attempt, contact a Froniustrained service technician, for checking the device.

22

Page 23

Before commissioning

EN

Safety

Proper use/intended purpose

WARNING!

Operating the equipment incorrectly can cause serious injury and damage.

Do not use the functions described here until you have thoroughly read and understood the

following documents:

► these operating instructions

► all operating instructions of the vehicle, the refuelling system and other system compo-

nents, particularly the safety rules

Responsibility for operation of the device rests with the user. Overall vehicle safety (HyLOG Fleet, vehicle and its operation in a working area) is the responsibility of the vehicle

system supplier. The vehicle system supplier must ensure that all safety issues relating to

the integration of the device into the vehicle have been clarified with the device manufacturer.

The device is intended exclusively for the generation of electrical energy from hydrogen

with oxygen from the air and may only be used in a suitable transport vehicle for in-house

logistics, and for production of the electrical energy for driving such vehicles.

In-house transport vehicles are deemed to be suitable if the following conditions are met:

- Analysis of overall system safety and supply of general system user documentation

(energy cell and vehicle) adapted for use of the vehicle with HyLOG Fleet.

- Information provided to the driver and surrounding area concerning safety-relevant

operating states of HyLOG Fleet (warning of hydrogen leak, etc.)

- Weight compensation, if required due to the fact that HyLOG Fleet is lighter than a battery (driving stability, traction, etc.)

Any use above and beyond this purpose is deemed improper. The manufacturer shall not

be held liable for any damage arising from such usage.

Proper use also includes:

- ensuring that the device is undamaged and in perfect condition

- verifiable training of users before using for the first time

- carefully reading and obeying all the instructions in these Operating Instructions, especially the safety rules and all safety and danger notices

- installing the device in accordance with the vehicle manufacturer's Operating Instructions

- carrying out all the specified inspection and maintenance work

- observing all instructions of the vehicle manufacturer and the refuelling system manufacturer

- obeying other relevant national safety rules

WARNING!

Improper operation, maintenance or transportation can result in serious injuries and

damage.

There is a container of pressurised hydrogen in the device, and it must therefore be treated

with care. The regulations on proper use must be observed.

23

Page 24

WARNING!

If operation of the device is impaired due to the device coming into contact with water, there is a risk of suffocation and explosion.

The device may not be used if any part has been submerged in or flooded with water. Notify

the manufacturer or its representative immediately so that the device can be checked and

any affected parts replaced.

Remove the device before washing the vehicle. Never clean the device itself with water,

liquid detergents or steam cleaners.

WARNING!

If operation of the device is impaired due to use in frosty or humid conditions, there

is a risk of suffocation and explosion.

Do not use the device in frosty or humid conditions. Operating the device in frosty or humid

conditions can result in damage. Only use the device in rooms that are free from frost and

condensing air. Detailed information can be found in the "Technical data" chapter.

Information on cleaning the device can be found in the "Care, maintenance and disposal"

chapter.

Before using for

the first time

If operation of the device is impaired by blocked material flows, there is a risk of suffocation and explosion.

Keep all air openings and the condensate drainage connector completely clear.

1

2

3

Connections The device is designed for the output voltages indicated on the rating plate. The hydrogen

refuelling system must be suitable for this connector. The necessary design of the hydrogen refuelling connector is described in the "System Configuration" section of the "General" chapter. If connectors, lines or valves are not attached to your version of the appliance,

fit these components so that they conform to the relevant national standards. The setup

examples are merely recommendations and do not necessarily comply with national standards.

WARNING!

Check that there are no obstructions to the following flows:

- Cooling air supply

- Process air supply

- Process air extraction

- Hydrogen supply

- Condensate drainage

Ensure that the user has received verifiable training from an authorised person

If necessary, charge the battery using a suitable charger.

More information can be found under "Fault diagnosis" in the "Troubleshooting" section.

24

Page 25

During transport the manual tank valve (1)

must be closed. Before using the device,

the manual tank valve (1) has to be opened.

This can be done without openening the

housing from the outside. Using a 3/16 inch

Allen key, open the tank valve by turning it

counterclockwise.

(1)

CAUTION!

Inadequately dimensioned installations and consumers can cause serious damage.

Consumers connected to the device must conform to the output voltages of the device. The

technical data shown on the rating plate applies.

EN

WARNING!

Leaks and escaping hydrogen during the refuelling process in combination with an

ignition source carry the risk of fire, suffocation and explosion.

The refuelling system must be configured according to the applicable standards and the

"Technical data" chapter. Refuelling must only be carried out by properly trained personnel. The technical data shown on the rating plate applies.

25

Page 26

Start-up

Safety

WARNING!

Faulty installation can cause serious damage and injury.

Installation may only be carried out by suitable trained experts in an in-house transport vehicle suitable for that purpose, in accordance with the "Proper use" section of the "Before

commissioning" chapter.

When installing the device, make sure that all material flows are unobstructed, in accordance with the "Before using for the first time" section of the "Before commissioning" chapter. Only operate the charger in accordance with the degree of protection shown on the

rating plate. Observe the "Operating conditions" of the "Operation" chapter.

WARNING!

Work carried out incorrectly can cause overheating and fire.

► Covers and the housing in general should only be opened or removed by the manufac-

turer's trained technicians

► Unauthorised opening or tampering with the device will invalidate the warranty and cre-

ate the risk of serious injury or damage

► Do not carry out any modifications, alterations, etc. to the device without the manufac-

turer's consent.

Advance information

WARNING!

Work carried out incorrectly can cause overheating and fire.

If the device is electrically connected to the integrated back-up battery during installation,

there is a risk of serious injury and damage. Do not carry out any work on the connectors,

unless the device

► is electrically isolated from the integrated back-up battery

► is turned off and in the safe state. For detailed information about the "Safe state", refer

to the "Control panel" section of the "Control elements and connections" chapter

Overall vehicle safety (HyLOG Fleet, vehicle and its operation in a working area) is the responsibility of the vehicle system supplier. The vehicle system supplier must ensure that

all safety issues relating to the integration of the device into the vehicle have been clarified

with the device manufacturer.

Integration of the device into the vehicle is vehicle-specific and requires in-depth knowledge of all safety issues and operation-relevant factors associated with the type of vehicle

in question. The following instructions do not therefore address the integration of the device into the vehicle, but only with the connection and actual start-up of the device.

Connecting the

power interface to

the vehicle

26

WARNING!

Operation with excessive power consumption can result in serious injuries and

damage.

The power consumption of the vehicle must not exceed the power delivery of the device.

Page 27

NOTE!

Pin assignment

for the vehicle

connection

Careless handling of plug connections can cause damage.

When connecting the plug connection for the vehicle's power supply, do not kink, catch or

strain the cables. Renew faulty cables and plug connections.

Connect the power interface (1) on top

1

of the housing with a suitable plug for

(1)

3

2

the vehicle's power supply.

M12 plug connection IEC 61076-2-101

12-pin with coding A

EN

Specification for

the vehicle connection

4

11

10

1

5

9

12

6

7

Relay outputs

K1 max. 30 V, 1 A

K2 max. 30 V, 1 A

Battery_EN

Switching voltage max. 60 V

Switching current max. 1 mA

8

Input

Supply voltage at input max. 60 V

Supply current min. 2 mA

27

Page 28

Potential Equalization

Application example for the vehicle connection

A permanent potential equalization must be established between the HyLOG Fleet system

and the vehicle chassis. The total resistance between the HyLOG Fleet system and the hall

floor should not exceed 25 MOhm. There are 2 possibilities for connecting the device to

the vehicle chassis.

1. Use the grounding contact at the power interface (AUX-contact)

2. Assembly of the control panel (display) on the metal chassis, using a screw connection, which ensures a permanent electrical connection of the display housing to the vehicle chassis.

K1

K2

1

2

3

4

5

6

7

8

9

10

11

12

not connected

CAN-GND

CANH

CANL

Akku_EN+

Akku_ENInput+

Input-

OUT1+

OUT1OUT2+

OUT2-

S1

U1

S2

28

Page 29

Refuelling

EN

Safety

General

WARNING!

Leaks in the hydrogen supply in combination with an ignition source pose a risk of

fire, explosion or suffocation.

The hydrogen refuelling system must therefore be approved by the manufacturer, set up

in compliance with the applicable standards and guidelines and operated in accordance

with the manufacturer's instructions. Refuelling must only be carried out by suitably trained

personnel. The technical data shown on the rating plate applies. The additional instructions

in the following sections of this chapter must be observed.

WARNING!

Overfilling the hydrogen tank poses a risk of explosion and can result in serious injuries and damage.

The refuelling process must be carried out according to the SAE J2601-3 parameters and

the refuelling guideline of the HyLOG Fleet unit. Do not exceed the indicated fuelling rate,

as well as the nominal pressure of 350 bar (5074.55 psi.) at 15 °C (59 °F) and the maximum

filling pressure of 438 bar (6350.43 psi.) at 85 °C (1232.39 °F).

WARNING!

Failure to adhere to the specified fuelling parameters could result in serious injury

or damage.

The specified fuelling parameters must be observed at all times.

- The HyLOG Fleet system may only be refuelled in accordance with the refuelling

guidelines.

- The fuelling system and the fuelling process must be compliant with SAE J26013:JUN2013.

- The nominal pressure of the HyLOG Fleet system is 350 bar (5074.55 psi) at 15 °C

(59 °F). The maximum filling pressure is 438 bar (6350.43 psi) at 85 °C (185 °F).

- The hydrogen temperature stated in the tables below (Hydrogen Temperature, T

refers to the temperature of the hydrogen output by the fuelling system.

- The specified pressure ramp rates must be observed without exception!

- The pressure ramp rates are based on a maximum hydrogen temperature of 85 °C

(185 °F) inside the HyLOG Fleet system.

General refuelling - The HyLOG Fleet system must be refuelled at no more than the specified pressure

ramp rates (Average Pressure Ramp Rate, APRR) in accordance with the hydrogen

temperature of the refuelling system.

- The target pressure (Fuelling Target Pressure) must be observed at all times.

gas

)

Example: A gas temperature ≤ 25 °C (77 °F) and an initial pressure of 2.5 MPa (25 bar)

(362.47 psi) translates into a permissible pressure ramp rate of 14.0 MPa/min (140 bar/

min) (2029.82 psi/min). The maximum filling pressure is 42.5 MPa (425 bar) (6161.95 psi).

29

Page 30

General

24015F Initial Tank Pressure, P0, MPa (psi.)

General refuelling table for HyLOG Fleet 24015F

Average

Pressure

Ramp

Rate,

APRR,

MPa/min

(psi./min)

>65

(149)

65

(149)

60

(140)

55

(131)

50

(122)

45

(113)

40

(104)4(580)

35

(95)

30

(86)

25

(77)14(2030)

20

(68)

10

(50)

0

(32)

Hydrogen Temperature, Tgas, °C (°F)

-10

(14)

-20

(-4)

-30

(-22)

-40

(-40)

>-40

(-40)

no

fuelling

no

fuelling

0,5

(72)1(145)2(290)

no

fuellingnofuellingnofuellingnofuellingnofuellingnofuellingnofuellingnofuellingnofuellingnofuellingnofuelling

no

fuelling

no

fuelling

no

fuellingnofuellingnofuellingnofuellingnofuellingnofuellingnofuellingnofuellingnofuellingnofuellingnofuelling

42,9

(6220)

42

(6089)

Fuelling Target Pressure, Ptarget, MPa (psi.)

2,5

(362)5(725)10(1450)15(2175)20(2900)30(4350)35(5075)

42,9

(6220)

42,5

(6162)

43

(6234)

43

(6234)

>35

(5075)

no

fuelling

no

fuelling

no

fuelling

no

fuelling

no

fuelling

no

fuelling

no

fuelling

no

fuelling

no

fuellingnofuelling

no

fuellingnofuelling

no

fuellingnofuelling

no

fuellingnofuelling

no

fuellingnofuelling

no

fuellingnofuellingnofuelling

no

fuellingnofuellingnofuelling

no

fuellingnofuellingnofuelling

Time-optimised

refuelling

General

Average

24015F

Hydrogen Temperature,

Tgas, °C (°F)

Refuelling time and flow rate for HyLOG Fleet 24015F

40 (104)

25 (77)

Pressure Ramp

Rate, APRR,

MPa/min (psi./min)

4 (580)

14 (2030)

Estimated Refuelling Time, s

Average Flow rate, g/s (lb./s)

Initial Tank Pressure, P0, MPa (psi.)

1 (145)

629 s

1,0 g/s (.00220 lb/s)

176 s

3,6 g/s (.00794 lb/s)

- To optimise the refuelling time, the pressure ramp rate is variable in relation to the initial tank pressure.

- The HyLOG Fleet system must be refuelled at no more than the specified pressure

ramp rates (Average Pressure Ramp Rate, APRR) in accordance with the hydrogen

temperature of the refuelling system and the initial tank pressure.

- The target pressure (Fuelling Target Pressure) as stated in the general refuelling table

must be observed at all times.

Example: A gas temperature ≤ 25 °C (77 °F) and an initial pressure of 2.5 MPa (25 bar)

(362.47 psi) translates into a permissible pressure ramp rate of 20 MPa/min (200 bar/min)

(2899.74 psi/min) for time-optimised refuelling. The maximum filling pressure is 42.5 MPa

(425 bar) (6161.95 psi).

30

Page 31

Optimized Average Pressure Ramp Rate, APRR, MPa/min. (psi./min.)

24015F Initial Tank Pressure, P0, MPa (psi.)

0,5

(72)

>65

(149)

65

(149)

60

(140)

55

(131)

50

(122)

45

(113)

40

(104)

35

(95)

30

(86)

25

(77)

20

(68)

10

(50)

0

(32)

Hydrogen Temperature, Tgas, °C (°F)

-10

(14)

-20

(-4)

-30

(-22)

-40

(-40)

>-40

(-40)

Optimised refuelling for HyLOG Fleet 24015F with variable pressure ramp rate

no

fuellingnofuellingnofuellingnofuellingnofuellingnofuellingnofuellingnofuellingnofuellingnofuellingnofuelling

no

fuellingnofuellingnofuellingnofuellingnofuellingnofuellingnofuellingnofuellingnofuellingnofuellingnofuelling

1

(145)2(290)

4

(580)

14

(2030)

2,5

(362)5(725)10(1450)15(2175)20(2900)30(4350)35(5075)

5

(725)

20

(2900)

16

(2320)

600

(8699)

>35

(5075)

no

fuelling

no

fuelling

no

fuelling

no

fuelling

no

fuelling

no

fuelling

no

fuelling

no

fuelling

no

fuellingnofuelling

no

fuellingnofuelling

no

fuellingnofuelling

no

fuellingnofuelling

no

fuellingnofuelling

no

fuellingnofuellingnofuelling

no

fuellingnofuellingnofuelling

no

fuellingnofuellingnofuelling

EN

24015F

1 (145) 2,5 (362) 15 (2175)

Average

Pressure

Ramp Rate,

APRR,

MPa/min

40 (104)

Hydrogen

Temperature,

Tgas, °C (°F)

25 (77)

Refuelling time and flow rates for HyLOG Fleet 24015F

(psi./min)

Average

Flow Rate,

(g/s)

Estimated

Refuelling

Time (s)

Average

Pressure

Ramp Rate,

APRR,

MPa/min

(psi./min)

Average

Flow Rate,

(g/s)

Estimated

Refuelling

Time (s)

4 (580)

1 (.00220) 1,2 (.00265) 3,4 (.00750)

629 485 105

14 (2030) 20 (2900) 60 (8699)

3,6 (.00794) 5 (.01102) 12,1 (.02668)

176 120 28

Estimated Refuelling Time, s

Average Flow rate, g/s (lb./s)

Initial Tank Pressure, P0, MPa (psi.)

5 (725) 16 (2320)

31

Page 32

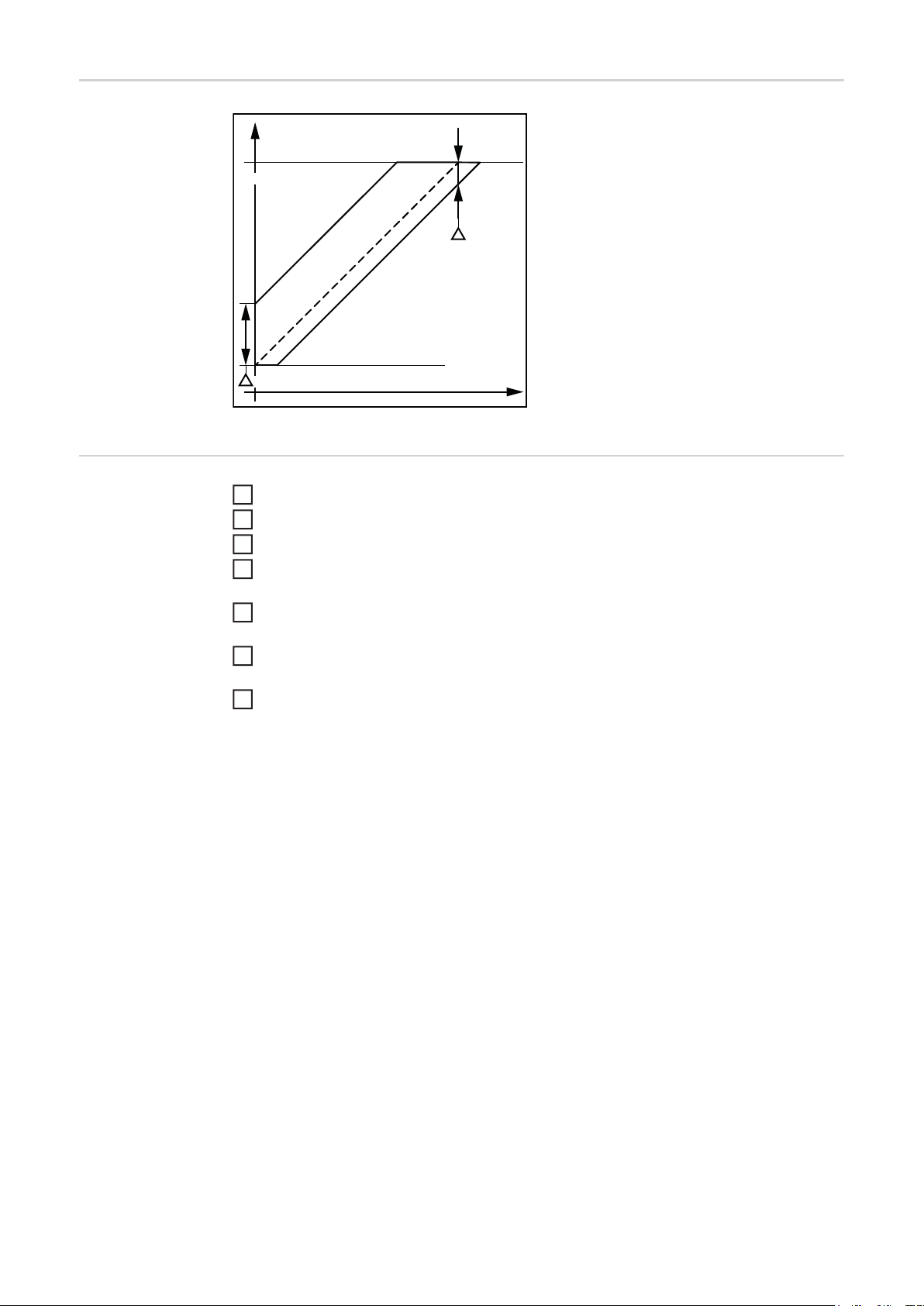

Pressure tolerances

p

p

target

p=25 bar

(362.47 psi)

Upper Pressure Tolerance

Stationary Pressure

Lower Pressure Tolerance

p

p=70 bar (1041.91 psi)

Pressure tolerance range for HyLOG Fleet 24015F

0

During refuelling, the pressure tolerance

range as specified in the following standard

must be observed: SAE J2601:DEC2016

8.3.2.

t

Refuelling process

Press the "OFF" button to shut down the fuel cell and place it in the safe state

1

Open fuel filler flap

2

Connect the condensate drain

3

Connect the filler coupling of the hydrogen refuelling system to the filler connection in

4

accordance with the refuelling system manufacturer's instructions

Carry out the refuelling process in accordance with the instructions of the manufactur-

5

er of the hydrogen refuelling system

Once the hydrogen tank has reached a pressure of 350 bar (5074.55 psi.), the hydro-

6

gen refuelling system automatically stops the refuelling process

Close fuel filler flap

7

32

Page 33

Operation

EN

Safety

WARNING!

Operating the equipment incorrectly can cause serious injury and damage.

Do not use the functions described here until you have thoroughly read and understood the

following documents:

► these operating instructions

► all operating instructions of the vehicle, the refuelling system and other system compo-

nents, particularly the safety rules

WARNING!

Using the device in spaces with inadequate ventilation poses a risk of explosion and

suffocation with no visible or otherwise detectable warning.

This is mainly because of the oxygen consumption of the device. However, it is also possible that a combustible gas mixture will gradually accumulate in the surrounding air.

Therefore, the device must only be operated in rooms with a volume of not less than 10 m³

(353.15 ft ³) and with an air circulation rate of not less than 0.6/h. Example: With a room

volume of 10 m³ (353.15 ft³), an air circulation rate of 0.6/h means that 6 m³ (211.89 ft³) of

air are renewed per hour. Other spatial conditions require an exact calculation of the air

circulation rate in consultation with the device manufacturer.

WARNING!

Operating conditions

Operating and storing the device under environmental conditions different from

those specified here can cause serious injury and damage.

The surrounding air must be clean and free from

► smoke

► open flames and fire

► petrol and other inflammable materials, such as liquids, vapours and dust

► corrosive gases or substances

Can be used at altitudes of up to 1600 m (5249 ft)

Detailed information on the permitted environmental conditions can be found in the "Technical data" chapter.

This device is designed to be operated within a temperature range of between +2 °C

(+36 °F) and +60 °C (+140 °F).

If the device is started at an ambient temperature of between +2 °C (+36 °F) and +20 °C

(+68 °F), the nominal output will not be available until the required process temperature is

reached.

At an ambient temperature range between +40 °C (+104 °F) and +60 °C (+140 °F), or with

inadequate heat dissipation, derating occurs in order to prevent an overload. Premature

degradation of the device can also occur following operation at very high temperatures.

A maximum relative humidity of 85% (non-condensing) is permissible.

33

Page 34

Starting energy

delivery

WARNING!

Operating the device outside the permitted temperature range can result in serious

injuries and damage.

The permitted ambient temperature range is from +2 °C to +60 °C (+36 °F to +140 °F).

Energy is available as soon as you switch on the device. Initially it is provided only by the

back-up battery, which at the same time supplies the energy needed to start the fuel cell.

Start energy delivery as follows:

Press the "ON" button

1

OFF

ON

The "Power ON" indicator lights up - the energy for operat-

2

ing the vehicle is available immediately.

The fuel cell meets the energy demand according to the operating strategy by interacting

accordingly with the back-up battery. The hydrogen in the tank together with the ambient

air sucked into the unit is converted into electricity and water as a combustion product. The

back-up battery primarily caters for low loads and peak demand.

Stopping energy

delivery

The fuel cell operates in its optimal efficiency range and recharges the back-up battery.

Once the back-up battery is fully charged, the fuel cell can be automatically and temporarily

shut down.

The operating strategy for interaction of the back-up battery and fuel cell can be adapted

to the operating cycle. Contact the manufacturer for further details.

To turn off the fuel cell and stop energy delivery:

Press the "OFF" button - the fuel cell is shut down.

1

OFF

Once the fuel cell has been switched off, it is in the "safe state". This means that all valves

for the hydrogen supply that can be activated by the fuel cell are closed. In the event that

the device is not used for a prolonged period, an automatic safeguard ensures that it does

not consume any energy.

– The display shows that the shut-down process has

been initiated.

The "Power ON" indicator goes off - the energy for operat-

2

ing the vehicle is immediately turned off.

34

Page 35

Troubleshooting

EN

Safety

WARNING!

Work carried out incorrectly can cause overheating and fire.

► All covers of the device and the housing in general should only be opened or removed

by trained technicians

► Unauthorised opening or tampering with the device will invalidate the warranty and cre-

ate the risk of serious injury or damage.

If the covers of the device or the housing are opened by trained personnel, the following

warnings apply:

WARNING!

An electric shock can be fatal.

Do not touch any components in the housing interior before the integrated back-up battery

has been electrically isolated from the device and electrically charged parts (e.g. capacitors) have been discharged. Before opening the device:

► Stop energy delivery by pressing the "OFF" button

► Wait until the "Power ON" indicator has gone off

WARNING!

An electric shock can be fatal.

Do not touch any components in the housing interior before the integrated back-up battery

has been electrically isolated from the device and electrically charged parts (e.g. capacitors) have been discharged. After opening the device

► Electrically isolate the integrated back-up battery from the device

► Put up an easy-to-understand warning sign to stop anybody inadvertently switching it

back on again

► Using a suitable measuring instrument, ensure that electrically charged parts (e.g. ca-

pacitors) have been electrically discharged

Fault diagnosis Contact:

Fronius International GmbH

4600 Wels-Thalheim, Günter-Fronius-Straße 1, Austria

E-mail: energynet.se@fronius.com

http://www.fronius.com

The unit does not function

Cause: The device's integrated battery is flat

Remedy: Recharge the battery using a suitable battery charging system

(maximum current 35 A)

(e.g. Fronius Acctiva Professional 35A, item number 4,010,335,874)

35

Page 36

Displayed service

codes

The basic service messages are shown on the control panel by the specific indicators lighting up, and more specific information is provided in corresponding text messages. Notify

the service technician of the exact combination of indicator and text message.

NOTE!

Ignoring service messages can lead to power reduction.

Arrange for the device to be repaired immediately by a Fronius-trained service technician.

If an error message without a cause that can be rectified immediately appears on the indicators and it cannot be concluded that the cause of the fault is a defect in the safety system, an attempt should first be made to rectify the problem through the following approach:

Stop energy delivery by pressing the "OFF" button

1

Wait until the "Power ON" indicator has gone off

2

Start energy delivery by pressing the "ON" button

3

Wait until the "Power ON" indicator lights up

4

If the fault reoccurs in spite of the restart, it is obviously a defect in the safety system, or

the rectification measures listed here do not result in success:

Note the combination of indicator and text message

1

Note the configuration of the device

2

Contact the device manufacturer with a detailed description of the fault

3

36

Page 37

"Service" indicator lights up

Cause: Important maintenance is due soon.

Remedy: Contact the manufacturer immediately to arrange the necessary maintenance

NOTE!

Delaying necessary maintenance work can lead to power reduction.

As soon as the "Service" indicator lights up, contact the manufacturer to arrange for the

necessary maintenance work to be carried out.