Frigidaire FRT18SJGW0 Service Data Sheet

17

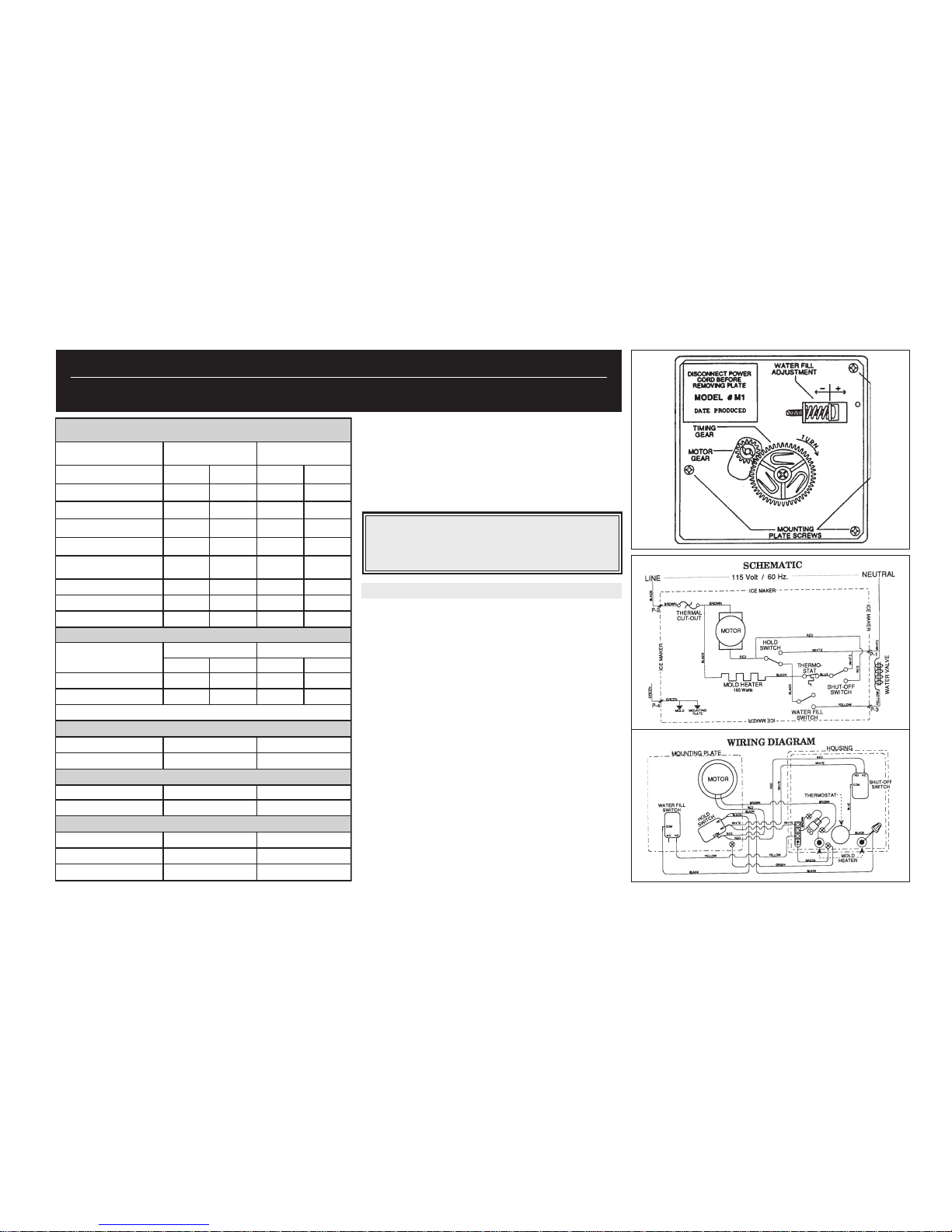

SERVICE DATA SHEET 218758400

STANDARD - AUTOMATIC DEFROST

TOP FREEZER MODELS

ATADECNAMROFREP

GNITTESLORTNOCTNIOP-DIMTASGNINEPOROODONDNADAOLON

htiWAepyT

roticapaCnuR

htiWBepyT

roticapaCoN

tneibmAF°56

BepyTAepyT

tneibmAF°09

BepyTAepyT

emiTgnitarepO%54ot03%54ot53%56ot45%76ot55

erutarepmeTrezeerFF°8ot°0F°6ot°0F°6ot°0F°6ot°0

erutarepmeTrotaregirfeRF°04ot°53F°04ot°53F°04ot°53F°04ot°53

)ni-tuc(erusserPediSwoLgisp31ot6gisp9ot6gisp31ot6gisp9ot6

))tuo-tuc(erusserPediSwoLgisp2+ot2-gisp2+ot2-gisp3+ot2-gisp2+ot2-

GISP-erusserPediShgiH

)elcycfo3/1tsaL(

511ot501511ot501581ot061581ot061

)elcycfo3/1tsaL(egattaW002ot051022-091002ot051022-091

)gninnuR(spmA8.1ot3.16.2ot2.28.1ot3.16.2ot2.2

egatloVesaBCAV511CAV511CAV511CAV511

SNOITACIFICEPSTSORFED

eziStenibaC

tatsomrehTretaeH

ni-tuCtuo-tuCsttaWsmhO

'71ot'31F°52+F°74+00433

'81F°52+F°74+57482

emiTnuRrosserpmoCfosruoH8yrevEsetuniM12tsorfeD

ROTOMNAFRESNEDNOC

sttaWMPRspmA

3.2tfahSetisoppOWC0031gninnuR51.

REPMADCITATSOMREHT

nepOlluFdesolC

F°2-/+F°33F°2-/+F°22

SNOITACIFICEPSREKAMECI

lacirtcelEstloV511ztreH06

tatsomrehTF°84tasnepOF°51tasesolC

egattaWretaeH561

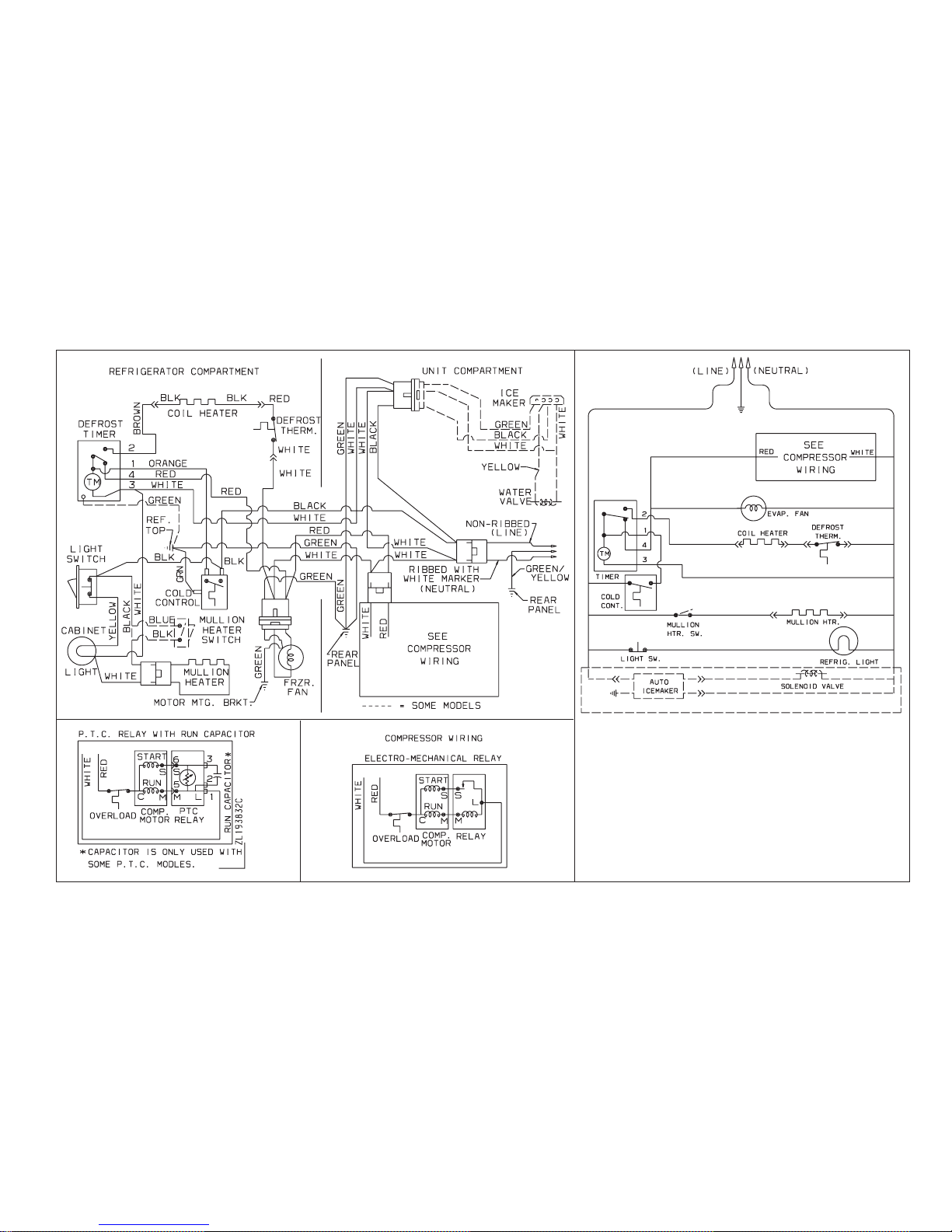

IMPORTANT SAFETY NOTICE

The information provided herein is designed to assist qualified repair

personnel only. Untrained persons should not attempt to make repairs

due to the possibility of electrical shock. Disconnect power cord before

servicing.

IMPORTANT

If any green grounding wires are moved during servicing, they must

be returned to their original position and properly secured.

CAUTION: System parts must be removed from cabinet before

brazing. All electrical parts and wiring must be shielded from torch

flame. Do not allow torch to contact insulation; it will char at 200°F

and flash ignite (burn) at 500°F. Excessive heat will distort the

plastic liner.

ICE MAKER INFORMATION

Test Cycling

Remove cover by inserting screwdriver in notch at bottom and prying

cover from housing. Use a screwdriver to rotate motor gear counterclockwise until holding switch circuit is completed. All components of

ice maker should function to complete the cycle.

Water Fill Volume

The water fill adjustment screw will change the fill time. One full turn is

equal to 20cc (.68 oz.). The correct fill is 90 to 120cc (3.0 to 4.0 oz.).

When a water valve is replaced, the fill volume must be checked.

18

Loading...

Loading...