INSTALLATION AND SERVICE MUST BE PERFORMED BY

A QUALIFIED INSTALLER.

IMPORTANT' SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE,

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

If the information in this manual is not followed exactly, a fire

or explosion may result causing property damage, personal injury or death.

FOR YOUR SAFETY:

= Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

= WHAT TO DO IF YOU SHELL GAS:

= Do not try to Eght any appliance.

= Do not touch any electrical switch; do not use any phone in your building.

= Immediately call your gas supplier from a neighbor's phone. Follow the gas

suppEer's instructions.

= If you cannot reach your gas suppEer, call the fire department.

= Installation and service must be performed by a qualified installer, service

agency or the gas supplier.

Dimensions and Clearance

Provide adequate clearance between range

and adjacent combustible surfaces.

_--36" (91.4 cm)----_

Appliances Installed

in the state of

Massachusetts:

This Appliance can only

be installed in the state

of Massachusetts by a

Massachusetts licensed

plumber or gasfitter.

This appliance must be

installed with a 3 foot (36 in.)

long flexible gas connector.

A "T" handle type manual

gas valve must be installed

in the gas supply line to this

appliance.

Minimum clearance on / _5" (12.7 cm)

either side of range_

above 36" (91.4 cm)--

height if a wall is

installed

Figure 1

NOTE: Wiring diagram for this appliance is enclosed in this booklet.

Printed in United States

Minimum A

(45.7cm) either side

Minimum to cabi-

18" nets on

of range

P/N 318201765 (1010) Rev. A

13" i

(33 cm)_"

Maximum depth

for cabinets

above range top

0" Min. Clearance

at rear of range

below cooktop

from the back wall.

English - pages 1-7

Espa_ol - p_ginas 8-15

Wiring Diagram - pages 16

1. Read all instructions contained in these installation

instructions before installing range.

2. Remove all packing material from the oven

compartments before connecting the gas and

electrical supply to the range.

3. Observe all governing codes and ordinances.

4. Be sure to leave these instructions with the consumer.

5. Note: For operation at 2000 ft. elevations above see

level, appliance rating shall be reduced by 4 percent

for each additional 1000 ft.

Keep these instructions with your Use & Care Guide for

future reference.

Important Note to the Consumer

Keep these instructions with your Use & Care Guide for

future reference.

IMPORTANT SAFETY

INSTRUCTIONS

Installation of this range must conform with local codes

or, in the absence of local codes, with the National Fuel

Gas Code ANSI Z223.1/NFPA .54-latest edition.

This range has been design certified by CSA

International. As with any appliance using gas and

generating heat, there are certain safety precautions

you should follow. You will find them in the Use and

Care Guide, read it carefully.

• Be sure your range is installed and grounded

properly by a qualified installer or service

tech nician.

• This range must be electrically grounded

in accordance with local codes or, in their

absence, with the National Electrical Code

ANSI/NFPA No. 70=latest edition. See

Grounding Instructions.

- The installation of appliances designed for

manufactures (mobile) home installation must

conform with Manufactured Home Construction and

t!

All ranges

can tip.

t!

Injury to

persons

could

result.

Install anti-

tip device

packed with

range.

To reduce the risk of

tipping of the range, the

range must be secured

by properly installed anti-

tip bracket (s) provided

with the range. To

check if the bracket(s) is

installed properly, grasp

the top rear edge of the

range and carefully tilt it

forward to make sure the

range is anchored.

Safety Standard, title 24CFR, part 3280 [Formerly

the Federal Standard for Mobile Home Construction

and Safety, title 24, HUD (part 280)] or when

such standard is not applicable, the Standard for

Manufactured Home Installation 1982 (Manufactured

Home Sites, Communities and Set ups), ANSI Z225.1

latest edition, or local codes.

• Before installing the range in an area covered with

linoleum or any other synthetic floor covering,

make sure the floor covering can withstand heat

at least 90°F above room temperature without

shrinking, warping or discoloring. Do not install the

range over carpeting unless you place an insulating pad

or sheet of 1/4"(10,16 cm) thick plywood between the

range and carpeting.

• Make sure the wall coverings around the range

can withstand the heat generated by the range.

• Do not obstruct the flow of combustion air at

the oven vent nor around the base or beneath

the lower front panel of the range. Avoid touching

the vent openings or nearby surfaces as they may

become hot while the oven is in operation. This range

requires fresh air for proper burner combustion.

Never leave children alone or

unattended in the area where an appliance is

in use. As children grow, teach them the proper, safe

use of all appliances. Never leave the oven door open

when the range is unattended.

Stepping, leaning or sitting on

the doors or drawers of this range can result in

serious injuries and can also cause damage to

the range.

• Do not store items of interest to children in

the cabinets above the range,Children could be

seriously burned climbing on the range to reach items.

• To eliminate the need to reach over the

surface burners, cabinet storage space above

the burners should be avoided.

• Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil.

Excessive flame is hazardous.

• Do not use the oven as a storage space. This

creates a potentially hazardous situation.

• Never use your range for warming or heating

the room. Prolonged use of the range without

adequate ventilation can be dangerous.

• Do not store or use gasoline or other

flammable vapors and liquids near this or any

other appliance. Explosions or fires could result.

Do not make any attempt to

operate the electric ignition oven during an

electrical power failure. Resumption of electric

power when OVEN TEMP and OVEN SET controls

are in any position other than OFF will result in

2

automaticignitionoftheovenorbroilerburner.The

oven burner and broil burner on your range

are lighted by electrical ignition. The oven and

broiler cannot be operated in the event of a

power failure.

- In the event of an electrical power outage, the

surface burners can be lit manually. To light a

surface burner, hold a lit match to the burner head

and slowly turn the Surface Control knob to LITE.

Use caution when lighting surface burners manually.

= Reset all controls to the "off" position

whenever the oven is done cooking.

FOR MODELS WITH SELF=CLEAN FEATURE:

= Remove broiler pan, food and other utensils

before self=cleaning the oven, Wipe up excess

spillage. Follow the precleaning instructions in the

Use and Care Guide.

• Unlike the standard gas range, THIS COOl(TOP

IS NOT REHOVABLE, Do not attempt to remove

the cooktop.

1. Before Installing the Range

Remove shipping material

Remove all tape, shipping and packaging materials and

the oven rack packaging.

2. Provide an adequate Gas Supply

When shipped from the factory, this unit is designed

to operate on 4"(10,16 cm) water column (1.0 kPa)

Natural gas manifold pressure. A convertible pressure

regulator is connected to the range manifold and

MUST be connected in series with the gas supply line.

If LP/Propane conversion kit has been used, follow

instructions provided with the kit for converting the

pressure regulator to LP/Propane use.

Care must be taken during installation of range not to

obstruct the flow of air for combustion and ventilation.

3. Seal the openings

Seal any openings in the wall behind the range and

in the floor under the range after gas supply line is

installed.

4. Connect the range to the gas

supply

Important: Remove

all packing material and

literature from range before

connecting gas and electrical

supply.

To prevent leaks, put pipe

joint sealant on all external

pipe threads.

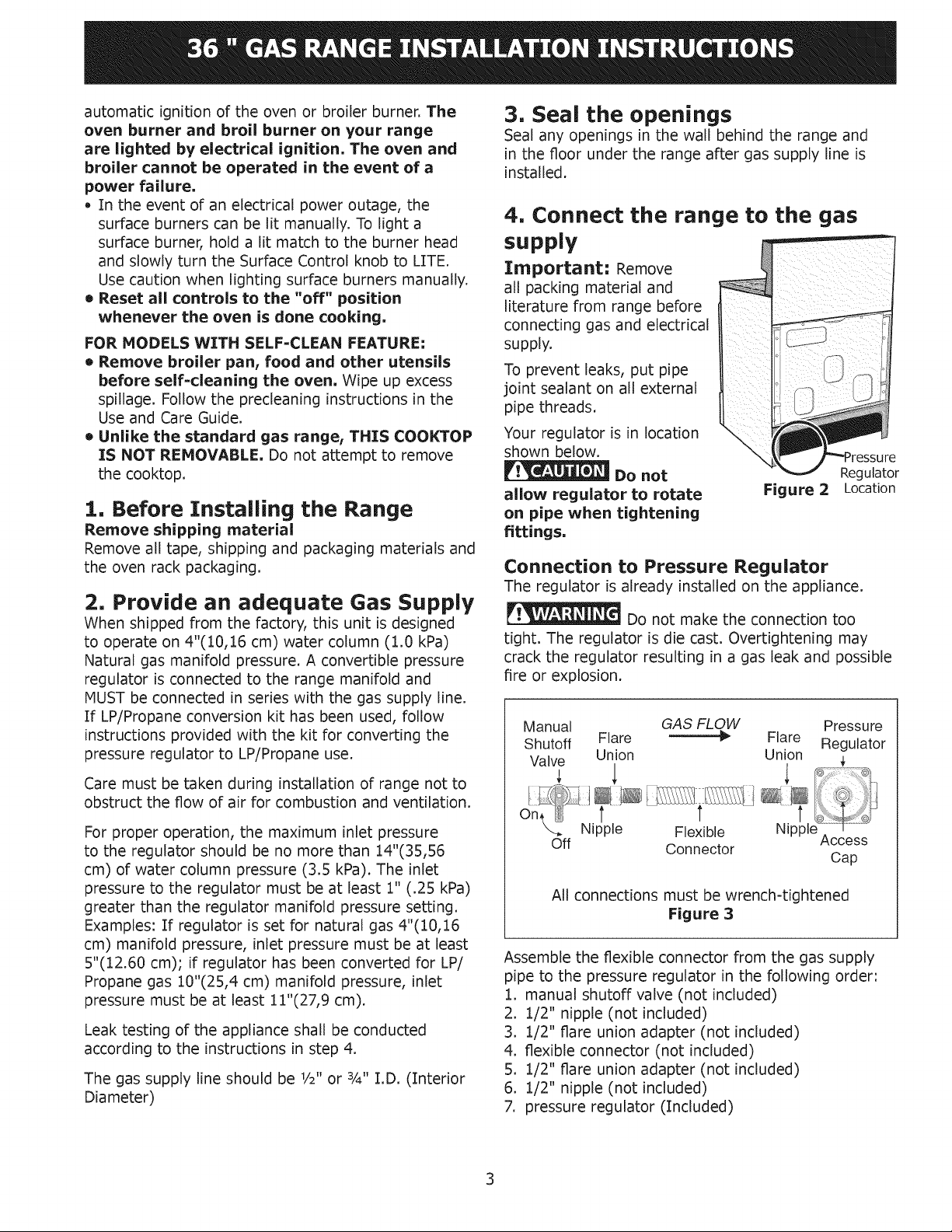

Your regulator is in location

shown below.

Do not

allow regulator to rotate Figure 2

on pipe when tightening

fittings.

Connection to Pressure Regulator

The regulator is already installed on the appliance.

Do not make the connection too

tight. The regulator is die cast. Overtightening may

crack the regulator resulting in a gas leak and possible

fire or explosion.

Manual GAS FLOW Pressure

Shutoff Flare _I_ Flare Regulator

Valve Union Union

Regulator

Location

For proper operation, the maximum inlet pressure

to the regulator should be no more than 14"(35,56

cm) of water column pressure (3.5 kPa). The inlet

pressure to the regulator must be at least 1" (.25 kPa)

greater than the regulator manifold pressure setting.

Examples: If regulator is set for natural gas 4"(10,16

cm) manifold pressure, inlet pressure must be at least

5"(12.60 cm); if regulator has been converted for LP/

Propane gas 10"(25,4 cm) manifold pressure, inlet

pressure must be at least 11"(27,9 cm).

Leak testing of the appliance shall be conducted

according to the instructions in step 4.

The gas supply line should be 1/2"or 3/4" I.D. (Interior

Diameter)

Off Connector

All connections must be wrench-tightened

Figure 3

Assemble the flexible connector from the gas supply

pipe to the pressure regulator in the following order:

1. manual shutoff valve (not included)

2. 1/2" nipple (not included)

3. 1/2" flare union adapter (not included)

4. flexible connector (not included)

5. 1/2" flare union adapter (not included)

6. 1/2" nipple (not included)

7. pressure regulator (Included)

3

Access

Gap

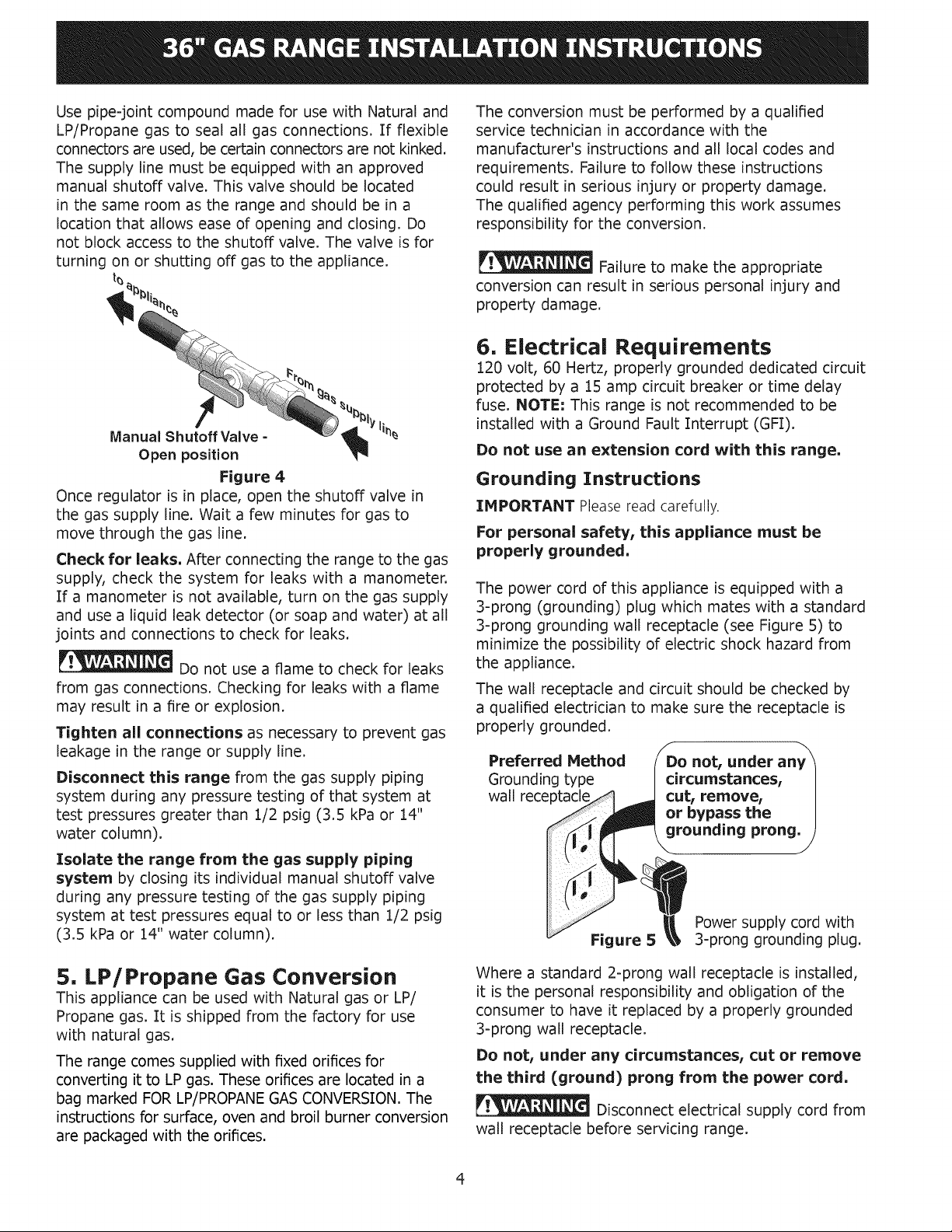

Use pipe-joint compound made for use with Natural and

LP/Propane gas to seal all gas connections. If flexible

connectors are used, be certain connectors are not kinked.

The supply line must be equipped with an approved

manual shutoff valve. This valve should be located

in the same room as the range and should be in a

location that allows ease of opening and closing. Do

not block access to the shutoff valve. The valve is for

turning on or shutting off gas to the appliance.

t_

Manual Shutoff Valve - li%

Open position

Figure 4

Once regulator is in place, open the shutoff valve in

the gas supply line. Wait a few minutes for gas to

move through the gas line.

Check for leaks. After connecting the range to the gas

supply, check the system for leaks with a manometer.

If a manometer is not available, turn on the gas supply

and use a liquid leak detector (or soap and water) at all

joints and connections to check for leaks.

Do not use a flame to check for leaks

from gas connections. Checking for leaks with a flame

may result in a fire or explosion.

Tighten all connections as necessary to prevent gas

leakage in the range or supply line.

Disconnect this range from the gas supply piping

system during any pressure testing of that system at

test pressures greater than 1/2 psig (3.5 kPa or 14"

water column).

Isolate the range from the gas supply piping

system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 psig

(3.5 kPa or 14" water column).

The conversion must be performed by a qualified

service technician in accordance with the

manufacturer's instructions and all local codes and

requirements. Failure to follow these instructions

could result in serious injury or property damage.

The qualified agency performing this work assumes

responsibility for the conversion.

Failure to make the appropriate

conversion can result in serious personal injury and

property damage.

6, Electrical Requirements

120 volt, 60 Hertz, properly grounded dedicated circuit

protected by a 15 amp circuit breaker or time delay

fuse. NOTE: This range is not recommended to be

installed with a Ground Fault Interrupt (GF[).

Do not use an extension cord with this range.

Grounding Instructions

IMPORTANT Pleaseread carefully.

For personal safety,this appliance must be

properly grounded.

The power cord of this appliance is equipped with a

3-prong (grounding) plug which mates with a standard

3-prong grounding wall receptacle (see Figure 5) to

minimize the possibility of electric shock hazard from

the appliance.

The wall receptacle and circuit should be checked by

a qualified electrician to make sure the receptacle is

properly grounded.

Preferred Method not, under any'_

Grounding type circumstances, |

wall receptack cut, remove, /

or bypass the |

grounding prong.J

Power supply cord with

Figure 5

3-prong grounding plug.

5. LP/Propane Gas Conversion

This appliance can be used with Natural gas or LP/

Propane gas. It is shipped from the factory for use

with natural gas.

The range comes supplied with fixed orifices for

converting it to LP gas. These orifices are located in a

bag marked FOR LP/PROPANE GASCONVERSION. The

instructions for surface, oven and broil burner conversion

are packaged with the orifices.

Where a standard 2-prong wall receptacle is installed,

it is the personal responsibility and obligation of the

consumer to have it replaced by a properly grounded

3-prong wall receptacle.

Do not, under any circumstances, cut or remove

the third (ground) prong from the power cord.

Disconnect electrical supply cord from

wall receptacle before servicing range.

4

7, Moving the Appliance for

Servicing and Cleaning

Turn off the range line fuse or circuit breakers at the

main power source, and turn off the manual gas shut-

off valve. Make sure the range is cold. Remove the

service drawer (warmer drawer on some models) and

open the oven door. Lift the range at the front and

slide it out of the cut-out opening without creating

undue strain on the flexible gas conduit. Make sure

not to pinch the flexible gas conduit at the back of

the range when replacing the unit into the cut-out

opening. Replace the drawer, close the door and

switch on the electrical power and gas to the range.

8. Check Operation

Refer to the Use and Care Guide packaged with the

range for operating instructions and for care and

cleaning of your range.

Remove all packaging from the oven before testing.

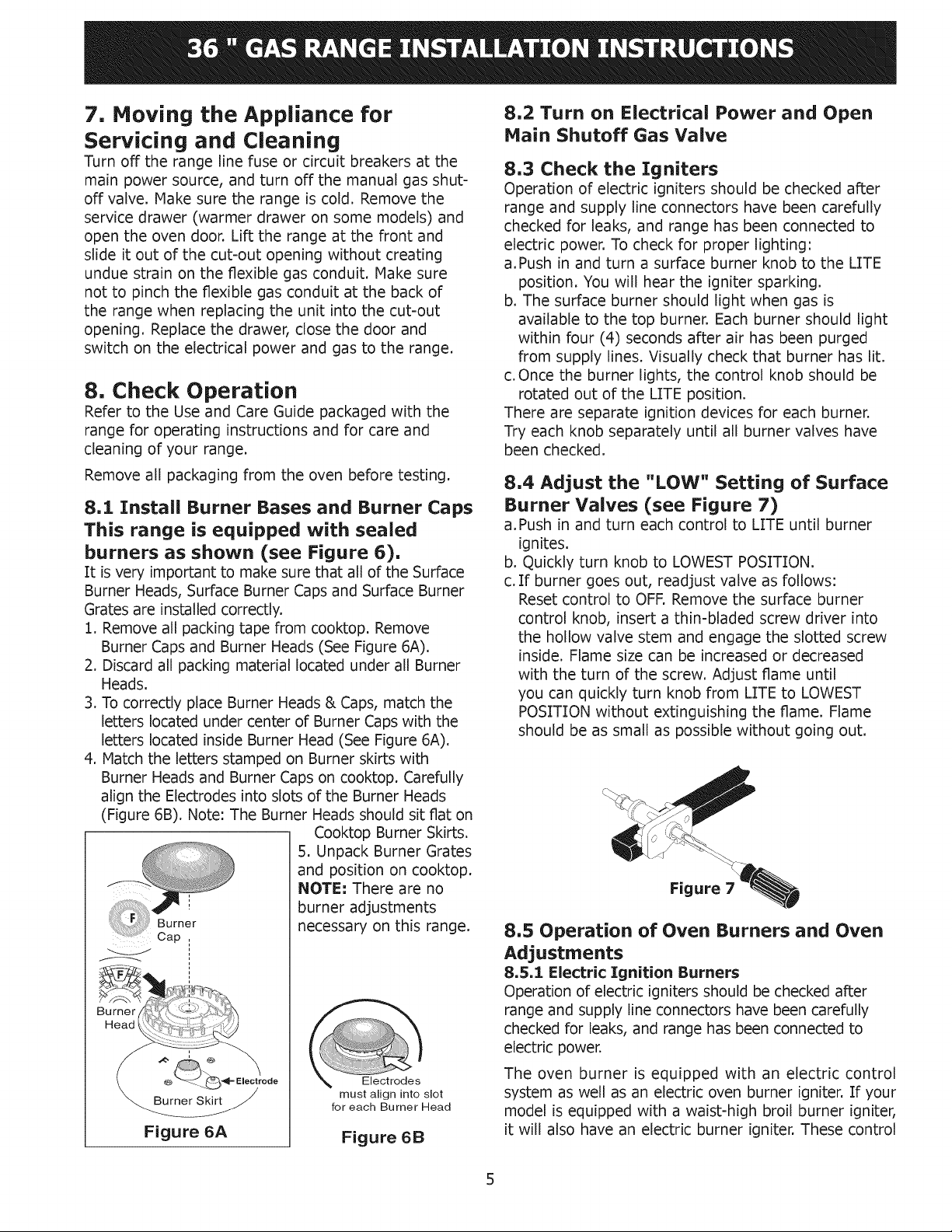

8,1 Install Burner Bases and Burner Caps

This range is equipped with sealed

burners as shown (see Figure 6),

It isvew important to make sure that all of the Surface

Burner Heads, Surface Burner Caps and Surface Burner

Grates are installed correctly.

1. Remove all packing tape from cooktop. Remove

Burner Caps and Burner Heads (See Figure 6A).

2. Discard all packing material located under all Burner

Heads.

3. To correctly place Burner Heads & Caps, match the

letters located under center of Burner Caps with the

letters located inside Burner Head (See Figure 6A).

4. Match the letters stamped on Burner skirts with

Burner Heads and Burner Caps on cooktop. Carefully

align the Electrodes into slots of the Burner Heads

(Figure 6B). Note: The Burner Heads should sit fiat on

Cooktop Burner Skirts.

5. Unpack Burner Grates

and position on cooktop.

NOTE" There are no

burner adjustments

necessary on this range.

must align into slot

for each Burner Head

Figure 6A

Figure 6B

8,2 Turn on Electrical Power and Open

Main Shutoff Gas Valve

8,3 Check the Igniters

Operation of electric igniters should be checked after

range and supply line connectors have been carefully

checked for leaks, and range has been connected to

electric power. To check for proper lighting:

a.Push in and turn a surface burner knob to the LITE

position. You will hear the igniter sparking.

b. The surface burner should light when gas is

available to the top burner. Each burner should light

within four (4) seconds after air has been purged

from supply lines. Visually check that burner has lit.

c.Once the burner lights, the control knob should be

rotated out of the LITE position.

There are separate ignition devices for each burner.

Try each knob separately until all burner valves have

been checked.

8,4 Adjust the "LOW" Setting of Surface

Burner Valves (see Figure 7)

a.Push in and turn each control to LITE until burner

ignites.

b. Quickly turn knob to LOWEST POSITION.

c. If burner goes out, readjust valve as follows:

Reset control to OFF. Remove the surface burner

control knob, insert a thin-bladed screw driver into

the hollow valve stem and engage the slotted screw

inside. Flame size can be increased or decreased

with the turn of the screw. Adjust flame until

you can quickly turn knob from LITE to LOWEST

POSITION without extinguishing the flame. Flame

should be as small as possible without going out.

Figure 7

8.5 Operation of Oven Burners and Oven

Adjustments

8,5,1 Electric Ignition Burners

Operation of electric igniters should be checkedafter

range and supply line connectors have been carefully

checked for leaks, and range has been connected to

electric power.

The oven burner is equipped with an electric control

system as well as an electric oven burner igniter. If your

model is equipped with a waist-high broil burner igniter,

it will also have an electric burner igniter. These control

systemsrequirenoadjustment.Whentheovenisset

tooperate,currentwil!flowtothe igniter.It will "glow"

similarto a light bulb.Whenthe igniterhasreached

atemperaturesufficientto ignitegas,theelectrically

controlledovenvalvewillopenandflamewillappearatthe

ovenburner.Thereisatimelapsefrom30to60seconds

afterthermostatisturnedONbeforetheflameappears

attheovenburner.Whentheovenreachesthedisplay

setting,theglowingigniterwillgooff.Theburnerflame

willgo"out"in20to30secondsafterignitergoes"OFF".

Tomaintainanygivenoventemperature,thiscyclewill

continueaslongasthedisplayissettooperate.

Afterremovingallpackingmaterialsandliteraturefrom

theoven:

a)SettheoventoBAKEat300°RSeeUse&CareGuide

foroperatinginstructions.

b)Within60secondstheovenburnershouldignite.

Checkforproperflame(see8.5.2),andallowthe

burnertocycleonce(seecycleexplanationabove).

Resetcontrolstooff.

c) If yourmodelisequippedwithawaist-highbroiler

burner,setovento broil.SeeUse& CareGuidefor

operatinginstructions.

d)Within60secondsthebroilburnershouldignite.Check

forproperflame(see8.5.3).Resetcontrolstooff.

8.5.2 Oven Burner Flame Adjustment

Oven Burner Tube

(_) Lock Scre_

Air Shutter==_!

i==(_ Orifice Hood

Figure 9

8.5.3 Broil Burner Flame Adjustment

The approximate flame length of the burner is 1 inch

(distinct inner cone of blue flame). To determine if the

broil burner flame is proper, set the oven to broil. If

flame is yellow, increase air shutter opening size (see "2"

in Figure 9 ). If the entire flame is blue, reduce the air

shutter opening size. To adjust, loosen lock screw (see

"3" in Figure 9), reposition air shutter, and tighten lock

screw.

9. Make Sure Range Is Level

Check if the range is level by placing a level horizontally

on an oven rack. Check diagonally from front to back,

then level the range by either adjusting the leveling legs

or by placing shims under the corners of the range as

needed.

Llwer

!i -._Air Shutter

Oven Burner

Baffle

Waist=High Burner

(

1

Figure 8

The approximate oven burner flame length is 1 inch

(distinct inner cone of blue flame).

To determine if the oven burner flame is proper, remove

the oven bottom and burner baffle and set the oven to

bake at 30001:.

To remove the oven bottom, remove oven hold down

screws at rear of oven bottom. Pull up at rear, disengage

front of oven bottom from oven front frame, and pull the

oven bottom out of the oven. Remove burner baffle so

that burner flame can be observed.

[f the flame is yellow, increase air shutter opening size

(see "2" in Figure 9). If the entire flame is blue, reduce

the air shutter opening size.

To adjust flame loosen lock screw (see "3" in Figure 9),

reposition air shutter, and tighten lock screw. Replace

oven bottom.

_l--Air Shutter (removable)

Lower Oven Bottom

When Al! Hookups are Complete

Make sure all controls are left in the OFF position.

Make sure the flow of combustion and ventilation air to

the range is unobstructed.

Model and Serial Number Location

The serial plate is located on the oven front frame

behind the drawer.

When ordering parts for or making inquiries about

your range, always be sure to include the model and

serial numbers and a lot number or letter from the

serial plate on your range.

Your serial plate also tells you the rating of the

burners, the type of fuel and the pressure the range

was adjusted for when it left the factory.

Before You Call for Service

Read the Before You Call for Service Checklist and

operating instructions in your Use and (::are Guide.

It may save you time and expense. The list includes

common occurrences that are not the result of

defective workmanship or materials in this appliance.

Refer to the warranty in your Use and (::are Guide for

our service phone number and address. Please call or

write if you have inquiries about your product and/or

need to order parts.

6

10. Anti-tip Bracket Installation

Important Safety Warning

This range must be properly secured to the floor

by using the included anti-tip brackets and screws.

Failure to install the brackets could allow the range

to accidentally tip over if excessive weight is placed

on an open door or if a child climbs upon it. Serious

injury might result from spilled hot liquids or from the

range itself. Refer to the instructions below for proper

installation (Figure 10).

NOTE: If the range is ever moved to a different

location, the anti-tip brackets must also be moved and

installed with the range.

The anti-tip kit is located in a plastic bag in the

oven,

Tools Required:

5/16" Nutdriver or Flat Head Screwdriver

Adjustable Wrench

3/16" Dia. Masonry Drill Bit (if installing in concrete)

Attach brackets to the floor at the back of the range

to hold both rear leg levelers. When fastening to the

floor, be sure that screws do not penetrate electrical

wiring or plumbing. The screws provided will work in

either wood or concrete.

Range may be anchored to floor in a house with hold

down brackets as illustrated in Figure 10. These hold

down brackets allow range to be freely pulled out from

the wall for cleaning or servicing without the use of

tools.

1. Attach brackets to the floor or rear wall with screws

provided. Important: Attachment must be secured

to solid floor or wall. Do not attach to plaster, sheet

rock, or other soft material. If attachment is to rear

wall, any moldings must be removed in area behind

range.

2. If brackets are to be attached to masonry or

ceramic floors, position brackets on floor and mark

hole location. Drill 3/16" holes.

3. Lower both rear leg levelers about three turns so

the brackets will slide over leveler head.

4. Level the range front to back and side to side with

the two front leg levelers and the rear levelers.

5. Slide range into place making sure rear legs are

trapped by ends of brackets. Range may need to

be shifted slightly to one side as it is being pushed

back to allow rear legs to align with brackets.

Remove lower panel or storage drawer to inspect

brackets or grasp the top rear edge of the range

and carefully attempt to tilt it forward to make sure

range is properly anchored.

_1 _Insta Ho d

3/8"

LA INSTALACI6N Y EL SERVICIO DEBEN SER EFECTUADOS POR UN INSTALADOR

CALIFICADO,

IMPORTANTE: GUARDE ESTAS INSTRUCCIONES PARA USO DEL INSPECTOR LOCAL DE

ELECTRICIDAD, LEA Y GUARDE ESTAS INSTRUCCIONES PARA REFERENCIA FUTURA,

Si todas ias instrucciones de _ste manual no son

observadas a la letra, se puede ocurrir incendios o explosiones que

pueden causar da_os materiales, lesiones o la muerte.

- No almacene o utilice gasolina u otros vapores y liquidos

inflamables cerca de este o cualquier otto artefacto.

= QUE HACER SI HAY FUGAS DE GAS

= No intente de encender ning_n artefacto

= No toque ning_n interruptor el_ctrico; no utilice ning_n

aparato telef6nico en su edificio.

= Llame inmediatamente el abastecedor de gas desde el

telef6nico

de un vecino. Siga ias instrucciones dei abastecedor de

gas

= En caso que no puede contactar el abastecedor de gas,

ilame al departamento de bomberos.

= La instalaci6n y el servicio t_cnico deben set realizados pot

un instalador caEficado, pot un servicio t_cnico certificado o

pot el abastecedor de gas.

Aparatos Instalados en el

estado de Massachusetts;

EsteAparato s61opuedeser instalado

en el estado de Massachusettspot un

plomero o ajustador de gas licenciado

de Massachusett,

Este aparato se debe instalar con un

largo conector flexible de gas de tres

(3) pies/36 pulgadas,

Una v_lvula manual de gas de tipo

manija de forma de "T" se debe

instalar en la Ifnea del suministro de

gas de este aparato,

Dimensiones y espacios libres

Provee adecuados espacios libres entre la estufa y las superficies combustibles adyacentes

25 518"

(65.1 cm)

---36" (91.4 cm)

30"

(76.2 cm) ;'

Espacio libre m[n. hasta / 15"

la pared a cualquier lado_

de la estufa superior a--

36" (91.4 cm) de altura.

i.................................................................................i

il

(12.7 cm)

Mfnimo

(45.7 Cm)cualquier lado Profundidad _

M[nimo hasta

18"

los gabinetes a

de la estufa, m_xima para los

L 361/4'' (92.1 cm)

entre los gabinetes.............................................=_1

Figura 1

(33 cm)

gabinetes que _-

se encuentran

por arriba de la

estufas

Separaci6n m[nima de

0" en la parte posterior

de la estufa debajo de la

cubierta de la pared trasera

NOTA:

Se adjunta los diagramas de cables de estas estufas con el libreta, P/N 318201765 (1010) Rev.A

Impreso en los Estados Unidos

English - pages i-7

Espa_ol - paginas 8-15

Diagrama de la instalaci6n alambica - paginas 16

Notas importantes para ei Instalador

1. Lea todas las instrucciones contenidas en este

manual antes de instalar la estufa.

2. Saque todo el material usado en el embalaje del

compartimiento de! homo antes de conectar el

suministro el_ctrico o de gas a la estufa.

3. Observe todos los c6digos y reglamentos pertinentes.

4. Deje estas instrucciones con e! comprador.

5. Nota: Para la utilizaci6n a m_s de 2 000 pies de

altura, la potencia del aparato deber_ set reducida

de 4 pot ciento a cada 1 000 pies adicionales.

Nora Importante para el Consumidor

Conserve estas instrucciones y el Manual del Usuario

para referencia futura.

IMPORTANTES INSTRUCCIONES

DE SEGURIDAD

Instalaci6n de esta estufa debe cumplir con todos los

c6digos locales, o en ausencia de c6digos locales con

el C6digo National de Gas Combustible ANSI Z223.1/

NFPA.54--_ltima edici6n.

El dise_o de esta estufa ha sido certificado pot la CSA

Internacional. En _ste como en cualquier otto artefacto

que use gas y genere calor, hay ciertas precauciones de

seguridad que usted debe seguir. Estas ser_n encontradas

en el Manual del Usuario, I_alo cuidadosamente.

o Aseg_rese de que la estufa sea instalada y

conectada a tierra en forma apropiada por un

instalador calificado o pot un t_cnico.

o Esta estufa debe ser el_ctricamente puesta a

tierra de acuerdo con los c6digos locales, o en

su ausencia, con el C6digo El_ctrico Nacional

ANSI/NFPA No, 70, _ltima edici6n, Vea las

instrucciones para la puesta a tierra

La instalaci6n de unidades dise_adas para casas

(movibles) deben cumplir con los estandares de

"Manufactured Home Construction and Safety

Standard, title 24 CFR part 3280". (Anteriormente

"The Federal Standard for Mobile Home Construction

and Safety title 24, HUD (Part 280)". O cuando estos

estandares no sean aplicables: "The Standard for

I_ Reducir el riesgo de

Todas las

estufas pueden

volcarse.

Esto podr[a

resultar en

lesiones

personales.

Instale el

dispositivos

antivuelco que

se ha empacado

junto con esta

estufa,

que se vuelque la estufa,

hay que asegurarla

adecuadamente colocandole

los soportes antivuelco

que se proporcionan. Para

comprobar si estos est_n

instalados y apretados en

su lugar como se debe, ase

el borde trasero superior de

la estufa y cuidadosamente

incl[nela hacia adelante para

asegurar que la estufa se

ancle.

Manufactured Home Installation 1982, (Manufactured

Home Sites, Communities and set-ups), ANSI Z225.1,

Oltima edici6n o c6digos y regulaciones locales.

- Aseg_rese de que el material que recubre las

paredes alrededor de la estufa, pueda resistir

el calor generado por la estufa.

* No obstruya el flujo del aire de combusti6n en

la ventilaci6n del homo ni tampoco alrededor

de la base o debajo del panel inferior

delantero de la estufa, Evite tocar las aberturas

o areas cercanas de la ventilaci6n, ya que pueden

estar muy calientes durante el funcionamiento

del horno. La estufa requiere aire fresco para la

combusti6n apropiada de los quemadores.

Nunca deje ni_os solos o

desatendidos en un _rea donde un artefacto

est_ siendo usado, A medida que los ni_os crecen,

ens_eles el uso apropiado y de seguridad para todos

los artefactos. Nunca deje la puerta del homo abierta

cuando la estufa est_ desatendida.

No se pare, apoye o siente en

las puertas o cajones de esta estufa pues puede

resultar en serias lesiones y puede tambi_n causar

da_o a la estufa.

- No almacene articulos que puedan interesar

a los nifios en los gabinetes sobre la estufa.

Los ni_os pueden quemarse seriamente tratando de

trepar a la estufa para alcanzar estos art[culos.

o Los gabinetes de almacenamiento sobre la estufa

deben ser evitados, para eliminar la necesidad de

tener que pasar sobre los quemadores superiores

de la estufa para Ilegar a ellos.

- Ajuste el tamafio de la llama de los

quemadores superiores de tai manera que

_sta no sobrepase el borde de los utensilios de

cocinar, La llama excesiva es peligrosa.

- No use el homo como espacio de almacenaje.

Esto crearc_ una situaci6n potencialmente peligrosa.

- Nunca use la estufa para calentar el cuarto.

El uso prolongado de la estufa sin la adecuada

ventilaci6n puede resultar peligroso.

- No almacene ni utilice gasolina u otros vapores

y liquidos inflamables en la proximidad de _ste

o de cualquier otto artefacto el_ctrico. Puede

provocar incendio o explosi6n.

No trate de usar el homo de

encendido el_ctrico durante un corte de energia.

El reestablecimiento del servicio el_ctrico cuando los

controles de TEMP DEL HORNO y de REGULACION

DEL HORNO est_n en cualquier posici6n diferente

a APAGADO causar[a el encendido autom_tico del

quemador del homo o del quemador de la parrilla.

Durante un corte de energia el_ctrica se pueden

encender los quemadores de la cubierta con una

cerilla. Acerque una cerilla encendida al quemador

9

y luegogirelentamenteel bot6nalaposici6n

ENCENDIDO(LITE).Tongaextreme cuidado al

encender los quemadores en esta forma,

* En caso de una interrupci6n del servicio el6ctrico, es

posible de encender los quemadores de superfide

a mano. Para encender un quemador de superficie,

acerque un f6sforo encendido del cabezal del

quemador, y gire delicadamente el bot6n de control

de superficie a LITE (encendido). Tener cuidado al

encender los quemadores a mano.

* Ajuste todos los controles a la posici6n "OFF"

(apagada) despu_s de haber hecho una

operaci6n,

PARA MODELOS AUTOLIMPIANTES:

* Saque la asadera, alirnentos o cualquier

otro utensilio antes de usar el ciclo de auto

lirnpieza del homo, Limpie todo exceso de

derrame de alimentos. Siga las instrucciones de pre

limpiado en el Manual del Usuario.

= A diferencia de la gama est_ndar cocinas

de gas, ESTA PLANCHA DE COCINA NO ES

MOVIBLE. No intente quitar la plancha de cocina.

1. Antes de instalar la estufa a gas

Remueva todos los articulos de embalaje

Retire toda la cinta, todos los artfculos de embalaje y de

expedici6n, y el embalaje de la rejilla del horno. Levante

la plancha para cocinar y remueva los dos tornillos de

expedici6n de los quemadores de la plancha para cocinar.

Un examen de detecci6n de fugas del aparato debe set

realizado segOn las instrucciones en el paso 4.

La Ifnea de fuente de gas debe set de 1/2"o de 3/4".

3. $elle ias aperturas

Sella todas las aperturas en la pared detr_s de la

estufa yen el suelo debajo de la estufa despu_s que la

Ifnea del suministro de gas sea instalada.

4. Conecte ia estufa al suministro

de gas

Importante: Quite todo el

material de embalaje y literatura

de la estufa antes de

conectar el gas y la fuente

el6ctrica.

Para evitar fugas, aplique

sellador de tubefias en todas

las partes roscadas machos

(exterior) de la tubefia.

El regulador se encuentra en

el lugar que se muestra en

la ilustraci6n.

llr:_l_;_m_ No perrnita

que el regulador gire

sobre la tuberia al

apretar las uniones,

Ubicaci6n del

regulador de

presi6n

Figure 2

2. Proporcione un surninistro de

gas adecuado

Cu_ndo se envfa de la f_brica, Esta unidad ha sido

ajustada para operar con un mOltiple de admisi6n para

gas natural de 4" (10.16 cm)(1.0 kPa). Un regulador

de presi6n convertible esta conectado a la v_lvula

distribuidora y DEBE ser conectado con la tuber[a

del suministro de gas. Si el juego de conversi6n

de! propano LP/Propano se ha utilizado, sigue las

instrucciones proporcionadas el juego para convertir el

regulador de presi6n al uso de LP/Propano.

Se debe de tenet cuidado durante la instalaci6n de la

estufa para no obstruir el flujo de aire de combusti6n y

ventilaci6n

Para la operaci6n apropiadas, la maxima presi6n de

entrada al regulador no debe exceder la presi6n de

una columna de agua de 14"(35,56 cm) (3.5 kPa). La

presi6n de entrada al regulador debe set pot Io menos

1" (.25 kPa) m_s grande que la v_lvula distribuidora.

Ejemplos: Si regulador se pone para el gas natural con

una presi6n de 4"(10,16 cm), la presi6n de entrada

al regulador debe set pot Io menos 5"(12.60 cm); si

el regulador se ha convertido para gas LP/Propane

10"(25,4 cm) la presi6n de entrada al regulador debe

ser por Io menos 11"(27,9 cm).

Conecte el Regulador de Presi6n

El regulador de presi6n esta ya instalada para la estufa.

I_.,_J__ No haga la conexi6n demasiado

apretada. El regulador es de die cast. El apretar

demasiado puede agrietar el regulador dando por

resultado una fuga de gas y un fuego o una explosi6n.

Valvula de FLUJO DEL GAS Flegulador

cierre Uni6n Uni6n

manual

Ablerto _ _

(On)\_L Boquilla Conector

Apagado flexible Tapa de

(Off) entrada

Todas las conexiones deben ser apretadas con

una Ilave inglesa- Figura 3

ReOna el conector flexible del tubo del suministro de

gas al regulador de la presi6n en la orden siguiente:

1. V_lvula de cierre manual (no incluido)

2. Boquilla de 1/2" (no incluido)

3. 1/2" Adaptador de uni6n (no incluido)

4. Conector flexible (no incluido)

5. 1/2" Adaptador de uni6n (no incluido)

6. Boquilla de 1/2" (no incluido)

7. regulador de presi6n (incluido)

_ de presi6n

10

Useselladorparaunionesdetuberfashechoparael

usodegasnaturaly LP/Propanoparasellartodaslas

conectionesdegas.Siseutilizanlosconectadores

flexibles,aseg_resedequelosconectadoresnoest_n

enroscados.

LaI_neadelsuministrosedebedesetequipadade

unav_lvuladecierremanualaprobada.Estav_lvula

sedebeIocalizarenel mismocuartoquelaestufay

debeestarenunaIocalizaci6nquepermitalafacilidad

delaaberturaydelcierre.Nobloqueeelaccesoa la

v_lvula.Lav_lvulaesparaencendero apagarelgas

delaparato. AI

I

Valvula manual de cierre -

Abierta

Figura 4

5. Conversi6n para uso de Propano

Liquido

Este aparato puede set usado con gas natural o

propano I_quido. Ha sido ajustado en la f_brica para

operar con gas natural solamente.

Si desea convertir su estufa para uso con propano

I{quido, use los orificios provistos ubicados en e! bolso

que contiene la literatura titulada "FOR LP/PROPANE

GAS CONVERSION." Siga las instrucciones que vienen

con los orificios.

La conversi6n debe set efectuado pot un t6cnico de

servicio capacitado, de acuerdo con las instrucciones

del fabricante y con todos los c6digos y requisitos

de las autoridades correspondiente. El no seguir las

instrucciones podfia dar como resultado lesiones

graves o dafios a la propiedad. El organismo

autorizado para Ilevar a cabo este trabajo asume la

responsabilidad de la conversi6n.

La falta de una conversi6n apropiada

puede resultar en lesiones graves y dafios a la

propiedad.

Una vez que regulador est_ en su lugar, abra la v_lvula

en la I{nea del suministro de gas. Espere algunos

minutos para que el gas pueda moverse a trav6s de la

I_neade gas.

Compruebe para saber si hay fugas de gas.

Despu_s de conectar la estufa con la fuente de

gas, compruebe el electrodom6stico para saber si

hay fugas con un man6metro. Si un man6metro no

est_ disponible, gire la fuente de gas y utilice un

detector I{quido de fugas (o jab6n y agua) en todos

los empalmes y conexiones has la comprobaci6n para

fugas.

No utilice una llama para verificar

fugas en las conexiones de gas. Verificar para fugas

con una llama puede tener como resultado un fuego o

la explosi6n.

Apriete todas las conexiones como necesario para

prevenir fugas de gas en la superficie de la estufa o en

la linea de suministro.

Desconecte la estufa del sistema de tuber_a del

suministro de gas durante cualquier prueba de presi6n

de ese sistema a presiones mayores de 1/2psig (3,5

kPa o 14" columna de agua).

Aisle la estufa del sistema de tuberia del

suministro de gas cerrando su v_lvula de cierre

manual durante cualquier prueba de presi6n del

sistema de tuberfa del suministro de gas prueba de

presi6n iguala a o a menos de 1/2psig (3,5 kPa o 14"

columna de agua).

6, Requisitos ei ctricos

120 voltio, 60 Hertzio, circuito dedicado

apropiadamente puestos a tierra protegido por un

circuito de amperio o fusible de demora de tiempo de

15 amp. Nota: no es recomendado instalarlo con un

Interruptor (GFI) de puesta a tierra.

No utilice una extensi6n con esta estufa.

Instrucciones de puesta a tierra

IMPORTANTE Por favor lea con cuidado.

Para la seguridad personal, este aparato debe

ser puesto a tierra apropiadamente.

El cable del suministro el6ctrico de esta estufa est_

equipado con un enchufe de tres patillas (para puesta

a tierra) que coincida con un enchufe de pared

est_ndar con puesta a Uerra de tres patillas para

minimizar la posibilidad que se produzcan descargas

el6ctricas.

El cliente deber_ encargar a un t_cnico para

asegurarse de que el enchufe se encuentra

debidamente conectado a tierra y polarizado.

M_todo

Enchufe de pared o derribe, |

con toma d_ baje ninguna |

tierra circunstancia, la |

preferido

No corter retire

patilla de la tema de I

tierra del enchufe/

Cable de suministro

el6ctrico con enchufe

con toma de tierra

Figura 5

11

En lugares en los que aya un enchufe de pared

est_ndar de dos patillas, el cliente tendr_

responsabilidad directa y la obligaci6n de reemplazarlo

pot un enchufe de pared de tres patillas debidamente

cableado a tierra.

Bajo ninguna circunstanciar cotter retire o

derribe la tercera patilla (de toma de tierra) del

cable del surninistro de energia el_ctrica,

Desenchufa el cable del suministro

de energ_a el_ctrica del enchufe de pared antes de

mantener la estufa.

7. La mudanza del aparato para

reparaciones o lirnpieza

Apague la corriente el_ctrica a la estufa a la fuente de

poder principal, y apague la v_lvula de cierre manual

de gas. Aseg_rese de que la estufa est_ fresca. Quite

el caj6n de servicio (el caj6n calentador en algunos

modelos) y abre la puerta del homo. Levante la frente

de la estufa y desl_cela fuera de la abertura sin crear

tensi6n desmedida sobre el conducto flexible de gas.

Aseg_rese de no pellizque el conducto flexible de

gas detr_s de la estufa al reemplazar la unidad en

la abertura. Reemplace el caj6n, cierre la puerta y

enciende el gas y la corriente el_ctrica a la estufa.

8. Comprobaci6n del

funcionarniento

Consulte el Manual del Usuario inclufdo con la estufa

para instrucciones de operaci6n y instrucciones para el

cuidado y limpieza de su estufa.

No toque los elementos o quemadores. Pueden estar

bastante calientes para causar quemaduras.

Quite todo el embalaje de la unidad antes de

comprobarla.

8.1 Instala las Bases y las tapas de los

Quemadores

Esta estufa esta equipada con

quemadores sellados como mostrado

(vea la Figura 6),

Es muy importante asegurarse de que todas las

cabezas de los quemadores superiores, las tapas de los

quemadores superiores y las rejillas de los quemadores

superiores est_n instaladas correctamente y en sus

lugares correctos.

1. Retire toda la cinta de empaque de la cubierta. Retire

las tapas y cabezas de los quemadores (Figura 6A).

2. Descarte todo el material de empaque que se encuentra

debajo de las cabezas de los quemadores.

3. Paravolver a instalar las cabezas y tapas de los quema-

dotes, haga concordat las letras ubicadas debajo de las

tapas (en el centro) con las letras que se encuentran

dentro de las cabezas de los quemadores (Figura 6A).

4. Haga concordar las letras estampadas en los deflectores

de los quemadores con las de las cabezas y tapas de los

quemadores. Vuelva a colocar las cabezas y tapas de

los quemadores en la cubierta. Alinee cuidadosamente

los electrodos en la ranura o agujero de cada cabeza de

quemador (Figura 6B).

Nora: Las cabezas de

los quemadores deben

quedar planas sobre los

rapa del

quemador

deflectores de los que-

madores de la cubierta.

5. Desempaque las reji-

Ilas de los quemadores

y col6quelas sobre la

cubierta.

Deflector del

quemador

Figura 6A

Figura 6B

electrodosdeben

estar alineados con la

ranura de cada cabeza

de quemador

8,2 Enciende la corriente el_ctrica y abre

la v_lvula principal de cierre,

8,3 Comprobaci6n de los Encendedores

El funcionamiento de los encendedores el_ctricos

debe ser comprobado despu_s de que la estufa y los

conectores a la tuberfa de suministro de gas hayan

sido comprobados para las fugas y la estufa haya

sido conectada el_ctricamente. Para comprobar que

el encendido sea correcto:

a. Empuje y gire un bot6n control del quemador

superior hasta la posici6n LITE (encender). Se

podffa oft el encendedor haciendo chispas.

b. El quemador se deber_ encender en cuatro (4)

segundos para un funcionamiento normal, despu_s

de que el aire haya sido purgado de la tubeffa de

suministro de gas. Controle visualmente que el

quemador se haya encendido.

c. Despu_s de que el quemador se haya encendido,

la plancha de cocina debe ser girada fuera de la

posici6n LITE. Cada quemador tiene su encendedor

individual. Controle las perillas separadamente

hasta que todas las v_lvulas hayan sido controladas.

Los

12

8.4 Ajuste de la Posici6n LOW (BA3A)

Para la Vblvula del Quemador Superior

(Figura 7)

a. Gire el bot6n de control a la posid6n LITE

(encender) hasta que el quemador endenda.

b. R_pida,mente gire el bot6n de control a la

POSICION MAS BAJA.

c. Si el quemador se apaga, reajuste la v_lvula de la

siguiente forma: Mueva el control a la posid6n OFF

(apagada). Saque la perilla de control del quemador

superior, inserte un destornillador piano pequefio en

el hueco del v_stago del a v_lvula hasta enganchar

el tornillo interior. El tamafio de la llama puede ser

aumentado o disminuido girando el tornillo. Ajuste

el tamafio de la llama hasta que pueda pasar

r_pidamente de la posici6n LITE hasta la posid6n

MAS BAJA sin que se apague la llama. La llama debe

ser Io m_s pequefia posible sin que se apague.

desaparecer_ por 20 a 30 segundos despu_s de que

el encendedor se apaga. Para mantener cualquier

temperatura de homo dada, este ciclo continuar_ tanto

como el dial (o visualizador) est_ configurado para

operar.

Despu_s de retirar todos los materiales del empaque y la

literatura del homo:

a) Fije el homo en HOP,NEAR(BAKE) a 300°R Vea la

gala de Uso y Cuidado para conocer las instrucciones

de funcionamiento.

b) En 60 segundos el quemador de! homo se encender&

Revise que exista un fuego adecuado (vea 8.5.2), y

permita que el quemador cumpla su ciclo una vez.

Gire los controladores hacia off (APAGADO).

c) Sisu modelo esta equipado con un asador central

superior, fije e! homo en ASAR. Vea la Gufa de

Uso y Cuidado para conocer las instrucciones de

funcionamiento.

d) En 60 segundos el quemador de asar debe de

encenderse. Revise si exista una llama adecuada (vea

8.5.3). Gire los controles hacia off (APAGADO).

8.5.20bturador dei Aire =Quemador dei homo

Figura 7 %

8,50peraci6n de Quemadores del Homo

y Ajustes de Homo

8.5.1 Quemador de ignici6n el_ctrica

La operaci6n de los encenderse el_ctricos debe de ser

revisada despu_s de que la cocina y los conectores

de la Ifnea de suministro haya sido cuidadosamente

revisada para descartar fugas y que la cocina haya sido

conectada a la corriente el_ctrica.

El quemador del homo est_ equipado con un sistema de

control el_ctrico asf como un encendedor de quemador

de homo el_ctrico. Si su modelo esta equipado con un

quemador de asado central superior, tambi_n contar_

con un encendedor de quemador e!_ctrico. Estos

sistemas de control no requieren ajustes. Cuando el

homo esta configurado para operar, la corriente fluir_

hacia el encendedor y tendr_ un resplandor de manera

similar a una bombilla de luz. Cuando el encendedor a

alcanzado una temperatura suficiente para encender el

gas, la v_lvula del homo controlada el_ctricamente se

abrir_ y el fuego aparecer_ en el quemador del homo.

hay un lapso de tiempo de 30 a 60 segundos despu_s

de que el termostato se enciende y antes de que la

llama aparezca en el quemador del homo. Cuando el

homo alcanza la configuraci6n del dial, el encendedor

resplandeciente se apagar& La llama del quemador

Deflector inferior la altura de la

del homo aire cintura

(extra[ble inferior

_-Obturador homo (extrafbie)

Figura 8 de aire

La Iongitud aproximada de la llama del quemador del

homo es 1 pulgada (interior claro, llama azul). Para

determinar si la llama del quemador de horno es la

adecuada, retire el rondo del homo y el deflector del

quemador i flje el homo en la opci6n hornear a 300°E

Para retirar el fondo del homo, retire los tornillos de

ajuste del homo en la parte posterior del rondo del

homo. jale hacia arriba, desenganche el frente del rondo

del marco anterior del homo, y jale la base hacia a fuera

de _ste. retire el deflector del quemador de manera que

la llama del quemador pueda ser observada.

Si la llama es de color amarillo, aumente el tamafio de la

abertura del obturador de aire (Vea el tamafio "2" en el

flgura 9). Si la llama es de azul claro, reduzca el tamafio

de la abertura del obturador de aire. Para ajustar un

tornillo de cierre flojo (Vea el tamafio "3" en el flgura 9),

vuelva a colocar el obturador de aire, y ajuste el tornillo

de cierre. Reemplace el rondo del homo.

Quemador a

Parte del

13

Tornillos de _ _i==

(_) seguridad

Tubos del

quemador

del homo

Despu_s de Terminar la Znstalaci6n

Aseg_rese de que todos los controles est6n en la posici6n

OFF (apagada).

AsegQresede que el fluir del aire de combusti6n y de

ventilaci6n a la estufa no est6 obstruido.

Obturador=l_

de aire

Figura 9 j

8.53 Obturador de aire = Quemador de asado

La Iongitud aproximada de la llama del quemador de

asado es 1 pulgada (interior claro, llama azul). Para

determinar si la llama del quemador de asado es la

adecuada, poner el homo en la opci6n asar.

Si la llama es de color amarillo, aumente el tama_o de la

abertura del obturador de aire (Vea el tama_o "2" en el

figura 9). Si la llama es de azul claro, reduzca el tama_o

de la abertura del obturador de aire, y ajuste el tornillo

de cierre (Vea el tama_o "3" en el figura 9).

(_Tapa del

orificio

9, Aseg_rese que ia estufa esta a

nivel

Nivele la estufa, instalado un nivel horizontalmente sobre

una rejilla del horno. Verifique en diagonal de adelante

hacia atr_s, y nivele la estufa ajustando las paras de

nivelaci6n o poniendo cutlas pot debajo de los ric6nes

de la estufa como sea necesario.

Ubicaci6n del N_mero de !odelo y de

Serie

La placa con el nQmero de serie est_ ubicada en el

marco delantero del horno detr_s de la puerta del horno

(algunos modelos) o detr_s del caj6n (algunos modelos).

Cuando haga pedidos de repuestos o solicite informaci6n

con respecto a su estufa, est6 siempre seguro de incluir

el nQmero de modelo y de serie y el nQmero o letra del

Iote de la placa de serie de su estufa.

La placa con el nQmero de serie tambi6n le da la potencia

nominal de los quemadores, el tipo de combustible y la

presi6n a la cual rue ajustada la estufa en la f_brica.

Antes de Ilamar al servido

Lea la secci6n Lista de Control de Averfas en su

Manual del Usuario. Esto le podr_ ahorrar tiempo y

gastos. Esta lista incluye ocurrencias comunes que

no son el resultado de defectos de materiales o

fabricaci6n de este artefacto.

Lea la garant[a y la informaci6n sobre el servicio en

su M n I I ri para obtener el nOmero de

tel6fono y la direcci6n del servicio. Por favor Ilame

o escriba si tiene preguntas acerca de su estufa o

necesita repuestos.

14

10, Instrucciones para de

instalaci6n dei soporte antivueico

Advertencia de seguridad importante

Esta estufa debe ser asegurada al piso usando las

platinas de anclaje y los tornillos suministrados. El

no instalar apropiadamente los soportes antivuelco

puede Ilegar a permitir que la estufa se incline hacia

adelante, accidentalmente, si se coloca un peso

excesivo sobre la puerta abierta o si un nifio se sube

en ella. La estufa caliente a los liquidos calientes

derramados podrfan causar serias lesiones personales.

Refi_rase alas instrucciones que se dan a continuaci6n

para la correcta instalaci6n de los soportes antivuelco

(Figura 10).

NOTA: Si mueva la estufa a otro sitio, deba tambi_n

mover los soportes antivuelco para instalarlas

con la estufa.

Las piezas se encuentran en un saco de pl_stico

en el homo,

Herrarnientas requeridas:

Llave de tuerca de 5/16" o destornillador de cabeza

plana

Llave ajustable

Broca para mamposterfa de 3/16" de di_metro (para

taladrar concreto)

5. Deslice la estufa hasta que quede en su lugar

asegur_ndose de que las patas traseras est_n

atrapadas bajo las platinas de anclaje. Puede

set necesario balancear la estufa hacia los lados

a medida que se desliza hacia arras para Iograr

que las platas traseras se alineen con las platinas

de anclaje. Para asegurarse de que la estufa

est_ correctamente anclada remueva el caj6n de

almacenamiento o el panel inferior, tambi_n puede

verificarse la instalaci6n tratando, cuidadosamente,

de inclinar la estufa hacia adelant_3/8,,

,_" /_ Instalar

/ platinas

I deanclaje

3/8" J---__ .

- ..-_ Borde posterior de la 4-.

._" ?_%<. .... estufa o pared posterior..f

_J._l_ :_ 2 Torni!los _/

::_._ por platina Ubicaci6n de los panel_ es

laterales de la estufa

Instalar/ .............

platinas ..........

de anclaje ....._"

Figura 10

Asegure las platinas al piso en la parte posterior

de la estufa de forma que soporten las dos platas

niveladoras traseras. AI colocarlas aseg0rese de no

perforar alambres el_ctricos o tuber[a. Los tornillos

suministrados pueden usarse en concreto o madera.

La estufa puede anclarse al piso en una residencia con

las platinas de anclaje, tal como se ilustra en la figura

10. Estas platinas permiten que la estufa se hale hacia

adelante para su limpieza o reparaci6n, sin necesidad

de usar herramientas.

1. Asegure las platinas de anclaje al piso o a la

pared posterior con los tornillos suministrados.

Importante: las platinas deben anclarse sobre

madera o piso s61ido. No deben anclarse sobre

estuco, chapa de roca o algOn otto material de baja

resistencia. Si el anclaje va a hacerse sobre la pared

posterior, deben removerse todas la molduras que

queden detr_s de la estufa.

2. Si las platinas van a anclarse en pisos de

manposter[a o cer_mica, coloque las platinas en el

piso y marque la ubicaci6n de los orificios. Taladre

orificios de

3/16".

3. Gire las patas niveladoras 3 vueltas hacia abajo de

forma que las platinas deslicen sobre las cabezas

niveladoras.

4. Nivele la parte delantera y trasera de la estufa y

las partes laterales con los dos niveladores de pata

delanteros y los niveladores traseros.

En casas m6viles la estufa debe anclarse al piso come

se muestra en la figura 11.

1. Remueva el panel falso o el caj6n de

almacenamiento para poder alcanzar los orificios de

anclaje.

2. En el centro de cada riel de la base de la estufa se

suministra un orificio de V_" para el anclaje al piso.

lateral del

Riel

de la base

Orificio para anclar la es-

tufa al piso orificio ubicado

aproximadamente en la mitad

del riel Figura 11

Pararse, apoyarse o sentarse en la

puerta o caj6n de esta estufa causar serias lesiones per-

sonales y tambi_n puede dafiar la estufa.

15

_uerpo

Armazdn

frontal

Parte

OVEN CIRCUIT // CIRCUITO DE HORNO

ii

r...........................................

BAKE IGNITER

i ELECTRONIC OVEN CONTROL

i CONTROL DE HORNO ELECTRONICO

i BS 345

i 15 P5

i MOTOR LATCH

BK-19 i

0-19 3> ' i <(

......................................................._#o_ o _ j

_<, BL-19 BK-19 : RI 1 ....................................._ _ W-!

DOOR SWITCH BK-19

INTERROPTOR DE /_\

LUZ DE PUERTA i

\\

i MOTOR DE CERROJO

i GY- I _:;::% W+ 1

ENCENDIDO DE HORNEAR '_2_::ZZI_:: ' W-1

\_/

OVEN LAMP

LUZ DE HORNO

L O00K:roE_c!RcuI!_JJ_C!RCU!!O_DE_PbANCHA_DE_COC!NAR

R-1

BAKE VALVE

VALVULA DE HORNEAR

BROIL VALVE

VALVULA DE ASAR

N

\

R-1 , ,

i i

TOP BURNER IGNITER

OUEMADOR E ENCENDIDO SUPERIOR

iit _ IGNITER MODULE BOARD

NOTE: 11

sERVICE:IF REPLACEMENT OF TERMINALS BECOMES NECESSARY_COMPARABLE WIRE TYPE AND 12

GAGE AND COMPARABLE TERMINALS MUST BE USED. 13

EN CABO QUE SEA NECESARIO DE REEMPLAZAR LOS BORNES_ES NECESARIO DE UTILZZAR EL 16

MISMO TIPO DE ALAMBRE Y DE MEDIDOR Y EL MISMO TIPO DE BORNES. 17

i ; 21

CAUTION:DISCONNECT POWER BEFORE SERVICING UNIT. 22

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING CONTROLS. 40

WIRINGS ERRORS CAN CAUSE IMPROPER AND DANGEROUS OPERATION.

VERIFY PROPER OPERATION AFTER SERVICING.

ATENCION:CORTAR LA CORRIENTE ANTES DE REALIZAR EL MANTENIMIENTO OEL ELECTRODOMESTICO,

ETIGUETE TODOS LOS CABLES ANTES DE DESCONECTAR CUANDO HAGA EL SERV[CIO A LOS CONTROLES.

ERRORES AL VOLVER A ENSAMBLAR LOS CABLES PUEDE CAUSAR FALLAS U OPERACIONES PELIGROSAS.

CUARDO DE MODULO BE BNCENDIDO

COLOR CODE/CODIGOS DE COLOR i

B.GREEN_MEROE i

W. -WHITE/BLANCO i

R. -RBD/ROJO i i

O, -ORANGE/NARANJA i i

¥. -YELLOW/AMARILLO i i

BR. -BROWN/MORENO i i

BL, -BLUE/AZUL i i

BK. -BLACK/NEGRO i

2 16 126 0L1251 3173 i i

3 14 125 011251 3173

4 12 i25 0L1251 3173

5 18 i50 EXL-150 332i i i

6 16 i50 EXL+150 332i

7 14 150 EXL*150 3321

8 12 150 EX[-150 3321

9

10 150 EXL-150 3321 _ i

lO

1. 2oo.6..3,22,,

16 200 SEW-1 3122

12 260 3262 _ i

16 250 3252 i i

14

20 150 EXL-150 3321 i i

............... ii

6 66 ii

10 60

18

10 200 SEW 1 3122

19

20 i26 SEW 1 3i73

20

20 200 SEW 1 3122

22 126 0L1251 3266 i i

20 125 CL1251 3266

.......... ii

318045814 REV'A

i

i

iE

Loading...

Loading...